Page 1

LAUNAMNOITAMROFNIS'RESU

™GCS

RELIOBDERIF-SAG

WARNING: If the information in this

manual is not followed exactly, a re or

explosion may result causing property

damage, personal injury or loss of life.

-

Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the re department.

-

Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

AVERTISSEMENT. Assurez-vous de bien

suivre les instructions données dans cette

notice pour réduire au minimum le risque

d'incendie ou d'explosion ou pour éviter

tout dommage matériel, toute blessure ou

la mort.

Ne pas entreposer ni utiliser d'essence ni

-

d'autres vapeurs ou liquides inam-mables

dans le voisinage de cet appareil ou de tout

autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ:

• Ne pas tenter d'allumer d'appareils.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones dans le

bâtiment où vous vous trouvez.

• Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service

des incendies.

L'installation et I'entretien doivent être

-

assuréx par un installateur ou un service

d'entretien qualié ou par le fournisseur de

gaz.

8140704R3-12/08

Page 2

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

CAUTION

Basic Operation

CAUTION

Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply at a location external to the appliance.

En cas de surchauffe ou si I'admission de gaz ne peut étre coupée, ne pas couper ni débrancher

l'alimentation électrique de la pompe. Fermer plutôt le robinet d'admission de gaz à l'extérieur de I'appareil.

Do not use this boiler if any part has been under water. Immediately call a qualied service technician to

inspect the boiler and to replace any part of the control system and any gas control which has been under

water.

A. General. This water boiler utilizes fan-assisted

combustion and is equipped with controls for proper

operation. All controls must be in proper working order.

Contact a qualied service agency to provide annual

maintenance as specied in Installation, Operating and

Service Instructions.

Service on this boiler should be undertaken only

by trained and skilled personnel from a qualied

service agency.

WARNING

1. Limit. See Figure 1. A device which automatically

interrupts boiler operation when the water

temperature exceeds the set point. Maximum

allowable temperature is 240°F.

Original equipment with this boiler is a Honeywell

L4080D1036. Boiler operation is interrupted when

system temperature reaches cut-out temperature.

Boiler operation resumes automatically when system

temperature falls 30°F to cut-out temperature.

2. Flame Rollout Switch. See Figure 1. A device

which automatically interrupts boiler operation

when ames or excessive heat are present in the

combustion area enclosure. The control is a single

use device. The control is located in the combustion

area enclosure. If the control was activated to

interrupt boiler operation, do not attempt to place

boiler in operation. Contact a qualied service

agency.

3. Pressure Switch. See Figure 1. A device which

automatically prevents or interrupts boiler

operation when the induced draft blower fails to

move sufcient combustion air for proper burner

operation. Boiler operation resumes automatically

when sufcient combustion air ow is reestablished.

Electronic Ignition System. The Electronic Ignition

4.

(EI) System consists of:

a. a solid state ignition control module to initiate,

monitor and stop burner operation. See Figure 1.

b. a combination gas valve to regulate gas ow to

the burners. See Figure 1.

c. a pilot burner to provide the ignition source for

the main burners. See Figure 4.

2

Page 3

Figure 1: Control Locations

A Blower Relay

B Limit

C/D J-Box & Transformer/Relay

E Flame Roll-out Switch

F Blower

G Pressure Switch

H Ignition Control Module

J Gas Valve

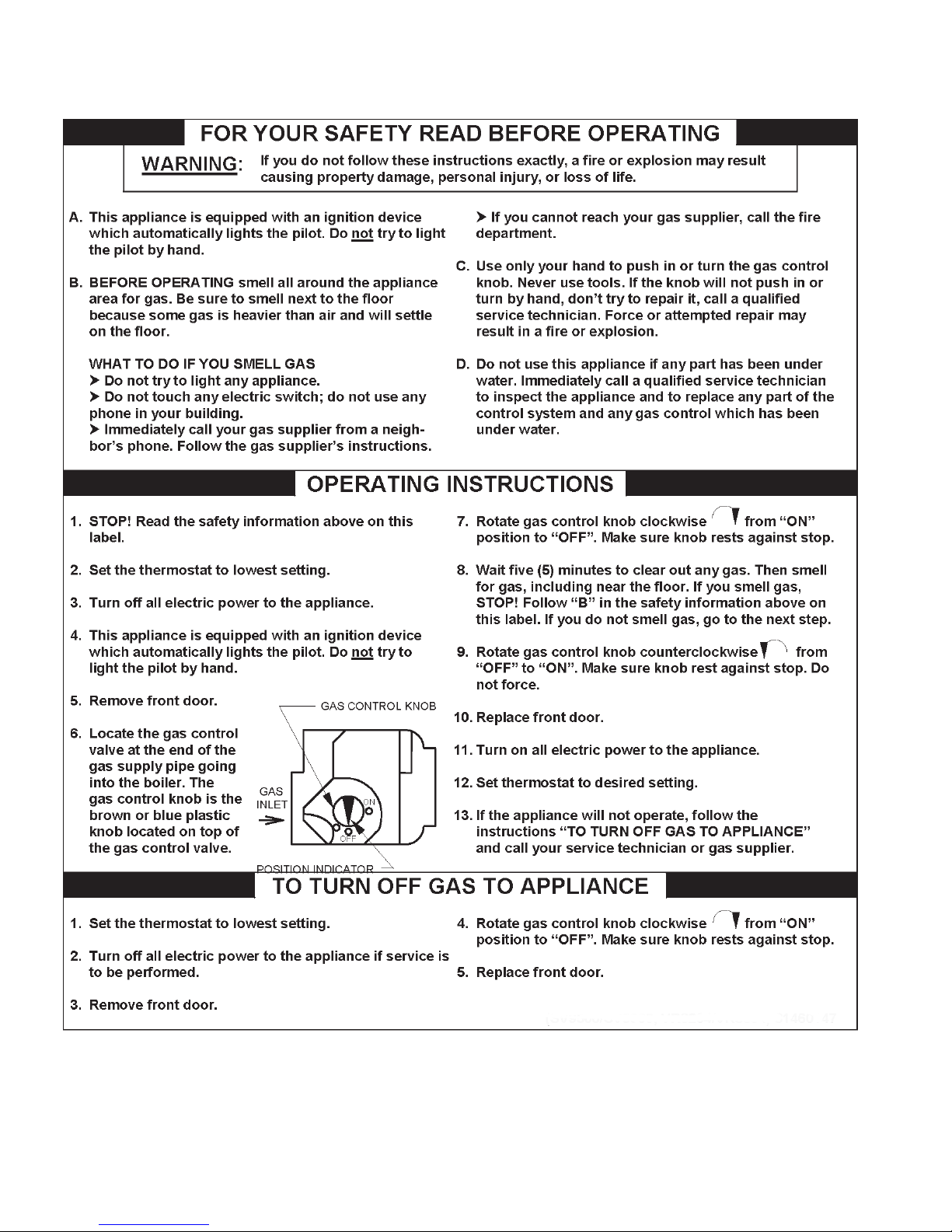

B. Instructions to place the boiler in operation and to turn

off the boiler are shown on the Operating Instruction

Label posted on the left jacket panel of the boiler. The

Operating Instruction Label is shown in Figure 2.

C. The Sequence of Operation is shown in Figure 3.

3

Page 4

NOTE: YOUR BOILER IS EQUIPPED WITH A HONEYWELL VR8204 OR VR8304 GAS

VALVE. PLEASE FOLLOW THESE OPERATING INSTRUCTIONS:

4

Figure 2: Operating Instructions

Page 5

Figure 3: Sequence of Operation

5

Page 6

User Maintenance

WARNING

Service on this boiler should be undertaken only by trained and skilled personnel from a qualied service

agency. Inspections should be performed at intervals specied in Installation, Operating and Service

Instructions and this manual. Maintain manuals in a legible condition.

Keep boiler area clear and free of combustible materials, gasoline and other ammable vapors and liquids.

Do not place any obstructions in boiler room that will hinder ow of combustion and ventilation air.

A. General Housekeeping (Continuous).

1. Keep boiler area clear and free of combustible

materials and obstructions to the free ow of

combustion and ventilation air to the boiler.

2. Do not store or use gasoline or other ammable

vapors or liquids in the vicinity of the boiler or any

other appliance.

3. Do not store or use sources of hydrocarbons in

the vicinity of the boiler. Sources of hydrocarbons

include bleaches, cleaners, chemicals, sprays, paint

removers, fabric softeners and refrigerants.

B. Inspect Inlet Air and Vent System (Monthly). Check

the following. If corrective action is required contact

qualied service agency.

1. Inlet air terminal and vent terminal must be free of

obstruction, undamaged, with screens securely in

place.

2. Inlet air terminal, vent terminal, and wall thimble (if

used) must be weather-tight.

3.

Inlet air pipe and vent pipe must be full round

shape, showing no damage from impact or excessive

temperature.

4. Inlet air pipe and vent pipe must be supported at

minimum 5 foot intervals and must not sag.

a. Disconnect condensate drain from drain tting.

b. Flush condensate drain with water.

c. Securely fasten condensate drain to drain tting,

providing gas-tight and water-tight seal.

C. Inspect Pilot and Main Burner Flames (Monthly).

1. Remove jacket front panel.

2. View ames through combustion area enclosure.

See Figure 1.

3. Adjust thermostat to highest setting.

4. Check pilot ame. See Figure 4. The pilot produces

three (3) ames. The center ame should be steady,

medium hard blue enveloping 3/8 to ½ inch of

sensing probe. If ame is yellow and lazy, follow

instructions TO TURN OFF GAS TO APPLIANCE

(see Figure 2), and contact qualied service agency.

5. Check main burner ames. See Figure 5. Flame

should have clearly dened inner cone with no

yellow tipping. Orange-yellow streaks caused

by dust should not be confused with true yellow

tipping. If yellow ames are observed, follow

instructions TO TURN OFF GAS TO APPLIANCE

(see Figure 2), and contact qualied service agency.

6. Adjust thermostat to normal setting.

5. All inlet pipe joints must be secure and airtight.

6. All vent pipe joints must be secure and watertight.

7. Condensate drain (if used) must have minimum 6

inch trap and allow condensate to ow freely. To

clean:

6

D. ScheduleInspectionbyQualiedServiceAgency

(Annual or at Beginning of Heating Season). For

continued safe operation a qualied service agency

must provide a more detailed inspection of burners, heat

exchanger and vent system, and provide maintenance

as specied in Installation, Operating and Service

Instructions.

Page 7

Figure 4: Pilot Burner

Figure 5: Main Burner Flame

7

Page 8

All SCG Series repair parts may be obtained through your local Burnham Wholesale distributor. Should

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures about 1805°F, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

you require assistance in locating a Burnham distributor in your area, or have questions regarding the

availability of Burnham products or repair parts, please contact Burnham Customer Service at (717) 4818400 or Fax (717) 481-8408.

Page 9

LAUNAMNOITAMROFNIS'RESU

™GVP

RELIOBDERIF-SAG

WARNING: If the information in this

manual is not followed exactly, a re or

explosion may result causing property

damage, personal injury or loss of life.

-

Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the re department.

-

Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

AVERTISSEMENT. Assurez-vous de bien

suivre les instructions données dans cette

notice pour réduire au minimum le risque

d'incendie ou d'explosion ou pour éviter

tout dommage matériel, toute blessure ou

la mort.

Ne pas entreposer ni utiliser d'essence ni

-

d'autres vapeurs ou liquides inam-mables

dans le voisinage de cet appareil ou de tout

autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR

DE GAZ:

• Ne pas tenter d'allumer d'appareils.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones dans le

bâtiment où vous vous trouvez.

• Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service

des incendies.

L'installation et I'entretien doivent être

-

assuréx par un installateur ou un service

d'entretien qualié ou par le fournisseur de

gaz.

8140709R2-6/09

Page 10

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

CAUTION

Basic Operation

CAUTION

Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the electrical

supply to the pump. Instead, shut off the gas supply at a location external to the appliance.

En cas de surchauffe ou si I'admission de gaz ne peut étre coupée, ne pas couper ni débrancher

l'alimentation électrique de la pompe. Fermer plutôt le robinet d'admission de gaz à l'extérieur de I'appareil.

Do not use this boiler if any part has been under water. Immediately call a qualied service technician to

inspect the boiler and to replace any part of the control system and any gas control which has been under

water.

A. General. This water boiler utilizes fan-assisted

combustion and is equipped with controls for proper

operation. All controls must be in proper working order.

Contact a qualied service agency to provide annual

maintenance as specied in Installation, Operating and

Service Instructions.

1. Limit. See Figure 1. A device which automatically

interrupts boiler operation when the water

temperature exceeds the set point. Maximum

allowable temperature is 240°F.

Original equipment with this boiler is a Honeywell

L4080D1036. Boiler operation is interrupted when

system temperature reaches cut-out temperature.

Boiler operation resumes automatically when system

temperature falls 30°F to cut-out temperature.

2. Flame Rollout Switch. See Figure 1. A device

which automatically interrupts boiler operation

when ames or excessive heat are present in the

combustion area enclosure. The control is a single

use device. The control is located in the combustion

area enclosure. If the control was activated to

interrupt boiler operation, do not attempt to place

boiler in operation. Contact a qualied service

agency.

WARNING

Service on this boiler should be undertaken only

by trained and skilled personnel from a qualied

service agency.

3. Pressure Switch. See Figure 1. A device which

automatically prevents or interrupts boiler

operation when the induced draft blower fails to

move sufcient combustion air for proper burner

operation. Boiler operation resumes automatically

when sufcient combustion air ow is reestablished.

4. Electr

onic Ignition System. The Electronic Ignition

(EI) System consists of:

a. a solid state ignition control module to initiate,

monitor and stop burner operation. See Figure 1.

b. a combination gas valve to regulate gas ow to

the burners. See Figure 1.

c. a pilot burner to provide the ignition source for

the main burners. See Figure 4.

2

Page 11

A Blower Relay

B Limit

C/D J-Box & Transformer/Relay

E Flame Roll-out Switch

F Blower

G Pressure Switch

H Ignition Control Module

J Gas Valve

Figure 1: Control Locations

B. Instructions to place the boiler in operation and to turn

off the boiler are shown on the Operating Instruction

Label posted on the left jacket panel of the boiler. The

Operating Instruction Label is shown in Figure 2.

C. The Sequence of Operation is shown in Figure 3.

3

Page 12

NOTE: YOUR BOILER IS EQUIPPED WITH A HONEYWELL VR8204 OR VR8304 GAS

VALVE. PLEASE FOLLOW THESE OPERATING INSTRUCTIONS:

4

Figure 2: Operating Instructions

Page 13

Figure 3: Sequence of Operation

5

Page 14

User Maintenance

WARNING

Service on this boiler should be undertaken only by trained and skilled personnel from a qualied service

agency. Inspections should be performed at intervals specied in Installation, Operating and Service

Instructions and this manual. Maintain manuals in a legible condition.

Keep boiler area clear and free of combustible materials, gasoline and other ammable vapors and liquids.

Do not place any obstructions in boiler room that will hinder ow of combustion and ventilation air.

A. General Housekeeping (Continuous).

1. Keep boiler area clear and free of combustible

materials and obstructions to the free ow of

combustion and ventilation air to the boiler.

2. Do not store or use gasoline or other ammable

vapors or liquids in the vicinity of the boiler or any

other appliance.

3. Do not store or use sources of hydrocarbons in

the vicinity of the boiler. Sources of hydrocarbons

include bleaches, cleaners, chemicals, sprays, paint

removers, fabric softeners and refrigerants.

B. Inspect Inlet Air and Vent System (Monthly). Check

the following. If corrective action is required contact

qualied service agency.

1. Inlet air terminal and vent terminal must be free of

obstruction, undamaged, with screens securely in

place.

2. Inlet air terminal, vent terminal, and wall thimble (if

used) must be weather-tight.

3. Inlet air pipe and vent pipe must be full round

shape, showing no damage from impact or excessive

temperature.

4. Inlet air pipe and vent pipe must be supported at

minimum 5 foot intervals and must not sag.

a. Disconnect condensate drain from drain tting.

b. Flush condensate drain with water.

c. Securely fasten condensate drain to drain tting,

providing gas-tight and water-tight seal.

C. Inspect Pilot and Main Burner Flames (Monthly).

1. Remove jacket front panel.

2. View ames through burner access panel. See

Figure 1.

3. Adjust thermostat to highest setting.

4. Check pilot ame. See Figure 4. The pilot produces

three (3) ames. The center ame should be steady,

medium hard blue enveloping 3/8 to ½ inch of

sensing probe. If ame is yellow and lazy, follow

instructions TO TURN OFF GAS TO APPLIANCE

(see Figure 2), and contact qualied service agency.

5. Check main burner ames. See Figure 5. Flame

should have clearly dened inner cone with no

yellow tipping. Orange-yellow streaks caused

by dust should not be confused with true yellow

tipping. If yellow ames are observed, follow

instructions TO TURN OFF GAS TO APPLIANCE

(see Figure 2), and contact qualied service agency.

6. Adjust thermostat to normal setting.

5. All inlet pipe joints must be secure and airtight.

6.

All vent pipe joints must be secure and watertight.

7. Condensate drain (if used) must have minimum 6

inch trap and allow condensate to ow freely. To

clean:

6

D. ScheduleInspectionbyQualiedServiceAgency

(Annual or at Beginning of Heating Season). For

continued safe operation a qualied service agency

must provide a more detailed inspection of burners, heat

exchanger and vent system, and provide maintenance

as specied in Installation, Operating and Service

Instructions.

Page 15

Figure 4: Pilot Burner

Figure 5: Main Burner Flame

7

Page 16

All PVG™ Series repair parts may be obtained through your local Burnham Wholesale distributor.

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures about 1805°F, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

Should you require assistance in locating a Burnham distributor in your area, or have questions

regarding the availability of Burnham products or repair parts, please contact Burnham Customer

Service at (717) 481-8400 or Fax (717) 481-8408.

Loading...

Loading...