Page 1

Type 8012

Flowmeter with paddle-wheel

Durchfluss-Messgerät mit Flügelrad

Débitmètre à ailette

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2009-2012 Bürkert SAS

Operating Instructions 1202/1_EU-ML_00563643_ORIGINAL_FR

Page 3

Type 8012

Table of Contents

1. ABOUT THIS MANUAL .................................................................................5

1.1. Symbols used .......................................................................................5

1.2. Definition of the word "device" ....................................................5

2. INTENDED USE ................................................................................................6

2.1. Restraints ................................................................................................6

3. BASIC SAFETY INFORMATION ...............................................................6

4. GENERAL INFORMATION ...........................................................................8

4.1. Manufacturer's address and international contacts .........8

4.2. Warranty conditions ...........................................................................8

4.3. Information on the Internet ............................................................8

5. DESCRIPTION ...................................................................................................8

5.1. Area of application .............................................................................8

5.2. General description ...........................................................................8

5.2.1. Construction ........................................................................... 8

5.2.2. Version with pulse output .................................................... 9

5.2.3. Version with pulse output and current output ..............10

5.3. Description of the name plate of the 8012 ........................ 11

5.4. Description of the name plate of the SE12 ...........................11

5.5. Order codes for the basic versions of the SE12

module ................................................................................................... 12

6. TECHNICAL DATA ........................................................................................14

6.1. Conditions of use ............................................................................. 14

6.2. Conformity to standards and directives...............................14

6.3. General technical data .................................................................. 14

6.3.1. Mechanical data ..................................................................14

6.3.2. General data .........................................................................21

6.3.3. Electrical data.......................................................................23

6.3.4. Electrical connections ........................................................23

6.3.5. K factors ................................................................................23

7. INSTALLATION AND WIRING .................................................................25

7.1. Safety instructions...........................................................................25

7.2. Installation onto the pipe ............................................................. 26

7.2.1. Recommendations for installing the 8012 on

the pipe ..................................................................................26

7.2.2. Installing a device with welding ends .............................28

7.2.3. Installing a device with Clamp connections ..................29

7.2.4. Installing a device with flange connections ...................29

7.3. Graphs ................................................................................................... 30

7.4. Electrical wiring .................................................................................31

7.4.1. Assembling the M12 female connector .........................32

7.4.2. Wiring a version with adjustable M12 fixed

English

3

Page 4

Type 8012

connector ..............................................................................32

7.4.3. Wiring a version with cable gland ...................................33

8. COMMISSIONING ........................................................................................ 35

8.1. Safety instructions...........................................................................35

9. ADJUSTMENT AND FUNCTIONS .........................................................35

9.1. Safety instructions...........................................................................35

9.2. Pulse output ........................................................................................35

9.2.1. Frequency proportional to a volume ...............................35

9.2.2. Switching function ..............................................................36

9.2.3. Detection of a change in the fluid direction (only

8012 with optical sensor) .................................................37

9.3. Current output ................................................................................... 39

9.3.1. Extension of the current range .........................................39

9.3.2. Conversion of the frequency into a flow rate ................39

9.3.3. Current attenuation variations ..........................................40

10. MAINTENANCE AND TROUBLESHOOTING ................................40

10.1. Safety instructions...........................................................................40

10.2. Cleaning ................................................................................................ 41

10.3. Replacing the seal ...........................................................................41

10.4. If you encounter problems ..........................................................42

10.4.1. Problems signalled by the LEDs ......................................42

10.4.2. Problems not signalled by the LEDs ...............................43

11. SPARE PARTS AND ACCESSORIES ............................................... 43

12. PACKAGING, TRANSPORT, STORAGE .......................................... 45

4

English

Page 5

Type 8012

Warns against material damage.

Failure to observe this warning may result in damage to the device

About this manual

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep

this manual in a safe place, accessible to all users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

• This manual must be read and understood.

1.1. Symbols used

danger

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious

injury.

Warning

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or even

death.

attention

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor

injuries.

note

•

or system.

indicates additional information, advice or important

recommendations.

refers to information contained in this manual or in other

documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

→ The word "device" used within this manual refers to the flow-

meter type 8012.

English

5

Page 6

Type 8012

Intended use

2. INTENDED USE

Use of the flowmeter that does not comply with the instructions could present risks to people, nearby installations and

the environment.

• The 8012 flowmeter is intended exclusively to measure flow rate

in liquids.

• This device must be protected against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects

of climatic conditions.

• This device must be used in compliance with the characteristics

and commissioning and use conditions specified in the contractual documents and in the user manual.

• Requirements for the safe and proper operation of the device

are proper transport, storage and installation, as well as careful

operation and maintenance.

• Only use the device as intended.

2.1. Restraints

Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during assembly,

use and maintenance of the devices.

• the local safety regulations that the operator must ensure the staff

in charge of installation and maintenance observe.

Danger due to high pressure in the installation.

Danger due to electrical voltage.

Danger due to high temperatures of the fluid.

Danger due to the nature of the fluid.

Various dangerous situations

To avoid injury take care:

• to prevent any unintentional power supply switch-on.

• to ensure that installation and maintenance work are

carried out by qualified, authorised personnel in possession of

the appropriate tools.

• to guarantee a defined or controlled restarting of the process,

after a power supply interruption.

6

English

Page 7

Type 8012

The device may be damaged by the fluid in contact with.

Elements / Components sensitive to electrostatic discharges

Intended use

note

Various dangerous situations

To avoid injury take care:

• to use the device only if in perfect working order and in compliance with the instructions provided in the instruction manual..

• to observe the general technical rules when installing and using

the device.

• not to use this device in explosive atmospheres.

• not to use the device for the measurement of gas flow rates.

• not to use fluid that is incompatible with the materials the device

is made of.

• not to use this device in an environment incompatible with the

materials it is made of.

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external modifications to the device. Do not paint

any part of the device.

note

• Systematically check the chemical compatibility of the component materials of the device and the fluids likely to come into

contact with it (for example: alcohols, strong or concentrated

acids, aldehydes, alkaline compounds, esters, aliphatic compounds, ketones, halogenated aromatics or hydrocarbons,

oxidants and chlorinated agents).

• This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they are touched

by an electrostatically charged person or object. In the worst

case scenario, these components are instantly destroyed or go

out of order as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 norms.

• Also ensure that you do not touch any of the live electrical

components.

English

7

Page 8

Type 8012

General information

4. GENERAL INFORMATION

4.1. Manufacturer's address and international contacts

To contact the manufacturer of the device use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices can be found on the

last pages of this manual. They are also available on the Internet at:

www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of

the 8012 in observance of the operating conditions specified in this

manual.

4.3. Information on the Internet

You can find the user manuals and technical data sheets regarding

the type 8012 at: www.burkert.com

5. DESCRIPTION

5.1. Area of application

The 8012 flowmeter with magnetic sensor is intended to measure the

flow rate of neutral or slightly aggressive liquids free of solid particles.

The 8012 flowmeter with optical sensor is intended exclusively for

measuring the flow rate of liquids that allow the passage of infrared rays.

5.2. General description

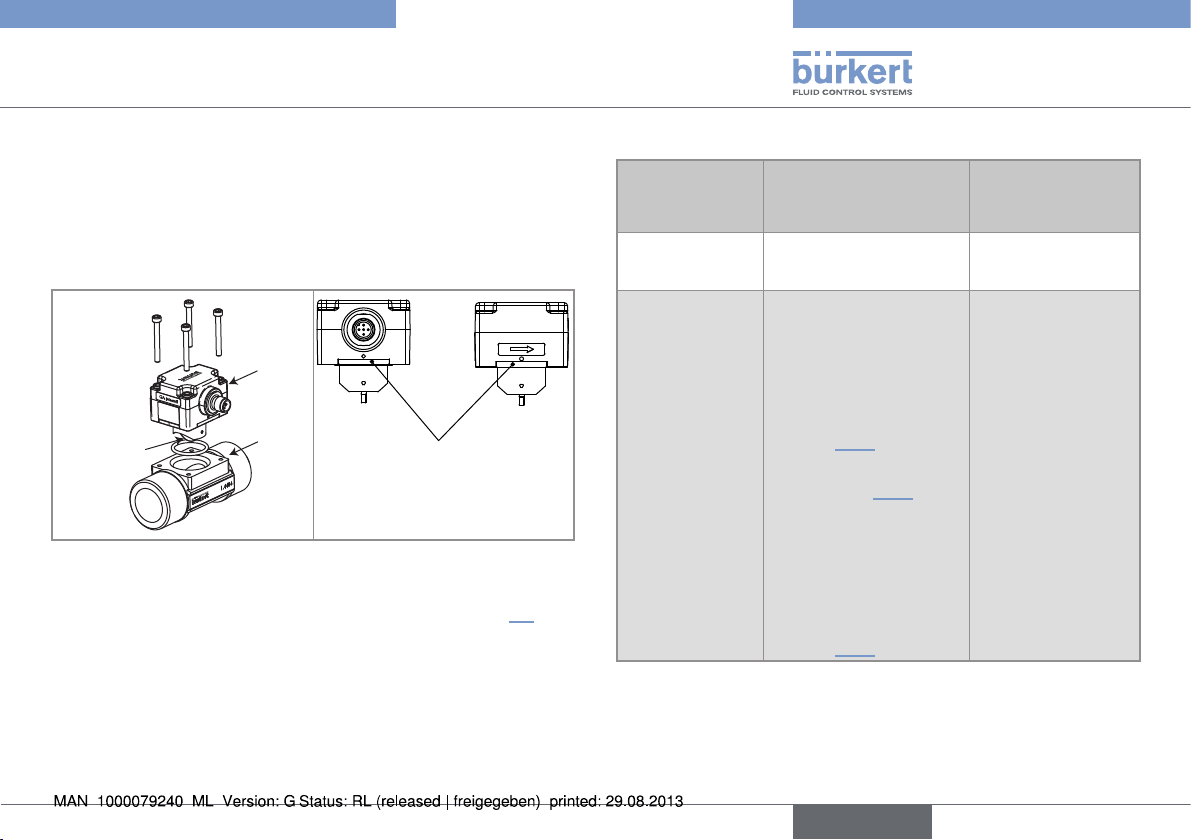

5.2.1. Construction

The 8012 flowmeter comprises the SE12 electronics incorporating

the measuring paddle-wheel and an S012 fitting allowing the device

to be fitted to all types of pipes from DN6 to DN65.

The sensor detects the rotation of the paddle-wheel; it generates a

signal in which the frequency f is proportional to the rotation frequency

of the paddle-wheel.

The electronic module is fitted with 2 LEDs visible by transparency on

the side of the housing:

• A green LED is on when the device is energized (the paddlewheel is not running) and then flashes proportionally to the

rotation frequency of the paddle-wheel.

• A red LED signals a malfunction of the flowmeter (see chap.

10.4.1).

8

English

Page 9

Type 8012

General information

Depending on the version, the electrical connection is made using a

1 m long cable or a multi-pin M12 fixed connector which position can

be adjusted.

Depending on the version, the device is equipped:

• with one pulse output

• or one pulse output and one 4-20 mA current output.

SE12

Paddle-wheel

S012

Location of the LEDs

(depending on the version)

5.2.2. Version with pulse output

On the 16 basic versions of the SE12 module (see chap. 5.5), the

NPN pulse output generates a signal with a frequency f proportional

to the rotation frequency of the paddle-wheel.

To obtain a flow rate Q, this frequency must be divided by a proportionality factor K according to the following formula:

Q = f/K

Table 1 : Characteristics of the pulse output

Characteristic

of the pulse

Possible configurations (on request)

output

Transistor wiring • NPN

• or PNP

Behaviour of the

output

• Frequency proportional to the rotation of

the paddle-wheel (see

above)

• or frequency proportional to a volume (see

chap. 9.2.1)

• or switching mode

(see chap. 9.2.2)

• or mode detecting the

immediate or delayed

change of circulation

direction of the fluid

(only on versions with

optical sensor) (see

chap. 9.2.3)

Pulse output of

the basic versions

NPN

Frequency proportional to the rotation

of the paddle-wheel

English

9

Page 10

Type 8012

mA

0

20

4

Q

Q =

(I - 4)

125

8K

General information

5.2.3. Version with pulse output and

current output

Pulse output

The characteristics of the pulse output are identical to those on a

version with pulse output only. See chap. 5.2.2.

Current output

The current output on the basic versions is connected in sink mode

and delivers a current I, an image of the rotation frequency f of the

paddle-wheel:

I = 8f/125 + 4

As f = KQ, the flow Q is therefore proportional to this current:

Q: flow rate [litre/s]

K: K factor [pulse/litre]

l: current [mA]

Flow rate

Current attenuation variations

When the flow varies quickly, the current output signal from your

device can be stabilised. On the basic versions, the current variations

are slightly attenuated.

Generation of an alarm current (versions with optical sensor

only)

On the basic versions, an "alarm" current of 22 mA is generated when

the circulation direction of the fluid is the opposite of the direction of

the arrow on the side of the housing.

10

English

Table 2 : Current output data

Characteristic Possible configurations (on

request)

Wiring • source

• or sink

Current output

range and associated measuring

range

• 4-20 mA, corresponding to

the rotation frequency range

0-250 Hz of the paddle-wheel

(see above)

• or 4-20 mA, corresponding to a

flow range, in the unit specific to

the application (see chap. 9.3.1)

• or 4-21.6 mA, corresponding

to the rotation frequency range

0-275 Hz of the paddle-wheel

(see chap. 9.3.1)

• or 4-21,6 mA, corresponding

to a flow range, in the unit

specific to the application (see

chap. 9.3.2)

Current attenuation variations

Ten possible attenuation levels:

ranging from "no attenuation" to

"maximum attenuation" (see chap.

9.3.3)

Configuration

on a basic

version

sink

4-20 mA, corresponding to

the 0-250 Hz

rotation

frequency

range of the

paddle-wheel

Slight attenuation of

the current

variations

Page 11

Type 8012

General information

5.3. Description of the name plate of the 8012

1

FLOW:8012 HALL

NPN/PNP : 0,7A - 36 VDC

12-36 VDC 4-20 mA

MS FKM 0,3-10 M/S

S-N:1092

Made in France

00557060 W47LE

1. Measured value and type of the device

2. Type of sensor

3. Characteristics of the pulse output

4. Type of current output

5. Flow range

6. Conformity logo

7. Manufacturing code

8. Materials the fitting and the seal in contact with the fluid are

made of

9. Serial number

10. Order code

11. Supply voltage

2

3

4

5

8 11 10

6 7 9

5.4. Description of the name plate of the SE12

1

FLOW:SE12 HALL

NPN/PNP : 0,7A - 36 VDC

12-36 VDC 4-20 mA

0,3-10 M/S

S-N:1092

Made in France

00557060 W47LE

1. Measured value and type of the device

2. Type of sensor

3. Characteristics of the pulse output

4. Type of current output

5. Flow range

6. Conformity logo

7. Manufacturing code

8. Serial number

9. Order code

10. Supply voltage

2

3

4

5

8 10

6 7 9

English

11

Page 12

Type 8012

General information

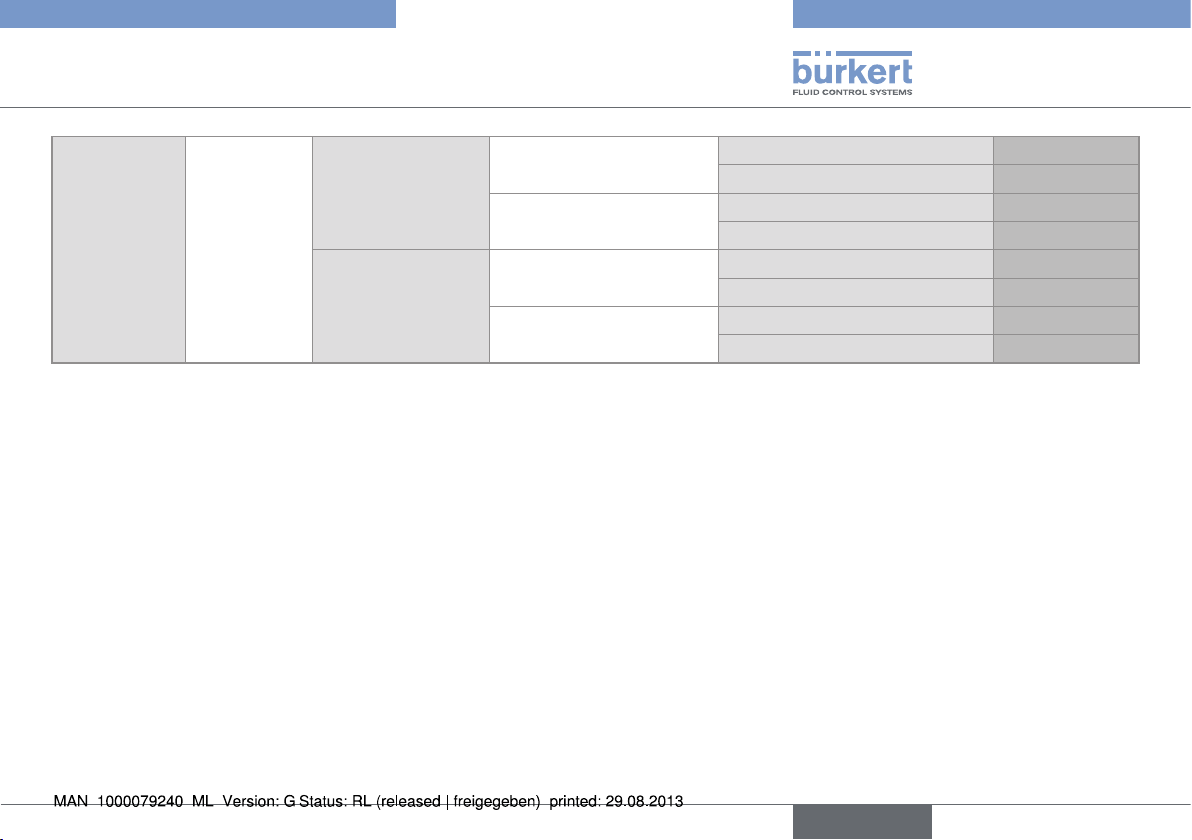

5.5. Order codes for the basic versions of the SE12 module

The fitting S012 is not available as a separate part.

Two versions of the S012 in DN15 and DN20 exist, having different K factors.

Only version 2, identified by the "v2" marking, is available from March 2012. The "v2" marking can be found:

V2

• on the bottom of the DN15 or DN20 fitting in plastic:

V2

• on the side of the DN15 or DN20 fitting in metal:

Supply

voltage

12-36 V DC Hall

12

Measurement

principle

Fitting Electrical connection Outputs Order code

DN6, DN8, DN15 v2

and DN20 v2

DN15 to DN65

(except DN15 v2

and DN20 v2)

English

Male 5-pin M12 fixed

connector

Cable gland, including 1 m

cable

Male 5-pin M12 fixed

connector

Cable gland, including 1 m

cable

Pulse, NPN 557054

Pulse, NPN + 4-20 mA 557058

Pulse, NPN 557056

Pulse, NPN + 4-20 mA 557060

Pulse, NPN 557053

Pulse, NPN + 4-20 mA 557057

Pulse, NPN 557055

Pulse, NPN + 4-20 mA 557059

Page 13

Type 8012

General information

12-36 V DC Optical

DN6, DN8, DN15 v2

and DN20 v2

DN15 to DN65

(except DN15 v2

and DN20 v2)

Male 5-pin M12 fixed

connector

Cable gland, including 1 m

cable

Male 5-pin M12 fixed

connector

Cable gland, including 1 m

cable

Pulse, NPN 557062

Pulse, NPN + 4-20 mA 557066

Pulse, NPN 557064

Pulse, NPN + 4-20 mA 557068

Pulse, NPN 557061

Pulse, NPN + 4-20 mA 557065

Pulse, NPN 557063

Pulse, NPN + 4-20 mA 557067

English

13

Page 14

Type 8012

Technical data

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature -15 to +60 °C

Air humidity < 80%, non condensated

Protection rating • IP67 (version with M12 fixed

connector), female connector wired,

plugged in and tightened

• IP65 (version with cable gland)

6.2. Conformity to standards and directives

The device conforms to the EC directives through the following

standards:

• EMC : EN 61000-6-2, EN 61000-6-3

• Safety: EN 61 010-1

• Vibration: EN 60068-2-6

• Shock: EN 60068-2-27

• Pressure (S012 fitting of DN06 to DN65 in PP, PVC, PVDF, brass

or stainless steel): the device can only be used in the following

cases (depending on the max. pressure, the DN of the pipe and

the fluid)

Type of fluid Conditions

Fluid group 1, par. 1.3.a DN ≤ 25 only

Type of fluid Conditions

Fluid group 2 par. 1.3.a

Fluid group 1 par. 1.3.b PNxDN ≤ 2000

Fluid group 2 par. 1.3.b DN ≤ 200

DN ≤ 32

or DN > 32 and PNxDN ≤ 1000

6.3. General technical data

6.3.1. Mechanical data

Component Material

SE12 electronic housing PPS

Cable gland, M12 fixed

connector

Cable, 1 m PVC, T

Seal exposed to the fluid FKM (EDPM on request)

Seal exposed to the ambient air EDPM

Paddle-wheel holder PVDF

Paddle-wheel PVDF

Paddle-wheel axis and

bearings

Body of the S012 fitting

Screws Stainless steel A4

PA

= 80 °C

max

ceramic

stainless steel (316L/DIN1.4404),

brass, PVC, PP, PVDF

14

English

Page 15

Type 8012

D

Technical data

Cable

L = 1 m

68

69

46

40

50

35

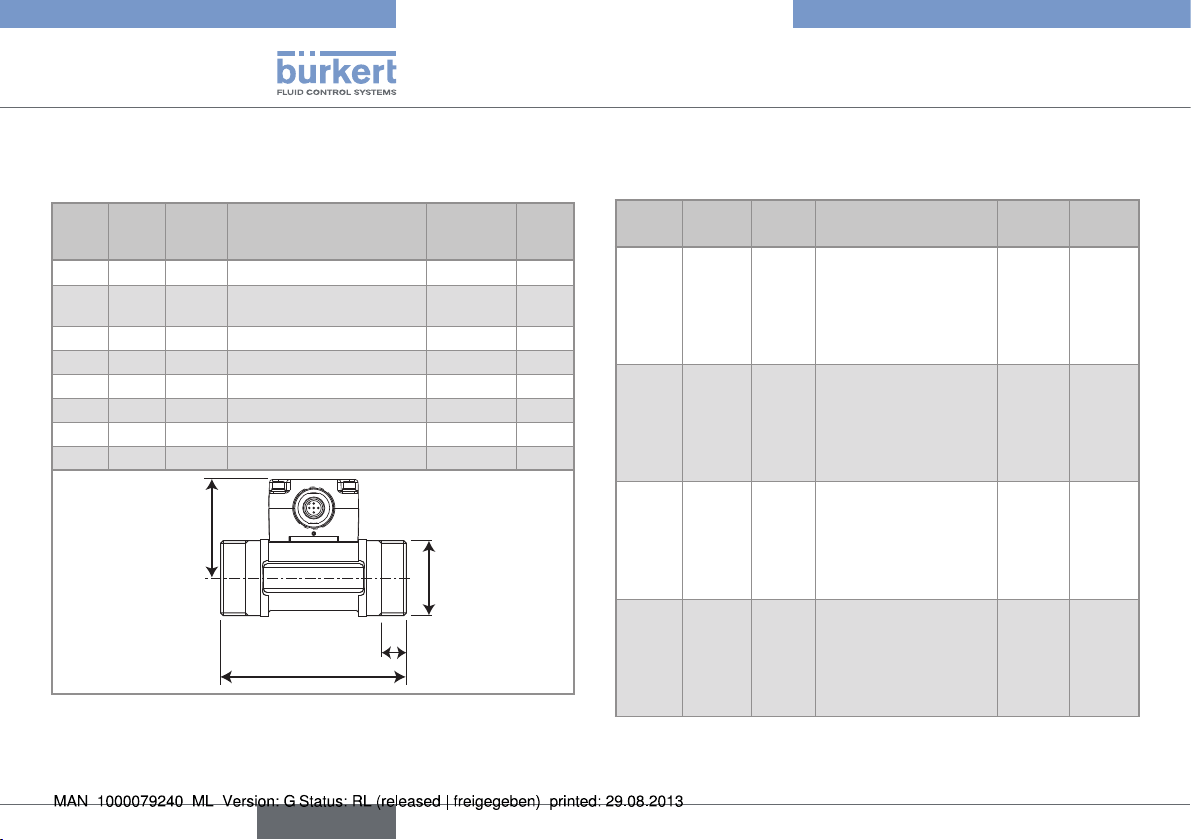

Fig. 1 : Dimensions of the SE12 module

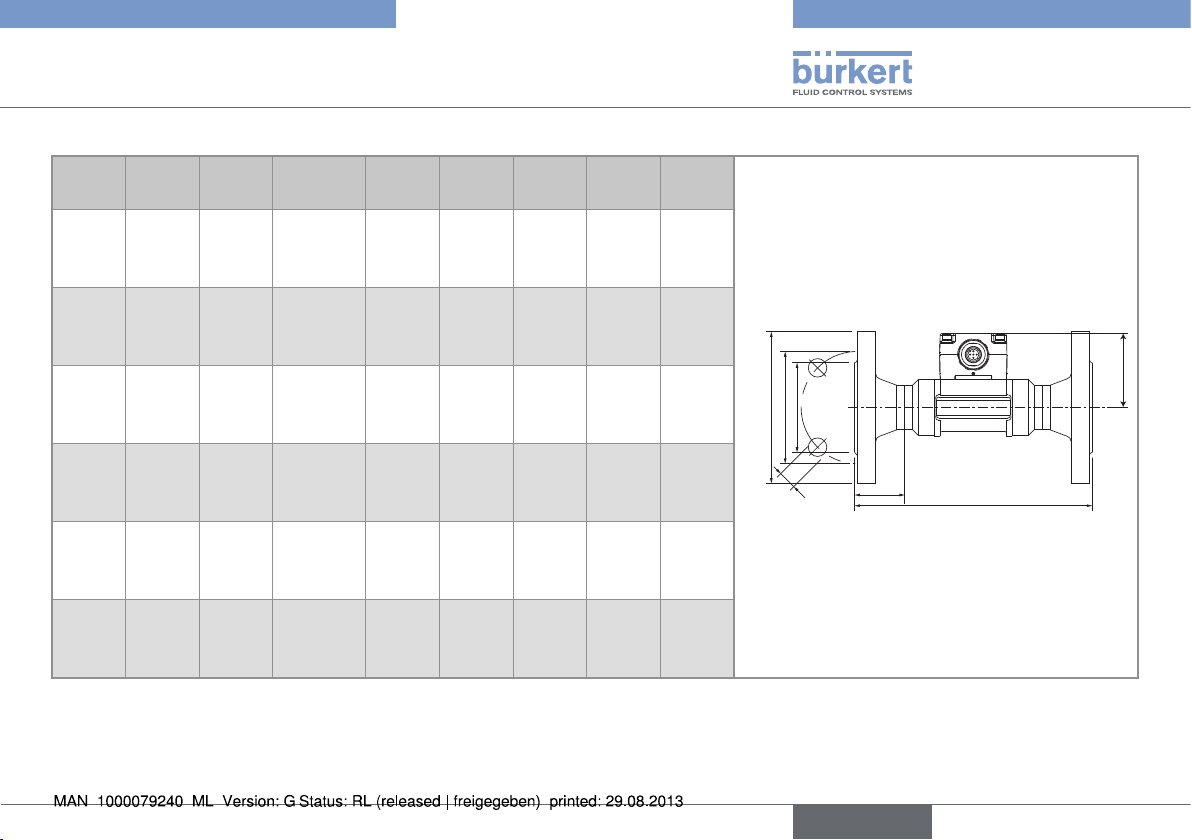

Table 3 : Dimensions of the 8012 with internal thread connections

acc. to G, Rc, NPT, in stainless steel or brass

DN [mm] P [mm] A [mm] D [inch] L [mm]

15 57.5 84.0 G 1/2

NPT 1/2

Rc 1/2

20 55.0 94.0 G 3/4

NPT 3/4

Rc 3/4

25 55.2 104.0 G 1

NPT 1

Rc 1

32 58.8 119.0 G 1 3/4

NPT 1 3/4

Rc 1 3/4

40 62.6 129.0 G 1 1/2

NPT 1 1/2

Rc 1 1/2

16.0

17.0

15.0

17.0

18.3

16.3

23.5

18.0

18.0

23.5

21.0

21.0

23.5

20.0

19.0

50 68.7 148.5 G 2

NPT 2

Rc 2

27.5

24.0

24.0

P

D

L

A

Table 4 : Dimensions of the 8012 with external thread

connections acc. to SMS 1145, in stainless steel

DN [mm] P [mm] A [mm] D [inch]

25 55.0 130 Rd40 x 1/6"

40 58.8 164 Rd60 x 1/6"

50 62.6 173 Rd70 x 1/6"

P

A

English

15

Page 16

Type 8012

Technical data

Table 5 : Dimensions of the 8012 with external thread

connections acc. to G, Rc, NPT, in stainless steel, brass,

PVC or PVDF

DN

[mm]P[mm]A[mm]D[inch] [mm]

6 52.5 90.0 G 1/4 or G 1/2 - 14.0

8 52.5 90.0 G 1/2 or NPT 1/2 or

Rc 1/2

15 57.5 84.0 G 3/4 - 11.5

20 55.0 94.0 G 1 - 13.5

25 55.2 104.0 G 1 1/4 - 14.0

32 58.8 119.0 G 1 1/2 - 18.0

40 62.6 129.0 - M55 x 2 19.0

50 68.7 148.5 - M64 x 2 20.0

M16 x 1.5 14.0

L

[mm]

P

D

L

A

Table 6 : Dimensions of the 8012 with welding end connections

acc. to EN ISO 1127/ISO 4200, SMS 3008, BS 4825/

ASME BPE and DIN 11850 Rg2, in stainless steel

DN

[mm]P[mm]A[mm]

8 -

-

-

52.5

15 57.5

-

-

57.5

20 55.0

-

57.5

57.5

25 55.2

55.0

55.0

55.0

-

-

-

90.0

84.0

-

-

84.0

94.0

-

84.0

84.0

104.0

94.0

94.0

94.0

Standard

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

D

[mm]s[mm]

-

-

-

13.00

21.30

-

-

19.00

26.90

-

19.05

23.00

33.70

25.00

25.40

29.00

-

-

-

1.50

1.60

-

-

1.50

1.60

-

1.65

1.50

2.00

1.20

1.65

1.50

16

English

Page 17

Type 8012

Technical data

32 58.8

-

55.2

55.2

40 62.6

58.8

58.8

58.8

50 68.7

62.6

62.6

62.6

65 -

68.7

68.7

-

119.0

-

104.0

104.0

129.0

119.0

119.0

119.0

148.5

128.0

128.0

128.0

-

147.0

147.0

-

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

EN ISO 1127 / ISO

4200

SMS 3008

ASME BPE

DIN 11850 Rg2

42.40

-

32.00

35.00

48.30

38.00

38.10

41.00

60.30

51.00

50.80

53.00

-

63.50

63.50

-

2.00

-

1.65

1.50

2.00

1.20

1.65

1.50

2.60

1.20

1.65

1.50

-

1.60

1.65

-

s

P

D

A

Table 7 : Dimensions of the 8012 with Clamp connections acc.

to ISO (for pipes acc. to EN ISO 1127 / ISO 4200),

SMS 3017 / ISO 2852 1), BS 4825 / ASME BPE 1) and

1)

Available with an internal surface finish of Ra = 0.8 μm

DN

[mm]P[mm]A[mm]

8 -

DIN 32676, in stainless steel

Standard

-

-

52.5

-

-

-

125

ISO (pipe EN ISO

1127 / ISO 4200)

SMS 3017/ISO 2852

ASME BPE

DIN 32676

D2

[mm]D1[mm]D[mm]

-

-

-

-

-

-

-

-

-

10.00

27.5

34.0

English

17

Page 18

Type 8012

Technical data

15 57.5

-

-

52.5

20 55.0

-

57.5

57.5

25 55.2

55.0

55.0

55.0

32 58.8

-

-

-

130.0

ISO (pipe EN ISO

1127 / ISO 4200)

-

SMS 3017/ISO 2852

-

ASME BPE

119.0

DIN 32676

150.0

ISO (pipe EN ISO

1127 / ISO 4200)

-

SMS 3017/ISO 2852

119.0

ASME BPE

119.0

DIN 32676

160.0

ISO (pipe EN ISO

1127 / ISO 4200)

129.0

SMS 3017/ISO 2852

129.0

ASME BPE

136.0

DIN 32676

180.0

ISO (pipe EN ISO

1127 / ISO 4200)

-

SMS 3017/ISO 2852

-

ASME BPE

-

DIN 32676

18.10

-

-

16.00

23.70

-

15.75

20.00

29.70

22.60

22.10

26.00

38.4

-

-

-

27.5

-

-

27.5

43.5

-

19.6

27.5

43.5

43.5

43.5

43.5

43.5

-

-

-

34.0

-

-

34.0

50.5

-

25.0

34.0

50.5

50.5

50.5

50.5

50.5

-

-

-

40 62.6

58.8

58.8

58.8

50 68.7

62.6

62.6

62.6

65 -

68.7

68.7

-

P

200.0

ISO (pipe EN ISO

1127 / ISO 4200)

161.0

SMS 3017/ISO 2852

161.0

ASME BPE

161.0

DIN 32676

230.0

ISO (pipe EN ISO

1127 / ISO 4200)

192.0

SMS 3017/ISO 2852

192.0

ASME BPE

170.0

DIN 32676

-

ISO (pipe EN ISO

1127 / ISO 4200)

216.0

SMS 3017/ISO 2852

216.0

ASME BPE

-

DIN 32676

44.3

35.6

34.8

38.0

55.1

48.6

47.5

50.0

-

60.3

60.2

-

56.5

43.5

43.5

43.5

70.5

56.5

56.5

56.5

-

70.5

70.5

-

D2

D1

64.0

50.5

50.5

50.5

77.5

64.0

64.0

64.0

-

77.5

77.5

-

D

18

A

English

Page 19

Type 8012

Technical data

Table 8 : Dimensions of the 8012 with flange connections acc. to EN 1092-1 (ISO PN16), ANSI B16-5-1988 and JIS 10K, in stainless steel

DN

L

Standard

[mm]P[mm]A[mm]

15 57.5

57.5

57.5

20 55.0

55.0

55.0

25 55.2

55.2

55.2

32 58.8

58.8

58.8

40 62.6

62.6

62.6

50 68.7

68.7

68.7

130.0

130.0

152.0

150.0

150.0

178.0

160.0

160.0

216.0

180.0

180.0

229.0

200.0

200.0

241.0

230.0

230.0

267.0

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

DIN

ANSI

JIS

[mm]Z[mm]D2[mm]D1[mm]D[mm]

23.5

23.5

23.5

28.5

28.5

28.5

28.5

28.5

28.5

31.0

31.0

31.0

36.0

36.0

36.0

41.0

41.0

41.0

4x14.0

4x15.8

4x15.0

4x14.0

4x15.8

4x15.0

4x14.0

4x15.8

4x19.0

4x18.0

4x15.8

4x19.0

4x18.0

4x15.8

4x19.0

4x18.0

4x19.0

4x19.0

45.0

34.9

51.0

58.0

42.9

56.0

68.0

50.8

67.0

78.0

63.5

76.0

88.0

73.0

81.0

102.0

92.1

96.0

65.0

60.3

70.0

75.0

69.8

75.0

85.0

79.4

90.0

100.0

88.9

100.0

110.0

98.4

105.0

125.0

120.6

120.0

95.0

89.0

95.0

105.0

99.0

100.0

115.0

108.0

125.0

140.0

117.0

135.0

150.0

127.0

140.0

165.0

152.0

155.0

D

D2

D1

Z

L

A

P

English

19

Page 20

Type 8012

H

A

Technical data

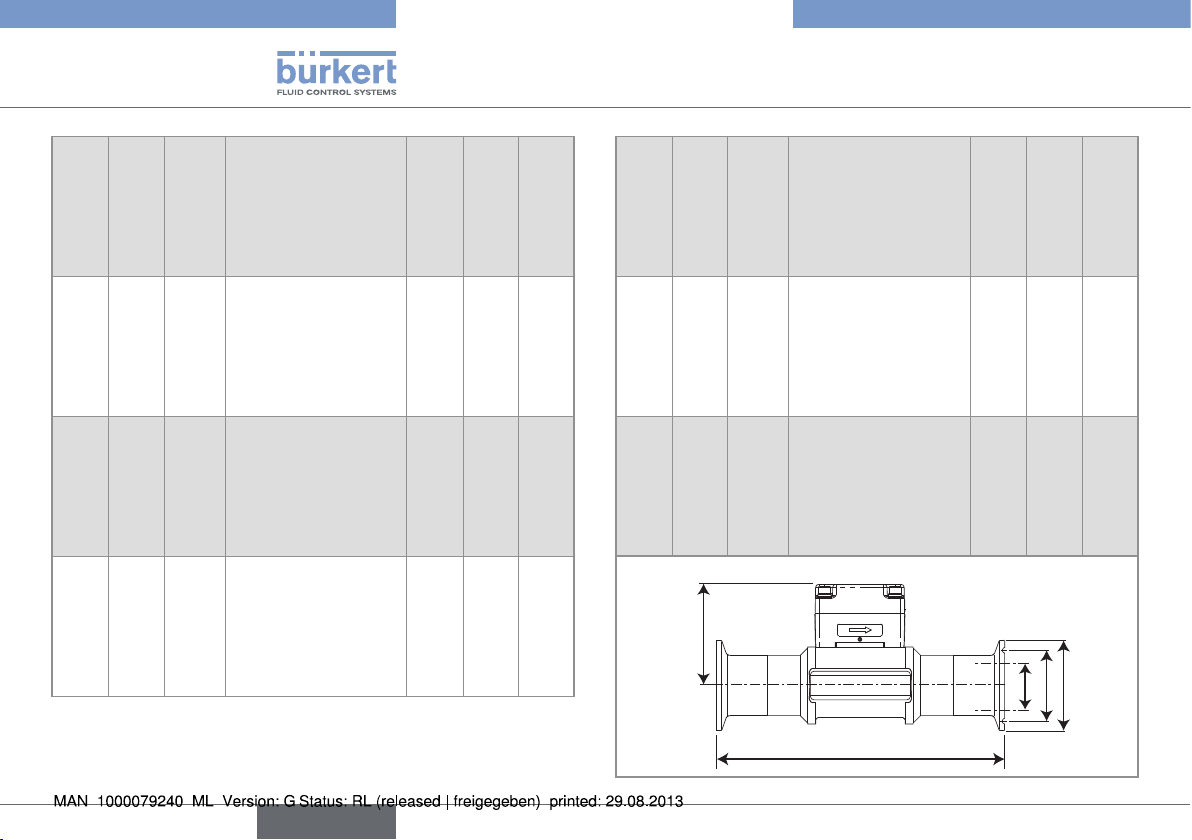

Table 9 : Dimensions of the 8012 with true union connections acc. to DIN 8063, ASTM D 1785/76 and JIS K in PVC, acc. to DIN 16962

in PP or acc. to ISO 10931 in PVDF

DN

[mm]P[mm]D[mm]

8* 29.5 31 122 - - 12 - - 90 92

15 34.5 43 128 130.0 129 20 21.3 18.40 90 96

20 32.0 53 144 145.6 145 25 26.7 26.45 100 106

25 32.2 60 160 161.4 161 32 33.4 32.55 110 116

32 35.8 74 168 170.0 169 40 42.2 38.60 110 116

40 39.6 83 188 190.2 190 50 48.3 48.70 120 127

50 45.7 103 212 213.6 213 63 60.3 60.80 130 136

* Only PVC

Table 10 : Dimensions of the 8012 with spigot connections acc. to DIN 8063 in PVC, acc. to DIN 16962 in PP or acc. to ISO 10931 in

PVDF

DN

[mm]

15 20 17.5 90 85 16.5 14 57.5

20 25 17.5 100 92 20 16 55.0

25 32 21.5 110 95 23 18 55.2

32 40 27.5 110 100 27.5 20 58.8

40 50 31.5 120 106 30 23 62.6

50 63 39.5 130 110 37 27 68.7

D

[mm]

A

DIN/ISO

H

[mm]

ASTM JIS

A [mm]

DIN 8063 DIN 16962

ISO 10931

D1

ASTM JIS

DIN/ISO

L [mm]

DIN 8063 DIN 16962

ISO 10931

A2

[mm]A1[mm]

P

P

D1

A2

A1

A

P

D

L

D

20

English

Page 21

Technical data

6.3.2. General data

Type 8012

Pipe diameter

Connections Material

Internal threads Stainless steel

External threads Stainless steel acc. to SMS

Welding ends Stainless steel

Clamp Stainless steel

True union PVC

Flanges Stainless steel

Spigot PVC

DN6 to DN65, depending on the design:

(the appropriate diameter is determined using the flow/DN/fluid velocity diagrams in chap. 7.3).

Brass

1145

Others

PP

PP

6 8 15 20 25 32 40 50 65

Available DN

- - yes yes yes yes yes yes -

- - - - yes - yes yes -

yes yes yes yes yes yes yes yes -

- yes yes yes yes yes yes yes yes

- yes yes yes yes yes yes yes yes

- yes yes yes yes yes yes yes -

- - yes yes yes yes yes yes -

- - yes yes yes yes yes yes -

- - yes yes yes yes yes yes -

English

21

Page 22

Type 8012

Technical data

Type of fluid

transparent to infrared rays

(optical sensor)

Max. temperature

of the fluid

Fitting in stainless steel, brass, PVDF:

a) 100 °C if the ambient temperature ≤ +45 °C

b) 90 °C if the ambient temperature is

between 45 °C and 60 °C

Fitting in PP: 80 °C

Fitting in PVC: 60 °C

Min. fluid

temperature

Fitting in stainless steel, brass: -15 °C

Fitting in PP or PVC: +5 °C

Fitting in PVDF: -15 °C

Fluid pressure

depends on the fitting material; see the

pressure / temperature diagramme in chap.

7.1

Fluid viscosity 300 cSt max.

Rate of solid

1% max.

particles

Measurement

0.3 m/s to 10 m/s (depending on the fitting)

range

Measurement

accuracy

≤ ± (0.5% of the full scale (10 m/s) + 2.5%

of the measured value), with standard K

factor

Linearity

≤

±0.5 % of the full scale (10 m/s)

Repeatability 0.4% of the measured value

Max. error [%]

10

8

6

4

2

1 9 2 3 4 5 6 7 8 10

-2

-4

-6

-8

-10

Velocity of fluid [m/s]

Typical Bürkert

curve

With standard K

factor (no calibration on site)

Fig. 2 : Measurement accuracy. These values were determined in

the following reference conditions:

medium = water, water and ambient temperatures 20 °C,

min. upstream and downstream distances respected,

appropriate pipe dimensions

Measuring

element

22

magnetic or optical sensor

English

Page 23

Type 8012

Technical data

6.3.3. Electrical data

Power supply 12-36 V DC, filtered and regulated

Current consumption

Protection against

polarity reversal

Protection against

spike voltages

Protection against

short circuits

Pulse output

Current output

(depending on

version)

• max. loop

impedance

max. 60 mA (at 12 V DC for the version

with current output - no load)

yes

yes

yes, for the pulse output

transistor, NPN by default (can be configured as PNP, on request), open collector,

700 mA max., NPN output: 0,2-36 V DC

and PNP output: supply voltage, frequency

up to 300 Hz (frequency = K factor x flow

rate). Configurable on request

4-20 mA, sinking wiring by default, equals

the rotation frequency of the paddle-wheel

(by default). Configurable on request

• 1125 W at 36 V DC

• 650 W at 24 V DC

• 140 W at 12 V DC

6.3.4. Electrical connections

Version Type

With a cable gland Cable, 1 m

With a fixed

connector

5-pin M12 fixed connector, adjustable in

position

6.3.5. K factors

The K factors have all been determined in the following reference

conditions:

medium = water, water and ambient temperatures 20 °C, min. upstream

and downstream distances respected, appropriate pipe dimensions

Two versions of the S012 in DN15 and DN20 exist, having

different K factors.

Only version 2, identified by the "v2" marking, is available

from March 2012. The "v2" marking can be found:

• on the bottom of the DN15 or DN20 fitting in plastic:

V2

• on the side of the DN15 or DN20 fitting in metal:

V2

English

23

Page 24

Type 8012

Technical data

Material Type of connections and standard

Stainless

steel

welding ends

• acc. to SMS 3008

• acc. to BS 4825 / ASME BPE

• acc. to EN ISO 1127 / ISO 4200

• acc. to DIN 11850 Rg2

Stainless

steel

external threads

• acc. to SMS 1145

• G

Stainless

steel

Stainless

steel

internal threads

• G, Rc, NPT

Clamp

• acc.to SMS 3017/ ISO 2852

• acc. to BS 4825 / ASME BPE

• acc. to ISO (for pipes acc. to

EN ISO 1127 / ISO 4200)

• acc. to DIN 32676

Stainless

steel

flanges

• acc. to EN1092-1 (ISO PN16)

• acc. to ANSI B16-5-1998

K factor [pulse/litre]

DN6 DN8 DN15 DN15 v2 DN20 DN20 v2 DN25 DN32 DN40 DN50 DN65

- - - - 97,0 73,4 61,5 47,5

- - - - 97,0 73,4 61,5 47,5

450 288

- 288

- - - - 97,0 73,4 61,5 47,5

450 288

450 288

- - - - 97,0 73,4 61,5 47,5

- - - - 97,0 73,4 61,5 47,5

450 288

- 288

450 288

1)

29.5 18.9 10.5

29.5 18.9 10.5

97,0 73,4 61,5 - 47,5 29,5 18,9 10,5 97,0 73,4 97,0 73,4 61,5 47,5

29.5 18.9 -

29.5 18.9 10.5

97,0 73,4 61,5 - 47,5 29,5 18,9 10,5 -

97,0 73,4 61,5 - 47,5 29,5 18,9 10,5 -

29.5 18.9 10.5

29.5 18.9 10.5

97,0 73,4 61,5 - 47,5 29,5 18,9 10,5 -

97,0 73,4 97,0 73,4 61,5 47,5

29.5 18.9 -

97,0 73,4 61,5 - 47,5 29,5 18,9 10,5 -

• acc. to JIS 10K

Brass all

450 288

97,0 73,4 61,5 - 47,5 29,5 18,9 10,5 -

PVC all 450 288 110 83,5 76,5 - 51,5 28,2 17,5 10,2 PP all - - 115 86,6 77,0 - 52,0 29,2 17,0 10,0 PVDF all 450 288 120 89,6 73,2 - 52,5 29,5 18,0 10,3 -

1)

K factor in pulse/US gallon = K factor in pulse/l x 3,785; K factor in pulse/UK gallon = K factor in pulse/l x 4,546

24

English

Page 25

Type 8012

Installation and wiring

7. INSTALLATION AND WIRING

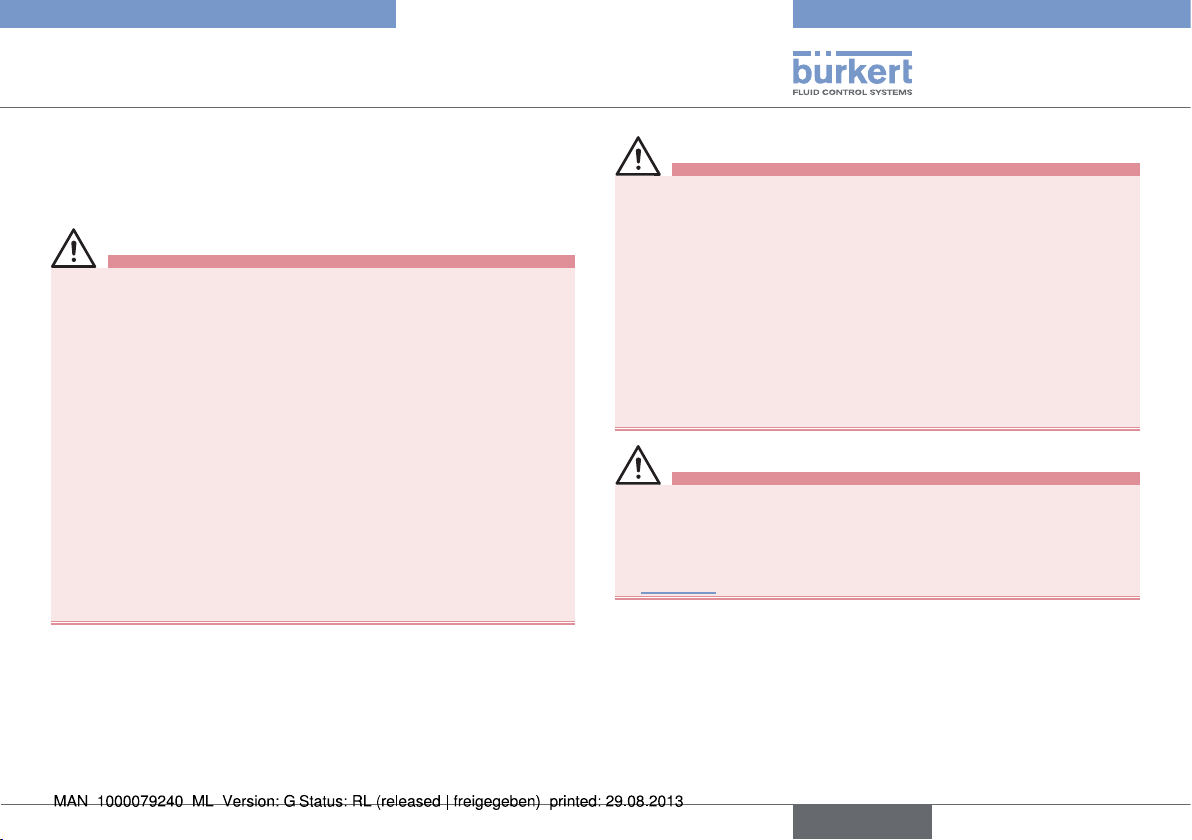

7.1. Safety instructions

danger

Danger due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Danger due to electrical voltage.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Danger due to high temperatures of the fluid.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Danger due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

Warning

Risk of injury due to non-conforming installation.

• The electrical and fluid installation can only be carried out by

qualified and skilled staff with the appropriate tools.

• Install appropriate safety devices (correctly rated fuse and/or

circuit-breaker).

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of

the installation.

• Guarantee a defined or controlled restarting of the process

subsequent to the installation of the device.

Warning

Risk of injury if the fluid pressure/ temperature dependency

is not respected.

• Take the fluid pressure / temperature dependency into account

according to the nature of the material of the fitting used (see

Fig. 3Fig. ).

English

25

Page 26

T ( ° C)

Fluid pressure

When installing an 8012 with optical sensor:

Protect the device from strong light intensity to prevent any

Check that the DN of the fitting is dimensioned to the process

P (bar)

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

A

Metal (PN16)

PVDF

PVC + PP

PVDF (PN10)

PVC + PP

(PN10)

PP (PN10)

-20 0 +20 +40 +60 +80 +100 +120

Type 8012

Installation and wiring

7.2. Installation onto the pipe

danger

Danger due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Danger due to high temperatures of the fluid.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Danger due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

7.2.1. Recommandations for installing the

8012 on the pipe

A : range of use for the complete device

Fig. 3 : Fluid pressure /temperature dependency curves

26

English

Fluid temperature

•

disruption of measurements.

• Ensure that the arrow on the side of the housing is in line

with the flow direction of the fluid.

according to the graphs in chap. 7.3.

Page 27

Type 8012

5 x DN

Installation and wiring

→ Install the device on the pipe in such a way that the upstream

and downstream distances are respected according to the

design of the pipes, as per Fig. 4 and the EN ISO 5167-1

standard.

50 x DN

5 x DN

With regulating valve

40 x DN

Pipe with 2 elbows at 90°

in 3 dimensions

at 90°

5 x DN

5 x DN

20 x DN

Pipe with 1 elbow at 90°

or 1 T-piece

15 x DN

25 x DN

Pipe with 2 elbows

18 x DN

With pipe expansion With pipe reduction

5 x DN

5 x DN

→ If necessary, use a flow conditioner to improve measurement

precision.

→ Install the device in such a way that the paddle-wheel axis is

horizontal (Fig. 5).

→ Prevent the formation of air bubbles in the pipe in the section

around the device (Fig. 6).

→ Ensure that the pipe is always filled in the section around the

device (Fig. 7).

Correct

Fig. 5 : The paddle-wheel axis must be horizontal

Incorrect

Fig. 4 : Upstream and downstream distances depending on the

design of the pipes.

English

27

Page 28

Correct

Fluid circulation

direction

Correct

Fig. 6 : Air bubbles within the pipe

Correct

Correct

Incorrect

Incorrect

Incorrect

Incorrect

Type 8012

Installation and wiring

7.2.2. Installing a device with welding

ends

note

The SE12 electronic module and the seal may be damaged

when welding the connections to the pipe.

• Before welding to the pipe, unscrew the 4 locking screws on

the SE12 electronic module.

• Remove the electronic module.

• Remove the seal.

→ Follow the installation recommendations in chap. 7.2.2.

→ Weld the connections.

→ After welding the connections to the pipe, correctly replace the

seal.

→ Properly replace the electronic module.

→ Tighten the 4 screws in an alternating pattern, applying a torque

of 1.5 Nm.

Fig. 7 : Filling the pipe

28

English

Page 29

Type 8012

Installation and wiring

7.2.3. Installing a device with Clamp

connections

→ Follow the installation recommendations in chap. 7.2.1.

• Check that the seals are in good condition.

• Place the seals, that have been chosen depending on the

process temperature and fluid, into the grooves of the

Clamp connections.

→ Fit the Clamp connections to the pipe using a clamping collar.

7.2.4. Installing a device with flange

connections

→ Follow the installation recommendations in chap. 7.2.1.

• Check that the seals are in good condition.

• Insert a seal, that has been chosen depending on the

process temperature and fluid, into the grooves of the

connections.

Make sure the seal remains in its groove when tightening

the flange.

→ Tighten the flange to mount the device to the pipe.

English

29

Page 30

Type 8012

Installation and wiring

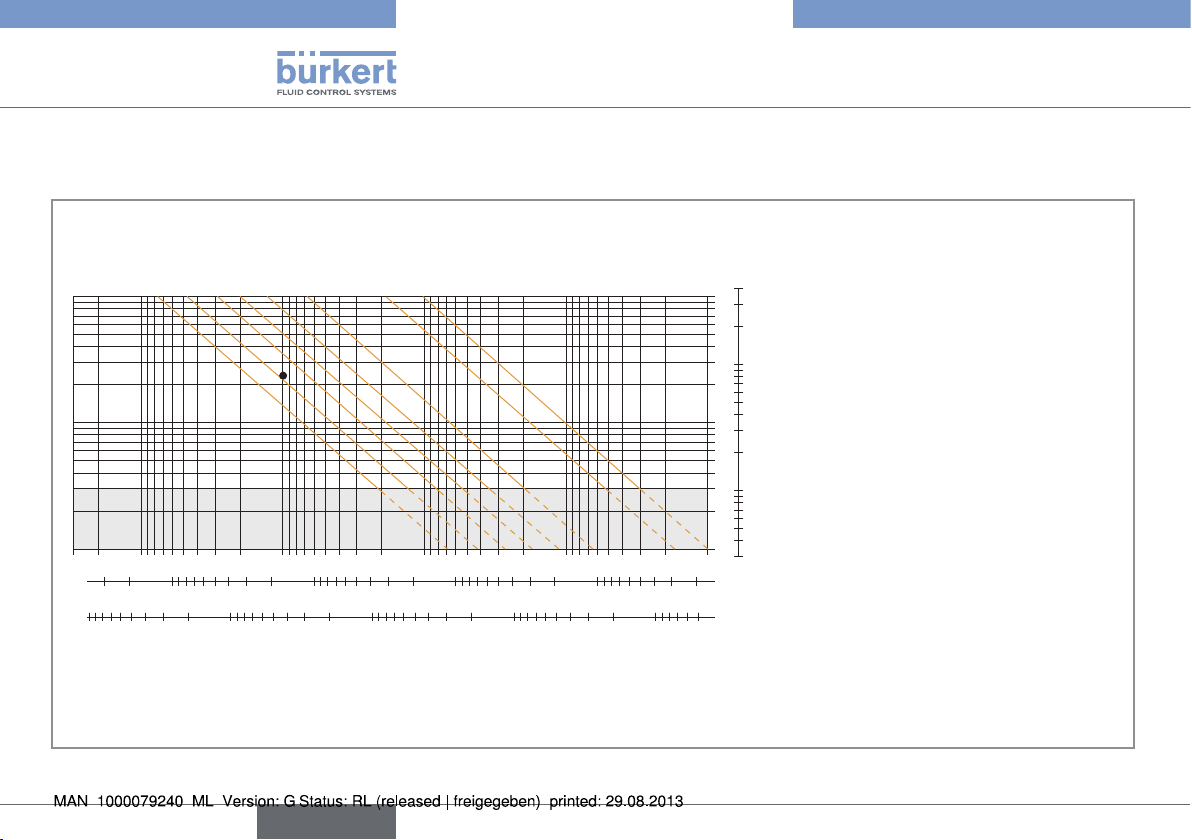

7.3. Graphs

These graphs are used to determine the DN of the pipe and the fitting appropriate to the application, according to the fluid velocity and the flow rate.

fps

/h

3

m

l/min

gpm

1000

200

3000

DN 50 (DN65)*

100

1000

2000

500

DN 40 (DN50)*

DN 32 (DN40)*

DN 25 (DN32)*

20

50

500

100

200

DN 20 (DN25)*

DN 15 (DN15

/ 20)*

5

10

100

200

20

50

Flow rate

50

2

10

DN 08

20

1

5

DN 06

10

0.5

2

0.1

0.2

1

2

5

1

0.5

0.05

0.2

0.02

0.5

0.1

0.01

0.2

0.05

m/s

0.1 0.3 0.5 1 3 5 10

0.3 0.5 1 3 5 10 30

Fluid velocity

/h. If the ideal fluid velocity is 2 to 3 m/s, ,

3

30

English

* For fittings:

• with external thread connections acc. to SMS 1145,

BS 4825 / ASME BPE or DIN 11850 Rg2,série2

• with welding end connections acc. to SMS 3008,

• Clamp connections acc. to SMS 3017/ ISO 2852, BS 4825 /

ASME BPE or DIN 32676

Selection example:

The flow rate in the pipe is 10 m

then use a DN 40 (or DN 50)* pipe according to the graphs.

Page 31

Type 8012

Under normal conditions of use, cable with a cross section

Do not install the cable near high voltage or high frequency

Connect the different earth connections of the installation to

one another in order to remove any differences in potential

Connect the negative power supply terminal to the earth

to eradicate the effects of common mode currents. If this

connection cannot be made directly, a 100 nF/50 V capacitor

can be fitted between the negative power supply terminal

Installation and wiring

7.4. Electrical wiring

danger

Risk of injury due to electrical discharge

• Shut down and isolate the electrical power source before

carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

note

• Use cables with an operating temperature limit suitable for your

application.

Use a high quality electrical power supply (filtered and

regulated).

•

of 0.75 mm2 should be enough to transmit the signal.

•

cables.

• If this is unavoidable, keep a minimum distance of 30 cm.

Make sure the installation is equipotential (power supply

- 8012):

•

which may arise between two earth connections.

• Correctly connect the cable shielding to the earth.

•

and the earth.

Power supply

12-36VDC

+

-

(*)

8012 with cable gland

8012 with M12 fixed

(**)

Power supply

12-36VDC

+

-

(*)

connector

*) If a direct earth connection is not possible, fit a 100 nF/50 V condenser

between the negative power supply terminal and the earth

**) If the cable used is shielded.

English

31

Page 32

Type 8012

Installation and wiring

7.4.1. Assembling the M12 female

connector

1 2

→ Completely unscrew the

nut [1]

→ Remove the rear section of

the connector [2].

→ Wire the device (see chap.

9.2.3)

Fig. 8 : M12 multi-pin connector (not supplied, ordering code

917116)

7.4.2. Wiring a version with adjustable

M12 fixed connector

Not connected

4

(*)

(12-36 VDC)

5

1

V+

0 VDC

3

2

Pulse output

(NPN by default)

Version with pulse output

Fig. 9 : Pin assignment of the M12 male fixed connector

4-20 mA

4

(*)

(12-36 VDC)

5

1

V+

0 VDC

3

2

Pulse output

(NPN by default)

Version with pulse and current

outputs

Pin of the M12 female cable available as

accessory equipment (order code 438680)

Color of the

wire

1 brown

2 white

3 blue

4 black

5

grey

The M12 fixed connector of the device is adjustable in position:

→ Unscrew the locknut.

→ Turn the fixed connector to the desired position, by 360° max. so

as not to twist the cables inside the enclosure.

→ Tighten the locknut using a spanner, while keeping the fixed

connector in the desired position.

12-36 VDC

+-

34

blue

brown

5

1 2

white

grey

Fig. 10 : NPN wiring (default) of the pulse output of a version with

M12 fixed connector

(*) Functional earth; If a direct earth connection is not possible, fit a 100 nF / 50 V

capacitor between the negative power supply terminal and the earth.

Power supply

(*)

Load

32

English

Page 33

Type 8012

Installation and wiring

12-36 VDC

Power supply

+-

(*)

34

blue

5

1 2

whitebrown

grey

Load

Fig. 11 : PNP wiring of the pulse output of a version with M12 fixed

connector

4-20mA

input at

external

device

+-

12-36 VDC

+-

Power supply

(*)

5

1 2

34

blue

grey

brown

black

Fig. 12 : Wiring the current output in sinking mode (by default) on a

version with M12 fixed connector.

4-20mA

input at

external

device

+-

12-36 VDC

+-

Power supply

(*)

34

black

1 2

blue

grey

5

brown

Fig. 13 : Wiring the current output in sourcing mode on a version

with M12 fixed connector

(*) Functional earth; If a direct earth connection is not possible, fit a 100 nF /

50 V capacitor between the negative power supply terminal and the earth.

7.4.3. Wiring a version with cable gland

Color of the

wire

Signal on a

version with

pulse output

Signal on a

version with

pulse and

current outputs

BN (brown)

V+ (12-36 V DC) 0 V DC

V+ (12-36 V DC) 0 V DC

WH

(white)

GN (green) YE (yellow)

Functional

earth

Functional

earth

Not connected

Current in mA

GY

(grey)

NPN or

PNP

NPN or

PNP

English

33

Page 34

Type 8012

Installation and wiring

12-36 VDC

Power supply

+-

brown

white

green

(*)

YE GY BN WH GN

grey

Load

Fig. 14 : NPN wiring (default) of the pulse output of a version with

cable gland

12-36 VDC

Power supply

+-

brown

white

green

(*)

YE GY BN WH GN

grey

Load

Fig. 15 : PNP wiring of the pulse output of a version with cable

gland

4-20mA input

at external

device

+-

12-36 VDC

+-

Power

supply

(*)

yellow

brown

white

green

YE GY BN WH GN

Fig. 16 : Wiring the current output in sinking mode (by default) on a

version with cable gland

(*) Functional earth; If a direct earth connection is not possible, fit a 100 nF /

50 V capacitor between the negative power supply terminal and the earth.

4-20mA input

at external

device

+-

12-36 VDC

+-

Power

supply

(*)

yellow

brown

white

green

YE GY BN WH GN

Fig. 17 : Wiring the current output in sourcing mode on a version

with cable gland

(*) Functional earth; If a direct earth connection is not possible, fit a 100 nF /

50 V capacitor between the negative power supply terminal and the earth.

34

English

Page 35

Type 8012

Commissioning

8. COMMISSIONING

8.1. Safety instructions

Warning

Danger due to nonconforming commissioning.

Non conforming commissioning may lead to injuries and damage

the device and its surroundings.

• Before commissioning, make sure that the staff in charge have

read and fully understood the contents of the manual.

• In particular, observe the safety recommendations and intended

use.

• The device / the installation must only be commissioned by

suitably trained staff.

note

Risk of damage to the device due to the environment

• Protect this device against electromagnetic interference,

ultraviolet rays and, when installed outdoors, the effects of the

climatic conditions.

9. ADJUSTMENT AND FUNCTIONS

9.1. Safety instructions

Warning

Risk of injury due to non-conforming adjustment.

Non-conforming adjustment could lead to injuries and damage the

device and its surroundings.

• The operators in charge of adjustment must have read and

understood the contents of this manual.

• In particular, observe the safety recommendations and intended

use.

• The device/installation must only be adjusted by suitably trained

staff.

9.2. Pulse output

The pulse output of the device can be parametered with one of the

following functions.

9.2.1. Frequency proportional to a volume

This function is used to generate a pulse each time a predetermined

volume of fluid passed.

English

35

Page 36

Type 8012

Adjustment and functions

9.2.2. Switching function

The pulse output of the 8012 can be parametered to switch a solenoid

valve or activate an alarm.

The following parameters can be preset:

• hysteresis or window operating, inverted or not

• the switching thresholds, low and high

• immediate or delayed switching

Hysteresis operating

The output status changes when a threshold is reached:

• by increasing flow rate, the output status changes when the high

threshold is reached.

• by decreasing flow rate, the output status changes when the low

threshold is reached.

The behaviour of the output depends on the output wiring, NPN or

PNP.

Low

Inverted

High

threshold

Contact

ON

OFF

Low

threshold

Not inverted

High

threshold

Contact

ON

OFF

threshold

Not invertedContact

ON

OFF

Low

threshold

Fig. 19 : PNP pulse output, hysteresis operating, non inverted and

inverted

Window operating

The output status changes when either threshold is reached. The

behaviour of the output depends on the output wiring, NPN or PNP.

Contact

High

threshold

Not inverted

ON

OFF

Fig. 20 : NPN pulse output, window operating, non inverted and

threshold

inverted

Low

High

threshold

ON

OFF

threshold

ON

OFF

Low

Low

threshold

InvertedContact

High

threshold

InvertedContact

High

threshold

Fig. 18 : NPN pulse output, hysteresis operating, non inverted and

inverted

36

English

Page 37

Type 8012

Adjustment and functions

Not invertedContact

ON

OFF

Fig. 21 : PNP pulse output, window operating, non inverted and

threshold

inverted

Low

High

threshold

Contact

ON

OFF

threshold

Low

Inverted

High

threshold

9.2.3. Detection of a change in the fluid

direction (only 8012 with optical

sensor)

On an 8012 with optical sensor, the pulse output can be configured

to indicate a change in the fluid circulation direction. Furthermore the

change of direction can be indicated immediately or after a configurable time delay.

The behaviour of the output depends on the output wiring, NPN or

PNP, and on the operating, inverted or not.

F = Fluid direction same as direction of the arrow on the housing

T = Time delay before switching

T F

ON

OFF

Change

of direction

NPN pulse output, non inverted

Fig. 22 : Detection of the change in fluid circulation direction; NPN

pulse output, not inverted and inverted

ON

OFF

of direction

NPN pulse output, inverted

T F

ON

OFF

Change

of direction

PNP pulse output, non inverted

Fig. 23 : Detection of the change in fluid circulation direction; PNP

pulse output, not inverted and inverted

ON

OFF

of direction

PNP pulse output, inverted

T F

Change

T F

Change

English

37

Page 38

Type 8012

Adjustment and functions

Time delay before switching

Switching occurs if one of the thresholds (low, high) is exceeded for a duration higher than the parametered time delay. The time delay is

applied to both switching thresholds. If the time delay equals 0, switching occurs immediately.

Flow rate

High threshold

Low threshold

2 s 2 s

2 s

Flow rate

High threshold

Low threshold

2 s 2 s

2 s

t

Hysteresis operating

Time delay = 0s

Time delay = 2s

Window operating

Time delay = 0s

Time delay = 2s

NPN output

Inverted

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Not inverted

Inverted

Not inverted

Not inverted

Inverted

Not inverted

Inverted

NPN pulse output

Hysteresis operating

Time delay = 0s

Time delay = 2s

Window operating

Time delay = 0s

Time delay = 2s

PNP output

Not inverted

Inverted

Not inverted

Inverted

Not inverted

Inverted

Not inverted

Inverted

PNP pulse output

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Fig. 24 : Examples of behaviour of the 8012 depending on the flow rate in the pipe and the switching operating chosen for the pulse output

38

English

t

Page 39

Type 8012

Adjustment and functions

9.3. Current output

The current output, if one exists, can be parametered with the following

functions:

• an extended output range or the current output range corresponding

to a flow range

• an attenuation of the current variations, different from that of the

basic versions.

9.3.1. Extension of the current range

The current output of the device can be configured to deliver a current

varying from 4 to 21.6 mA, depending on the paddle-wheel rotation

frequency.

mA

22

21,6

20

4

0

Fig. 25 : Curve for the current proportional to the paddle-wheel

rotation frequency

250

275

300

f (Hz)

9.3.2. Conversion of the frequency into a

flow rate

The 8012 can be parametered to convert the paddle-wheel rotation

frequency into a flow rate, in a unit specific to the application.

In this case, the 8012 is parametered with the K factor of the device

and the desired flow rate unit.

The following flow units are available:

l/s, l/min., l/h, m

USGa/min., USGa/h.

The current output then delivers a current of 4 to 20 mA or 4 to 21.6 mA

proportional to a flow rate range:

mA

21,6

20

4

0

Fig. 26 : Curve for the current proportional to the flow rate

10

3

/min., m3/h, Ga/s, Ga/min., Ga/h, USGa/s,

800

880

Flow rate (l/min., for

example)

English

39

Page 40

Type 8012

t (s)

t (s)

Maintenance and troubleshooting

9.3.3. Current attenuation variations

When the flow varies quickly, the current output signal from your device

can be stabilised.

The device can be configured with one of the 10 filter levels available,

varying from no filter to maximum filter.

Signal with minimum filter

t (s)

Signal without filter

Signal with maximum filter

Fig. 27 : Different filter levels for current fluctuations

10. MAINTENANCE AND

TROUBLESHOOTING

10.1. Safety instructions

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

40

English

Page 41

Type 8012

Maintenance and troubleshooting

Warning

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

• Ensure that the restart of the installation is controlled after any

interventions.

10.2. Cleaning

Depending on the nature of the fluid, regularly check for clogging of

the paddle-wheel.

note

The device may be damaged by the cleaning liquid.

• Clean the device with a cloth slightly dampened with water or a

cleaning liquid compatible with the materials the device is made

of.

10.3. Replacing the seal

O-ring for plastic fitting

Fig. 28 : Exploded view of the 8012

O-ring for metal fitting

→ Unscrew the 4 screws in the electronic module and remove it

from the fitting.

→ Remove the used seal.

→ Clean the surfaces on which the seal is placed.

→ Insert the new seal (see Fig. 28).

→ Position the electronic module on the fitting so that the arrow

points in the fluid direction on versions with optical sensor.

→ Insert the 4 screws into the electronic module (use the long

screws for a plastic S012, DN6 or DN8 fitting).

→ Tighten the 4 screws in an alternating pattern, to a torque of

1.5 Nm.

English

41

Page 42

Type 8012

Maintenance and troubleshooting

10.4. If you encounter problems

danger

Risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to electrical voltage.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Risk of injury due to high fluid temperatures.

• Use safety gloves to handle the device.

• Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

10.4.1. Problems signalled by the LEDs

Status

red LED

Flashes

3 times

every

second

On Off 22 mA Memory

Off Flashes

Status

green

LED

Off 22 mA Full scale

twice

every

second

Status

current

output

22 mA The device

Possible

cause

exceeded (flow

rate in the pipe

is too high)

problem

with optical

detection is

mounted in the

wrong direction

Recommended

action

Check the process

parameters

Switch the power

supply off then on.

If the error persists, contact your

Bürkert retailer.

Mount the device,

ensuring that the

arrow on the side

of the housing indicates the direction

of the fluid.

42

English

Page 43

Type 8012

Maintenance and troubleshooting

10.4.2. Problems not signalled by the LEDs

Problem Recommended action see chap.

The device does not

function

The pulse output

does not work

The current output

does not work

The flow rate measurement is incorrect

• Check the wiring

• Check that the device is

energized

Check whether the wiring is

suitable for the output type,

NPN or PNP

Check whether the wiring is

suitable for the output type,

source or sink

Recalculate and change the

setting of the K factor

7.4

7.4

7.4

6.3.5

11. SPARE PARTS AND ACCESSORIES

attention

Risk of injury and/or damage caused by the use of unsuitable

parts.

Incorrect accessories and unsuitable spare parts may cause

injuries and damage the device and the surrounding area.

• Use only original accessories and original spare parts from

Bürkert.

Spare part Order code

Seal for metal fitting (Fig. 29)

FKM (DN6 to DN65) 426340

EPDM (DN6 to DN65) 426341

Set of 2 O-rings for the end pieces (true

union connections only) + 1 flat seal and

1 O-ring for the SE12 electronic module

connection (Fig. 30)

FKM - DN8 448679

FKM - DN15 431555

FKM - DN20 431556

FKM - DN25 431557

FKM - DN32 431558

FKM - DN40 431559

FKM - DN50 431560

English

43

Page 44

Spare part Order code

EPDM - DN8 448680

EPDM - DN15 431561

EPDM - DN20 431562

EPDM - DN25 431563

EPDM - DN32 431564

EPDM - DN40 431565

EPDM - DN50 431566

Set of screws: 4 short screws (M4x35 - A4) + 4

long screws (M4x60 - A4)

Accessory Order code

5-pin M12 female connector, moulded on

shielded cable (2 m)

5-pin M12 female connector, to be wired 917116

Set including:

• 1 CD with TACT (TrAnsmitter Configuration

Tool) configuration software

• 1 TACT interface board

• 2 connection cables

Set of connection cables for the TACT interface 556160

555775

438680

556500

Type 8012

Maintenance and troubleshooting

Fig. 29 : Seal for metal fitting

Fig. 30 : Seals for plastic fitting

44

English

Page 45

Type 8012

Packaging, transport, storage

12. PACKAGING, TRANSPORT,

STORAGE

attention

Damage due to transport

Transport may damage an insufficiently protected part.

• Transport the device in shock-resistant packaging and away

from humidity and dirt.

• Do not expose the device to temperatures that may exceed the

admissible storage temperature range.

• Protect the electrical interfaces using protective plugs.

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Storage temperature -15 to +60°C.

Damage to the environment caused by products contaminated by fluids.

• Dispose of the device and its packaging in an environmentallyfriendly way.

• Keep to the existing provisions on the subject of waste disposal

and environmental protection.

English

45

Page 46

Type 8012

46

English

Page 47

Typ 8012

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ...............................................................5

1.1. Darstellungsmittel ..............................................................................5

1.2. Begriffsdefinition "Gerät" ................................................................5

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ......................................6

2.1. Beschränkungen .................................................................................6

3. GRUNDLEGENDE SICHERHEITSHINWEISE ....................................6

4. ALLGEMEINE HINWEISE .............................................................................8

4.1. Herstelleradresse und internationale Kontaktadressen 8

4.2. Gewährleistung ....................................................................................8

4.3. Informationen im Internet ...............................................................8

5. BESCHREIBUNG .............................................................................................8

5.1. Vorgesehener Einsatzbereich ......................................................8

5.2. Allgemeine Beschreibung ..............................................................8

5.2.1. Aufbau ...................................................................................... 8

5.2.2. Version mit Pulsausgang ..................................................... 9

5.2.3. Version mit Pulsausgang und Stromausgang ...............10

5.3. Beschreibung des Typenschilds des 8012 ........................ 11

5.4. Beschreibung des Typenschilds des SE12 ...........................11

5.5. Bestellnummern der Basisversionen des Moduls

SE12 ........................................................................................................ 12

6. TECHNISCHE DATEN ................................................................................ 14

6.1. Betriebsbedingungen .................................................................... 14

6.2. Einhaltung von Normen und Richtlinien ..............................14

6.3. Allgemeine Technische Daten ..................................................14

6.3.1. Mechanische Daten ............................................................14

6.3.2. Allgemeine Daten ................................................................21

6.3.3. Elektrische Daten ................................................................23

6.3.4. Elektrische Anschlüsse ......................................................23

6.3.5. K-Faktoren .............................................................................23

7. INSTALLATION UND VERKABELUNG ...............................................25

7.1. Sicherheitshinweise ....................................................................... 25

7.2. Fluidischer Anschluss ................................................................... 26

7.2.1. Empfehlungen für die Montage des 8012 in die

Rohrleitung............................................................................26

7.2.2. Installation eines Gerätes mit Schweißstutzen-

Anschlüssen .........................................................................28

7.2.3. Installation eines Gerätes mit Clamp-Anschlüssen.....29

7.2.4. Installation eines Gerätes mit Flansch-Anschlüssen ..29

7.3. Geeignete Nennweiten-Auswahl .............................................30

7.4. Verkabelung ........................................................................................ 31

7.4.1. Bauen Sie die M12-Buchse zusammen ........................32

deutsch

3

Page 48

Typ 8012

7.4.2. Verkabelung einer Version mit ausrichtbarem

M12-Gerätestecker ............................................................32

7.4.3. Verkabelung der Version mit Kabelverschraubung ......33

8. INBETRIEBNAHME ...................................................................................... 35

8.1. Sicherheitshinweise ....................................................................... 35

9. BEDIENUNG UND FUNKTION .............................................................. 35

9.1. Sicherheitshinweise ....................................................................... 35

9.2. Pulsausgang .......................................................................................35

9.2.1. Zu einem Volumen proportionale Frequenz ..................35

9.2.2. Schaltfunktion ......................................................................36

9.2.3. Erkennung der Fließrichtungsumkehr (nur 8012

mit optischem Sensor) .......................................................37

9.3. Stromausgang ................................................................................... 39

9.3.1. Erweiterung des Strombereichs ......................................39

9.3.2. Umwandlung der Frequenz in einen Durchfluss ..........39

9.3.3. Dämpfung der Stromschwankungen ..............................40

10. WARTUNG, FEHLERBEHEBUNG....................................................... 40

10.1. Sicherheitshinweise ....................................................................... 40

10.2. Wartung und Reinigung ................................................................ 41

10.3. Wechseln der Dichtung .................................................................41

10.4. Problemlösung .................................................................................. 42

10.4.1. Durch die LEDs angezeigte Probleme ...........................42

10.4.2. Nicht durch die LEDs angezeigte Probleme .................43

11. ERSATZTEILE UND ZUBEHÖR...........................................................43

12. VERPACKUNG, TRANSPORT, LAGERUNG ..................................45

4

deutsch

Page 49

Typ 8012

Warnt vor Sachschäden!

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

Diese Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

Gefahr!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die

Folge.

WarnunG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen oder Tod.

VOrSIChT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

hInWeIS!