Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could

result in personal injury and/or property damage! Retain instructions for future reference.

IN974200AV 11/09

Operating Instructions & Parts Manual Models WG3080, WG3090 and WG4130

Wire Feed

Arc Welder

Description

These Campbell Hausfeld wire feed

welders are designed to be used on

standard 120V (WG3080 & WG3090) or

230V (WG4130) outlet. The welder is

equipped with infinite wire speed

control to accurately select the proper

wire feed rate needed for various

welding conditions. Internal components

are thermostatically protected.

This welding system is designed for use

with the Flux Cored Arc Welding

(FCAW) or the Gas Metal Arc Welding

(GMAW) process. As delivered from the

factory, this welder can weld with .030"

(0.8mm) diameter flux core wire. A

starter spool of .030" (0.8 mm) flux

cored wire is included.

CIRCUIT REQUIREMENTS

This equipment requires a dedicated

120 volt or 230 volt circuit (depending

on model). Refer to the following chart

for correct circuit breaker or fuse

rating for 120 volt models. Do not run

other appliances, lights or tools on this

circuit while operating this equipment.

Extension cords are not recommended.

Blown fuses and tripped circuit

breakers can result from failure to

comply with this recommendation.

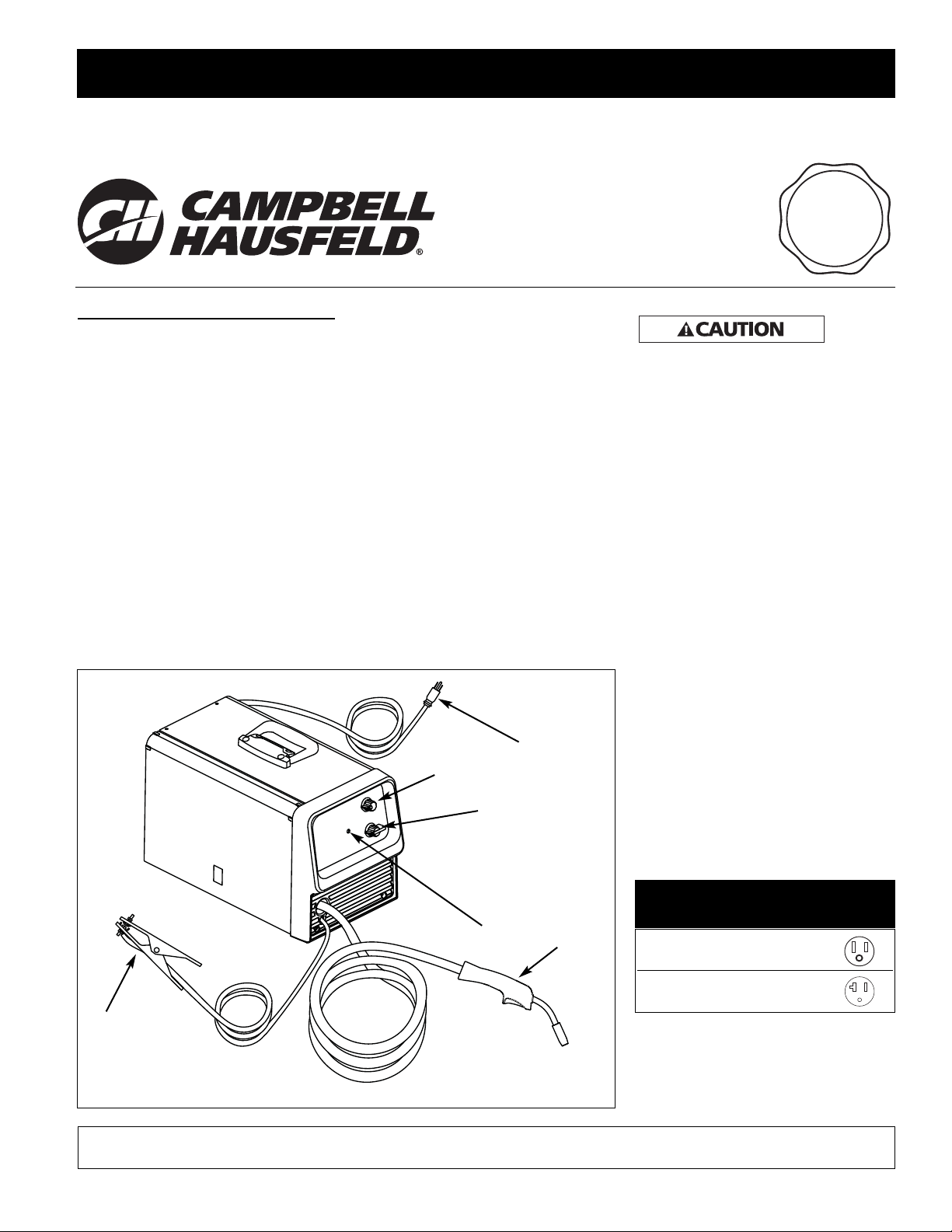

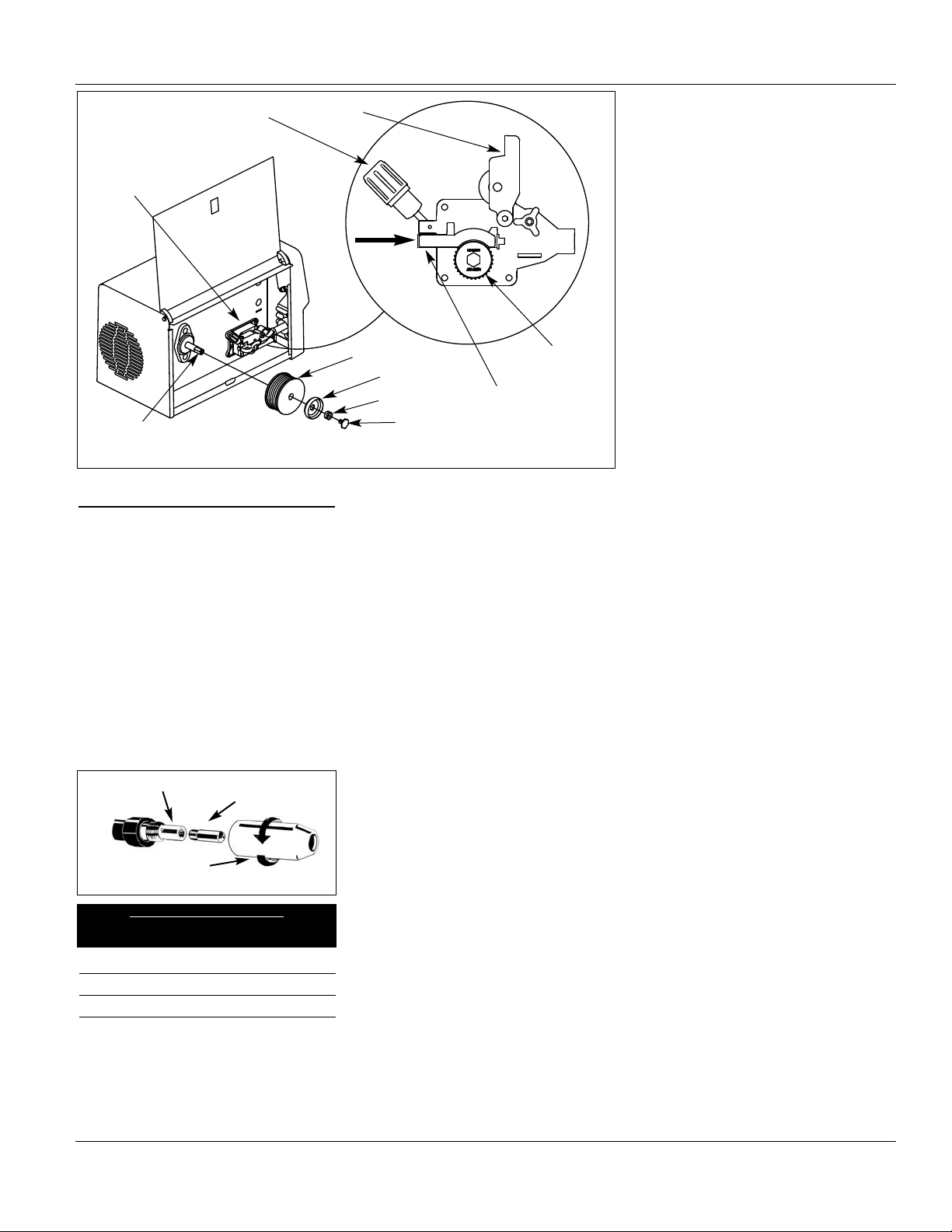

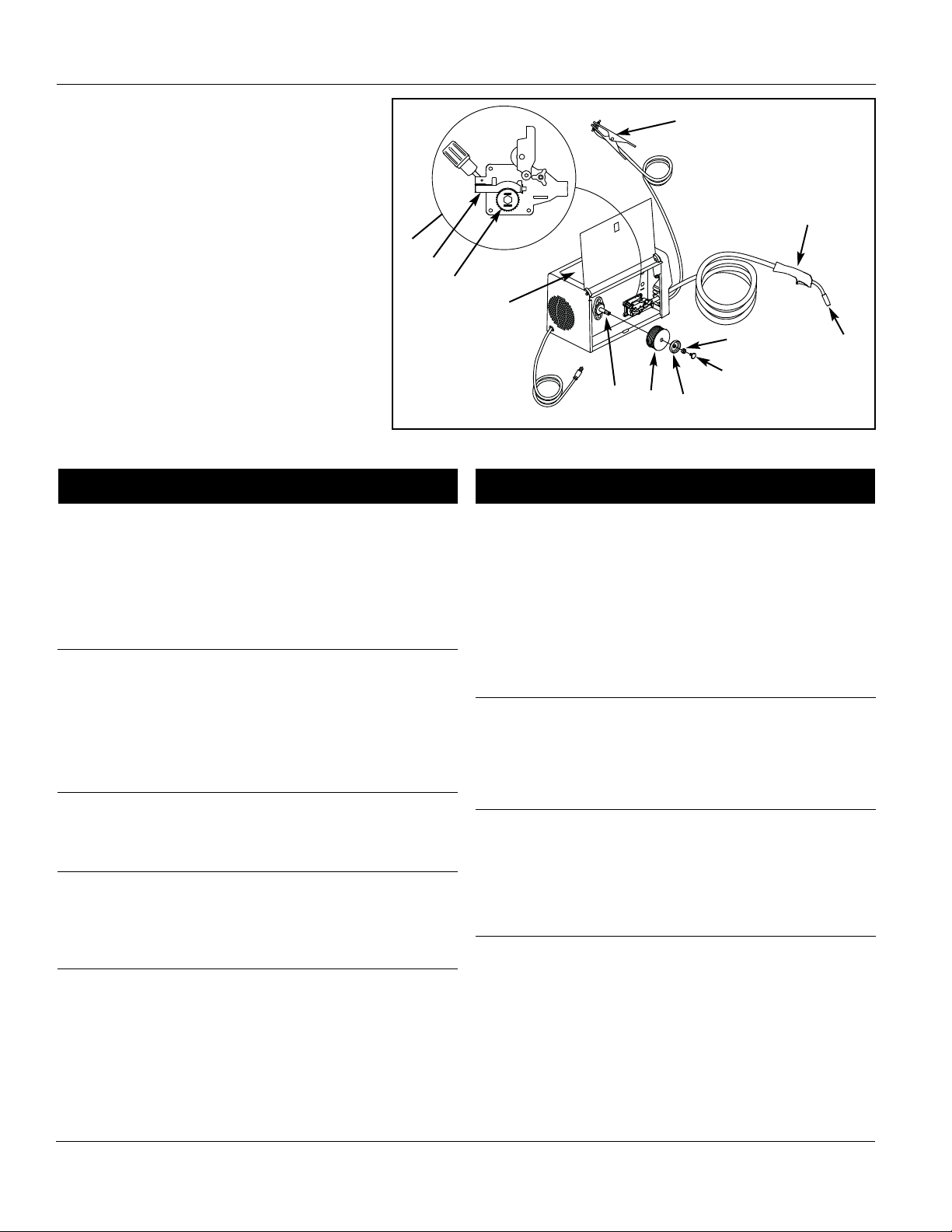

COMPONENTS AND CONTROLS

(FIGURE 1)

1. Work Clamp – connects to work

piece.

2. Torch with .030" tip.

3. Power Cord – plug into 120 volt or

230 volt outlet (depending on

model).

4. Light – illuminates if thermostat has

automatically shut welder off.

5. Infinite Wire Speed Control – turn

clockwise to increase wire speed and

counterclockwise to decrease wire

speed.

6. Off/Heat Selector - Selects welding

power and turns welder on.

Five selections are possible:

1 – 2 – 3 – 4 – 5.

See page 8 for supply cable

replacement instructions.

To use the GMAW process with the

WG3090 and WG4130, it is necessary to

purchase shielding gas and MIG wire

only. With the WG3080, a regulator

/hose kit must be purchased in addition

to the shielding gas and MIG wire.

Unpacking

When unpacking, inspect carefully for any

damage that may have occurred during

transit. Make sure any loose fittings and

screws, etc., are tightened before putting

unit into service. Report any missing or

damaged items by calling

1-800-746-5641.

For parts, product & service information

visit www.chpower.com

or call 1-800-746-5641

© 2009 Campbell Hausfeld/Scott Fetzer

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

Circuit Breaker or

Heat Slow Blow Fuse for

Selector 120V Models

1-2-3 15 amp

4-5 20 amp

Figure 1 - Welder Components and Controls

3

1

6

4

5

2

N

A

C

R

E

U

P

S

R

S

O

A

Y

T

I

L

A

U

Q

Assistance?

Need

G

R

A

M

Call Us First!

1-888-629-8748

2

Wire Feed Arc Welder

General Safety

Danger

indicates

an imminently hazardous situation

which, if not avoided, will result in

death or serious injury.

Warning

indicates

a potentially hazardous situation

which, if not avoided, COULD result in

death or serious injury.

Caution

indicates

a potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

NOTE: Note means any additional

information pertaining to the product

or its proper usage.

Always keep a fire

extinguisher accessible while

performing arc welding

operations.

Before starting or

servicing any electric arc

welder, read and

understand all

instructions. Failure to

follow safety precautions or

instructions can cause equipment

damage and/or serious personal

injury or death.

All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Improper use of electric arc

welders can cause electric

shock, injury, and death! Take

all precautions described in

this manual to reduce the possibility of

electric shock.

Verify all components of the arc

welder are clean and in good

condition prior to operating welder.

Be sure insulation on all cables,

torch and power cord is not

damaged. Always repair or replace

damaged components before

operating the welder. Always keep

welder panels, shields, etc. in place

when operating welder.

Always wear dry, protective

clothing, welding gloves and

insulated footwear when operating

unit.

Always operate welder in a clean,

dry, well ventilated area. Do not

operate welder in humid, wet, rainy

or poorly ventilated areas.

Be sure work piece is properly

supported and grounded prior to

beginning any electric arc welding

operation.

Spread out coiled welding cable

before use to avoid overheating and

damage to insulation.

Never

immerse

wire or torch in water. If welder

becomes wet for any reason, be

absolutely certain it is completely clean

and dry before use!

Always shut equipment off and

unplug power cord prior to moving

the unit.

Always attach the work lead first.

Verify work piece is securely

grounded.

Always shut off electric arc welding

equipment when not in use and cut off

any excess wire from torch.

Never allow any part of the body to

touch welding wire and ground or

grounded work piece at the same

time.

Awkward welding conditions and

positions can be electrically hazardous.

When crouching, kneeling or at

elevations, be sure to insulate all

conductive parts, wear appropriate

protective clothing and take

precautions to prevent injury from falls.

Never attempt to use this equipment

at current settings or duty cycles

higher than specified on equipment

labels.

Never use an electric arc welder to

thaw frozen pipes.

Flying sparks and hot metal

can cause injury. As welds

cool, slag can be thrown off.

Take all precautions described

in this manual to reduce the possibility

of injury from flying sparks and hot

metal.

Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

Electric arc welding

operations produce intense

light and heat and ultraviolet

(UV) rays. This intense light

and UV rays can cause injury to eyes and

skin. Take all precautions described in

this manual to reduce the possibility of

injury to eyes and skin.

All persons operating this equipment

or in the area while equipment is in

use, must wear protective welding

gear including: welding helmet or

shield with at least shade 10 lens, flame

resistant clothing, leather welding

gloves and full foot protection.

Never

look at

arc welding operations without eye

protection as described above. Never

use a shade filter lens that is cracked,

broken, or rated below number 10.

Warn others in the area not to look at

the arc.

Electric arc welding

operations cause sparks and

heat metal to temperatures

that can cause severe burns!

Use protective gloves and clothing when

performing any metal working

operation. Take all precautions

described in this manual to reduce the

possibility of skin and clothing burns.

Make sure all persons in welding

area are protected from heat, sparks

and ultraviolet rays. Use additional

face shields and flame resistant

barriers as needed.

Never touch work pieces until

completely cooled.

Heat and sparks produced

during electric arc welding

and other metal working

operations can ignite

flammable and explosive materials!

Take all precautions described in this

manual to reduce the possibility of

flames and explosions.

www.chpower.com

MANUAL

General Safety

(Continued)

Remove all flammable materials

within 35 feet (10.7 meters) of

welding arc. If removal is not

possible, tightly cover flammable

materials with fire proof covers.

Do not operate any electric arc

welder in areas where flammable or

explosive vapors may be present.

Take precautions to ensure flying

sparks and heat do not cause flames

in hidden areas, cracks, etc.

Fire hazard! Do not weld on

containers or pipes that

contain or have contained

flammable materials or

gaseous or liquid combustibles.

Arc welding closed cylinders

or containers such as tanks

or drums can cause explosion

if not properly vented!

Verify that any cylinder or container to

be welded has an adequate ventilation

hole, so that expanding gases can be

released.

Do not

breathe fumes produced by arc

welding operation. These fumes are

dangerous. If welding area cannot be

adequately ventilated, be sure to use

an air-supplied respirator.

Keep head and face out of welding

fumes.

Extremely toxic fumes are

created when galvanized or

cadmium plated metals or metals

which contain zinc, mercury or

beryllium are heated. Complete

the following precautions before

performing electric arc welding

operations on these metals:

a. Remove coating from base metal.

b. Make sure welding area is well

ventilated.

c. Use an air-supplied respirator.

The electromagnetic field

generated during arc welding

may interfere with the

operation of various electrical

and electronic devices such as cardiac

pacemakers. Persons using such devices

should consult with their physician prior

to performing any electric arc welding

operations.

Use only correct shielding gas

cylinders, regulators, hoses and

fittings designed for the specific

application; maintain all parts

properly.

Turn face away from valve outlet

when opening cylinder valve.

Keep protective cap in place over

valve except when cylinder is in use

or connected for use.

Read and follow instructions on

compressed gas cylinders, associated

equipment, and CGA publication P-1

listed in Safety Standards.

Never

use

flammable gasses with MIG welders.

Only inert or non-flammable gasses

such as carbon dioxide, argon, helium

or mixtures of one or more of these

gasses are suitable for MIG welding.

Never

lift

cylinders off the ground by their valves

or caps or with chains or slings.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. Le June Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from Superintendent

of Documents, U.S. Government Printing

Office, Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed Gas

Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale,

Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

3

Route torch and work cables

together and secure with tape when

possible.

Never wrap arc welder cables around

the body.

Always position torch and work leads

on the same side of the body.

Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

CALIFORNIA PROPOSITION 65

This product, when used for

welding, produces fumes or

gases which contain chemicals

known to the State of

California to cause birth defects (or other

reproductive harm) and, in some cases,

cancer (California Health & Safety Code

Section 25249.5 et seq.).

The

power

cord and other cables on this product

contain chemicals, including lead,

known to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

GENERAL SAFETY

Always be sure welding area

is secure and free of hazards

(sparks, flames, glowing metal

or slag) prior to leaving. Be

sure equipment is turned off and excess

wire is cut off. Be sure cables are loosely

coiled and out of the way. Be sure all

metal and slag has cooled.

Cylinders can explode if

damaged. Shielding gas

cylinders contain gas under

high pressure. If damaged, a

cylinder can explode. Since gas

cylinders are normally part of the

welding process, be sure to treat them

carefully.

Protect compressed gas cylinders

from excessive heat, mechanical

shocks and arcs.

Install and secure cylinders in an

upright position by chaining them

to stationary support or equipment

cylinder rack to prevent falling or

tipping.

Keep cylinders away from any

welding or other electrical circuits.

Never allow a welding electrode to

touch any cylinder.

Models WG3080, WG3090 and WG4130

www.chpower.com

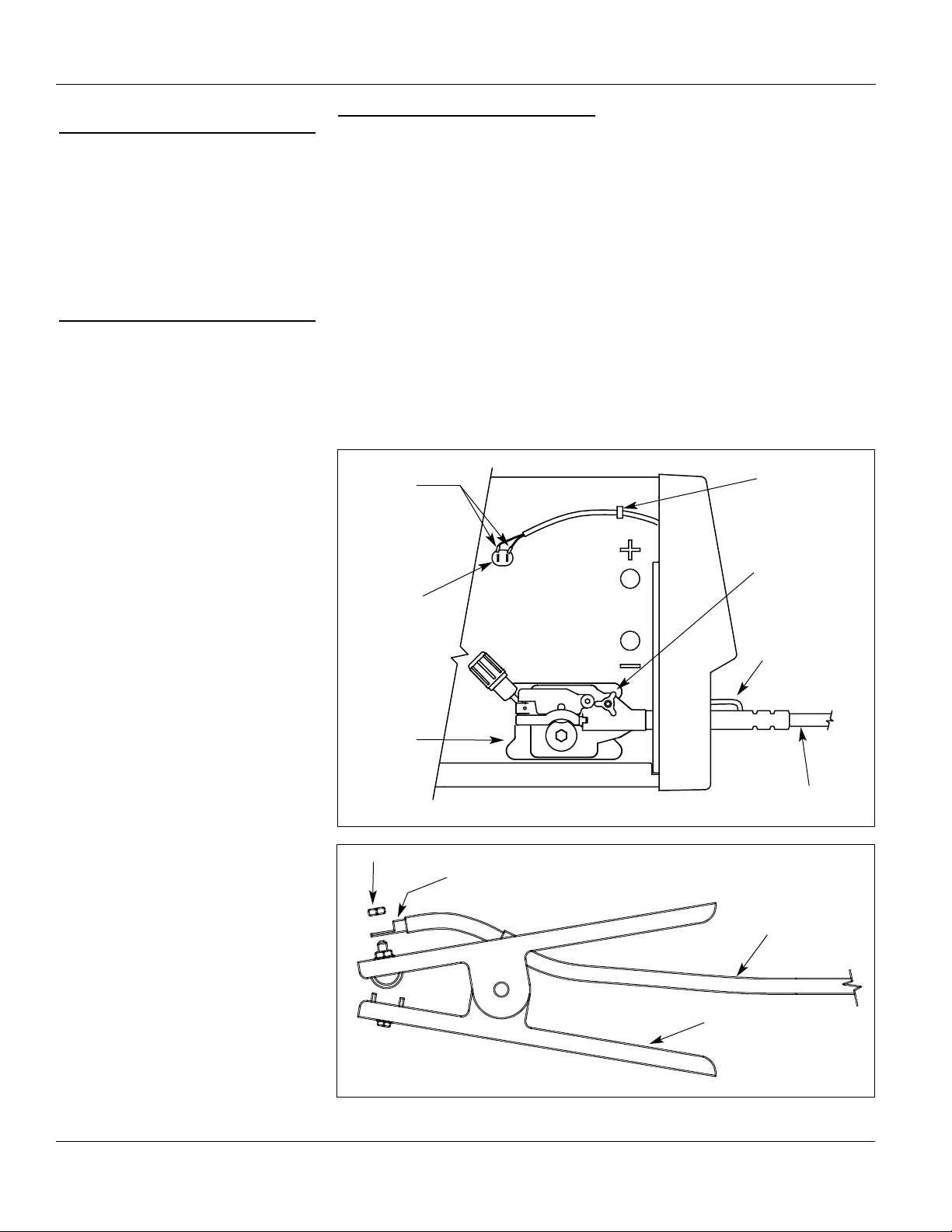

Assembly

TORCH INSTALLATION (See Fig. 2)

1. Make sure unit is off and unplugged.

2. Feed the connectors for the torch

switch through the hole in the control

panel. These leads are to be fed up

over the polarity studs and through the

hanger on the center wall.

3. Insert the brass torch connector

through the hole in the control panel

and into the drive deck. Make sure the

connector is inserted fully into the

drive deck. Loosen the torch clamp

knob a few turns if the connector will

not insert fully. Tighten the torch

clamp knob securely after the brass

torch connector is fully inserted.

Wire Feed Arc Welder

General Safety

(Continued)

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to Material Safety Data Sheets and

manufacturers instructions for metals,

wire, coatings and cleaners.

Installation

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

For best results locate welder in a

clean and dry environment. Dust

and dirt in the welder retain

moisture and increase wear of

moving parts.

Place welder in an area with at least

twelve inches (305 mm) of ventilation

space at both the front and rear of

unit. Keep all obstructions out of this

ventilation space.

Store welding wire in a clean, dry

location with low humidity to

prevent oxidation.

Use a properly grounded receptacle

for the welder and ensure welder is

the only load on power supply

circuit. Refer to chart on page 1 for

correct circuit capacity.

Use of an extension cord is not

recommended for electric arc welding

machines. Voltage drop in the

extension cord may significantly

degrade performance of the welder.

4. Connect the torch switch connectors to

the two 1/4" terminals in the center

wall. Polarity is not important. Make

sure these wires do not interfere with

the polarity studs or drive deck.

WORK CLAMP INSTALLATION

(See Fig. 3)

1. Remove one hex nut from work clamp.

2. Slide welding cable with ring

connector through hole in work clamp.

3. Attach ring connector to work clamp

with hex nut removed in step 1.

4

www.chpower.com

Work clamp

Welding cable

Ring connector

Hex Nut

Figure 3 - Clamp Installation

Hanger

Torch switch leads

Torch clamp knob

Torch switch

connectors

Drive deck

Torch switch

terminals

Torch

Figure 2 - Torch Installation

Assembly (Continued)

WIRE INSTALLATION

NOTE: Before installing welding wire,

be sure:

a. Diameter of welding wire matches

groove in drive roller on wire feed

mechanism (See Fig. 4).

b. Wire matches contact tip in end of

torch (See Fig. 5).

A mismatch on any item could cause the

wire to slip and/or bind.

NOTE: Always maintain control of loose

end of welding wire to prevent

unspooling.

7. Unscrew nozzle and contact tip from

end of welding torch (See Figure 5).

Plug welder into a proper power

supply receptacle.

8. Turn on welder and set wire speed

to 10. Activate torch trigger until

wire feeds out past the torch end.

Turn welder off.

9. Carefully slip contact tip over wire,

screw tip into torch end and reinstall

nozzle (See Figure 5). Cut wire off

approximately 1/4 inch from nozzle

end.

DUTY CYCLE / THERMOSTATIC

PROTECTION

Welder duty cycle is the percentage of

actual weld time that can occur in a ten

minute interval. For example, at a 20%

duty cycle, actual welding can occur for

two minutes, then the welder must cool

for eight minutes.

Internal components of this welder are

protected from overheating with an

automatic thermal switch. A red lamp is

illuminated on the front panel if the

duty cycle is exceeded. Do not switch

unit off. This will allow the internal fan

to cool the unit quickly. Welding

operations may continue when the red

lamp is no longer illuminated.

OVERLOAD PROTECTION

The welder is equipped with a circuit

breaker which protects the machine if

the maximum output is exceeded, such as

when the output is short-circuited. The

circuit breaker button will extend out

when tripped. Manually push the button

in to reset.

Models WG3080, WG3090 and WG4130

5

www.chpower.com

1. Verify unit is off and open door

panel to expose wire feed

mechanism.

2. Remove the spool lock by pushing in

and rotating 1/4 turn

counterclockwise. Then remove lock,

spring and retainer.

3. Flip tensioning knob down and

swing arm up on drive mechanism.

This allows initial feeding of wire

into torch liner by hand.

4. Install wire spool onto spindle so

wire can come off spool bottom of

spool. Do not cut the wire loose

yet. Install spool retainer, spring and

lock by pushing in and turning lock

1/4 rotation clockwise.

5. Hold wire and cut the wire end from

spool. Do not allow wire to

unravel. Be sure end of wire is

straight and free of burrs.

6. Feed wire through wire guide, over the

groove in drive roller and back into

wire guide. Flip swing arm down and

tension knob up. Adjust tension by

rotating tension knob.

Contact Tip Markings

Mark Wire Size

0.6 mm .024"

0.8 mm .030"

0.9 mm .035"

Torch Diffuser

Contact Tip

Nozzle

Figure 5 - Torch Nozzle

Spindle

Welding wire

Lock

Spring

Retainer

Tension knob

Wire guide

Swing arm

Drive deck

Drive

roller

Figure 4 - Weld Wire Installation

Shielding Gas Preparation

Improper

handling

and maintenance of compressed gas

cylinders and regulators can result in

serious injury or death! Always secure

gas cylinders to a wall or other fixed

support to prevent cylinder from falling

over. Read, understand and follow all

compressed gas and equipment

warnings in the safety instructions.

NOTE: Shielding gas is not required if

flux-core welding wire is used.

GAS TYPES

There are 3 types of gas generally used

for gas metal arc welding; 100% argon,

a mixture of 75% argon and 25%

carbon dioxide (C25) or 100% carbon

dioxide.

Use ONLY

the type of gas recommended for your

welder. Use ONLY an inert, nonflammable type of gas. Failure to do so

will result in a very hazardous situation.

The 75/25 mixture is recommended for

general steel welding. For aluminum

welding, use 100% argon. Cylinders of

either type gas may be obtained at your

local welding supply outlet. Secure

cylinder to prevent it from falling over.

Assembly (Continued)

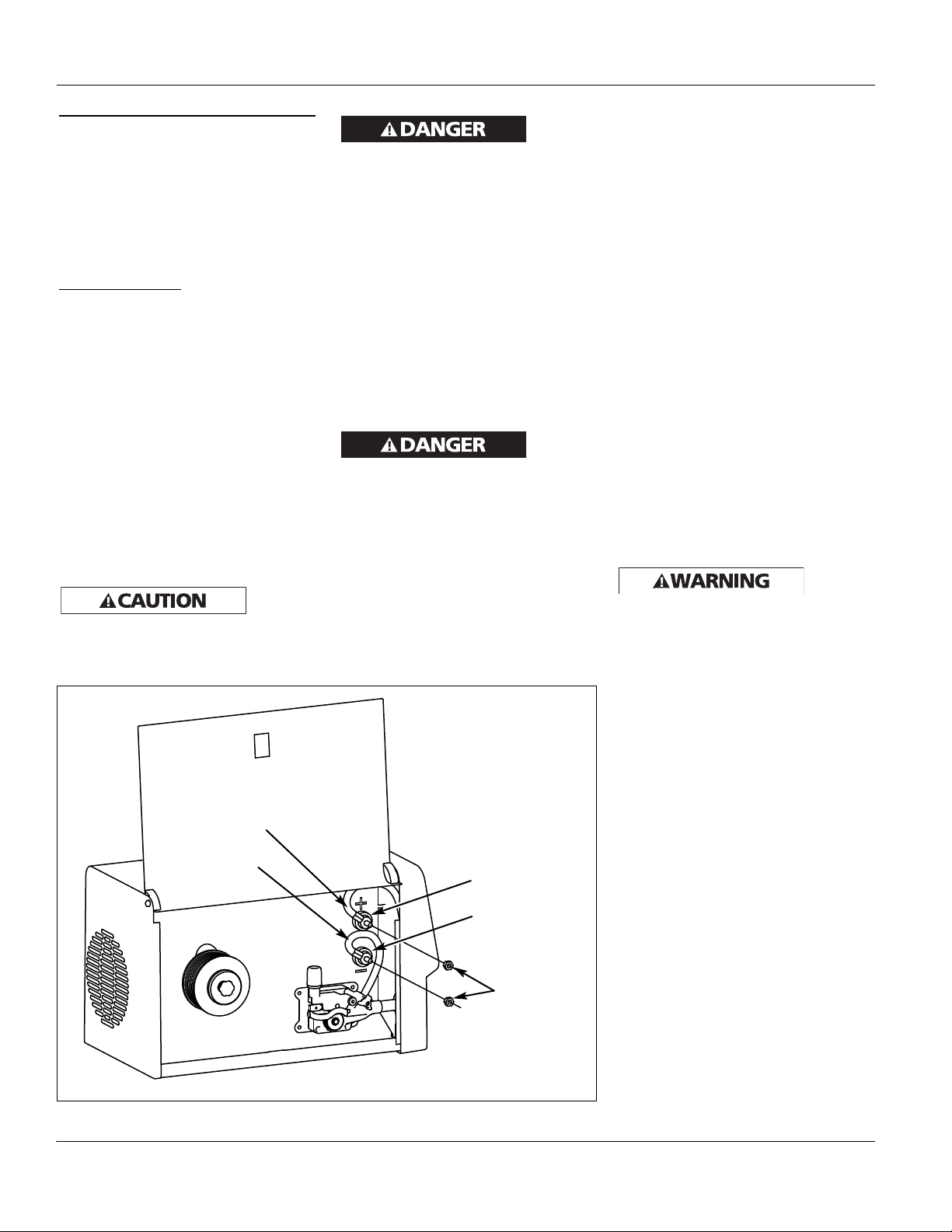

POLARITY

MIG welding wire requires the

electrode to be positive.

Flux welding wire requires the

electrode to be negative. Always use

the polarity recommended by the

welding wire manufacturer. The welder

is factory set for flux welding wire.

To Change Polarity

(See Figure 6)

1. Unplug power cord from socket.

2. Open wire feed compartment door.

3. Remove two nuts from polarity

studs.

4. Connect cable from drive deck to

positive stud and cable from work

clamp to negative stud for

electrode positive polarity for MIG

welding. Connect cable from drive

deck to negative stud and cable

from work clamp to positive stud

for electrode negative polarity for

flux core welding.

5. Reinstall two nuts and tighten

securely.

If the

nuts are

not tightened properly, excessive heat

will be generated by the loose

connection and the insulators on the

studs will be damaged.

Wire Feed Arc Welder

Obtaining Correct Gas Type. The gas

used in any welding application for your

welder must be an INERT, NONFLAMMABLE TYPE. You can get the type

of gas needed from a nearby welding

gas distributor (often found in the

yellow pages under “Welders” or

“Welding Equipment”).

REGULATOR

An adjustable regulator with two gauges

is supplied with the WG3090 and

WG4130. The WG3080 is not supplied

with a regulator (see parts list for

optional regulator/hose kit). The

regulator provides a constant shielding

gas pressure and flow rate during the

welding process. Each regulator is

designed to be used with a specific gas or

mixture of gases. The argon and argon

mixture use the same thread type. The

100% carbon dioxide uses a different

thread type. An adapter is available at

your local welding gas supplier to

change between the two.

HOSE AND REGULATOR HOOKUP

PROCEDURE

Cylinder

gas is

under high pressure. Point cylinder

outlet away from yourself and any

bystanders before opening.

1. With cylinder securely supported,

stand on side of cylinder opposite

cylinder outlet then remove cylinder

cap and open valve slightly by

turning counterclockwise. When gas is

emitted from cylinder, close valve by

turning clockwise. This will blow out

dust or dirt that may have

accumulated around valve seat.

2. Install regulator onto cylinder valve.

Tighten stem nut securely to gas

valve.

3. Install one end of gas hose to fitting

on the back of welder and other end

of hose to fitting on regulator. Make

sure gas hose is not kinked or twisted.

4. While standing opposite cylinder

outlet, slowly open cylinder valve.

Inspect for leaks in the connections.

5. Turn unit on and pull trigger on

torch to allow gas to flow. Adjust gas

regulator to between 20 and 40 CFH.

Release trigger and turn unit off.

6. Remember to close gas cylinder valve

when finished welding.

6

www.chpower.com

Figure 6 - Polarity control

Ground cable

Brass nuts

Drive deck cable

Positive stud

Negative stud

NOTE: Electrode negative

polarity (typical for flux core

welding) shown in figure.

Reverse cables for electrode

positive polarity (typical for

MIG welding).

Models WG3080, WG3090 and WG4130

Operation

1. Be sure to read, understand

and comply with all

precautions in the General

Safety Information section.

Be sure to read entire

“Welding Guidelines” section before

using this equipment.

2. Turn welder off.

3. Verify surfaces of metals to be joined

are free from dirt, rust, paint, oil,

scale or other contaminants. These

contaminants make welding difficult

and cause poor welds.

All persons operating this equipment or

in the area while equipment is in use

must wear protective welding gear

including: eye protection with proper

shade, flame resistant clothing, leather

welding gloves and full foot protection.

If heating, welding or cutting

galvanized, zinc plated, lead,

or cadmium plated materials,

refer to the General Safety

Information Section for instructions.

Extremely toxic fumes are created when

these metals are heated.

4. Connect work clamp to work piece or

workbench (if metal). Make sure

contact is secure. Avoid surfaces with

paint, varnish, corrosion or nonmetallic materials.

5. Rotate Wire Speed Control to setting

per decal inside wire feed

compartment, then adjust as needed

after test.

6. Plug power cord into a proper

voltage receptacle with proper circuit

capacity (see circuit requirements on

Page 1).

7. Switch welder on to desired heat

setting per decal inside wire feed

compartment, then adjust as needed

after test.

NOTE: These settings are general

guidelines only. Heat setting may vary

according to welding conditions and

materials.

8. Verify wire is extended 1/4" from

contact tip. If not, squeeze trigger to

feed additional wire, release trigger,

turn welder off, and cut wire to

proper length. Then, switch back on

to desired heat setting.

9. Position torch near work piece, lower

welding helmet by nodding head or

positioning the hand shield, and

squeeze torch trigger. Adjust heat

setting and wire speed as needed.

10. When finished welding, turn welder

off and store properly.

Maintenance

Disconnect power supply and turn

machine off before inspecting or

servicing any components. Keep wire

compartment cover closed at all times

unless wire needs to be changed.

BEFORE EVERY USE:

1. Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2. Check condition of power cord and

immediately repair or replace any

cord if damaged.

3. Inspect the condition of the torch

contact tip and nozzle. Remove any

weld slag. Replace torch contact tip or

nozzle if damaged.

Do not

operate

this welding machine with cracked or

missing insulation on welding cables,

torch or power cord.

EVERY 3 MONTHS:

1. Replace any unreadable safety labels

on the welder.

2. Use compressed air to blow all dust

and lint from ventilation openings.

3. Clean wire groove on drive roller.

Remove drive roller and use a small

wire brush to clean. Replace if worn

or damaged.

Consumable and Wear Parts

The following parts require replacement:

• Wire feed drive roller

• Wire guide

• Torch liner

• Nozzle/contact tips

• Wire - This welder will accept either 4"

or 8" diameter spools. Flux-Cored

welding wire is susceptible to

moisture and oxidizes over time, so it

is important to select a spool size that

will be used within approximately 6

months. For mild steel welding, AWS

ER70S6 solid wire or AWS E71T-GS

Flux-Cored wire is recommended.

CHANGING WIRE SIZES

This welder is setup for .030" (0.8 mm)

wire. If a different wire size is used, the

wire feed drive roller and contact tip

may need changing. There are two

grooves in the drive roller. The small

groove is for .024" (0.6 mm) MIG wire

and the large groove is for .030 - .035"

(0.8 - 0.9 mm) flux core and MIG wire.

Rotate the tension knob down and

swing arm up and flip the drive roller

to choose the correct groove. Optional

drive rollers for other wire sizes are

available (See parts breakdown). The

contact tip should also match the wire

diameter used. The tip diameter is

marked on the contact tip in inches

and/or millimeters.

7

www.chpower.com

Supply Cable Replacement

1. Verify that welder is OFF and

power cord disconnected.

2. Remove welder side panel to

expose switches.

3. Disconnect the power cord leads

per the diagram inside the unit.

4. Disconnect the ground wire

connected to welder base.

5. Loosen the cord strain relief

screws and pull cord out of strain

relief.

6. Install new cord in reverse order

per the diagram inside the unit.

MANUAL

Wire Feed Arc Welder

8

www.chpower.com

WIRE SPEED

The wire speed is controlled by the

knob on the front panel. The speed

needs to be “tuned” to the rate at

which the wire is being melted in the

arc. Tuning is one of the most critical

functions of wire feed welding. Tuning

should be performed on a scrap piece

of metal the same type and thickness as

that to be welded. Begin welding with

one hand “dragging” the torch nozzle

across the scrap piece while adjusting

the wire speed with the other hand.

Too slow of speed will cause sputtering

and the wire will burn up into the

contact tip. Too fast a speed will also

cause a sputtering sound and the wire

will push into the plate before melting.

A smooth buzzing sound indicates the

wire speed is properly tuned. Repeat

the tuning procedure each time there is

a change in heat setting, wire diameter

or type, or work piece material type or

thickness. For Aluminum, wire speed is

typically set higher (7-9 speed range).

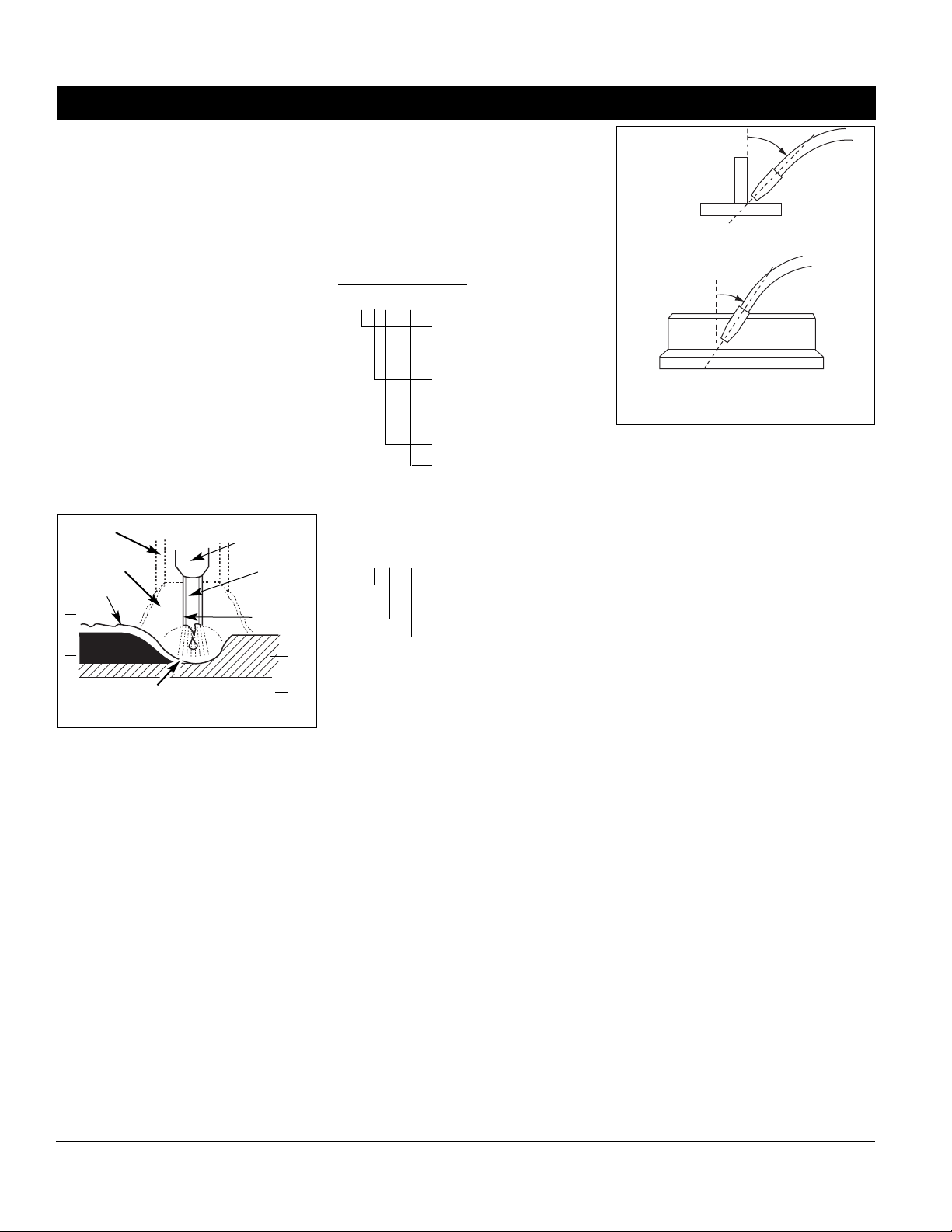

TRAVEL SPEED

The travel speed is the rate at which the

torch is moved across the weld area.

Factors such as diameter and type of

weld wire, amperage, position, and work

piece material thickness all affect the

speed of travel necessary for completing

a good weld (See Figure 9). When the

speed is too fast, the bead is narrow and

bead ripples are pointed as shown. When

the speed is too slow, the weld metal

piles up and the bead is high and wide.

For Aluminum, travel speed is typically

faster.

Welding Guidelines

General

This welding machine can utilize the Flux

Cored Arc Welding (FCAW) process or

the Gas Metal Arc Welding (GMAW)

process. The weld must be protected

(shielded) from contaminants in the air

while it is molten. The FCAW process

uses a tubular wire with a flux material

inside. The flux creates a shielding gas

when melted. The GMAW process uses

inert gas to shield the weld while

molten.

When current is produced by a

transformer (welding machine) and

flows through the circuit to the weld

wire, an arc is formed between the end

of the weld wire and the work piece.

This arc melts the wire and the work

piece. The melted metal of the weld wire

flows into the molten crater and forms a

bond with the work piece as shown

(Figure 7).

Arc Welding Basics

Six basic techniques affect weld quality.

These are: wire selection, heat setting,

weld angle, wire speed, travel speed, and

electrode extension. An understanding of

these techniques is necessary for effective

welds.

HEAT SETTING

The correct heat involves the adjustment

of the welding machine to the required

setting. Heat or voltage is regulated by a

switch on the welder. The heat setting

used depends on the size (diameter) and

type of wire, position of the weld, and

the thickness of the work piece. Consult

specifications listed on the welder. It is

suggested that the welder practice with

scrap metal to adjust settings, and

compare welds with Figure 9.

WIRE TYPE AND SIZE

The correct choice of wire type involves

a variety of factors, such as welding

position, work piece material type,

thickness, and condition of surface to

be welded. The American Welding

Society, AWS, has set up certain

requirements for each type of wire.

FLUX-CORED WIRE

E - 7 0T- GS

AWS E71T-GS or E71T-11 is

recommended for this welder.

SOLID WIRE

ER - 70S- 6

ER-70S6 is recommended for this

welder.

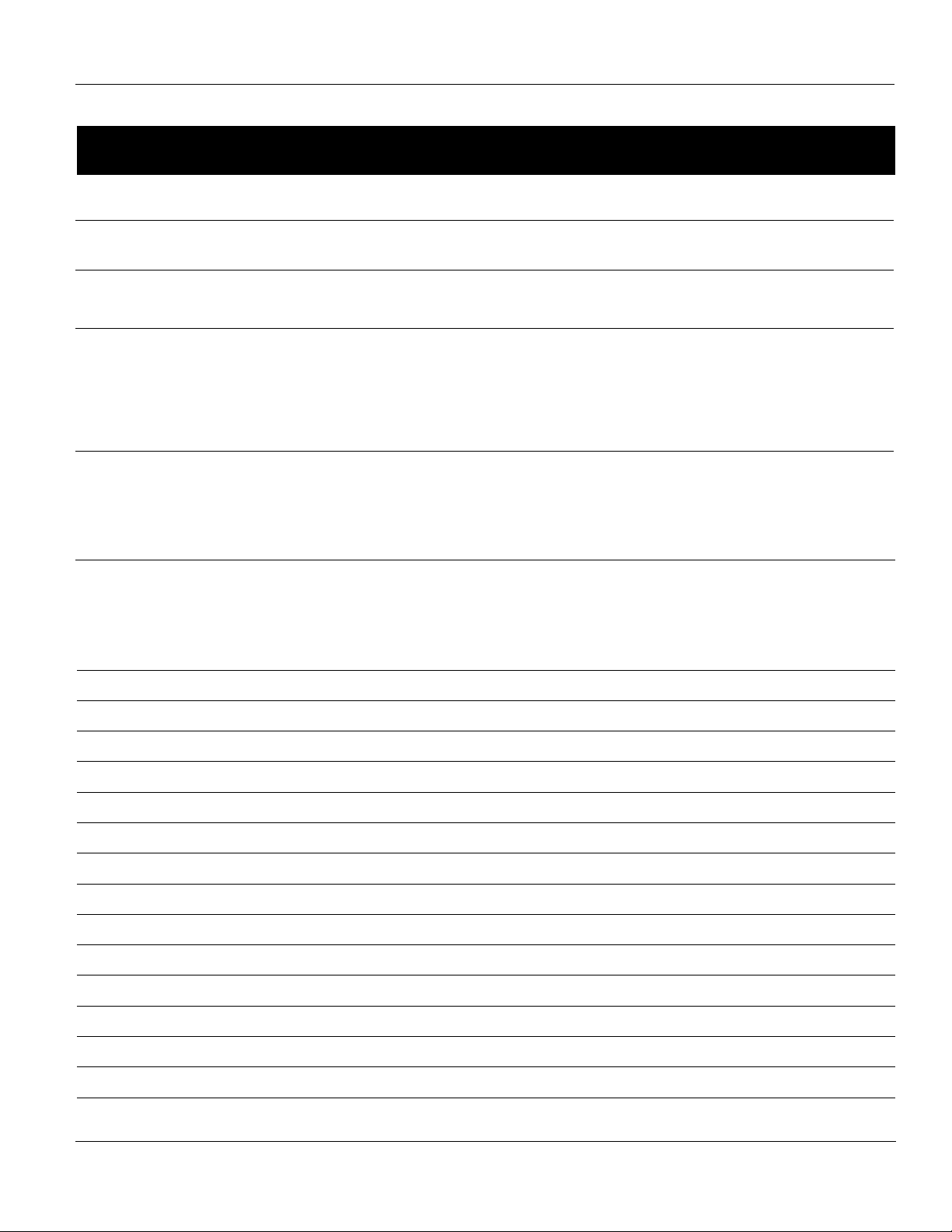

WELD ANGLE

Weld angle is the angle at which the

nozzle is held during the welding

process. Using the correct angle ensures

proper penetration and bead formation.

As different welding positions and weld

joints become necessary, nozzle angle

becomes an increasingly important

factor in obtaining a satisfactory weld.

Weld angle involves two positions travel angle and work angle.

Travel angle

is the angle in the line of

welding and may vary from 5º to 45º

from the vertical, depending on welding

conditions.

Work angle

is the angle from

horizontal, measured at right angles to

the line of welding. For most

applications, a 45º travel angle and 45º

work angle is sufficient. For specific

applications, consult an arc welding

handbook.

Weld strength, times

10,000 pounds per

square inch

Welding positions (0 for

flat or horizontal, 1 for

any position)

Tubular flux-cored wire

Flux type

Slag

Weld

Wire

Flux

(Gasless

only)

Work Piece

Shielding

Gas

Contact

Tip

Crater

Nozzle

Figure 7 - Weld Components

Weld strength, times

1,000 PSI

Solid wire

Wire composition

TRAVEL ANGLE

WORK ANGLE

5º - 45º

5º - 45º

Figure 8 - Weld Angle

Models WG3080, WG3090 and WG4130

9

www.chpower.com

ELECTRODE EXTENSION

Electrode extension (or electrode stickout) is the distance between the end of

the contact tip and and the end of the

welding wire. The recommended

electrode extension is from 1/4 to 1/2 in

(6 to 13 mm). If the electrode extension

is too long, welding current will be

reduced and the bead will be high and

narrow with less penetration.

SLAG REMOVAL

(FLUX-CORED WIRE ONLY)

Wear ANSI approved safety

glasses (ANSI Standard Z87.1)

and protective clothing when

removing slag. Hot, flying

debris can cause personal injury to

anyone in the area.

After completing the weld, wait for the

welded sections to cool. A protective

coating called slag now covers the weld

bead which prevents contaminants in

the air from reacting with the molten

metal. Once the weld cools to the point

that it is no longer glowing red, the

slag can be removed. Removal is done

with a chipping hammer. Lightly tap

the slag with the hammer and break it

loose from the weld bead. The final

clean-up is done with a wire brush.

When making multiple weld passes,

remove the slag before each pass.

WELDING POSITIONS

Four basic welding positions can be used;

flat, horizontal, vertical, and overhead.

Welding in the flat position is easier than

any of the others because welding speed

can be increased, the molten metal has

less tendency to run, better penetration

can be achieved, and the work is less

fatiguing. Welding is performed with the

wire at a 45º travel angle and 45º work

angle.

Other positions require different

techniques such as a weaving pass,

circular pass, and jogging. A higher skill

level is required to complete these welds.

Overhead welding is the least desirable

position as it is the most difficult and

dangerous. Heat setting and wire selection

will vary depending upon the position.

All work should be performed in the

flat position if possible. For specific

applications, consult an arc welding

technical manual.

WELD PASSES

Sometimes more than one pass is

necessary to fill the joint. The root pass

is first, followed by filler passes and the

cover pass. If the pieces are thick, it

may be necessary to bevel the edges

that are joined at a 60º angle.

Remember to remove the slag before

each pass for the FCAW process.

Welding Guidelines (Continued)

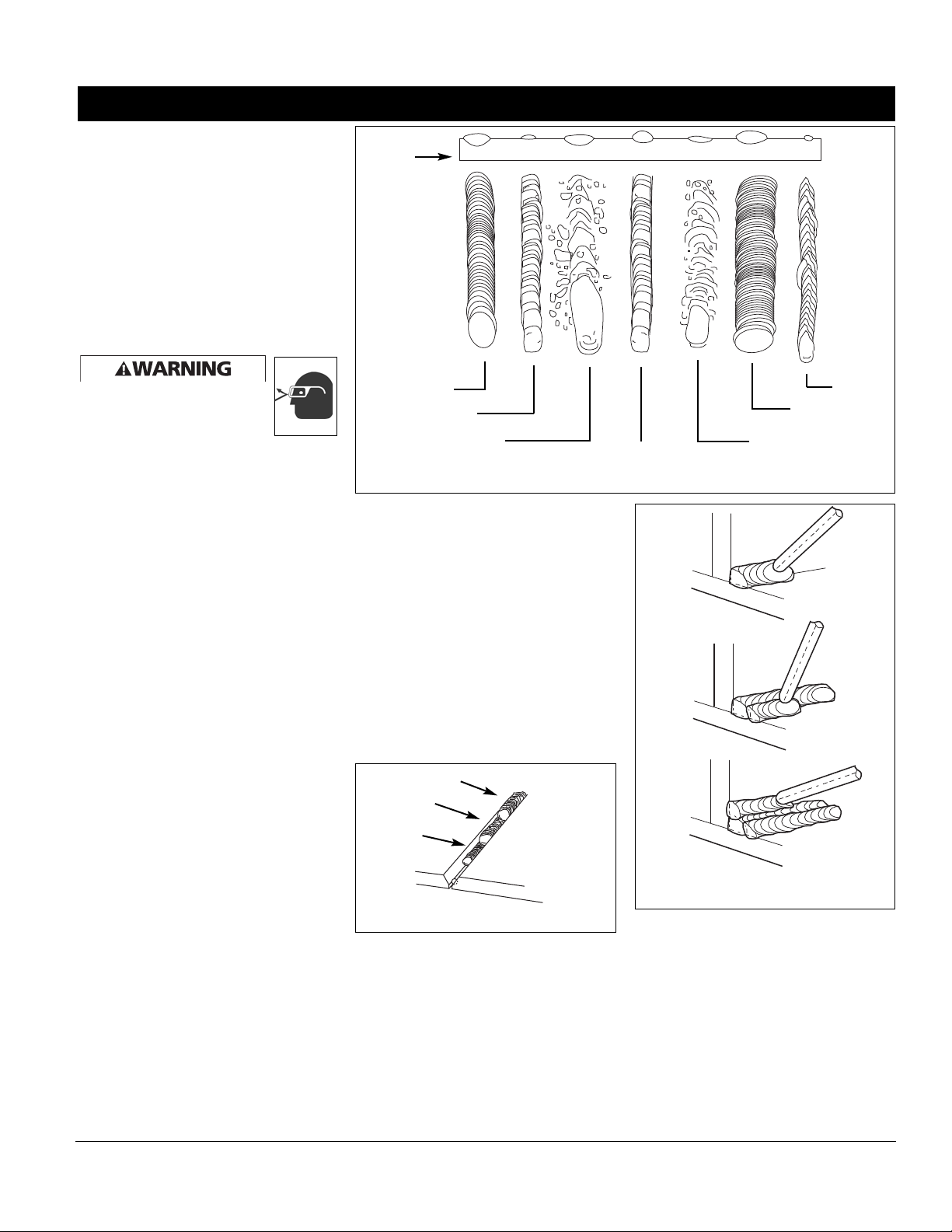

Normal Heat,

Wire Speed,

Travel Speed

Heat Too Low

Heat Too High

Wire Speed

Too Fast

Wire Speed Too Slow

Travel Speed

Too Slow

Travel

Speed

Too Fast

Base

Metal

Figure 9 - Weld Appearance

Figure 10 - Weld Passes

Cover

Filler

Root

Figure 11 - Multiple Weld Passes

Wire Feed Arc Welder

10

www.chpower.com

ALUMINUM WELDING

Any aluminum surface to be welded,

must be cleaned thoroughly with a

stainless steel brush to eliminate any

oxidation on the weld and grounding

surface. 100% Argon shielding gas

must be used when welding aluminum.

If 100% Argon is not used, metal

penetration is unlikely. A Teflon

®

wire

liner, smooth-groove drive roller and

aluminum contact tips are

recommended when welding

aluminum. Campbell Hausfeld offers

these parts in Kit WT2532. Call 1-800746-5641 to order.

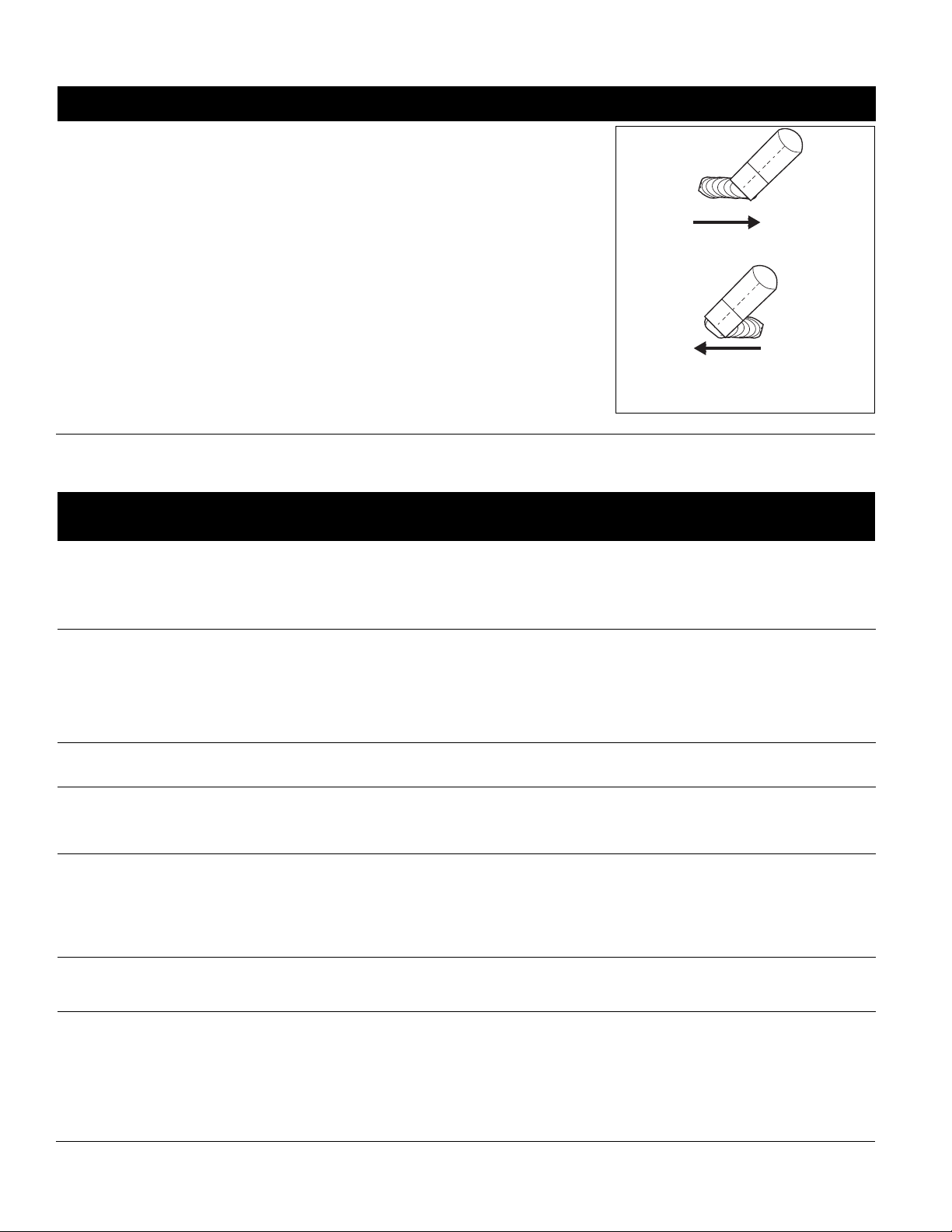

PUSH

PULL

Figure 12

Welding Guidelines (Continued)

PUSH VS PULL TECHNIQUE

The type and thickness of the work piece

dictates which way to point the torch

nozzle. For thin materials (18 gauge and

smaller) and all aluminum, the nozzle

should point out in front of the weld

puddle and push the puddle across the

workpiece. For thicker steel, the nozzle

should point into the puddle to increase

weld penetration. This is called backhand

or pull technique (See Figure 12).

Troubleshooting Chart - Welder

Symptom Possible Cause(s) Corrective Action

For Information About This Product Call 1-800-746-5641

1. Duty cycle exceeded

2. Poor work clamp connection

3. Tripped circuit breaker

4. Blown breaker or fuse

1. Wrong size contact tip

2. Torch liner clogged or

damaged

3. Contact tip clogged or

damaged

4. Drive roller worn

5. Not enough tension

1. Slag inside gun nozzle

2. Insulation ring melted/expired

1. Poor contact

2. Using an extension cord with

excessive length

1. Wire jammed

2. Out of wire

3. Not enough tension

4. Wire liner worn

5. Wire disconnected internally

6. Contact tip clogged

1. Wire speed too slow

2. Travel speed too slow or heat

is too high

1. Wire speed setting

2. Contact tip size too large

3. Polarity set incorrectly

4. Drive roller slipping

5. Gas bottle empty

1. Allow welder to cool until lamp goes out

2. Be sure all connections are secure, and attaching surface

is clean

3. Reset by pushing button on back of unit

4. Reduce circuit load, reset breaker or replace fuse

1. Use proper size contact tip

2. Clean or replace wire liner

3. Clean or replace contact tip

4. Replace

5. Tighten tension knob

1. Clean slag from gun nozzle

2. Replace nozzle

1. Be sure all connections are secure, and attaching surface

is clean

2. Never use an extension cord longer than 20 ft

1. Reload wire

2. Replace wire spool

3. Tighten tension knob if wire is slipping

4. Replace liner

5. Call 1-800-746-5641 for assistance

6. Replace contact tip

1. Run speed in 7 - 10 range

2. Increase the travel speed or reduce heat settings

1. Tune in correct setting (1-5 mild steel; 5-10 aluminum)

2. Replace contact tip

3. Reverse polarity

4. Increase tension

5. Replace gas bottle

No output

Wire tangles at drive roller

Gun nozzle arcs to work

surface

Work clamp and/or cable

gets hot

Wire does not feed

(Aluminum) Wire burns back

into tip or (Aluminum) Metal

bubbles or burns through

Weld pops and sputters

Models WG3080, WG3090 and WG4130

11

www.chpower.com

For Information About This Product Call 1-800-746-5641

Troubleshooting Chart - Welds

Symptom Possible Cause(s) Corrective Action

Bead is intermittently

too thin

Bead is intermittently

too thick

Ragged depressions at

edge of weld

Weld bead does not

penetrate base metal

Wire sputters and

sticks

1. Inconsistent travel speed

2. Output heat setting too low

1. Slow and/or inconsistent travel speed

2. Output heat setting too high

1. Travel speed too fast

2. Wire speed too fast

3. Output heat setting too high

1. Inconsistent travel speed

2. Output heat setting too low

3. No or low shielding gas

4. Wrong shielding gas (aluminum)

5. Extension cord is too long

6. (Aluminum) Possible oxide buid-up on

surface

1. Damp wire

2. Wire speed too fast

3. Wrong type of wire

4. No or low shielding gas

1. Decrease and maintain constant travel speed

2. Increase output heat setting

1. Increase and maintain travel speed

2. Reduce output heat setting

1. Decrease travel speed

2. Decrease wire speed

3. Reduce output heat setting

1. Decrease and maintain constant travel speed

2. Increase output heat setting

3. Use gas for MIG process or refill bottle

4. Use only 100% Argon gas

5. Never use an extension cord longer than 20 ft

6. Clean surface thoroughly with a stainless steel brush

only

1. Use dry wire and store in dry location

2. Reduce wire speed

3. Use flux-cored wire when not using gas

4. Use gas for MIG process or refill bottle

Notes

Wire Feed Arc Welder

12

www.chpower.com

1 Torch

(MIG, 8 ft., WG3080) WC601810AJ 1

Torch

(MIG, 10 ft., WG3090 & WG4130) WC601820AJ 1

2 Wire Liner – 0.024" - 0.035"

(0.6 - 0.9 mm), Cut to Length WC601801AV 1

Optional Wire Liner – 0.040" - 0.045"

(1.0 - 1.2 mm), Cut to Length

(WG4130) WC601802AV †

3 Contact Tip – 0.024" (0.6 mm) WT501200AV 1

Contact Tip – 0.030" (0.8 mm) WT501300AV 1

Contact Tip – 0.035" (0.9 mm) WT501400AV 1

Optional Contact Tip – 0.024"

(0.6 mm) 4 Pack WT501200AJ †

Optional Contact Tip – 0.030"

(0.8 mm) 4 Pack WT501300AJ †

Optional Contact Tip – 0.035"

(0.9 mm) 4 Pack WT501400AJ †

4 Nozzle WT502100AV 1

5 Drive Roller – 0.024" - 0.035"

(0.6 - 0.9 mm) WC500930AV 1

Optional Drive Roller – 0.040" - 0.045"

(1.0 - 1.2 mm) (WG4130 only) WC500932AV †

6 Drive Deck Wire Guide WC500920AV 1

7 Drive Deck Assembly WC500900AV 1

8 Spool Spindle WC707430AV 1

9 Spool Retainer WC707023AV 1

10 Spool Spring WC707026AV 1

11 Spool Lock WC707024AV 1

12 Flux Weld Wire – 0.030" (0.8 mm)

2 lb. Spool (E71T-GS) WE200001AV †

Flux Weld Wire – 0.030" (0.8 mm)

10 lb. Spool (E71T-GS) WE201000AV †

Flux Weld Wire – 0.035" (0.9 mm)

2 lb. Spool (E71T-GS) WE200501AV †

Flux Weld Wire – 0.035" (0.9 mm)

10 lb. Spool (E71T-GS) WE201500AV †

MIG Weld Wire – 0.024" (0.6 mm)

2 lb. Spool (ER70S6) WE300001AV †

Ref. Part

No. Description Number Qty

MIG Weld Wire – 0.024" (0.6 mm)

11 lb. Spool (ER70S6) WE301500AV †

MIG Weld Wire – 0.030" (0.8 mm)

2 lb. Spool (ER70S6) WE300501AV †

MIG Weld Wire – 0.030" (0.8 mm)

11 lb. Spool (ER70S6) WE302000AV †

MIG Weld Wire – 0.035" (0.9 mm)

2 lb. Spool (ER70S6) WE301001AV †

MIG Weld Wire – 0.035" (0.9 mm)

11 lb. Spool (ER70S6) WE302500AV †

Aluminum MIG Welding Wire –

0.030" (0.8 mm), 1 lb. Spool WE303001AV †

13 Safety Decal DK689105AV 1

14 Work Clamp WC100700AV 1

15 Gas Hose – 4 ft. (WG3090 & WG4130) WC803720AV 1

16 Regulator with 2 gauges

(WG3090 & WG4130) WC803710AV 1

17 Optional Regulator Kit

(includes items 15 & 16) (WG3080) WC803700AJ †

18 Optional Welding Helmet WT100500AV †

19 Optional Aluminum Welding Kit

[Includes Teflon

®

Wire liner, U-groove

drive roller for 0.030" (0.8 mm)

aluminum wire and four 0.030"

(0.8 mm) contact tips for aluminum

wire] WT253200AV †

20 Handle Assembly WC707405AJ †

Not Shown

† Optional Accessory

Address any correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Please provide following information:

- Model number

- Serial number

- Part description and number as shown in

parts list

Replacement Parts List - Models WG3080, WG3090 and WG4130

For replacement parts or

technical assistance, call

1-800-746-5641.

Ref. Part

No. Description Number Qty

Figure 13- Replacement Parts

14

1

11

5

7

8

9

6

13

12

10

4

Models WG3080, WG3090 and WG4130

13

www.chpower.com

Glossary of Welding Terms

AC or Alternating Current - electric

current that reverses direction

periodically. Sixty cycle current travels

in both directions sixty times per

second.

Arc Length - the distance from the

end of the electrode to the point

where the arc makes contact with the

work surface.

Base Metal - the material to be

welded.

Butt Joint - a joint between two

members aligned approximately in the

same plane.

Crater - a pool, or pocket, that is

formed as the arc comes in contact

with the base metal.

DC or Direct Current - electric current

which flows only in one direction. The

polarity (+ or -) determines which

direction the current is flowing.

DC Reverse Polarity - occurs when

the electrode holder is connected to

the positive pole of the welding

machine. Reverse Polarity directs more

heat into melting the electrode rather

than the work piece. It is used on

thinner material.

DC Straight Polarity - occurs when

the electrode holder is connected to

the negative pole of the welding

machine. With straight polarity more

heat is directed to the work piece for

better penetration on thicker material.

Electrode - a coated metal wire having

approximately the same composition as

the material being welded.

Fillet Weld - approximately a triangle

in cross-section, joining two surfaces at

right angles to each other in a lap, T or

corner joint.

Flux - a coating, when heated, that

produces a shielding gas around the

welding area. This gas protects the

parent and filler metals from impurities

in the air.

Flux Cored Arc Welding (FCAW) also called Gasless, is a welding process

used with a wire-feed welding

machine. The weld wire is tubular with

flux material contained inside for

shielding.

Gas Metal Arc Welding (GMAW) also called MIG, is a welding process

used with a wire feed welding

machine. The wire is solid and an inert

gas is used for shielding.

Gas Tungsten Arc Welding (GTAW) also called TIG, is a welding process

used with welding equipment with a

high frequency generator. The arc is

created between a non-consumable

tungsten electrode and the work piece.

Filler metal may or may not be used.

Lap Joint - a joint between two

overlapping members in parallel

planes.

Open Circuit Voltage (OCV) - the

voltage between the electrode and the

work clamp of the welding machine

when no current is flowing (not

welding). The OCV determines how

quickly the arc is struck.

Overlap - occurs when the amperage is

set too low. In this instance, the molten

metal falls from the electrode without

actually fusing into the base metal.

Porosity - gas pockets, or cavities,

formed during weld solidification. They

weaken the weld.

Penetration - the depth into the work

piece that has been heat effected by

the arc during the welding process. A

good weld achieves 100% penetration

meaning that the entire thickness of

the work piece has been heated and

resolidified. The heat effected area

should be easily seen on the opposite

side of the weld.

Shielded Metal Arc Welding

(SMAW) - also called Stick, is a welding

process with uses a consumable

electrode to support the arc. Shielding

is achieved by the melting of the flux

coating on the electrode.

Slag - a layer of flux soot that protects

the weld from oxides and other

contaminants while the weld is

solidifying (cooling). Slag should be

removed after weld has cooled.

Spatter - metal particles thrown from

the weld which cool and harden on the

work surface. Spatter can be minimized

by using a spatter resistant spray on the

work piece before welding.

Tack Weld - weld made to hold parts

in proper alignment until final welds

are made.

Travel Angle - the angle of the

electrode in the line of welding. It

varies from 5º to 45º depending on

welding conditions.

T Joint - made by placing the edge of

one piece of metal on the surface of

the other piece at approximately a 90º

angle.

Undercut - a condition that results

when welding amperage is too high.

The excessive amperage leaves a

groove in the base metal along both

sides of the bead which reduces the

strength of the weld.

Weld Pool or Puddle - a volume of

molten metal in a weld prior to its

solidification as weld metal.

Weld Bead - a narrow layer or layers

of metal deposited on the base metal

as the electrode melts. Weld bead

width is typically twice the diameter of

the electrode.

Work Angle - the angle of the

electrode from horizontal, measured at

right angles to the line of welding.

Wire Feed Arc Welder

14

www.chpower.com

Limited Warranty

Limited Warranty

1. Duration: The manufacturer warrants that it will repair, at no charge for parts or labor, the Welder, Welding Gun, or

Cables, proven defective in material or workmanship, during the following time period(s) after date of original retail

purchase:

For 5 Years: The Welder Transformer and Rectifier

For 3 Years: The Entire Welder (excluding clamps, welding gun, electrode holder, cables, or accessories packed with welder)

For 90 Days: The Welding Clamps, MIG Gun, Electrode Holder, Accessories, and Welding Cables (as applicable)

2. Who Gives This Warranty (Warrantor):

Campbell Hausfeld / Scott Fetzer Company

100 Production Drive

Harrison, OH 45030 U.S.A.

Telephone: 1-800-746-5641

3. Who Receives This Warranty (Purchaser): The original purchaser of the Campbell Hausfeld product.

4. What is covered under this warranty: Defects in material and workmanship which occur within the duration of the

warranty period. This warranty extends to the Welder, the Welders Transformer and Rectifier, Welding Gun or Electrode

Holder, and cables only.

5. What is not covered under this warranty:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN

DURATION TO THIS EXPRESS WARRANTY. After this period, all risks of loss, from whatever reason, shall be on the

purchaser. Some states do not allow limitations on how long an implied warranty lasts, so above limitations may not

apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT FAILURE OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow limitations on

how long an implied warranty lasts, so above limitations may not apply to you.

C. This warranty does not apply to any accessory items included with the product which are subject to wear from usage;

the repair or replacement of these items shall be at the expense of the owner. These MIG items include but are not

limited to; Contact Tips, Nozzles, Gun Liners, Drive Rollers, Felt Wire Cleaner. In addition, this warranty does not

extend to any damage caused by the untimely replacement or maintenance of any of the previously listed

CONSUMABLE parts.

D. Any failure that results from accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with the product.

E. Pre-delivery service, i.e. assembly and adjustment.

6. Responsibilities of Warrantor under this warranty: Repair or replace, at Warrantor’s option, products or components

which have failed within duration of the warranty period.

7. Responsibilities of purchaser under this warranty:

A. Please call 1-800-746-5641 for warranty assistance.

B. Provide dated proof of purchase and maintenance records.

C. All welders must be delivered or shipped to the nearest Campbell Hausfeld Authorized Service Center. Freight costs,

if any, must be borne by the purchaser.

D. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

8. When Warrantor will perform repair or replacement under this warranty: Repair or replacement will be scheduled

and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement

parts.

This Limited Warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Figure 1 - Commandes et Pièces Du Soudeur

3

1

6

4

5

2

EXIGENCES DE CIRCUIT

Cet équipement doit avoir un circuit

réservé de 120 ou 230 volts (selon le

modèle). Se reporter au tableau suivant

pour le disjoncteur ou la valeur de

fusible appropriés pour les modèles à

120 volts. Ne pas faire fonctionner

d’autres appareils, lampes ou outils sur

ce circuit pendant l’utilisation de cet

équipement. Les cordons prolongateurs

ne sont pas recommandés. Ne pas

suivre ces recommandations peut

résulter en fusibles sautés et

disjoncteurs déclenchés.

PIÈCES DÉTACHÉES ET CONTRÔLES

(FIGURE 1)

1. Pince de soudeur - s’attache à l’objet

de travail.

2. Chalumeau à buse de 0,08 cm

(0,030 po)

3. Cordon d’alimentation - brancher

dans une prise de 120 ou 230 volts

(selon le modèle).

4. Voyant- le voyant s’active si le

thermostat éteint automatiquement

le soudeur

5. Contrôle de vitesse de fil infini tourne dans le sens horaire pour

augmenter la vitesse et dans le sens

antihoraire pour diminuer la vitesse

du fil.

6. Sélecteur arrêt/chaleur - Choisit le

courant de soudure et met l’appareil

en marche. Cinq choix possibles :

1 - 2 - 3 - 4 - 5.

15 Fr

Description

Ces soudeurs à fil Campbell Hausfeld

sont conçus pour être utilisés sur une

prise standard de 120 V (WG3080 &

WG3090) ou 230 V (WG4130). Le

soudeur est doté d’un contrôle de vitesse

de fil continu pour choisir avec

exactitude la bonne vitesse

d’alimentation du fil pour les diverses

conditions de soudage. Les pièces

internes sont protégées par un

thermostat.Ce système de soudure est

conçu pour être utilisé dans le procédé de

soudage à l’arc avec fil-électrode fourré

(Flux-Cored Arc Welding (FCAW)) ou de

soudage à l’arc sous protection de gaz

inerte avec fil-électrode fusible (Gas Metal

Arc Welding (GMAW)). À sa livraison de

l’usine, ce soudeur peut souder avec un

fil fourré de 0,8 mm (0,030 po) de

diamètre. Une bobine de démarrage

de fil fourré de 0,8 mm (0,030 po)

est incluse.

Pour utiliser le processus de soudage

à l’arc sous protection gazeuse avec les

WG3090 et WG4130, il faut acheter

seulement un gaz de protection et un fil

MIG. Avec le WG3080, il faut acheter

une trousse de boyau / régulateur en

plus du gaz de protection et du fil MIG.

Déballage

Lors du déballage, l’examiner

soigneusement pour rechercher toute

trace de dommage susceptible de s’être

produit en cours de transport. Assurer

que tous raccords, vis, etc., soient serrés

avant de mettre ce produit en service.

Rapportez tout article manquant ou

endommagé en composant le

1-800-746-5641.

IN974200AV 11/09

Se référer à la page 22 pour les

instructions de remplacement du

cordon d’alimentation.

© 2009 Campbell Hausfeld/Scott Fetzer

MÉMENTO: Gardez votre preuve datée d’achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Sélecteur Disjoncteur ou Fusée

de à Retardement pour

Chaleur Modéles de 120-V c.a.

1-2-3 15 amp

4-5 20 amp

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à

l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a

risque de blessure et/ou dégâts matériels ! Conserver ces instructions comme référence.

Instructions d’Utilisation et

Modèles WG3080, WG3090 et WG4130

Manuel de Pièces de Rechange

Soudeur À L’Arc

Alimenté En Fil

Soudeur à l’Arc Alimenté en Fil

Généralités sur la

Sécurité

Danger

indique

une situation hasardeuse imminente

qui RÉSULTERA en perte de vie ou

blessures graves.

Avertissement indique une situation

hasardeuse potentielle qui PEUT résulter

en perte de vie ou blessures graves.

Attention indique une situation

hasardeuse potentielle qui PEUT

résulter en blessures.

REMARQUE: Remarque indique : des

renseignements additionnels

concernant le produit ou son utilisation.

Toujours avoir un extincteur

d’incendie disponible

pendant le soudage à l’arc.

Lire et comprendre toutes

les instructions avant de

mettre en marche ou de

procéder à l’entretien

d’un soudeur à l’arc

électrique. Ne pas suivre les

précautions et les instructions peut

causer le dommage à l’équipement

et/ou blessures personnelles graves

ou la mort.

Toute installation, entretien,

réparation et utilisation de cet

équipement doivent être effectués

par les personnes qualifiées

conformément aux codes nationaux,

provinciaux et locaux.

L’utilisation incorrecte des

soudeurs à l’arc électriques

peut avoir comme résultat,

secousse électrique, blessure,

et perte de vie ! Suivre toutes les

précautions indiquées dans ce manuel

afin de réduire le risque de secousse

électrique.

Vérifier que toutes les pièces du

soudeur à l’arc soient propres et en

bon état avant de l’utiliser. S’assurer

que l’isolant de tous les câbles,

du chalumeau et du cordon

d’alimentation n’est pas

endommagé. Toujours réparer ou

remplacer les pièces détachées

endommagées avant d’utiliser le

soudeur. Toujours garder les

panneaux, les écrans de soudage,

etc. en place pendant le

fonctionnement du soudeur.

Toujours porter des vêtements

protecteurs et gants de soudage secs,

ainsi que des chaussures isolantes.

Toujours faire fonctionner le

soudeur dans un endroit propre, sec

et bien ventilé. Ne pas faire

fonctionner le soudeur dans un

endroit humide, trempe, pluvieux,

ou mal-ventilé.

S’assurer que l’objet sur lequel vous

travaillez soit bien fixé et mis à la

terre correctement avant de

commencer votre soudage à l’arc

électrique .

Le câble de soudage roulé devrait

être étendu avant l’utilisation afin

d’éviter le surchauffage et le

dommage à l’isolation.

Ne jamais

plonger le

fil ou le chalumeau dans l’eau. Si le

soudeur devient trempe, il est

nécessaire qu’il soit complètement sec

et propre avant l’utilisation!

Toujours mettre l’équipement hors

circuit et le débrancher avant de le

déplacer.

Toujours brancher le conducteur de

travail en premier lieu.

Vérifier que l’objet sur lequel vous

travaillez soit mis à la terre

correctement.

Toujours éteindre l’équipement de

soudure à l’arc électrique lorsqu’il n’est

pas utilisé et couper tout surplus de fil

du chalumeau.

Ne jamais laisser toute partie du corps

toucher le fil de soudure, la masse ou la

pièce de travail mise à la terre en

même temps.

Les conditions et positions de

soudage difficiles peuvent poser des

risques électriques. Si vous êtes

accroupis, à genoux ou aux

élévations, s’assurer que toutes les

pièces conductrices soient isolées.

Porter des vêtements protecteurs

convenables et prendre ses

précautions contre les chutes.

Ne jamais essayer d’utiliser cet

équipement aux réglages de courant

ni aux facteurs d’utilisation

supérieurs à que ceux indiqués sur

les étiquettes de l’équipement.

Ne jamais utiliser de soudeur à l’arc

électrique pour dégeler les tuyaux

congelés.

Les étincelles volantes et le

métal chaud peuvent causer

des blessures. La scorie peut

s’échapper quand les

soudures se refroidissent. Prenez

toutes précautions indiquées dans ce

manuel pour réduire la possibilité de

blessure par les étincelles volantes et

le métal chaud.

Porter un masque de soudure ou des

lunettes de sécurité avec écrans

protecteurs approuvés par ANSI

pendant le burinage ou l’ébarbage

des pièces en métal.

Utiliser des protège-tympans pour

le soudage aérien afin d’éviter que

la scorie ou la bavure tombe dans

vos oreilles.

Le soudage à l’arc électrique

produit une lumière intense,

la chaleur et les rayons

ultraviolets (UV). Cette

lumière intense et ces rayons UV

peuvent causer des blessures aux yeux

et à la peaux. Prenez toutes précautions

indiquées dans ce manuel afin de

réduire la possibilité des blessures aux

yeux et à la peau.

Toutes personnes qui utilisent cet

équipement ou qui sont dans

l’endroit pendant l’utilisation de

l’équipement doivent porter des

vêtements de soudage protecteurs

y compris : un masque ou un casque

de soudeur ou un écran avec un

filtre numéro 10 (au moins), des

vêtements incombustibles, des gants

de soudeur en cuir, et la protection

complète pour les pieds.

Ne jamais observer le soudage à l’arc

sans la protection pour les yeux telle

qu’indiquée ci-dessus. Ne jamais

utiliser une lentille filtrante qui est

fendue, cassée ou classifiée moins

que le numéro 10. Avertir les autres

personnes sur place de ne pas

observer l’arc.

16 Fr

MANUAL

Ne pas inspirer les vapeurs

qui sont produites par le

soudage à l’arc. Ces vapeurs

sont dangereuses. Utiliser un

respirateur fourni d’air si l’endroit de

soudage n’est pas bien ventilé.

Garder la tête et le visage hors des

vapeurs de soudage.

Des vapeurs extrêmement

toxiques sont produites pendant

le chauffage des métaux

galvanisés, plaqués de cadmium,

ou des métaux qui contiennent le

zinc, le mercure, ou le beryllium.

Compléter les précautions suivantes

avant d’exécuter le soudage à l’arc

électrique sur ces métaux:

a. Enlever l’enduit du métal commun.

b. S’assurer que l’endroit de soudage

soit bien ventilé.

c. Utiliser un respirateur fourni d’air.

Le champ électromagnétique

qui est produit pendant le

soudage à l’arc peut causer de

l’interférence avec le

fonctionnement de plusieurs appareils

électriques tels que les pacemakers

cardiaques. Toutes personnes utilisant

ces appareils doivent consulter leur

médecin avant d’exécuter le soudage à

l’arc électrique.

Acheminer les câbles de chalumeau

et de travail ensemble et fixer avec

du ruban si possible.

Ne jamais envelopper les câbles de

soudage à l’arc autour du corps.

Toujours placer le chalumeau et les

fils de travail du même côté du corps.

L’exposition aux champs

électromagnétiques peut avoir

autres réactions inconnues

concernant la santé.

PROPOSITION 65 CALIFORNIE

Ce produit, utilisé pour la

soudure, produit des vapeurs

ou gaz qui contiennent des

produits chimiques prouvés

par I’État de Californie de provoquer

des dé fauts de naissance (ou autre tort

aux organes de la reproduction), et en

quelques circonstances, le cancer.

(le code `California Health & Safety

Code Section 25249.5 et seq’.).

Ce produit et son cordon contient du

plomb, un produit chimique qui de

l’avis de l’État de Californie peut

causer le cancer et des anomalies

congénitales ou d’autres problèmes

Généralités sur la

Sécurité (Suite)

Le soudage à l’arc électrique

produit des étincelles et

chauffe le métal aux

températures qui peuvent

causer des brûlures graves! Utiliser des

gants et des vêtements protecteurs

pendant n’importe quel travail de

métal. Prenez toutes précautions

indiquées dans ce manuel afin de

réduire la possibilité de brûlures de

peau ou de vêtements.

S’assurer qui toutes personnes dans

l’endroit de soudage soient protégées

contre la chaleur, les étincelles et les

rayons ultraviolets. Utiliser des écrans

de visage additionnels et des écrans

coupe-feu si nécessaire.

Ne jamais toucher les objets de travail

avant qu’ils soient complètement

refroidis.

La chaleur et les étincelles

qui sont produites pendant

le soudage à l’arc électrique

et autres travaux de métal

peuvent allumer les matériaux

inflammables et explosifs! Prenez

toutes les précautions indiquées dans

ce manuel afin de réduire la possibilité

de flammes et d’explosions.

Enlever tous les matériaux

inflammables à moins de 35 pieds

(10,7 m) de l’arc de soudage.

Si l’enlevage n’est pas possible, bien

couvrir les matériaux inflammables

avec des couvertures incombustibles.

Ne pas utiliser un soudeur à l’arc

électrique dans les endroits qui

contiennent des vapeurs

inflammables ou explosifs.

Prenez précaution pour assurer que

les étincelles volantes et la chaleur

ne produisent pas de flammes dans

des endroits cachés, fentes, etc.

Risque d’incendie! Ne pas souder les

récipients ni les tuyaux qui contiennenet

ou qui ont contenus des matériaux

inflammables ou combustibles gaseux ou

liquides.

Le soudage à l’arc des

bouteilles ou des récipients

fermés tels que les réservoirs

ou bidons, peuvent causer

une explosion s’ils ne sont pas bien

ventilés! Vérifier qu’il y a un trou de

ventilation suffisant dans n’importe

quel bouteille ou récipient afin de

permettre la ventilation des gaz

pendant l’expansion.

pour la reproduction. Se laver les mains

après toute manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

Avant de laisser l’endroit,

s’assurer que l’endroit de

soudage est en état sûr et

sans risques (étincelles,

flammes, métal chauffé au rouge, ou

scorie). S’assurer que l’équipement soit

hors circuit et que l’excès de fil soit

taillé. S’assurer que les câbles soient

roulés (sans serrer) et hors du chemin.

S’assurer que tout métal et scorie

soient refroidis.

Les bouteilles peuvent

exploser si elles sont

endommagées. Les bouteilles

de gaz de protection

contiennent du gaz sous haute pression.

Si elles sont endommagées, elles

peuvent exploser. Puisque les bouteilles

de gaz font normalement partie du

processus de soudure, s’assurer de les

manipuler avec soin.

Protéger les bouteilles de gaz

comprimé contre la chaleur excessive,

les chocs mécaniques et les arcs.

Installer et fixer les bouteilles dans

une position verticale en utilisant une

chaîne sur un support stationnaire ou

un support de bouteille afin d’éviter

le renversement ou le basculage.

Garder les bouteilles à l’écart du

soudage ou autres circuits électriques.

Ne jamais permettre que l’électrode

de soudage touche une bouteille.

Utiliser seulement les bouteilles

de gaz correctes; régulateurs,

tuyaux et raccords conçus pour

votre application et les tenir en

bon état de marche.

Tourner le visage à l’écart de la

soupape d’échappement en ouvrant

la soupape de la boutille.

Garder le capuchon protecteur en

place sur la soupape sauf si la

bouteille est soi en service ou

brancher pour le service.

Lire et suivre les instructions pour les

bouteilles de gaz et autre équipement,

ainsi que la publication CGA, P-1

indiquée dans les Normes de Sécurité.

Ne jamais

utiliser les

gaz inflammables avec les soudeurs MIG.

Seuls les gaz inertes ou ininflammables tels

que le bioxyde de carbone, l’argon, le

helium ou un mélange d’un ou plus de ces

gaz sont convenables pour le soudage MIG.

Modèles WG3080, WG3090 et WG4130

17 Fr

ventilation en avant et en arrière du

modèle. Garder cet espace libre

d’obstructions.

Ranger le fil de soudage dans un

endroit propre et sec à faible

humidité pour éviter l’oxydation.

Utiliser une prise de courant mise à

la terre correctement pour le

soudeur, et s’assurer que le soudeur

soit le seul appareil de charge sur le

circuit d’alimentation. Se référer au

tableau sur la page 1 pour la

capacité correcte du circuit.

L’utilisation d’un cordon

prolongateur n’est pas recommandé

pour les soudeurs à l’arc électriques.

Une perte de tension dans le cordon

prolongateur peut diminuer de

façon spectaculaire, le rendement du

soudeur.

Montage

INSTALLATION DU CHALUMEAU

(VOIR FIG. 2)

1. S’assurer que l’appareil soit éteint et

débranché.

Soudeur à l’Arc Alimenté en Fil

Généralités sur la

Sécurité (Suite)

Ne jamais

soulever

les bouteilles par leurs soupapes,

capuchons ni avec les chaînes ou

élingues.

NORMES DE SÉCURITÉ ADDITIONNELLES

Normes ANSI Standard Z49.1 de la Société

American Welding Society, 550 N.W. Le June

Rd. Miami, FL 33126

Normes de Sécurité et de Santé

OSHA 29 CFR 1910, du Superintendent of

Documents, U.S. Government Printing Office,

Washington, D.C. 20402

Code Électrique National

Norme NFPA 70, de l’Association National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269

Manipulation Sûr des Bouteilles de Gaz

Comprimé

Brochure CGA P-1, de l’Association

Compressed Gas Association, 1235 Jefferson

Davis Highway, Suite 501, Arlington, VA

22202

Code pour la Sécurité concernant le

Soudage et le Coupage

Norme CSA W117.2, de l’Association Canadian

Standards Association, Standards Sales, 178

Rexdale Boulevard, Rexdale, Ontario, Canada

M9W 1R3

Procédés de Coupage et Soudage

Norme NFPA 51B, le l’Association National

Fire Protection Association, Batterymarch

Park, Quincy, MA 02269

Règlements Professionnels et

d’Éducation de Sécurité pour la

Protection des Yeux et du Visage

Norme ANSI Z87.1, de l’Institut American

National Standards Institute, 1430 Broadway,

New York, NY 10018

Se référer aux Données de Sécurité

(Material Safety Data Sheets) et les

instructions des fabricants pour les

métaux, les fils, les enduits et les

produits pour le nettoyage.

Installation

ENDROIT

La sélection de l’endroit correct peut

amélioré de façon spectaculaire, le

rendement, la fiabilité, et la durée du

soudeur à l’arc.

Pour un meilleur résultat, situer le

soudeur dans un endroit propre et

sec. La poussière et la sâleté dans le

soudeur conservent l’humidité et

augmentent l’usure des pièces

mobiles.

Placer le soudeur dans un endroit

avec au moins douze pouces

(305 mm) d’espace pour la

2. Acheminer les connecteurs de

l’interrupteur du chalumeau par le

trou dans le panneau de contrôle.

Ces fils doivent être acheminés vers le

haut sur les goujons de polarité et à

travers le crochet sur le mur central.

3. Insérer le connecteur de chalumeau

en laiton par le trou du panneau de

contrôle et dans le tablier

d’entraînement. S’assurer que le

connecteur est inséré entièrement

dans le tablier d’entraînement.

Desserrer le bouton de la pince de

chalumeau de quelques tours si le

connecteur ne s’insère pas

entièrement. Resserrer le bouton de

la pince de chalumeau après que le

connecteur de chalumeau de laiton

soit entièrement inséré.

4. Brancher les connecteurs de

l’interrupteur du chalumeau aux

deux bornes de 6 mm (1/4 po) dans

le mur central. La polarité n’est pas

importante. S’assurer que ces fils

n’entravent pas les goujons de

polarité ou le tablier d’entraînement.

18 Fr

Crochet

Fils d’interrupteur

de chalumeau

Bouton de pince

de chalumeau

Connecteurs

d’interrupteur

de chalumeau

Tablier

d’entraînement

Bornes

d’interrupteur

de chalumeau

Chalumeau

Figure 2 - Installation de chalumeau

Pince de travail

Câble de soudure

Connecteur à anneau