Page 1

BU IL T T O LA S T

See Warranty on page 8 for important information about commercial use of this product.

Operating Instructions AT122601, AT125102, AT121002, and AT121102

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Sandblasting

Kits

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .

General Safety Information . . . . . . . . .

1

1

Assembly . . . . . . . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . . . . . .3

Technical Service . . . . . . . . . . . . . . . . . .

Types of Abrasives. . . . . . . . . . . . . . . . .

Suggested Uses . . . . . . . . . . . . . . . . . . .

Troubleshooting Chart

. . . . . . . . . . . . .6

3

4

5

Warranty . . . . . . . . . . . . . . . . . . . . . . . .8

Description

Campbell Hausfeld sandblasting

equipment is designed for cleaning and

removing rust, scale, and paint. It is the

ideal method for stripping, polishing

and etching projects. This equipment

can be used with sand, abrasive

powders, water and other liquids.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make sure

to tighten fittings, bolts, etc., before

putting unit into service.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger

indicates

an imminently hazardous situation

which, if not avoided, WILL result in

death or serious injury.

Warning

indicates

a potentially hazardous situation which,

if not avoided, COULD result in death or

serious injury.

Caution

indicates

a potentially hazardous situation which,

if not avoided, MAY result in minor or

moderate injury.

Notice

indicates

important information, that if not

followed, may cause damage to

equipment.

NOTE: Information that requires special

attention.

General Safety Information

CALIFORNIA PROPOSITION 65

This

product

or its power cord may contain chemicals

known to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

You can create dust when

you cut, sand, drill or grind

materials such as wood,

paint, metal, concrete, cement, or other

masonry. This dust often contains

chemicals known to cause cancer, birth

defects, or other reproductive harm.

Wear protective gear.

STATIC ELECTRICITY

Fire or Explosion Hazard!

Never use a sand blaster

around combustible or

flammable liquids, gases,

dusts, oily rags, or other

materials that can explode or

burn quickly. Some abrasives

create sparks when they hit

metal. Abrasives similar to aluminum

oxide may generate static electric

sparks. In an unsafe environment, these

sparks will start fires or explosions that

will result in death or serious personal

injury. For your safety and the safety

of people nearby, DO NOT USE this sand

blaster where there are combustible

or flammable liquids, gases, dusts,

oily rags, or other materials that can

explode or burn quickly.

Static electric shocks can

be painful. Some abrasives

similar to aluminum oxide can

create static electricity while you are

sand blasting. If you are not grounded,

the static electricity can build up on

your body and cause a shock when

you touch a metal object. You can

avoid static electricity by wearing

leather soled shoes and standing on

the ground. If necessary, a grounded

wire attached to the sand blast gun

will safely remove the static electricity.

Remember, you are not grounded if

you are insulated from the ground.

Rubber soled shoes, rubber boots, or

other rubber or plastic footwear are

insulators. Avoid standing on dry wood

REMINDER: Keep your dated proof of purchase for warranty purposes!

© 2007 Campbell Hausfeld/Scott Fetzer

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.chpower.com

IN239801AV 12/07

Page 2

MANUAL

Operating Instructions

General Safety Information

(Continued)

(like a wooden pallet) a dry mat, or dry

carpet.

GENERAL SAFETY

• Read all manuals included

with this product carefully.

Be thoroughly familiar

with the controls and the

proper use of the equipment. Follow

all instructions.

• Only persons well acquainted with

these rules of safe operation should

be allowed to use the unit.

Do not

misuse

this product. Excessive exposure to

vibration, work in awkward positions,

and repetitive work motions can cause

injury to hands and arms. Stop using

any tool if discomfort, numbness,

tingling or pain occur, and consult a

physician.

1. Read this instruction manual before

connecting this device to the

compressor.

2. Safety glasses or face shield, gloves

and a NIOSH approved respirator

must be worn during operation.

Always work in a well ventilated

area.

Disconnect the sandblaster from the air

supply before changing accessories or

attempting to install, service, relocate

or perform any maintenance.

7. Check hoses and air lines for weak

or worn condition before each use.

Make sure all connections are secure

before use.

Do not

point

the sandblast gun at anyone or objects

other than the intended work object.

8. Do not depress the trigger when

connecting the air supply hose.

Do not

work

around oily rags or flammable liquids.

Sand striking metal can cause a spark

and create a fire or explosion.

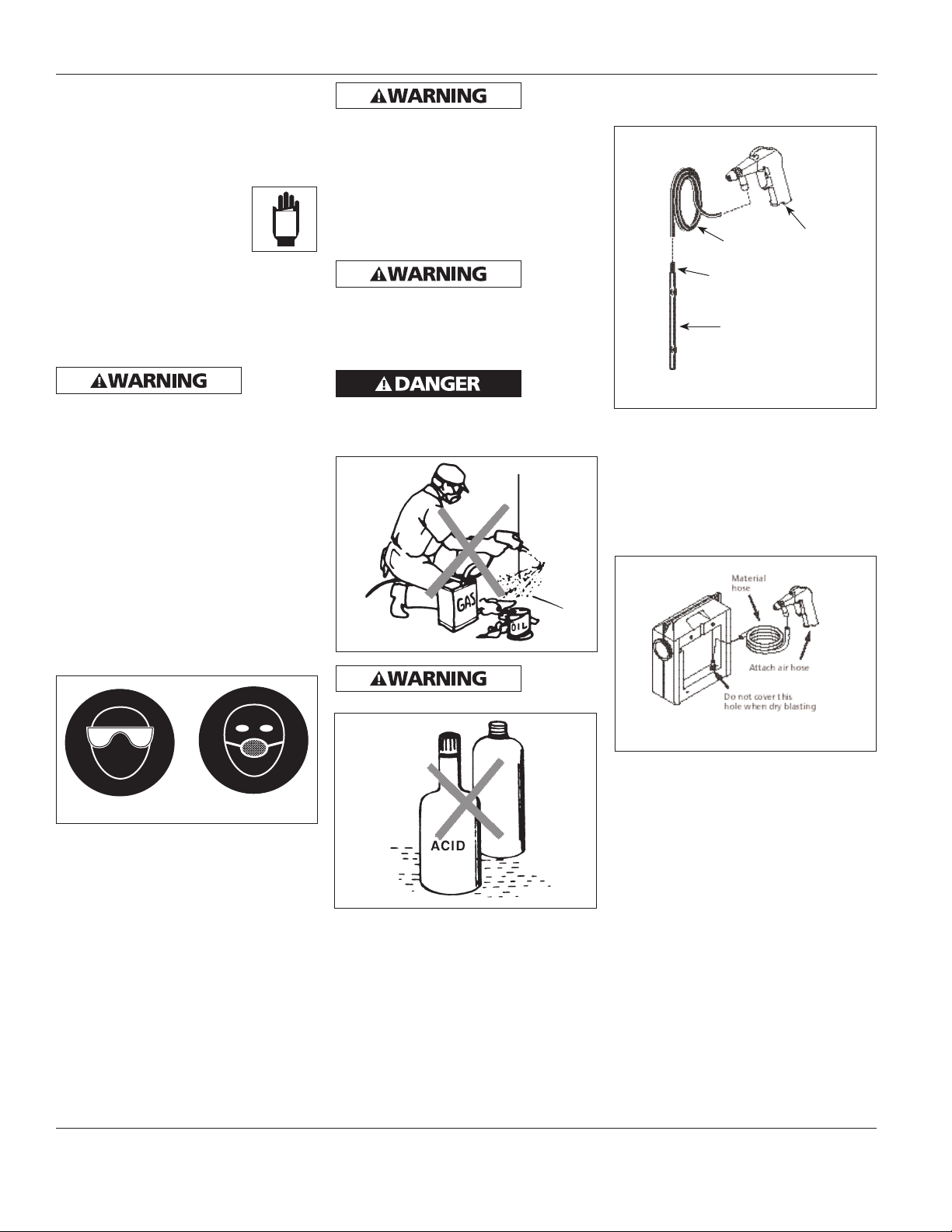

Figure 2

Do not

spray

acids or caustics.

connector can be used to attach the

hose to the gun.

Material

hose

Do not cover outer

tube with hose for dry

blasting

Pick-up tube

Figure 4 - Model AT122601

Attach air

hose

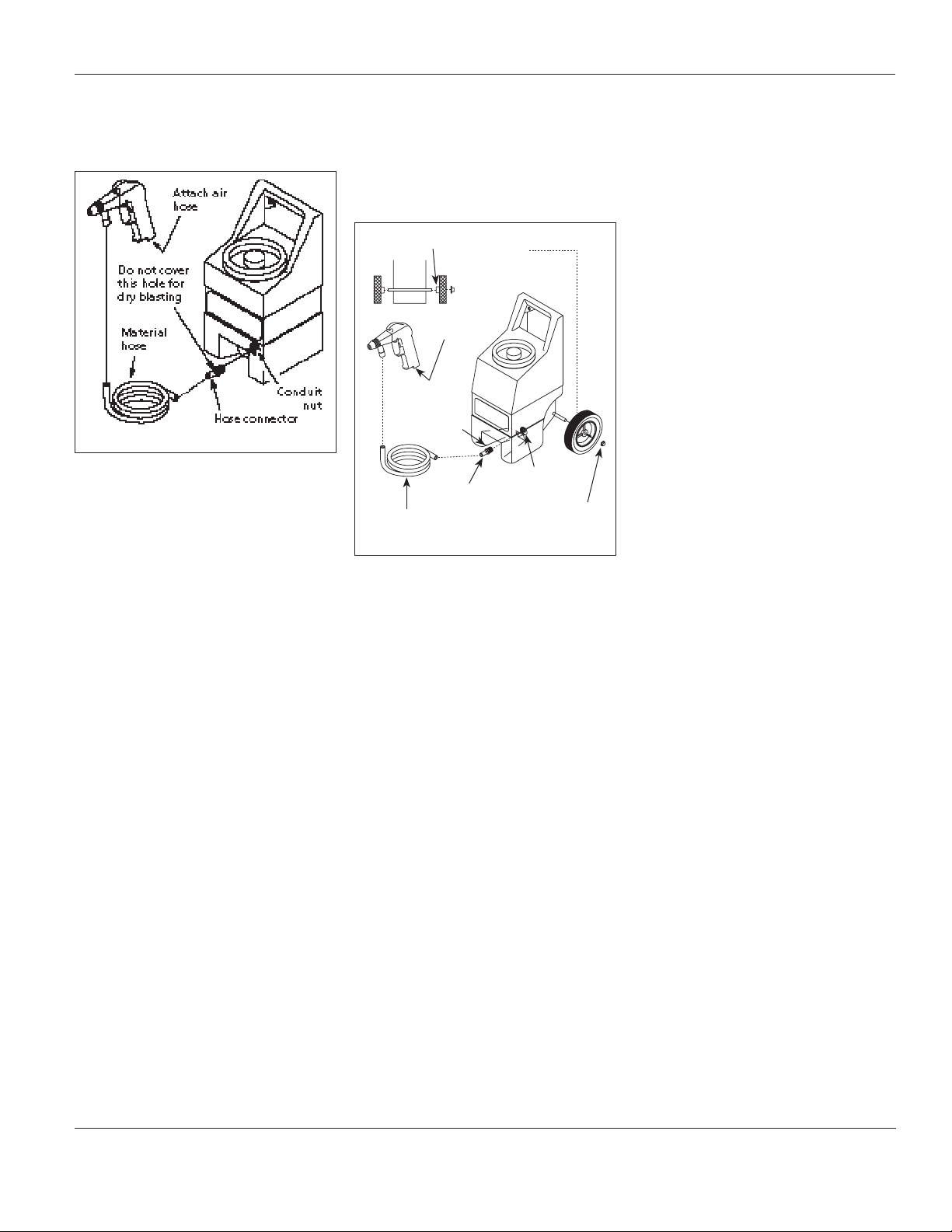

MODEL AT125102

1. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Figure 5). Never use hose clamps to

secure the hose.

Figure 1

3. During operation, do not expose the

hands or skin directly in the line of

the blast nozzle.

4. After installation, inspect to make

sure all components seal properly.

5. Keep children away at all times. All

visitors must be kept a safe distance

and wear safety glasses, gloves and a

respirator.

6. Do not exceed the maximum

operating pressure of the

sandblasting equipment (125 psi).

www.chpower.com

Figure 3

Assembly

MODEL AT122601

1. Attach material hose to the pick-up

tube. Place pick-up tube in bag of

medium. (See FIgure 4).

2. Attach the air compressor hose

to the air inlet (1/4 inch NPT(F))

at the bottom of the gun handle.

An optional quick coupler and

2

Figure 5 - Model AT125102

NOTE: Do not cover the hole in the

hose connector for dry blasting. For

spraying liquids, slip the material hose

fully on to the hose connector covering

the hole.

2. Attach the air compressor hose

to the air inlet (1/4 inch NPT(F))

at the bottom of the gun handle.

An optional quick coupler and

connector can be used to attach the

hose to the gun.

MODEL AT121002

1. Attach the hose connector to the

hopper using the supplied conduit

nut.

2. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Page 3

AT122601, AT125102, AT121002, and AT121102

Assembly (Continued)

Figure 6). Never use hose clamps to

secure the hose.

Figure 6 - Model AT121002

NOTE: Do not cover the hole in the

hose connector for dry blasting. For

spraying liquids, slip the material hose

fully on to the hose connector covering

the hole.

3. Attach the air compressor hose

to the air inlet (1/4 inch NPT(F))

at the bottom of the gun handle.

An optional quick coupler and

connector can be used to attach the

hose to the gun.

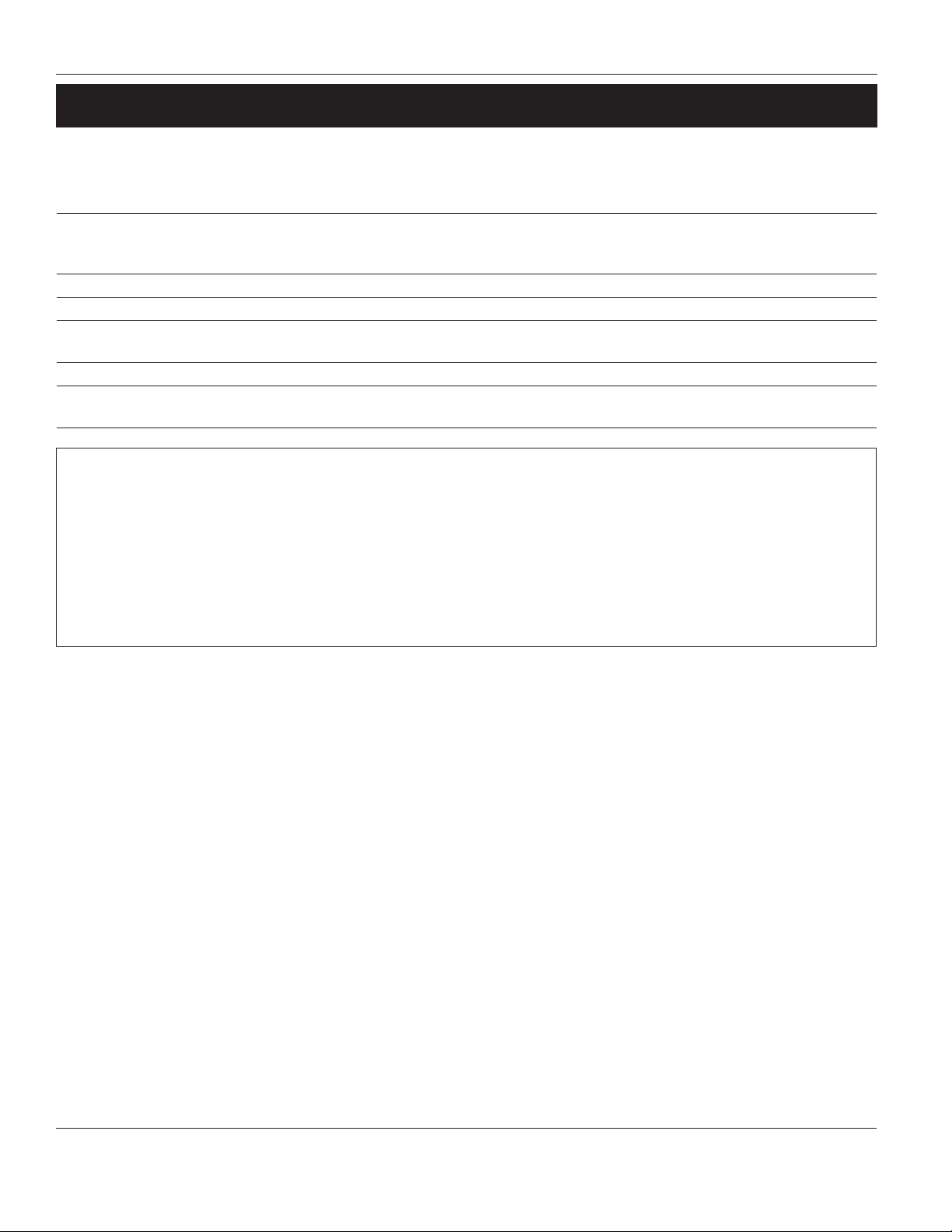

ASSEMBLY FOR MODEL AT121102

1. Slide the wheel onto the axle. (See

Figure 7). Lightly hammer on the

wheel cap to secure, making sure

the protruding hub on the wheel is

facing the hopper. Repeat for the

opposite side.

Protruding Hub

Attach Air

Hose

Do not

cover this

hole when

dry blasting

Hose

Connector

Material Hose

Figure 7 - Model AT121102

Conduit

Nut

Wheel Cap

2. Attach the hose connector to the

hopper using the supplied conduit

nut.

3. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Figure 7). Never use hose clamps to

secure the hose.

NOTE: Do not cover the hole in the

hose connector for dry blasting. For

spraying liquids, slip the material hose

fully on to the hose connector covering

the hole.

4. Attach the air compressor hose

to the air inlet (1/4 inch NPT(F))

at the bottom of the gun handle.

An optional quick coupler and

connector can be used to attach the

hose to the gun.

Operation

1. Locate the compressor as far away

as possible from the sandblasting

area to minimize the dust in the

compressor intake.

2. The air supply must be clean and

free of moisture and oil.

3. Use a compressor that can supply

enough air (See Specifications). A

compressor too small will cause air

pressure to drop and the sandblaster

will not operate satisfactorily.

4. Always trial test the sandblaster to

make sure the job is done without

damage by testing on a hidden

surface.

5. Always filter (screen) the abrasive

material to remove any caked

material and debris to prevent

clogging.

6. Do not try to spray thick liquids or

large grain size abrasives.

7. Use the lowest effective pressure on

soft surfaces to prevent pitting the

surface.

8. Liquids, such as soap and water, can

be sprayed for cleaning purposes on

automobiles, lawn chairs, etc.

9. Fill the hopper with abrasive to

about 3/4 full.

10. With air hose and material hose

connected, and wearing proper

safety equipment, aim sandblast gun

at surface and pull trigger.

11. Whenever the nozzle is removed

and cleaned or replaced, use a brush

to clean the threads and replace the

o-ring.

Technical Service

For information regarding the

operation or repair of this product,

please call 1-800-543-6400.

www.chpower.com

3

Page 4

Operating Instructions

Type of Abrasive

(Sieve/Size) Application

Sand (20-40) General purpose use. Removing light rust and paint from metal, wood or other

surfaces; wood finishing; metal cleaning; glass and stone etching; hole drilling

in glass, brick or cement block; light stone cleaning; exterior automotive parts

cleaning and water deposit removal

Sand 50-100) Used for a fine polish finish or antique wood finish, brass and silver polishing,

automotive parts cleaning and polishing, sheet metal surface polishing, and fine

glass etching

Aluminum oxide Heavy rust removal and rough surface paint removal

Corn cob meal Wood and glass cleaning (fine)

Walnut or pecan

Wood and glass cleaning (coarse)

shells (ground)

Plastic beads Removal of flash, burrs and paint from metal or glass without abrading work

NOTE: Abrasive media that has not been cleaned and screened could contain material that will clog the gun nozzle and

should be avoided.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as the air comes from the compressor pump. When humidity is high or

when a compressor is in continuous use for an extended period of time, moisture will collect in the tank. When using a

sandblast gun, this water will be carried from the tank through the hose and out of the gun as droplets mixed with the

material being sprayed.

IMPORTANT: THIS CONDENSATION WILL CAKE THE SAND AND CLOG THE SANDBLASTING GUN. A CLOGGED GUN WILL

NOT OPERATE.

A compressed air dryer and/or air line filter will help eliminate this moisture.

www.chpower.com

4

Page 5

Suggested Uses

AT122601, AT125102, AT121002, and AT121102

Type of Abrasive

(Sieve/Size) Application

Sand

(30-50)

Glass beads

Sand (40)

Ground walnut

shells

Sand (50-100) Glass

beads, ground

walnut shells

Sand

(20-40)

Sand (20-40)

Aluminum oxide

Sand

(20-40)

Ground pecan or

walnut shells and

corn cob meal

Sand (20-50)

Aluminum

oxide (50-80)

Etching and

drilling holes in glass

Antiquing or

weathering wood

Wood sanding and

refinishing furniture

Cleaning barbeque

grills and iron pots

Cleaning automotive

parts

Cleaning and stripping

masonry

Cleaning or preparing

for paint

Cleaning or stripping

outdoor equipment

Distance

from Work PSI

1 - 4 inches 40 - 90 Move gun back and forth over the template in

2 - 6 inches 40 - 90 Use brushing strokes and watch the abrasion

1 - 6 inches 40 - 70 Use brushing strokes and watch the abrasion rate

1 - 4 inches 50 - 125 Be sure to mask any glass or painted surface that

1 - 4 inches 40 - 80 Use larger grit sand on a hidden area. If the base

1 - 4 inches 50 - 125 Use a heavy grit sand with a sweeping overlapping

1 - 6 inches 40 - 125 Use brushing strokes and watch the abrasion rate

1 - 3 inches 50 - 125 Remove flaking paint first with wire brush, then

Suggestions

a brushing manner. Blast at a 90° angle. For fine

polishing, use glass beads for the abrasive. For

drilling holes, use 30 sieve sand.

rate carefully. Soft wood will wear faster than

hardwood. Smaller grit sizes gives smoother finish.

Start with low pressure and gradually build up

pressure. Blast at a 45° angle.

carefully. Use walnut shells for coarse finishing and

glass beads or fine sand for fine finishing. Blast at a

45° angle.

could be accidentally damaged. Blast at a 80 - 90°

angle.

material is being damaged, use a smaller grit. Blast

at a 80 - 90° angle.

stroke. Blast at a 80 - 90° angle.

carefully. Soft wood will wear faster than hard

wood. Smaller grit sizes five a smoother finish. Start

with low pressure and gradually build up pressure.

Blast at a 45 - 60° angle.

sandblast with a heavy grit abrasive. Multiple

layer of old paint should be scraped first. Prime

immediately following sandblasting to prevent

corrosion. Blast at a 45 - 60° angle.

www.chpower.com

5

Page 6

Operating Instructions

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Low or no air pressure 1. Regulator set incorrectly 1. Reset regulator

2. Pinched hose 2. Straighten hose

3. Dirty compressor filter 3. Clean or replace filter

Material not blasting from

gun

Gun will not shut off - trigger

stuck

Sputtering - low vacuum 1. Worn jet and/or nozzle 1. Replace jet and/or nozzle

Sputtering - air/abrasive leaks

at nozzle/jet area

Sputtering - vacuum leak 1. Loose material hose 1. Tighten material hose

Sputtering - particle clogging Hose connector hole is covered Uncover hose connector hole

1. Clogged material hose 1. Lower the pressure below 40 psi. Firmly

hold the gun tip flat against the ground

and pull the trigger to force the material

back out of the material hose

2. Buildup around jet 2. Remove nozzle and clean around jet

3. Damp or heavy material 3. Replace with dry abrasive. (Damp material

can be dried and reused)

4. Water in air supply 4. Drain air tank and install air filter, See

“Moisture in Compressed Air” box

Damaged o-rings in air valve Remove and replace o-rings

2. Abrasive buildup around jet/nozzle 2. Remove nozzle and jet and clean. Make

sure the threads are clean before reassembling

1. Loose nozzle or jet 1. Tighten nozzle or jet

2. Damaged o-ring 2. Replace o-ring

2. Damaged o-ring 2. Replace o-ring

www.chpower.com

6

Page 7

Notes

AT122601, AT125102, AT121002, and AT121102

www.chpower.com

7

Page 8

Operating Instructions

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: for five (5) years, with exceptions noted below.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Maxus, 100 Production Drive, Harrison, Ohio, 45030, Telephone: (888)

Maxus4U – www.maxustools.com

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Maxus

product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Maxus abrasive blaster supplied or manufactured by

Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects due to material and workmanship with the exceptions noted

below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used for rental purposes, the warranty

will apply for ninety (90) days from the date of purchase. Some States do not allow limitations on how long an implied

warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE, OR MALFUNCTION OF THE PRODUCT. Some States do not allow the exclusion or limitations of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product.

D. Pre-delivery service, i.e. assembly, filtration, and adjustment.

E. Normal adjustments or expendable items which are explained in the owner’s manual(s) provided with the product

including but not limited to parts subject to normal wear such as nozzles, air jets, seal blocks, valves, o-rings, hose

connections, hoses and blast gun.

F. Items or service that require periodic replacement to maintain the product, i.e. filters, gaskets, valves, etc.

G. Additional items not covered under this warranty:

a. Any component damaged in shipment or any failure caused by installing or operating unit under conditions not in

accordance with installation and operation guidelines.

b. Failure caused by rain, excessive humidity or corrosive environments.

c. Cosmetic defects that do not interfere with blaster functionality.

d. Rusted tanks, including but not limited to rust due to improper cleaning/storage.

e. Other items not listed but considered general wear parts.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Maxus (888-629-8748) to obtain your warranty service options. Freight costs must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will

be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability

of replacement parts.

Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other

rights which vary from State to State or country to country.

www.chpower.com

8

Page 9

Voir la Garantie à la page 16 pour de l’information importante sur l’utilisation commercial de ce produit.

BU IL T T O LA S T

Instructions d’Utilisation AT122601, AT125102, AT121002, et AT121102

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir

l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité. Négliger d'appliquer ces instructions peut

résulter en des blessures corporelles et/ou en des dommages matériels ! Conserver ces instructions pour références ultérieures.

Jeux de

Décapage au

Sable

Table des matières

Description . . . . . . . . . . . . . . . . . . . . . .9

Déballage . . . . . . . . . . . . . . . . . . . . . . .9

Directives de Sécurité

Généralités sur la Sécurité . . . . . . . . . .

. . . . . . . . . . . . . .9

9

Montage . . . . . . . . . . . . . . . . . . . . . . .10

Fonctionnement . . . . . . . . . . . . . . . . .11

Service Technique . . . . . . . . . . . . . . . .

Type D’Abrasif . . . . . . . . . . . . . . . . . .

Usages Suggérés

. . . . . . . . . . . . . . . . .13

Tableau de dépannage. . . . . . . . . . . .

11

12

14

Garantie . . . . . . . . . . . . . . . . . . . . . . .16

Description

L’équipement pour décapage au sable

Campbell Hausfeld est conçu pour

nettoyer et enlever la rouille, les écailles

et la peinture. C’est la méthode idéale

pour le dégarnissage, le polissage et

le décapage. Cet équipement peut

être utilisé avec le sable, les poudres

abrasives, l’eau et autres liquides.

Déballage

Dès que l’appareil est déballé,

l’inspecter attentivement pour tout

signe de dommages en transit. S’assurer

de resserrer tous les raccords, boulons,

etc. avant de le mettre en service.

LIRE ET SUIVRE TOUTES LES

INSTRUCTIONS

CONSERVER CES INSTRUCTIONS

NE LES JETEZ PAS

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger

indique

une situation hasardeuse imminente qui

RÉSULTERA en perte de vie ou blessures

graves.

Avertissement indique une situation

hasardeuse potentielle qui PEUT résulter

en perte de vie ou blessures graves.

Attention

indique

une situation hasardeuse potentielle

qui PEUT résulter en blessures.

Avis

indique

de l’information importante pour éviter

le dommage de l’équipement.

REMARQUE : L’information qui exige

une attention spéciale.

Généralités sur la Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce

produit

ou son cordon peuvent contenir des

produits chimiques qui, de l’avis de

l’État de Californie, causent le cancer et

des anomalies congénitales ou autres

problèmes de reproduction. Lavez-vous

les mains après la manipulation.

Vous pouvez créer de la

poussière en coupant,

ponçant, perçant ou

meulant les matériaux tels que le

bois, la peinture, le métal, le béton,

le ciment ou autre maçonnerie. Cette

poussière contient souvent des produits

chimiques reconnus pour causer le

cancer, les déformations congénitales

ou autres problèmes de la reproduction.

Porter de l’équipement de protection.

ÉLECTRICITÉ STATIQUE

Risque d’explosion et

d’incendie ! Ne jamais

utiliser de sableuse autour

de liquides, gaz, poussières,

chiffons huileux ou autres

matériaux combustibles

ou inflammables qui

pourraient exploser ou brûler

rapidement. Certains abrasifs créent

des étincelles en frappant le métal.

Des abrasifs semblables à l’oxyde

d’aluminium peuvent provoquer des

étincelles électriques statiques. Dans

un milieu dangereux, ces étincelles

provoqueront des incendies ou

des explosions menant à de graves

blessures ou à la mort. Pour la sécurité

de l’utilisateur et celle des personnes

dans les environs, NE PAS UTILISER

cette sableuse à des endroits où il

y a des liquides, gaz, poussières,

chiffons huileux ou autres matériaux

combustibles ou inflammables

qui pourraient exploser ou brûler

rapidement.

Les chocs d’électricité

statique peuvent être

douloureux. Certains abrasifs

semblables à l’oxyde d’aluminium

peuvent créer de l’électricité statique

en sablant. Si vous n’êtes pas mis

à la terre, l’électricité statique

peut s’accumuler sur votre corps et

provoquer un choc lorsque vous touchez

un objet métallique. Vous pouvez éviter

l’électricité statique en portant des

chaussures à semelles en cuir et en

vous tenant sur le sol. Si nécessaire, un

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2007 Campbell Hausfeld/Scott Fetzer IN239801AV 12/07

9-Fr

Page 10

MANUEL

Instructions d’utilisation

Généralités sur la Sécurité

(Suite)

fil mis à la terre attaché au pistolet de

sablage retirera sans danger l’électricité

statique. N’oubliez pas que vous

n’êtes pas mis à la terre si vous êtes

isolé du sol. Les souliers à semelle de

caoutchouc, les bottes de caoutchouc

ou autres chaussures de caoutchouc ou

de plastique sont des isolants. Évitez de

vous tenir sur un bois sec (comme une

palette en bois), un tapis sec ou une

carpette sèche.

GÉNÉRALITÉS SUR LA SÉCURITÉ

• Lire attentivement

tous les manuels inclus

avec ce produit. Bien

se familiariser avec les

commandes et la bonne

utilisation de l’équipement. Suivez

toutes les instructions.

• Seules les personnes familières avec

ces règles d'utilisation sans danger

devraient utiliser cette unité.

Ne pas abuser de ce produit. Toute

exposition excessive à la vibration, tout

travail dans les positions mal à l’aise

et les motions de travail à répétition

peuvent provoquer des blessures aux

mains et aux bras. Cesser d'utiliser

tout outil si l'on ressent un malaise, un

engourdissement, un fourmillement ou

une douleur et consulter un médecin.

1. Lire ce manuel avant de brancher cet

appareil au compresseur.

2. Il est nécessaire de porter des

lunettes de sécurité ou un écran

pour visage, des gants et un

respirateur approuvé par NIOSH

pendant le fonctionnement.

Toujours travailler dans un endroit

bien ventilé.

4. Inspecter les pièces détachées

après l’installation pour assurer un

branchement sûr.

5. Ne jamais permettre les enfants dans

l’endroit de travail. Tous les visiteurs

doivent se tenir à distance et doivent

porter des lunettes de sécurité, des

gants et un respirateur.

6. Ne pas dépasser la pression de

service maximale de cet équipement

de décapage (862 kPa).

Débrancher l’équipement de décapage

de la source d’air avant de changer

les accessoires ou avant d’essayer

d’installer, de déplacer ou de procéder à

l’entretien.

7. Vérifier les tuyaux et les

canalisations d’air pour rechercher

tout signe de faiblesse ou d’usure

avant chaque utilisation. Assurer

que tous les raccordements sont sûrs

avant l’utilisation.

Ne pas

diriger le

pistolet de décapage vers une personne

ou autre objet.

8. Ne pas appuyer sur la gâchette

pendant le branchement du tuyau

d’air.

Ne pas

travailler

près des torchons huileux ou des

liquides inflammables. Le sable qui

contact le métal peut produire une

étincelle qui peut résulter en feu ou en

explosion.

Essence

Figure 2

L'huile

ACIDE

Figure 3

Montage

MODÈLE AT122601

1. Attacher le tuyau de matériel au

tuyau de receuil. Placer le tuyau de

receuil dans le sac de matériel. (Voir

FIgure 4).

Brancher

Tuyau De

Matériaux

Ne pas couvrir le

tuyau extérieur avec

le tuyau pour le

décapage au sec

Tuyau de

receuil

Figure 4 - Modèle AT122601

2. Fixer le tuyau du compresseur d’air

à l’arrivée d’air (1/4 po NPT(F)) au

fond du manche du pistolet. Un

raccord rapide facultatif peut être

utilisé pour fixer le tuyau au pistolet.

MODÈLE AT125102

1. Brancher le tuyau flexible de

matériaux au raccord. Brancher

l’autre sens du tuyau de matériaux

au pistolet (Voir Figure 5). Ne jamais

utiliser des colliers de serrage pour

fixer le tuyau.

Tuyau De

Matériaux

le tuyau

d’air

Figure 1

3. Ne pas exposer les mains ou

la peau dans le chemin de la

buse de décapage pendant son

fonctionnement.

Ne pas pulvériser les produits acides ou

caustiques.

Brancher le tuyau

d’air

Ne pas couvrir ce trou lors

du décapage au sec

Figure 5 - Modèle AT125102

10-Fr

Page 11

AT122601, AT125102, AT121002, et AT121102

Montage (Suite)

NOTE: Ne pas couvrir le trou dans

le raccord de tuyau flexible pour le

décapage sec. Pour pulvériser des

liquides, glisser le tuyau de matériel

complètement sur le raccord de tuyau

et couvrir le trou.

2. Fixer le tuyau du compresseur d’air à

l’arrivée d’air (1/4 po NPT(F)) au fond

du manche du pistolet. Un raccord

rapide facultatif peut être utilisé

pour fixer le tuyau au pistolet.

MODÈLE AT121002

1. Fixer le raccord de tuyau à la trémie

en se servant de l’écrou de conduit.

2. Brancher le tuyau de matériaux au

raccord de tuyau flexible. Brancher

l’autre sens du tuyau de matériaux

au pistolet (Voir Figure 6). Ne jamais

utiliser des colliers de serrage pour

fixer le tuyau.

Brancher le

tuyau d’air

Ne pas couvrir

ce trou pour

le décapage

sec

Tuyau De

Matériaux

Écrou de

conduit

Raccord de tuyau

Figure 6 - Modèle AT121002

REMARQUE: Ne pas couvrir le trou dans

le raccord de tuyau pour le décapage

sec. Pour pulvériser les liquides, glisser le

tuyau de matériel complètement sur le

raccord de tuyau covrant le trou.

3. Fixer le tuyau du compresseur d’air à

l’arrivée d’air (1/4 po NPT(F)) au fond

du manche du pistolet. Un raccord

rapide facultatif peut être utilisé

pour fixer le tuyau au pistolet.

MODÈLE AT121102

1. Glisser la roue sur l’arbre de roue.

(Voir Figure 7). Cogner légèrement

au marteau sur le capuchon de roue

pour fixer, s’assurant que le moyeu

saillant fait face à la trémie. Répéter

pour le côté opposé.

Moyeu saillant

Brancher le

tuyau d’air

Ne pas

couvrir ce

trou pour le

décapage

sec

Écrou de

conduit

Raccord

de tuyau

Tuyau De Matériaux

Figure 7 - Modèle AT121102

Écrou de

conduit

2. Fixer le raccord de tuyau à la trémie

à l’aide de l’écrou de conduit

fournit.

3. Brancher le tuyau de matériaux au

raccord du tuyau flexible. Brancher

le sens opposé du tuyau flexible au

pistolet (Voir Figure 7). Ne jamais

utiliser des colliers de serrage pour

fixer le tuyau.

REMARQUE: Ne pas couvrir le trou

dans le raccord de tuyau flexible pour

le décapage sec. Pour pulvériser les

liquides, glisser le tuyau de matériel

complètement sur le raccord de tuyau,

couvrant le trou.

4. Fixer le tuyau du compresseur à

l’arrivée d’air (1/4 po NPT(F)) au fond

du manche du pistolet. Un raccord

rapide facultatif peut être utilisé

pour fixer le tuyau au pistolet.

Fonctionnement

1. Situer le compresseur d’air aussi

loin que possible de l’endroit

de décapage afin de réduire

la poussière dans l’arrivée du

compresseur.

2. La source d’air doit être propre et

libre d’humidité et d’huile.

3. Utiliser un compresseur qui peut

fournir assez d’air (Voir la section

Spécifications). Un compresseur

trop petit peut causer une perte de

pression et l’appereil de décapage

ne fonctionnera pas bien.

4. Toujours mettre l’appareil pour le

décapage à l’épreuve sur une surface

cachée avant d’utiliser pour votre

projet.

5. Toujours tamisser (filtrer) les

matériaux abrasifs pour enlever

le matériel sec et le débris pour

empêcher le blocage.

6. Ne pas essayer de pulvériser les

liquides épais our les abrasifs à gros

grains.

7. Utiliser une pression basse sur les

objets doux afin d’éviter la pîqure.

8. Les liquides tels que le savon et l’eau

peuvent être pulvérisés pour laver

les automobiles, lawn chairs, etc.

9. Remplir la trémie d’abrasif au 3/4

plein.

10. Avec les tuyaux d’air de matériel

branchés, et en portant des lunettes

de sécurité convenables, diriger le

pistolet pour décapage au sable vers

la surface et tirer la gâchette.

11. Lorsque la buse est enlevée et

nettoyée ou remplacée, utiliser une

brosse pour nettoyer les filets et

remplacer le joint torique.

Service Technique

Pour des informations concernant le

fonctionnement ou la réparation de ce

produit, composer le 1-800-543-6400.

11-Fr

Page 12

Instructions d’utilisation

Type D’Abrasif

(Taille/Crible) Application

Sable (20-40) Usage général. Enlevage de la rouille légère et de la peinture du métal, bois ou

autres surfaces; la finition du bois; le nettoyage du métal; la gravure de verre

et de pierre; le perçage des trous dans le verre, la brique ou blocs de béton; le

nettoyage de pierre léger; le nettoyage et enlevage des dépôts d’eau des pièces

d’automobiles

Sable (50-100) Utiliser pour un fini fin ou pour la finition des antiques, le polissage du laiton et

de l’argenterie, le nettoyage et le polissage des pièces d’automobiles, le polissage

de surface de tôle et la gravure du verre fin

Alumine L’enlevage de la rouille lourde et de surfaces de peinture rugueuses

Poudre d’épi de maïs Le nettoyage du bois et du verre (fin)

Écales de noix ou de pacanes (moulus) Le nettoyage du bois et du verre (brut)

Perles en plastique L’enlevage de la brocaille, la bavure et la peinture du métal ou de verre sans

frotter l’objet de travail.

REMARQUE: Éviter l’abrasif qui n’a pas été nettoyé et criblé car il peut contenir du matériel qui peut obstruer la buse du

pistolet.

L’HUMIDITÉ DANS L’AIR COMPRIMÉ

L’humidité dans l’air comprimé peut former des goutelettes où l’air sort de la pompe du compresseur. L’humidité peut

s’accumuler dans le réservoir quand l’humidité est haute ou si un compresseur est utilisé continuellement ou pour un

temps prolongé. Pendant l’utilisation d’un pistolet pour le décapage au sable, cet eau se transportera du réservoir à

travers du tuyau et hors du pistolet en forme de goutelettes mélangées avec le matériel utilisé.

IMPORTANT: CETTE CONDENSATION PEUT CAUSER L’AGGLUTINAGE DU SABLE ET PEUT OBSTRUER LE PISTOLET. UN

PISTOLET OBSTRUÉ NE FONCTIONNERA PAS.

Un sécheur pour air comprimé et/ou un filtre en canalisation peut aider à éliminer l’humidité.

12-Fr

Page 13

Usages Suggérés

Type

D’Abrasif

(Sieve/Size) Application

Sable

(30-50)

Perles en verre

Sable (40)

Écales de noix

Sable (50-100)

Perles en verre,

écales de noix

moulus

Sable (20-40) Le nettoyage des

Sable (20-40)

Alumine

Sable

(20-40)

Écales de pacanes

et de noix moulus

et poudre d’épi de

maïs

Sable (20-50)

Alumine

(50-80)

Gravure et perçage des

trous dans le verre

Les finis antique et la

patine de bois

Sablage du bois et la

finition des meubles

barbecues et des

marmites en fer

Le nettoyage des

barbecues et des

marmites en fer

Nettoyage et le

décapage de la

maçonnerie

Nettoyage ou

préparation pour la

peinture

Nettoyage

ou décapage

d’équipement de plein

air

AT122601, AT125102, AT121002, et AT121102

Distance

du Travail kPa Suggestions

1 - 4 po 276 - 621 Diriger le pistolet en avant et en arrière sur le

patron de manière “brossage”. Décaper à un angle

de 90º. Pour le polissage fin, utiliser des perles en

verre. Pour le perçage des trous, utiliser le sable 30.

2 - 6 po 276 - 621 Utiliser des coups de brossage et observer le taux

d’abrasion soigneusement. Le bois tendre s’usera

plus vite que le bois dur. La taille de particules

plus petite donne un fini plus fin. Commencer

avec la pression basse et augmenter la pression

graduellement. Décaper à un angle de 45º.

1 - 6 po 276 - 483 Utiliser des coups de brossage et observer le taux

d’abrasion soigneusement. Utiliser des écales de

noix pour la finition rude et les perles en verre ou

du sable fin pour un fini fin. Décaper à un angle de

45º.

1 - 4 po 345 - 862 Protéger toutes surfaces en verre ou surfaces

peintes qui peuvent être endommagées. Décaper à

un angle de 80-90º.

1 - 4 po 276 - 552 Utiliser des particules plus larges sur une surface

cachée. Si le matériel est endommagé, essayer une

taille de particules plus petite. Décaper à un angle

de 80-90º.

1 - 4 po 345 - 862 Utliser le sable à particules larges avec un coup

allongé et chevauché. Décaper à un angle de 8090º.

1 - 6 po 276 - 862 Utiliser des coups de brossage et observer le

taux d’abrasion soigneusement. Le bois tendre

s’usera plus vite que le bois dur. Les tailles de

particules plus petites donnent un fini plus fin.

Commencer avec une basse pression et l’augmenter

graduellement. Décaper à un angle de 45-60º.

1 - 3 po 345 - 862 Enlever la peinture qui s’écaille avec une brosse

métallique et procéder avec le décapage au sable

avec un abrasif lourd. Les couches multiples de

peinture doivent être grattées avant le décapage.

Apprêter immédiatement après le décapage pour

éviter la corrosion. Décaper à un angle de 45-60º.

13-Fr

Page 14

Instructions d’utilisation

Tableau de dépannage

Symptôme Cause(s) possible(s) Action corrective

Pression d’air basse ou

manque de pression

Le matériel ne sort pas du

pistolet

Gâchette grippée - Pistolet

ne s’arrête pas

Crépitement - vide bas 1. Jet et/ou buse usé(s) 1. Remplacer le jet et/ou la buse

Crépitement - Fuite d’air/

abrasif à l’endroit de la

buse/jet

Crépitement - fuite de vide 1. Tuyau de matériaux dégagé 1. Serrer le tuyau de matériaux

Crépitement - obstruction de

particules

1. Réglage du régulateur incorrect 1. Régler à nouveau le régulateur

2. Tuyau pincé 2. Ranger le tuyau

3. Filtre de compresseur sale 3. Nettoyer ou remplacer le filtre

1. Tuyau flexible de matériaux obstrué 1. Baisser la pression sous 276 kPa. Tenir le

bout du pistolet contre la terre et tirer la

gâchette afin de forcer le matériel du tuyau

2. Accumulation autour du jet 2. Enlever la buse et nettoyer autour du jet

3. Matériel trempe ou lourd 3. Remplacer avec de l’abrasif sec (l’abrasif

trempe peut être séché et utiliser à

nouveau)

4. Eau dans l’air 4. Vider le réservoir d’air et installer un filtre

d’air, voir la section “Humidité dans L’air

Comprimé”

Joints toriques dans la soupape d’air

endommagés

2. Accumulation d’abrasif autour du jet/

buse

1. Buse ou jet dégagé(s) 1. Serrer la buse ou le jet

2. Joint torique endommagé 2. Remplacer le joint torique

2. Joint torique endommagé 2. Remplacer le joint torique

Trou du raccord de tuyau couvert Découvrir le trou du raccord de tuyau

Enlever et remplacer les joints toriques

2. Enlever la buse et le jet et les nettoyer.

Assurer que les filets sont propres avant

d’assembler à nouveau

14-Fr

Page 15

Notes

AT122601, AT125102, AT121002, et AT121102

15-Fr

Page 16

Instructions d’utilisation

Garantie Limitée

1. DURÉE : De la date d’achat de l’acheteur original comme suit : pendant cinq (5) ans avec les exceptions indiquées plus bas.

2. QUI OFFRE CETTE GARANTIE (GARANT) : Maxus, 100 Production Drive, Harrison, Ohio, 45030, Téléphone : (888)

Maxus4U – www.maxustools.com

3. QUI REÇOIT CETTE GARANTIE (ACHETEUR) : L’acheteur original (sauf en cas de revente) du produit Maxus.

4. QUELS PRODUITS SONT COUVERTS SOUS CETTE GARANTIE : Tout souffleur abrasif Maxus fourni ou fabriqué par le

garant.

5. CE QUI EST COUVERT PAR LA PRÉSENTE GARANTIE : Défauts de matériau et de fabrication avec les exceptions

indiquées ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS :

A. Les garanties implicites, y compris celles de commercialité et D’ADAPTATION À UNE FONCTION PARTICULIÈRE SONT

LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si ce produit est utilisé

à des fins de location, la garantie s’applique pendant quatre-vingt-dix (90) jours de la date d’achat. Certaines Provinces

(États) n’autorisent pas de limitations de durée pour les garanties implicites, donc les limitations précédentes peuvent ne

pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT, INDIRECT OU CONSÉCUTIF POUVANT RÉSULTER DE TOUT DÉFAUT,

PANNE OU MAUVAIS FONCTIONNEMENT DU PRODUIT. Quelques Provinces (États) n’autorisent pas l’exclusion ni la

limitation des dommages fortuits ou indirects. La limitation ou l’exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation de l’acheteur ne

respectant pas les instructions données dans le(s) manuel(s) accompagnant le produit.

D. Service pré-livraison soit l’assemblage, la filtration et l’ajustement.

E. Les ajustements normaux ou les articles non réutilisables expliqués dans le(s) manuel(s) du propriétaire fourni(s) avec le

produit y compris, mais sans s’y limiter, les pièces sujettes à l’usure normale comme les embouts, les jets d’air, les blocs

étanches, les soupapes, les joints toriques, les connexions de tuyau, les tuyaux et les pistolets de sablage.

F. Articles ou services qui sont exigés pour l’entretien normal du produit, soit filtres, joints d’étanchéité, soupapes, etc.

G. Articles supplémentaires qui ne sont pas couverts sous cette garantie :

a. Tout composant endommagé pendant l’expédition ou par n’importe quelle panne causée par un montage ou

fonctionnement de l’appareil sous des conditions qui ne se conforment pas aux directives de montage et de

fonctionnement.

b. La défaillance causée par la pluie, l’humidité excessive ou des environnements corrosifs.

c. Les défauts cosmétiques qui n’ont pas d’effet sur le fonctionnement du souffleur.

d. Les réservoirs rouillés, y compris, mais sans s’y limiter, la rouille causée par le nettoyage/rangement inapproprié.

e. Autres articles non indiqués mais considérés pièces d’usure générale.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE : Réparation ou remplacement, au choix du Garant,

de produits ou composants défectueux, ont connu une défaillance ou qui ne sont pas conformes pendant la durée de

validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE :

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Livraison ou expédition du produit ou de la pièce Maxus au Centre De Service Autorisé Campbell Hausfeld. Taux de frais,

si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonnable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. LORSQUE LE GARANT FOURNIT LA RÉPARATION OU LE REMPLACEMENT SOUS LA GARANTIE : La réparation ou

le remplacement se fera et sera établi conformément au déroulement du travail normal du centre de service et selon la

disponibilité des pièces de rechange.

Cette Garantie limitée s’applique aux É.-U., au Canada, et Le Mexique seulement et vous donne des droits juridiques précis.

Vous pourriez aussi avoir d’autres droits qui varient d’une province, d’un état ou d’un pays à l’autre.

16-Fr

Page 17

Ver la Garantía en página 24 para información importante sobre el uso comercial de este producto.

BU IL T T O LA S T

Manual de Instrucciones de Operación AT122601, AT125102, AT121002 y AT121102

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto

aquí descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. ¡El no cumplir con las instrucciones puede

ocasionar daños, tanto personales como a la propiedad! Guarde estas instrucciones para referencia en el futuro.

Juegos de

Rociadoras de

Arena

Índice

Descripción . . . . . . . . . . . . . . . . . . . . .17

Desempaque . . . . . . . . . . . . . . . . . . . .17

Medidas de Seguridad . . . . . . . . . . . .

Informaciones Generales

de Seguridad. . . . . . . . . . . . . . . . . . . .

Ensamblaje . . . . . . . . . . . . . . . . . . . . .18

Funcionamiento . . . . . . . . . . . . . . . . .19

Assistência Técnica . . . . . . . . . . . . . . .

Tipo de Abrasivo . . . . . . . . . . . . . . . . .

Usos Sugeridos . . . . . . . . . . . . . . . . . .

Guía de Diagnóstico de Averías . . . .

Garantía . . . . . . . . . . . . . . . . . . . . . . .

17

17

19

20

21

22

24

Descripción

Las rociadoras de arena Campbell

Hausfeld están diseñadas para trabajos

de limpieza, eliminación de óxido,

desencofrar y eliminación de pinturas.

Es un método ideal para desencofrar,

pulir y grabar al agua fuerte. Esta

pistola se puede utilizar con arena,

polvos abrasivos, agua y otros líquidos.

Desempaque

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Cericiórese de

apretar todas las conexiones, pernos,

etc. antes de comenzar a utilizar la

unidad.

LEA Y SIGA TODAS LAS

INSTRUCCIONES

GUARDE ESTAS INSTRUCCIONES

NO LAS DESECHE

Medidas de Seguridad

Este manual contiene información

que es muy importante que sepa

y comprenda. Esta información se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le

que hay una situación inmediata que LE

OCASIONARIA la muerte o heridas de

gravedad.

Ésto

que hay una situación que PODRIA

ocasionarle la muerte o heridas de

gravedad.

Ésto

que hay una situación que PODRIA

ocasionarle heridas no muy graves.

Ésto le

una información importante, que de no

seguirla, le podría ocasionar daños al

equipo.

NOTA: Información que requiere

atención especial.

Informaciones Generales de

Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este

o su cordón eléctrico, puede contener

productos químicos conocidos por el

estado de California como causantes de

cáncer y defectos de nacimiento u otros

daños reproductivos. Lave sus manos

después de usar.

indica

le indica

le indica

indica

producto,

Cuando corta lija, taladra

o pule materiales como

por ejemplo madera,

pintura, metal, hormigón, cemento,

u otro tipo de mampostería se puede

producir polvo. Con frecuencia este

polvo contiene productos químicos

que se conocen como causantes de

cáncer, defectos congénitos u otros

daños reproductivos. Use equipo de

protección.

ELECTRICIDAD ESTÁTICA

¡Peligro de incendio o

explosión! No use nunca una

chorreadora de arena cerca

de líquidos, gases, polvos,

trapos empapados de aceite u

otros materiales inflamables

o combustibles que puedan

explotar o incendiarse.

Algunos abrasivos producen chispas

cuando golpean metal. Los abrasivos

similares al óxido de aluminio pueden

producir chispas de corriente estática.

En un medio no seguro, estas chispas

causarán incendios o explosiones que

pueden resultar en muerte o lesiones

personales graves. Para la seguridad

suya y de las demás personas cerca, NO

USE esta chorreadora de arena donde

haya líquidos, gases, polvos, trapos

empapados de aceite u otros materiales

inflamables que puedan explotar o

incendiarse.

Los choques de electricidad

estática pueden ser

dolorosos. Algunos abrasivos

similares al óxido de aluminio pueden

crear electricidad estática mientras

usted usa la chorreadora de arena. Si

usted no tiene una conexión a tierra, la

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2007 Campbell Hausfeld/Scott Fetzer IN239801AV 12/07

17-Sp

Page 18

MANUAL

Manual de Instrucciones de Operación

Informaciones Generales de

Seguridad (Continuación)

electricidad estática puede acumularse

en su cuerpo y acusar un choque cuando

usted toque un objeto metálico. Usted

puede evitar la electricidad estática

usando zapatos con suela de cuero

y manteniendo los pies en el piso. Si

fuese necesario, un cable conectado

a tierra y a la pistola chorreadora de

arena eliminará el peligro descargando

la electricidad estática. Recuerde,

usted no está conectado a tierra si

está aislado del piso. Los zapatos con

suela de caucho, las botas de caucho

u otros zapatos de caucho o plástico

son aislantes. Evite estar parado sobre

madera seca (como una paleta de

madera) un tapete o alfombra secos.

INFORMACIONES GENERALES DE

SEGURIDAD

• Lea con atención todos los

manuales que se incluyen

con este producto.

Familiarícese bien con

los controles y el uso

adecuado del equipo. Siga todas las

instrucciones.

• Sólo se les debe permitir usar esta

unidad a aquellas personas bien

familiarizadas con estas reglas de

manejo seguro.

No use

este

producto en forma inadecuada. La

exposición excesiva a la vibración,

trabajar en posiciones incómodas y los

movimientos de trabajo repetitivos

pueden causar lesiones a las manos

y brazos. Deje de usar cualquier

herramienta si aparece incomodidad,

cosquilleo o dolor y consulte a un

médico.

1. Lea este manual de instrucciones

antes de conectar la unidad al

compresor de aire.

2. Siempre debe utilizar anteojos de

seguridad o una máscara, guantes

y un respirador aprobado por la

organización NIOSH, o un organismo

regulatorio de su país, para operar

Figura 1

esta rociadora. Siempre trabaje en

áreas bien ventiladas.

3. Nunca exponga sus manos o piel

directamente al chorro de arena que

sale por la boquilla.

4. Después de instalar la unidad, revise

las conexiones para cerciorarse

de que estén adecuadamente

apretadas.

5. Mantenga a los niños alejados del

área de trabajo. Igualmente, todos

los visitantes se deben mantener

a una distancia prudente y usar

anteojos de seguridad, guantes y

repirador.

6. Nunca exceda la presión máxima

de trabajo de la rociadora de arena

(8,58 barras) (125 psi).

Desconecte la rociadora de arena de

la fuente de suministro de aire antes

de cambiar de accesorios o tratar de

instalarla, darle servicio, reubicarla o

darle cualquier tipo de mantenimiento.

7. Antes de cada uso cerciórese de

que las mangueras y líneas de

aire estén en buenas condiciones

de funcionamiento. Igualmente,

cerciórese de que todas las

conexiones estén bien apretadas.

No

apunte

la rociadora de arena hacia nadie u

objetos que no sean la pieza de trabajo.

8. No oprima el gatillo mientras

esté conectando la manguera de

suministro de aire.

No trabaje cerca de trapos empapados

de aceite o líquidos inflamables. El

impacto de la arena con el metal podría

ocasionar chispas creando incendios o

explosiones.

Gasolina

Figura 2

Aceite

ACIDO

Figura 3

No rocíe

ácidos o

cáusticos.

Ensamblaje

MODELO AT122601

1. Conecte la manguera de material al

tubo de recolección. Coloque el tubo

de recolector en una bolsa mediana.

(Vea la FIgura 4).

Conecte la

manguera

Manguera

de material

No cubra el tubo

exterior al rociar arena

al secp

Tubo

recolector

Figura 4 - Modelo AT122601

2. Conecte la manguera del compresor

de aire al orificio de entrada de aire

(6,4 mm (1/4”NPT)(H)) ubicado en

la parte inferior del mango de la

pistola. Puede utilizar un acoplador

rápido opcional y un conector para

conectar la manguera a la pistola.

MODELO AT125102

1. Conecte la manguera de material al

conector de la manguera. Conecte

el otro extremo de la manguera de

material a la pistola (Vea la Figura

5). Nunca asegure la manguera con

abrazaderas.

NOTA: No cubra el orificio del conector

de la manguera al rociar arena al

seco. Para rociar líquidos, conecte la

de aire

aquí

18-Sp

Page 19

AT122601, AT125102, AT121002 y AT121102

Ensamblaje (Continuación)

Manguera

de material

Conecte la manguera

de aire aquí

No cubra el tubo exterior

al rociar arena al seco

Figura 5 - Modelo AT125102

manguera de modo que cubra el orificio

ubicado en el conector.

2. Conecte la manguera del compresor

de aire al orificio de entrada de aire

(6,4 mm (1/4”NPT)(H)) ubicado en

la parte inferior del mango de la

pstola. Puede utilizar un acoplador

rápido opcional y un conector para

conectar la manguera a la pistola.

MODELO AT121002

1. Asegure el conector de la manguera

a la tolva con la tuerca de conducto

suministrada.

2. Conecte la manguera de material al

conector. Conecte el otro extremo de

la manguera de material a la pistola

(Vea la Figura 6). Nunca asegure la

manguera con abrazaderas.

Conecte la

manguera

de aire aquí

No cubra este

orificio al

rociar arena al

seco

Manguera

de material

Tuerca de

conducto

Manguera de material

Figura 6 - Modelo AT121002

NOTA: No cubra el orificio del conector

de la manguera al rociar arena al

seco. Para rociar líquidos, conecte la

manguera de modo que cubra el orificio

ubicado en el conector.

3. Conecte la manguera del compresor

de aire al orificio de entrada de aire

(6,4 mm (1/4”NPT)(H)) ubicado en

la parte inferior del mango de la

pstola. Puede utilizar un acoplador

rápido opcional y un conector para

conectar la manguera a la pistola.

MODELO AT121102

1. Conecte la rueda al eje. (Vea la

Figura 7). Golpée levemente la tapa

de la rueda, con un martiillo, de

modo que calce bien, cerciórese de

que el cubo protuberante esté hacia

la tolva. Repita estos pasos en el

lado opuesto.

Lengüeta

Conecte la

manguera

de aire

No cubra

este orificio

para rociar

arena al

seco

Tuerca de

Conector de

la manguera

Manguera de material

Figure 7 - Modèle AT121102

conducto

Tapa de

la rueda

2. Asegure el conector de la manguera

a la tolva con la tuerca de conducto

suministrada.

3. Conecte la manguera de material al

conector. Conecte el otro extremo de

la manguera de material a la pistola

(Vea la Figura 7). Nunca asegure la

manguera con abrazaderas.

NOTA: No cubra el orificio del conector

de la manguera al rociar arena al

seco. Para rociar líquidos, conecte la

manguera de modo que cubra el orificio

ubicado en el conector.

4. Conecte la manguera del compresor

de aire al orificio de entrada de aire

(6,4 mm (1/4” NPT)(H)) ubicado en

la parte inferior del mango de la

pstola. Puede utilizar un acoplador

rápido opcional y un conector para

conectar la manguera a la pistola.

Funcionamiento

1. Ubique el compresor lo más lejos

posible del área de trabajo para

minimizar la cantidad de polvo que

entre al compresor.

2. El aire suminsitrado debe estar

limpio y libre de residuos de agua y

aceite.

3. Use un compresor que pueda

sumi-nistrar suficiente aire

(Vea las especificaciones). Un

compresor demasiado pequeño

ocasionaría una baja de presión y la

rociadora de arena no funcionaría

adecuadamente.

4. Siempre pruebe la rociadora de

arena rociando en una parte fuera

de vista para cerciorarse de que no

va a dañar la pieza.

5. Siempre filtre (con un filtro de rejilla)

el material abrasivo para evitar

el paso de material aglutinado y

basurilla y evitar que se obstruya la

unidad.

6. No trate de rociar líquidos espesos o

abrasivos en granos muy grandes.

7. Use la presión más baja en superficies

delicadas para evitar daños.

8. Líquidos, tales como agua

enjabonada, pueden rociarse para

lavar automóviles, sillas de patios,

etc.

9. Llene la tolva de abrasivo hasta

aproximadamente 3/4 fde su

capacidad.

10. Una vez que haya conectado las

mangueras de aire y material, y se

haya puesto el equipo de seguridad

adecuado, apunte la pistola de

la rociadora de arena hacia la

superficie de trabajo y oprima el

gatillo.

11. Cada vez que desconecte la boquilla,

para limpiarla o reemplazarla, use

un cepillo para limpiar las roscas y

reemplace el anillo en O.

Assistência Técnica

Para obtener información con relación

al funcionamiento o reparación de este

producto, sírvase llamar al 1-800-543-

6400.

19-Sp

Page 20

Manual de Instrucciones de Operación

Tipo de Abrasivo

(Cernido/Tamaño) Aplicación

Arena

(20-40)

Todo tipo de uso. Para eliminar capas ligeras de óxido y pintura de metales,

maderas u otras su-perficies; acabado de maderas; limpiar metal; grabado de

vidrio y piedra; taladrar vidrios, ladrillos o bloques de cemento; limpiar piedras;

limpiar piezas exteriores de automóviles y eliminar depósitos de agua

Arena

(50-100)

Óxido de Aluminio Para eliminar capas gruesas de óxido y pintura de superficies rústicas

Granos de mazorca molida Limpiar maderas y vidrios (finos)

Cáscara de nuez o pacana (molidas) Limpiar maderas y vidrios (rústicos)

Balines de plástico Para eliminar rebabas, quemaduras y pintura de metales o vidrios sin dañarlos.

NOTA: Los abrasivos impuros podrían obstruir la boquilla de la pistola y no se deben usar.

HUMEDAD EN EL AIRE COMPRIMIDO

La humedad que se acumula en el aire comprimido se convierte en gotas a medida que sale del cabezal del compresor

de aire. Cuando el nivel de humedad es muy alto o cuando el compresor ha estado en uso continuo por mucho tiempo,

ésta se acumulará en el tanque. Al usar una rociadora de arena, esta agua saldrá a través de la manguera y la pistola en

forma de gotas mezclada con el material que esté rociando.

IMPORTANTE: ESTA CONDENSACION OCASIONARA QUE LA ARENA SE AGLUTINE Y OBSTRUYA LA PISTOLA. SI LA

PISTOLA SE OBSTRUYE NO FUNCIONARA.

A compressed air dryer and/or air line filter will help eliminate this moisture.

Usada para pulir superficies finas o madera antigua, pulir bronce y plata, limpiar

y pulir piezas de automóviles, pulir superficies metálicas y grabado de vidrio fino

20-Sp

Page 21

Usos Sugeridos

Tipo de Abrasivo

(Cernido/

Tamaño) Aplicación

Arena

(30-50)

Balines de vidrio

Arena (40)

Cáscaras molidas

de núez

Arena (50-100)

balines de vi-drio,

cáscara molida de

nuez

Arena

(20-40)

Arena (20-40)

óxido de aluminio

Arena

(20-40)

Cáscaras molidas

de pecano o nuez

y ma-zorca molida

Arena (20-50)

Óxido de aluminio

(50-80)

Para grabar o ta-ladrar

vidrios

Preparación o

meteorización de

maderas

Para lijar maderas y

acabar muebles

Para limpiar anafes y

ollas de hierro

Para limpiar piezas de

automóviles

Para limpiar y raspar

manpostería

Para limpiar o preparar

superficies para pintar

Para limpiar o raspar

equipos a aire libre

AT122601, AT125102, AT121002 y AT121102

Distancia de

la Superficie bar Sugerencias

2,54 cm 10,16 cm

5,08 cm 15,24 cm

2,54 cm 15,24 cm

2,54 cm 10,16 cm

2,54 cm 10,16 cm

2,54 cm 10,16 cm

2,54 cm 15,24 cm

2,54 - 7,62 cm 3,45 -

2,76 6,21

2,76 6,21

2,76 4,83

3,45 8,62

2,76 5,52

3,45 8,62

2,76 8,62

8,62

Mueva la pistola de atrás hacia adelante y siga un

patrón como si estuviera usando una brocha. Rocíe

en un ángulo de 90o. Para pulir superficies finas,

use balines de vidrio como abrasivo. Para abrir

orificios (taladrar), use arena de grado 30.

Use la pistola como una brocha y observe la

rapidez de la abrasión con cuidado. Las maderas

blandas se desgastarán más rápido que las duras.

Mientras más fino sea el abrasivo el acabado será

de mejor calidad. Comience con una presión baja y

auméntela gradualmente. Rocíe en un ángulo de

45°.

Use la pistola como un a brocha y observe la rapidez

de la abrasión con cuidado. Use cáscara molida

de nuez para acabados rústicos o arena fina para

acabados de mejor calidad. Rocíe en un ángulo de

45°.

Cerciórese de cubrir las superficies de vidrio o

pintadas que se podrían dañar accidentalmente.

Rocíe en un ángulo de 80 - 90°.

Use arena más gruesa en las superficies fuera de la

vista. Si el material se está dañando, use una arena

más fina. Rocíe en un ángulo de 80 - 90°.

Use arena más gruesa y dele varias manos. Rocíe en

un ángulo de 80 - 90°.

Use la pistola como un a brocha y observe la

rapidez de la abrasión con cuidado. Las maderas

blandas se desgastarán más rápido que las duras.

Mientras más fino sea el abrasivo el acabado será

de mejor calidad. Comience con una presión baja y

auméntela gradualmente. Rocíe en un ángulo de

45 - 60°.

Primero quítele la pintura desconchada con un

cepillo de alambre, después use la rociadora

de arena con un abrasivo fuerte. Si hay varias

capas de pintura vieja, las debe raspar primero.

Inmediatamente después, cúbrala con una capa de

anticorrosivo para evitar que se oxide. Rocíe en un

ángulo de 45 - 60°.

21-Sp

Page 22

Manual de Instrucciones de Operación

Guía de Diagnóstico de Averías

Problema Posible(s) Causa(s) Acción a Tomar

La presión está baja o no hay

nada de presión

El material no sale de la

pistola

La pistola no cesa de rociar el gatillo está atascado

Chisporreo - el nivel del

sistema al vacio está bajo

Chisporreo - fuga de aire/

abrasivo en la boquilla/

propulsor

Chisporreo - fuga en el

sistema al vacio

Chisporreo - obstrucción El orificio del conector está cubierto Destape el orificio del conector

1. El regulador está fijado incorrectamente 1. Fije el regulador

2. Hay una manguera rota 2. Enderece la manguera

3. El filtro del compresor de aire está sucio 3. Limpie o reemplace el filtro

1. La manguera de material está obstruída 1. Reduzca la presión a menos de 2,76 bar.

Sostenga con firmeza la boquilla de la

pistola contra el piso y oprima el gatillo

para forzar el material a salir de la

manguera

2. El propulsor está obstruído 2. Desconecte la boquilla y límpiele el

propulsor

3. El material está húmedo o muy espeso

(pesado)

4. Hay agua en el aire suministrado 4. Drene el tanque de aire e instale un filtro

Los anillos en O de la válvula de aire están

dañados

1. La boquilla o el propulsor están

desgastados

2. Hay acumulación de abrasivos en el

propulsor/boquilla

1. La boquilla o el propulsor están flojos 1. Apriete la boquilla o el propulsor

2. El anillo en O está dañado 2. Reemplace el anillo en o

1. La manguera de material está floja 1. Apriete la manguera de material

2. El anillo en O está dañado 2. Reemplace el anillo en o

3. Reemplácelo con abrasivo seco. (El material

húmedo se puede secar para usarlo otra

vez)

de aire, Vea la sección “Humedad en el aire

comprimido”

Reemplace los anillos en O

1. Reemplace el propulsor y/o la boqui-lla

2. Desconecte la boquilla y el propulsor y

límpielos. Cerciórese de que las roscas estén

limpias antes de conectarlos una vez más

22-Sp

Page 23

Notas

AT122601, AT125102, AT121002 y AT121102

23-Sp

Page 24

Manual de Instrucciones de Operación

Garantía Limitada

1. DURACIÓN: A partir de la fecha de compra por parte del comprador original del modo siguiente: durante 5 (cinco) años,

con las excepciones que se detallan a continuación.

2. QUIÉN OTORGA ESTA GARANTÍA (GARANTE): Maxus, 100 Production Drive, Harrison, Ohio, 45030 , Teléfono: (888)

Maxus4U – www.maxustools.com

3. QUIÉN RECIBE ESTA GARANTÍA (COMPRADOR): El comprador original (sin fines de reventa) del producto de Maxus.

4. QUÉ PRODUCTOS ESTÁN CUBIERTOS POR ESTA GARANTÍA: Toda chorreadora de Maxus suministrada y fabricada por el

Garante.

5. QUÉ ESTÁ CUBIERTO POR ESTA GARANTÍA: Defectos en los materiales y en la mano de obra con las excepciones que se

detallan a continuación.

6. QUÉ NO ESTÁ CUBIERTO POR ESTA GARANTÍA:

A. Las garantías implícitas, incluyendo aquellas de comercialización y APTITUD PARA UN PROPÓSITO DETERMINADO

ESTÁN LIMITADAS DESDE LA FECHA DE COMPRA ORIGINAL SEGÚN SE ESTABLECE EN LA DURACIÓN. Si este producto es

empleado para alquiler, la garantía será aplicable durante 90 (noventa) días a partir de la fecha de compra. En algunos

estados no se permiten las limitaciones a la duración de una garantía implícita, por lo cual las limitaciones antedichas

pueden no ser aplicables en su caso.

B. CUALQUIER PÉRDIDA, DAÑO O GASTO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR DE CUALQUIER

DEFECTO, FALLA O MAL FUNCIONAMIENTO DEL PRODUCTO. En algunos estados no está permitida la exclusión ni la

limitación de los daños incidentales o consecuentes, por lo cual la limitación o exclusión antedicha puede no ser aplicable

en su caso.

C. Cualquier fallo que sea el resultado de accidente, abuso, negligencia por parte del comprador o si éste no hace funcionar

los productos de acuerdo con las instrucciones proporcionadas en el(los) manual(es) del propietario que se entrega(n) con

el producto.

D. Servicio previo a la entrega, es decir, armado, filtrado y ajuste.

E. Ajustes normales o artículos fungibles que se explican en el(los) manual(es) del propietario que se entregan con el

producto incluyendo, pero sin limitarse a, piezas sujetas a desgaste normal tales como boquillas, inyectores de aire,

bloques de sellado, válvulas, anillos en O, conexiones de mangueras, mangueras y pistolas.

F. Artículos o servicios que exijan el reemplazo periódico para mantener el producto, es decir, filtros, juntas, válvulas, etc.

G. Artículos adicionales no cubiertos por esta garantía:

a. Todo componente dañado durante el envío o toda falla causada al instalar u operar la unidad bajo condiciones que

no estén de acuerdo con las pautas de instalación y funcionamiento.

b. Fallas causadas por lluvia, humedad excesiva o entornos corrosivos.

c. Defectos estéticos que no interfieren con la funcionalidad de la chorreadora.

d. Tanques oxidados incluyendo, pero sin limitarse a, óxido debido a limpieza/almacenamiento inadecuado.

e. Otros artículos que no estén enumerados pero que se consideren piezas de desgaste general.

7. RESPONSABILIDAD DEL GARANTE EN VIRTUD DE ESTA GARANTÍA: Según elija el Garante, la reparación o el

reemplazo del producto o los componentes que estén defectuosos, que hayan funcionado en forma inadecuada y/o que no

hayan cumplido con su función dentro de la duración del período de la garantía.

8. RESPONSABILIDAD DEL COMPRADOR EN VIRTUD DE ESTA GARANTÍA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Entregar o enviar el producto o componente Maxus al Centro de Servicio autorizado Campbell Hausfeld más cercano. Los

gastos de flete, de haberlos, deben ser pagados por el comprador.

C. Emplee un cuidado razonable para el manejo y el mantenimiento de los productos, según se describe en el (los)

manual(es) del propietario.

9. EN QUÉ CASOS EL GARANTE PROPORCIONARÁ REPARACIÓN O REEMPLAZO EN VIRTUD DE ESTA GARANTÍA: La

reparación o el reemplazo se establecerán y se llevarán a cabo de acuerdo al flujo de trabajo normal en la instalación de

servicio, y dependerá de la disponibilidad de piezas de repuesto.

Esta garantía limitada se aplica únicamente en los EE.UU., Canadá y México y le proporciona derechos legales específicos.

Puede que también tenga otros derechos que pueden variar de un estado a otro, o de un país a otro.

24-Sp

Loading...

Loading...