Page 1

PVG & SCG

High Efficiency Direct Vent & Sealed Combustion

Cast Iron Water Boilers

The Ultimate Combination

of Efficiency and Value!

• 85+% AFUE (5 sizes)

ENERGY STAR® Certified

• 70 to 280 MBH in 7 Sizes

• Rugged Cast Iron Sectional Design

• Natural or LP Gas

• PVG - Power Vented

SCG - Sealed Combustion Venting

• Limited Lifetime Warranty

Page 2

PVG & SCG

High Efficiency Direct Vent and Sealed Combustion Cast Iron Water Boilers

Unbeatable Efficiency & Value!

Burnham’s PVG & SCG boilers offer a unique combination of high efficiency and value to

homeowners. Available in direct vent (PVG) or sealed combustion (SCG) both models utilize either

3 or 4-inch stainless steel vent pipe to direct the flue products out of the building. This eliminates

the need to install a liner in an existing chimney – which is often a major expense when replacing

an older boiler.

PVG and SCG series boilers are simple to install, and require very little service and maintenance

–especially compared to higher-efficiency condensing boilers. This can save homeowners hundreds

of dollars in up-front installation costs, as well as several hundred dollars a year in maintenance

and tune-up’s. Factoring in installation, annual service, and fuel usage - over time the operating

costs of the SCG and PVG may be well below those of condensing boilers. While low temperature

radiant heat systems are becoming more popular in newer buildings, many still utilize baseboard

heat, convectors, air handlers. & indirect water heaters - which generally require higher water

temperatures. Cast iron boilers are the best choice for these applications. The PVG and SCG deliver

the winning combination of efficiency and durability in high-temp heating applications.

Reliable Cast Iron Heat Exchanger

PVG & SCG boilers have rugged cast iron heat exchanger sections

that are poured in Burnham’s own state-of-the-art foundry in

Zanesville, Ohio. This means that Burnham is able to control the

quality of this vital component from the time that it’s poured to the

time that it’s installed and tested in the boiler. The heat exchanger

itself is designed for efficiency. Round pins on the outside of the

exchanger increase the surface area which increases heat transfer.

Inside, dimpled waterways promote turbulence as water flows

through the castings. This helps to thoroughly mix cooler return water with the water inside

the heat exchanger. As a result, PVG and SCG boilers are more resistant to thermal shock and

condensation than other comparable boilers. Steel nipples are used to join sections together. This

vital component is impervious to petroleum-based chemicals (like antifreeze) which can break

down the rubber gaskets that are used by competitors.

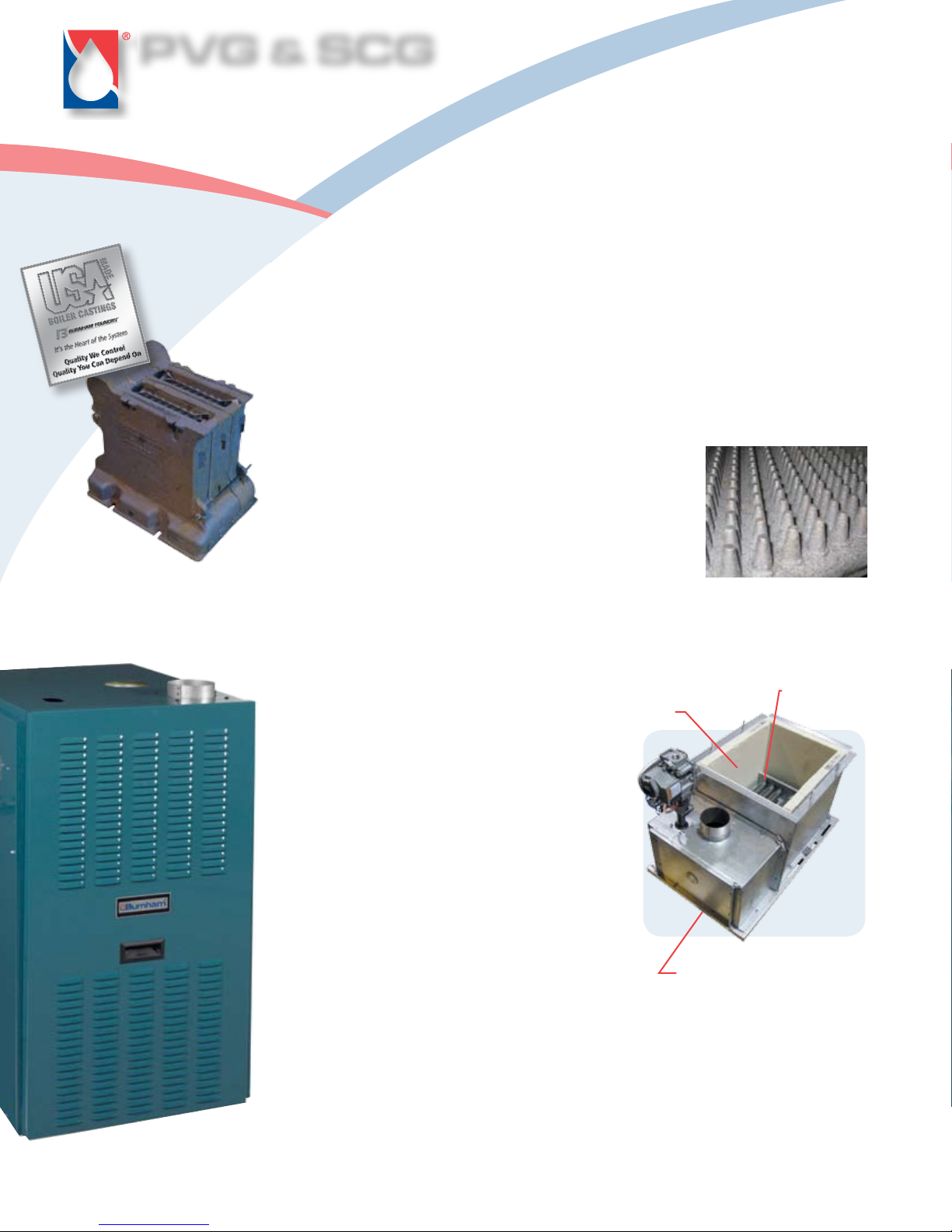

A Better Burner Base

The burner base in the PVG & SCG has been engineered

to deliver on Burnham’s ongoing commitment to safety,

reliability, and durability. Underneath it’s simple two piece

design sits stainless steel burner tubes which are secured

by lock-in burner slots. A 1/4” pilot tube provides an

ample flow of gas which contributes to reliable burner

performance. An isolated combustion area beneath

the burner tubes optimizes airflow and keeps floor

temperatures low beneath the boiler. The combustion

chamber itself is lined with thick 1” insulation on the sides

and 1-1/2” insulation on the rear. This keeps the heat

generated in combustion directed upward toward the heat

exchanger, not out into the boiler jacket and surrounding area.

Safety Without Compromise

Burnham’s reputation for building safe products is an ongoing commitment that is taken very seriously.

Many additional safety features have been built into the PVG & SCG.

• Blocked Vent Switch

Safely shuts the boiler down if a chimney or vent blockage is detected.

• Flame roll-out switch

If an internal flueway restriction is detected, this device will automatically stop

the flow of gas to prevent combustion gases from seeping into the home.

• Concealed Controls

All boiler controls are safely hidden under the jacket to prevent damage & tampering.

Thick Insulation

Isolated Combustion Area

Lock-in

Burner Slots

Page 3

Reliable Controls

W

I

N

T

E

R

W

A

R

M

T

H

A

S

S

U

R

A

N

C

E

BURNHAM

High quality, reliable controls

are safely concealed inside the

boiler jacket.

“Plug & Play”

Component Installation

Plug-in wiring harnesses

for installation of LWCO

and auxiliary high limit are

accessible and clearly labeled.

Step Opening Gas

Valve

This type of gas valve enables

the boiler to start on low fire

and continue on to high fire

safely and smoothly. This

provides quiet ignition and

promotes long boiler life.

Limited Lifetime

Warranty

Burnham backs the

PVG & SCG with a limited

lifetime warranty on the heat

exchanger. Additional coverage is

available by purchasing the Winter

Warmth Assurance Plan, which

provides extended protection on

parts and labor for 5 or 10 years.

from the date of installation.

PVG & SCG Boilers

Contractor-Friendly

Design

High mounted control

panel, easy access to fan,

simple field conversion

kit available for LP

applications.

1” Insulation

Surrounds boiler block which

reduces heat loss through the

boiler jacket.

Rugged Jacket

Tough powder

coated steel

jacket designed

for durability.

Trapezoidal Legs with

Nylon Glides

These high strength

legs & glides allow

for easy positioning

of the boiler, and protect against

potential damage to flooring.

Burnham Alliance SL™

Indirect-fired Water Heaters

For an abundant supply of domestic hot water,

be sure to use an Burnham Alliance SL indirectfired water heater with every boiler application.

The Alliance SL water heaters are designed

with an effective hydrastone lining that offers

superior corrosion resistance and outstanding

performance in a wide variety of water

conditions.

Water heaters are available in five sizes and come with a unique

10/2/1 warranty – 10 years on the tank and coil, 2 years labor and

1 year on parts. An optional lifetime warranty is also available.

Page 4

Ratings

Model

Number Input

Heating Capacity (MBH) I=B=R Water Ratings AFUE%

DOE

SCG3 / PVG3 70 60 52 85.5

SCG4 / PVG4 105 90 78 85.4

SCG5 / PVG5 140 120 104 85.3

SCG6 / PVG6 175 150 130 85.2

SCG7 / PVG7 210 179 156 85.0

SCG8 / PVG8 245 208 181 84.5*

SCG9 / PVG9 280 238 207 84.0*

*Only SCG3/PVG3 through SCG7/PVG7 are ENERGY STAR certified at 85+% AFUE

Specifications

Model

Number

SCG3 / PVG3 11.65 26.60 38.09 3 3 2.16 210

SCG4 / PVG4 14.72 26.60 38.09 3 3 3.00 254

SCG5 / PVG5 17.78 26.60 38.09 3 4 3.84 298

SCG6 / PVG6 20.84 26.60 38.09 3 4 4.68 342

SCG7 / PVG7 23.90 26.60 38.09 3 5 5.52 386

SCG8 / PVG8 26.97 26.60 38.09 4 5 6.36 430

SCG9 / PVG9 30.03 26.60 38.09 4 5 7.20 474

Dimensions (inches) Connections (inches)

Water

Content (gal.)

Shipping Weight (lbs.)‘A’ ‘B’ ‘C’ Vent Air Intake

Approximate

Form No. PL81401051001-11/08-20Ms

(3/4” NPT)

(1-1/4” NPT)

(1-1/4” NPT)

SCG Model shown with vent connection

© 2008 U.S. Boiler Company, Inc. - Lancaster, PA

Phone: 1-888-432-8887

www.burnham.com Printed in the U.S.A.

Loading...

Loading...