CAME Z 24 Series ZL170N Installation Manual

SERIES Z 24

CONTROL PANEL

FOR 24V GEARMOTORS

INSTALLATION MANUAL

ZL170N

nglis

h

319U34EN

P.

2

2 - Manual code

319U34

319U34 ver.

1.0

1.0 09/2011 © CAME cancelli automatici s.p.a. - The data and information in this manual may be changed at any time with no obligation to notify said changes.

ENGLISH

4 Description

2.1 Intended use

Legend of symbols

This symbol shows parts which must be read with care.

This symbol means the parts which describe safety issues.

This symbol tells you what to tell the end-user.

2 Conditions of use

The ZL170N control panel is engineered to command single 24 V DC powered gearmotors of the FERNI, EMEGA and FROG

series.

Any installation and use other than that specified in this manual is forbidden.

3 Reference standards

"IMPORTANT INSTALLATION SAFETY INSTRUCTIONS"

“WARNING: IMPROPER INSTALL ATION MAY RESULT IN SERIOUS HARM. PLEASE FOLLOW ALL INSTALLATION INSTRUCTIONS”

“THIS MANUAL IS INTENDED ONLY FOR PROFES SIONAL INSTALLERS OR OTHER COMPETENT INDIVIDUALS”

2.2 Application settings

Engineered and built entirely by Came Cancelli Automatici

S.p.A.

The control panel should be powered by 230 V AC, at 50/60

Hz frequency.

The command devices and accessories are powered by 24V.

Warning! The accessories must not exceed 40 W overall.

All connections are protected by quick fuses, see table.

The transformer is fitted with a protection which, in case

overheating, keeps the gate leaf open. Reclosing will happen

only after the temperature has dropped below the overload

limit.

The card provides and controls the following functions:

- automatic closing after an opening command;

- pre-flashing movement indicator;

- obstacle detections when gate is not moving at any point;

- opening recoil:.

The available command modes are:

- opening/closing;

-opening/closing with maintained action;

- open only with radio command;

- total stop.

The photocells, after detecting an obstacle, may trigger:

- the reopening of the closing gate;

- a partial stop if gate is moving;

- a total stop.

The control panel features a safety amperometric sensor (see

p. 12).

Special trimmers regulate:

- the working time for automatic closing;

- adjusting amperometric sensitivity during while gate is

moving: min/max.

- adjusting amperometric sensitivity during deceleration:

min/max

- adjusting the stopping zone final stop (see p. 11)

You can also adjust the gate movement and deceleration

speeds (see p. 12).

You can also connect:

- gate open warning-lamp;

- electro lock.

- Movement flashing light.

- courtesy -lamp lighting the parking area for opening/closing

cycle.

- LB18 board to power gearmotors via batteries in case of

power outages. When power is back on it also recharges

them.

Came Cancelli Automatici employs an ISO 9001:2000 cer tified quality management system and an ISO 14001 environmental

management system. Came entirely engineers and manufactures in Italy.

This product is compliant with: see statement of compliance.

The overall power load of the connected motor must not exceed 180 W.

FUSE TABLE

to protect: fuses for:

Electronic board (line)

3.15 A-F

Command devices (control unit) 630 mA-F

Accessories 3.15 A-F

TECHNICAL DATA

line voltage 230V - 50/60Hz

power draw when idle 120 mA

maximum power for 24 V accessories 40 W

circuit insulation class

container material ABS

container protection rating IP54

working temperature -20 / +55°C

15

32 4 5

6

1

10

14

11

12

7

8

9

13

RA R R C FA F M N

MNR

ADT x ZL170

16

17

P.

3

3 - Manual code

319U34

319U34 ver.

1.0

1.0 09/2011 © CAME cancelli automatici s.p.a. - The data and information in this manual may be changed at any time with no obligation to notify said changes.

ENGLISHENGLISHENGLISH

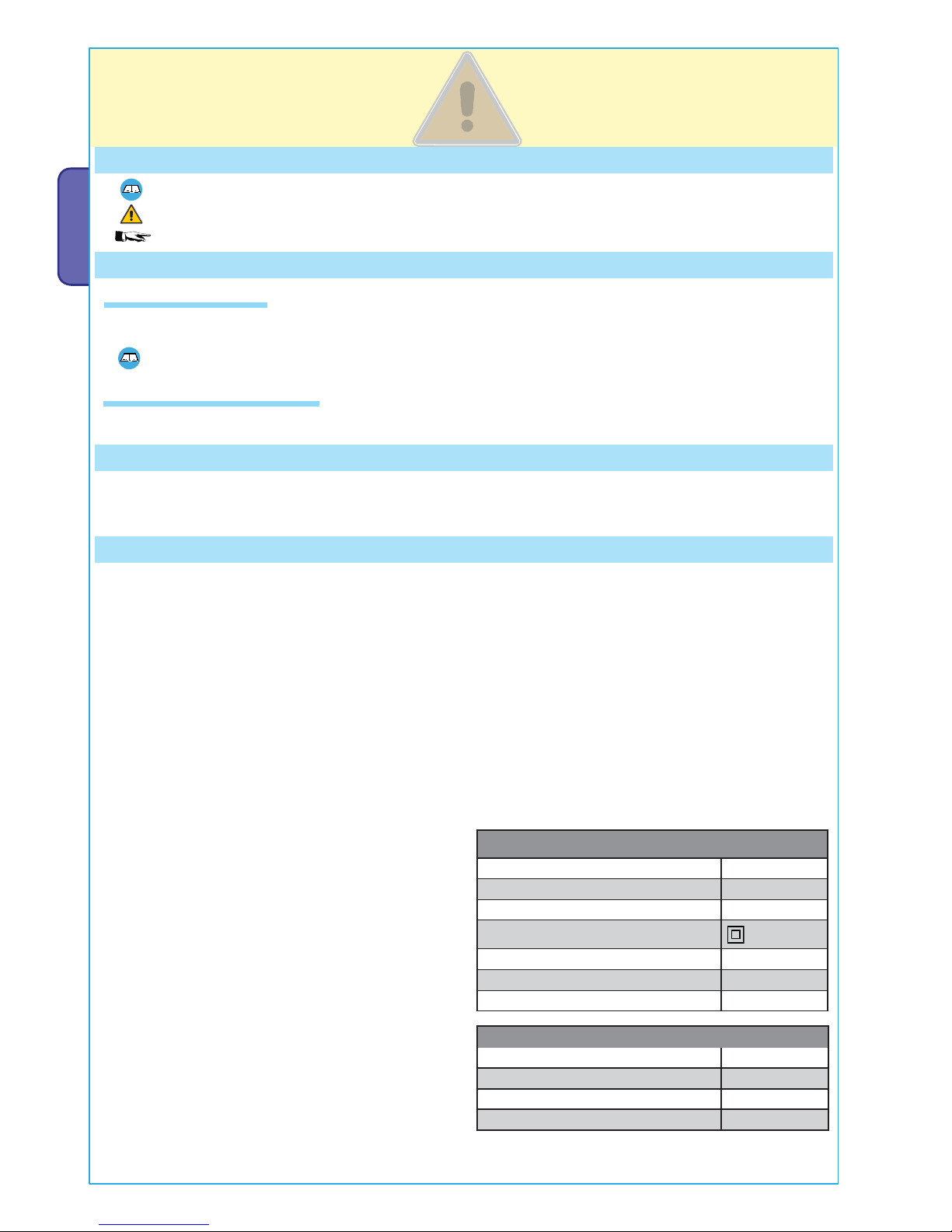

4.1 Dimensions, centre distances and anchoring holes

4.2 Main components

(mm)

1. Transformer

2. Amperometric sensitity during travel

adjustment trimmer

3. Amperometric sensitity during deceleration

adjustment trimmer

4. Opening / closing strike zone adjustment

trimmer

5. Automatic closing adjustement trimmer

6. Code memorising button

7. Terminals for connecting to the

LB18 battery charger (see p. 9)

8. 630mA-F control unit fuse

9. 3.15F accessories fuse

10. Radio code notifi cation LED light

11. Functions selector

12. Output selector jumper B1-B2/cycle lamp

13. 3.15A-F line fuse

14. Radio frequency card socket

15. Connection terminals

16. ADT card for managing

decelerations (see pages 5-6)

17. ADT terminals (use only with Frog

24V, see p. 6)

BLACK

BLUE

BROWN

RED

WHITE

BLUE

PURPLE

P.

4

4 - Manual code

319U34

319U34 ver.

1.0

1.0 09/2011 © CAME cancelli automatici s.p.a. - The data and information in this manual may be changed at any time with no obligation to notify said changes.

ENGLISH

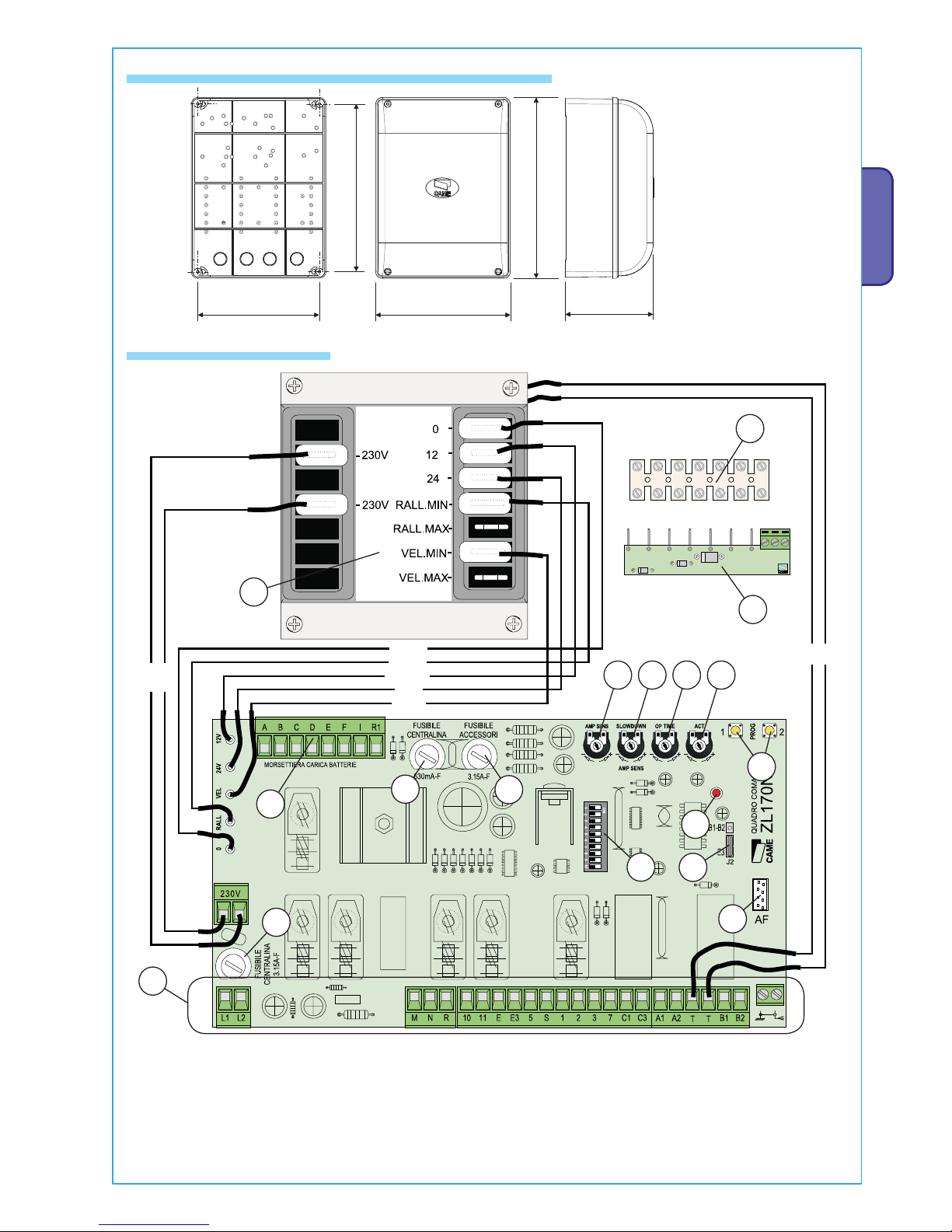

5 Installation

5.1 Preliminary checks

5.2 Tools and equipment

5.3 Anchoring and installing the box

Make sure that the point where the electrical panel is anchored is free from any impacts, and that the surface is solid and that

proper tools and materials are used (i.e. screws, wall plugs, etc.).

Set up a suitable omnipolar cut-off device, with distances greater than 3 mm between contacts, with sectioned power

source

•

Check that any connections inside the container (made for continuity purposes of the protective circuit) are fitted with

extra insulation compared to other internal conductive parts.

• Set up proper conduits and electric cable raceways, making sure these are protected from any mechanical damage.

Make sure you have all the tools and materials needed to carry out the installation in total safety and in accordance with

current regulations. Here are some examples.

Secure the base of the panel in a safe area; we suggest using

bolts with max. diametre of 6 mm Philips rounded heads.

Perforate the marked holes and insert the cable glands with

corrugated tubes for the electrical cables to run through.

N.B.: the pre-perforated holes have different diameters: 23,

29 and 37 mm.

Careful not to damage the electronic board inside the panel!!

After adjusting and setting, secure the cover using the issued

screws.

Before beginning to install, the following is necessary:

Installation must be carried by skilled, qualified technicians in accordance with current regualtions.

Warning! Before acting on the eqipment, cut off the main power supply and disconnect the emergency batteries (if

present).

RA R RC FA F M N

MNR

ADT x ZL170

RA R RC FA F M N

RA R RC FA F M N

MNR

ADT x ZL170

RA R RC FA F M N

FROG

FERNI EMEGA

P.

5

5 - Manual code

319U34

319U34 ver.

1.0

1.0 09/2011 © CAME cancelli automatici s.p.a. - The data and information in this manual may be changed at any time with no obligation to notify said changes.

ENGLISHENGLISHENGLISH

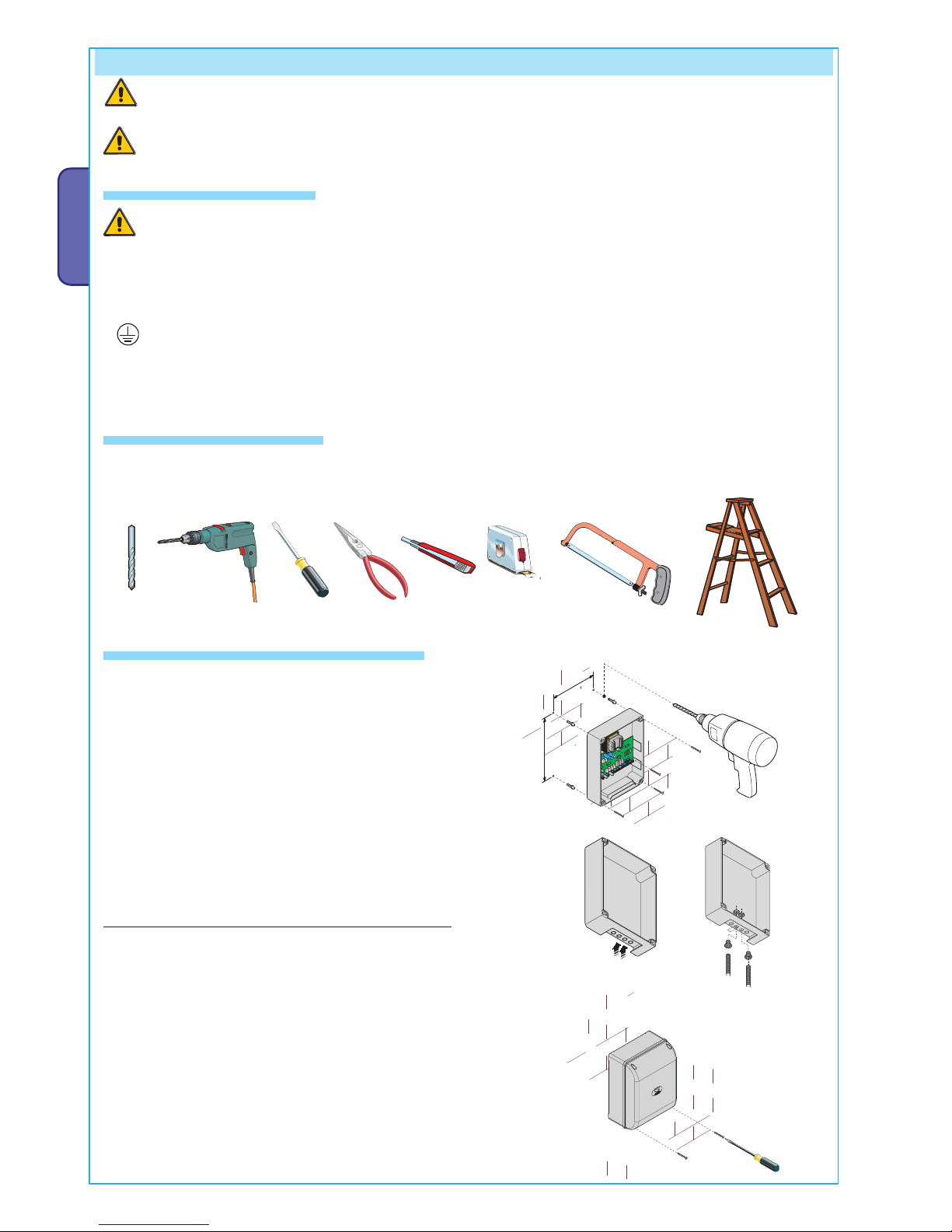

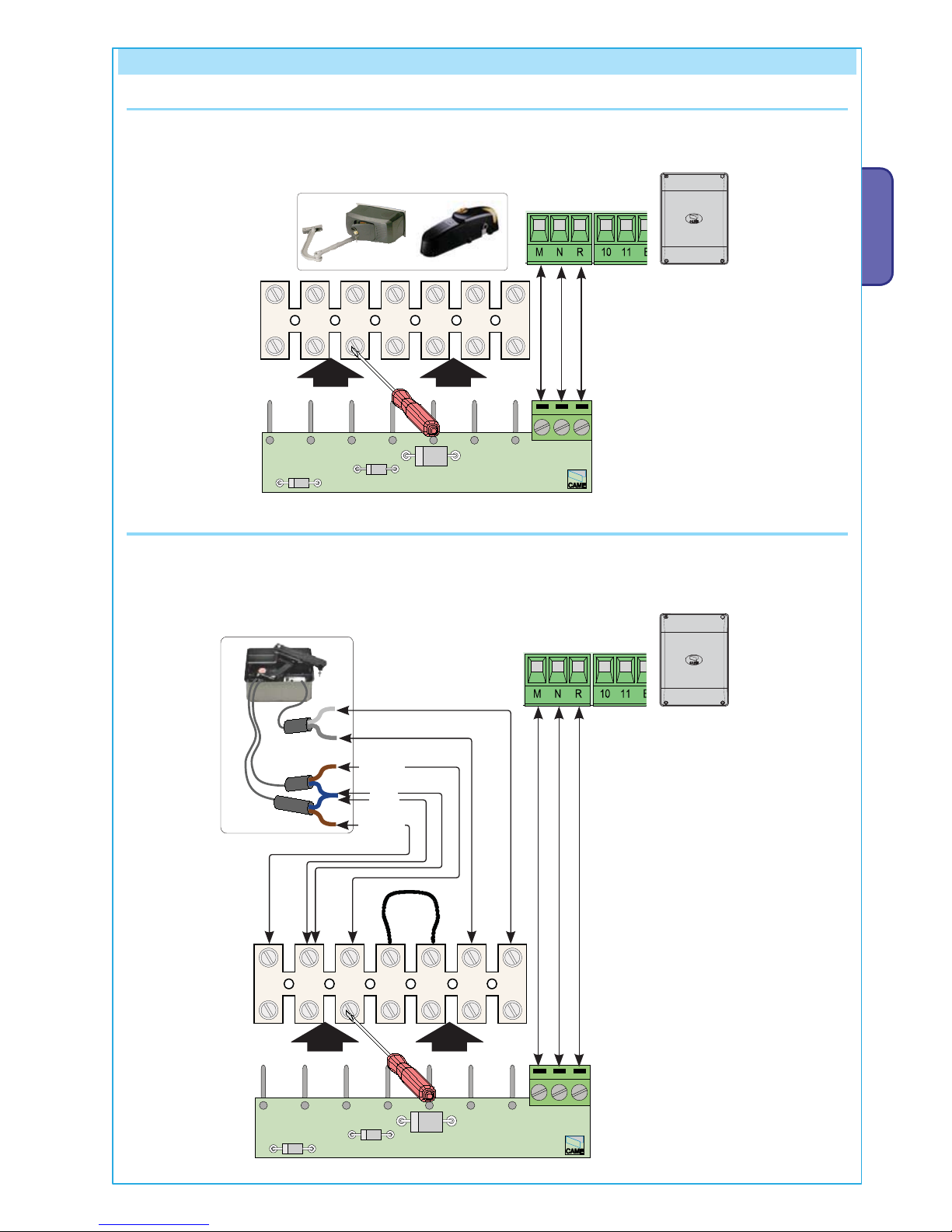

6 Electrical connections

Gearmotor FERNI and EMEGA

The ADT card should be fastened to the gearmotor terminals as shown, and connected to the control panel on terminals M, N

and R (the RA terminal is not active on the FERNI and EMEGA models).

FROG Gearmotor

Whereas with Frog, ADT card and terminals, after connecting to the cables coming out of the gearmotor, they can be left inside the control

panel or in a similar water-tight box.

BROWN

BLUE

BLUE

BROWN

Loading...

Loading...