Page 1

I N T R O D U C T I O N

THESE INSTRUCTIONS WILL SHOW YOU HOW TO INSTALL

A UNIV GARAGE DOOR KIT.

PLEASE READ THESE INSTRUCTIONS AND DIAGRAMS

CAREFULLY BEFORE STARTING ANY WORK.

UNDER NO CIRCUMSTANCES SHOULD THIS EQUIPMENT BE OPERATED UNLESS FITTED TO A GARAGE DOOR.

FAILURE TO COMPLY WILL INVALIDATE THE GUARANTEE.

1

Page 2

INSTALLATION INSTRUCTIONS

CONTENTS

1) Stage 1:- Civil & Mechanical Section Page

1.1 WHICH GARAGE DOOR? 3

1.2 V122 3

1.3 V201 4

1.4 V203 4

1.5 ASSEMBLING THE OPERATOR 5

1.6 EXTERNAL DIMENSIONS 6

1.7 FITTING THE OPERATOR 6

2) Stage 2:- Wiring & Electrical

2.1 WIRING THE CONTROL PANEL 9

2.2 DIPSWITCH SETTINGS 10

2.3 SETTING POTENTIOMETERS 11

3) Stage 3:- Commissioning

3.1 INITIAL COMMISSIONING AND & SETTING CAMS 13

3.2 INSERTING FREQUENCY CARD 14

3.3 CODING THE REMOTES 14

3.4 STORING THE CODE 15

3.5 WIRING THE TUNED ANTENNA 15

4) Troubleshooting Guide 17

5) Contact Information

“TIME MARCHES ON BUT CAME AUTOMATION EQUIPMENT STANDS THE TEST OF TIME...”

Page 3

STAGE 1

CIVIL & MECHANICAL SECTION

1.1- Which Garage Door?

BEFORE STARTING YOUR GARAGE DOOR INSTALLATION FIRST DETERMINE WHICH

GARAGE DOOR YOU HAVE.

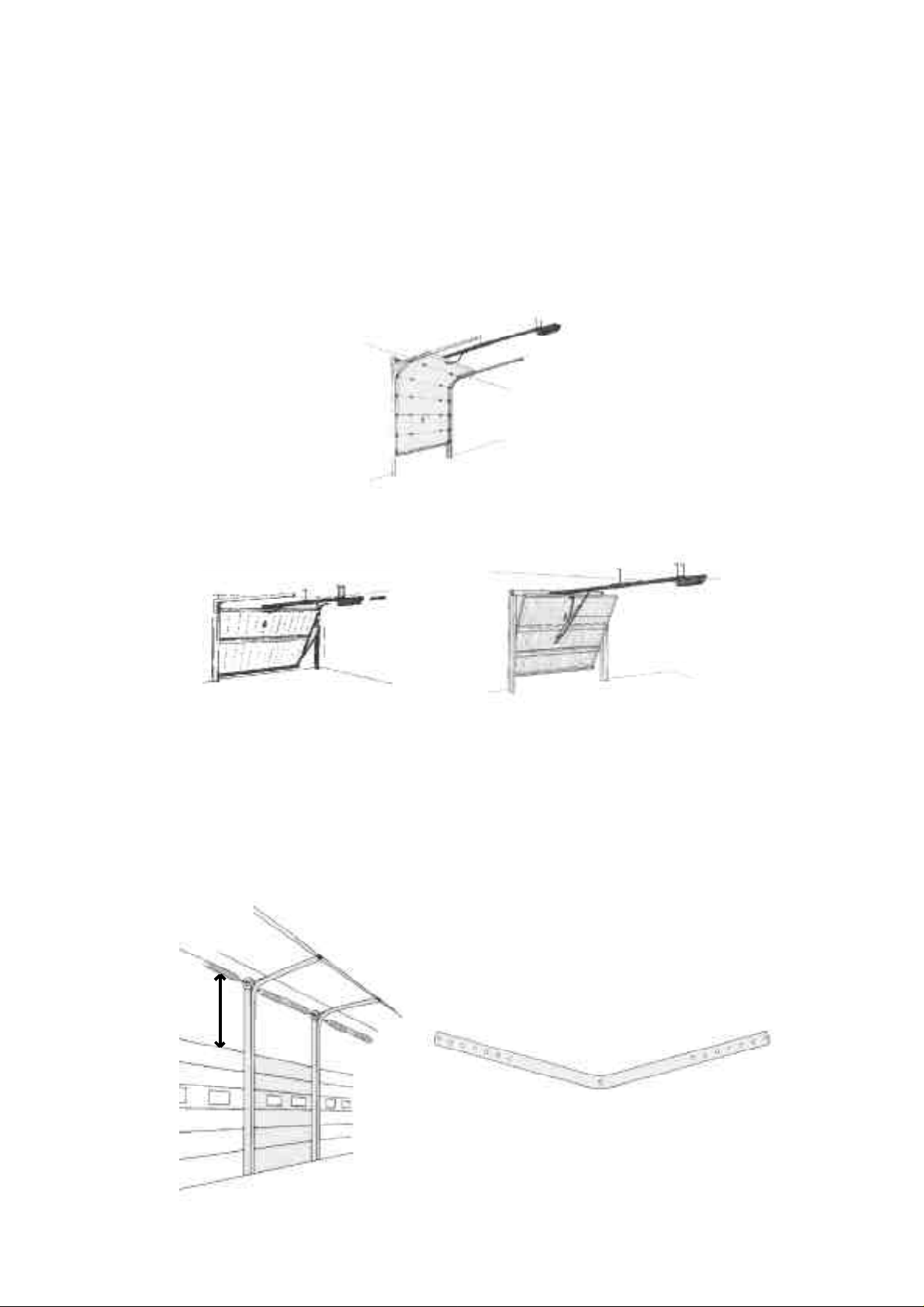

Fig 1

A: Sectional Door

B: Spring Balance Up

and Over Door

C: Overhead Door with Counter

Balancing or Canopy Door

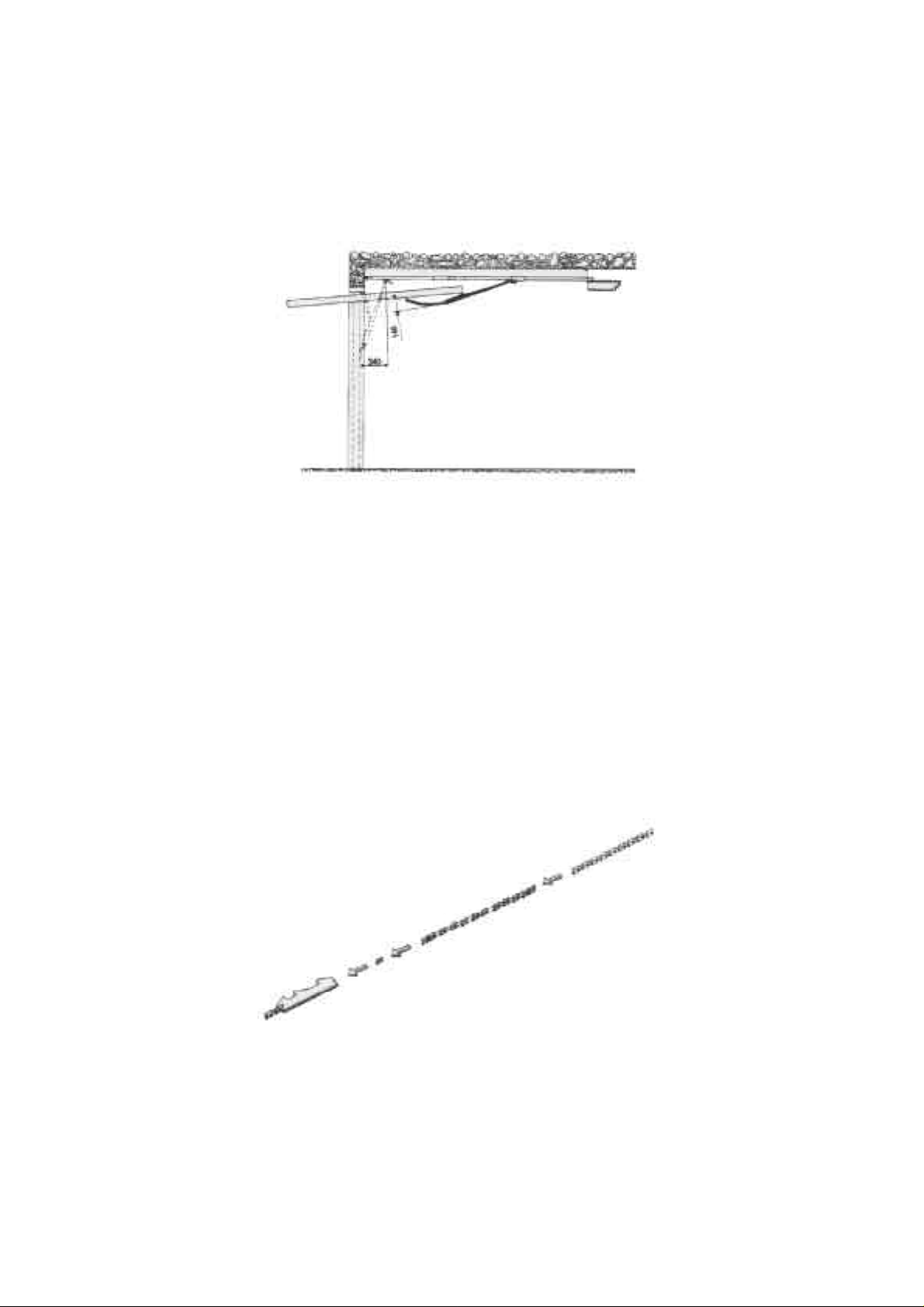

1.2- V122

IF A SECTIONAL DOOR IS BEING FITTED AN EXTENSION ARM IS RECOMMENED WHEN

THE DISTANCE BETWEEN THE SPRING BAR AND THE UPPER EDGE OF THE DOOR IS

BETWEEN 30 AND 60cm (see A).

Fig 2

A

Lever for Sectional Doors

3

Page 4

1.3- V201

IF YOU ARE FITTING THE OPERATOR TO A COUNTERWEIGHT BALANCING DOOR OR A

CANOPY SYLE DOOR THE V201 ADAPTER KIT IS REQUIRED.

Fig 3

1.4- V203

IF THE HEIGHT OF THE GARAGE DOOR IS BETWEEN 2.5m AND 3.5m THE V203

EXTENSION GUIDE KIT IS REQUIRED TO GIVE 1m EXTENSION OF TRAVEL.

Fig 4

4

Page 5

1.5 - Assembling the Operator

Fig 5

TURN THE GUIDE AROUND 180 AS SHOWN ABOVE ENSURING THAT THE CHAIN IS

AROUND THE DRIVE SPROCKET CORRECTLY.

N.B: IF THE HEIGHT OF THE DOOR IS OVER 2.5m IN HEIGHT THEN THE ADDITION OF

THE V203 EXTENSION KIT IS REQUIRED. ADDING THE SUPPLEMENTARY GUIDE AND

JUNCTION BRACKET. CONNECT THE CHAIN USING THE CHAIN COUPLING LINK.

SLIDE THE SLEEVE OVER THE TWO GUIDES SO THAT THE SLEEVE IS IN THE CENTRE

OF THE TWO GUIDES. TURN THE UNIT UP-SIDE-DOWN. USING A SCREWDRIVER BEND

THE TWO TABS (MARKED ‘A’) TO SECURE THE SLEEVE IN POSITION. BEND THE TAB

MARKED ‘B’ UP SO IT CAN BE USED TO SECURE THE GUIDE IN POSITION ON

INSTALLATION.

Fig 6

Junction Bracket

Tab A

Tab B

FIT THE WASHER, SPRING AND LOCK NUT AND TENSION THE CHAIN UNTIL IT IS

SLIGHTLY TAUT. FIT FRONT MOUNTING BRACKET ‘A’ WITH THE NUTS AND BOLTS

PROVIDED.

Fig 7

Bracket ‘A’

Nut

Tab A

Guide

5

Page 6

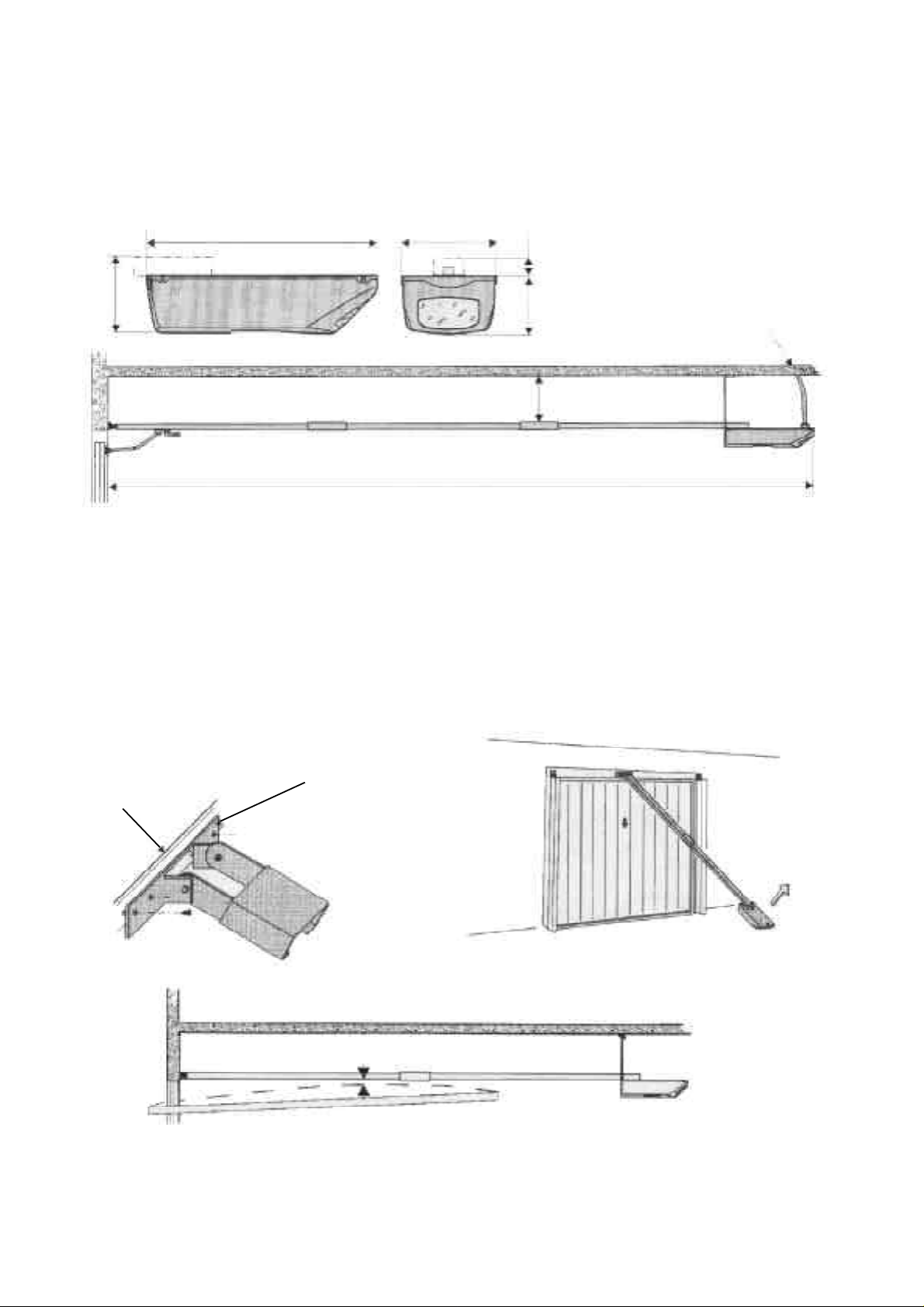

1.6 - External Dimensions

FOR HEIGHTS EXCEEDING 540mm, IT IS NECESSARY TO USE ADDITIONAL BRACKETS

AND STRUTS.

Fig 8

150

440

184

40

110

540 MAX

3400

1.7 - Fitting the Operator

BOLT, RIVET OR SCREW BRACKET ‘A’ TO THE DOOR FRAME, WALL OR SOLID

STRUCTURE ABOUT 10-20mm ABOVE THE HIGHEST POSITION REACHED BY THE DOOR

DURING ITS TRAVEL.

Door

Frame

Fig 9

Bracket

‘A’

min. 10 mm

6

Page 7

REMOVE THE BLUE COVER AND FIT THE CABLE STUFFING GLAND PROVIDED. FIT THE

BRACKETS TO THE MOTOR AND GUIDE SLEEVE AND USING THE ANGLE BRACKETS

PROVIDED, SECURE THE OPERATOR TO SUITABLE HANGING POINTS.

Angle

Brackets

Brackets

Cover

FIT THE DOOR BRACKET ‘C’ TO THE CROSS MEMBER OF THE DOOR FRAME USING THE

RIVETS SUPPLIED OR IF FITTING TO A WOODEN DOOR FRAME USE SUITABLE SCREWS

OR FIXINGS.

Fig 10

Stuffing

Gland

Hole for cable

Stuffing Glad

Cross-

member

Fig 11

Arm

Rivet

Bracket

‘C’

7

Page 8

END OF INSTALLATION

STAGE 1

BEFORE STARTING STAGE 2 - Wiring & Electrical

PLEASE CHECK THAT YOU HAVE CORRECTLY:

Ref Page

1. ASSEMBLED THE OPERATOR 1.5 5

2. CORRECTLY FITTED THE OPERATOR 1.7 6

NOW STAGE 1 IS FULLY COMPLETED YOU ARE READY TO

BEGIN STAGE 2 OF YOUR UNIV AUTOMATION KIT

INSTALLATION

8

Page 9

STAGE 2

WIRING & ELECTRICAL

2.1 - Wiring the Control Panel

CONNECT A SUITABLE MAINS SUPPLY TO THE MOTOR L2 BEING LIVE AND CONNECT

THE EARTH TO THE MOTOR.

Fig 12

L1 L2

CONNECT THE COAXIAL CABLE TO THE CORRECT TERMINALS ON THE P.C.B. BOARD.

Fig 13

CONNECT THE PUSHBUTTON WIRE TO TERMINALS 2 AND 7. THIS WILL GIVE YOU

OPEN/CLOSE REVERSE.

Fig 14

10 11 E E3 1 2 7 C1

9

Page 10

2.2 - Dipswitch Settings

Fig 15

1 2 3 4 5 6 7 8 9 10

ON

OFF

FOR NORMAL OPERATIONS ENSURE ALL DIPSWITCHES ARE SET TO OFF EXC EPT 7, 8

AND 9 WHICH SHOULD BE SET TO ON.

1 Off Automatic Closure Disabled

2 On “Open-Stop-Close-Stop” Control Function Enabled

2 Off “Open-Close-Reverse” Control Function Enabled

3 Off “Open Only” Control Function Disabled

4 Off Pre-Flashing light (Open and Close) Disabled

5 Off Obstacle Detection Device

(Motor at Limit Position) Disabled

6 Off “Present Man” Operation Disabled

7 On Re-Opening During Closure Phase

(Safety Device 2-C1) Disabled

8 On “Total-Stop” (Safety Device) Disabled

9 On Courtesy Light Enabled

10 Not Used

10

Page 11

Fig 16

2.3 - Setting Potentiometers

Trimmer T.C.A

FOR COMMISSIONING SET POTENTIOMETER

T.C.A TO MINIMUM.

Trimmer Sens

SET POTENTIOMETER SENS TO THE HALFWAY

POSITION FOR COMMISSIONING AND ADJUST

ACCORDINGLY

Trimmer Rall

SET POTENTIOMETER RALL TO MINIMUM FOR

COMMISSIONING AND ADJUST ACCORDINGLY

IF YOU ARE USING THE SLOWDOWN

FACILITY.

11

Page 12

END OF INSTALLATION

STAGE 2

BEFORE STARTING STAGE 3 -

Commissioning

PLEASE CHECK THAT YOU HAVE CORRECTLY:

Ref Page

1. WIRED THE MOTORS 2.1 9

2. SET DIPSWITCHES 2.2 10

3. SET POTENTIOMETERS 2.3 11

NOW STAGE 2 IS FULLY COMPLETED YOU ARE READY TO

BEGIN STAGE 3 OF YOUR UNIV AUTOMATION KIT

INSTALLATION

12

Page 13

STAGE 3

COMMISSIONING

3.1 - Initial Commissioning and Setting the Cams

White Cam (Open)

ENGAGE THE DOOR ONTO THE CHAIN DRIVE BY MOVING THE MANUAL RELEASE

HANDLE TO THE REAR AND LIFTING THE DOOR UNTIL IT ENGAGES ONTO THE CHAIN.

YOU ARE NOW READY TO ADJUST THE OPEN AND CLOSE CAMS.

Fig 17

Red Cam

(Slowdown/Close)

OPEN/STOP

PRESS THE OPEN/CLOSE BUTTON AND THE DOOR WILL START TO OPEN. MOVE THE

WHITE CAM UNTIL THE CORRECT OPEN POSITION IS ACHIEVED. ONCE THE DESIRED

POSITION HAS BEEN ACHIEVED TIGHTEN THE SCREW OF THE WHITE CAM TO SECURE

IN POSITION.

DECELERATION DURING CLOSING

PRESS THE OPEN/CLOSE BUTTON AGAIN UNTIL THE DOOR IS ABOUT 200mm FROM

THE CLOSED POSITION THEN PRESS THE OPEN/CLOSE BUTTON AGAIN TO STOP THE

DOOR IN THAT POSITION. TURN THE RED CAM AROUND UNTIL THE MICROSWITCH

HAS BEEN TRIPPED. THEN TIGHTEN THE SCREW ON THE CAM. TURN THE

POTENTIOMETER TR TO THE + POSITION UNTIL THE DOOR HAS REACHED THE FULLY

CLOSED POSITION.

CHECKING SENSITIVITY

CHECK THE SENSITIVITY OF THE DOOR BY TRYING TO STOP THE DOOR WHEN IT IS

CLOSING IF IT STOPS VERY EASILY, TURN THE SENSITIVITY TOWARDS - TO GIVE MORE

POWER AND TO DECREASE THE POWER TURN THE SENSITIVITY TO +.

13

Page 14

3.2 - Inserting the Frequency Card

Fig 18

Frequency Card

BEFORE INSERTING THE RADIO FREQUENCY CARD ENSURE THAT THE

POWER IS TURNED OFF TO THE CONTROL PANEL.

3.3 - Coding the Remote Controls

1. REMOVE THE BATTERY COVER & CASING OF THE REMOTE CONTROL

HANDSET TO REVEAL THE DIAGRAM BELOW

Fig 19

2. SET THE BANK OF

DIPSWITCHES ON

ALL REMOTES TO

EXACTLY THE SAME

CODE OF YOUR

CHOICE.

3. UNLESS PROGRAMMING FOR GATES AND

GARAGE DOORS TO OPEN BY REMOTE

CONTROL FROM THE SAME HANDSET ENSURE

THAT THE JUMPER STRAPS SHOWN HERE ARE

IN THE SAME POSITIONS ON ALL REMOTES

14

Page 15

3.4 - Storing the Code

Fig 20

Radio Code Save

Button

PRESS AND HOLD THE RADIO CODE SAVE BUTTON, AT THE SAME TIME

TRANSMIT BY PRESSING THE TOP BUTTON OF THE REMOTE CONTROL.

THE SIGNAL L.E.D WILL FLASH AND THEN GO CONSTANT TO INDICATE

THAT THE CODE HAS BEEN STORED.

3.5 - Wiring in the Tuned Antenna

Fig 21

ANTENNA

WIRING

POINT

15

Page 16

END OF INSTALLATION

STAGE 3

PLEASE CHECK THAT YOU HAVE CORRECTLY:

Ref Page

1. SET THE CAMS 3.1 13

2. INSERTED FREQUENCY CARD 3.2 14

3. CODED REMOTES 3.3 14

4. STORED CODE 3.4 15

5. WIRED THE TUNED ANTENNA 3.5 15

16

Page 17

4. TROUBLESHOOTING GUIDE

A MULTIMETER WILL BE NEEDED

PROBLEM SOLUTION

OPERATOR WILL NOT

RESPOND

WHEN GIVEN A COMMAND

DOOR IS OPEN BUT WILL

NOT CLOSE

DOOR CLOSES AND THEN

RE-OPENS AFTER PUTTING

A LOT OF PRESSURE ON

THE DOOR

1. CHECK POWER SUPPLY TO THE

CONTROL PANEL.

2. CHECK CONTROL PANEL FUSES.

3. CHECK DIPSWITCH SETTINGS 7,8

AND 9 ARE ON.

1. CHECK SAFETY BEAM CIRCUIT IS

SWITCHED OFF (DIPSWITCH 7 ON).

2. IF SAFETY BEAMS ARE FITTED

ENSURE THAT THEY ARE WIRED

CORRECTLY.

1. CLOSE CAM NOT SET CORRECTLY.

2. RALL NOT SET CORRECTLY. TOO

MUCH POWER GOING TO OPERATOR.

THE REMOTE CONTROL

WILL NOT WORK

1. FREQUENCY CARD NOT FITTED.

2. CODE HAS NOT BEEN TRANSMITTED

TO CONTROL PANEL.

IF THE PROBLEM IS STILL APPARENT CONTACT THE

CCAAMME

E TECHNICAL HELPLINE:

0115 938 7203

17

Page 18

NOTES

18

Page 19

5. CONTACT INFORMATION

CAME UNITED KINGDOM LTD

UNIT B3

GILTBROOK INDUSTRIAL ESTATE

GILTBROOK, NOTTINGHAM, NG16 2GN

TEL: 0115 938 7200

FAX: 0115 938 2694

INTERNET : www.cameuk.com

E-MAIL: enquiries@cameuk.com

THIS INSTALLATION WAS COMPLETED BY:

..............................................................................

NAME .............................................................................

ADDRESS............................................................

..............................................................................

............................................................................

...........................................................................

TEL........................ MOBILE................................

DATE OF INSTALLATION.......................................

19

Loading...

Loading...