1 Cover Sheet

TEST REPORT

Project-No.: 17-8981

Test Specimen: Shipping Unit - Outdoorcase -

Client: B&W International GmbH

Junkendiek 5

49479 Ibbenbühren

Responsible Persons: Waldemar Masur (B&W International GmbH)

Johannes Frick (PAConsult GmbH)

Purpose:

By means of a transport simulation an outdoorcase - Type 4000 - is tested to climatic-, vibrationand shock strains. Furthermore a water resistance test is performed. The transport simulation is

performed according to the specification of the client: MIL-STD-810G w/Change 1 [1].

Summary:

The tests are performed successfully; visible changes are observed.

During the pre-conditioned drop test on face 3, the closure (buckle) opened halfway. The case

opened at the drop on face 1. During the unconditioned drop on face 1 and 3, one closure

(buckle) opened halfway. No damages could be detected. The immersion test showed no ingress

of water.

The evaluation of the result is performed by the client.

Date of Delivery: May 11, 2017

Testing Period: May 17 to 23, 2017

Page: 1 of 25

Revision: 0

Written: Johannes Frick June 14, 2017

(Project Leader) Signature

Reviewed: Dr. Karim Esfahlani June 14, 2017

PAConsult GmbH · Environmental Testing Laboratory · Birkenau 3 · D-22087 Hamburg · Tel 040-229 48 79-0 · Fax 040-229 48 79-1 ·

(Managing Director) Signature

e-mail info@paconsult.de

Page 2 of 25 Test Report 17-8981 Outdoorcase

List of Revision:

Revision Date Reason

0 2017-06-12 Original Document

2 Table of Contents

1 Cover Sheet ........................................................................................................................ 1

2 Table of Contents ............................................................................................................... 2

3 Specimen ............................................................................................................................ 3

4 Test and Equipment ............................................................................................................ 4

4.1 Test Facility ................................................................................................................. 5

4.2 Laboratory Conditions ................................................................................................. 5

4.3 Equipment used for Test .............................................................................................. 6

5 Test Procedures .................................................................................................................. 7

5.1 Temperature Shock ...................................................................................................... 7

5.2 Drop Test ..................................................................................................................... 9

5.3 Immersion Test ............................................................................................................ 9

5.4 Shock Test ................................................................................................................. 12

5.5 Random Vibration Test ............................................................................................. 14

5.6 Loose Load Vibration Test ........................................................................................ 14

6 Test and Results ............................................................................................................... 16

6.1 Temperature Shock .................................................................................................... 16

6.2 Drop Test ................................................................................................................... 16

6.3 Immersion Test .......................................................................................................... 17

6.4 Shock Test ................................................................................................................. 18

6.5 Random Vibration Test ............................................................................................. 21

6.6 Loose Load Vibration Test ........................................................................................ 22

7 Additional Tests ............................................................................................................... 23

7.1 Drop test with Splint .................................................................................................. 23

7.2 Drop Test Unconditioned .......................................................................................... 23

8 Summary .......................................................................................................................... 24

9 References ........................................................................................................................ 25

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 3 of 25 Test Report 17-8981 Outdoorcase

3 Specimen

For the tests three similar outdoorcases (see Fig. 1) are provided by the client. Tab. 1 specifies

the shipping units. In the following designation the specimens are abbreviated by EUT

(Equipment Under Test).

Tab. 1: Specimen

EUT

No

1 Shipping Unit

2 Shipping Unit

3 Shipping Unit

Specimen Content

Note: The specified dimensions are client identification values and not measurement results.

Empty Case

Type 4000

Empty Case

Type 4000

Empty Case Type 4000

with Splint

Dimensions in mm

Length Width Height

420 330 180 2159

420 330 180 2154

420 330 180 2161

Weight

The incoming goods control showed no visible damages at the packaging.

in kg

Shipping

Unit

Construction

Black

Synthetic

Case with

Closure and

Carrying

Handle

Fig. 1: EUT

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 4 of 25 Test Report 17-8981 Outdoorcase

4 Test and Equipment

The test standards and parameters were given by the client. Tab. 2 describes the tests according

to the specification.

Tab. 2: Test Parameters

Test / EUT Test Parameter Test Level Reference

Temperature

Shock

EUT 1

Drop Test

Conditioned

EUT 1

Immersion Test

EUT 2

Shock Test

EUT 1

3 Cycles

Basic Hot (Day): + 63 ° C

Basic Cold (Night): - 33° C

Drop Height:

1.220 mm

Specimen conditioned

(Water Temperature + 10° C)

Depth: 1 m

Half Sine

Acceleration: 40 g

Duration: 11 ms

Specimen fixed on the Shaker

Stabilization 1h per Temperature

Temperature Change Rate < 1 min

All Faces (6)

All Edges (12)

All Corners (8)

Duration: 30 min

± 3 Shocks

3 Axes

MIL-STD 810 G

Change 1

Method 503.6

Procedure I-D

Shocks from

Controlled Ambient

MIL-STD 810 G

Change 1

Method 516.7

Procedure IV

Logistic Transit

Drop

MIL-STD 810 G

Change 1

Method 512.6

Procedure I

MIL-STD 810 G

Change 1

Method 514.7

Category 5

Procedure II

Loose Cargo

Random

Vibration

EUT 1

Loose Load

Vibration Test

EUT 1

Vertical:

Frequency: 10 - 500 Hz

G

: 1.04

rms

Longitudinal and transversal:

Frequency: 10 - 500 Hz

G

: 0.74

rms

Specimen fixed on the Shaker

Amplitude: 25.4 mm

Frequenz: 5 Hz

Specimen loose

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Duration: 1.5 h per Axis

3 Axes

Duration: 20 min (~ 240 km)

Axes: 1 Axis, most stable,

Transport orientation)

MIL-STD 810 G

Change 1

Method 514.7

Category 4

Procedure I

Common Carrier

Figure 514.7C-2

Secured Cargo

MIL-STD 810 G

Change 1

Method 514.7

Category 5

Procedure II

Loose Cargo

Page 5 of 25 Test Report 17-8981 Outdoorcase

Additional Tests:

Test / EUT Test Parameter Test Level Reference

MIL-STD 810 G

Drop Test

(Unconditioned

with Splint)

EUT 3

Drop Test

(Unconditioned)

EUT 2

Drop Height:

1.220 mm

Drop Height:

1.220 mm

All Faces (6)

All Edges (12)

All Corners (8)

Face 1

Face 3

Change 1

Method 516.7

Procedure IV

Logistic Transit

Drop

Based on

MIL-STD 810 G

Change 1

Method 516.7

Procedure IV

Logistic Transit

Drop

4.1 Test Facility

The tests were performed in the laboratory of:

PAConsult GmbH

Site Hamburg

Birkenau 3

D-22087 Hamburg

info@paconsult.de

ISTA Member ID: ST-9678

4.2 Laboratory Conditions

All tests are performed under the conditions listed in Tab. 3, if not stated otherwise in the test

report.

Tab. 3: Environmental Conditions

Temperature 15 °C-35 °C

Relative Humidity < 85 %

Air Pressure 860 hPa – 1060 hPa

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 6 of 25 Test Report 17-8981 Outdoorcase

4.3 Equipment used for Test

The test equipment used in the laboratory of PAConsult GmbH is listed in Tab. 4 .

Tab. 4: Test Equipment

Devices Manufacturer Type

Vibrating Table Lansmont MS-400 M-13091 2016/12

Drop Table Lansmont PDT-56ED M-15943 2016/09

Shaker RMS 8130 RMS SW 8130 11382 2017/01

Test Manager 1

(Lab. 0)

Accelerometer

Lab. 0/ Ch. 1

Stop Watch Atech SW 328 12307036 2016/11

Climatic Cabinet 2

(5K)

Climatic Cabinet 7

(CTS)

Temperature

Sensor C5

Data Logger Testo 174H 36946057 2016/06

The calibration of the laboratory test equipment is performed annually (± 2 months).

LDS Laser USB 9364940 2017/01

PCB M353B03 91672 2017/01

Weiss

Umwelttechnik

CTS CS 70/350-5 123074 2016/10

Ahlborn ZA 9020-FS Thermo E4

WK 340-70-5 58226073510010 2017/01

Serial number /

Version

C5 2016/10

Date of last

calibration

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 7 of 25 Test Report 17-8981 Outdoorcase

5 Test Procedures

5.1 Temperature Shock

With the EUT in its appropriate logistic configuration, stabilize the EUT at controlled ambient

conditions. Transfer the EUT in no more than one minute to an atmosphere at temperature T2

that will produce the thermal shock and stabilize the temperature. Transfer the EUT back to

controlled ambient conditions (T1) in no more than one minute, and stabilize the temperature.

Repeat this procedure 2 times (3 cycles in total).

T1 = -33°C

T1 = +63°C

Stabilization time: 1 hour per temperature

The test is performed with EUT 1.

Fig. 2 and 3 show the setup in the two different chambers.

Fig. 2: Cold Chamber

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 8 of 25 Test Report 17-8981 Outdoorcase

Fig. 3: Hot Chamber

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 9 of 25 Test Report 17-8981 Outdoorcase

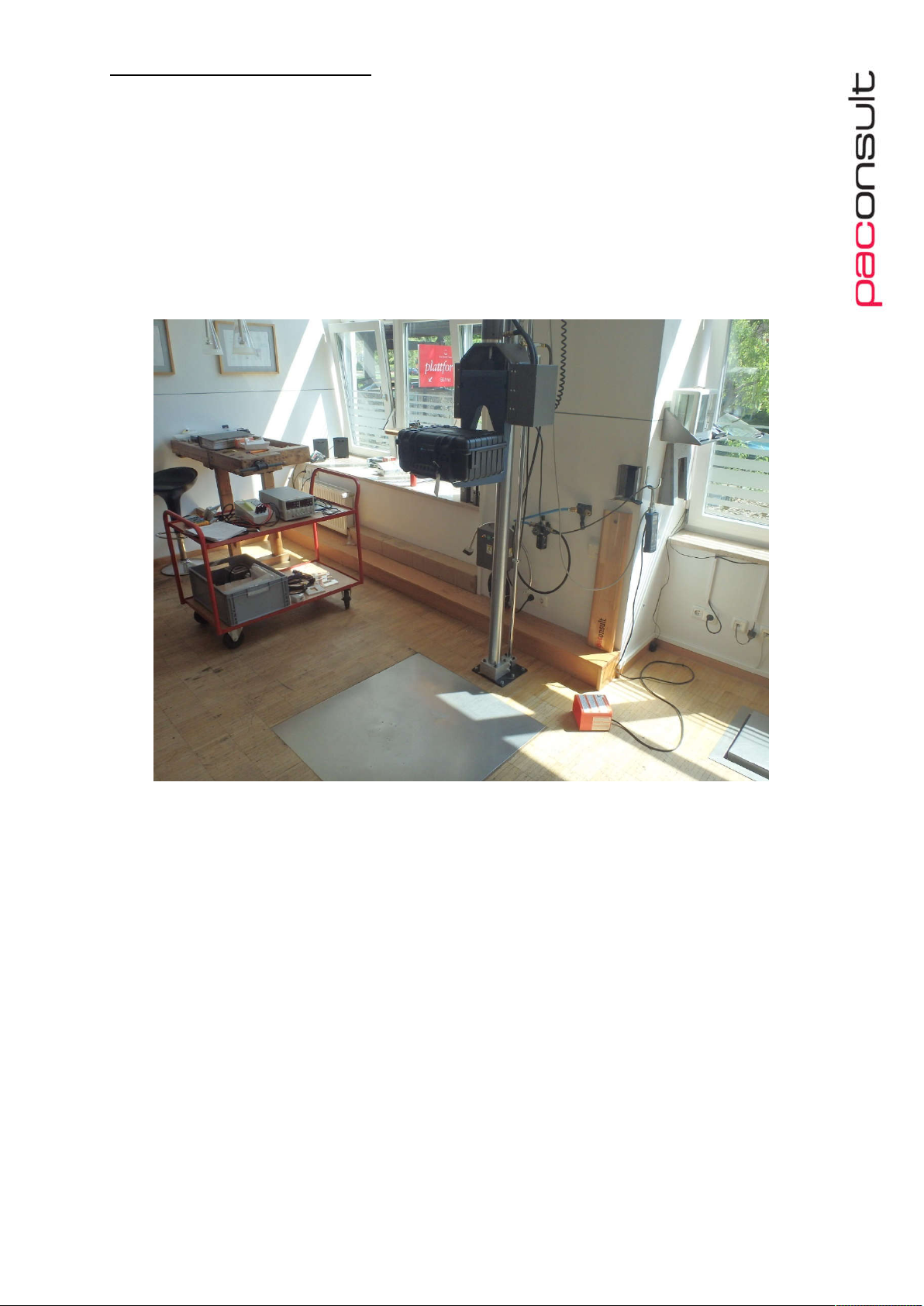

5.2 Drop Test

The EUT is dropped immediately after the end of the third temperature cycle with a

temperature of + 63°C. The EUT is dropped from a height of 1.220 mm. It is dropped on all

faces (6 drops), all edges (12 drops) and all corners (8 drops.). Fig. 4 shows the setup

exemplarily.

The test is performed with EUT 1.

Fig. 4: Setup

5.3 Immersion Test

Measure and record the immersion water temperature. Condition the EUT at a temperature 10°C

higher than the water temperature. Close all sealed areas and valves; assemble the EUT in its

test configuration and, as quickly as possible, immerse the EUT in water so that the uppermost

point of the EUT is 1 m below the surface of the water. The orientation of the EUT should

represent that of its expected in-service orientation. If several orientations are possible, select

that which is most severe. Following a 30-minute immersion period, remove the EUT from the

water, wipe the exterior surfaces dry (giving special attention to areas around seals and relief

valves) and, if applicable, equalize the air pressure inside by activating any manual valves. Be

careful to not allow water to enter the EUT while activating the manual valves. Open the EUT

and examine the interior and contents for evidence of, and quantity of any leakage and, if

leakage occurred, for probable areas of entry.

The test is performed with EUT 2.

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 10 of 25 Test Report 17-8981 Outdoorcase

Fig. 5 shows the ambient (EUT) temperature. Fig. 6 shows the water temperature.

Fig. 5: Ambient (EUT) Temperature

Fig. 6: Water Temperature

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 11 of 25 Test Report 17-8981 Outdoorcase

Fig. 7: Water Filling and EUT Fixation (Wood Restraints)

Fig. 8: Immersion Depth

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 12 of 25 Test Report 17-8981 Outdoorcase

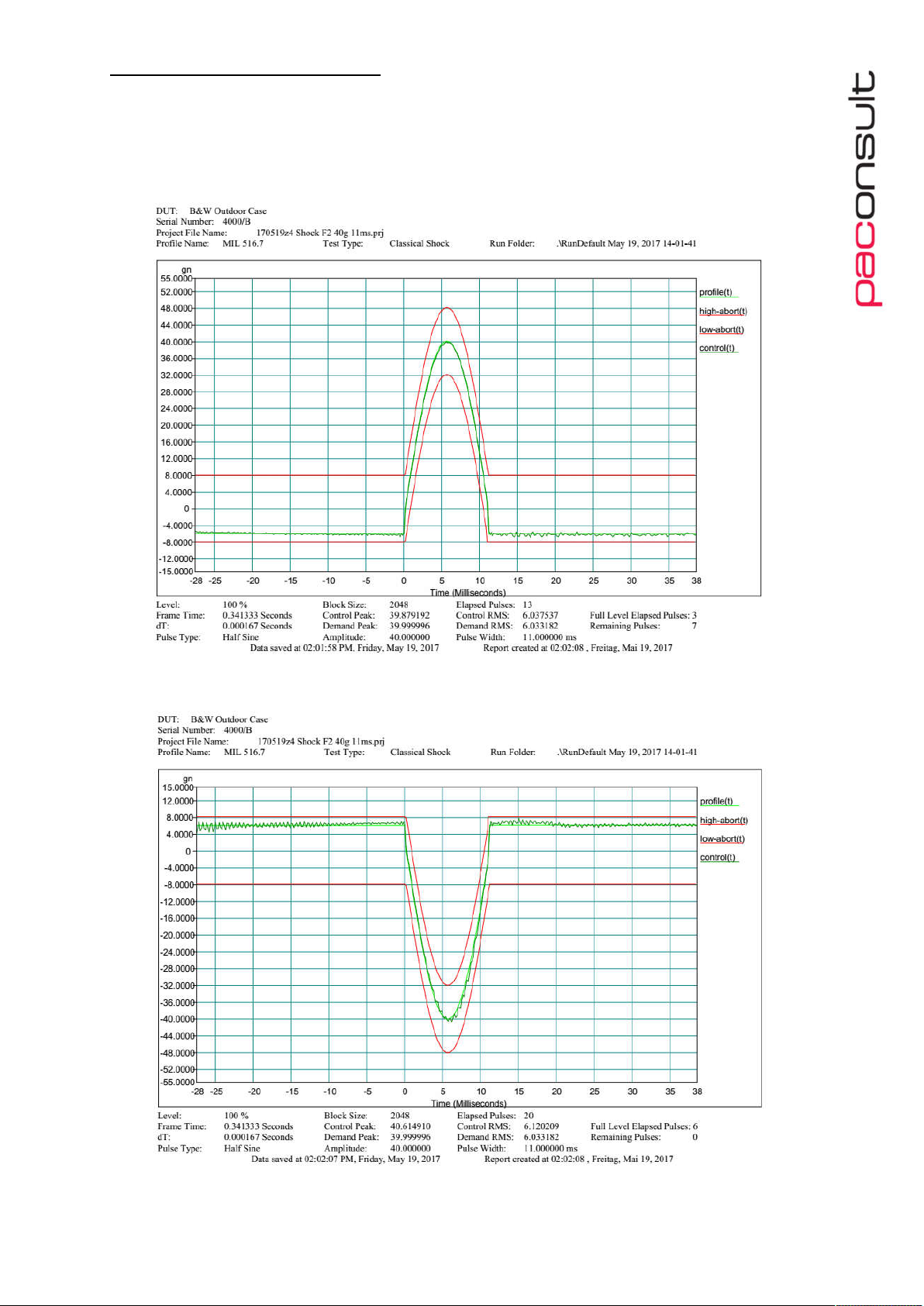

5.4 Shock Test

The EUT is fixed on the shaker with fixation devices (tension belts). With the shaker in vertical

direction, the EUT is fixed in three different (mutual perpendicular) axes. Fig. 9 to 11 show the

position and fixation on the shaker.

The shock pulse is a half sine pulse with a duration of 11 ms and a peak acceleration of 40 g.

Three positive and three negative shocks are applied.

The test is performed with EUT 1.

Fig. 9: Setup x-Axis (Transversal)

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 13 of 25 Test Report 17-8981 Outdoorcase

Fig. 10: Setup y-Axis (Longitudinal)

Fig. 11: Setup z-Axis (Vertical)

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 14 of 25 Test Report 17-8981 Outdoorcase

5.5 Random Vibration Test

The EUT is fixed on the shaker with fixation devices (tension belts). The EUT is fixed on the

shaker in three different (mutual perpendicular) axes / positions. Fig. 9 to 11 show the position

and fixation on the shaker.

There are three different levels of vibration exposure:

Vertical: 10 -500 Hz; g

Longitudinal: 10 -500 Hz; g

Transversal: 10 -500 Hz; g

Level 1.04

rms

Level 0.20

rms

Level 0.74

rms

The vertical level is applied in vertical axis (z-Axis), the transversal level is applied in x-Axis

transversal and y-Axis (longitudinal).

The exposure duration is 1.5h per axis, representing a transportation distance of

approximately 2.500 km.

The test is performed with EUT 1.

5.6 Loose Load Vibration Test

The cargo has freedom to bounce, scuff and collide with other cargo and with the sides of the

vehicle. The loose cargo environment includes conditions experienced by cargo transported in

a vehicle traversing irregular surfaces. This test replicates the repetitive random shock

environment incurred by cargo transported under these conditions.

A duration of 20 minutes represents 240 km (150 miles) of transportation (encompassing

truck, two-wheeled trailer, and tracked vehicle), over the various road profiles found in the

transport scenario from the Corps Staging Area to a Using Unit.

Two methodology studies (paragraph 6.1, references g and h) determined that a standard

package tester (300 rpm, circular synchronous mode), provides a reasonable simulation of the

loose cargo transportation environment. The movement of the package tester bed is a 2.54 cm

(1.0 inch) diameter orbital path at 5 Hz (each point on the bed moves in a circular path in a

plane perpendicular to the horizontal plane). The test item is allowed to collide with

established test setup restraints.

Fig. 11 shows the setup on the loose load vibration teable (package tester).

The test is performed with EUT 1.

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 15 of 25 Test Report 17-8981 Outdoorcase

Fig. 12: Setup Loose Load Vibration Test

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 16 of 25 Test Report 17-8981 Outdoorcase

6 Test and Results

6.1 Temperature Shock

The test is performed with the specified parameters (see Tab. 2). During the test no visible

changes were observed.

6.2 Drop Test

The test is performed with the specified parameters (see Tab. 2). During the test visible changes

were observed. During the drop on face 3, the closing devices (buckles) opened halfway (see

Fig. 13); They were closed and the drop test continued. During the drop on face 1, the case

opened completely (see Fig. 14).

Fig. 13: Opening Halfway

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 17 of 25 Test Report 17-8981 Outdoorcase

Fig. 14: Opened Case

6.3 Immersion Test

The test was performed with the specified parameters (see Tab. 2). During and after the test no

visible changes could be observed. No ingress of water could be detected.

Fig. 15: Dry Case

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 18 of 25 Test Report 17-8981 Outdoorcase

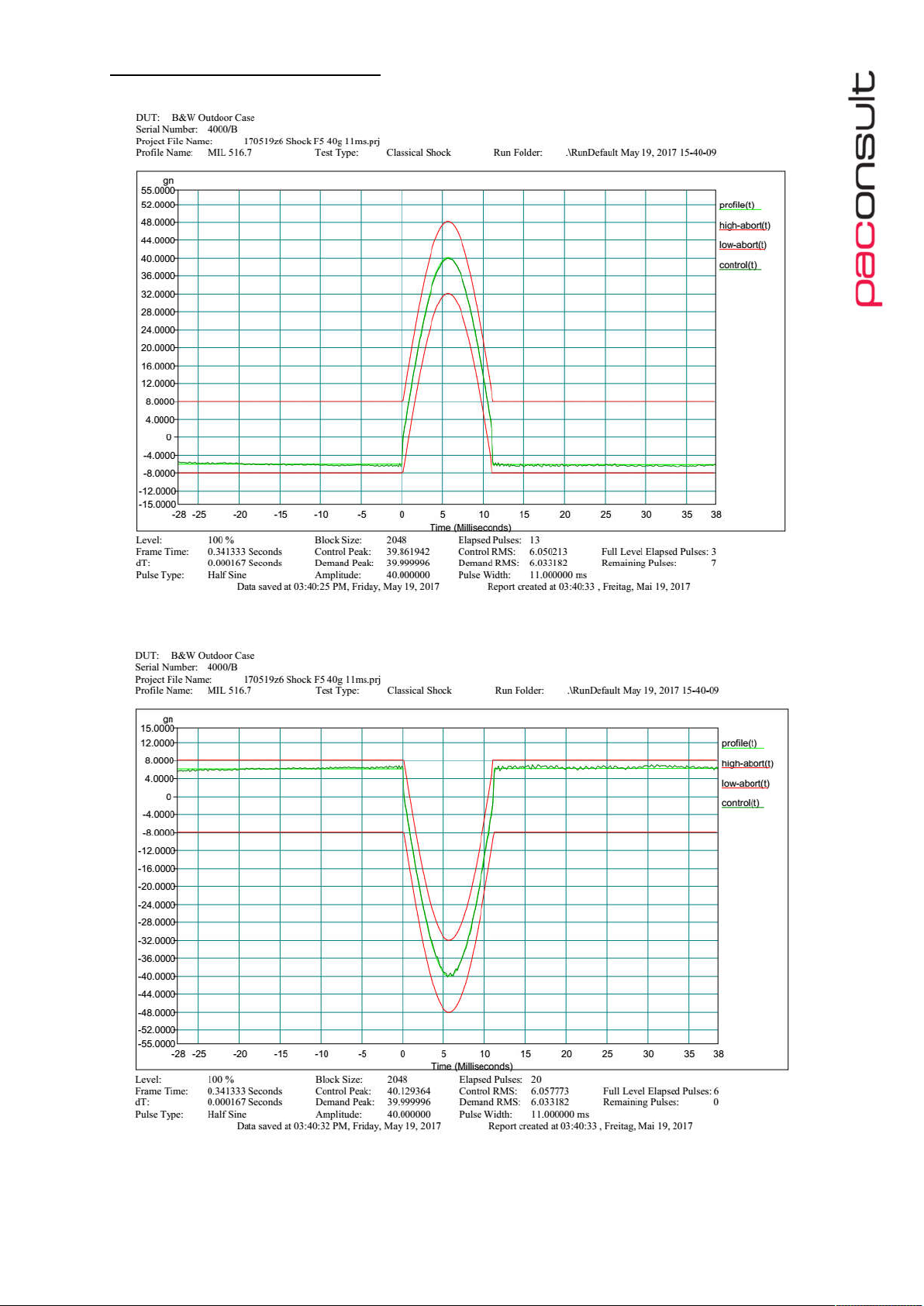

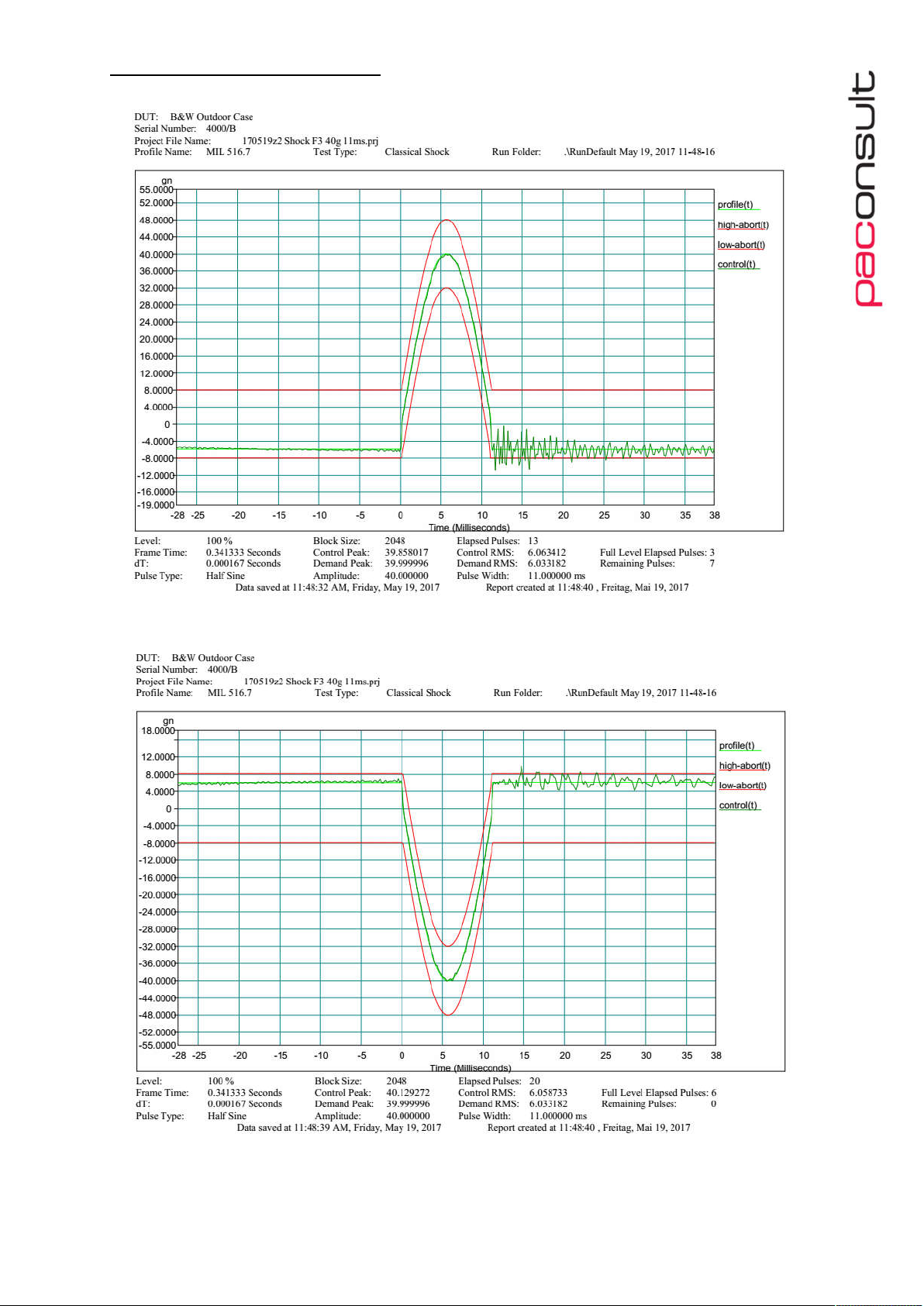

6.4 Shock Test

The test is performed with the specified parameters (see Tab. 2). During the test no visible

changes were observed. Fig. 16 to 21 show the shock proceeding.

Fig. 16: Positive Shock x-Axis

Fig. 17: Negative Shock x-Axis

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 19 of 25 Test Report 17-8981 Outdoorcase

Fig. 18: Positive Shock y-Axis

Fig. 19: Negative Shock y-Axis

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 20 of 25 Test Report 17-8981 Outdoorcase

Fig. 20: Positive Shock z-Axis

Fig. 21: Negative Shock z-Axis

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 21 of 25 Test Report 17-8981 Outdoorcase

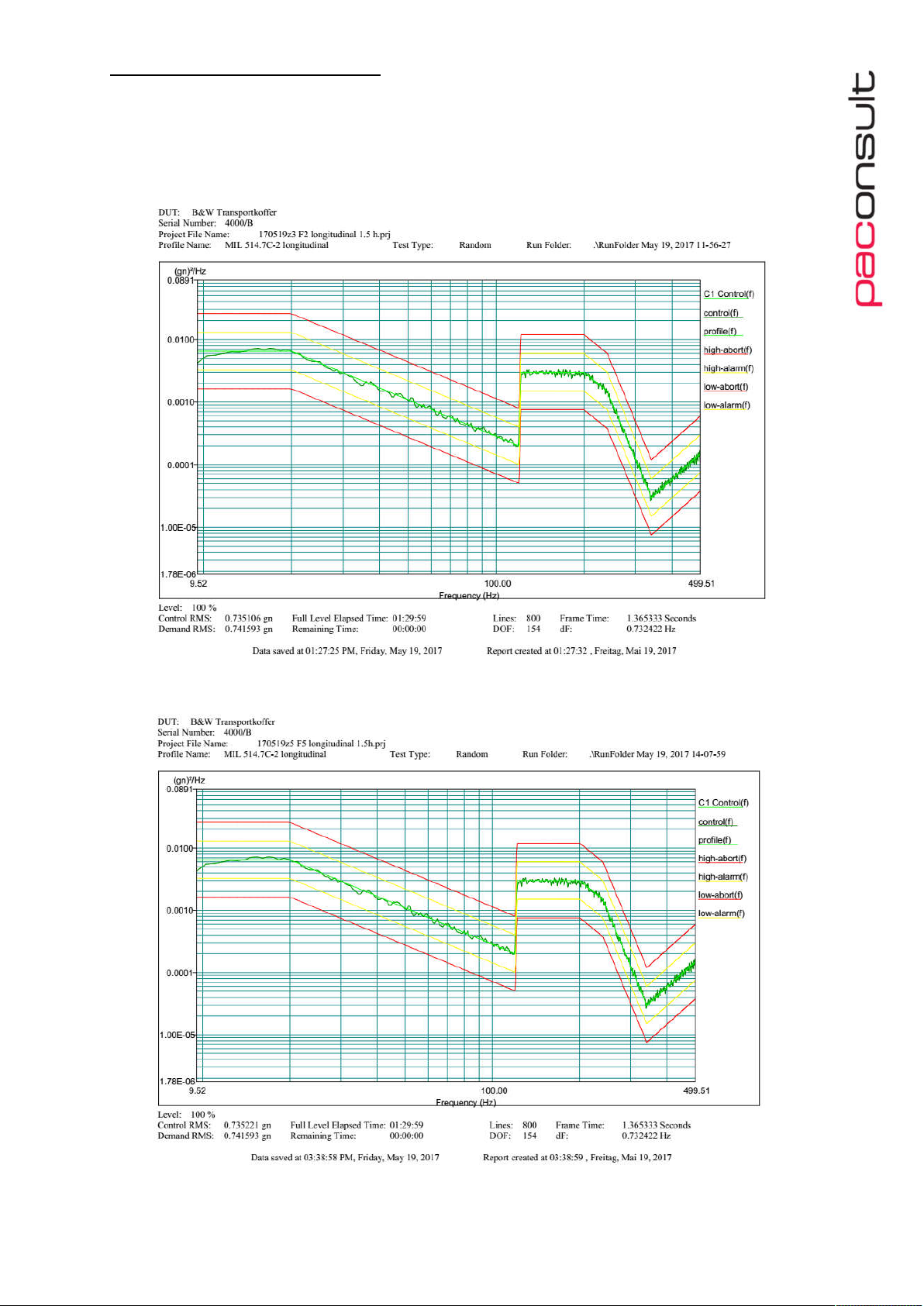

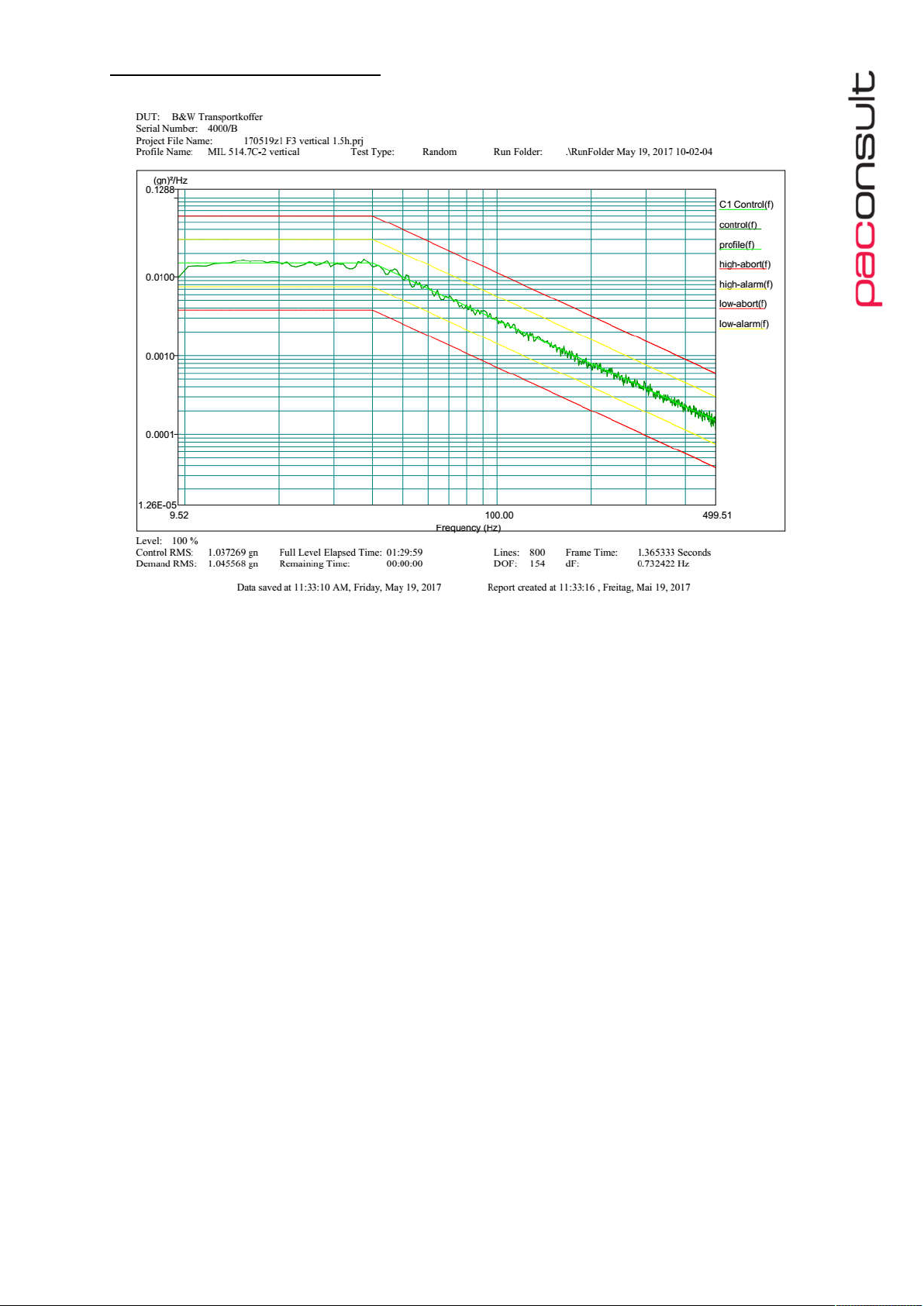

6.5 Random Vibration Test

The test is performed with the specified parameters (see Tab. 2). During the test no visible

changes were observed. Fig. 22 to 24 show the vibration proceeding.

Fig. 22: Random Vibration x-Axis

Fig. 23: Random Vibration y- Axis

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 22 of 25 Test Report 17-8981 Outdoorcase

Fig. 24: Random Vibration z-Axis

6.6 Loose Load Vibration Test

The test is performed with the specified parameters (see Tab. 2). During the test no visible

changes were observed.

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 23 of 25 Test Report 17-8981 Outdoorcase

7 Additional Tests

7.1 Drop test with Splint

A complete drop test (see chapter 5.2) was performed with EUT 3 (outdoor case with splints).

Result:

No damages could be detected, no opening of the case or the closing devices could be

detected.

7.2 Drop Test Unconditioned

A drop test on face 1 and 3 was performed with EUT 2. This test was performed

unconditioned (first drop test: EUT temperature: +63°C). The drops were performed from a

height of 1.220 mm.

Result:

One closure (buckle) opened halfway on both drops.

Fig. 25: Opened Buckle

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 24 of 25 Test Report 17-8981 Outdoorcase

8 Summary

The tests were finished successfully. During the tests visible changes were observed. Tab. 5

summarizes the results of all tests.

Tab. 5: Summary Results

Test Result Transport Simulation with Outdoorcase according to MIL-STD 810G

Seq. Test Type EUT 1 EUT 2 EUT 3

Temperature

1

2 Drop Test

Shock

No changes or damages

Halfway opening of

buckle

(drop on face 3; Fig. 13)

Opening of case

(drop on face 1; Fig .14)

Not performed Not performed

Not performed Not performed

3 Immersion Test Not performed

4 Shock Test

5

Additional Tests

6

7

Random

Vibration Test

Drop Test with

Splint

(unconditioned)

Drop Test on

Face 1 and 3

(unconditioned)

No changes or damages

No changes or damages

Not performed Not performed

Not performed

No ingress of water

detected

Not performed Not performed

Not performed Not performed

Halfway opening

of one buckle

(both drops; Fig. 25)

Not performed

No changes or damages

Not performed

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Page 25 of 25 Test Report 17-8981 Outdoorcase

9 References

[1] MIL-STD-810G w/Change 1: Department of Defense Test Method Standard;

Environmental Engineering Considerations and Laboratory Tests. 15 April 2014

Johannes Frick

(Project Leader)

Note

This test report may only be reproduced in its entirety and without alterations. Publication in

parts is subject to the approval by the test laboratory. The test results refer exclusively to the

designated test specimens. Test reports without signature are not valid.

© PAConsult GmbH Copyright Reserved Fri.: 2017-06-14

Loading...

Loading...