Page 1

SHUTTER

h

OPERATOR

FA00135-EN

INSTALLATION MANUAL

VLR01DX - VLR01SX - VLR02

Englis

Page 2

2

FA00135-EN

2

WARNING!

important safety instructions for people:

READ CAREFULLY!

PREMISE

• THIS PRODUCT SHOULD ONLY BE USED FOR THE PUR-

POSE FOR WHICH IT WAS EXPLICITLY DESIGNED. ANY OTH-

ER USE IS DANGEROUS. CAME S.P.A. IS NOT LIABLE

FOR ANY DAMAGE CAUSED BY IMPROPER, WRONGFUL AND

UNREASONABLE USE • KEEP THESE WARNINGS TOGETHER

WITH THE INSTALLATION AND OPERATION MANUALS THAT

COME WITH THE DEVICE.

EFORE INSTALLING

B

(CHECKING WHAT'S THERE: IF SOMETHING IS MISSING,

DO NOT CONTINUE UNTIL YOU HAVE COMPLIED WITH ALL

SAFETY PROVISIONS)

HECK THAT THE AUTOMATED PA RTS ARE IN PROPER

• C

MECHANICAL ORDER, THAT THE OPERATOR IS LEVEL AND

ALIGNED, AND THAT IT OPENS AND CLOSES PROPERLY.

AKE SURE YOU HAVE SUITABLE MECHANICAL STOPS • IF

M

THE OPERATOR IS TO BE INSTALLED AT A HEIGHT OF LESS

THAN 2.5 M FROM THE GROUND OR OTHER ACCESS LEV-

EL, MAKE SURE YOU HAVE ANY NECESSARY PROTECTIONS

AND/OR WARNINGS IN PLACE • MAKE SURE THAT THE

OPENING AUTOMATED DOOR OR GATE CANNOT ENTRAP

PEOPLE AGAINST THE FIXED PARTS OF THE OPERATOR •

D

O NOT FIT UPSIDE DOWN OR ONTO ELEMENTS THAT

COULD BEND. IF NECESSARY, ADD SUITABLE REINFORCE-

MENTS TO THE ANCHORING POINTS • DO NOT INSTALL

DOOR OR GATE LEAVES ON TILTED SURFACES • MAKE

SURE ANY SPRINKLER SYSTEMS CANNOT WET THE OPERA-

TOR FROM THE GROUND UP • MAKE SURE THE TEM-

PERATURE RANGE SHOWN ON THE PRODUCT LITERATURE IS

SUITABLE TO THE CLIMATE WHERE IT WILL BE INSTALLED •

OLLOW ALL INSTRUCTIONS AS IMPROPER INSTALLATION

F

MAY RESULT IN SERIOUS BODILY INJURY

INSTALLING

• SUITABLY SECTION OFF AND DEMARCATE THE ENTIRE

INSTALLATION SITE TO PREVENT UNAUTHORIZED PERSONS

FROM ENTERING THE AREA, ESPECIALLY MINORS AND

CHILDREN • BE CAREFUL WHEN HANDLING OPERATORS

THAT WEIGH OVER 20 KG. IF NEED BE, USE PROPER

SAFETY HOISTING EQUIPMENT • ALL OPENING COM-

MANDS (BUTTONS, KEY SWITCHES, MAGNETIC READERS,

ETC.) MUST BE INSTALLED AT LEAST 1.85 M FROM THE

EDGE OF THE MANOEUVRING AREA, OR WHERE THEY

CANNOT BE REACHED FROM THE OUTSIDE THROUGH THE

DEVICE. ALSO, ANY DIRECT COMMANDS (WHETHER BUT-

TONS, TOUCH PANELS, AND SO ON) MUST BE INSTALLED

AT LEAST 1.5 M FROM THE GROUND AND MUST NOT BE

REACHABLE BY UNAUTHORIZED PERSONS • ALL MAIN-

TAINED ACTION COMMANDS, MUST BE FITTED IN PLACES

FROM WHICH THE MOVING GATE LEAVES AND TRANSIT AND

DRIVING AREAS ARE VISIBLE • APPLY, IF MISSING, A PER-

MANENT SIGN SHOWING THE POSITION OF THE RELEASE

DEVICE • BEFORE DELIVERING TO THE USERS, MAKE SURE

THE SYSTEM IS EN 12453 STANDARD COMPLIANT (RE-

GARDING IMPACT FORCES), AND ALSO MAKE SURE THE

SYSTEM HAS BEEN PROPERLY ADJUSTED AND THAT ANY

SAFETY, PROTECTION AND MANUAL RELEASE DEVICES ARE

WORKING PROPERLY • APPLY WARNING SIGNS WHERE

NECESSARY AND IN A VISIBLE PLACE.

PECIAL INSTRUCTIONS

S

AND

RECOMMENDATIONS FOR USERS

• KEEP GARAGE-DOOR OPERATION AREAS CLEAN AND

FREE OF ANY OBSTRUCTIONS. CHECK THAT THERE ARE

NO OBSTRUCTIONS WITHIN THE OPERATING RANGE OF THE

OPERATOR • DO NOT ALLOW CHILDREN TO PLAY WITH

FIXED CONTROLS, OR TO LOITER IN THE OPERATOR'S MA-

NEUVERING AREA. • THIS APPARATUS IS NOT FOR PEO-

PLE (INCLUDING CHILDREN) WITH PHYSICAL, MENTAL AND

SENSORY ISSUES, OR EVEN ONES WITHOUT ANY EXPERI-

ENCE, PROVIDED THIS HAPPENS UNDER CLOSE SUPERVI-

SION OR ONCE THEY HAVE BEEN PROPERLY INSTRUCTED

TO USE THE APPARATUS SAFELY AND TO THE POTENTIAL

HAZARDS INVOLVED.

EEP ANY REMOTE CONTROL TRANSMITTERS OR ANY

K

OTHER COMMAND DEVICE AWAY FROM CHILDREN, TO

PREVENT THE OPERATOR FROM BEING ACCIDENTALLY AC-

TIVATED. • FREQUENTLY CHECK THE SYSTEM FOR ANY

MALFUNCTIONS OR SIGNS OF WEAR AND TEAR OR DAM-

AGE TO THE MOVING STRUCTURES, TO THE COMPONENT

PARTS , ALL ANCHORING POINTS, INCLUDING CABLES AND

ANY ACCESSIBLE CONNECTIONS. KEEP ANY HINGES, MOV-

ING JOINTS AND SLIDE RAILS PROPERLY LUBRICATED • IF

REPAIRS OR MODIFICATIONS ARE REQUIRED TO THE SYS-

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

2 - Manual code

Page

Page 3

3

FA00135-EN

2

TEM, RELEASE THE OPERATOR AND DO NOT USE IT UNTIL

SAFETY CONDITIONS HAVE BEEN RESTORED • CUT OFF

THE POWER SUPPLY BEFORE RELEASING THE OPERATOR

FOR MANUAL OPENINGS AND BEFORE ANY OTHER OPERA-

TION, TO PREVENT POTENTIALLY HAZARDOUS SITUATIONS.

EAD THE INSTRUCTIONS IF THE POWER SUPPLY CABLE

R

IS DAMAGED, IT MUST BE REPLACED BY THE MANUFAC-

TURER OR AUTHORIZED TECHNICAL ASSISTANCE SERVICE,

OR IN ANY CASE, BY SIMILARLY QUALIFIED PERSONS, TO

PREVENT ANY RISK • IT IS FORBIDDEN FOR US-

ERS TO PERFORM ANY OPERATIONS THAT ARE

NOT EXPRESSLY REQUIRED OF THEM AND

WHICH ARE NOT LISTED

ANY REPAIRS, MODIFICATIONS AND ADJUSTMENTS AND

FOR EXTRA-ORDINARY MAINTENANCE, CALL TECHNI-

CAL ASSISTANCE • L

INTO THE PERIODIC MAINTENANCE LOG.

IN THE MANUALS. FOR

OG THE JOB AND CHECKS

A COMMAND IN MAINTAINED ACTIONS, KEEP CHECKING

THAT THERE ARE NO PERSONS WITHIN THE OPERATING

RANGE OF ANY MOVING PARTS , UNTIL THE COMMAND IS

RELEASED • THE OPERATOR MAY MOVE THE DOOR AT

ANY TIME AND WITHOUT WARNING • ALWAYS CUT OFF

THE MAINS POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE OR CLEANING.

DDITIONAL INSTRUCTIONS AND RECOMMENDATIONS

A

FOR

EVERYONE

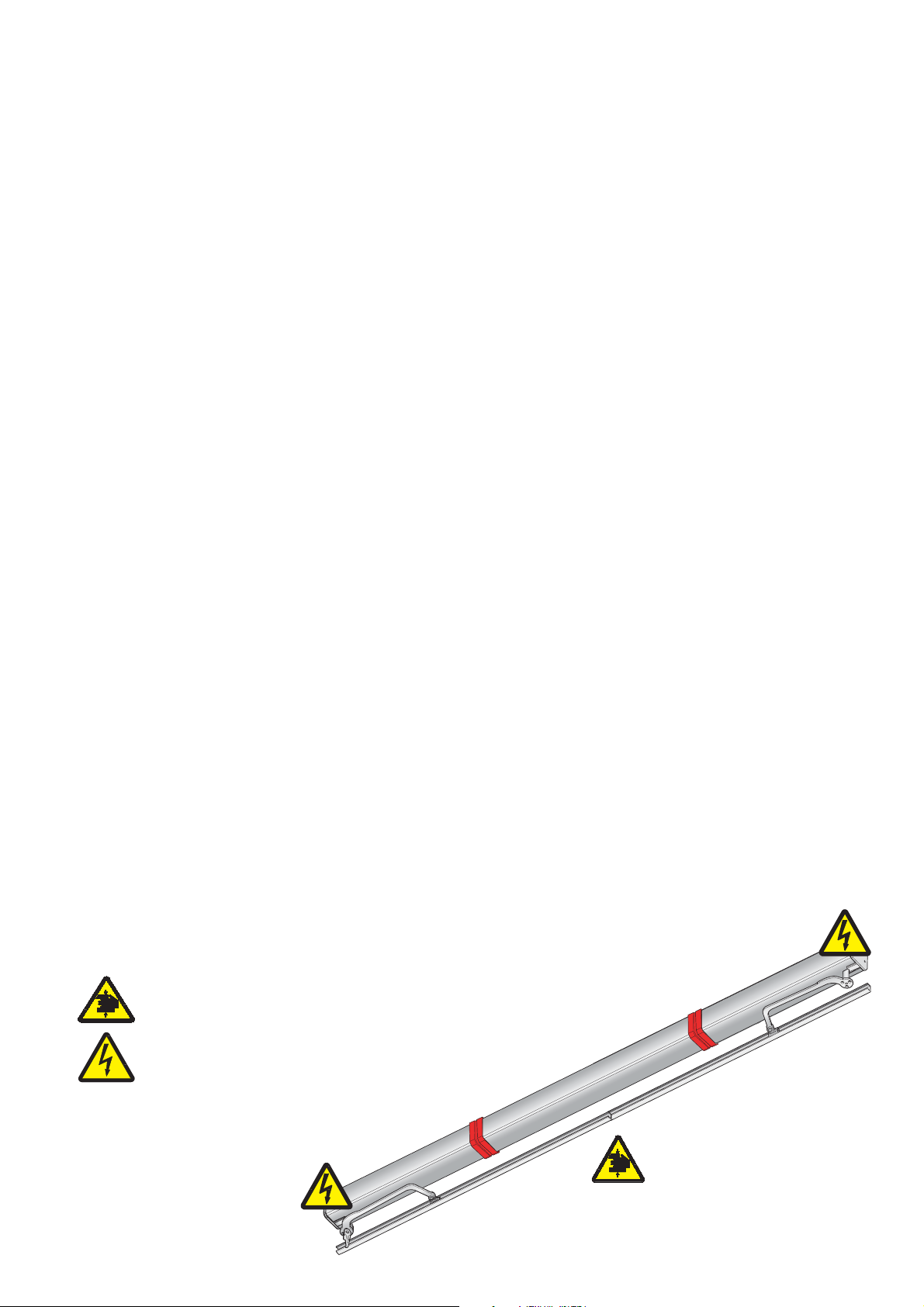

• KEEP CLEAR OF HINGES AND MECHANICAL MOVING

PARTS • DO NOT ENTER THE OPERATOR'S AREA OF OP-

ERATION WHEN IT IS MOVING • DO NOT COUNTER THE

OPERATOR'S MOVEMENT AS THIS COULD RESULT IN DAN-

GEROUS SITUATIONS • ALWAYS PAY SPECIAL ATTENTION

TO ANY DANGEROUS POINTS, WHICH HAVE TO BE LABELED

WITH SPECIFIC PICTOGRAMS AND/OR BLACK AND YEL-

LOW STRIPES • WHEN USING A SELECTOR SWITCH OR

DANGER OF HAND CRUSHING

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

DANGER! HIGH VOLTAGE.

FA00135-EN - vers.

3 - Manual code

Page

Page 4

4

FA00135-EN

2

KEY

This symbol shows which parts to read carefully.

This symbol shows the parts which describe safety issues.

⚠

This symbol indicates what should be communicated to users.

☞

All measurements, unless otherwise stated, are expressed in millimeters.

REFERENCE REGULATIONS

CAME S.p.A. is certified for its ISO 9001 quality and ISO 14001 environmental management systems.

This product complies with the current regulations mentioned in the declaration of conformity.

DESCRIPTION

This product has been designed and built by CAME S.p.A. in compliance with current legal safety standards.

The operator is composed of a part made of cast aluminium inside of which works the irreversible gearmotor plus an

aluminium casing.

The Sipario

The operators:

001VLR01DX

001VLR01SX

001VLR02 Irreversible operator for controlling two-leaf swing shutters, complete with control board and transmission-

The transmission arms:

001VLR07DX RIGHT-HAND curved transmission arm for single-panel shutters.

001VLR07SX LEFT-HAND curved transmission arm for single-panel shutters.

001VLR08DX Adjustable RIGHT-HAND curved transmission arm for shutters with single- or double-jointed panels.

001VLR08SX Adjustable LEFT-HAND curved transmission arm for shutters with single- or double-jointed panels.

001VLR09DX Adjustable RIGHT-HAND augmented curved transmission arm for shutters with double-jointed panels.

001VLR09SX Adjustable LEFT-HAND augmented curved transmission arm for shutters with double-jointed panels.

001VLR10DX RIGHT-HAND augmented curved transmission arm for single-panel shutters.

001VLR10SX LEFT-HAND augmented curved transmission arm for single-panel shutters.

The optional accessories:

001VLR04 Covering cross-piece for the VLR02 with light bays greater than 970 mm.

001VLR05 Emergency operation device, complete with 12 V batteries and battery-charging card.

RIGHT-HAND irreversible OPERATOR for controlling one-leaf swing shutters, complete with control board

and transmission-arm guide.

LEFT-HAND irreversible OPERATOR for controlling one-leaf swing shutters, complete with control board and

transmission-arm guide.

arm guides.

Intended use

The VOILA operator is designed for opening and closing one or two-leaf swing leaves.

By shutters we mean

Any installation and use other than that specified in this manual is forbidden.

Limits to use

Model VLR01DX - VLR01SX VLR02

Max. leaf width (m) 1.05 2.1

Maximum gate-leaf weight (kg) 35 35

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

4 - Manual code

Page

Page 5

5

FA00135-EN

2

Technical data

Type VLR01DX - VLR01SX VLR02 command

Protection rating (IP) 44 44

Power supply (V - 50/60 Hz) 230 AC 230 AC

Motor power supply (V) 24 DC 24 DC

Current draw (A) 3 max 6 max

Power (W) 75 150

Opening time at 180° (s) Adjustable Adjustable

Duty cycle (%) Intensive duty Intensive duty

Torque (Nm) 33 2 x 33

Working temperature (°C) -20 to +55 -20 to +55

Dimensions

VLR02 + VLR04

маx. 2090

85

VLR01DX

77

1040

70

VLR01SX

1040

37

VLR07SX VLR07DX

VLR08SX VLR08DX

114

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

VLR09SX VLR09DX

FA00135-EN - vers.

VLR10SX VLR10DX

5 - Manual code

Page

Page 6

6

FA00135-EN

2

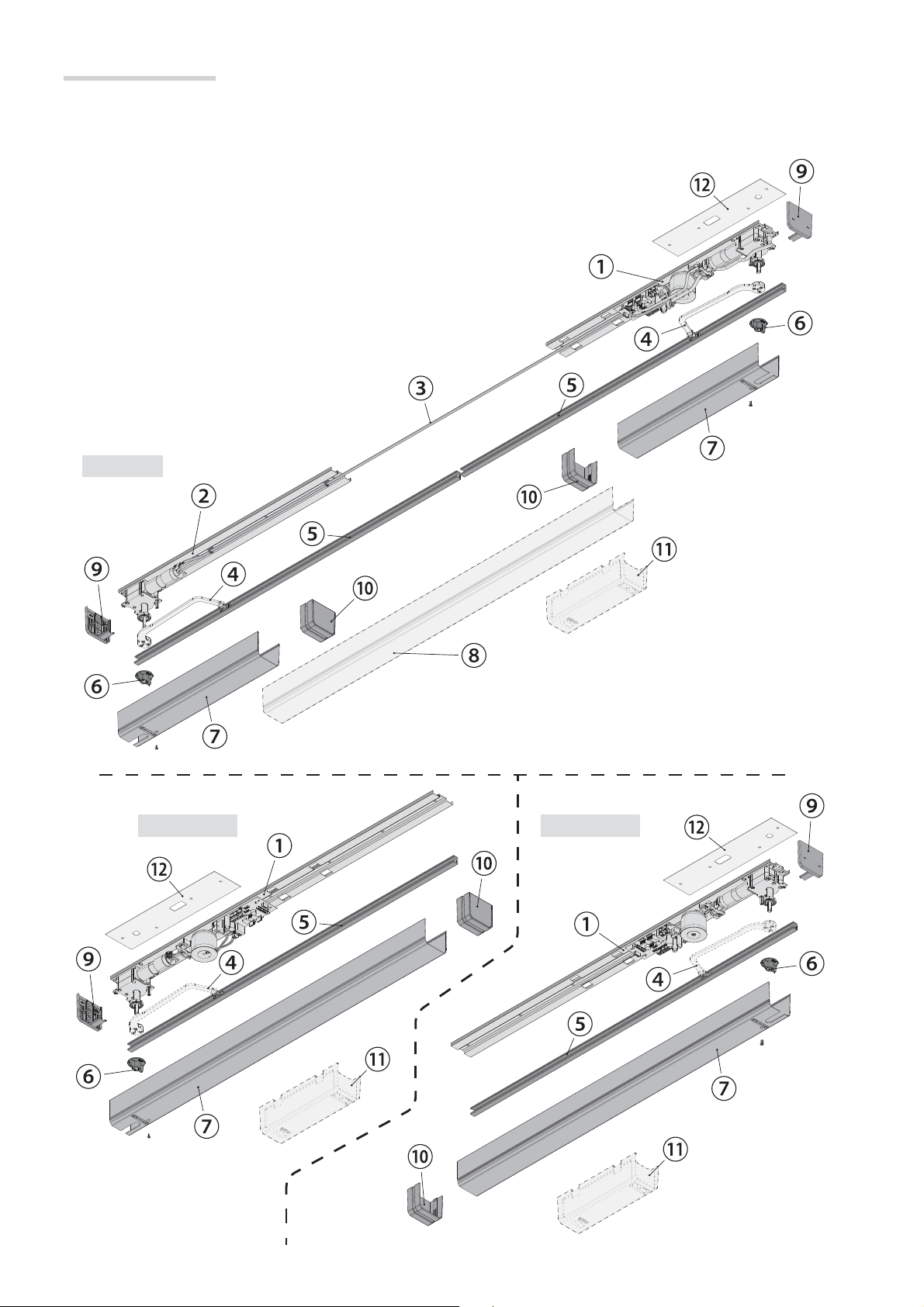

Description of parts

1. MASTER operator assembly: anchoring base/control board/transformer/gearmotor

2. SLAVE operator: anchoring base/gearmotor

3. Master/Slave connection cable

4. Transmission arms (see following tables)

5. Arm slide-guides

6. Manual release lever

7. Protective carter for operators

8. Continuous protective carter (OPTIONAL, item VLR04)

9. End caps

10. Carter closing/connecting strips

11. Emergency battery device (OPTIONAL, item VLR05)

12. Drilling template

VLR02

VLR01SX

VLR01DX

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

6 - Manual code

Page

Page 7

7

FA00135-EN

2

One or two-leaved single panel retractable shutter

Unfoldable type of transmission arm VLR07 VLR08

A - Minimum space between the inner fi xture and the

(without batteries / with VLR05 batteries)

B - Bay width (min./max.)

One leaf, without VLR01xx batteries

One leaf, with VLR01xx+VLR05 batteries

Two leaves, without VLR02 batteries

Two leaves with VLR02+VLR05 batteries

C - Recessing of outer edge (min./max.) 60 130 / 170

The angle

must always exceed 90°; install a simple strike plate for this.

shutter

90 / 110 130

500 / 1050

750 / 1050

720 / 2100

970 / 2100

500 / 1050

750 / 1050

820 / 2100

970 / 2100

One or two-leaf single-panel shutter, with outer edge

Unfoldable type of transmission arm VLR07 VLR08 VLR010

A - Minimum space between the inner fi xture and the

(without batteries / with VLR05 batteries)

B - Bay width (min./max.)

One leaf, without VLR01xx batteries

One leaf, with VLR01xx+VLR05 batteries

Two leaves, without VLR02 batteries

Two leaves with VLR02+VLR05 batteries

D - Hinge position beyond the bay (min./max.) 30 / 40 30 / 90 0 / 60

E - Hinge position beyond the outer edge (min./max.) 25 / 40 30 / 100 -

The angle

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

must always exceed 90°; install a simple strike plate for this.

shutter

90 / 110 130 165

500 / 1050

750 / 1050

720 / 2100

970 / 2100

500 / 1050

750 / 1050

820 / 2100

970 / 2100

500 / 1050

750 / 1050

720 / 2100

970 / 2100

FA00135-EN - vers.

7 - Manual code

Page

Page 8

8

FA00135-EN

2

One or two-leaved jointed double-paneled shutter

Unfoldable type of transmission arm VLR08 VLR09

A - Minimum space between the inner fi xture and the

shutter

130 160

B - Bay width (min./max.)

One leaf, without VLR01xx batteries

One leaf, with VLR01xx+VLR05 batteries

Two leaves, without VLR02 batteries

Two leaves with VLR02+VLR05 batteries

500 / 1050

750 / 1050

820 / 2100

970 / 2100

500 / 1050

750 / 1050

900 / 2100

970 / 2100

F - Width of internal panel (min./max.) 140 / 170 170 / 240

The angle

For this application, fi t a corner protection

must always exceed 90°; install a simple strike plate for this.

for the arm.

GENERAL INSTRUCTIONS FOR INSTALLING

Installation must be carried out by expert qualified personnel and in full compliance with the regulations in force.

⚠

Preliminary checks

• Check that the operator fixing point is protected from possible knocks, and that the fixing surface is solid. Also check that

appropriate screws, plugs, etc. are used to fix the panel;

• Set up suitable conduits and tubes to safely run the electrical cables through and to protect them from mechanical damage.

• Remove the shutter opening stops and replace them with strike plates.

• Make sure the angles between the two leaves always exceeds 90°.

Tools and materials

Make sure you have all the tools and materials you will need for installing in total

safety and in compliance with applicable regulations. The figure shows some of the

equipment installers will need.

Cable types and minimum thicknesses

Connection Cable type Cable length

1 < 10 m 10 < 20 m 20 < 30 m

Power supply to control panel 230 V

Accessories powered at 24 V 2 x 0.5 mm

Command and safety device 2 x 0.5 mm

Home & building automation connections CAT5 - U/UTP - AWG24 max 1200 m

FROR CEI 20-22

CEI EN 50267-2-1

3G x 1.5 mm23G x 2.5 mm

2

2 x 0.5 mm

2

2 x 0.5 mm

2

2

2

3G x 4 mm

2 x 1 mm

2 x 0.5 mm

2

2

2

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

If the cable lengths differ from that specified in the table, then you must determine the cable diameter based on the actual

☞

power draw from the connected devices and according to the CEI EN 60204-1 standard.

For multiple, sequential loads along the same line, the dimensions on the table need to be recalculated according to the actual

power draw and distances. For connecting products that are not contemplated in this manual, see the literature accompanying

said products

8 - Manual code

Page

Page 9

9

FA00135-EN

2

INSTALLING

The following illustrations are examples. It is up to the installer to find the most suitable solution.

The template features the indications for use on both the right and left.

Tracing the holes

Rest the template against the shutters and the bay side

panel of the bay and mark the holes using a pencil; finish

marking out the holes ❶ on the metal anchoring base of the

Voilà unit.

So, drill for using suitable fasteners.

For laying the cables, see details on page 14; zone

shows the cable entry point, in option 1.

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

❷

FA00135-EN - vers.

9 - Manual code

Page

Page 10

10

FA00135-EN

2

Fastening the operator

If the bay width is less than the dimensions of the operator base(s), cut off any excess ❸. The emergency batteries

(item VLR05) may not be fitted.

Fit the operator using suitable screws and dowels.

For the two-leaf swing configuration, install the MASTER

Fitting the transmission arms and the slide rails

operator

the left.

❹ on the right and the SLAVE operator ❺ on

Before fitting the transmission arm, lubricate the motor

shaft thread.

Fit the arm (also see detail

the motor shaft.

Leave the lever loose so as to make it easier to insert

the arm skid in the slide guide.

) and the release lever on

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

The VLR08 and VLR09 arms

need to be preassembled with a

loosened screws, for subsequent

adjustment.

Always use all three of the

screws supplied.

FA00135-EN - vers.

10 - Manual code

Page

Page 11

11

FA00135-EN

2

Cut the slide rails to the required length, leaving a minimum clearance at the ends.

One or two-leaf single-panel shutter One or two-leaved jointed double-paneled shutter

Fit the arm skid into the slide rail

(see ).

Fit the guide to the shutter and

check that it is level and that the

skid slides smoothly.

Use the premarked holes and

use flat countersunk screws (not

issued).

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

The operation should be

performed with the transmission

arm fixed to the motor shaft.

FA00135-EN - vers.

The VLR08/VLR09 adjustable arms, allow you to adjust the leaf opening more accurately, by changing the joining holes of the

two semi-arms (see page 10, figure ).

11 - Manual code

Page

Page 12

1÷2

0

12

FA00135-EN

2

VLR02 operator Master and Slave connection

Attach the cable clips ❻.

Connect the Slave gearmotor to the Master operator using the wired cable❼ on the MOTOR1 terminal.

In this way, the right-hand leaf will open first.

If you need the left-hand leaf to open first while keeping the Master to the right, swap the MOTOR1 and

MOTOR2 connectors.

Manual release of the operator

Activating the manual release could result in the shutter moving inadvertently due to possible mechanical failures or

balance issues.

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

12 - Manual code

Page

Page 13

13

FA00135-EN

2

ELECTRICAL CONNECTIONS AND PROGRAMMING

The control panel is powered by 230 V AC, with 50/60Hz frequency. The control devices and accessories run on 24 V.

The accessories must never exceed 15 W in total.

⚠

Fuses

Type

Line (mA) 400

Accessories (mA) 630

Description of parts

1. 230 V AC power-supply terminals

2. Transformer connection terminals

3. Line fuse

4. Accessories fuse

5. 24 V power-supply terminals for

control and safety devices

6. CRP connection terminals

7. AF card connector

8. RSE board connector

9. Built-in antenna

③ ④ ⑤⑮

L N

①

210 411CX3

10. DIP-switch for selecting functions with RSE

11. Programming button

12. Battery-charger connector

13. MOTOR 1 and MOTOR 2 sockets

14. Power on signalling LED

15. Programming warning LED

16. Dip-switches for selecting functions and programming

⑥ ⑦ ⑧ ⑨

BAGND

⑩

⑭

L1TL2T

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

②

Power supply

FA00135-EN - vers.

13 - Manual code

Page

20V

0V

L N

J8

M1

J7

M3

630mA-F

ACCESSORIES

11

⑬

2 10 4

R9

R25

C13

C23

CH1

⑪

Terminals for powering 24 V AC accessories.

Maximum allowed power: 15 W.

CX 3

R22 R23

B A GND

M6

R3

R6

C17

C11 C12

⑫

⑯

Page 14

14

FA00135-EN

2

There are two possible points to pass the power-supply and accessory-control cables through: either on the anchoring base

through the existing slots (option 1), or on the end cap which features pre-shaped apertures (option 2).

Connect the ground to both gearmotors.

Option 1 Option 2

Command and control devices

The AF and RSE cards must be fitted

into the control board AFTER CUTTING

OFF THE MAINS POWER.

N.B.: the basic control board recognises

them only when it is powered up.

LEFT-HAND MOTOR

RSE card

RIGHT-HAND MOTOR

GND

B

A

CX3

210 4

11

CRP - Came Remote Protocoll.

Connection to the home-automation

system.

AF card

B A GND

M6

OPEN-STOP function (NO contact)

LINE 1A-F

CLOSE-STOP function (NO contact)

⚠ If the PARTIAL OPENING function is activated via a dip-switch on the button connected to 2-3, then the button connected

to 2-4 will automatically operate as a sequential OPEN-STOP-CLOSE-STOP command.

⚠ If MAINTAINED ACTION is activated via dip-switches, the two buttons will operate as automatically OPEN and CLOSE,

respectively.

⚠When the MAINTAINED ACTION function is active, the PARTIAL OPENING function cannot be set.

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

14 - Manual code

Page

Page 15

15

FA00135-EN

2

Safety devices

REOPENING DURING CLOSING (NC). During the leaf closing phase, opening the contact inverts the movement until the leaves

are fully open.

TX

TX

2 NC C TX 2 10

If contacts 2-CX are unused,

they should be bridged.

L N

LINE 1A-F

L1TL2T

20V

0V

001AF43S - 001AF868 card fitting

210 411CX3

BAGND

C23

CH1

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

15 - Manual code

Page

AF card

Page 16

16

FA00135-EN

2

Programming the features

Before programming functions, release the gearmotors, manually close the shutter leaves and re-lock the gearmotors.

DIP1 DIP2 DIP3 DIP4 Description of functions

ON ON ON OFF Self-learning of the gate-leaf travel

OFF OFF OFF ON Partial opening from button

ON OFF OFF ON Button-activated maintained action

ON OFF OFF OFF Transmitter activated partial opening

OFF ON OFF OFF OPEN-STOP from trasmitter

ON ON OFF OFF CLOSE-STOP from transmitter

OFF OFF ON OFF Transmitter activated OPEN-STOP-CLOSE-STOP

ON OFF ON OFF Weather unit

OFF ON ON OFF Deleting memorized transmitters and weather units

OFF ON OFF ON Increasing the maneuvering speed

ON ON OFF ON Reducing the slow-down speed

OFF OFF ON ON Adjusting the sensitivity

ON OFF ON ON Slowed-down start when closing

OFF ON ON ON Immediate closing in case of a power outage

ON ON ON ON Resetting parameters

Self-learning of the gate-leaf travel

Select the DIPs as shown and press the PROG key on the

board.

To calibrate the travel the leaves must be closed.

The leaves will perform a series of maneuvers to establish the

limit switch points.

During calibration the red LED flashes. Once the calibration is

To disable the function: with the DIP switches set as shown,

press again the PROG key on the control boar.

Button-activated maintained action

Select the DIP switches as shown or press PROG on the

control board.

Once memorized the buzzer sounds off for one second.

done the buzzer sounds off for one second.

To restore the default parameters press

If calibration was not successful, the LED flashes quickly and

the buzzer sounds 4 times.

The self-learning procedure can be interrupted

by pressing the PROG key .

To configure for one swing-leaf, connect the operator to

⚠

MOTOR2.

Partial opening from button

Use the buttons to move the leaves to the desired position

Only consider the first leaf's opening angle. During the first

maneuver, the second leaf will memorize the opening angle

PROG again. The LED flashes and the buzzer sounds off

twice.

The opening button connected to 2-3 (NO contact) is

⚠

default set to the OPEN-STOP function.

If I enable maintained action from a button, I cannot enable

partial opening from a button and neither from a transmitter.

You can memorize up to a maximum of ten different

radio codes.

Partial opening using transmitter (only if already saved to

a button).

of the first leaf.

Select the DIP switches as shown or press PROG on the

Select the DIP switches as shown or press PROG on the

control board.

Once memorized the buzzer sounds off for one second.

control board. The red LED flashes. Within ten seconds press

the button on the transmitter you wish to memorize. Once

memorized the buzzer sounds off for one second.

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

If the partial opening angle does not come within the

minimum and maximum default-set limits (fro 10% to 50%

of the travel), upon sending the next command the opening

angle will automatically set to the closest level.

If the key has already been memorized, the LED will flash

quickly and buzzer will flash four times.

16 - Manual code

Page

Page 17

17

FA00135-EN

2

OPEN-STOP from transmitter

Select the DIP switches as shown or press PROG on the

control board. The red LED flashes. Within ten seconds press

the button on the transmitter you wish to memorize.

control board. The LED stays on and the buzzer sounds off

for 1 s.

To return to the default settings, press the PROG key again.

The LED flashes and the buzzer sounds off twice.

Once memorized the buzzer sounds off for one second.

If the key has already been memorized, the LED will flash

quickly and buzzer will flash four times.

CLOSE-STOP from transmitter

Select the DIP switches as shown or press PROG on the

control board. The red LED flashes. Within ten seconds press

the button on the transmitter you wish to memorize.

Once memorized the buzzer sounds off for one second.

If the key has already been memorized, the LED will flash

quickly and buzzer will flash four times.

Transmitter activated OPEN-STOP-CLOSE-STOP

Select the DIP switches as shown or press PROG on the

control board. The red LED flashes. Within ten seconds press

the button on the transmitter you wish to memorize.

Once memorized the buzzer sounds off for one second.

If the key has already been memorized, the LED will flash

quickly and buzzer will flash four times.

Weather unit

The weather unit occupies 3 radio codes.

⚠

Select the DIP switches as shown or press PROG on the

control board. The red LED flashes. Within ten seconds press

the P2 key on the weather unit. Once memorized the buzzer

sounds off for one second.

If the weather unit has already been memorized, the LED will

flash quickly and the buzzer will sound off four times.

Deleting memorized transmitters and weather units

Select the DIP-switches as shown and press PROG on the

control board for five seconds.

After deleting, the red LED flashes and the buzzer sounds off

for one second.

Adjusting the sensitivity

The default obstruction-intervention time is one second.

To increase the intervention time to two seconds:

Select the DIP switches as shown or press PROG on the

control board. The LED stays on and the buzzer sounds off

for 1 s.

To return to the default parameters, press PROG again. The

LED flashes and the buzzer sounds off twice.

Slowed-down start when closing

The slow-down is disabled by default.

To enable it:

Select the DIP switches as shown or press PROG on the

control board. The LED stays on and the buzzer sounds off

for 1 s.

To return to the default parameters, press PROG again. The

LED flashes and the buzzer sounds off twice.

Immediate closing in case of a power outage

This function can be used only where there are batteries.

⚠

To enable it:

Select the DIP switches as shown or press PROG on the

control board. The LED stays on and the buzzer sounds off

for 1 s.

To return to the default parameters, press PROG again. The

LED flashes and the buzzer sounds off twice.

Resetting parameters

Once reset, the LED flashes and the buzzer sounds off twice.

With this function the transmitters and weather unit are not

deleted.

Increasing the maneuvering speed

The default maneuvering speed is set to 70%.

To increase the maneuvering speed by 20%:

Select the DIP switches as shown or press PROG on the

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

control board. The red LED stays lit and buzzer sounds off

for one second.

To return to the default settings, press the PROG key again.

The LED flashes and the buzzer sounds off twice.

Reducing the slow-down speed

FA00135-EN - vers.

The default maneuvering speed is set to 50%.

To reduce the slow-down speed by 10%:

Select the DIP switches as shown or press PROG on the

17 - Manual code

Page

Page 18

18

FA00135-EN

2

FINAL OPERATIONS

Fasten the end caps using the supplied screws.

Fit the snap-in casing onto the gearmotor and secure it using the

supplied screws.

With two-leaved installations like with the Voilà VLR02, whose window-bay width exceeds 970 mm, we suggest also fitting

the VLR04 covering cross-piece so that it also covers the Master/Slave connection.

After reducing it to the right size (L1 = L - 14 mm), snap it into the guides and cover the joints using suitably modified strips

with the end caps removed.

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

18 - Manual code

Page

Page 19

19

FA00135-EN

2

DISMANTLING AND DISPOSAL

CAME S.p.A. applies a certified Environmental Management System at its premises, which is compliant with the UNI EN

☞

ISO 14001 standard to ensure environmental protection.

Please continue safeguarding the environment. At CAME we consider it one of the fundamentals of our operating and market

strategies. Simply follow these brief disposal guidelines:

DISPOSING OF THE PACKAGING

The packaging materials (cardboard, plastic, and so on) should be disposed of as solid household waste, and simply

separated from other waste for recycling.

Always make sure you comply with local laws before dismantling and disposing of the product.

DISPOSE OF RESPONSIBLY!

DISPOSING OF THE PRODUCT

Our products are made of various materials. Most of these (aluminium, plastic, iron, electrical cables) are classified as solid

household waste. They can be recycled by separating them before dumping at authorized city plants.

Whereas other components (control boards, batteries, transmitters, and so on) may contain hazardous pollutants.

These must therefore be disposed of by authorized, certified professional services.

Before disposing, it is always advisable to check with the specific laws that apply in your area.

DISPOSE OF RESPONSIBLY!

DECLARATION OF CONFORMITY

This product complies with the law.

2 - 01/2017 - © Came S.p.A . - The contents of this manual may be changed, at any time, and without notice.

FA00135-EN - vers.

19 - Manual code

Page

Page 20

www. came.com

CAME S.p.A.

Dosson di Casier

Treviso

Sesto al Reghena

Pordenone

English

FA00135-EN

2

2 - 01/2017 - © Came S.p.A .

FA00135-EN - vers.

The data and information in this manual are susceptible to changes at any time and without prior notice

English - Manual code

CAME S.p.A.

Via Martiri Della Libertà, 15 Via Cornia, 1/b - 1/c

31030

Dosson di Casier

Treviso - Italy

(+39) 0422 4940

(+39) 0422 4941

www. came.com

33079

Pordenone - Italy

Sesto al Reghena

(+39) 0434 698111

(+39) 0434 698434

Loading...

Loading...