Page 1

Type 2000

2/2-way angle seat valve

Operating Instructions

Page 2

We reserve the right to make technical changes without notice.

© Bürkert Werke GmbH & Co. KG, 2008 - 2019

Operating Instructions 1908/17_EUml 00893086 / Original DE

Page 3

Type 2000

Contents

CONTENTS

1 About these instructions ............................................................................................................................5

1.1 Symbols............................................................................................................................................ 5

1.2 Definition of terms ............................................................................................................................ 5

2 Intended use ...............................................................................................................................................7

3 Basic safety instructions............................................................................................................................8

4 General information..................................................................................................................................10

4.1 Contact address ............................................................................................................................. 10

4.2 Warranty ......................................................................................................................................... 10

4.3 Information on the Internet ............................................................................................................. 10

5 Product description..................................................................................................................................11

5.1 Features.......................................................................................................................................... 11

5.2 Structure and function.................................................................................................................... 11

5.2.1 Flow direction below seat ..................................................................................................13

5.2.2 Flow direction above the seat............................................................................................13

5.3 Device options................................................................................................................................ 13

5.4 Variants........................................................................................................................................... 14

6 Technical data ..........................................................................................................................................15

6.1 Conformity ...................................................................................................................................... 15

6.2 Standards ....................................................................................................................................... 15

6.3 Type label ....................................................................................................................................... 15

6.3.1 Designation of the actuator size ........................................................................................15

6.4 Operating conditions ...................................................................................................................... 15

6.4.1 Temperature ranges...........................................................................................................16

6.4.2 Pressure ranges .................................................................................................................16

6.4.3 Minimum pilot pressure values ..........................................................................................16

6.5 Mechanical data ............................................................................................................................. 20

7 Installation ................................................................................................................................................22

7.1 Safety instructions installation........................................................................................................ 22

7.2 Preparatory work ............................................................................................................................ 23

7.2.1 Attach dirt trap ...................................................................................................................23

7.3 Installing valve body ....................................................................................................................... 23

7.4 Installing devices with welded connection ..................................................................................... 23

7.4.1 Removing actuator from the valve body for devices without control unit .........................23

7.4.2 Removing actuator from the valve body for devices with installed control unit ................24

7.4.3 Installing actuator on valve body .......................................................................................24

7.5 Installing control unit ...................................................................................................................... 25

7.6 Turning actuator ............................................................................................................................. 25

7.6.1 Turning the actuator, devices with hexagon nut................................................................25

7.7 Connecting device pneumatically .................................................................................................. 26

7.7.1 Connecting control medium ..............................................................................................26

3

Page 4

Type 2000

Contents

8 Start-up .....................................................................................................................................................28

9 Deinstallation ............................................................................................................................................29

10 Servicing ...................................................................................................................................................30

10.1 Safety instructions maintenance .................................................................................................... 30

10.2 Maintenance work .......................................................................................................................... 30

10.2.1 Actuator .............................................................................................................................30

10.2.2 Wearing parts.....................................................................................................................30

10.2.3 Visual inspection ................................................................................................................31

10.2.4 Cleaning .............................................................................................................................31

11 Faults ........................................................................................................................................................32

12 Replacement parts, accessories .............................................................................................................33

12.1 Installation tools.............................................................................................................................. 33

12.2 Replacement part set ..................................................................................................................... 33

12.3 Spare parts for seal set for SET 5 actuator .................................................................................... 34

12.4 Spare parts for valve set SET 6 ...................................................................................................... 35

13 Transportation, storage, disposal............................................................................................................37

4

Page 5

Type 2000

About these instructions

1 ABOUT THESE INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions ready to hand at the operation site.

Important safety information.

▶ Carefully read these instructions.

▶ Observe in particular the safety instructions, intended use and operating conditions.

▶ Persons, who work on the device, must read and understand these instructions.

1.1 Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in fatal or serious injuries.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious or fatal injuries.

CAUTION!

Warns of a possible danger.

▶ Failure to observe the warning may result in moderate or minor injuries.

ATTENTION!

Warns of damage to property.

▶ Failure to observe the warning may result in damage to the device or system.

Indicates important additional information, tips and recommendations.

Refers to information in these instructions or in other documentation.

Designates an instruction for risk prevention.

Designates a procedure which you must carry out.

Indicates a result.

1.2 Definition of terms

In these instructions the term "device" denotes the following device types:

2/2-way angle seat valve Type 2000

The abbreviation “Ex” used in these instructions always stands for “potentially explosive atmosphere”.

5

Page 6

Type 2000

About these instructions

The term “büS” (Bürkert system bus) used in this manual refers to the communication bus developed by

Bürkert, based on the CANopen protocol.

6

Page 7

Type 2000

Intended use

2 INTENDED USE

The angle seat valve Type 2000 is designed to control the flow rate of media. The permitted media are listed in the "Technical data".

▶ Use the device for its intended purpose only. Non-intended use of the device may be dangerous to

people, nearby equipment and the environment.

▶ Correct transportation, correct storage as well as correct installation, commissioning, operation and

maintenance are essential for reliable and problem-free operation.

▶ When using the device, observe the permitted data, operating conditions and application conditions.

This information can be found in the contractual documents, the operating instructions and on the type

label.

▶ Use the device only in conjunction with third-party devices and components recommended and author-

ized by Bürkert.

▶ In potentially explosive atmospheres, only use devices approved for use in those areas. These devices

are labeled with a separate Ex type label. For such use, note the information provided on the separate

Ex type label and the additional explosion-related information or separate explosion-related operating instructions.

▶ Protect device from environmental influences (e.g. radiation, air humidity, fumes). If you have any ques-

tions, contact your Bürkert sales department.

7

Page 8

Type 2000

Basic safety instructions

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not take into account any unforeseen circumstances and events which occur

during installation, operation and maintenance.

The operator is responsible for observing the location-specific safety regulations, also with reference to the

personnel.

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the device or system, switch off the pressure. Vent or drain lines.

DANGER!

Electric shock due to installed electrical component.

▶ Before working on the device or system, switch off the power supply. Secure against reactivation.

▶ Observe the applicable accident prevention and safety regulations for electrical devices.

WARNING!

Risk of injury when opening the actuator.

The actuator contains a spring under tension. When the actuator is opened, the spring will jump out and

may cause injuries.

▶ Do not open the actuator.

WARNING!

Risk of injury due to moving parts.

▶ Do not reach into openings in the device.

WARNING!

Danger of burns and risk of fire.

Quickly switching actuators or hot medium may cause the surface of the device to become hot.

▶ Only touch the device while wearing protective gloves.

▶ Keep the device away from highly flammable substances and media.

WARNING!

Danger due to loud noises.

Depending on the usage conditions, the device may generate loud noises. Detailed information on the

probability of loud noises is available from the respective sales department.

▶ Wear hearing protection when in the vicinity of the device.

WARNING!

Discharge of medium if packing gland worn.

▶ If media are hazardous, safeguard the environment around the discharge point.

8

Page 9

Type 2000

Basic safety instructions

To prevent injuries, observe the following:

▶ Secure device or plant to prevent unintentional activation.

▶ Only trained technicians may perform installation and maintenance work.

▶ Perform installation and maintenance with suitable tools only.

▶ Heavy equipment must only be transported, assembled, installed or dismantled with the help of a

second person as appropriate and using suitable apparatus.

▶ Following interruption of the process, ensure that the process is restarted in a controlled manner.

Observe sequence:

1. Apply electrical or pneumatic supply.

2. Charge with medium.

▶ Do not make any changes to the device and do not subject it to mechanical stress.

▶ Feed only those media, which are listed in the chapter "Technical data", into the medium ports.

▶ Operate the device only in perfect state and in consideration of the operating instructions.

▶ For applications planning and operation of the device, observe the plant-specific safety regulations.

▶ Observe the general rules of technology.

▶ The plant owner is responsible for the safe operation and handling of the plant.

To protect the environment, observe the following:

▶ The pilot exhaust air of the device may be contaminated by lubricants.

9

Page 10

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13−17

D-74653 Ingelfingen

Phone: + 49 (0) 7940 - 10 91 111

Fax: + 49 (0) 7940 - 10 91 448

E-mail: info@burkert.com

Type 2000

General information

International

The contact addresses can be found on the back pages of the printed Quickstart. Also on the Internet at:

http://www.burkert.com

4.2 Warranty

A precondition for the warranty is that the device is used as intended in consideration of the specified usage conditions.

4.3 Information on the Internet

Operating instructions and data sheets for the Bürkert products can be found on the Internet at:

https://www.burkert.com/en

10

Page 11

Type 2000

Product description

5 PRODUCT DESCRIPTION

The device is specially optimised for decentralised process automation and meets all the relevant requirements, even under difficult usage conditions.

Its design enables the easy integration of automation modules in all extension stages, whether they are

electrical/optical position feedback, pneumatic control units, or even an integrated fieldbus interface. Long

service life and high tightness are achieved by the tried and tested self-adjusting packing gland. The system, consisting of valve and automation module is distinguished by a compact and sleek design, integrated

pilot air ducts, a high chemical resistance, the degrees of protection IP65 or IP67 as well as the NEMA protection class 4X.

The device uses neutral gases or air to control the flow rate of liquid or gaseous media, such as water, alcohol, oil, fuel, saline solution, hydraulic fluid, lye, organic solvent or vapour.

5.1 Features

▪ Actuator can be rotated steplessly by 360°

▪ Valve body made of stainless steel with threaded connection, clamp connection or welded connection

▪ Easy integration of automation modules

▪ High chemical resistance

▪ High tightness and long service life due to self-adjusting packing gland

▪ High flow values through flow rate-optimised valve body made of stainless steel

▪ High seat tightness by swivel plate

▪ Maintenance-free under normal conditions

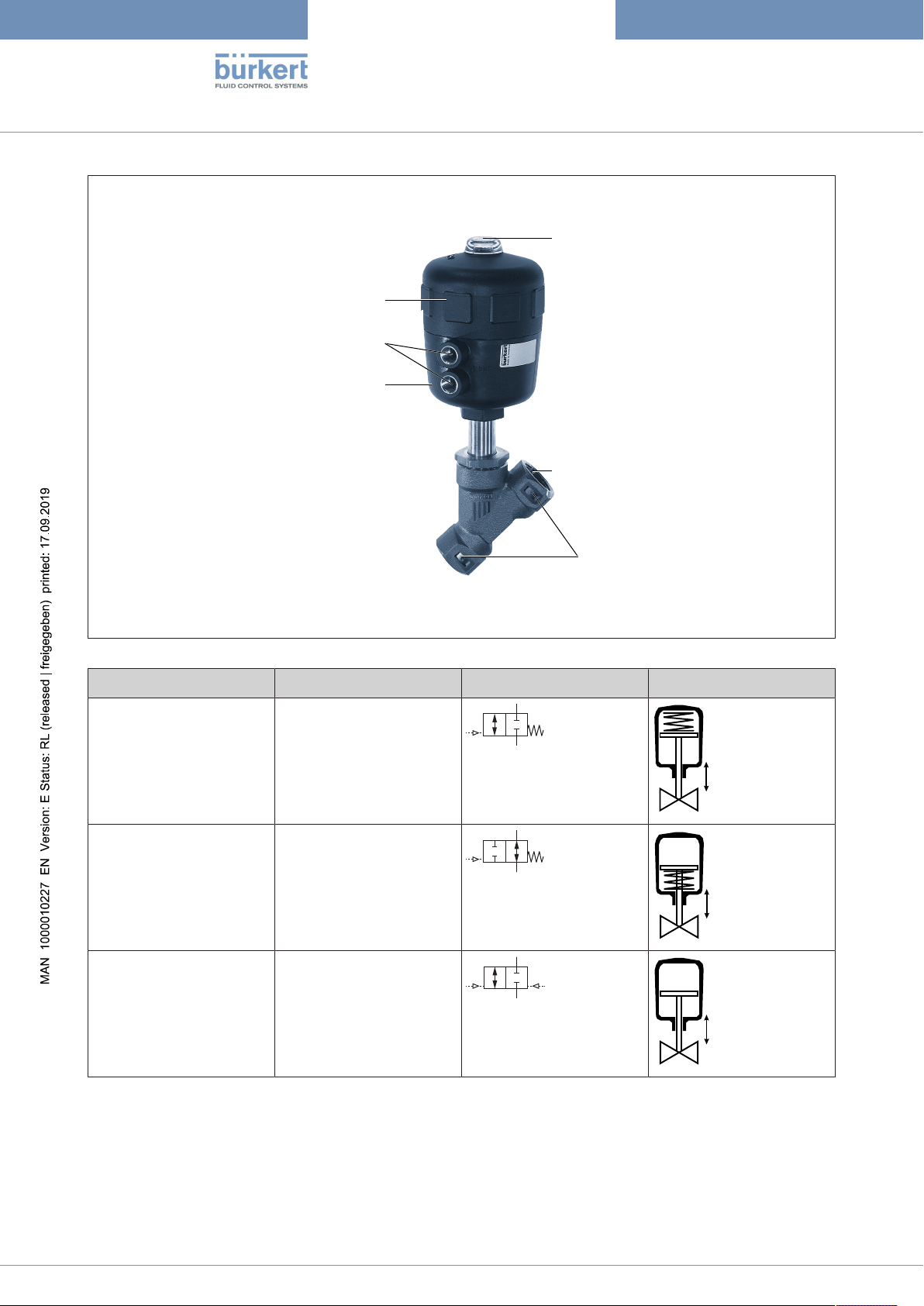

5.2 Structure and function

The angle seat valve consists of a pneumatically actuated piston actuator and a 2-way valve body. The actuator is made of PA or PPS. The proven, self-adjusting packing gland guarantees a high degree of tightness. Valve bodies made of stainless steel or red bronze 1.

Depending on the variant, the valve seat is connected in the direction of or against the medium flow. Spring

force (SFA) or pneumatic pilot pressure (SFB and SFI) generate the closing force on the swivel plate. A

spindle connected to the actuator piston transmits the force.

1

not for seat size 80

11

Page 12

Type 2000

Pilot air ports

Transparent cap

with position indicator

Actuator cover

Actuator housing

Port connection

Angle seat body

Type 2000

Characters for designation

of flow direction

2 (A),(P)

1 (P),(A)

up

down

2 (B),(P)

1 (P),(B)

up

down

2(A),(P)

1(P),(A)

up

down

Product description

Fig.1: Structure and description

Control function Definition Circuit symbol Figure

A (CFA) Closed by spring force in

rest position.

B (CFB) Opened by spring force

in rest position.

I (CFI) Actuating function via re-

ciprocal pressurisation.

Tab.1: Control functions

12

Page 13

Type 2000

CFA /

CFI

CFB /

CFI

Product description

5.2.1 Flow direction below seat

WARNING!

Valve seat leaking when control pressure is too low or medium pressure is too high.

If control pressure is too low for control function B and control function I or medium pressure is too high,

the valve seat may leak.

▶ Observe values for minimum control pressure and maximum medium pressure.

Depending on the control function, the valve closes by spring force (control function A) or pilot pressure

(control function B and I) against the medium flow.

As the medium is present under the swivel plate, the medium pressure contributes to the opening of the

valve.

Fig.2: Flow direction below seat, valve closes against medium flow

5.2.2 Flow direction above the seat

DANGER!

Risk of injury from rupturing lines and device when flow direction above the seat.

A pressure surge of liquid media may cause the lines and device to rupture.

▶ Do not use valves with flow direction above the seat for liquid media.

Flow direction above the seat is possible only on valves with control function A (closed by spring force in

rest position)2.

The valve closes by spring force with the medium flow. As the medium is present above the swivel plate,

the medium pressure contributes to the closing of the valve. The medium pressure also supports the sealing of the valve seat.

The valve opens by the pilot pressure.

Fig.3: Flow direction above the seat, valve closes with medium flow

5.3 Device options

▪ Stroke limit

Limiting the maximum or minimum flow rate volume with an adjusting screw.

2

Not for seat size 80

13

Page 14

Type 2000

Product description

▪ Control unit

Different variants are available depending on the requirement.

▪ Position feedback

The device is available with mechanical limit switches or inductive proximity switches.

5.4 Variants

Information on the variants of the device can be found in the data sheet at https://www.burkert.com/en or in your sales department.

14

Page 15

Type 2000

Ma de i n Ge rman y

Flow 1

2000 A 50.0 NBR RG

G 2 Pmed 16 bar

Pilot 1.6 - 10 bar

00182076

W14UN

Device variant

Control function

Manufacture code (encrypted)

Flow direction

Type

2 R

Seat size

Seal material

Body material

Nominal pressure

Pilot pressure

CE marking

Order number

Connection type

Technical data

6 TECHNICAL DATA

6.1 Conformity

The device conforms to the EC directives as per the EC Declaration of Conformity (if applicable).

6.2 Standards

The applied standards, which are used to demonstrate conformity with the directives, are listed in the EU

type examination certificate and/or the EU Declaration of Conformity (if applicable).

6.3 Type label

Fig.4: Example of a type label

6.3.1 Designation of the actuator size

Actuator size [mm] Designation

ø40 C

ø50 D

ø63 E

ø80 R

ø100 G

ø125 H

Tab.2: Designation of the actuator size

6.4 Operating conditions

Degree of protection IP67 according to IEC 529 / DIN EN 60529

Flow media Water, alcohols, oils, fuels, hydraulic fluids, saline solutions,

Control media Neutral gases, air

Sound pressure level <70dB(A)

lyes, organic solvents, vapour, air, neutral gases

15

Page 16

6.4.1 Temperature ranges

Ambient

temperature [°C]

Medium

temperature (°C)

Type 2000

Technical data

The sound pressure level may be higher depending on the usage conditions

Actuator size [mm] Actuator material Medium temperature (with

Ambient temperature3 [°C]

PTFE seal) [°C]

ø40...ø63 PA −10...see image below −10...see image below

ø80...ø125 PA −10...+180 −10...+60

ø40...ø80 PPS −10...+180 +5...+140

ø125 PPS −10...+180 +5...+90

Tab.3: Temperature ranges

Fig.5: Temperature range of maximum medium and ambient temperature for PA actuators

4

6.4.2 Pressure ranges

Tab.4: Maximum pilot pressure

6.4.3 Minimum pilot pressure values

Minimum control pressure when flow direction below seat

(Medium flow against valve closing direction)

The required minimum pilot pressure P

16

Tab.5: Minimum pilot pressure SFA

3

4

Actuator material Actuator size [mm] Max. Pilot pressure [bar]

PA ø40...ø80 10

ø125 7

PPS ø40...ø80 10

ø125 7

for control function A is:

min

Actuator

ø40 ø50 ø63 ø80 ø100 ø125 ø125 DN80

size [mm]

P

[bar] 4.0 3.9 4.5 5.0 4.4 3.2 4.1

min

When using a pilot valve the max. ambient temperature is +55 °C.

briefly up to a max. of 140°C

Page 17

Type 2000

SFB / SFI, ø40 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN15

DN20

SFB / SFI, ø50 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN15

DN20

DN25

SFB / SFI, ø63 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN20

DN25

DN32

DN40

DN50

Technical data

Required minimum control pressure depending on the medium pressure

In the following graphs the required minimum control pressure is shown for the respective control function

depending on the medium pressure.

Fig.6: Actuator ø40 mm, control function B und I, flow direction below the seat

Fig.7: Actuator ø50 mm, control function B und I, flow direction below the seat

Fig.8: Actuator ø63 mm, control function B und I, flow direction below the seat

17

Page 18

SFB / SFI, ø80 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN25

DN32

DN40

DN50

DN65

Fig.9: Actuator ø80 mm, control function B und I, flow direction below the seat

SFB / SFI, ø100 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN32

DN40

DN50

DN65

SFB / SFI, ø125 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN40

DN50

DN65

DN80

Type 2000

Technical data

Fig.10: Actuator ø100 mm, control function B und I, flow direction below the seat

Fig.11: Actuator ø125 mm, control function B und I, flow direction below the seat

Minimum control pressure when flow direction above the seat

(Medium flow in valve closing direction)

Required minimum control pressure depending on the medium pressure

In the following graphs the required minimum control pressure is shown for the respective control function

depending on the medium pressure.

18

Page 19

Type 2000

SFA, ø40 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN15

DN20

SFA, ø50 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN15

DN20

DN25

SFA, ø63 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN20

DN25

DN32

DN40

DN50

Technical data

Fig.12: Actuator ø40 mm, control function A, flow direction above the seat

Fig.13: Actuator ø50 mm, control function A, flow direction above the seat

Fig.14: Actuator ø63 mm, control function A, flow direction above the seat

19

Page 20

SFA, ø80 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN25

DN32

DN40

DN50

DN65

Fig.15: Actuator ø80 mm, control function A, flow direction above the seat

SFA, ø100 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN32

DN40

DN50

DN65

SFA, ø125 mm

Medium pressure

[bar]

Pilot pressure

[bar]

DN40

DN50

DN65

Type 2000

Technical data

Fig.16: Actuator ø100 mm, control function A, flow direction above the seat

Fig.17: Actuator ø125 mm, control function A, flow direction above the seat

6.5 Mechanical data

Actuator size See type label

20

Installation position any, preferably actuator face up

Materials

Threaded connection Red bronze

Stainless steel 316L

Page 21

Type 2000

Technical data

Welded connection and clamp connec-

Stainless steel 316L

tion

actuator PA or PPS

Seal PTFE

(NBR, FKM, EPDM on request)

Packing gland (with silicone grease)

PTFE V-rings with spring compensation

Stainless steel valve body

Packing gland (with silicone grease) Red

PTFE and FKM V-rings with spring compensation

bronze valve body

Ports

Threaded connection G⅜...G2½ (VA G3)

(NPT on request)

welded connection in accordance with EN 1127,

DIN 11850 R2

Clamp connection in accordance with ISO 2852, ASME BPE,

BS 4825

Pilot air port Push-in connector 6/4 mm or threaded connection ¼"

More on request

21

Page 22

Type 2000

Installation

7 INSTALLATION

7.1 Safety instructions installation

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the device or system, switch off the pressure. Vent or drain lines.

WARNING!

Risk of injury due to improper installation.

▶ Only trained technicians may perform installations.

▶ Perform installations with suitable tools only.

WARNING!

Risk of injury due to unintentional activation of the system and uncontrolled restart.

▶ Secure plant to prevent unintentional activation..

▶ Ensure that the plant starts up in a controlled manner only.

DANGER!

For control function I: Danger due to the control pressure failing.

If the control pressure fails, the valve remains in an undefined position.

▶ For a controlled restart, pressurize the device with control pressure and then connect the medium.

WARNING!

Risk of injury due to moving parts.

▶ Do not reach into openings in the device.

CAUTION!

Risk of injury from heavy device.

During transportation or installation work, a heavy device may fall down and cause injuries.

▶ Transport, install and remove heavy device with the aid of a second person only.

▶ Use suitable tools.

WARNING!

22

Valve seat leaking when control pressure is too low or medium pressure is too high.

If control pressure is too low for control function B and control function I or medium pressure is too high,

the valve seat may leak.

▶ Observe values for minimum control pressure and maximum medium pressure.

DANGER!

Risk of injury from rupturing lines and device when flow direction above the seat.

A pressure surge of liquid media may cause the lines and device to rupture.

▶ Do not use valves with flow direction above the seat for liquid media.

Page 23

Type 2000

Installation

7.2 Preparatory work

Observe flow direction on the type label.

Remove soiling from pipelines.

Ensure that pipelines are in alignment.

7.2.1 Attach dirt trap

Dirt trap for devices with approval according to DIN EN 161

According to DIN EN 161 "Automatic shut-off valves for gas burners and gas appliances", a dirt trap, which

prevents the penetration of a 1 mm test pin, must be installed upstream of the valve.

Attach dirt trap upstream of the valve.

7.3 Installing valve body

Connect valve body to pipeline.

Devices with welded connection: Weld valve body into pipeline. To do this, observe chapter "Installing

devices with welded connection".

7.4 Installing devices with welded connection

ATTENTION!

Damage to the actuator when welding the valve body into the pipeline.

▶ Before welding into the pipeline, remove the actuator.

7.4.1 Removing actuator from the valve body for devices without control unit

Clamp valve body into a holding device.

Devices with collet

ATTENTION!

Damage to the valve seat seal or seat contour.

▶ When removing the actuator, the valve must be in the open position.

For control function A pressurise the pilot air port 1 with compressed air (5 bar). Valve opens.

Place a suitable open-end wrench on the wrench flat of the body connection.

Unscrew actuator from the valve body.

Devices without collet

For control function A: Install control unit. To do this, follow the operating instructions for the control

unit.

ATTENTION!

Damage to the valve seat seal or seat contour.

▶ When removing the actuator, the valve must be in the open position.

23

Page 24

Type 2000

Seal

Installation

For control function A pressurise the pilot air port 1 with compressed air (5 bar). Valve opens.

For control function A with pilot valve: Manually switch device with pilot valve. To do this, follow the operating instructions for the control unit. Valve opens.

Place a suitable open-end wrench on the wrench flat of the body connection.

Unscrew actuator from the valve body.

7.4.2 Removing actuator from the valve body for devices with installed control unit

Clamp valve body into a holding device.

ATTENTION!

Damage to the valve seat seal or seat contour.

▶ When removing the actuator, the valve must be in the open position.

For control function A pressurise the pilot air port 1 with compressed air (5 bar). Valve opens.

For control function A with pilot valve: Manually switch device with pilot valve. To do this, follow the operating instructions for the control unit. Valve opens.

Place a suitable open-end wrench on the wrench flat of the body connection.

Unscrew actuator from the valve body.

7.4.3 Installing actuator on valve body

Fig.18: Seal

Check seal and replace if required.

DANGER!

24

Danger due to lubricant.

Lubricant may contaminate the medium. There is a risk of explosion in oxygen applications.

▶ For specific applications use only approved lubricants (e.g. for oxygen applications or analysis applica-

tions).

Before re-installation, grease the thread of the body connection (e.g. with Klüberpaste UH1 96-402 from

Klüber).

ATTENTION!

Damage to the valve seat seal or seat contour.

▶ When installing the actuator, the valve must be in the open position.

Page 25

Type 2000

Hexagon head

Body connection

Actuator

Valve body

Installation

Screw actuator into the valve body. Observe tightening torques of the following table.

Seat size Tightening torque [Nm]

15 45 ±3

20 50 ±3

25 60 ±3

32 65 ±3

40 65 ±3

50 70 ±3

65 70 ±3

80 120 ±5

Tab.6: Tightening torques valve body and body connection

7.5 Installing control unit

Description see chapter "Installation" in the operating instructions for the corresponding control

unit.

7.6 Turning actuator

7.6.1 Turning the actuator, devices with hexagon nut

The following description applies only to devices with a hexagon head on the actuator.

For devices without a hexagon head on the actuator: in the operating instructions observe the

chapter "Turning actuator, devices without a hexagon head".

The position of the ports can be steplessly aligned by turning the actuator through 360°.

Fig.19: Turn actuator (1)

Clamp valve body in a holding device (only for valves which have not yet been installed).

ATTENTION!

Damage to the seat seal or seat contour.

▶ When turning the actuator, the valve must be in the open position.

25

Page 26

Type 2000

Installation

For control function A und I5:

pressurise lower pilot air port with compressed air.

Counter with a suitable open-end wrench on the wrench flat of the body connection.

Place a suitable open-end wrench on the hexagon head of the actuator.

DANGER!

Risk of injury from high pressure and discharge of medium.

If the direction of rotation is wrong, the body connection may become detached.

▶ Only turn the actuator is the prescribed direction.

Move the actuator into the required position by turning it counterclockwise (seen from below).

Fig.20: Turn actuator (2)

7.7 Connecting device pneumatically

DANGER!

For control function I: Danger due to the control pressure failing.

If the control pressure fails, the valve remains in an undefined position.

▶ For a controlled restart, pressurize the device with control pressure and then connect the medium.

DANGER!

Risk of injury due to connection of unsuitable hoses.

▶ Use only hoses which can withstand the pressure and temperature of the medium.

▶ Observe technical data of the hose manufacturer.

7.7.1 Connecting control medium

The position of the ports can be steplessly aligned by turning the actuator through 360°. The procedure is described in the chapter "Turning actuator [}25]".

Control function A:

Connect control medium to pilot air port at the bottom.

Control function B:

Connect control medium to pilot air port at the top.

Control function I:

26

5

If variant available

Page 27

Type 2000

Pilot air

connection

Top

Bottom

Installation

Connect control medium to pilot air port at the top and bottom.

Pressure on top connector closes the valve.

Pressure on bottom connector opens the valve.

Control function Pilot air port

Top Bottom

A X

B X

I X X

Closes Opens

valve

Tab.7: Pilot air port

When operating in an aggressive environment, divert free pneumatic ports into a neutral atmosphere

using a pneumatic hose.

Pilot air hose:

Pilot air hoses of sizes G¼" or G⅛" (actuator ø40 mm) can be used.

27

Page 28

Type 2000

Start-up

8 START-UP

DANGER!

For control function I: Danger due to the control pressure failing.

If the control pressure fails, the valve remains in an undefined position.

▶ For a controlled restart, pressurize the device with control pressure and then connect the medium.

WARNING!

Risk of injury from high pressure or hot medium.

Excessively high pressure or temperatures may damage the device and cause leaks.

▶ Observe values for pressure and medium temperature indicated on the type label.

In the case of devices with control unit, observe start-up in the operating instructions for the corresponding control unit.

Adjust pilot pressure in accordance with information on type label and in technical data.

28

Page 29

Type 2000

Deinstallation

9 DEINSTALLATION

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the device or system, switch off the pressure. Vent or drain lines.

Loosen pneumatic connection.

Disassemble the device.

29

Page 30

Type 2000

Servicing

10 SERVICING

10.1 Safety instructions maintenance

DANGER!

Risk of injury from high pressure and discharge of medium.

▶ Before working on the device or system, switch off the pressure. Vent or drain lines.

DANGER!

For control function I: Danger due to the control pressure failing.

If the control pressure fails, the valve remains in an undefined position.

▶ For a controlled restart, pressurize the device with control pressure and then connect the medium.

DANGER!

Risk of injury due to electric shock.

▶ Before working on the device or system, switch off the power supply. Secure against reactivation.

▶ Observe the applicable accident prevention and safety regulations for electrical devices.

WARNING!

Risk of injury due to unintentional activation of the system and uncontrolled restart.

▶ Secure plant to prevent unintentional activation..

▶ Ensure that the plant starts up in a controlled manner only.

WARNING!

Risk of injury due to moving parts.

▶ Do not reach into openings in the device.

DANGER!

Risk of injury due to improper maintenance.

▶ Only trained technicians may perform maintenance work.

▶ Perform maintenance work using suitable tools only.

30

10.2 Maintenance work

The maintenance work is described in the separate service instructions. These instructions can be found on

our homepage at www.buerkert.de

10.2.1 Actuator

When used in accordance with these operating instructions, the actuator is maintenance-free.

10.2.2 Wearing parts

The following parts are subject to natural wear:

▪ Seal

.

Page 31

Type 2000

Relief bore

Servicing

▪ Swivel plate

If leaks occur, replace the respective wearing part.

10.2.3 Visual inspection

According to the usage conditions, perform regular visual inspections:

Check medium ports for tightness.

Check relief bore on the pipe for leaks.

Fig.21: Relief bore

10.2.4 Cleaning

Commercially available cleaning agents can be used to clean the outside.

ATTENTION!

Avoid causing damage with cleaning agents.

▶ Before cleaning, check that the cleaning agents are compatible with body materials and seals.

31

Page 32

11 FAULTS

Fault Cause Elimination

Type 2000

Faults

Actuator does not switch Pilot air port inter-

changed

Pilot pressure too low Observe pressure specifications on the type label

Medium pressure too

high

Flow direction interchanged

Valve is not tight Dirt between seal and

valve seat

Valve seat seal worn Install new swivel plate

Flow direction interchanged

Medium pressure too

high

Pilot pressure too low

Valve is leaking on the

relief bore

Packing gland worn Replace packing gland or actuator

CFA Connect pilot air port at bottom

CFB Connect pilot air port at top

CFI Pilot air port at bottom: Open, pilot air

port at top: Closing

Observe direction of arrow on the type label

Install dirt trap

Observe direction of arrow on the type label

Observe pressure specifications on the type label

32

Page 33

Type 2000

Replacement parts, accessories

12 REPLACEMENT PARTS, ACCESSORIES

CAUTION!

Risk of injury and/or damage due to the use of incorrect parts.

Incorrect accessories and unsuitable spare parts may cause injuries and damage the device and its environment.

▶ Use original accessories and original spare parts from Bürkert only.

12.1 Installation tools

Installation wrench for packing gland (series-production status up to January 2013)

Spindle [mm] Seat size Order No.

ø10 15...40 665700

ø14 32...65 665701

Tab.8: Installation wrench

Modified socket wrench for packing gland (series-production status as of January 2013)

Spindle [mm] Seat size Width across flats Order No.

ø10 15...50

ø14 32...80 21 683223

Tab.9: Modified socket wrench

Special wrench for turning the actuator (series-production status up to end of 2011)

Order No. 665702

Tab.10: Special wrench

If you have any questions, contact your Bürkert sales department.

6

19 683221

12.2 Replacement part set

The following spare part sets are available for the device:

▪ Valve set consists of swivel plate with PTFE seal, pin and seal.

▪ Seal set for actuator consists of the seal and wearing parts of the actuator.

6

As of series-production status January 2017 also for seat size 50

33

Page 34

Type 2000

FKM only with

body material RG

Seal set for actuator

SET 5

Valve set

SET 6

Replacement parts, accessories

Fig.22: Spare parts for angle seat valve

12.3 Spare parts for seal set for SET 5 actuator

PA actuator

Actuator size Matching valve sizes Order no.

C (ø40)

C (ø40) DN15/20/25 288011 288011

D (ø50) DN15/20/25 233588 233588

E (ø63) DN25...50 233591 233591

F (ø80) DN25...65 233593 233593

G (ø100) DN32...65 233594 233594

H (ø125) DN40...65 233596 233596

H (ø125) DN80 - 276132

Tab.11: SET 5; PA actuator

Order no.

(Red bronze valve body)

7

DN15/20/25 233587 233587

(Stainless steel valve body)

34

7

Actuator cover without transparent cap

Page 35

Type 2000

Replacement parts, accessories

PPS actuator

Actuator size Matching valve sizes Order no.

(Red bronze valve body)

C (ø40)

8

DN15/20/25 233581 233581

Order no.

(Stainless steel valve body)

C (ø40) DN15/20/25 288013 288013

D (ø50) DN15/20/25 233582 233582

E (ø63) DN25...50 233583 233583

F (ø80) DN25...65 233584 233584

G (ø100) DN32...65 233585 233585

H (ø125) DN40...65 233586 233586

H (ø125) DN80 - 276130

Tab.12: SET 5; PPS actuator

12.4 Spare parts for valve set SET 6

RG body

DN Order no.

(PTFE seal)

Order no.

(FKM seal)

15 010984 011065

20 010986 011070

9

25

25

10

010988 011085

159635 -

32 011044 011088

40 011046 011107

50 233819 233821

65 233820 233822

Tab.13: SET 6; Red bronze valve body

VA body

DN Order no.

(PTFE seal)

Order no.

(FKM seal)

15 011134 011234

20 011171 011253

11

25

011202 011259

8

Actuator cover without transparent cap

9

Actuator size ø50

10

Actuator size ø63

11

Actuator size ø50

35

Page 36

Type 2000

Replacement parts, accessories

DN Order no.

(PTFE seal)

12

25

160737 168816

Order no.

(FKM seal)

32 011208 011262

40 011209 011267

50 233813 233817

65 233815 233818

80 350831 -

Tab.14: SET 6; Stainless steel valve body

36

12

Actuator size ø63

Page 37

Type 2000

Transportation, storage, disposal

13 TRANSPORTATION, STORAGE, DISPOSAL

ATTENTION!

Damage in transit due to inadequately protected devices.

▶ Protect the device against moisture and dirt in shock-resistant packaging during transportation.

▶ Observe permitted storage temperature.

ATTENTION!

Incorrect storage may damage the device.

▶ Store the device in a dry and dust-free location.

▶ Storage temperature: -20 to +65 °C

ATTENTION!

Damage to the environment caused by device components contaminated with media.

▶ Dispose of the device and packaging in an environmentally friendly manner.

▶ Observe applicable disposal and environmental regulations.

Observe national regulations on the disposal of waste.

37

Loading...

Loading...