Page 1

Airless Paint

Systems

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Operating Instructions and Parts Manual

IN422500AV 12/02

Thank you for purchasing a Campbell Hausfeld product. If you have any technical

questions about this product, please call 1-800-626-4401.

For Parts and Accessories: 1-800-626-4401

AL2810

For parts, product & service information

visit www.chpower.com

© 2002 Campbell Hausfeld/Scott Fetzer

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

BUILT TO LAST

Page 2

2

Operating Instructions and Parts Manual

Airless Paint Systems

Description

Airless paint sprayers are capable of

spraying a wide variety of latex, oilbased, and alkyd paints, as well as

stains, preservatives and other nonabrasive finishes.

These sprayers are also powerful and

versatile enough to be used with a

variety of options (roller attachment,

extra lengths of hose, etc.) to make it

an even more efficient tool.

NOTE: Guns pictured in illustrations

may be different than the one included

with your unit.

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, MAY

cause damage to equipment.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make

sure to tighten fittings, bolts, etc.,

before putting unit into service.

Do not operate

unit if damaged

during shipping, handling or use.

Damage may result in bursting and

cause injury or property damage.

General Safety

Information

1. Read all manuals included with this

product carefully. Be thoroughly

familiar with the controls and the

proper use of the equipment.

2. Always wear a mask or respirator

and eye protection when painting.

Be certain mask or respirator will

provide necessary protection

against inhalation of harmful

vapors.

3. Keep visitors away and NEVER allow

children or pets in the work area.

www.chpower.com

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Safety Information . . . . . . . . . . . . . . . . . . . . . . .2

Pre-Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

How to Flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Spray Tip Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Spray Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

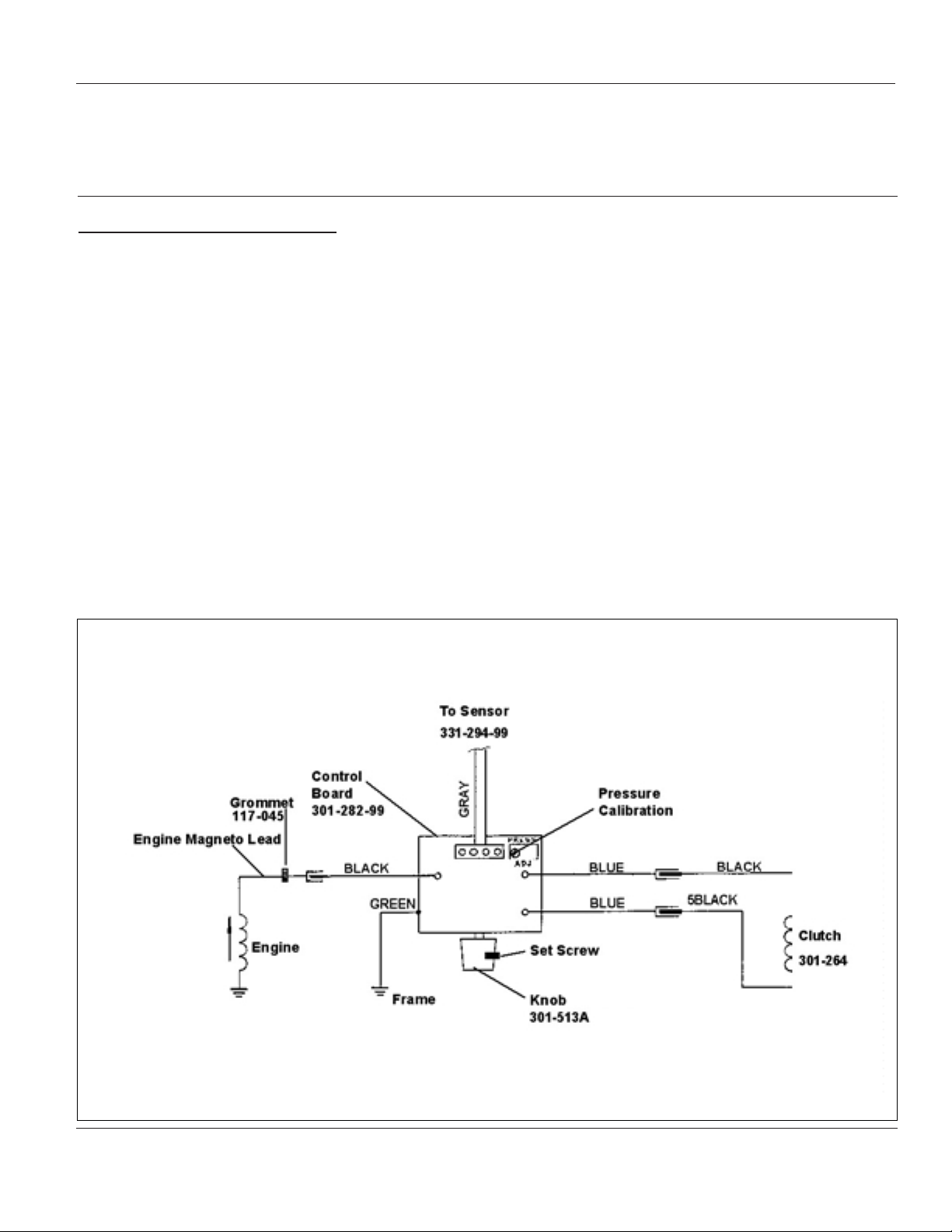

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Replacement of Electrical Control Board . . . . . . . . . .8

Pressure Calibration on Electrical Board . . . . . . . . . . .9

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fluid Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Inlet Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Outlet Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Clutch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Regular Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .12

Oil and Lubrication Procedure . . . . . . . . . . . . . . . . .13

V-Packing Replacement . . . . . . . . . . . . . . . . . . . . . . .13

Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . .14

Parts Diagrams and Parts Lists . . . . . . . . . . . . . . . . . . . .18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Specifications

Max. Pressure . . . . . . . . . . . . . 3000 psi

Output. . . . . . . . . . . . . . . . . . . 1.5 GPM

Tip size . . . . . . . . . . . 1 gun up to 0.041

2 guns up to 0.028

Engine . . . . . . . . . . . . . . . 5.5HP Honda

Weight . . . . . . . . . . . . . . . . . . . 160 lbs.

AL2810

!

DANGER

!

WARNING

!

CAUTION

NOTICE

!

WARNING

Page 3

Airless Paint Systems

3

Operating Instructions and Parts Manual

General Safety

Information

(Cont.)

4. Do not smoke or eat when spraying

paint, insecticides, or other

flammable substances.

5. Always work in a clean

environment. To avoid injury and

damage to the workpiece, do not

aim the spray gun at any dust or

debris.

6. When spraying and cleaning,

always follow the instructions and

safety precautions provided by the

material manufacturer (Refer to

MSDS).

GASOLINE ENGINE PRECAUTIONS:

● Locate unit 25 feet away from

spray area in well-ventilated area.

● NEVER operate in closed building

unless exhaust is piped outside.

● NEVER allow hose to lay against

engine mufflers or hot parts.

● NEVER refill fuel tank while engine

is hot or running.

SKIN INJECTION HAZARD:

● High pressure spray

can inject toxins

into blood stream.

If injection occurs,

seek emergency medical treatment.

Use a face mask/respirator

and protective clothing

when spraying. Always

spray in a well ventilated

area to prevent health and fire

hazards. Refer to Material Safety Data

Sheets (MSDS) of spray material for

details.

● Never try to stop leaks with any

part of your body.

● This system is capable of producing

3000 psi. Use only Campbell

Hausfeld replacement parts rated

at 3000 psi or higher.

● Never spray without tip guard.

● Ensure trigger lock is functioning

properly.

● Always engage trigger lock when

not spraying.

● Do not remove spray tip while

cleaning pump.

● Never leave equipment pressurized

while unattended.

● Do not clean spray tip while it is

attached to the spray gun. Remove

spray tip from gun to clean tip

guard.

● Ensure tightness of high pressure

connections.

● Do not use pliers to tighten or

loosen high pressure connections.

● Motor is equipped with an automatic

thermal overload. Motor will restart

without warning, after cooling.

Never aim or

spray at yourself

or anyone else or serious injury could

occur.

FIRE OR EXPLOSION HAZARD:

● Do not use solvents with flash

points less than 70°F (21°C) to clean

this equipment (examples of

acceptable cleaning solvents are

water, mineral spirits, lacquer

thinner, Xylene and high flash

napha. A partial example list of

unacceptable cleaning solvents are

low flash napha, mek, acetone,

alcohol and toluene).

Do not spray flammable

materials in vicinity of

open flame or near

ignition sources. Motors, electrical

equipment and controls can cause

electrical arcs that will ignite a

flammable gas or vapor. Never store

flammable liquids or gases in the

vicinity of the unit.

Do not spray acids,

corrosive materials,

toxic chemicals, fertilizers or pesticides.

Using these materials could result in

death or serious injury.

www.chpower.com

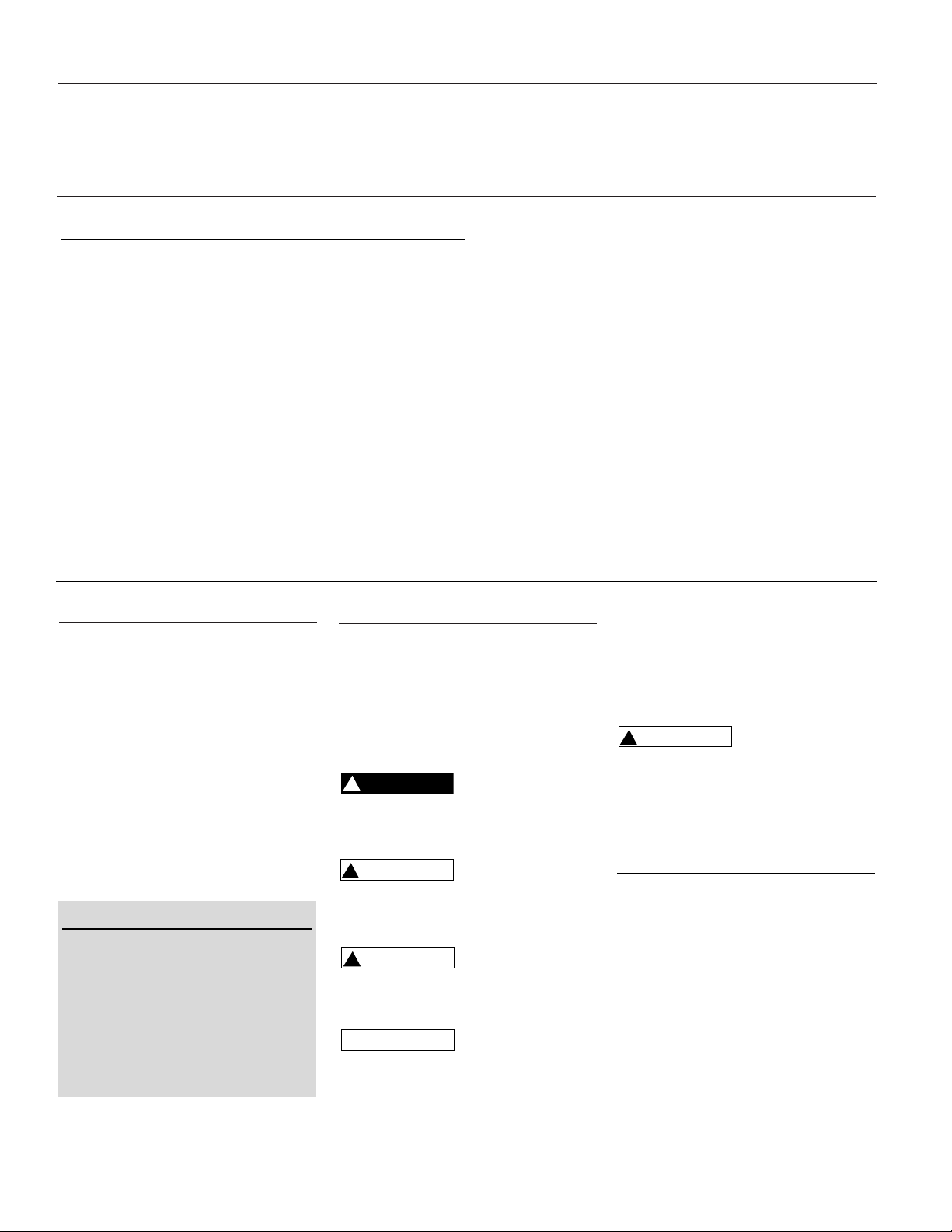

PRESSURE RELIEF PROCEDURE

Before servicing or resting unit,

relieve pressure from system by

following this procedure:

1. Engage gun trigger lock.

2. Turn off engine.

3. Disengage

gun trigger

lock and

trigger gun

to relieve

residual fluid

pressure. Hold metal part of gun

in contact with grounded metal

pail.

4. Re-engage gun trigger lock.

5. Turn

Prime/Pressure

Relief Valve to

open (priming)

position to

relieve fluid

pressure.

6. Leave

Prime/Pressure

Relief Valve OPEN until you are

ready to spray again.

NOTE: If spray tip or hose is clogged,

follow Step 1 to 5 above. Expect

paint splashing into the pail while

relieving pressure during Step 5. If

you suspect that pressure has not

been relieved after following the

above procedure, engage gun trigger

lock and take your unit to an

authorized Campbell Hausfeld

Service Center

.

AL2810

OPEN POSITION

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

!

WARNING

WARNING

!

WARNING

Page 4

4

Operating Instructions and Parts Manual

Airless Paint Systems

General Safety

Information

(Cont.)

● Paints and solvents containing

HALOGENATED HYDROCARBONS can

react explosively with aluminum. Do

not use halogenated hydrocarbons

with this equipment. Consult the

paint or solvent product label or

Material Safety Data Sheets (MSDS)

to help determine if it contains

halogenated hydrocarbons.

● Do not use fuels to clean this

equipment.

● Keep spraying area well ventilated.

Keep doors and windows open.

● Remove all ignition sources (i.e.

Static electricity, pilot lights,

cigarettes and electrical arcing).

● Airless spraying can cause static

electricity. Always ground the

pump and spraying surface.

● Do not use solvents containing

halogenated hydrocarbons.

Keep hose away

from sharp objects.

Bursting hoses may cause injury.

Examine hoses regularly and replace if

damaged.

● Check hoses for weak or worn

condition before each use, making

certain that all connections are

secure.

Pre-Operation

FLUSHING

1. NEW SPRAYER:

Your sprayer was

factory tested in an oil solution which

was left in the pump. Before using oilbased paint, flush with mineral spirits

only.Before using water-based paint

flush with mineral spirits, followed by

soapy water, then a clean water flush.

2. CHANGING COLORS:

Flush with a

compatible solvent such as mineral

spirits or water.

www.chpower.com

3. CHANGING FROM WATER-BASED TO

OIL-BASED PAINT: Flush with soapy

water, then mineral spirits.

4. CHANGING FROM OIL-BASED TO

WATER-BASED PAINT: Flush with

mineral spirits, followed by soapy

water, then a clean water flush.

5. STORAGE:

Always relieve pressure

(See pressure relief procedure on

page 3) prior to storage or when

machine is unattended. Follow the

storage procedure based on the kind of

paint you used:

● Oil-based paint: Flush with mineral

spirits.

● Water-based paint: Flush with

water, then mineral spirits. Leave

the pump, hose and gun filled with

mineral spirits.

● For longer term storage use a 50/50

mixture of mineral spirits and motor

oil. Always ensure that there is no

pressure in the unit, and close the

prime/pressure relief valve for

storage.

Never leave pump

unattended while it

is under pressure!

6. START UP AFTER STORAGE: Before

using water-base paint, flush with

soapy water and then a clean water

flush. Before using oil-based paint,

flush out the mineral spirits with

the material to be sprayed.

HOW TO FLUSH

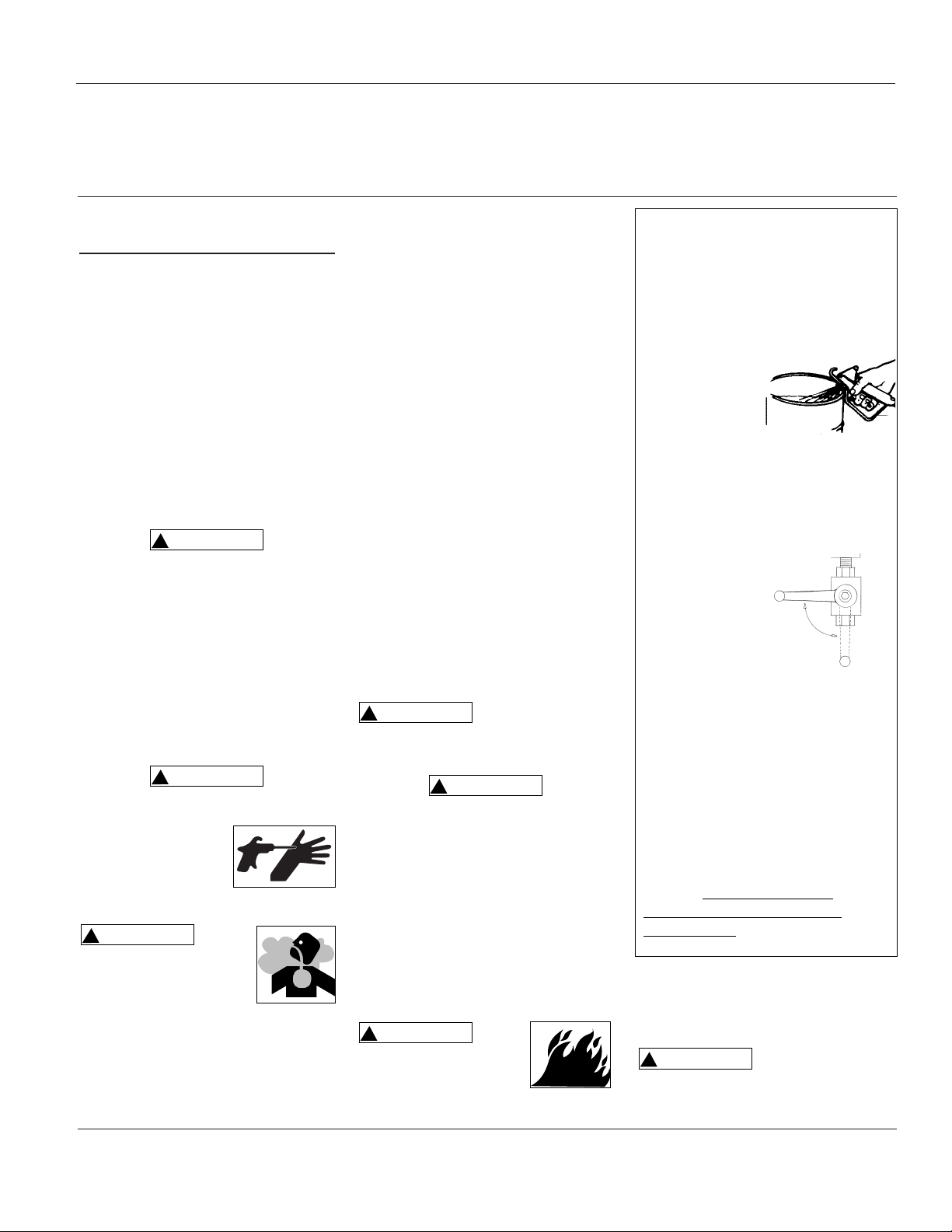

IMPORTANT COMPONENTS

● Prime/Pressure Relief Valve

(Prime/PR Valve, Figure 1). Used to

relieve pressure from gun, hose and

tip and to prime the unit when in

OPEN position.

● Pressure Control Knob (Figure 2).

Used to adjust pressure. Turn

clockwise to increase pressure and

counterclockwise to decrease it.

● Choke Lever, Fuel Valve, and

Throttle Lever (Figure 3).

PROCEDURE

1. Be sure the gun safety lock is

engaged and there is no spray tip

in the gun.

2. Pour enough clean, compatible

solvent into a large,

empty metal pail to fill the pump

and hoses.

3. Place the suction tube into the pail

or place the pail under the pump.

4. Turn the pressure control knob to

low pressure. Refer to Fig. 2.

AL2810

OPEN POSITION

(Prime and Pressure Relief)

CLOSED

POSITION

(Pressure)

Figure 1 - Prime/Pressure Relief Valve

Figure 2 - Pressure Control Knob

Low Pressure

High

Pressure

Figure 3 - Choke Lever, Fuel Valve,

and Throttle Lever

Choke Lever

Fuel Valve

Throttle

Lever

!

CAUTION

!

WARNING

Page 5

Airless Paint Systems

5

Operating Instructions and Parts Manual

Pre-Operation (Cont.)

5. Open the prime valve to the open "Priming Position". This will allow

for an easy start. Refer to Figure 1

on page 4.

6. Turn the engine ON/OFF switch to

ON.

7. Move the choke toward the closed

position as per Figure 3.

8. Move the throttle lever slightly to

the left as per Figure 3.

9. Turn the fuel valve ON as per Figure

3. Pull the start rope. Pull the

engine over against compression

stroke and then let the rope rewind

slowly into the starter. Pull firmly

and rapidly to start the engine. Do

NOT drop the rope. Hold onto the

handle while rewinding, or the

rope may rewind improperly and

jam the assembly. If the engine

does not start, open the choke a

little more. If the engine floods,

open the choke all the way and

continue cranking.

10. After the engine is warm, gradually

close the choke lever, increase the

RPM of engine slightly by moving

throttle to the left. Close the prime

valve. Refer to Figure 1.

11. Point the gun into the metal pail

and hold a metal part of the gun

firmly against the pail Refer to

Figure 4.

12. Disengage the gun trigger lock and

squeeze the gun trigger. At the

same time, slowly turn the pressure

control knob clockwise just enough

www.chpower.com

to move liquid at low pressure.

13. Allow the pump to operate until

clean solvent comes from the gun.

14. Release the trigger and engage the

gun trigger lock.

15. If you are going to start spraying,

place the pump or suction tube into

the supply container. Release the

gun safety latch and trigger the

gun into another empty, metal

container, holding a metal part of

the gun firmly against the metal

pail (Figure 4) and force the solvent

from the pump and hose. When

paint starts coming from gun, turn

pressure control knob to minimum

pressure, place prime valve in prime

(open) position and engage the

gun trigger lock.

16. If you are going to store the

sprayer, remove the suction tube or

pump from the solvent pail force

the solvent from the pump and

hose. Engage the gun safety

latch and refer to the "Storage"

Procedure on page 4, Step 5.

17. Whenever you shut off the sprayer

follow the Pressure Relief

Procedure warning on page 3.

SETTING UP

1. Connect the hose and gun.

a. Remove the plastic cap plug from

the outlet and screw a conductive or

grounded 3000 psi spray hose onto

fluid outlet.

b. Connect an airless spray gun to the

other end of the hose, but do not

install the spray tip yet!

NOTE: Do not use thread sealer on

swivel unions as they are made to self

seal.

NOTE: The first 50' of hose should

always be 3/8".

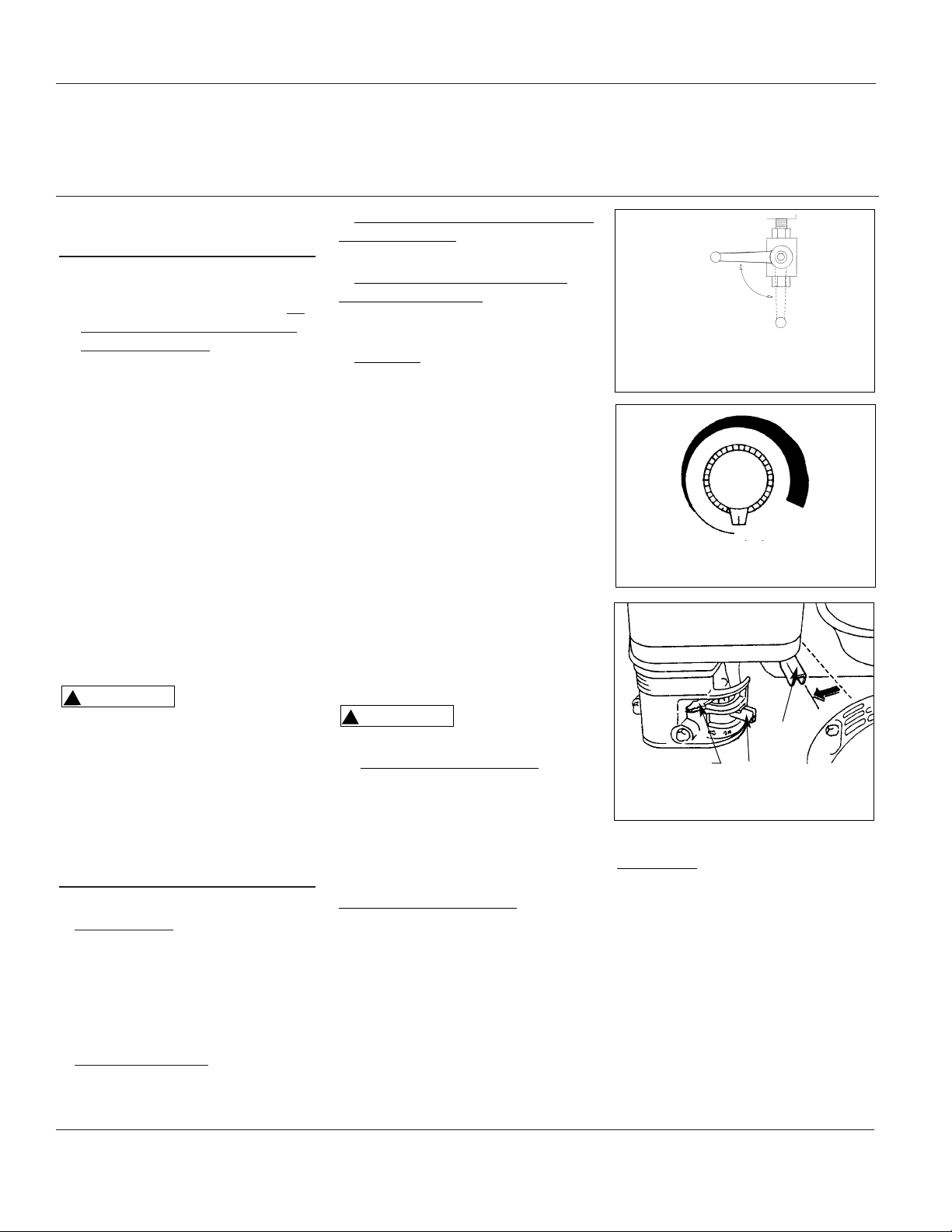

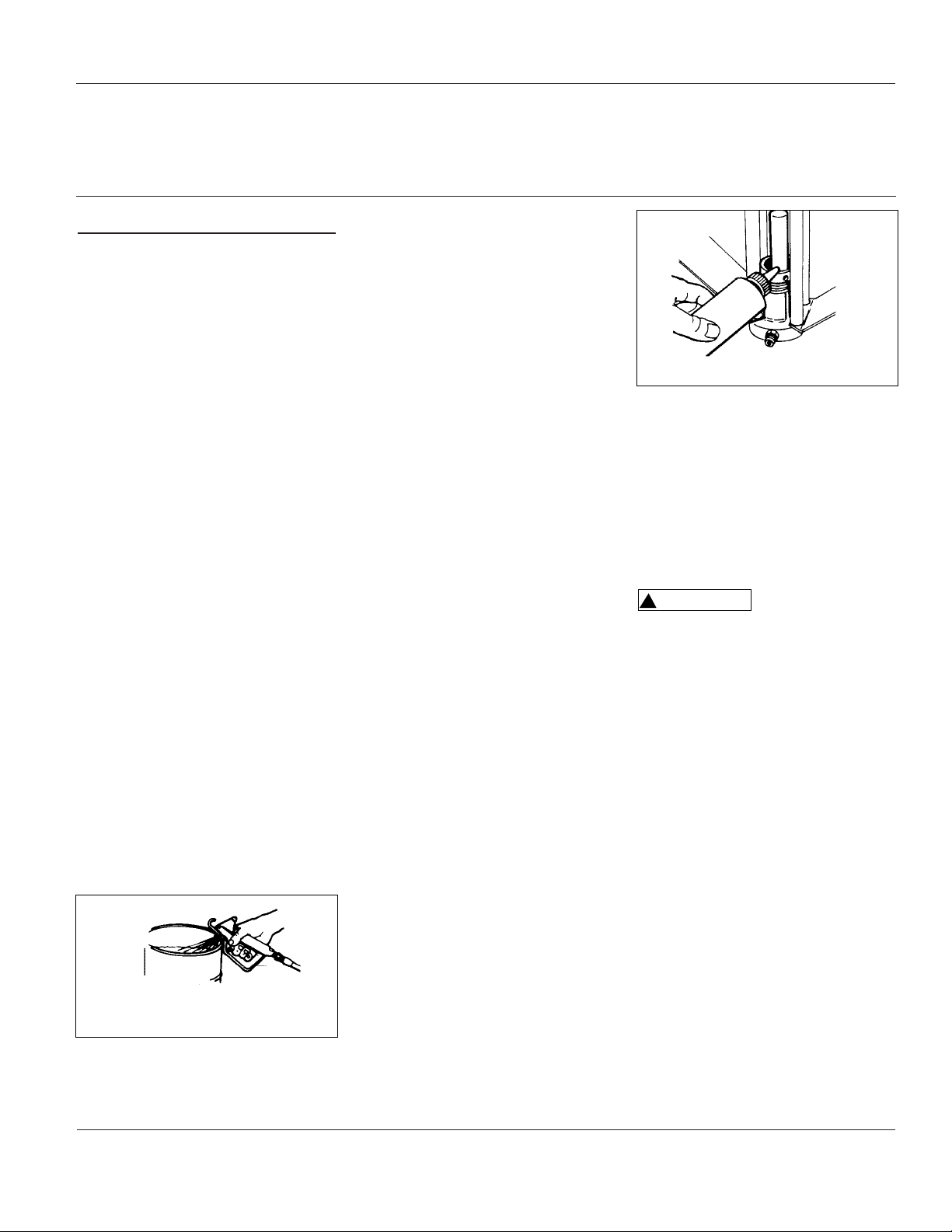

2. Fill the Packing Nut/Wet Cup 1/3 full

with Throat Seal Oil (TSO) supplied.

See Figure 5.

3. Check the engine oil level.

a. Unscrew the oil fill plug. The

dipstick is attached to the plug.

b. Without threading the plug into

place, check to be sure the oil is up

to the top mark on the dipstick.

c. If oil is needed, refer to engine

manual.

4. Fill the fuel tank.

Fuel spilled on a hot

surface can cause a

fire or explosion and cause serious

bodily injury and property damage.

Always shut off engine and let it cool

before filling the tank, and carefully

follow steps a to c below, making sure

you do not spill any fuel.

a. Close the fuel shutoff valve.

b. Use only clean, fresh, wellknown brands of unleaded regular

grade gasoline.

c. Remove the fuel cap and fill

tank. Be sure the air vent in the fill

cap is not plugged so fuel can flow

to the carburetor, then replace the

cap.

SPRAY TIP SELECTION

See Tip Selection Chart on Page 6.

Spray tip selection is based on paint

viscosity, paint type, and job needs. For

light viscosity (thin paints), use a

smaller tip. For heavier viscosities

(thicker paints), use a larger tip size.

Spray tip size is based on how many

gallons of paint per minute can be

sprayed through the tip. Do not use a

tip larger than the maximum pump

AL2810

Figure 4 - Spray Gun Against Metal

Container

Figure 5 - Applying throat seal oil

!

WARNING

Page 6

6

Operating Instructions and Parts Manual

Airless Paint Systems

www.chpower.com

Pre-Operation (Cont.)

flow rate or capacity the sprayer can

accommodate. Pump flow rate is

measured in gallons per minute (GPM).

PATTERN WIDTH

Thickness of the paint coat is

determined by spray tip “fan width,”

rate of the spray gun movement, and

distance to surface.

SPRAY TIP SELECTION

Two tips having the same tip size, but

different pattern widths, will deliver

the same amount of paint over a

different area (wider or narrower

strip).

A spray tip with a narrow pattern

width makes it easy to spray in tight

places.

SPRAY TIP REPLACEMENT

During use, especially with latex paint,

high pressure will cause the orifice to

grow larger. This destroys the pattern.

Replace tips before they become

excessively worn. Worn tips waste

paint, cause overspray, make cutting-in

difficult, and decrease sprayer

performance.

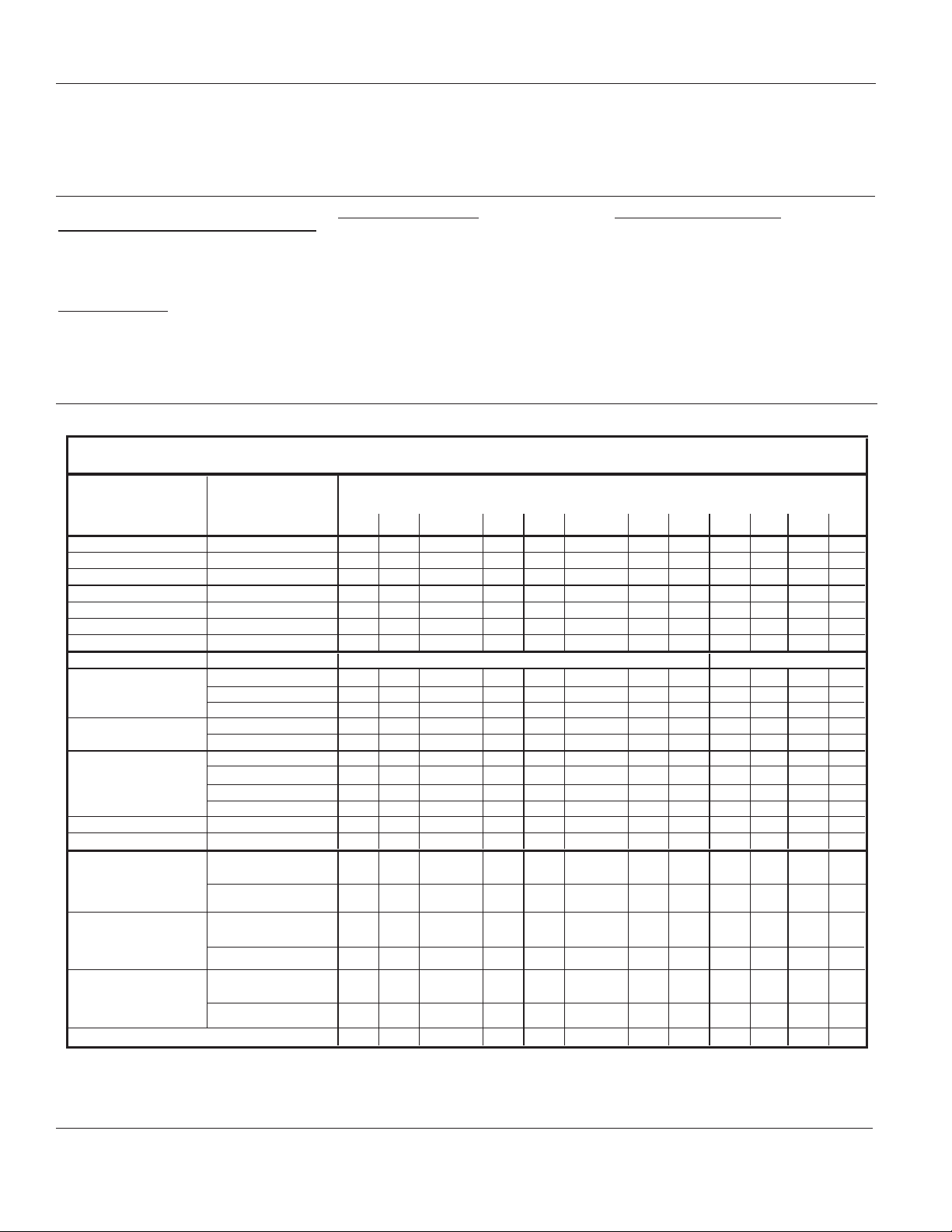

Table 1 - Tip Selection Chart

AL2810

16-18 406-457

St

l

QuadraflowTM Tip

Fan Width (in.) (mm)

4-6 102-152

6-8 152-203

8-10 203-254

10-12 254-305

12-14 305-356

14-16 356-406

Gun Filter 2 types (part #)

Wood Interior

Wood Exterior

Masonry

Ceiling Hi Build, Mil White

ructural Stee

for painting

(12" from surface)

Lacquer, Varnish

Stain, Sealer

Enamel

Exterior Stain

Vinyl, Acrylic, Latex

Vinyl, Oil Base Alkyd

Latex, Acrylic

Block Filler

Elastomer

Heavy Coatings

Tip Selection Chart

Orifice Size (inches)

.009 .011 .013 .015 .017 .019 .021 .023 .025 .027 .035

AL3116 AL3117 AL3119 AL3122 AL3125

AL2211 AL2213 AL3126 AL3131

AL3118 AL3120 AL2215 AL2217 AL3130 AL3132 AL3135 AL3137

AL3121 AL3124 AL3127 AL2219 AL2221 AL3136 AL3138

AL3134

l---------AL086101AJ------l l--------------AL086100AJ---------------l

REMOVE FILTER

.029

.031

AL3139

AL3140

Water Flow Rate (gpm)

(water @ 2000psi,

138

bar)

Paint Flow Rate (gpm)

(latex paint @ 2000psi, 138

bar/1.36 spec. gr.)

Pump Minimum

Output*

*pump will support tip worn to next larger size.

.12 .18 .24 .31 .38 .47 .57 .67 .77

(lpm)

.49 .69 .91 1.17 1.47 1.79 2.15 2.54 2.96

.10 .15 .21 .27 .33 .40 .49 .58 .66

(lpm)

(gpm)

(lpm)

.38 .57 .79 1.02 1.25 1.51 1.85 2.20 2.50

.25 .25 .33 .40 .50 .60 .75 .88 1.00

1.00 1.00 1.25 1.50 1.90 2.30 2.80 3.30 3.80

Consult your paint manufacturer for application recommendation

1.03

3.90

.88

3.33

1.25

4.70

1.31

4.98

1.12

4.24

1.50

5.70

Page 7

7

Airless Paint Systems

Operating Instructions and Parts Manual

www.chpower.com

Operation

STARTING UP

1. Learn the functions of the controls

(see “How to Spray / Important

Components” for more

information).

2. Prepare the Material

a. Prepare the material according

to material manufacturer's

recommendations.

b. Place the pump or suction tube

into the material container.

3. Start the sprayer.

a. Prime/PR Valve must be open in

the priming position.

b. Pressure Control Knob must be

in low pressure position.

c. Follow procedure under “How

to Flush,” page 5, Steps 6 to 12.

To stop the unit in

an emergency or

before performing any service or

maintenance procedure follow the

Pressure Relief Procedure on page 3 to

relieve the fluid pressure.

4. Prime the pump.

a. Allow pump to operate until

paint comes from gun.

b. Release the trigger and engage

the gun safety latch.

c. Turn Prime Valve OPEN to the

prime position ensuring the

pressure is released from the

system.

d. Turn Pressure Control Knob to

minimum pressure.

e. Install spray tip onto gun.

f. Close the prime valve to the

pressure position.

g. Turn the pressure control knob

to desired spray pressure.

h. Disengage the gun safety lock

and you are ready to start

spraying.

If you spray paint

into the paint

bucket, always use the lowest spray

pressure and maintain firm metal-tometal contact between gun and

container.

5. Adjust pressure.

a. Turn the Pressure Control Knob

clockwise to increase pressure and

counterclockwise to decrease

pressure.

b. Always use the lowest pressure

necessary to completely atomize

the material.

Operating the

sprayer at higher

pressure than needed wastes material,

causes early tip wear and reduces the

life of the spray equipment.

c. If more coverage is needed, use

a larger tip rather than increasing

the pressure.

d. Check the spray tip. The tip size

and angle determine the pattern

width and flow rate.

6. Reduce clutch wear.

a. The first 50 feet of airless spray

hose should be 3/8", the larger

diameter works as a pulsation

damper and saves unnecessary

cycling of the clutch. A minimum

of 100 feet of hose should be used.

b. Adjust the Engine Speed and

Pump Pressure. First set the

throttle lever to the maximum

RPM setting (fully left). Trigger the

gun onto a test paper to check the

spray pattern and atomization.

Adjust the Pressure Control Knob

until you get a good pattern.

Reduce RPM of engine to support

pressure without overworking

engines.

7. Clean tip if clogged. If tip is

becoming worn, replace it. Worn

tips waste paint, cause overspray,

make cutting-in difficult, and

decrease sprayer performance.

IMPORTANT: Always follow the

Pressure Relief Procedure on page 3

before servicing unit.

Never hold your

hand, body, fingers,

or hand in a rag in front of the spray

tip when cleaning or checking it for a

cleared tip. Always point the gun

toward the front or into a waste

container when checking to see if the

tip is cleared or when using a selfcleaning tip.

a. Follow the Pressure Relief

Procedure on page 3.

b. Clean the front of the tip

frequently (with toothbrush only)

during the day to keep material

from building up and clogging the

tip.

c. To clean and clear a tip if it clogs,

refer to the separate instruction

manual received with your gun and

nozzle.

NOTE: When pausing during a paint

job, keep tip clean by locking the gun

and submerging the tip in a small

bucket of paint thinner. This will help

reduce buildup and drying of paint in

tip, tip guard, and gun.

Clean a clogged

standard flat tip

only after it has been removed from

the gun. Follow the Pressure Relief

Procedure on page 3.

8. When shutting off the sprayer,

follow this procedure.

a. Whenever you stop spraying,

even for a short break, follow the

Pressure Relief Procedure on page 3.

b. Clean the tip and gun as

recommended by your separate

gun instruction manual.

c. Flush the sprayer at the end of

each work day if the material you

are spraying is water-based, or if it

could harden in the sprayer

overnight. See "Flushing" on page 4.

Use a compatible solvent to flush,

then fill the pump and hoses with an

oil based sovent such as mineral

spirits.

AL2810

!

WARNING

!

WARNING

NOTICE

!

WARNING

NOTICE

Page 8

8

Operating Instructions and Parts Manual

Airless Paint Systems

www.chpower.com

Operation (Cont.)

d. For long term shutdown or

storage, refer to page 4.

Be sure to relieve

pressure in the

pump after filling with mineral spirits.

SPRAY TECHNIQUE

Good Spray Gun Technique is at the

core of any spray paint operation.

Operator skill and efficiency is as

important as good equipment and

good paint. Good spray technique is a

skill that can be developed by

following these simple instructions.

If you are not familiar with spraying

techniques, study this section of your

manual and practice the proper

technique on pieces of cardboard or a

suitable surface.

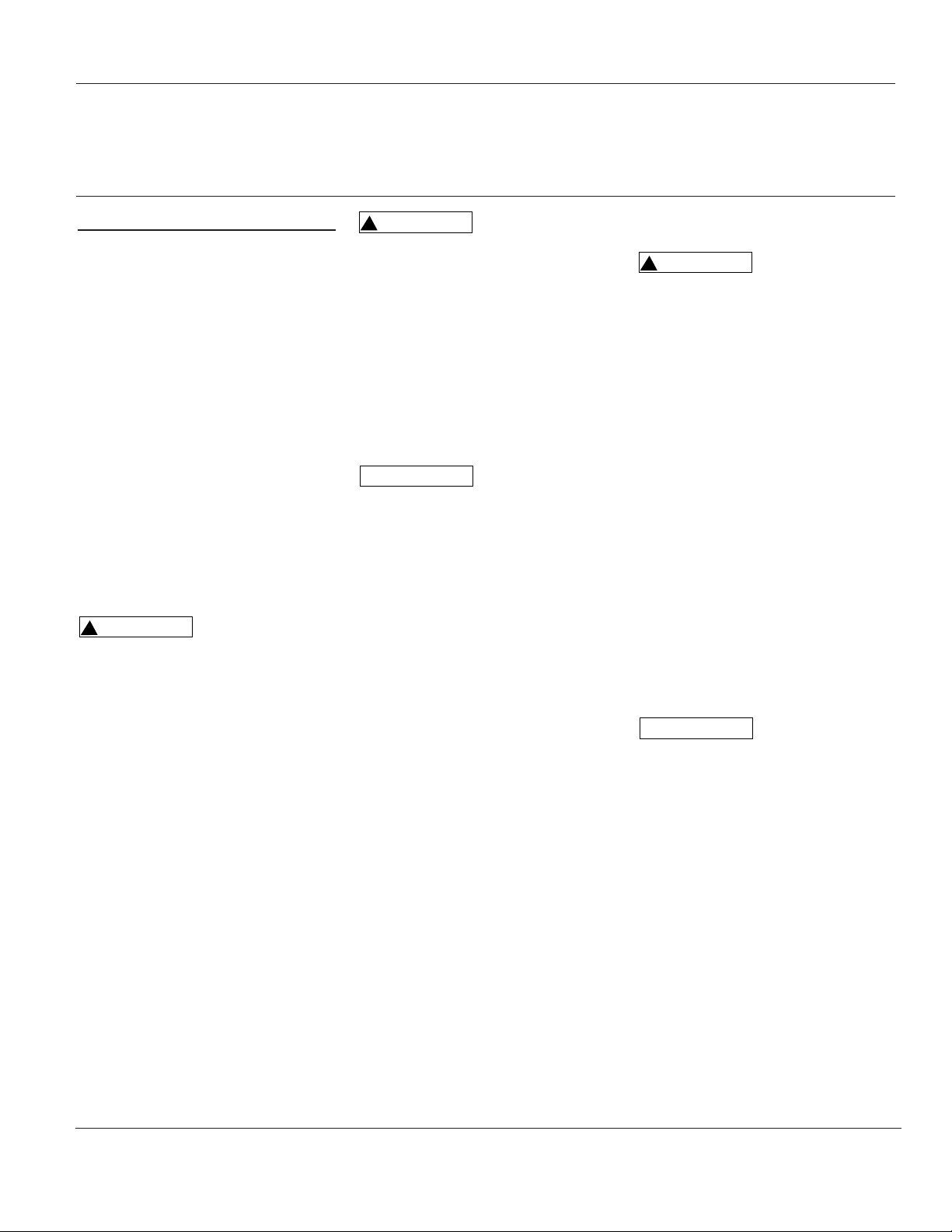

Hold the spray gun 12 - 15 inches away

from the work surface and keep it

perpendicular (straight) to the surface.

Move the spray gun parallel to the

work and at a right angle to the

surface. (See Figure 6).

Move the gun at a steady rate in order

to apply a good coverage. The wet

coat should be just under the thickness

at which a run or sag will occur. Slow

gun movement or gun held too close

will result in an overly wet or thick wet

or thick coat coverage that is likely to

run or sag.

Do not wave the spray gun. This

waving is called arching. Instead, hold

the spray gun at a 12 to 15 inch

distance perpendicular from the work.

(See Figure 7.)

The closer the spray gun is held to the

work, the thicker the paint is deposited

and the faster the gun must be moved

to prevent sags and runs. Holding the

gun too far from the work will cause

excessive fog, overspray, and a thin

and grainy coat.

It is important to "trigger" the gun

after gun movement (arm movement)

has started and release trigger (shut

gun off) before gun movement ends.

Gun movement is always longer than

actual paint (spray) stroke. In that

manner, even blending and uniform

paint coat thickness is achieved over

the entire surface. When the gun is in

motion as the trigger is pulled, it

deposits an even amount of paint.

Overlap the previous pass by half the

width of the spray pattern. Aim at the

bottom of the previous pass.

Adjust Pressure Control Knob so that

paint is completely atomized from the

spray gun. Insufficient pressure will

result in “tailing.” Too much pressure

will result in excess fog and overspray,

excessive tip wear, and increased

sprayer wear and tear.

Always use the lowest pressure possible

to obtain desirable results. Test the

spray pattern on a piece of cardboard

or other surface.

To cover “inside” and “outside”

corners (on walls or other objects), aim

the spray gun toward the center of the

corner. The spray pattern is divided in

half, and the edges of the spray

pattern on both walls are the same.

Electrical System

REPLACEMENT OF ELECTRICAL

CONTROL BOARD

1. Remove electrical cover.

2. Disconnect sensor lead from

electrical board.

3. Disconnect two clutch leads on

electrical board from leads on

clutch.

4. Using a 1/16” allen wrench, loosen

set screw in Pressure Control Knob

RIGHT

WRONG

Gun is held at an angle,

fluid disperses unevenly

Gun is held perpendicular

to work piece, fluid

disperses evenly

Figure 6 - How to hold spray gun when spraying

Figure 7 - Proper Spray Technique

INCORRECT

CORRECT

Start

Pull

Trigger

Release

Trigger

End

12-15”

AL2810

!

WARNING

Page 9

9

Airless Paint Systems

Operating Instructions and Parts Manual

www.chpower.com

Electrical System (Cont.)

and remove knob.

5. Using a 1/2” nut driver or 1/2” deep

socket, remove nut from pressure

control shaft. This will allow

removal of electrical control board

from frame.

6. Replace electrical board assembly in

reverse order. Adjust pressure

according to the procedure given in

Pressure Calibration on Electrical

Board section.

PRESSURE CALIBRATION ON

ELECTRICAL BOARD

1. Turn "Pressure Calibration" Trimpot

adjustment on electrical control

board in the counter clockwise

direction at least 15 revolutions.

2. Connect 5000 psi glycerine pressure

guage on output of pump between

fluid pump and airless hose to

monitor Fluid Pump Pressure.

3. Start engine and run at maximum

RPM. Turn Prime/Pressure Relief

Valve to the open (Prime) position.

Turn Pressure Control Knob to

maximum position (fully clockwise).

4. Using an insulated screwdriver,

adjust "Pressure Calibration"

Trimpot by turning clockwise until

the clutch engages. When the

clutch engages the pump will

commence Priming. When pump is

primed, turn the Prime/Pressure

Relief Valve to the Closed (Pressure)

position. The pump will begin to

pressurize and the clutch will

disengage at a low pressure.

Continue turning the Trimpot

clockwise to increase pressure to

3000 psi.

5. Trigger gun. The pressure should

drop approximately 350-400 psi

(when using a 3/8" hose), the clutch

will engage and build pressure to

3000 psi and disengage. Trigger

gun several times to ensure proper

pressure setting.

6. Turn Pressure Control Knob to

minimum position. The clutch

should disengage and pump stop

moving.

7. Secure leads with tie strap.

8. Replace cover on unit. Ensure the

leads are not pinched or damaged

in the process of replacing covers.

AL2810

Figure 8 - Electrical Board/Pressure Calibration

Page 10

10

Operating Instructions and Parts Manual

Airless Paint Systems

www.chpower.com

Service

FLUID PUMP

FLUID PUMP DISCONNECT

1. Flush out the material you are

spraying, if possible.

2. Follow the Pressure Relief

Procedure on page 3. Stop the

pump in the middle of down

stroke.

3. Remove the suction tube and fluid

hose (if so equipped) from the fluid

pump. Detach the hose from the

front of the fluid pump.

4. Remove 2 retaining rings and slip

the sleeve of the coupling down

and remove both coupling halves.

This will disconnect fluid pump

from the connecting rod.

5. Unscrew the two tie rod locknuts.

6. Pull the pump down off the tie

rods.

FLUID PUMP REINSTALL

1. Loosen packing nut and extend

piston rod so that it is in the “fully

up” position.

2. Make sure that spacer tubes (301-

048) are in place.

3. Connect connecting rod with fluid

pump by installing coupling halves.

Slide sleeve over coupling halves.

Secure with retaining rings.

4. Secure the fluid pump housing to

the tie rods and screw nuts with

lock washers on loosely.

5. Tighten the tie rod nuts evenly to

30 ft. lb.

6. Reconnect fluid hoses and suction

tube (if so equipped).

NOTE: After all the rod locknuts are

tight, the alignment of both rods

should allow easy assembly and

disassembly of the coupling. If there is

any binding, loosen and retighten all

the rod locknuts to improve the

alignment. Misalignment causes

premature wear of seal and packings.

7. Tighten the packing nut until there

is resistance, then tighten it 1 full

turn. Approximately 4 threads will

show when new packings are

installed. Fill the wet cup of the

packing nut 1/3 full with Throat

Seal Oil.

8. Start the pump and operate it

slowly (at low engine speed and

pressure setting ) to check the

piston rod for binding.

Adjust tie rod lock nuts if necessary

to eliminate binding.

9. Run at maximum pressure for

several minutes, relieve pressure

and repeat step 7.

AL2810

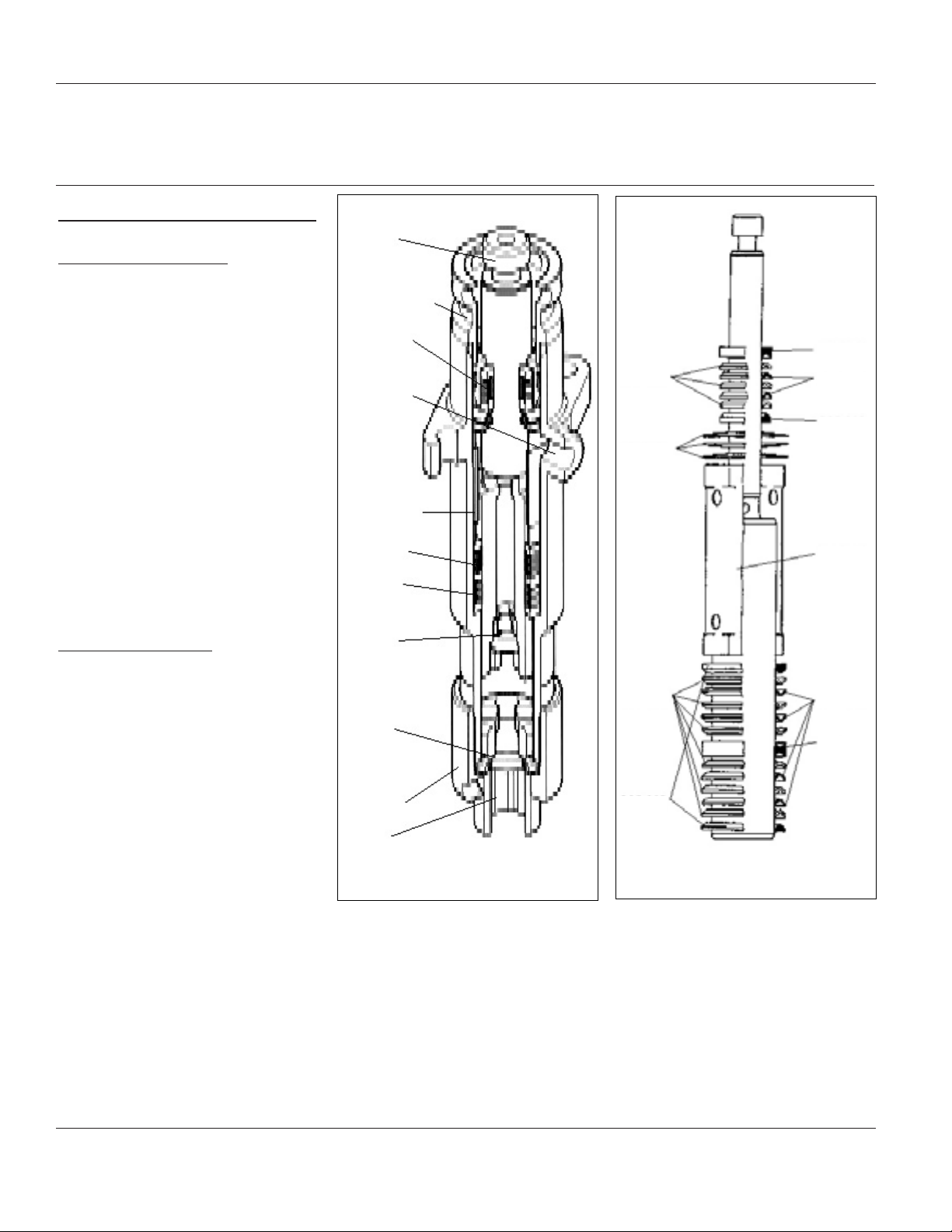

Figure 9 - Inlet Valve, Outlet Valve,

Piston Assembly

Piston

Packing nut/

wet cup

Upper

packing

Fluid

outlet

Distance

tube

Lower

packing

Wiper

packing

Outlet

valve

Inlet

valve

Suction

nut

Fluid

inlet

Figure 10 - Piston Assembly

187-030

187-031

187-029

187-037

187-026

187-060

187-025

187-315

187-059

187-058

Page 11

11

Airless Paint Systems

Operating Instructions and Parts Manual

www.chpower.com

halves and remove both coupling

halves. This will disconnect piston

rod from connecting rod and

gearbox assembly.

3. Screw the suction nut off the pump

and remove inlet valve assembly.

4. Using the rod collar tool, loosen

the packing nut (CCW) and push

the piston down and out of the

fluid body.

5. Place piston holder in a vise. Slide

the piston into the holder and lock

in place with a 1/4" pin.

6. Clean all parts and inspect them

carefully for wear or damage.

Inspect the outside of the piston

rod for scoring or wear. Replace

these parts if needed. A worn

piston rod will cause premature

wear of packings.

7. Using a 3/8" allen wrench to

unscrew the outlet seat support

from the piston.

8. Remove the outlet seat, O-ring,

outlet ball and ball cage.

9. Inspect the outlet ball and seat for

wear. Replace as required.

NOTE: Inlet seat is reversible.

10. Install parts back into piston rod as

shown in Figure 11.Place two drops

of loctite No. 242 (blue) on threads

of the outlet seat support before

assembling and torque to 20 ft-lbs.

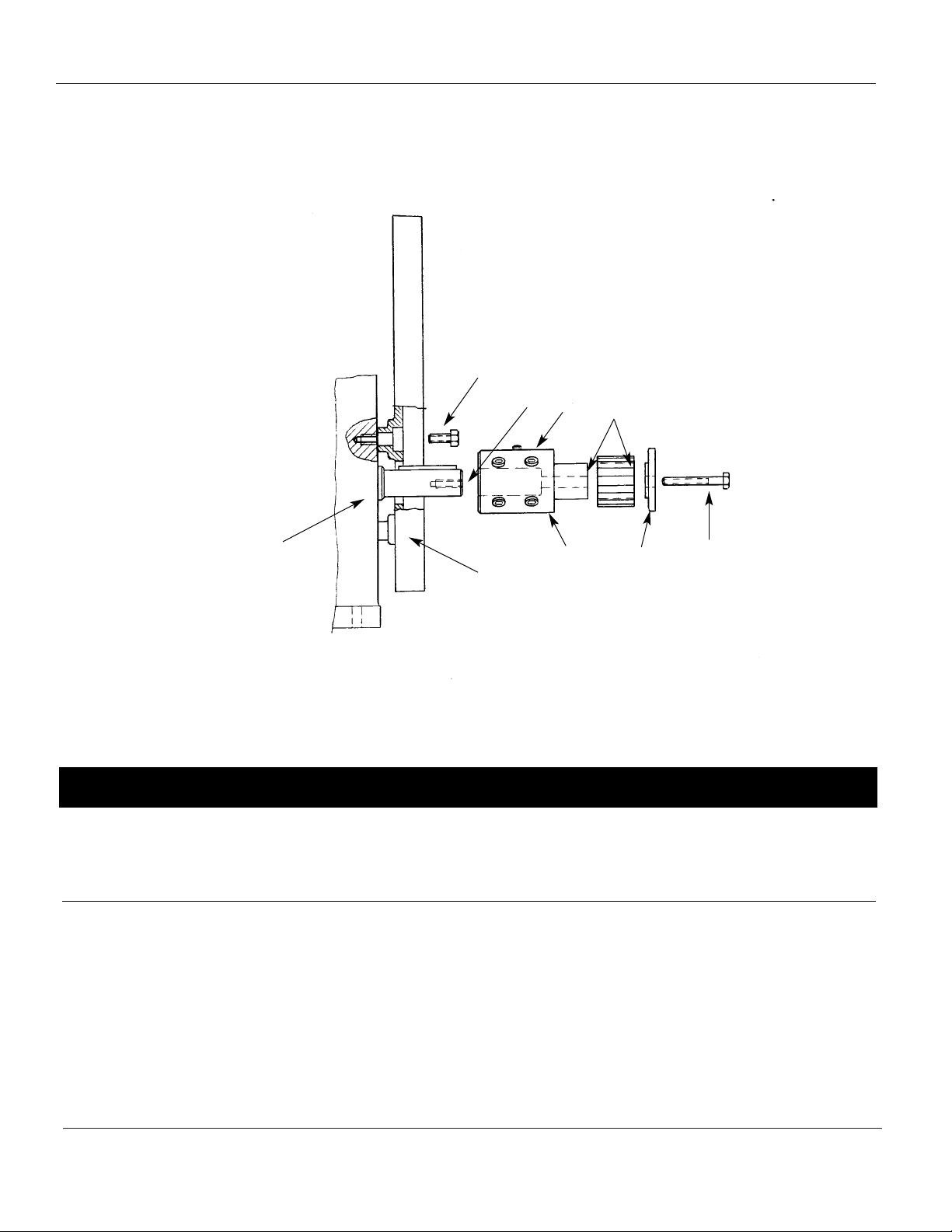

CLUTCH REPLACEMENT

NOTE: See clutch assembly parts list on

page 26.

Remove clutch as follows:

1. Remove upper and lower clutch

covers.

2. Remove splash cover from clutch

brackets and spacer tubes.

3. Disconnect two clutch leads from

electrical control board leads.

4. Remove gearbox cover with

manifold filter from gearbox.

AL2810

Service

(Cont.)

INLET VALVE

1. Using the rod collar tool, screw

suction nut off of fluid body.

(Suction nut contains intake seat

support.)

2. Remove inlet seat, O-ring, inlet ball

and ball cage with O-ring.

3. Clean all parts and inspect them for

wear or damage. Replace parts as

needed. Old O-rings should be

replaced with new ones.

NOTE: Inlet seat is reversible.

4. Clean inside of fluid body.

5. Reassemble the valve and screw it

onto the fluid body if no further

service is needed.

OUTLET VALVE

1. Stop piston rod in middle of its

stroke. Remove retaining rings.

2. Slip the sleeve off the coupling

Figure 11 - Piston Assembly

Page 12

12

Operating Instructions and Parts Manual

Airless Paint Systems

www.chpower.com

Service (Cont.)

Disconnect hose from fluid section.

5. Disconnect and remove fluid

section from gearbox, including

Connecting Rod Assy. (See"Fluid

Pump Disconnect, page 10)

6. Remove four nuts (page 20, Item

23) on the engine side of (Item 18)

from screws (Item 24) which pass

through spacer tubes (Item 15). This

will allow removal of Gearbox &

Clutch Assembly from "HolderManifold" (Item 18).

7. Pull the cog belt loose from the

engine shaft cog pulley and remove

the gearbox/clutch assembly from

the rest of the unit.

8. Place gearbox in vice by gripping

the flat part of the drive crank

allowing the clutch assembly to

face up. Use caution and not allow

gearbox to swing and damage

casting against vice.

9. Hold coupling screw, with 13/16"

wrench, then with 5/16" allen

wrench, screw differential screw

out of coupling screw and gearbox

shaft.

10.Screw large end of differential

screw into coupling nut assembly

and pull out of clutch assembly.

11.The clutch can now be removed

Spacers, removable spacer,

replacement clutch, bearings,

retaining rings should be inspected

and replaced if needed. (Items 3

through 8 on Parts List).

Install new clutch as follows:

1. With gearbox held as described in

Step 8 above, place first spacer and

bearing onto gearbox shaft.

2. Insert snap rings (2 into recesses of

cog pulley portion of clutch. Place

cog pulley portion of clutch with

cog belt attached onto shaft.

3. Place second spacer into cog pulley

portion of clutch. This spacer will

rest on the first bearing installed.

4. Insert second bearing on top of

upper snap ring.

5. Lay removable spacer on top of last

bearing. If the clutch air gap is

larger than .028", do not use

removable spacer. Put spacer over

removable spacer, if used, and top

bearing.

6. Place coil portion of clutch down

onto cog pulley portion of clutch

and center on gearbox shaft.

7. Screw differential screw into

coupling screw and nut until 1/16"

is showing.

8. Push coupling nut assembly into

clutch assembly until it comes to a

positive stop. (Differential screw

comes into contact with the

threaded gearbox shaft.)

9. With 13/16" wrench on coupling

screw and 5/16" allen wrench in

differential screw, simultaneously

with both wrenches screw coupling

nut assembly into gearbox shaft by

turning clockwise until a positive

stop is reached.

10. Hold coupling nut assembly and

tighten diffential screw to 30 ft.-lbs.

This will expand the coupling

assembly, thereby holding the

clutch assembly to gearbox shaft.

Turn clutch observing clutch gap.

The pulley should turn freely with

a gap of .012 to .024" between the

two clutch faces. If the gap is

greater than .028, remove the

spacer. Reassemble and check gap

for proper clearance.

11. Place cog belt over cog pulley

portion of clutch. Loosen set screws

until set screws are approximately

1/4" above block tensioner.

12. Reassemble the spacers onto

screws. Simultaneously lift gearbox

assembly with clutch into position

by placing cog belt over engine

shaft log pulley and inserting the

four screws into Holder-Manifold

and replacing nuts (4). Tighten nuts

to hold assembly in place.

13. Slightly loosen screws (4).

14. Evenly tighten Set Screws until

flush with tip of block tensioner..

Check tension on cog belt by

pressing hard with thumb. Proper

tensioning should allow for

approximately 1/8". If belt is too

loose, tighten set screws further.

15. Replace connecting rod and fluid

section. Preplace front cover on

gearbox. Connect hose to fluid

section.

16. Connect the clutch and board leads.

Connect spring to spacer tube.

17. Replace the splash shield.

18. Test the clutch for proper operation

19. Replace clutch covers.

Maintenance

REGULAR MAINTENANCE

1. Always stop the pump at the

bottom of its stroke when you take

a break or at the end of the day.

This helps keep material from

drying on the rod and damaging

the packings.

2. Keep the displacement pump

packing nut/wet cup1/3 full of TSO

(Throat Seal Oil) at all times. The

TSO helps protect the packings and

rod.

3. Inspect the packing nut daily.

Your pump has a patented "Triple

Life Packing System". Packing life

will be extended a minimum of

3 times if the following Packing

Tightening Procedure is

followed:

AL2810

Page 13

13

Airless Paint Systems

Operating Instructions and Parts Manual

www.chpower.com

Maintenance (Cont.)

Inspect the packing nut daily. If

seepage of paint into the packing

nut and/or movement of the piston

upward is found (while not

spraying), the packing nut should

be tightened enough to stop

leakage only, but not any tighter.

Overtightening will damage the

packings and reduce the packing

life.

4. Lubricate connecting rod pin every

3 months.

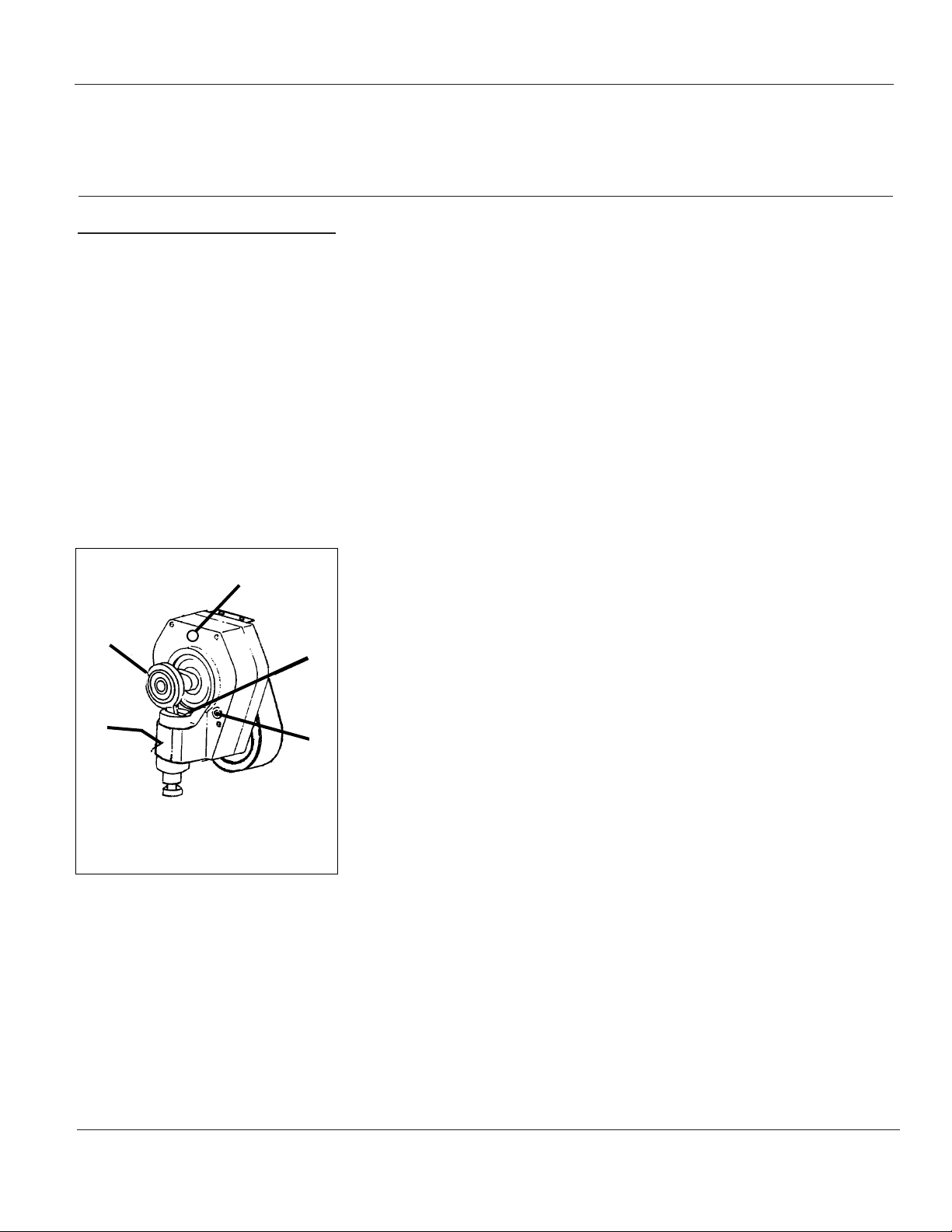

OIL AND LUBRICATION PROCEDURE

Figure 12 shows the necessary steps

involved in proper lubrication.

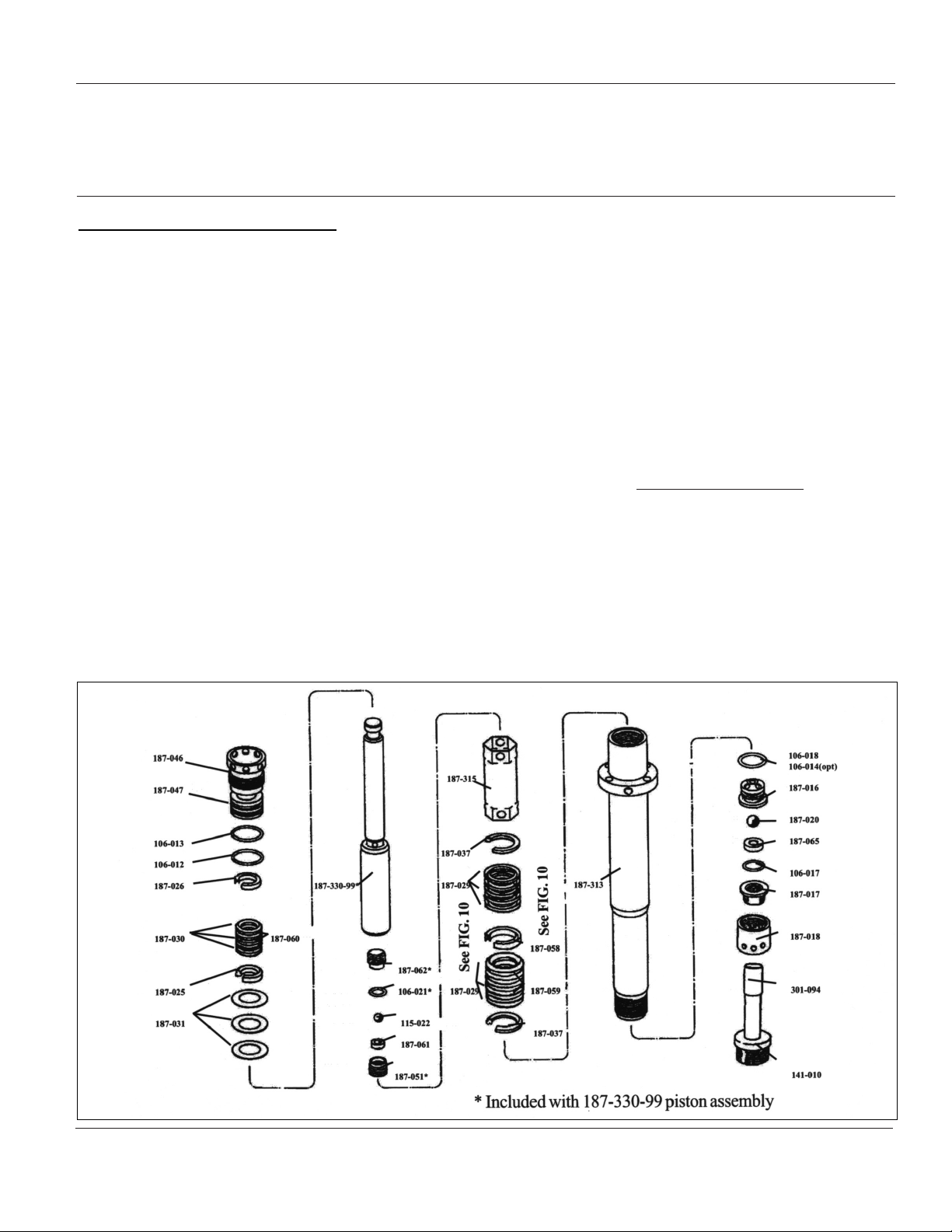

V-PACKING REPLACEMENT

Refer to Figure 9, 10 and 11 on pages

10 and 11 for corresponding part

illustrations.

V-Packing Replacement Kit Severe Duty

(PN 187-040) contains leather and

plastic packing, Teflon and Viton Orings, balls and plastic dual-sided

female adapter and larger male

glands. Gland Kit: PN 187-064.

1. Remove fluid pump as described in

“Fluid Pump Disconnect”

instructions on page 10.

2. Unscrew and remove the inlet valve

per instructions on page 11.

3. Unscrew and remove the packing

nut (187-046). Push the piston rod

down through the packings and

out of the pump. Utilizing packing

removal tool (187-249) the

complete packing set can be

removed quickly and easily.

Another method is to wrap some

masking tape around the bottom of

the piston. Now push the piston

back through the pump and

remove through the top. The

packings and glands will be

removed with the piston rod,

leaving the fluid body empty.

4. Disassemble and clean all parts for

reassembly. Discard old packings.

Save metal upper glands.

Replace metal lower glands

with new metal glands from

Packing Kit. If the old packing

had metal gland for 187-058

discard and replace with plastic

187-058.

5. Remove the outlet seat support,

outlet seat, outlet ball, O-ring and

ball cage as previously described on

page 11.

AL2810

Sealed

bearing

Bleed

(Weep hole)

1 oz. SAE

30W oil

every 3

months

Fill Plug.

NOTE:

Gearbox has

permanent gear grease

and does not require changing.

Oil

impregnated

sleeve. Dip

in hot 10W

oil when

removed.

Figure 12 - Oil and Lubrication

Procedure

Page 14

Operating Instructions and Parts Manual

Airless Paint Systems

14

www.chpower.com

Coarse spray

Excessive fogging

(overspray)

Pattern too wide

Pattern too narrow

Too much material

Too little material

Thin distrubtion in center

of pattern “horns”

Thick skin on work

Coating fails to close and

smooth over

Spray pattern irregular,

deflected

Craters or pock marks,

bubbles on work

Clogged screens

Low pressure

1. High pressure

2. Material too thin

Spray angle too large

Spray angle too small

1. Nozzle too small

2. Material too thin

3. Pressure too high

1. Nozzle too small

2. Material too thick

1. Worn tip

1. Wrong tip

1. Material too viscous

2. Application too heavy

Material too viscous

1. Orifice clogged.

2. Tip damaged.

Solvent balance

1. Extraneous material in paint.

2. Coarse pigments.

3. Poorly milled pigments (paint

pigments glocculate) cover

screen. Incompatible paint

mixture and thinners.

Symptom Possible Cause(s) Corrective Action

Troubleshooting Chart

Increase the pressure

1. Reduce pressure to satisfactory pattern distribution.

2. Use less thinner.

Use smaller spray angle tip.

Use larger spray angle tip (if coverage is OK, try tip in same

nozzle group).

1. Use next smaller nozzle.

2. Thicken spray material.

3. Reduce pressure.

1. Use next larger nozzle.

2. Thin spray material.

1. Change for new tip.

2. Use nozzle with narrow spray angle.

1. Thin cautiously.

2. Reduce pressure and/or use tip in next larger nozzle group.

Thin cautiously.

1. Clean carefully.

2. Replace with new tip.

Use 1 to 3% “short” solvents remainder “long” solvents.

(This is most likely to happen with material of low viscosity,

lacquers, etc.)

1. Clean screen

2. Use coarse screen if orifice size allows.

3. Use coarser screen, larger orifice tips. Obtain ball milled

paint. If thinner has been added, test to see if a drop

placed on top of paint mixes or flattens out on the surface.

If not, try different thinner in fresh batch of paint.

AL2810

Page 15

15

Airless Paint Systems

Operating Instructions and Parts Manual

www.chpower.com

AL2810

There is splitting from the

gun.

Paint leaks into the wet

cup.

Engine operates, but

paint pump does not

cycle

Engine and displacement

pump operate, but paint

pressure is too low or

none

Displacement pump

operates, but output is

too low on downstroke

on on both strokes

Clutch does not engage.

Clutch slips.

Engine stops.

1. Fluid supply low or empty

2. Air trapped in fluid pump or

hose

1. Packing nut/wet cup is loose

2. Upper packings worn or

damaged

3. Piston rod worn

1. Pressure setting is too low

2. Clutch not engaged

3. Displacement pump stopped

1. Pressure setting too low.

2. Tip or gun filter clogged.

3. Tip worn.

4. Fluid displacement pump

filter clogged.

5. Large pressure drop in fluid

hose.

1. Upper check valve ball not

seating properl.

2. Lower packings are worn or

damaged

Symptom Possible Cause(s) Corrective Action

Troubleshooting Chart Part II

1. Refill supply container.

2. Check for loose hose connections on the siphon

assembly. Tighten if needed. Reprime pump.

1. Tighten just enough to stop leakage.

2. Replace packings.

3. Replace piston rod.

1. Increase pressure.

2. See Troubleshooting Part III - Clutch Does Not Engage

3. Service pump.

1. Increase pressure.

2. Remove tip and/or filter. Clean if necessary.

3. Replace tip.

4. Clean filter.

5. Use a larger diameter hose.

1. Service upper check valve.

2. Replace packings.

See Troubleshooting Part III - Clutch Does Not Engage

Take unit to an authorized Campbell Hausfeld Service

Center.

Refer to engine manual.

Page 16

Operating Instructions and Parts Manual

16

www.chpower.com

AL2810

STEP 1: Ensure that the pressure control knob is in the maximum (fully clockwise) position.

STEP 2: Remove the upper and lower clutch and electrical covers.

STEP 3: Check all electrical connections between the engine magneto, sensor, control board and clutch for loose connections

or damaged leads. See Figure 8 on page 9.

STEP 4: Disconnect the two leads from the control board (blue) and the clutch assembly (black). Using a multimeter, with

the engine at maximum RPM, pressure control knob in the maximum position and the prime valve open (priming) position,

test the DC voltage across the boards leads (blue). This voltage must be 13-14 VDC. If the readings are correct, the board,

sensor and magneto are okay and the problem is the clutch assembly. If this is the case, proceed to Step 5. If the voltage is

outside this range go to Step 7.

STEP 5: Measure resistance between the clutch leads (black). This value must be 10-16 ohms. If this reading is out of

specifications the clutch is defective and must be replaced, otherwise continue troubleshooting.

STEP 6: If the clutch resistance readings of Step 5 are correct, check the spacing between the clutch field and plate. The gap

must be approximately .028". If this gap is too wide, remove the spacer from the clutch assembly. Should the clutch still not

engage, replace the clutch assembly. See page 11.

STEP 7: When the DC voltage from the board is not 13-14 VDC, disconnect the control board lead (black) from the engine

magneto lead (pink), located on the side of the engine. With the engine at maximum RPM, pressure control knob in

maximum (fully clockwise) position and prime valve open (priming), read the AC voltage from the magneto lead to the

sprayer frame. This reading should be 11-30 VAC. If outside this range, contact your local Honda repair facility for magneto

replacement. If the magneto is producing the proper AC voltage, continue to Step 8.

STEP 8: Test the sensor by reading the resistance between the red and black wires. The resistance runs between 1.8-3.5

kohms. A defective sensor usually shows no resistance (open). If the reading is outside standards, replace the sensor. An

alternative method to test the sensor, is to plug a new sensor into the board and see if the clutch will engage. Caution!

When using this method, ensure prime/pressure valve is in the prime position. This is important because the sensor plugged

into the board is not measuring pressure in the fluid section.

STEP 9: When Steps 7 and 8 have been completed and the magneto and sensor check good, the electrical control board is

the only item left, replace the board. See page 8.

Steps to Follow if Clutch Does Not Engage

Troubleshooting Chart Part III - Clutch Does Not Engage

Page 17

Operating Instructions and Parts Manual

17

www.chpower.com

AL2810

Notes

Page 18

18

For Replacement Parts, Call 1-800-626-4401

See Figures 10 & 11 on pages 10 & 11 for more Part Numbers in Diagrams

Please provide following information:

-Model number

-Serial number (if any)

-Part descriptions and number as shown in parts list

Address parts correspondence to:

Campbell Hausfeld

100 Production Drive

Harrison, OH 45030 U.S.A.

Paint System Assembly

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Page 19

19

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Ref. No. Description Part Number Qty.

1 007 Gun with swivel (Optional) 120-201XL 1

2 50’ x 1/4” Hose (Optional) 100-011 1

3 50’ x 3/8” Hose (Optional) 100-023 1

4 3/8” M x 3/8” M Nipple 169-010 1

5 Manifold filter assembly 111-200-99 1

6 3/8” plug 100-129 1

7 3/8” cap with ring 100-161 1

8 1/4” x 1/4” nipple 100-070 1

9 Ball valve 100-119 1

10 1/4” M x 1/4” F x 4’ Swivel hose 100-012 1

11 1/4” M x 1/4” f Elbow 100-004 1

12 1/4” Return tube 188-177 1

13 3/8” M x 3/8” F Elbow 169-013 2

14 3/8” F x 3/8” M x 21” Hose 100-123 2

15 1/4” M x 3/8” M Elbow 100-141 1

16 Manifold 301-253 1

17 1/4” Plug 100-028 2

18 1/4” Nut 100-317 2

19 1/4” Bolt 100-345 2

20 3/8 M x 1/4 M NPS Nipple 100-109 1

21 SL Fluid Pump 187-410 1

22 3/8 M x 3/8 M Elbow 167-016 1

Parts List for Paint System Assembly

Page 20

20

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Power Unit Assembly

Part No. 301-530

Page 21

21

Operating Instructions and Parts Manual

www.chpower.com

AL2810

301-530

Ref. No. Description Part Number Qty.

1 Sleeve bearing 301-047 1

2 Shield front 301-189 1

3 Coupling set assembly 189-046A 1

4 Shield-rear 301-092 1

5 Spacer-tube 301-048 2

6 Washer, lock 140-035 2

7 Nut 140-051 2

8 Stud 100-328 1

9 Holder 305-013 1

10 Cog Belt 301-231 1

11 Cover-bottom 305-067 1

12 Adapter 305-012 1

13 Screw 100-339 4

14 5.5 HP Engine Assembly 301-524 1

15 Spacer tube 305-046 4

16 Clutch assembly 301-264 1

17 Cover 301-529 1

18 Holder-manifold 305-064 1

19 Plate-Gearbox mount 305-045 1

20 Sensor assembly 331-294-99 1

21 Pressure control board 301-282-99 1

22 Knob assembly 301-523A 1

23 Nut 140-044 8

24 Screw 305-047 4

25 Gearbox 301-208 1

26 Connecting rod assembly 301-333 1

27 Cover top 301-531 1

28 Grommet 301-135 6

29 Screw 100-312 4

30 Cover-Gearbox 301-320 1

31 Screw 301-337 2

32 Bolt 301-547 2

33 Lock nut 100-317 2

34 Washer 140-029 4

35 Washer 100-344 4

36 Shock mount 301-536 4

Ground assembly 188-160 1

Parts List for Power Unit Assembly

Page 22

22

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Frame Assembly

Part No. 301-515

13

11

1

12

2

3

4

10

9

8

7

6

5

Page 23

23

Operating Instructions and Parts Manual

www.chpower.com

AL2810

301-515

Ref. No. Description Part Number Qty.

1 Frame weldment 301-510 1

2 Axle 5/8 x 21.81 188-367 1

3 Spacer 5/8 ID 113-031 2

4 Wheel 13 x 500-6T 301-165 2

5 Set collar 5/8 ID 143-029 2

6 Centerlock nut 5/16-18 100-317 2

7 Rubber foot 163-008A 2

8 Spacer .25 x .08 188-185 2

9 Washer 1.25 x .31 163-011A 2

10 Screw 5/16-18 169-050 2

11 Cup 100-170 1

12 Screw 10-24 301-546 2

13 Nut 10-24 120-021 2

Parts List for Frame Assembly

Page 24

24

Operating Instructions and Parts Manual

www.chpower.com

AL2810

7

8

9

Engine Assembly

Part No. 301-524

2

3

4

5

6

1

301-524

Ref. No. Description Part Number Qty.

1 Honda 5.5 HP Engine 301-160 1

2 Adapter 305-012 1

3 Screw 136-091 4

4 Key 112-029 1

5 Screw 100-357 1

6 Screw 100-383 4

7 Sheave 301-222A 1

8 Thrust Plate 301-229 1

9 Screw 301-230 1

Parts List for Engine Assembly

Page 25

25

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Clutch Replacement Parts

Ref. No. Description Part Number Qty.

1 Cog belt 301-231 1

2 Clutch 301-264 1

3 Screw 305-088 1

4 Shoulder screw 100-175 1

5 Screw flanged 100-173 4

6 Set screw 100-174 2

7 Block tensioner 301-534 1

8 New gearbox 301-208 1

9 Plate 305-045 1

10 Spacer tube 305-046 4

Parts List for Clutch Replacement

Page 26

26

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Clutch Assembly

Ref. No. Description Part Number Qty.

1 Screw-Differential 112-041 1

2 Coupling nut assembly 112-054 1

3 Spacer 301-412 1

4 Spacer-Removable 301-413 1

5 Clutch-Replacement 301-264 1

6 Bearing 301-037 2

7 Retaining ring 100-333 2

8 Spacer 301-274 2

9 Spring 136-068 1

10 Rubber edge 301-316 1

Parts List for Clutch Assembly

Page 27

27

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Ball Valve

Part No. 100-119

100-119

Ref. No. Description Part Number Qty.

1 Handle 100-162 1

2 Screw 100-163 1

3 Ball 100-164 1

* Repair Kit KIT-119 1

Parts List for Ball Valve

1

2

*

3

*

*

*

*

Page 28

28

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Manifold Filter

Part No. 111-200-99

111-200-99

Ref. No. Description Part Number Qty.

1 Base* 111-202 1

2 Spring* 301-356 1

3 O-ring* 106-007 1

4 Filter 111-204 1

5 Support* 111-203 1

6 Base* 111-201 1

7 3/8” M x 3/8” M Elbow 169-013 1

8 3/8” NPT (M) x 3/8” NPS (M) Hose connector 100-034 1

9 Plug 3/8” 100-129 1

10 3/8” NPT (M) x 3/8” NPS (M) Elbow 169-013 1

11 3/8” Cap with Ring 100-161 1

* Filter assembly 111-200 1

Parts List for Manifold Filter

Page 29

29

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Suction Assembly - 5 Gallon

Part No. 301-090-99

Suction Assembly - 55 Gallon

Part No. 301-543-99

Ref. No. Description Part Number Qty.

- Suction Hose Assembly (Includes Items 1-5) for 5 Gallon 301-517 1

1 Inlet strainer 141-008 1

2 Suction tube for 5 Gallon 301-514 1

Suction tube for 55 Gallon 301-545 1

3 Hose clamps 301-516 2

4 Hose for 5 Gallon 301-513A 1

Hose for 55 Gallon 301-544 1

5 Elbow 100-165 1

6 Return pipe 188-377 1

7 Elbow 100-128 1

8 Whip 100-012 1

9 Elbow* 100-126 1

10 Reducer* 100-385 1

11 Fitting 187-017 1

12 Suction nut 187-018 1

* Used on units equipped with either the 100-180 or 331-050 prime valves. The 301-090 suction assembly also includes the

100-081A Elbow for units with the 138-001 marathon prime valve.

Parts List for Suction Assembly (5 Gallon and 55 Gallon)

10

9 8

7

6

5

3

3

1

2

4

12

11

FLUID PUMP

Page 30

30

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Notes

Page 31

31

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Notes

Page 32

32

Operating Instructions and Parts Manual

www.chpower.com

AL2810

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty Paint Application Systems and

all Paint Application Accessories - 1 year, Serious Duty Paint Application Systems - 3 years, Extreme Duty Paint Application

Systems - 5 years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld/A Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio, 45030, Telephone: 1-800-626-4401.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale or rental) of the

Campbell Hausfeld Product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: All non-compressor driven paint application systems, HVLP spraying

systems, and paint application accessories supplied or manufactured by the Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects in material and workmanship which occur within the duration of the

warranty period. Warrantor will also cover normal wear items for a period of thirty days from the date of original purchase

against defects in material and workmanship. These wear items are: HVLP-filters, motor brushes, gun packing, gun

canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and orings.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If product is used for rental purposes, the warranty

will apply for ninety (90) days from the date of original purchase. Some states do not allow limitation on how long an

implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE , OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser’s abuse, neglect or failure to

operate products in accordance with instructions shall also include the removal or alteration of any safety devices. If

such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or services that are normally required to maintain the product: HVLP-filters, motor brushes, gun packing, gun

canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and

o-rings., or any other expendable part not specifically listed, will only be covered for thirty days from date of original

purchase.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or

components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have

other rights which vary from state to state, or country to country.

Loading...

Loading...