Page 1

Type 2036

Robolux multiple-way diaphragm valve

Robolux Mehrwege-Membranventil

Vanne à membrane multivoies Robolux

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2011 - 2013 Bürkert Werke GmbH

Operating Instructions 1312/01_EU-ML_00809601 / Original DE

Page 3

Type 2036

Contents

1. OPERATING INSTRUCTIONS ...................................................................5

1.1. Symbols ..............................................................................................5

1.2. Definition of term / abbreviation ....................................................5

2. AUTHORIZED USE .........................................................................................6

2.1. Restrictions ........................................................................................6

3. BASIC SAFETY INSTRUCTIONS .............................................................6

3.1. Use in Ex area ...................................................................................7

3.2. Special conditions ...........................................................................8

4. GENERAL INFORMATION ...........................................................................9

4.1. Contact address ............................................................................... 9

4.2. Warranty ............................................................................................. 9

4.3. Information on the Internet ............................................................. 9

5. PRODUCT DESCRIPTION ...........................................................................9

5.1. General description ......................................................................... 9

5.2. Device versions ................................................................................. 9

5.3. Options .............................................................................................10

5.4. Valve self-draining ..........................................................................10

5.5. Valve symbols and flow diagrams ................................................ 12

5.6. Valve marking ..................................................................................14

5.7. Intended application area .............................................................15

6. STRUCTURE AND FUNCTION...............................................................15

6.1. Structure ..........................................................................................15

6.2. Position indicator ............................................................................16

7. TECHNICAL DATA ........................................................................................17

7.1. Conformity .......................................................................................17

7.2. Standards .........................................................................................17

7.3. Approvals .........................................................................................17

7.4. Type label .........................................................................................17

7.5. Operating conditions .....................................................................17

7.6. Mechanical data .............................................................................17

7.7. Fluidic data ......................................................................................19

8. ASSEMBLY .......................................................................................................21

8.1. Safety instructions .........................................................................21

8.2. Before installation ...........................................................................21

8.3. Installation ........................................................................................22

8.4. Pneumatic connection .................................................................23

9. ELECTRICAL CONTROL UNIT ............................................................... 25

10. DISASSEMBLY ............................................................................................ 25

11. MAINTENANCE, CLEANING ................................................................. 25

11.1. Safety instructions .......................................................................25

11.2. Servicing intervals ........................................................................26

11.3. Servicing work ..............................................................................26

11.4. Cleaning .........................................................................................26

12. REPAIRS ......................................................................................................... 27

12.1. Safety instructions .......................................................................27

12.2. Replacing the diaphragm ...........................................................27

english

3

Page 4

13. MALFUNCTIONS ........................................................................................ 30

14. SPARE PARTS ............................................................................................. 31

14.1. Order table ....................................................................................31

15. TRANSPORT, STORAGE, PACKAGING .......................................... 32

Type 2036

4

english

Page 5

Type 2036

Operating instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

WARNING!

The operating instructions contain important safety information.

Failure to observe these instructions may result in hazardous

situations.

▶ The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or minor

injury.

NOTE!

Warns of damage to property.

▶ Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

▶ Indicates an instruction to prevent risks.

→ Designates a procedure which you must carry out.

1.2. Definition of term / abbreviation

In these instructions, the term 'device' always refers to the Robolux

Multiway Diaphragm Valve Type 2036.

In these instructions, the term 'Diaphragm Valve' always refers to the

Robolux Multiway Diaphragm Valve Type 2036.

In these instructions, the abbreviation “Ex” always refers to

“potentially explosive”.

english

5

Page 6

Type 2036

Authorized use

2. AUTHORIZED USE

Improper use of the Robolux Multiway Diaphragm Valve

Type 2036 may represent a hazard to persons, neighboring

equipment and the environment.

The device is designed for controlling the flow-rate of liquid media.

▶ The approved data, the operating conditions and conditions of use

specified in the contract documents, operating instructions and on

the type label are to be observed during use. The designated areas

of application are specified in chapter "5. Product description".

▶ Use the device only in conjunction with third-party devices and

components recommended and authorized by Bürkert.

▶ Correct transportation, storage, and installation, as well as care-

ful use and maintenance are essential for reliable and faultless

operation.

▶ Use the device only as intended.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

3. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

• Contingencies and events which may arise during the installation,

operation, and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing

these regulations, also in relation to the installation personnel.

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before reaching into the device, switch off the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury when opening the actuator.

The actuator contains tensioned springs. If the actuator is opened,

injuries may be caused by the springs jumping out!

▶ The actuator must not be opened.

6

english

Page 7

Type 2036

Basic safety instructions

CAUTION!

Risk of burns.

The surface of the device may become hot during long-term operation.

▶ Do not touch the device with bare hands.

Risk of being crushed by moving spindle ends.

▶ Install transparent cap.

Generally hazardous situations.

To prevent injuries:

▶ Ensure that the system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the electrical or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The device must only be operated when in a perfect condition

and in consideration of the operating instructions.

▶ The general rules of technology must be observed for applica-

tion planning and operation of the device.

To prevent material damage:

▶ Supply only media to the media connections that are specified

in chapter "7. Technical Data" as flow media.

▶ Do not place the valve under mechanical stress (e.g. by placing

objects on it or standing on it).

▶ Do not make any external alterations to the valves. Do not apply

paint to body parts or screws.

3.1. Use in Ex area

Abbreviation “Ex”: see chapter "1.2. Definition of term / abbreviation"

3.1.1. Safety instructions

For operation in Ex area Zone (gas) 1 and 2,

Zone (dust) 21 and 22, the following

applies:

The valve actuator is suitable for use as a Category 2 device for

Zone 1 and 21, non-electrical production equipment.

DANGER!

Danger of explosion caused by electrostatic charge.

Depending on the conductivity of the medium, electrostatic charges

may occur on the valve membrane if plastic bodies are used.

To prevent electrostatic charges in the fluid, the following instructions

must be observed (as per IEC 60079-32-1):

▶ (1) Media with a conductivity ≤ 100 pS/m may only be used if no

flow speeds > 1 m/s occur or if the possibility of the pipe system

running dry is excluded by suitable monitoring.

▶ (2) Media with a conductivity > 100 pS/m and ≤ 1000 pS/m may

only be used if they are liquids without any particles, steam or pure

gases/steam, or if the instructions in (1) are observed.

▶ (3) Media with a conductivity > 1000 pS/m are not subject to any

restrictions.

english

7

Page 8

Type 2036

Basic safety instructions

Further instructions:

▶ The user must ensure that the appliance is used in Zone 1/21 or

2/22 only.

▶ The control unit may restrict use in an explosive atmosphere. Follow

operating instructions for control unit.

▶ Check that any cleaning agents are approved for use in explosive

atmospheres.

3.1.2. Media temperature

DANGER!

▶ If explosive media are used this can cause additional explosion risks.

▶ If media temperatures are used between 130 °C and 150 °C, the

temperature class T3 / 200 °C applies (dust).

Media temperature max. 130 °C

3.1.3. Marking Ex area

PTB 13 ATEX D103 X

II 2G c IIC T4

II 2D c T135°C

Warning: Not valid when Non-Ex devices added.

The Ex marking is not valid if Non-Ex devices are added.

3.2. Special conditions

→ To ensure potential equalization, ground the valve body to the

pipe system using an electrically conductive connection.

DANGER!

Danger of explosion caused by electrostatic charge.

In the event of a sudden discharge from electrostatically charged

devices or individuals there is a risk of an explosion in the Ex area.

▶ Implement suitable measures to ensure that there are no

electrostatically charges in the Ex area (see also "3.1. Use in Ex

area").

▶ Clean the device surface by gently wiping it with a damp or anti-

static cloth only.

▶ Earth the actuator and valve body.

▶ If a plastic body is used, earth the actuator separately.

Ambient temperature range: 0 °C ≤ Tamb ≤ 60 °C

Do not open actuator. Spring loaded cover.

Fig. 1: Marking Ex area

8

english

Page 9

Type 2036

General information

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

Email: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2. Warranty

The warranty is only valid if the diaphragm valve is used as intended in

accordance with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Types 2036 can be

found on the Internet at:

www.burkert.com

5. PRODUCT DESCRIPTION

5.1. General description

The manually or pneumatically operated Robolux Multiway Diaphragm Valves

of ultra-pure, sterile, aggressive or abrasive media. They allow for

optimal collection, draining or distribution of critical process media.

1) In the following text the Robolux Multiway Diaphragm Valve is

referred to as 'diaphragm valve' for brevity's sake.

5.2. Device versions

The diaphragm valve can be adapted to very different usage conditions on account of its modular design.

Depending on the connection size of the diaphragm valves three

construction sizes are available (RV5O, RV7O, RV110).

The valve body is made from a stainless steel block. For certain

usage conditions valve bodies made of plastic (PVDF or PP) are

available.

High-quality diaphragms ensure complete separation of the critical

medium from the actuator.

1)

have been designed as a system for the control

Observe instructions on operation in an explosion-risk (Ex)

area. See chapter "3.1. Use in Ex area".

english

9

Page 10

Type 2036

Product description

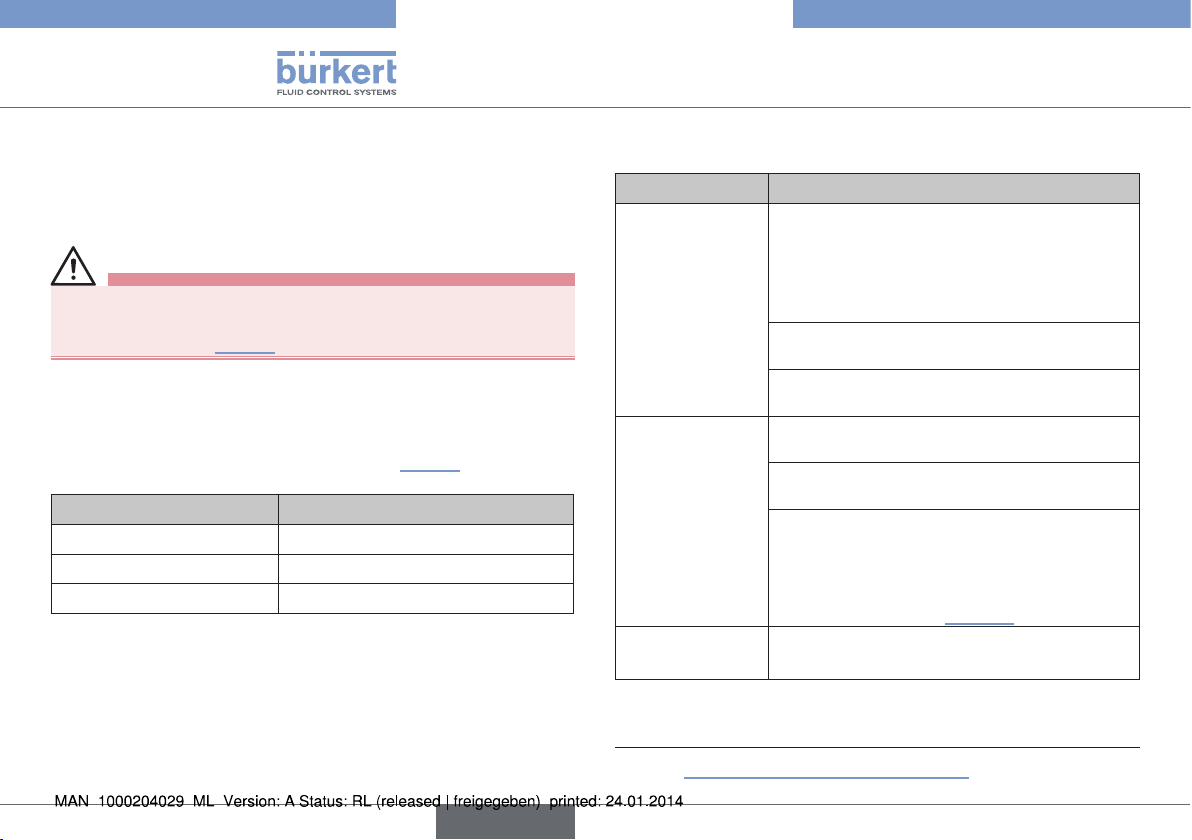

The diaphragm valves can be used for a large variety of control

functions. Accordingly, there is a very wide range of configuration

variations. Depending on the function the valve can have one, two or

three actuators.

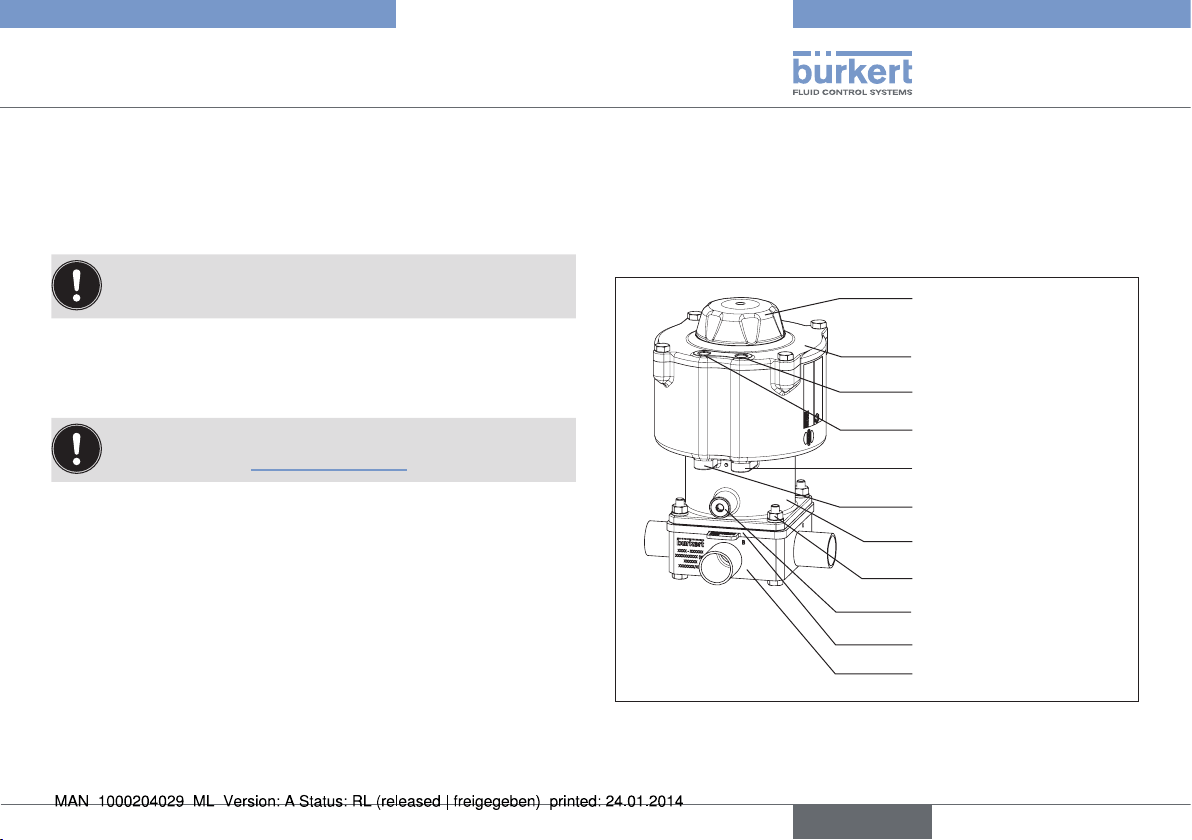

Pneumatically operated

actuator

Diaphragm

Valve body

5.3. Options

The following options are available for controlling the actuators and

feedback of the different switching positions.

• Feedback head Type 8685 with up to four position feedback indicators in the versions 24 V DC, AS-Interface and EExi.

• Control head Type 8686 with up to two pilot valves and position

indicators in the versions 24 V DC, AS-Interface and EExi.

5.4. Valve self-draining

The way in which self-draining takes place varies according to the

valve type. It is very important to know the flow paths for each individual valve before the port / connection (marked with A, B, C or D)

for draining is selected.

Contact your Bürkert sales office or our Sales Center, email:

info@de.buerkert.com if you have any queries.

Fig. 2: Diaphragm valve, structure and description

10

english

Page 11

Type 2036

Product description

Installation positions for self-drainage:

A

B

3C2S / 4C2S

drainage connection

B (D)

Fig. 3: Self-draining - 3C2S / 4C2S

C

A

B

A

D

B

A

B

C

3C2S / 4C2S

drainage connection

C (A)

C

C

Installation positions for self-drainage:

A

B

C

D

4C4S CF

drainage connection

D

Fig. 4: Self-draining - 4C4S CF

B

D

A

C

english

11

Page 12

Type 2036

Product description

Installation positions for self-drainage:

C

D

A

4C4S DFP

drainage connection

A (C)

Fig. 5: Self-draining - 4C4S DFP

B

A

B

A

4C4S DFP

drainage connection

B (D)

D

C

5.5. Valve symbols and flow diagrams

D

C

B

3 connections, 2 seats

3C2S

Seat

U1

A

U1 U2

B

Seat

U2

C

4 connections, 2 seats

4C2S

Seat

U1

D

A

U1 U2

B

Seat

U2

C

12

Fig. 6: Valve symbols and flow diagrams - 3C2S / 4C2S

english

Page 13

Type 2036

Product description

C

Seat

U1

4 connections, 4 seats

4C4S CF

upper side lower side

A

D

L2

L1

Seat

B

U2

B

B

Seat

L1

A

D

A

D

U1

U2

C

Seat

L2

4 connections, 4 seats

4C4S DFP

upper side lower side

D

A

C C

D

C

Seat

U1

Seat

B

L2

U2

A

U1

Seat

L1

D

B

L1

C

U2

Seat

L2

B

Fig. 7: Valve symbols and flow diagrams - 4C4S CF

Fig. 8: Valve symbols and flow diagrams - 4C4S DFP

english

13

Page 14

Type 2036

Product description

5.6. Valve marking

Type label

Marking and warning

notices in Ex area

Actuator orientation

marking

Port connection

markings

Valve body labeling

Bürkert company logo, Orifice and connection dimensions

Material, charge, manufacturing order and serial No.

Fig. 9: Valve marking

5.6.1. Marking and warning notices in Ex

area

See chapter "Use in Ex area" on page 7.

5.6.2. Type label

Company logo

Identification

number

Connection dimensions

Fig. 10: Type label

Date of manufacture

Type - Size - Design

- Diaphragm material

Actuator 1 - Actuator

2 - Pilot pressure

Max. medium pressure medium temperature

5.6.3. Port connection markings

All port connections are provided with letters corresponding to the

flow diagrams (see chapter "5.5. Valve symbols and flow diagrams").

5.6.4. Actuator orientation marking

The actuator has a marking close to connection A as an aid to

ensure correct assembly.

14

Fig. 11: Actuator orientation marking

english

Page 15

Type 2036

Structure and function

5.7. Intended application area

The diaphragm valve has been designed for use with soiled and

aggressive media which do not corrode the body and the seal

materials.

Observe the maximum pressure range according to the

type label.

• Ultra-pure, sterile, aggressive or abrasive media.

• Highly viscous media.

Observe instructions on operation in an explosion-risk (Ex)

area. See chapter "3.1. Use in Ex area".

5.7.1. Application areas

e.g. plant construction

luxury food and food processing industry

bottling plant

chemical engineering

pharmaceutics

6. STRUCTURE AND FUNCTION

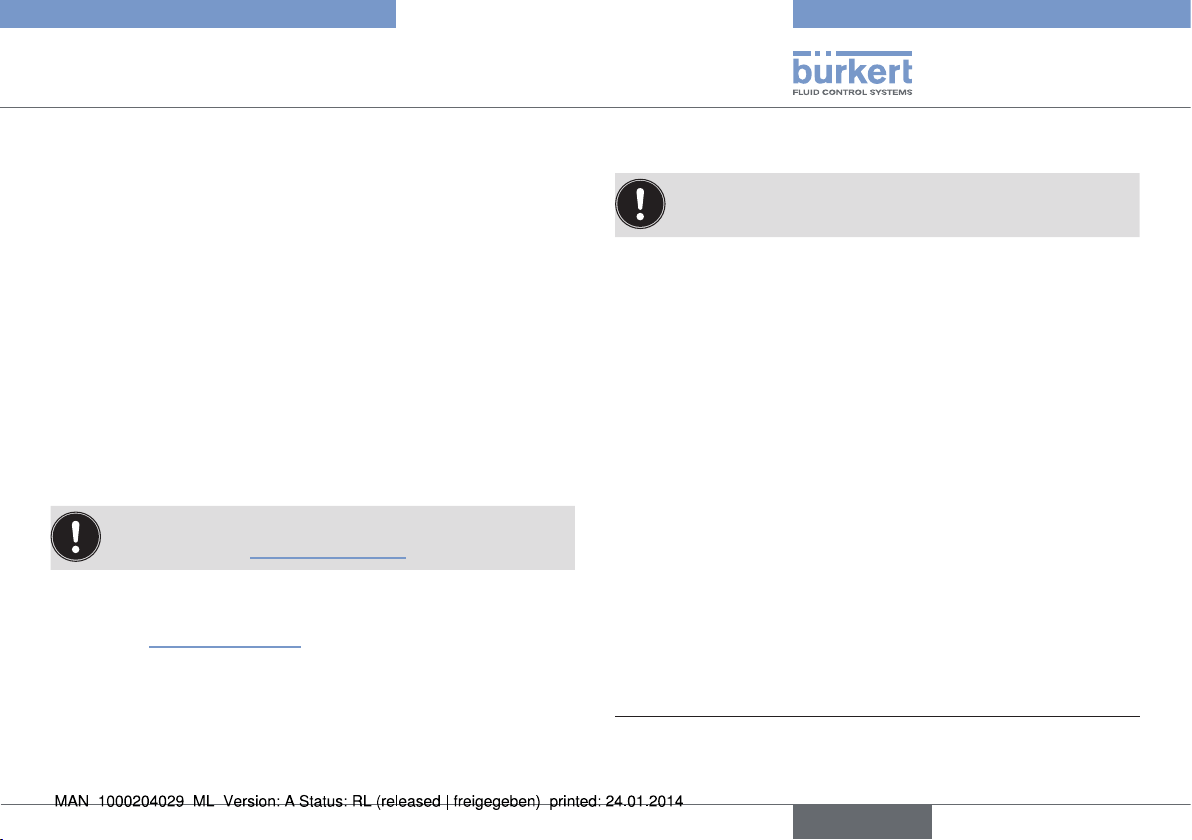

6.1. Structure

The diaphragm valve consists of a pneumatically operated piston

actuator, diaphragm and multi-port valve body.

Transparent cap with

position indicator

Actuator cover

Pilot air port 4

Pilot air port 2

Pilot air port 3

Pilot air port 1

Actuator body

Body screws

Guide pin

Diaphragm

Valve body

Fig. 12: Piston-controlled diaphragm valve, structure and

description

english

15

Page 16

Type 2036

1(P)

2(A)

1(P)

2(B)

Structure and function

6.1.1. Actuator

The actuator has two actuator chambers that can be controlled

independently of each other and act on one body seat each (double

action). Where only one actuator is in operation only one actuator

chamber is equipped with the internal functional parts.

Spring force (CFA, NC) or pneumatic pilot pressure (CFB, NO)

generates the closing force of the actuator.

The force is transmitted onto the corresponding pressure piece and

the diaphragm in each case via a spindle connected to the actuator

piston.

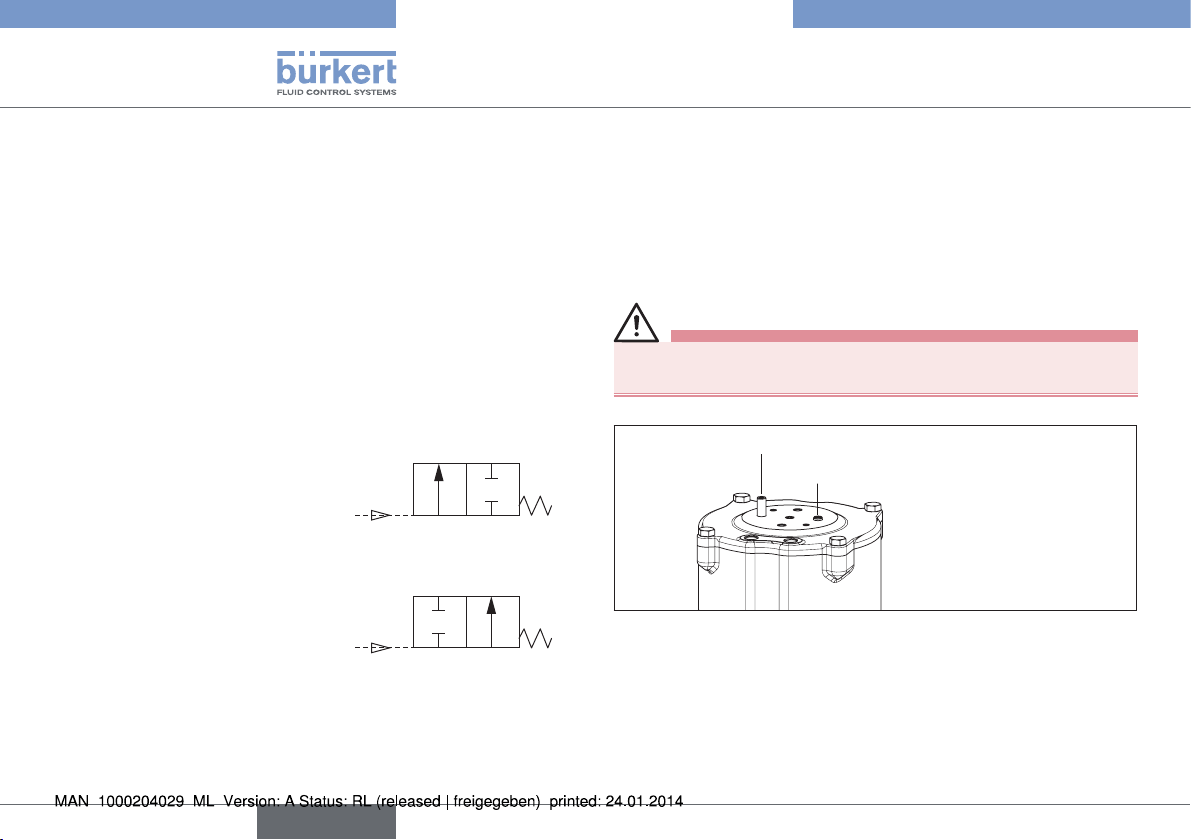

6.1.2. Control functions (CF)

Control function A, NC (CFA)

Closed by spring force in rest

position

Control function B, NO (CFB)

Opened by spring force in rest

position

6.2. Position indicator

The position of both actuator chambers is signaled via position indicators. Two positions are possible:

• Short protrusion of the position indicator → valve closed.

• Long protrusion of the position indicator → valve open

CAUTION!

Risk of being crushed by moving spindle ends.

▶ Install transparent cap.

Long protrusion

Short protrusion

Transparent cap

removed

Fig. 13: Position indicator

16

english

Page 17

Type 2036

Technical Data

7. TECHNICAL DATA

7.1. Conformity

The diaphragm valve of Type 2036 comply with EC Directives in

accordance with the EC Declaration of Conformity.

7.2. Standards

The applied standards on the basis of which compliance with the EC

Directives is confirmed are listed in the EC type examination certificate

and/or the EC Declaration of Conformity.

7.3. Approvals

The product is approved for use in zone 1 and 21 in accordance

with ATEX directive 94/9/EC category 2 GD.

Observe instructions on operation in an explosion-risk (Ex)

area. See chapter "3.1. Use in Ex area".

7.4. Type label

See chapter "5.6. Valve marking".

7.5. Operating conditions

Observe permitted pressure ranges given on the type label

of the device.

2)

Ambient temperature -10 − +60 °C

higher temperatures on request

Relative humidity max. 80 % (non-condensing)

7.6. Mechanical data

Dimensions see data sheet

Materials

Body material stainless steel: 1.4435/316L

(other materials on request)

Diaphragm EPDM, Advanced PTFE/EPDM, FKM,

silicone

Actuator

Body stainless steel precision casting 1.4308

Pressure piece PPS (Polyphenylensulfid) and V2A

2) If a control unit or a pilot valve is used, the max. ambient

temperature is +55 °C.

english

17

Page 18

Type 2036

Technical Data

Connections

Port connections welded spigots

DIN EN ISO 1127 / ISO 4200) /

DIN 11866 Series 2,

DIN 11850 Series 2 / DIN 11866 Series A

ASME BPE / DIN 11866 Series C

Clamp

DIN 32676 Series A (DIN pipe)

DIN 32676 Series B (ISO pipe)

ASME BPE

(other connections on request)

Pilot air port G1/8

Surface quality interior Ra 0.6 µm passivated

exterior Ra 1.6 µm machined

optional electro-polished

(other surface finishes on request)

Installation position any position; preferably connection B

downwards; for self-drainage see chapter

"5.4. Valve self-draining"

The service life of the device depends heavily on the conditions of use.

Especially the service life of the diaphragm depends very heavily on

the conditions of use, such as the medium, temperatures, switching

frequency, pressure etc., and may vary widely in individual cases.

7.6.1. Diaphragm

The diaphragm seals the valve. It must be selected with care. The

choice of material should be made bearing in mind the process

medium, the temperature and the mechanical boundary conditions

(e.g. operating pressure, switching frequency etc.).

The standard materials are contained in the following table.

For conformity with FDA CFR 21 Para. 177.2600 or Para. 177.1550

and USP VI certification, see "Tab. 1: Diaphragm materials".

Diaphragm

material

EPDM AD Peroxide-vulca-

Advanced

PTFE /

EPDM

FKM KL Fluorinated

Silicone SK Platinum-sta-

Tab. 1: Diaphragm materials

Code Description of

material

nized ethylenepropylene

rubber

EK Advanced PTFE

laminated

EPDM

rubber

bilized silicone

rubber

Use FDA USP

VI

Oxidizing

chemicals,

steam and hot

water

Most chemicals and

acids

Acids and

mineral oils

Aliphatic oils x x

x x

x x

x

18

english

Page 19

Type 2036

Technical Data

7.7. Fluidic data

Media

flow media ultra-pure, sterile, aggressive,

(see also chapter "7.6.1. Diaphragm")

Media pressure see chapter "7.7.1. Pressure ranges"

Media temperature

stainless steel/EPDM +5 to +130 °C

(max. +143 °C for 60 min.)

stainless steel/

Advanced PTFE +5 to +90 °C

(no steam sterilization)

stainless steel/FKM +5 to +130 °C

(dry heat up to max. +143 °C)

stainless steel/silicone +5 to +130 °C

(dry heat up to max. +143 °C)

Observe instructions on operation in an explosion-risk (Ex)

area. See chapter "3.1. Use in Ex area".

Pilot medium Neutral gases, dry air (min. 10 K below

min. operating temperature), preferably

unoiled

Pilot pressure

3) Pressure values [bar]: Overpressure with respect to atmospheric

pressure

3)

6 – 10 bar (RV50, RV70)

6 – 7 bar (RV110)

from 4.2 bar (with reduced medium

pressure) on request

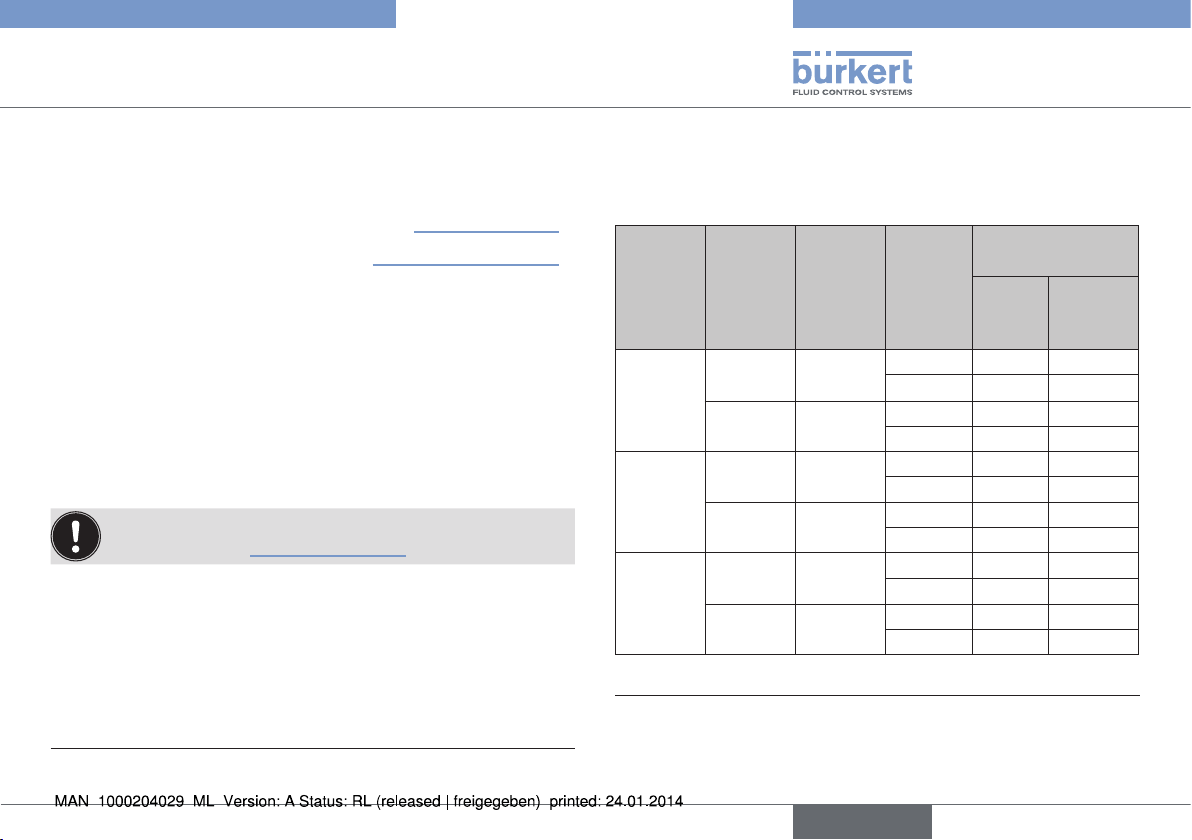

7.7.1. Pressure ranges

Pilot pressure and operation pressure for CFA, NC

Values for stainless steel body

max. operation

pressure [bar]

EPDM,

FKM,

Size

Actuator

version

Pilot

pressure

4)

[bar]

Test

criterion

5)

Silicone

Static 7.5 7.5

Dynamic 6.5 5.5

Static 5.0 3.5

Dynamic 4.0 2.5

Static 8.0 8.0

Dynamic 6.0 6.0

Static 5.5 6.0

Dynamic 3.5 4.0

Static 7.0 7.5

Dynamic 5.0 5.5

Static 5.0 5.0

Dynamic 3.0 3.0

RV50

RV70

RV110

D11

D1x; Dx1

6 – 10

D55 4.2 – 10

D11

D1x; Dx1

6 – 10

D55 4.2 – 10

D11

D1x; Dx1

6 – 7

D55 4.2 – 7

Tab. 2: Pilot pressure and operation pressure

4) See type label.

5) Pressure values [bar]: Overpressure with respect to atmospheric

pressure

english

5)

Advanced

PTFE/

EPDM

19

Page 20

Type 2036

Technical Data

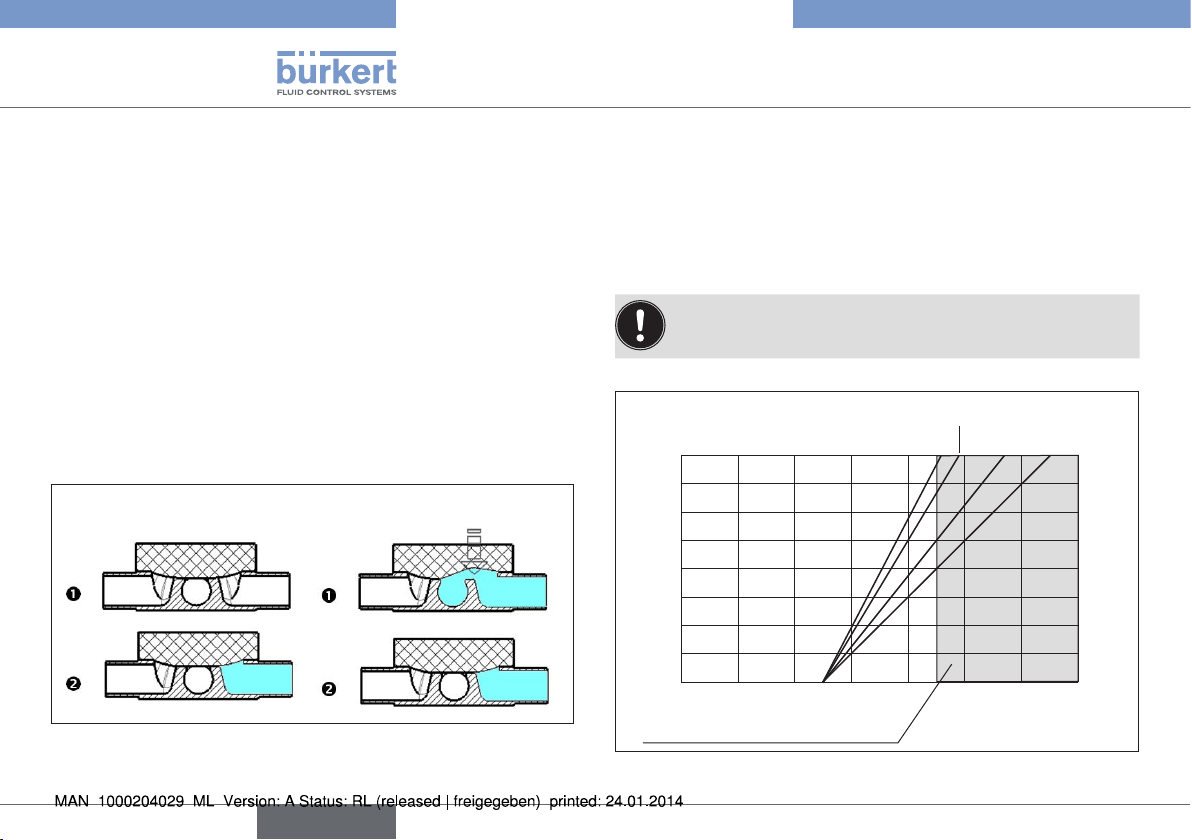

Remarks

Static leak-tightness:

Valve is closed (diaphragm is in contact with the body seat). One

side of the body seat is under pressure. At the given pressure no

leakage takes place via the body seat.

Dynamic leak-tightness:

Valve is open and the medium is flowing through it. The downstream

flow is only slightly throttled by components placed downstream.

Both sides of the body seat are under pressure. The valve is closed

(CFA, NC via spring force; CFB, NO via pilot pressure). At the

given pressure the valve closes onto the body seat and the seal is

complete.

Static leak-tightness:

Dynamic leak-tightness:

Fig. 14: Static and dynamic leak-tightness

Pilot pressure and operation pressure for CFB, NO

The following graphs illustrate the required minimum pilot pressure

depending on the medium pressure for control function B.

Permitted pilot pressure range: 2 – 7 bar.

The pilot pressure should be selected to be as low as possible to reduce wear on the diaphragm.

RV50/RV110

static

RV70

8

7

6

5

4

3

Medium pressure [bar]

2

1

0

0 1 2 3 4 5 6 7

Range for valves with control unit

static

RV70

dynamic

Pilot pressure [bar]

RV50/RV110

dynamic

Fig. 15: Pilot pressure depending on the medium pressure

20

english

Page 21

Type 2036

Assembly

8. ASSEMBLY

8.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

WARNING!

Risk of injury from improper assembly.

▶ Installation must only be carried out by authorized technicians

and with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

8.2. Before installation

→ Before connecting the valve, ensure the pipelines are flush.

→ Pay attention to the flow direction.

8.2.1. Installation position

• The piston-controlled diaphragm valve can be installed in any

position, preferably with connection B downwards.

• Installation for self-drainage of the body:

see chapter "5.4. Valve self-draining"

8.2.2. Preparatory work

→ Clean pipelines (sealing material, swarf, etc.).

→ Support and align pipelines.

Devices with welded body

NOTE!

Damage to diaphragm or actuator.

▶ Before welding in the body disassemble the actuator and

diaphragm.

Remove the actuator from the valve body:

→ Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

→ Mark the position of the actuator in relation to the valve body.

→ Unscrew the four body screws that connect the valve body with

the actuator. Remove the actuator and the diaphragm.

english

21

Page 22

Actuator

Guide pin

Body screws

Diaphragm

Valve body

Fig. 16: Assembly

8.3. Installation

WARNING!

Risk of injury from improper assembly.

Non-compliance with the tightening torques is dangerous due to

possible discharge of medium and possible release of pressure.

▶ Observe the tightening torque (see "Tab. 3: Tightening torque").

Type 2036

Assembly

8.3.1. Installing the body

Welded body

→ Weld valve body in pipeline system.

Other body designs

→ Connect body to pipeline.

8.3.2. Installing the actuator (welded body)

→ Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

→ Put the actuator / diaphragm on the body with correct alignment

(so that the markings made previously align). In the case of RV110

the four spacer sleeves must be inserted in the designated body

holes (see "Fig. 20: Disassembly / assembly the diaphragm" on

page 28).

→ Tighten the diagonally opposed body screws / nuts until there

is visible, uniform mechanical contact between the valve body,

diaphragm and actuator.

→ Switch the diaphragm valve twice.

22

english

Page 23

Type 2036

Assembly

WARNING!

Risk of injury from discharge of medium and release of

pressure.

▶ Tighten the body screws sufficiently (see "Tab. 3").

→ Move the actuator to the lower actuator position (CFA, NC: by

removing pilot pressure; CFB, NO: by applying the pilot pressure).

→ Without applying pilot pressure, tighten the body screws to the

permitted tightening torque (see "Tab. 3").

Size Tightening torque [Nm]

RV50 6

RV70 17

RV110 30

Tab. 3: Tightening torque

8.4. Pneumatic connection

DANGER!

Risk of injury from high pressure in the system.

▶ Before disconnecting lines and valves, turn off the pressure and

vent the lines.

WARNING!

Risk of injury from unsuitable connection hoses.

Hoses which cannot withstand the pressure and temperature

range may result in hazardous situations.

▶ Use only hoses which are authorized for the indicated pressure

and temperature range.

▶ Observe the data sheet specifications from the hose manufacturers.

8.4.1. Connection of the pilot medium

To comply with the degree of protection IP65 / IP67 on the

pilot air port which is not required (for CFA, NC and CFB,

NO), install an exhaust air line in the dry area.

For the assignment of pilot air ports refer to the installation and dimensional drawing included with delivery of the valve. Compare also the

information given in chapter "6. Structure and function".

The use of pneumatic hose with a minimum size of 6/4 is recommended.

For longer hose lengths the hose cross-sections should be adapted

accordingly.

In aggressive surroundings and in situations where moisture

could enter the actuator via the exhaust air port or muffler

the exhaust air should be collected and ducted to a noncritical location.

english

23

Page 24

Type 2036

Assembly

Control function A:

→ Connect the control medium to the pilot air port 1 and/or 3

(see "Fig. 17").

Control function B:

→ Connect the control medium to the pilot air port 2 and/or 4

(see "Fig. 17").

Silencer

→ Connect the silencer into the free air discharge connection

(see "Fig. 17").

Actuator 1

(left)

Pilot air port

2 (P2)

Pilot air port

1 (P1)

Actuator 2

(right)

Pilot air port

4 (P4)

Pilot air port

3 (P3)

Actuator

version

D11, D55

CFA/CFA

(NC/NC)

D12

CFA/CFB

(NC/NO)

D21

CFB/CFA

(NO/NC)

D22

CFB/CFB

(NO/NO)

Tab. 4: Pneumatic connection for actuator versions

CFA, NC : Valve normally closed by spring action

CFB, NO : Valve normally open by spring action

Numbers for

actuator 1

Actuator 1 Actuator 2

CF Connection CF Connection

Pilot air P1

CFA,

NC

CFA,

NC

CFB,

NO

CFB,

NO

indicating

P2: air discharge

Pilot air P1

P2: air discharge

Pilot air P2

P1: air discharge

Pilot air P2

P1: air discharge

CFA

CFB

CFA

CFB

Pilot air P3

P4: air discharge

Pilot air P4

P3: air discharge

Pilot air P3

P4: air discharge

Pilot air P4

P3: air discharge

Numbers for

indicating

actuator 2

Fig. 17: Pneumatic connection

24

Fig. 18: Cover film

english

Page 25

Type 2036

Electrical control unit

9. ELECTRICAL CONTROL UNIT

The electrical connection of the pilot valve / control unit is

described in the operating instructions for the pilot valve /

control unit.

Observe instructions on operation in an explosion-risk (Ex)

area. See chapter "3.1. Use in Ex area".

10. DISASSEMBLY

DANGER!

Risk of injury from discharge of medium and release of

pressure.

It is dangerous to remove a device which is under pressure due to

the sudden release of pressure or discharge of medium.

▶ Before removing a device, switch off the pressure and vent the

lines.

If the valve is to be reused after removal, the actuator must

be removed before disassembly where welded bodies are

involved. For this, refer to the assembly instructions.

Procedure:

→ Loosen pneumatic connection.

→ Remove device.

11. MAINTENANCE, CLEANING

11.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before reaching into the device, switch off the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper maintenance.

▶ Installation must only be carried out by authorized technicians

and with the appropriate tools.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

english

25

Page 26

Type 2036

Maintenance, Cleaning

11.2. Servicing intervals

Check the diaphragm valves regularly for proper operation in terms

of assembly, installation and operation. Take the following factors into

account when planning servicing intervals:

• Operational conditions (amount of usage, improper usage),

• manufacturer's specifications in the technical documentation (e.g.

mechanical service life,

• major system modifications.

11.3. Servicing work

Do not repair the device yourself, but replace it with an

equivalent device. Repairs may be performed by the manufacturer only.

11.3.1. Actuator

The actuator of the diaphragm valve is maintenance-free provided it

is used according to these operating instructions.

11.3.2. Wearing parts of the diaphragm valve

The diaphragm is subject to wear.

→ If leakage occurs replace the diaphragm (see chapter "12. Repairs").

A bulging diaphragm may reduce the flow rate.

The replacement of the diaphragm is described in chapter

"12. Repairs".

11.4. Cleaning

NOTE!

Avoid causing damage with cleaning agents.

▶ Before cleaning, check that the cleaning agents are compatible

with the device materials.

Observe instructions on operation in an explosion-risk (Ex)

area. See chapter "3.1. Use in Ex area".

Actuator

Clean the actuator surface using a moist cloth. Only use cleaning

agents that do not attack the actuator surface.

Body / Diaphragm

The bodies are suitable for CIP. Clean the valves using cleaning

agents that do not attack the body and diaphragm materials. Avoid

cleaning agents with high pH values.

26

english

Page 27

Type 2036

Repairs

12. REPAIRS

12.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Risk of electric shock.

▶ Before reaching into the device, switch off the power supply

and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations

for electrical equipment.

WARNING!

Risk of injury from improper repair.

▶ Installation must only be carried out by authorized technicians

and with the appropriate tools.

▶ Observe the tightening torques.

▶ On completion of the work check valve for leaks and function.

Risk of injury from unintentional activation of the system and

uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following maintenance, ensure a controlled restart.

12.2. Replacing the diaphragm

Required spare part

• Diaphragm

12.2.1. Disassembly of the actuator and

diaphragm

→ Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

→ Mark the position of the actuator in relation to the valve body.

→ Unscrew the four body screws that connect the valve body with

the actuator. Remove the valve body.

→ Move the actuator to the lower actuator position (CFA, NC: by

removing pilot pressure; CFB, NO: by applying the pilot pressure).

→ Unscrew guide pin all the way.

english

27

Page 28

Type 2036

Repairs

Fig. 19: Repairs

Guide pin

Actuator

Guide pin

Body screws

Diaphragm

Valve body

2

Diaphragm

Pressure

pieces

Spacer sleeve

Fig. 20: Disassembly / assembly the diaphragm

1

→ Turn the diaphragm and pressure pieces through 30° and take

them out (step 1).

→ Take the diaphragm out of the pressure pieces sideways

(step 2).

28

english

Page 29

Type 2036

Repairs

12.2.2. Assembly of actuator and

diaphragm

WARNING!

Risk of injury from moving parts in the device.

• When applying or removing the pilot pressure on the actuator,

keep limbs and objects away from the openings of the actuator.

→ Move the actuator to the lower actuator position (CFA, NC: by

removing pilot pressure; CFB, NO: by applying the pilot pressure).

→ Insert the diaphragm into the guide of the pressure pieces. Make

sure that the four spacing sleeves are installed (see "Fig. 20").

→ Insert the pressure pieces into the actuator. Make sure that

the actuator spindles are fully inserted into the corresponding

recesses of the pressure pieces (see "Fig. 21").

→ Turn the diaphragm and pressure pieces through approx. 30°.

2

1

Fig. 21: Assembly pressure pieces

approx. 30°

Pressure

pieces

Actuator

spindle

NOTE!

Damage to the diaphragm.

• Turn diaphragm and pressure pieces only as far as is required

until the actuator and diaphragm screw holes are in alignment.

→ Screw guide pin all the way in ("Fig. 19").

→ Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

Guide pin

Identification plate

diaphragm

Body seat

Fig. 22: Assembly of the actuator

→ Put the actuator / diaphragm on the body with correct alignment

(so that the markings made previously align, or guide pin, identification plate and body seats have been aligned in parallel). In the

case of RV110 the four spacer sleeves must be inserted in the

designated body holes.

english

29

Page 30

Type 2036

Malfunctions

→ Tighten the diagonally opposed body screws / nuts until there

is visible, uniform mechanical contact between the valve body,

diaphragm and actuator.

→ Switch the diaphragm valve twice.

WARNING!

Risk of injury from discharge of medium and release of

pressure.

▶ Tighten the body screws sufficiently (see "Tab. 5").

→ Move the actuator to the lower actuator position (CFA, NC: by

removing pilot pressure; CFB, NO: by applying the pilot pressure).

→ Without applying pilot pressure, tighten the body screws to the

permitted tightening torque (see "Tab. 5").

Size Tightening torque [Nm]

RV50 6

RV70 17

RV110 30

Tab. 5: Tightening torque

13. MALFUNCTIONS

Malfunction Cause / remedial action

Actuator

does not

switch.

Valve is not

sealed.

Pilot air port interchanged

CFA, NC:

CFB, NO:

Pilot pressure too low

See pressure specifications on the type label.

Medium pressure too high

See pressure specifications on the type label.

Medium pressure too high

See pressure specifications on the type label.

Pilot pressure too low

See pressure specifications on the type label.

Actuator is rotated by 90° and installed opposite

the valve body.

Connect the pilot air port 1 and/or 3

Connect the pilot air port 2 and/or 4

→ Guide pin, identification plate and body seats

must be aligned in parallel (see "Fig. 22").

Flow rate

reduced.

Tab. 6: Malfunctions

Diaphragm bulging

→ Replace diaphragm.

6)

30

6) see "Fig. 17: Pneumatic connection".

english

Page 31

Type 2036

Spare parts

14. SPARE PARTS

WARNING

Risk of injury when opening the actuator.

The actuator contains a tensioned spring. If the actuator is opened,

there is a risk of injury because the spring may jump out.

▶ The actuator must not be opened.

CAUTION!

Risk of injury and/or damage by the use of incorrect parts.

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

▶ Use original accessories and original spare parts from Bürkert

only.

The diaphragm is available as a spare part for the diaphragm valve

Type 2036.

If you have any queries, please contact your Bürkert sales

office.

14.1. Order table

Size Order numbers for diaphragms

EPDM

Code AD

RV50 236 280 236 281

RV70 236 282 236 283

RV110 236 284 236 285

Tab. 7: Diaphragm ordering table

Other diaphragms on request.

Advanced PTFE/EPDM

Code EK

english

31

Page 32

15. TRANSPORT, STORAGE,

PACKAGING

NOTE!

Transport damage.

Inadequately protected devices may be damaged during

transportation.

▶ Protect the device against moisture and dirt in shock-resistant

packaging during transportation.

▶ Prevent the temperature from exceeding or dropping below the

permitted storage temperature.

▶ Protect the pneumatic connections from damage by placing

protective caps on them.

Incorrect storage may damage the device.

▶ Store the device in a dry and dust-free location.

▶ Storage temperature 0 – +60 °C.

If the device is stored with tightened body screws, the diaphragm may be permanently deformed.

▶ If the device is stored for a prolonged period, slacken the body

screws.

Type 2036

Transport, Storage, Packaging

Damage to the environment caused by device components

contaminated with media.

▶ Ensure that the device and packaging are disposed of in an

environmentally sound manner.

▶ Observe applicable disposal and environmental regulations.

32

english

Page 33

Typ 2036

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ............................................................35

1.1. Darstellungsmittel ...........................................................................35

1.2. Begriffsdefinition / Abkürzung .....................................................35

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ...................................36

2.1. Beschränkungen ............................................................................36

3. GRUNDLEGENDE SICHERHEITSHINWEISE ................................. 36

3.1. Hinweise für den Einsatz im Ex-Bereich ...................................37

3.2. Besondere Bedingungen .............................................................38

4. ALLGEMEINE HINWEISE .......................................................................... 39

4.1. Kontaktadresse ...............................................................................39

4.2. Gewährleistung...............................................................................39

4.3. Informationen im Internet ..............................................................39

5. PRODUKTBESCHREIBUNG ................................................................... 39

5.1. Allgemeine Beschreibung ............................................................39

5.2. Gerätevarianten ..............................................................................39

5.3. Optionen ..........................................................................................40

5.4. Selbstentleerung der Membranventile ......................................40

5.5. Ventilsymbole und Fließbilder ......................................................42

5.6. Ventilkennzeichnung ......................................................................44

5.7. Vorgesehener Einsatzbereich ......................................................45

6. AUFBAU UND FUNKTION ....................................................................... 45

6.1. Aufbau ...............................................................................................45

6.2. Antrieb ..............................................................................................46

6.3. Stellungsanzeige ............................................................................46

7. TECHNISCHE DATEN ................................................................................ 47

7.1. Konformität .......................................................................................47

7.2. Normen .............................................................................................47

7.3. Zulassungen ....................................................................................47

7.4. Typschild ..........................................................................................47

7.5. Betriebsbedingungen ....................................................................47

7.6. Mechanische Daten .......................................................................47

7.7. Fluidische Daten .............................................................................49

8. MONTAGE ........................................................................................................51

8.1. Sicherheitshinweise .......................................................................51

8.2. Vor dem Einbau ..............................................................................51

8.3. Einbau ...............................................................................................52

8.4. Pneumatischer Anschluss ............................................................53

9. ELEKTRISCHE ANSTEUERUNG ...........................................................55

10. DEMONTAGE ............................................................................................... 55

11. WARTUNG, REINIGUNG ......................................................................... 55

11.1. Sicherheitshinweise.....................................................................55

11.2. Wartungsintervalle .......................................................................56

11.3. Wartungsarbeiten ........................................................................56

11.4. Reinigung .......................................................................................56

12. INSTANDHALTUNG ...................................................................................57

12.1. Sicherheitshinweise.....................................................................57

12.2. Austausch der Membran ............................................................57

deutsch

33

Page 34

13. STÖRUNGEN ................................................................................................60

14. ERSATZTEILE ...............................................................................................61

14.1. Bestelltabelle.................................................................................61

15. TRANSPORT, LAGERUNG, VERPACKUNG ..................................62

Typ 2036

34

deutsch

Page 35

Typ 2036

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Geräts. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Geräts

wieder zur Verfügung steht.

WARNUNG!

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit.

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

▶ Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr.

▶ Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation.

▶ Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung.

▶ Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden.

▶ Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

▶ markiert eine Anweisung zur Gefahrenvermeidung.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2. Begriffsdefinition / Abkürzung

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer für

das Robolux Mehrwege-Membranventil Typ 2036.

Der in dieser Anleitung verwendeten Begriff „Membranventil“ steht

immer für das Robolux Mehrwege-Membranventil Typ 2036.

Die in dieser Anleitung verwendete Abkürzung „Ex“ steht

immer für „explosionsgefährdet“.

deutsch

35

Page 36

Typ 2036

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßer Verwendung des Robolux

Mehrwege-Membranventils Typ 2036 können Gefahren

für Personen, Anlagen in der Umgebung und die Umwelt

entstehen.

Das Gerät ist für die Steuerung des Durchflusses von flüssigen

Medien konzipiert.

▶ Für den Einsatz sind die in den Vertragsdokumenten, der Bedie-

nungsanleitung und auf dem Typschild spezifizierten zulässigen

Daten, Betriebs- und Einsatzbedingungen zu beachten. Die vorgesehenen Einsatzfälle sind im Kapitel „5. Produktbeschreibung“

aufgeführt.

▶ Gerät nur in Verbindung mit von Bürkert empfohlenen bzw. zuge-

lassenen Fremdgeräten und -komponenten einsetzen.

▶ Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instandhaltung.

▶ Gerät nur bestimmungsgemäß verwenden.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

GEFAHR!

Verletzungsgefahr durch hohen Druck in Anlage/Gerät.

▶ Vor Arbeiten an Anlage oder Gerät, den Druck abschalten und

Leitungen entlüften/entleeren.

Verletzungsgefahr durch Stromschlag.

▶ Vor Arbeiten an Anlage oder Gerät, die Spannung abschalten

und vor Wiedereinschalten sichern.

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten.

WARNUNG!

Verletzungsgefahr beim Öffnen des Antriebs.

Der Antrieb enthält gespannte Federn. Beim Öffnen des Antriebs

kann es durch herausspringende Federn zu Verletzungen kommen.

▶ Der Antrieb darf nicht geöffnet werden.

36

deutsch

Page 37

Typ 2036

Grundlegende Sicherheitshinweise

VORSICHT!

Verbrennungsgefahr.

Bei Dauerbetrieb kann die Geräteoberfläche heiß werden.

▶ Gerät nicht mit bloßen Händen berühren.

Quetschgefahr durch sich bewegende Spindelenden.

▶ Klarsichthaube montieren.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

▶ Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

▶ Installations- und Instandhaltungsarbeiten dürfen nur von auto-

risiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

▶ Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung einen definierten oder kontrollierten Wiederanlauf des

Prozesses gewährleisten.

▶ Gerät nur in einwandfreiem Zustand und unter Beachtung der

Bedienungsanleitung betreiben.

▶ Für die Einsatzplanung und den Betrieb des Geräts die allgemeinen

Regeln der Technik einhalten.

Zum Schutz vor Sachschäden am Gerät ist zu beachten:

▶ In die Medienanschlüsse nur Medien einspeisen, die im Kapitel

„7. Technische Daten“ aufgeführt sind.

▶ Gerät nicht mechanisch belasten (z. B. durch Ablage von Gegen-

ständen oder als Trittstufe).

▶ Keine äußerlichen Veränderungen an den Geräten vornehmen.

Gehäuseteile und Schrauben nicht lackieren.

3.1. Hinweise für den Einsatz

im Ex-Bereich

Abkürzung „Ex“: siehe Kapitel „1.2. Begriffsdefinition / Abkürzung“.

3.1.1. Sicherheitshinweise

Bei Einsatz im Ex-Bereich Zone (Gas) 1 und 2,

Zone (Staub) 21 und 22, gilt:

Der Ventilantrieb ist geeignet als Kategorie 2 Gerät für Zone 1 & 21,

nichtelektrisches Betriebsmittel.

GEFAHR!

Explosionsgefahr durch elektrostatische Aufladungen.

An der Ventilmembran sowie bei Verwendung von Kunststoffgehäusen

kann es je nach Leitfähigkeit des Mediums zu elektrostatischen Aufladungen kommen.

Um elektrostatische Aufladungen in der Fluidik zu vermeiden, müssen

folgende Hinweise beachtet werden (nach IEC 60079-32-1):

▶ (1) Medien mit einer Leitfähigkeit ≤ 100 pS/m dürfen nur einge-

setzt werden, wenn keine Strömungsgeschwindigkeiten > 1 m/s

auftreten oder wenn der Trockenlauf des Rohrsystems durch eine

diesbezügliche Überwachung ausgeschlossen ist.

▶ (2) Medien mit einer Leitfähigkeit > 100 pS/m und ≤ 1000 pS/m

dürfen nur eingesetzt werden, wenn es Flüssigkeiten ohne Partikel,

Wasserdampf oder reine Gase/Dämpfe sind oder die Hinweise aus

(1) beachtet werden.

▶ (3) Medien mit einer Leitfähigkeit > 1000 pS/m unterliegen keinen

Einschränkungen.

deutsch

37

Page 38

Typ 2036

Grundlegende Sicherheitshinweise

Weitere Hinweise:

▶ Der Anwender muss sicherstellen, dass das Gerät nur in Zone 1/21

bzw. 2/22 eingesetzt wird.

▶ Die Ansteuerung kann den Einsatz in explosionsfähiger Atmosphäre

einschränken. Bedienungsanleitung der Ansteuerung beachten.

▶ Reinigungsmittel auf Zulassung in explosionsfähiger Atmosphäre

prüfen.

3.1.2. Medientemperatur

GEFAHR!

▶ Werden explosionsfähige Medien verwendet, kann dadurch eine

zusätzliche Explosionsgefahr auftreten.

▶ Sollten Medientemperaturen zwischen 130 °C und 150 °C zur

Anwendung kommen, gilt Temperaturklasse T3 / 200 °C (Staub).

Medientemperatur max. 130 °C

3.1.3. Ex-Kennzeichnung

PTB 13 ATEX D103 X

II 2G c IIC T4

II 2D c T135°C

Warning: Not valid when Non-Ex devices added.

Die Ex-Kennzeichnung ist nicht gültig, wenn Nicht-Ex-Geräte

hinzugefügt werden.

3.2. Besondere Bedingungen

→ Zur Sicherstellung des Potentialausgleichs das Ventilgehäuse

durch elektrisch leitenden Anschluss an das Rohrsystem erden.

GEFAHR!

Explosionsgefahr durch elektrostatische Aufladung.

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im Ex-Bereich Explosionsgefahr.

▶ Durch geeignete Maßnahmen sicherstellen, dass es im Ex-

Bereich zu keinen elektrostatischen Aufladungen kommen kann

(siehe auch „3.1. Hinweise für den Einsatz im Ex-Bereich“).

▶ Die Geräteoberfläche nur durch leichtes Abwischen mit einem

feuchten oder antistatischen Tuch reinigen.

▶ Antrieb und Ventilgehäuse erden.

▶ Bei Verwendung von Kunststoffgehäusen den Antrieb separat erden.

Umgebungstemperaturbereich: 0 °C ≤ Tamb ≤ 60 °C

Do not open actuator. Spring loaded cover.

Bild 1: Ex-Kennzeichnung

38

deutsch

Page 39

Typ 2036

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des Membranventils unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 2036 finden Sie

im Internet unter:

www.buerkert.de

5. PRODUKTBESCHREIBUNG

5.1. Allgemeine Beschreibung

Die pneumatisch betätigten Robolux-Mehrwege-Membranventile1)

wurden als Systeme für die Steuerung von hochreinen, sterilen, aggressiven oder abrasiven Medien konstruiert. Sie ermöglichen das optimale

Sammeln, Entleeren oder Verteilen von kritischen Prozessmedien.

Hinweise für den Einsatz im Ex-Bereich beachten.

Siehe Kapitel „3.1“.

1) Das Robolux Mehrwege-Membranventil wird im folgenden Text

verkürzt als Membranventil bezeichnet.

5.2. Gerätevarianten

Das Membranventil lässt sich aufgrund seiner Modularität an die

unterschiedlichsten Einsatzbedingungen anpassen.

Je nach Anschlussgröße der Membranventile stehen drei Baugrößen

(RV5O, RV7O, RV110) zur Verfügung.

Das Ventilgehäuse ist aus einem Edelstahlblock gefertigt. Für

bestimmte Einsatzbedingungen werden Ventilgehäuse aus Kunststoff (PVDF oder PP) angeboten.

Membranen von hoher Qualität trennen das kritische Medium komplett vom Antrieb.

deutsch

39

Page 40

Typ 2036

Produktbeschreibung

Die Membranventile können eine Vielzahl von Steuerfunktionen realisieren. Dementsprechend ist die Konfiguration der Membranventile

sehr vielfältig. Abhängig von der Funktion kann das Membranventil

über einen oder zwei Antriebe verfügen.

Pneumatisch

betätigter

Antrieb

Membran

Ventilgehäuse

5.3. Optionen

Für die Ansteuerung der Antriebe und Rückmeldung der verschiedenen Schaltstellungen stehen folgende Optionen zur Verfügung.

• Rückmeldekopf Typ 8685 mit bis zu vier Stellungsrückmeldern in

den Versionen 24 V DC, AS-Interface und EExi.

• Steuerkopf Typ 8686 mit bis zu zwei Steuerventilen und vier

Stellungsrückmeldern in den Versionen 24 V DC, AS-Interface

und EExi.

5.4. Selbstentleerung der

Membranventile

Die Selbstentleerung erfolgt je nach Ventiltypen unterschiedlich. Es

ist sehr wichtig, die Durchflusswege jedes einzelnen Membranventils

zu kennen, bevor der Port / Anschluss (markiert mit A, B, C oder D)

für die Entleerung ausgewählt wird.

Wenden Sie sich bei Fragen an Ihre Bürkert Vertriebsniederlassung

oder an unser Sales Center, E-mail: info@de.buerkert.com

Bild 2: Kolbengesteuertes Membranventil, Aufbau und

Beschreibung

40

deutsch

Page 41

Typ 2036

Produktbeschreibung

Einbaulagen für die Selbstentleerung:

A

B

3C2S / 4C2S

Entleerungsanschluss

B (D)

Bild 3: Selbstentleerung - 3C2S / 4C2S

C

A

A

B

Entleerungsanschluss

C

B

D

C

B

A

C

3C2S / 4C2S

C (A)

Einbaulagen für die Selbstentleerung:

A

B

C

D

4C4S CF

Entleerungsanschluss

D

Bild 4: Selbstentleerung - 4C4S CF

B

D

A

C

deutsch

41

Page 42

Typ 2036

Produktbeschreibung

Einbaulagen für die Selbstentleerung:

C

D

A

4C4S DFP

Entleerungsanschluss

A (C)

Bild 5: Selbstentleerung - 4C4S DFP

B

D

A

B

D

A

B

4C4S DFP

Entleerungsanschluss

B (D)

C

C

5.5. Ventilsymbole und Fließbilder

3-Anschlüsse, 2-Sitze

3C2S

Sitz

U1

A

U1 U2

B

Sitz

U2

C

4-Anschlüsse, 2-Sitze

4C2S

Sitz

U1

D

A

U1 U2

B

C

Sitz

U2

42

Bild 6: Ventilsymbole und Fließbilder - 3C2S / 4C2S

deutsch

Page 43

Typ 2036

Produktbeschreibung

4-Anschlüsse, 4-Sitze

4C4S CF

obere Seite untere Seite

A

B

B

A

obere Seite untere Seite

A

Sitz

L2

C

Sitz

U1

C

Sitz

U1

D

L2

L1

Sitz

U2

B

D

Sitz

L1

A

D

U1

U2

C

4-Anschlüsse, 4-Sitze

4C4S DFP

D

Sitz

B

L2

U2

A

U1

C C

D

B

Sitz

L1

D

Sitz

B

L1

L2

C

U2

Bild 7: Ventilsymbole und Fließbilder - 4C4S CF

Bild 8: Ventilsymbole und Fließbilder - 4C4S DFP

deutsch

43

Page 44

Typ 2036

Produktbeschreibung

5.6. Ventilkennzeichnung

Typschild

Ex-Kennzeichnung und

Warnhinweise

Kennzeichnung

Antriebsausrichtung

Kennzeichnung

Leitungsanschlüsse

Beschriftung Ventilgehäuse

Bürkert Firmenzeichen, Nennweite und Stutzenmaße

Werkstoff, Charge, Fertigungsauftrag und Serien-Nr.

Bild 9: Ventilkennzeichnung

5.6.1. Kennzeichnung Ex-Bereich und

Warnhinweise

Siehe Kapitel „3.1. Hinweise für den Einsatz im Ex-Bereich“ auf

Seite 37.

5.6.2. Typschild

Herstellerkennzeichen

Ident.-Nr.

Anschlussmaße

Bild 10: Typschild

Baudatum

Ventiltyp - Baugröße

- Bauform

- Membranwerkstoff

Antrieb 1 - Antrieb 2

- Steuerdruck

max. Mediumsdruck

- Mediumstemperatur

5.6.3. Kennzeichnung Leitungsanschlüsse

Alle Leitungsanschlüsse sind mit Buchstaben versehen, in Übereinstimmung mit den Fließbildern (siehe Kapitel „5.5. Ventilsymbole und

Fließbilder“).

5.6.4. Kennzeichnung Antriebsausrichtung

Der Antrieb ist im Bereich von Anschluss A mit einem Kennzeichen

versehen, um die lagerichtige Montage zu erleichtern.

44

Bild 11: Kennzeichnung Antriebsausrichtung

deutsch

Page 45

Typ 2036

Aufbau und Funktion

5.7. Vorgesehener Einsatzbereich

Das Membranventil ist für den Einsatz bei verschmutzten und

aggressiven Medien konzipiert, die das Gehäuse- und den Dichtwerkstoff nicht angreifen.

Den maximalen Druckbereich laut Typschild beachten.

• Hochreine, sterile, aggressive oder abrasive Medien.

• Höherviskose Medien.

Hinweise für den Einsatz im Ex-Bereich beachten.

Siehe Kapitel „3.1“.

5.7.1. Anwendungsgebiete

z. B. Anlagenbau

Genuss- und Nahrungsmittelindustrie

Abfüllanlagen

Chemische Verfahrenstechnik

Pharmazie

6. AUFBAU UND FUNKTION

6.1. Aufbau

Das Membranventil besteht aus pneumatisch betätigtem Kolbenantrieb, Membran und Multiport-Ventilgehäuse.

Klarsichthaube mit

Stellungsanzeige

Antriebsdeckel

Steuerluftanschluss 4

Steuerluftanschluss 2

Steuerluftanschluss 3

Steuerluftanschluss 1

Antriebsgehäuse

Gehäuseschrauben

Führungsbolzen

Membran

Ventilgehäuse

Bild 12: Kolbengesteuertes Membranventil, Aufbau und

Beschreibung

deutsch

45

Page 46

1(P)

2(A)

1(P)

2(B)

Typ 2036

Aufbau und Funktion

6.2. Antrieb

Der Antrieb besitzt zwei Antriebskammern, die unabhängig voneinander angesteuert werden können und je auf einen Gehäusesitz

wirken (Doppelantrieb). Im Falle Einfachantrieb ist nur eine Antriebskammer mit Funktionsinnenteilen bestückt.

Federkraft (bei SFA) oder pneumatischer Steuerdruck (bei SFB)

erzeugen die Schließkraft des Antriebs.

Über je eine Spindel, die mit dem Antriebskolben verbunden ist,

wird die Kraft auf das zugehörige Druckstück und die Membran

übertragen.

.

6.2.1. Steuerfunktionen (SF)

Steuerfunktion A (SFA)

In Ruhestellung durch Federkraft

geschlossen

Steuerfunktion B (SFB)

In Ruhestellung durch Federkraft

geöffnet

6.3. Stellungsanzeige

Die Position beider Antriebskammern wird über Stellungsanzeigen

signalisiert. Es sind zwei Positionen möglich:

• Kurzer Überstand der Stellungsanzeige → Membranventil

geschlossen

• Langer Überstand der Stellungsanzeige → Membranventil offen

VORSICHT!

Quetschgefahr durch sich bewegende Spindelenden.

▶ Klarsichthaube montieren.

langer Überstand

kurzer Überstand

Ansicht ohne

Klarsichthaube

Bild 13: Stellungsanzeige

46

deutsch

Page 47

Typ 2036

Technische Daten

7. TECHNISCHE DATEN

7.1. Konformität

Das Membranventil Typ 2036 ist konform zu den EG-Richtlinien

entsprechend der EG-Konformitätserklärung.

7.2. Normen

Die angewandten Normen, mit denen die Konformität mit den EGRichtlinien nachgewiesen wird, sind in der EG-Konformitätserklärung

nachzulesen.

7.3. Zulassungen

Das Produkt ist entsprechend der ATEX Richtlinie 94/9/EG der

Kategorie 2 G/D zum Einsatz in Zone 1 und 21 zugelassen.

Hinweise für den Einsatz im Ex-Bereich beachten.

Siehe Kapitel „3.1“.

7.4. Typschild

Siehe Kapitel „5.6. Ventilkennzeichnung“.

7.5. Betriebsbedingungen

Die zulässigen Bereiche auf dem Typschild des Geräts

beachten.

2)

Umgebungstemperatur 0 ... +60 °C

höhere Temperaturen auf Anfrage

Relative Luftfeuchte max. 80 % (nicht kondensierend)

7.6. Mechanische Daten

Abmessungen siehe Datenblatt

Werkstoffe

Gehäusematerial Edelstahl: 1.4435/316L

(andere Werkstoffe auf Anfrage)

Membran EPDM, Advanced PTFE/EPDM, FKM,

Silikon

Antrieb Gehäuse Edelstahl Feinguss 1.4308

Druckstück PPS (Polyphenylensulfid)

und V2A

2) Bei Verwendung einer Ansteuerung oder eines Vorsteuerventils

beträgt die max. Umgebungstemperatur +55 °C.

deutsch

47

Page 48

Typ 2036

Technische Daten

Anschlüsse

Leitungsanschlüsse Schweißstutzen

DIN EN ISO 1127 / ISO 4200 /

DIN 11866 Reihe B

DIN 11850 Reihe 2 / DIN 11866 Reihe A

ASME BPE / DIN 11866 Reihe C

Clamp

DIN 32676 Reihe A (DIN Rohr)

DIN 32676 Reihe B (ISO Rohr)

ASME BPE

(weitere Ausführungen auf Anfrage)

Steuerluftanschluss G 1/8

Oberflächengüte innen Ra 0,6 µm passiviert

außen Ra 1,6 µm spanend hergestellt

optional elektropoliert

(weitere Oberflächengüten auf Anfrage)

Einbaulage beliebig, vorzugsweise Anschluss B

nach unten; für Selbstentleerung siehe

Kapitel „5.4. Selbstentleerung der

Membranventile“

Die Gerätelebensdauer wird stark von den Einsatzbedingungen

beeinflusst. Insbesondere die Membranlebensdauer hängt sehr stark

von den Betriebsbedingungen, wie z. B. Medium, Temperaturen,

Schaltfrequenz, Druck, usw. ab, und kann im Einzelfall stark streuen.

7.6.1. Membran

Die Membran dichtet das Membranventil ab. Sie muss sorgfältig

gewählt werden. Die Auswahl des Werkstoffs sollte abgestimmt

sein auf das Prozessmedium, die Temperatur und die mechanischen

Gegebenheiten (z. B. Betriebsdruck, Schalthäufigkeit, usw.).

Die nachfolgende Tabelle zeigt die Standardwerkstoffe.

Konformität zu FDA CFR 21 §177.2600 bzw. §177.1550 und

USP VI Zertifizierung siehe „Tab. 1: Membranwerkstoffe“.

Membranwerkstoff

EPDM AD peroxidvulkani-

Advanced

PTFE/

EPDM

FKM FL Fluorkautschuk Säuren und

Silikon SK Platin-stabilisierter

Tab. 1: Membranwerkstoffe

Code Werkstoffbe-

schreibung

sierter ÄthylenPropylen-Kautschuk

EK Advanced PTFE

kaschiertes EPDM

Silikonkautschuk

Anwendung FDA USP

VI

oxidierende

Chemikalien,

Dampf und

Heißwasser

die meisten

Chemikalien und

Säuren

mineralische Öle

aliphatische

Öle

x x

x x

x

x

48

deutsch

Page 49

Typ 2036

Technische Daten

7.7. Fluidische Daten

Medien

Durchflussmedien hochrein, steril, aggressiv,

(siehe auch Kapitel „7.6.1. Membran“)

Mediendruck siehe Kapitel „7.7.1. Druckbereiche“

Medientemperatur

Edelstahl/EPDM +5 bis +130 °C

(max. +143 °C für 60 Min.)

Edelstahl/Advanced PTFE +5 bis +90 °C

(keine Dampfsterilisation)

Edelstahl/FKM +5 bis +130 °C

(trockene Hitze bis max. +143°C)

Edelstahl/Silikon 5+ bis +130 °C

(trockene Hitze bis max. +143°C)

Hinweise für den Einsatz im Ex-Bereich beachten.

Siehe Kapitel „3.1“.

Steuermedium

Steuermedium Neutrale Gase, Luft

getrocknet (min. 10 K unter min. Betriebstemperatur), vorzugsweise ungeölt

Steuerdruck

3) Druckangabe [bar]: Überdruck zum Atmosphärendruck

3)

6 ... 10 bar (RV50, RV70)

6 ... 7 bar (RV110)

ab 4,2 bar (bei reduziertem Mediumsdruck)

auf Anfrage

7.7.1. Druckbereiche

Steuerdruck und Betriebsdruck in SFA

Werte für Edelstahlgehäuse

max. Betriebsdruck [bar]

EPDM,

FKM,

Silikon

Baugröße

RV50

RV70

RV110

Antriebsausführung

D11

D1x; Dx1

D55 4,2 ... 10

D11

D1x; Dx1

D55 4,2 ... 10

D11

D1x; Dx1

D55 4,2 ... 7

4)

Steuerdruck

5)

[bar]

6 ... 10

6 ... 10

6 ... 7

Prüfkriterium

Statisch 7,5 7,5

Dynamisch 6,5 5,5

Statisch 5,0 3,5

Dynamisch 4,0 2,5

Statisch 8,0 8,0

Dynamisch 6,0 6,0

Statisch 5,5 6,0

Dynamisch 3,5 4,0

Statisch 7,0 7,5

Dynamisch 5,0 5,5

Statisch 5,0 5,0

Dynamisch 3,0 3,0

Tab. 2: Steuerdruck und Betriebsdruck

4) Siehe Typschild.

5) Druckangabe [bar]: Überdruck zum Atmosphärendruck.

5)

Advanced

PTFE/

EPDM

deutsch

49

Page 50

Typ 2036

Technische Daten

Anmerkungen

Statische Dichtheit:

Membranventil ist geschlossen (Membran liegt am Gehäusesitz an).

Druck steht auf einer Seite des Gehäusesitzes an. Bei dem angegebenem Druck entsteht keine Leckage über den Gehäusesitz.

Dynamische Dichtheit:

Membranventil ist geöffnet und wird vom Medium durchströmt. Die

Abströmseite wird durch nachfolgende Komponenten nur geringfügig abgedrosselt. Druck steht auf beiden Seiten des Gehäusesitz

an. Das Membranventil wird geschlossen (SFA durch Federkraft;

SFB durch Steuerdruck). Bei dem angegebenem Druck schließt das

Membranventil über den Gehäusesitz dicht ab.

Statische Dichtheit:

Dynamische Dichtheit:

Bild 14: Statische und dynamische Dichtheit

Steuerdruck und Betriebsdruck in SFB