Page 1

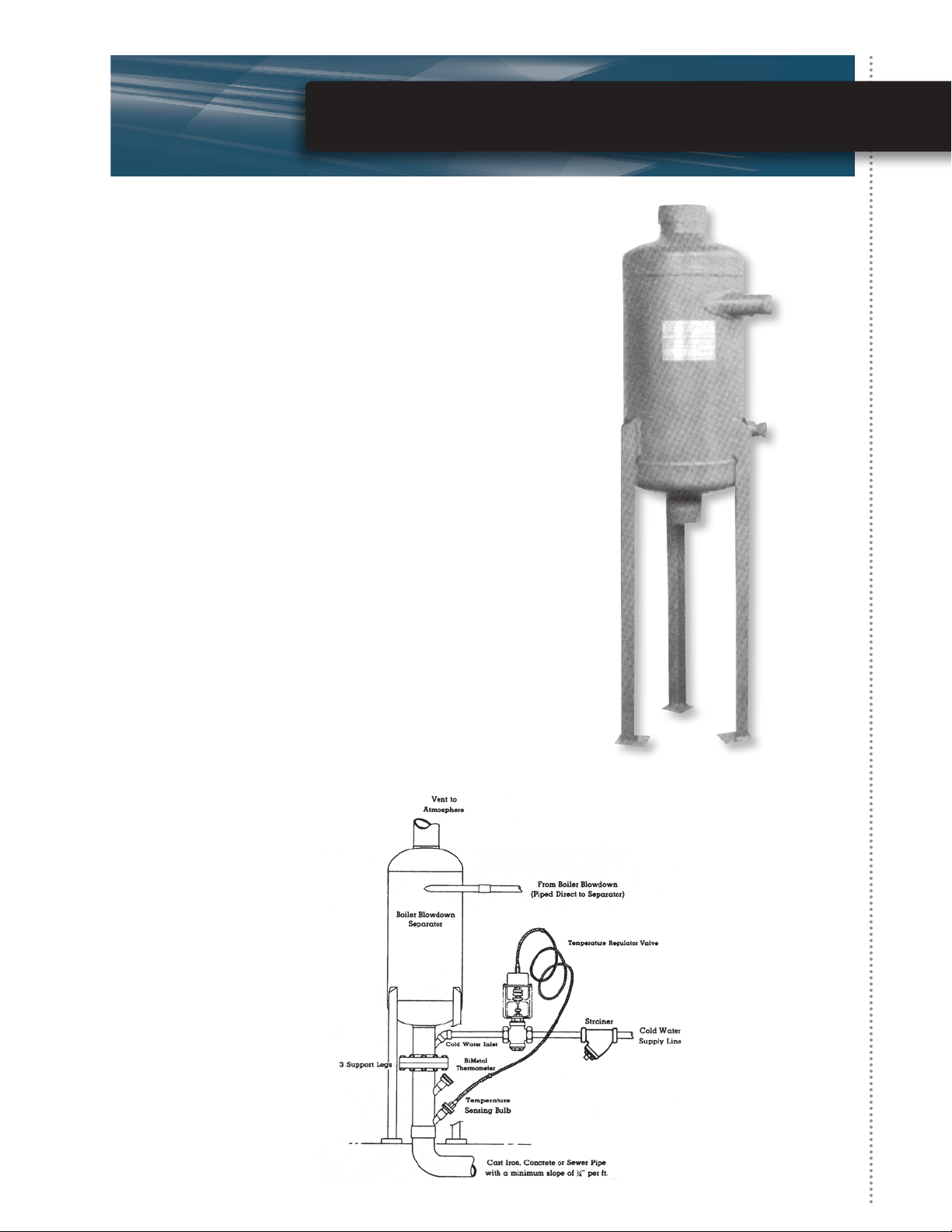

Bottom Blowdown Separator

• Eliminate precipitated solids from the bottom of the boiler.

• Cools blowdown to 140°F or below before dumping to

drain by introducing cooling water via an aftercooler.

• ASME Section VIII “UE” stamped separator

(“U” stamp available as option).

• Sized to accommodate ow based on boiler blowdown

line size and boiler operating pressure.

• Model Range:

14" diameter x 22" through 56" in height

for standard boilers.

(10" diameter x 14" high option available

for boilers under 1000 #/hour).

• Modular conguration to meet customer requirements

includes: separator, legs (or wall bracket), aftercooler,

temperature regulating valve and thermometer.

• Can be custom congured to meet customer requirements.

• Stainless steel striking plate standard and internal steel

restrictor plates standard.

• Multiple separators with manifold for high pressure

applications available.

Page 2

Bottom Blowdown Separator

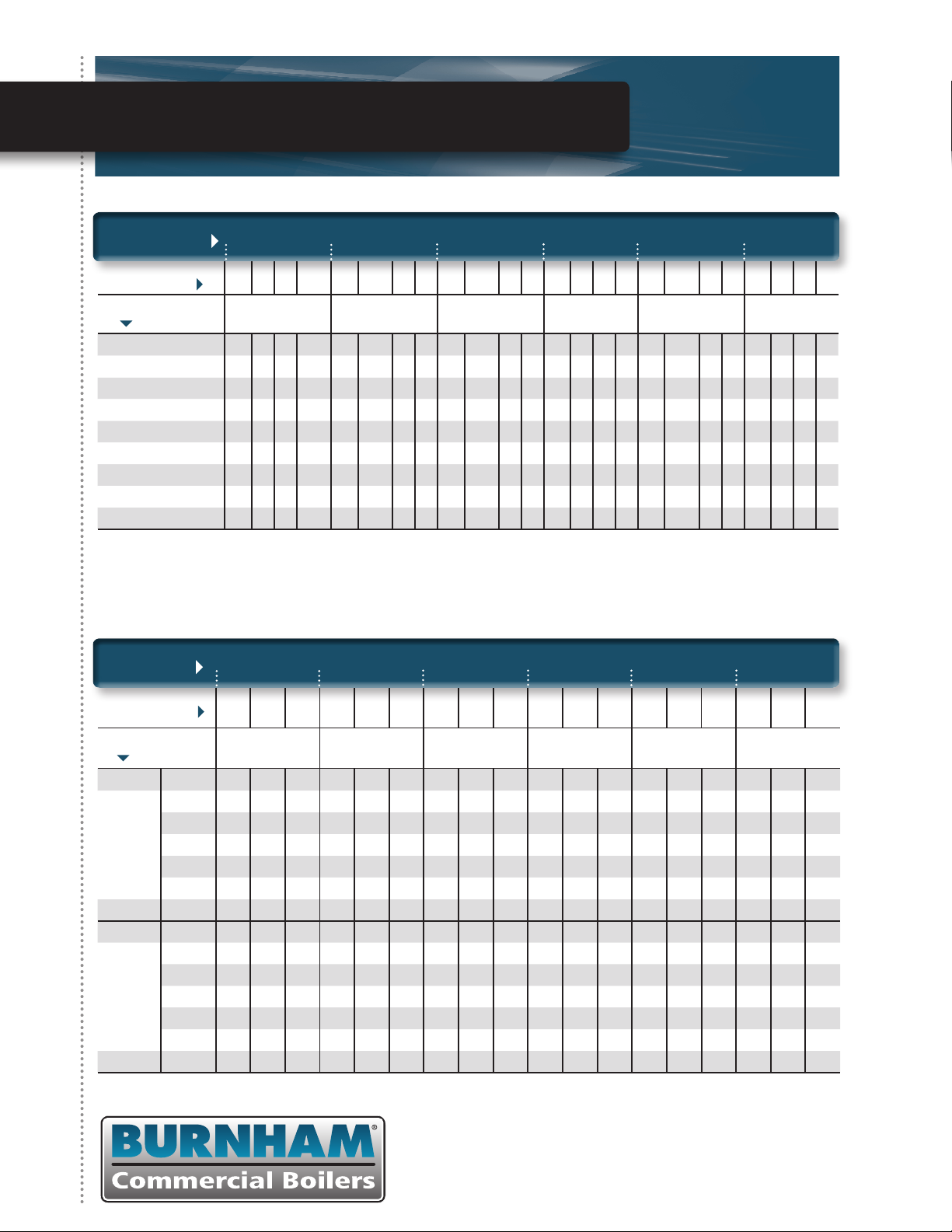

Chart A—Boiler Blowdown Separators

BLOWDOWN VALVE

SIZE SEPARATOR

DIMENSIONS H I D V H I D V H I D V H I D V H I D V H I D V

BOILER OPERATING

PRESSURE

0 – 15 14 1 2 2-1/2 20 1-1/4 3 4 20 1-1/2 3 4 20 2 4 5 34 2-1/2 5 6 34 3 6 5

16 – 50 20 1 2 2-1/2 20 1-1/4 3 4 34 1-1/2 3 4 34 2 4 5 34 2-1/2 5 6 34 3 6 5

51 – 100 20 1 3 2-1/2 34 1-1/4 4 4 34 1-1/2 4 4 34 2 5 5 34 2-1/2 6 6 34 3 8 6

101 – 125 34 1 3 3 34 1-1/4 4 4 34 1-1/2 4 4 34 2 5 5 56 2-1/2 6 6 – – – –

126 – 150 34 1 3 3 34 1-1/4 4 4 34 1-1/2 4 5 56 2 5 6 56 2-1/2 6 6 – – – –

151 – 175 34 1 3 4 34 1-1/4 4 4 34 1-1/2 4 5 56 2 5 6 56 2-1/2 6 8 – – – –

176 – 200 34 1 3 4 34 1-1/4 4 5 56 1-1/2 5 5 56 2 6 6 56 2-1/2 6 8 – – – –

201 – 225 34 1 4 4 56 1-1/4 4 5 56 1-1/2 5 5 56 2 6 6 56 2-1/2 8 8 – – – –

** 226 – 300 56 1 4 4 56 1-1/4 4 5 56 1-1/2 5 6 56 2 6 6 56 2-1/2 8 8 – – – –

* Miniature Boilers: 1/2" – 1" Blowdown Valve up to 1000 #/hour. Blowdown use 14" high, 1" Inlet, 2" Drain, 2-1/2" Vent.

** 251 – 300 PSIG required.

U Symbol Construction and Stamping. See price sheet for adder.

* 1"

11/4"

11/2"

2"

21/2"

3"

Chart B—Cooling Water Line & Valve Size

SEPARATOR

INLET SIZE

COOLING WATER

PRESSURE PSI 40# 60# 80# 40# 60# 80# 40# 60# 80# 40# 60# 80# 40# 60# 80# 40# 60# 80#

BOILER OPERATING

PRESSURE

0 – 50 1/2 1/2 1/2 1 1 3/4 1-1/4 1 1 1-1/4 1-1/4 1-1/4 1-1/2 1-1/2 1-1/4 2 2 2

Use for

50 – 70°F

Cooling

Water

Temperature

Use for

71 – 80°F

Cooling

Water

Temperature

51 – 100 1 3/4 3/4 1 1 1 1-1/4 1-1/4 1 1-1/2 1-1/4 1-1/4 2 2 2 2-1/2 2-1/2 2

101 – 125 1 3/4 3/4 1-1/4 1 1 1-1/4 1-1/4 1-1/4 2 1-1/2 1-1/4 2 2 2 2-1/2 2-1/2 2-1/2

126 – 175 1 1 1 1-1/4 1-1/4 1 1-1/4 1-1/4 1-1/4 2 2 1-1/2 2-1/2 2 2 2-1/2 2-1/2 2-1/2

176 – 225 1 1 1 1-1/4 1-1/4 1-1/4 1-1/2 1-1/4 1-1/4 2 2 2 2-1/2 2 2 3 2-1/2 2-1/2

226 – 250 1-1/4 1-1/4 1 1-1/4 1-1/4 1-1/4 1-1/2 1-1/4 1-1/4 2 2 2 2-1/2 2 2 3 2-1/2 2-1/2

251 – 300 1-1/4 1-1/4 1 1-1/4 1-1/4 1-1/4 1-1/2 1-1/4 1-1/4 2 2 2 2-1/2 2-1/2 2 3 3 2-1/2

0 – 50 3/4 1/2 1/2 1 1 1 1 1 1 1-1/4 1-1/4 1-1/4 2 1-1/2 1-1/2 2-1/2 2 2

51 – 100 1 3/4 3/4 1-1/4 1 1 1-1/4 1-1/4 1-1/4 2 1-1/2 1-1/4 2 2 2 2-1/2 2-1/2 2

101 – 125 1 1 3/4 1-1/4 1-1/4 1 1-1/4 1-1/4 1-1/4 2 2 1-1/2 2-1/2 2 2 2-1/2 2-1/2 2-1/2

126 – 175 1 1 1 1-1/4 1-1/4 1-1/4 1-1/4 1-1/4 1-1/4 2 2 2 2-1/2 2 2 3 2-1/2 2-1/2

176 – 225 1 1 1 1-1/4 1-1/4 1-1/4 1-1/4 1-1/4 1-1/4 2 2 2 2-1/2 2-1/2 2 4 3 2-1/2

226 – 250 1-1/4 1-1/4 1 1-1/4 1-1/4 1-1/4 1-1/4 1-1/4 1-1/4 2-1/2 2 2 2-1/2 2-1/2 2 4 3 2-1/2

251 – 300 1-1/4 1-1/4 1-1/4 1-1/2 1-1/4 1 1-1/2 1-1/2 1-1/2 2-1/2 2 2 2-1/2 2-1/2 2-1/2 4 3 2-1/2

1"

11/4"

11/2"

2"

21/2"

3"

©2012 Burnham Commercial

P.O. Box 3939 • Lancaster, PA 17604

Phone: 888.791.3790 • Fax: 717.293.5803

www.burnhamcommercial.com

Form No. PL81465601007-12/12-1Mc

Printed in the U.S.A.

Loading...

Loading...