Page 1

Operating Instructions

Air Die Grinders

Model: Cl252100AV, Cl254100AV

Description

Air die grinders are designed for grinding, polishing, deburring and smoothing sharp

edges. This tool may be used with carbide burrs. Multiple collet sizes are available to

allow use of standard grinding accessories. Angled head models allow access to tight

or difficult to reach areas.

Unpacking

After unpacking the unit, inspect carefully for any damage that may have occurred

during transit. Make sure to tighten fittings, bolts, etc., before putting unit into service.

Read & Follow all InstRuctIons

save these InstRuctIons

do not dIscaRd

Safety Guidelines

This manual contains information that is very important to know and understand. This

information is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS. To

help recognize this information, observe the following symbols.

Danger indicates an imminently hazardous situation which, if

not avoided, WILL result in death or serious injury.

Warning indicates a potentially hazardous situation which, if not

Caution indicates a potentially hazardous situation which, if not

Notice indicates important information, that if not followed, may

NOTE: Information that requires special attention.

avoided, COULD result in death or serious injury.

avoided, MAY result in minor or moderate injury.

cause damage to equipment.

General Safety Information

calIFoRnIa pRoposItIon 65

This product or its power cord may contain chemicals, including

lead, known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

IN742400AV 10/12© 2012 Campbell Hausfeld/Scott Fetzer

For parts, product & service information visit

www.campbellhausfeld.com

Page 2

Operating Instructions

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

General Safety

Information (Continued)

You can create dust when

you cut, sand, drill or grind

materials such as wood,

paint, metal, concrete, cement, or

other masonry. This dust often contains

chemicals known to cause cancer, birth

defects, or other reproductive harm.

Wear protective gear.

GeneRal saFety

This product is a part of a high pressure

system and the following safety

precautions must be followed at all times

along with any other existing safety rules.

1. Read ALL manuals included

with this product carefully.

Be thoroughly familiar with

the controls and the proper

use of the equipment.

2. ONLY persons well acquainted with

these rules of safe operation should

be allowed to use the air tool.

Do NOT exceed maximum

operating pressure of the air

tool (90 PSI). The air tool COULD explode

and result in death or serious personal

injury.

3. Do NOT exceed any pressure rating

of any component in the system.

Maximum operating pressure of 90

PSI is measured at the tool inlet while

the tool is running. The pressure drop

between the compressor and tool

needs to be compensated for at the

compressor.

2

www.campbellhausfeld.com

MANUAL

Release ALL pressure from the

system before attempting to

install, service, relocate or perform any

maintenance.

4. Disconnect air tool from air supply

when not in use and before changing

tools, attachments or performing

service.

Safety glasses and ear

protection MUST be worn

during operation.

5. Do NOT wear loose fitting clothing,

scarves, neck ties or jewelry when

operating any tool. Loose clothing

or jewelry may become caught in

moving parts and result in serious

personal injury.

6. Do NOT depress trigger when

connecting air supply hose to tool.

7. Do NOT put hands near or under

moving parts.

Excessive exposure

working in awkward positions and

repetitive work motions can cause injury

to hands and arms. Stop using any tool

if discomfort, numbness, tingling or pain

occur and consult a physician.

8. Check air hoses for weak or worn

condition before each use. Make sure

ALL connections are secure.

9. Protect air lines from damage or

puncture. Do NOT carry tool by air

hose.

10. NEVER trigger the tool when

not applied to a work object.

Attachments MUST be securely

to vibration,

Page 3

CL252100AV, CL254100AV

attached. Loose attachments can

cause serious injury.

11. ALWAYS use attachments designed

for use with air powered tools.

Do NOT use damaged or worn

attachments.

12. Keep ALL nuts, bolts and screws

tight and ensure equipment is in safe

working condition.

13. ALWAYS secure workpiece in a vise

or clamp. Do not place hands on the

back cylinder when operating the

tool.

14. NEVER point an air tool at oneself

or any other person. Serious injury

COULD occur.

15. ALWAYS work in a well ventilated

area and wear OSHA approved dust

mask.

16. Do not use a cut-off disc mandrel on

this tool.

Operation

set-up InstRuctIons

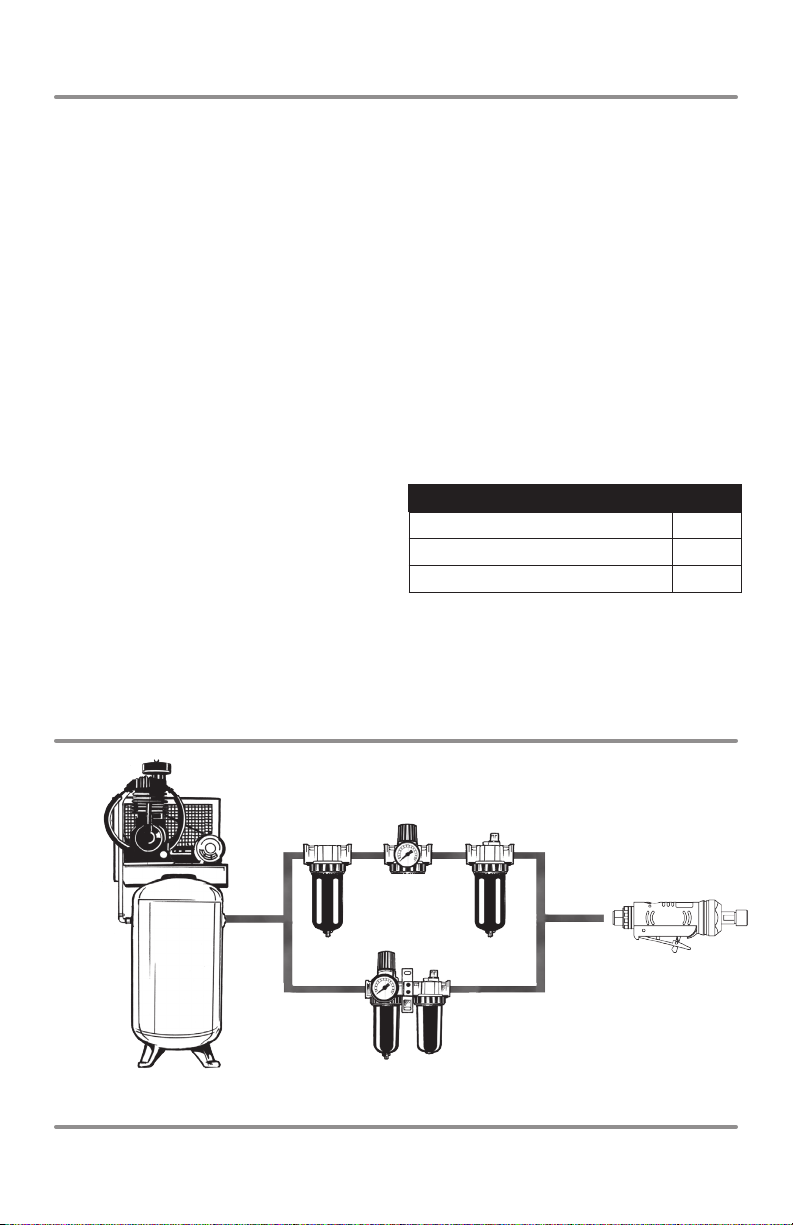

Air tools require a supply of clean, dry air

at 90 PSI (6.2 bar). An air supply system

with filter, regulator, and lubricator (FRL)

as shown in Figure 1 should be used.

Campbell Hausfeld FRL model PA2104

(3/8 inch) or PA2114 (1/2 inch) is

recommended.

Water in the air supply can damage the

tool. Drain condensate from compressor

tank and filter daily.

All hoses and fittings must be the correct

size and tightly fastened. Refer to Chart 1

for minimum sizes.

Tool Air Consumption Hose ID

Less than 9 SCFM @ 100% usage 1/4 inch

9 to 34 SCFM @ 100% usage 3/8 inch

Greater than 34 SCFM @ 100% usage 1/2 inch

Chart 1 - Suggested minimum hose diameter to

use based on 50 ft length hose and continuous

SCFM rating of tool. The use of fittings and longer

hose may require a larger diameter hose to be

used.

Figure 1

Option 1: Individual components

Filter LubricatorRegulator

Option 2: 3 piece combo

Filter, Regulator, and Lubricator

www.campbellhausfeld.com

3

Page 4

Operating Instructions

Operation (Continued)

Do not use

hoses or fittings

that are damaged or deteriorated.

Never carry a tool

by the hose or

pull the hose to move the tool or a

compressor. Keep hoses away from

heat, oil and sharp edges. Replace any

hose that is damaged, weak or worn.

luBRIcatIon

Air tools require lubrication throughout

the life of the tool and is the owner’s

responsibility. Failure to lubricate the air

tool properly will dramatically shorten the

life of the tool and will void the warranty.

This air tool

requires lubrication

BEFORE the initial use and BEFORE and

AFTER each additional use.

AUTOMATIC LUBRICATION

The recommended method for

lubrication is with an air line lubricator

installed as part of the air piping system.

See Figure 1. Use Campbell Hausfeld air

tool oil ST127000AV or equivalent ISO

grade 32 oil.

After an air tool

has been

lubricated, oil will discharge through

the exhaust port during the first few

seconds of operation. The exhaust port

must be directed away from your body

before applying air pressure.

4. Connect the air tool to the air supply

and cover the exhaust port with a

towel (refer to replacement parts

manual for tool features). Run the

tool in both the forward and reverse

directions, if applicable, for 20 to 30

seconds. Oil will discharge from the

exhaust port when air pressure is

applied.

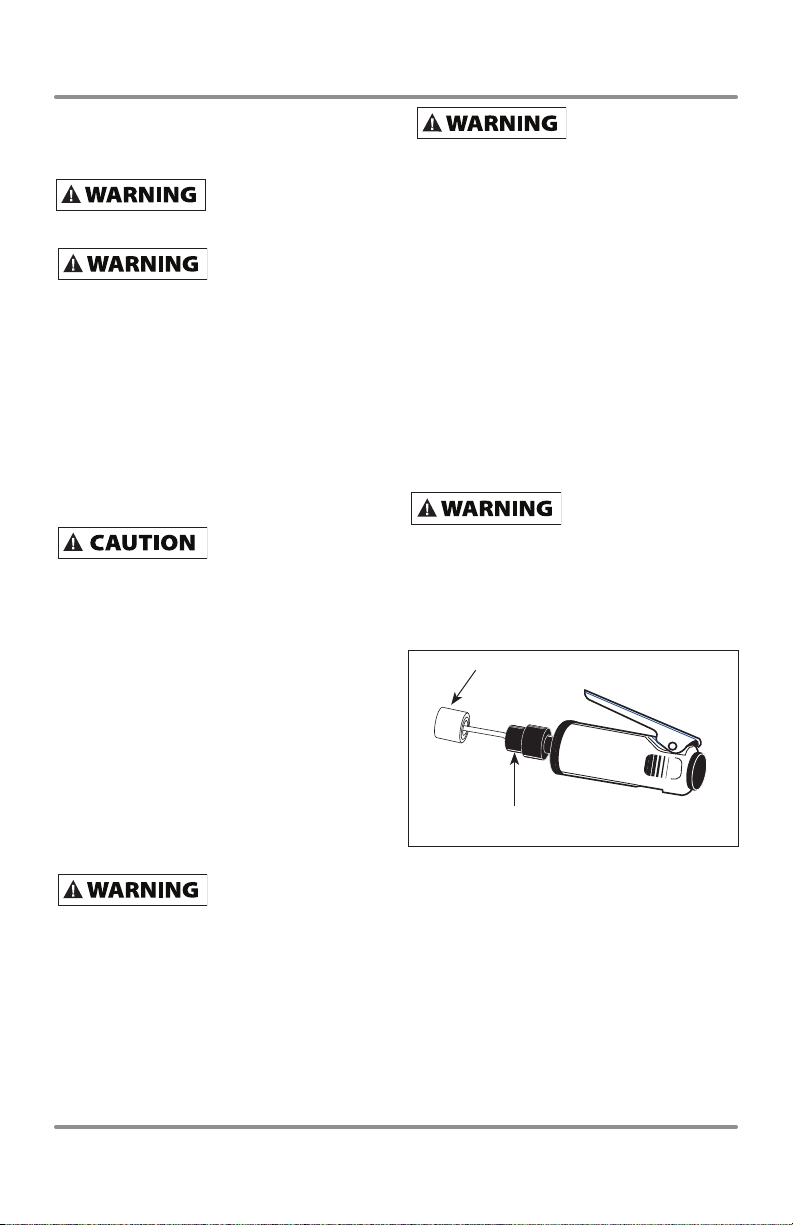

attachments

Disconnect air

tool from air supply

before changing attachments or serious

injury could occur.

1. Insert stem of grinder attachment into

collet opening (See Figure 2). Make

sure stem is fully inserted.

Grinder

Attachment

MANUAL LUBRICATION

If an air line lubricator is not used, the

tool must be lubricated daily.

Disconnect the

air tool from the air

supply before lubricating.

1. Disconnect the air tool from the air

supply.

2. Turn the air tool upside down.

3. While pulling the trigger, squeeze

approximately a 1/4 oz. of Campbell

Hausfeld airtool oil in the air inlet. If

applicable, switch the forward and

reverse valve in both directions.

4

www.campbellhausfeld.com

Collet Nut

Figure 2

2. Securely tighten collet with

wrenches (supplied with some

models) (See Figures 3 & 4). Apply

one wrench to the collet nut and

the other to the spindle. Turn the

wrench on the collet nut to the right,

simultaneously turning the other

wrench in the opposite direction.

Make sure stem does not slip out of

position.

Page 5

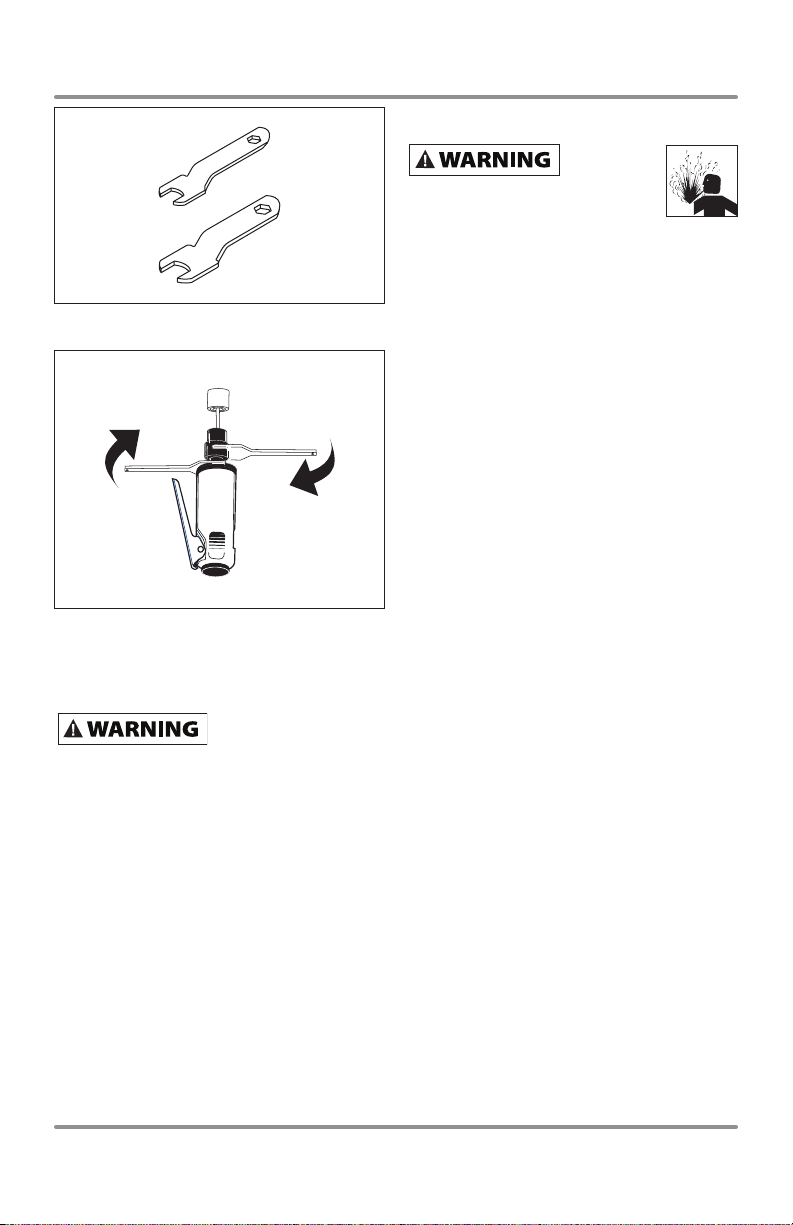

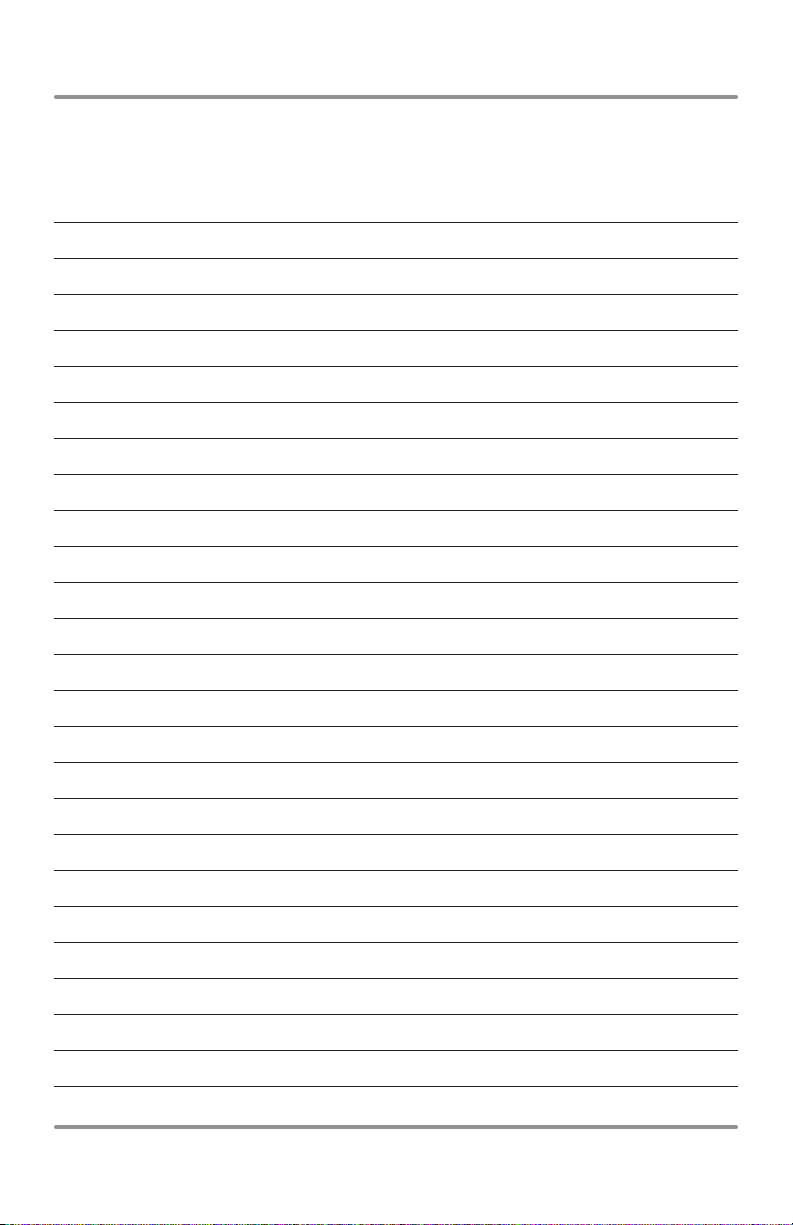

Figure 3 - Wrenches

To Tighten

Collet Turn

Wrench To The

Right

Always Turn

This Wrench In

The Opposite

Direction

Figure 4

3. Do the opposite of Step 2 to loosen

and change the grinder attachment.

Make sure

attachment stem

is fully inserted into collet opening

and collet is securely tightened. Loose

attach-ments could fly off during

operation and cause serious injury. Only

use attachments rated for a minimum of

25,000 RPM.

CL252100AV, CL254100AV

Maintenance

Release all pressure before

attempting to install, service,

relocate or perform any

maintenance on the air system. Personal

injury and/or property damage could

occur.

stoRaGe

The tool must be lubricated before

storing. Follow the air motor lubrication

instructions with an exception to step

4. Only run the tool for 2 to 3 seconds

instead of 20 to 30 seconds because

more oil needs to remain in the tool when

storing.

technIcal seRvIce

For information regarding the operation

or repair of this product, please call

1-855-504-5678.

Replacement paRts

InFoRmatIon

For information regarding where to order

replacement parts, call toll free 1-855504-5678.

Please provide the following information:

• Model number

• Stamped code

• Part number and description

Address parts correspondence to:

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030 U.S.A.

www.campbellhausfeld.com

5

Page 6

Operating Instructions

General Troubleshooting Guide

Symptom Possible Cause(s) Corrective Action

Tool runs slowly

or will not operate

Moisture blowing

out of tool

Excessive

vibration

1. Grit or gum in tool 1. Flush the tool with Campbell Hausfeld air tool

2. No oil in tool 2. Lubricate the tool according to the lubrication

3. Low air pressure 3. Adjust the compressor regulator to tool

4. Air hose leaks 4. Tighten and seal hose fittings if leaks are

5. Pressure drops 5. Be sure hose is properly sized. Long hoses

6. Regulator adjusted

wrong

7. Worn ball bearing

in motor or in angle

head

8. Worn gears (angle

die grinders only)

1. Water in tank 1. Drain tank (See air compressor manual). Oil

2. Water in the air

lines/hoses

1. Damaged stone or

burr

2. Collet shaft bent 2. Replace shaft or collet (See parts list manual)

oil, gum solvent, or an equal mixture of SAE

10 motor oil and kerosene. If Campbell

Hausfeld oil is not used, lubricate the tool

after cleaning

instructions in this manual

maximum while the tool is running free

found

or tools using large volumes of air may

require a hose with an I.D. of 1/2 inch or

larger depending on total hose length

6. Adjust air flow regulator with a flathead

screwdriver to maximum speed

7. Remove and inspect bearing for rust, dirt,

grit or worn race. Clean and regrease bearing

with bearing grease or replace bearing

8. Replace gears

tool and run until no water is evident. Oil tool

again and run 1-2 seconds

2. a. Install a water separator/filter (PA2100

or PA2110). NOTE: Separators work

properly only when air steam is cool.

Locate separator/filter as far as possible

from compressor

2. b. Install an air dryer

2. c. Anytime water enters the tool, the tool

should be oiled immediately

1. Replace with new stone or burr

6

www.campbellhausfeld.com

Page 7

Notes

CL252100AV, CL254100AV

www.campbellhausfeld.com

7

Page 8

Operating Instructions

REGISTER YOUR PRODUCT ONLINE NOW!

http://reg.ch-commercial.com

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: One Year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100

Production Drive, Harrison, Ohio, 45030, Telephone: (855) 504-5678.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of

resale) of the Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld air die grinder.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which

occur within the duration of the warranty period with the exceptions below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE

ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. Some

States do not allow limitation on how long an implied warranty lasts, so the above limitations may

not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY

RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD

PRODUCT. Some States do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products

in accordance with instructions provided in the owner’s manual(s) supplied with product. Accident,

purchaser’s abuse, neglect or failure to operate products in accordance with instructions shall

also include the removal or alteration of any safety devices. If such safety devices are removed or

altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product, e.g. o-rings, springs, gaskets,

packings or seals, lubricants, motor vanes, abrasives, cutters, collets, chucks, bevel gears, or

any other expendable part not specifically listed. These items will only be covered for ninety (90)

days from date of original purchase. Underlined items are warranted for defects in material and

workmanship only.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s

option, products or components which are defective, have malfunctioned and/or failed to conform within

the duration of the specific warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Campbell Hausfeld (855) 504-5678 to obtain your warranty service options. Freight costs must

be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s

manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or

replacement will be scheduled and serviced according to the normal work flow at the servicing location,

and depending on the availability of replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal

rights. You may also have other rights which vary from state to state or country to country.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

8

www.campbellhausfeld.com

Page 9

Instructions d’utilisation

Meule À Matrices

Pneumatique

Modèle: Cl252100AV, Cl254100AV

Description

Les meules à rectifier les matrices pneumatiques sont conçues pour le meulage, le

polissage, l’ébavurage et le polissage des rebords tranchants. Cet outil peut être

utilisé avec des fraises au carbure. Plusieurs dimensions de pinces de serrage sont

disponibles afin de permettre l’utilisation d’accessoires de meulage standard. Les

modèles à tête inclinée assurent l’accès aux zones étroites ou difficiles à atteindre.

Déballage

Dès que l’appareil est déballé, l’inspecter attentivement pour tout signe de

dommages en transit. S’assurer de resserrer tous les raccords, boulons, etc. avant de

le mettre en service.

lIRe et suIvRe toutes les InstRuctIons.

conseRveR ces InstRuctIons

ne les jetez pas

Directives de Sécurité

Ce manuel contient de l’information très importante qui est fournie pour la SÉCURITÉ

et pour ÉVITER LES PROBLÈMES D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger indique une situation hasardeuse imminente qui

RÉSULTERA en perte de vie ou blessures graves.

Avertissement indique une situation hasardeuse potentielle qui

PEUT résulter en perte de vie ou blessures graves.

Attention indique une situation hasardeuse potentielle qui

PEUT résulter en blessures.

Avis indique de l’information importante pour éviter le

dommage de l’équipement.

REMARQUE: L’information qui exige une attention spéciale.

Généralités sur la Sécurité

pRoposItIon 65 de calIFoRnIe

Ce produit ou son cordon peuvent contenir des produits

chimiques, y compris du plomb, relevés par l’État de Californie

comme cause de cancer, d’anomalies congénitales ou d’autres problèmes

reproductifs. Lavez-vous les mains après la manipulation.

IN742400AV 10/12© 2012 Campbell Hausfeld/Scott Fetzer

Page 10

Instructions d’utilisation

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer,

faire fonctionner ou entretenir l’appareil décrit. Protégez-vous et les autres en observant toutes les

informations sur la sécurité. Négliger d’appliquer ces instructions peut résulter en des blessures

corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Généralités sur la

Sécurité (Suite)

Vous pouvez créer de la

poussière en coupant,

ponçant, perçant ou meulant les

matériaux tels que le bois, la peinture,

le métal,le béton, le ciment ou autre

maçonnerie. Cette poussière contient

souvent des produits chimiques

reconnus pour causer le cancer, les

déformations congénitales ou autres

problèmes de la reproduction. Porter de

l’équipement de protection.

GénéRalItés suR la sécuRIté

Ce produit fait part d’un système

haute pression et il faut respecter en

tout temps les précautions de sécurité

suivantes en plus de toute autre règle de

sécurité actuelle.

1. Lire attentivement TOUS

les manuels inclus avec ce

produit. Bien se familiariser

avec les commandes et

l’utilisation adéquate de l’équipement.

2. SEULES les personnes bien

familiarisées avec ces consignes de

sécurité sont autorisées à se servir de

l’outil pneumatique.

NE PAS dépasser la pression

maximum de fonctionnement

de l’outil pneumatique (621 kPa). Cet

outil pneumatique POURRAIT exploser

et entraîner la mort ou des blessures

graves.

Fr2

MANUAL

3. RESPECTER la pression nominale

de tous les éléments du système.

La pression maximum de

fonctionnement de 621 kPa est

mesurée à la prise d’air de l’outil

en cours de fonctionnement. Il est

nécessaire de compenser au niveau

du compresseur la perte de pression

entre le compresseur et l’outil.

Évacuer TOUTE pression du

système avant d’entreprendre

d’installer, de réviser, de

déplacer le produit, ou de procéder à

son entretien.

4. Débrancher la source d’air de l’outil

pneumatique lorsqu’il ne sert pas

et avant de changer des outils et

accessoires ou de procéder à une

opération d’entretien.

Il est NÉCESSAIRE de porter

des lunettes de sécurité et une

protection auditive durant l’utilisation.

5. NE PAS porter de vêtements amples,

de foulards, de cravates ou de

bijoux durant le fonctionnement d’un

quelconque outil. Les vêtements

amples et les bijoux pourraient se

prendre dans des pièces mobiles et

entraîner de graves blessures.

6. NE PAS appuyer sur la gâchette au

moment du raccordement du tuyau

d’alimentation d’air à l’outil.

7. NE PAS mettre les mains près ou

sous des pièces mobiles.

Toute exposition

excessive aux

vibrations, tout travail dans des

Page 11

positions difficiles et tout mouvement

répétitif peuvent entraîner des

blessures aux mains et aux bras. Cesser

l’utilisation d’un outil en cas de malaise,

d’engourdissement, de fourmillements

ou de douleur, et consulter un médecin.

8. Vérifier les tuyaux d’air à la recherche

de signes de faiblesse ou d’usure

avant chaque utilisation. S’assurer

que TOUS les branchements soient

bien serrés.

9. Protéger les canalisations d’air contre

les dommages et perforations. NE

PAS transporter l’outil par le tuyau

d’air.

10. NE JAMAIS appuyer sur la gâchette

de l’outil tant que celui-ci n’est pas

en contact avec l’objet de travail.

Les accessoires DOIVENT être fixés

solidement. Tout accessoire desserré

peut provoquer de graves blessures.

11. TOUJOURS utiliser des accessoires

conçus pour les outils pneumatiques.

NE PAS utiliser d’accessoires

endommagés ou usés.

12. Veiller à ce que TOUS les écrous,

boulons et vis soient serrés et que

CL252100AV, CL254100AV

l’équipement soit en bon état de

marche.

13. TOUJOURS immobiliser l’objet de

travail avec un étau ou un serrejoint. Ne jamais placer les mains sur

l’arrière-cylindre pendant l’opération

de l’outil.

14. NE JAMAIS diriger un outil

pneumatique vers soi-même ni vers

toute autre personne. Des blessures

graves POURRAIENT en résulter.

15. TOUJOURS travailler dans une zone

bien ventilée et porter un masque

anti-poussières homologué OSHA.

16. N’utilisez pas de mandrin à disque à

tronçonner avec cet outil.

Fonctionnement

InstRuctIons d’InstallatIon

Les outils pneumatiques nécessitent

une alimentation en air propre et sec

de 620,5 KPA (6,2 bars). Un système

d’alimentation en air avec filtre,

régulateur et lubrificateur (FRL), comme

indiqué sur la Figure 1, doit être utilisé.

Option 1 : Composants individuels

Filtre LubricateurRégulateur

Option 2 : Combo 3 pièces : ltre,

régulateur et lubricateur

Figure 1

Fr3

Page 12

Instructions d’utilisation

Fonctionnement (Suite)

Nous recommandons le modèle FRL

Campbell Hausfeld PA2104 de 9,5 mm

(3/8 po) ou le PA2114 de 12,7 mm (1/2

po).

La présence d’eau dans l’alimentation

en air peut endommager l’outil. Vidanger

chaque jour le liquide de condensation

du réservoir du compresseur et du filtre.

Tous les tuyaux et raccords doivent être

de la bonne dimension et solidement

fixés. Se référer au Tableau 1 pour les

dimensions minimum.

Diamètre

Consommation d’air des outils

Inférieure à 254 L/min pour une

utilisation à 100 %

254 à 963 L/min pour une utilisation

à 100 %

Supérieure à 963 L/min pour une

utilisation à 100 %

Tableau 1 - Diamètre minimum suggéré du tuyau

à utiliser pour une longueur de tuyau de 15,25 m

et une consommation continue en air de l’outil.

L’utilisation de raccords et de tuyaux plus longs

peut nécessiter l’utilisation d’un tuyau de plus

grand diamètre.

Ne pas utiliser

de tuyaux ou de

raccords endommagés ou détériorés.

Ne jamais

transporter un

outil en le tenant par le tuyau ni tirer

sur celui-ci afin de déplacer l’outil ou

un compresseur. Ne pas approcher les

tuyaux de la chaleur, de l’huile ni des

bords coupants. remplacer tout tuyau

endommagé, peu robuste ou usé.

GRaIssaGe

Les outils pneumatiques exigent un

graissage pendant toute leur durée de

vie. Il appartient au propriétaire de se

Fr4

intérieur

du tuyau

1/4 po

3/8 po

1/2 po

plier à ces exigences. L’absence d’un

graissage correct de l’outil pneumatique

peut en raccourcir considérablement la

durée de vie et entraîner l’annulation de

la garantie.

Cet outil

pneumatique

exige un graissage AVANT la première

utilisation puis AVANT et APRÈS chaque

utilisation ultérieure.

LUBRIFICATION AUTOMATIQUE

La méthode de lubrification

recommandée consiste en un

lubrificateur installé sur un tuyau d’air

et faisant partie intégrante du circuit de

tuyauteries d’air. Voir la Figure 1. Utiliser

l’huile pour outil pneumatique Campbell

Hausfeld ST127000AV ou une huile ISO

équivalente d’indice 32.

LUBRIFICATION MANUELLE

Si un lubrificateur n’est pas présent sur le

tuyau d’air, l’outil doit être lubrifié chaque

jour.

Débrancher l’outil

pneumatique de

l’alimentation en air avant de graisser.

1. Débrancher l’outil pneumatique de

l’alimentation en air.

2. Retourner l’outil pneumatique.

3. Tout en appuyant sur la gâchette,

faire sortir à peu près 7,4 mL d’huile

pneumatique dans la prise d’air. Le

cas échéant, basculer la soupape

d’inversion dans les deux sens.

Une fois qu’un

outil pneumatique

a été graissé, de l’huile s’écoulera de

l’orifice de sortie lors des quelques

premières secondes de fonctionnement.

Avant d’utiliser l’air sous pression,

veiller à ce que l’orifice d’échappement

ne soit pas dirigé vers vous.

4. Raccorder l’outil pneumatique à

l’alimentation en air et recouvrir

Page 13

l’orifice d’échappement avec

un chiffon (se référer au manuel

des pièces de rechange pour les

caractéristiques de l’outil). Le cas

échéant, faire fonctionner l’outil en

marche avant et arrière pendant 20 à

30 secondes. L’huile se met à sortir

de l’orifice d’échappement d’air une

fois que l’air est sous pression.

accessoIRes

Debrancher l’outil

pneumatique de

la source d’air avant de changer les

accessoires afin d’éviter des blessures

graves.

1. Introduire la tige de l’accessoire de

meulage dans l’ouverture du mandrin

(Voir Figure 2). S’assurer que la tige

soit complètement introduite.

Accessoire de

Meulage

CL252100AV, CL254100AV

Figure 3 - Clés

Tourner la Clé

à la Droite

pour Serrer le

Mandrin

Toujours

Tourner Cette

Clé au Sens

Opposé

Figure 4

S’assurer que la

tige d’accessoire

Écrou de Mandrin

Figure 2

2. Bien serrer la mandrin avec les clés

(fournies avec quelques modèles)

(Voir Figures 3 et 4). Appliquer

soit complètement introduite dans

l’ouverture du mandrin et serrée avec

sûreté. Les accessoires desserrés

peuvent s’envoler pendent le

fonctionnement et peuvent causer des

blessures graves. Utiliser seulement les

accessoires classifiés pour un tr/min

minimum de 25,000.

une clé sur l’écrou du mandrin et

l’autre sur la tige. Tourner la clé sur

l’écrou du mandrin à la droite, et

simultanément, tourner l’autre clé au

sens opposé. S’assurer de ne pas

laisser glisser la tige.

3. Faire l’action opposé de l’Étape

2 pour desserrer et changer

l’accessoire de meulage.

Fr5

Page 14

Instructions d’utilisation

Entretien

Dissiper toute la pression avant

d’essayer d’installer, maintenir,

déplacer ou procéder à l’entretien.

Sinon il pourrait y avoir des blessures

personnelles et/ou des dommages à la

propriété.

entReposaGe

Il est nécessaire de lubrifier l’outil avant

de l’entreposer. Suivez les consignes

de lubrification du moteur pneumatique,

à l’exception de l’étape 4. Faites

fonctionner l’outil pendant seulement 2 à

3 secondes, au lieu de 20 à 30 secondes,

car une plus grande quantité d’huile

doit être laissée dans l’outil lors de son

entreposage.

seRvIce technIque

Pour des informations concernant le

fonctionnement ou la réparation de ce

produit, composer le 1-855-504-5678.

InFoRmatIon conceRnant les

pIèces de RechanGe

Pour des renseignements sur la

commande de pièces de rechange,

appeler sans coût le numéro 1-855-504-

5678.

S’il vous plaît fournir l’information

suivante:

• Numéro de Modèle

• Code estampé

• No. et Description de Pièce

Correspondance Concernant les Pièces:

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030 U.S.A.

Fr6

Page 15

Cl252100AV, Cl254100AV

Guide Général De Dépannage

Symptôme Cause(s) Possible(s) Mesures correctives

L’outil fonctionne

lentement ou ne

fonctionne pas

Humidité expulsée

de l’outil

Vibration

excessive

1. Présence de

grenaille ou de

gomme dans l’outil

2. Absence d’huile

dans l’outil

3. Pression d’air basse 3. Ajuster le régulateur du compresseur au

4. Fuites dans le tuyau

d’air

5. Chute de pression 5. S’assurer que le tuyau soit de la bonne taille.

6. Régulateur malajusté

7. Roulement usé dans

le moteur ou dans la

tête coudée

8. Engrenages usés

(meules à rectifier

les matrices

inclinées seulement)

1. Présence d’eau

dans le réservoir

2. Eau dans les

canalisations/

tuyaux

1. Meule ou burin

endommagé

2. Arbre de mandrin

courbé

1. Rincer l’outil avec de l’huile pour outils

pneumatiques Campbell Hausfeld, du

dissolvant de gomme ou un mélange en

proportions égaux d’huile de moteur SAE

10 et de kérosène. En cas d’utilisation d’un

produit autre que l’huile Campbell Hausfeld,

graisser l’outil après l’avoir nettoyé

2. Graisser l’outil conformément aux instructions

de graissage données dans ce manuel

réglage maximum pour l’outil pendant que

l’outil fonctionne librement

4. Serrer et assurer l’étanchéité des raccords du

tuyau en cas de fuites

Les longs tuyaux ou les outils exigeant de

grands volumes d’air peuvent nécessiter un

tuyau de diamètre intérieur d’au moins 1/2 po,

suivant la longueur totale du tuyau

6. Réglez le contrôleur de débit à la vitesse

maximale à l’aide d’un tournevis à tête plate.

7. Enlever et inspecter le roulement pour la

rouille, la saleté, la grenaille ou pour une voie

usée. Nettoyer et graisser le roulement de

nouveau avec la graisse pour roulements, ou

le remplacer

8. Remplacer les engrenages

1. Vidanger le réservoir (Voir le manuel du

compresseur). Huiler l’outil et le faire

fonctionner jusqu’à ce qu’il semble ne

plus contenir d’eau. Huiler encore et faire

fonctionner pendant 1-2 secondes.

2. a. Monter un séparateur/filtre d’eau

(PA2100 ou PA2110). REMARQUE: Les

séparateurs ne fonctionnent correctement

que lorsque l’air qui les traversent est

frais. Positionner le séparateur/filtre aussi

loin que possible du compresseur

2. b. Monter un sécheur d’air

2. c. Huiler l’outil immédiatement quand l’eau

entre l’outil

1. Remplacer avec une nouvelle meule ou un

nouveau burin

2. Remplacer l’arbre ou le mandrin (Référezvous au manuel de la liste des pièces)

Fr7

Page 16

Instructions d’utilisation

ENREGISTREZ VOTRE PRODUIT EN LIGNE MAINTENANT !

http://reg.ch-commercial.com

Garantie Limitée

1. DURÉE : de la date d’achat de l’acheteur original comme suit : un (1) an.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production

Drive, Harrison, Ohio, 45030, Téléphone: (855) 504-5678.

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du

produit Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Cette meule pneumatique à rectifier les matrices

Campbell Hausfeld.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts importants de matériaux et de main d’oeuvre qui

se produisent durant la période de garantie à l’exception de ce qui est noté plus bas.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION

PARTICULIÈRE SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE

DANS LA SECTION DURÉE. Quelques Provinces (États) n’autorisent pas de limitations de durée

pour les garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE

TOUT DÉFAUT, PANNE OU MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD.

Quelques Provinces (États) n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou

indirects. La limitation ou exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation

ne respectant pas les instructions données dans le(s) manuel(s) accompagnant le produit. Un

accident, l’utilisation abusive par l’acheteur, la négligence ou le manque de faire fonctionner les

produits selon les instructions comprend aussi l’enlevage ou la modification de n’importe quel

appareil de sûreté. Si ces appareils de sûreté sont enlevés ou modifiés, la garantie sera annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le produit.

E. Articles ou services qui sont exigés normalement pour l’entretien du produit, par ex. joints toriques,

ressorts, joints d’étanchéité, garnitures d’étanchéité ou joints, lubrifiants, valves de moteur, abrasifs,

fraises, pinces de serrage, mandrins, engrenages coniques, ou toute autre pièce consommable

non spécifiquement indiquée. Ces articles ne seront couverts que pendant quatre-vingt-dix (90)

jours de la date d’achat original. Les articles soulignés sont garanties pour défauts de matière et de

fabrication seulement.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparer ou remplacer, au choix

du Garant, les produits ou composants défectueux, qui ont connu une défaillance et/ou qui ne sont pas

conformes pendant la durée précise de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Appelez Campbell Hausfeld (855) 504-5678 pour obtenir vos options de service sous garantie. Les

frais de transport sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s)

d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE

GARANTIE: La réparation ou le remplacement sera prévu et exécuté en fonction de la charge de travail

dans le centre de service et dépendra de la disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits

juridiques précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un

Pays à l’autre.

MÉMENTO: Gardez votre preuve datée d’achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Fr8

Page 17

Instruções de Uso

Esmerilhadores

pneumáticos de matriz

Modelo: Cl252100AV, Cl254100AV

Descrição

Esmerilhadores de matrizes pneumáticas foram desenvolvidos para esmerilhar,

polir, remover rebarbas e alisar pontas afiadas. Esta ferramenta pode ser usada

com rebarbas de carbeto. Múltiplas dimensões de pinças e torno estão disponíveis

para permitir o uso de acessórios de esmerilhamento padrão. Modelos de cabeça

angulares possibilitam acesso a áreas pequenas ou de difícil acesso.

Remoção da Embalagem

Al desempacar este producto, revíselo con cuidado para cerciorarse de que esté en

perfecto estado. Aperte firmemente conexões, parafusos, etc., antes de colocar a

unidade em operação.

leIa e sIGa todas as InstRuÇÕes

GuaRde estas InstRuÇÕes -

nÃo descaRte

Normas de Segurança

Este manual contém informações muito importantes que devem ser conhecidas e

compreendidas. Essas informações são fornecidas para SEGURANÇA e para EVITAR

PROBLEMAS NO EQUIPAMENTO. Para ajudar a reconhecer essas informações,

observe os seguintes símbolos.

Perigo indica uma situação eminentemente perigosa, que se

não for evitada, causará a morte ou infortúnios gravosos.

Aviso indica uma situação potencialmente perigosa, que se não

for evitada, poderá resultar em morte ou infortúnios gravosos.

Cuidado indica uma situação potencialmente perigosa, que se

não for evitada poderá causar danos menos graves ou de grau

moderado.

Nota indica uma informação importante, que se não for

seguida, poderá causar danos ao equipamento.

OBSERVAÇÃO: Informações que requerem atenção especial.

Informações Gerais Sobre Segurança

pRoposIÇÃo 65 da calIFÓRnIa

Este produto ou o seu cabo de força pode conter produtos

químicos, incluindo o chumbo, conhecidos, no Estado da

Califórnia, como causadores de câncer e defeitos congênitos ou outras lesões

reprodutivas. Lave as mãos após manusear este produto.

IN742400AV 10/12© 2012 Campbell Hausfeld/Scott Fetzer

Page 18

Instruções de Uso

Por favor, leia e guarde essas instruções. Leia com atenção antes de tentar montar, instalar, usar

ou fazer manutenção no produto descrito. Siga todas as informações de segurança para proteger a

si mesmo e a outras pessoas; caso contrário, podem ocorrer lesões pessoais e/ou danos materiais!

Guarde essas instruções para futuras consultas.

Informações Gerais

Sobre Segurança

(Continuação)

Você pode criar poeira ao

cortar, lixar, furar ou esmerilar

materiais tais como madeira, tinta,

metal, concreto, cimento ou outro tipo

de alvenaria. Esse pó freqüentemente

contém químicos conhecidos por causar

câncer, defeitos congênitos ou outros

danos reprodutivos. Use equipamento de

proteção.

seGuRanÇa GeRal

Este produto é parte de um sistema de

alta pressão e as seguintes precauções

de segurança devem ser seguidas

sempre junto com todas as outras regras

de segurança existentes.

1. Leia com atenção TODOS

os manuais inclusos neste

produto. Familiarize-se com

os controles e com o uso

apropriado do equipamento.

2. SOMENTE pessoas bem

familiarizadas com estas normas

de operação segura devem ter

permissão para usar a ferramenta

pneumática.

NÃO exceda a pressão de

operação da ferramenta

pneumática (90 psi). A

ferramenta pneumática PODERÁ

explodir resultando em morte ou

ferimentos pessoais graves.

3. NÃO exceda os limites de pressão

de quaisquer componentes do

sistema. A pressão de operação

Pt2 Pt2

MANUAL

máxima de 90 psi é medida na

entrada da ferramenta enquanto ela

está em funcionamento. A queda

de pressão entre o compressor e a

ferramenta precisa ser compensada

no compressor.

Libere TODA a pressão do

sistema antes de tentar

instalar, utilizar, reposicionar ou realizar

qualquer manutenção.

4. Desconecte a ferramenta pneumática

do suprimento de ar quando essa

não estiver em uso e antes de trocar

ferramentas, uniões ou realizar

alguma manutenção.

Os óculos de segurança e

protetor auditivo DEVEM ser

usados durante a operação.

5. NÃO utilize roupas largas ou soltas,

lenços, gravatas ou joias durante a

utilização de quaisquer ferramentas.

Roupas soltas ou joias podem

prender nas peças em movimento

resultando em ferimentos pessoais

graves.

6. NÃO aperte o gatilho durante

a conexão da mangueira de

fornecimento de ar à ferramenta.

7. NÃO coloque as mãos próximas ou

debaixo de peças móveis.

A exposição

excessiva à

vibração, o trabalho em posições

incômodas e os movimentos de

trabalho repetitivos podem causar

lesões às mãos e aos braços. Pare de

usar qualquer ferramenta se ocorrer

Page 19

desconforto, dormência, formigamento

ou dor e consulte um médico.

8. Verifique se as mangueiras de ar

estão fracas ou desgastadas antes

de cada utilização. Certifique-se de

que TODAS as conexões estejam

firmes.

9. Proteja as linhas de ar contra danos

ou furos. NÃO puxe a ferramenta pela

mangueira de ar.

10. NUNCA acione a ferramenta quando

não aplicada a um objeto de trabalho.

As conexões DEVEM ser firmemente

conectadas. Conexões frouxas

podem causar dano sério.

11. SEMPRE use conexões projetadas

para uso com ferramentas

pneumáticas. NÃO use conexões

danificadas ou gastas.

12. Mantenha apertados TODAS as

porcas e parafusos e mantenha o

equipamento em condições seguras

de operação.

13. Fixe SEMPRE a peça de trabalho em

uma morsa ou braçadeira. Não use

um mandril de disco de corte nesta

ferramenta.

CL252100AV, CL254100AV

14. NUNCA aponte uma ferramenta

pneumática para si mesmo ou para

outra pessoa. Isso PODE causar

dano sério.

15. SEMPRE trabalhe em um ambiente

bem ventilado e utilize uma máscara

contra poeira aprovada pela OSHA.

16. Não use um mandril de disco de

corte nesta ferramenta.

Operação

InstRuÇÕes de InstalaÇÃo

As ferramentas pneumáticas necessitam

de um suprimento de ar limpo, seco a 90

PSI (6,2 bar). Um sistema de suprimento

de ar com filtro, regulador e lubrificante

(FRL) como mostrado na figura 1 deve

ser usado.

Recomenda-se o modelo Campbell

Hausfeld FRL PA2104 9,5 mm (3/8 pol)

ou PA 2114 12,7 mm (1/2 pol).

Água no suprimento de ar pode danificar

a ferramenta. Drene diariamente o

condensado do tanque compressor e do

filtro.

Opção 1: Componentes individuais

Filtro LubricanteRegulador

Opção 2: Combinação de três

peças ltro, regulador e lubricante

Figura 1

Pt3

Page 20

Instruções de Uso

Operação

(Continuação)

Todas as mangueiras e conexões

devem ser do tamanho correto e estar

firmemente presas. Consulte a Tabela 1

para tamanhos mínimos.

Consumo da ferramenta

pneumática

Menos de 254 L/min. a 100% de uso 6,4 mm

254 a 962 L/min. a 100% de uso 9,5 mm

Maior que 962 L/min. a 100% de uso 12,7 mm

Tabela 1 - Diâmetro mínimo da mangueira

sugerido para usar com base em mangueira de

comprimento de 15,25 metros e classificação

L/min. contínua da ferramenta. A utilização de

conexões e mangueira mais longa pode exigir o

uso de uma mangueira de diâmetro maior.

Não utilize

mangueiras ou

conexões que estiverem danificadas ou

deterioradas.

Nunca transporte

uma ferramenta

segurando pela mangueira e nunca

puxe a mangueira para movimentar

a ferramenta ou um compressor.

Mantenha as mangueiras afastadas de

calor, óleo e bordas afiadas. Troque as

mangueiras que estiverem danificadas,

fracas ou desgastadas.

luBRIFIcaÇÃo

As ferramentas pneumáticas requerem

lubrificação ao longo da vida e é da

responsabilidade do proprietário. A falta

de lubrificação adequada da ferramenta

pneumática diminui enormemente a vida

da ferramenta e anula a sua garantia.

Esta ferramenta

requer lubrificação

ANTES do uso inicial e ANTES e APÓS

cada uso adicional.

Pt4

Diâmetro

interno da

mangueira

LUBRIFICAÇÃO AUTOMÁTICA

O método recomendado para a

lubrificação é com um lubrificante de

linha de ar instalado como parte do

sistema de tubos de ar. Consulte a

figura 1. Uso do óleo para ferramenta

pneumática Campbell Hausfeld

ST127000AV ou óleo equivalente ISO

grau 32.

LUBRIFICAÇÃO MANUAL

Se um lubrificante de linha de ar não é

usado, a ferramenta deve ser lubrificada

diariamente.

Desconecte a

ferramenta

pneumática do suprimento de ar antes

de lubrificar.

1. Desconecte a ferramenta pneumática

do suprimento de ar.

2. Vire a ferramenta pneumática para

baixo.

3. Vire a chave de fenda para baixo.

Enquanto segura o gatilho, despeje

aproximadamente 7,4 mL de óleo

Campbell Hausfeld na entrada de

ar. Se aplicável, mude a válvula para

frente e para trás em ambos os

sentidos.

Após a lubrificação

da ferramenta

pneumática, ocorre a saída de óleo pelo

orifício de exaustão durante os primeiros

segundos da operação. O orifício de

exaustão deve estar direcionado para

longe do seu corpo antes de aplicar

pressão de ar.

4. Conecte a ferramenta pneumática

à fonte de suprimento de ar e cubra

o orifício de exaustão com uma

toalha (consulte as características

da ferramenta no manual de

peças). Coloque a ferramenta

em funcionamento em ambas as

direções, se aplicável, durante 20 a

30 segundos. Ocorre a descarga de

Page 21

CL252100AV, CL254100AV

óleo do orifício de exaustão quando

se aplica a pressão pneumática.

acessÓRIos

Desconecte

a ferramenta

pneumática do abastecimento de ar

antes de trocar acessórios ou podem

ocorrer lesões sérias.

1. Insira o braço do acessório do

esmerilhador na abertura na pinça

Figura 3 - Chaves

de retorno (consulte a Figura 2).

Certifique-se de que o braço esteja

completamente inserido.

Acessório de

esmerilhador

Sempre gire

esta chave na

direção oposta

Porca de pinça de torno

Para apertar a

pinça de torno

na direção

oposta

Figura 2

2. Prenda a pinça de torno com

chaves (fornecidas com alguns

modelos) (consulte as figuras 3

e 4). Aplique uma chave na porca

da pinça de torno e a outra ao fuso.

Gire a chave na pinça de torno para

a direita, virando simultaneamente

virando a outra chave na direção

oposta. Certifique-se de que o braço

Figura 4

Certifique-se

de que o braço do

acessório esteja completamente inserido

na abertura de pinça de torno e a pinça

esteja presa firmemente. Acessórios

soltos podem ser atirados durante a

operação e causar danos sérios. Use

somente acessórios classificados para

um mínimo de 25.000 RPM.

não saia do lugar.

3. Faça o oposto da etapa 2 para

afrouxar e trocar o acessório do

esmerilhador.

Pt5

Page 22

Instruções de Uso

Manutenção

Libere toda a pressão antes

de tentar realizar a instalação,

reparo, mudar de local ou efetuar

qualquer tipo de manutenção no sistema

de ar. Podem ocorrer lesões pessoais e/

ou danos à propriedade.

aRmazenamento

A ferramenta deve ser lubrificada antes

de ser armazenada. Siga as instruções

de lubrificação de motor pneumático

com uma exceção para a etapa 3. Só

ligue a ferramenta por 2 a 3 segundos

ao invés de 20 a 30, uma vez que é

necessário que mais óleo permaneça na

ferramenta ao armazenar.

assIstêncIa técnIca

Para informações sobre a operação ou

reparo deste produto, por favor entre

em contato com o centro de assistência

técnica Campbell Hausfeld mais

próximo.

InFoRmaÇÕes soBRe as peÇas

de ReposIÇÃo

Para obter informações sobre onde pedir

peças de reposição, ligue grátis para

1-855-504-5678.

Forneça as seguintes informações:

• Número do modelo

• Código impresso

• Número de peça e descrição

Envie a correspondência sobre as peças

para:

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030 U.S.A.

Pt6

Page 23

Cl252100AV, Cl254100AV

Guia geral de detecção de problemas

Sintoma Possíveis causas Ação a tomar

A ferramenta

funciona devagar

ou não funciona

Umidade sendo

soprada para fora

da ferramenta

Vibração

excessiva

1. Areia ou goma na

ferramenta

2. Não há óleo na

ferramenta

3. Baixa pressão de ar 3. Ajuste o regulador de compressor para o

4. A mangueira de ar

vaza

5. Quedas de pressão 5. a. Certifique-se do tamanho correto da

6. Regulador ajustado

incorretamente

7. Mancal de esfera

gasto no motor ou

na cabeça angular

8. Engrenagens

gastas (somente

para esmerilhador

angular de matriz)

1. Água no tanque 1. Purgue o tanque (consulte o manual

2. Água nos tubos/

mangueiras de ar

1. Pedras ou rebarbas

danificadas

2. Eixo de pinça de

torno dobrado

1. Purgue a ferramenta com óleo para

ferramentas a ar Campbell Hausfeld com

solvente de goma ou com uma mistura de

partes iguais de óleo de motor SAE 10 e

querosene. Se não for utilizado óleo Campbell

Hausfeld, lubrifique a ferramenta após a

limpeza.

2. Lubrifique a ferramenta de acordo com as

instruções de lubrificação neste manual.

máximo da ferramenta enquanto ela está

ligada mas sem operar

4. Aperte e vede as conexões da mangueira em

caso de vazamento.

mangueira. Mangueiras longas ou

ferramentas .que utilizam grandes

volumes de ar podem requerer uma

mangueira de 1/2 pol. de diâmetro interno

ou maior, dependendo da extensão total

da mangueira

6. Ajuste o regulador de fluxo de ar com uma

chave de fenda de cabeça plana para a

máxima velocidade

7. Remova e inspecione o mancal em busca de

ferrugem, sujeira, partículas finas ou sulcos

gastos. Limpe e aplique graxa novamente no

mancal com graxa de mancal ou substitua-o

8. Substitua as engrenagens

do compressor de ar). Aplique óleo na

ferramenta e a opere até que não reste mais

água evidente. Torne a lubrificar a ferramenta

e ative-a por 1 ou 2 segundos.

2. a. Instale um separador/filtro de água

(PA2100 ou PA2110). OBSERVAÇÃO:

Separators only work properly when

the air passing through the separator is

cool. Locate the separator/filter as far as

possible from the compressor

2. b. Instale um secador de ar.

2. c. Sempre que água entrar na ferramenta,

deve-se aplicar óleo imediatamente

1. Substitua com uma nova pedra ou rebarba

2. Substitua o eixo ou pinça de torno (consulte o

manual da lista de peças)

Pt7

Page 24

Instruções de Uso

REGISTRE SEU PRODUTO ON-LINE AGORA!

http://reg.ch-commercial.com

Garantia Limitada

1. DURAÇÃO: A partir da data de compra por parte do comprador original, da seguinte maneira: Um (1)

ano.

2. QUEM CONCEDE ESTA GARANTIA (GARANTIDOR): Campbell Hausfeld / Scott Fetzer Company, 100

Production Drive, Harrison, Ohio, 45030, Telefone: (855) 504-5678.

3. QUEM RECEBE ESTA GARANTIA (COMPRADOR): O comprador original (não para objetivo de revenda)

dos produtos da Campbell Hausfeld.

4. QUAIS SÃO OS PRODUTOS COBERTOS POR ESTA GARANTIA: Este esmerilhador de matrizes da

Campbell Hausfeld.

5. O QUE ESTÁ COBERTO NESTA GARANTIA: Defeitos substanciais no material e na fabricação que

ocorrerem dentro da vigência do período de garantia com exceção dos casos abaixo.

6. O QUE NÃO ESTÁ COBERTO NESTA GARANTIA:

A. Garantias implícitas, incluindo as de comerciabilidade e ADEQUAÇÃO PARA UM OBJETIVO

ESPECÍFICO SÃO LIMITADAS A PARTIR DA DATA DA COMPRA ORIGINAL, CONFORME

ESTABELECIDO NO ITEM DURAÇÃO ACIMA. Alguns estados (nos Estados Unidos) não permitem

limites referentes ao prazo de duração da garantia implícita, de forma que os limites acima podem

não se aplicar ao seu caso.

B. QUALQUER PERDA, DANO OU DESPESA INCIDENTAIS, INDIRETOS OU RESULTANTES QUE

POSSAM RESULTAR DE QUALQUER DEFEITO, FALHA OU MAU FUNCIONAMENTO DOS

PRODUTOS DA CAMPBELL HAUSFELD. Alguns estados (nos Estados Unidos) não permitem a

exclusão ou limite de danos incidentais ou resultantes, de forma que o limite e exclusão acima

podem não se aplicar ao seu caso.

C. Qualquer falha resultante de acidente, abuso por parte do comprador, negligência ou da

não operação do produto de acordo com as instruções no(s) manual(ais) do proprietário que

acompanha(m) este produto. Acidente, abuso por parte do comprador, negligência, não operação

dos produtos de acordo com as instruções incluirão também a retirada ou alteração de qualquer

dispositivo de segurança. Se tais dispositivos de segurança forem retirados ou alterados, esta

garantia será anulada.

D. Ajustes normais explicados nos manuais do proprietário são fornecidos com o produto.

E. Peças de substituição que costumam ser necessárias à manutenção do produto, por exemplo,

anéis-O, molas, gaxetas, enchimentos ou vedações, lubrificantes, escapamentos de motor,

abrasivos, cortadores, pinças de torno, mandris, engrenagens cônicas ou qualquer outra peça

descartável não especificamente listada. Estes itens estarão cobertos apenas por noventa (90) dias

a partir da data da compra original. Os itens sublinhados possuem garantia apenas para defeitos de

materiais e de fabricação.

7. RESPONSABILIDADES DO GARANTIDOR DE ACORDO COM ESTA GARANTIA: Repare ou substitua, a

critério do avalista, produtos ou componentes que apresentam defeito, mau funcionamento e/ou falhas

de conformidade dentro do período de garantia especificado.

8. RESPONSABILIDADES DO COMPRADOR DE ACORDO COM ESTA GARANTIA:

A. Fornecer comprovante de compra datado e registros de manutenção.

B. Ligue para a Campbell Hausfeld (855) 504-5678 para obter suas opções de serviço de garantia. Os

custos de frete devem ser pagos pelo comprador.

C. Usar cuidado adequado na operação e manutenção dos produtos conforme descrito no(s)

manual(ais) do proprietário.

9. QUANDO O GARANTIDOR IRÁ CONSERTAR OU SUBSTITUIR DE ACORDO COM ESTA GARANTIA:

Consertos ou substituições serão programados e realizados de acordo com o fluxo de trabalho normal

no local de conserto e dependendo da disponibilidade da peças de substituição.

Esta garantia limitada é valida somente nos E.U.A., no Canadá e no México e oferece direitos legais

específicos.Você pode também ter outros direitos, que variam de um estado para outro (nos Estados

Unidos), ou de um país para outro.

LEMBRETE: Guarde sua comprovação de compra datada até o fim da garantia!

Junte-a a este manual o arquive-a para mais segurança.

Pt8

Page 25

Manual de Instrucciones de Operación

Rectificadora de

Neumática de Matrices

Modelo: Cl252100AV, Cl254100AV

Descripción

Las esmeriladoras neumáticas de troqueles están diseñadas para el esmerilado,

pulido, desbastado y suavizado de bordes filosos. Esta herramienta puede usarse

en combinación con fresas de carburo. Se encuentran disponibles varios tamaños

de boquillas portaherramientas que permiten el uso de accesorios estándar para

esmerilado. Los modelos de cabeza angular permiten el acceso en áreas estrechas o

de difícil acceso.

Desempaque

Al desempacar este producto, revíselo con cuidado para cerciorarse de que esté en

perfecto estado. Cericiórese de apretar todas las conexiones, pernos, etc. antes de

comenzar a utilizar la unidad.

lea y sIGa todas las InstRuccIones

GuaRde estas InstRuccIones –

no las deseche

Medidas de Seguridad

Este manual contiene información que es muy importante que sepa y comprenda.

Esta información se la suministramos como medida de SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Debe reconocer los siguientes símbolos.

Ésto le indica que hay una situación inmediata que LE

OCASIONARIA la muerte o heridas de gravedad.

Ésto le indica que hay una situación que PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica que hay una situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una información importante, que de no seguirla,

le podría ocasionar daños al equipo.

NOTA: Información que requiere atención especial.

Informaciones Generales de Seguridad

pRoposIcIÓn 65 de calIFoRnIa

Este producto, o su cable de corriente pueden contener

químicos, incluido plomo, que es conocido por el Estado

de California como causante de cáncer y defectos de nacimiento u otros daños

reproductivos. Lávese las manos después de manipularlo.

IN742400AV 10/12© 2012 Campbell Hausfeld/Scott Fetzer

Page 26

Manual de Instrucciones de Operación

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar,

instalar, operar o dar mantenimiento al producto aquí descrito. Protéjase usted mismo y a los demás

observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede ocasionar

daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Informaciones

Generales

de Seguridad

(Continuación)

Cuando corta lija, taladra

o pule materiales como

por ejemplo madera, pintura, metal,

hormigón, cemento, u otro tipo de

mampostería se puede producir polvo.

Con frecuencia este polvo contiene

productos químicos que se conocen

como causantes de cáncer, defectos

congénitos u otros daños reproductivos.

Use equipo de protección.

InFoRmacIones GeneRales de

seGuRIdad

Este producto es parte de un sistema de

alta presión y siempre deben seguirse

las siguientes medidas de seguridad al

igual que otras medidas de seguridad

establecidas.

1. Lea atentamente TODOS

los manuales incluidos con

este producto. Familiarícese

bien con los controles y el

uso adecuado del equipo.

2. Esta herramienta neumática SÓLO

debe ser usada por personas que

estén bien familiarizadas con las

reglas de seguridad de manejo.

NO exceda la presión máxima

de funcionamiento de la

herramienta neumática (6,21 bar), la

cual PODRÍA explotar y ocasionar la

muerte o lesiones graves.

Es2

MANUAL

3. NO exceda ninguna capacidad

máxima de presión de ningún

componente del sistema. La presión

máxima de trabajo de 6,21 bar se

mide en la entrada de aire de la

herramienta con la herramienta

encendida. El compresor de aire

debe compensar la baja de presión

entre éste y la herramienta.

Descargue TODA la presión

del sistema antes de intentar

instalar, dar servicio, reubicar o efectuar

cualquier mantenimiento.

4. Desconecte el suministro de aire a la

herramienta cuando no esté en uso

y antes de cambiar herramientas,

accesorios o efectuar mantenimiento.

Use SIEMPRE protección para

los oídos y gafas de seguridad

durante el funcionamiento.

5. NO use ropa suelta, bufandas,

corbatas o joyas cuando opere

cualquier herramienta. La ropa

o joyas sueltas pueden quedar

atrapadas en las partes móviles y

ocasionar lesiones graves.

6. NO presione el gatillo cuando

conecte la manguera de suministro

de aire a la herramienta.

7. NO ponga las manos cerca o debajo

de piezas en movimiento.

La exposición

excesiva a la

vibración, trabajar en posiciones

incómodas y los movimientos de trabajo

repetitivos pueden causar lesiones a las

manos y brazos. Deje de usar cualquier

herramienta si aparece incomodidad,

Page 27

entumecimiento, cosquilleo o dolor y

consulte a un médico.

8. Antes de cada uso compruebe que

las mangueras de aire no estén

debilitadas o desgastadas. Asegúrese

de que TODAS las conexiones estén

seguras.

9. Proteja las líneas de aire de daños

o perforaciones. NO lleve la

herramienta por la manguera de aire.

10. NUNCA oprima el gatillo a menos

que la herramienta esté en la pieza de

trabajo. Los accesorios DEBEN estar

bien conectados. Si los accesorios

están flojos le podrían ocasionar

heridas graves.

11. SIEMPRE use accesorios que

estén diseñados para usarse con

herramientas neumáticas. NO use

accesorios que estén dañados o

desgastados.

12. Mantenga ajustadas TODAS

las tuercas, pernos y tornillos,

y compruebe que el equipo

se encuentre en estado de

funcionamiento seguro.

CL252100AV, CL254100AV

13. SIEMPRE coloque la pieza en una

prensa de tornillos o abrazadera.

No coloque las manos en el cilindro

negro mientras esté operando la

herramienta.

14. NUNCA apunte la herramienta

neumática hacia usted ni hacia otras

personas. Esto PODRÍA ocasionar

heridas de gravedad.

15. Trabaje SIEMPRE en un lugar

bien ventilado y use una máscara

para polvo aprobada por la OSHA

(Administración de Seguridad y Salud

Ocupacional de EE. UU.).

16. No utilice mandriles para discos de

corte con esta herramienta.

Funcionamiento

InstRuccIones de montaje

Las herramientas neumáticas requieren

un suministro de aire limpio y seco a 90

PSI (6,2 bar). Se debe usar un sistema de

suministro de aire con filtro, regulador y

lubricador (FRL) como se muestra en la

Figura 1.

Opción 1: componentes individuales

Filtro LubricadorRegulador

Opción 2: combinación de 3 piezas

Figura 1

Es3

de ltro, regulador y lubricador

Page 28

Manual de Instrucciones de Operación

Se recomienda FRL modelo PA2104 (9,5

mm [3/8 pulg.]) o PA2114 (12,7 mm [1/2

pulg.]) de Campbell Hausfeld.

El agua en el suministro de aire

puede dañar la herramienta. Drene la

condensación del tanque compresor y

filtre diariamente.

Todas las mangueras y conexiones

deben ser del tamaño correcto y estar

bien ajustadas. Consulte la Tabla 1 para

conocer los tamaños mínimos.

Consumo de aire de la

herramienta

Menos de 254 L/min. al 100% del

uso

254 a 962 L/min. al 100% del uso 9,5 mm

Más de 962 L/min. al 100% del uso 12,7 mm

Tabla 1 - El diámetro mínimo sugerido de la

manguera para usar basado en una manguera de

15,25 m de largo y calificación continua L/min.

de la herramienta. El uso de conexiones y una

manguera más larga podría requerir el uso de una

manguera de mayor diámetro.

No use mangueras

ni conexiones que

estén dañadas o deterioradas.

Nunca cargue una

herramienta por

la manguera o hale la manguera para

mover la herramienta o un compresor.

Mantenga las mangueras alejadas

del calor, aceite o puntas afiladas,

reemplace cualquier manguera que esté

dañada, deteriorada o desgastada.

DI de la

manguera

6,4 mm

luBRIcacIÓn

Las herramientas neumáticas requieren

lubricación a lo largo de la vida útil de la

herramienta y esto es responsabilidad

del propietario. Si no lubrica en forma

adecuada la herramienta de aire,

acortará dramáticamente la vida útil de la

misma y anulará la garantía.

Esta herramienta

neumática

requiere lubricación ANTES del uso

inicial y ANTES y DESPUÉS de cada uso

adicional.

LUBRICACIÓN AUTOMÁTICA

El método recomendado para la

lubricación es con un lubricador de línea

de aire instalado como parte del sistema

de tuberías de aire. Vea la Figura 1. Use

el aceite ST127000AV para herramientas

neumáticas de Campbell Hausfeld o un

aceite equivalente a ISO 32.

LUBRICACIÓN MANUAL

Si no se usa un lubricador de línea de

aire, la herramienta debe lubricarse

diariamente.

Desconecte la

herramienta

neumática del suministro de aire antes

de lubricar.

1. Desconecte la herramienta neumática

del suministro de aire.

2. Dé vuelta la herramienta neumática.

3. Mientras tira del gatillo, introduzca

aproximadamente 7,4 ml (1/4

onza) de aceite para herramientas

neumáticas Campbell Hausfeld en la

entrada de aire. Si correspondiera,

coloque la válvula de avance y

retroceso en ambas direcciones.

Luego de haber

lubricado una

herramienta neumática, saldrá aceite a

través del puerto de escape durante los

primeros segundos de funcionamiento.

El puerto de escape debe dirigirse en

sentido opuesto a su cuerpo antes de

aplicar la presión de aire.

4. Conecte la herramienta neumática

al suministro de aire y cubra el

puerto de escape con una toalla

(consulte el manual de piezas

de repuesto para conocer las

Es4

Page 29

funciones de la herramienta). Haga

funcionar la herramienta en las

direcciones de avance y retroceso,

si correspondiera, durante 20 a

30 segundos. Cuando se aplica la

presión de aire, el aceite sale del

puerto de escape.

accesoRIos

Desconecte la

herramienta de

la fuente de suministro de aire antes

de cambiar los accesorios o podría

ocasionarle lesiones graves.

1. Introduzca el extremo del accesorio

para rectificar dentro del orificio de la

boquilla (Vea la Figura 2).

CL252100AV, CL254100AV

Figura 3 - Llaves

Para Apretar la

Boquilla Gire la

Llave Hacia la

Derecha

Accesorio para

Recticar

Tuerca de Boquilla

Figura 2

2. Ajuste firmemente el mandil

portapieza con llaves (incluidas

con algunos modelos) (Vea la

Figura 3 y 4). Aplique una llave a

la tuerca del mandril y la otra al

eje. Gire la llave de la tuerca del

mandril hacia la derecha, mientras

al mismo tiempo gira la otra llave en

la dirección opuesta, Asegúrese de

que el vástago no quede posicionado

incorrectamente.

3. Haga lo opuesto del Paso 3 para

aflojar y cambiar el accesorio

rectificador.

Siempre Gire

esta Llave

en Sentido

Opuesto

Figura 4

Cerciórese de

que el extremo

del accesorio esté completamente

introducido al orificio de la boquilla y

que la boquilla esté bien apretada. Los

accesorios flojos podrían salir volando

durante el funcionamiento y ocasionarle

lesiones graves. Sólo utilice accesorios

diseñados para un mínimo de 416,6 s-1

(25,000 revoluciones por minuto).

Es5

Page 30

Manual de Instrucciones de Operación

Mantenimiento

Libere toda la presión del

sistema antes de tratar de

instalar, darle servicio, reubicar o darle

cualquier tipo de mantenimiento al

sistema de aire. De no hacerlo podría

ocasionarle heridas personales o daños

a su propiedad.

almacenamIento

Antes de guardarse, la herramienta

debe lubricarse. Siga las instrucciones

de lubricación del motor neumático

con la excepción del paso 4. Solo

haga funcionar la herramienta de 2 a 3

segundos en vez de 20 a 30 segundos

debido a que es necesario que una

mayor cantidad de aceite permanezca en

la herramienta cuando se guarda.

assIstêncIa técnIca

Para mayor información en relación

al funcionamiento o reparación de

este producto, comuníquese con el

concesionario de Campbell Hausfeld

más cercano a su domicilio.

InFoRmacIÓn soBRe Repuestos

Para obtener información con respecto

a piezas de repuesto pedidas, llame sin

costo al 1-855-504-5678.

Sírvase suministrarnos la siguiente

información:

• Número del Modelo

• Código estampado

• Número y descripción del repuesto.

Puede escribirnos a:

Campbell Hausfeld

100 Production Drive

Harrison, Ohio 45030 U.S.A.

Es6

Page 31

Cl252100AV, Cl254100AV

Guía General de Diagnóstico de Averías

Problema Causa(s) Posible(s) Accion a tomar

La herramienta

funciona

lentamente o no

funciona

La herramienta

expulsa humedad

Vibración excesiva 1. La piedra/accesorio

1. Hay impurezas en la

herramienta

2. La herramienta no

tiene aceite

3. Baja presión de aire 3. Ajuste el regulador del compresor al máximo

4. Fugas en la

manguera de aire

5. Baja la presión 5. Asegúrese de que el tamaño de la manguera

6. El regulador está mal

ajustado

7. Los cojinetes de

bolas del motor o la

cabeza angular

están desgastados

8. Los engranajes

están desgastados

(solamente

esmeriladoras

angulares)

1. Hay agua en el

tanque

2. Hay agua en las

líneas/mangueras de

aire

para rectificar está

desgastado

2. El eje de la boquilla

está doblado

1. Limpie la herramienta con aceite para

herramientas neumáticas Campbell Hausfeld,

solventes adecuados o una mezcla de iguales

proporciones de aceite para motores SAE 10

y queroseno. Si no utiliza aceite

Campbell Hausfeld, lubrique la herramienta

después de limpiarla

2. Lubrique la herramienta según las

instrucciones de lubricación

permitido para la herramienta mientras ésta

funciona libremente

4. Apriete y selle las conexiones de la manguera,

si consigue fugas

sea el apropiado. Las mangueras largas o las

herramientas que utilizan grandes volúmenes

de aire pueden requerir una manguera con un

D.I. de 12,7 mm (1/2 pulg.) o superior, según

la longitud total de la manguera

6. Ajuste el regulador de flujo de aire con un

destornillador de cabeza plana a la máxima

velocidad

7. Desarme los cojinetes y revise si están

oxidados, sucios o desgastados. Limpie

los cojinetes con grasa para cojinetes o

reemplácelos

8. Reemplace los engranajes

1. Vacíe el tanque (Vea el manual del compresor

de aire). Lubrique la herramienta y déjela

funcionar hasta que no expulse residuos de

agua. Lubrique la herramienta una vez más y

déjela funcionar de 1s a 2s

2. a. Instale un separdor/filtro de agua (PA2100

o PA2110). NOTA: Los separadores

funcionan debidamente sólo cuando

el flujo de aire está fresco. Ubique el

separador/filtro lo más lejos posible del

compresor

2. b. Instale un secador de aire

2. c. En cualquier momento que entre agua

en la herramienta, deberá lubricarla

inmediatamente

1. Reemplace la piedra o el accesorio para

rectificar

2. Reemplace el eje o la boquilla (véase el

manual del listado de partes)

Es7

Page 32

Manual de Instrucciones de Operación

¡REGISTRE SU PRODUCTO EN LÍNEA AHORA MISMO!

http://reg.ch-commercial.com

Garantía Limitada

1 DURACIÓN: A partir de la fecha de compra por parte del comprador original del modo siguiente: 1 (un)

año.

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld / The Scott Fetzer Company 100

Production Drive, Harrison, Ohio 45030 Teléfono: (855) 504-5678.

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor)

del producto Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Esta esmeriladora neumática de troquel.

5. COBERTURA DE LA GARANTIA: Defectos importantes en el material y la mano de obra que ocurran

durante la duración del período de garantía con las excepciones que se mencionan a continuación.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES

PARTICULARES, ESTAN LIMITADOS A LO ESPECIFICADO EN EL PARRAFO DE DURACION. En

algunos estados no se permiten limitaciones a la duración de las garantías implícitas, por lo tanto,

en tales casos esta limitación no es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA

RESULTAR DE UN DEFECTO, FALLA O MALFUNCIONAMIENTO DEL PRODUCTO CAMPBELL

HAUSFELD. En algunos estados no se permite la exclusión o limitación de daños incidentales o

consecuentes, por lo tanto, en tales casos esta limitación o exclusión no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las

instrucciones de funcionamiento y uso indicadas en el (los) manual(es) que se adjunta(n) al

producto. Dichos accidentes, abusos por parte del comprador, o falta de operar el producto

siguiendo las instrucciones del manual de instrucciones suministrado también debe incluir la

desconexión o modificación de los instrumentos de seguridad. Si dichos instrumentos de seguridad

son desconectados, la garantía quedaría cancelada.

D. Los ajustes normales explicados en el(los) manual(es) suministrado(s) con el producto.

E. Los artículos o servicios que son necesarios normalmente para mantener el producto, p. ej. juntas

tóricas, resortes, juntas, empaques o sellos, lubricantes, paletas del motor, abrasivos, cortadores,

boquillas porta herramienta, mandriles, engranes cónicos, o cualquier otra pieza fungible no

mencionada específicamente. Estos artículos solamente estarán cubiertos durante noventa (90)

días a partir de la fecha de compra original. Los artículos subrayados sólo están garantizados por

defectos de material o fabricación.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Según elija el Garante, la reparación o

el reemplazo del producto o los componentes que estén defectuosos, que hayan funcionado en forma

inadecuada y/o que no hayan cumplido con su función dentro de la duración del período específico de

la garantía.

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Llame a Campbell Hausfeld (855) 504-5678 por sus opciones de servicio incluidas en la garantía.

Los costos de flete correrán por cuenta del comprador.