Page 1

Spray Guns for

Airless Paint Sprayers

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Operating Instructions and Replacement Parts List

IN424400AV 3/10© 2010 Campbell Hausfeld/Scott Fetzer

For Replacement Parts and Accessories,

Contact Your Local Service Center or Call 1-800-626-4401

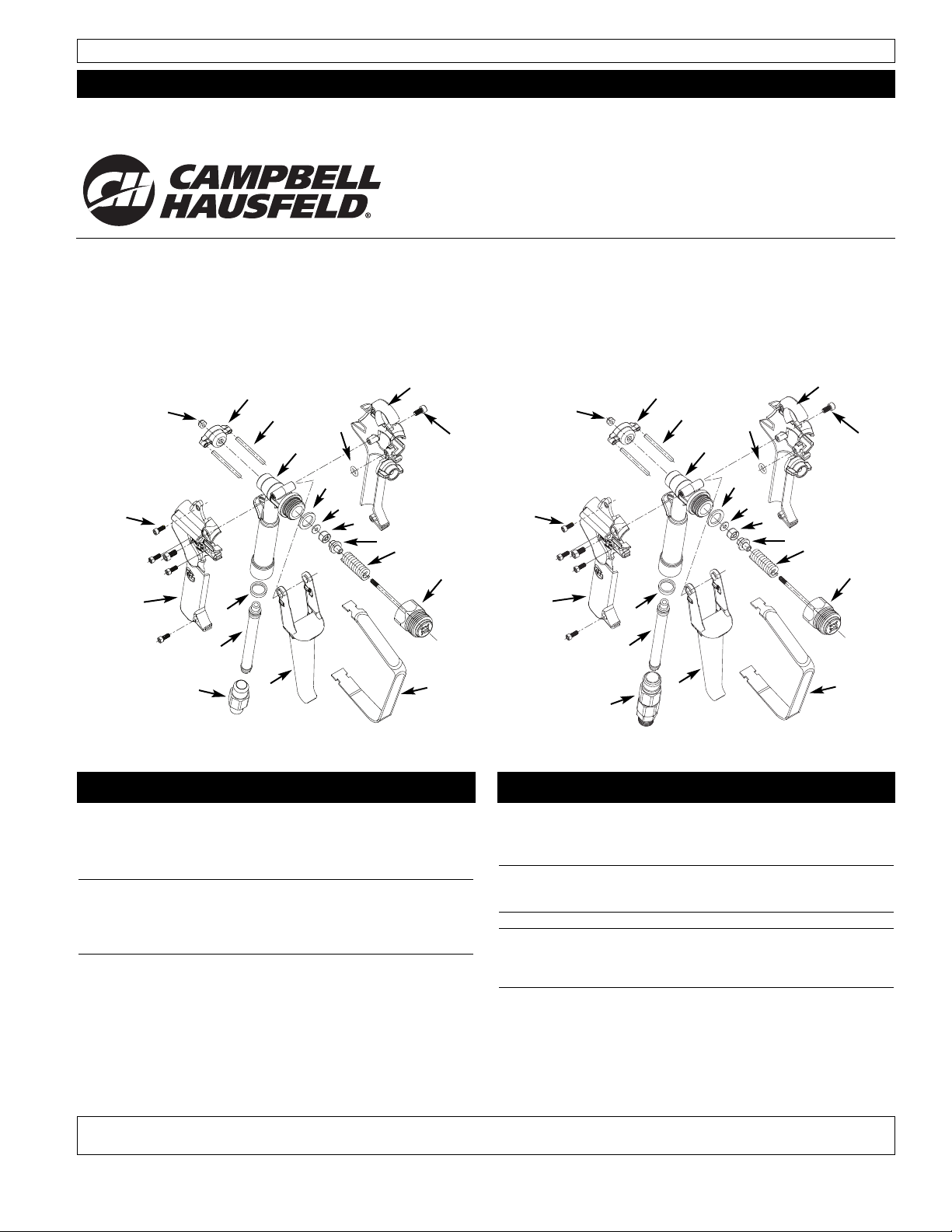

1 Kit, Black Gun Left Grip, Lock and Guard AL184401SV 1

2 Kit, Pro Gun Left Grip, Lock and Guard AL184400SV 1

3 Insert, Gun AL179801AV 1

4 Kit, Stem and Diffuser (includes #7) AL179802AG 1

5 Spring, Gun AL048600AV 1

6 Retainer, Gun Spring AL020201AV 1

7 Seal, Gun AL020300AV 1

8 Washer, Seal AL153801AV 1

9 Washer, Gun Seat Retainer AL005404AV 1

10 Kit, Gun Seal (Includes #7, #8, #9) AL183600SV

11 Pin, Gun Actuator AL024102AV 2

12 Actuator, Gun AL182700AV 1

13 Nut, #5-40 Hex Lock ST073804AV 1

14 Kit, Gun Trigger (Trigger, Screws) AL183100SV

15 Gun Filters,

100 Mesh (yellow) AL086101AJ 2 pk

50 Mesh (white) AL086100AJ 2 pk

16 Washer, Long Filter MJ105402AV 1

17 Adapter, Long Filter AL072301AV 1

18 Assembly, Pro Gun Swivel (optional) AL183500AJ 1

19 Guard, Pro Gun Trigger AL184600AV 1

20 O-Ring MJ106511AV 1

21 Screw, #5-40 x 5/16” SHC MJ103804AV 4

22 Grip, Right, Pro Gun AL184302AV 1

23 Grip, Right, Black Gun AL184301AV 1

Additional Items Available:

Kit, Gun Valve –

Includes #4 - #9, #13 AL183200SV

Kit, Gun Actuator –

Includes #11, #12, #13 AL183700SV

Kit, Pro Gun Insert –

Includes #3 - #9, #16 AL184100SV

Kit, Pro Gun Full Grip –

Includes #2, #19 - #22 AL184500SV

Replacement Parts List

Ref. Part

No. Description Number Qty.

3

11

(2x)

14 (2x)

21 (4x)

12

13

22

16

15

18

14

19

4

5

6

7

8

9

2

20

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.chpower.com

See Warranty on page 6 for important information about commercial use of this product.

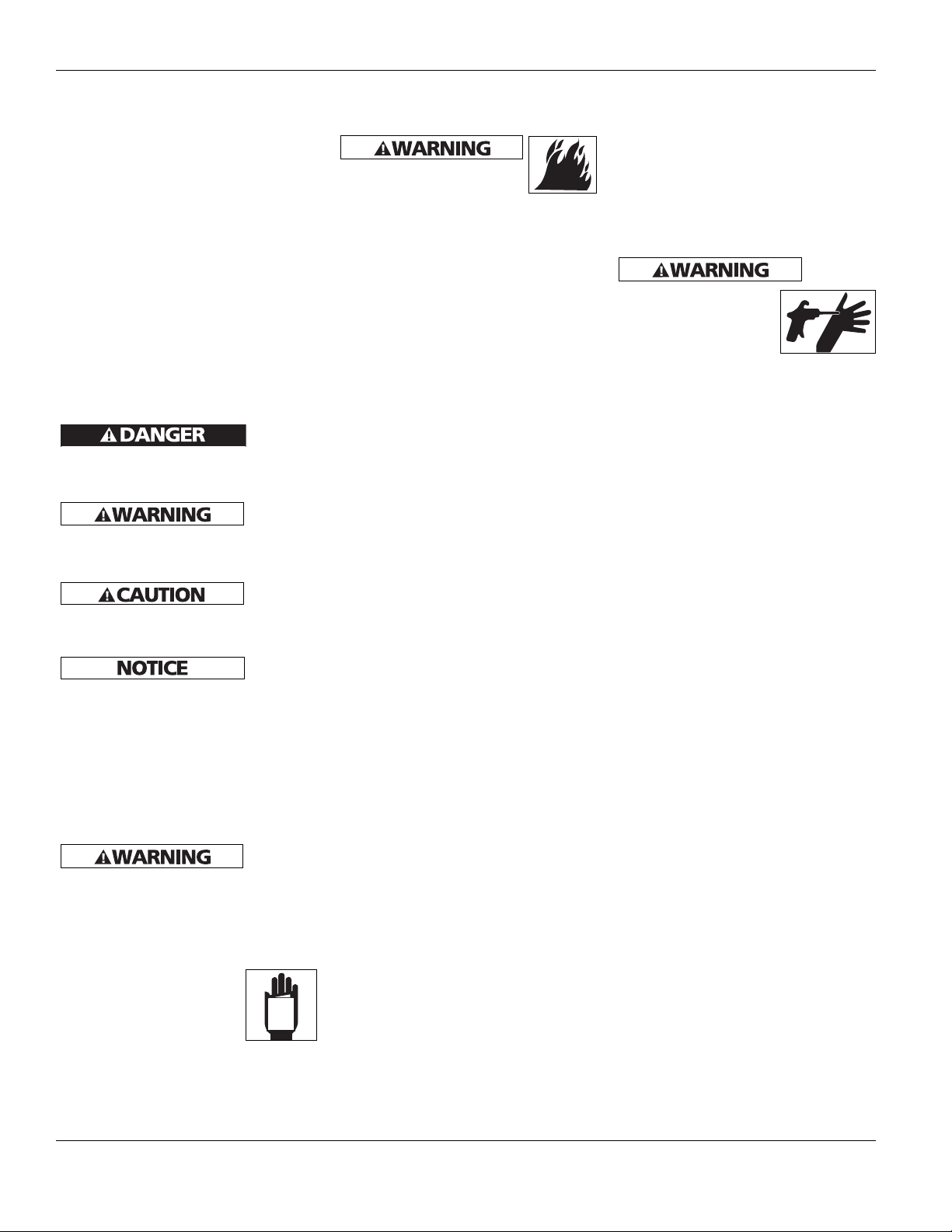

3

11

(2x)

14 (2x)

21 (4x)

12

13

23

16

15

17

14

19

4

5

6

7

8

9

1

20

AL2150 - BLACK

Address parts correspondence:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Please provide the following information:

- Model number

- Serial number

- Part description and number as shown in parts list

Ref. Part

No. Description Number Qty.

AL1860 - METAL

Page 2

2

Operating Instructions and Replacement Parts List

Description

Airless paint sprayers are capable of

spraying a wide variety of latex, oilbased, and alkyd paints, as well as

stains, preservatives and other nonabrasive finishes. Sprayers are also

powerful and versatile enough to be

used with a variety of options (roller

attachment, extra lengths of hose, etc.)

to be an even more efficient tool.

Important Safety Instructions

Save these instructions.

This manual contains information that is

very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger

indicates

an imminently hazardous situation

which, if not avoided, WILL result in

death or serious injury.

Warning

indicates

a potentially hazardous situation

which, if not avoided, COULD result in

death or serious injury.

Caution

indicates a

potentially hazardous situation which, if

not avoided, MAY result in minor or

moderate injury.

Notice

indicates

important information, that if not

followed, may cause damage to

equipment.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make

sure to tighten fittings, bolts, etc.,

before putting unit into service.

Do not

operate

unit if damaged during shipping,

handling or use. Damage may result in

bursting and cause injury or property

damage.

General Safety Information

1. To reduce the risk of fire

or explosion, electrical

shock, and injury to

persons, read and

understand all

instructions included with this

product. Be familiar with the controls

and the proper use of the

equipment.

2. This product should be grounded.

Follow all grounding instructions

included with your sprayer (pump).

To reduce risk of fire or

explosion:

1. Do not spray flammable or

combustible materials near an open

flame or sources of ignition such as

cigarettes, motors, and electrical

equipment.

2. Paint or solvent flowing through the

equipment is able to result in static

electricity. Static electricity creates a

risk of fire or explosion in the

presence of paint or solvent fumes. All

parts of the spray system, including

the pump, hose assembly, spray gun,

and objects in and around the spray

area shall be properly grounded to

protect against static discharge and

sparks. Use only conductive or

grounded high-pressure airless paint

sprayer hoses specified by the

manufacturer.

3. Verify that all containers and

collection systems are grounded to

prevent static discharge.

4. Connect your sprayer to a grounded

outlet and use grounded extension

cords. Do not use a 3 prong to 2

prong adapter.

5. Do not use paints or solvents

containing halogenated

hydrocarbons such as methyl

bromine, carbon tetrachloride, and

ethyl iodine.

6. Keep spray area well ventilated.

Keep a good supply of fresh air

moving through the spray area.

7. Do not smoke or eat in the spray

area.

8. Do not operate light switches,

engines, or similar spark producing

products in the spray area.

9. Keep area clean and free of paint

or solvent containers, rags, and

other flammable materials.

10. Know the contents of the paints

and solvents being sprayed. Read all

Material Safety Data Sheets (MSDS)

and container labels provided with

the paints and solvents. Follow the

paint and solvent manufacturer’s

safety instructions.

11. Do not use materials with a flash

point less than 20°C (70°F) in or to

clean this equipment. (Examples of

acceptable cleaning solvents are:

water, mineral spirits, lacquer

thinner, Xylene and high flash

naphtha. A PARTIAL example list of

unacceptable cleaning solvents are

low flash naphtha, mek, acetone,

alcohol, toluene and fuels of any

kind.

12. Have fire extinguisher equipment

present and working.

To reduce the risk of

skin injection:

1. Do not aim the gun

at, or spray, any

person or animal.

2. Keep hands and other body parts

away from the discharge. For

example, do not try to stop leaks

with any part of the body.

3. Always use the nozzle tip guard. Do

not spray without nozzle tip guard

in place.

4. Do not remove tip while cleaning

the pump.

5. Only use a nozzle tip specified by

the manufacturer.

6. Use caution when cleaning and

changing nozzle tips. Before

removing the nozzle tip, follow the

manufacturer’s instructions for

turning off the unit and relieving

the pressure.

7. Do not leave the unit energized or

under pressure while unattended.

When not in use turn off the unit

and relieve the pressure in

accordance with the manufacturer’s

instructions.

8. High pressure spray is able to inject

toxins into the body and cause

serious bodily injury. In the event

that injection occurs, seek medical

attention immediately.

9. Check parts for signs of damage.

Replace any damaged parts.

10. This spray gun is rated for 3000 psi

(205 bar). Do not use on systems

designed to produce more than

3000 psi (205 bar).

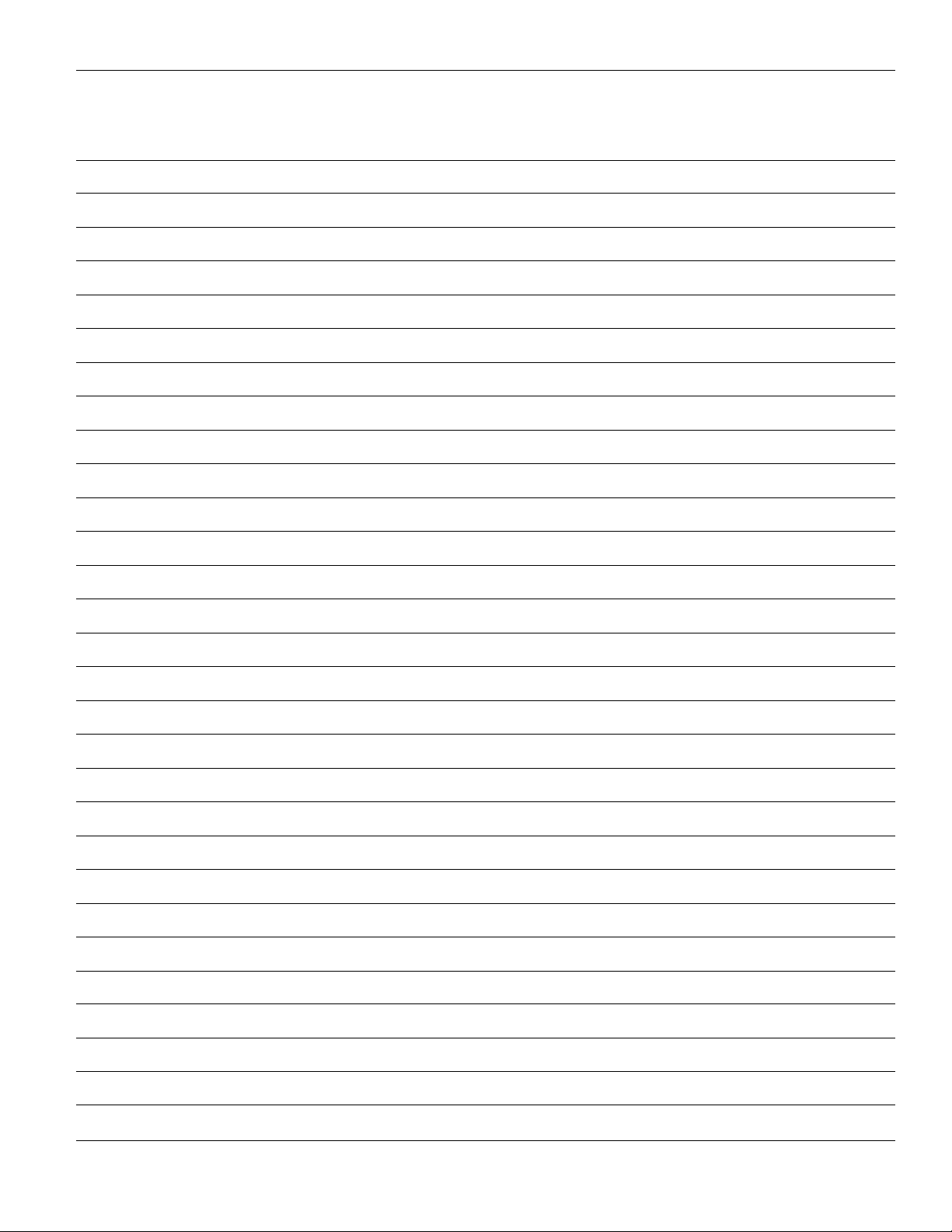

11. Always engage the trigger lock

when not spraying. Verify the

trigger lock is functioning properly.

• To lock (engage): rotate tabs on

lock to horizontal position.

• To unlock (disengage) to spray:

rotate tabs on lock to vertical position.

MANUAL

www.chpower.com

Page 3

Spray Guns for Airless Paint Sprayers

3

General Safety Information

(Cont.)

NOTE: If gun sprays while in the locked

position follow instructions in

Maintenance section for trigger lock.

12. Verify that all connections are

secure before operating. Do not use

pliers to tighten or loosen high

pressure connections.

13. Know how to stop your unit and

bleed pressure quickly. Be

thoroughly familiar with the

controls.

To reduce the risk of injury:

1. Do not spray acids,

corrosive materials, toxic

chemicals, fertilizers, or pesticides.

Using these materials could result

in death or serious injury.

2. Always wear appropriate gloves,

eye protection, and a respirator or

mask when painting.

3. Always work in a clean

environment. Do not aim the spray

gun at any dust or debris.

4. Do not operate or spray near

children. Keep children, pets, and

visitors away from equipment and

work area at all times.

5. Do not over reach or stand on an

unstable support. Keep effective

footing and balance at all times.

6. Stay alert and watch what you are

doing.

7. Do not operate the equipment

when fatigued or under the

influence of drugs or alcohol.

Preparation

Airless painting systems, unlike most

other power tools, require additional

care to ensure proper working order.

CONSULT YOUR AIRLESS PAINT

SPRAYER OWNER'S MANUAL FOR

OPERATING INSTRUCTIONS.

Spraying Instructions

Professional looking results can be

obtained by following the spray tips

below.

1. Keep the gun perpendicular to the

surface.

Always hold the gun perpendicular

to the surface with the tip

approximately 12” from the surface.

If held at an angle (up and down or

side to side), paint will build up

unevenly, leave the work splotchy,

and cause excessive overspray (See

Figure 1).

2. Move with a smooth arm stroke

Move the gun at a steady, even

pace while keeping the gun

perpendicular to the surface (See

Figures 1 & 2). Do not fan the gun.

Fanning the gun will cause excessive

overspray and uneven coverage

(See Figure 2).

3. Start moving the gun before triggering

To get a smooth overlap and

prevent initial paint buildup, start

your stroke movement before

pulling the trigger. Release the

trigger before stopping at the end

of the stroke (See Figure 3).

NOTE: To assure uniform paint coverage,

overlap each stroke by 20% - 30% and

use two coats with a cross pattern (one

coat horizontal, second coat vertical).

HOW TO CHANGE SPRAY TIPS:

It may be necessary to change spray

tips during a paint job. Follow these

steps for safe, easy tip changes.

1. Depressurize and turn off unit per

manufacturer’s instructions.

2. Engage gun trigger lock.

3. Pull red tip insert

out of spray base

and replace with

different tip, fully

inserting tip into base.

HOW TO ATTACH ROLLER

ACCESSORY:

1. Depressurize and turn off unit per

manufacturer’s instructions.

2. Engage gun trigger lock.

3. Remove spray base, tip, seal and

washer assembly.

4. Attach roller

accessory

(AL2275

shown) to

airless spray

gun. If needed

use thread adapter and washer

between roller and spray gun as

shown.

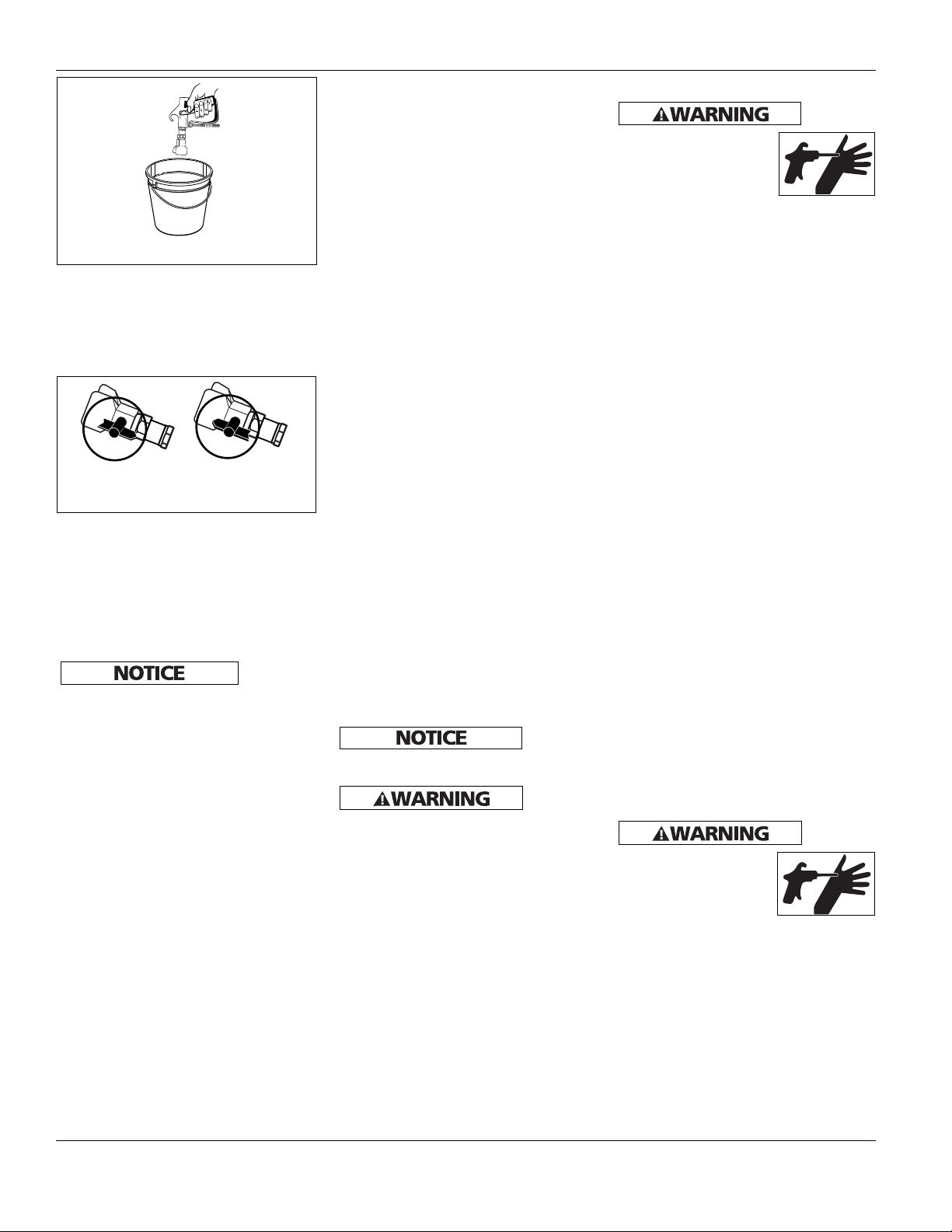

INTERMITTENT USE

If you are spraying and decide to stop

for several minutes, lock the spray gun

trigger and submerge the tip in a

container of suitable solvent (See Figure

4). This will prevent paint from

hardening in the tiny spray opening and

clogging the tip. Be sure to release

the pressure in the system and turn

the unit off according to the

manufacturer’s instructions.

12”

Figure 1 - Holding the Spray Gun

Approx.

10-12”

Start

Stroke

Pull

Trigger

Release

Trigger

End

Stroke

Figure 3 - Proper Way to Trigger

Spray Gun

Thin Coat

Thin Coat

Heavy

Coat

Overspray

Overspray

Figure 2 - Result of Flexing Wrist

While Spraying

INCORRECT

www.chpower.com

FAILURE TO FOLLOW

THESE INSTRUCTIONS

CAN RESULT IN SERIOUS

INJURY INCLUDING

DEATH.

Page 4

Spraying Instructions (Cont.)

CLEARING CLOGS

REVERSIBLE TIP: (Included)

1. Rotate the tip to the clean position

(See Figure 5).

2. Point gun in a safe direction and spray.

This should clear tip of any blockage.

3. Rotate the tip back to the spray

position and continue spraying (See

Fig. 5).

4. If clogging continues, replace gun filter

and consider straining the paint prior

to use.

Equipment

damage

can occur if a needle or sharp object is

used to clean the tip. Tungsten carbide

is brittle and can be chipped.

FIXED TIP:

1. Depressurize and turn off the unit

per manufacturer’s instructions.

2. Lock gun trigger.

3. Remove tip and tip guard from the gun.

4. Soak tip in water or appropriate

solvent and brush away old paint or

impurities with a toothbrush until

the tip orifice has been cleared.

ADJUSTABLE TIP:

1. Turn adjustment knob fully

counterclockwise to open tip to

largest spray pattern.

2. Pull trigger and spray into a bucket

or container. This should clear the tip

of any blockage.

3. If clogging continues, replace gun

filter and consider straining the paint

prior to use.

CLEANING YOUR GUN: Follow

cleaning, use and maintenance

instructions included with your paint

sprayer. After flushing the pump and

when finishing:

1. Rotate Spray Tip to the cleaning

position.

2. Release Trigger Lock.

3. Point Spray Gun into an empty waste

bucket and pull the Trigger. Spray at

least 1 gallon of fluid into waste

bucket. To reduce splashing, direct

the fluid stream along the inside of

the bucket and well above the fluid

level.

REFER TO PAINT SPRAYER SHUTDOWN PROCEDURES.

4. Depressurize and turn off sprayer per

manufacturer’s instructions.

5. With the gun pointed in a safe

direction, pull the gun trigger with

the trigger lock disengaged to ensure

system is depressurized.

6. Engage Trigger Lock.

7. At this point the pump and spray gun

are clean, but still require

preparation for storage. Spray Tip

Guard or any accessory being used

still require cleaning.

CLEANING SPRAY TIP GUARD:

1. Remove Spray Tip with 1” or

adjustable wrench.

2. Clean Tip Guard with a cleaning

brush.

Maintenance

Pump

damage

may occur if these instructions are not

followed.

Before

performing any maintenance, make

sure to relieve pressure from system

and disconnect power from sprayer.

• Do not use oil based solvents to

clean equipment after using latex

based coatings. Use only warm

soapy water.

• Always replace clogged gun filters,

do not attempt to clean them.

• Carefully follow cleaning and

storage instructions for your

sprayer.

• Do not use metal or other hard

objects to pick dried paint material

from Spray Tip Orifice.

TRIGGER LOCK

Pulling the trigger must

not open the gun valve

when trigger lock is

activated.

You should be able to get the actuator

to wiggle slightly with your finger

while holding the trigger against the

trigger lock when it is in the locked

position. If you cannot, adjust the

trigger position by following these

instructions:

1. Place trigger in locked orientation

(tabs horizontal).

2. With one hand holding trigger

lightly against lock, use a 1/4” nut

driver to turn nut in until trigger

starts to come off the lock.

3. Reverse the nut (counterclockwise)

1/2 turn.

TIP SEAL AND WASHER

Occasionally, you will need to replace

the silver seal and black washer located

inside the tip base.

1. To replace seal and washer, first

loosen tip base with adjustable

wrench, and then remove by hand.

2. Remove spray tip.

3. With Phillips screwdriver, push seal

and washer out from front of tip

base.

4. With flat side of seal facing up,

place seal in base. Make sure it lines

up properly with base.

5. Place washer in base. Make sure it

lines up properly with base.

6. Put spray tip back in tip base.

7. Reattach tip base to gun valve.

Make sure spray tip and

tip base fit snugly in

place. A loose fit can

lead to misdirected

spray discharge and a

skin injection hazard.

CLEAN

SPRAY

Figure 5 - Clean and Spray Position

SOLVENT

Figure 4 - Prevent Clogged Tip

4

Operating Instructions and Replacement Parts List

www.chpower.com

Page 5

Spray Guns for Airless Paint Sprayers

5

www.chpower.com

Notes

Page 6

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: All Paint Application Accessories - 1 year.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld/A Scott Fetzer Company, 100 Production Drive, Harrison,

Ohio, 45030, Telephone: 1-800-626-4401.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale or rental) of the

Campbell Hausfeld Product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: All non-compressor driven paint application systems, HVLP spraying

systems, and paint application accessories supplied or manufactured by the Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects in material and workmanship which occur within the duration of the

warranty period. Warrantor will also cover normal wear items for a period of thirty days from the date of original purchase

against defects in material and workmanship. These wear items are: HVLP-filters, motor brushes, gun packing, gun canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and o-rings.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If standard duty product is used for commercial or

industrial purposes, the warranty will apply for ninety (90) days from the date of original purchase. If product is used

for rental purposes, the warranty will apply for ninety (90) days from the date of original purchase. Some states do not

allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE , OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with

instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser’s abuse, neglect or failure to

operate products in accordance with instructions shall also include the removal or alteration of any safety devices. If

such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E. Items or services that are normally required to maintain the product: HVLP-filters, motor brushes, gun packing, gun

canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and

o-rings., or any other expendable part not specifically listed, will only be covered for thirty days from date of original

purchase.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service

Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be

scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have

other rights which vary from state to state, or country to country.

6

Operating Instructions and Replacement Parts List

www.chpower.com

Page 7

Pistolets Vaporisateurs pour

Pulvérisateurs de Peinture Sans Air

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

Instructions d’Utilisation et Liste de Pièces de Rechange

IN424400AV 3/10© 2010 Campbell Hausfeld/Scott Fetzer

Pour Pièces de Rechange et Accessoires, Contacter Votre Centre de Service ou

Appeler 1-800-626-4401

1 Trousse, prise gauche du pistolet,

verrou et dispositif de protection AL184401SV 1

2 Trousse, prise gauche du pistolet Pro Gun,

verrou et dispositif de protection AL184400SV 1

3 Garniture, pistolet AL179801AV 1

4 Trousse, tige et diffuseur (inclut #7) AL179802AG 1

5 Ressort, pistolet AL048600AV 1

6 Fixation, ressort de pistolet AL020201AV 1

7 Joint d'étanchéité, pistolet AL020300AV 1

8 Rondelle, joint d'étanchéité AL153801AV 1

9 Rondelle, fixation du siège du pistolet AL005404AV 1

10 Trousse, joint d'étanchéité du pistolet

(inclut #7, #8, #9) AL183600SV

11 Goupille, activateur de pistolet AL024102AV 2

12 Activateur, pistolet AL182700AV 1

13 Écrou, verrou hex #5-40 ST073804AV 1

14 Trousse, gâchette de pistolet (pistolet, vis)AL183100SV

15 Filtres de pistolet,

100 mèches ((jaune) AL086101AJ2 pqt

50 mèches (blanc) AL086100AJ2 pqt

16 Rondelle, long filtre MJ105402AV 1

17 Adaptateur, long filtre AL072301AV 1

18 Assemblage, pivot Pro Gun (optionnel) AL183500AJ 1

19 Dispositif de protection, gâchette

Pro Gun AL184600AV 1

20 Joint torique MJ106511AV 1

21 Vis, #5-40 x 5/16 po SHC MJ103804AV 4

22 Prise, droite, Pro Gun AL184302AV 1

23 Prise, côté à gauche, pistolet noir AL184301AV 1

Autres articles disponibles :

Trousse, soupape de pistolet -

Inclut #4 - #9, #13 AL183200SV

Trousse, activateur de pistolet -

Inclut #11, #12, #13 AL183700SV

Trousse, garniture Pro Gun -

Inclut #3 - #9, #16 AL184100SV

Trousse, prise complète Pro Gun -

Inclut #2, #19 - #22 AL184500SV

Liste de Pièces de Rechange

Nº de Numéro

Réf. Description de Pièce Qté.

3

11

(2x)

14 (2x)

21 (4x)

12

13

22

16

15

18

14

19

4

5

6

7

8

9

2

20

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Voir la Garantie à la page 12 pour de l’information importante sur l’utilisation commercial de ce produit.

3

11

(2x)

14 (2x)

21 (4x)

12

13

23

16

15

17

14

19

4

5

6

7

8

9

1

20

AL2150 - NOIR

Correspondance:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

S’il vous plaît fournir l’information suivante:

- Numéro de modèle

- Numéro de série

- Description et numéro de la pièce

Nº de Numéro

Réf. Description de Pièce Qté.

AL1860 - METAL

7Fr

Page 8

8Fr

Instructions d’Utilisation et Liste de Pièces de Rechange

Description

Les pulvérisateurs de peinture sans air

peuvent pulvériser une variété de

peintures latex, à base d’huile et alkyd,

ainsi que les teintures, préservatifs et

autres finis non-abrasifs. Les

pulvérisateurs sont aussi assez puissants

et polyvalents pour utiliser avec un

assortiment d’accessoires (rouleaux, et

prolongements extra de tuyaux, etc.).

Importantes instructions

de sécurité

Conserver ces instructions

Ce manuel contient de l’information

très importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT.

Rechercher les symboles suivants pour

cette information.

Danger

indique

une situation hasardeuse imminente

qui RÉSULTERA en perte de vie ou

blessures graves.

Avertissement indique une situation

hasardeuse potentielle qui PEUT

résulter en perte de vie ou blessures

graves.

Attention

indique

une situation hasardeuse potentielle

qui PEUT résulter en blessures.

Avis

indique

l’information importante pour éviter le

dommage de l’équipement.

Déballage

Lors du déballage, l’examiner

soigneusement pour rechercher toute

trace de dommage susceptible de s’être

produit en cours de transport. Serrer

tous raccords, boulons, etc., avant

d’utiliser le modèle.

Ne pas

faire

fonctionner un modèle qui a été

endommagé pendant le transport, la

manipulation ou l’utilisation. Le

dommage peut résulter en éclatement

et peut causer des blessures ou dégâts

matériels.

Généralités Sur La Sécurité

1. Pour réduire les risques

d'incendie ou d'explosion,

de chocs électriques et de

blessures, lire et

comprendre toutes les

instructions incluses avec ce produit.

Se familiariser avec les contrôles et la

bonne utilisation de l'équipement.

2. Ce produit doit être mis à la terre.

Suivre toutes les instructions de mise

à la terre incluses avec votre

pulvérisateur (pompe).

Pour réduire les risques

d’incendie ou d’explosion:

1. Ne pas pulvériser de matériaux

combustibles ou inflammables près

de flammes nues ou de sources

d'incendie telles que cigarettes,

moteurs et équipement électrique.

2. La peinture et les solvants qui

circulent dans l'équipement

peuvent créer de l'électricité

statique. Cette électricité crée à son

tour un risque d'incendie ou

d'explosion en présence de fumées

de peinture ou de solvants. Toutes

les pièces du système de

pulvérisation, y compris la pompe,

l'assemblage du boyau, le pistolet

de pulvérisation et les objets

entourant la région de

pulvérisation doivent être bien mis

à la terre pour se protéger contre

les étincelles et les décharges

statiques. Utiliser seulement des

tuyaux de pulvérisateurs de

peinture sans air haute pression mis

à la terre ou conducteurs spécifiés

par le fabricant.

3. Vérifier que tous les contenants et

systèmes de cueillette sont mis à la

terre pour éviter toute décharge

statique.

4. Connecter votre pulvérisateur à une

prise mise à la terre et utiliser des

rallonges mises à la terre. Ne pas

utiliser d'adaptateur à 2 fiches à 3

fiches.

5. Ne pas utiliser de peintures ou de

solvants contenant des

hydrocarbures halogénés tels que le

brome de méthyle, le tétrachlorure

de carbone et l'iode d'éthyle.

6. Garder l'endroit de la pulvérisation

bien ventilé. Faire circuler de l'air

frais dans cet endroit.

7. Ne pas fumer ni manger dans

l'endroit de pulvérisation.

8. Ne pas faire fonctionner

d'interrupteurs, de moteurs ou

autres produits produisant des

étincelles dans le secteur de

pulvérisation.

9. Garder l'endroit propre et libre de

contenants de peinture ou de

solvants, de chiffons et autres

matériaux inflammables.

10. Il faut connaître le contenu des

peintures et des solvants pulvérisés.

Lire les fiches signalétiques de

sécurité des produits (FSSP) et les

étiquettes des contenants de

peintures et de solvants. Suivre les

instructions de sécurité du fabricant

de peintures et de solvants.

11. Ne pas utiliser de matériaux avec un

point d'éclair de moins de 20 °C (70

°F) dans ou pour nettoyer cet

équipement. (Exemples de solvants

de nettoyage acceptables : eau,

essence minérale, diluant de laque,

xylène et naphte lourd. Voici une

liste PARTIELLE d'exemples de

solvants de nettoyage inacceptables

: naphte à point d'éclair bas,

méthyléthylcétone, acétone, alcool,

toluène et carburants de toute

sorte.

12. Avoir sur place de l'équipement

d'extinction et en état de

fonctionner.

Pour réduire les risques d’injection dans

la peau.

1. Ne pas pointer le

pistolet ou le

pulvérisateur vers

toute personne ou animal.

2. Garder les mains et autres parties

du corps loin de la décharge. Par

exemple, ne pas essayer d'arrêter

les fuites avec toute partie du corps.

3. Toujours utiliser un embout

protecteur de la buse. Ne pas

pulvériser sans avoir l'embout

protecteur de buse en place.

4. Ne pas retirer la buse en nettoyant

la pompe.

5. Utiliser seulement la buse spécifiée

par le fabricant.

6. Prudence pour le nettoyage et le

changement de buses. Avant de

retirer la buse, suivre les instructions

du fabricant pour mettre l'appareil

hors tension et dégager la pression.

7. Ne pas laisser l'appareil sous tension

ou sous pression sans supervision.

Lorsque l'appareil n'est pas utilisé,

le mettre hors tension et retirer la

pression conformément aux

instructions du fabricant.

8. La pression haute pression peut

injecter des toxines dans le corps et

provoquer de graves blessures. S'il y

a injection, consulter

immédiatement un médecin.

MANUEL

Page 9

Pistolets Vaporisateurs pour Pulvérisateurs de Peinture Sans Air

9Fr

Généralités Sur La Sécurité

(Suite)

9. Vérifier les pièces pour tout signe

de dommage. Remplacer toutes les

pièces endommagées.

10. Ce pistolet pulvérisateur est d'une

valeur nominale de 3 000 lb/po_

(205 bar). Ne pas utiliser de

systèmes conçus pour produire plus

de 3 000 lb/po_ (205 bar).

11. Toujours engager le verrou de la

gâchette lorsqu'on ne pulvérise pas.

Vérifier que le verrou fonctionne

correctement.

• Pour verrouiller (engager) :

tourner les languettes de

verrouillage en position

horizontale.

•Pour déverrouiller (désengager)

pour pulvériser : tourner les

languettes de verrouillage en

position verticale.

NOTE: Si le pistolet pulvérise en

position verrouillée, suivre les

instructions sous la section d'entretien

pour le verrouillage de gâchette.

12. Vérifier que toutes les connexions

sont bien en place avant de faire

fonctionner. Ne pas utiliser de

pinces pour resserrer ou desserrer

les connexions à haute pression.

13. Il faut savoir comment arrêter

l'appareil et purger la pression

rapidement. Il faut aussi connaître

les commandes.

Pour réduire les risques de

blessures :

1. Ne pas pulvériser

d'acides, de matières corrosives, de

produits chimiques toxiques, de

fertilisants ni de pesticides. Le fait

d’utiliser ces produits pourraient

causer la mort ou de graves

blessures.

2. Toujours porter des gants

appropriés, une protection pour les

yeux et un respirateur ou un

masque pendant la peinture.

3. Toujours travailler dans un

environnement propre. Ne pas

pointer le pulvérisateur vers toute

poussière ou débris.

4. Ne pas faire fonctionner près

d'enfants. Garder les enfants, les

animaux domestiques et les

visiteurs loin de l’équipement et du

secteur de travail en tout temps.

5. Ne pas se pencher ou se tenir

debout sur un support instable.

Garder les pieds bien au sol et un

bon équilibre en tout temps.

6. Il faut être vigilant et savoir ce

qu'on fait.

7. Ne pas faire fonctionner

l'équipement fatigué ou sous

l’influence de drogues ou d’alcool.

Préparation

Les systèmes de peinture sans air exigent

un entretien additionnel par rapport à la

plupart d’outils pour assurer le bon

fonctionnement.

CONSULTER LE MANUEL

D’UTILISATION DU PULVÉRISATEUR

DE PEINTURE SANS AIR POUR LES

INSTRUCTIONS D’OPÉRATION.

Instructions de Pulvérisation

Vous pouvez obtenir un résultat

Professionnel en suivant les conseils

cidessous.

1. Garder le pistolet perpendiculaire à

la surface.

Toujours tenir le pistolet

perpendiculaire à la surface avec la

buse approximativement 30,48 cm

(12 po) de la surface. Si vous tenez le

pistolet à un angle (du haut en bas

ou d’un côté à l’autre), la peinture

s’accumulera de manière inégale,

laissera des taches et causera la

surpulvérisation excessive (Voir

Figure 1).

2. Diriger le pistolet avec un coup de

bras régulier

Diriger le pistolet à une allure

modérée et égale avec le pistolet

perpendiculaire à la surface (Voir

Figures 1 & 2). Ne pas vanner le

pistolet car ceci causera la

surpulvérisation excessive et

l’application inégale (Voir Figure 2).

3. Commencer le déplacement du

pistolet avant de tirer sur la gâchette

Pour un recouvrement lisse sans

accumulation de peinture,

commencer le coup avant de tirer sur

la gâchette. Lâcher la gâchette avant

d’arrêter à la fin du parcours (Voir

Figure 3).

REMARQUE: Pour assurer un

recouvrement de peinture uniforme,

chevaucher chaque coup par 20% - 30%

et enduire deux fois avec une

configuration de croix (une horizontale,

la deuxième verticale).

30,5 cm

Figure 1 - La tenue du Pistolet

Vaporisateur

Approx. 25,4

à 30,5 cm

Commencer

le coup

Tirer la

Gâchette

Lâcher la

Gâchette

Fin du

coup

Figure 3 - La méthode de

pulvérisation correcte

Enduit

mince

Enduit

mince

Enduit

épais

Surpulvérisation

Surpul-

vérisation

Figure 2 - Résultat d’un poignet

fléchi pendant la pulvérisation

INCORRECT

NE PAS SUIVRE CES

INSTRUCTIONS PEUT

RÉSULTER EN BLESSURES

GRAVES, Y COMPRIS LA

MORT.

Page 10

10 Fr

Instructions d’Utilisation et Liste de Pièces de Rechange

Instructions de Pulvérisation

(Suite)

COMMENT CHANGER LES BUSES DE

PULVÉRISATION :

Il faudra peut-être changer les buses

durant un travail de peinture. Suivre

ces étapes pour des changements sans

danger et faciles de la buse.

1. Dépressuriser et mettre l'appareil

hors tension selon les instructions

du fabricant.

2. Engager le verrou de la gâchette du

pistolet.

3. Tirer la garniture

de la buse rouge

de la base de

pulvérisation et

remplacer avec une

buse différente

l'insérant complètement dans la

base.

COMMENT FIXER LE ROULEAU

ACCESSOIRE :

1. Dépressuriser et mettre l'appareil

hors tension selon les instructions

du fabricant.

2. Engager le verrou de la gâchette du

pistolet.

3. Retirer la buse de pulvérisation, la

buse, le joint et la rondelle.

4. Fixer le

rouleau

(AL2275

illustré) au

pulvérisateur

sans air. Au

besoin, utiliser un adaptateur fileté

et une rondelle entre le rouleau et

le pistolet de pulvérisation tel

qu'illustré.

USAGE INTERMITTENT

Si vous arrêtez de pulvériser pendant

plusieurs minutes, verouiller la gâchette

du pistolet et immerger la buse dans une

boîte de dissolvant convenable (Voir

Figure 4). Ceci empêchera que la

peinture durçisse dans l’ouverture et

bouche la buse. S’assurer de dissiper

la pression en tournant le bouton de

dérivation à la position d’amorçage

et en mettant la pompe hors circuit.

DÉBLOCAGE

BUSE RÉVERSIBLE: (Comprise)

1. Tourner la buse à la position de

nettoyage (Voir Figure 5).

2. Diriger le pistolet dans une direction

sûre et pulvériser. Ceci devrait

débloquer la buse.

3. Tourner la buse à la position de

pulvérisation et continuer la

pulvérisation (Voir Fig. 5).

4. Si le blocage continue, remplacer le

filtre du pistolet et considérer filtrer

la peinture avant de l'utiliser.

N’utilisez

pas une

aiguille ni un objet pointu pour le

nettoyage de la buse. Ceci peut

endommager l’équipement. Les buses

en carbure de tungstène sont fragiles

et peuvent s’ébrécher.

BUSE FIXE:

1. Dépressuriser et mettre l'appareil

hors tension selon les instructions du

fabricant

2. Verouiller la gâchette du pistolet.

3. Enlever la buse et le protecteur de

buse du pistolet.

4. Faire tremper la buse dans l’eau ou

dans un dissolvant convenable et la

brosser avec une brosse à dents afin

d’enlever la peinture ou impuretés

du bout de la buse.

BUSE RÉGLABLE:

1. Tourner le bouton de réglage

complètement dans le sens contraire

des aiguilles d’une montre afin

d’ouvrir la buse à sa configuration la

plus large.

2. Tirer la gâchette et pulvériser dans

un seau ou dans un récipient pour

débloquer la buse.

3. Si le blocage continue, remplacer le

filtre du pistolet et considérer filtrer

la peinture avant de l'utiliser.

NETTOYER LE PISTOLET : Suivre les

instructions de nettoyage, d'utilisation

et d'entretien incluses avec votre

pulvérisateur. Après avoir vidangé la

pompe et avant de terminer :

1. Tourner la buse en position de

nettoyage.

2. Dégager le verrou de la gâchette.

3. Pointer le pistolet de pulvérisation

vers un seau vide et tirer la gâchette.

Pulvériser au moins 1 gallon de

liquide dans un seau. Pour réduire les

éclaboussures, diriger le jet le long

du seau et bien au-dessus du liquide.

CONSULTER LES PROCÉDURES

D’ARRÊT DU PULVÉRISATEUR

4. Dépressuriser et mettre l'appareil

hors tension selon les instructions du

fabricant.

5. Pointer le pistolet dans une direction

sans danger, tirer la gâchette avec

son verrou désengagé pour s'assurer

que le système est dépressurisé.

6. Engager le verrou de la gâchette

7. À ce moment, la pompe et le pistolet

de pulvérisation sont propres, mais

doivent être préparés pour leur

entreposage. L'embout protecteur ou

tout accessoire utilisé doit être nettoyé.

NETTOYAGE DU PROTECTEUR DE

BUSE:

1. Enlever la buse avec une clé de 25,40

mm (1 po) ou une clé à ouverture

variable.

2. Nettoyer le protecteur de buse avec

une brosse.

Entretien

Manque

de suivre

ces instructions peut causer du

dommage à la pompe.

Avant

tout

entretien s’assurer de dégager la

pression du système et couper le

courant au pulvérisateur..

• Ne pas utiliser de dissolvants à base

d’huile pour le nettoyage d’équipement

après l’usage d’enduits latex. Utilisez

l’eau tiède savonneuse seulement.

• Toujours remplacer les filtres de

pistolet obstrués, ne pas essayer de

les nettoyer.

• Suivre attentivement les instructons

de nettoyage et d'entreposage.

• N'utilisez pas d'objets en métal ou durs

pour l'enlevage de matériel dans

l'orifice de buse de pulvérisation.

SOLVENT

Figure 4 - Empêcher une buse obstruée

Dissolvant

NETTOYER

PULVÉRISER

Figure 5 - Position de nettoyage et de

pulvérisation

Page 11

Pistolets Vaporisateurs pour Pulvérisateurs de Peinture Sans Air

11 Fr

Entretien (Suite)

VERROU DE LA GÂCHETTE

En tirant la gâchette

cela ne doit pas

ouvrir la soupape du

pistolet lorsque le

verrou est activé

On devrait pouvoir faire bouger un peu

l'atomisateur avec le doit tout en

tenant la gâchette contre le verrou en

position fermé. Si l'on ne peut pas, il

faut ajuster la position de la gâchette

selon ce qui suit :

1. Placer la gâchette en position

verrouillée (languettes

horizontales).

2. D'une main, tenir la gâchette un

peu contre le verrou et utiliser un

tourne-écrou de 1/4 po pour

tourner l'écrou jusqu'à ce que la

gâchette commence à sortir du

verrou.

3. Inverser l'écrou d'un demi-tour

(dans le sens contraire des aiguilles

d'une montre).

JOINT DE BUSE ET RONDELLE

À l'occasion, l'on doit remplacer le joint

d'argent et la rondelle noire à

l'intérieur de la base de la buse.

1. Pour remplacer le joint et la

rondelle, desserrer d'abord la base

de la buse avec une clé à ouverture

réglable, puis retirer à la main.

2. Retirer la buse de pulvérisation.

3. Avec un tournevis Phillips, pousser

le joint et la rondelle pour les sortir

de la base de la buse.

4. Avec le côté plat du joint vers le

haut, placer le joint sur la base.

S'assurer que le tout s'aligne avec la

base.

5. Placer la rondelle sur la base.

S'assurer que le tout s'aligne avec la

base.

6. Remettre la buse de pulvérisation

dans la base de la buse.

7. Rattacher la base à la soupape du

pistolet.

S'assurer que la

buse de

pulvérisation et la

base s'installe bien

en place. Un raccord

desserré peut mener à une mauvaise

décharge et à un danger d'injection

dans la peau.

Notes

Page 12

12 Fr

Instructions d’Utilisation et Liste de Pièces de Rechange

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Tous les Accessoires pour Application de Peinture - 1 An.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive, Harrison, Ohio,

45030, Téléphone: (800) 626-4401

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente ou de location) du produit

Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Tous les systèmes pour application de peinture qui ne sont pas actionnés par

un compresseur d’air, systèmes HVLP (haut volume, basse pression), et accessoires pour application de peinture qui sont

fournis par ou fabriqués par le Garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication qui se révèlent pendant la période de

validité de la garantie. Le garant couvert aussi les articles d’usure normal contre les défauts de matière et de fabricatin

pendant trente jours à partir de la date d’achat. Les articles d’usure normal sont: les filtres HVLP, les balais de moteur, les

garnitures de pistolets, le joint de la boîte du pistolet, le clapet du pistolet, et la bague de circulation d’air du pistolet;

soupape d’arrivée sans air, soupape de sortie, soupape de pistolet, filtres, buses tous les joints et joints toriques.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTICULIÈRE SONT

LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION DURÉE. Si le produit Service

Standard est utilisé pour une fonction commerciale ou industrielle, la durée de la garantie sera quatre-vingt-dix (90) jours

à compté de la date d’achat. Si le produit est utilisé pour la location, la durée de la garantie sera quatre-vingt-dix jours

(90) à compté de la date d’achat. Quelques Provinces (États) n’autorisent pas de limitations de durée pour les garanties

implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE OU

MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États) n’autorisent pas

l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou exclusion précédente peut donc ne pas

s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne respectant pas les

instructions données dans le(s) manuel(s) accompagnant le produit. Un accident, l’utilisation abusive par l’acheteur, la

négligence ou le manque de faire fonctionner les produits selon les instructions comprend aussi l’enlevage ou la

modification de n’importe quel appareil de sûreté. Si ces appareils de sûreté sont enlevés ou modifiés, la garantie sera

annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le produit.

E. Articles ou services qui sont exigés pour l’entretien du produit; filtres HVLP, balais de moteur, joint de boîte de pistolet,

clapet de pistolet et bague de circulation d’air du pistolet; Soupape d’arrivée sans air, soupape de sortie, soupape de

pistolet, filtres, buses, tous les joints et les joints toriques, ou n’importe quelle pièce qui n’est pas indispensable et n’est

pas spécifiée seront couverts pendant seulement trente (30) jours à partir de la date d’achat original.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix du Garant, des

produits ou pièces qui se sont révélés défectueux, qui se sont tombés en panne et/ou qui n’a pas conformé pendant la durée

de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Livraison ou expédition du produit ou de la pièce Campbell Hausfeld au Centre De Service Autorisé Campbell Hausfeld.

Taux de frais, si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE: La réparation ou

le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de service et dépendra de la

disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques précis.

L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

Page 13

Pistolas Para Rociadoras de

Pintura Sin Aire

Sírvase leer y guardar estas instrucciones. Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad. Guarde este manual como referencia.

Manual de Instrucciones y Lista de Repuestos

IN424400AV 3/10© 2010 Campbell Hausfeld/Scott Fetzer

Para Ordenar Repuestos y Accesorios, Comuníquese con el Distribuidor de

Productos Campbell Hausfeld más cercano a su domicilio

1 Juego, Mango derecho de la pistola de negro,

seguro y protección de pistola AL184401SV 1

2 Juego, Mango izq., seguro y

protección de pistola prof. AL184400SV 1

3 Inserción, Pistola AL179801AV 1

4 Juego, vástago y difusor (incluye #7) AL179802AG 1

5 Resorte, Pistola AL048600AV 1

6 Retén, Resorte de la pistola AL020201AV 1

7 Sello, Pistola AL020300AV 1

8 Arandela, Sello AL153801AV 1

9 Arandela, Retén asiento de la pistola AL005404AV 1

10 Juego, Sello de la pistola

(Incluye #7, #8, #9) AL183600SV 1

11 Pasador, Actuador de la pistola AL024102AV 2

12 Actuador, Pistola AL182700AV 1

13 Tuerca, #5-40 seguro hexagonal ST073804AV 1

14 Juego, gatillo de la pistola

(gatillo y tornillos) AL183100SV 1

15 Filtros de la pistola,

Malla 100 (amarilla) AL086101AJ 2 pk

Malla 50 (blanca) AL086100AJ 2 pk

16 Arandela, filtro largo MJ105402AV 1

17 Adaptador, filtro largo AL072301AV 1

18 Ensamblaje, conector giratorio de

la pistola prof. (opcional) AL183500AJ 1

19 Protección, Gatillo de la pistola prof. AL184600AV 1

20 Anillo en O MJ106511AV 1

21 Tornillo, #5-40 x 5/16" SHC MJ103804AV 4

22 Mango, derecho, pistola prof. AL184302AV 1

23 Mango, izquierdo, pistola negro AL184301AV 1

Artículos adicionales disponibles:

Juego, válvula de la pistola

Incluye #4 - #9, #13 AL183200SV

Juego, Actuador de la pistola

Incluye #11, #12, #13 AL183700SV

Juego, Inserto de la pistola prof.-

Incluye #3 – #9 y #16 AL184100SV

Juego, mango completo de la pistola prof.

Incluye #2, #19 - #22 AL184500SV

Lista de Repuestos

No. de Número del

Ref. Descripción Repuesto Ctd.

3

11

(2x)

14 (2x)

21 (4x)

12

13

22

16

15

18

14

19

4

5

6

7

8

9

2

20

Ver la Garantía en página 18 para información importante sobre el uso comercial de este producto.

3

11

(2x)

14 (2x)

21 (4x)

12

13

23

16

15

17

14

19

4

5

6

7

8

9

1

20

AL2150 - NEGRO

Puede escribirnos a:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Sírvase suministrarnos la siguiente información:

- Número del modelo

- Número de Serie (de haberlo)

- Descripción y número del repuesto según la lista de repuestos

No. de Número del

Ref. Descripción Repuesto Ctd.

AL1860 - METALICA

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

13 Sp

Page 14

14 Sp

Manual de Instrucciones y Lista de Repuestos

Descripción

Las rociadoras de pintura sin aire están

diseñadas para rociar una gran variedad de pinturas látex, a base de aceite

y alquidas, al igual que tinturas,

preservativos y otros materiales no

abrasivos. Estas rociadoras son

potentes y lo suficientemente versátiles

para permitirle usar una gran variedad

de accesorios (rodillos, mangueras más

largas, etc.) que le permiten aumentar

su eficacia.

Importantes instrucciones

de seguridad

Guarde estas instrucciones.

Este manual contiene información que

es muy importante que sepa y

comprenda. Esta información se la

suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le

indica

que hay una situación inmediata, que si

no la evita, LE OCASIONARIA la muerte

o heridas de gravedad.

Ésto le

indica

que hay una situación posiblemente

peligrosa, que si no la evita, PODRIA

ocasionarle la muerte o heridas de

gravedad.

Ésto le

indica

que hay una situación posiblemente

peligrosa, que si no la evita, PODRIA

ocasionarle heridas menores o moderadas

Ésto le

indica

una información importante, que de no

seguirla, le podría ocasionar daños al

equipo.

Para desempacar

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Igualmente,

cerciórese de apretar todos los pernos,

tuercas,conexiones, etc. antes de

usarlo.

No debe

utilizar la

unidad si se ha dañado durante el

envío, manejo o uso. Los daños podrían

ocasionar una explosión y ocasionarle

heridas o daños a su propiedad.

Informaciones Generales de

Seguridad

1. Para reducir el riesgo de

incendio o explosión,

choque eléctrico, y

lesiones a las personas,

lea y comprenda todas las

instrucciones que se incluyen con

este producto. Familiarícese con los

controles y el uso adecuado del

equipo.

2. Este producto debe estar conectado

a tierra. Siga todas las instrucciones

de conexión a tierra que se incluyen

con su pistola rociadora (bomba).

Para reducir el riesgo de

incendio o explosión:

1. No rocíe materiales inflamables ni

combustibles cerca de llamas o

fuentes de ignición como por ejemplo

cigarrillos, motores y equipo eléctrico.

2. La pintura o el solvente que fluye a

través del equipo es capaz de crear

electricidad estática. La electricidad

estática crea un riesgo de incendio o

explosión ante la presencia de

vapores de pintura o solvente. Todas

las piezas del sistema de rociado,

incluyendo la bomba, el ensamblaje

de la manguera, la pistola rociadora,

y los objetos dentro y alrededor del

área de rociado deben estar

conectados a tierra adecuadamente

para protegerlos contra descargas y

chispas de estática. Use sólo

mangueras de rociado de pintura sin

aire de alta presión que sean

conductoras o que estén conectadas

a tierra según las especificaciones del

fabricante.

3. Verifique que todos los recipientes y

sistemas de recolección estén

conectados a tierra para evitar

descargas de electricidad estática.

4. Conecte su rociadora a un

tomacorriente con conexión a tierra

y utilice cordones de extensión. No

utilice un adaptador de tres clavijas

para dos.

5. No use pinturas ni solventes que

contengan hidrocarburos

halogenados como por ejemplo

bromuro de metilo, tetracloruro de

carbono y yoduro de etilo.

6. Mantenga el área de rociado bien

ventilada. Mantenga un buen

suministro de corriente de aire fresco

en el área de rociado.

7. No fume ni coma en el área de

rociado.

8. No haga funcionar llaves de luz,

motores o productos similares que

produzcan chispas en el área de

rociado.

9. Mantenga el área limpia y libre de

recipientes de pintura o solvente,

trapos y otros materiales inflamables.

10.Conozca los componentes de las

pinturas y solventes que utiliza para

rociar. Lea las hojas de información

de seguridad sobre el material (MSDS

por su sigla en inglés) y las etiquetas

de los recipientes que se

proporcionan con las pinturas y los

solventes. Siga las instrucciones de

seguridad del fabricante de la

pintura y del solvente.

11.No utilice materiales con puntos de

inflamabilidad menores a 20°C (70°F)

en el equipo ni para limpiar el

mismo. (Ejemplos de solventes de

limpieza aceptables son: agua,

solventes minerales, solventes para

laca, xileno y nafta con alto punto de

inflamabilidad. Una lista de ejemplo

PARCIAL de los solventes de limpieza

no aceptables está compuesta por

nafta con bajo punto de

inflamabilidad, metil etil cetona

(MEK), acetona, alcohol, tolueno y

combustibles de cualquier tipo.

12.Mantenga en el lugar un equipo

extintor que funcione.

Para reducir el riesgo de

inyección en la piel:

1. No apunte la pistola a

ninguna persona o

animal ni lo rocíe.

2. Mantenga las manos y otras partes

del cuerpo alejadas de la descarga.

Por ejemplo, no intente detener las

pérdidas con ninguna parte de su

cuerpo.

3. Utilice siempre el protector de la

boquilla No rocíe si no está colocado

el protector de la boquilla.

4. No quite la boquilla mientras limpia

la bomba.

5. Utilice solamente la boquilla

especificada por el fabricante.

6. Tenga precaución cuando limpie y

cambie las boquillas. Antes de quitar

la boquilla, siga las instrucciones del

fabricante para apagar la unidad y

liberar la presión.

MANUAL

Page 15

30,48cm

Figura 1 - Cómo Sostener la Pistola

Pistolas Para Rociadoras de Pintura Sin Aire

15 Sp

Informaciones Generales de

Seguridad (Cont.)

7. No deje la unidad con energía o con

presión si la misma queda sin

atención. Cuando no esté en uso

apague la unidad y libere la presión

de acuerdo con las instrucciones del

fabricante.

8. El rociado de alta presión es capaz de

inyectar toxinas dentro del

organismo y provocar graves lesiones

corporales. En el caso de que ocurra

dicha inyección, obtenga atención

médica de inmediato.

9. Revise las piezas para detectar

señales de daños. Reemplace

cualquier pieza que esté dañada.

10.Esta pistola rociadora está clasificada

para 205 bar (3000 psi). No la utilice

en sistemas diseñados para producir

más de 205 bar (3000 psi).

11.Siempre trabe el seguro del gatillo

cuando no esté pulverizando.

• Verifique que el seguro del gatillo

esté funcionando adecuadamente.

• Para trabar: gire las lengüetas de

la traba a la posición horizontal.

• Para destrabar y rociar: gire las

lengüetas de la traba a la posición

vertical.

NOTA: si la pistola rocía mientras está

en la posición de trabado siga las

instrucciones que se detallan en la

sección de Mantenimiento sobre la

traba del gatillo.

12. Verifique que todas las conexiones

estén ajustadas antes de poner en

funcionamiento. No use pinzas para

apretar o aflojar las conexiones de

alta presión.

13. Aprenda cómo detener su unidad y

liberar la presión rápidamente.

Familiarícese bien con los controles.

Para reducir el riesgo de

lesión:

1. No rocíe ácidos,

materiales corrosivos, productos

químicos tóxicos, fertilizantes o

pesticidas. El uso de estos

materiales podría dar como

resultado la muerte o lesiones

graves.

2. Cuando pinte, use siempre guantes

apropiados, protección para los

ojos y un respirador o máscara.

3. Siempre trabaje en un ambiente

limpio. No apunte la pistola

rociadora a ningún punto con

polvo o desechos.

4. No la haga funcionar ni rocíe

próximo a niños. Mantenga a los

niños, las mascotas y los visitantes

alejados del equipo y del área de

trabajo en todo momento.

5. No se estire ni se pare en sobre un

apoyo inestable. Mantenga un

soporte y equilibrio eficaz en todo

momento.

6. Manténgase alerta y mire lo que

está haciendo.

7. No haga funcionar el equipo

cuando esté fatigado o bajo la

influencia de drogas o alcohol.

Preparación

Los sistemas e rociadoras de pintura sin

aire, a diferencia de la mayoría de otras

herramientas neumáticas o eléctricas,

requieren cuidado adicional para

garantizar su funcionamiento

adecuado.

VEA LAS INSTRUCCIONES DE

FUNCIONAMIENTO EN EL MANUAL

DE SU ROCIADORA SIN AIRE.

Instrucciones para rociar

Los siguientes pasos le permitirán

obtener acabados profesionales de

primera calidad.

1. Mantenga la pistola perpendicular a

la superficie.

Siempre sostenga la pistola perpendi-

cular a la superficie con la boquilla a

una distancia de 30,48cm. Si la sostiene

en un ángulo (hacia arriba, hacia abajo

o de lado) la pintura se acumulará en

forma dispareja, el acabado lucirá mal

y tendrá desperdicio excesivo de

pintura (Vea la Figura 1).

2. Desplazamiento parejo

Desplace la pistola en forma pareja y

siempre mantenga la pistola

perpendicular a la superficie (Vea las

Figuras 1 & 2). Si mueve la muñeca

ocasionará desperdicio excesivo de

material y un acabado disparejo (Vea

la Figura 2).

3. Comience el desplazamiento antes de

oprimir el gatillo

Comenzar el desplazamiento antes

de oprimir el gatillo, le permite

lograr un mejor acabado, sin rastros

de empates, y evita la acumulación

inicial de la pintura. Igualmente, es

recomendable soltar el gatillo antes

de parar el desplazamiento (Vea la

Figura 3).

NOTA: Para garantizar un acabado

parejo es recomendable que recubra

20% - 30% del área cubierta en cada

desplazamiento utilizando patrones

cruzados (uno horizontal y el otro

vertical).

SI NO SIGUE ESTAS

INSTRUCCIONES PODRIA

OCASIONARLE HERIDAS

GRAVES E INCLUSIVE LA

MUERTE.

Capa poco

espesa

Capa poco

espesa

Capa

espesa

Desperdicio

Desperdicio

Figura 2 - Resultados si mueve la

muñeca al desplazar la pistola

INCORRECTO

Aprox.

25,40-

30,48 cm

Comience el

desplazamiento

Oprima

el gatillo

Suelte el

gatillo

Termine el

desplazamiento

Figura 3 - Método correcto para

desplazar la pistola

Page 16

16 Sp

Manual de Instrucciones y Lista de Repuestos

Instrucciones para rociar

(Cont.)

CÓMO CAMBIAR LAS PUNTAS DE

ROCIADO:

Es posible que sea necesario cambiar las

puntas de rociado durante un trabajo

de pintura. Siga estos pasos para

cambios seguros y rápidos de las

puntas.

1. Despresurice y apague la unidad de

acuerdo a las instrucciones del

fabricante.

2. Trabe el seguro del gatillo de la

pistola.

3. Tire de la punta

roja para quitarla

de la base de rociado

y cámbiela por una

punta diferente,

insertando totalmente

la nueva punta en la base.

CÓMO CONECTAR EL ACCESORIO DE

RODILLO:

1. Despresurice y apague la unidad de

acuerdo a las instrucciones del

fabricante.

2. Trabe el seguro del gatillo de la

pistola.

3. Quite la base de rociado, la punta,

el sello y la arandela.

4. Conecte el

accesorio de

rodillo

(AL2275 se

muestra) en

la pistola

rociadora sin aire. Si es necesario,

use un adaptador de rosca y una

arandela entre el rodillo y la pistola

rociadora como se muestra en la

figura.

USO INTERMITENTE

Si está pintando y decide descansar por

varios minutos, póngale el seguro al

gatillo y sumerja la boquilla en un

envase con un solvente adecuado (Vea

la Figura 4). Ésto evitará que la pintura

se seque y obstruya la boquilla.

Cerciórese de liberar la presión

girando la perilla de desvio hacia la

posición “Prime” y apagando la

bomba.

SI LA BOQUILLA SE OBSTRUYE:

BOQUILLAS REVERSIBLES: (Incluídas)

1. Gire la boquilla a la posición de

limpieza (Vea la Figura 5).

2. Apunte la pistola hacia una posición

segura y comience a rociar. Ésto

eliminará cualquier obstrucción.

3. Coloque la boquilla en la posición

para rociar y continue rociando (Vea

la Figura 5).

4. Si continúa la obstrucción, cambie el

filtro de la pistola y vea la posibilidad

de colar la pintura antes de usarla.

El equipo

se puede

dañar si utiliza una aguja o cualquier

tipo de objeto afilado para limpiar la

boquilla. El Carburo de Tungsteno es

muy frágil y podría romperse.

BOQUILLAS FIJAS:

1. Despresurice y apague la unidad de

acuerdo a las instrucciones del

fabricante.

2. Póngale el seguro al gatillo.

3. Desconecte la boquilla y la tapa

protectora de la pistola.

4. Sumerja la boquilla en agua o un

solvente adecuado y utilice un cepillo

de dientes para eliminar todos los

residuos de pintura o impurezas que

puedisen atascar el orificio de salida.

BOQUILLAS AJUSTABLES:

1. Gire la perilla completamente en

sentido contrario a las agujas del

reloj para abrir la boquilla al

máximo.

2. Oprima el gatillo y rocíe dentro de un

cubo o envase. Ésto eliminará

cualquier residuo que pudiese estar

obstruyendo el orificio de salida de la

boquilla.

3. Si continúa la obstrucción, cambie el

filtro de la pistola y vea la posibilidad

de colar la pintura antes de usarla.

LIMPIEZA DE SU PISTOLA: siga las

instrucciones de limpieza, uso y

mantenimiento que se incluyen con su

rociadora de pintura. Después de

enjuagar la bomba y cuando haya

finalizado:

1. Gire la boquilla de rociado a la

posición de limpieza.

2. Suelte el seguro del gatillo.

3. Apunte la pistola pulverizadora

dentro de un cubo de desechos vacío

y presione el gatillo. Rocíe al menos 1

galón de líquido dentro del cubo de

desechos. Para reducir las

salpicaduras, dirija el chorro de

líquido a lo largo del interior del

balde y bastante por encima del nivel

de líquido.

CONSULTE LOS PROCEDIMIENTOS

DE APAGADO DE LA ROCIADORA

DE PINTURA.

4. Despresurice y apague la unidad de

acuerdo a las instrucciones del

fabricante.

5. Mientras apunta la pistola en una

dirección segura, presione el gatillo

de ésta con seguro del gatillo sin

trabar para asegurarse de que el

sistema está despresurizado.

6. Trabe el seguro del gatillo.

7. En este momento la bomba y la

pistola rociadora están limpias, pero

aún requieren preparación para

guardarlas. El protector de la

boquilla rociadora o cualquier

accesorio que se haya utilizado aún

necesitan ser limpiados.

PARA LIMPIAR LA TAPA DE

PROTECCION DE LA BOQUILLA

1. Desconecte la boquilla con una llave

de 25,40 mm o una llave inglesa.

2. Limpie la tapa de protección con un

cepillo.

SOLVENT

Figura 4 - Cómo Evitar que la Boquilla

se obstruya

Solvente

PARA LIMPIAR

PARA ROCIAR

Figura 5 - Posiciones para Limpiar y Rociar

Page 17

Pistolas Para Rociadoras de Pintura Sin Aire

17 Sp

Mantenimiento

Si no

sigue

estas instrucciones la bomba se podria

daãr.

• No use solventes a base de aceite para

limpiar el equipo después de haber

utilizado pinturas a base de látex. Sólo

use agua tibia enjabonada.

• Siempre reemplace los filtros

obstruídos, no trate de limpiarlos.

• Siga atentamente las instrucciones de

limpieza y almacenamiento de su

rociadora.

• No use objectos de metal u otros

materiales duros para quitarle los

residuos de pintura seca al orificio de

la boquilla.

Antes de

realizar

cualquier tipo de mantenimiento,

asegúrese de liberar la presión del

sistema y de desconectar la energía de

la rociadora.

SEGURO DEL GATILLO

Presionar el gatillo

no debería abrir la

válvula de la pistola

cuando está activado

el seguro del gatillo.

Usted debería ser capaz de hacer que el

actuador se mueva levemente de un

lado al otro con su dedo mientras

sostiene el gatillo contra el seguro del

gatillo cuando éste se encuentra en la

posición de trabado. Si no puede

hacerlo, ajuste la posición del gatillo

siguiendo estas instrucciones:

1. Coloque el gatillo en la posición de

trabado (lengüetas en posición

horizontal).

2. Mientras sostiene con una mano

suavemente el gatillo contra el

seguro, use una llave de tuercas de

6,35mm (1/4") para girar la tuerca

hasta que el gatillo comience a

soltarse del seguro.

3. Vuelva a apretar la tuerca (hacia la

izquierda) 1/2 vuelta.

SELLO Y ARANDELA DE LA PUNTA

En ocasiones, usted deberá reemplazar

el sello plateado y la arandela negra

ubicadas dentro de la base de la punta.

1. Para cambiar el sello y la arandela,

afloje primero la base de la punta

con una llave ajustable y luego

quítela con la mano.

2. Quite la punta de rociado.

3. Usando un destornillador Phillips,

empuje el sello y la arandela fuera

de la base de la punta.

4. Coloque el sello en la base con el

lado plano del mismo hacia arriba.

Asegúrese de que quede alineado

adecuadamente con la base.

5. Coloque la arandela en la base.

Asegúrese de que quede alineada

adecuadamente con la base.

6. Vuelva a colocar la punta en la base

de la punta.

7. Vuelva a conectar la base de la

punta a la válvula de la pistola.

Asegúrese de que la

punta de rociado y

la base de la punta

queden bien

ajustadas en su

lugar. Si no quedan bien ajustadas

pueden provocar una descarga de

rociado en la dirección incorrecta y

representar un peligro de inyección

en la piel.

Notas

Page 18

18 Sp

Manual de Instrucciones y Lista de Repuestos

Garantía Limitada

1. DURACIÓN: A partir de la fecha de compra por parte del comprador original, es como sigue: Todos los accesorios de

aplicación de pintura: 1 año

2. QUIÉN EMITE ESTA GARANTÍA (EL GARANTE): Campbell Hausfeld/Una Empresa Scott Fetzer, 100 Production Drive,

Harrison, OH 45030, Teléfono: 1-800-626-4401.

3. QUIÉN RECIBE ESTA GARANTÍA (EL COMPRADOR): El comprador original (que no sea para fines de reventa o alquiler)

del producto de Campbell Hausfeld.

4. QUÉ PRODUCTOS ESTÁN AMPARADOS POR ESTA GARANTÍA: Todos los sistemas de aplicación de pintura no accionados

por compresor, los sistemas de rociado de HVLP y los accesorios de aplicación de pintura suministrados o fabricados por

el garante.

5. QUÉ ES LO QUE CUBRE ESTA GARANTÍA: Defectos de material y mano de obra que ocurran dentro del período de

duración de la garantía. El garante también cubrirá artículos de desgaste normal por un período de 30 días a partir de la

fecha de compra original, contra defectos de material y mano de obra. Estos artículos de desgaste son: filtros de HVLP,

escobillas de motor, empaque de la pistola, sello del depósito de la pistola, válvula de retención de la pistola y el aro de

flujo de aire de la pistola; válvula de admisión sin aire, válvula de salida, válvula de pistola, filtros, boquillas, todas las

juntas y los anillos en "O".

6. QUÉ ES LO QUE NO CUBRE ESTA GARANTÍA:

A. Las garantías implícitas, incluyendo las de comercialización E IDONEIDAD PARA UN PROPÓSITO ESPECÍFICO, TIENEN

UN LÍMITE DE UN AÑO A PARTIR DE LA FECHA DE COMPRA ORIGINAL, TAL COMO SE ESTABLECE EN LA

"DURACIÓN". Si un producto de servicio normal se utiliza para fines comerciales o industriales, la garantía regirá por

noventa (90) días a partir de la fecha de compra original. Si el producto se usa para fines de alquiler, la garantía

regirá por noventa (90) días desde la fecha de compra original. Algunos estados no permiten la limitación de la

duración de una garantía implícita, de modo que estas restricciones tal vez no rijan para Ud.

B. CUALQUIER PÉRDIDA, DAÑO O GASTO EMERGENTE, INDIRECTO O DERIVADO QUE PUEDA RESULTAR DE CUALQUIER

DEFECTO, FALLA O DESPERFECTO DEL PRODUCTO DE CAMPBELL HAUSFELD. Algunos estados no permiten la

exclusión o limitación de daños emergentes o consecuentes, por lo que la limitación arriba mencionada podría no

regir para Ud.

C. Cualquier falla resultante de un accidente, mal uso, negligencia u omisión en operar el producto conforme a las

instrucciones contenidas en el manual o manuales del propietario, suministrados con el producto. El accidente, mal

uso del comprador, negligencia u omisión en operar los productos de acuerdo a las instrucciones incluirán también la

remoción o alteración de cualquier dispositivo de seguridad. Si tales dispositivos de seguridad son removidos o

alterados, esta garantía no tendrá validez.

D. Ajustes normales que se explican en el manual del propietario suministrado con el producto.

E. Artículos o servicios normalmente requeridos para mantener el producto: filtros de HVLP, escobillas de motor,

empaque de la pistola, sello del depósito de la pistola, válvula de retención de la pistola, y el aro de flujo de aire de

la pistola; válvula de admisión sin aire, válvula de salida, válvula de pistola, filtros, boquillas, todas las juntas y los

anillos en "O" o cualquier otra pieza consumible no indicada específicamente, serán cubiertos solamente durante 30

días desde la fecha de compra original.

7. RESPONSABILIDADES DEL GARANTE EN VIRTUD DE ESTA GARANTÍA: Reparar o reemplazar, a opción del garante, los

productos o componentes que sean defectuosos, hayan funcionado mal o que no estén conformes dentro del período

de garantía.

8. RESPONSABILIDADES DEL COMPRADOR EN VIRTUD DE ESTA GARANTÍA:

A. Proporcionar prueba de fecha de la compra y registros de mantenimiento.

B. Entregar o embarcar el producto de Campbell Hausfeld al Centro de Servicio Autorizado de Campbell Hausfeld más

cercano. El costo de fletes, si lo hubiera, será sufragado por el comprador.

C. Ejercer cuidado razonable en la operación y mantenimiento del producto descrito en el (los) manual(es) del

propietario.

9. CUÁNDO EFECTUARÁ EL GARANTE LA REPARACIÓN O REEMPLAZO AL AMPARO DE ESTA GARANTÍA: La reparación o el

reemplazo se programarán de acuerdo al flujo normal de trabajo en el centro de servicio, dependiendo de la

disponibilidad de piezas de repuesto.

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales específicos, pudiendo

también asistirle otros derechos, los cuales varían de un estado a otro o de un país a otro.

Page 19

19

Notes / Notes / Notas