Page 1

● Do not use any type

of flammable gases

or oxygen as a power

source for the nailer.

Use filtered, lubricated, regulated

compressed air only. Use of a compressed gas instead of compressed

air may cause the nailer to explode

which will cause death or serious

personal injury.

● Do not exceed maxi-

mum operating pressure of the nailer

(125 psi). The nailer

will not function

properly. Do not use

a compressed air source capable of

more than 200 PSI. The nailer could

explode which will cause death or

serious personal injury.

● Never use gasoline

or other flammable

liquids to clean the

nailer. Never use the

nailer in the presence

of flammable liquids or gases.

Vapors could ignite by a spark and

cause an explosion which will result

in death or serious personal injury.

● Always remain in

a firmly balanced

position when

using or handling

the nailer.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

● Always

disconnect

nailer from

air line

before

adjusting or servicing the nailer, or

when the nailer is not in use.

● Protect your eyes and ears. Wear

Z87 safety glasses, with side shields.

Wear hearing protection. Employers

and users are responsible for ensuring the

user or anyone near

the nailer wears this

safety protection.

Serious eye injury or permanent

hearing loss could result.

● Never carry the nailer

by the air hose or

pull the hose to

move the nailer or a

compressor. Keep

hoses away from

heat, oil and sharp edges. Replace

any hose that is damaged, weak or

worn. Personal injury or tool damage could occur.

● Do not operate or

allow anyone else

to operate the

nailer if any warnings or warning

labels are not legible.

Warnings or warning

labels are located on the nailer body.

● Do not drop or throw the tool.

Dropping or throwing the tool can

result in damage that will make the

tool unusable or unsafe. If the tool

Table Of Contents

General Safety . . . . . . . . . 1 - 2

Specifications . . . . . . . . . . . . . 2

Operating The Nailer . . . .2 - 3

Troubleshooting . . . . . . . . . . 4

Warranty . . . . . . . . . . . . . . . . 4

Description

This nailer is designed for framing,

decking, joist hanger installation, cross

bridging, and fencing. Features include

a padded leather cover for user comfort, an offset magnetic nose for easy

fastener placement, and a compact

design for working in tight applications.

General Safety Information

This manual contains safety, operational and maintenance information.

Read this manual and

understand all safety warnings and instructions before

operating the nailer.

Contact your Campbell

Hausfeld representative if you have

any questions.

OPERATOR’S RESPONSIBILITY:

Before operating the nailer, read and

understand all safety warnings and

labels. Follow the operating instructions outlined in this manual.

EMPLOYER’S RESPONSIBILITY:

Distribute this instruction manual to all

users before allowing use of the nailer.

Ensure all operators read, understand

and follow all safety warnings, labels

and instructions outlined in this

manual.

Danger indicates

an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Air Palm

Hammer

Operating Instructions Model PN0090

IN268801AV 6/01

Model PN0090

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Campbell Hausfeld Nailers meet or exceed Industries’ Standards as set forth by the American National

Standard Institute/International Staple, Nail and Tool Association in ANSI/ISANTA SNT-101-1993.

© 2001 Campbell Hausfeld

Locate model and serial number on

tool and record below:

Model No. ________________________

Serial No. _________________________

Retain these numbers for

future reference.

BUILT TO LAST

TM

O

CO

2

!

DANGER

MANUAL

!

WARNING

125 psi

MAX.

!

WARNING

!

WARNING

Page 2

150 PSI WP

3/8" I.D.

A

2

has been dropped or thrown, examine the tool closely for bent, cracked

or broken parts and air leaks. STOP

and repair before using or serious

injury could occur.

● Avoid long extended periods of

work with the nailer. Stop using the

nailer if you feel pain in hands or

arms.

Caution indicates a

potentially hazardous situation which, if not avoided,

MAY result in minor or moderate

injury.

● Do not modify or alter the nailer or

any nailer parts. Do not use the nailer

if any shields or guards are removed

or altered. Do not use the nailer as a

hammer. Personal injury or tool

damage may occur.

● Do not use a check

valve or any other

fitting which allows

air to remain in the

nailer. Personal injury

may occur.

● Never place hands or

any other body parts

in the nail discharge

area of the nailer.

Use caution when

placing a nail in the

nail guide. The nailer could eject the

fastener causing personal injury.

●

Never use the nailer as a toy. Do not

engage in horseplay. Always keep

others at a safe distance from the

work area. Never point the nailer at

anyone. Accidental triggering of the

nailer could result in personal injury.

● Never leave the nailer unattended or

connected to an air compressor when

not in use. Personal injury can occur

if someone picks up and uses the

nailer without knowing the correct

way to operate the nailer.

Notice indicates

important information, that if not followed, MAY

cause damage to equipment.

● Inspect the tool daily

for loose or broken

parts. Do not use the

tool until all parts

have been tightened

or replaced.

● Clean and check all air supply hoses

and fittings before connecting the

nailer to an air supply. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may

be reduced.

● Air compressors providing air to the

nailer should follow the requirements established by the American

National Standards Institute

Standard B19.3-1991; Safety

Standard for Compressors for

Process Industries. Contact your air

compressor manufacturer for

information.

Operating the Nailer

Read this manual and understand

all safety warnings and instructions before operating the nailer.

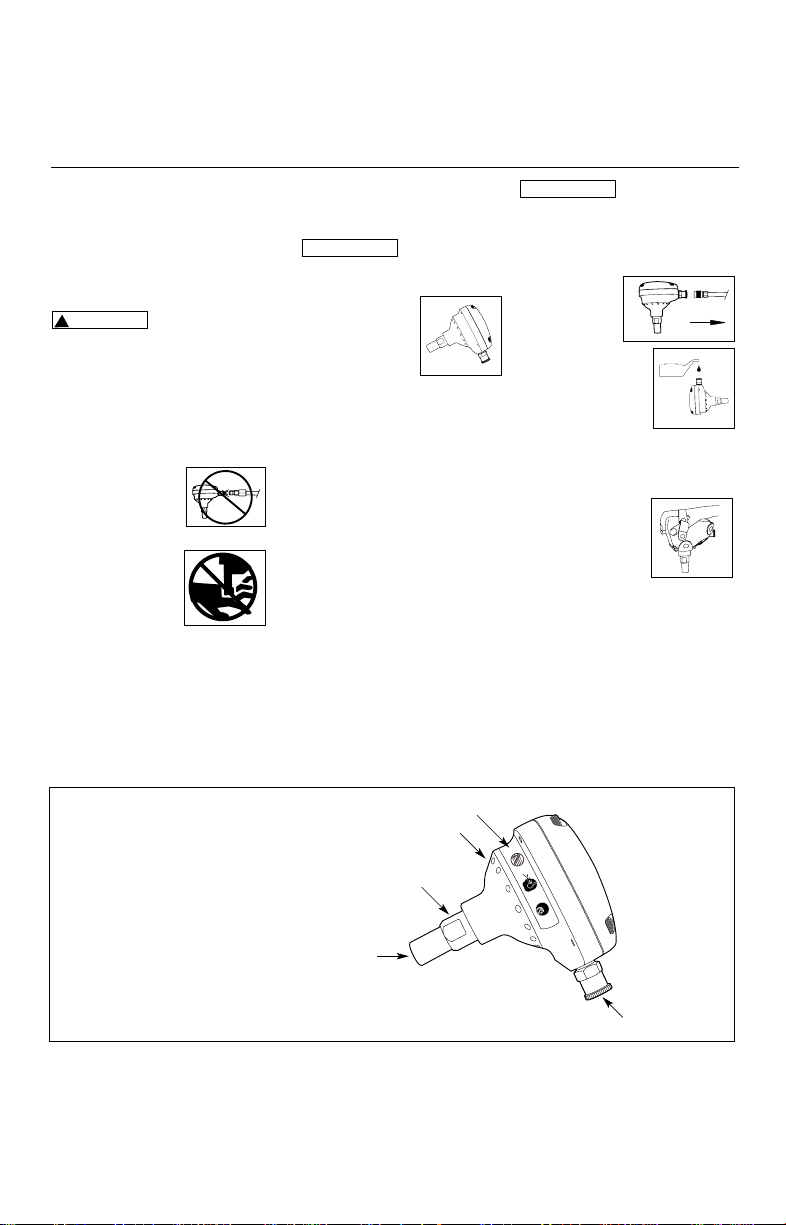

LUBRICATION

This nailer requires lubrication before

using the nailer for the first time and

before each use. If an inline oiler is

used, manual lubrication through the

air inlet is not required on a daily basis.

The work surface

can become damaged by excessive lubrication. Proper

lubrication is the owner’s responsibility. Failure to lubricate the nailer properly will dramatically shorten the life

of the nailer and void the warranty.

1. Disconnect the

air supply from

the nailer to

add lubricant.

2. Turn the nailer so

the air inlet is facing

up. Place 4-5 drops

of 30 W non-detergent oil into air inlet.

Do not use detergent oils, oil additives, or air tool oils. Air tool oils

contain solvents which will damage

the nailer's internal

components.

3. After adding oil, run

nailer briefly. Wipe

off any excess oil

from the exhaust.

NOTICE

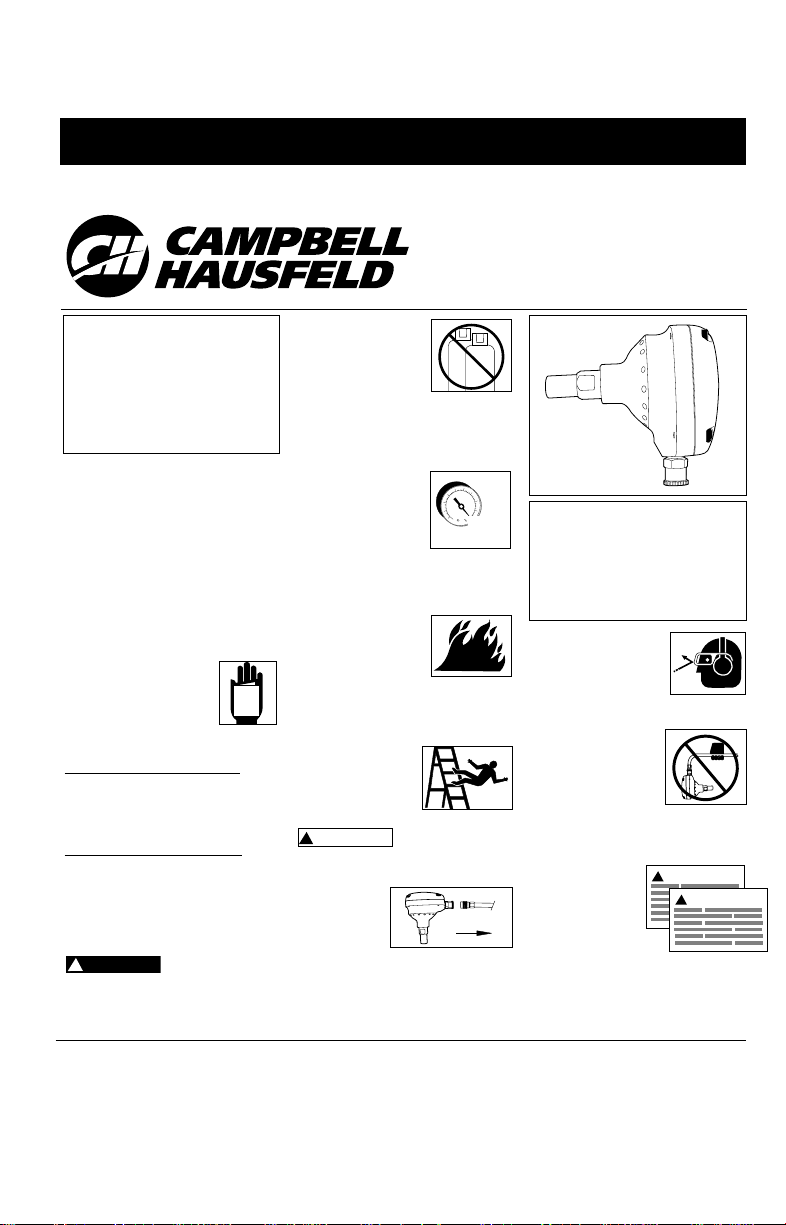

Nailer Components and Specifications

Model PN0090

Operating Instructions

• REQUIRES: 3.6 SCFM @ 90 psi

• AIR INLET: 1/4” NPT

• NAIL SIZE RANGE: 6d to 60d*

• WEIGHT: 2 lbs., 14 oz.

• LENGTH: 4.5”

• HEIGHT: 5”

• WIDTH: 3.5”

• MAXIMUM PRESSURE: 125 psi

• PRESSURE RANGE: 50 - 125 psi

* Optional accessories are available for finishing nails and larger framing nails.

OIL

Nail guide

Nose

Exhaust

Danger decal

Air inlet

!

CAUTION

NOTICE

OIL

Page 3

3

RECOMMENDED HOOKUP

Please refer to Air Tool Set Up

(IN170102AV) for system hookup

instructions.

1. The air compressor must

be able to

maintain a

minimum of

50 psi when

the nailer is

being used. An inadequate air supply can cause a loss of power and

inconsistent driving.

2. An oiler can be used

to provide oil circulation through the nailer. A filter can be

used to remove liquid

and solid impurities

which can rust or

“gum up” internal parts of the

nailer.

3. Use 3/8” air

hoses with a

minimum

working pressure of 150

psi. Use 1/2” air hoses for 50’ run or

longer. For better performance,

install a 3/8” quick plug (1/4” NPT

threads) with an inside diameter of

.315" (8mm) on the nailer and a

3/8” quick coupler on the air hose.

4. Use a pressure regulator on the

compressor, with an operating pressure of 0 -125 psi. A pressure regulator is required to control the operating pressure of the nailer

between 50 and 125 psi.

TECHNICAL SUPPORT

Should you have any questions regarding the operation or repair of this nailer, please call our Nailer Hotline at

1-800-543-6400 for assistance. If you are

calling from Ohio or outside of the continental United States, please call collect, 1-513-367-1182.

Replacement Parts

Use only genuine

Campbell Hausfeld

replacement parts. Never substitute

parts. Do not use modified parts or

parts which will not give equivalent

performance to the original equipment.

Tool performance, safety and durability

could be reduced. When ordering parts,

specify by part number.

Nailer Repair

Nailer repairs must be performed by

qualified and experienced service people ONLY.

Assembly Procedure for Seals

When repairing a nailer, the internal

parts must be cleaned and lubricated.

Parker O-lube or equivalent must be

used on all o-rings. Each o-ring must be

coated with O-lube before assembling.

A small amount of oil must be used on

all moving surfaces and pivots. After

reassembling, a few drops of 30W nondetergent oil or equivalent, must be

added through the air line before

testing.

Driving a Fastener

1. Hold tool with

nose pointed

toward work surface.

2. Align fastener

and tool in the

location where

fastener is to be

driven.

3. Push gently

against nail head

to drive fastener.

4. Continue to apply

pressure until fastener is driven

completely or until reaching desired

penetration.

Adjusting the Nail

Penetration

Nail penetration can be adjusted on

the PN0090 Nailer by installing or

removing spacers (Campbell Hausfeld

part number SV348700AV - sold separately) located in the nose assembly of

the tool. Adding or removing spacers

changes the nail penetration by 1/32”

per spacer. No more than three spacers

should be installed.

1. Disconnect air supply

from tool.

2. Remove the nose

from the tool.

3. Remove nail guide

and spring assembly

from tool.

4. Add or remove spacers to achieve

desired nail penetration.

5. Replace nail guide

and spring assembly

on tool.

6. Replace nose over

nail guide and

secure tightly in

place. Nose assembly

should be secured

with a thread-locking compound prior to assembly.

150 PSI WP

3/8” I.D.

50 psi

Min.

125 psi

Max.

Model PN0090

Operating Instructions

!

WARNING

Page 4

4

Troubleshooting Guide

Stop using nailer immediately if any of the following problems occur. Serious personal injury could

result. Any repairs or replacements must be done by a Qualified Service Person or Authorized Service

Center.

!

Symptom Possible Cause(s) Corrective Action

Air leaking between housing and cap 1. Loose screws in housing 1. Tighten screws

2. Damage to cap gasket 2. Replace cap gasket

Air leaking through cap exhaust or Damaged O-rings Replace O-rings

nose area

Nailer not setting fastener completely 1. Nail guide loose 1. Tighten nose guide

2. Inadequate air flow to nailer 2. Check hose, fitting, or compressor

Nailer operates slowly or has loss 1. Nailer not lubricated sufficiently 1. Lubricate nailer

of power 2. Worn O-rings 2. Replace and lubricate O-rings

3. Low air pressure 3. Check and adjust pressure

Model PN0090

Operating Instructions

Printed in Taiwan

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty Products - One Year, Serious

Duty Products - Two Years, Extreme Duty Products - Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 543-6400

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the

Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool, spray gun, inflator or air accessory supplied or manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED

FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial,

industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States

do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance

with instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser's abuse, neglect or

failure to operate products in accordance with instructions shall also include the removal or alteration of any safety

devices. If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, i.e. o-rings, springs, bumpers, debris shields,

driver blades, fuses

, batteries, gaskets, packings or seals, fluid nozzles, needles, sandblast nozzles, lubricants, mater-

ial hoses, filter elements

, motor vanes, abrasives, blades, cut-off wheels, chisels, chisel retainers, cutters, collets,

chucks, rivet jaws, screw driver bits

, sanding pads, back-up pads or any other expendable part not specifically listed.

These items will only be covered for ninety (90) days from date of original purchase. Underlined items have warran

-

ty for defects in material and workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability

of replacement parts.

This Limited Warranty applies in the U.S. and Canada only and gives you specific legal rights. You may also have other rights

which vary from state to state or country to country.

WARNING

Loading...

Loading...