Bush Hog TOUGH 4045 User Manual

Front End Loaders

BUSH HOG,® L.L.C.

Models 3545 / 4045 / 5045 / 6045

OPERATOR’S MANUAL

ASSEMBLY ● OPERATION ● MAINTENANCE

1106 |

$4.00 |

50051956 |

CONGRATULATIONS!

You have invested in the best implement of its type on the market today.

The care you give your Great Bend implement will greatly determine your satisfaction with its performance and its service life. We urge a careful study of this manual to provide you with a thorough understanding of your new implement before operating, as well as suggestions for operation and maintenance.

If your manual should become lost or destroyed, Great Bend will be glad to provide you with a new copy. Order from Great Bend, P. O. Box 1039, Selma, Alabama 36702-1039.

As an authorized Great Bend dealer, we stock genuine Great Bend parts which are manufactured with the same precision and skill as our original equipment. Our trained service personnel are well informed on methods required to service Great Bend equipment, and are ready and able to help you.

Should you require additional information or assistance, please contact us.

YOUR AUTHORIZED

GREAT BEND DEALER

3545 / 4045 / 5045 / 6045

TABLE OF CONTENTS

SECTION/PARA |

PAGE |

SECTION/PARA |

PAGE |

|

Warranty ..................................................................... |

2 |

|

Dealer Preparation Check List.................................... |

3 |

|

Safety Alert Symbols .................................................. |

4 |

|

Safety Precautions ..................................................... |

5 |

|

Federal Laws & Regulations....................................... |

7 |

I |

INTRODUCTION & DESCRIPTION ........................... |

8 |

|

1-1 Introduction........................................................... |

8 |

|

1-2 Description ........................................................... |

8 |

II |

LOADER MOUNTING & DISMOUNTING ................ |

10 |

|

2-1 Preparing Tractors.............................................. |

10 |

|

2-2 Mounting Loader ................................................ |

10 |

|

2-3 Dismounting Loader .......................................... |

12 |

III |

OPERATING INSTRUCTIONS ................................ |

13 |

|

3-1 General Safety ................................................... |

13 |

|

3-2 Pre Operation ..................................................... |

13 |

|

3-3 Initial Loader Operation ...................................... |

13 |

|

3-4 External Loader and/or Tractor Valve ................ |

14 |

|

3-5 Loader Mounted or Tractor Mounted |

|

|

Single Lever Control Handle..................................... |

14 |

|

3-6 Loader Mounted Series Control Valve With Single |

|

|

Lever Control Handle................................................ |

14 |

|

3-7 Neutral Position .................................................. |

14 |

|

3-8 Float Position...................................................... |

14 |

|

3-9 Regenerative Valve Position .............................. |

14 |

|

3-10 Load Sense Loader Valve ................................ |

14 |

|

3-11 Loader Operation ............................................. |

14 |

|

3-12 Removing Air From Hydraulic System |

...............15 |

|

3-13 Hose Identification............................................ |

15 |

|

3-14 Bucket Level Indicator Rod .............................. |

15 |

|

3-15 Bale Spear Operation....................................... |

20 |

|

3-16 Fork Lift Operation............................................ |

21 |

|

3-17 Transporting ..................................................... |

21 |

|

3-18 Skid Steer Quick Hitch Operation..................... |

22 |

IV |

MAINTENANCE ..................................................... |

23 |

|

4-1 Maintenance Check List .................................... |

23 |

|

4-2 Lubrication ......................................................... |

23 |

|

4-3 Hydraulic System |

|

|

Pressure Requirements ..................................... |

24 |

|

4-4 Troubleshooting ................................................. |

24 |

V |

ASSEMBLY .............................................................. |

26 |

|

5-1 Tractor Preparation ............................................ |

26 |

|

5-2 Tractor Ballast .................................................... |

27 |

|

5-3 Installation .......................................................... |

27 |

|

5-4 Hydraulic Hookup ............................................... |

27 |

|

5-5 Bucket Level Indicator Rod ................................ |

27 |

|

5-6 Fork Lift Option................................................... |

28 |

|

5-7 Bale Spear Option .............................................. |

28 |

|

5-8 Optional Bucket Items ........................................ |

29 |

|

Torque Specifications ............................................... |

30 |

|

Safety Decals ........................................................... |

31 |

OPTIONAL EQUIPMENT INSTRUCTIONS AT END OF MANUAL

NOTE: Some optional equipment information may not apply to your particular loader.

RETAIL CUSTOMER’S RESPONSIBILITY

UNDER THE GREAT BEND WARRANTY

It is the Retail Customer and/or Operator’s responsibility to read the Operator’s Manual, to operate, lubricate, maintain and store the product in accordance with all instructions and safety procedures. Failure of the operator to read the Operator’s Manual is a misuse of this equipment.

It is the Retail Customer and/or Operator’s responsibility to inspect the product and to have any part(s) repaired or replaced when continued operation would cause damage or excessive wear to other parts or cause a safety hazard.

It is the Retail Customer’s responsibility to deliver the product to the authorized Great Bend Dealer, from whom he purchased it, for service or replacement of defective parts which are covered by warranty. Repairs to be submitted for warranty consideration must be made within forty-five (45) days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or hauling of the product for the purpose of performing a warranty obligation or inspection.

1

Great Bend

LIMITED WARRANTY

Great Bend / Bush Hog L.L.C., warrants to the original purchaser of any new Great Bend equipment, purchased from an authorized Great Bend dealer, that the equipment be free from defects in material and workmanship for a period of one (1) year for non-commercial, state, and municipalities’ use and ninety (90) days for commercial use from date of retail sale. The obligation of Great Bend / Bush Hog L.L.C. to the purchaser under this warranty is limited to the repair or replacement of defective parts.

Replacement or repair parts installed in the equipment covered by this limited warranty are warranted for ninety (90) days from the date of purchase of such part or to the expiration of the applicable new equipment warranty period, whichever occurs later. Warranted parts shall be provided at no cost to the user at an authorized Great Bend dealer during regular working hours. Great Bend reserves the right to inspect any equipment or parts which are claimed to have been defective in material or workmanship.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Great Bend’s obligation under this limited warranty, to the extent allowed by law, is in lieu of all warranties, implied or expressed, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE and any liability for incidental and consequential damages with respect to the sale or use of the items warranted. Such incidental and consequential damages shall include but not be limited to: transportation charges other than normal freight charges; cost of installation other than cost approved by Great Bend; duty; taxes; charges for normal service or adjustment; loss of crops or any other loss of income; rental of substitute equipment, expenses due to loss, damage, detention or delay in the delivery of equipment or parts resulting from acts beyond the control of Great Bend.

THIS LIMITED WARRANTY SHALL NOT APPLY:

1.To transportation to and from dealership or service calls made by dealers, ie, driving time, towing, pickup and delivery.

2.To vendor items which carry their own warranties, such as engines, tires, and tubes.

3.If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

4.If parts not made or supplied by Great Bend have been used in connection with the unit, if, in the sole judgement of Great Bend such use affects its performance, stability or reliability.

5.If the unit has been altered or repaired outside of an authorized Great Bend dealership in a manner which, in the sole judgement of Great Bend, affects its performance, stability or reliability.

6.To normal maintenance service and normal replacement items such as gearbox lubricant, hydraulic fluid, worn blades, or to normal deterioration of such things as belts and exterior finish due to use or exposure.

7.To expendable or wear items such as teeth, chains, sprockets, belts, springs and any other items that in the company’s sole judgement is a wear item.

NO EMPLOYEE OR REPRESENTATIVE OF GREAT BEND IS AUTHORIZED TO CHANGE THIS LIMITED WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE IN WRITING AND SIGNED BY GREAT BEND’S SERVICE MANAGER, POST OFFICE BOX 1039, SELMA, ALABAMA 36702-1039.

Record the model number, serial number and date purchased. This information will be helpful to your dealer if parts or service are required.

MAKE CERTAIN THE WARRANTY REGISTRATION CARD HAS BEEN FILED WITH GREAT BEND/ SELMA, ALABAMA

MODEL NUMBER

SERIAL NUMBER

DATE OF RETAIL SALE

2

DEALER PREPARATION CHECK LIST

3545 / 4045 / 5045 / 6045

BEFORE DELIVERING MACHINE - The following check list should be completed. Use the Operator’s Manual as a guide.

Machine properly assembled.

All safety decals readable. (See decal page)

All bolts tightened to torque specifications given in torque chart.

Machine operates properly.

Customer has appropriate mounting kit for his tractor and loader.

Customer has appropriate attachments for loader operations. ( Buckets for lifting loose materials; bale spear for lifting round bales; fork lift for lifting palletized material)

CAUTION

CAUTION

USE ROPS (ROLLOVER PROTECTIVE STRUCTURE) AND

SEAT BELT EQUIPPED TRACTORS FOR OPERATOR USE

IN ALL LOADER OPERATIONS.

Operators manual has been delivered to owner and he has been instructed on the safe and proper use of the front end loader.

Dealer’s Signature

Purchaser’s Signature

THIS CHECK LIST TO REMAIN IN OPERATOR’S MANUAL

It is the responsibility of the dealer to complete the procedures listed above before delivery of this implement to the customer.

3

Safety Alert Symbol

This Safety Alert Symbol means: “ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!”

This symbol is used to call attention to safety precautions that should be followed by the operator to avoid accidents. When you see this symbol, carefully read the message that follows and heed its advice. Failure to comply with safety precautions could result in death or serious bodily injury.

Safety Signs Signal Words

The signal words DANGER, WARNING, AND CAUTION are used on the equipment safety signs. These words are intended to alert the viewer to the existence and the degree of hazard seriousness.

This signal word indicates a potentially hazardous situation which, if not avoided, will result in death or serious injury.

White letters on RED

This signal word indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

It may also be used to alert against unsafe practices.

Black letters on ORANGE

This signal word indicates a potentially hazardous situation exist which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

Black letters on YELLOW

4

THE TRACTOR

1.Read the tractor operator’s manual to learn how to operate your tractor safely. Failure to do so could result in serious injury or death and equipment damage.

2.Use ROPS (Roll-Over Protective Structure) and seat belt equipped tractors for operator use in all loader operations.

3.Add wheel ballast or rear weight for stability.

4.Move wheels to the tractor manufacturer’s widest recommended settings to increase stability.

5.For better stability, use tractor with wide front axle rather than tricycle front wheels.

6.Move and turn the tractor at low speeds.

7.Stop tractor engine, place transmission in park (or neutral), engage parking brake, lower loader arms to ground, cycle all hydraulic controls to relieve pressure, allow machine moving parts to stop, remove ignition key to prevent unauthorized person from starting engine before dismounting tractor or servicing, repairing, or making adjustments to the equipment.

8.Wear personal protective equipment (PPE), such as, but not limited to, protection for eyes, ears, lungs, head, hands and feet when operating, servicing, or repairing equipment. Avoid wearing loose clothing or jewelry that may catch and entangle on equipment moving parts.

THE LOADER

1.Read the loader operator’s manual to learn how to operate your loader safely. Failure to do so could result in serious injury or death and equipment damage.

2.Become familiar with all the machine’s controls and all the caution, warning and danger decals affixed to the machine before attempting to start or operate.

3.Improper use of a loader can cause serious injury or death.

4.Do not lift or carry anybody on the loader or in the bucket or attachment.

5.Never allow anyone to get under the loader bucket or reach through the booms when the bucket is raised.

6.Do not walk or work under a raised loader bucket or attachment unless it is is securely blocked or held in position

7.Avoid overhead wires and obstacles when loader is raised. Contacting electrical lines can cause electrocution.

8.Make sure all parked loaders on stands are on a hard, level surface.

9.Use a piece of cardboard or wood rather than hands and wear eye protection when searching for hydraulic leaks. Escaping hydraulic oil under pressure can penetrate skin. If oil is injected into skin, it must be surgically removed within a few hours by a doctor or gangrene may result.

5

SAFETY PRECAUTIONS CONTINUED

10.Before disconnecting hydraulic lines, relieve all hydraulic pressure.

11.Do not tamper with the relief valve setting. The relief valve is pre-set at the factory. Changing the setting can cause overloading the loader and tractor and serious operator injury may result.

12.Always wear safety goggles when repairing or servicing machine.

13.When servicing or replacing pins in cylinder ends, buckets, etc., always use a brass drift and hammer. Failure to do so could result in injury from flying fragments.

14.Replace damaged or illegible safety decals. See decal page for required decals.

15.Do not modify or alter or permit anyone else to modify or alter the loader, any of its components or any loader function without first consulting your local dealer.

OPERATING THE LOADER

1.It is the loader owner’s responsibility to instruct and have a person read operator’s manual, safety decals and become familiar with machine controls before allowing them to operate loader.

2.Do not allow children to operate the loader.

3.Before starting or operating the equipment, make a walk around inspection and check for loose or damaged components. Correct any deficiency before starting.

4.Keep the area of operation clear of all persons, particularly small children. The operator should cease operation whenever anyone comes within the operating area.

5.Operate the loader from the “Operator’s Seat Only.”

6.Exercise caution when operating the loader with a raised loaded bucket, fork, or large round hay bale handling attachments.

7.Avoid loose fill, rocks and holes. They can be dangerous for loader operation or movement.

8.Be extra careful when working on inclines.

9.Allow for the loader length when making turns.

10.Stop the loader arms gradually when lowering or lifting.

11.Use caution when handling loose or shiftable loads.

12.Carry loader arms at a low position during transport.

13.Lower loader arms, stop engine, and lock brakes before leaving the tractor seat.

14.Operate the loader controls only when properly seated at the controls.

15.Do not use loader for handling large, heavy objects such as logs, oil drums, etc.

16.Handling large, heavy objects is dangerous due to: *Possibility of rolling the tractor over.

*Possibility of upending the tractor.

*Possibility of the object rolling or sliding down the loader arms onto the operator.

17.Use large round hay bale handler attachment with bale retaining devices (grapples, bale spears, clamps, etc.) to handle large round hay bales. Failure to use retaining devices could allow round hay bales to roll or fall down loader boom arms onto the operator causing serious injury or death and equipment damage.

6

EMPLOYEE TRACTOR OPERATING INSTRUCTIONS:

1.Securely fasten your seat belt if the tractor has a ROPS.

2.Where possible, avoid operating the tractor near ditches, embankments, and holes.

3.Reduce speed when turning, crossing slopes, and on rough, slick, or muddy surfaces.

4.Stay off slopes too steep for safe operation.

5.Watch where you are going, especially at row ends, on roads, and around trees.

6.Do not permit others to ride.

7.Operate the tractor smoothly - no jerky turns, starts, or stops.

8.Hitch only to the drawbar and hitch points recommended by tractor manufacturers.

9.When tractor is stopped, set brakes securely and use park lock if available.

7

SECTION I

INTRODUCTION AND DESCRIPTION

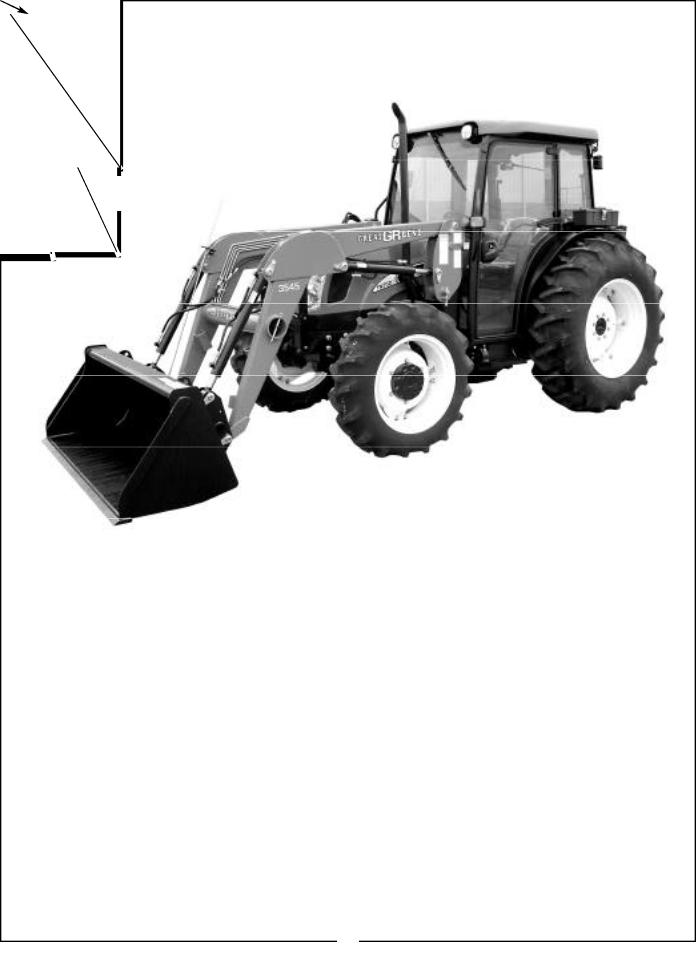

Figure 1-1 Major Components

Bucket Level

Indicator Rod

Bucket Cylinder

Cross Tube

Bucket

Pedestal

Mainframe Boom

Parking Stands Stored |

Boom Cylinder |

|

1-1 INTRODUCTION

We are pleased to have you as a Great Bend customer. Your Front End Loader has been carefully designed to give maximum service with minimum down time. This manual is provided to give you the necessary operating and maintenance instructions for keeping your front end loader in top operating condition. Please read this manual thoroughly. Understand what each control is for and how to use it. Observe all safety precautions decaled on the machine and noted throughout the manual for safe operation of implement. If any assistance or additional information is needed, contact your authorized Great Bend dealer.

1-2 DESCRIPTION

Model 3545/4045/5045/6045 Front End Loaders are designed for two wheel and four wheel drive tractors. They come equipped with parking stands to support the loader so the tractor can be “driven in” for quick attachment and a bucket level indicator that allows operator to gauge bucket position when the bucket cannot be seen. Available attachments include buckets for lifting loose materials; a bale spear for lifting round hay bales; and a fork lift for palletized material. All operations should be conducted within the loader limits specified in Table 1-1.

8

Loading...

Loading...