Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

Type 1150

Process and Program controller

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2004 Bürkert Werke GmbH & Co.

Operating Instructions 0507/02_EU-EN_00804664

Page 3

Table of Contents

Process and Program Controller

Type 1150

C

ONTENTS

GENERAL NOTES .................................................................................................................................................................................................................................5

Typographical conventions ............................................................................................................................................................................................ 6

Safety instructions

Protection from damage by electrostatic charging

Scope of delivery

Warranty conditions

................................................................................................................................................................................................................... 6

......................................................................................................................... 7

....................................................................................................................................................................................................................... 7

................................................................................................................................................................................................................ 7

SYSTEM DESCRIPTION ......................................................................................................................................................................................................... 9

Function description.............................................................................................................................................................................................................. 10

Technical data

Order table

............................................................................................................................................................................................................................... 11

......................................................................................................................................................................................................................................... 15

INSTALLATION, COMMISSIONING AND MAINTENANCE......................................................................................... 17

General notes ............................................................................................................................................................................................................................. 18

Location and climatic conditions

Close mounting

Assembly

Installation

Accessories

Maintenance

......................................................................................................................................................................................................................... 18

.......................................................................................................................................................................................................................................... 18

........................................................................................................................................................................................................................................ 19

.................................................................................................................................................................................................................................. 20

.................................................................................................................................................................................................................................. 20

.......................................................................................................................................................................... 18

1150 - 1

Page 4

CONTENTS

ELECTRICAL CONNECTIONS

................................................................................................................................................................................ 21

Connection diagram............................................................................................................................................................................................................ 22

Terminal Strip Numerical Assignment

OPERATION AND CONTROLLER FUNCTIONS

.......................................................................................................................................................... 22

........................................................................................................................ 25

Operation.............................................................................................................................................................................................................................................. 26

Displays and controls.......................................................................................................................................................................................................... 26

Overview of operation ......................................................................................................................................................................................................... 28

Entering values and selecting settings.............................................................................................................................................................. 31

Setpoint input .............................................................................................................................................................................................................................. 32

Recording ........................................................................................................................................................................................................................................ 33

Operation “Controller“....................................................................................................................................................................................................... 34

Setpoint ............................................................................................................................................................................................................................................. 34

Manual mode ............................................................................................................................................................................................................................... 34

Operating „program controller/generator“................................................................................................................................................ 36

Program editor............................................................................................................................................................................................................................ 36

Starting the program............................................................................................................................................................................................................. 39

Overview of operation ......................................................................................................................................................................................................... 40

Shifting the program profile ........................................................................................................................................................................................... 41

PARAMETERIZATION

CONFIGURATION

............................................................................................................................................................................................................ 43

........................................................................................................................................................................................................................... 47

Parameters and functions at the configuration level.................................................................................................................. 48

Analog inputs

Controller

Generator

Limit comparators

Outputs

Logic functions

............................................................................................................................................................................................................................... 51

........................................................................................................................................................................................................................................... 56

.......................................................................................................................................................................................................................................... 60

................................................................................................................................................................................................................... 64

................................................................................................................................................................................................................................................ 67

........................................................................................................................................................................................................................... 69

Math and logic module

C-level control

Display

................................................................................................................................................................................................................................................. 78

Interfaces

Device data

Recording

2 - 1150

..................................................................................................................................................................................................... 74

............................................................................................................................................................................................................................. 76

.......................................................................................................................................................................................................................................... 81

.................................................................................................................................................................................................................................... 82

......................................................................................................................................................................................................................................... 83

Page 5

CONTENTS

OPTIMIZATION

..................................................................................................................................................................................................................................... 85

Self-optimization....................................................................................................................................................................................................................... 86

Oscillation method.................................................................................................................................................................................................................. 86

Step response method....................................................................................................................................................................................................... 86

Starting self-optimization ................................................................................................................................................................................................ 88

Canceling self-optimization ........................................................................................................................................................................................... 88

Check of the optimization............................................................................................................................................................................................. 89

RETROFITTING OF MODULES

............................................................................................................................................................................... 91

Safety notes .................................................................................................................................................................................................................................. 92

Identifying the module

Removing the back panel from the housing

Slot assignment

Retrofitting of modules

....................................................................................................................................................................................................... 92

......................................................................................................................................... 93

........................................................................................................................................................................................................................ 94

........................................................................................................................................................................................................ 94

1150 - 3

Page 6

CONTENTS

4 - 1150

Page 7

GENERAL NO TES

GENERAL NOTES

Typographical conventions ............................................................................................................................................................................................ 6

Safety instructions

Protection from damage by electrostatic charging

Scope of delivery

Warranty conditions

................................................................................................................................................................................................................... 6

......................................................................................................................... 7

....................................................................................................................................................................................................................... 7

................................................................................................................................................................................................................ 7

1150 - 5

Page 8

GENERAL NOTES

Typographical conventions

Symbols

Indicates procedure(s) that you must carry out.

ATTENTION!

NOTE

CAUTION!

Indicates information, where failure to observe, your safety or the proper function of the

device will be compromised.

Indicates important additional information, tips and recommendations.

This device is sensitive to electrostatic discharge (ESD). Contact with an electrically

charged personnel or object will damage this device. In the worst case, immediate damage

or failure on commissioning will occur .

Representation

Menu items

Texts relating to screen representations are shown in italics (e .g. Exit program).

Factory Preset Parameters

Factory presets or setting at delivery (E.g.: 0 ... 9999, where 9999 is the factory setting at delivery).

Safety instructions

Please observe the notes in these operating instructions together with the conditions of use and permitted

data that are specified in the data sheets for the Process and Program Controller and for the respective

pneumatically operated valve, in order that the device will function perfectly and remain operable for a long

time:

•

Keep to standard engineering rules in planning the use of and operating the device!

•

Installation and maintenance work are only allowed by specialist personnel using suitable tools!

•

Observe the current regulations on accident prevention and safety for electrical devices during

operation and maintenance of the device!

•

Switch off the supply voltage in all cases before intervening in the system!

•

T ak e suitable precautions to prev ent inadvertent operation or damage by unauthorized action!

•

Make sure that after an interruption to the electrical or pneumatic supply , the process is configured to

resume in a well-defined, controlled manner!

6 - 1150

Page 9

Protection from damage by electrostatic charging

This device contains electronic components that are sensitive to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects will damage these components. In the worst case, they

will be immediately destroyed or will fail after commissioning.

Observe the requirements of EN 100 015 - 1 in order to minimize the possibility of, or avoid, damage from

instantaneous electrostatic discharge. Also take care not to touch components that are under supply

voltage.

Scope of delivery

Immediately after receipt of a shipment, make sure that the contents are undamaged and match the

scope of delivery stated on the packing slip.

If there are discrepancies, please contact immediately our customer service:

Bürkert Fluid Control Systems

Service Department

Chr.-Bürkert-Str . 13-17

GENERAL NOTES

D-76453 Ingelfingen

T el.: 07940 10-111, F ax: 07940 10-448, Email info@de.b uerkert.com

or maybe local Bürkert Rep. See back page for contact information in other countries.

W arranty conditions

This document contains no warranty statements. Please refer to our general sales and business

conditions. A prerequisite for validity of the warranty is use of the device als intended with observance of

the specified conditions of use.

ATTENTION!

The warranty covers only f aultless condition of the Process and Program controller. No

liability will be accepted for consequential damage of any kind that may arise from

failure or malfunctioning of the device.

1150 - 7

Page 10

GENERAL NOTES

8 - 1150

Page 11

SYSTEM

DESCRIPTION

SYSTEM DESCRIPTION

Function description.............................................................................................................................................................................................................. 10

Technical data

Order table

............................................................................................................................................................................................................................... 11

......................................................................................................................................................................................................................................... 15

1150 - 9

Page 12

SYSTEM DESCRIPTION

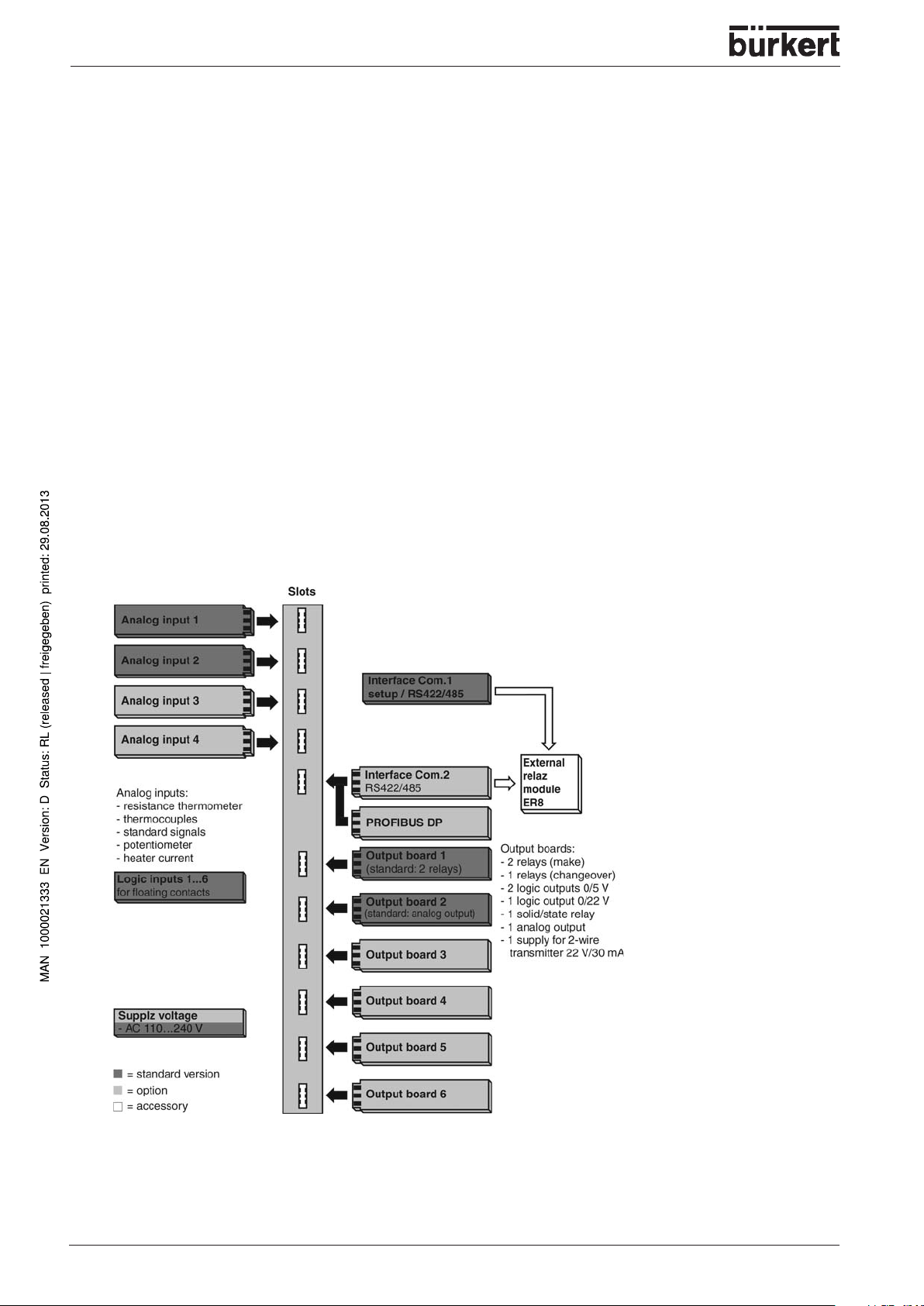

Function description

T ype 1150 is a process and progr am controller with up to four controller or program channels. The

instrument is built to the format 144 mm x 130 mm for a standard 92 mm x 92 mm panel cut-out and a

mounting depth of 170 mm.

The display is a 5" color screen with 27 colors. The lay out of the screen templates can be individually

adapted and adjusted. Two freely configurable screen templates make it possible to customiz e the placing

of texts, process values, background pictures and icons.

A maximum of 4 analog inputs and 6 logic inputs are available, as well as six expansion slots for switched

or analog outputs.

A setup program is available for direct configuration via a PC. Linearizations for the usual transmitter

outputs are stored within the instrument, four customer-specific linearization tables can be programmed.

A math and logic module can be used to adapt the instrument to a very wide range of control tasks.

A serial interface RS422/485 or Profibus-DP can be used to integrate the instrument into a data network.

Modules can be retrofitted quite simply by the user.

The electrical connection is made at the back of the instrument, via plug-in screw terminals.

Block structure

10 - 1150

Page 13

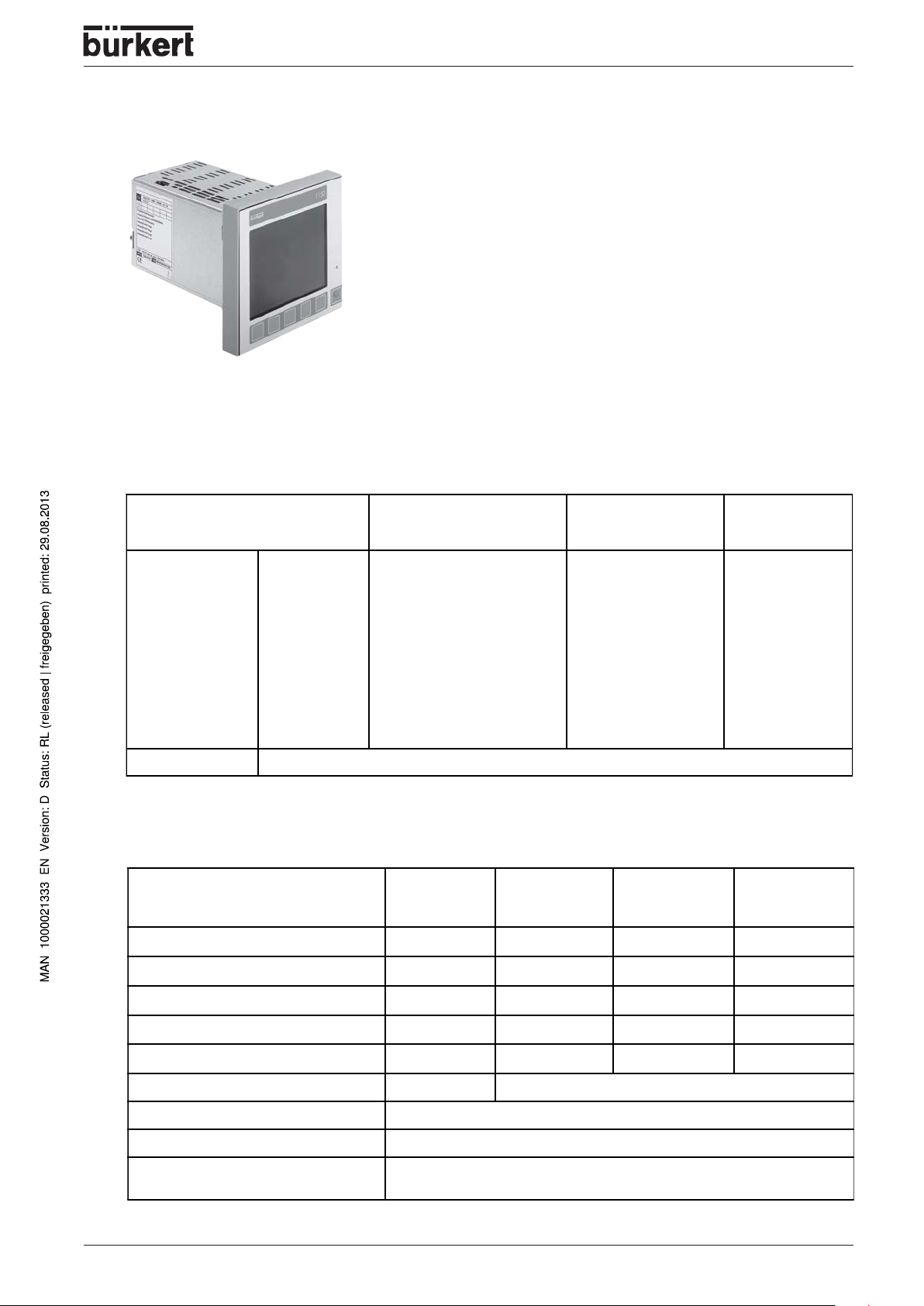

Visual Representation

Technical data

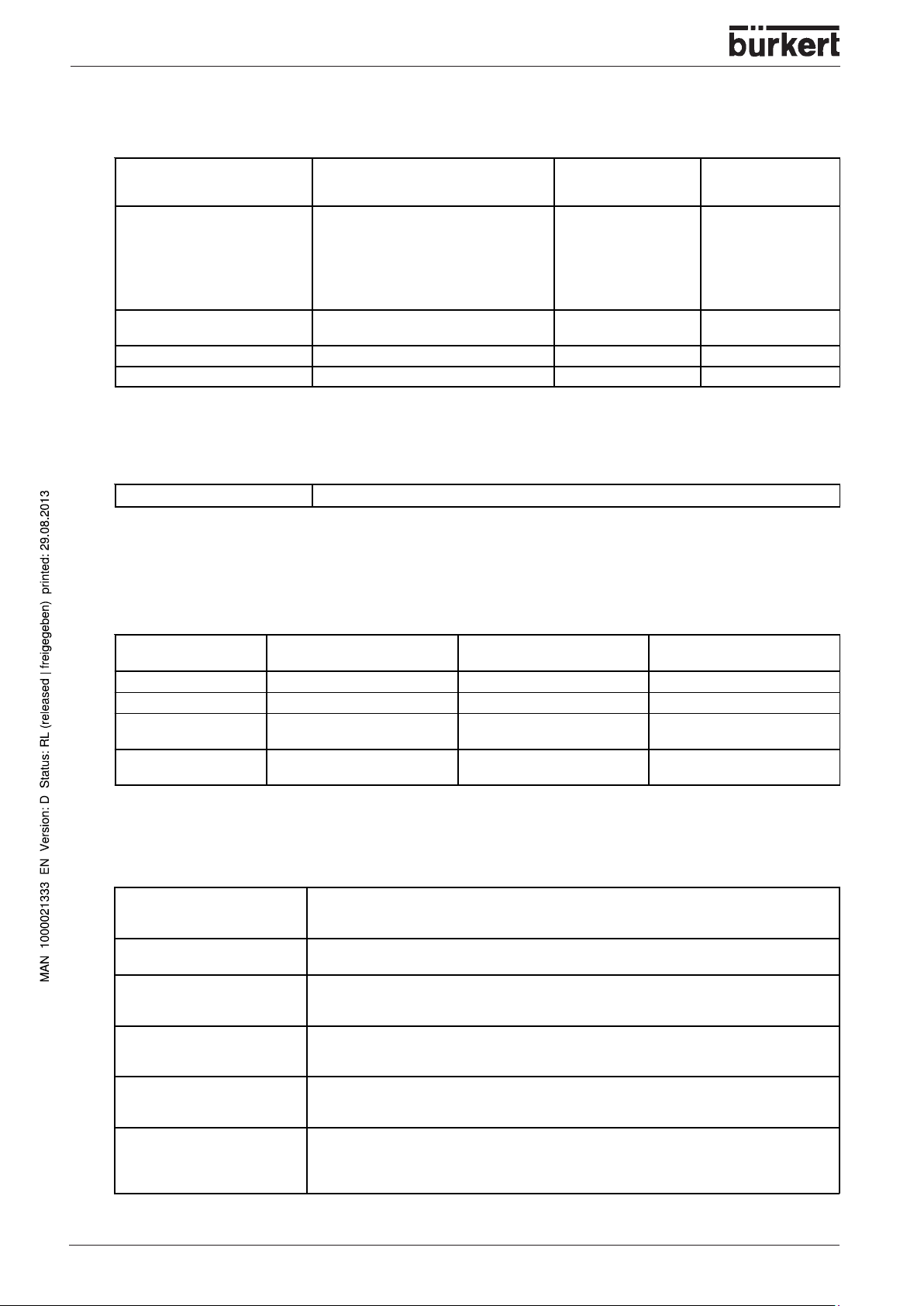

Thermocouple input

SYSTEM DESCRIPTION

Designation Measurement range Meas. accuracy

Fe-CuN i "L "

Fe-CuN i "J "

Cu-CuNi "U"

Cu-CuNi "T"

NiCr-Ni "K"

NiCr-CuNi "E"

NiCrSi-NiSi "N"

Pt10Rh-Pt "S"

Pt13Rh-Pt "R"

Pt30Rh-Pt6Rh "B"

W5Re-W26Re "C"

W3Re-W25Re "D"

W3Re-W26Re

Cold junction Pt 100 internal, external or constant

DIN EN 60584

DIN EN 60584

DIN EN 60584

DIN EN 60584

DIN EN 60584

DIN EN 60584

DIN EN 60584

DIN EN 60584

1

With 250 msec sampling time.

-200 to +900°C

-200 to +1200°C

-200 to +600°C

-200 to +400°C

-200 to +1372°C

-200 to +1000°C

-200 to +1300°C

0 to 1768°C

0 to 1768°C

0 to 1820°C

0 to 2320 °C

0 to 2495 °C

0 to 2400 °C

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

0.25%

Input for resistance thermometer (RTD)

Designation Connection

circuit

Pt100 DIN EN 60751 2-wire/3-wire -200 to +850°C

Measurement

range

Meas. accuracy1Ambient

0.05%

1

Ambient

tempera ture

error

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

temperature

error

50 ppm/K

Pt 50,500, 1000 DIN EN 60751 2-wire/3-wire -200 to +850°C

Cu50 2-wire/3-wire -50 to +200°C

Ni100 DIN 43 760 2-wire/3-wire -60 to +250°C

KTY11-6 2-wire -50 to +150°C

PtK9 2-wire lithium-chloride transducer

Sensor lead resistance max. 30 ohms per lead for 2-wire or 3-wire circuit

Meas. current 250 A

Lead compensation is not required for 3-wire circuit. With a 2-wire circuit, the lead resistance can be

1

With 250 msec sampling time.

compensated in software by a correction of the process value.

0.1%

0.1%

0.05%

1.0%

50 ppm/K

50 ppm/K

50 ppm/K

50 ppm/K

1150 - 11

Page 14

SYSTEM DESCRIPTION

Input for standard signals

Designation Measurement range Meas. accuracy

Voltage 0 to 10 V

Current 4 to 20 mA, voltage drop 1 V

Heater current 0 to 50 mA AC

Potentiometer min. 100 max. 10 k

-10 to +10 V

-1 to +1 V

0 to +1 V

0 to 100 mV

-100 to +100 mV

Input resitance R

0 to 20 mA, voltage drop 1 V

1

With 250 msec sampling time.

100 k

E

0.05 %

0.05 %

0.05 %

0.05 %

0.05 %

0,05 %

0.1 %

0.1 %

1 %

Logic inputs

Floating contacts

Measurement circuit monitoring

In the event of fault, the outputs move to a defined (configurable) status.

1

Ambient

temperature

error

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

100 ppm/K

Sensor Overrange /

underrange

Thermocouple

Resistance thermometer

Voltage 2 to 10V

0 to 10V

Current 4 to 20 mA

0 to 20 mA

recognized - not recognized

Outputs

Relay

contact rating

contact life

Logic

current limiting

Solid-state relay

contact rating

protection circuitry

Voltage

output signals

load resistance

Current

output signals

load resistance

Supply voltage for 2-wire

transmitter

voltage

current

0/5 V

20 mA

Probe or lead short-circuit Probe or lead break

-

-

-

-

-

changeover contact or 2 x make

3A at 250 V AC resistive load

150.000 operations at rated load

or 0/22 V

30 mA

1 A at 230 V

varistor

0 to 10 V / 2 to 10 V

500

R

Last

0 to 20 mA / 4 to 20 mA

450

R

Last

22 V

30 mA

12 - 1150

Page 15

Controller

Controller type single-setpoint controller

double-setpoint controller, modulating controller, proport ional controller,

proportional controller with integrated actuator driver

Controller structures P/PD/PI/PID/I

A/D converter dynamic resolution up to 16 Bit

Sampling time 250 msec

50 msec, 150 msec, 250 msec (configurable)

Color screen

Resolution 320 x 240 pixels

Size (screen diagonal) 5" (12.7 cm)

No. of colors 27 colors

Electrical data

SYSTEM DESCRIPTION

Supply voltage (switchmode PSU) AC 48 to 63 Hz, 110 to 240 V -15/+10%

Electrical safety to DIN EN 61 010, Partl 1

Power consumtion max. 30 VA

Data backup flash memory

Electrical connection at rear, via plug-in screw terminals

Electromagnetic compatibility

interference emission

interference immunity

overvoltage category III, pollution degree 2

conductor cross-selection max. 2.5mm

with core ferrules (length: 10mm)

EN 61 326

Class B

to industrial requirements

Interface COM1

Interface type PC-Interface or RS 422/RS 485

Protocol MOD-Bus

Baud rate 9600, 19200, 38400

Device address 1 to 255

Minimum response time 0 to 500 ms

Interface COM2

2

MOD bus

Interface type RS 422/RS 485

protocol MOD-Bus

Baud rate 9600, 19200, 38400

Device address 1 to 255

Profibus DP

Device address 1 to 128

Data transmission rate 12 MBaud

1150 - 13

Page 16

SYSTEM DESCRIPTION

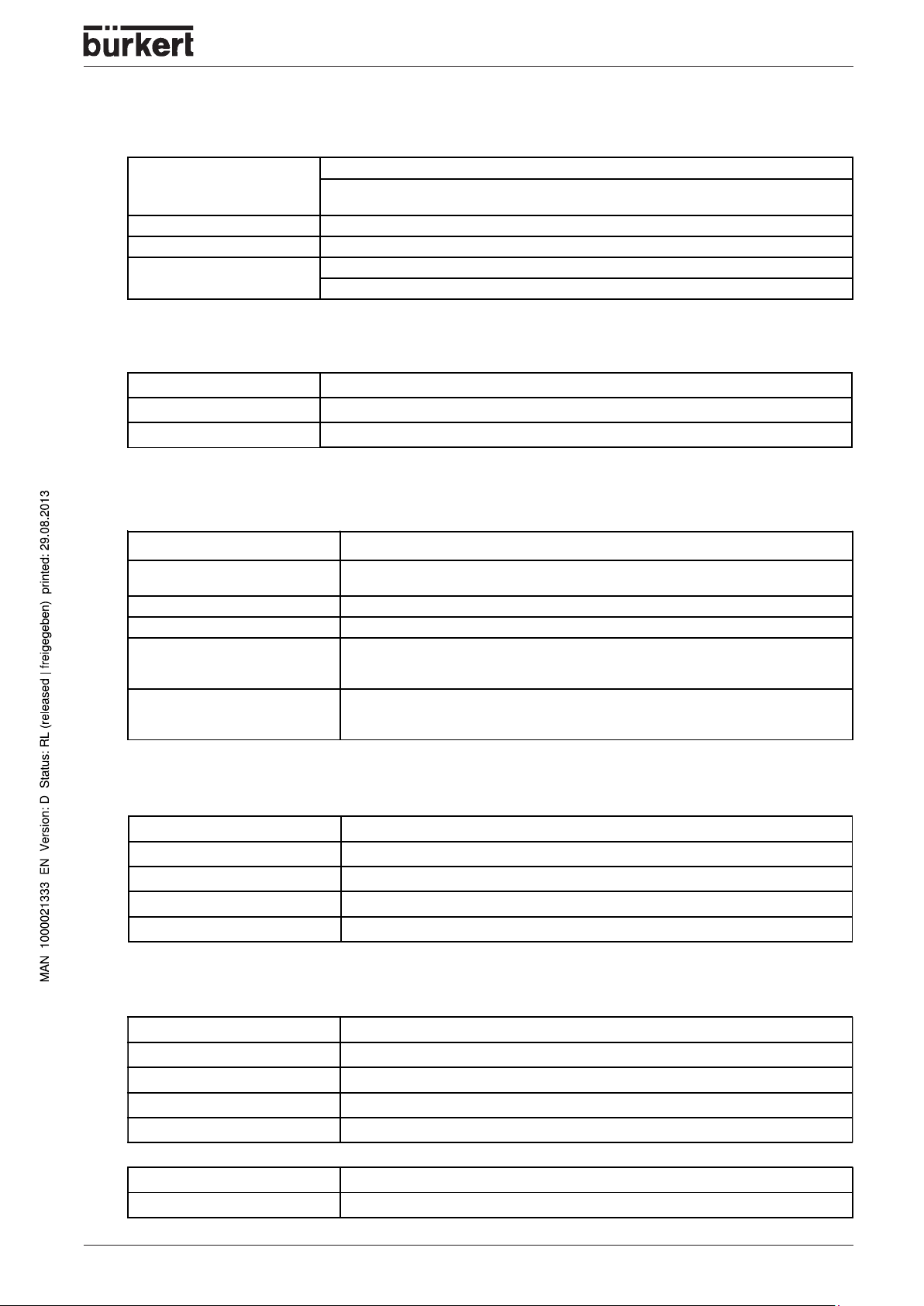

Housing

Housing type housing and back panel: metal for panel mounting as per DIN 43700

Front bezel plastic to UL 94 V0 144 mm x 130 mm

Mounting depth 170 mm

Panel cut-out 92+

Ambient/storage temperature range -5 to 50 °C / -40 to +70 °C

Climatic conditions rel. humidity 75 % annual mean, no condensation

Operating position horizontal

Enclosure protection to EN 60 529,

Weight (fully fitted) approx. 1400 g

Membrane keypad polyester film, resistant to normal washing and cleaning agents

Dimensions

0,8

0,8

x 92+

mm

front IP 65, rear IP 20

18 162

170

188

Panel cut-out

to DIN ISO 43 700

+0,8

92

0

Front viewSide view

144

130

Rear view

91.5

setup plug

14 - 1150

+0,8

0

92

91.5

Page 17

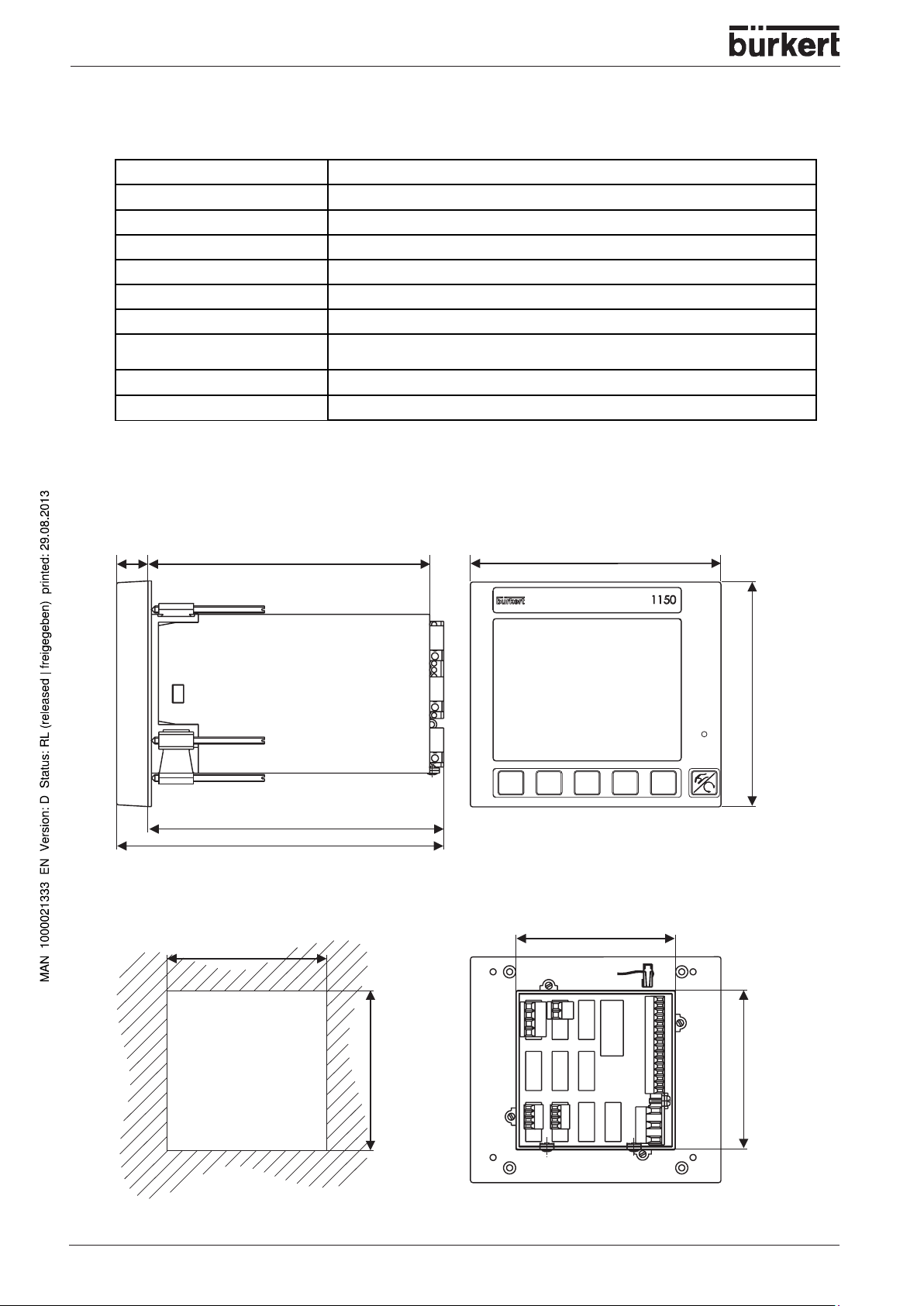

Order table

Process and program controller Type 1150 ID-No.

Basic unit

20 to 30 V AC/DC 787703

110 to 240 V 48 to 63 H z 787704

Input modules

1 analog inpu t 787750

Output modules

1 relay, changeover 787751

1 solid-state relay 787752

2 relay, n.o. 787753

1 analog output 787754

SYSTEM DESCRIPTION

Interface

Profibus DP 787755

Added optional functions *

Controller channels 3+4 787756

Recording fu nctio n 787757

Math and logic module 787758

Accessories

PC-Interface for setup program 787759

Setup software with Program editor 787760

Configuration o f adde d opti onal func tion s is onl y poss ible by mea ns of

*

the Setup-Software PC edi tor.

1150 - 15

Page 18

SYSTEM DESCRIPTION

16 - 1150

Page 19

INSTALLATION, COMMISSIONING AND MAINTENANCE

INSTALLATION,

COMMISSIONING

AND MAINTENANCE

General notes ............................................................................................................................................................................................................................. 18

Location and climatic conditions

Close mounting

Assembly

Installation

Accessories

Maintenance

......................................................................................................................................................................................................................... 18

.......................................................................................................................................................................................................................................... 18

........................................................................................................................................................................................................................................ 19

.................................................................................................................................................................................................................................. 20

.................................................................................................................................................................................................................................. 20

.......................................................................................................................................................................... 18

1150 - 17

Page 20

INSTALLATION, COMMISSIONING AND MAINTENANCE

General notes

ATTENTION!

• This device should only be installed or repaired by qualified personel using the correct

tools!

• Always disconnect the power this device before servicing or changing signal

connections!

• Failure or interf erence may result from contamination, short circuit, voltage interruption

or faulty/missing wiring termination.

• Check for loose or improper electrical connections or under voltage if unit does not

power up.

Location and climatic conditions

• The conditions at the location must meet the requirements specified in the technical data.

• The ambient temperature at the location should be - 5 to + 50 °C with a relative humidity below 75%

Close mounting

• Minimum spacing of panel cut-outs

horizontal min. 54 mm

vertical min. 54 mm

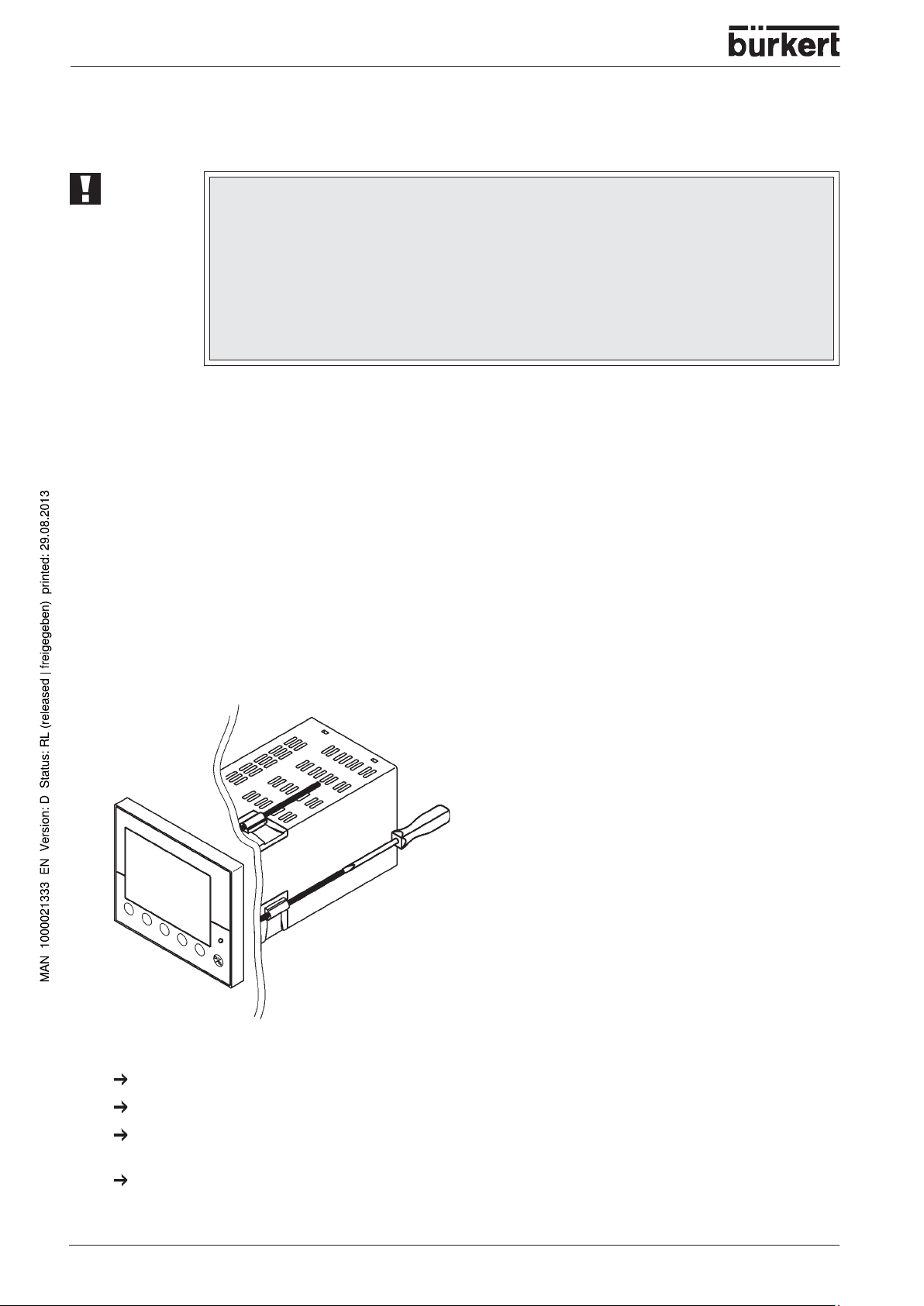

Assembly

From the bac k, fit the seal that is supplied onto the instrument.

Insert the instrument from the front into the panel cut-out.

18 - 1150

From behind the panel, slide the mounting brac kets into the guides on the sides of the housing. The flat

faces of the mounting brackets must lie against the housing.

Push the mounting brackets up to the bac k of the panel, and tighten them e venly with a scre wdriv er .

Page 21

Installation

INSTALLATION, COMMISSIONING AND MAINTENANCE

ATTENTION!

• The choice of cable - the installation and the electrical connection must conform to the requirements of

VDE 0100 “Regulations on the Installation of P ower Circuits with Nominal V oltages below 1000 V” or the

appropriate local regulations.

• The electrical connection may only be carried out by properly qualified personnel.

• The instrument must be disconnected/isolated electrically incase of accidental contact with live parts.

• A current-limiting resistor interrupts the supply circuit in the event of a short-circuit. Ho we v er , the load

must be fused for the maximum relay current to prevent the contacts of the output relay from becoming

welded in the event of a short-circuit.

• Electromagnetic compatibility conforms to the standards and regulations cited in the technical data

(see Chapter Technical data).

• Run input, output and supply cables separately and not parallel to one another .

• All input and output signal cables must be shielded twisted pairs to prevent crosstalk, electrical noise

and interferences.

• The shield of all transmission lines must be connected on the instrument side to potential earth.

• The PE terminal on the instrument must be connected to earth ground. This cab le must ha ve at least

the same conductor cross-section as used for the supply cables. Grounding and earthing leads must be

wired in a star configuration to a common earth point that is connected to the protective earth of the

electrical supply . Do not loop earth or ground connections, i.e . do not run them from one instrument to

another.

Please observe the relevant safety regulations and electrical installation codes for your

area.

• Do not connect any additional loads to the supply terminals of the instrument.

• The instrument is not suitable for use in areas with an explosion hazard (Ex areas).

• In addition to faulty installation, incorrect programming/configuration of the controller (setpoint, data of

the parameter and configuration levels, internal alterations) can also interfere with the correct operation

of dependent processes, or even cause damage. Safety devices should always be provided that are

independent of the controller (such as overpressure valves or temperature monitors/limiters) and only

capable of adjustment by authorized personnel.

• Since adaptation (self-optimization) cannot be expected to handle all possible control loops, an unstable

process parameterization is theoretically possible. The stability of the actual value derived from the selftune should therefore be checked.

• The measurement inputs of the controller must not exceed a maximum potential of 30 V A C or 50 V DC

against PE.

1150 - 19

Page 22

INSTALLATION, COMMISSIONING AND MAINTENANCE

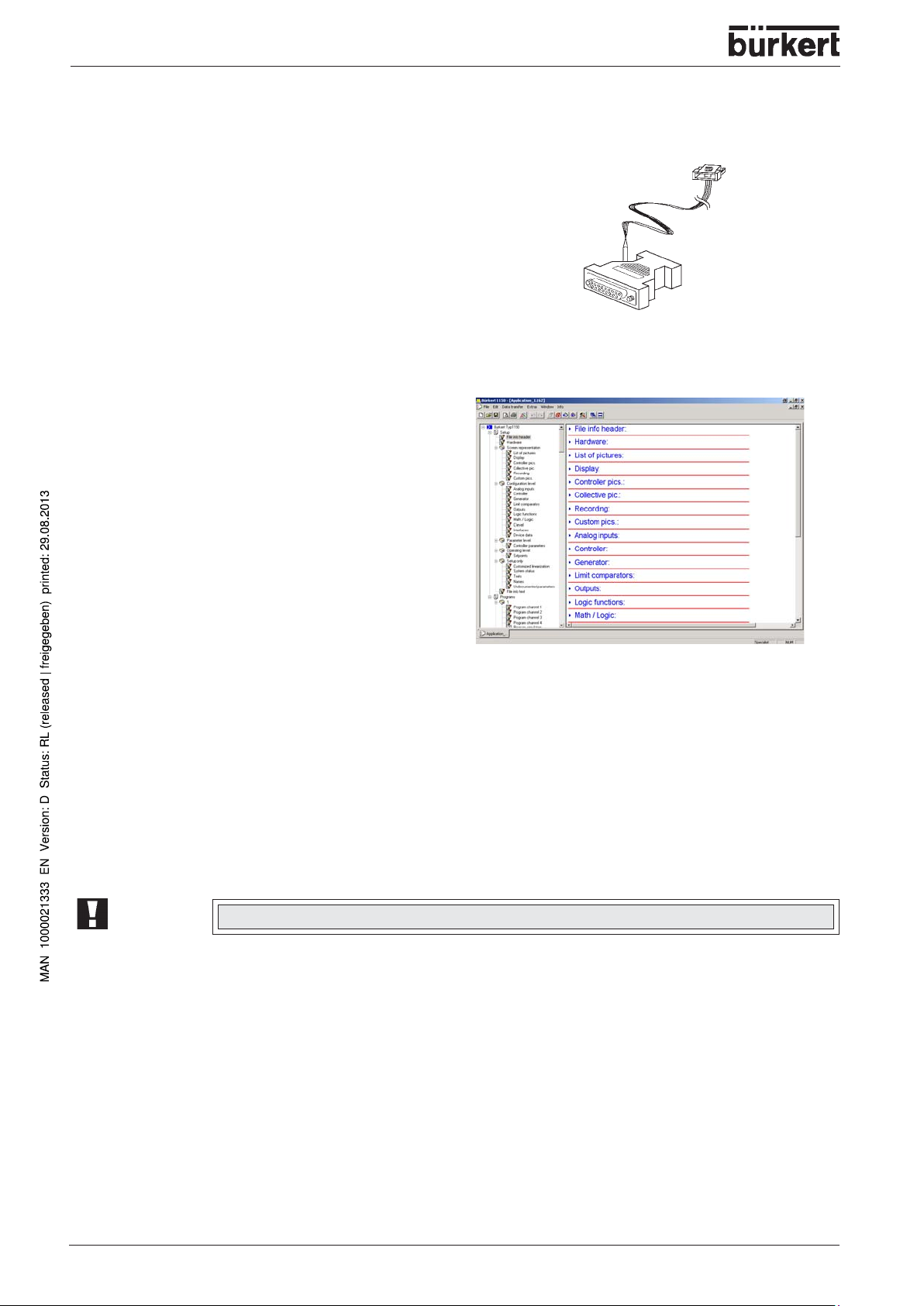

Accessories

PC Interface

PC interface for setup program

Setup programs

Setup program with program editor

Maintenance

Cleaning

The front panel can be cleaned with normal commercial washing, rinsing and cleaning agents. It has a

limited resistance to organic solvents (e.g. methylated spirits, white spirit, P1, xylol etc.). Do not use highpressure cleaning equipment.

Disposal

ATTENTION!

Please refer to local bylaws/regulations for proper disposal of device.

20 - 1150

Page 23

ELECTRICAL CONNECTIONS

ELECTRICAL

CONNECTIONS

Connection diagram............................................................................................................................................................................................................ 22

Terminal strip numerical assignment

............................................................................................................................................................. 22

1150 - 21

Page 24

ELECTRICAL CONNECTIONS

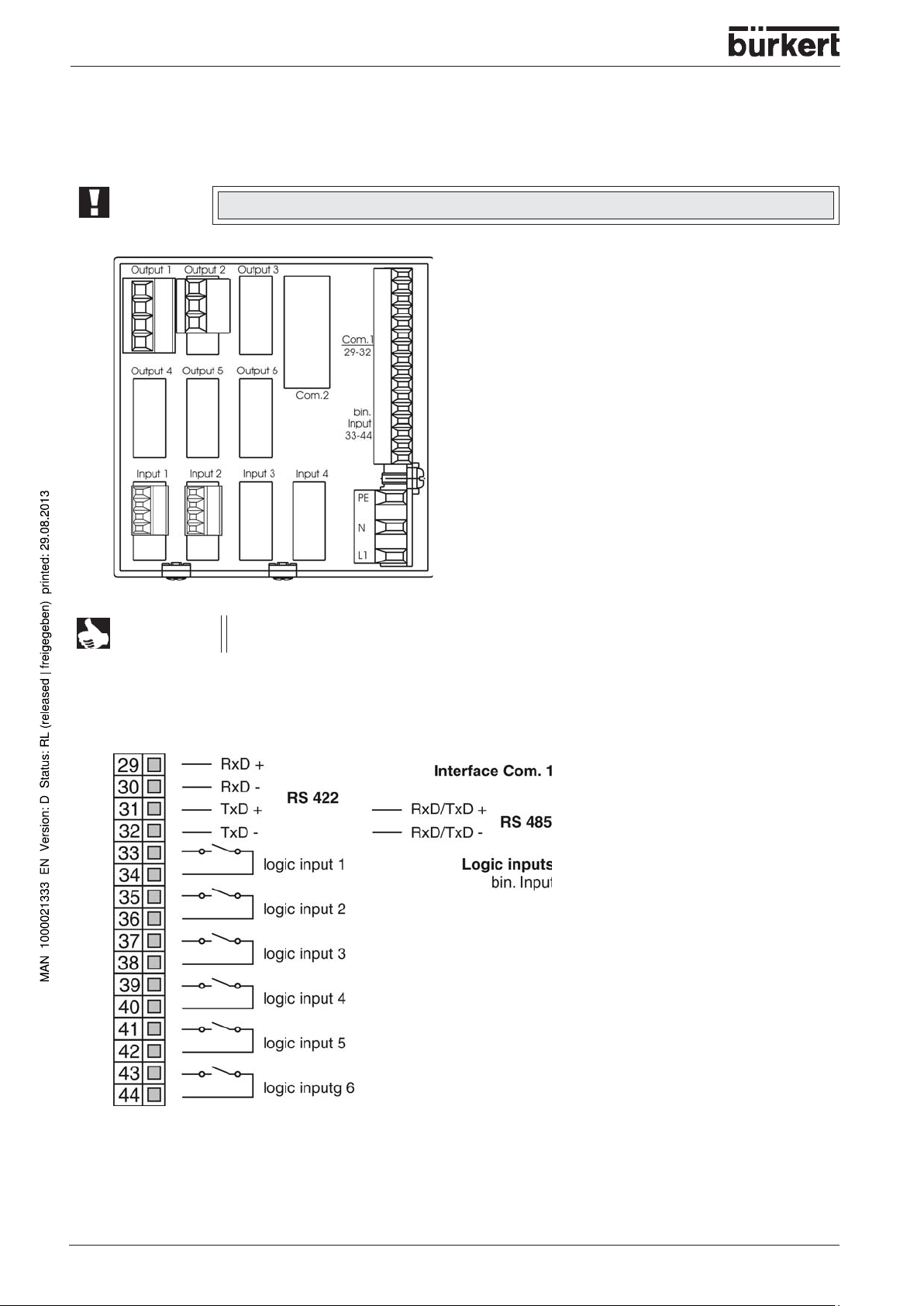

Connection diagram

ATTENTION!

NOTE

The electrical connection must only be carried out by properly qualified personnel.

The instrument version can be identified by means of the type code (See nameplate on

the housing).

Terminal strip numerical assignment

22 - 1150

Page 25

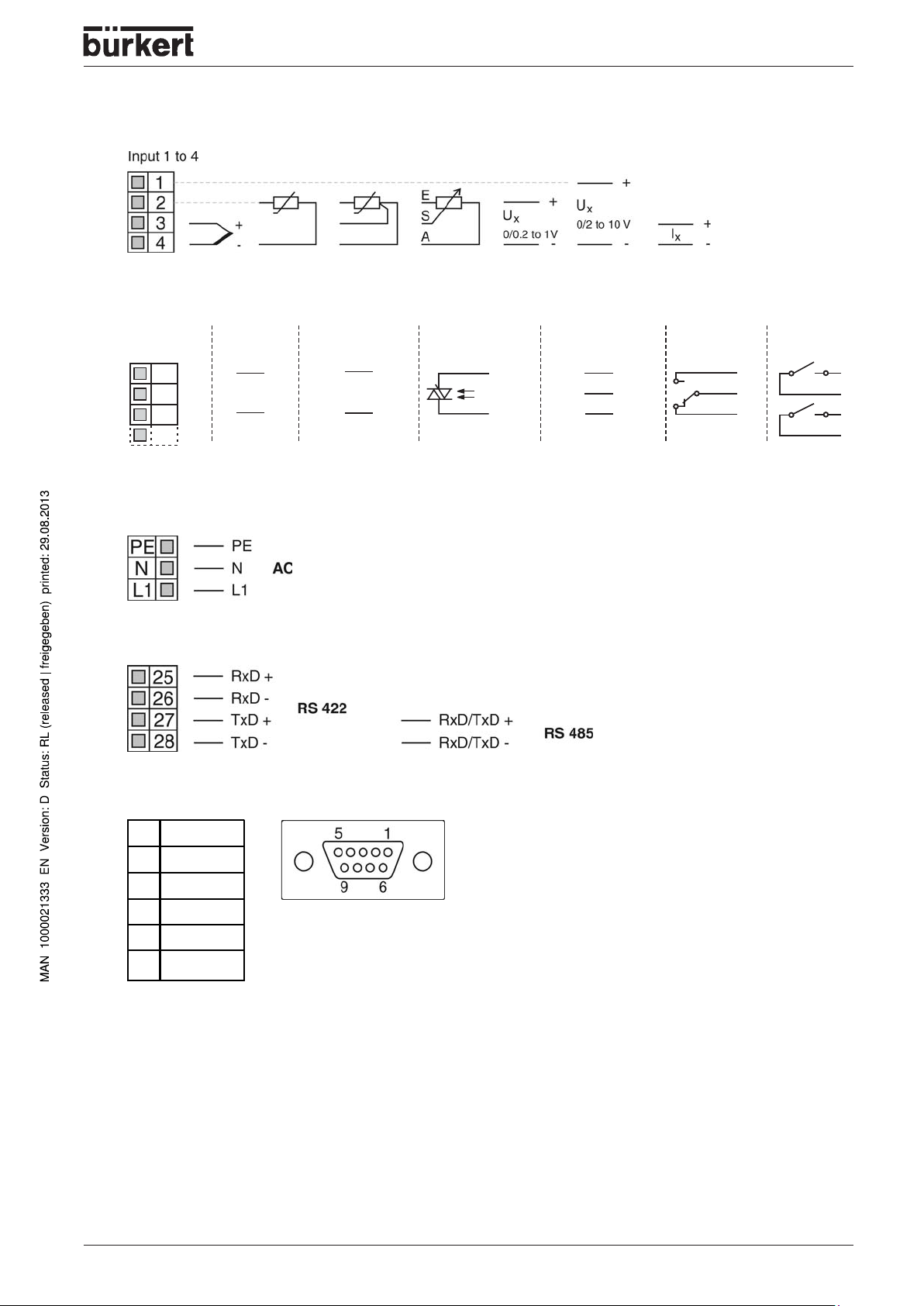

Analog inputs

1 analog

output

1 logic output

0/22 V *

1 solid/state relay

230 V/1 A

2 logic outputs

0/5 V

1 changeover 2 makeOutput

1 to 6

X

X

X

X

5

6

K1

7

8

K2

9

10

11

12

S

Ö

P

13

15

GND

A1

16

17

19

20

GND

A

22

24

-

+

0/2 - 10 V

0/4 - 20 mA

* or supplz for 2-wire transmitter

23

21

18

14A2

Outputs

ELECTRICAL CONNECTIONS

Supply voltage

Interface COM.2

Profibus-DP

Pin Assignment

3 RxD/TxD-P

4RTS

5DGND

6VP

8 RxD/TxD-N

1150 - 23

Page 26

ELECTRICAL CONNECTIONS

24 - 1150

Page 27

OPERATION AND CONTROLLER FUNCTIONS

OPERATION AND

CONTROLLER FUNCTIONS

Operation.............................................................................................................................................................................................................................................. 26

Displays and controls.......................................................................................................................................................................................................... 26

Overview of operation ......................................................................................................................................................................................................... 28

Entering values and selecting settings.............................................................................................................................................................. 31

Setpoint input .............................................................................................................................................................................................................................. 32

Recording ........................................................................................................................................................................................................................................ 33

Operation “Controller“ ....................................................................................................................................................................................................... 34

Setpoint ............................................................................................................................................................................................................................................. 34

Manual mode ............................................................................................................................................................................................................................... 34

Operating „program controller/generator“................................................................................................................................................ 36

Program editor............................................................................................................................................................................................................................ 36

Starting the program............................................................................................................................................................................................................. 39

Overview of operation ......................................................................................................................................................................................................... 40

Shifting the program profile ........................................................................................................................................................................................... 41

1150 - 25

Page 28

OPERATION AND CONTROLLER FUNCTIONS

Operation

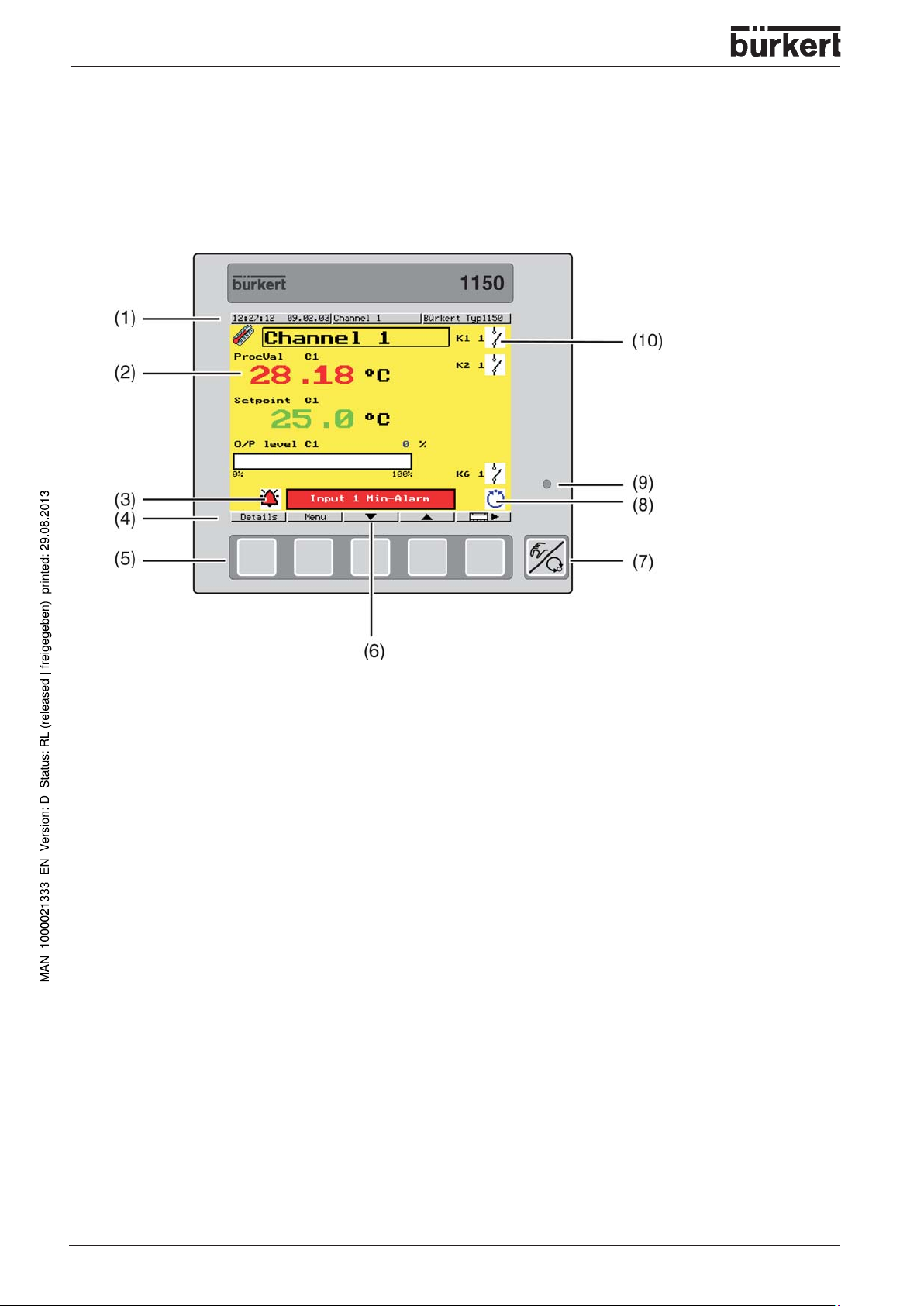

Displays and controls

Front view

Displays and controls

(1)

Status line

with time, date, name of screen template and instrument name

(2)

Color screen (screen templates can be configured)

Factory setting for fix ed-setpoint controller: process value, setpoint, output (bar graph)

Factory setting for program controller: process value, setpoint, program number/name,

segment number, remaining programm time

(3)

Info/alarm symbol

(4)

Title

Current meaning of the softkeys

(5)

Keys

(Softkeys) with various interpretations in the colot screen

(6)

Info/alarm symbol

Display of infos (blue) or alarms (red)

(7)

EXIT/manual key

for manual mode, navigation, and for aprogram pause

(8)

Operating mode/state

(9)

Po wer LED

lights up green when voltage is applied

(10)

26 - 1150

Status indicators of the outputs (configurable)

Page 29

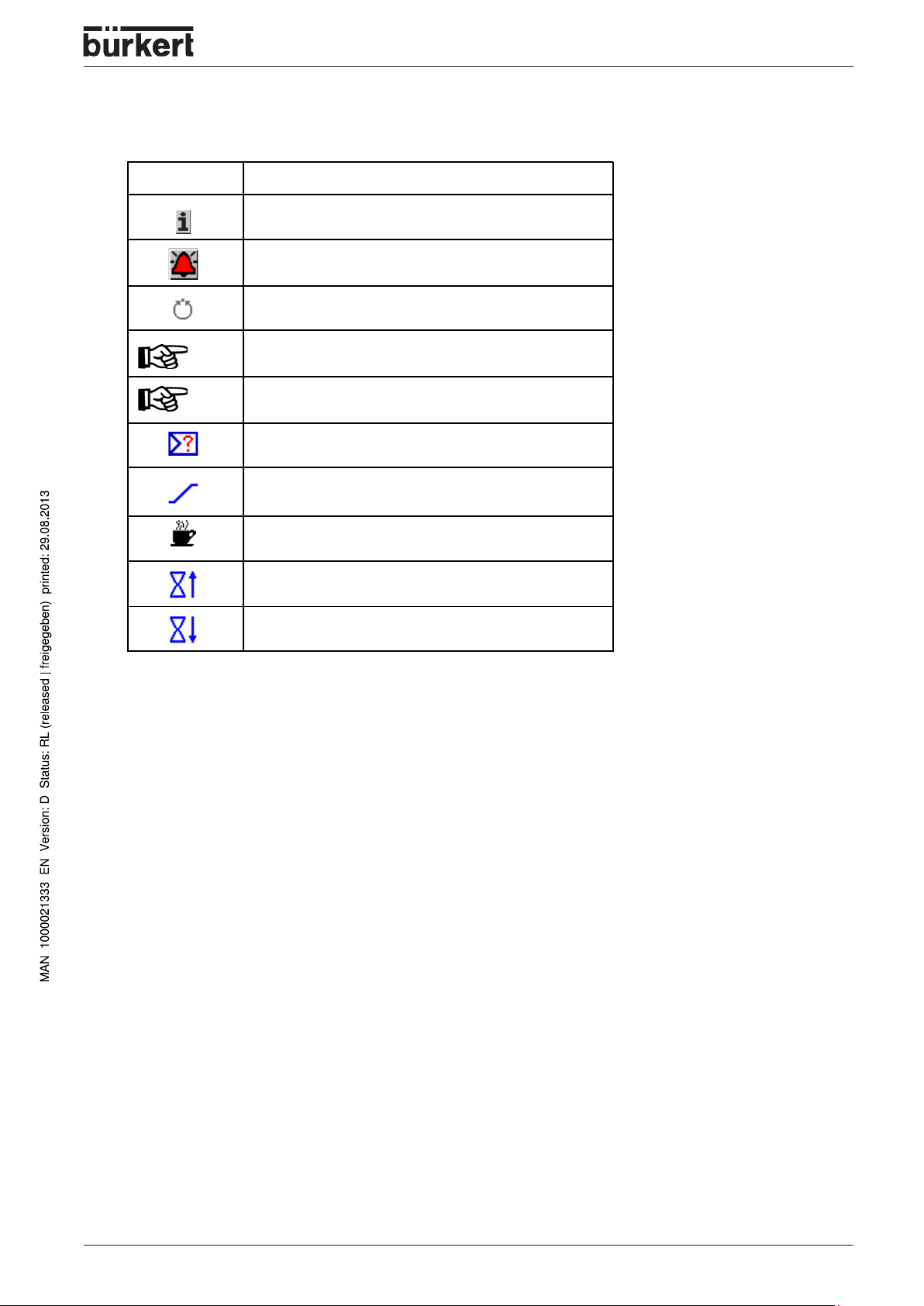

Symbols in display

Symbol Meaning

Info

Alarm is present

Automatic mode/Program is ru nning

OPERATION AND CONTROLLER FUNCTIONS

(blue)

(green)

Manual mode /"Manua l" operating m ode

Controller manual mode

Self-optimization is a ctive (symbol flash es)

Ramp function is active

Program pause

Actuator open (modulating controller)

Actuator closed (modulating controller)

1150 - 27

Page 30

OPERATION AND CONTROLLER FUNCTIONS

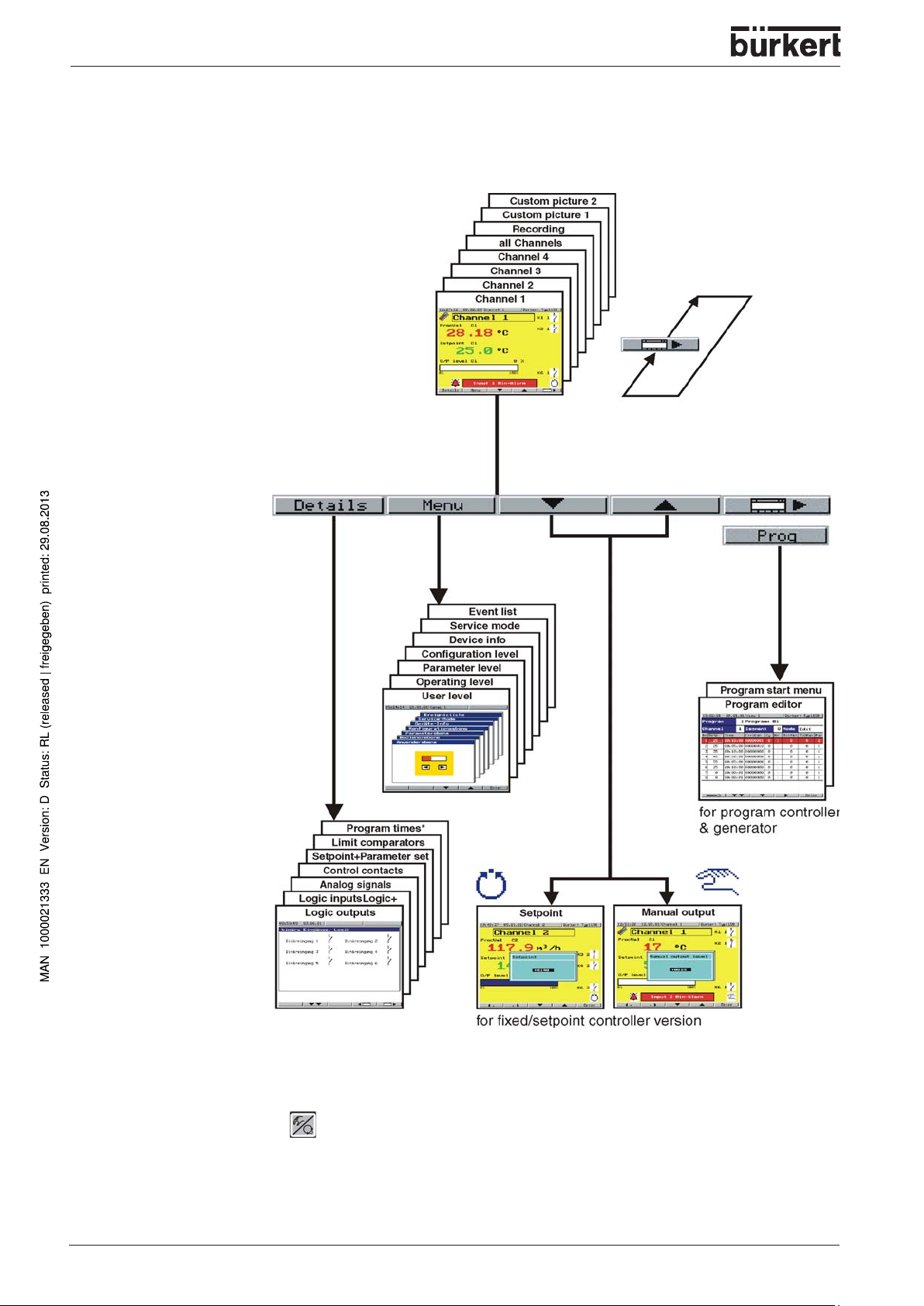

Overview of operation

Screen operating loop

Menu

Program

start menu

Details

see Chapter

Configuration/Display

Setpoint/

Manual output

28 - 1150

(> 2 s) = back to the screen operating loop

Time Out = If no key is pressed the display will automatically return to the

screen operating loop after a definable time.

Page 31

OPERATION AND CONTROLLER FUNCTIONS

Screen operating loop

The operating loop contains the screen templates for a maximum of four controller channels, the collective

picture of all the active controller channels, the recording function as well as two freely definable screen

templates. The screen templates can be individually switched into display.

(see Chapter Configuration/Display)

Meaning of the keys

:

- additional functions of the softkeys

- start/cancel self-optimization for the channel that is displayed

- acknowledge alarm messages and limit comparators

- step on one segment (program controller)

- controller manual mode (program controller)

Details

The states and values of the various process variab les are presented in a clear and structered manner .

* Screens only available for process controllers

- scroll screen down

1150 - 29

Page 32

OPERATION AND CONTROLLER FUNCTIONS

Menu

•

User level

With the help of this screen template, the user can compile parameters that have to be frequently

altered, through the setup program. This screen template is only displa yed when appropriately

configured.

•

Operating level

Here the setpoints for all four controller channels are defined and self optimization is started

(see Chapter

•

Parameter level

The controller parameters for the controller channels are defined here (see Chapter

•

Configuration level

The instrument is adapted to the control task here (see Chapter

•

Device info

Information on hardware equipment, software version and instrument options are shown here.

•

Service mode

This screen template can only be accessed by service personnel.

•

Event list

Different events (e.g. alarm messages, limit comparator signals) are documented here.

“Self-optimization“

).

“Parameterization“

“Configuration“

).

).

30 - 1150

Page 33

OPERATION AND CONTROLLER FUNCTIONS

Entering values and selecting settings

Entering values

Parameters can be altered in a number of screen templates:

Select parameters

Increase parameter value with

Decrease parameter value with

The longer the key is pressed the f aster the v alue changes . Approx. 2 sec after releasing the key, the

entry will be automatically accepted.

Parameters can be altered within their range of v alues or within the maximum displa yab le values (e . g. tw o

decimal places: -99.99 to +99.99).

Shifting the decimal point

Increase decimal place with

Decrease decimal place with

Selecting

Select parameter

Move up in selection list with

Move down in selection list with

Confirm entry with

Entering codes and times

Times and codes are entered digit by digit.

Increase or decrease value (digit) with and

On to the next digit with or

Confirm entry with

1150 - 31

Page 34

OPERATION AND CONTROLLER FUNCTIONS

Setpoint input

Configuration in controller

Each controller channel has four setpoints and the provisions to switch between them. Setpoints for the

controller are defined as shown below:

(see Chapter “

Controller and Logic functions“

)

32 - 1150

Page 35

OPERATION AND CONTROLLER FUNCTIONS

Recording

Screen template

The recording function can be used to show the traces of up to four analog signals and the switching

actions of up to three logic signals.

Momentary values of up

to four analog signals

Graphical representation

of the analog signals

Scaling of the analog

signals (switchable)

Time axis

(format hh:mm:ss)

Graphical representation

of the logic signals

Time grid

Keys

- call up history

- switch display for the analog signal scalings

History

Data that have already been recorded can be vie wed here. The recorded time span is shown on the time

axis. The recorded time span depends on the sampling rate (adjustab le) and varies between 12 hours and

a maximum of 1 day.

Shift the trace with , , ,

Call up zoom function with (key field is switched)

Zoom in /zoom out of trace with or

Return to the scroll functions with

Quit history with

1150 - 33

Page 36

OPERATION AND CONTROLLER FUNCTIONS

Operation “Controller“

If the instrument has been configured as a fixed-setpoint controller , the following actions can be perf ormed

in automatic/manual mode:

Altering the setpoint

The active setpoint of a controller channel can be altered in the corresponding screen template. The

controller must be in automatic mode.

Alter setpoint using and

(the meaning of the softkeys changes, an input window appears)

automatic mode

Shift the decimal point using and

New setpoint is automatically accepted after 2 sec or by using

Manual mode

Altering the output

The control loop of the controller channel that is displayed can be interrupted by switching to manual

mode.

Switch to manual mode with (hold key down for at least 2 sec!)

(the symbol for manual mode appears in the operating mode display)

Alter the output with and

(the meaning of the softkeys changes, an input window appears)

34 - 1150

manual mode

Shift the decimal point using and

The new output is automatically accepted after about 2 sec or by using

Page 37

OPERATION AND CONTROLLER FUNCTIONS

Altering the output for modulating controllers

In the case of modulating controllers, the keys are used to directly influence the right and left motion of a

motorized actuator. The output is only indicated if the output f eedback is connected.

- open actuator

- close actuator

The manual mode can be inhibited.

1150 - 35

Page 38

OPERATION AND CONTROLLER FUNCTIONS

Operating „program controller/generator“

If the instrument is configured as a program controller/generator, progr ams hav e to be created first, by

using the internal program editor or the setup program.

Program editor

General

50 programs with up to 99 segments can be programmed; a total of 1000 segments can be implemented.

Programs are created by programming setpoints and segment times, segment by segment.

Furthermore, the states of the control contacts 1 — 8 and the active parameter set can be defined for

each segment.

The setpoint profiles can be output either as a ramp or a step (configurable).

Output as a ramp has been chosen for the following diagrams.

Tolerance band

To monitor the process value, a tolerance band can be applied around the setpoint profile f or each

segment.

If the upper or lower limit is infringed, a tolerance band signal is generated, which is internally processed

or produced via an output.

(see Chapter

36 - 1150

“Outputs and Logic functions“

)

Page 39

Program editor

OPERATION AND CONTROLLER FUNCTIONS

Call up with

Select program using the cursor keys

Select program channel using the cursor keys

Number of program channel

edit program

Program number and name

Number of program

segments

Entry mode

- edit

- temporary alteration

Segment setpoint

Segment number

- call up additional softkey functions

Parameter set number

Lower and upper tolerance band

Number of repeat cycles (Cy) with

start segment (No.)

Control contacts 8 — 1 (1=On)

Segment time

1150 - 37

Page 40

OPERATION AND CONTROLLER FUNCTIONS

Entering a new program

The segments are edited in sequence when creating a new program.

Append a new segment to the last segment of the profile trace with

Copying segments

Existing segments can be copied and inserted in another position in the program. The segment that was

copied is inserted above the cursor position.

Position the cursor on the segment to be copied

Copy segment with

Position the cursor on the desired position

Insert segment with

Inserting segments

A new segment can be inserted above the cursor position into an existing sequence of segments .

Insert segment with

Removing segments

Delete marked segment with

Entering repeat cycles

A group of segments that are arranged in sequence can be repeated up to 99 times or repeated endlessly

(input: -1). The repeat cycles are progr ammed in the last segment of the group .

Example: S02 - S04 are to be repeated once.

Edit segment 4

Set number of repeat cycles to Cy=1

Set start segment of repeat to No.=2

Checking the program profile

The program segments entered in the table can be graphically displayed and checked. Repeat cycles are

not taken into account for the display.

Show program profile with

38 - 1150

Page 41

OPERATION AND CONTROLLER FUNCTIONS

Starting the program

Immediate start of program

The program displayed on the screen in the basic status is started.

Start program with

A program can also be selected, started and canceled via the logic functions. The logic function “Progr am

selection” has priority over the settings in the menu “Program start”.

(see Chapter “Logic functions“)

Selecting and starting the program

The representation of the program selection can be configured as a list or an icon.

(see Chapter

“Device data”

)

Call up program selection with

Select program using the cursor keys

Start program with 2x the program starts immediately at the start

start program

Starting the program with time input

A program can be started at a specific point of time. There are two configurable options:

1. Start at a specified date and time

2. Start with a specified start delay in hours, minutes and seconds.

(see Chapter

NOTE

Call up program selection with

Select program using the cursor keys

Change to menu “Program start” with

“Generator”)

The settings are reset to their standard values after the start of the program.

start program

Enter start time/start date or start delay, start segment and remaining segment time

Start program with

1150 - 39

Page 42

OPERATION AND CONTROLLER FUNCTIONS

Overview of operation

The diagram below provides an overview of the different operating modes and operating options of a program controller .

Many operating options can also be implemented via the logic functions.

Buttons and can be accessed via “Details”.

Basic status

In basic status the system state is defined, with the following factory settings for all program channels:

controller, control contacts and limit comparators are inactiv e

the controller setpoints are 0

parameter set 1 is active for all controllers

The system state can be modified via the setup program.

Temporary alterations

T emporary alterations are modifications to the current program in the program editor . They are not stored in

the program memory, i.e. modifications will be lost after a restart.

In the case of alterations concerning the current segment, the setpoint sequence is automatically adapted.

40 - 1150

Page 43

OPERATION AND CONTROLLER FUNCTIONS

Shifting the program profile

The function “External setpoint with correction” can be used to shift the program profile upwards or

downwards.

The external setpoint is defined via an analog signal (see Chapter “Controller”).

1150 - 41

Page 44

OPERATION AND CONTROLLER FUNCTIONS

42 - 1150

Page 45

PARAMETERIZATION

PARAMETERIZATION

1150 - 43

Page 46

PARAMETERIZATION

Parameter sets

General

Two parameters sets can be stored f or each controller channel.

Access code

Factory-set code:

0001

The access code can be modified via the setup program.

Parameter level / Controller 1 (2...4) / Parameter set 1 (2)

Parameter Value range Factory setting Meaning

Controller structure 1 P, I, PD, PI, PID PID Only PI and PID can be implemented on modulating

Proportional band 0 - 9999 Digit 0 Digit Size of the proportional band

Derivative time 0 - 9999 sec 80 sec Determines the derivative component of the controller output

Reset time 0 - 9999 sec 350 sec Determines the integral component of the contoller output

Cycle time 0 - 9999 sec 20 sec When using a switched output, the cycle time should be

Contact spacing 0 - 999 Digit 0 Digit The spacing between the two control contacts for 2-setpoints

controllers.

Proportional band = 0 means that the controller structure is

ineffective! (limit comparator response)

In the case of proportional controllers, the proportional band

must be > 0.

signal.

signal.

chosen so that a) the pulsed energy flow to the process does

not cause any intermissible fluctuations of the process value

and b) the switching elements are not overloaded.

or modulating controllers, or proportional controllers with an

integrated actuator driver.

Switching differential 0 - 999 Digit 1 Digit Hysteresis for switching controllers with proportional band = 0

Actuator time 5 ... 3000 sec 60 sec T he actually utilized operating time of the regulating valve for

Working point - 100 ... + 100 % 0 % Output level for P and PD controllers

Output level limiting 0 ... 100 % 100 % The maximum limit for the output level.

- 100 ... + 100 % - 100 % The minimum limit for the output level.

Minimum relay ON

time

0 ... 60 sec 0 sec Limits the frequency of switching for switched outputs.

modulating controllers or proportional controllers with an

integrated actuator driver.

(when x = then y = Y0)

44 - 1150

Page 47

Controller structure 2 / ...

PARAMETERIZATION

Controller structure 2 P, I, PD, PI,

Proportional band 0 - 9999 Digit 0 Dig it

Derivative time 0 - 9999 s 80 sec

Reset time 0 - 9999 s 350 sec

Cycle time 0 - 9999 s 20 sec

Switching differential 0 - 999 Digi t 1 Digit

Minimum rel ay ON ti me 0 - 60 s 0 sec

NOTE

The parameter display on the instrument depends on the controller type selected.

(see Chapter

PID

“Controller“

PID The parameters refer to the second controller outp ut for 2-setpoint

)

and modulating controllers.

1150 - 45

Page 48

PARAMETERIZATION

46 - 1150

Page 49

CONFIGURATION

CONFIGURATION

Parameters and functions at the configuration level.................................................................................................................. 48

Analog inputs

Controller

Generator

Limit comparators

Outputs

Logic functions

............................................................................................................................................................................................................................... 51

........................................................................................................................................................................................................................................... 56

.......................................................................................................................................................................................................................................... 60

................................................................................................................................................................................................................... 64

................................................................................................................................................................................................................................................ 67

........................................................................................................................................................................................................................... 69

Math and logic module

C-level control

Display

................................................................................................................................................................................................................................................. 78

Interfaces

Device data

............................................................................................................................................................................................................................. 76

.......................................................................................................................................................................................................................................... 81

.................................................................................................................................................................................................................................... 82

..................................................................................................................................................................................................... 74

Recording

......................................................................................................................................................................................................................................... 83

1150 - 47

Page 50

CONFIGURATION

Parameters and functions at the configuration level

General

The following applies to the representation of parameters and functions at the configuration level:

The parameter is not displayed or cannot be selected if

• the instrument features do not permit the function assigned to the parameter .

Example:

Output 3 cannot be configured if no output 3 is available in the instrument.

• the parameter is irrelevant to the function that has been configured.

Example:

Analog input 1 is configured to “Pt100”, which means that displa y start and end for standard signals

cannot be selected.

NOTE

Some parameters are only available for a fixed-setpoint controller (with or without ramp

function) or a program controller/generator . For fixedsetpoint controllers , these parameters

and settings are marked by a superscript “F” (e.g. rampF), for program controllers /generators

by a “P”.

Access code

Factory-set code: 0002

Selectors

Selectors are menus which fold down when an individual parameter is selected.

Two standard selectors are defined for the configur ation tables below , f or reasons of clarity:

E.G. Analog selector

Switched off

Analog Imp. 1

...

Analog Imp. 4

Math 1

...

Math 8

Process value C1

Setpoint C1

Ramp end C1

Contro l d ev. C1

Output C1

Process value C2

Setpoint C2

Ramp end C2

Contro l d ev. C2

Output C2

Process value C3

Setpoint C3

Ramp end C3

Contro l d ev. C3

Output C3

Switched off

Measurement of analog input 1

...

Measurement of analog input 4

Result of math formula 1

...

Result of math formula 8

Process value for controller 1

Setpoint for controller 1

Ramp end value for controller 1

Control deviation for controller 1

Output for controller 1

Process value for controller 2

Setpoint for controller 2

Ramp end value for controller 2

Control deviation for controller 2

Output for controller 2

Process value for controller 3

Setpoint for controller 3

Ramp end value for controller 3

Control deviation for controller 3

Output for controller 3

48 - 1150

Page 51

CONFIGURATION

Process value C4

Setpoint C4

Ramp end C4

Control dev. C4

Output C4

Y cascade C1

...

Y cascade C4

Setpoint 1 C1

...

Setpoint 4 C1

Setpoint 1 C2

...

Setpoint 4 C2

Setpoint 1 C3

...

Setpoint 4 C3

Setpoint 1 C4

...

Setpoint 4 C4

Setpoint 1 PCh1

...

Setpoint 1 PCh4

Setpoint 2 PCh1

...

Setpoint2 PCh4

P

P

P

P

Seg. end val. PCh1

...

Seg. end val. PCh4

Output 1 C1

Output 2 C1

Output 1 C2

Output 2 C2

Output 1 C3

Output 2 C3

Output 1 C4

Output 2 C4

RemSegT PCh1

...

RemSegT PCh4

Seg. Time PCh1

...

Seg. Time PCh4

Program time

RemProgT

P

P

P

P

P

P

Analog value

Internal Pt100

Sampling ti me

Process value for controller 4

Setpoint for controller 4

Ramp end value for controller 4

Control deviation for controller 4

Output for controller 4

Standardized output with cascade control for controller 1

...

Standardized output with cascade control for controller 4

Setpoint 1 for controller 1

...

Setpoint 4 for controller 1

Setpoint 1 for controller 2

...

Setpoint 4 for controller 2

Setpoint 1 for controller 3

...

Setpoint 4 for controller 3

Setpoint 1 for controller 4

...

Setpoint 4 for controller 4

Setpoint 1 for program channel 1

...

Setpoint 1 for program channel 4

Setpoint 2 for program channel 1

...

P

P

Setpoint 2 for program channel 4

Current final segment value for program channel1

...

Current final segment value for program channel 4

Controller output 1 for controller 1

Controller output 2 for controller 1

Controller output 1 for controller 2

Controller output 2 for controller 2

Controller output 1 for controller 3

Controller output 2 for controller 3

Controller output 1 for controller 4

Controller output 2 for controller 4

Remaining segment time for progam channel 1 (in seconds)

...

Remaining segment time for progam channel 4 (in seconds)

Segment time for program channel 1 (in seconds)

...

Segment time for program channel 4 (in seconds)

Total program time (in seconds)

Remaining run time of program (in seconds)

any analog value (from adress)

Temperature measurement of internal Pt100

Sampling time of instrument

1150 - 49

Page 52

CONFIGURATION

E.G. Binary selectors

Switched off

Output 1 C1

Output 2 C1

Output 1 C2

Output 2 C2

Output 1 C3

Output 2 C3

Output 1 C4

Output 2 C4

Limit comp. 1

...

Limit comp. 16

Contr. contact 1

...

Contr. contact 8

Logic input 1

...

Logic input 6

Logic 1

...

Logic 8

Binary logic value

Program end

Ramp end 1

...

Ramp end 4

Tolerance band

Manual mode C

...

Manual mode C

Transmitter

Logic OFF

Logic ON

P

F

F

P

Switched off

Controller output 1 for Controller 1

Controller output 2 for Controller 1

Controller output 1 for Controller 2

Controller output 2 for Controller 2

Controller output 1 for Controller 3

Controller output 2 for Controller 3

Controller output 1 for Controller 4

Controller output 2 for Controller 4

Controller output 1

...

P

P

1

4

Limit comparator 16

Control contact 1

...

Control contact 8

Logic input 1

...

Logic input 6

Result of logic linkage 1

...

Result of logic linkage 8

any binary logic value (from address)

Program end signal

Ramp end signal for controller 1

...

Ramp end signal for controller 4

Signal on going above/below tolerance band

Controller 1 in manual mode / program pause

...

Controller 4 in manual mode / program pause

Signal always active

Logic 0

Logic 1

Definition of program times

Different times are defined for the prog ram controller/generator , which can be internally processed and

displayed.

(1) Program time

(2) Remaining program time

(3) Segment time

(4) Remaining segment time

50 - 1150

Page 53

Analog inputs

CONFIGURATION

Configuration

Analog inputs

Controller

Generator

Limit comparators

Outputs

Logic functions

Math / Logic

C-level

Display

Interfaces

Device data

Recording

Depending on the instrument version, up to four analog inputs are a vailable. The

analog inputs are numbered in sequence (input 1 — 4) according to their slot

assignment.

Analog input 1 (2 to 4) / ...

Value / selection Description

Probe

No function No function

RTD 3 - wire

RTD 2-wire Resistance thermometer in 2-wire circuit

RTD 4-wire Resistance thermometer in 4-wire circuit

T/C int. Thermocouple (internal cold junction)

T/C ext. Thermocouple (external cold junction)

T/C const. Thermo couple (constant cold junction)

Pot Potentiometer

Heater current Heater current 0 to 50 mA AC

0 to 20 mA 0 to 20 mA

0 to 10 V 0 to 10 V

0 to 1 V 0 to 1 V

0 to 100 mV 0 to 100 mV

- 10 to + 10 V - 10 V to + 10 V

- 1 to + 1 V - 1 to + 1 V

- 100 to + 100 mV - 100 to + 100 mV

4 to 20 mA 4 to 20 mA

2 to 10 V 2 to 10 V

0,2 to 1 V 0,2 to 1 V

20 to 100 mV 20 to 100 mV

- 6 to 10 V - 6 to 10 V

- 0,6 to 1 V - 0, 6 to 1 V

- 60 to + 100 mV - 60 to + 100 mV

Resistance thermometer in 3-wire circuit

Factory-set on analog input 2 to 4: No function

1150 - 51

Page 54

CONFIGURATION

Analog input 1 (2 to 4) / ...

Value / selection Description

Linearization

Linear

Pt100

Pt100 JIS

Ni100

Pt500

Pt1000

Ni1000

Pt50

CU50

Pt K9

KTY11-6

Fe-CuNi J

NiCr-CuNi E

NiCr-Ni K

NiCrSi-NiSi N

Cu-CuNi T

Pt30Rh-Pt6Rh B

Pt13Rh-Pt R

Pt10Rh-Pt S

Cu-CuNi U

Fe-CuNi L

W5Re_W26Re C

W3Re_W25Re D

W3Re_W26Re

C-level

Customized 1

Customized 2

Customized 3

Customized 4

For customized linearizaton (e.g. „customized 1“) a maximum of 20 knee-points can

be implemented, or a 5th order polynominal functi on programmed (only with setup

program).

„C-level“ linearization is used for the C-level control with a zircon dioxide sensor.

For the linearization „KTY11-6“, the resistance is 2 k at 25 °C. The resistance

value can be adapted via the parameter „KTY: at 25°C / 77°F.

Offset

- 1999 to 0 to + 9999 The offset is used to correct a measured value by certain amount upwards or

NOTE

The controller uses the corrected value (l.e. displayed value) f or its computation. This value

downwards.

Example:

Measured Displayed

value Offset value

294,7 + 0,3 295,0

295,3 - 0,3 295,0

does not correspond to the actual measured value.

If incorrectly applied, this can result in impermissible values of the control variable.

52 - 1150

Page 55

Analog input 1 (2 to 4) / ...

Value / selection Description

Range

CONFIGURATION

Start

to + 9999

- 1999

End

- 1999 to + 9999

The instrumen t will chang e over earli er to the res ponse de fined for

overrange / underrange if the range is restri cted.

Example:

Pt100 (Range: - 200 to + 8 50 ° C). An alarm message is to be generated

for temperatures outside the range 15 to 200 °C.

Range start: 15

Range end: 200

Display

Start

- 1999 to 0

End

- 1999 to 100

to + 9999

to + 9999

On transducers with standard si gnal an d on po tentiome ters, a display

value is assigned to the physical signal .

Example: 0 to 20 mA = 0 to 1500 °C.

The range of the physical signal ca n be 20 % wider or narr ower without

generating an out-of-range si gnal.

Filter

0 to 0,6 to 100 s To adjust the digital input filter (0 s = filter off). 63 % of the alternations

are accounted for after 2x filter time cons tant at a sign al step ch ange.

When the filter time constant is large:

- high damping of distur bance si gnal s

- slow reaction of the process value displ ay to process value chang es

- low limit-frequency (2nd ord er low-pass fi lter)

TK constant val ue

0 to 50 to 100 Temperature of the external cold-junction thermostat.

TK external

Analog input 1

Analog input 2

Analog input 3

Analog input 4

Measurement of the c ol d-ju nction temperature with an temperature

probe.

Heater current monitoring (output)

No function.

Output 1

...

Output 12

The heater current is evaluated using a curren t transforme r with a

standard signal output, wh ich can be monito red by linkin g the anal og

input with a limit comparator.

The measurement is always made when the he ating co ntact is c losed .

The measurement is retaine d until the next measureme nt.

Correction value KTY

0 to 400

1 k * Correction value

1150 - 53

Page 56

CONFIGURATION

Analog input 1 (2 to 4) / ...

Value / selection Description

Recalibration

Start

- 1999 to 0

End

- 1999 to 1

to + 9999

to + 9999

(See below for explanation)

NOTE

As opposed to all the other settings, entry of the start and end value is linked to the latest

measurement at the input concerned.

As a rule, these values cannot be adopted by another instrument.

Customized recalibration

A signal is processed electronically (conversion, linearization …) to produce a measured value via the

analog inputs of the controller. This measured v alue enters into the computations of the controller and can

be visualized on the displays (measured value = displayed value).

This fixed relationship can be modified if required, i.e. the position and the slope of the measurement

characteristic can be altered.

Procedure

Apply two measurement points ((1), (3)), one after another , to the controller; they should be as f ar apart as

possible.

At these measurement points, enter the required display v alue (start value, end value) in the controller. A

reference instrument is most convenient for determining the measured values M1 and M2.

Measurement conditions must remain stable during programming.

54 - 1150

Page 57

CONFIGURATION

Programming

(1) Move to measurement point

(2) Enter start value

(3) Move to measurement point

(4) Enter end value E

1)

If start value=0 or end value=1 is to be set, then the value must first be altered using or

to enable correction.

1)

1)

NOTE

If recalibration is carried out without a reference instrument, the offset must be taken into

account when moving to measurement point (3).

To cancel recalibration, the start and end values have to be prog rammed to the same v alue. This

automatically sets the start value to 0 and the end value to 1.

Any subsequent recalibration will otherwise be based on the corrected characteristic.

1150 - 55

Page 58

CONFIGURATION

Controller

Configuration

Analog inputs

Controller

Generator

Limit comperators

Outputs

Logic functions

Math / Logic

C-level

Display

Inter faces

Device data

Recording

The following are set here: controller type, input v ariables of the controller , the

setpoint limits, conditions for manual mode and the presettings for selfoptimization

of the four controller channels.

Controller 1 (2 to 4) / Configuration

Value / selection Description

Controller type

2 point process controller

3 point process controller

3 point step

Position control

Continuous

2 point process controller

3 point process controller

3 point step automatic controller

Continuous automatic controller with integrated position control

Continuous automatic controller

Control action

Direct

Inverse

Direct:

The controller output Y is > 0 when the process value is smaller than the setpoint

(e.g. cooling).

Inverse:

The controller output Y is > 0 when the process value is larger than the setpoint

(e.g. heating).

Inhibit manual mode

Free

Inhibited

If the manual mode is inhibited, changing over to "manual" is not possible from

the keys or via the logic input.

Manual output

- 100 to 101 Defines the output after changing over to manual mode.

101 = last output

Range output

- 100 to 0 to 101 Output on out-of-range.