Page 1

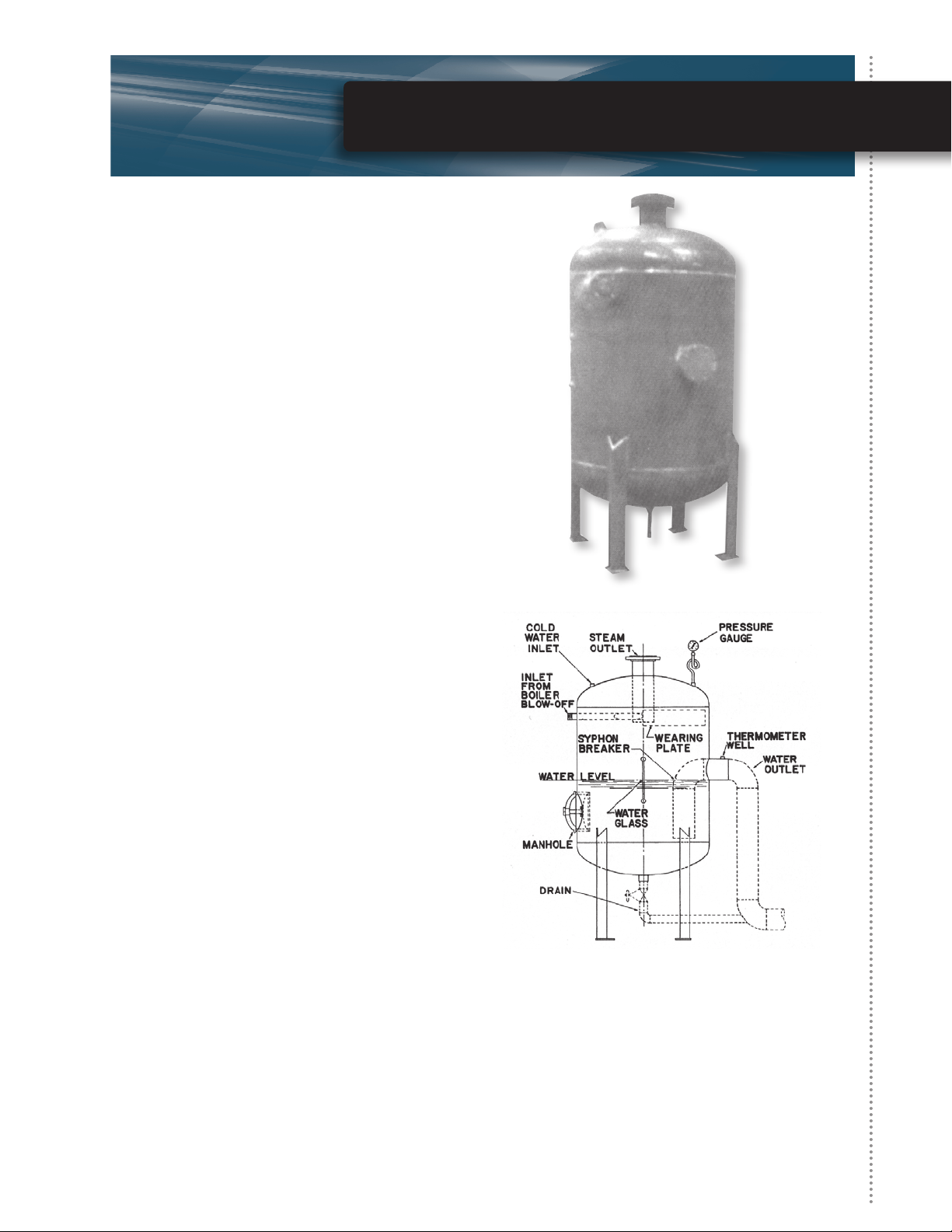

Bottom Blowdown Tank

• Eliminate precipitated solids from the bottom

of the boiler.

• Cools blowdown to 140°F or below before

dumping to drain by storing one entire

blowdown in a reservoir and using it to cool

the next blowdown.

• ASME Section VIII code-stamped tank.

• Sized either to accommodate one complete

boiler blowdown or to satisfy New Jersey

regulations.

• Model Range:

18" diameter x 24" height through

72" diameter x 92" height

• Modular conguration to meet customer

requirements includes: tank, legs, gauge glass

and pressure gauge.

• Can be custom congured to meet customer

requirements.

• Stainless steel striking plate standard.

• Openings to facilitate cleaning and inspection

standard.

• Safety valve and thermometer may be included

as options.

New Jersey Regulations for Blowdown Tanks

• Closed or Pressure Type—A Blowdown Tank

subjected to the maximum steam boiler

pressure must be constructed for such pressure

and stamped with either New Jersey, National

Board or ASME Standard.

• When the blowdown from any steam boiler

is disposed in a sewer or other interconnected

system, a Blowdown Tank must be placed

between the boiler and the sewer or system.

• The minimum metal thickness of Blowdown

Tanks, whether pressure or atmospheric, must

not be less than 5/16".

• Atmospheric or Vented Type—The outlet from

the Blowdown Tank shall be twice the area of

the boiler blowdown pipe and made to extend

internally within 6" from the bottom of the tank.

• A vent pipe, at least twice the diameter to the

inlet, shall lead to the outside atmosphere.

• Vents shall be as direct as possible to the outside

of the atmosphere and discharge at a point

not less than seven feet above the adjacent

walkway or areas without a valve or other

possible obstruction such as a water pocket.

• General—All Blowdown Tanks, whether of the

closed or vented type should be of the following

dimensions in relation to the boiler rating, and

must have approved openings for cleaning and

inspections (see reverse side).

Page 2

Bottom Blowdown Tank

Boiler Pressure

PSIG Blow-o Line Pipe Size Vent Pipe Size Outlet Pipe Size Diameter of Tank Height of Tank

100

150

200

250

300

350

400

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3/4"

1"

1-1/4"

1-1/2"

2"

2-1/2"

2-1/2"

3"

3-1/2"

4"

5"

6"

3"

3-1/2"

4"

5"

6"

8"

3"

4"

5"

6"

8"

8"

3-1/2"

4"

5"

6"

8"

10"

3-1/2"

5"

6"

8"

8"

10"

4"

5"

6"

8"

10"

10"

4"

5"

6"

8"

10"

10"

3"

3"

4"

5"

6"

6"

3"

3-1/2"

4"

5"

6"

8"

3"

4"

5"

6"

8"

8"

3"

4"

5"

6"

8"

10"

3-1/2"

5"

6"

8"

8"

10"

4"

5"

6"

8"

8"

10"

4"

5"

6"

8"

8"

10"

20"

24"

30"

42"

48"

54"

20"

24"

36"

42"

54"

60"

20"

30"

36"

42"

48"

60"

24"

30"

42"

48"

54"

60"

24"

30"

42"

48"

60"

66"

24"

30"

42"

48"

60"

72"

24"

30"

42"

48"

66"

72"

3'6"

4'0"

4'2"

4'0"

4'6"

6'0"

3'6"

5'0"

5'0"

5'0"

5'6"

6'0"

4'3"

4'6"

5'0"

6'0"

7'3"

7'0"

4'0"

4'6"

4'6"

5'0"

7'0"

7'2"

4'6"

5'6"

5'0"

5'6"

6'3"

7'8"

5'0"

5'6"

5'6"

6'2"

6'10"

7'0"

5'6"

6'0"

6'0"

6'4"

6'0"

8'0"

Boiler Rating

HP Cu. Ft. Minimum Size Tank Gallons

2 – 20 3.5 18" diameter x 24" 26.4

21 – 50 7.7 24" diameter x 30" 59

51 – 100 14.7 30" diameter x 36" 110

101 – 200 21.6 36" diameter x 36" 160

201 – 400 24.8 36" diameter x 42" 185

401 – 800 39.5 42" diameter x 48" 288

801 – 1000 63.0 48" diameter x 60" 470

©2012 Burnham Commercial

P.O. Box 3939 • Lancaster, PA 17604

Phone: 888.791.3790 • Fax: 717.293.5803

www.burnhamcommercial.com

Form No. PL81465601008-12/12-1Mc

Printed in the U.S.A.

Loading...

Loading...