Page 1

Type 2031

INOX

2/2-way Diaphragm valve

2/2-Wege Membranventil

Vanne à membrane 2/2 voies

Quickstart

English Deutsch Français

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2014 Bürkert Werke GmbH

Operating Instructions 1403/00_EU-ML_00810366 / Original DE

Page 3

Type 2031 INOX

Quickstart

Contents

1 QUICKSTART ..................................................................................................3

2 CONTACT ADDRESSES ...........................................................................3

3 INTENDED USE .............................................................................................4

4 BASIC SAFETY INSTRUCTIONS ..........................................................4

5 TECHNICAL DATA ........................................................................................5

6 INSTALLATION ...............................................................................................7

7 START-UP .........................................................................................................9

8 MAINTENANCE, CLEANING ...................................................................9

9 TRANSPORTATION, STORAGE, DISPOSAL ................................ 10

1 QUICKSTART

The quickstart comprises important information.

▶ Carefully read the quickstart and observe any safety information.

▶ The quickstart must be available to every user.

▶ The liability and warranty for type 2031 INOX do not apply if the quick-

start are not observed.

The quickstart illustrates the installation and commissioning of the

equipment with examples. A detailed description of the device can be

found in the operating instructions in the internet at: www.burkert.com

1.1 Definition of term

The term “device” used in these instructions always stands for the

diaphragm valve Type 2031 INOX.

2 CONTACT ADDRESSES

Bürkert Fluid Control Systems / Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found in the internet at: www.burkert.com

If you have any queries, please contact your Bürkert sales

office.

english

3

Page 4

Type 2031 INOX

Basic safety instructions

2.1 Symbols

Warning to prevent death or serious injuries:

DANGER!

Warns of an immediate danger!

WARNING!

Warns of a potentially dangerous situation!

Warning to prevent moderate or minor injuries:

CAUTION!

Warns of a possible danger!

NOTE!

Warns of material damage!

Important tips and recommendations.

→ designates a procedure which you must carry out.

3 INTENDED USE

Diaphragm valve Type 2031 INOX is designed to control the flow-rate

of liquid and gaseous media.

• Observe the permitted application conditions for using the equipment.

• Operate only when in perfect condition and pay attention to correct

storage, transportation, installation and operation.

4 BASIC SAFETY INSTRUCTIONS

Danger – high pressure!

▶ Before dismounting the lines and valves, turn off the pressure and

vent the lines.

Risk of electric shock!

▶ Before reaching into the device, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

Risk of crushing from moving pneumatic connection!

▶ When opening and closing the device, do not touch the moving

pneumatic connection.

▶ Do not reach into the area immediately above and below the

control air connection.

Risk of burns/risk of fire if used during long-term operation

through hot device surface!

▶ Do not touch the device with bare hands.

▶ Keep the device away from highly flammable substances and

media.

4

english

Page 5

Type 2031 INOX

Technical data

General hazardous situations.

To prevent injury, ensure:

▶ Secure system/equipment against unintentional activation.

▶ Supply only media to the media connections which have been

specified as flow media in the chapter “Technical data”.

▶ Do not make any internal or external changes to type 2031 INOX

and do not load mechanically.

▶ Installation and repair work may be carried out by authorized

technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

▶ The general rules of technology apply to application planning and

operation of the device.

5 TECHNICAL DATA

5.1 Conformity

The diaphragm valve Type 2031 INOX is compliant with the EC Directives according to the EC Declaration of Conformity.

5.2 Standards

The applied standards which are used to demonstrate compliance with

the EC Directives are listed in the EC type test certificate and/or the

EC Declaration of Conformity.

5.3 Operating conditions

5.3.1 Temperature ranges

Ambient temperature: 0 °C … +60 °C

Medium temperature: -10 °C … +140 °C

Permitted medium temperature depending on diaphragm material:

Diaphragm

material

EPDM -10 ... +130 °C Steam sterilization up to 140 °C

PTFE / EPDM -10 ... +130 °C Steam sterilization up to 140 °C

Laminated

advanced PTFE

1)

The specified medium temperature applies only to media which does not

attack diaphragm materials. The behavior of the medium with respect to the

diaphragm may be changed by the temperature of the medium.

The functional characteristics, in particular the service life of the diaphragm,

may be impaired as the temperature of the medium rises.

Medium

temperature

1)

-10 ... +90 °C -

Remark

english

5

Page 6

Type 2031 INOX

P

A

P

A

2031 A 8,0 EPDM VA

00445286

Technical data

5.3.2 Pressure ranges

WARNING!

Risk of bursting due to overpressure!

If the device bursts, there is a risk of serious injury, chemical burns,

scalding.

▶ Do not exceed the maximum pilot and medium pressure. Observe

specifications on the rating plate.

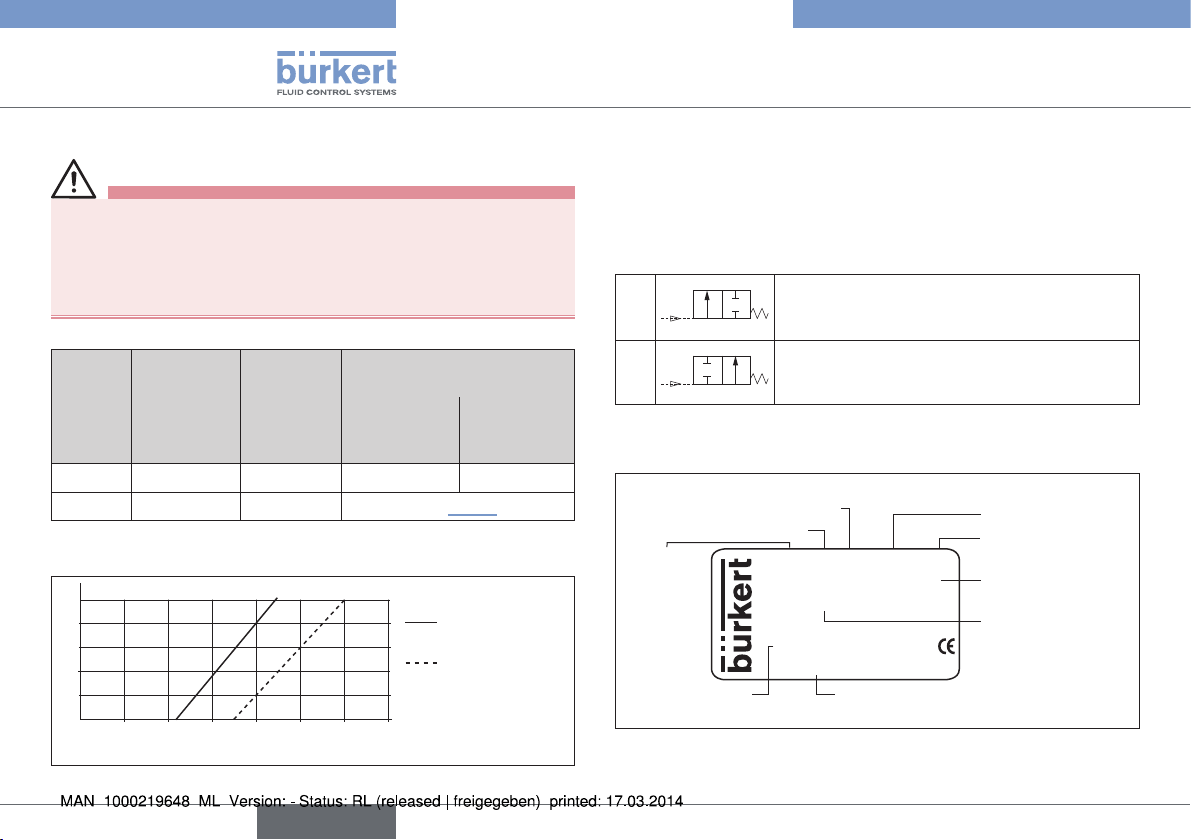

Permitted pilot- and medium pressure:

Control

function

(CF)

CFA 5.5 10 10 6

CFB 2.2 7 see “Fig. 1”

Minimum

pilot

pressure

[bar]

Maximum

pilot

pressure

[bar]

Maximum medium pressure

Elastomer

(including

coated)

[bar]

PTFE and

Advanced

PTFE

Required minimum pilot pressure for control function B

depending on the medium pressure on one side:

10

8

6

4

2

0 1 2

Medium pressure [bar]

Fig. 1: Pressure graph, elastomer and Advanced PTFE diaphragm

6

3

4 5 6 7

Pilot pressure [bar]

english

Elastomer

(including coated)

PTFE and

Advanced PTFE

5.3.3 Permitted media

Control medium: neutral gases, air

Flow media: neutral gases and liquids, high-purity, sterile,

aggressive and abrasive media

5.4 Control functions

A

B

Closed in rest position by spring force

Open in rest position by spring force

5.5 Type label

Orifice (Diaphragm size)

Control function

Type

G1/4 Pmed 8,5 bar

Pilot 5,5-10 bar

S/N 1060

Made in Germany

Serial number

Fig. 2: Description of the type label

Identifications number

W36LP

Seal material

Body material

Connections, Max.

medium pressure

Pilot pressure

Page 7

Type 2031 INOX

Installation

6 INSTALLATION

DANGER!

Danger – high pressure!

▶ Before dismounting the lines and valves, turn off the pressure and

vent the lines.

Risk of electric shock!

▶ Before reaching into the device, switch off the power supply and

secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Risk of injury from improper installation, unintentional activation

of the system and uncontrolled restart!

▶ Installation must only be carried out by authorized technicians and

with the appropriate tools!

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

Risk of crushing from moving pneumatic connection!

▶ When opening and closing the device, do not touch the moving

pneumatic connection.

▶ Do not reach into the area immediately above and below the

control air connection.

6.1 Before installation

• Before connecting the valve, ensure the lines are flush.

• The flow direction is optional.

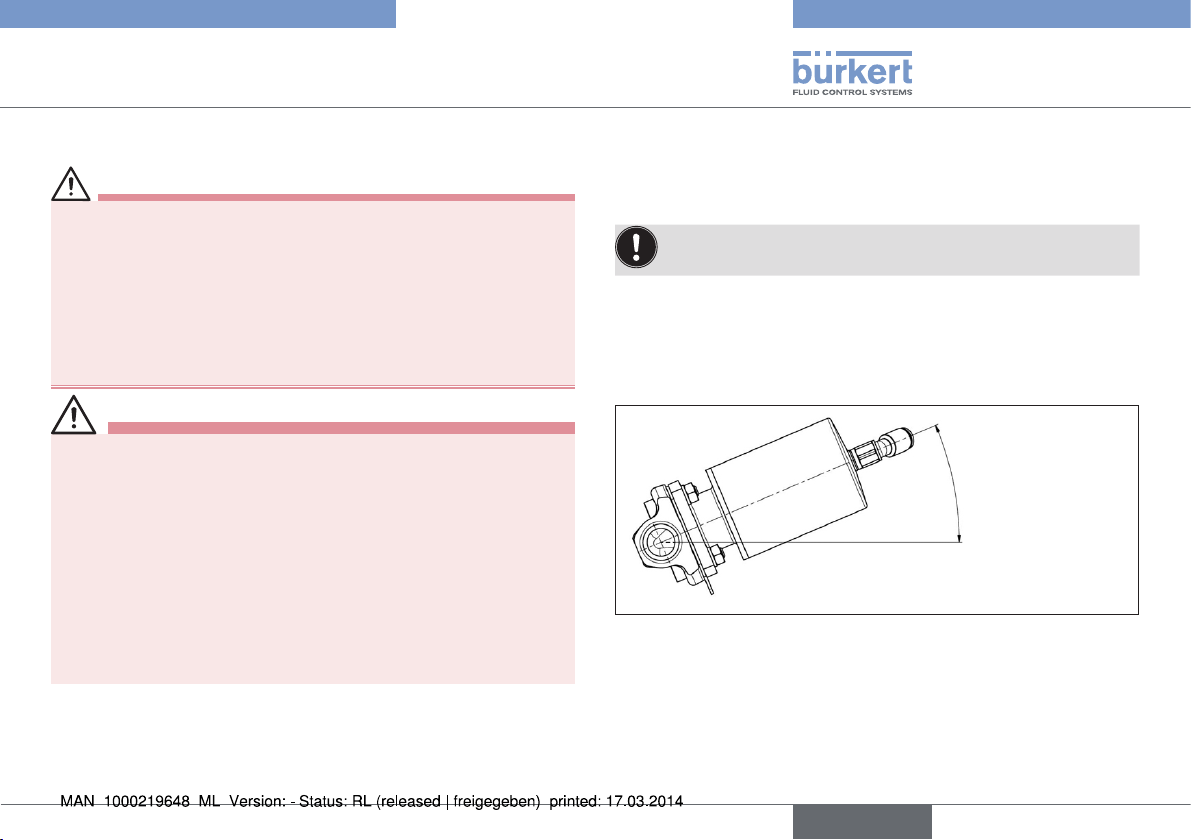

6.1.1 Installation position

Installation position: any, preferably with the actuator face up.

Installation for self-drainage of the body:

It is the responsibility of the installer and operator to ensure

self-drainage.

To ensure self-drainage:

• mark (-) on the body must be at 12 o’clock,

• hole in the diaphragm base must be at the lowest point to monitor

leakage.

Drainage angle -2°

Fig. 3: Installation position for self-drainage of the body

6.1.2 Preparatory work

→ Clean pipelines (sealing material, swarf, etc.).

→ Support and align pipelines.

english

7

Page 8

Type 2031 INOX

Installation

Devices with VG/VS welded body

Before welding the body, the actuator must be removed.

6.2 Installation

WARNING!

Risk of injury from incorrect installation!

Non-observance of the specified tightening torque is hazardous

as the device may be damaged.

▶ Observe tightening torque during installation.

6.2.1 Devices with VG/VS welded body

Before welding the body, the actuator must be removed.

Remove actuator and diaphragm from the body

Procedure for control function A:

→ Apply control air connection with compressed air (5.5 bar).

→ Loosen fastening screws in diagonal pairs and remove actuator

together with diaphragm from the body.

→ Weld body into the pipeline.

Procedure for control function B:

→ Loosen fastening screws in diagonal pairs and remove actuator

together with diaphragm from the body.

→ Weld body into the pipeline.

6.2.2 Installation

Installation for actuator with control function A:

→ Align diaphragm.

The mark tab of the diaphragm must be vertical to the flow

of direction.

→ Place actuator on the body.

→ Apply control air connection with compressed air (5.5 bar).

→ Lightly tighten fastening screws crosswise until the diaphragm is

situated between the body and actuator.

Do not tighten screws yet!

→ Switch diaphragm valve twice.

→ Tighten fastening screws.

Observe tightening torque (2.5 Nm)!

Installation for actuator with control function B:

→ Align diaphragm.

The mark tab of the diaphragm must be vertical to the flow

of direction.

→ Place actuator on the body.

→ Lightly tighten fastening screws crosswise until the diaphragm is

situated between the body and actuator.

Do not tighten screws yet!

→ Apply control air connection with compressed air (5.5 bar).

→ Switch diaphragm valve twice.

→ Tighten fastening screws.

Observe tightening torque (2.5 Nm)!

8

english

Page 9

Type 2031 INOX

Installation

6.3 Pneumatic connection

WARNING!

Risk of injury from unsuitable connection hoses!

Hoses which cannot withstand the pressure and temperature range

may result in hazardous situations.

▶ Use only hoses which are authorized for the indicated pressure

and temperature range.

▶ Observe the data sheet specifications from the hose manufacturers.

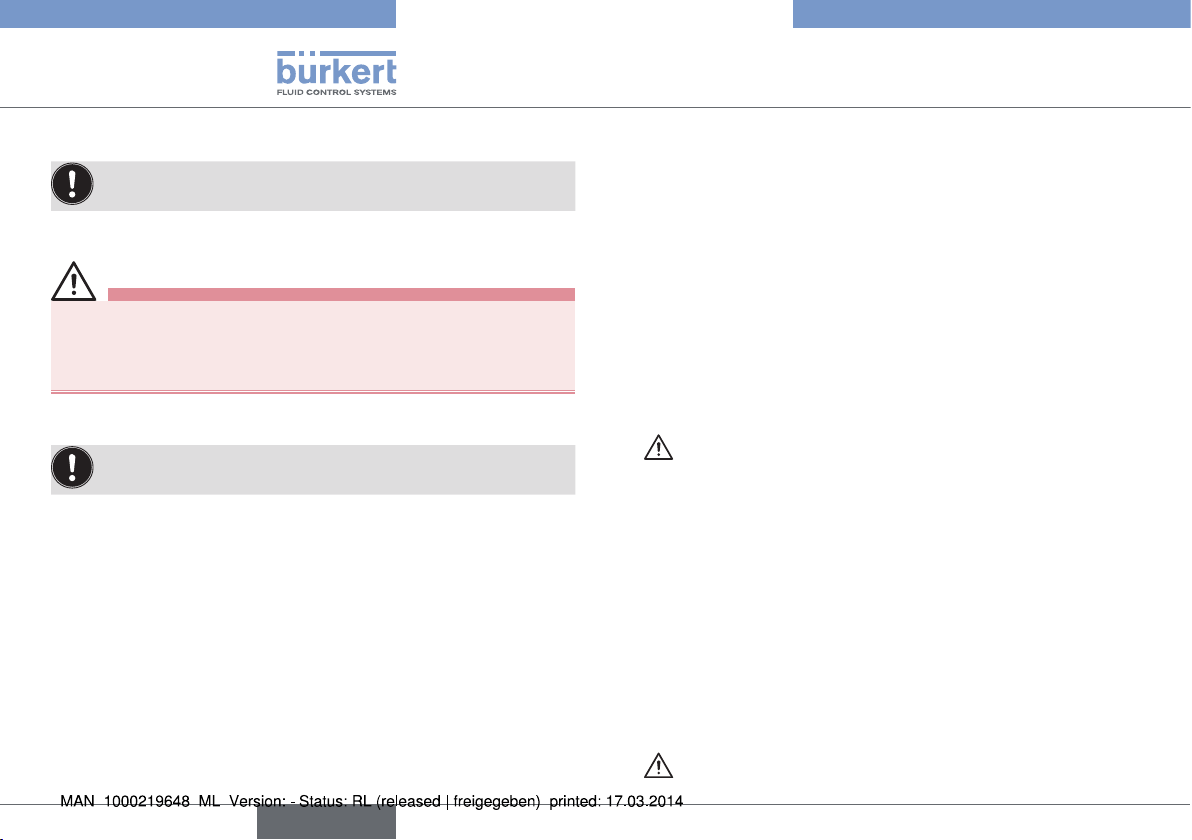

6.3.1 Control air connections

The 45° angle connection, which can be ordered

separately, is recommended for the control air connection! In this case the free-moving hose length

should be min. 250 mm. If the hose length is shorter,

the durability and function of the plug-in coupling

will be impaired!

If a straight control air connection is used, the freemoving hose length should be min. 400 mm.

If the hose length is shorter, the durability and

function of the plug-in coupling will be impaired!

Risk of crushing!

▶ Due to the risk of crushing, a 90° control air con-

nection must not be used!

7 START-UP

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

▶ Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the manual.

▶ Observe the safety instructions and intended use.

▶ Only adequately trained personnel may start up the device.

Observe the type label specifications and information on pressure

and temperature values in chapter “Technical data”.

8 MAINTENANCE, CLEANING

8.1 Actuator

The actuator of the diaphragm valve is maintenance-free provided it is

used according to these operating instructions.

8.1.1 Wearing parts of the diaphragm valve

Parts which are subject to natural wear:

• Diaphragm

→ If leaks occur, replace the diaphragm with a new one.

A distended PTFE diaphragm may reduce the flow-rate.

english

9

Page 10

Type 2031 INOX

Transportation, Storage, Disposal

8.1.2 Inspection intervals

→ Check diaphragm for wear after a maximum 10

Muddy and abrasive media require correspondingly shorter

inspection intervals!

5

switching operations.

8.2 Cleaning

Commercially available cleaning agents can be used to clean the

surface of the device.

NOTE!

Before cleaning, check that the cleaning agents are compatible

with the body materials and seals.

9 TRANSPORTATION, STORAGE,

DISPOSAL

NOTE!

Transport and storage damage!

• Protect the device against moisture and dirt in shock-resistant

packaging during transportation and storage.

• Permitted storage temperature: -20 … +65 °C.

Storage with tightened body screws may result in permanent

deformation of the diaphragm.

• Slacken body screws for prolonged storage.

Damage to the environment caused by device components

contaminated with media.

• Dispose of the device and packaging in an environmentally

friendly manner!

10

english

Page 11

Typ 2031 INOX

Der Quickstart

InhaltsverzeIChnIs

1 DER QUICKSTART .................................................................................... 11

2 KONTAKTADRESSEN ..............................................................................11

3 BESTIMMUNGSGEMÄSSER GEBRAUCH ................................... 12

4 GRUNDLEGENDE SICHERHEITSHINWEISE .............................. 12

5 TECHNISCHE DATEN ............................................................................. 13

6 MONTAGE .....................................................................................................15

7 INBETRIEBNAHME ...................................................................................17

8 WARTUNG, REINIGUNG ........................................................................ 17

9 TRANSPORT LAGERUNG, ENTSORGUNG .................................18

1 DER QUICKSTART

Der Quickstart enthält wichtige Informationen.

▶ Quickstart sorgfältig lesen und Hinweise zur Sicherheit beachten.

▶ Quickstart muss jedem Benutzer zur Verfügung stehen.

▶ Die Haftung und Gewährleistung für Typ 2031 INOX entfällt, wenn

die Anweisungen des Quickstarts nicht beachtet werden.

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme

des Geräts. Die ausführliche Beschreibung des Geräts finden Sie im

Internet unter: www.buerkert.de

1.1 Begriffsdefinition Gerät

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer für

das Membranventil Typ 2031 INOX.

2 KONTAKTADRESSEN

Bürkert Fluid Control Systems / Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie im Internet unter: www.burkert.com

Bei Fragen Ihre Bürkert-Vertriebsniederlassung kontaktieren.

deutsch

11

Page 12

Typ 2031 INOX

Grundlegende Sicherheitshinweise

2.1 Darstellungsmittel

Warnung vor tödlichen oder schweren Verletzungen:

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

Warnung vor mittelschweren oder leichten Verletzungen:

VORSICHT!

Warnt vor einer möglichen Gefährdung!

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

3 BESTIMMUNGSGEMÄSSER

GEBRAUCH

Das Membranventil Typ 2031 INOX ist für die Steuerung des Durchflusses von flüssigen und gasförmigen Medien konzipiert.

• Für den Einsatz die zulässigen Einsatzbedingungen beachten.

• Nur in einwandfreiem Zustand betreiben und auf sachgerechte

Lagerung, Transport, Installation und Bedienung achten.

4 GRUNDLEGENDE

SICHERHEITSHINWEISE

Gefahr durch hohen Druck!

▶ Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten

und Leitungen entlüften.

Gefahr durch elektrische Spannung!

▶ Vor Eingriffen in das Gerät oder die Anlage, Spannung abschalten

und vor Wiedereinschalten sichern!

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

Quetschgefahr durch sich bewegenden pneumatischen

Anschluss!

▶ Beim Öffnen und Schließen des Geräts nicht den sich bewegen-

den pneumatischen Anschluss berühren.

▶ Nicht in den unmittelbaren Bereich oberhalb und unterhalb des

Steuerluftanschlusses fassen.

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch heiße

Geräteoberfläche!

▶ Das Gerät nicht mit bloßen Händen berühren.

▶ Das Gerät von leicht brennbaren Stoffen und Medien fernhalten.

12

deutsch

Page 13

Typ 2031 INOX

Technische Daten

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

▶ Anlage/Gerät vor unbeabsichtigtem Betätigen sichern.

▶ In die Medienanschlüsse nur Medien einspeisen, die im Kapitel

„Technische Daten“ als Durchflussmedien aufgeführt sind.

▶ An Typ 2031 INOX keine inneren oder äußeren Veränderungen

vornehmen und nicht mechanisch belasten.

▶ Nur geschultes Fachpersonal darf Installations- und Instandhal-

tungsarbeiten ausführen.

▶ Nach Unterbrechung der elektrischen Versorgung für einen kon-

trollierten Wiederanlauf des Prozesses sorgen.

▶ Die allgemeinen Regeln der Technik einhalten.

5 TECHNISCHE DATEN

5.1 Konformität

Das Membranventil, Typ 2031 INOX ist konform zu den EG-Richtlinien

entsprechend der EG-Konformitätserklärung.

5.2 Normen

Die angewandten Normen, mit denen die Konformität zu den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

5.3 Betriebsbedingungen

5.3.1 Zulässige Temperaturen

Umgebungstemperatur: 0 °C … +60 °C

Mediumstemperatur: -10 °C … +140 °C

Zulässige Mediumstemperatur abhängig von Membranwerkstoff:

Membran-

werkstoff

EPDM -10 ... +130 °C Dampfsterilisation bis 140 °C

PTFE / EPDM -10 ... +130 °C Dampfsterilisation bis 140 °C

Advanced

PTFE kaschiert

1)

Die angegebene Mediumstemperatur gilt nur für Medien, welche die Membranwerkstoffe nicht angreifen. Das Verhalten des Mediums gegenüber der

Membran kann sich durch die Mediumstemperatur verändern.

Die Funktionseigenschaften, insbesondere die Lebensdauer der Membran,

können sich bei steigender Mediumstemperatur verschlechtern.

Mediumstem-

peratur

1)

-10 ... +90 °C -

Bemerkung

deutsch

13

Page 14

Typ 2031 INOX

P

A

P

A

2031 A 8,0 EPDM VA

00445286

Technische Daten

5.3.2 Druckbereiche

WARNUNG!

Berstgefahr bei Überdruck!

Beim Bersten des Geräts drohen schwere Verletzung, Verätzung,

Verbrühung.

▶ Den maximalen Steuer- und Mediumsdruck nicht überschreiten.

Angaben auf dem Typschild beachten.

Zulässiger Steuer- und Mediumsdruck:

Steuer-

funktion

(SF)

SFA 5,5 10 10 6

SFB 2,2 7 siehe „Bild 1“

Min.

Steuerdruck

[bar]

Max.

Steuerdruck

[bar]

Max. Mediumsdruck

[bar]

Elastomer

(inkl.

kaschiert)

PTFE und

Advanced

PTFE

Erforderlicher Mindeststeuerdruck bei Steuerfunktion B in

Abhängigkeit vom Mediumsdruck einseitig anstehend:

10

8

6

4

2

0 1 2

Mediumsdruck [bar]

Bild 1: Druckdiagramm, Elastomer- und Advanced PTFE Membran

14

3

4 5 6 7

Steuerdruck [bar]

Elastomer

(inkl. kaschiert)

PTFE und

Advanced PTFE

deutsch

5.3.3 Zulässige Medien

Steuermedium: neutrale Gase, Luft

Durchflussmedien: neutrale Gase und Flüssigkeiten, hochreine,

sterile, aggressive und abrasive Medien

5.4 Steuerfunktionen

A

B

In Ruhestellung durch Federkraft geschlossen

In Ruhestellung durch Federkraft geöffnet

5.5 Typschild

Nennweite (Membrangröße)

Steuerfunktion

Typ

G1/4 Pmed 8,5 bar

Pilot 5,5-10 bar

S/N 1060

W36LP

Seriennummer

Made in Germany

Identnummer des Geräts

Bild 2: Beschreibung des Typschildes

Dichtwerkstoff

Gehäusewerkstoff

Leitungsanschluss,

max. Mediumsdruck

Steuerdruck

Page 15

Typ 2031 INOX

Montage

6 MONTAGE

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

▶ Vor dem Lösen von Leitungen oder Ventilen den Druck abschal-

ten und Leitungen entlüften.

Gefahr durch elektrische Spannung!

▶ Vor Eingriffen in das Gerät oder die Anlage, Spannung abschal-

ten und vor Wiedereinschalten sichern!

▶ Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage, ungewolltes

Einschalten der Anlage und unkontrollierten Wiederanlauf!

▶ Die Montage darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

▶ Anlage vor unbeabsichtigtem Betätigen sichern.

▶ Nach der Montage einen kontrollierten Wiederanlauf gewährleisten.

Quetschgefahr durch sich bewegenden pneumatischen Anschluss!

▶ Beim Öffnen und Schließen des Geräts nicht den sich bewegen-

den pneumatischen Anschluss berühren.

▶ Nicht in den unmittelbaren Bereich oberhalb und unterhalb des

Steuerluftanschlusses fassen.

6.1 Vor dem Einbau

• Vor dem Anschluss des Ventils auf fluchtende Rohrleitungen achten.

• Durchflussrichtung ist beliebig.

6.1.1 Einbaulage

Einbaulage: beliebig, vorzugsweise Antrieb nach oben.

Einbau für Selbstentleerung des Gehäuses:

Die Sicherstellung der Selbstentleerung liegt in der Verantwortung des Installateurs und Betreibers.

Um die Selbstentleerung zu gewährleisten muss die

• Markierung (-) auf dem Gehäuse auf 12 Uhr liegen,

• Bohrung im Membransockel, zur Überwachung der Leckage am

tiefsten Punkt sein.

Entleerungswinkel -2°

Bild 3: Einbaulage zur Selbstentleerung des Gehäuses

6.1.2 Vorbereitende Arbeiten

→ Rohrleitungen von Verunreinigungen säubern (Dichtungsmaterial,

Metallspäne etc.).

→ Rohrleitungen abstützen und ausrichten.

deutsch

15

Page 16

Typ 2031 INOX

Montage

Geräte mit VG/VS-Schweißgehäuse:

Vor dem Einschweißen des Gehäuses muss der Antrieb

demontiert werden.

6.2 Einbau

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Einbau!

Das Nichtbeachten des Anziehdrehmoments ist wegen der möglichen Beschädigung des Geräts gefährlich.

▶ Anziehdrehmoment beim Einbau beachten.

6.2.1 Geräte mit VG/VS-Schweißgehäuse

Vor dem Einschweißen des Gehäuses muss der Antrieb

demontiert werden.

Antrieb und Membran vom Gehäuse abnehmen

Vorgehensweise bei Steuerfunktion A:

→ Steuerluftanschluss mit Druckluft (5,5 bar) beaufschlagen.

→ Befestigungsschrauben über Kreuz lösen und Antrieb mit Membran

vom Gehäuse abnehmen.

→ Gehäuse in die Rohrleitung einschweißen.

Vorgehensweise bei Steuerfunktion B:

→ Befestigungsschrauben über Kreuz lösen und Antrieb mit

Membran vom Gehäuse abnehmen.

→ Gehäuse in die Rohrleitung einschweißen.

6.2.2 Montage

Montage für Antrieb mit Steuerfunktion A:

→ Membran ausrichten.

Der Markierungslappen der Membran muss senkrecht zur

Durchflussrichtung stehen.

→ Antrieb auf das Gehäuse setzen.

→ Steuerluftanschluss mit Druckluft (5,5 bar) beaufschlagen.

→ Befestigungsschrauben über Kreuz leicht anziehen, bis die

Membran zwischen Gehäuse und Antrieb anliegt.

Schrauben noch nicht festziehen!

→ Membranventil zweimal schalten.

→ Befestigungsschrauben anziehen.

Anziehdrehmoment ( 2,5 Nm) beachten!

Montage für Antrieb mit Steuerfunktion B:

→ Membran ausrichten.

Der Markierungslappen der Membran muss senkrecht zur

Durchflussrichtung stehen.

→ Antrieb auf das Gehäuse setzen.

→ Befestigungsschrauben über Kreuz leicht anziehen, bis die

Membran zwischen Gehäuse und Antrieb anliegt.

Schrauben noch nicht festziehen!

→ Steuerdruckanschluss mit Druckluft (5,5 bar) beaufschlagen.

→ Membranventil zweimal schalten.

→ Befestigungsschrauben anziehen.

Anziehdrehmoment ( 2,5 Nm) beachten!

16

deutsch

Page 17

Typ 2031 INOX

Montage

6.3 Pneumatischer Anschluss

WARNUNG!

Verletzungsgefahr durch ungeeignete Anschlussschläuche!

Schläuche, die dem Druck- und Temperaturbereich nicht standhalten,

können zu gefährlichen Situationen führen.

▶ Nur Schläuche verwenden, die für den angegeben Druck- und

Temperaturbereich zugelassen sind.

▶ Die Datenblattangaben der Schlauchhersteller beachten.

6.3.1 Steuerluftanschlüsse

Als Steuerluftanschluss ist der separat bestellbare

45°-Winkelanschluss zu empfehlen!

Hier sollte die freibewegliche Schlauchlänge min.

250 mm betragen. Bei einer kürzeren Schlauchlänge wird die Haltbarkeit und Funktion der Steckkupplung beeinträchtigt!

Bei der Verwendung eines geraden Steuerluftanschlusses sollte die freibewegliche Schlauchlänge

min. 400 mm betragen.

Bei einer kürzeren Schlauchlänge wird die Haltbarkeit

und Funktion der Steckkupplung beeinträchtigt!

Quetschgefahr!

▶ Aufgrund der Quetschgefahr darf ein

90°-Steuerluftanschluss nicht verwendet werden!

7 INBETRIEBNAHME

WARNUNG!

Gefahr bei unsachgemäßem Betrieb!

▶ Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

▶ Die Sicherheitshinweise und die bestimmungsgemäße Verwen-

dung müssen beachtet werden.

▶ Nur ausreichend geschultes Personal darf die Anlage/das Gerät

in Betrieb nehmen.

Typschildangaben und die Hinweise zu Druck- und Temperaturwerten in Kapitel „Technische Daten“ beachten.

8 WARTUNG, REINIGUNG

8.1 Antrieb

Der Antrieb des Membranventils ist, wenn für den Einsatz die Hinweise dieser Bedienungsanleitung beachtet werden, wartungsfrei.

8.2 Verschleißteile des Membranventils

Teile, die der natürlichen Abnutzung unterliegen sind:

• Membran

→ Bei Undichtheiten, die Membran gegen eine neue austauschen.

Eine ausgebeulte PTFE-Membran kann zur Reduzierung des

Durchflusses führen.

deutsch

17

Page 18

Typ 2031 INOX

Transport Lagerung, Entsorgung

8.3 Kontrollintervalle

→ Membran nach maximal 10

Schlammartige und abrasive Medien erfordern entsprechend

kürzere Kontrollintervalle!

5

Schaltspielen auf Verschleiß prüfen.

8.4 Reinigung

Zur Reinigung der Geräteoberfläche können handelsübliche Reinigungsmittel verwendet werden.

HINWEIS!

Die Verträglichkeit der Mittel mit den Gehäusewerkstoffen und

Dichtungen vor der Reinigung prüfen.

9 TRANSPORT LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden und Lagerschäden!

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren und lagern.

• Zulässige Lagertemperatur: -20 … +65 °C.

Lagerung mit festgezogenen Gehäuseschrauben kann zu bleibenden Verformungen der Membran führen.

• Gehäuseschrauben bei längerer Einlagerung lockern.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

18

deutsch

Page 19

Typ 2031 INOX

Ce Quickstart

table des matIères

1 CE QUICKSTART ....................................................................................... 19

2 ADRESSES ................................................................................................... 19

3 UTILISATION CONFORME ................................................................... 20

4 CONSIGNES DE SÉCURITÉ FONDAMENTALES......................20

5 CARACTÉRISTIQUES TECHNIQUES .............................................21

6 MONTAGE .....................................................................................................23

7 MISE EN SERVICE .................................................................................... 25

8 MAINTENANCE, NETTOYAGE .............................................................25

9 TRANSPORT STOCKAGE, ÉLIMINATION ..................................... 26

1 CE QUICKSTART

Ce quickstart contient des informations importantes.

▶ Lire attentivement ce quickstart et tenir compte des consignes de

sécurité.

▶ Ce quickstart doit être mis à disposition de chaque utilisateur.

▶ La responsabilité et la garantie légale concernant le type 2000 INOX

sont exclues en cas de non-respect des instructions contenues

dans ce quickstart.

Quickstart explique au moyen d’exemples le montage et la mise en

service de l’appareil. Vous trouverez la description détaillée de l’appareil

sur Internet sous : www.buerkert.fr

1.1 Définition du terme

Le terme « appareil » utilisé dans ce manuel désigne toujours la vanne

à membrane Type 2031 INOX.

2 ADRESSES

Bürkert Fluid Control Systems / Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses se trouvent sur Internet sous: www.burkert.com

français

Si vous avez des questions, veuillez contacter votre filiale de

distribution Bürkert.

19

Page 20

Typ 2031 INOX

Consignes de sécurité fondamentales

2.1 Symboles

Mise en garde contre des blessures graves ou mortelles :

DANGER!

Met en garde contre un danger imminent.

AVERTISSEMENT !

Met en garde contre une situation éventuellement dangereuse.

Mise en garde contre des blessures moyennes ou légères :

ATTENTION !

Met en garde contre un risque éventuel.

REMARQUE !

Met en garde contre des dommages matériels.

Conseils et recommandations importants.

→ Identifie une opération que vous devez effectuer.

3 UTILISATION CONFORME

Vanne à membrane Type 2031 INOX a été conçue pour commander

le débit de fluides liquides et gazeux.

• Pour son utilisation, il convient de respecter les conditions d’exploitation et d’utilisation autorisées.

• Utiliser uniquement en parfait état et veiller au stockage, au transport,

à l’installation et à l’utilisation conformes.

4 CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Danger dû à la haute pression.

▶ Avant de desserrer les conduites et les vannes, couper la pres-

sion et purger l’air des conduites.

Danger présenté par la tension électrique.

▶ Avant d’intervenir dans l’appareil ou l’installation, couper la ten-

sion et empêcher toute remise sous tension par inadvertance.

▶ Respecter les réglementations en vigueur pour les appareils élec-

triques en matière de prévention des accidents et de sécurité.

Risque de pincement dû à un raccord pneumatique en

mouvement.

▶ Lors de l’ouverture et de la fermeture de l’appareil, ne pas entrer

en contact avec le raccord pneumatique en mouvement.

▶ Ne pas mettre la main dans la zone immédiatement au-dessus

et en-dessous du raccord d’air de commande.

Risque de brûlures/d’incendie en fonctionnement continu dû à

des surfaces d’appareil brûlantes.

▶ Ne pas toucher l’appareil à mains nues.

▶ Tenir l’appareil éloigné des matières et fluides facilement

inflammables.

20

français

Page 21

Typ 2031 INOX

Caractéristiques techniques

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respectez ce qui suit :

▶ Protéger l’installation/l’appareil contre tout actionnement

involontaire.

▶ Alimenter les raccords de fluides seulement avec les liquides

énumérés au chapitre « Caractéristiques techniques ».

▶ N’effectuer aucune modification interne ou externe sur le type 2031

INOX et ne pas le soumettre à des charges mécaniques.

▶ Seul du personnel qualifié peut effectuer l’installation et la

maintenance.

▶ Après une interruption de l’alimentation électrique ou pneuma-

tique, un redémarrage défini ou contrôlé du processus doit être

garanti.

▶ Les règles générales de la technique sont d’application pour

planifier l’utilisation et utiliser l’appareil.

5 CARACTÉRISTIQUES TECHNIQUES

5.1 Conformité

La vanne à membrane, Type 2031 INOX répond aux directives CE

conformément à la déclaration de conformité CE.

5.2 Normes

Les normes utilisées, avec lesquelles la conformité avec les directives

CE sont prouvées, figurent dans l’attestation CE de type et/ou la

déclaration de conformité CE.

5.3 Conditions d’utilisation

5.3.1 Températures admissibles

Température ambiante : 0 °C … +60 °C

Température du fluide : -10 °C … +140 °C

Température de fluide admissible en fonction du matériau de la membrane :

Matériau du

membrane

EPDM -10 ... +130 °C

PTFE / EPDM -10 ... +130 °C

Advanced

stratifié PTFE

1)

La température du fluide indiquée ne s’applique qu’aux fluides n’attaquant

pas les matériaux de la membrane. Le comportement du fluide par rapport

à la membrane peut changer en fonction de la température du fluide.

Les propriétés fonctionnelles, notamment la durée de vie de la membrane,

peuvent se détériorer au fur et à mesure que la température du fluide

augmente.

Température

du fluide

1)

-10 ... +90 °C -

Remarque

Stérilisation à la vapeur jusqu’à

Stérilisation à la vapeur jusqu’à

140 °C

140 °C

français

21

Page 22

Typ 2031 INOX

P

A

P

A

2031 A 8,0 EPDM VA

00445286

Caractéristiques techniques

5.3.2 Plages de pression

AVERTISSEMENT !

Risque de rupture en cas de surpression.

En cas de rupture de l’appareil, il y a risque de graves blessures,

de brûlures par acide et autres.

▶ Ne pas dépasser les pressions de pilotage et de fluide maximales.

Respecter les indications figurant sur la plaque signalétique.

Pression de pilotage et pression du fluide admissible :

Fonction

de com-

mande

(CF)

CFA 5,5 10 10 6

CFB 2,2 7 voir « Fig. 1 »

Pression

de pilotage

minimale

[bar]

Pression

de pilotage

maximale

[bar]

Pression du fluide

maximale [bar]

Élastomère

(y compris

stratifié)

PTFE et

PTFE

advanced

Pression de pilotage minimale nécessaire pour la fonction de commande B selon la pression du fluide appliquée sur un seul côté :

10

8

6

4

2

0 1 2

Pression du fluide [bar]

Fig. 1 : Diagramme de pression, membrane en élastomère et en PTFE advanced

22

Pression de pilotage [bar]

3

4 5 6 7

Élastomère (y

compris stratifié)

PTFE et PTFE

advanced

5.3.3 Fluides admissibles

Fluide de commande: gaz neutres, air

Fluides transportés: gaz et liquides neutres, fluides très purs, sté-

riles, agressifs et abrasifs

5.4 Fonctions

A

B

Fermé en position de repos par l’action d’un

ressort

Ouvert en position de repos par l’action d’un

ressort

5.5 Plaque signalétique

Diamètre nominal

(Taille de membrane)

Fonction

Type

G1/4 Pmed 8,5 bar

Pilot 5,5-10 bar

S/N 1060

Made in Germany

N° de série

Fig. 2 : Description de la plaque signalétique

N° d’identification

W36LP

Matériau du joint

Matériau du corps

Type de raccord,

pression du fluide

maximale

Pression de

pilotage

français

Page 23

Typ 2031 INOX

Montage

6 MONTAGE

DANGER !

Danger dû à la haute pression.

▶ Avant de desserrer les conduites et les vannes, couper la pres-

sion et purger l’air des conduites.

Danger présenté par la tension électrique.

▶ Avant d’intervenir dans l’appareil ou l’installation, couper la tension

et empêcher toute remise sous tension par inadvertance.

▶ Respecter les réglementations en vigueur pour les appareils élec-

triques en matière de prévention des accidents et de sécurité.

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme, la mise

en marche involontaire de l’installation et au redémarrage

non contrôlé.

▶ Le montage doit être effectué uniquement par un personnel qualifié

et habilité disposant de l’outillage approprié.

▶ Empêcher tout actionnement involontaire de l’installation.

▶ Garantir un redémarrage contrôlé après le montage.

Risque de pincement dû à un raccord pneumatique en mouvement.

▶ Lors de l’ouverture et de la fermeture de l’appareil, ne pas entrer

en contact avec le raccord pneumatique en mouvement.

▶ Ne pas mettre la main dans la zone immédiatement au-dessus

et en-dessous du raccord d’air de commande.

6.1 Avant le montage

• Avant de raccorder la vanne, veiller à ce que les tuyauteries soient

correctement alignées.

• Le sens de débit est indifférent.

6.1.1 Position de montage

Position de montage: au choix, de préférence actionneur vers le haut.

Montage pour la vidange automatique du corps :

Il est de la responsabilité de l’installateur et de l’exploitant de

garantir la vidange automatique.

Pour une vidange automatique, il faut que :

• le marquage (-) sur le corps se trouve sur 12 h,

• l’alésage dans le socle de la membrane se trouve au point le plus

bas pour surveiller les fuites éventuelles

Angle de vidange -2°

Fig. 3 : Position de montage permettant au corps de se vider

automatiquement

6.2 Travaux préparatoires

→ Nettoyer les tuyauteries (matériau d’étanchéité, copeaux de

métal, etc.).

→ Soutenir et aligner les tuyauteries.

français

23

Page 24

Typ 2031 INOX

Montage

Appareils avec corps à souder VG/VS :

Avant le soudage du corps, il est nécessaire de démonter

l’actionneur.

6.3 Montage

AVERTISSEMENT !

Risque de blessures dû à un montage non conforme.

Le non-respect du couple de serrage est dangereux du fait de

l’endommagement possible de l’appareil.

▶ Respecter le couple de serrage lors du montage.

6.3.1 Appareils avec corps à souder VG/VS

Avant le soudage du corps, il est nécessaire de démonter

l’actionneur.

Retirer l’actionneur et la membrane du corps

Procédure à suivre pour la fonction de commande A :

→ Appliquer de l’air comprimé à 5,5 bar au raccord d’air de commande.

→ Desserrer les vis de fixation en croix et retirer l’actionneur avec la

membrane du corps.

→ Souder le corps dans la tuyauterie.

Procédure à suivre pour la fonction de commande B :

→ Desserrer les vis de fixation en croix et retirer l’actionneur avec la

membrane du corps.

→ Souder le corps dans la tuyauterie.

6.3.2 Montage

Montage de l’actionneur avec la fonction de commande A :

→ Aligner la membrane.

La patte de marquage de la membrane doit être verticale

par rapport au sens du débit.

→ Placer l’actionneur sur le corps.

→ Appliquer de l’air comprimé à 5,5 bar au raccord d’air de commande.

→ Serrer les vis de fixation légèrement en croisant jusqu’à ce que la

membrane soit en contact entre le corps et l’actionneur.

Ne pas encore serrer les vis à fond !

→ Actionner deux fois la vanne à membrane.

→ Serrer les vis de fixation.

Respecter le couple de serrage (2,5 Nm) !

Montage de l’actionneur avec la fonction de commande B :

→ Aligner la membrane.

La patte de marquage de la membrane doit être verticale

par rapport au sens du débit.

→ Placer l’actionneur sur le corps.

→ Serrer les vis de fixation légèrement en croisant jusqu’à ce que la

membrane soit en contact entre le corps et l’actionneur.

Ne pas encore serrer les vis à fond !

→ Appliquer de l’air comprimé à 5,5 bar au raccord d’air de commande.

→ Actionner deux fois la vanne à membrane.

→ Serrer les vis de fixation.

Respecter le couple de serrage (2,5 Nm) !

24

français

Page 25

Typ 2031 INOX

Mise en service

6.4 Raccordement pneumatique

AVERTISSEMENT !

Risque de blessures dû aux tuyaux flexibles de raccordement

non appropriés.

Les tuyaux flexibles ne résistant pas à la plage de pression et de

température peuvent entraîner des situations dangereuses.

▶ Utiliser uniquement des tuyaux flexibles homologués pour la plage

de pression et de température indiquée.

▶ Respecter les indications figurant sur la fiche technique du fabri-

cant de tuyaux flexibles.

6.4.1 Control air connections

Nous recommandons le raccord angulaire de 45° à commander séparément pour faire office de raccord d’air de

commande.

À cet effet, la longueur de tuyau flexible bougeant

librement doit être de 250 mm min. En cas de tuyau

flexible plus court, la durée de vie et le fonctionnement du

raccord enfichable seront réduits.

En cas d’utilisation d’un raccord d’air de commande droit,

la longueur de tuyau flexible bougeant librement doit être

de 400 mm min.

En cas de tuyau flexible plus court, la durée de vie et le

fonctionnement du raccord enfichable seront réduits.

Risque de pincement.

▶ Il est interdit d’utiliser un raccord d’air de com-

mande de 90° en raison du risque de pincement.

7 MISE EN SERVICE

AVERTISSEMENT !

Risque de blessures dû à une exploitation non conforme !

Une utilisation non conforme peut entraîner des blessures et

endommager l’appareil et son environnement.

▶ Avant la mise en service, il faut s’assurer que le contenu du

manuel est connu et parfaitement compris par les opérateurs.

▶ Respecter les consignes de sécurité et l’utilisation conforme.

▶ L’appareil/l’installation doit être mis(e) en service uniquement

par un personnel suffisamment formé.

Respecter les indications de la plaque signalétique et les

consignes concernant la pression et les valeurs de températures au chapitre « Caractéristiques techniques ».

8 MAINTENANCE, NETTOYAGE

8.1 Actionneur

À condition de respecter les consignes de ces instructions de service,

l’actionneur de la vanne à membrane ne nécessite aucun entretien.

8.1.1 Pièces d’usure de la vanne à

membrane

Les pièces soumises à une usure naturelle sont les suivantes :

• Membrane

→ En cas de fuite, remplacer la membrane par une neuve.

français

25

Page 26

Typ 2031 INOX

Transport Stockage, Élimination

Une membrane PTFE déformée peut entraîner une réduction

du débit.

8.1.2 Intervalles de contrôle

→ Contrôler l’usure de la membrane après au maximum 10

de commutation.

Les fluides boueux et abrasifs exigent des intervalles de contrôle

plus rapprochés.

5

cycles

8.2 Nettoyage

Pour nettoyer la surface de l’appareil, des produits de nettoyage

courants peuvent être utilisés.

REMARQUE !

Vérifier la compatibilité des produits avec les matériaux du boîtier

et les joints avant d’effectuer le nettoyage.

9 TRANSPORT STOCKAGE,

ÉLIMINATION

REMARQUE !

Dommages dus au transport/au stockage.

• Transporter et stocker l’appareil à l’abri de l’humidité et des

impuretés et dans un emballage résistant aux chocs.

• Température de stockage autorisée : -20 … +65 °C.

Le stockage avec les vis de corps serrées à fond peut entraîner

des déformations définitives de la membrane.

• Desserrer les vis de corps en cas de stockage prolongé.

Dommages à l’environnement causés par des pièces d’appareil

contaminées par des fluides.

• Éliminer l’appareil et l’emballage dans le respect de

l’environnement.

26

français

Page 27

Page 28

www.burkert.com

Loading...

Loading...