Page 1

See Warranty on page 10 for important information about commercial use of this product.

Operating Instructions CHG00189 (Model CHN10401)

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

2-in-1 Nailer / Stapler

REGISTER YOUR PRODUCT ONLINE NOW! http://www.chpower.net/reg

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .1

Important Safety Instructions . . . . . . .2

Tool Components and

Specifications. . . . . . . . . . . . . . . . . . . . .2

Operating the Tool . . . . . . . . . . . . . . . .5

Maintenance . . . . . . . . . . . . . . . . . . . . .7

Fasteners . . . . . . . . . . . . . . . . . . . . . . . .8

Troubleshooting Chart . . . . . . . . . . . . .9

Warranty . . . . . . . . . . . . . . . . . . . . . . .10

Description

This tool is designed for decorative trim,

molding, window casings, furniture

trim, picture frame assembly, cabinetry,

casebacks, and crafts. Features include:

convenient top loading magazine

which holds up to 100 brads or staples,

adjustable depth control, adjustable

exhaust, quick clear nose.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make sure

to tighten fittings, bolts, etc., before

putting unit into service.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

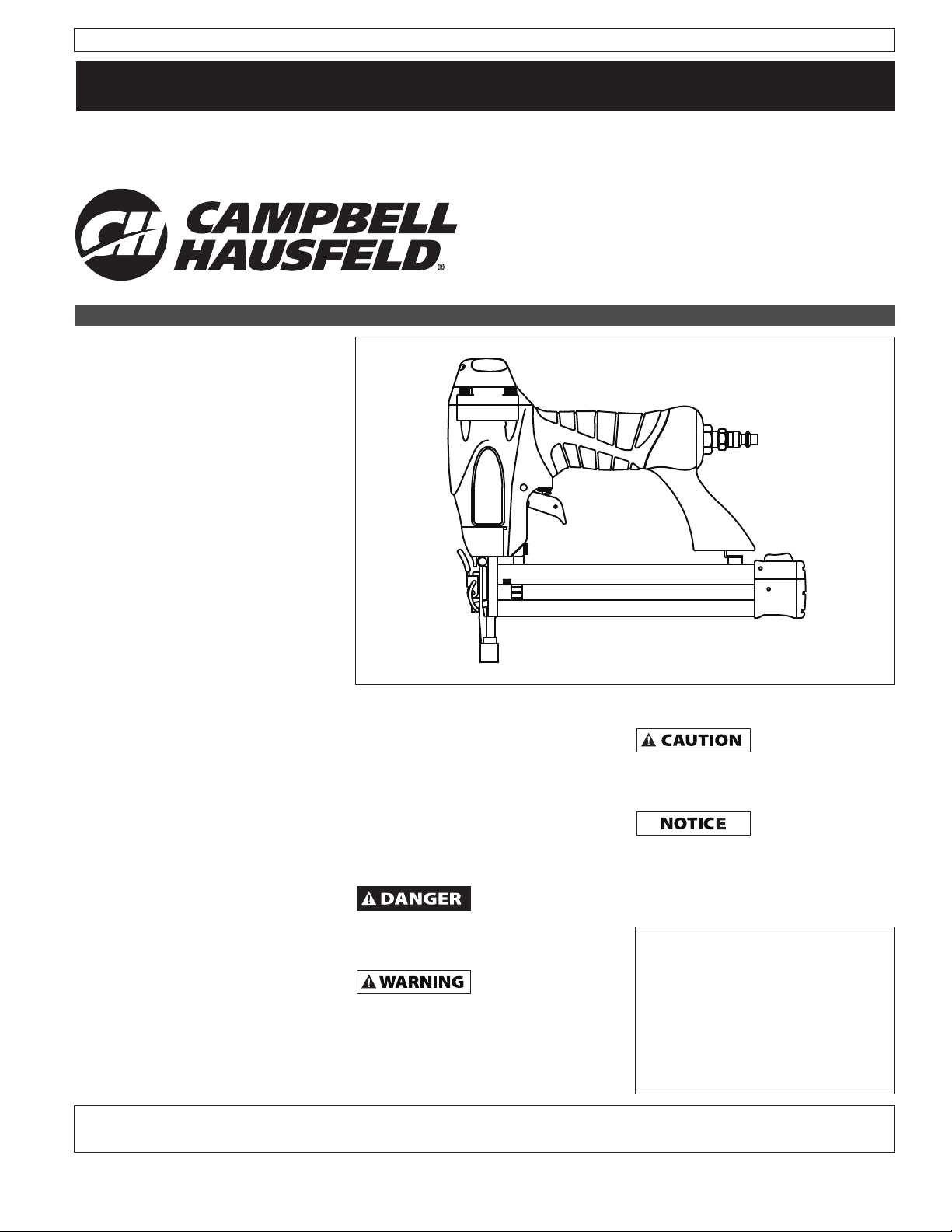

Figure 1 - Model CHN10401

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

NOTE: Information that requires special

attention.

Locate model and date code on

tool and record below:

Model No. ______________________

Date Code ______________________

Retain these numbers

for future reference.

REMINDER: Keep your dated proof of purchase for warranty purposes!

© 2012 Campbell Hausfeld/Scott Fetzer

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.chpower.com

IN738400AV 1/12

Page 2

Operating Instructions

Important Safety Instructions

INSTRUCTIONS PERTAINING TO A

RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS

This manual contains safety, operational

and maintenance information. Contact

your Campbell Hausfeld representative

if you have any questions.

When using tools,

basic precautions

should always be followed, including

the following:

CALIFORNIA PROPOSITION 65

This product or

its power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

You can create dust when

you cut, sand, drill or grind

materials such as wood,

paint, metal, concrete, cement, or other

masonry. This dust often contains

chemicals known to cause cancer, birth

defects, or other reproductive harm.

Wear protective gear.

GENERAL

a. To reduce the risks of

electric shock, fire, and

injury to persons, read all

the instructions before

using the tool.

b. Be thoroughly familiar with the

controls and the proper use of the

equipment. Follow all instructions.

Contact your Campbell Hausfeld

representative if you have any

questions.

c. Only persons well acquainted with

these rules of safe operation should

be allowed to use the unit.

Read and

understand tool

labels and manual. Failure to follow

warnings, dangers, and cautions could

result in DEATH or SERIOUS INJURY.

WORK AREA

a. Keep the work area clean and well

lighted. Cluttered benches and dark

areas increase the risks of electric

shock, fire, and injury to persons.

b. Do not operate the tool

in explosive atmospheres,

such as in the presence of

flammable liquids, gases,

or dust. The tool is able to create

sparks resulting in the ignition of

the dust or fumes.

c. Keep bystanders, children, and

visitors away while operating the

tool. Distractions are able to result in

the loss of control of the tool.

PERSONAL SAFETY

a. Stay alert. Watch what you are

doing and use common sense

when operating the tool. Do not

use the tool while tired or under

the influence of drugs, alcohol,

or medication. A moment of

inattention while operating the

tool increases the risk of injury to

persons.

b. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long

hair increases the risk of injury to

persons as a result of being caught

in moving parts.

c. Avoid unintentional starting.

Be sure the switch is off before

connecting to the air supply. Do not

carry the tool with your finger on

the switch or connect the tool to the

air supply with the switch on.

d. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in

unexpected situations.

e. Use safety equipment. A dust mask,

non-skid safety shoes and a hard

hat must be used for the applicable

conditions.

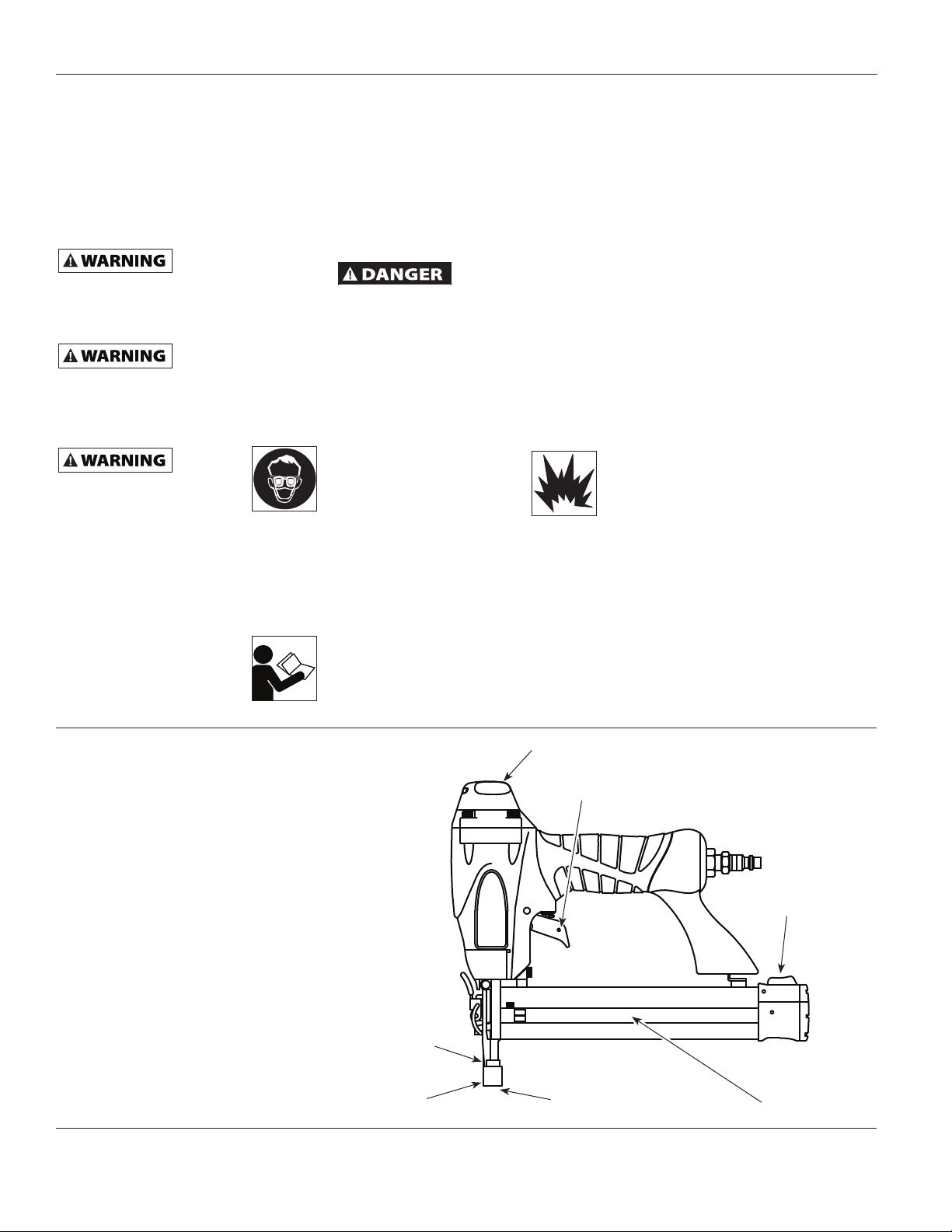

Tool Components and Specifications

• REQUIRES: 0.3 SCFM with

10 fasteners per minute @ 90 psi

• AIR INLET: 1/4 inch NPT

• FASTENER SIZE RANGE:

3/8 inch to 1-1/4 inch

• MAGAZINE CAPACITY:

100 fasteners per load, 18 gauge

• STAPLES: 1/4 inch crown

• WEIGHT: 2 lbs., 15 oz.

• LENGTH: 10-1/2 inch

• HEIGHT: 9-1/2 inch

• MAXIMUM PRESSURE: 100 psi

• PRESSURE RANGE: 60 psi to 100 psi

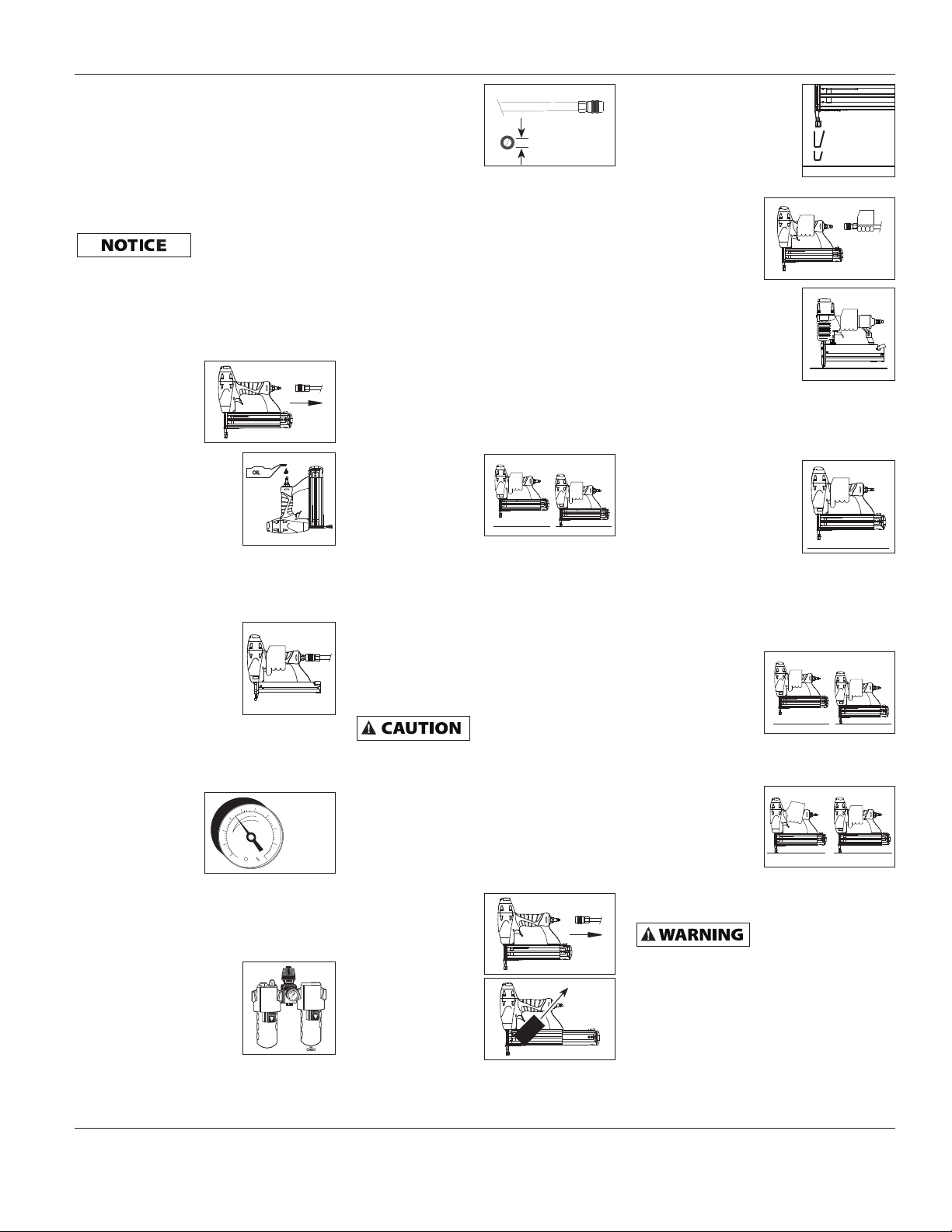

Work Contact Element (WCE)

www.chpower.com

Quick

Clear

Nose

Cap Exhaust

Trigger

Latch Button

Fastener

Discharge Area

Magazine

2

Page 3

CHG00189 (Model CHN10401)

Important Safety Instructions

(Continued)

f. Always wear eye

protection.

g. Always wear hearing

protection when using

the tool. Prolonged

exposure to high intensity

noise is able to cause

hearing loss.

h. Do not attach the hose or tool to

your body. Attach the hose to the

structure to reduce the risk of loss of

balance if the hose shifts.

i. Always assume that the tool

contains fasteners. Do not point

the tool toward yourself or anyone

whether it contains fasteners or not.

j.

nail. This is able to cause the nail to

be deflected and hit someone, or

cause the tool to react and result in a

risk of injury to persons.

k. Remove finger

when not driving fasteners. Never

carry the tool with finger on trigger,

the tool is able to fire a fastener.

Always remain in a

position when using or handling the

tool.

Avoid long

work with the tool. Stop using the tool

if you feel pain in hands or arms.

TOOL USE AND CARE

a. Use clamps or another practical way

to secure and support the workpiece

to a stable platform. Holding the

work by hand or against the body is

unstable and is able to lead to loss

of control.

b. Do not force the tool. Use the

correct tool for the application. The

correct tool will do the job better

and safer at the rate for which the

tool is designed.

c. Do not use the tool if the switch

does not turn the tool on or off. Any

tool that cannot be controlled with

the switch is dangerous and must be

repaired.

Do not nail on

top of another

from the trigger

firmly balanced

extended periods of

d.

source before making adjustments,

doing tool maintenance, clearing

jams, leaving work area,loading,

or unloading the tool. Such

Disconnect the

tool from the air

precautionary measures reduce the

risk of injury to persons.

e. Store the tool when it is idle out

of reach of children and other

untrained persons. A tool is

dangerous in the hands of untrained

users.

f. Maintain the tool with care. Keep

a cutting tool sharp and clean. A

properly maintained tool, with sharp

cutting edges reduces the risk of

binding and is easier to control.

g. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that affects

the tool’s operation. If damaged,

have the tool serviced before using.

Many accidents are caused by poorly

maintained tools. There is a risk of

bursting if the tool is damaged.

h. Use only those fasteners listed

in the Accessories section of this

manual. Fasteners not identified

for use with this tool by the tool

manufacturer are able to result in

a risk of injury to persons or tool

damage when used in this tool.

i. Selecting an appropriate tool

actuation system, taking into

consideration the work application

for which the tool is used.

gasoline or other flammable

liquids to clean the tool.

Never use the tool in the

presence of flammable liquids or gases.

Vapors could ignite by a spark and

cause an explosion which will result in

death or serious personal injury.

Do

remove, tamper with,

or otherwise cause the

trigger lock or trigger

to become inoperable.

Do not operate any

tool which has been modified in a like

fashion. Death or serious personal

injury could result.

Never

use

not

Do

not

touch the trigger unless

driving fasteners. Never

attach air line to tool or

carry tool while touching the trigger.

The tool could eject a fastener which

will result in death or serious personal

injury. Also actuate the trigger lock to

the safe position when not in use.

Always disconnect the

tool from the power

source when unattended, performing

any maintenance or repair, clearing

a jam, or moving the tool to a new

location. Do not load the tool with

fasteners when the trigger is depressed.

The tool could eject a fastener causing

death or serious personal injury.

Always fit tool with a

fitting or hose coupling

on or near the tool in

such a manner that all

compressed air in the tool is discharged

at the time the fitting or hose coupling

is disconnected. Do not use a check

valve or any other fitting which allows

air to remain in the tool. Death or

serious personal injury could occur.

Never

place

hands or any other body

parts in the fastener

discharge area of the tool.

The tool might eject a fastener and

could result in death or serious personal

injury.

Never carry the tool by

the air hose or pull the

hose to move the tool or

a compressor. Keep hoses

away from heat, oil and

sharp edges. Replace any

hose that is damaged,

weak or worn. Personal

injury or tool damage could occur.

www.chpower.com

3

Page 4

Operating Instructions

Important Safety Instructions

(Continued)

Always assume the

tool contains

fasteners. Respect the tool as a working

implement; no horseplay. Always keep

others at a safe distance from the work

area in case of accidental discharge of

fasteners. Do not point the tool toward

yourself or anyone whether it contains

fasteners or not. Accidental triggering

of the tool could result in death or

serious personal injury.

Do

drive a fastener on top

of other fasteners. The

fastener could glance

and cause death or a

serious puncture wound.

not operate or allow

anyone else to operate

the tool if any warnings

or warning labels are not legible.

Warnings or warning labels are located

on the tool magazine and body.

Do not drop or

Dropping or throwing the tool can

result in damage that will make the tool

unusable or unsafe. If the tool has been

dropped or thrown, examine the tool

closely for bent, cracked or broken parts

and air leaks. STOP and repair before

using or serious injury could occur.

Avoid using the

magazine is empty. Accelerated wear on

the tool may occur.

not

!

Do

throw the tool.

tool when the

WARNING

Clean and check all

air supply hoses

and fittings before connecting the

tool to an air supply. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may be

reduced.

SERVICE

a. Tool service must be performed only

by qualified repair personnel.

b. When servicing a tool, use only

identical replacement parts. Use

only authorized parts.

c. Use only the lubricants supplied

with the tool or specified by the

manufacturer.

Do not make any

modifications to

the tool without first obtaining written

approval from Campbell Hausfeld. Do

not use the tool if any shields or guards

are removed or altered. Do not use the

tool as a hammer. Personal injury or

tool damage may occur.

Disconnect air

supply and release

tension from the pusher before

attempting to clear jams because

fasteners can be ejected from the front

of the tool. Personal injury may occur.

AIR SOURCE

a. Never connect to an air source that

is capable of exceeding 200 psi.

Over pressurizing the tool is able

to result in bursting, abnormal

operation, breakage of the tool or

serious injury to persons. Use only

clean, dry, regulated compressed air

at the rated pressure or within the

rated pressure range as marked on

the tool. Always verify prior to using

the tool that the air source has been

adjusted to the rated air pressure or

within the rated air-pressure range.

b. Never use oxygen, carbon dioxide,

combustible gases or any bottled

gas as an air source for the tool.

Such gases are capable of explosion

and serious injury to persons.

Do not

use any

type of reactive gases,

including, but not limited

to, oxygen and combustible

gases, as a power source. Use filtered,

lubricated, regulated compressed air

only. Use of a reactive gas instead of

compressed air may cause the tool

to explode which will cause death or

serious personal injury.

Use only a pressure-regulated

compressed air source to limit

the air pressure supplied to

the tool. The regulated pressure must

not exceed 100 psi. If the regulator

fails, the pressure delivered to the

tool must not exceed 200 psi. The tool

could explode which will cause death or

serious personal injury.

O

CO

2

100 psi

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

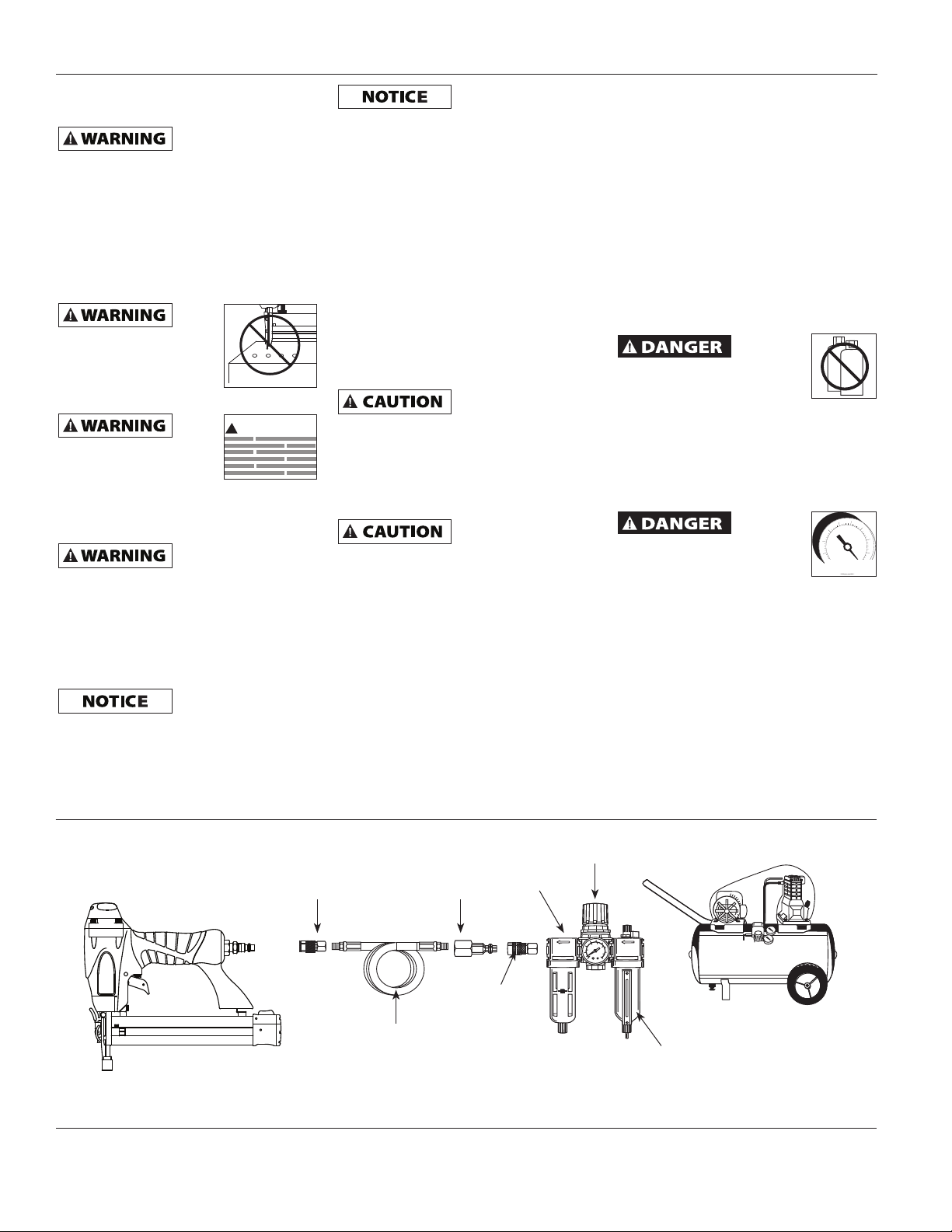

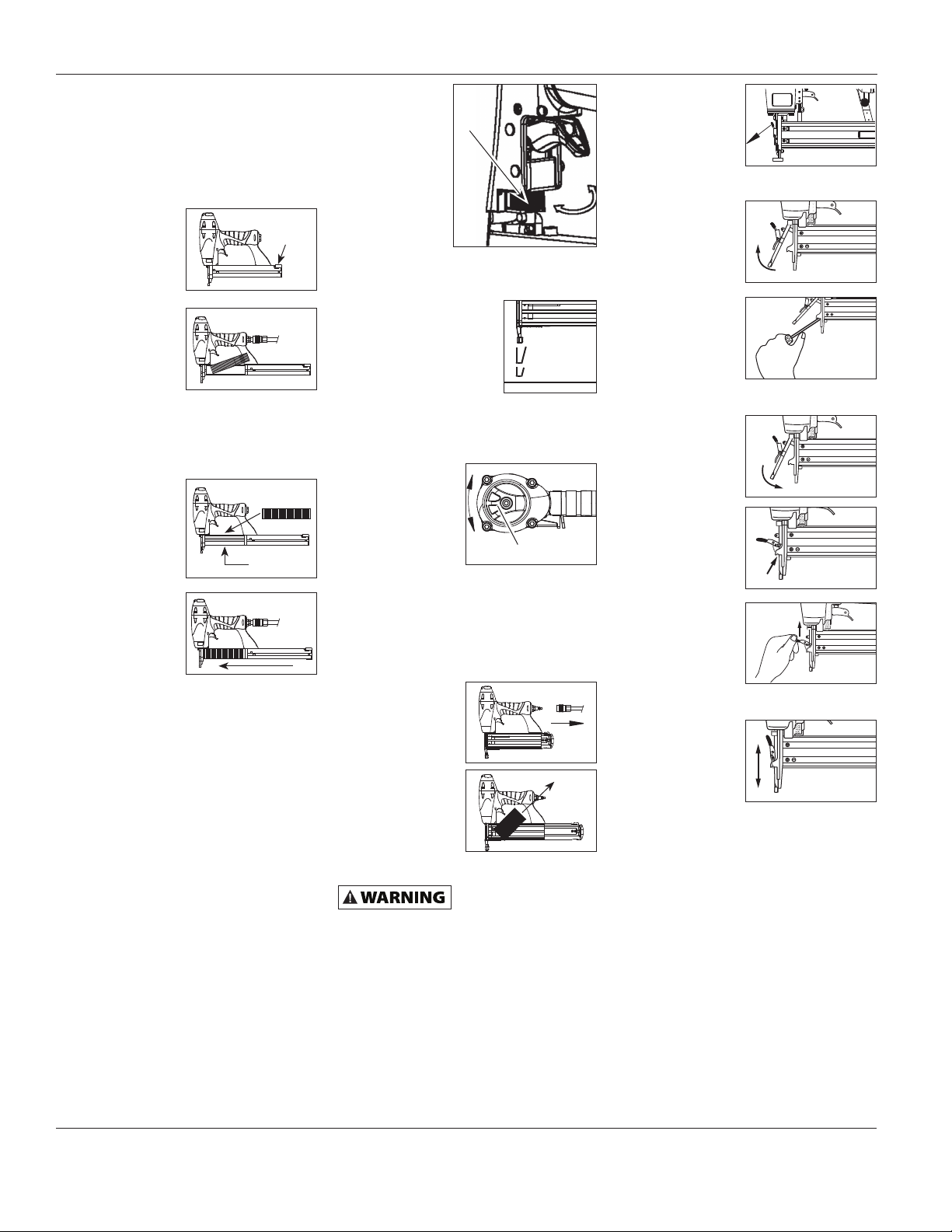

Recommended Hookup

www.chpower.com

Quick

Coupler

Air Hose

Quick Plug

(Optional)

Quick Coupler

(Optional)

4

Regulator

Oiler

Filter

Page 5

CHG00189 (Model CHN10401)

BUILT TO LAST

Operating the Tool

LUBRICATION

This tool requires lubrication before

using the tool for the first time and

before each use. If an inline oiler is

used, manual lubrication through the

air inlet is not required on a daily basis.

The work surface

can become

damaged by excessive lubrication.

Proper lubrication is the owner’s

responsibil- ity. Failure to lubricate

the tool properly will dramatically

shorten the life of the tool and void the

warranty.

1. Disconnect the

air supply from

the tool to add

lubricant.

2. Turn the tool so the

air inlet is facing up.

Place 4-5 drops of 30

W non-detergent oil

into air inlet. Do not

use detergent oils, oil

additives, or air tool oils. Air tool oils

contain solvents which will damage

the tool's internal components.

3. After adding oil, run

tool briefly. Wipe off

any excess oil from

the cap exhaust.

RECOMMENDED HOOKUP

The illustration below shows the

recommended hookup for the tool.

1. The air

compressor

must be able

to maintain a

minimum of

60 psi when the tool is being used.

An inadequate air supply can cause

a loss of power and inconsistent

driving.

2. An oiler can be

used to provide oil

circulation through

the tool. A filter can

be used to remove

liquid and solid

60 psi

min.

100 psi

max.

3. Use 1/4 inch

150 psi WP

air hoses with

a minimum

working

1/4 inch I.D.

pressure of

150 psi. Use 3/8 inch air hoses for

50 ft. run or longer. For better

performance, install a 3/8 inch quick

plug (1/4 inch NPT threads) with an

inside diameter of .315 inch (8mm)

on the tool and a 3/8 inch quick

coupler on the air hose.

4. Use a pressure regulator on the

compressor, with an operating

pressure of 0 -125 psi. A pressure

regulator is required to control

the operating pressure of the tool

between 60 and 100 psi.

SINGLE SEQUENTIAL MODE

This mode requires

the trigger to be

pulled each time a

fastener is driven.

The tool can be

actuated by depressing the WCE against

the work surface followed by pulling

the trigger.

The trigger must be released to reset

the tool before another fastener can be

driven.

CHECKING THE WORK CONTACT

ELEMENT (WCE)

Check the operation

of the Work Contact

Element (WCE) trip mechanism before

each use. The WCE must move freely

without binding through its entire

travel distance. The WCE spring must

return the WCE to its fully extended

position after being depressed. Do

not operate the tool if the WCE trip

mechanism is not operating properly.

Personal injury may occur.

1. Disconnect the

air supply from

the tool.

2. Remove all

fasteners from

the magazine

(see Loading/

Unloading).

3. Make sure the trigger

and work contact

element (WCE) move

freely up and down

Movement

without sticking or

binding.

4. Reconnect air

supply to the

tool.

5. Depress the Work

Contact Element

(WCE) against the

work surface without

pulling the trigger.

The tool MUST NOT

OPERATE. Do not use the tool if it

operates without pulling the trigger.

Personal injury may result.

6. Remove the tool from

the work surface.

The Work Contact

Element (WCE) must

return to its original

down position.

The tool MUST NOT OPERATE.

Do not use the tool if it operates

while lifted from the work surface.

Personal injury may result.

7. Pull the trigger

and depress the

work contact

element (WCE)

against the

work surface. The tool MUST NOT

OPERATE.

8. Depress the

Work Contact

Element (WCE)

against the

1 2

work surface.

Pull the trigger. The tool MUST

OPERATE.

An improperly

functioning tool

must not be used. Do not actuate the

tool unless the tool is placed firmly

against the work piece.

impurities which can rust or “gum

up” internal parts of the tool.

www.chpower.com

5

Page 6

Operating Instructions

BUILT TO LAST

Operating the Tool

(Continued)

LOADING/UNLOADING THE TOOL

1. Always disconnect the tool from

the air supply before loading

fasteners.

2. Push down

on the latch

button. Pull

back on the

magazine cover.

3a. For nails, insert

a stick into

the magazine.

Make sure the

pointed ends

of the fasteners are resting on the

bottom ledge of the magazine when

loading. Make sure the nails are not

dirty or damaged.

3b. For staples, load

a clip of staples

with the crowns

straddling the

magazine rail.

4. Push the

magazine cover

forward until

latch button

pops up.

5. Always unload all fasteners before

removing tool from service.

Unloading is the reverse of loading,

except that you must disconnect

the air supply before unloading.

ADJUSTING THE FASTENER

PENETRATION

The tool is equipped with an adjustable

depth of drive feature. This allows the

user to determine how deep a fastener

will be driven into the work surface.

1. Adjust operating pressure so

fasteners are driven consistently. Do

not exceed 100 psi.

Latch

button

Magazine

rail

2. For shallow

penetration,

turn the

(C)

wheel (C)

to right to

the extent

desired.

3. For deeper

penetration,

turn the wheel (C) to left to the

extent desired.

4. Make sure trigger

and work contact

element (WCE) move

freely up and down

Movement

without binding or

sticking after each

adjustment.

ADJUSTING THE DIRECTION OF THE

EXHAUST

The tool is

equipped with

an adjustable

direction exhaust

Rotate

deflector. This is

intended to allow

the user to change the direction of the

exhaust. Simply twist the deflector to

any direction desired.

CLEARING A JAM FROM THE TOOL

1. Disconnect the

air supply from

the nailer.

2. Remove all

fasteners from

the magazine

(see “Loading/

Unloading The

Nailer”).

Failure to remove

all fasteners will

cause the fasteners to eject from the

front of the tool.

3. Undo latch by

pulling out

and down. The

wire latch will

disengage from

the hooks on the nose.

4. The door can

now be rotated,

exposing

the jammed

fastener.

5. Remove the

jammed

fastener, using

pliers or a

screwdriver if

required.

6 Rotate door

back into the

closed position.

7. Extend the wire

latch and place

over the hooks

on the nose.

8. Close the latch

by pushing the

latch up and

in until the

latch snaps into

place.

9. Make sure the

trigger and

work contact

element (WCE)

move freely

up and down

without sticking or binding.

www.chpower.com

6

Page 7

CHG00189 (Model CHN10401)

Maintenance

TECHNICAL SERVICE

Please call our Tool Hotline at 1-800543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual.

FASTENER AND REPLACEMENT

PARTS

Use only genuine

Campbell Hausfeld

18 gauge fasteners (or equivalent - see

Fastener Interchange Information).

Use only genuine Campbell Hausfeld

replacement parts. Never substitute

parts. Do not use modified parts or

parts which will not give equivalent

performance to the original equipment.

Tool performance, safety and durability

could be reduced. When ordering

replacement parts or fasteners, specify

by part number.

TOOL REPAIR

Only qualified personnel should repair

the tool, and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently.

ASSEMBLY PROCEDURE FOR SEALS

When repairing a tool, the internal

parts must be cleaned and lubricated.

Parker O-lube or equivalent must be

used on all o-rings. Each o-ring must be

coated with O-lube before assembling.

A small amount of oil must be used on

all moving surfaces and pivots. After

reassembling, a few drops of 30W

non-detergent oil or equivalent, must

be added through the air line before

testing.

STORAGE

The tool should be stored in a cool, dry

place.

Notes

www.chpower.com

7

Page 8

Operating Instructions

Fasteners

Fasteners

NAILS

The following Campbell Hausfeld Brad nails are available at local retail stores. For help locating any item, call customer service

at 1-800-543-6400. Campbell Hausfeld nails meet or exceed ASTM Standard F1667.

Nails Per

Model Length Shank Gauge Finish Head Collation

FB002000 3/4 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 5000

FB180016 5/8 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

FB180025 1 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

FB180030 1-1/4 inch 18 Gauge Galvanized Brad / Brown Adhesive 100 1000

INTERCHANGE INFORMATION

Can use brad nails from the following branded air-powered brad nailers: Bostitch BT125SK-2 & BT200K-2, Campbell Hausfeld

NB0030 & NB0040, DeWalt D51238K, Paslode T125-F18 & T200-F18, Porter Cable BN125 & BN200, and Senco Finish Pro 15 & 18.

STAPLES

The following Campbell Hausfeld staples are available at local retail stores. If you need help locating any item, call customer

service at 1-800-543-6400. Campbell Hausfeld staples meet or exceed astm Standard F1667.

Wire

Model Length

FN180615 1/2 inch 18 Gauge 1/4 inch Chisel Galvanized / Vinyl Coated Adhesive 100 1000

FN180620 3/4 inch 18 Gauge 1/4 inch Chisel Galvanized / Vinyl Coated Adhesive 100 1000

FN180625 1 inch 18 Gauge 1/4 inch Chisel Galvanized / Vinyl Coated Adhesive 100 1000

FN180630 1-1/4 inch 18 Gauge 1/4 inch Chisel Galvanized / Vinyl Coated Adhesive 100 1000

Diameter

Crown

Size Point Finish Collation

Stick

Staples

Per Stick

Nails Per

Box

Staples

Per Box

INTERCHANGE INFORMATION

Staples used in the SB514000 will also work in: Senco LN4450, SJS-LR, SKS L11-15, Hitachi N3804A, Duofast BN-1832S, KN-1848, StanTech SDS 18-14, Atro Minor 90/30, 90/32, 90/40, and Porter Cable NS100.

www.chpower.com

8

Page 9

CHG00189 (Model CHN10401)

Troubleshooting Chart

Stop using tool immediately if any of the following problems occur. Serious personal injury could occur.

Any repairs or replacements must be done by a Qualified Service Person or Authorized Service Center.

Symptom Possible Cause(s) Corrective Action

Air leaking at trigger valve

area

Air leaking between housing

and nose

Air leaking between housing

and cap

Tool skips driving fastener 1. Worn bumper 1. Replace bumper

Tool runs slow or has loss of

power

Fasteners are jammed in tool 1. Guide on driver is worn 1. Replace guide

O-rings in trigger valve housing are

damaged

1. Loose screws in housing 1. Tighten screws

2. Damaged o-rings 2. Replace o-rings

3. Damage to bumper 3. Replace bumper

1. Loose screws 1. Tighten screws

2. Damaged gasket 2. Replace gasket

2. Dirt in nose piece 2. Clean drive channel

3. Dirt or damage prevent fasteners or

pusher from moving freely in magazine

4. Damaged pusher spring 4. Replace spring

5. Inadequate air flow to tool 5. Check fitting, hose, or compressor

6. Worn o-ring on piston or lack of

lubrication

7. Damaged o-ring on trigger valve 7. Replace o-rings

8. Air leaks 8. Tighten screws and fittings

9. Cap gasket leaking 9. Replace gasket

1. Tool not lubricated sufficiently 1. Lubricate tool

2. Broken spring in cylinder cap 2. Replace spring

3. Exhaust port in cap is blocked 3. Replace damaged internal parts

2. Fasteners are not correct size 2. Use only recommended fasteners

3. Fasteners are bent 3. Replace with undamaged fasteners

4. Magazine or nose screws are loose 4. Tighten screws

5. Driver is damaged 5. Replace driver

Replace o-rings. Check operation of Work

Contact Element (WCE)

3. Clean magazine

6. Replace and lubricate o-rings

www.chpower.com

9

Page 10

Operating Instructions

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: One (1) Year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio, 45030, Telephone: (800) 543-6400.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld air tool.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the

duration of the warranty period with the exceptions below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for commercial, industrial

or rental purposes, the warranty will apply for ninety (90) days from the date of purchase. Some States do not allow

limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser's abuse, neglect or failure

to operate products in accordance with instructions shall also include the removal or alteration of any safety devices.

If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or service that are normally required to maintain the product.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within the duration of the specific warranty

period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Campbell Hausfeld (800) 543-6400 to obtain your warranty service options. Freight costs must be borne by the

purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights. You may also

have other rights which vary from state to state or country to country.

www.chpower.com

10

Page 11

Ver la Garantía en página 10-Sp para información importante sobre el uso comercial de este producto.

Manual de Instrucciones de Operación CHG00189 (Modelo CHN10401)

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto

aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede

ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Clavadora /

Agrapadora 2-en-1

¡REGISTRE SU PRODUCTO EN LÍNEA AHORA MISMO! http://www.chpower.net/reg

Índice

Descripción . . . . . . . . . . . . . . . . . . . 1-Sp

Desempaque . . . . . . . . . . . . . . . . . . 1-Sp

Medidas de Seguridad . . . . . . . . . . 1-Sp

Instrucciones de Seguridad

Importantes. . . . . . . . . . . . . . . . . . . 2-Sp

Componentes y Specificaciones

de la Herramienta . . . . . . . . . . . . . . 2-Sp

Cómo usar la Herramienta . . . . . . . 5-Sp

Mantenimiento . . . . . . . . . . . . . . . 7-Sp

Sujetadores . . . . . . . . . . . . . . . . . . . 8-Sp

Guía de Diagnóstico de Averías. . . 9-Sp

Garantía Limitada . . . . . . . . . . . . . 10-Sp

Descripción

Esta herramienta está diseñada para

contramarcos y molduras decorativas,

contramarcos de ventanas, chambranas,

ensamblaje de marcos de cuadros,

marquetería, fondo de cajas, y

manualidades. Las características

incluyen: conveniente cargador con

entrada superior con una capacidad

de hasta 100 sujetadores, control de

profundidad ajustable, orificio de salida

ajustable, boquilla de desobstrucción

rápida.

Desempaque

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Cericiórese de

apretar todas las conexiones, pernos,

etc. antes de comenzar a utilizar la

unidad.

LEA Y SIGA TODAS LAS

INSTRUCCIONES

GUARDE ESTAS INSTRUCCIONES –

NO LAS DESECHE

Figura 1 - Modelo CHN10401

Medidas de Seguridad

Este manual contiene información

que es muy importante que sepa

y comprenda. Esta información se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una

información

importante, que de no seguirla, le

podría ocasionar daños al equipo.

NOTA: Información que requiere

atención especial.

Localice el modelo y el código de

fecha y regístrelo debajo:

Modelo Nº ______________________

Código de fecha ________________

Conserve estos números para

referencia.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2012 Campbell Hausfeld/Scott Fetzer IN738400AV 1/12

1-Sp

Page 12

Manual de Instrucciones de Operación

Instrucciones de Seguridad

Importantes

INSTRUCCIONES EN REFERENCIA AL

PELIGRO DE INCENDIOS, CHOQUE

ELÉCTRICO O LESIONES PERSONALES

Este manual contiene información

sobre seguridad, funcionamiento y

mantenimiento. Póngase en contacto

con su representante Campbell Hausfeld

si tiene alguna pregunta.

Cuando se usen

herramientas,

siempre se deberán seguir precauciones

básicas, incluyendo las siguientes:

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o

su cordón eléctrico,

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

Cuando

corta

lija, taladra o pule materiales

como por ejemplo madera,

pintura, metal, hormigón,

cemento, u otro tipo de mampostería se

puede producir polvo. Con frecuencia

este polvo contiene productos químicos

que se conocen como causantes de

cáncer, defectos congénitos u otros

daños reproductivos. Use equipo de

protección.

GENERAL

a. Para reducir el riesgo de

choque eléctrico, incendio

y lesiones personales, lea

todas las instrucciones

antes de usar la herramienta.

b. Familiarísece con los controles

y el uso adecuado del equipo.

Siga todas las instrucciones. Póngase

en contacto con su representante

Campbell Hausfeld si tiene alguna

pregunta.

c. Sólo se les debe permitir usar esta

unidad a aquellas personas bien

familiarizadas con estas reglas de

manejo seguro.

Lea y comprenda

las etiquetas y el

manual de la herramienta. Si no respeta

las advertencias, los riesgos y las

recomendaciones, eso podría resultar en

la MUERTE o en LESIONES GRAVES.

ÁREA DE TRABAJO

a. Mantenga el área de trabajo limpia

y bien iluminada. Los bancos

desordenados y las áreas oscuras

aumentan el riesgo de choque

eléctrico, incendio y lesiones

personales.

b. No haga funcionar la

herramienta en entornos

explosivos, como por

ejemplo cuando haya

polvo, líquidos o gases

inflamables. La herramienta puede

crear chispas y provocar la ignición

de polvo o vapores.

Componentes y Specificaciones de la Herramienta

• RequieRe:0,01 m3/min con

10 sujetadores por minuto a 6,21 bar

• eNTRADADeAiRe:

6,4 mm (1/4 pulg.) NPT

• RANGODeLOSSuJeTADOReS:

9,5 mm a 3,18 cm

(3/8 pulg. a 1-1/4 pulg.)

• CAPACiDADDeLCARGADOR:

100 sujetadores por carga, calibre 18

• GRAPAS:

corona de 6,4 mm (1/4 pulg.)

• PeSO:1,33 kg

• LONGiTuD: 26,67 cm (10-1/2 pulg.)

• ALTuRA: 24,13 cm (9-1/2 pulg.)

• PReSiONMáXiMA:6,90 bar

• RANGODeLAPReSióN:

4,14 bar a 6,90 bar

Elemento de contacto

Boquilla de

desobstrucción

rápida

de trabajo (WCE)

c. Mantenga alejados a los

observadores, niños y visitantes

mientras hace funcionar la

herramienta. Las distracciones

pueden dar como resultado

la pérdida del control de la

herramienta.

SEGURIDAD PERSONAL

a. Manténgase alerta. Mire lo que

está haciendo y use el sentido

común cuando haga funcionar la

herramienta. No use la herramienta

si está cansado o bajo la influencia

de drogas, alcohol o medicamentos.

Un momento de desatención

mientras hace funcionar la

herramienta aumenta el riesgo

de lesiones personales.

b. Vístase adecuadamente. No use

alhajas ni vestimenta suelta.

Sujétese el cabello largo. Mantenga

el cabello, vestimenta y guantes

alejados de las piezas móviles.

La vestimenta suelta, las alhajas o el

cabello largo aumentan el riesgo de

lesiones personales como resultado

de quedar atrapados en las piezas

móviles.

c. Evite que se encienda

accidentalmente. Asegúrese de

que el interruptor esté en la

posición de apagado antes de

conectar el suministro de aire.

No lleve la herramienta con su dedo

sobre el interruptor ni conecte la

herramienta al suministro de aire

con el interruptor en la posición de

encendido.

Orifico de salida de aire

Gatillo

Área de descarga de

los sujetadores

Botón del

seguro

Cargador

2-Sp

Page 13

CHG00189 (Modelo CHN10401)

Instrucciones de Seguridad

Importantes (Continuación)

d. No intente alcanzar lugares alejados.

Mantenga un buen soporte y

equilibrio en todo momento.

Un soporte y equilibrio adecuados

permiten un mejor control de

la herramienta en situaciones

inesperadas.

e. Use equipo de seguridad. Se debe

usar una mascara para polvo,

calzado de seguridad antideslizante

y casco para las condiciones que se

apliquen.

f. Siempre use protección

para los ojos.

g. Use siempre una

protección para el

oído cuando use

la herramienta.

La exposición prolongada

a ruido de alta intensidad

puede causar pérdida de

audición.

h. No ate la manguera ni la

herramienta a su cuerpo. Adjunte la

manguera a la estructura para

reducir el riesgo de pérdida de

equilibrio si la manguera se cambia

de posición.

i. Siempre asuma que la herramienta

contiene clavos. No apunte con la

herramienta hacia usted o hacia otra

persona, ya sea que contenga clavos

o no.

j. No clave ningún

clavo encima de

otro clavo. Esto puede hacer que el

clavo se desvíe y golpee a alguien,

o provocar que la herramienta

reaccione y cause el riesgo de

lesiones personales.

k. Quite el dedo

del gatillo

cuando no esté clavando clavos.

Nunca lleve la herramienta con su

dedo en el gatillo: la herramienta

puede disparar un clavo.

Siempre colóquese

en una posición

firme y balanceada para usar o

manipular la herramienta.

Evite trabajar con

esta herramienta

por largos periodos. Deje de usar la

herramienta si siente dolor en las

manos o en los brazos.

USO Y CUIDADO DE LA

HERRAMIENTA

a. Use sujetadores u otra manera

práctica de asegurar y apoyar la

pieza de trabajo a una plataforma

estable. Sostener el trabajo con

la mano o contra el cuerpo es

algo inestable y puede producir la

pérdida de control.

b. No fuerce la herramienta. Use la

herramienta correcta para la

aplicación. La herramienta correcta

hará el trabajo mejor y en forma

más segura a la velocidad para la

cual fue diseñada.

c. No use la herramienta si el

interruptor no la enciende o no

la apaga. Cualquier herramienta

que no pueda ser controlada con

el interruptor es peligrosa y debe

repararse.

d.

Desconecte la

del suministro de aire antes de

hacer cualquier ajuste, realizar el

mantenimiento de la herramienta,

eliminar obstrucciones, dejar el

área de trabajo, cargar o descargar

la herramienta. Estas medidas de

herramienta

precaución reducen el riesgo de

lesiones personales.

e. Cuando no esté en uso, guarde

la herramienta fuera del alcance

de los niños y otras personas no

capacitadas. Una herramienta es

peligrosa cuando está en manos de

usuarios inexpertos.

f. Cuide su herramienta. Mantenga

una herramienta para cortar

afilada y limpia. Una herramienta

mantenida adecuadamente con

bordes de corte afilados reduce el

riesgo de atascarse y es más fácil de

controlar.

g. Verifique que las piezas móviles no

estén desaliñadas ni adheridas, que

no haya piezas rotas y que no exista

ningún otro problema que afecten el

funcionamiento de la herramienta.

Si está dañada, haga que le realicen

un servicio a la herramienta antes

de usarla. Muchos accidentes son

causados por herramientas que no

tienen un mantenimiento adecuado.

Si la herramienta sufre un daño, hay

riesgo de explosión.

h. Use únicamente los clavos

detallados en la sección Accesorios

de este manual. Los sujetadores

no identificados por el fabricante

de la herramienta para uso con

esta herramienta pueden provocar

riesgos de lesiones personales o

daño a la herramienta al usarse con

esta herramienta.

i. Seleccionar un sistema de activación

de la herramienta adecuado,

tomando en cuenta la aplicación

de trabajo para la cual se usa la

herramienta.

Nunca

limpie

la herramienta con gasolina

o ningún otro líquido

inflamable. Nunca use la

herramienta en la cercanías de líquidos

o gases inflamables. Una chispa podría

encender los vapores y ocasionar una

explosión que podría ocasionarle la

muerte o heridas graves.

No quite, modifique

ni cause de otro modo

que la traba del gatillo

deje de funcionar. No

haga funcionar ninguna

herramienta que haya sido modificada

de manera similar. Eso puede resultar en

muerte o graves lesiones personales.

No toque el gatillo a

menos que se estén

clavando sujetadores.

Nunca conecte la línea de aire a la

herramienta ni mueva la herramienta

cuando esté tocando el gatillo. La

herramienta podría expulsar un

sujetador y producir la muerte o

lesiones personales graves. También

coloque el protector del gatillo en la

posición de seguro cuando no esté en

uso.

Desconecte siempre

la herramienta de la

fuente de energía cuando no la esté

atendiendo, cuando le esté realizando

mantenimiento o reparaciones,

desobstruyéndola o moviéndola a un

nuevo sitio. No cargue la herramienta

con sujetadores cuando el gatillo

esté oprimido. La herramienta puede

expulsar un sujetador y producir la

muerte o lesiones personales graves.

Siempre ajuste la

herramienta con un

conector o acoplador

de mangueras colocado

en o cerca de la herramienta de un

modo tal que se descargue todo el

aire comprimido en la herramienta

en el momento en que se desconecte

el conector o acoplador. No use una

válvula de chequeo o ninguna conexión

que permita que el aire permanezca en

la herramienta. Se puede producir la

muerte o lesiones personales graves.

3-Sp

Page 14

Manual de Instrucciones de Operación

Instrucciones de Seguridad

Importantes (Continuación)

Nunca ponga las manos

ni ninguna otra parte del

cuerpo en el área de descarga

de la herramienta. Ésta puede expulsar

un sujetador y producir la muerte

o lesiones personales graves.

Nunca cargue la

herramienta por la

manguera de aire ni

hale la manguera para

mover la herramienta

o el compresor de aire.

Mantenga las mangueras

alejadas del calor, aceite

y objetos puntiagudos.

Reemplace cualquier manguera que

esté dañada, débil o desgastada. Ésto

podría ocasionar heridas o daños a la

herramienta

Siempre asuma

tiene sujetadores. Respete la

herramienta como un implemento

de trabajo; no jugue con ella.

Siempre mantenga a los demás a una

distancia segura del área de trabajo,

en caso de una descarga accidental

de sujetadores. No apunte con la

herramienta hacia usted o hacia otra

persona, ya sea que contenga o no

sujetadores. El disparo accidental de

la herramienta podría resultar en la

muerte o en graves lesiones personales.

No clave un sujetador

encima de otro.

El sujetador podría saltar

y ocasionarle la muerte

o heridas graves.

No opere la herramienta

ni permita que otros la

operen si las etiquetas

de advertencia están

ilegibles. Éstas se encuentran en el

cargador o el cuerpo de la herramienta.

que la herramienta

!

ADVERTENCIA

Conexión Recomendada

Acoplador

rápido

No deje que la

caiga ni la tire. Ésto podría dañarla o

convertirla en algo peligroso de usar.

En caso de que la herramienta se haya

caído o la hayan tirado, revísela con

cuidado a ver si está doblada o rota, si

tiene alguna pieza dañada o tiene fugas

de aire. DEJE de trabajar y repárela

antes de usarla o podría ocasionarle

heridas graves.

Evite usar la

el depósito está vacío. Ésto podría

acelerar su desgaste.

Limpie y chequee

mangueras de suministro de aire

y conexiones antes de conectar la

herramienta al compresor. Reemplace

las mangueras y conexiones que estén

dañadas o desgastadas. El rendimiento

de la herramienta o su durabilidad

podrían reducirse.

herramienta se

herramienta cuando

todas las

SERVICIO

a. El servicio de la herramienta debe

ser realizado sólo por personal de

reparaciones calificado.

b. Al realizarle un servicio a la

herramienta, utilice únicamente

piezas de repuesto idénticas.

Use sólo piezas autorizadas.

c. Use sólo los lubricantes que el

fabricante proporciona con la

herramienta.

No haga ninguna

herramienta sin obtener primero la

aprobación por escrito de Campbell

Hausfeld. No use la herramienta si le

faltan alguna de las tapas protec-toras

o si éstas han sido modifi-cadas. No use

la herramienta como un martillo. Se

pueden producir lesiones personales o

daños a la herramienta.

Desconecte la

suministro de aire y elimine la tensión

del disparador antes de tratar de sacar

cualquier sujetador atascado, ya que

la herramienta podría disparar un

sujetador por el frente. Ésto podría

ocasionarle heridas.

modificación a la

fuente de

Regulador

Conector rápido

(Opcional)

Lubricador

SUMINISTRO DE AIRE

a. Nunca conecte a un suministro de

aire capaz de exceder las 13,79 bar.

Someter la herramienta a presión

excesiva puede resultar en una

explosión, funcionamiento anormal,

daños a la herramienta o graves

lesiones personales. Use sólo aire

comprimido limpio, seco y regulado

a la presión de funcionamiento

o dentro del rango de presiones

indicado en la herramienta. Antes

de usar la herramienta, verifique

siempre que el suministro de aire

haya sido regulado a la presión de

funcionamiento o esté dentro del

rango de presiones indicadas.

b. No use nunca oxígeno, dióxido

de carbono, gases combustibles

o ningún gas en botellas como

suministro de aire para la

herramienta. Tales gases puede

explotar y causar graves lesiones

personales.

No use

tipo de gas reactivo,

incluyendo, pero no

limitado a, oxígeno y gases

combustibles, como fuente de energía.

Use sólo aire comprimido filtrado,

lubricado y regulado. El uso de un gas

reactivo en vez de aire comprimido

puede provocar que la herramienta

explote, lo cual puede ocasionar la

muerte o graves lesiones personales.

Use solamente una fuente de

aire comprimido de presión

regulada para limitar la

presión de aire suministrada

a la herramienta. La presión regulada

no debe exceder los 6,90 bar. Si el

regulador falla, la presión transmitida

a la herramienta no debe exceder

los 13,79 bar. La herramienta puede

explotar, lo cual puede ocasionar la

muerte o graves lesiones personales.

ningún

O

CO

2

6,90 bar

GUARDE ESTAS INSTRUCCIONES –

NO LAS DESECHE

Acoplador rápido

Manguera de aire

4-Sp

(Opcional)

Filtro

Page 15

BUILT TO LAST

CHG00189 (Modelo CHN10401)

Cómo usar la Herramienta

(Continuación)

Cómo usar la Herramienta

LUBRICACION

Esta herramienta requiere lubricación

antes de usarse por primera vez y antes

de cada uso. Si utiliza un lubricador

incorporado a la línea, no tendrá que

lubricarla manualmente a diario.

La superficie de

trabajo se

podría dañar debido a la lubricación

excesiva. La lubricación adecuada es la

responsabilidad del propietario. Si no

lubrica la herramienta adecuadamente,

ésta se dañará rápidamente y la

garantía se cancelaría

1. Desconecte la

herramienta

de la fuente

de suministro

de aire para

lubricarla.

2. Gire la herramienta

de modo que la

entrada de aire

quede mirando hacia

arriba. Agregue de

4 a 5 gotas de aceite

no detergente 30W en la entrada

de aire. No use aceites detergentes,

aditivos de aceite, ni aceites para

herramientas neumáticas. Los aceites

para herramientas neumáticas

contienen solventes que pueden

averiar los componentes internos de

la herramienta.

3. Después de agregar

aceite, haga funcionar

la herramienta

brevemente. Limpie

todo exceso de aceite

que salga del orificio

de salida de aire.

CONEXIÓN RECOMENDADA

La ilustración de abajo le muestra la

conexión recomendada para la herramienta.

1. El compresor de

aire debe tener

la capacidad

de suministrar

un mínimo

de 4,14 bar

cuando la herramienta esté en

uso. Si el suministro de aire es

inadecuado podría haber pérdida de

potencia y falta de consistencia en el

funcionamiento.

4,14 bar

Min.

6,9 bar

Max.

2. Puede utilizar

un lubricador

para lubricar la

herramienta.

Igualmente, puede

utilizar un filtro

para remover las

impurezas líquidas y sólidas que

podrían oxidar u obstruir las partes

internas de la herramienta.

3. Use mangueras

1034 kPa PS

de aire de

6,4 mm (1/4

pulg.) diseñadas

para presiones

6,4 mm

(1/4") D.I.

mínimas de

trabajo de 10,34 bar. Use mangueras

de aire de 9,5 mm (3/8 pulg.) si la

longitud de las mismas es de 15m

ó más. Para un mejor rendimiento,

instálele a la herramienta un

conector rápido de 9,5 mm

(3/8 pulg.) [roscas de 6,4 mm

(1/4 pulg.) NPT] cuyo diámetro

interno sea de 8 mm (0,315 pulg.) y

un acoplador rápido de 9,5 mm

(3/8 pulg.) a la manguera de aire.

4. Use un regulador de presión

(de 0 bar-8,62 bar) en el compresor.

Se necesita un regulador de

presión para controlar la presión de

operación de la herramienta entre

4,14 bar y 6,90 bar.

MODO DE SECUENCIA SINGULAR

Este sistema

requiere que

oprima el gatillo

cada vez que

vaya a clavar un

sujetador. Para

clavar el elemento de contacto debe

tocar la superficie de trabajo y el

operador debe oprimir el gatillo.

Debe soltar el gatillo antes de clavar

otro sujetador.

COMO CHEQUEAR EL ELEMENTO DE

CONTACTO

Cheque el

funcionamiento del

mecanismo del elemento de contacto

antes de cada uso. El elemento de

contacto se debe desplazar libremente,

sin pegarse, a lo largo del área

de desplazamiento. El resorte del

elemento de contacto debe regresar

el elemento de contacto a su posición

original totalmente extendido. No

use la herramienta si el mecanismo

del elemento de contacto no está

funcionando adecudamente. Podría

ocasionarle heridas.

1. Desconecte la

herramienta

de la fuente de

suministro de

aire.

2. Saque todos los

sujetadores del

cargador (Vea la

Sección CargaDescarga).

3. Cerciórese de

que el gatillo y el

elemento de contacto

se muevan libremente

Movemiento

en ambos sentidos sin

atascarse o pegarse.

4. Reconecte la

herramienta

a la fuente de

suministro de

aire.

5. Presione el Elemento

de Contacto de

Trabajo contra la

superficie de trabajo

sin apretar el gatillo.

La herramienta

NO DEBE OPERAR. No use la

herramienta si opera sin apretar el

gatillo. Se pueden producir lesiones

personales.

6. Remueva la

herramienta de la

superficie de trabajo.

El Elemento de

Contacto de Trabajo

tiene que volver a su

posición original. La herramienta

NO DEBE OPERAR. No use la

herramienta si opera mientras

está levantada de la superficie de

trabajo.

7. Apriete el

gatillo y

presione el

Elemento de

Contacto de

Trabajo contra la superficie de

trabajo. La herramienta NO DEBE

hacerse funcionar.

5-Sp

Page 16

Manual de Instrucciones de Operación

BUILT TO LAST

Cómo usar la Herramienta

(Continuación)

8. Presione el

Elemento de

Contacto de

Trabajo contra

la superficie de

trabajo. Apriete

el gatillo. La herramienta DEBE

OPERAR.

Una herramienta

manera inadecuada no debe usarse. No

active la herramienta a menos que esté

colocada firmemente contra la pieza de

trabajo.

PARA CARGAR Y DESCARGAR LA

HERRAMIENTA

1. Siempre desconecte la herramienta

del suministro de aire antes de

cargar los sujetadores.

2. Empuje hacia

abajo sobre

el boton del

seguro. Mueva

la tapa del

cargador hacia

atrás.

3a. Para puntillas,

inserte una tira

de puntillas en

el cargador.

Cerciórese

de que los

extremos puntiagudos de los clavos

estén hacia la parte inferior del

cargador. Cerciórese de que los

clavos no estén sucios ni dañados.

3b. Para grapas,

cargue una

tira de grapas

con las coronas

montadas

sobre el riel del

cargador.

4. Empuje la tapa

del cargador

hacia delante

hasta que

el botón del

seguro salte

hacia arriba.

5. Siempre descargue el sujetador

antes de remover la herramienta de

servicio. La descarga es lo opuesto

a la carga, excepto que debe

desconectar el suministro de aire

antes de realizar la descarga.

1 2

que funciona de

Botón

del

seguro

Carril del

cargador

PARA AJUSTAR LA PENETRACION DE

LOS SUJETADORES

La herramienta viene equipada con un

mecanismo clavador de profundidad

ajustable. Esto le permite al usuario

determinar a qué profundidad se va a

clavar en la superficie de trabajo.

1. Ajuste la presión de operación a

aquella que usará con regularidad

para clavar los sujetadores. No

exceda la presión de 6,90 bar.

2. Para dirigir la

herramienta,

gire la rueda

(C)

(C) hacia la

derecha hasta

el punto

deseado.

3. Para clavar el

sujetador más

profundo,

gire la rueda (C) hacia la izquierda

hasta el punto deseado.

4. Asegúrese que el

gatillo y el Elemento

de Contacto de

Trabajo se mueven

Movemiento

libremente hacia

arriba y hacia abajo

sin atascarse o

pegarse después de cada ajuste.

PARA AJUSTAR LA DIRECCION DEL

TUBO DE ESCAPE

La herramienta

está equipado

con un deflector

ajustable de la

dirección del tubo

de escape. Éste le

Gire

permite al usuario

cambiar la dirección del tubo de escape.

Simplemente mueva el deflector hacia

la dirección deseada.

QUÉ HACER CUANDO LA

HERRAMIENTA TENGA UN

SUJETADOR ATASCADO

1. Desconecte la

clavadora de

la fuente de

suministro de

aire.

2. Remuezva

todos los clavos

del depósito

(vea “Carga/

Descarga de la

Clavadora”).

Si no se retiran

todos los

sujetadores éstos saldrán por el frente

de la herramienta.

3. Destrabe el

seguro halando

hacia afuera y

abajo. El seguro

de alambre se

destraba de los

ganchos de la boquilla.

4. Ahora se puede

girar la puerta,

dejando al

descubierto el

sujetador que

esté trabado.

5. Retire todos los

sujetadores que

estén trabados,

utilizando unas

pinzas o un

destornillador si

fuera necesario.

6 Vuelva a girar

la puerta a su

posición de

cerrado.

7. Extienda el

seguro de

alambre y

colóquelo sobre

los ganchos de

la boquilla.

8. Cierre el seguro

empujándolo

hacia arriba y

adentro hasta

que quede a

presión en su

lugar.

9. Asegúrese de

que el gatillo

y el elemento

de contacto de

trabajo (WCE)

se muevan

libremente hacia arriba y hacia abajo

sin adherirse ni trabarse.

6-Sp

Page 17

CHG00189 (Modelo CHN10401)

Mantenimiento

ASSISTÊNCIA TÉCNICA

Para mayor información en relación

al funcionamiento o reparación de

este producto, comuníquese con el

concesionario de Campbell Hausfeld

más cercano a su domicilio.

SUJETADORES Y PIEZAS DE

REPUESTO

Use solamente

sujetadores

Campbell Hausfeld originales calibre 18

(o su equivalente) - (vea la información

sobre intercambio de sujetadores). Use

solamente partes de repuesto Campbell

Hausfeld originales. Nunca substituya

las partes. No use partes modificadas

o partes que no den un rendimiento

equivalente al equipo original. El

rendimiento de las herramientas, la

seguridad y la duración pueden verse

reducidos. Cuando ordene partes de

repuesto o sujetadores, especifique el

número de la parte.

PARA REPARAR LA HERRAMIENTA

La herramienta debe ser reparada

únicamente por personal calificado,

y deben usar piezas de repuesto y

accesorios originales Campbell Hausfeld,

o piezas y accesorios que funcionen de

manera equivalente.

PARA COLOCARLE LOS SELLOS

Cada vez que repare una herramienta

deberá limpiarle y lubricarle las partes

internas. Le recomendamos que

use Parker O-lube o un lubricante

equivalente en todos los anillos en O.

A cada anillo en O se le debe dar un

baño de lubricante para anillos antes de

instalarlos. Igualmente, deberá ponerle

un poco de aceite a todas las piezas

que se mueven y muñones. Finalmente,

después de haberla ensamblado y

antes de probar la herramienta deberá

ponerle unas cuantas gotas de aceite sin

detergente 30W u otro aceite similar, en

las líneas de aire.

ALMACENAMIENTO

La clavadora debe guardarse en un

lugar fresco y seco.

Notas

7-Sp

Page 18

Manual de Instrucciones de Operación

Sujetadores

CLAVOS

Estos clavos para acabado de Campbell Hausfeld los puede comprar en su tienda más cercana. Si necesita ayuda para

encontrar un artículo, comuníquese al 1-800-543-6400. Los clavos de Campbell Hausfeld cumplen o exceden el estándar ASTM

F1667.

Calibre del

Modelo Longitud

FB002000 19,1 mm (3/4 inch) 18 Galvanisé Étêtée / Brun Adhésive 100 5000

FB180016 15,9 mm (5/8 inch) 18 Galvanisé Étêtée / Brun Adhésive 100 1000

FB180025 2,54 cm (1 inch) 18 Galvanisé Étêtée / Brun Adhésive 100 1000

FB180030 3,18 cm (1-1/4 inch) 18 Galvanisé Étêtée / Brun Adhésive 100 1000

INFORMATION D’INTERCHANGEABILITÉ

Los clavos usados con la SB514000 también se pueden usar con las clavadoras: Bostitch BT125SK-2 & BT200K-2, Campbell

Hausfeld NB0030 & NB0040, DeWalt D51238K, Paslode T125-F18 & T200-F18, Porter Cable BN125 & BN200, and Senco Finish

Pro 15 & 18.

GRAPAS

Estas grapas para acabado de Campbell Hausfeld los puede comprar en su tienda más cercana. Si necesita ayuda

para encontrar un artículo, comuníquese al 1-800-543-6400. Las grapas de Campbell Hausfeld cumplen o exceden las

especificaciones Federales FF-N-105B.

Calibre de

Modelo Longitud

FN180615 12,7 mm

(1/2 inch)

FN180620 19,1 mm

(3/4 inch)

FN180625 2,54 cm

(1 inch)

FN180630 3,18 cm

(1-1/4 inch)

la Grapa Corona Punta Acabodo Unión

18 6,4 mm

18 6,4 mm

18 6,4 mm

18 6,4 mm

Cuerpo Acabodo Cabeza Unión

Burin Galvanisé / Enduit de Vinyle Adhésive 100 1000

(1/4 inch)

Burin Galvanisé / Enduit de Vinyle Adhésive 100 1000

(1/4 inch)

Burin Galvanisé / Enduit de Vinyle Adhésive 100 1000

(1/4 inch)

Burin Galvanisé / Enduit de Vinyle Adhésive 100 1000

(1/4 inch)

Clavos

por Linea

Grapes

por Linea

Clavos

por Caja

Grapes

por Caja

INFORMATION D’INTERCHANGEABILITÉ

Las grapas usadas con la SB514000 también se pueden usar con las grapadoras: Senco LN4450, SJS-LR, SKS L11-15, Hitachi N3804A,

Duofast BN-1832S, KN-1848, ST-18, Stan-Tech SDS 18-14, Atro Minor 90/30, 90/32, 90/40, y Porter Cable NS100.

8-Sp

Page 19

CHG00189 (Modelo CHN10401)

Guía de Diagnóstico de Averías

Deje de usar la grapadora inmediatamente si alguno de los si guientes problemas ocurre. Podría

ocasionarle heridas graves. Cualquier reparación o reemplazo de piezas los debe hacer un técnico

calificado personal de un centro autorizado de servicio.

Problema Causa Solución

Hay una fuga de aire en el

área de la válvula del gatillo

Hay una fuga de aire entre la

cubierta y la boquilla

Hay una fuga de aire entre la

cubierta y la tapa

La herramienta deja de clavar

un sujetador

La herramienta funciona

lentamente o pierde potencia

Hay sujetadores atascados

en la herramienta

Los anillos en O de la cubierta de la válvula

del gatillo están dañados

1. Los tornillos de la cubierta están flojos 1. Debe apretar los tornillos

2. Los anillos en O están dañados 2. Debe reemplazar los anillos en O

3. La defensa está dañada 3. Debe reemplazar la defensa

1. Los tornillos están flojos 1. Debe apretar los tornillos

2. El empaque está dañado 2. Debe reemplazar el empaque

1. La defensa está desgastada. 1. Debe reemplazar la defensa

2. La boquilla está sucia 2. Debe limpiar el canal del sistema de impulso.

3. La suciedad o daños evitan el

desplazamiento libre de los sujetadores o

el mecanismo de impulso en el cargador

4. El resorte del mecanismo de impulso está

dañado

5. El flujo de aire hacia la herramienta

es inadecuado

6. El anillo en O del pistón está desgastado

o le falta lubricación

7. Los anillos en O de la válvula del gatillo

están dañados

8. Hay fugas de aire 8. Debe apretar los tornillos y las conexiones

9. Hay una fuga en el empaque de la tapa 9. Debe reemplazar el empaque

1. La herramienta no está bien lubricada

2. El resorte de la tapa del cilindro está roto 2. Reemplace el resorte

3. El orificio de salida de la tapa está

obstruído

1. La guía del mecanismo de impulso está

desgastada

2. Los sujetadores no son del

tamaño adecuado

3. Los sujetadores están doblados 3. Reemplácelos con sujetadores en buenas

4. Los tornillos del cargador o de la boquilla

están flojos.

5. El mecanismo de impulso está dañado 5. Debe reemplazar el mecanismo de impulso

Debe reemplazar los anillos en O

3. Debe limpiar el cargador

4. Debe reemplazar el resorte

5. Chequée las conexiones, la manguera

o el compresor

6. Debe reemplazar los anillos en O.

Lubríquelos.

7. Debe reemplazar los anillos en O.

1. Necesita lubricar la herramienta

3. Debe reemplazar las partes internas

dañadas.

1. Debe reemplazar la guía

2. Debe usar sólo los sujetadores

recomendados para esta herramienta

condiciones

4. Debe apretar los tornillos

de grapas

9-Sp

Page 20

Manual de Instrucciones de Operación

Garantía Limitada

1 DURACION: A partir de la fecha de compra por el comprador original tal como se especifica a continuación: Un año.

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld / The Scott Fetzer Company 100 Production Drive,

Harrison, Ohio 45030 Teléfono: (800) 543-6400.

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor) del producto

Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Esta herramienta neumática Campbell Hausfeld.

5. COBERTURA DE LA GARANTIA: Defectos importantes en el material y la mano de obra que ocurran durante la duración del

período de garantía con las excepciones que se mencionan a continuación.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES PARTICULARES, ESTAN

LIMITADOS A LO ESPECIFICADO EN EL PARRAFO DE DURACION. Si este producto es empleado para uso comercial,

industrial o para renta, la garantía será aplicable por noventa (90) días a partir de la fecha de compra. En algunos

estados no se permiten limitaciones a la duración de las garantías implícitas, por lo tanto, en tales casos esta limitación

no es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR DE UN DEFECTO, FALLA

O MALFUNCIONAMIENTO DEL PRODUCTO CAMPBELL HAUSFELD. En algunos estados no se permite la exclusión o

limitación de daños incidentales o consecuentes, por lo tanto, en tales casos esta limitación o exclusión no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las instrucciones de

funcionamiento y uso indicadas en el (los) manual(es) que se adjunta(n) al producto. Dichos accidentes, abusos

por parte del comprador, o falta de operar el producto siguiendo las instrucciones del manual de instrucciones

suministrado también debe incluir la desconexión o modificación de los instrumentos de seguridad. Si dichos

instrumentos de seguridad son desconectados, la garantía quedaría cancelada.

D. Los ajustes normales explicados en el(los) manual(es) suministrado(s) con el producto.

E. Los artículos o servicios que son necesarios normalmente para mantener el product.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Según elija el Garante, la reparación o el reemplazo del

producto o los componentes que estén defectuosos, que hayan funcionado en forma inadecuada y/o que no hayan

cumplido con su función dentro de la duración del período específico de la garantía.

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Llame a Campbell Hausfeld (800) 543-6400 por sus opciones de servicio incluidas en la garantía. Los costos de flete

correrán por cuenta del comprador.

C. Seguir las instrucciones sobre operación y mantenimiento del producto, tal como se indica(n) en el (los) manual(es) del

propietario

9. CUANDO EFECTUARA EL GARANTE LA REPARACION O REEMPLAZO CUBIERTO BAJO ESTA GARANTIA: La reparación o

reemplazo dependerá del flujo normal de trabajo del centro de servicio y de la disponibilidad de repuestos.

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales específicos. Usted también

puede tener otros derechos que varían de un Estado a otro. o de un país a otro.

10-Sp

Loading...

Loading...