Page 1

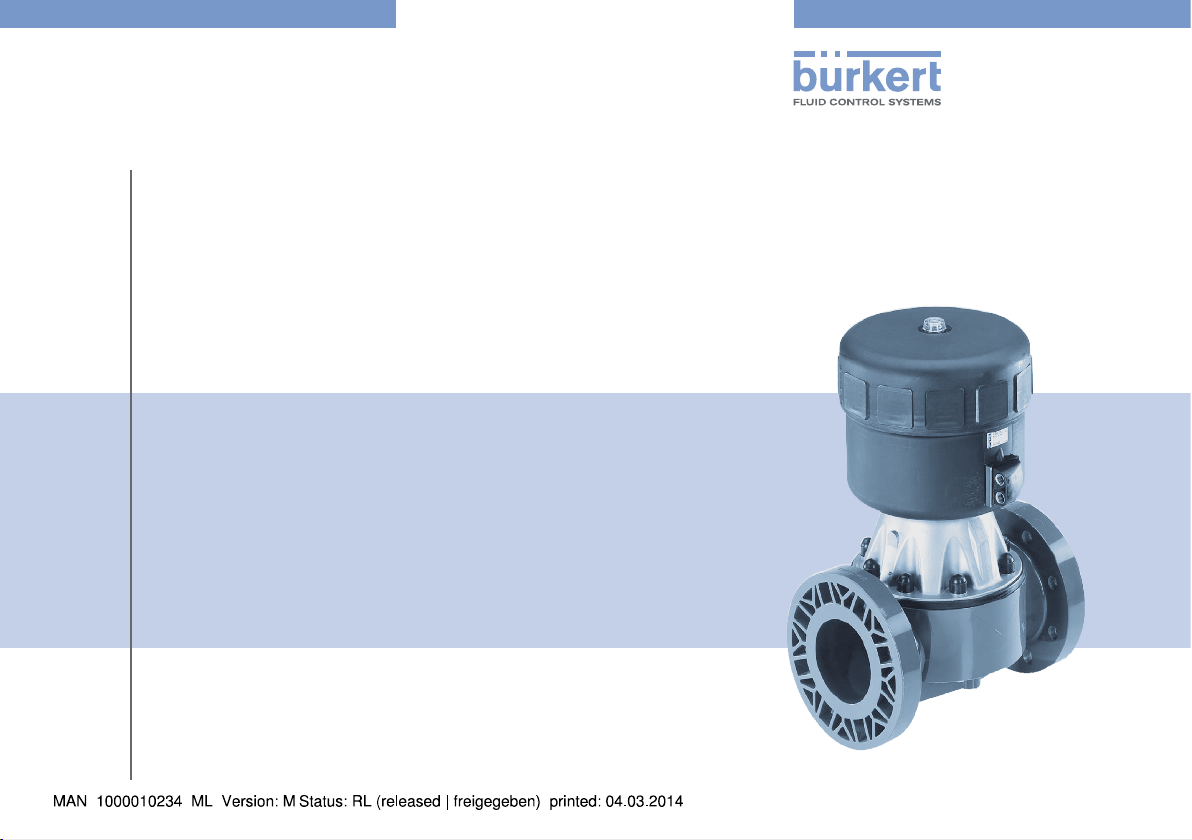

Type 2030, 2031, 2031 K, 2032, 2033, 2037

Piston operated diaphragm valve,

Actuator sizes 175 and 225 mm, Diameter DN65 - DN100

Kolbengesteuerte Membranventile,

Antriebsgrößen 175 und 225 mm, Nennweiten DN65 - DN100

Vannes à membrane commandée par piston, Tailles

de mécanisme 175 et 225 mm, Piston section nominale DN65 - DN100

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modification techniques.

© 2000 - 2014 Bürkert Werke GmbH

Operating Instructions 1403/11_EU-ML_00803968 / Original DE

Page 3

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Piston operated diaphragm valves type 2030, 2031, 2031 K, 2032, 2033, 2037

1 OPERATING INSTRUCTIONS ................................................................4

1.1 Definition of the Term “Device”............................................... 4

1.2 Symbols .......................................................................................4

2 AUTHORIZED USE ......................................................................................5

2.1 Restrictions .................................................................................5

3 BASIC SAFETY INSTRUCTIONS ..........................................................6

4 GENERAL INFORMATION ........................................................................7

4.1 Contact Addresses ................................................................... 7

4.2 Warranty ......................................................................................7

4.3 Information on the Internet ......................................................7

5 SYSTEM DESCRIPTION ............................................................................7

5.1 General Description .................................................................. 7

5.2 Intended Application Area ....................................................... 7

5.3 Conformity ................................................................................... 7

5.4 Standards .................................................................................... 7

6 TECHNICAL DATA ........................................................................................8

6.1 Inscription on the type label ....................................................8

6.2 Labeling of the forged bodies ................................................8

6.3 Operating Conditions ............................................................... 8

6.4 General Technical Data..........................................................12

7 STRUCTURE AND FUNCTION............................................................12

7.1 Structure ....................................................................................12

7.2 Function .....................................................................................14

8 INSTALLATION ............................................................................................ 15

8.1 Safety instructions ...................................................................15

8.2 Before installation ....................................................................15

8.3 Installation .................................................................................18

8.4 Disassembly..............................................................................20

9 ELECTRICAL CONNECTION ................................................................21

10 MAINTENANCE, CLEANING ................................................................21

10.1 Safety instructions ...................................................................21

10.2 Maintenance Work ..................................................................21

11 REPAIRS.........................................................................................................22

11.1 Safety instructions ...................................................................22

11.2 Replacing the diaphragm ......................................................23

12 MALFUNCTIONS ........................................................................................25

13 SPARE PARTS.............................................................................................26

13.1 Order table ................................................................................27

14 PACKAGING AND TRANSPORT ........................................................27

15 STORAGE ......................................................................................................28

16 DISPOSAL ..................................................................................................... 28

english

3

Page 4

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Operating Instructions

1 OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

WARNING!

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

▶ The operating instructions must be read and understood.

1.1 Definition of the Term “Device”

In these instructions, the term “device” always refers to the

diaphragm valves of Types 2030, 2031, 2031 K, 2032, 2033, 2037.

1.2 Symbols

DANGER!

Warns of an immediate danger!

▶ Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

▶ Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

▶ Failure to observe this warning may result in a medium or minor

injury.

NOTE!

Warns of damage to property!

▶ Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Page 5

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Authorized Use

2 AUTHORIZED USE

Non-authorized use of the devices may be dangerous to

people, nearby equipment and the environment.

▶ The diaphragm valves of Types 2030, 2031, 2031 K, 2032, 2033

and 2037 are designed for the control of contaminated, ultra-pure

or sterile media, as well as for abrasive or aggressive media (also

with higher viscosity).

▶ The devices may be used only for media which do not attack

the body and seal materials (see type label). Information on the

resistance of materials to the media is available from your Bürkert

sales office or on the Internet at: www.burkert.com.

▶ During use observe the authorized data, the operating condi-

tions and conditions of use specified in the contract documents

and operating instructions. These are described in the chapter

“5 System Description” and “6 Technical Data”.

▶ The device may be used only in conjunction with third-party

devices and components recommended and authorized by

Bürkert.

▶ Correct transportation, correct storage and installation and

careful use and maintenance are essential for reliable and faultless operation.

▶ Use the device only as intended.

2.1 Restrictions

If exporting the system/device, observe any existing restrictions.

2.1.1 Explosion Protection Approval

The explosion protection approval is only valid if you use the

modules and components authorized by Bürkert, as described in

these operating instructions.

If you make unauthorized changes to the system, the modules or

components, the explosion protection approval will also be terminated.

english

5

Page 6

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Basic Safety Instructions

3 BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

DANGER!

Danger – high pressure!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of electric shock!

▶ Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Danger of bursting from overpressure!

▶ Observe the specifications on the type label for max. control

and medium pressure.

▶ Observe permitted medium temperature.

CAUTION!

Risk of burns/risk of fire if used continuously through hot

device surface!

▶ Keep the device away from highly flammable substances and media

and do not touch with bare hands.

General hazardous situations.

To prevent injury, ensure that:

▶ The system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device may be operated only when in perfect condition and

in consideration of the operating instructions.

▶ The general rules of technology apply to application planning

and operation of the device.

▶ Do not put any loads on the body (e.g. by placing objects on it or

standing on it).

▶ Do not make any external modifications to the device bodies. Do

not paint the body parts or screws.

The diaphragm valves Types 2030, 2031, 2031 K, 2032, 2033

and 2037 were developed with due consideration given to the

accepted safety rules and are state-of-the-art. Nevertheless,

dangerous situations may occur.

6

english

Page 7

Type 2030, 2031, 2031 K, 2032,

2033, 2037

General Information

4 GENERAL INFORMATION

4.1 Contact Addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2 Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3 Information on the Internet

The operating instructions and data sheets for Types 2030, 2031,

2031 K, 2032, 2033 and 2037 can be found on the Internet at:

www.buerkert.com

5 SYSTEM DESCRIPTION

5.1 General Description

The Types 2030, 2031, 2031 K, 2032, 2033 and 2037 are an externally

controlled diaphragm valve with piston drive and diaphragm seal. The

valve is self-draining in the appropriate installation position.

5.2 Intended Application Area

The diaphragm valve of Type 2030 is designed for the control of

contaminated and aggressive media. The valves of Type 2031, 2031

K, 2032, 2033 and 2037 can be used even for ultra-pure or sterile

media with a higher viscosity. The valves may only control media

which do not attack the body and seal materials (see type label).

Information on the resistance of materials to the media is available

from your Bürkert sales office.

5.3 Conformity

Type 2030, 2031, 2031 K, 2032, 2033 and 2037 conforms with the

EC Directives according to the EC Declaration of Conformity.

5.4 Standards

The applied standards, which verify conformity with the EC Directives, can be found on the EC-Type Examination Certificate and / or

the EC Declaration of Conformity.

english

7

Page 8

00147838

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Technical Data

6 TECHNICAL DATA

WARNING!

Risk of injury from high pressure!

Important device-specific technical specifications are indicated on

the type label.

▶ Observe permitted pressure range on the type label of the

device.

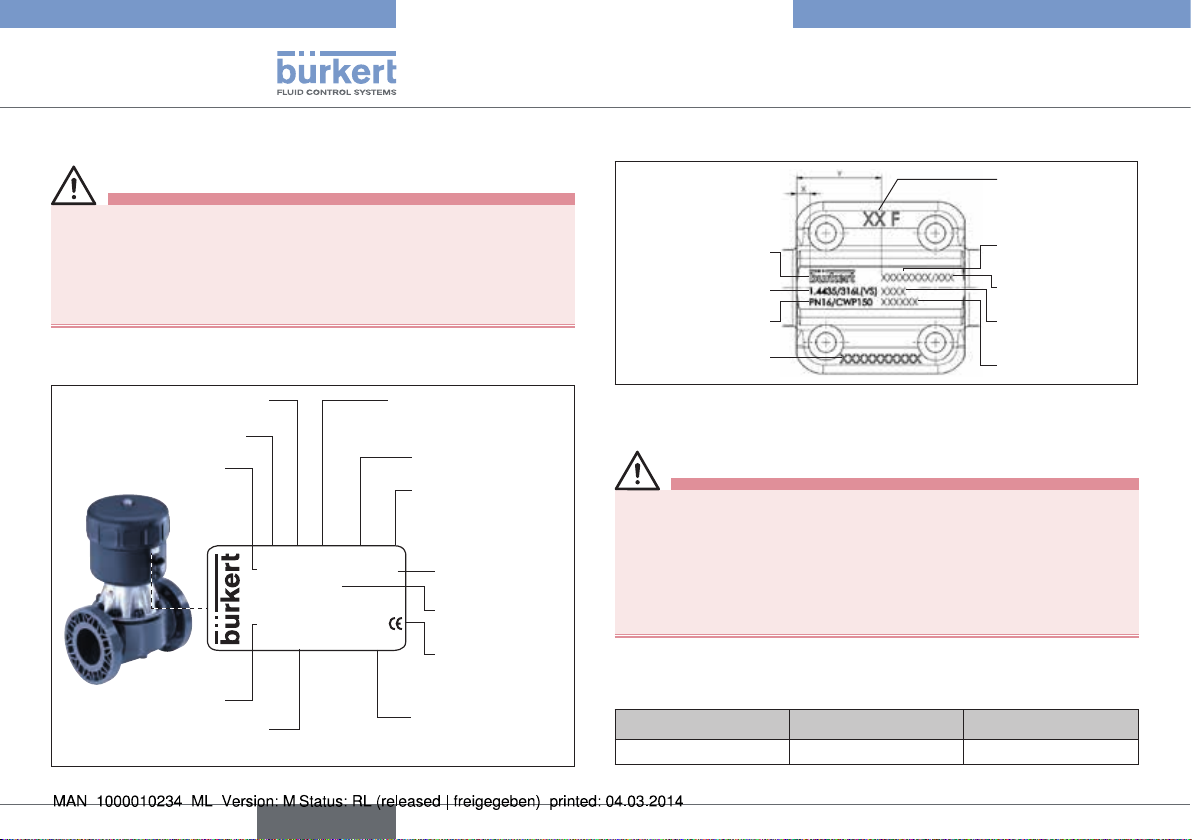

6.1 Inscription on the type label

Control function Orifice

Type

Port connection

2030 A 65,0 EPDM PV

FLNSCH Pmed

Pilot 4,5-6bar

S/N 1060

Made in Germany

Serial number

Identification number of

the device

Fig. 1: Inscription on the type label (Example)

(Diaphragm size)

Seal material

Body material

10bar

W36LP

Date of

manufacture

Max. medium

pressure

Control pressure

Approval rating

6.2 Labeling of the forged bodies

Batch number/

manufacturer sign

Production number/

Company logo

Material

Pressure stage

Connection orifice

and pipe dimensions

order number

(F-part)

Serial number

Surface quality

code

Customer-specific

text (optional)

Fig. 2: Labeling of the forged bodies

6.3 Operating Conditions

WARNING!

Danger of bursting from overpressure!

If the device ruptures, the medium may cause injuries, chemical

burns or scalds!

▶ Do not exceed the maximum control and medium pressure.

Observe specifications on the type label!

▶ Observe permitted ambient and media temperature.

6.3.1 Allowable Temperatures

Ambient temperature for actuators:

Material

PA 175 mm / 225 mm -10 ... +50 °C

Tab. 1: Ambient temperature for actuators

Size ø Temperature

8

english

Page 9

DN 65 - 100

10

20 40 60

80

100 120

140

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Technical Data

Medium temperature for body:

Body material

Temperature

Stainless steel -10 ... +140 °C

PVC (see PT-graph) -10 ... +60 °C

PVDF (see PT-graph) -10 ... +120 °C

PP (see PT-graph) -10 ... +80 °C

Tab. 2: Medium temperature for body

Medium temperature for diaphragms:

Material

Temperature Remarks

EPDM / PTFE -10 ... +130 °C Steam sterilization up to +150 °C

FKM -5 ... +130 °C

Dry up to +150 °C

Otherwise only briefly up to +150 °C

Tab. 3: Medium temperature for diaphragms

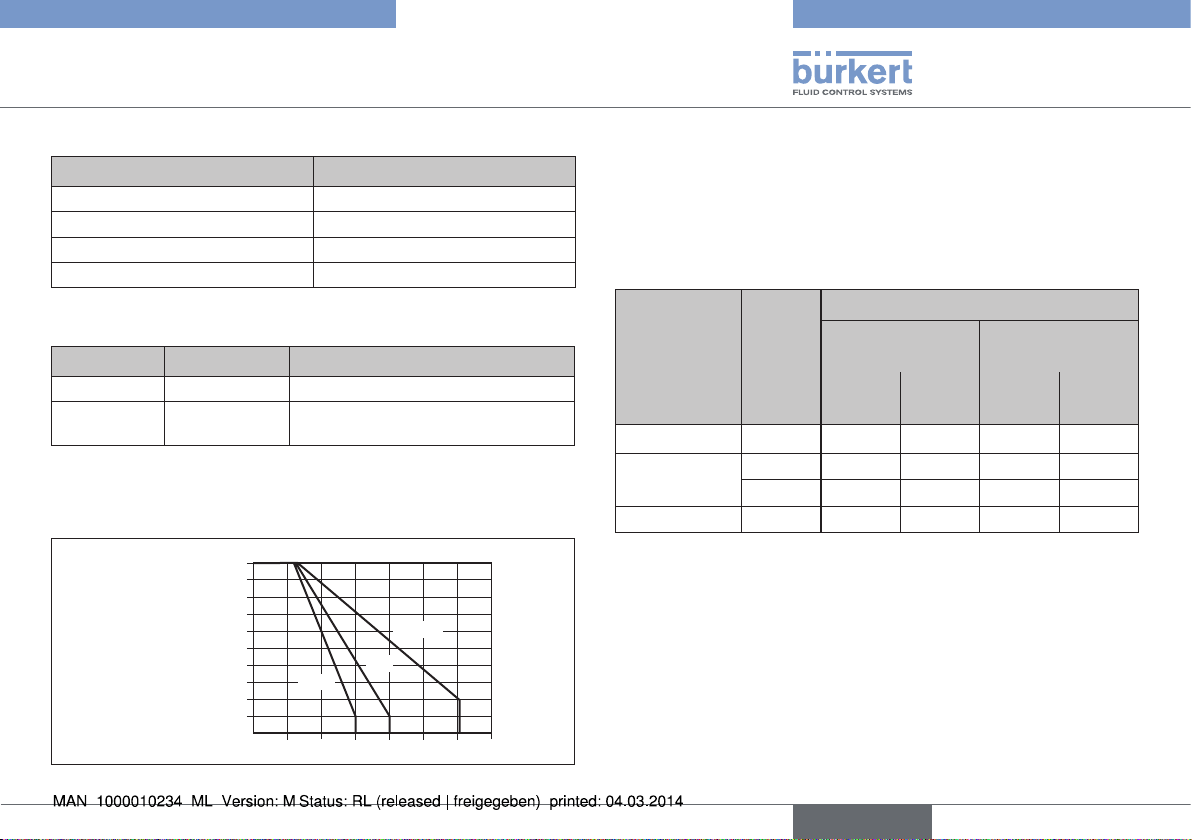

6.3.2 Maximum permitted medium pressure

Permitted medium pressure depending on the medium temperature.

8

6

4

PVC

2

Medium pressure [bar]

Temperature [°C]:

Fig. 3: Graph of medium pressure / Medium temperature

PVDF

PP

Maximum permitted medium pressure for control function A

The values apply to body made of:

• Plastic,

• VA forged steel and VA precision casting, VA block material as well

as VA tube-formed body with socket, DIN welding neck flange and

welded connection in accordance with EN ISO 1127 (ISO 4200).

Orifice

(Diaphragm

size)

DN [mm]

Actuator

size ø

[mm]

Max. sealed medium pressure [bar]

Pressure on one

side

EPDM/

PTFE EPDM/

FKM

Pressure on both

sides

PTFE

FKM

65 175 8.0 5.0 5.0 4.5

80

175 5.0 4.5 2.5 2.0

225 10.0 10.0 6.0 4.5

100 225 8.0 4.0 3.5 1.5

Tab. 4: Maximum permitted medium pressure CFA

english

9

Page 10

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Technical Data

6.3.3 Control Pressure

WARNING!

Danger of bursting from overpressure!

If the device explodes, there is a risk of serious injury, chemical

burns, scalding!

▶ Do not exceed the maximum control and medium pressure.

Observe specifications on the type label!

NOTE!

Malfunction due to incorrect control pressure!

The specifications on the type label apply to valves with reduced

spring force (i.e. with lower control pressure). If you are unsure,

please contact your Bürkert sales office.

Permitted control pressure*

Orifice

(Diaphragm size)

DN [mm]

65 175 2 6

80 175 2 6

80 225 2 6

100 225 2 6

Tab. 5: Permitted control pressure

Actuator

size

ø mm

Min. control

pressure

[bar]

Max. control

pressure

[bar]

Control pressure for control function A

Orifice

(Diaphragm

size)

DN [mm]

65 175 6 4.5

80 175 6 5.0

80 225 6 5.0

100 225 6 5.0

Tab. 6: Control pressure CFA

Actuator size

[mm]

Control pressure [bar]

for medium pressure

0 bar maximum

6.3.4 Minimum Control Pressure

Required minimum control pressure depending on medium

pressure

The values apply to body made of:

• Plastic

• All models with VA forged steel, VA precision casting and VA

block material

• VA tube-formed body with socket, DIN welding neck flange and

weld-on ends in accordance with EN ISO 1127 (ISO 4200)

10

* Observe the permitted pressure range according to the

type label!

english

Page 11

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Technical Data

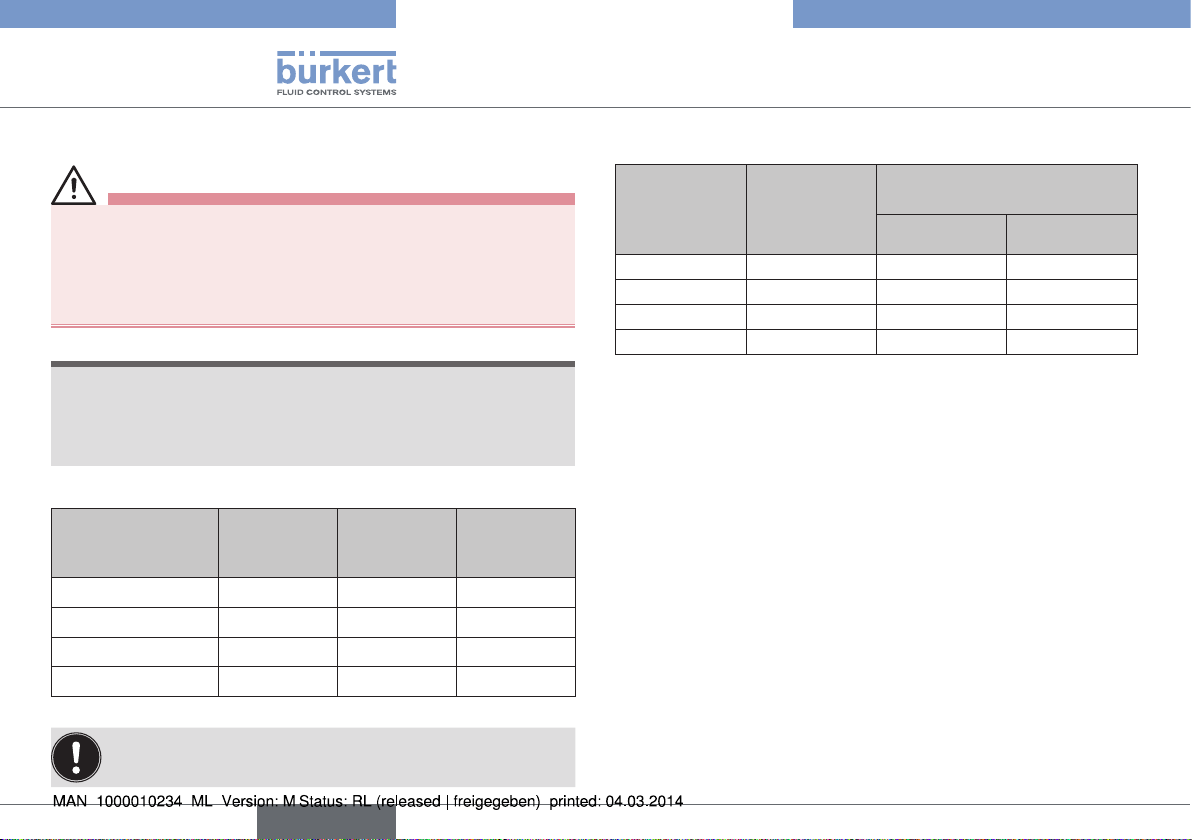

Control function B (CFB)

NOTE!

Important for the service life of the diaphragm!

• Do not select control pressure higher than required.

Elastomer diaphragm

10

9

8

7

6

5

4

3

2

1

0

Medium pressure [bar]

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

Diaphragm size / Actuator diameter

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Control pressure [bar]

Fig. 4: Control function B - Elastomer diaphragm

PTFE - Diaphragm

10

9

8

7

6

5

4

3

2

1

0

Medium pressure [bar]

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0

Diaphragm size / Actuator diameter

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Control pressure [bar]

Fig. 5: Control function B - PTFE diaphragm

Control function I

Elastomer diaphragm

Diaphragm size / Actuator diameter

10

9

8

7

6

5

4

3

2

1

0

Medium pressure [bar]

0 1.0 2.0 3.0 4.0 5.0 6.0

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Control pressure [bar]

Fig. 6: Control function I - Elastomer diaphragm

PTFE - Diaphragm

Diaphragm size / Actuator diameter

10

9

8

7

6

5

4

3

2

1

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

Medium pressure [bar]

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Control pressure [bar]

Fig. 7: Control function I - PTFE Diaphragm

english

11

Page 12

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Structure and Function

6.4 General Technical Data

Materials

Body

Type 2030 PP, PVC, PVDF

Type 2031 Stainless steel precision casting (VG),

Forged steel (VS)

Type 2031 K Stainless steel tubular body (VA)

Type 2032, 2033, 2037 Stainless steel - block material

Actuator PA

Sealing elements actuator NBR

Diaphragm EPDM, PTFE, FKM

Connections

Control air connection G1/4

Medium connection Welded connection: in accordance with

DIN EN 1127 (ISO 4200), DIN 11850 R2

other connections on request

Media

Control medium neutral gases, air

Flow media Type 2030:

contaminated and aggressive media

Type 2031, 2032, 2033 and 2037:

contaminated, aggressive, ultra-pure, sterile

media and media with higher viscosity

Installation position any position, preferably with the actuator

face up,

Tank bottom valve Type 2033: Actuator to

the bottom

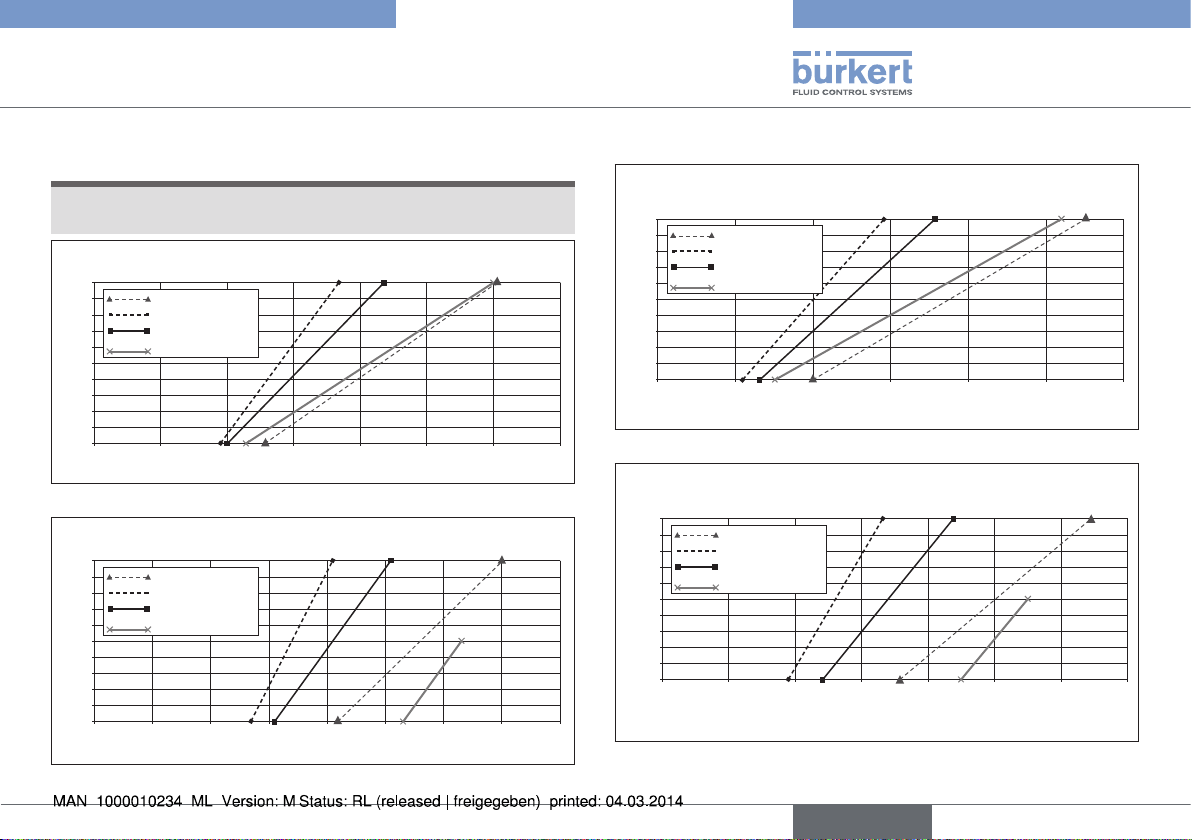

7 STRUCTURE AND FUNCTION

7.1 Structure

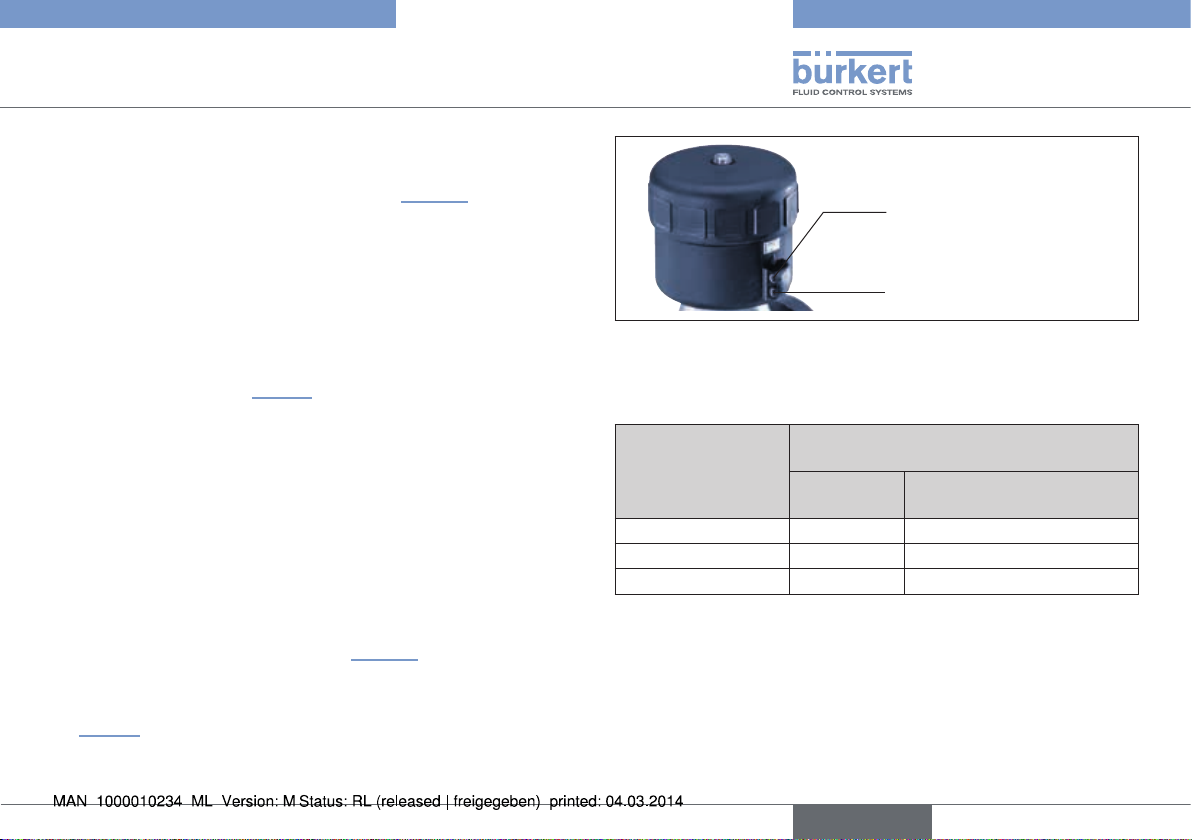

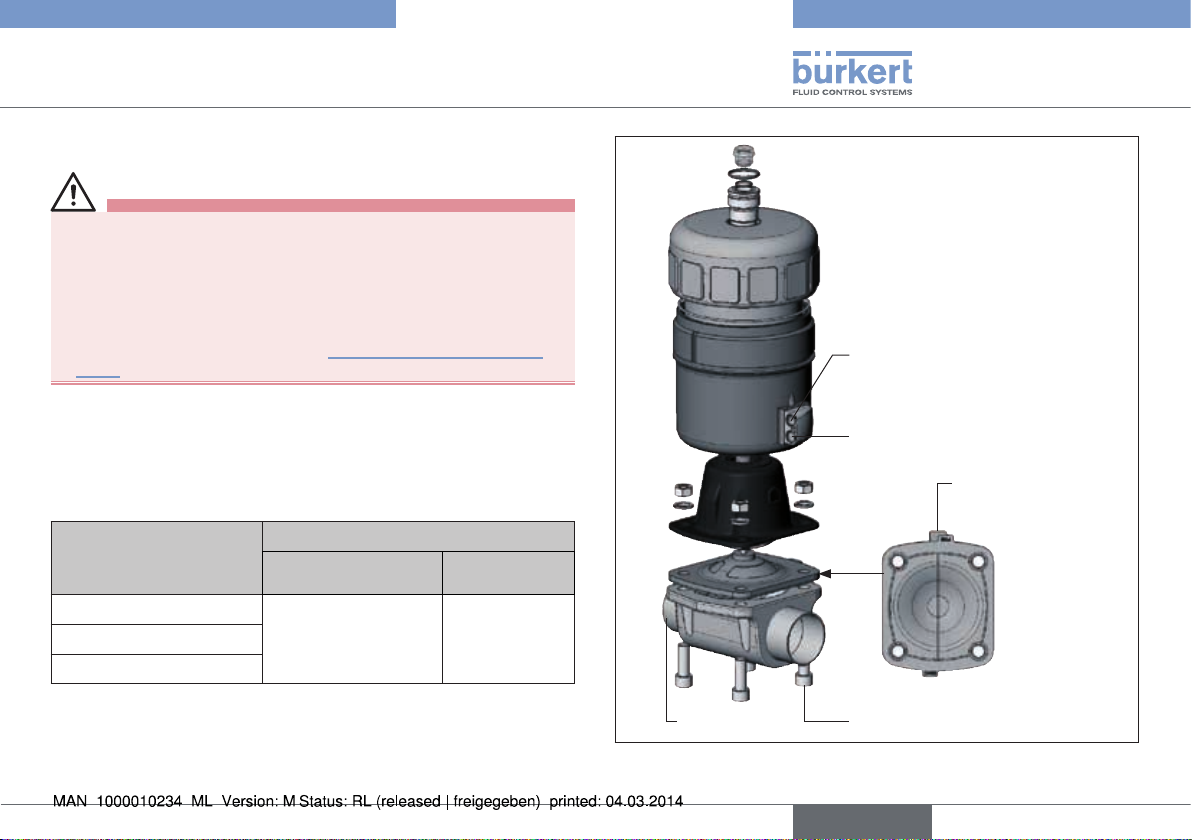

7.1.1 2/2-way valve type 2030, 2031 and

2031 K

The piston-controlled diaphragm valve consists of a pneumatically

actuated piston actuator and a 2/2-way valve body.

Transparent cap with

position indicator

Actuator body with cover

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Diaphragm socket

Diaphragm body

Port connection

Fig. 8: Structure and description type 2030

12

english

Page 13

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Structure and Function

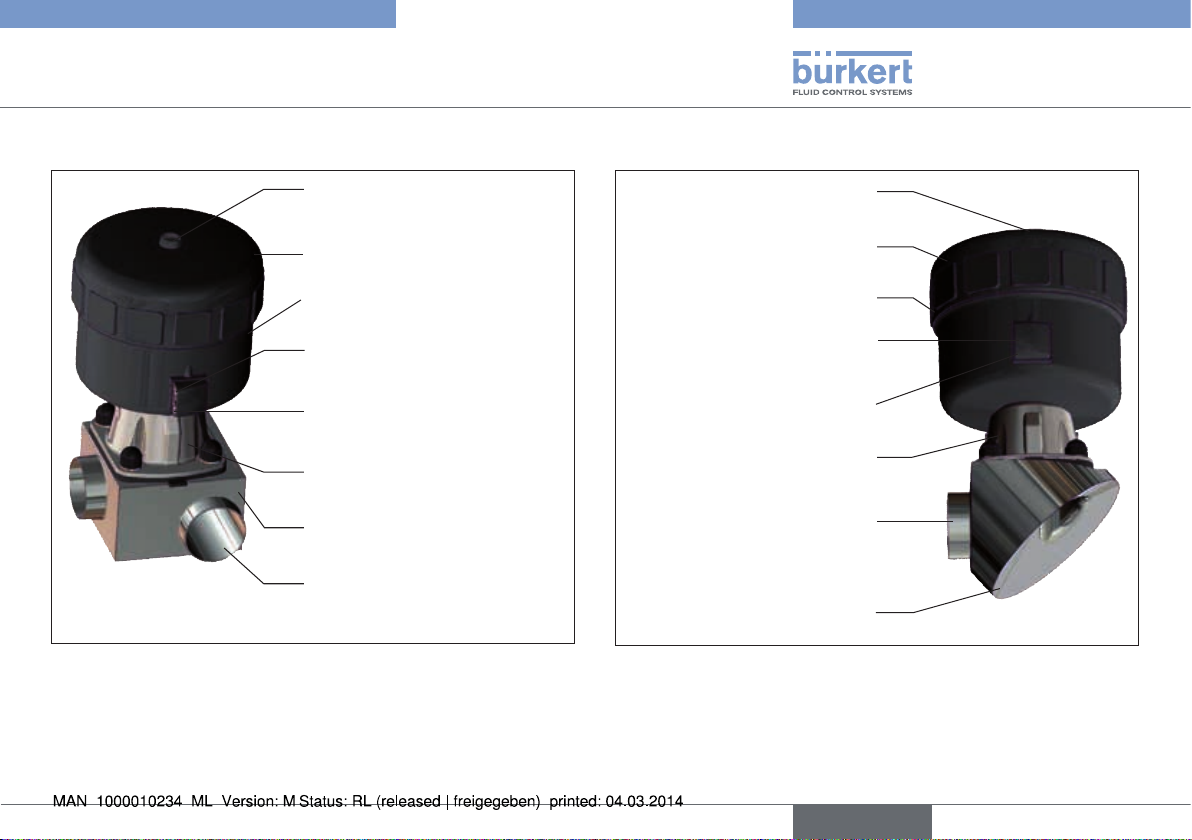

7.1.2 T-valve Type 2032

Transparent cap with

position indicator

Actuator cover

Actuator body

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Diaphragm socket

T-valve body

Port connection

Fig. 9: Structure and descriptions type 2032

7.1.3 Tank bottom valve type 2033

Transparent cap with position

indicator

Actuator cover

Actuator body

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Diaphragm socket

Port connection

Tank bottom valve with

welding flange

Fig. 10: Structure and description type 2033

english

13

Page 14

A

P

B

P

P

A

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Structure and Function

7.1.4 Y-valve type 2037

Transparent cap

with position indicator

Actuator cover

Actuator body

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Diaphragm socket

Y-valve body

Port connection

Fig. 11: Structure and description type 2037

7.2 Function

Spring force (CFA) or pneumatic control pressure (CFB and CFI) generates the closing force on the diaphragm pressure piece. The force

is transferred via a spindle which is connected to the actuator piston

and the valve is opened and closed.

7.2.1 Control functions

Control function A (CFA)

Closed by spring force in rest position

Control function B (CFB)

Opened by spring force in rest position

Control function I (CFI)

Double-acting actuator without spring

14

english

Page 15

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Installation

8 INSTALLATION

8.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the device or the equipment , switch off the

power supply and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

8.2 Before installation

• Before connecting the valve, ensure the pipelines are flush.

• The flow direction is optional.

8.2.1 Installation position general

Installation for self-drainage of the body

It is the responsibility of the installer and operator to ensure

self-drainage.

Installation for leakage detection

One of the bores (in the actuator base) for monitoring

leakage must be at the lowest point.

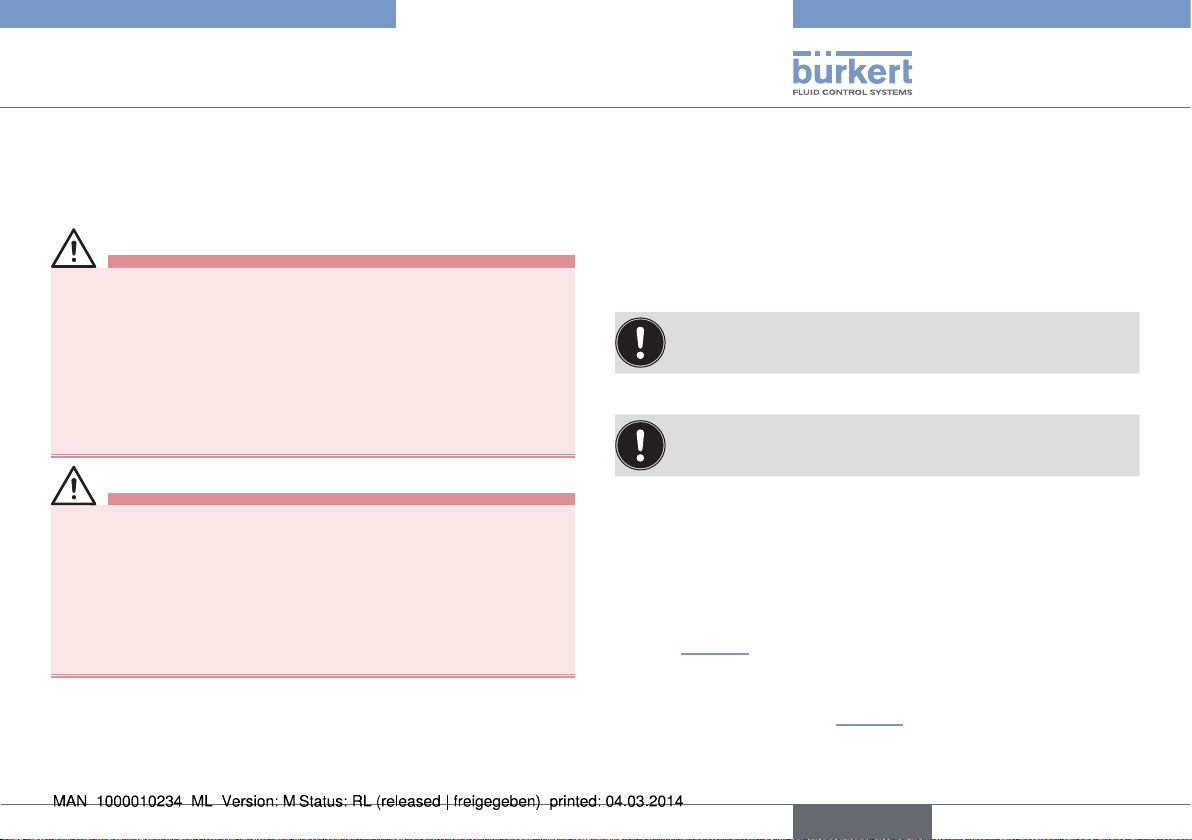

8.2.2 Installation position 2/2-way valve

• The piston-controlled diaphragm valve can be installed in any

installation position, preferably with the actuator face up.

To ensure self-drainage:

→ Install body inclined by angle α = 10° bis 40° to the horizontal

(see “Fig. 12”).

→ Observe an inclination angle of 1° – 5°. Forged and cast bodies

feature a mark which must face upwards

(12 o‘clock position, see “Fig. 13”).

→ One of the bores (in the actuator base) for monitoring leakage

must be at the lowest point.

english

15

Page 16

Angle α: 10° to 40°

Inclination to the

line axis 1° ... 5°

Fig. 12: Installation position for self-drainage of the body

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Installation

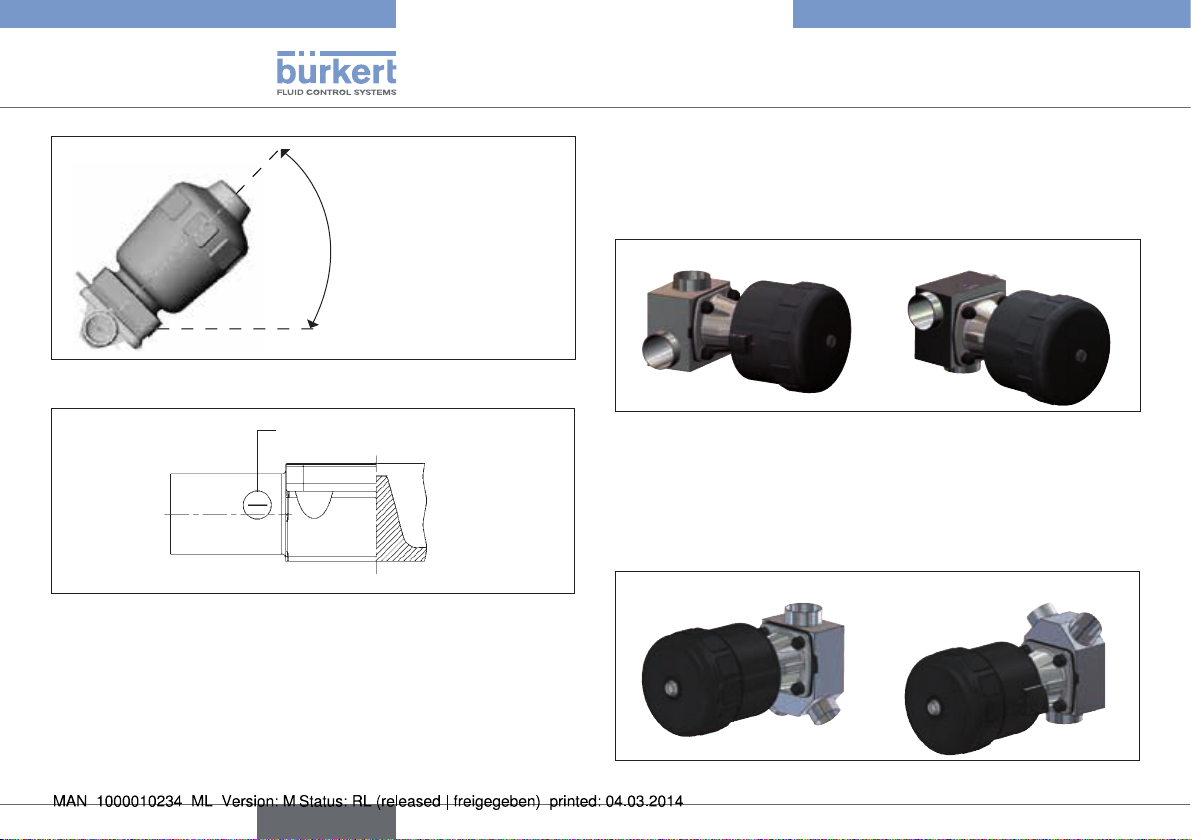

8.2.3 Installation position of T-valve

Type 2032

For the installation of the T-valves into circular pipelines, we recommend the following installation positions:

When media is supplied: When media is removed:

Mark for self-drainage

angle

Fig. 13: Mark for the correct installation position

16

english

Fig. 14: Installation position of type 2032

8.2.4 Installation position of Y-valve

Type 2037

For the installation of the Y-valves into systems, we recommend the

following installation positions:

When media is supplied: When media is removed:

Fig. 15: Installation position of type 2037

Page 17

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Installation

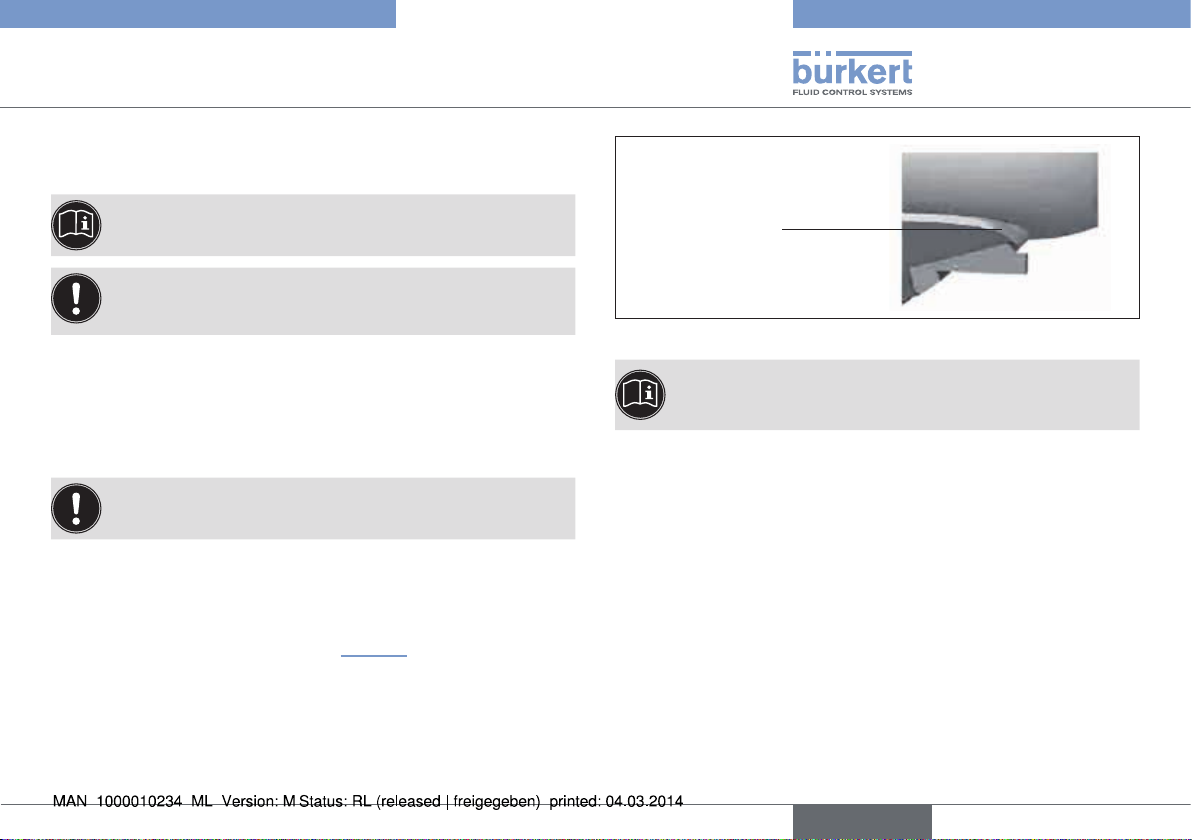

8.2.5 Installation of the tank bottom valve

Type 2033

For further information on containers and welding instructions, please refer to the standard ASME VIII Division I.

It is recommended to weld the valve prior to the container

installation. However, it is possible to weld the valves to readyassembled containers.

Prior to welding, please check to ensure that:

• The tank bottom valve does not collide with other equipment compo-

nents and assembly/disassembly of the actuator is always possible.

• A minimal distance between two welding joints three times the

thickness of the container wall is adhered to.

It is recommended to weld the valve in the center of the drain

to ensure optimum draining of the container.

The diameter of the hole in the container and the flange must be equal.

The valve has two welding edges to make welding and positioning of

the valve easier. The length of the welding edges is approximately 3

mm. In case the thickness of the container wall exceeds 3 mm, the

valve must be positioned as shown in “Fig. 16”.

→ Prior to welding the valve, grind the outlet wall.

Grinding point

on tank

Fig. 16: Grinding point on tank

Prior to commencing the welding process, check the charge

number indicated on the supplied manufacturer’s certificate

3.1.B.

Procedure:

→ Position the flange into the hole so that the flange surface is

tangent to the drain surface.

→ Tack 4 welding points and check the position of the valve.

→ Weld the valve evenly to the inside and outside of the container,

with gas being supplied and using welding material compatible

with the valve’s stainless steel 316L (DIN 1.4435).

→ Allow the welds to cool down before burnishing and cleaning

them according to the applicable specifications.

These instructions assist in the installation of the tank bottom valves

and allow the prevention of deformation and softening within the

containers.

english

17

Page 18

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Installation

Please observe the applicable laws and regulations of the

respective country with regard to the qualification of welders

and the execution of welding work.

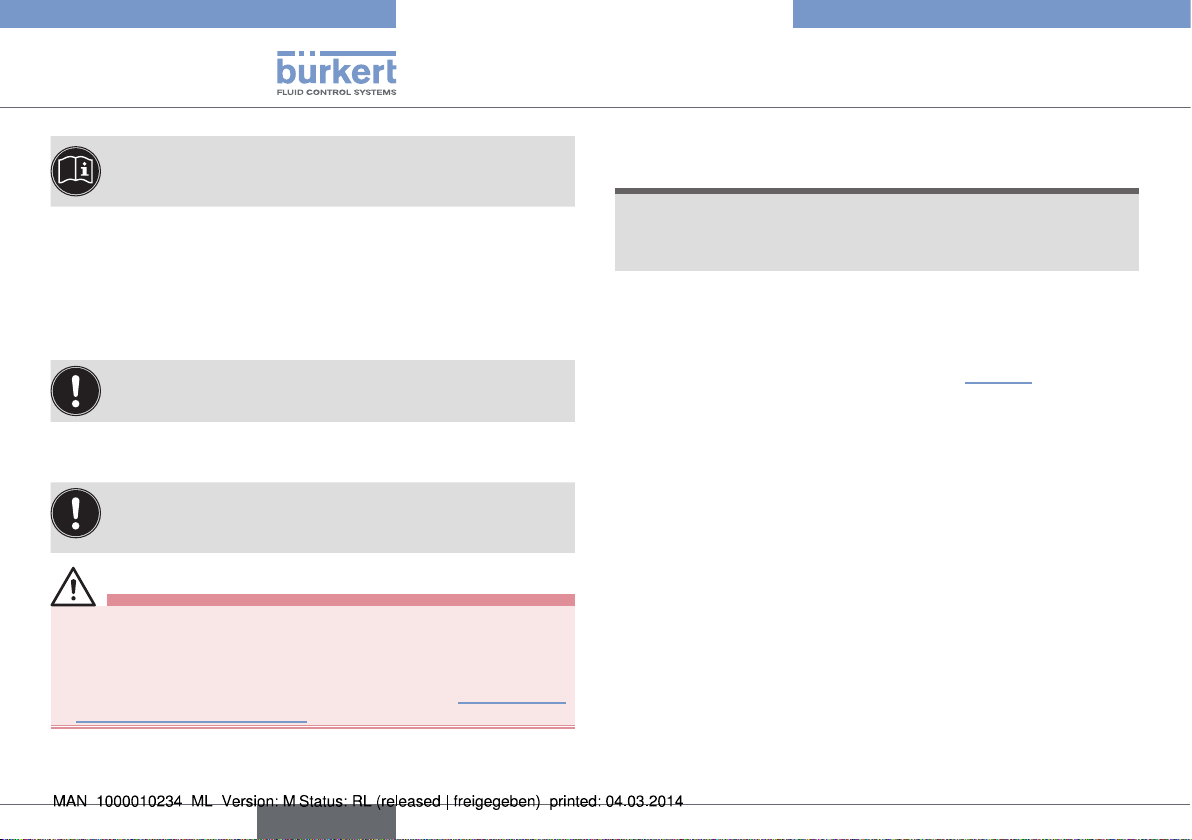

8.2.6 Preparatory Work

→ Clean pipelines (sealing material, swarf, etc.).

→ Support and align pipelines.

Devices with welded body:

Before welding the body, the actuator and the diaphragm

must be removed.

8.3 Installation

If used in an aggressive environment, we recommend conveying all free pneumatic connections into a neutral atmosphere with the aid of a pneumatic hose.

WARNING!

Risk of injury from improper installation!

Non-observance of the tightening torque is dangerous as the

device may be damaged.

▶ Observe tightening torque during installation (see “Tab. 7: Tight-

ening torques for diaphragms”).

8.3.1 Devices with welded body

NOTE!

To prevent damage!

Before welding the body (only device with welded body), the

actuator and the diaphragm must be removed.

Remove actuator and diaphragm from the body:

Procedure for control function A

→ Pressurize lower control air connection with compressed air

(value as indicated on the type label) (see “Fig. 17”).

This is required to detach the diaphragm without damage from

the body.

→ Loosen fastening screws crosswise and remove actuator

together with diaphragm from the body.

→ Weld body into the pipeline.

Procedure for control functions B and I

→ Loosen fastening screws crosswise and remove actuator

together with diaphragm from the body.

→ Weld body into the pipeline.

Mount actuator and diaphragm on the body:

→ After welding in the body, smooth the body surface by grinding if

required.

→ Carefully clean the body.

18

english

Page 19

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Installation

Procedure for control function A

→ Pressurize lower control air connection with compressed air

(value as indicated on the type label) (see “Fig. 17”).

→ Place actuator on the body.

→ Lightly cross-tighten the body screws until the diaphragm is

between the body and actuator.

Do not tighten the screws yet.

→ Actuate the diaphragm valve twice to position the diaphragm

correctly.

→ Without applying pressure, tighten the body screws to the permitted

tightening torque (see “Tab. 7”).

→ Pressurize lower control air connection with compressed air (value

as indicated on the type label).

→ Check the tightening torque of the screws again.

Procedure for actuator with control functions B and I:

→ Place actuator on the body.

→ Lightly cross-tighten the body screws without pressurization until

the diaphragm is between the body and actuator.

Do not tighten the screws yet.

→ Pressurize upper control air connection with compressed air (value

as indicated on the type label) (see “Fig. 17”).

→ Actuate the diaphragm valve twice.

→ Tighten the body screws to the permitted tightening torque (see

“Tab. 7”)

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for SFA and SFI)

Fig. 17: Control air connection

Tightening torques for plastic body, VA tubular body (VA) and

forged body

Orifice

(Diaphragm size)

DN [mm]

65 20 30

80 30 40

100 40 50

Tab. 7: Tightening torques for diaphragms

EPDM/FKM PTFE / advanced PTFE /

Tightening torque [Nm]

(values for guidance)

laminated advanced PTFE

english

19

Page 20

Stainless Steel Insert (only for units without diaphragm and

casing)

If you have ordered and received a unit without diaphragm and casing,

a stainless steel insert (Id.-Nr. 648 864) will have been included with it.

Use of an EPDM / FKM diaphragm:

Insert

→ When assembling a unit with an

elastomer diaphragm (EPDM/FKM),

lay the stainless steel insert into the

groove in the pressure component.

Use of a PTFE - Diaphragm:

→ When using a PTFE diaphragm, the

insert is not required.

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Installation

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Fig. 18: Pneumatic connection

Control air hose:

Control air hoses of sizes 6/4 mm or 1/4“ can be used.

8.3.2 Connection of the control medium

Control function A:

→ Connect control medium to lower connection.

Control function B:

→ Connect control medium to upper connection.

Control function I:

→ Connect control medium to upper and lower connections.

(see “Fig. 18”)

→ Pressure on the upper connection closes the valve.

→ Pressure on the lower connection opens the valve.

20

english

8.4 Disassembly

DANGER!

Risk of injury from discharge of medium (acid, alkali, hot

media)!

It is dangerous to remove the device under pressure due to the

sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the

lines.

▶ Completely drain the lines.

Replacement of the diaphragm is described in the chapter

entitled “11 Repairs”.

Page 21

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Electrical connection

9 ELECTRICAL CONNECTION

The electrical connection is described in the respective

operating instructions for the pilot valve.

Note the voltage and current type as specified on the type label

(Voltage tolerance ±10%)!

10 MAINTENANCE, CLEANING

10.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the system , switch off the power supply

and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper maintenance!

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

10.2 Maintenance Work

10.2.1 Actuator

The actuator of the diaphragm valve is maintenance-free provided it is

used according to these operating instructions.

10.2.2 Wearing parts of the diaphragm

valve

Parts which are subject to natural wear:

• Seals • Diaphragm

→ If leaks occur, replace the particular wearing parts with an appro-

priate spare part. (see Chapter “13 Spare Parts”).

A bulging PTFE diaphragm may reduce the flow-rate.

english

21

Page 22

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Repairs

10.2.3 Inspection Intervals

→ Check diaphragm for wear after maximum 10

Muddy and abrasive media require correspondingly shorter

inspection intervals!

5

switching cycles.

10.2.4 Service life of the diaphragm

The service life of the diaphragm depends on the following factors:

• Diaphragm material • Medium temperature

• Medium • Actuator size

• Medium pressure • Control pressure for CFB and CFI

Protecting the diaphragm

→ For CFA match the actuator size (actuator force) to the medium

pressure to be actuated. If required, select the actuator with

reduced spring force EC04.

→ For CFB and CFI try and select the control pressure not higher

than is required to actuate the medium pressure.

10.2.5 Cleaning

Commercially available cleaning agents can be used to clean the outside.

NOTE!

Avoid causing damage with cleaning agents.

▶ Before cleaning, check that the cleaning agents are compatible

with the body materials and seals.

11 REPAIRS

11.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the system , switch off the power supply

and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper maintenance!

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

▶ Observe the tightening torques.

▶ On completion of the work check valve for leaks and function.

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

22

english

Page 23

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Repairs

11.2 Replacing the diaphragm

DANGER!

Risk of injury from discharge of medium (acid, alkali, hot media)!

It is dangerous to remove the device under pressure due to the

sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the lines.

▶ Completely drain the lines.

▶ Disassembly and installation see “8.3.1 Devices with welded

body”.

Required spare part

• Diaphragm

Fastening types

Orifice

(Diaphragm size)

DN [mm]

65

80

100

Tab. 8: Fastening types for diaphragms

Fastening types for diaphragms

PTFE EPDM / FKM

Diaphragm with

bayonet catch

Diaphragm

screwed in

Example:

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Mark tab for direction

of flow

Diaphragm

Body 4 fastening screws

Fig. 19: Replacement of diaphragm

english

23

Page 24

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Repairs

Replacement of the diaphragm for control function A

→ Clamp the valve body in a holding device.

(applies only to valves not yet installed).

→ Pressurize lower control air connection with compressed air

(value as indicated on the type label) (see picture below “Fig.

20”).

This is required to detach the diaphragm without damage from

the body.

→ Loosen fastening screws crosswise and remove actuator

together with diaphragm from the body.

→ Unbutton or unscrew the old diaphragm. If attachment is with a

bayonet catch, remove the diaphragm by rotating it through 90°

(see “Tab. 8”).

→ Install new diaphragm in actuator (see “Tab. 8”).

→ Align diaphragm.

Observe mark tab for direction of flow!

→ Place actuator back on the body.

→ Lightly cross-tighten the body screws until the diaphragm is

between the body and actuator.

Do not tighten the screws yet.

→ Actuate the diaphragm valve twice to position the diaphragm

correctly.

→ Without applying pressure, tighten the body screws to the permitted

tightening torque (see “Tab. 7”).

→ Pressurize lower control air connection with compressed air (value

as indicated on the type label).

→ Check the tightening torque of the screws again.

Replacement of the diaphragm for control functions B and I

→ Clamp the valve body in a holding device.

(applies only to valves not yet installed).

→ Loosen the fastening screws crosswise and remove actuator

together with diaphragm from the body.

→ Unbutton or unscrew old diaphragm. If attachment is with a

bayonet catch, remove the diaphragm by rotating it through 90°

(see “Tab. 8”).

→ Install new diaphragm in actuator (see “Tab. 8”).

→ Align diaphragm.

Observe mark tab for direction of flow!

→ Place actuator back on the body.

→ Lightly cross-tighten the body screws without pressurization until

the diaphragm is between the body and actuator.

Do not tighten the screws yet.

→ Pressurize upper control air connection with compressed air (value

as indicated on the type label) (see “Fig. 17”).

→ Actuate the diaphragm valve twice.

→ Tighten the body screws to the permitted tightening torque (see

“Tab. 7”).

24

english

Page 25

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Malfunctions

12 MALFUNCTIONS

Fig. 20: Control air connection

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Malfunctions Cause / Remedial action

Actuator

does not

switch

Valve is not

sealed

Flow rate

reduced

Control connection interchanged*

CFA:

CFB:

CFI

* see “Fig. 20”

Control pressure too low

See pressure specifications on the type label.

Medium pressure too high

See pressure specifications on the type label.

Medium pressure too high

See pressure specifications on the type label.

Control pressure too low

See pressure specifications on the type label.

PTFE diaphragm bulging

Replace diaphragm.

→ Connect lower control connection

→ Connect upper control connection

→ Upper control connection: Close

Lower control connection: Open

english

25

Page 26

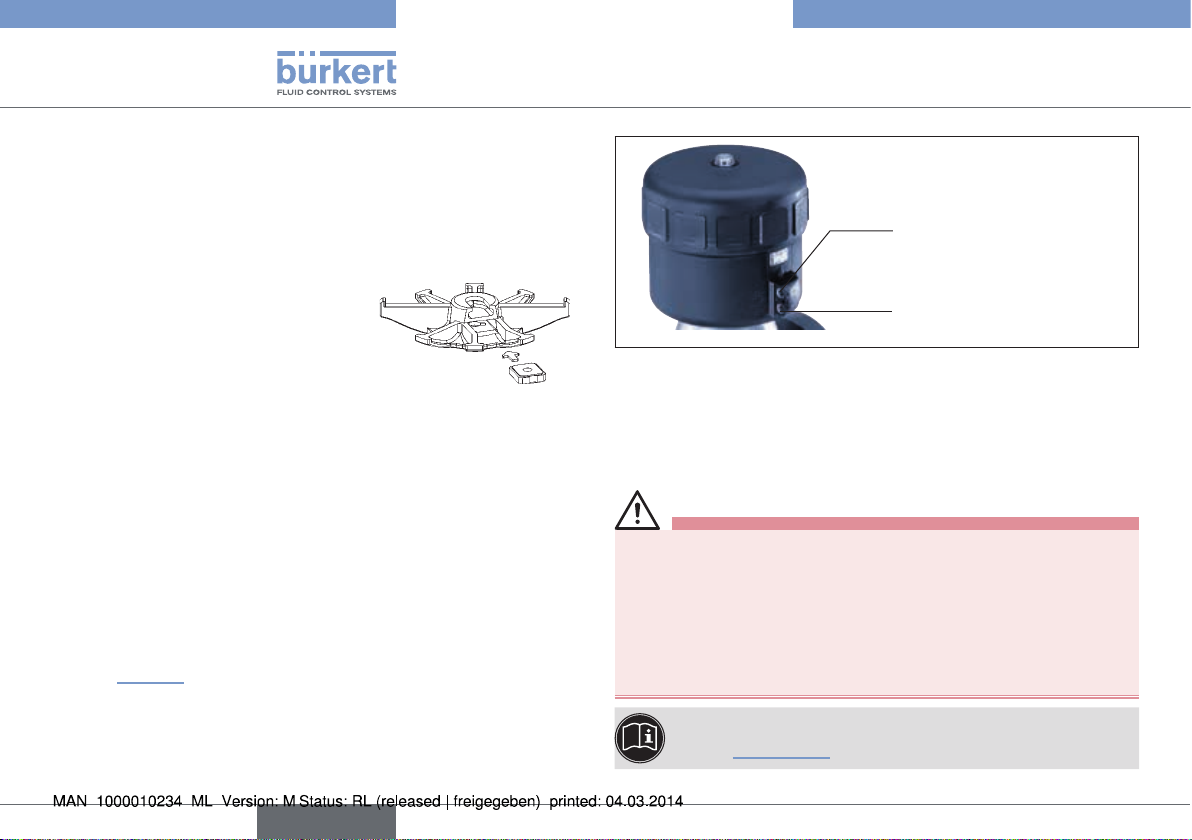

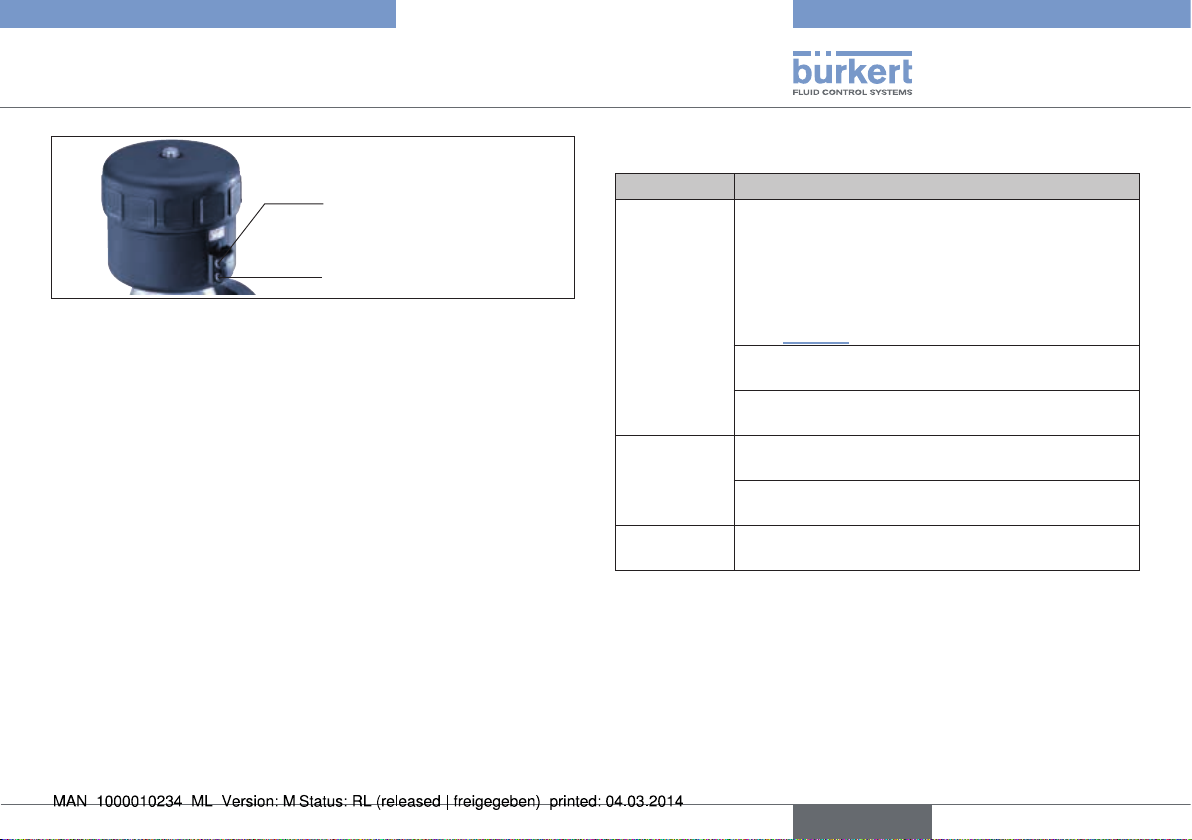

13 SPARE PARTS

WARNING!

Risk of injury when opening the actuator body!

The actuator contains a tensioned spring. If the body is opened,

there is a risk of injury from the spring jumping out!

▶ Carefully open the actuator body and hold it in such a way

that any parts which jump out cannot injure anyone or damage

anything.

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

▶ Use only original accessories and original spare parts from

Bürkert.

Types 2030, 2031, 2031 K, 2032, 2033 and 2037 are available as

spare parts for the piston-controlled diaphragm valves.

• Seal set for actuator

• Diaphragm

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Spare Parts

Seal set

Diaphragm

26

Fig. 21: Spare parts

english

Page 27

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Spare Parts

13.1 Order table

Actuator Orifice

(Diaphragm size)

DN [mm]

175 65, 80, 100 181 802

225 80, 100 186 775

Tab. 9: Order numbers for seal sets

Orifice

(Diaphragm

size)

DN [mm]

65 677 671 688 428 677 691

80 677 672 688 429 677 692

100 677 673 688 430 677 693

65 677 681 679 743

80 677 682 679 744

100 677 683 679 745

Tab. 10: Order numbers for diaphragms

*) SAP-Code

Order numbers for diaphragms

EPDM (AB*) EPDM (AD*) FKM (FF*)

PTFE (EA*) advanced PTFE (EU*)

Order numbers for

seal sets

The data sheet and further information for the type can be

found on the Internet at: www.burkert.com

If you have any queries, please contact your Bürkert sales

office.

14 PACKAGING AND TRANSPORT

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

• Protect the electrical interfaces of the coil and the pneumatic

connections from damage by placing protective caps on them.

english

27

Page 28

Type 2030, 2031, 2031 K, 2032,

2033, 2037

Storage

15 STORAGE

NOTE!

Incorrect storage may damage the device.

• For prolonged storage, slacken the body screws to prevent the

diaphragm from becoming distorted.

• Identify slackened screws for reasons of safety!

• Store the device in a dry and dust-free location!

• Storage temperature. -40 ... +55 °C.

DANGER!

Risk of injury during re-installation. Risk of injury from discharge of medium through slackened body screws (acid,

alkali, hot media)!

Before re-installing the valves, ensure that the body screws have

been tightened correctly.

▶ Before re-installation, check the tightening torque of the body

screws.

16 DISPOSAL

→

Dispose of the device and packaging in an environmentally friendly

manner.

NOTE!

Damage to the environment caused by device components

contaminated with media.

▶ Observe applicable regulations on disposal and the environment.

Observe the national waste disposal regulations.

28

english

Page 29

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Kolbengesteuerte Membranventile Typ 2030, 2031, 2031 K, 2032, 2033, 2037

1 DIE BEDIENUNGSANLEITUNG .........................................................30

1.1 Begriffsdefinition Gerät ..........................................................30

1.2 Darstellungsmittel ....................................................................30

2 BESTIMMUNGSGEMÄSSE VERWENDUNG................................31

2.1 Beschränkungen ......................................................................31

3 GRUNDLEGENDE SICHERHEITSHINWEISE .............................. 32

4 ALLGEMEINE HINWEISE ....................................................................... 33

4.1 Kontaktadressen ......................................................................33

4.2 Gewährleistung ........................................................................33

4.3 Informationen im Internet .......................................................33

5 SYSTEMBESCHREIBUNG .................................................................... 33

5.1 Allgemeine Beschreibung .....................................................33

5.2 Vorgesehener Einsatzbereich ...............................................33

5.3 Konformität ................................................................................33

5.4 Normen ......................................................................................33

6 TECHNISCHE DATEN ............................................................................. 34

6.1 Beschriftung des Typschildes ..............................................34

6.2 Beschriftung der Schmiedegehäuse ..................................34

6.3 Betriebsbedingungen .............................................................34

6.4 Allgemeine Technische Daten ..............................................38

7 AUFBAU UND FUNKTION .................................................................... 38

7.1 Aufbau ........................................................................................38

7.2 Funktion .....................................................................................40

8 MONTAGE .....................................................................................................41

8.1 Sicherheitshinweise ................................................................41

8.2 Vor dem Einbau........................................................................41

8.3 Einbau ........................................................................................44

8.4 Demontage ...............................................................................46

9 ELEKTRISCHER ANSCHLUSS ...........................................................47

10 WARTUNG, REINIGUNG ........................................................................ 47

10.1 Sicherheitshinweise ................................................................47

10.2 Wartungsarbeiten ....................................................................47

11 INSTANDHALTUNG ..................................................................................48

11.1 Sicherheitshinweise ................................................................48

11.2 Austausch der Membran .......................................................49

12 STÖRUNGEN ............................................................................................... 51

13 ERSATZTEILE .............................................................................................. 52

13.1 Bestelltabelle ............................................................................53

14 VERPACKUNG, TRANSPORT .............................................................. 53

15 LAGERUNG ...................................................................................................54

16 ENTSORGUNG ........................................................................................... 54

deutsch

29

Page 30

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Die Bedienungsanleitung

1 DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Geräts. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Geräts

wieder zur Verfügung steht.

WARNUNG!

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

▶ Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1 Begriffsdefinition Gerät

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer

für das kolbengesteuerte Membranventil Typ 2030, 2031, 2031 K,

2032, 2033, 2037.

1.2 Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

▶ Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

▶ Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

▶ Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

Bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

Verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

30

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

deutsch

Page 31

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Bestimmungsgemäße Verwendung

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz der Geräte können

Gefahren für Personen, Anlagen in der Umgebung und die

Umwelt entstehen.

▶ Die kolbengesteuerten Membranventile des Typs 2030, 2031,

2031 K, 2032, 2033 und 2037 sind für die Steuerung von verschmutzten, hochreinen oder sterilen Medien, sowie für abrasive

oder aggressive Medien (auch mit höherer Viskosität) konzipiert.

▶ Die Geräte dürfen nur für Medien eingesetzt werden, welche die

Gehäuse und Dichtwerkstoffe (siehe Typschild) nicht angreifen.

Informationen zur Medienbeständigkeit der Werkstoffe erhalten

Sie bei Ihrer Bürkert-Vertriebsniederlassung oder im Internet

unter: www.buerkert.de

▶ Für den Einsatz die in den Vertragsdokumenten und der Bedie-

nungsanleitung spezifizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten. Diese sind im Kapitel „5 Systembeschreibung“ und „6 Technische Daten“ beschrieben..

▶ Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -Komponenten einsetzen.

▶ Voraussetzungen für den sicheren und einwandfreien Betrieb

sind sachgemäßer Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und Instandhaltung.

▶ Das Gerät nur bestimmungsgemäß einsetzen.

2.1 Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

2.1.1 Ex-Zulassung

Die EX-Zulassung ist nur gültig, wenn Sie die von Bürkert zugelassenen

Module und Komponenten so verwenden, wie es in dieser Bedienungsanleitung beschrieben ist.

Nehmen Sie unzulässige Veränderungen am System, den Modulen

oder Komponenten vor, erlischt die Ex-Zulassung ebenfalls.

deutsch

31

Page 32

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Grundlegende Sicherheitshinweise

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können,

• Ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

GEFAHR!

Gefahr durch hohen Druck!

▶ Vor dem Lösen von Leitungen und Ventilen den Druck abschalten

und Leitungen entlüften.

Gefahr durch elektrische Spannung!

▶ Vor Eingriffen in das Gerät oder die Anlage Spannung abschalten

und vor Wiedereinschalten sichern!

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

WARNUNG!

Berstgefahr bei Überdruck!

▶ Die Angaben auf dem Typschild für max. Mediumsdruck einhalten.

▶ Zulässige Mediumstemperatur beachten.

VORSICHT!

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch

heiße Geräteoberfläche!

▶ Das Gerät von leicht brennbaren Stoffen und Medien fernhalten

und nicht mit bloßen Händen berühren.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

▶ Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

▶ Das Gehäuse nicht mechanisch belasten (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

▶ Keine äußerlichen Veränderungen an den Gerätegehäusen vor-

nehmen. Gehäuseteile und Schrauben nicht lackieren.

▶ Installations- und Instandhaltungsarbeiten dürfen nur von auto-

risiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

▶ Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf

des Prozesses zu gewährleisten.

▶ Das Gerät darf nur in einwandfreiem Zustand und unter Beach-

tung der Bedienungsanleitung betrieben werden.

▶ Für die Einsatzplanung und den Betrieb des Geräts müssen die

allgemeinen Regeln der Technik eingehalten werden.

Die Membranventile Typ 2030, 2031, 2031 K, 2032, 2033 und

2037 wurden unter Einbeziehung der anerkannten sicherheitstechnischen Regeln entwickelt und entsprechen dem Stand der

Technik. Trotzdem können Gefahren entstehen.

32

deutsch

Page 33

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Allgemeine Hinweise

4 ALLGEMEINE HINWEISE

4.1 Kontaktadressen

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten

Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2 Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Geräts unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3 Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 2030, 2031,

2031 K, 2032, 2033 und 2037 finden Sie im Internet unter:

www.buerkert.de

5 SYSTEMBESCHREIBUNG

5.1 Allgemeine Beschreibung

Der Typ 2030, 2031, 2031 K, 2032, 2033 und 2037 ist ein fremdgesteuertes Membranventil mit Kolbenantrieb und Membran-Abdichtung.

Das Ventil ist bei entsprechender Einbaulage selbstentleerend.

5.2 Vorgesehener Einsatzbereich

Das Membranventil des Typs 2030, ist für die Steuerung von verschmutzten und aggressiven Medien konzipiert. Die Ventile des Typs

2031, 2031 K, 2032, 2033 und 2037 können auch für hochreine

oder sterile Medien mit höherer Viskosität eingesetzt werden. Mit

den Ventilen dürfen nur Medien gesteuert werden, die die Gehäuse

und Dichtwerkstoffe (siehe Typschild) nicht angreifen. Informationen

zur Medienbeständigkeit der Werkstoffe erhalten Sie bei Ihrer

Bürkert-Vertriebsniederlassung.

5.3 Konformität

Der Typ 2030, 2031, 2031 K, 2032, 2033 und 2037 ist konform zu

den EG-Richtlinien entsprechend der EG-Konformitätserklärung.

5.4 Normen

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

deutsch

33

Page 34

00147838

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Technische Daten

6 TECHNISCHE DATEN

WARNUNG!

Verletzungsgefahr durch hohen Druck!

Wichtige gerätespezifische technische Angaben sind auf dem

Typschild angegeben.

▶ Zulässiger Druckbereich auf dem Typschild des Geräts

beachten.

6.1 Beschriftung des Typschildes

Steuerfunktion Nennweite

Typ

Leitungsanschluss

2030 A 65,0 EPDM PV

FLNSCH Pmed

Pilot 4,5-6bar

S/N 1060

Made in Germany

Seriennummer

Identnummer des Geräts

Bild 1: Lage und Beschriftung des Typschildes

34

(Membrangröße)

Dichtwerkstoff

Gehäusewerkstoff

10bar

W36LP

Herstellerdatum

(verschlüsselt)

max.

Mediumsdruck

Steuerdruck

Zulassungskennzeichnung

deutsch

6.2 Beschriftung der Schmiedegehäuse

Chargennummer /

Herstellkennzeichen

Firmenzeichen

Werkstoff

Druckstufe

Anschlussnennweite

und Rohrmaße

Fertigungs-/

Auftragsnummer

(F-

Teil)

Seriennummer

Code

Oberflächengüte

kundenspezifischer

Text (optional)

Bild 2: Beschriftung der Schmiedegehäuse

6.3 Betriebsbedingungen

WARNUNG!

Berstgefahr bei Überdruck!

Beim Bersten des Geräts können durch das Medium Verletzungen,

Verätzungen oder Verbrühungen entstehen!

▶ Den maximalen Steuer- und Mediumsdruck nicht überschreiten.

Angaben auf dem Typschild beachten!

▶ Zulässige Umgebungs- und Medientemperatur einhalten.

6.3.1 Zulässige Temperaturen

Umgebungstemperatur für Antriebe:

Werkstoff

PA 175 mm / 225 mm -10 ... +50 °C

Tab. 1: Umgebungstemperatur für Antriebe

Größe ø Temperatur

Page 35

DN 65 - 100

10

20 40 60

80

100 120

140

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Technische Daten

Mediumstemperatur für Gehäuse:

Gehäusewerkstoff

Temperatur

Edelstahl -10 ... +140 °C

PVC (siehe PT-Diagramm) -10 ... +60 °C

PVDF (siehe PT-Diagramm) -10 ... +120 °C

PP (siehe PT-Diagramm) -10 ... +80 °C

Tab. 2: Mediumstemperatur für Gehäuse

Mediumstemperatur für Membranen:

Werkstoff

Temperatur Bemerkungen

EPDM / PTFE -10 ... +130 °C Dampfsterilisation bis +150 °C

FKM -5 ... +130 °C

Trocken bis +150 °C

Sonst nur kurz bis +150 °C

Tab. 3: Mediumstemperatur für Membranen

6.3.2 Maximal zulässiger Mediumsdruck

Zulässiger Mediumsdruck in Abhängigkeit zur Mediumstemperatur.

8

6

4

2

Mediumsdruck [bar]

Temperatur [°C]:

PVC

PVDF

PP

Maximal zulässiger Mediumsdruck bei Steuerfunktion A

Die Werte sind gültig für Gehäuse aus:

• Kunststoff,

• VA-Schmiedestahl, VA-Feinguss und VA-Blockmaterial sowie

VA Rohrumformgehäuse mit Muffe, DIN-Vorschweißflansch und

Schweißanschluss nach EN ISO 1127 (ISO 4200)

Nennweite

(Membran-

größe)

DN

[mm]

Antriebs-

größe ø

[mm]

Max. dichtgehaltener Mediumsdruck

[bar]

Druck einseitig

anstehend

EPDM/

PTFE EPDM/

FKM

Druck beidseitig

anstehend

PTFE

FKM

65 175 8,0 5,0 5,0 4,5

80

175 5,0 4,5 2,5 2,0

225 10,0 10,0 6,0 4,5

100 225 8,0 4,0 3,5 1,5

Tab. 4: Maximal zulässiger Mediumsdruck SFA

Bild 3: Diagramm Mediumsdruck / Mediumstemperatur

deutsch

35

Page 36

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Technische Daten

6.3.3 Steuerdruck

WARNUNG!

Berstgefahr bei Überdruck!

Beim Bersten des Geräts können durch das Medium Verletzungen,

Verätzungen oder Verbrühungen entstehen!

▶ Den maximalen Steuer- und Mediumsdruck nicht überschreiten.

Angaben auf dem Typschild beachten!

HINWEIS!

Fehlfunktion bei falschem Steuerdruck!

Für Ventile mit reduzierter Federkraft (d.h. mit geringerem Steuerdruck), gelten die Angaben auf dem Typschild. Wenden Sie sich

bei Unklarheiten an Ihre Bürkert-Vertriebsniederlassung.

Zulässiger Steuerdruck*

Nennweite

(Membrangröße)

DN [mm]

65 175 2 6

80 175 2 6

80 225 2 6

100 225 2 6

Tab. 5: Zulässiger Steuerdruck

Antriebs-

größe

ø mm

Min. Steuer-

druck [bar]

Max. Steuer-

druck [bar]

Druckwerte für Steuerfunktion A

Nennweite

(Membran-

größe)

DN [mm]

65 175 6 4,5

80 175 6 5,0

80 225 6 5,0

100 225 6 5,0

Tab. 6: Steuerdruck SFA

Antriebsgröße

[mm]

Steuerdruck [bar]

bei Mediumsdruck

0 bar maximal

6.3.4 Mindeststeuerdruck

Erforderlicher Mindeststeuerdruck in Abhängigkeit vom

Mediumsdruck

Die Werte sind gültig für Gehäuse aus:

• Kunststoff

• Alle Varianten mit VA-Schmiedestahl, VA-Feinguss und

VA-Blockmaterial

• VA-Rohrumformgehäuse mit Muffen, DIN-Vorschweißflansch und

mit Schweißenden nach EN ISO 1127 (ISO 4200)

36

* Den zulässigen Druckbereich laut Typschild beachten!

deutsch

Page 37

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Technische Daten

Steuerfunktion B (SFB)

HINWEIS!

Wichtig für die Lebensdauer der Membran!

• Steuerdruck nicht höher als erforderlich wählen.

Elastomermembrane

10

9

8

7

6

5

4

3

2

1

Mediumsdruck [bar]

0

0 1,0 2,0 3,0 4,0 5,0 6,0 7,0

Membrangröße / Antriebsdurchmesser

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Steuerdruck [bar]

Bild 4: Steuerfunktion B - Elastomermembrane

PTFE-Membrane

10

9

8

7

6

5

4

3

2

1

Mediumsdruck [bar]

0

0 1,0 2,0 3,0 4,0 5,0 6,0 7,0 8,0

Membrangröße / Antriebsdurchmesser

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Steuerdruck [bar]

Bild 5: Steuerfunktion B - PTFE Membrane

Druckwerte für Steuerfunktion I

Elastomermembrane

10

9

8

7

6

5

4

3

2

1

Mediumsdruck [bar]

0

0 1,0 2,0 3,0 4,0 5,0 6,0

Membrangröße / Antriebsdurchmesser

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Steuerdruck [bar]

Bild 6: Steuerfunktion I - Elastomermembrane

PTFE-Membrane

10

9

8

7

6

5

4

3

2

1

Mediumsdruck [bar]

0

0 1,0 2,0 3,0 4,0 5,0 6,0 7,0

Membrangröße / Antriebsdurchmesser

DN 65 / Ø 125

DN 65 / Ø 175

DN 80 / Ø 175

DN 100 / Ø 175

Steuerdruck [bar]

Bild 7: Steuerfunktion I - PTFE Membrane

deutsch

37

Page 38

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Aufbau und Funktion

6.4 Allgemeine Technische Daten

Werkstoffe

Gehäuse

Typ 2030 PP, PVC, PVDF

Typ 2031

Typ 2031 K Edelstahl-Rohrumformgehäuse (VA)

Typ 2032, 2033, 2037 Edelstahl-Blockmaterial

Antrieb PA

Dichtelemente Antriebe NBR

Membran EPDM, PTFE, FKM

Anschlüsse

Steuerluftanschluss G1/4

Mediumsanschluss Schweißanschluss: nach DIN EN 1127

Medien

Steuermedium neutrale Gase, Luft

Durchflussmedien Typ 2030:

Edelstahl-Feinguss (VG), Schmiedestahl (VS)

(ISO 4200), DIN 11850 R2

andere Anschlüsse auf Anfrage

verschmutzte und aggressive Medien

Typ 2031, 2031 K, 2032, 2033 und 2037:

verschmutzte, aggressive, hochreine, sterile

Medien u. Medien mit höherer Viskosität.

7 AUFBAU UND FUNKTION

7.1 Aufbau

7.1.1 2/2-Wege Ventil Typ 2030, 2031 und

2031 K

Das kolbengesteuerte Membranventil besteht aus einem pneumatisch

betätigten Kolbenantrieb und einem 2/2-Wege-Ventilgehäuse.

Klarsichthaube mit

Stellungsanzeige

Antriebsgehäuse mit Deckel

Oberer Steuerluftanschluss

(für SFB und SFI)

Unterer Steuerluftanschluss

(für SFA und SFI)

Membransockel

Membrangehäuse

Leitungsanschluss

Einbaulage beliebig, vorzugsweise Antrieb nach oben

Bodenablassventil Typ 2033:

Antrieb nach unten

38

deutsch

Bild 8: Aufbau und Beschreibung des Membranventils

Page 39

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Aufbau und Funktion

7.1.2 T-Ventil Typ 2032

Klarsichthaube mit

Stellungsanzeige

Antriebsdeckel

Antriebsgehäuse

Oberer Steuerluftanschluss

(für SFB und SFI)

Unterer Steuerluftanschluss

(für SFA und SFI)

Membransockel

T-Ventilgehäuse

Leitungsanschluss

Bild 9: Aufbau und Beschreibung Typ 2032

7.1.3 Bodenablassventil Typ 2033

Klarsichthaube mit

Stellungsanzeige

Antriebsdeckel

Antriebsgehäuse

Oberer Steuerluftanschluss

(für SFB und SFI)

Unterer Steuerluftanschluss

(für SFA und SFI)

Membransockel

Leitungsanschluss

Bodenablassgehäuse mit

Schweißflansch

Bild 10: Aufbau und Beschreibung Typ 2033

deutsch

39

Page 40

A

P

B

P

P

A

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Aufbau und Funktion

7.1.4 Y-Ventil Typ 2037

Klarsichthaube mit

Stellungsanzeige

Antriebsdeckel

Antriebsgehäuse

Oberer Steuerluftanschluss

(für SFB und SFI)

Unterer Steuerluftanschluss

(für SFA und SFI)

Membransockel

Y-Ventilgehäuse

Leitungsanschluss

Bild 11: Aufbau und Beschreibung Typ 2037

7.2 Funktion

Federkraft (SFA) oder pneumatischer Steuerdruck (SFB und SFI)

erzeugen die Schließkraft des Membrandruckstücks. Über eine Spindel,

die mit dem Antriebskolben verbunden ist, wird die Kraft übertragen

und das Ventil geöffnet oder geschlossen.

7.2.1 Steuerfunktionen

Steuerfunktion A (SFA)

In Ruhestellung durch Federkraft geschlossen

Steuerfunktion B (SFB)

In Ruhestellung durch Federkraft geöffnet

Steuerfunktion I (SFI)

Doppeltwirkender Antrieb ohne Feder

40

deutsch

Page 41

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Montage

8 MONTAGE

8.1 Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

▶ Vor dem Lösen von Leitungen und Ventilen den Druck abschal-

ten und Leitungen entlüften.

Verletzungsgefahr durch Stromschlag!

▶ Vor Eingriffen in das Gerät oder die Anlage die elektrische

Spannung abschalten und vor Wiedereinschalten sichern!

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

▶ Die Montage darf nur autorisiertes Fachpersonal mit geeigne-

tem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

▶ Anlage vor unbeabsichtigtem Betätigen sichern.

▶ Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

8.2 Vor dem Einbau

• Vor dem Anschluss des Ventils auf fluchtende Rohrleitungen

achten.

• Die Durchflussrichtung ist beliebig.

8.2.1 Einbaulage allgemein

Einbau für Selbstentleerung des Gehäuses

Die Sicherstellung der Selbstentleerung liegt in der Verantwortung des Installateurs und Betreibers.

Einbau für Leckagedetektion

Eine der Bohrungen (im Antriebssockel) zur Überwachung

der Leckage muss am tiefsten Punkt sein.

8.2.2 Einbaulage 2/2-Wege Ventile

• Die Einbaulage des kolbengesteuerten Membranventils ist

beliebig, vorzugsweise Antrieb nach oben.

Um die Selbstentleerung zu gewährleisten:

→ Gehäuse um den Winkel α = 10° bis 40° geneigt zur Horizontalen

einbauen (siehe „Bild 12“).

→ Zur Leitungsachse einen Neigungswinkel von 1° ... 5° einhalten.

Bei Schmiede- und Gussgehäusen ist hierfür eine Markierung

angebracht, welche nach oben zeigen muss (12 Uhr-Stellung,

siehe „Bild 13“).

deutsch

41

Page 42

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Montage

→ Eine der Bohrungen (im Antriebssockel) zur Überwachung der

Leckage muss am tiefsten Punkt sein.

Winkel α: 10° bis 40°

Neigung zur Leitungsachse 1° ... 5°

Bild 12: Einbaulage zur Selbstentleerung des Gehäuses

Markierung für

Selbstentleerungswinkel

Bild 13: Markierung für die korrekte Einbaulage

8.2.3 Einbaulage T-Ventil Typ 2032

Für den Einbau der T-Ventile in Ringleitungen werden folgende Einbaulagen empfohlen:

Bei Zuführung eines Mediums: Bei Entnahme von Medium:

Bild 14: Einbaulage des Typs 2032

8.2.4 Einbaulage Y-Ventil Typ 2037

Für den Einbau der Y-Ventile in Anlagen werden folgende Einbaulagen empfohlen:

Bei Zuführung eines Mediums: Bei Entnahme von Medium:

42

Bild 15: Einbaulage des Typs 2037

deutsch

Page 43

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Montage

8.2.5 Einbau des Bodenablassventils

Typ 2033

Für Informationen über Behälter und Schweißanweisungen,

beziehen Sie sich auf die Norm ASME VIII Division I.

Es empfiehlt sich das Ventil zu schweißen bevor der Behälter

aufgebaut wird. Trotzdem ist es möglich, die Ventile an fertig

montierte Behälter zu schweißen.

Vor dem Schweißen überprüfen, ob:

• Das Bodenablassventil mit keinem anderen Einrichtungsteil kollidiert

und dass Auf- und Abbau des Antriebs stets möglich sind.

• Eine Minimaldistanz zwischen zwei Schweißstellen von 3 mal die

Dicke der Behälterwand eingehalten wird.

Es empfiehlt sich das Ventil in der Mitte des Ablasses zu

schweißen, damit sich der Behälter optimal entleert.

Der Durchmesser des Lochs im Behälter und der Flansch müssen

gleich sein. Das Ventil ist mit zwei Schweißkanten versehen, um die

Schweißung und das Positionieren des Ventils einfacher zu machen.

Die Schweißkanten sind ungefähr 3 mm lang. Sollte die Behälterwand

mehr als 3 mm dick sein, muss das Ventil wie auf „Bild 16: Zu schleifende Stelle am Tank“ positioniert werden.

→ Schleifen Sie die Ablasswand ab, bevor das Ventil eingeschweißt

wird.

Zu schleifende Stelle

am Tank

Bild 16: Zu schleifende Stelle am Tank

Prüfen Sie die auf dem gelieferten Hersteller-Zertifikat

3.1.B angegebenen Chargen-Nummer, bevor Sie mit dem

Schweißen beginnen.

Vorgehensweise:

→ Den Flansch in das Loch positionieren, so dass die Flanschober-

fläche mit der Ablassoberfläche tangierend ist.

→ 4 Schweißpunkte heften und die Position des Ventils prüfen.

→ Das Ventil gleichmäßig innerhalb und außerhalb des Behälters

unter Zufuhr von Gas und mit dem Ventil-Edelstahl 316L (DIN

1.4435) kompatiblen Schweißmaterial einschweißen.

→ Die Schweißungen abkühlen lassen bevor sie gemäß den gel-

tenden Spezifikationen glanzgeschliffen und geputzt werden.

Diese Anweisungen helfen zum Einbau der Bodenablassventile und

ermöglichen es, Formänderungen und Entspannungen innerhalb der

Behälter zu vermeiden.

deutsch

43

Page 44

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Montage

Bitte beachten Sie die im Land geltenden Gesetze bezüglich

der Qualifikation von Schweißern und der Durchführung der

Schweißungen.

8.2.6 Vorbereitende Arbeiten

→ Rohrleitungen von Verunreinigungen säubern (Dichtungsmaterial,

Metallspäne etc).

→ Rohrleitungen abstützen und ausrichten.

Geräte mit Schweißgehäuse:

Vor dem Einschweißen des Gehäuses muss der Antrieb

und die Membran demontiert werden.

8.3 Einbau

Beim Einsatz in aggressiver Umgebung empfehlen wir,

sämtliche freien Pneumatikanschlüsse mit Hilfe eines Pneumatikschlauches in neutrale Atmosphäre abzuleiten.

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Einbau!

Das Nichtbeachten des Anziehdrehmoments ist wegen der möglichen Beschädigung des Geräts gefährlich.

▶ Anziehdrehmoment beim Einbau beachten (siehe „Tab. 7“)

8.3.1 Geräte mit Schweißgehäuse

HINWEIS!

Zur Vermeidung von Schäden!

Vor dem Einschweißen des Gehäuses (nur Schweißgehäuse)

muss der Antrieb und die Membran demontiert werden.

Antrieb und Membran vom Gehäuse abnehmen:

Vorgehensweise bei Steuerfunktion A

→ Unteren Steuerluftanschluss mit Druckluft (Wert wie auf dem

Typschild angegeben) beaufschlagen (siehe „Bild 17“).

Dies ist erforderlich, damit sich die Membran vom Gehäuse löst

und nicht beschädigt wird.

→ Befestigungsschrauben über Kreuz lösen und Antrieb mit

Membran vom Gehäuse abnehmen.

→ Gehäuse in die Rohrleitung einschweißen.

Vorgehensweise bei Steuerfunktion B und I

→ Befestigungsschrauben über Kreuz lösen und Antrieb mit

Membran vom Gehäuse abnehmen.

→ Gehäuse in die Rohrleitung einschweißen.

Antrieb und Membran auf das Gehäuse montieren:

→ Nach dem Einschweißen des Gehäuses, die Gehäuseoberfläche

falls nötig durch Abschleifen glätten.

→ Das Gehäuse sorgfältig reinigen.

44

deutsch

Page 45

Typ 2030, 2031, 2031 K, 2032,

2033, 2037

Montage

Vorgehensweise bei Steuerfunktion A

→ Unteren Steuerluftanschluss mit Druckluft (Wert wie auf dem

Typschild angegeben) beaufschlagen (siehe „Bild 17“).

→ Antrieb auf das Gehäuse setzen.

→ Die Gehäuseschrauben über Kreuz leicht anziehen, bis die

Membran zwischen Gehäuse und Antrieb anliegt.

Schrauben noch nicht festziehen.

→ Das Membranventil zweimal schalten, damit die Membran richtig

anliegt.

→ Ohne Druckbeaufschlagung die Gehäuseschrauben bis zum

zulässigen Anziehdrehmoment anziehen (siehe „Tab. 7“).

→ Unteren Steuerluftanschluss mit Druckluft (Wert wie auf dem Typ-

schild angegeben) beaufschlagen.

→ Das Anziehdrehmoment der Schrauben nochmals überprüfen.

Vorgehensweise für Antrieb mit Steuerfunktion B und I:

→ Antrieb auf das Gehäuse setzen.

→ Die Gehäuseschrauben ohne Druckbeaufschlagung über Kreuz

leicht anziehen, bis die Membran zwischen Gehäuse und Antrieb

anliegt.

Schrauben noch nicht festziehen.

→ Oberen Steuerluftanschluss mit Druckluft (Wert wie auf dem Typ-

schild angegeben) beaufschlagen (siehe „Bild 17“).

→ Das Membranventil zweimal schalten.

→ Die Gehäuseschrauben bis zum zulässigen Anziehdrehmoment

anziehen (siehe „Tab. 7“).

Oberer Steuerluftanschluss

(für SFB und SFI)

Unterer Steuerluftanschluss

(für SFA und SFI)

Bild 17: Steuerluftanschluss

Anziehdrehmomente für Kunstoffgehäuse, VA-Rohrgehäuse

(VA) und Schmiedegehäuse

Nennweite

(Membrangröße)

DN [mm]

65 20 30

80 30 40

100 40 50

Tab. 7: Anziehdrehmomente für Membranen