Burkert 8026, SE36, 8036 Quick Start Manual

Type 8026 - 8036 - SE36

Flowmeter and Flow transmitter

Durchfluss-Messgerät und Durchfluss-Transmitter

Débitmètre et transmetteur de débit

Quickstart

English Deutsch Français

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2009 - 2018

Operating Instructions 1809/03_EU-ML 00567366 / Original_FR

Type 8026 - 8036 - SE36

Contents

1 ABOUT THE QUICKSTART .....................................................................4

1.1 Definition of the word "device" ................................................... 4

1.2 Validity of the quickstart ............................................................... 4

1.3 Symbols used ................................................................................. 4

2 INTENDED USE .............................................................................................5

3 BASIC SAFETY INFORMATION ............................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Manufacturer's address and international contacts ...............7

4.2 Warranty conditions ...................................................................... 7

4.3 Information on the Internet ..........................................................7

5 DESCRIPTION OF THE RATING PLATE ............................................8

6 TECHNICAL DATA ........................................................................................9

6.1 Conditions of use .......................................................................... 9

6.2 Conformity to standards and directives ................................... 9

6.3 Dimensions of devices ................................................................. 9

6.4 Materials ........................................................................................10

6.5 Fluid data .......................................................................................12

6.6 Electrical data ...............................................................................14

7 INSTALLATION AND WIRING ..............................................................16

7.1 Safety instructions .......................................................................16

7.2 Installation of a 8026 on a pipe ...............................................16

7.3 Installation of a 8036 on a pipe ...............................................18

7.4 Installation of a flow transmitter SE36 with sensor-fitting

S070 or S077 in a pipe .............................................................19

7.5 Wiring .............................................................................................21

8 ADJUSTMENT AND COMMISSIONING .........................................27

8.1 Safety instructions .......................................................................27

8.2 Knowing the Operating levels ..................................................27

8.3 Using the navigation button ......................................................28

8.4 Using the dynamic functions .....................................................30

8.5 Knowing the display ....................................................................30

8.6 Knowing the process level ........................................................32

8.7 Knowing the configuration level ...............................................34

9 MAINTENANCE AND TROUBLESHOOTING ............................... 41

9.1 Safety instructions .......................................................................41

9.2 If you encounter problems .........................................................41

10 PACKAGING, TRANSPORT .................................................................. 41

11 STORAGE ......................................................................................................41

12 DISPOSAL OF THE DEVICE ................................................................ 42

English

3

Type 8026 - 8036 - SE36

About the Quickstart

1 ABOUT THE QUICKSTART

This quickstart describes the entire life cycle of the device. Please

keep this quickstart in a safe place, accessible to all users and any

new owners.

This quickstart contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations. Pay attention in particular to the chapters „Basic safety

information“ and „Intended use“.

▶ Irrespective the version of the device, this quickstart must be

read and understood.

The quickstart explains how to install, adjust, and start-up the device.

A detailed description of the device can be found in the related

Operating Instructions available on the internet at: www.burkert.com

1.1 Definition of the word "device"

The word "device" used within this quickstart refers to:

• the Type 8026 flowmeter,

• the Type 8036 flowmeter,

• or the Type SE36 flow transmitter.

1.2 Validity of the quickstart

This quickstart is valid for the following devices:

• Type 8026 flowmeter, from the version V2,

• Type 8036 flowmeter, from the version V2,

• Type SE36 flow transmitter, from the version V2.

These informations are available on the rating plate, see chap. 5.

1.3 Symbols used

Danger

Warns against an imminent danger.

▶ Failure to observe this warning can result in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or

even death.

Caution

Warns against a possible risk.

▶ Failure to observe this warning can result in substantial or minor

injuries.

notiCe

Warns against material damage.

4

English

Type 8026 - 8036 - SE36

Intended use

Indicates additional information, advice or important

recommendations.

Refers to information contained in this quickstart or in other

documents.

▶ Indicates an instruction to be carried out to avoid a danger, a

warning or a possible risk.

→ Indicates a procedure to be carried out.

Indicates the result of a specific instruction.

2 INTENDED USE

Use of the device that does not comply with the instructions

could present risks to people, nearby installations and the

environment.

Type 8026 flowmeter, Type 8036 flowmeter and Type SE36

flow transmitter associated with a sensor-fitting are intended to

measure the flow rate of liquids.

▶ Use this device in compliance with the characteristics and

commissioning and use conditions specified in the contractual

documents and in the Operating Instructions.

▶ Never use this device for security applications.

▶ Protect this device against electromagnetic interference, ultra-

violet rays and, when installed outdoors, the effects of climatic

conditions.

▶ Use this device only if in perfect working order.

▶ Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

▶ Only use the device as intended.

English

5

3 BASIC SAFETY INFORMATION

This safety information does not take into account any contingencies

or occurrences that may arise during installation, use and maintenance of the device.

The operating company is responsible for the respect of the local

safety regulations including staff safety.

Danger due to electrical voltage.

▶ If a 12...36 V DC or a 14...36 V DC powered version is installed

either in a wet environment or outdoors, all the electrical voltages must be of max. 35 V DC.

▶ Disconnect the electrical power for all the conductors and iso-

late it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Danger due to high pressure in the installation.

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Danger due to high temperatures of the fluid.

▶ Use safety gloves to handle the device.

▶ Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Danger due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and

safety relating to the use of dangerous fluids.

Type 8026 - 8036 - SE36

Basic safety information

Various dangerous situations

To avoid injury take care:

▶ not to use the device for the measurement of gas flow rates.

▶ not to use the device in explosive atmospheres.

▶ not to use the device in an environment incompatible with the

materials it is made of.

▶ not to use fluid that is incompatible with the materials the device

is made of.

▶ not to make any modifications to the device.

▶ not to subject the device to mechanical loads.

▶ to prevent any unintentional power supply switch-on.

▶ to carry out the installation and maintenance work by qualified

and skilled staff with the appropriate tools.

▶ to guarantee a defined or controlled restarting of the process,

after a power supply interruption.

▶ to observe the general technical rules when installing and using

the device.

6

English

Type 8026 - 8036 - SE36

General information

notiCe

The device may be damaged by the fluid in contact with.

▶ Systematically check the chemical compatibility of the com-

ponent materials of the device and the fluids likely to come

into contact with the materials (for example: alcohols, strong

or concentrated acids, aldehydes, alkaline compounds, esters,

aliphatic compounds, ketones, halogenated aromatics or hydrocarbons, oxidants and chlorinated agents).

notiCe

Elements / Components sensitive to electrostatic discharges

▶ This device contains electronic components that are sensitive

to electrostatic discharges. They may be damaged if they are

touched by an electrostatically charged person or object. In the

worst case scenario, these components are instantly destroyed

or go out of order as soon as they are activated.

▶ To minimise or even avoid any damage due to an electro-

static discharge, take all the precautions described in the

EN 61340-5-1 norm.

▶ Also make sure that you do not touch any of the live electrical

components.

4 GENERAL INFORMATION

4.1 Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at: www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of

the device in observance of the operating conditions specified in the

Operating Instructions.

4.3 Information on the Internet

You can find the Operating Instructions and technical data sheets for

Type 8026, Type 8036 and Type SE36 at: www.burkert.com

English

7

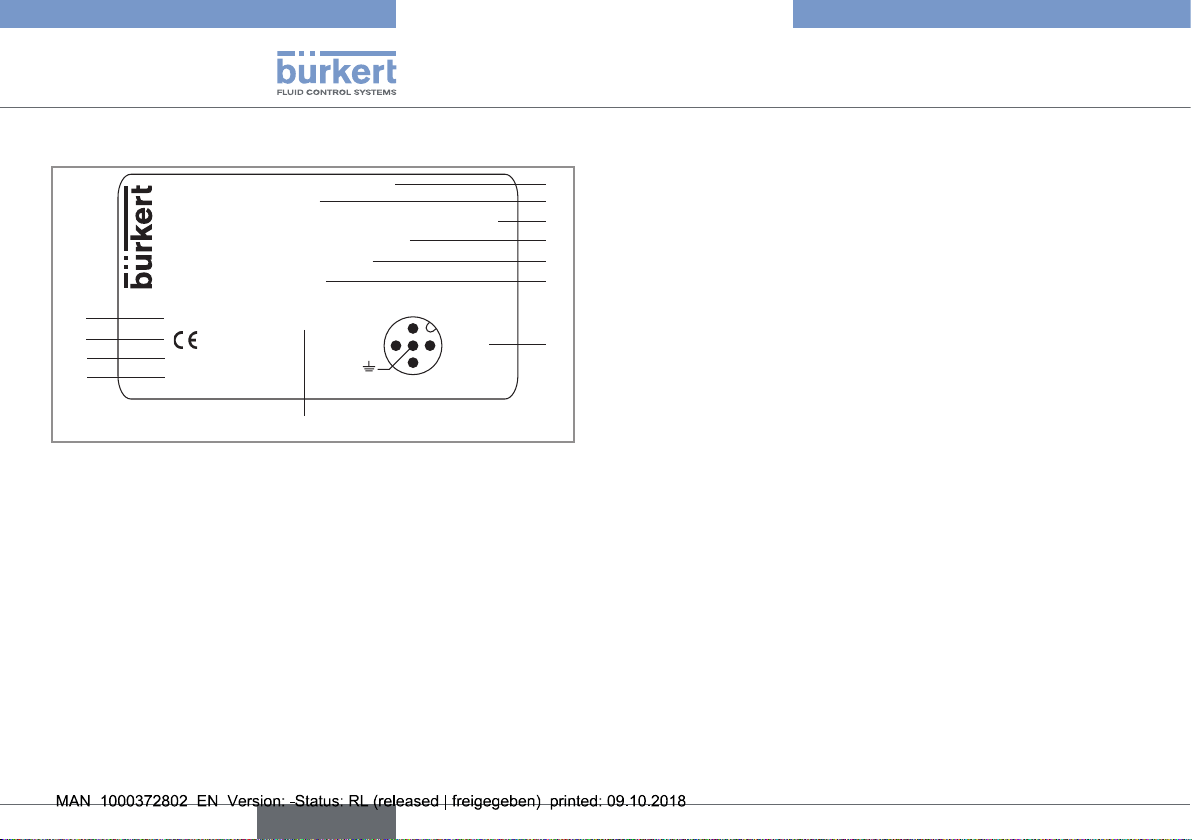

Type 8026 - 8036 - SE36

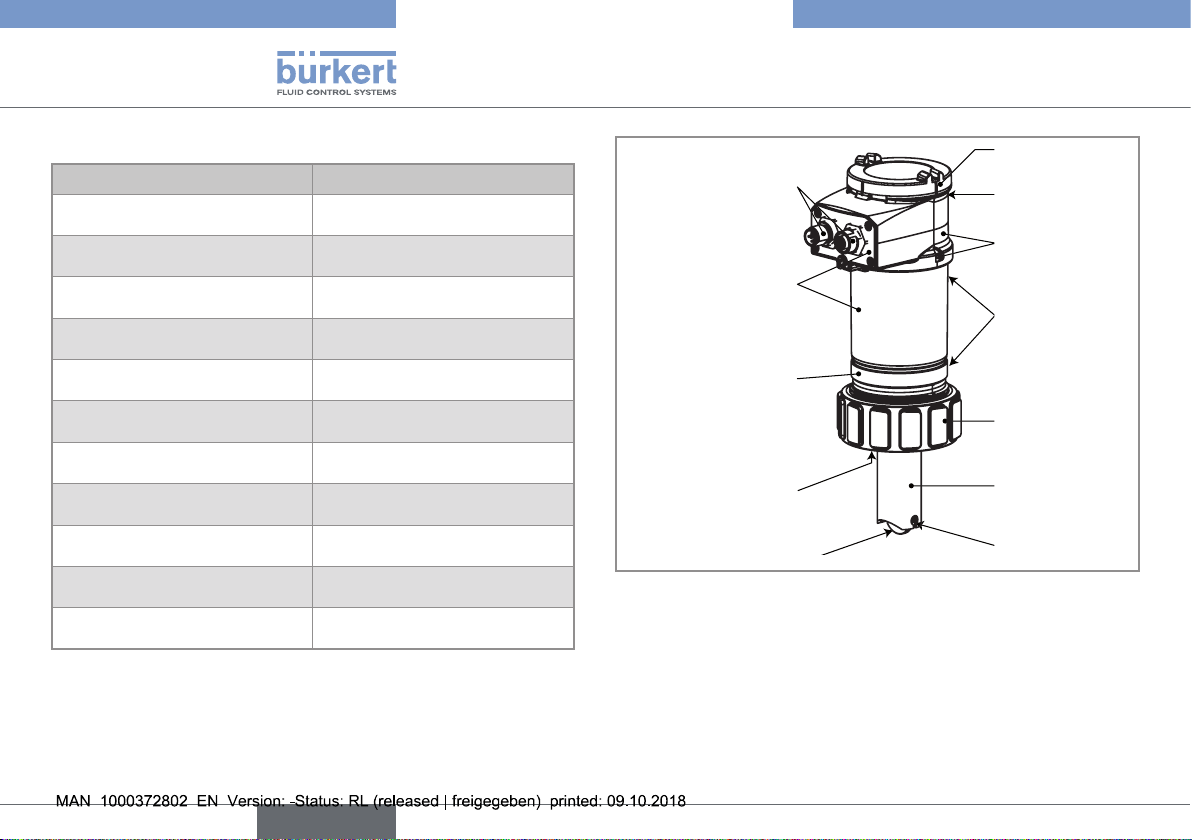

8026 Flow-Meter V2

1

8

10

11

12

Description of the rating plate

5 DESCRIPTION OF THE RATING PLATE

Supply: 14-36VDC

Output: 1x4-20mA 2xTransistors 500 mA Max

Cell: HALL INSERTION SHORT

Process: Temp -15/100°C

PN 10 Bar

Made in France

IP65-IP67 W41MT

9

Fig. 1: Rating plate of the Type 8026 flowmeter (example)

S-N:2024

00560861

2:NPN/PNP1

3:0V

4:NPN/PNP2

1:V+

2

3

4

5

6

7

1. Type of the device, measured variable and version

2. Power supply

3. Output specifications

4. Type of sensor

5. Fluid temperature range

6. Fluid pressure

7. Allocation of the pins on the M12 fixed connectors

8. Manufacturing code

9. Article number

10. Serial number

11. Conformity marking

12. Protection rating

8

English

Type 8026 - 8036 - SE36

Technical data

6 TECHNICAL DATA

6.1 Conditions of use

Ambient temperature

Air humidity

Protection rating

according to

IEC / EN 60529

Operating conditions

Mobility of the device

Use

Degree of pollution

Installation category

Max. height above

sea level

–10...+60 °C

< 85%, non condensing

IP65 and IP67 with connectors plugged

in and tightened and electronic module

cover fully sealed

Continuous

Fixed

Indoor

Degree 2 according to UL / EN 61010-1

Category I according to UL / EN 61010-1

2000 m

6.2 Conformity to standards and directives

The applied standards, which verify conformity with the EU directives, can be found on the EU-type examination certificate and/or the

EU declaration of conformity (if applicable).

6.2.1 Conformity to the pressure equipment

directive

→ Make sure the device materials are compatible with the fluid.

→ Make sure the pipe DN and the nominal pressure PN are

adapted for the device.

Type 8026 flowmeter, Type S030, Type S070 and Type S077 fittings conform to Article 4, Paragraph 1 of the Pressure Equipment

Directive 2014/68/EU under the following conditions:

• Device used on a piping (PS = maximum admissible pressure;

DN = nominal diameter of the pipe)

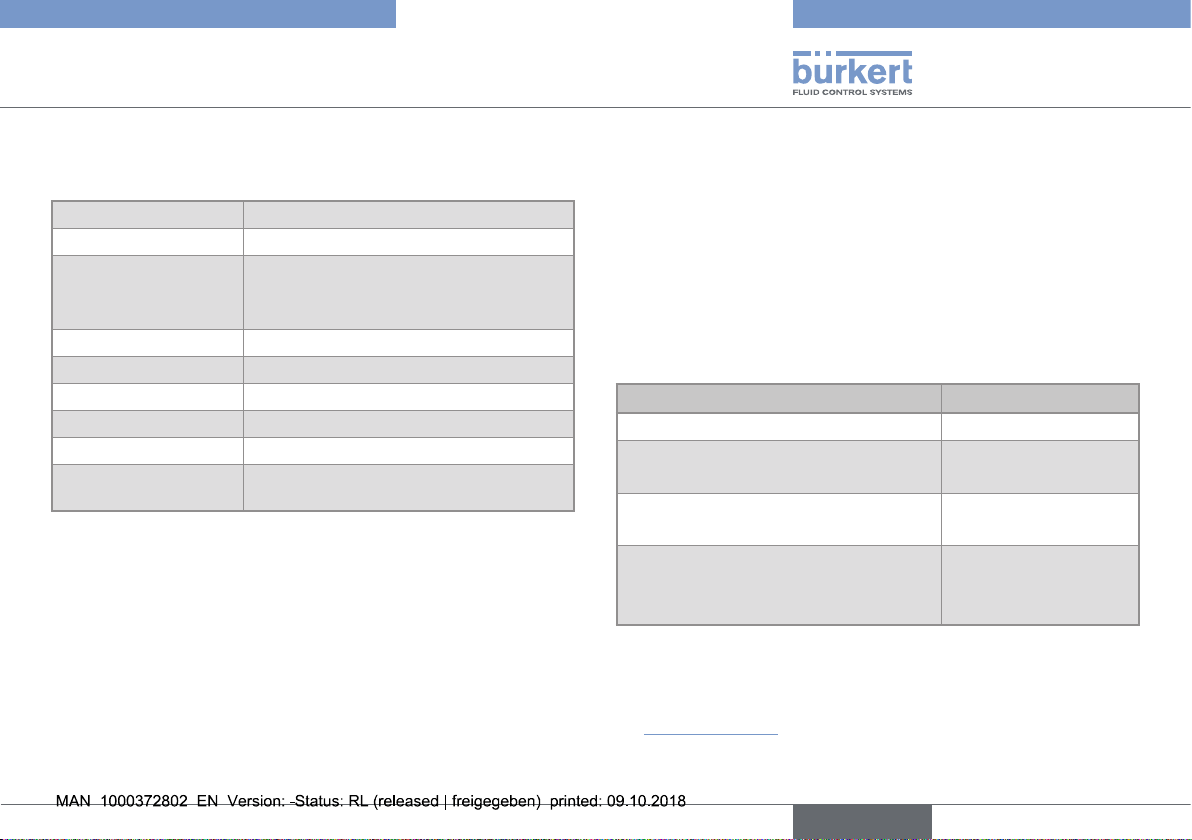

Type of fluid Conditions

Fluid group 1, Article 4, Paragraph 1.c.i DN≤25

Fluid group 2, Article 4, Paragraph 1.c.i

Fluid group 1, Article 4, Paragraph 1.c.ii

Fluid group 2, Article 4, Paragraph 1.c.ii

DN≤32

or PSxDN≤1000

DN≤25

or PSxDN≤2000

DN≤200

or PS≤10

or PSxDN≤5000

6.3 Dimensions of devices

→ Please refer to the technical data sheets related to the device at:

www.burkert.com

English

9

Type 8026 - 8036 - SE36

Technical data

6.4 Materials

Part Material

Box / seals

Cover / seal PC / Silicone

Display module PC / PBT

M12 fixed connector

Fixed connector holder Stainless steel 1.4404 (316L)

Screws Stainless steel

Nut PC

Flow sensor holder / seal

(only 8026)

Axis and shaft of the paddle

wheel (only 8026)

Paddle wheel (only 8026) PVDF

Quarter-turn system (only SE36) PC

Stainless steel 1.4404,

PPS / EPDM

Nickel-plated brass

(stainless steel on request)

PVDF / FKM (default)

Ceramic (Al

2O3

)

PC

Nickel-plated brass

(or stainless steel)

Silicone

PPS

Stainless steel

EPDM

PPS

PC

FKM

PVDF

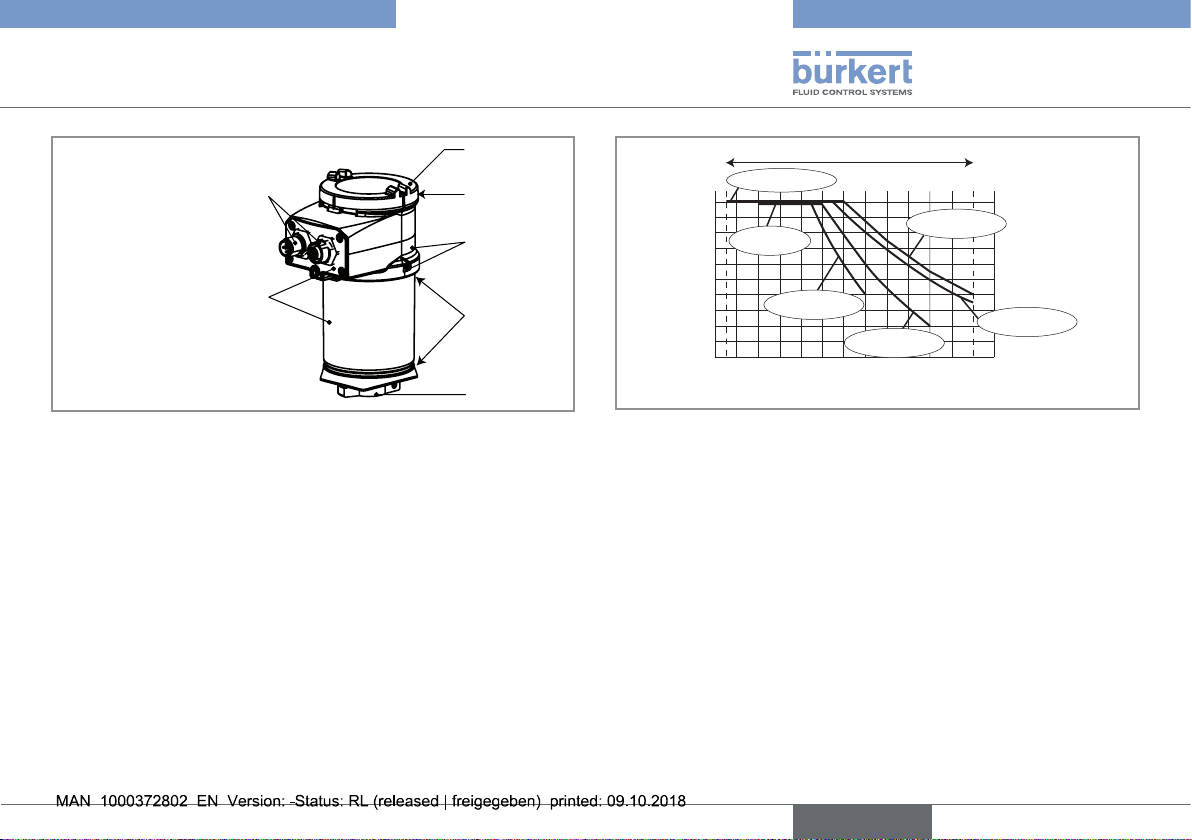

Fig. 2: Materials used in the flowmeter 8026

PVDF

Ceramic (Al

2O3

• Materials of the flowmeter 8026 in contact with the fluid: PVDF,

ceramic, FKM (default).

)

10

English

Type 8026 - 8036 - SE36

Technical data

Nickel-plated brass

(or stainless steel)

Stainless steel

Fig. 3: Materials used in the flow transmitter SE36

PC

Silicone

PPS

EPDM

PC

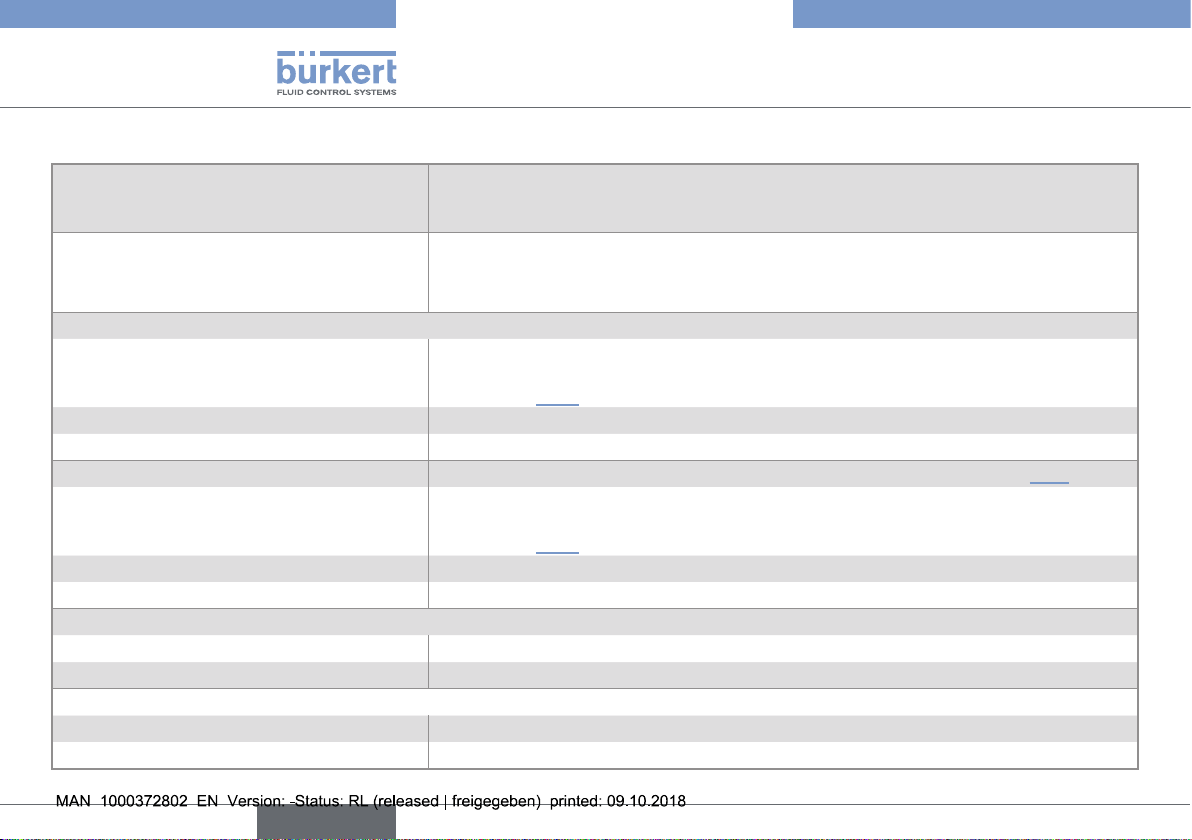

A

P (bar)

10

9

8

7

6

5

4

3

2

1

0

A: Operating range

-10 +10 +30 +50 +70 +90 +110

PVDF +

PVC + PP

Metal

PVC (PN10)

PP (PN10)

Metal

(PN10)

PVDF (PN10)

T (°C)

Fig. 4: Fluid temperature / fluid pressure dependency for flowmeter 8026

associated to a fitting S020

English

11

Type 8026 - 8036 - SE36

Technical data

6.5 Fluid data

Pipe diameter

Type of fitting

Fluid temperature

• 8026

• 8036 • see the Operating Instructions, delivered with the fitting S030

• SE36 with a fitting S070 or S077 • see the Operating Instructions, delivered with the fitting S070 or S077

Fluid pressure

• 8026

• 8036 • see the Operating Instructions, delivered with the fitting S030

• SE36 with a fitting S070 or S077 • see the Operating Instructions, delivered with the fitting S070 or S077

Type of fluid

• 8026 and 8036 • Neutral or slightly aggressive fluids

• SE36 with fitting S070 or S077 • Viscous fluids, free of solid particles

Fluid viscosity

• 8026 and 8036 • 300 cSt max.

• SE36 with fitting S070 or S077 • see the Operating Instructions, delivered with the fitting S070 or S077

DN06 to DN400;

For fitting S020 or S030, the appropriate diameter is determined using the

flow rate / DN / fluid velocity graphs: refer to the Operating Instructions of the related fitting

• S020 for flowmeter 8026: see the Operating Instructions of the fitting

• S030 for flowmeter 8036: see the Operating Instructions of the fitting

• S070 or S077 for flow transmitter SE36: see the Operating Instructions of the fitting

• –15...+100 °C;

Also factor in the fluid temperature / fluid pressure dependency for the 8026 with fitting

S020: see Fig. 4

Also refer to the requirements of the Pressure Equipment Directive: see chap. 6.2.1

• PN10;

Also factor in the fluid temperature / fluid pressure dependency for the 8026 with fitting

S020: see Fig. 4

12

English

Type 8026 - 8036 - SE36

Technical data

Solid particle rate in the fluid

• 8026 and 8036 • ≤ 1 %

• SE36 with fitting S070 or S077 • 0 %

Flow rate measurement for 8026 and 8036

• Measurement range • 0.3...10 m/s

• Linearity • ±0.5 % of the full scale (10 m/s)

• Repeatability • ±0.4 % of the measured value

• Measurement deviation with standard K factor • ±2.5 % of the measured value

1)

1)

1)

• Measurement deviation with a Teach-in procedure • ±1 % of the measured value (at the value of the teach-in flow rate)

Flow rate measurement for SE36 with fitting S070 or S077

• Measurement range

- viscosity > 5 mPa.s - S070: 2...1200 I/min

- S077: 2...1200 I/min

- viscosity < 5 mPa.s - S070: 3...616 I/min

- S077: 3...616 I/min

• Measurement deviation

- with standard K-factor of the

sensor-fitting

- with K-factor determined with a teach-in

procedure or with the specific K-factor,

- S070: ±0.5 % of the measured value

- S077: ±1 % of the measured value

- S070: ±0.5 % of the measured value (at the value of the teach-in flow rate)

- S077: ±0.5 % of the measured value (at the value of the teach-in flow rate)

1)

1)

engraved on the fitting

1)

• Repeatability

• ±0.03 % of the measured value

1)

1)

1)

1)

Determined in the following reference conditions: fluid = water, water and ambiant temperatures = 20 °C, upstream and downstream dis-

tances respected, appropriate pipe dimensions.

English

13

6.6 Electrical data

14...36 V DC power supply

version with 2 or 3 outputs (2 wires)

12...36 V DC power supply

version with 4 outputs (3 wires)

Specifications of the power source (not supplied)

of the UL devices

Current consumption

• version with 2 or 3 outputs (2 wires) • 25 mA max. (at 14 V DC)

• version with 4 outputs (3 wires) • 5 mA max. (at 12 V DC)

Current consumption, with loads on the transistors

Power consumption

Protection against polarity reversal

Protection against voltage spikes

Protection against short circuits

• Connection to main supply: permanent (through external SELV and through LPS

power supply)

• filtered and regulated

• oscillation rate: ±10 %

• Connection to main supply: permanent (through external SELV and through LPS

power supply)

• filtered and regulated

• oscillation rate: ±10 %

• Limited power source according to UL / EN 60950-1 standards

• or limited energy circuit according to UL / EN 61010-1, Paragraph 9.4

1 A max.

40 W max.

yes

yes

yes, transistor outputs

Type 8026 - 8036 - SE36

Technical data

14

English

Loading...

Loading...