Cambium Networks 45700 User Guide

Note

Chapter 5: Installation

This chapter describes how to install and test the hardware for a PTP 700 link. It contains the

following topics:

• Safety on page 5-2 contains important safety guidelines that must be observed by

personnel installing or operating PTP 700 equipment.

• ODU variants and mounting bracket options on page 5-6 provides details of six different

bracket options, including the type of ODu and range of pole diameters supported by each

option.

• Installing the ODU and top LPU on page 5-7 describes how to mount and ground a

Connectorized+Integrated or Connectorized ODU, and how to mount and ground the top

LPU.

• Install external antennas on page 5-14 describes how to mount and connect an external

antenna for the Connectorized or Connectorized+Integrated ODU.

• Installing the copper Cat5e Ethernet interface on page 5-16 describes how to install the

copper Cat5e power over Ethernet interface from the ODU (PSU port) to the PSU.

• Installing the PSU on page 5-24 describes how to install the AC+DC Enhanced Power

Injector power supply unit for the PTP 700.

• Installing a PTP-SYNC unit on page 5-26 describes how to install a PTP-SYNC unit for TDD

synchronization.

• Installing a GPS receiver on page 5-30 describes how to install a GPS receiver as the timing

reference source for PTP-SYNC.

• Installing a NIDU on page 5-40 describes how to install a network indoor unit (NIDU) for

TDM (T1 or E1) interfaces.

• Installing an SFP Ethernet interface on page 5-26 describes how to install an optical or

copper Cat5e Ethernet interface from the ODU (SFP port) to a connected device.

• Installing an Aux Ethernet interface on page 5-55 describes how to install a copper Cat5e

Ethernet interface from the ODU (Aux port) to a connected device.

• Supplemental installation information on page 5-56 contains detailed installation

procedures that are not included in the above topics, such as how to strip cables, create

grounding points and weatherproof connectors.

These instructions assume that LPUs are being installed from the PTP 650/700 LPU

and grounding kit (Cambium part number C000065L007). If the installation does not

require LPUs, adapt these instructions as appropriate.

If LPUs are being installed, only use the five black-capped EMC cable glands supplied

in the LPU and grounding kit. The silver-capped cable glands supplied in the ODU kits

must only be used in PTP 700 installations which do not require LPUs.

Page 5-1

Chapter 5: Installation Safety

Warning

Warning

Safety

To prevent loss of life or physical injury, observe the following safety guidelines. In no

event shall Cambium Networks be liable for any injury or damage caused during the

installation of the Cambium PTP 700. Ensure that only qualified personnel install a PTP

700 link.

Hazardous locations

When installing the PTP 700 ATEX/HAZLOC product variants in hazardous locations,

follow the instructions contained in the PTP 700 Series Hazardous Location Guide

(supplied in box with the products), in addition to the instructions in this user guide.

Power lines

Exercise extreme care when working near power lines.

Working at heights

Exercise extreme care when working at heights.

PSU

Always use one of the Cambium PTP 700 Series power supply units (PSU) to power the ODU.

Failure to use a Cambium supplied PSU could result in equipment damage and will invalidate

the safety certification and may cause a safety hazard.

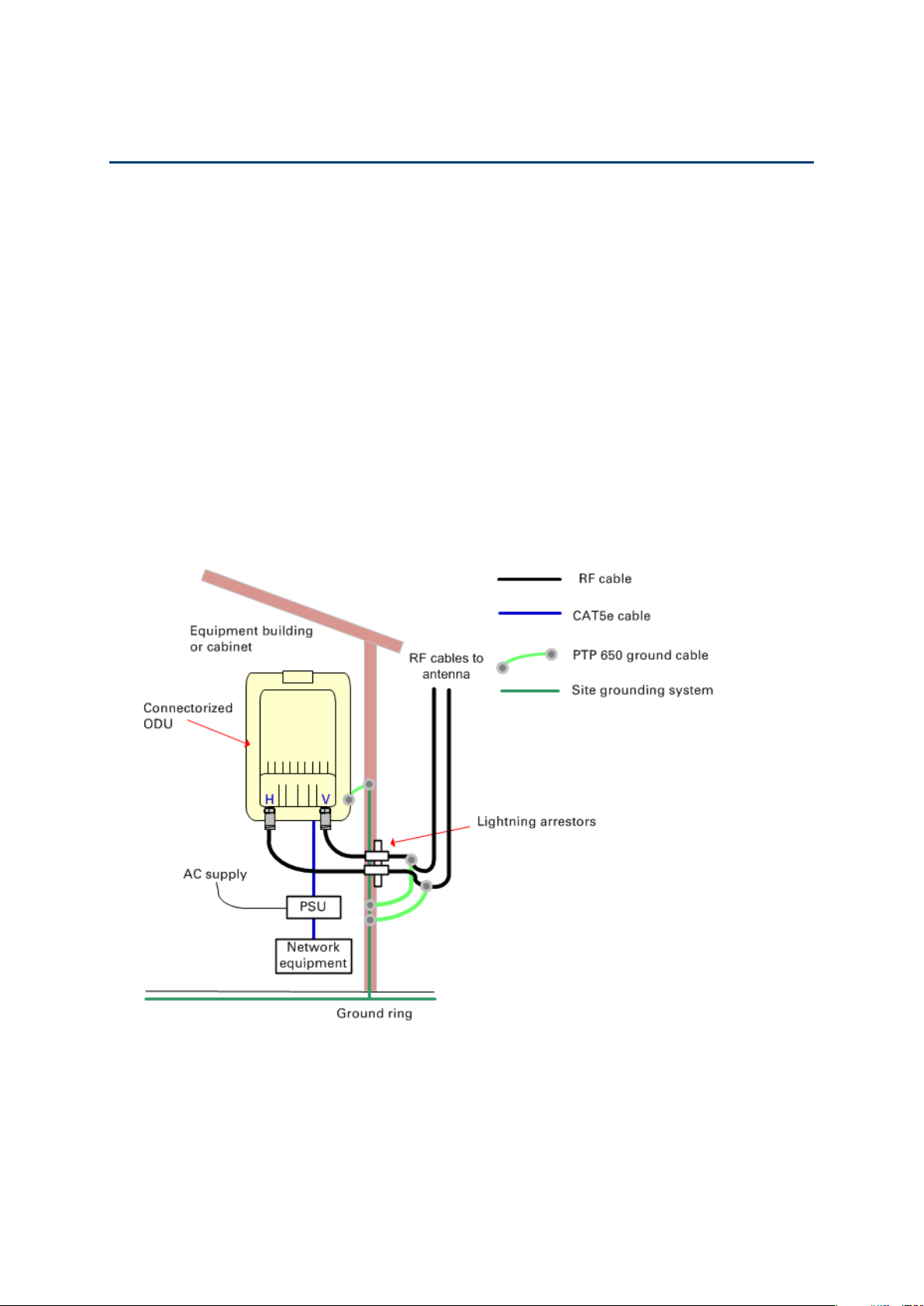

Grounding and protective earth

The Outdoor Unit (ODU) must be properly grounded to protect against lightning. It is the user’s

responsibility to install the equipment in accordance with national regulations. In the USA

follow the requirements of the National Electrical code NFPA 70-2005 and 780-2004 Installation

of Lightning Protection Systems. In Canada, follow Section 54 of the Canadian Electrical Code.

These codes describe correct installation procedures for grounding the outdoor unit, mast,

lead-in wire and discharge unit, size of grounding conductors and connection requirements for

grounding electrodes. Other regulations may apply in different countries and therefore it is

recommended that installation of the outdoor unit be contracted to a professional installer.

Page 5-2

Chapter 5: Installation Safety

DC supply

To power the ODU from a DC supply, use the PTP 650/700 AC+DC Enhanced Power Injector

(PSU) (Cambium part number C000065L002). Ensure that the DC power supply meets the

requirements specified in PSU DC power supply on page 3-15.

Powering down before servicing

Before servicing PTP 700 equipment, always switch off the power supply and unplug it from

the PSU.

Do not disconnect the RJ45 drop cable connectors from the ODU while the PSU is connected to

the power supply. Always remove the AC or DC input power from the PSU.

Primary disconnect device

The main power supply is the primary disconnect device. The AC+DC Enhanced power injector

is fused on the DC input. Some installations will also require an additional circuit breaker or

isolation switch to be fitted in the DC supply.

External cables

Safety may be compromised if outdoor rated cables are not used for connections that will be

exposed to the outdoor environment. For outdoor copper Cat5e Ethernet interfaces, always use

Cat5e cable that is gel-filled and shielded with copper-plated steel. Alternative types of drop

cable are not supported by Cambium Networks.

Drop cable tester

The PSU output voltage may be hazardous in some conditions, for example in wet weather. Do

NOT connect the drop cable tester to the PSU, either directly or via LPUs.

Grounding PTP-SYNC

In order to meet the safety requirements for deployment in Australia and New Zealand

(AS/NZS 60950-1), the PTP-SYNC unit, if deployed, must be grounded to a Protective Ground in

accordance with Local Electrical Regulations.

RF exposure near the antenna

Strong radio frequency (RF) fields will be present close to the antenna when the transmitter is

on. Always turn off the power to the ODU before undertaking maintenance activities in front of

the antenna.

Page 5-3

Chapter 5: Installation Safety

Minimum separation distances

Ensure that personnel are not exposed to unsafe levels of RF energy. The units start to radiate

RF energy as soon as they are powered up. Never work in front of the antenna when the ODU

is powered. Install the ODUs so as to provide and maintain the minimum separation distances

from all persons. For minimum separation distances, see Calculated distances on page 4-24.

Grounding and lightning protection requirements

Ensure that the installation meets the requirements defined in Grounding and lightning

protection on page 3-11.

Grounding cable installation methods

To provide effective protection against lightning induced surges, observe these requirements:

• Grounding conductor runs are as short, straight and smooth as possible, with bends and

curves kept to a minimum.

• Grounding cables must not be installed with drip loops.

• All bends must have a minimum radius of 200 mm (8 in) and a minimum angle of 90°. A

diagonal run is preferable to a bend, even though it does not follow the contour or run

parallel to the supporting structure.

• All bends, curves and connections must be routed towards the grounding electrode

system, ground rod, or ground bar.

• Grounding conductors must be securely fastened.

• Braided grounding conductors must not be used.

• Approved bonding techniques must be used for the connection of dissimilar metals.

Siting ODUs and antennas

ODUs, external antennas and GPS receivers for PTP-SYNC are not designed to survive direct

lightning strikes. For this reason they must be installed in Zone B as defined in Lightning

protection zones on page 3-11. Mounting in Zone A may put equipment, structures and life at

risk.

Thermal Safety

The ODU enclosure may be hot to the touch when in operation. The ODU must not be operated

in ambient temperatures exceeding 40°C unless mounted in a Restricted Access Location. For

more information, see ODU ambient temperature limits on page 3-13.

Page 5-4

Chapter 5: Installation Safety

Warning

Alerte

Do not install the ODU in a location where the ambient temperature could exceed 40°C

unless this is a Restricted Access Location as defined by EN 60950-1.

L’unité externe ne doit pas être installée dans un endroit où la température ambiante

est supérieure à 40C à moins que l’accès soit limité au personnel autorisé.

Page 5-5

Chapter 5: Installation ODU variants and mounting bracket options

Table 113

Bracket

Pole diameter

ODU variants

Bracket part

number

Note

ODU variants and mounting bracket options

Mounting bracket options

The PTP 700 series supports five mounting bracket options. Select the optimum mounting

bracket arrangement based on the pole diameter and the ODU variant:

Mounting bracket

(integrated)

Mounting bracket

(connectorized)

Extended integrated

mounting bracket

Mounting bracket

(integrated) with large

diameter extension kit

ODU mounting bracket part numbers

The connectorized mounting bracket is included with the PTP 700 Connectorized ODU.

Order a bracket separately for PTP 700 Connectorized+Integrated ODUs.

40 mm to 82 mm

(1.6 inches to 3.2

inches)

40 mm to 82 mm

(1.6 inches to 3.2

inches)

89 mm OR 114 mm

(3.5 inches OR 4.5

inches)

89 mm to 229 mm

(3.5 inches to 9.0

inches)

PTP 700

Connectorized+Integrated

PTP 700 Connectorized N000065L032

PTP 700 Connectorized

PTP 700

Connectorized+Integrated

PTP 700 Connectorized

PTP 700

Connectorized+Integrated

N000065L031

N000065L030

N000065L031

with

N000065L042

Page 5-6

Chapter 5: Installation Installing the ODU and top LPU

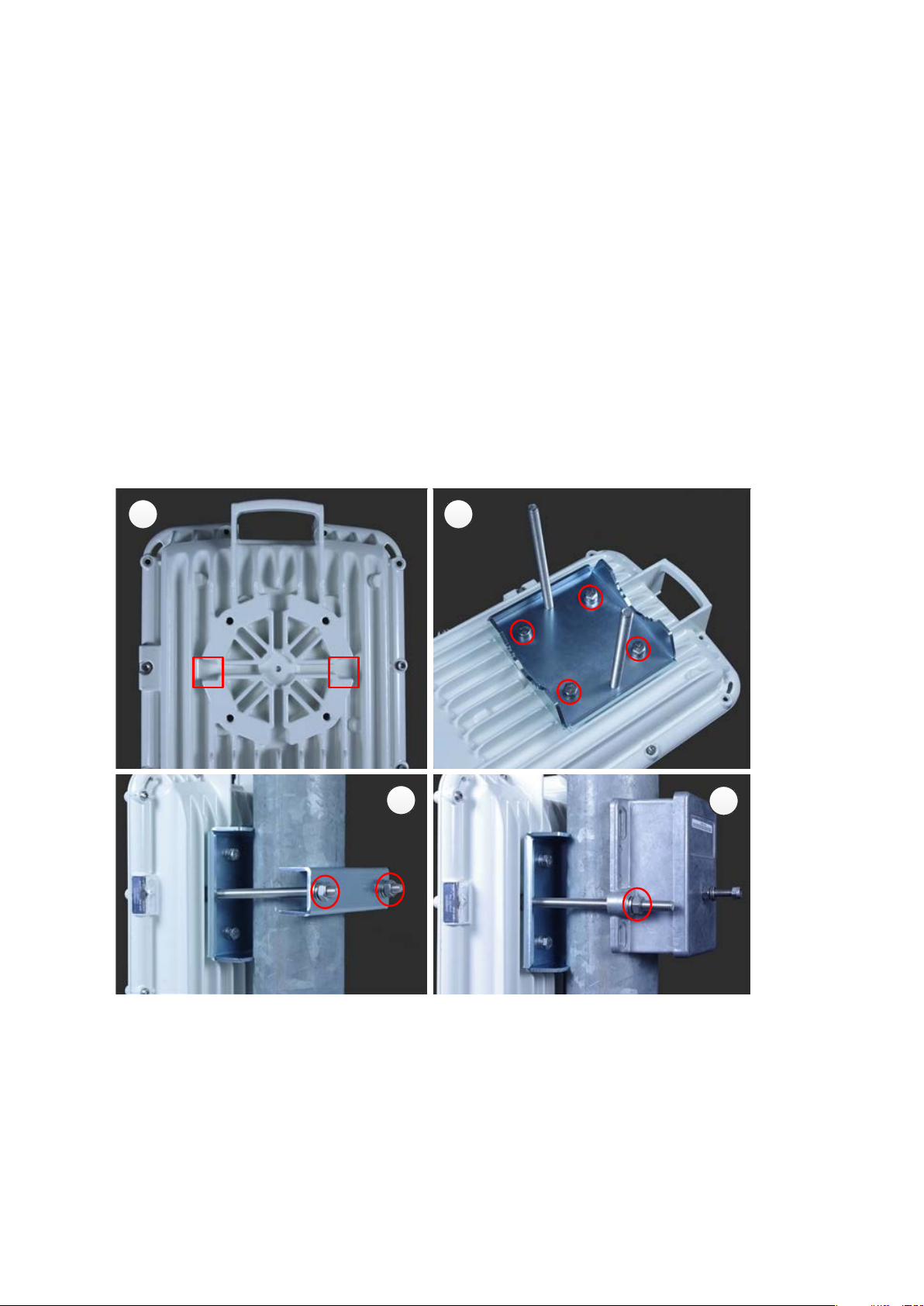

1

Fasten one ground cable to each ODU grounding point using the M6 (small) lugs: one is for the

top LPU (M6 lug at other end) and the other is for the tower or building (M10 lug at other end).

It does not matter which cable goes on which ODU grounding point.

2

T

21

Installing the ODU and top LPU

To install the ODU and top LPU, use the following procedures:

• Attach ground cables to the ODU on page 5-7

• Mount the ODU on the mast on page 5-7

• Mount the top LPU on page 5-12

• Interconnect and ground the ODU and top LPU on page 5-12

Attach ground cables to the ODU

ighten both ODU grounding bolts to a torque of 5 Nm (3.9 lb ft).

Mount the ODU on the mast

Select the most appropriate bracket mounting arrangement from the options listed in

Mounting bracket options on page 5-6. Refer to individual procedures below for each of the

options:

• Mounting bracket (integrated) on page 5-8

• Mounting bracket (connectorized) on page 5-9

• Extended integrated mounting bracket on page 5-10

• Mounting bracket (integrated) with large diameter extension kit on page 5-11

The procedure for the Mounting bracket (connectorized) can be readily adapted to attach the

ODU to a horizontal pole of similar size.

The procedure for the Mounting bracket (integrated) and the Extended integrated mounting

bracket can be adapted to attach the ODU to a suitable horizontal pole, but the adjustment of

azimuth angle is necessarily limited compared with an installation on a vertical pole.

Page 5-7

Chapter 5: Installation Installing the ODU and top LPU

Caution

1

2

3

4

5

1 2

4 5

7

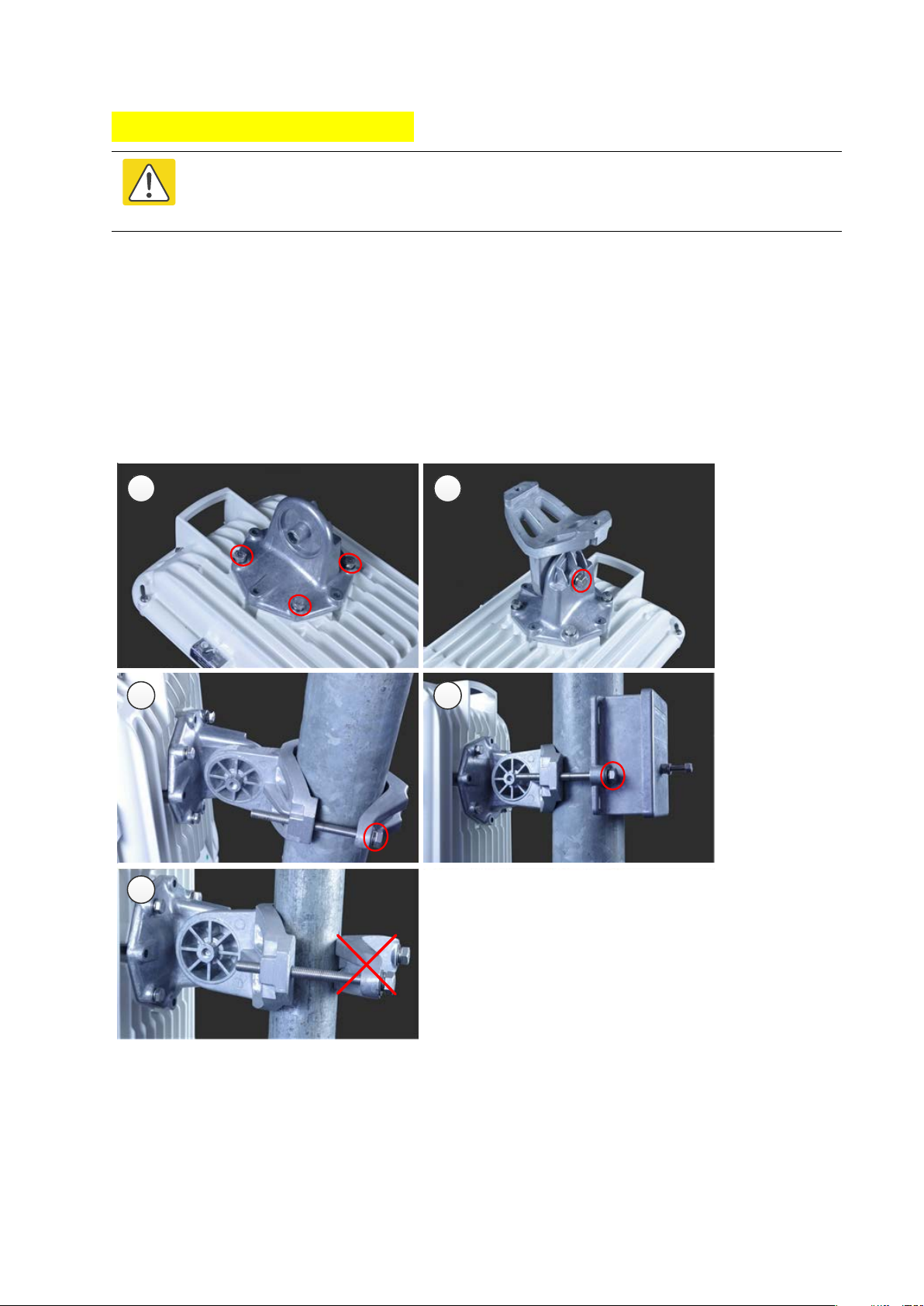

Mounting bracket (integrated)

Do not reverse the bracket clamp, as this arrangement may lead to failure of the

assembly. Do not over-tighten the bolts as this may lead to failure of the assembly.

Fix the mounting plate to the back of the ODU using the four bolts, and spring and plain

washers provided. Tighten the bolts to a torque setting of 5.0 Nm (3.7 lb ft).

Attach the bracket body to the mounting plate using the M8 bolt, spring and plain washers.

Hoist the ODU to the mounting position.

Attach the bracket body to the pole using the bracket clamp, M8 bolts, and spring and plain

washers. For back-to-back mounting, use the LPU in place of the clamp.

Adjust the elevation and azimuth to achieve visual alignment. Tighten all three bracket bolts to

a torque of 8.0 Nm (6.0 lb ft).

Page 5-8

Chapter 5: Installation Installing the ODU and top LPU

1

2

3

4

5

6

1 2

4

5

Mounting bracket (connectorized)

Identify the square cavities in the casting on the back of the ODU. These cavities will be used

to accommodate the heads of two M8 bracket bolts.

Fix the mounting plate to the ODU using the four M6 bolts, and spring and plain washers

provided. Ensure that the M8 bolts are correctly held between the mounting plate and the

ODU. Tighten the M6 bolts to a torque setting of 5.0 Nm (3.7 lb ft).

Hoist the ODU to the mounting position.

Attach the bracket body to the pole using the bracket clamp, spring and plain washers, and M8

nuts.

Alternatively, use the LPU in place of the clamp to provide a back-to-back arrangement.

Tighten the two M8 bracket bolts to a torque setting of 8.0 Nm (6.0 lb ft). Do not over-tighten

the bolts as this may lead to failure of the assembly.

Page 5-9

Chapter 5: Installation Installing the ODU and top LPU

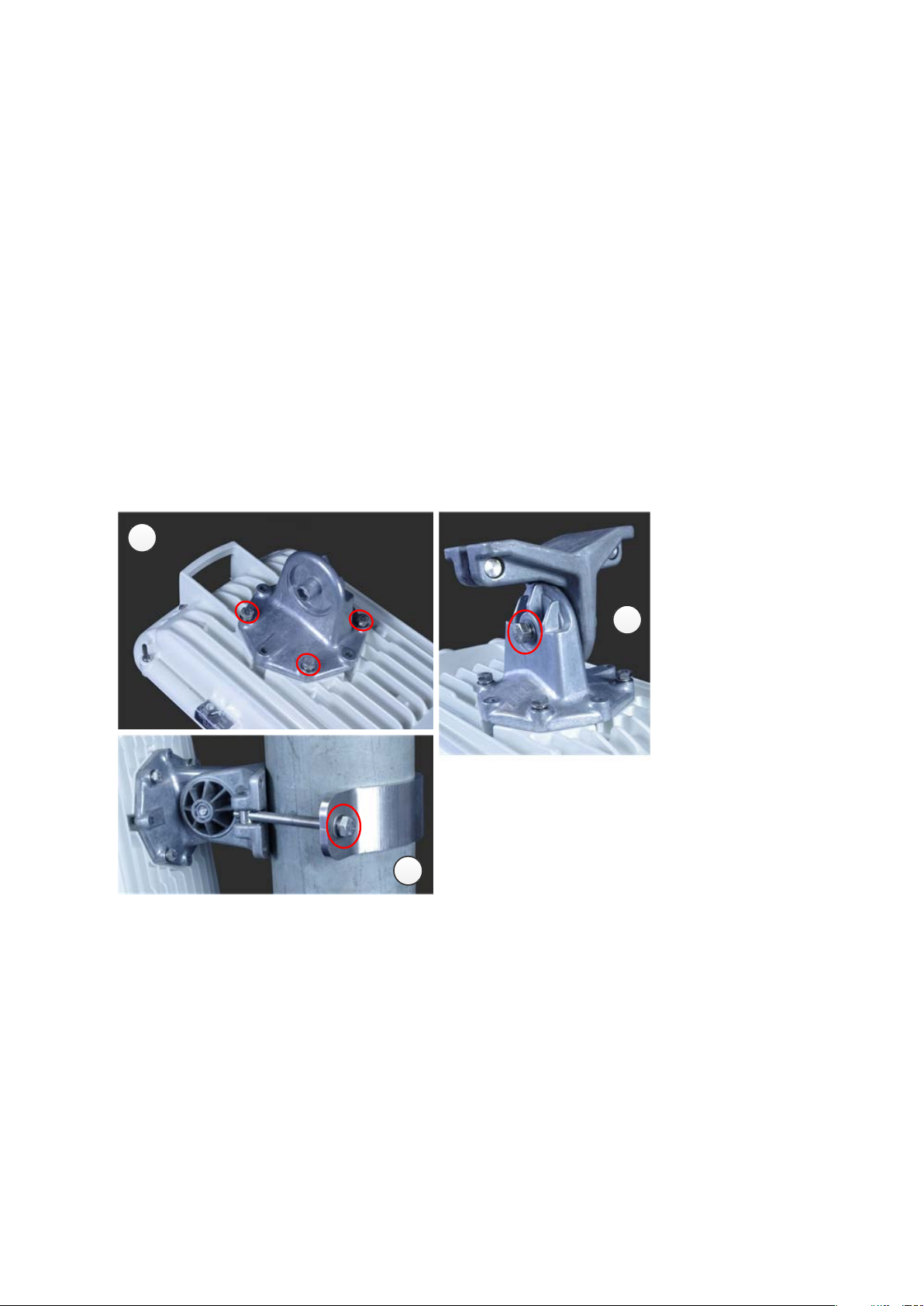

1

2

3

4

5

6

1

2

5

Extended integrated mounting bracket

Fix the mounting plate to the back of the ODU using the four M6 bolts, and spring and plain

washers provided. Tighten the bolts to a torque setting of 5.0 Nm (3.7 lb ft). The step is common

with the standard integrated bracket.

Attach the bracket body of the extended bracket on the mounting plate on the ODU to using the

M8 bolt and spring and plain washer.

Hoist the ODU to the mounting position.

Select the correct clamp. The larger clamp is intended for poles of diameter 114 mm (4.5

inches). The smaller clamp is intended for poles of diameter 89 mm (3.5 inches).

Attach the bracket body to the pole using the selected bracket clamp, washers and M8 bolts.

Adjust the elevation and azimuth to achieve visual alignment. Tighten all three M8 bracket bolts

to a torque setting of 8.0 Nm (6.0 lb ft). Do not over-tighten the bolts as this may lead to failure

of the assembly.

Page 5-10

Chapter 5: Installation Installing the ODU and top LPU

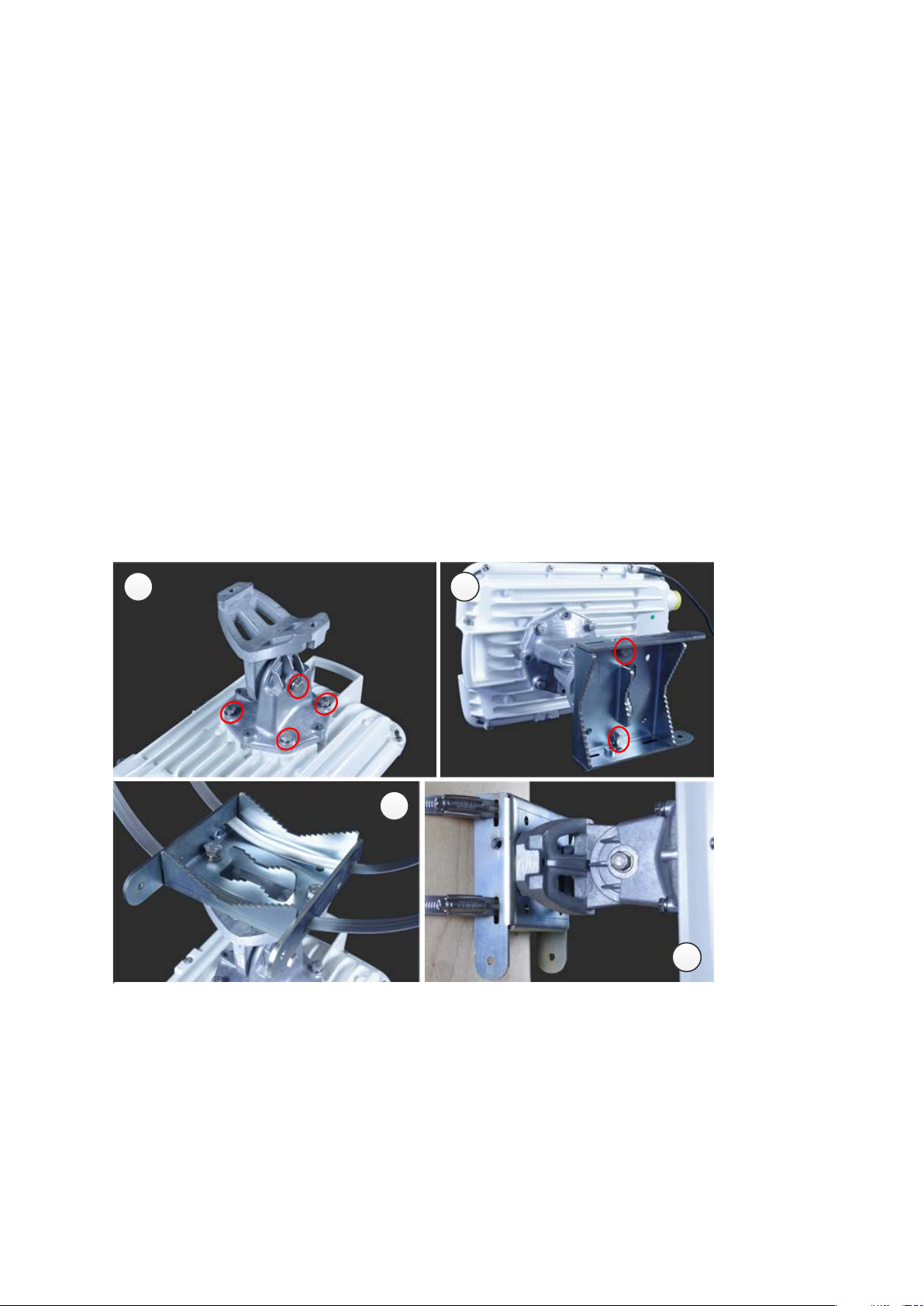

1

2

3

4

5

6

7

1

2

3

5

Mounting bracket (integrated) with large diameter extension kit

Fix the mounting plate to the back of the ODU using the bolts and washers provided. Tighten

the four bolts to a torque setting of 5.0 Nm (3.7 lb ft). Attach the bracket body to the mounting

plate using the M8 bolt and spring and plain washer. This is equivalent to the first two steps for

the standard integrated bracket.

Attach the adaptor plate of the large diameter extension kit to the bracket body using the bolts

and washers provided. Tighten the two bolts to a torque setting of 5.0 Nm (3.7 lb ft).

Feed the Jubilee straps through the slots in the adaptor plate.

Hoist the ODU to the mounting position.

Attach the adaptor plate to the pole using the Jubilee straps.

Adjust the azimuth to achieve visual alignment. Tighten the Jubilee straps to a torque setting of

6.0 Nm (4.5 lb ft).

Adjust the elevation to achieve visual alignment. Tighten M8 bracket bolt to a torque setting of

8.0 Nm (6.0 lb ft). Do not over-tighten this bolt as this may lead to failure of the assembly.

Page 5-11

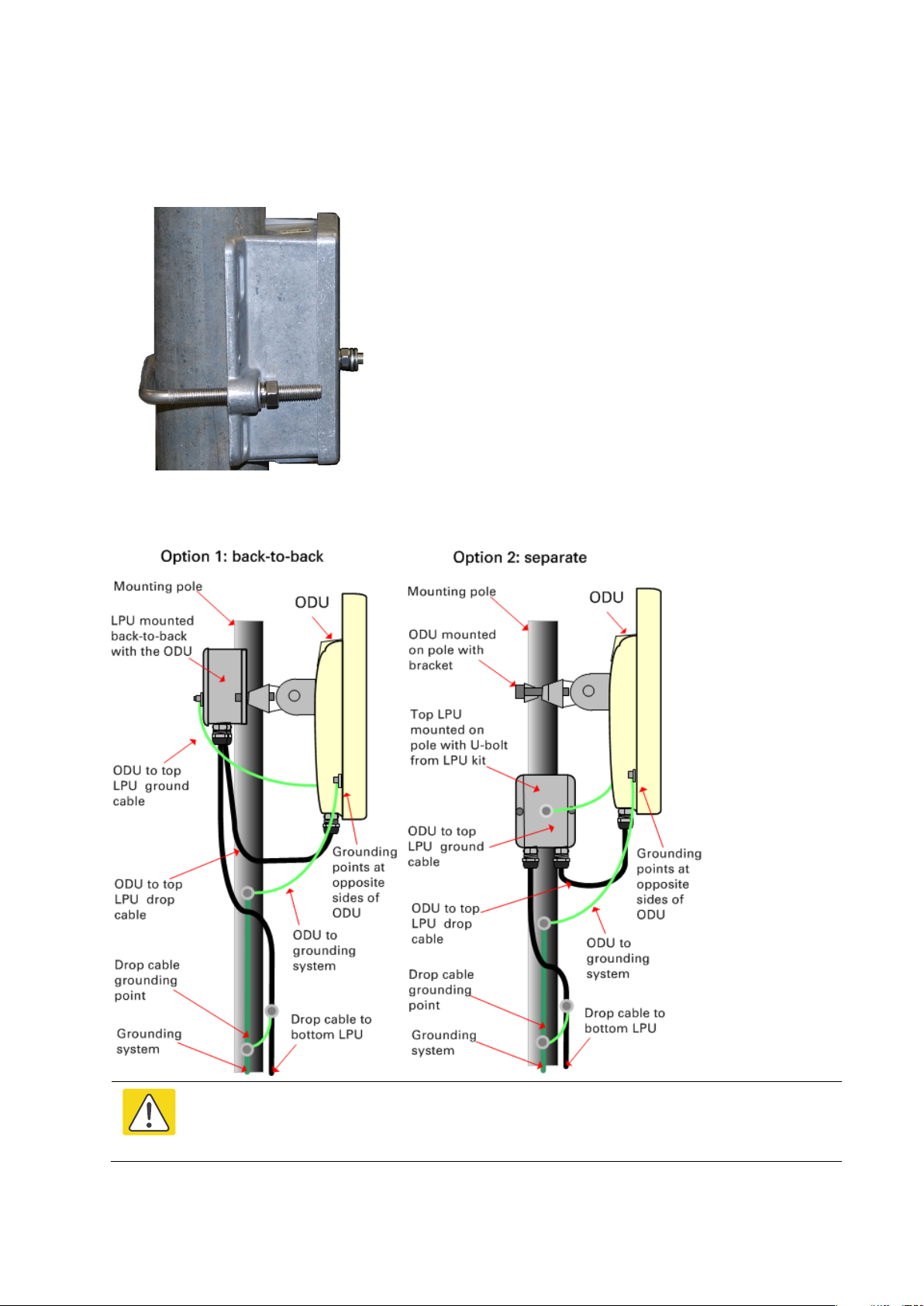

Chapter 5: Installation Installing the ODU and top LPU

1

For separate LPU mounting, use the U

pole below the ODU. Tighten

Caution

Mount the top LPU

-bolt bracket from the LPU kit to mount the top LPU on the

to a torque setting of 7.0 Nm (5.2 lb ft):

Interconnect and ground the ODU and top LPU

Do not attach grounding cables to the ODU mounting bracket bolts, as this

arrangement will not provide full protection.

Page 5-12

Chapter 5: Installation Installing the ODU and top LPU

1

Fasten the ODU grounding cable to the top LPU using the M6 (small) lug.

torque of 5

2

3

add a third ground cable to

Tighten both nuts to a

Nm (3.9 lb ft):

Locking nut

Washer

M6 lug

Washer

Nut

Toothed washer

M6 lug to ODU

Select a tower or building grounding point within 0.3 meters (1 ft) of the ODU bracket. Remove

paint from the surface and apply anti-oxidant compound. Fasten the ODU grounding cable to this

point using the M10 (large) lug.

If local regulations mandate the independent grounding of all devices,

connect the top LPU directly to the grounding system.

Page 5-13

Chapter 5: Installation Install external antennas

1

M

When using separate antennas to

achieve spatial diversity, mount

polarization.

2

Connect

part numbers 30010194001 and 30010195001) and

09010091001). Tighten the

3

If

4

Form

channeled towards the connector

5

If the ODU is mounted outdoors, wea

is complete) using PVC tape and

6

Weatherproof the antenna connectors in the same way (unless the antenna manufacturer

specifies a different method).

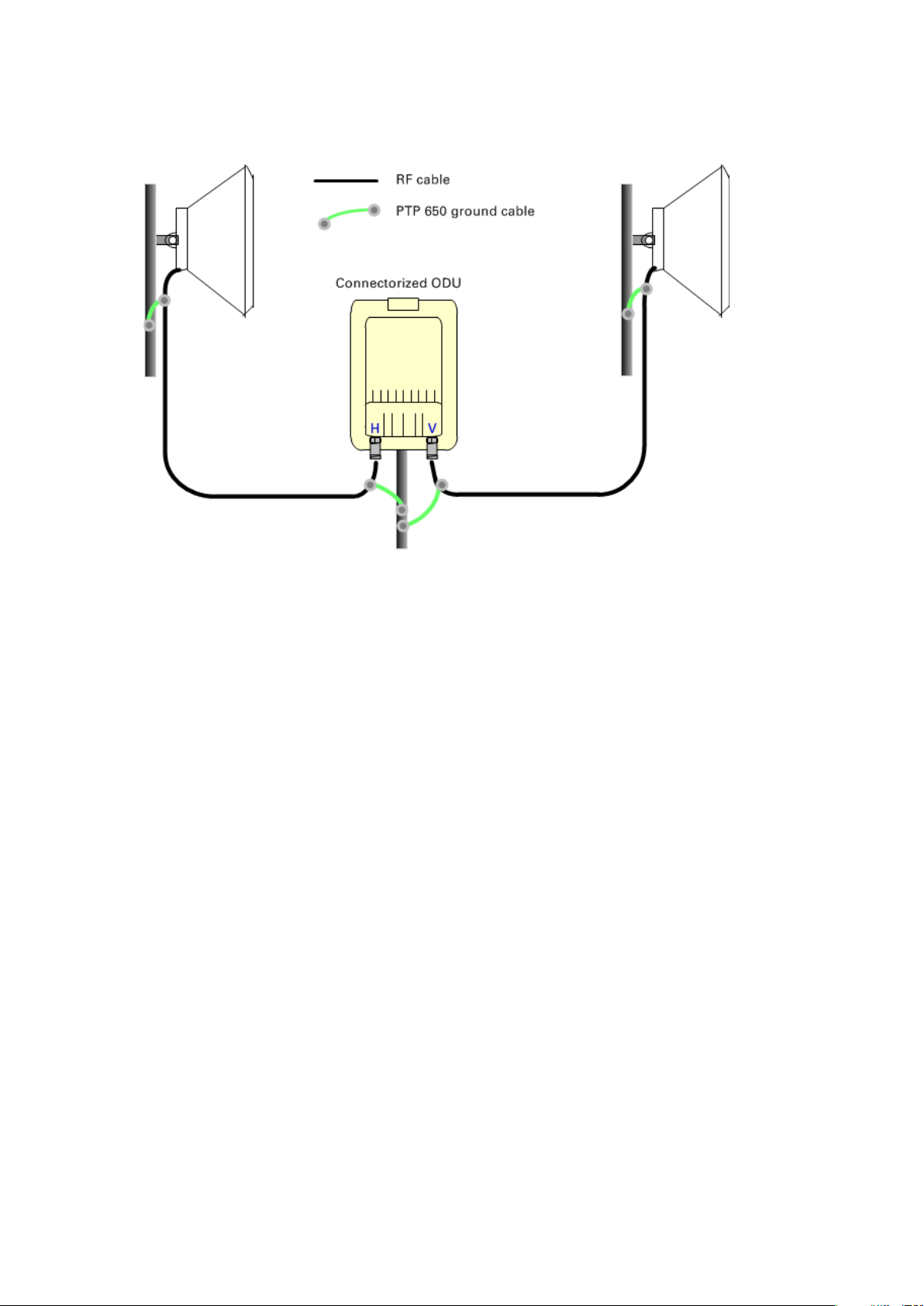

Install external antennas

To mount and connect an external antenna, proceed as follows:

ount the antenna(s) according to manufacturer’s instructions.

one with Horizontal polarization and the other with Vertical

the ODU V and H interfaces to the antenna(s) with RF cable of type LMR-400 (Cambium

N type connectors (Cambium part number

N type connectors to a torque setting of 1.7 Nm (1.3 lb ft).

the ODU is mounted indoors, install lightning arrestors at the building entry point:

drip loops near the lower ends of the antenna cables. These ensure that water is not

s.

therproof the N type connectors (when antenna alignment

self-amalgamating rubber tape.

Page 5-14

Chapter 5: Installation Install external antennas

7

Ground the

antennas using the Cambium grounding kit (part number 01010419001):

8

Fix the antenna cables to the supporting structure using site approved methods. Ensure that no

und

the wind, as flapping cables are prone to damage and induce unwanted vibrations in the

supporting structure.

antenna cables to the supporting structure within 0.3 meters (1 foot) of the ODU and

ue strain is placed on the ODU or antenna connectors. Ensure that the cables do not flap in

Page 5-15

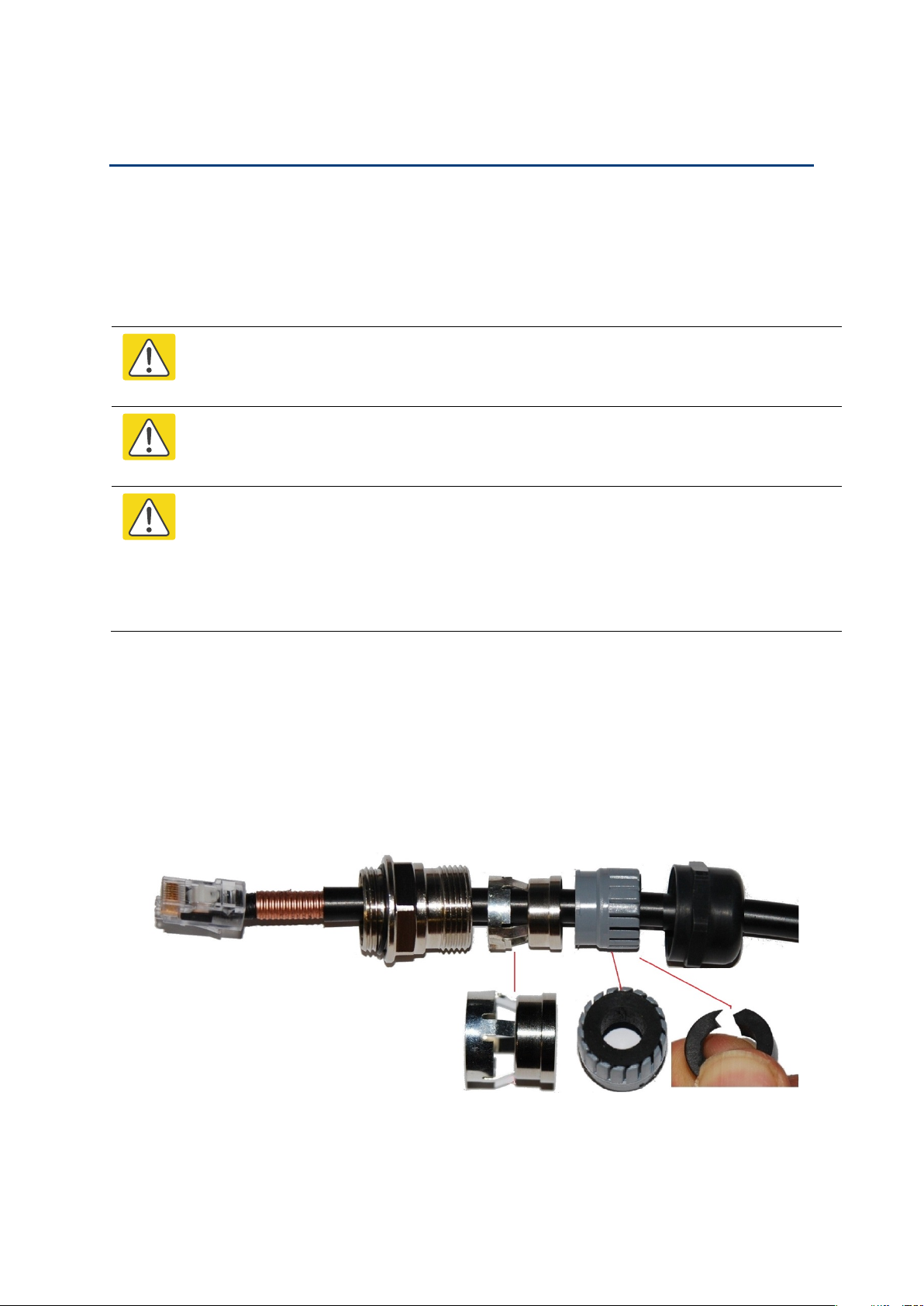

Chapter 5: Installation Installing the copper Cat5e Ethernet interface

Caution

Caution

Caution

1

Disassemble the gland and thread each part onto the cable (the rubber bung is sp

Assemble the spring clip and the rubber bung:

Installing the copper Cat5e Ethernet interface

To install the copper Cat5e Ethernet interface, use the following procedures:

• Install the ODU to top LPU drop cable on page 5-16

• Install the main drop cable on page 5-18

• Install the bottom LPU to PSU drop cable on page 5-21

• Test resistance in the drop cable on page 5-23

To avoid damage to the installation, do not connect or disconnect the drop cable when

power is applied to the PSU or network terminating equipment.

Do not connect the SFP or Aux drop cables to the PSU, as this may damage

equipment.

Always use Cat5e cable that is gel-filled and shielded with copper-plated steel.

Alternative types of Cat5e cable are not supported by Cambium Networks. Cambium

Networks supply this cable (Cambium part numbers WB3175 and WB3176), RJ45

connectors (Cambium part number WB3177) and a crimp tool (Cambium part number

WB3211). The LPU and grounding kit contains a 600 mm length of this cable.

Install the ODU to top LPU drop cable

Fit glands to the ODU to top LPU drop cable

Fit EMC strain relief cable glands (with black caps) to both ends of the 600 mm length of

pre-terminated cable. These parts are supplied in the LPU and grounding kit.

lit).

Page 5-16

Chapter 5: Installation Installing the copper Cat5e Ethernet interface

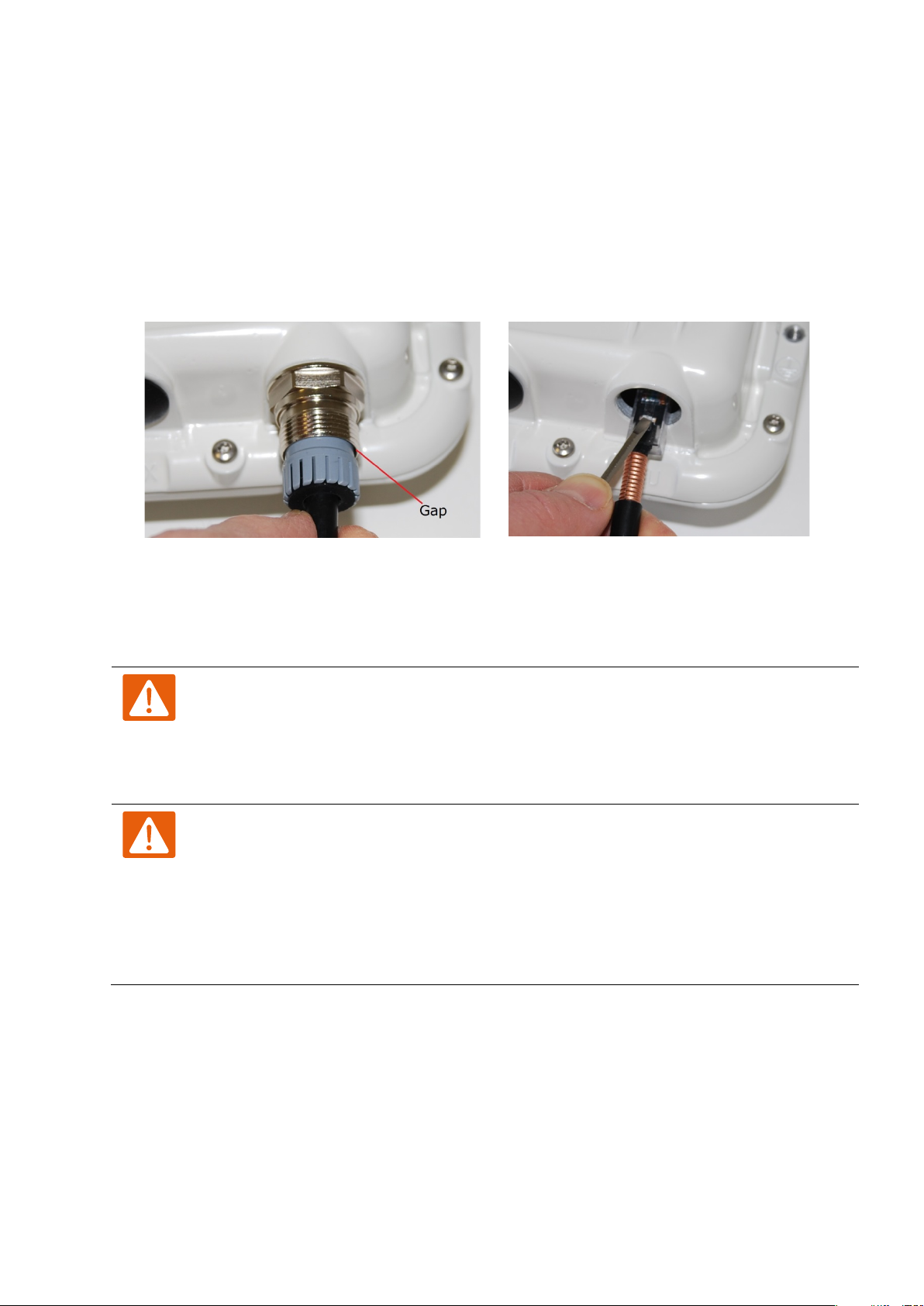

2

Fit the parts into the body and lightly screw on the gland nut (do not tighten it):

1

2

Connect the drop cable to the ODU (PSU port) and LPU

(a) Plug the RJ45 connector into the socket in the unit, ensuring that it snaps home.

(b) Fit the gland body to the RJ45 port and tighten it to a torque of 5.5 Nm (4.3 lb ft):

(a)

(a) Fit the gland nut and tighten until the rubber seal closes on the cable. (b) Do not overtighten the gland nut, as there is a risk of damage to its internal components:

(a)

(b)

(b)

Correct

Incorrect

Page 5-17

Chapter 5: Installation Installing the copper Cat5e Ethernet interface

1

(a) Remove the gland nut. Wiggle the drop cable to release the tension of the gland body. When

the tension in the gland body is released, a gap opens at the point show. Unscrew the gland

body.

(b) Use a small screwdriver to press the

(a)

Warning

Warning

1

Cut the main drop cable to length from the top LPU to the bottom LPU.

2

Slide one or more hoisting grips onto the top end of the

3

Secure the hoisting grip to the cable using a special tool, as recommended by the manufacturer.

Disconnect the drop cable from the LPU or ODU

Use this procedure if it is necessary to remove an EMC strain relief cable gland and RJ45

connector from the ODU (as illustrated) or LPU.

RJ45 locking tab, then remove the RJ45 connector.

Install the main drop cable

The metal screen of the drop cable is very sharp and may cause personal injury.

• ALWAYS wear cut-resistant gloves (check the label to ensure they are cut resistant).

(b)

• ALWAYS wear protective eyewear.

• ALWAYS use a rotary blade tool to strip the cable (DO NOT use a bladed knife).

Failure to obey the following precautions may result in injury or death:

• Use the proper hoisting grip for the cable being installed. If the wrong hoisting grip is

used, slippage or insufficient gripping strength will result.

• Do not reuse hoisting grips. Used grips may have lost elasticity, stretched, or become

weakened. Reusing a grip can cause the cable to slip, break, or fall.

• The minimum requirement is one hoisting grip for each 60 m (200 ft) of cable.

Cut to length and fit hoisting grips

drop cable.

Page 5-18

Chapter 5: Installation Installing the copper Cat5e Ethernet interface

Caution

1

Thread the cable gland (with black cap) onto the main drop cable.

2

Strip the cable outer sheath and fit the RJ45 connector load bar.

3

Fit

cable

Terminate with RJ45 connectors and glands

Check that the crimp tool matches the RJ45 connector, otherwise the cable or

connector may be damaged.

the RJ45 connector housing as shown. To ensure there is effective strain relief, locate the

inner sheath under the connector housing tang. Do not tighten the gland nut:

Page 5-19

Loading...

Loading...