Page 1

CC640

Digital Camera

Operating Manual

Issued 9.1.08

Copyright

Printed under Licence by Campbell Scientific Ltd.

2005 Campbell Scientific (Canada) Corp..

©

CSL 573

Page 2

Page 3

Guarantee

This equipment is guaranteed against defects in materials and

workmanship. This guarantee applies for twelve months from date of

delivery. We will repair or replace products which prove to be defective

during the guarantee period provided they are returned to us prepaid. The

guarantee will not apply to:

• Equipment which has been modified or altered in any way without the

written permission of Campbell Scientific

• Batteries

• Any product which has been subjected to misuse, neglect, acts of God

or damage in transit.

Campbell Scientific will return guaranteed equipment by surface carrier

prepaid. Campbell Scientific will not reimburse the claimant for costs

incurred in removing and/or reinstalling equipment. This guarantee and

the Company’s obligation thereunder is in lieu of all other guarantees,

expressed or implied, including those of suitability and fitness for a

particular purpose. Campbell Scientific is not liable for consequential

damage.

Please inform us before returning equipment and obtain a Repair Reference Number whether the repair is under guarantee or not. Please state the

faults as clearly as possible, and if the product is out of the guarantee

period it should be accompanied by a purchase order. Quotations for repairs can be given on request.

When returning equipment, the Repair Reference Number must be clearly

marked on the outside of the package.

Note that goods sent air freight are subject to Customs clearance fees

which Campbell Scientific will charge to customers. In many cases, these

charges are greater than the cost of the repair.

Campbell Scientific Ltd,

Campbell Park, 80 Hathern Road,

Shepshed, Loughborough, LE12 9GX, UK

Tel: +44 (0) 1509 601141

Fax: +44 (0) 1509 601091

Email: support@campbellsci.co.uk

www.campbellsci.co.uk

Page 4

Page 5

Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Specifications .............................................................. 1

2. Introduction.................................................................. 2

2.1 Connecting................................................................................................2

2.2 Configuring...............................................................................................3

2.3 Operating..................................................................................................4

2.4 Retrieving Images.....................................................................................4

2.5 Additional Reference Material..................................................................4

2.6 CC640 Quick Check List..........................................................................4

3. Camera Hardware Description ................................... 5

3.1 Terminal Block Connections...................................................................5

3.2 Power Switch............................................................................................6

3.3 Snap Button ..............................................................................................6

3.4 Set-up Button............................................................................................6

3.5 Video Output ............................................................................................6

3.6 External I/O Connector.............................................................................7

3.7 LED (Green).............................................................................................7

3.8 Compact Flash Memory Card...................................................................8

3.8.1 Firmware Update From Memory Card..........................................8

4. Communications .........................................................9

4.1 PakBus Communications..........................................................................9

4.2 RS-232 Port ..............................................................................................9

4.3 CS I/O Port .............................................................................................13

4.4 RS-485 Port ............................................................................................14

5. Device Configuration Utility ..................................... 14

6. Operational Description............................................ 18

6.1 Self Timed Mode....................................................................................18

6.2 External Trigger Mode ......................................................................... `18

7. Image Quality ............................................................. 19

7.1 Lighting conditions.................................................................................19

7.2 Night Time Images.................................................................................19

7.3 Date and Time Stamp .............................................................................19

7.4 JPEG Compression.................................................................................20

i

Page 6

8. Lens ............................................................................ 21

8.1 Lenses and Field of View.......................................................................21

8.2 Focus and Zoom Adjustment..................................................................22

8.2.1 Temperature Variations and Focus..............................................22

8.3 Lens Filter...............................................................................................23

9. Maintenance............................................................... 23

9.1 Lithium Battery.......................................................................................23

9.2 Lens Cleaning.........................................................................................24

10. Set-up and Interface Guide .....................................24

10.1 Trigger Mode........................................................................................24

10.1.1 External Trigger........................................................................24

10.1.2 Self-Timed Trigger...................................................................24

10.1.3 Combination of External and Self-Timed Triggers..................24

10.2 Communications ...................................................................................25

10.2.1 Communications Disabled........................................................25

10.2.2 CS I/O Communications...........................................................25

10.2.3 RS-232 Communications..........................................................25

10.2.4 RS-485 Communications..........................................................26

10.2.5 Concurrent Communications....................................................26

11. Power Calculations and Timings ...........................26

11.1 Standalone Operation ...........................................................................26

11.2 Operation with Communications ..........................................................27

12. CR10X Interface Guide............................................ 29

12.1 CR10X Datalogger Requirements........................................................29

12.2 CR10X Memory Allocation .................................................................29

12.3 CR10X PakBus Settings.......................................................................29

12.4 CR10X *D15 Settings..........................................................................30

12.5 CR10X Multiple Cameras....................................................................30

12.6 CR10X Connections.............................................................................30

13. CR1000 Interface Guide .......................................... 30

13.1 CR1000 Memory Set-up.......................................................................30

13.2 CR1000 Files Manager.........................................................................31

13.3 CR1000 CS I/O Communications ........................................................31

13.4 CR1000 RS-232 Port Communications................................................31

13.5 CR1000 COM Port (control port) Communications.............................31

14. Remote Image Retrieval.......................................... 32

14.1 LNCMD.EXE.......................................................................................32

14.2 Using Loggernet File Control...............................................................33

14.3 Task Set-up / LNCMD.EXE.................................................................34

15. Installation................................................................ 37

15.1 Enclosures.............................................................................................37

15.2 Mounting Holes....................................................................................37

ii

Page 7

Appendices

A. Camera Enclosures ................................................ A-1

B. Quick Set-up and Test Procedure CC640

In Standalone Mode................................................. B-1

Figures

1. CC640 Camera............................................................................................2

2. Terminal Block Position and Layout..........................................................5

3. Camera to Datalogger RS-232 port (DCE) connection ..............................9

4. Using C2006 adapter board to carry RS-232 TX and RX on multi-

conductor cable.........................................................................................10

5. RS-232 wiring using C2006 boards with multi-conductor cable..............11

6. Connections for Configuration.................................................................12

7. Camera connections for CS I/O port operation ........................................ 13

8. Device Configuration Utility Screen ........................................................15

9. Illustration of Time Stamp Banner ...........................................................20

10. Lens and Filter........................................................................................23

11. Task Set-up.............................................................................................35

12. Task using add after to collect images after scheduled call....................36

13. Mounting Holes......................................................................................37

A-1 Enc 17/19 Mounting........................................................................... A-1

A-1a Enc 16/18 Mounting......................................................................... A-2

A-2 CC4718 Enclosure with mounting location of optional Serial

Interface Board (C2006)..................................................................... A-3

A-3 Camera on CC4718 Mounting Plate................................................... A-4

A-4 CC4718 bottom view.......................................................................... A-4

A-5 Vertical Pipe Mount ........................................................................... A-5

A-6 Horizontal Pipe Mount....................................................................... A-5

Tables

1. Recommended cable colour connections....................................................3

2. Explanation of configuration settings.......................................................16

3. Standalone operation power usages..........................................................27

4. RS-232 Port File Transfer Times and power usage per image.................28

5. CR10XPB CS I/O File Transfer Times ....................................................28

6. CR1000 CS I/O File Transfer Times........................................................28

iii

Page 8

Page 9

CC640 Digital Camera

1. Specifications

Power Supply

Operating: 9-15 VDC 250 mA Max

Quiescent: 250 uA typical

Operating Temperature -40°C to +70°C

Ext. Input Signal

Logic Low Level: 0 - 0.7 VDC (-12VDC Absolute Min)

Logic High Level: 4 – 15 VDC (15VDC Absolute Max)

RS-485

Max. BAUD Rate: 230.4 KBAUD

RS-232

Max. BAUD Rate: 230.4 KBAUD

CS I/O

Max. BAUD Rate: 76.8 KBAUD

CSDC addresses: 7 or 8

Memory Card Interface:

Type: Compact Flash

File System: FAT16

File Type: JPEG

Size: Recommended 512 Mb or less

Clock Accuracy

+/- 4 Minutes/Year (-40°C to 70°C)

Lens

Mount: CS-Type

IRIS: DC Compatible

Resolution

640 x 504 (with Time Stamp banner)

Dimensions

Length: 235 mm (9.25 inches) With Lens

Width: 110 mm (4.33 inches)

Height: 64 mm (2.52 inches)

Weight: 0.9 kg (2.0 lbs)

+/- 1 Minute/Year (0°C to 40°C)

640 x 480 (307,200 pixels)

1

Page 10

CC640 Digital Camera

2. Introduction

The CC640 digital camera was designed to meet the stringent operational

requirements necessary for remote battery powered installations. The CC640 has a

very low quiescent power draw and can operate over a wide temperature range.

The camera contains a compact flash memory card interface that turns the camera

into a powerful image logger. The combination of JPEG compression and memory

card storage enables the CC640 to store over 10,000 images.

The CC640 can operate in a stand-alone mode with image acquisitions triggered

by the cameras own precision real time clock. Image acquisitions can also be

triggered by an externally applied digital signal.

For Quick Set-up and Test Procedure in Standalone Mode – refer to Appendix B.

2.1 Connecting

NOTE

Figure 1 CC640 Camera

The camera should be connected to the datalogger and power supply using the

wiring recommendations in Table 1, Cable Colour Connections. The wiring is

based on the use of the recommended FIN6COND cable supplied by Campbell

Scientific (Canada) Corp. (CSC). The colour connections may differ if other

cables are used.

It is essential that the Ground cable be connected first when wiring

the camera to the datalogger or the power supply.

2

Page 11

Table 1. Recommended cable colour connections

Colour Required Connections Recommended Signal Connection

Operating Manual

Black

Red

Green

White

Yellow

Blue

Clear/Shield

Mandatory Ground

Mandatory +12V

Optional Ext

N/A No connection or Ground

Optional RS-485 A or RS-232 TX (Camera Output)

Optional RS-485 B or RS-232 RX (Camera Input)

Mandatory Camera Shield Terminal

After connecting the camera to a power source, turn the power switch to the ON

position and verify the proper LED sequence before connecting the camera for

communication.

For Standalone Mode, the CC640 can be connected directly to the power supply

by wiring Ground first, and then +12VDC. Capturing images in Standalone mode

requires the use of a FAT16 formatted Compact Flash Memory Card (Section 3.6).

The only wire connections to the camera are the power supply wires (ground and

+12 V) that connect to a 12 VDC source.

2.2 Configuring

The recommended cable for use with the camera is a 3 pair individually shielded

24 AWG cable. The cable part number is L9721 and the Model number for a

finished cable is a FIN6COND-L (L is the required Length). Only shielded cable

should be used with the camera for proper operation. It is recommended to use the

cable supplied by Campbell Scientific, as the cable is of high quality and well

suited for communications between the camera and datalogger.

The individual conductor colours and their recommended connections are outlined

in Table 1. Following the recommended colour scheme is not mandatory and users

may be required to select their own colour schemes for cables with different

colour arrangements.

The maximum recommended cable length of 24 AWG cable is 30 Metres (98.1

feet). Longer lengths can be used, however a heavier gaug e of wire is su g gested . It

is recommended that the individual wire resistance on the +12VDC and Ground

conductors not exceed 2.7 Ohms. Using longer cable in conjunction with RS-232

communications will require slower BAUD rates. Depending on the cable len gth

and type of cable, RS-232 may not be suitable for communications and the use of

RS-485 should be considered.

The camera uses PakBus protocol to send image files to the datalogger and both

must be configured to enable communications. The RS-232 port is used in

conjunction with the Device Configuration software to change settings and

operating parameters in the camera (Section 5, Page 14). Device Configuration

Utility is a free download from any Campbell Scientific website.

3

Page 12

CC640 Digital Camera

2.3 Operating

2.4 Retrieving Images

2.5 Additional Reference Material

The CC640 is capable of acquiring images in a self-timed mode, an external

trigger mode, and by manually taking a picture using the Snap button (Section 3.3,

page 6). Self-timed mode is set using the Device Configuration Utility, while a

short pulse applied to the Ext. Input Signal on the camera will initiate image

acquisition in the External Trigger Mode. When taking a picture manually using

the Snap button, the power switch needs to be in the ON position.

Loggernet Version 3.1.3 or newer includes the executable LNCMD.EXE that is

required for image file retrieval from dataloggers (Section 14, page 32). Images

from cameras in standalone mode can be retrieved directly from the Compact

Flash Memory Card with a PC that has a Compact Flash socket.

The CC640 Operating Manual is intended for use by those experienced in working

with Campbell Scientific dataloggers. For further information regarding the

various uses and applications of the CR1000, CR10XPB, CR23X, MD485, or any

additional technology listed in this manual, refer to the appropriate Operating

Manuals of these products.

2.6 CC640 Quick Check List

• If interfacing to a Datalogger ensure that your datalogger has the

appropriate PakBus operating system.

• The compact flash memory card must be formatted to FAT16 (Do not use

FAT32).

• Use the Device Configuration Utility to change settings in the camera.

• Use the Device Configuration Utility to change settings in MD485 or

other PakBus devices.

• The Device Configuration Utility can also be used to set the Dataloggers

memory and PakBus parameters. These parameters can be incorporated

into the datalogger program or changed with a Keyboard display.

• Verify that the lens cable is properly seated, as the connector may

inadvertently become unplugged du ri n g handling or installation.

Always ensure that the Power Switch is placed in the Auto Position

4

Page 13

3. Camera Hardware description

3.1 Terminal Block Connections

Operating Manual

NOTE

Only shielded cable should be used for connections to the terminal

block.

Gnd Power Ground

+12VDC 9-15VDC Power, 250 mA

Ext. External Trigger Input, 5.0 Volt Logic Signal, 15Volts Max

RS-485A RS-485 communications

RS-485B RS-485 communications

Shield The shield (drain wire) needs to be connected to this terminal

Figure 2 Terminal Block Position and Layout

5

Page 14

CC640 Digital Camera

3.2 Power Switch

3.3 Snap Button

The power switch can be used to power the camera continuously on or to place the

camera in Auto power mode. The switch should not be left in the On position

under normal operation. Leaving the switch in the On position will prevent the

camera from entering its low power quiescent mode of operation. The power

switch does need to be placed to the On position to perform configuration set-up

or to focus the camera.

In the Auto position the camera will automatically reduce its power consumption

to the low power quiescent mode after an image is acquired. It is recommended to

place the switch in the Auto position when images are being triggered by either

the external input or the self-timed mode.

The Snap button is used to manually take a picture. The power switch needs to be

set to the On position for the Snap button to operate.

When the Snap button is pressed the LED will slowly flash 2 times, indicating

successful initiation of an image acquisition.

3.4 Set-up Button

The Set-up button performs 2 functions: it toggles the video output on or off and

it places the camera in set-up mode. The power switch will need to be in the On

position for the Set-up Button to operate.

When the Set-up Button is pressed the LED will slowly flash once.

Pressing the Set-up button will force the camera to its default BAUD rate

(115,200) on the RS-232 port for about 40 seconds so that the Device

Configuration Software can be used to configure the camera. Image acquisitions

will also be placed on hold for the same time period. To indicate that the camera is

in Set-up mode the LED will briefly flash once per second.

If no configuration communications occur during the 40 second s, the camera will

exit set-up mode and resume its normal operating mode. The LED will flash once

every 5 seconds.

Pressing the Set-up Button will toggle the Video output on or off. The video

output is used to focus and target the camera in conjunction with a normal

television or video monitor. The video output will remain on until the set-up

button is pressed to toggle it off. The video output will be turned off when the

camera enters its quiescent mode, 5 minutes after the camera’s power switch has

been placed in the Auto position.

3.5 Video Output

The video output connector provides an anal og ue vi de o si g nal for the pur pose of

focusing and targeting the camera. The video output can be configured to NTSC

(National Television System Committee) or PAL (Phase Alternating Line) using

the Device Configuration Software. NTSC is the standard used in North America

and PAL is the standard that is used in most European countries. Consult your

monitor owner’s manual for display information.

The video output signal is intended for use with a television or monitor that has a

NTSC or PAL video input. Most monitors will have one or two audio input

6

Page 15

connectors in addition to the video input. The audio inputs shou ld remain

unconnected, as the camera does not have audio capability.

The video output can be turned on and/or off by pressing the Set-up Button when

the power switch is in the ON position.

During every image acquisition sequence the video output will be momentarily

activated when the image is acquired, allowing the operator to view the image that

is being captured.

3.6 External I/O Connector

The External I/O connector provides Inputs and Outputs fo r operating camera

peripherals, such as the optional motorized enclosure that is used for operation

under extremely harsh environmental conditions. Please contact a Campbell

Scientific sales representative for details and availability of the CC640

peripherals.

The Ext. (External Control) input signal can be used to initiate an image

acquisition. An image acquisition can be initiated on demand by applying a

voltage pulse to the Ext. input. The camera will remain in its quiescent state when

the signal to this input remains at logic low (Less that 0.7 Volts). To initiate an

image acquisition the input should be pulsed hi g h (4 .0 - 15 Volt s ) . The

recommended duration of the pulse is between 1ms and 10 seconds.

Operating Manual

3.7 LED (Green)

Leaving the Ext. input signal high for more than 10 seconds will result in another

image acquisition starting immediately after the completion of the first.

If the Ext. input signal is left in the High state continuously, the camera will not

enter its low power mode and images will be acquired on a continuous basis.

The Ext. Control Input signal is operated with the power switch in the Auto mode.

If the power switch is left in the ON position the LED will flash twice and begin

an image acquisition when a positive Ext Signal is detected, providing easy

confirmation of an externally applied signal.

The green LED is intended to provide feedback for the operator. On power up the

LED will slowly flash 4 times, indicating that a normal power-on sequence has

occurred. If the LED flashes rapidly for several seconds, it means that the camera

failed one of the power-on tests. This response is rare and will require that the

camera be returned to an authorized repair facility.

The LED will also flash once if the Set-up button is pressed and twice if the SNAP

button is pressed. During communications or a firmware update the LED will

remain ON to indicate a process is in progress that should not be interrupted.

If the power switch is in the ON position the LED should flash once every 5

seconds to indicate that it is running. If the set-up button is pressed, the LED will

briefly flash once a second to indicate that the camera is ready for set-up using the

Device Configuration Utility.

7

Page 16

CC640 Digital Camera

The following table offers LED information at a glance:

LED

Always Off

Quick Flash

Every 5 Seconds

4 Slow Flashes

Rapid Flashes for 4

Seconds

Quick Flash Every

Second

Steadily On

The camera has no power connected to it or it is in Quiescent Mode

The camera is Powered ON (Power switch is in the ON position)

Normal Power-On Sequence

A Power on test did not pass.

The camera is in Set-up Mode

The camera is carrying out a process that should not be interrupted. This includes

acquiring an Image, transmitting an image via communications, or performing a

firmware update.

3.8 Compact Flash Memory Card

The camera is equipped to use compact flash memory cards. It is important for the

memory cards to be formatted as FAT16 and not FAT32, as the camera does not

support the FAT32 file system. When formatting a memory card using a PC

ensure that FAT32 is not selected (FAT16 or just FAT should be used).

Image files are stored on the compact flash memory card as JPEG files under the

root directory “IMAGES”. Each file will be uniquely named with a sequence

number (i.e. E1234567.JPG).

The compact flash card should not be inserted or removed while the camera is in

its ON state. Insertion or removal should only be done when the camera is in its

quiescent state or when power is removed.

The use of a memory card is optional and is not required for users who utilize

communications to retrieve the images. If a card is present, the camera will write

the images to it. Once the memory card is filled, the camera will stop recording

images to it unless deleting previous files creates additional image storage space.

It is generally recommended to delete older image files from the memory card

after downloading them to a permanent storage location.

3.8.1 Firmware Update From Memory Card

CAUTION

Failure to properly follow this procedure can result in

corruption of the operating system. If this occurs, it may be

necessary to send the camera to an authorized repair facility

to have the operating system reloaded.

The compact flash card is also used to provide a means of updating the camera’s

embedded firmware. This is done by downloading the appropriate files from any

Campbell Scientific website, renaming the new firmware hex file as

“NEWCODE.HEX” (all upper case), and placing it in the root directory of the

compact flash memory card. When the camera powers up and finds the file in the

root directory it will begin to update its firmware from the file. The LED will

remain continuously on during this process, which may take up to 5 minutes. It is

imperative that the power supply is not interrupted during this process. After

completion the LED will turn off. Power down the camera, remove the memory

card, and delete the “NEWCODE.HEX” file using a PC if no other cameras need

to be updated. Leaving the file on the memory card will cause the camera to

8

Page 17

repeatedly update its firmware every time the camera wakes up from its quiescent

mode.

4. Communications

4.1 PakBus Communications

The camera uses the PakBus protocol to send image files from the camera to the

datalogger or other PakBus compatible devi ces.

Communications are not enabled while the camera is in its quiescent mode. This is

done to conserve power in its low power state. When an image file is ready to be

transmitted, the camera will initiate communications and send the JPEG image via

the selected PakBus port.

The camera is a PakBus Leaf node and is not capable of performing any routing.

Operating Manual

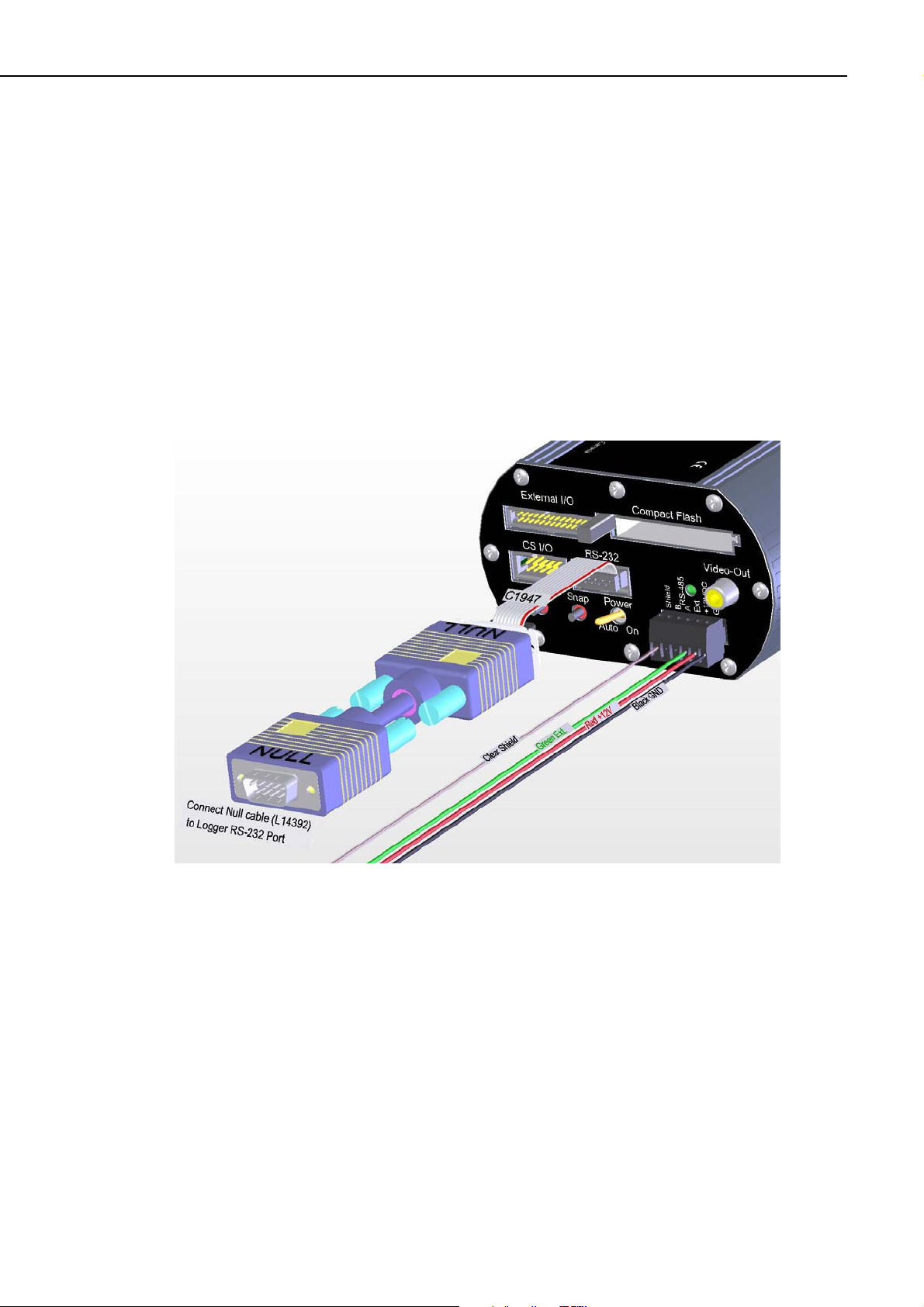

Figure 3 Camera to Datalogger RS-232 port (DCE) connection

4.2 RS-232 Port

The 10-pin RS-232 header connector is designed to provide a 9 Pin DCE type port

by using either of the ribbon cable adapters provided with the camera. Part number

C1946 provides a male 9-pin connector and C1947 provides a female 9-pin

connector.

The RS-232 port can also provide an additional communication port for

transmitting image files to a datalogger using the PakBus Protocol. Figure 3

illustrates the required connection to a RS-232 port on a Datalogger. A Datalogger

and camera are both DCE type RS-232 devices; thus, requiring a NULL modem

cable.

9

Page 18

CC640 Digital Camera

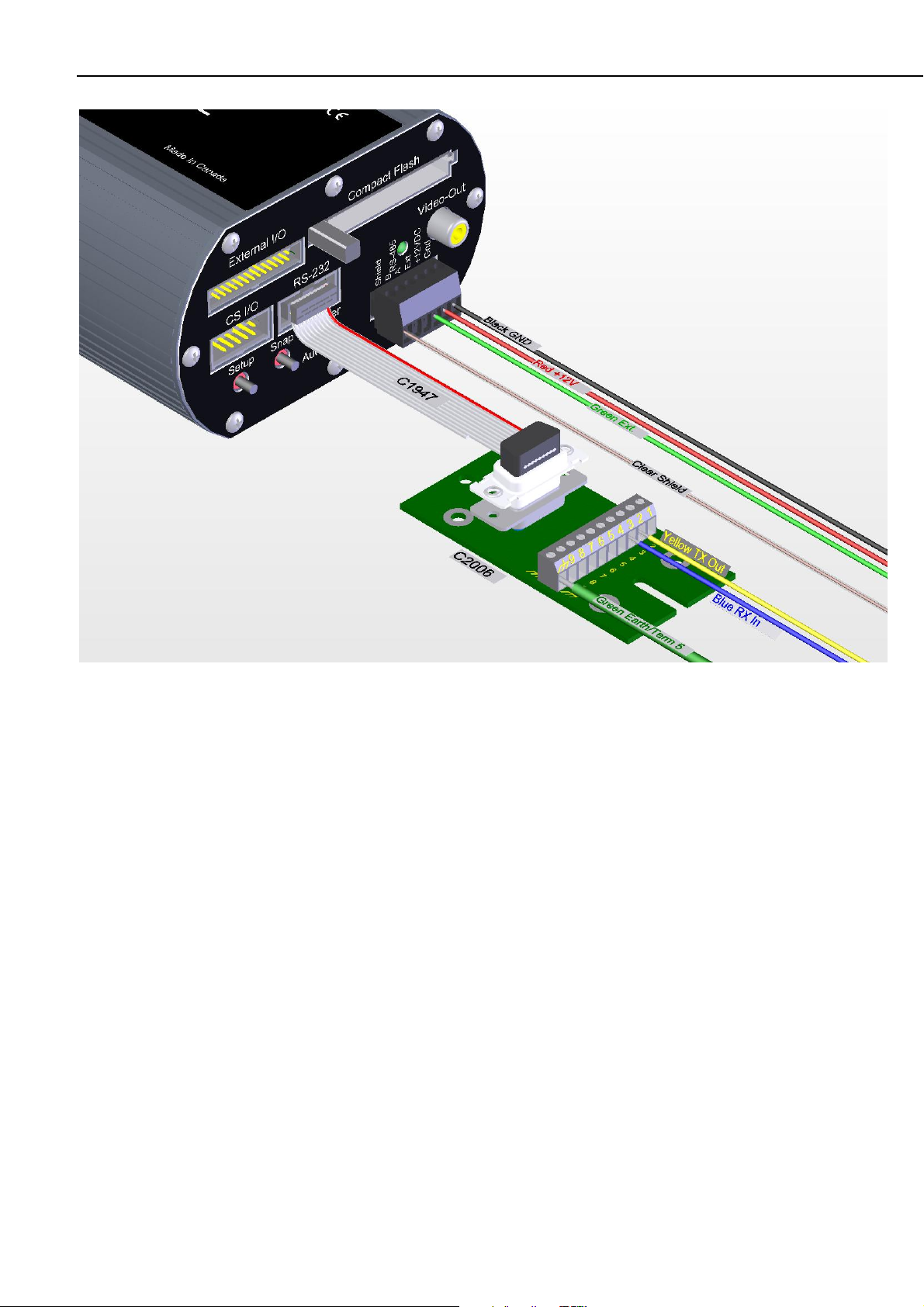

Figure 4 Using C2006 adapter board to carry RS-232 TX and RX on multi-conductor cable

The necessary RS-232 TX (transmit) and RX (receive) signals can also be carried

by the recommended 6 conductor cable. Figure 4 demonstrates using a DB-9 to

terminal breakout board (part C2006) and the standard cable to transmit the RS232 signals. This provides a practical means of carrying the RS-232 signals when

the camera is installed remotely from the datalogger.

If the recommended cable is used, the RS-232 can be used at distances up to 30

Metres (98.1 feet). Longer lengths or different cables may require that the BAUD

rate be set slower than the default 115200 BAUD.

10

Page 19

Operating Manual

Figure 5 RS-232 wiring using C2006 boards with multi-conductor cable

Depending on the datalogger the wires can be terminated directly on the control

ports or another C2006 adapter board can be used to provide a 9-pin connector at

the datalogger end (see Figure 5).

11

Page 20

CC640 Digital Camera

Figure 6 Connections for Configuration

The RS-232 port is used in conjunction with the Device Configuration software to

change settings in the camera such as the PakBus addresses. Figure 6 illustrates

the connections required for interfacing to a computer.

12

Page 21

Operating Manual

Figure 7 Camera connections for CS I/O port operation

4.3 CS I/O Port

The CS I/O port on the camera provides a connector for CS I/O communications.

The port is designed to communicate with Campbell Scientific dataloggers

equipped with CS I/O communication ports. A ribbon cable assembly (C1947) is

used to provide a male 9-pin connector that can plug directly to the CS I/O port or

to a SC-12 cable that connects to the CS I/O port (See Figure 7). The CS I/O port

is used to download image files to the datalogger. The image files can then be

collected remotely in conjunction with the regular data.

The camera will support only Concurrent Synchronous Device Communications

(CSDC) and will not support Modem Enabled (ME) Communications. The camera

can be assigned one of two CSDC addresses, 7 or 8. If another CSDC device is

connected to the CS I/O port, then the camera must have an address that is

different from the other device.

The CS I/O port cable lengths should be restricted to 12 feet or less to ensure

optimal operation.

13

Page 22

CC640 Digital Camera

4.4 RS-485 Port

The RS-485 terminals can be used in conjunction with the MD485 to interface a

datalogger to the camera over distances of up to 4000 feet. The +12V GND and

EXT control lines cannot be practically run these long distances. Normally the

RS-485A and RS-485B lines, and an additional ground connection, are run these

distances. Refer to the MD485 manual for additional information.

5. Device Configuration Utility

The Device Configuration Utility can be used to set the clock on the camera as

well as other operating parameters such as the PakBus addresses.

5.1 Using The Device Configuration Utility

• Connect an appropriate power supply to the camera.

• Connect the RS-232 cable to the camera and the computer.

• Turn the Power switch to the “ON” position.

• Press the Set-up Button (this temporarily forces the RS-232 port to

115KBAUD).

• Within 40 Seconds invoke the Device Configuration Utility (Figure 10).

• Select CC640 as the device and connect to the camera.

• Table 2 offers further information on con fi g u rat i on setti ngs.

14

Page 23

Operating Manual

Figure 8 Device Configuration Utility Screen

15

Page 24

CC640 Digital Camera

Table 2. Explanation of Configuration Settings

Parameter Type Description Default

Value

Version

PakBus Port

PakBus Address

PakBus Destination

Address

Extra

Communications

Delay

RS-485 BAUD rate

RS-232 BAUD rate

CS I/O SDC

ADDRESS

Compression Level

Start Minute

Stop Minute

Self-Timed Interval

Motorized Enclosure

Firmware Checksum

Read Only The firmware version of the CC640 operating system N/A

Read/Write Options: NONE, CS I/O, RS-485, RS-232

Only select a PakBus Port if communications are being used to

transfer images via PakBus.

Read/Write Options: 1 – 4094 55

A PakBus Address should be assigned to the camera for

PakBus Communications.

Read/Write Options: 1 – 4094 1

This is the PakBus address of the destination device wh ere the

image files will be transmitted. The device is normally a

Campbell Scientific datalogger.

Read/Write Options: 0 – 10 Seconds 1

Additional Delays can be added for PakBus networks with

long propagation delays.

Read/Write Options: 230400, 115200, 76800, 57600, 38400, 28800,

19200, 9600, 1200

Read/Write Options: 230400, 115200, 76800, 57600, 38400, 28800,

19200, 9600, 1200

Read/Write Options: 7 or 8 8

If other CSDC devices are connected to the same CS I/O port,

each device must have its own address.

Read/Write

Read/Write Options: 0-1339 0

Read/Write Options: 0-1440 1440

Read/Write Options: 0-1440 0

Read/Write Options: Disable, Enable Disable

Read Only This is the checksum calculated from the firmware present on

Options: Very High, High, Medium, Low, None High

This option selects the amount of compression to be applied to

the JPG files. Higher compression levels result in smaller files

but the images will lose subtle details. Selecting none will

produce a large sized (480Kb) Lossless image.

If the camera is in a Self-Timed Mode, this parameter allows a

start time from Midnight to be selected.

If the camera is in a Self-Timed Mode, this parameter allows a

stop time from Midnight to be selected.

If this parameter is non–zero then the camera will

automatically wake itself up and acquire images based on the

interval entered.

Select enable if the ENC-CC motorized covered enclosure is

used. It is important to select disable if the motorized

enclosure is not used. Selecting enable when a motorized

enclosure is not present will slow down the operation of the

camera.

the camera.

NONE

115,200

115,200

N/A

16

Page 25

Operating Manual

Video Output Type

Send Fixed Name

Fixed File Name

Time Stamp

Automatic Time Sync

Year

Month

Date

Weekday

Hour

Minute

Second

Temperature

Image Counter

Serial Number

Read/Write Options: NTSC, PAL

NTSC video is the North American Standard. PAL is the

VIDEO standard for most European Countries.

Read/Write Options: ON, OFF OFF

If set to off, then the camera will send each image with a

unique file name. The format will be

AAAA_EXXXXXXX.JPG

Where AAAA is the camera's PakBus Address and XXXXXX

is the Image Counter value.

If Send Fixed Name is on, then the image will always be sent

with the same name. The name used will be the text entered in

the Fixed File Name string followed by the JPG extension.

Read/Write Options: ON, OFF

An optional fixed name that can be used for naming the JPEG

files that are transferred from the camera. The name must be

less than 16 characters. The JPG extension will be added to

this name

The PakBus address of the camera will still be placed in front

of the filename.

This Name Field will also be placed on the IMAGE if the

Time Stamp is enabled.

Read/Write Options: ON, OFF CC640

If set to on, a date and time stamp will be placed on the image

in addition to the text entered in the Fixed File Name field.

The Images will be 640x504 pixels with the text added to the

bottom last 24 pixel rows.

Read/Write Options: ON, OFF OFF

If set to on, the camera will attempt to update its clock

automatically from the selected PakBus Destinati on A ddres s.

Read/Write Options: 2004 - 2104 N/A

Read/Write Options: Jan - Dec N/A

Read/Write Options: 1-31 N/A

Read/Write Options: Sun. – Sat. N/A

Read/Write Options: 0 – 23 N/A

In 24 Hour Format Only

Read/Write Options: 0-59 N/A

Read/Write Options: 0-59 N/A

Read Only Temperature in Degrees Celsius -55 to +125. Temperatures

beyond the operating temperature range are not recommended.

Read/Write Options: 0 – 9999999 (7 Digits) 1

The file counter can be changed if desired. The file counter

will loop back to zero after 9999999.

Read Only Serial Num ber N/A

NTSC

OFF

N/A

17

Page 26

CC640 Digital Camera

6. Operational Description

6.1 Self Timed Mode

In self-timed mode the camera is capable of waking itself up and acquiring an

image. In order to place the camera in self-timed mode use the Device

Configuration Software to set the Self-Timed Interval parameter to non-zero.

Self-Timed Example 1:

To take a picture every 15 minutes starting at Midnight the self-timed mode

parameters should be set as follows:

Start Minute: 0

Stop Minute: 1440

Self-Timed Interval: 15

Self-Timed Example 2:

To take a picture every Hour starting at 4:00AM and ending at 11:00PM the selftimed mode parameters should be set as follows:

Start Minute: 240 (4 hours * 60 Minutes)

Stop Minute: 1380 (23 Hours * 60 Minutes)

Self-Timed Interval: 60

6.2 External Trigger Mode

An image acquisition can also be triggered from the Ext. Input Signal on the

camera. It is recommended that a short pulse be used to initiate the image

acquisition. If a positive voltage is applied and not removed before the image

acquisition sequence is complete, the camera will begin another image acquisition

immediately after. An image acquisition can be as short as 10 Seconds.

NOTE

External Trigger Mode can be used in conjunction with the SelfTimed Mode by following all the steps as listed in this section.

18

Page 27

7. Image Quality

7.1 Lighting conditions

Lighting conditions have the greatest influence on image quality. The CC640

camera produces the best images under normal daylight conditions. Pictures taken

in good daylight conditions produce crisper and brighter images.

The CC640 uses the entire image to adjust the exposure settings for a particular

scene.

Scenes that contain small variations in light intensities will produce better images

as well. In scenes with high variations in light intensities, su ch as a bright sky and

a dark horizon, the image may contain portions that are under-exposed and

portions that are over-exposed, as with most cameras. The CC640 utilizes various

techniques to produce an overall good picture under most lighting conditions.

When the CC640 is over-exposed by an overly bright object, such as the sun in a

sky shot, the over-exposed object may begin to turn black. This is a result of the

CMOS image sensor being over-exposed to light and becoming saturated. It is

normal operation for the centre of the Sun to appear black under certain lighting

conditions.

Operating Manual

7.2 Night Time Images

Generally the camera does not produce distinguishable images at night time. If

lighting is present (such as street lights), then objects may become noticeable.

7.3 Date and Time Stamp

Setting the Time Stamp option of the camera to ON will add a banner to the

bottom of the images (Figure 9). The banner adds 24 pixel rows to the image and

increases the size of the image from 640x480 to 640x504 pixels.

The banner includes the text entered for the fixed file name. The text that can be

displayed includes numbers 0-9, letters A-Z (converted to upper case), and an

underscore symbol. Unsupported symbols/characters are displayed as a space.

Following the fixed file name string is the Date and time stamp. The First 3

characters are used for the month followed by the day of month and year. The time

is HH:MM in 24 hour clock format.

The banner ends with the internal camera temperature displayed in degrees

Kelvin. This is intended for diagnostic purposes. The temperature is displayed in

degrees Kelvin so that there is no confusion that the temperature represents some

ambient temperature. The temperature is internal and can vary substantially from

the actual ambient temperature. To convert the temperature to degrees Celsius

subtract 273 from the value displayed.

19

Page 28

CC640 Digital Camera

Figure 9 Illustration of Time Stamp banner

7.4 JPEG Compression

There are 5 selectable levels of JPEG compression:

• Very High (32 Kbytes Typical)

• High (48 Kbytes Typical)

• Medium (72 Kbytes Typical)

• Low (100 Kbytes Typical)

• None (Lossless) (480 Kbytes Typical)

NOTE

These are typical values with the time stamp enabled on the image

(640x504 pixels). The size of the images varies with the image

content.

Selecting None will produce the best quality JPEG files with Lossless

compression. Lossless compression does not introduce additional distortions and

every pixel is the same size as in the original image. Very High compression will

produce the smallest files but with the most degradation of the image.

Small files may be important for slow telecommunication links or for applications

that require a large number of pictures to be stored onto the memory card.

High compression is the recommended setting to produce satisfactory results for

most applications while taking advantage of the benefits of smaller file sizes.

20

Page 29

8. Lens

8.1 Lenses and Field of View

Operating Manual

The standard Lenses for the CC640 camera contain the following features:

• CS Mount

• Varifocal (manual zoom)

• Manual Focus

• DC Iris

The camera controls the iris of the lens using the cable with a 4-pin connector.

This connector must always be plugged into the receptacle (on the front lens plate

of the camera) for proper operation.

• Currently there are 2 optional lenses for the CC640 camera. A 3.5-8mm

and a 6-12mm.

• What does this mean? These numbers have a direct correlation to the

zoom or field of view.

• The 3.5-8mm Lens has a field of view ranging from 79.8 to 35.4 Degrees

• The 6-12mm Lens has a filed of view ranging from 47.3 to 23.0 Degrees

• Large angle is 79.8 Degrees Small angle is 23 degrees

21

Page 30

CC640 Digital Camera

8.2 Focus and Zoom Adjustment

The lens is equipped with manual zoom and focus adjustment rings. The most

practical way to adjust the lens is by utilizing a normal Television monitor or a

portable Television.

• Connect an appropriate video cable from the video output connector

(RCA Jack) of the camera to the video input on the video monitor of the

television.

• Turn the power switches of both the camera and the television to the ON

position and then press the Set-up Button. Within a few seconds the video

should appear on the monitor. Consult your monitor owner’ s manual for

additional instructions on displaying video from the video input jack.

• Once the video is observed on the monitor, loosen the 2 thumbscrews on

the adjustment rings of the lens.

• It is generally easier to adjust the zoom first and then the focus.

• Once the zoom is adjusted as desired tighten the thumbscrew so that the

zoom will not inadvertently move when the focus is adjusted.

• Adjust the focus ring and then tighten its thumbscrew as well.

Recommendation: If the camera is targeted at an object that is far away (100

Metres or more), then it may be beneficial to adjust the lens before taking the

camera into the field by using an object that is at a similar distance away. It is

generally much easier to use a larger monitor in an office environment, rather than

a portable TV at the installation site, as sunlight tends to make it difficult to view a

television screen outdoors.

8.2.1 Temperature Variations and Focus

The CC640 can operate under extreme temperature variations. The focus of the

lens can change slightly with large variations in temperature. For example, if a

lens is focused at +25°C the lens may be slightly out of focus at -30°C. The

change in focus will be less noticeable if the focus is adjusted closer to the

cameras operating temperature.

22

Page 31

8.3 Lens Filter

Operating Manual

The CC640 camera is equipped with an IR cut filter on its lens. This is threaded

onto the front of the lens and is required to filter out near-infrared light that can

have an undesirable affect on the images. It is recommended that the filter always

be left installed on the lens.

9. Maintenance

9.1 Lithium Battery

Figure 10 Lens and Filter

The CC640 requires little maintenance and no calibrations. Keeping the camera

clean and in a dry environment is important for the longevity of the camera.

The Camera is equipped with a Lithium Thionyl Chloride Battery. The battery

maintains the clock functionality for periods when power is not connected to the

camera. The expected battery life is 2 years. If the camera is in operation and

connected to a power supply, the battery life may be extended up to 10 Years.

It is recommended that the battery be replaced by a certified repair facility. The

sticker on the bottom of the camera indicates the date of battery installation.

23

Page 32

CC640 Digital Camera

9.2 Lens Cleaning

If the filter or lens requires cleaning, it is very important that only a proper lens

cloth (like those included with your CC640 camera) or lens tissue be used. The

use of inappropriate materials to clean the lens can permanently damage or reduce

the effectiveness of the filter or lens.

10. Set-up and Interface Guide

10.1 Trigger mode

Determine how the camera will be triggered to initiate an image acquisition. There

are 2 different trigger sources. The first is using the external trigger input and the

second is self-timed mode, which uses the cameras own real time clock. A

combination of external trigger and self-timed mode can be used as well.

10.1.1 External Trigger

If the camera is being triggered by an external signal provided by another device

then:

• Set the parameter Self-Timed Interval to zero

• Connect the external signal to the Ext input of the camera

10.1.2 Self-Timed Trigger

A camera that is used in self-timed mode should be set up as follows:

• Set the parameter Self-Timed Interval to a non zero value

• Change the Start Minute and Stop Minute values accordingly

• Leave the Ext input of the camera unconnected or connected to ground

10.1.3 Combination of External and Self-Timed Triggers

A camera that is used in this configuration should be set up as follows:

• Set the parameter Self-Timed Interval to an non zero value

• Change the Start Minute and Stop Minute values accordingly

• Connect the external signal to the Ext input of the camera

24

Page 33

10.2 Communications

Communications can enable remote retrieval and/or storage of images to external

devices such as compatible Campbell Scientific dataloggers. The PakBus protocol

is used to facilitate the transfer of images.

10.2.1 Communications Disabled

When a camera is not connected to other devices for communications then it is

important to:

• Set the parameter PakBus Port to None

10.2.2 CS I/O Communications

The camera can download images to a compatible Campbell Scientific datalogger

via the CS I/O port. The following items are required for CS I/O PakBus

communications:

• Set the parameter PakBus Port to CS I/O

Operating Manual

• Set the parameter PakBus Address to a unique value in the PakBus

network.

• Set the parameter PakBus Destination Address to the datalogger that is

intended to store the images.

• Ensure that the parameter CS I/O CSDC ADDRESS of the camera is

unique amongst the peripherals that are connected to the dataloggers’ CS

I/O port.

• Connect the camera’s CS I/O port to the datalogger using the supplied

ribbon cable adapter.

• Ensure that the dataloggers’ CS I/O BAUD rate is set to 76.8 KB or less

Refer to Figure 7 (page 13) for connections required when using the CS I/O port.

NOTE

The camera must always have +12Volts power connected to it when

connected to the CS I/O port of a datalogger. Failing to apply power

to the camera will prevent other devices from communicating with

the datalogger.

10.2.3 RS-232 Communications

The camera can download images via its RS-232 port using the PakBus protocol.

The following items are required for RS-232 PakBus communications:

• Set the parameter PakBus Port to RS-232

• Set the parameter PakBus Address to a unique value in the PakBus

network.

• Set the parameter PakBus Destination Address to the device that is

intended to retrieve the images.

• Set the RS-232 BAUD rate to match the BAUD rate of the device being

connected to the camera.

25

Page 34

CC640 Digital Camera

10.2.4 RS-485 Communications

10.2.5 Concurrent Communications

Refer to Section 4.2 for additional information and connections diagrams using the

RS-232 port.

The camera can download images via its RS-485 port using the PakBus protocol.

An MD485 can be used to transmit images via PakBus from a camera to other

devices:

• Set the parameter PakBus Port to RS-485

• Set the parameter PakBus Address to a unique value in the PakBus

network.

• Set the parameter PakBus Destination Address to the device that is

intended to retrieve the images.

• Set the RS-485 BAUD rate to match the BAUD rate of the RS-485

network that the camera is being connected to.

Refer to Section 4.4 for additional information on the RS-485 port.

PakBus allows the camera to download images to a datalogger simultaneously

with other datalogger communications. A communications task will take long er if

the datalogger is communicating with multiple devices at the same time.

It may be beneficial to set up the system to avoid image transfers when other

communications are scheduled.

For example, longer connect times on long distance telephone connections can be

avoided by scheduling image transfers from the camera to the datalogger outside

the scheduled data collection time. If a station is called on the hour to retrieve

data, image acquisitions could be initiated before the scheduled call (15 minutes

prior) to shorten the connect times.

11. Power Calculations and Timings

The CC640 was specifically designed for operation in power-constrained systems

such as solar powered sites. It is critical in such systems that the power switch on

the camera always be left in the AUTO position to take advantage of the low

power mode. This section outlines power consumption of the camera for purposes

of power supply design for a system.

11.1 Standalone Operation

In standalone mode the camera operates as a self-contained image logger.

The current draw of the camera while in low power quiescent mode is 250uA.

When the camera wakes up to take a picture, operating current draw increases to a

maximum of 250 mA for approximately 30 seconds. In order to calculate the daily

power usage of the camera, both the quiescent and operating power consumptions

need to be calculated.

26

Page 35

Operating Manual

The quiescent power consumption in Amp-Hours is calculated as follows:

P

= 250x10-6 Amps * 24 Hours = 0.006 Amp-Hrs / Day

quiescent

The operating power usage per picture in Amp-Hours is calculated as follows:

P

= 0.250 Amps * (30Sec. / 3600 Sec./Hr) = 0.00208 Amp-Hrs / Picture

operating

The daily power usage will depend on the number of pictures taken per day. The

power usage can be calculated using the following formula:

P

/ Day = 0.006 Amp-Hrs + (0.00208 Amp-Hrs * Number of Pictures Per Day)

usage

The following table shows the power usage versus the number of pictures t aken

per day:

Table 3. Standalone Operation Power Usages

Number of Pictures Per Day Power Usage Per Day

1 (Every 24 Hours) 0.008 Amp-Hrs

4 (Every 6 Hours) 0.014 Amp-Hrs

12 (Every 2 Hours) 0.031 Amp-Hrs

24 (Every 60 minutes) 0.056 Amp-Hrs

48 (Every 30 minutes) 0.106 Amp-Hrs

96 (Every 15 minutes) 0.206 Amp-Hrs

288 (Every 5 minutes) 0.606 Amp-Hrs

1440 (Every minute) 3.006 Amp-Hrs

11.2 Operation with Communications

If the camera is operating in a standalone mode, the time the camera is operational

in this mode is typically 30 seconds. The power calculations are more complicated

when communications are involved, as the amount of time the camera is in

operating mode is increased by the amount of time it takes for the camera to

transfer an image.

The transfer times are influenced by two main factors: the size of the image and

the transfer speed used to send the image. The amount of time the camera is on

will be increased as the size of the image becomes larger or as the communication

rate slows down.

To properly determine the power consum pt ion whe n usi n g communications, the

additional time the camera stays in operating mode needs to be accounted for. The

following table is a guideline for determining the amount of time it takes to

transfer an image using RS-232 Communications.

27

Page 36

CC640 Digital Camera

Table 4. RS-232 Port File Transfer Times and power usage per image

RS-232

Communica

BAUD RAT

9600

19200

38400

57600

115200

Very High High Medium Low

tio Compress

n

(32kB Files

E

47 seconds 71 seconds 105 seconds 147 seconds 706 seconds

0.0053 A-Hrs 0.007 A-H rs 0.0094 A-Hrs 0.0123 A-Hrs 0.0511 A-Hrs

26 seconds

0.0039 A-Hrs rs s rs rs

15 second 22 second 33 second 45 second 218 second

0.0031 A-H 0.0036 A-H 0.004 4 A-Hr 0.0052 A-H 0.0172 A-H

11 seconds

0.0028 A-H

8 seconds

0.0026 A-Hrs

ion Compressi Compressi

)

s

rs

rs

(42kB Files)

38 seconds 58 seconds 80 seconds 384 seconds

0.0047 A-H 0.0061 A-Hr 0.0076 A-H 0. 02 8 6 A-H

16 second

0.0032 A-H

12 seconds

0.0029 A-Hrs

on

(72kB Files

s

rs

s

rs

24 second

0.0038 A-Hr

18 seconds

0.0033 A-Hrs

o Lossless

n

) (100kb Files)

s

s

s

s

Compression

33 second

0.0044 A-H

25 seconds

0.0038 A-Hrs

s

rs

s

rs rs

None

Compression

(480kB Fil

160 seconds

0.0132 A-H

120 seconds

0.0104 A-Hrs

Table B CS I sfer T

5. CR10XP /O File Tran imes

CR10XPB-2 None

CS I/O

Comm (32kB Files (48kB Files (72kB Files (100kB File Compressi

BAUD RATE

76800

M

unication

Very High

Compression

)

49 seconds

0.0055 A-Hrs

High

Compression

)

74 seconds

0.0072 A-Hrs

Medium

Compression

)

111 seconds

0.0098 A-Hrs

Low

Compression

154 seconds

0.0128 A-Hrs

Lossless

s)

(480kB File

738 seconds

0.0533 A-Hrs

es)

s

rs

on

s)

Table 6. CR1000 CS I/O sfer Times

00 CS I/O

CR10 Very High High Medium Low None

Comm Compress Compres Compres Compress Lossless

unication

BAUD RATE

9600

19200

38400

57600

115200

(32kB Files (42kB Files (72kB Files (100kb Fil Compression

40 seconds 60 seconds 90 seconds 125 seconds 600 seconds

0.0049 A- 0.0063 A- 0.0083 A- 0.0108 A- 0.0438 A-Hrs

23 seconds

0.0037 A-Hrs Hrs Hrs rs Hrs

14 seconds

0.0031 A-Hrs

11 seconds

0.0028 A-Hrs

Do not use

ion

)

Hrs Hrs Hrs Hrs

34 seconds 51 seconds 71 seconds 342 seconds

0.0044 A- 0.0056 A- 0.007 A-H 0.0258 A21 seconds 31 seconds 43 seconds 209 seconds

0.0035 A-Hrs 0.0042 A-Hrs 0.0051 A-Hrs 0.0166 A-Hrs

16 seconds

0.0032 A-Hrs

Do not use Do not use Do not use Do not use

The communication transfer times indicated in the above tables do not include the

30 seconds that it takes for the camera to acquire the image. These times can be

used to determine the additional power used by the datalogger to receive the

image. The power usag

of on time for the camer

sion

)

File Tran

sion

)

24 seconds

0.0038 A-Hrs

e numbers, however, do include the additional 30 seconds

a.

33 seconds

0.0044 A-Hrs

ion

es)

(480kB Fil

160 seconds

0.0132 A-Hrs

es)

28

Page 37

Operating Manual

12.

CR10X Interface Guide

This section contains information for interfacing the CC640 camera to the

datalogger. The CC640 camera can interface to the CR10X datalogger via

I/O port directly or through an MD485 interfac

12.1 CR10X Datalogger Requirem

It is highly recommended that the datalogger be a 2Meg datalogger. The

datalogger must also contain the PakBus operating system to support the

communications and file storage capabilities.

12.2 CR10X Memory Allocation

Memory must be allocated in the CR10X for the purpose of storing files. The

or is allocated in m

mem y ultiples of 64Kbyte blocks. Memory allocated for file

storage comes out of final storage space. The files are stored in a circular buffer

g m mory). When new files are sent from the camera to the CR10X’s fina

(rin e l

e emory the oldest files will be deleted to make room for the new file.

storag m

The mem

ory can be allocated as follows:

• Enter *D16A

• 16:XX should be displayed . XX represents the number of 64 Kbyte

memory

blocks allocated for file storage.

CR10X

the CS

e.

ents

12.3 CR10X Pak

• Enter the number of blocks required followed by A. (Rec

blocks)

The number of memory

selected and the number of files required to reside in the dataloggers final storag

It is recommended to allocate between 6 to 16 memory blocks. If the compressio

level selected is none then 16 memory blocks (1024 kbytes) is recommended

Files can exceed 500Kbytes with N

blocks required will vary with the compression level

one selected as compression.

ommend 6 to 16

.

Bus Settings

PakBus communications facilitate the transfer of images from the camera to the

datalogger. Several parameters must be set on the CR10X to enable PakBus

communications with the Camera.

These parameters can be set either with a CR10KD, using Edlog \ Options \

PakBus Settings, or even with the Device Configuration Utility using Terminal

Emulator mode.

e.

n

29

Page 38

CC640 Digital Camera

12.4 CR10X *D15 Settings

12.5 CR10X Multiple Cameras

The *D15 Settings are used to set the PakBus Parameters necessary for

communications with the camera. Refer to PakBus Networking Guide for

additional information on PakBus and these settings. If values for parameters 01,

02, 03 are too small, you may not be able to connect to all network nodes.

• *D 13:00

• 15A 15:???? – PakBus Address (prefer 1) must match the destination

PakBus address of the camera setting.

• A 01:0000 –The Max number of Nodes recommend 3 or more

• A 02:0000 –The Max number of neighbours recommend 3 or

more.

• A 03:0000 –The Max number of routers recommend 3 or m ore.

• A 04:0000 – Default router recommend to leave at zero

Multiple cameras can be placed on a single CR10X datalogger. However, the

system should be configured so that image transfers to the datalogger from more

than one camera do not occur at the same time. If a collision does occur, images

will not get stored onto the datalogger. Each camera on the logger should be set to

have different PakBus addresses and CSDC addresses.

12.6 CR10X Connections

The Ext. connection is optional if the camera is set up in self-timed mode. It is

also recommended that the CS I/O cable length between the camera and the

CR10X be limited to 12 feet or less.

Refer to Figure 7 (page 13) for connections to the CR10X.

13. CR1000 Interface Guide

This section contains information for interfacing the CC640 camera to the

CR1000 datalogger. The CR1000 and the CC640 both have several different types

of communication ports. This provides many different interface options for the

user. This includes using the CS I/O port, the 9 Pin RS-232 Serial Port, the control

COM ports (1-4), and RS-485 if using an MD485 interface.

13.1 CR1000 Memory Set-up

To facilitate the storage of images a CFM100 allows the use of a compact flash

card on the CR1000. Memory can also be allocated from the CR1000’s internal

memory to create a virtual user drive “USR:” Entering a non-zero value for the

parameter “USR: drive size” allocates internal memory for the drive. The amount

of memory required will vary depending on each application. A good number to

start with is 524288 bytes (512K bytes which is 25% of the 2M bytes available on

a standard CR1000).

30

Page 39

The following methods can be used to set the drive size of the USR:

• The Device Configuration Utility program

• PakBus Graph

• Editing the parameter from the Status Table

• The CR1000’s optional keypad and display.

13.2 CR1000 Files Manager

The Files Manager setting on the CR1000 facilitates the management of JPEG

files that are received from the camera. The Files Manager allows the user to

specify a name for the files and the number of files kept in a ring memory type

fashion.

The format of the Files Manager setting is as follows:

(AAAA,DDD:NAME.EXT,NNNN)

• AAAA – Is the PakBus address of the camera

• DDD – Is the destination drive on the CR1000

USR for the user drive

CRD for the compact flash memory card

Operating Manual

• NAME – Is any name string that will be used to name the files

• EXT – The file extension of the incoming file must match. In the case of

the camera this must always be “JPG”.

• NNNN – The number of files kept in the ring memory. This number

should be low enough so that the memory required for the files is less

than what is available in the corresponding drive. However, for the

internal USR drive this would normally be between 3 and 10 images and

for CRD drive (memory card) this can be larger. When communications

are used to retrieve images, it is suggested to limit the number of files in

the ring memory to 200 in order to avoid long communication delays.

An example Files Manager setting is as follows:

(55,USR:SkySouth.JPG,3)

• Camera PakBus address is 55

• The files will be stored in the USR: director with a name

SkySouth####.JPG where #### is an incrementing number. Entering a

zero for this parameter will disable the automatic numbering and produce

a fixed file name.

• The 3 most recent files will be kept. A new incoming file will cause the

oldest to be deleted.

13.3 CR1000 CS I/O Communications

The camera can connect directly to the CS I/O port of the CR1000 to transfer

images to it. In addition to setting up the Memory (refer to

Memory

CR1000 SDC7 and SDC8 BAUD rates must be changed from the default 115200

BAUD to 57600 BAUD.

If desired, a control port on the CR1000 can be configured to pulse a control port

that is connected to the Ext. Input of the camera to initiate image acquisitions.

) and the Files Manager (refer to 0 13.2 CR1000 Files Manager) the

013.1 CR1000

31

Page 40

CC640 Digital Camera

13.4 CR1000 RS-232 Port Communications

Refer to Figure 7 Camera connections for CS I/O port (page 13) for an illustration

of the connections between the camera and the CR1000 datalogger.

The camera can be connected to the 9 pin RS-232 port of the CR1000. A Null

modem cable or adapter must be used between the camera and the CR1000. The

Null modem cable is required because both the camera and the CR1000 are DCE

type devices.

The camera can be left at its default RS-232 BAUD rate of 115200.

Camera to Datalogger RS-232 port (DCE) connection

camera connection required for interfacing to the CR1000.

(page 5) illustrates the

13.5 CR1000 COM Port (control port) Communications

On the CR1000 the control ports can be configured to function as RS-232

communication ports. Any of these 4 COM ports can be configured as PakBus

ports and used to communicate with the camera.

The COM ports can be activated as PakBus ports using the Device Configuration

utility or by using the SerialOpen instruction in the CR1000 program. The

following SerialOpen instruction configures COM port 2. (BAUD rate 115200,

PakBus Port - 4, transmit delay - 0, Buffer size - 1000.

SerialOpen (Com2,115200,4,0,1000)

To facilitate the RS-232 connection from the camera to the CR1000 terminal

block an adapter board can be used (Part number C2006). As illustrated in Figure

4 (page 10), terminal 2 is the RS-232 output from the camera and terminal 3 is the

RS-232 input to the camera. The C2006 adapter terminal block numbers

corresponds with the DB-9 pin numbers. For example pin 1 on a DB9 corresponds

with terminal #1 and pin 9 corresponds with terminal #9.

Figure 3

14. Remote Image Retrieval

Once the camera has transferred an image to a datalogger, existing

communications can be used to retrieve the image remotely from the datalogger

memory. For practical purposes it is recommended that the communication link

used for image retrieval maintain a speed of 9600 BAUD or more.

14.1 LNCMD.EXE

Loggernet (Version 3.1.3 or newer) include s t he execut a bl e LNC M D. EX E t hat

facilitates the image file retrieval from dataloggers. LNCMD.EXE is an

executable file that can be used to retrieve images from a datalogger. The file is

normally placed in the directory C:\Program Files\Campbellsci\LoggerNet. The

current command lines for the LNCMD.EXE executable are as follows:

• List_Stations

Lists the names of the stations available to call.

• List_Files <Station>

Lists the names of the files stored at a particular station.

32

Page 41

• Send_File <Station> <Filename>

Sends a particular file to a station.

• Delete_File <Station> <Filename>

Deletes a file stored in the datalogger. This is currently not supported on

the CR10X datalogger.

• Retrieve_File < Station > < Filename > <Output Filename >

This should be the only command required to collect images with the

CR10X. The files sent to the CR10X by the camera have a unique

filename by using a counter. To retrieve all images in memory simply use

the wildcard character * for the JPG files:

• Retrieve_File <Station> *.JPG

This will retrieve files that match the DOS type name entered.

Other options for Retrieve_File include Force and NoDateCheck

• Force: Will collect a file even if a file with the same name and date have

already been collected.

• NoDateCheck: Will collect a file with the same name only if the date is

different.

14.2 Using Loggernet File Control

Operating Manual

Images that are in the dataloggers memory can be viewed or collected on demand

by using the File Control feature that is available under the Tools menu of the

connect screen. Using the file control can also be useful for debugging purposes.

In the case of the CR10XPB datalogger only the CPU device exists where files

can be stored. In dataloggers such as the CR1000 Devices can include the CPU,

USR and the CRD (compact flash module). The devices show up in the left hand

side of the File Control panel. To view files of a certain device simply click on the

desired device listed in the panel.

33

Page 42

CC640 Digital Camera

14.3 Task Set-up / LNCMD.EXE

Automated image collection can be achieved by setting up a Task in Loggernet

that executes the LNCMD.EXE executable.

A sample screen of a Task set-up that executes LNCMD.EXE is shown in Figure

11 Task Set-up (below). In this example the station CR10XPB is a station that is

set-up in Loggernet. The Add Scheduled button can be used to create a task with a

programmable schedule. The task shown has the following functionality:

• Task schedule begins at 12:15 and collects images twice an hour at 15

minutes past and 45 minutes past, or every 30 minutes.

• Retrieves images from the station CR10XPB and stores them in the

directory C:\Temp_pics

• All files in the CR10X with the extension JPG will be collected.

LNCMD.exe will not collect previously collected files unless the Force

option is used in the command line.

34

Page 43

Operating Manual

Figure 11 Task Set-up

35

Page 44

CC640 Digital Camera

In the above example the task will execute on its own schedule separate from data

collection. A task can also be created that calls the LNCMD.EXE after scheduled

data is collected. This may be more desirable for stations that are called using a

dial up connection to eliminate separate dialling for data and images.

To set-up a task that executes after data is collected the desired station would be

selected and the Add After option would be selected in the Task Master set-up

screen. A pull down menu allows various stations event types to be selected. In

this case After Any Sched Call is selected.

Note: In the station set-up the parameter Delay Before Hangup should be Nonzero to allow the task to operate.

Figure 12 Task using Add After to collect images after scheduled call

Note that it is necessary to specify the directory in which the files are located for

the CR1000. In our example the USR: drive is selected. Another option is the

CRD: drive if the compact flash module is used with the CR1000.

36

Page 45

15. Installation

15.1 Enclosures

15.2 Mounting Holes

Operating Manual

The camera must be installed in an environmentally sealed enclosure that offers

protection from moisture or high humidity. It is also recommended that desiccant

be installed in the camera enclosure to absorb excess humidity. Failure to install or

replace the desiccant as required may cause malfunctions or damage the camera.

Refer to Appendix A for recommended encl osu res.

For flexibility, the camera is equipped with 2 different sets of mounting holes

(Figure 13). There are three ¼-20 threaded mounting holes along the centre of the

camera that are spaced 2.0” (50.8mm ) apart. The setscrew s need to be rem oved

with a 1/8” hex Allen key to use the ¼-20 threaded mounting holes. At least two

of the ¼-20 threaded holes are required for mounting the camera. The camera is

also equipped with four #4-40 threaded mounting holes that are spaced 1.5” x 5.0”

(38 mm x 127 mm) apart.

Important: The fasteners used for mounting must be 0.375 inches (9.5 mm) or

shorter. Using longer fasteners can cause damage to the camera by protruding too

far into the camera and damaging the circuit boards. It is recommended to use

only the fasteners provided with the camera.

Figure 13 Mounting Holes

37

Page 46

Page 47

Appendix A. Camera Enclosures

1. ENC 16/18-CC

The ENC16/18-CC enclosure provides a means of housing the camera along with

other equipment such as a datalogger and modem. The ENC 16/18-CC enclosure

uses the same fibreglass enclosure and mounts as the standard ENC 16/18

enclosure. The ENC 16/18-CC includes the following additional items to

facilitate the camera:

• A 100mm x 100mm window (4”x4”) is placed on the latch side of the

enclosure

• A mounting plate and grommets are included for mounting the camera on

the back-plate.

• The external sun-shroud reduces glare from the sun as well as provides

protection from rain and snow.

Using the ENC 16/18-CC enclosure eliminates the need for the external wiring

required if a separate housing is used for the camera.

Figure A-1 Enc 16/19 Mounting

A-1

Page 48

CC640 Digital Camera

Figure A-1a Enc 16/18 Mounting

A-2

Page 49

2. CC4718 Enclosure

The CC4718 Enclosure is an outdoor enclosure that can be used to house the

CC640 camera.

The FIN6COND cable would normally be used to carry power from the supply to

the camera. This cable also supplies enough conductors to use RS-485 or RS-232

communications to send images to a datalogger using PakBus. If RS-232