Page 1

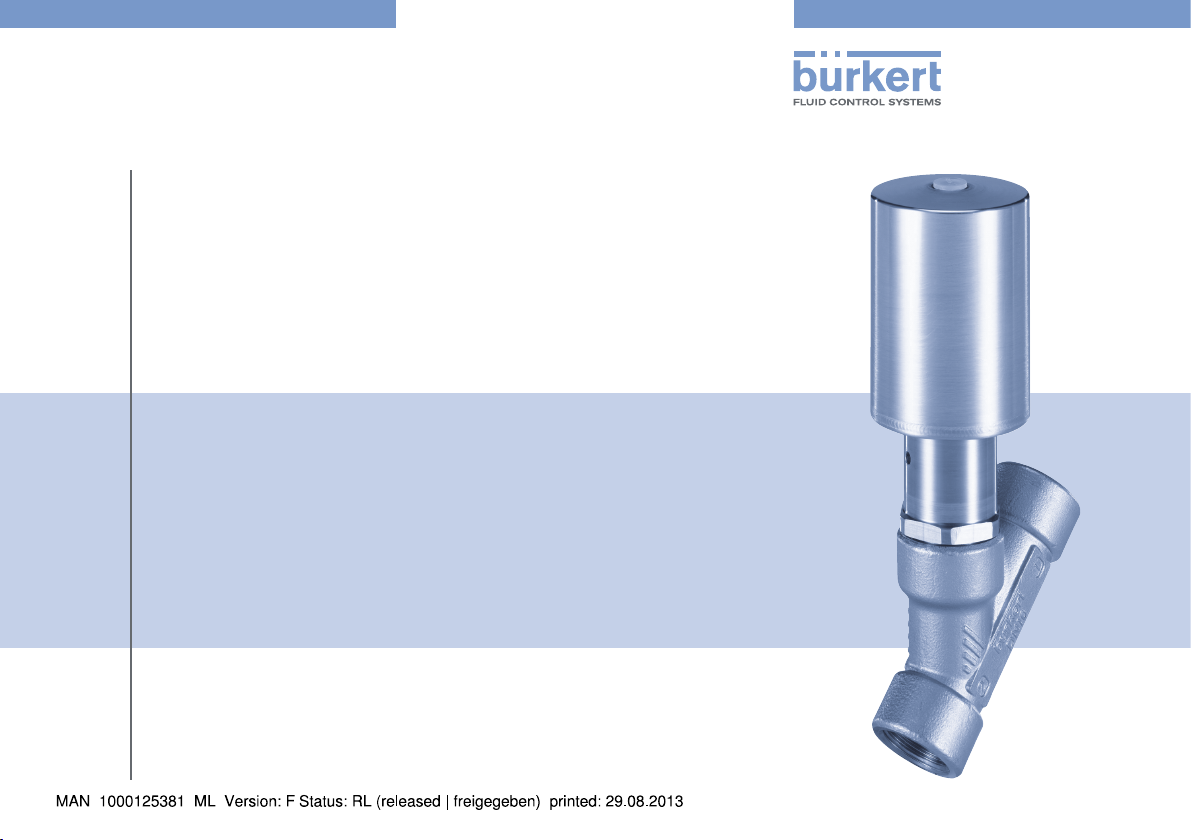

Type 2000

INOX

2/2-way angle seat valve

2/2-Wege Schrägsitzventil

Vanne à siège incliné 2/2 voies

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2010 – 2013 Bürkert Werke GmbH

Operating Instructions 1303/01_EU-ML_00805856 / Original DE

Page 3

Type 2000 INOX

Contents

1. THE OPERATING INSTRUCTIONS .........................................................4

1.1. Symbols ..............................................................................................4

1.2. Definition of the term 'Device' ........................................................ 4

2. AUTHORIZED USE .........................................................................................5

2.1. Restrictions ........................................................................................5

3. BASIC SAFETY INSTRUCTIONS .............................................................5

4. GENERAL INFORMATION ...........................................................................6

4.1. Contact address ...............................................................................6

4.2. Warranty .............................................................................................6

4.3. Information on the Internet ............................................................. 6

5. PRODUCT DESCRIPTION ...........................................................................7

5.1. General description ......................................................................... 7

5.2. Properties ........................................................................................... 7

6. TECHNICAL DATA ...........................................................................................7

6.1. Conformity .........................................................................................7

6.2. Standards ........................................................................................... 7

6.3. Operating conditions ....................................................................... 7

6.4. General technical data ....................................................................9

7. STRUCTURE AND FUNCTION...............................................................10

7.1. Structure ..........................................................................................10

7.2. Function ............................................................................................10

8. ASSEMBLY

8.1. Safety instructions .........................................................................10

8.2. Before installation ...........................................................................11

8.3. Installation ........................................................................................11

8.4. Pneumatic connection ..................................................................13

9. START-UP

9.1. Safety instructions .........................................................................14

10. MAINTENANCE, CLEANING ................................................................. 14

10.1. Safety instructions .......................................................................14

10.2. Maintenance work ........................................................................14

10.3. Cleaning .........................................................................................15

10.4. Recommended auxiliary materials ............................................15

11. REPAIRS

11.1. Replacing the valve set ...............................................................15

12. MALFUNCTIONS

13. SPARE PARTS ............................................................................................. 19

14. TRANSPORTATION, STORAGE, DISPOSAL ................................20

....................................................................................................... 10

.........................................................................................................14

.........................................................................................................15

........................................................................................ 19

english

3

Page 4

Type 2000 INOX

The operating instructions

1. THE OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning will result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderate or

minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

→ Designates a procedure which you must carry out.

1.2. Definition of the term 'Device'

In these instructions, the term "device" always refers to the angle

seat valve Type 2000 INOX.

4

english

Page 5

Type 2000 INOX

Authorized use

2. AUTHORIZED USE

Non-authorized use of the angle seat valve Type 2000 INOX

(designated as device in the following) can be dangerous to

people, nearby equipment and the environment.

• The device is designed for the controlled flow-rate of liquid and

gaseous media.

• Use according to the authorized data, operating conditions, and

conditions of use specified in the contract documents and operating instructions. These are described in chapter "6. Technical

data".

• Use the device only in conjunction with third-party devices and

components recommended and authorized by Bürkert.

• Correct transportation, storage, and installation, as well as careful use and maintenance are essential for reliable and faultless

operation.

• Use the device only as intended.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• Contingencies and events which may arise during the installation,

operation, and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing

these regulations, also in relation to the installation personnel.

Danger – high pressure!

• Turn off the pressure and vent the lines before loosening lines

or valves.

Risk of crushing from moving pneumatic connection!

• When opening and closing the device, do not touch the moving

pneumatic connection.

• Do not reach into the area immediately above and below the

control air connection.

Risk of water hammer when flow inlet over seat!

• When flow inlet over seat, do not use angle seat valve for liquid

media due to the risk of water hammer.

Risk of burns/risk of fire if used during long-term operation

through hot device surface!

• Do not touch the device with bare hands.

• Keep the device away from highly flammable substances and

media.

english

5

Page 6

Type 2000 INOX

General information

General hazardous situations.

To prevent injuries:

• Supply only media to the media connections which have been

specified as flow media in the chapter "Technical Data".

• Do not use the Type 2000 INOX in potentially explosive areas.

• Do not physically stress the housing (e.g. by placing objects on

it or standing on it).

• Ensure that the system cannot be activated unintentionally.

• Only trained technicians may perform installation and maintenance work.

• After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

• The device may be operated only when in perfect condition and

in consideration of the operating instructions.

• The general rules of technology apply to application planning

and operation of the device.

The angle seat valve Type 2000 INOX was developed with

due consideration given to the accepted safety rules and

is state-of-the-art. Nevertheless, dangerous situations may

occur.

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Germany

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

Email: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type 2000 INOX can

be found on the Internet at: www.burkert.com

6

english

Page 7

Type 2000 INOX

Product description

5. PRODUCT DESCRIPTION

5.1. General description

The 2/2-way angle seat valve Type 2000 INOX is suitable for liquid

and gaseous media.

It uses neutral gases or air (control media) to control the flow-rate

of water, alcohol, oil, fuel, hydraulic fluid, saline solution, lye, organic

solvent and steam (flow media).

5.2. Properties

• High leak-tightness.

• High flow values.

• Control air connection can be rotated centrally and steplessly

through 360°.

• Optical position indicator

• Maintenance-free

5.2.1. Restrictions

When flow inlet over seat, the angle seat valve must not be used for

liquid media due to the risk of water hammer!

6. TECHNICAL DATA

6.1. Conformity

The angle seat valve, Type 2000 INOX, conforms to the EC Directives

according to the EC Declaration of Conformity

6.2. Standards

The applied standards, which are used to demonstrate compliance

with the EC Directives, are listed in the EC type test certificate and/or

the EC Declaration of Conformity.

6.3. Operating conditions

6.3.1. Permitted temperatures

Ambient temperature: 0 °C ... +60 °C

Medium temperature: 0 °C ... +180 °C

The angle seat valve is autoclavable.

For this purpose, the control air connection must be

removed.

The combination of maximum medium temperature and maximum

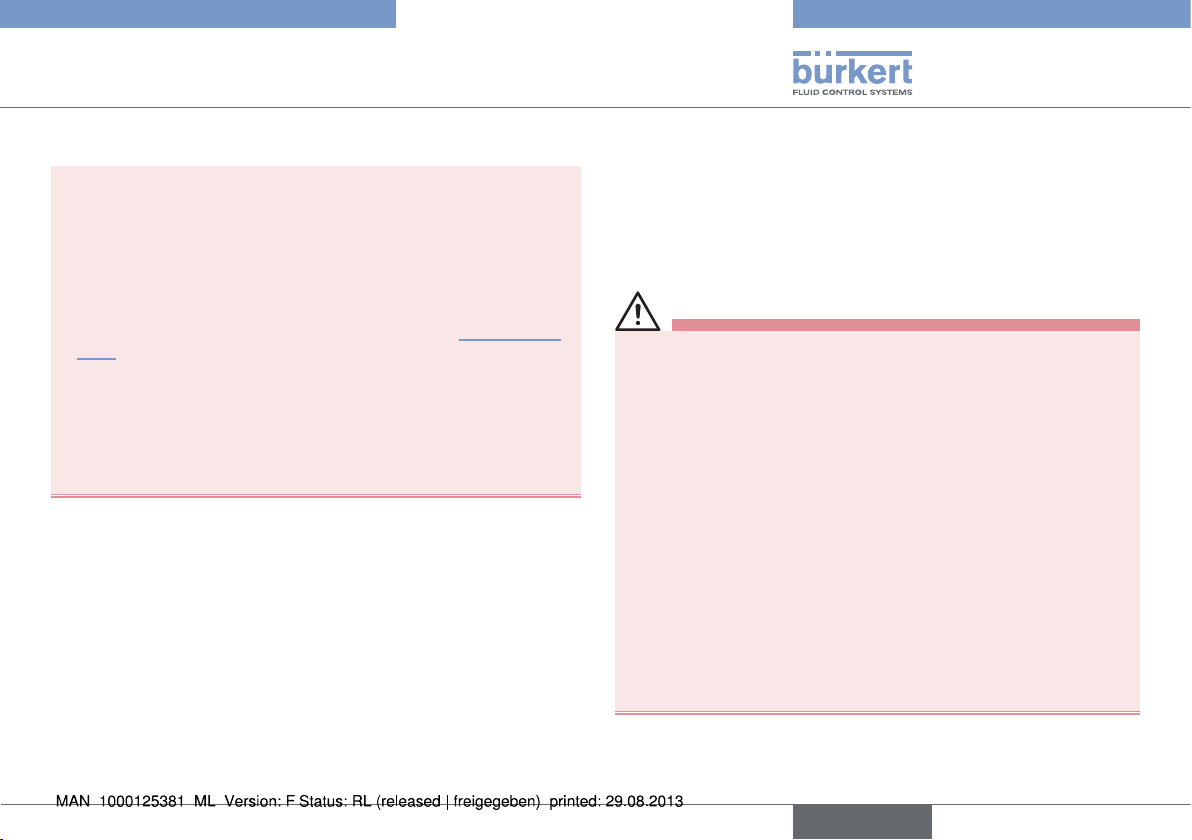

ambient temperature is indicated on the graph in "Fig. 1":

english

7

Page 8

Type 2000 INOX

Technical data

100

90

80

70

60

50

Ambient temperature [°C]

40

140 150 160 170

Medium temperature [°C]

Fig. 1: Combination of medium temperature / ambient temperature

180 190

6.3.2. Pressure ranges

WARNING!

Discharge of medium and danger of bursting.

If the permitted medium or control pressure is exceeded, lines or

device may leak and burst.

For control function B a too low control pressure may result in leaks.

• Do not exceed medium pressure and control pressure.

• For control function B observe the minimum control pressure of

4 bar.

6.3.3. Media

WARNING!

Risk of injury from bursting lines caused by water hammer!

If the valve is used for liquid media when flow inlet over seat, water

hammer may cause lines and device to burst.

• Do not use valves with flow inlet over seat for liquid media!

Control medium: neutral gases, air

Flow media: water, alcohols, oils, fuels, hydraulic fluids,

saline solutions, lyes, organic solvents, steam,

air, neutral gases

The product-specific pressure specifications are indicated on the

rating plate.

Minimum control pressure for control function B: 4 bar

8

english

Page 9

Type 2000 INOX

Technical data

6.4. General technical data

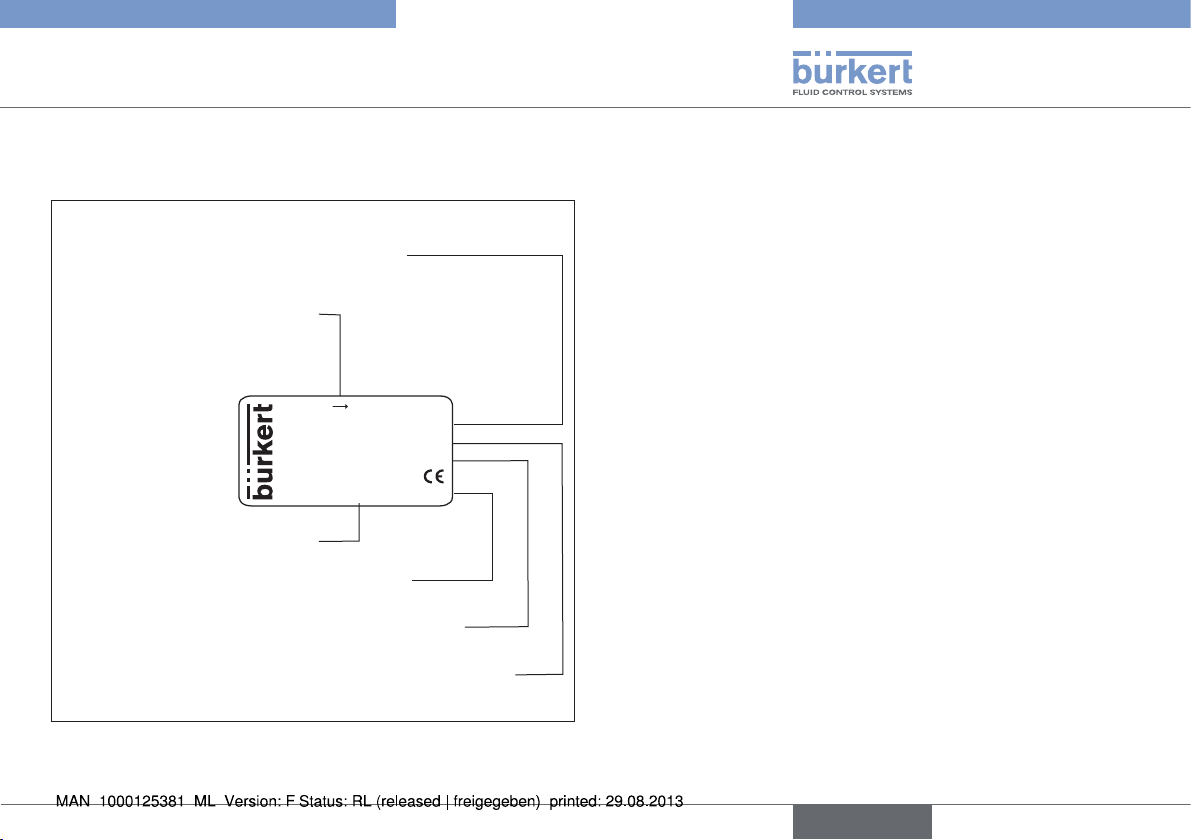

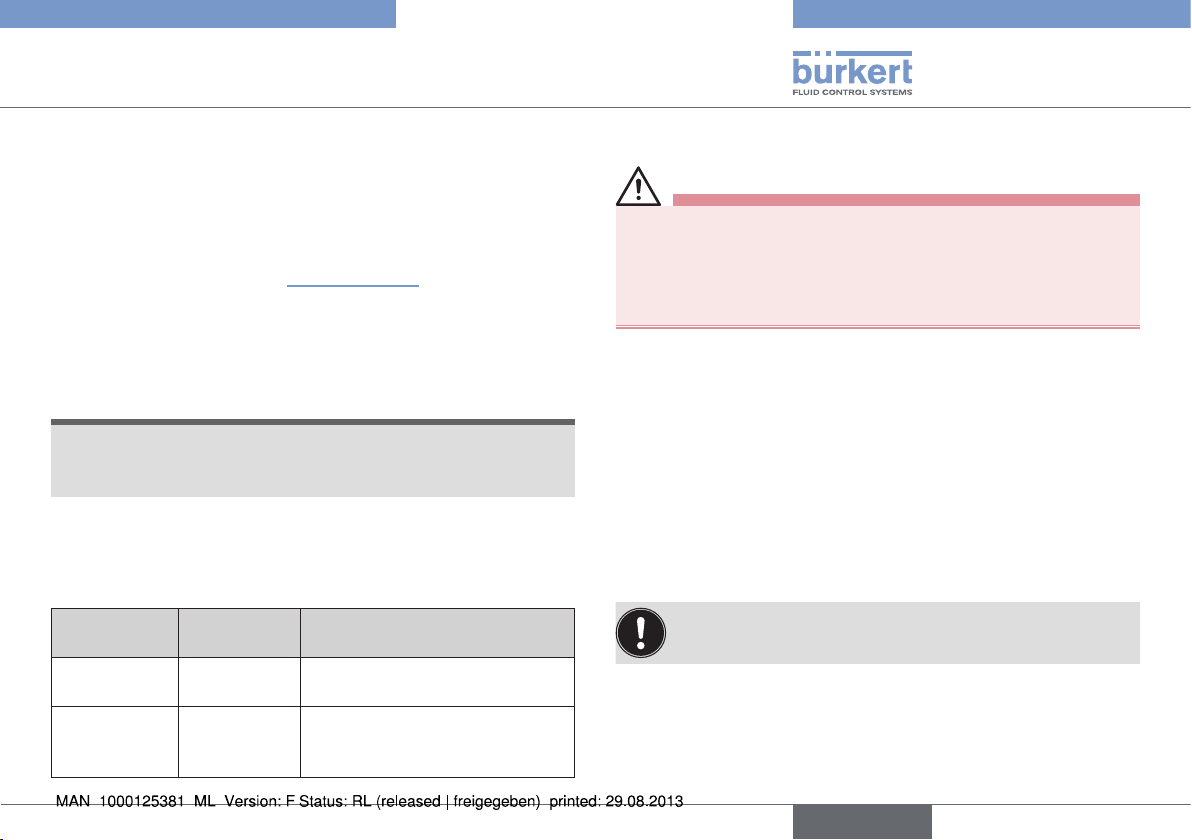

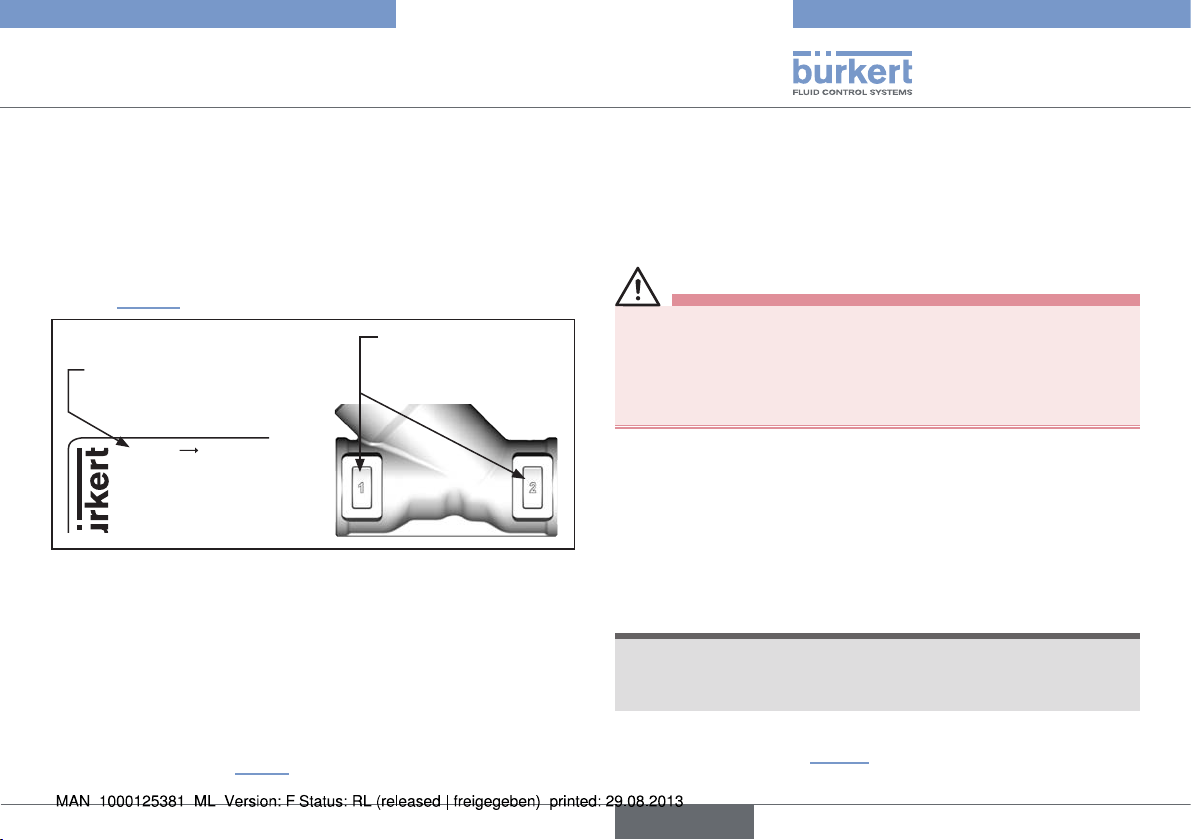

6.4.1. Inscription on the rating plate

Example:

Type, operating principle, orifice,

seal material, housing material

Direction of flow

(1 and 2 = identification of the

connections on the valve housing)

Flow 1 2

2000 A 10,0 PTFE VA

G3/8 P med 16 bar

Pilot 5,5 - 10 bar

Made in Germany

00182076

Identification number

Manufacturer code

Permitted control pressure range

permitted max. medium pressure

W1X LU

Connection type,

6.4.2. Materials

Valve housing stainless steel 316L

Actuator stainless steel 1.4404

Sealing elements FKM

Spindle sealing PTFE-V rings with spring compensation

(with silicone grease)

Seat seal PTFE

Spindle stainless steel 1.4401/1.4404

6.4.3. Connections

Control air connection 45° hose plug-in connection 4/2 M5

(recommendation) order no. 903383

Medium connection G3/8 and NPT3/8 socket connection

G1/2 external thread

Welded spigots according to

EN ISO 1127/ISO 4200, DIN 11850

Series 2, ASME BPE. Other connections

on request

6.4.4. Installation position

Any position, preferably with the actuator face up.

Fig. 2: Example of rating plate

english

9

Page 10

Type 2000 INOX

Structure and function

7. STRUCTURE AND FUNCTION

7.1. Structure

The angle seat valve consists of a pneumatically actuated piston

actuator with optical position indicator and a 2/2-way valve housing.

7.2. Function

Depending on the version, the valve is closed against the medium

flow by spring force (control function A, SFA) or by control pressure

(control function B, SFB).

Spring force (SFA) or pneumatic control pressure (SFB) generates

the closing force on the pendulum disc. The force is transferred via a

spindle which is connected to the actuator piston.

Flow inlet under seat:

As the medium pressure is under the pendulum disc, this pressure contributes to the opening of the valve. The flow inlet is under the valve seat.

If the minimum control pressure is too low for SFB or the permitted

medium pressure is exceeded, leaks may occur!

7.2.1. Control functions

Control function A (SFA)

Closed in rest position by spring force.

Control function B (SFB)

Open in rest position by spring force.

8. ASSEMBLY

8.1. Safety instructions

DANGER!

Risk of injury from high pressure in the system!

• Turn off the pressure and vent the lines before loosening lines

or valves.

WARNING!

Risk of injury from improper assembly!

• Installation must only be carried out by authorized technicians

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

Risk of crushing from moving pneumatic connection!

• When opening and closing the device, do not touch the moving

pneumatic connection.

• Do not reach into the area immediately above and below the

control air connection.

10

english

Page 11

2000 A 10,0 PTFE VA

med 16 bar

Type 2000 INOX

Assembly

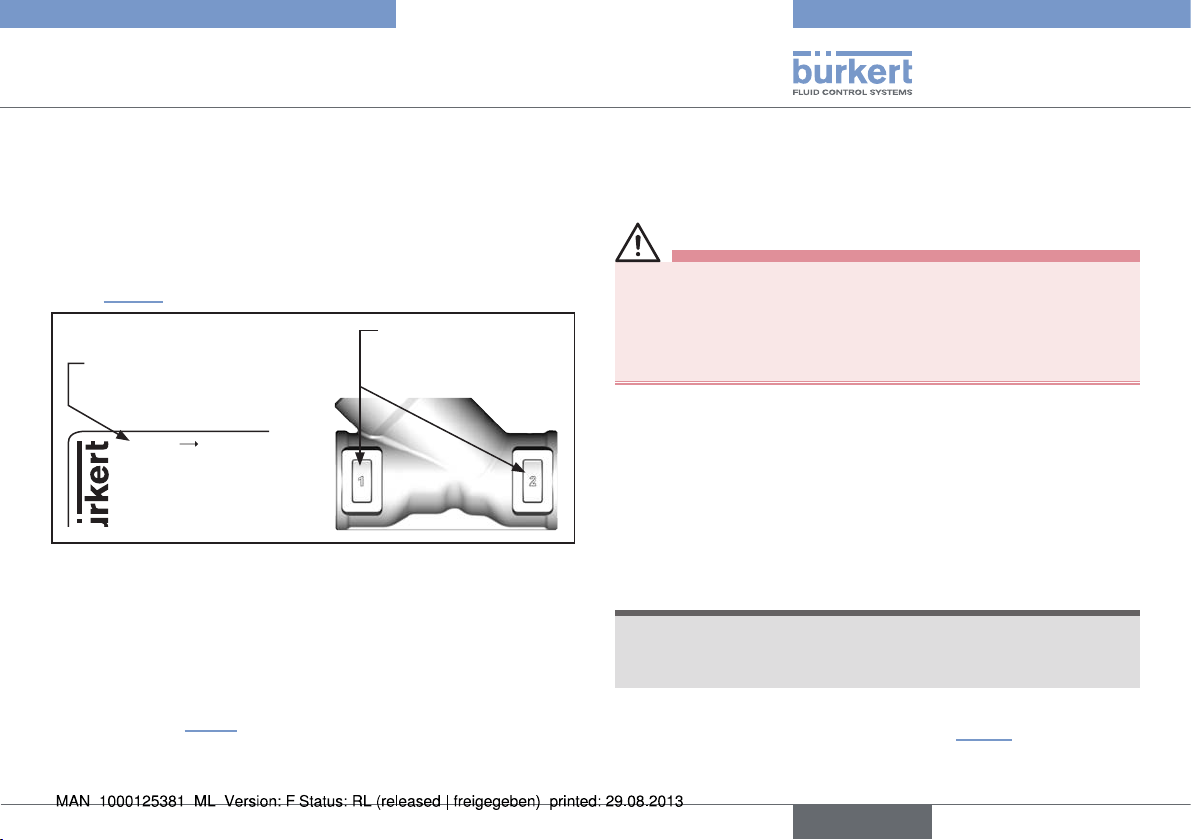

8.2. Before installation

• The angle seat valve can be installed in any position, preferably

with the actuator face up.

• Before connecting the valve, ensure the pipelines are flush

(stress-free).

• Observe direction of flow!

See "Fig. 3".

Example:

Direction of flow specified on

the rating plate

Flow 1 2

G3/8 P

Identification

of the connections on the

valve housing

Pilot 5,5 - 10 bar

Fig. 3: Identification of the connections / direction of flow

8.2.1. Preparatory tasks

→ Clean pipelines (sealing material, swarf, etc.).

Welded housing:

→ Before welding in the valve housing, remove the actuator

(see Chapter "8.3.1").

8.3. Installation

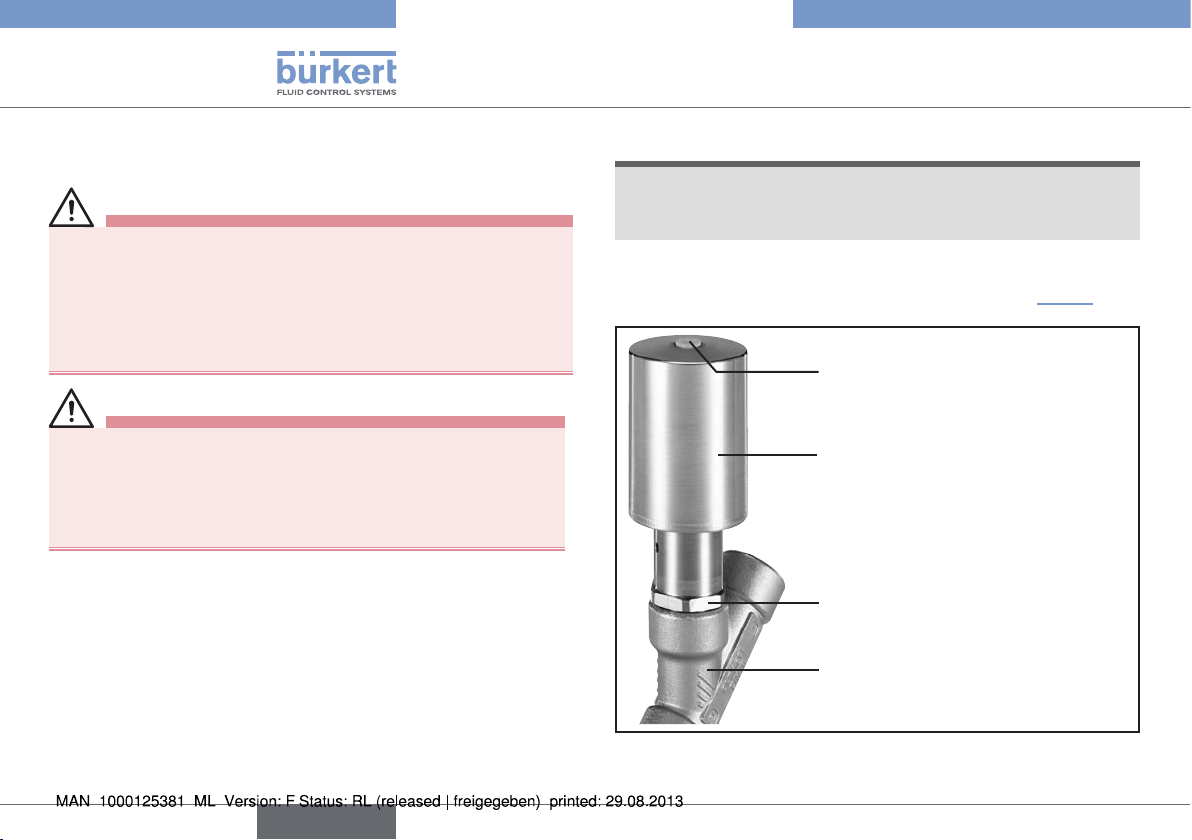

8.3.1. Remove actuator from the valve

housing (for welded housings only)

WARNING!

Risk of injury from damaged devices!

If the wrong tools are used for assembly work, the device may be

damaged.

• To remove the actuator from the valve housing, use an open-end

wrench, never a pipe wrench.

Control function A:

→ Pressurize control air connection with compressed air (5.5 bar)

so that the pendulum disc is lifted off the valve seat and is not

damaged.

Control function B:

For control function B it is not necessary to apply compressed air for

installation.

NOTE!

Damage to the seat seal or the seat contour!

• When removing the actuator, ensure that the valve is in the

open position.

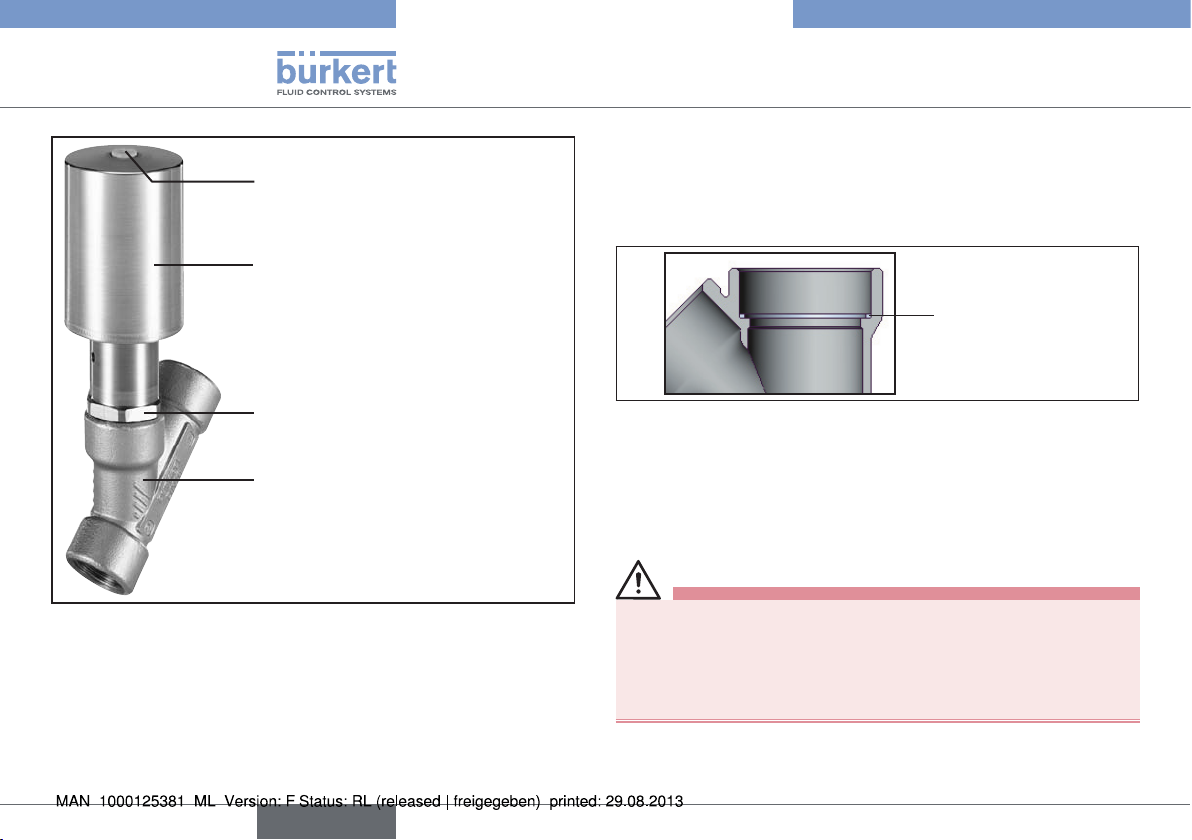

→ When valve is in open position, remove actuator from the valve

housing using an open-end wrench (see "Fig. 4").

english

11

Page 12

Optical position indicator

Yellow = valve open

Actuator

Type 2000 INOX

Assembly

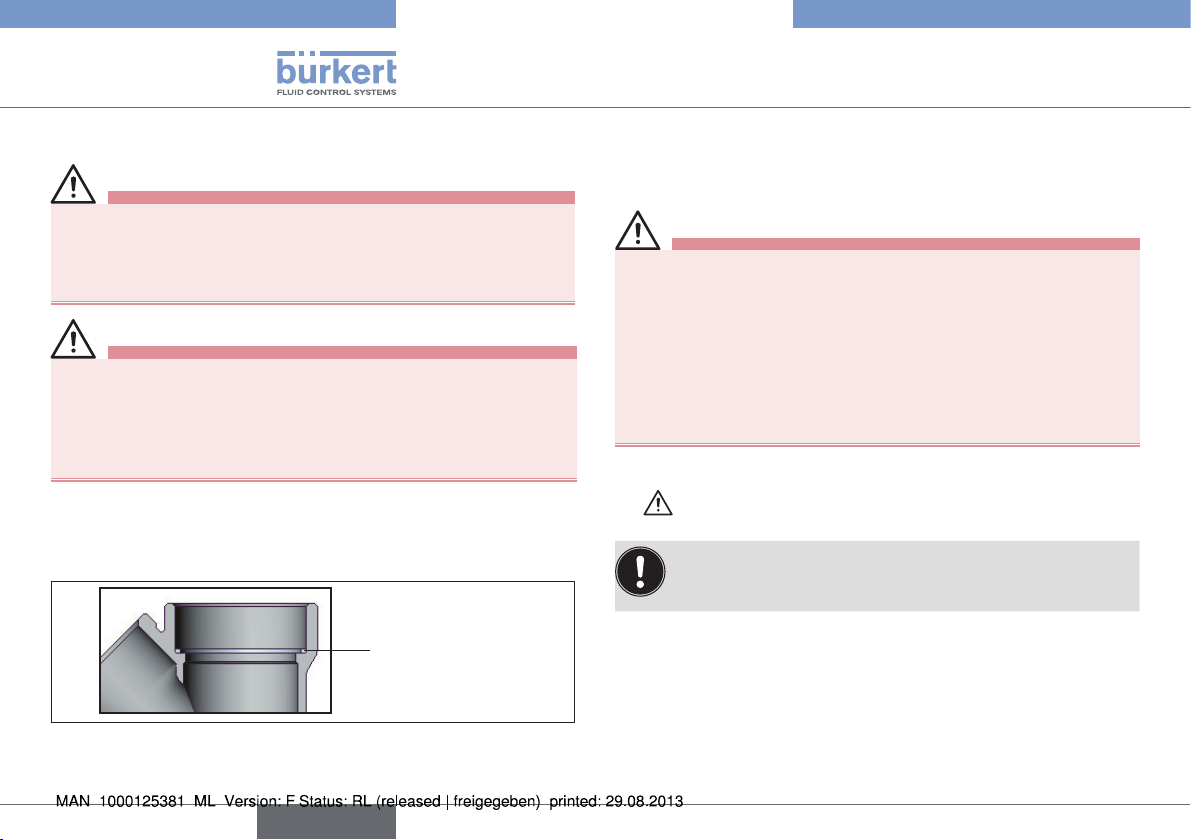

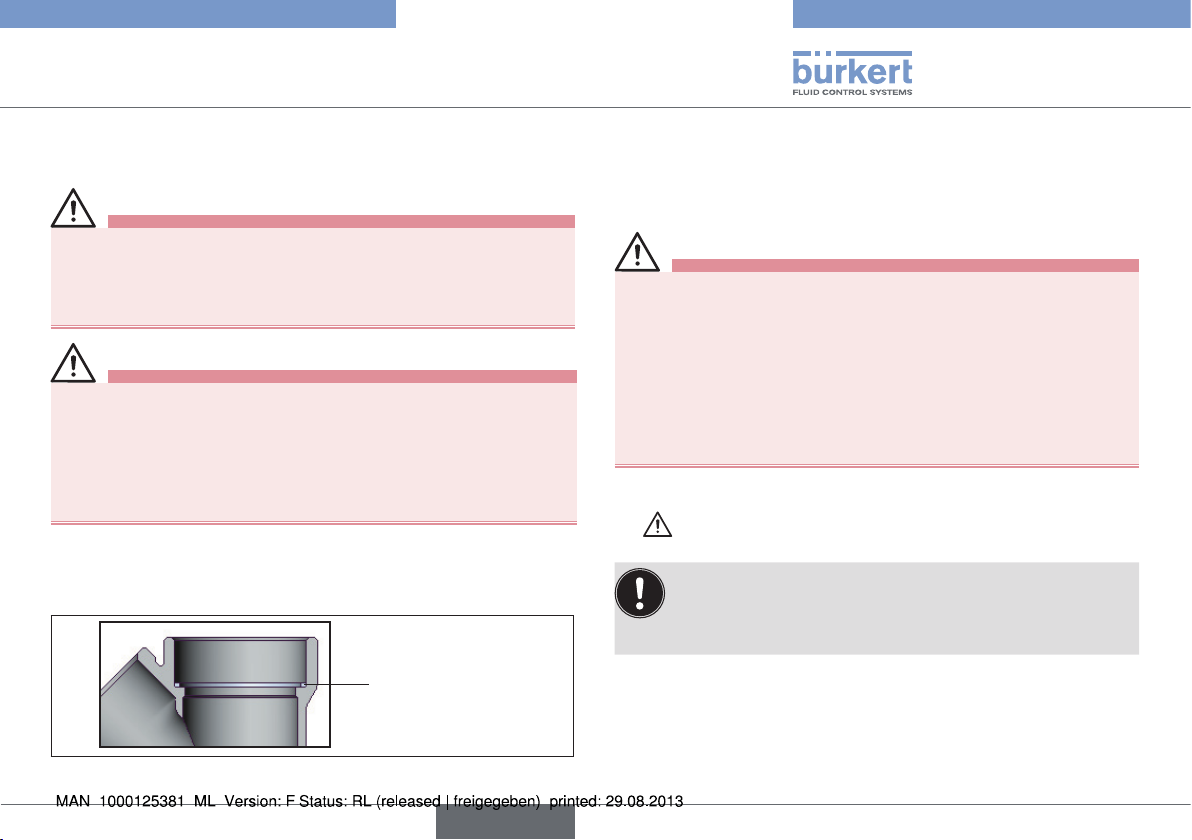

8.3.2. Installing valve housing in pipeline

For welded housings:

→ Weld valve housing in pipeline system.

→ Check graphite seal and, if required, replace.

Graphite seal

Fig. 4: Removing the actuator

12

Wrench flat for open-end wrench

(hexagonal)

Valve housing

english

Fig. 5: Graphite seal

For other housing models:

→ Connect valve housing to pipeline.

8.3.3. Installing actuator on valve housing

DANGER!

Risk of explosion if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen

applications there is a risk of explosion.

• In specific applications, e.g. oxygen or analysis applications, use

appropriately authorized lubricants only.

Page 13

Type 2000 INOX

Assembly

WARNING!

Risk of injury from damaged devices!

If the wrong tools are used for assembly work, the device may be

damaged. Also if tightening torque is incorrect.

• To remove the actuator from the valve housing, use an open-end

wrench, never a pipe wrench.

• Observe tightening torque (40 ± 3 Nm)

→ Grease pipe thread before re-installing the actuator

(e.g. with Klüber paste UH1 96-402 from Klüber).

→ For control function A: Pressurize control air connection with

compressed air (5.5 bar) so that the pendulum disc is lifted off the

valve seat and is not damaged when screwed in.

→ Screw actuator into the valve housing.

Observe tightening torque (40 ± 3 Nm)!

If the position of the control air connection for installation

of the hose is unfavorable, it can be aligned steplessly by

rotating the actuator through 360°.

8.4. Pneumatic connection

DANGER!

Risk of injury from high pressure in the system!

• Before disconnecting lines and valves, turn off the pressure and

vent the lines.

WARNING!

Risk of injury from unsuitable connection hoses!

Hoses which cannot withstand the pressure and temperature

range may result in hazardous situations.

• Use only hoses which are authorized for the indicated pressure

and temperature range.

• Observe the data sheet specifications from the hose

manufacturers.

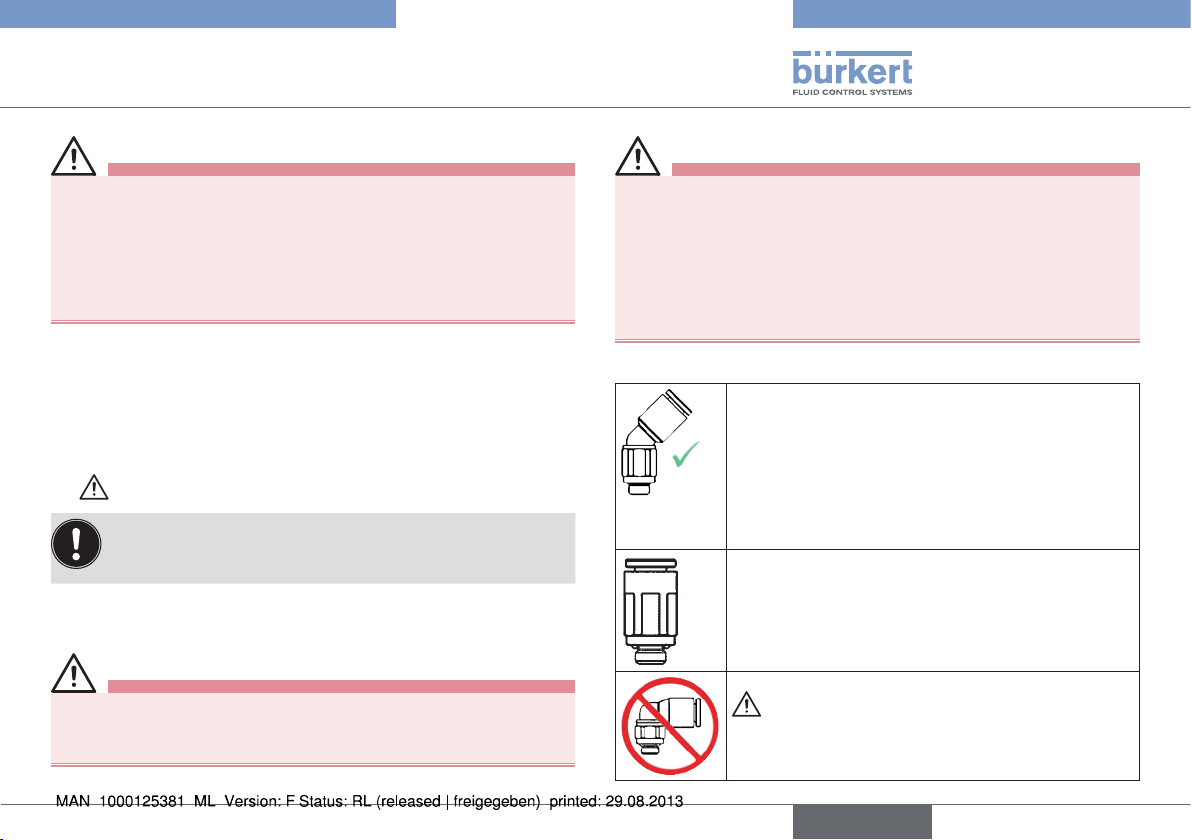

8.4.1. Control air connections

The 45° angle connection, which can be ordered

separately, is recommended for the control air

connection!

In this case the free-moving hose length should be

min. 250 mm.

Order no.

903383

If the hose length is shorter, the durability and

function of the plug-in coupling will be impaired!

If a straight control air connection is used, the freemoving hose length should be min. 400 mm.

If the hose length is shorter, the durability and

function of the plug-in coupling will be impaired!

Risk of crushing!

• Due to the risk of crushing, a 90° control air connection must not be used!

english

13

Page 14

Type 2000 INOX

Start-up

9. START-UP

9.1. Safety instructions

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• Observe the safety instructions and intended use.

• Only adequately trained personnel may start up the equipment/

the device.

10. MAINTENANCE, CLEANING

10.1. Safety instructions

DANGER!

Risk of injury from high pressure in the system!

• Turn off the pressure and vent the lines before loosening lines

or valves.

WARNING!

Risk of injury from improper maintenance!

• Maintenance may only be carried out by authorized technicians

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

• To screw in or unscrew the valve housing or actuator, use an

open-end wrench, never a pipe wrench, and observe tightening

torques.

10.2. Maintenance work

10.2.1. Actuator

The actuator of the angle seat valve is maintenance-free.

14

english

Page 15

Type 2000 INOX

Repairs

10.2.2. Angle seat valve

Parts which are subject to natural wear:

• Pendulum disc

• Graphite seal

If leaks occur, replace the particular wearing part with an appro-

priate spare part (see Chapter "13. Spare parts").

10.3. Cleaning

Commercially available cleaning agents can be used to clean the

surface of the device.

NOTE!

Avoid causing damage with cleaning agents.

• Before cleaning, check that the cleaning agents are compatible

with the housing materials and seals.

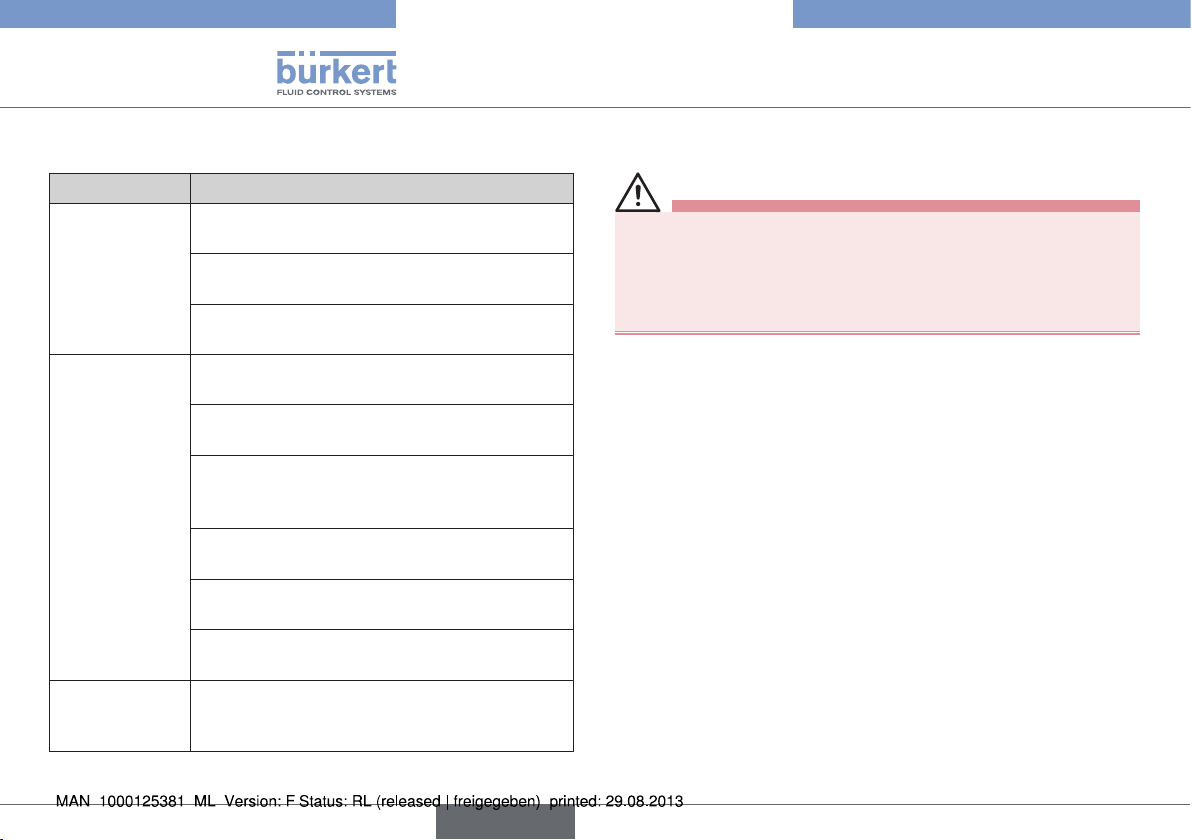

10.4. Recommended auxiliary materials

In this manual the following auxiliary materials are recommended for

faultless operation, maintenance and repair of the device:

Type of auxiliary material

Lubrication

paste

Adhesive Loctite 640 Marketing Loctite, Henkel AG &

Product

designation

Klüber paste

UH1 96-402

Manufacturer and Internet

address

Klüber Lubrication München KG,

www.klueber.de

Co.KGaA,

www.loctite.de

11. REPAIRS

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

• Use original accessories and original spare parts from Bürkert

only.

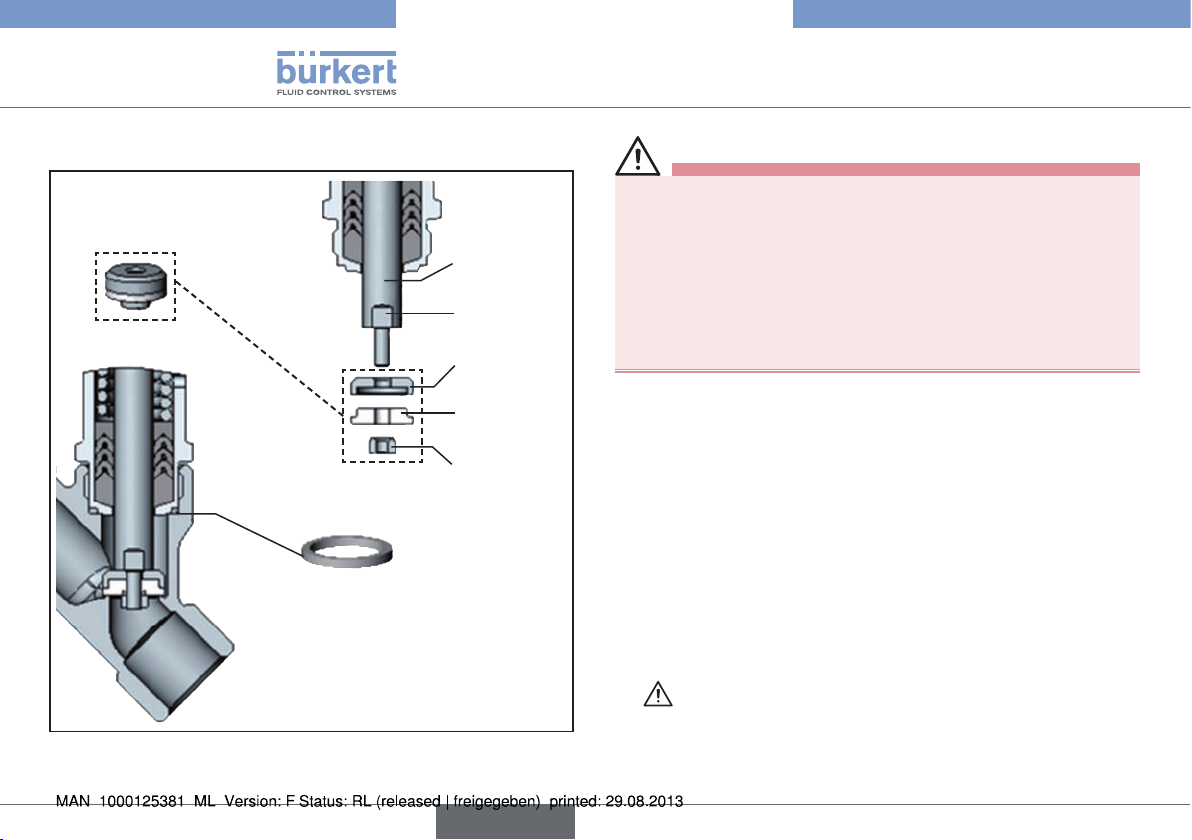

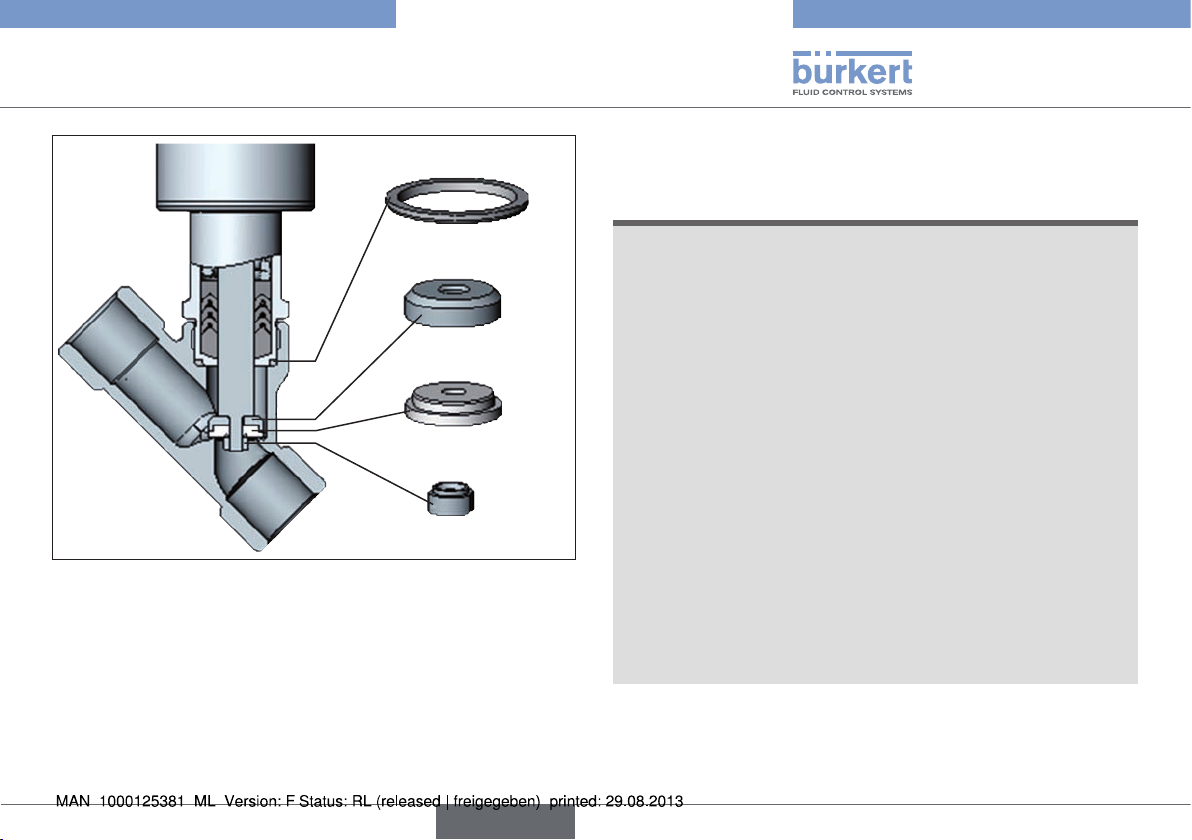

11.1. Replacing the valve set

The valve set consists of:

• The pendulum disc:

consisting of - Seal holder

- Seat seal

- Centering

• The graphite seal

This can also be ordered separately

Before the valve set can be replaced, the actuator must be

removed from the valve housing as described below.

english

15

Page 16

Type 2000 INOX

Repairs

11.1.1. Removing the actuator from the valve

housing

DANGER!

Risk of injury from discharge of medium and release of

pressure!

It is dangerous to remove the device under pressure due to the

sudden release of pressure or discharge of medium.

• Turn off the pressure and vent the lines before loosening lines

or valves.

WARNING!

Risk of injury from damaged devices!

If the wrong tools are used for assembly work, the device may be

damaged.

• To remove the actuator from the valve housing, use an openend wrench, never a pipe wrench.

Control function A:

→ Pressurize control air connection with compressed air (5.5 bar)

so that the pendulum disc is lifted off the valve seat and is not

damaged.

Control function B:

For control function B it is not necessary to apply compressed air for

removal.

NOTE!

Damage to the seat seal or the seat contour!

• When removing the actuator, ensure that the valve is in the

open position.

→ When valve is in open position, remove actuator from the valve

housing using an open-end wrench (WAF 22) (see "Fig. 6").

Optical position indicator

Yellow = valve open

Actuator

Wrench flat for open-end wrench

(hexagonal)

Valve housing

Fig. 6: Removing the actuator

16

english

Page 17

Type 2000 INOX

Repairs

11.1.2. Replacing valve set

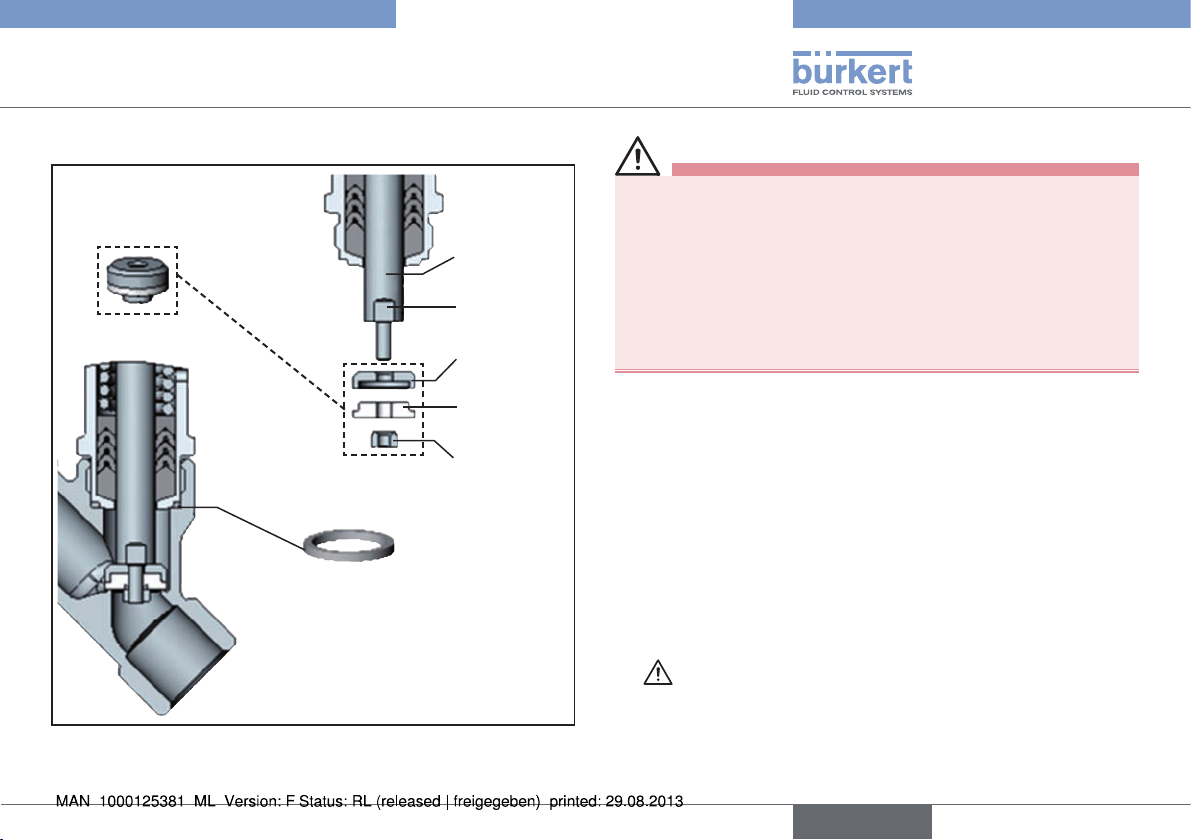

Pendulum disc

Graphite seal

Spindle

Wrench flat

Seal holder

Seat seal

Centering

WARNING!

Risk of injury from damaged devices!

If the wrong tools are used for assembly work, the device may be

damaged.

• To remove the actuator from the valve housing, use an open-end

wrench, never a pipe wrench.

If the tightening torque is too great, the spindle thread may be

damaged.

• Observe tightening torque (40 ± 3 Nm)

Procedure:

→ Counter spindle on the wrench flat using open-end wrench

(WAF 7).

→ Carefully loosen centering using a suitable open-end wrench

(WAF 5.5) to prevent damaging the spindle thread.

→ Unscrew centering.

→ Remove seal holder together with seat seal.

→ Attach new seal holder and new seat seal to the spindle.

→ Apply adhesive (Loctite 640) to spindle thread.

→ Screw on centering and tighten using a suitable open-end

wrench (WAF 5.5).

Observe tightening torque (40 ± 3 Nm)!

Fig. 7: Valve set

english

17

Page 18

Type 2000 INOX

Repairs

11.1.3. Installing actuator on valve housing

WARNING!

Risk of injury from unintentional activation of the system and

uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

DANGER!

Risk of explosion if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen applications there is a risk of explosion.

• In specific applications, e.g. oxygen or analysis applications, use

appropriately authorized lubricants only.

→ Grease pipe thread before re-installing the actuator

(e.g. with Klüber paste UH1 96-402 from Klüber).

→ Check graphite seal and, if required, replace.

Graphite seal

→ For control function A: Pressurize control air connection with

compressed air (5.5 bar) so that the pendulum disc is lifted off the

valve seat and is not damaged when screwed in.

WARNING!

Risk of injury from damaged devices!

If the wrong tools are used for assembly work, the device may be

damaged.

• To remove the actuator from the valve housing, use an open-end

wrench, never a pipe wrench.

If the tightening torque is too great, the spindle thread may be

damaged.

• Observe tightening torque (40 ± 3 Nm)

→ Screw actuator into the valve housing.

Observe tightening torque (40 ± 3 Nm)!

If the position of the control air connection for installation

of the hose is unfavorable, it can be aligned steplessly by

rotating the actuator through 360°.

Fig. 8: Graphite seal

18

english

Page 19

Type 2000 INOX

Malfunctions

12. MALFUNCTIONS

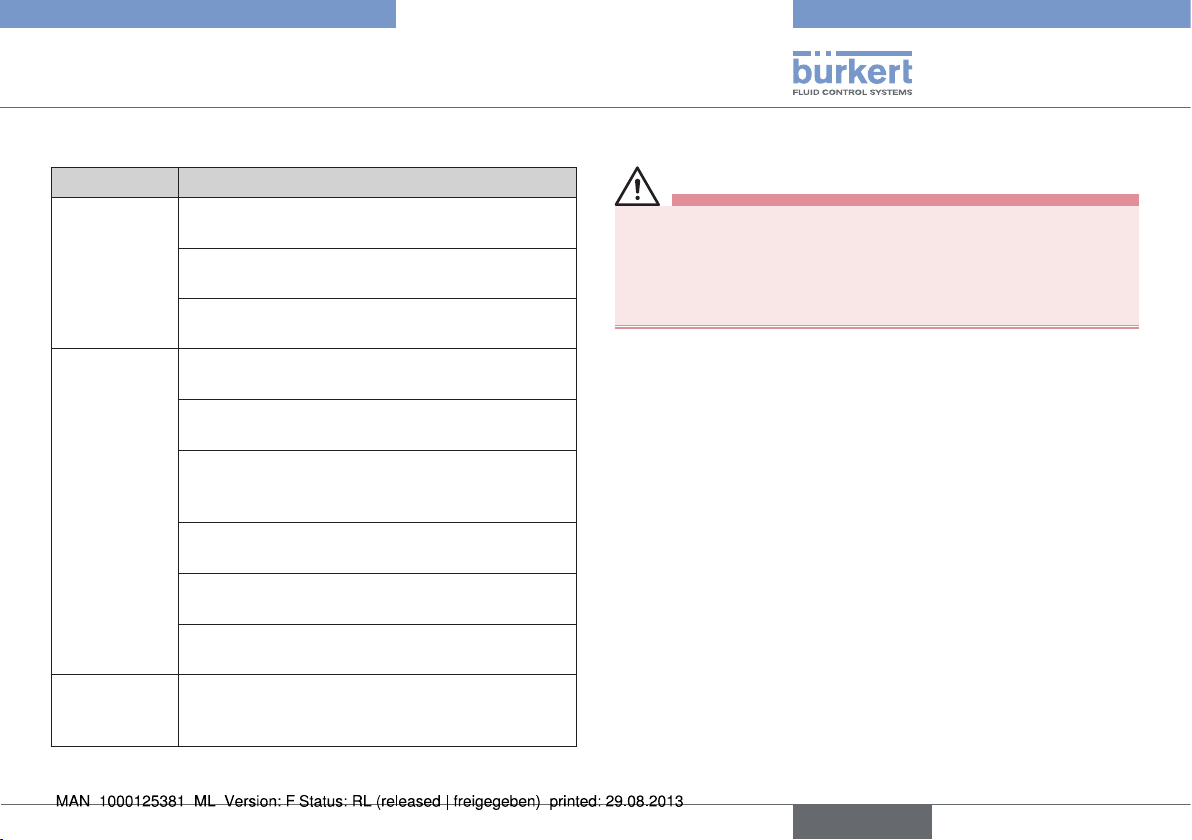

Malfunction Remedial action

Actuator does

not switch.

Control pressure too low.

→ See pressure specifications on the rating plate.

Medium pressure too high.

→ See pressure specifications on the rating plate.

Direction of flow reversed.

→ See identification on the rating plate.

Valve is not

sealed.

Dirt between seal and valve seat.

→ Install dirt trap.

Seat seal worn.

→ Install new pendulum disc.

Seat seal damaged, e.g. by foreign objects, swarf

or similar.

→ Install new pendulum disc.

Direction of flow reversed.

→ See identification on the rating plate.

Control pressure too low.

→ See pressure specifications on the rating plate.

Medium pressure too high.

→ See pressure specifications on the rating plate.

Valve is

leaking on the

release bore.

Tab. 1: Malfunctions

Spindle seal worn.

→ Replacing actuator.

13. SPARE PARTS

CAUTION!

Risk of injury and/or damage by the use of incorrect parts!

Incorrect accessories and unsuitable spare parts may cause injuries

and damage the device and the surrounding area.

• Use original accessories and original spare parts from Bürkert

only.

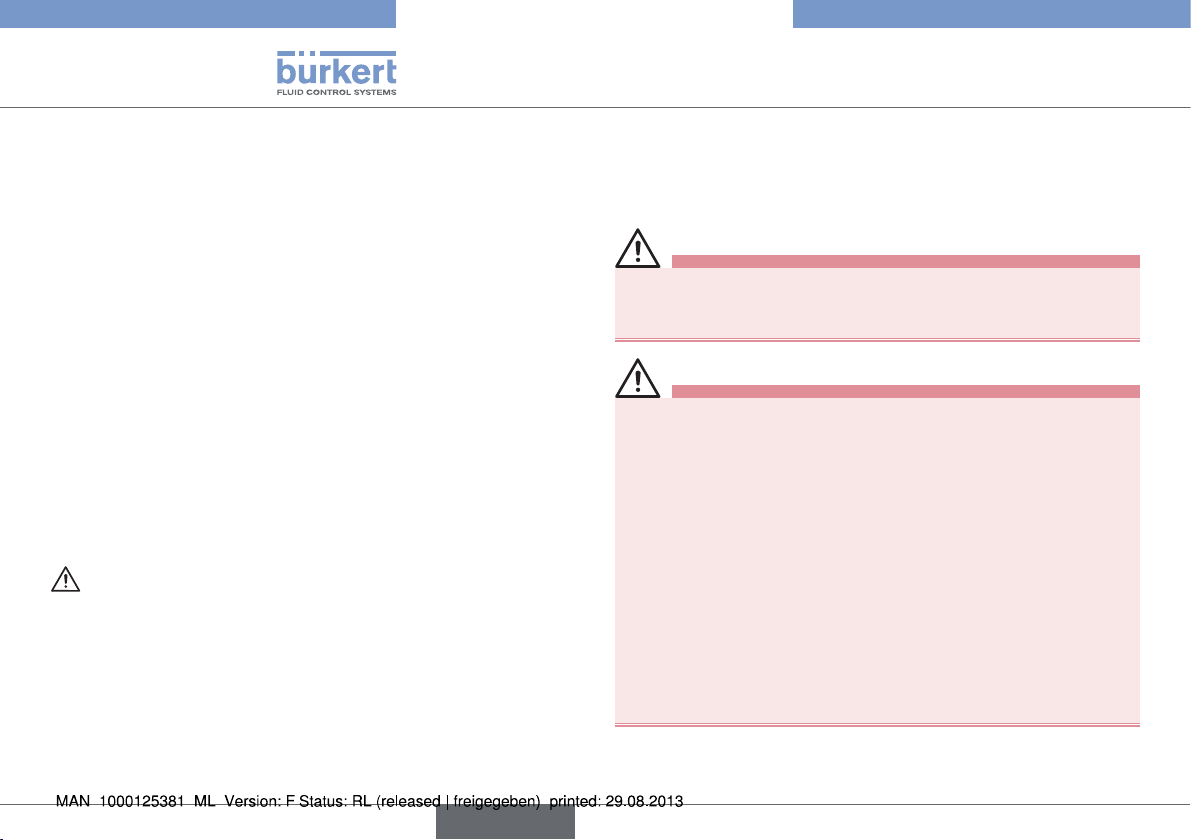

The valve set, order no. 220053, is available as a spare part for the

angle seat valve, Type 2000 INOX. This consists of:

• The pendulum disc:

consisting of - Seal holder

- Seat seal

- Centering

• The graphite seal

This can also be ordered separately

english

19

Page 20

Type 2000 INOX

Transportation, storage, disposal

Fig. 9: Valve set

Graphite seal

Seal holder

Seat seal

Centering

14. TRANSPORTATION, STORAGE,

DISPOSAL

NOTE!

Transport damage!

Inadequately protected devices may be damaged during

transportation.

• Protect the device against moisture and dirt in shock-resistant

packaging during transportation.

• Prevent the temperature from exceeding or dropping below the

permitted storage temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -20 °C ... +65 °C.

Damage to the environment caused by device components

contaminated with media.

• Dispose of the device and packaging in an environmentally

friendly manner!

• Observe applicable disposal and environmental regulations.

20

english

Page 21

Typ 2000 INOX

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ............................................................22

1.1. Darstellungsmittel ...........................................................................22

1.2. Begriffsdefinition Gerät .................................................................22

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ................................... 23

2.1. Beschränkungen ............................................................................23

3. GRUNDLEGENDE SICHERHEITSHINWEISE .................................23

4. ALLGEMEINE HINWEISE .......................................................................... 24

4.1. Kontaktadresse ...............................................................................24

4.2. Gewährleistung...............................................................................24

4.3. Informationen im Internet ..............................................................24

5. PRODUKTBESCHREIBUNG

5.1. Allgemeine Beschreibung ............................................................25

5.2. Eigenschaften .................................................................................25

6. TECHNISCHE DATEN ................................................................................ 25

6.1. Konformität .......................................................................................25

6.2. Normen .............................................................................................25

6.3. Betriebsbedingungen ....................................................................25

6.4. Allgemeine Technische Daten .....................................................27

7. AUFBAU UND FUNKTION ....................................................................... 28

7.1. Aufbau ...............................................................................................28

7.2. Funktion ............................................................................................28

................................................................... 25

8. MONTAGE

8.1. Sicherheitshinweise .......................................................................28

8.2. Vor dem Einbau ..............................................................................29

8.3. Einbau ...............................................................................................29

8.4. Pneumatischer Anschluss ............................................................31

9. INBETRIEBNAHME

9.1. Sicherheitshinweise .......................................................................32

10. WARTUNG, REINIGUNG .........................................................................33

10.1. Sicherheitshinweise.....................................................................33

10.2. Wartungsarbeiten ........................................................................33

10.3. Reinigung .......................................................................................33

10.4. Empfohlene Hilfsstoffe ................................................................34

11. INSTANDHALTUNG

11.1. Austausch des Ventilsatzes .......................................................34

12. STÖRUNGEN

13. ERSATZTEILE

14. TRANSPORT, LAGERUNG, ENTSORGUNG ................................. 39

........................................................................................................ 28

......................................................................................32

................................................................................... 34

................................................................................................ 38

............................................................................................... 38

deutsch

21

Page 22

Typ 2000 INOX

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Geräts

wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2. Begriffsdefinition Gerät

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht immer für

das Schrägsitzventil Typ 2000 INOX.

22

deutsch

Page 23

Typ 2000 INOX

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Schrägsitzventils Typ 2000 INOX (im nachfolgenden als Gerät

bezeichnet) können Gefahren für Personen, Anlagen in der

Umgebung und die Umwelt entstehen.

• Das Gerät ist für die Steuerung des Durchflusses von flüssigen

und gasförmigen Medien konzipiert.

• Für den Einsatz die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten. Diese sind im Kapitel „6. Techni-

sche Daten“ beschrieben.

• Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -komponenten einsetzen.

• Voraussetzungen für den sicheren und einwandfreien Betrieb

sind sachgemäßer Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Gerätes gegebenenfalls

bestehende Beschränkungen.

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entlüften.

Quetschgefahr durch sich bewegenden pneumatischen

Anschluss!

• Beim Öffnen und Schließen des Gerätes nicht den sich bewegenden pneumatischen Anschluss berühren.

• Nicht in den unmittelbaren Bereich oberhalb und unterhalb des

Steuerluftanschlusses fassen.

Schließschlaggefahr bei Anströmung über Sitz!

• Bei Anströmung über Sitz das Schrägsitzventil, wegen Schließschlaggefahr nicht für flüssige Medien einsetzen.

Verbrennungsgefahr/Brandgefahr bei Dauerbetrieb durch

heiße Geräteoberfläche!

• Das Gerät nicht mit bloßen Händen berühren.

• Das Gerät von leicht brennbaren Stoffen und Medien fernhalten.

deutsch

23

Page 24

Typ 2000 INOX

Allgemeine Hinweise

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• In die Medienanschlüsse nur Medien einspeisen, die im Kapitel

„Technische Daten“ als Durchflussmedien aufgeführt sind.

• Den Typ 2000 INOX nicht in explosionsgefährdeten Bereichen

einsetzen.

• Das Gehäuse nicht mechanisch belasten (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Nur geschultes Fachpersonal darf Installations- und Instandhaltungsarbeiten ausführen.

• Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung für einen definierten oder kontrollierter Wiederanlauf

des Prozesses sorgen.

• Das Gerät nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung betreiben.

• Für die Einsatzplanung und den Betrieb des Gerätes die allgemeinen Regeln der Technik einhalten.

Das Schrägsitzventil Typ 2000 INOX wurde unter Einbeziehung der anerkannten sicherheitstechnischen Regeln

entwickelt und entspricht dem Stand der Technik. Trotzdem

können Gefahren entstehen.

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 2000 INOX finden

Sie im Internet unter: www.buerkert.de

24

deutsch

Page 25

Typ 2000 INOX

Produktbeschreibung

5. PRODUKTBESCHREIBUNG

5.1. Allgemeine Beschreibung

Das 2/2-Wege Schrägsitzventil Typ 2000 INOX ist geeignet für flüssige

und gasförmige Medien.

Es steuert mittels neutraler Gase oder Luft (Steuermedien) den

Durchfluss von Medien wie Wasser, Alkohol, Öl, Treibstoff, Hydraulikflüssigkeit, Salzlösung, Lauge, organischem Lösungsmittel und Dampf

(Durchflussmedien).

5.2. Eigenschaften

• Hohe Dichtheit.

• Hohe Durchflusswerte.

• Steuerluftanschluss zentral und um 360° stufenlos drehbar.

• Optische Stellungsanzeige

• Wartungsfrei

5.2.1. Einschränkungen

Das Schrägsitzventil darf bei Anströmung über Sitz, wegen Schließschlaggefahr, nicht für flüssige Medien eingesetzt werden!

6. TECHNISCHE DATEN

6.1. Konformität

Das Schrägsitzventil, Typ 2000 INOX ist konform zu den EG-Richtlinien

entsprechend der EG-Konformitätserklärung

6.2. Normen

Die angewandten Normen, mit denen die Konformität zu den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

6.3. Betriebsbedingungen

6.3.1. Zulässigen Temperaturen

Umgebungstemperatur: 0 °C … +60 °C

Mediumstemperatur: 0 °C … +180 °C

Das Schrägsitzventil ist autoklavierbar.

Hierzu muss der Steuerluftanschluss entfernt werden.

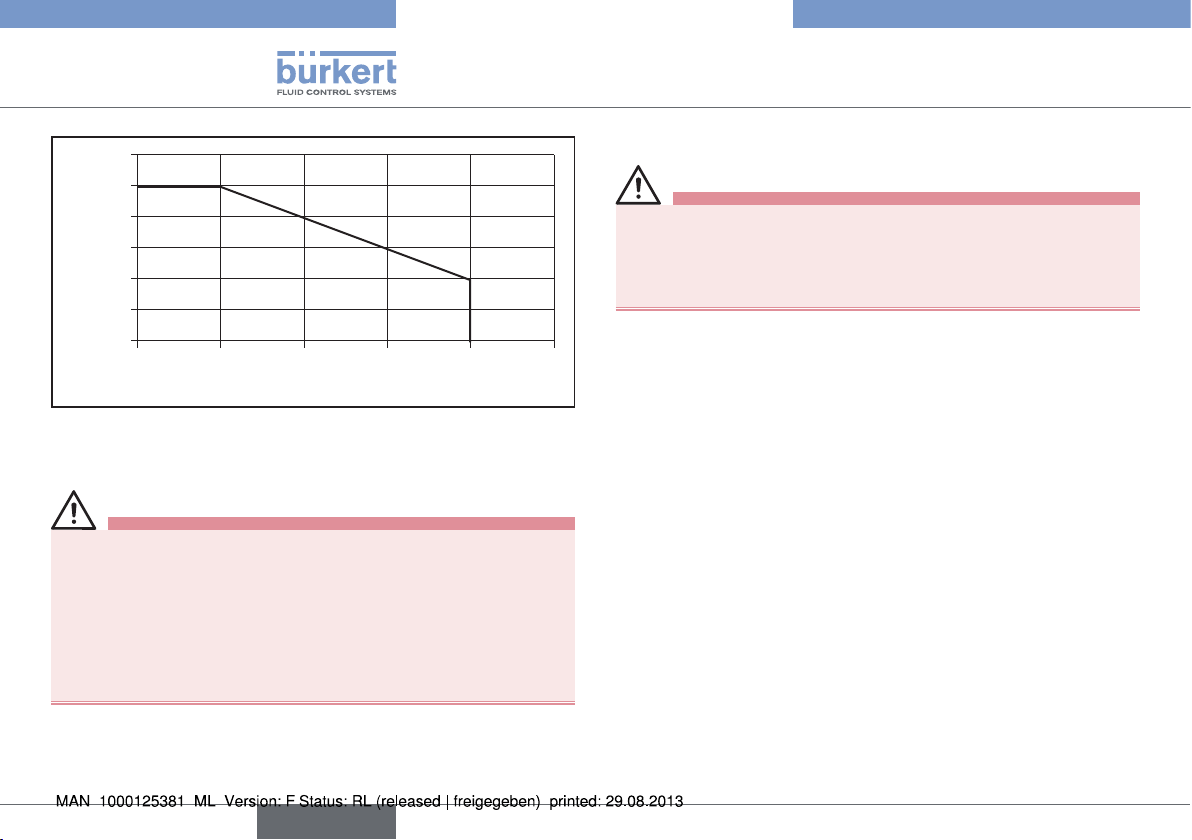

Die Kombination von maximaler Mediumstemperatur und maximaler

Umgebungstemperatur ist in dem Diagramm in „Bild 1“ angegeben:

deutsch

25

Page 26

Typ 2000 INOX

Technische Daten

100

90

80

70

60

50

40

Umgebungstemperatur [°C]

140 150 160 170

Mediumstemperatur [°C]

180 190

Bild 1: Kombination Mediumstemperatur / Umgebungstemperatur

6.3.2. Druckbereiche

WARNUNG!

Mediumsaustritt und Berstgefahr.

Ein Überschreiten des zulässigen Mediums- oder Steuerdrucks

kann zu Undichtigkeit und zum Bersten von Leitungen oder Gerät

führen.

Bei Steuerfunktion B kann ein zu geringer Steuerdruck zu Undichtigkeit führen.

• Mediumsdruck und Steuerdruck nicht überschreiten.

• Bei Steuerfunktion B den Mindeststeuerdruck von 4 bar

einhalten.

Die produktspezifischen Druckangaben sind auf dem Typschild

angegeben.

Mindeststeuerdruck bei Steuerfunktion B: 4 bar

6.3.3. Medien

WARNUNG!

Verletzungsgefahr durch und berstende Leitungen infolge

eines Schließschlags!

Wird bei Anströmung über Sitz das Ventil für flüssige Medien

eingesetzt, kann ein Schließschlag zum Bersten von Leitungen

und Gerät führen.

• Ventile mit Anströmung über Sitz nicht für flüssige Medien

einsetzen!

Steuermedium: neutrale Gase, Luft

Durchflussmedien: Wasser, Alkohole, Öle, Treibstoffe,

Hydraulikflüssigkeiten, Salzlösungen, Laugen,

organische Lösungsmittel, Dampf, Luft,

neutrale Gase

26

deutsch

Page 27

Typ 2000 INOX

Technische Daten

6.4. Allgemeine Technische Daten

6.4.1. Beschriftung des Typschilds

Beispiel:

Typ, Wirkungsweise, Nennweite,

Dichtwerkstoff, Gehäusewerkstoff

Durchflussrichtung

( 1 und 2 = Kennzeichnung der

Anschlüsse auf dem Ventilgehäuse)

Flow 1 2

2000 A 10,0 PTFE VA

G3/8 P med 16 bar

Pilot 5,5 - 10 bar

Made in Germany

00182076

Identnummer

Hersteller-Code

Zulässiger Steuerdruckbereich

zulässiger max. Mediumsdruck

W1X LU

Anschlussart,

6.4.2. Werkstoffe

Ventilgehäuse Edelstahl 316L

Antrieb Edelstahl 1.4404

Dichtelemente FKM

Spindelabdichtung PTFE-V-Ringe mit Federkompensation

(mit Silikonfett)

Sitzdichtung PTFE

Spindel Edelstahl 1.4401/1.4404

6.4.3. Anschlüsse

Steuerluftanschluss 45° Schlauchsteckverbindung 4/2 M5

(Empfehlung) Bestell-Nr. 903383

Mediumsanschluss G3/8 und NPT3/8 - Muffenanschluss

G1/2 - Außengewinde

Schweißstutzen nach EN ISO 1127/ISO

4200, DIN 11850 Reihe 2, ASME BPE.

Andere Anschlüsse auf Anfrage

6.4.4. Einbaulage

Beliebig, vorzugsweise Antrieb nach oben.

Bild 2: Beispiel für Typschild

deutsch

27

Page 28

Typ 2000 INOX

Aufbau und Funktion

7. AUFBAU UND FUNKTION

7.1. Aufbau

Das Schrägsitzventil besteht aus einem pneumatisch betätigten

Kolbenantrieb mit optischer Stellungsanzeige und einem 2/2-Wege

Ventilgehäuse.

7.2. Funktion

Je nach Ausführung wird das Ventil mit Federkraft (Steuerfunktion A,

SFA) oder mit Steuerdruck (Steuerfunktion B, SFB) gegen den Mediumsstrom geschlossen.

Federkraft (SFA) oder pneumatischer Steuerdruck (SFB) erzeugen

die Schließkraft auf den Pendelteller. Über eine Spindel, die mit dem

Antriebskolben verbunden ist, wird die Kraft übertragen.

Anströmung unter Sitz:

Da unter dem Pendelteller der Mediumsdruck ansteht, trägt dieser zur

Öffnung des Ventils bei. Die Anströmung erfolgt unter dem Ventilsitz.

Ein zu geringer Mindeststeuerdruck bei SFB oder das Über-

schreiten des zulässigen Mediumsdrucks kann zu Undichtigkeit führen!

7.2.1. Steuerfunktionen

Steuerfunktion A (SFA)

In Ruhestellung durch Federkraft geschlossen.

Steuerfunktion B (SFB)

In Ruhestellung durch Federkraft geöffnet.

8. MONTAGE

8.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

Quetschgefahr durch sich bewegenden pneumatischen

Anschluss!

• Beim Öffnen und Schließen des Gerätes nicht den sich bewegenden pneumatischen Anschluss berühren.

• Nicht in den unmittelbaren Bereich oberhalb und unterhalb des

Steuerluftanschlusses fassen.

28

deutsch

Page 29

2000 A 10,0 PTFE VA

med 16 bar

Typ 2000 INOX

Montage

8.2. Vor dem Einbau

• Die Einbaulage des Schrägsitzventils ist beliebig, vorzugsweise

Antrieb nach oben.

• Vor dem Anschluss des Ventils auf fluchtende (spannungsfreie)

Rohrleitungen achten.

• Durchflussrichtung beachten!

Siehe „Bild 3“.

Beispiel:

Angabe der Durchflussrichtung

auf dem Typschild

Flow 1 2

G3/8 P

Kennzeichnung

der Anschlüsse auf dem

Ventilgehäuse

Pilot 5,5 - 10 bar

Bild 3: Kennzeichnung der Anschlüsse / Durchflussrichtung

8.2.1. Vorbereitende Aufgaben

→ Rohrleitungen von Verunreinigungen säubern (Dichtungsmaterial,

Metallspäne etc.).

Schweißgehäuse:

→ Vor dem Einschweißen des Ventilgehäuses den Antrieb demon-

tieren (siehe Kapitel „8.3.1“).

8.3. Einbau

8.3.1. Antrieb vom Ventilgehäuse

demontieren (nur bei

Schweißgehäusen)

WARNUNG!

Verletzungsgefahr durch beschädigte Geräte!

Durch Montagearbeiten mit falschem Werkzeug kann das Gerät

beschädigt werden.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

Steuerfunktion A:

→ Steuerluftanschluss mit Druckluft (5,5 bar) beaufschlagen, damit

der Pendelteller vom Ventilsitz abhebt und nicht beschädigt wird.

Steuerfunktion B:

Bei Steuerfunktion B muss für den Einbau keine Druckluft angelegt

werden.

HINWEIS!

Beschädigung der Sitzdichtung bzw. der Sitzkontur!

• Das Ventil muss sich bei der Demontage des Antriebs in geöffneter Stellung befinden.

→ Antrieb bei offener Ventilstellung mit Gabelschlüssel vom Ventil-

gehäuse lösen (siehe „Bild 4“).

deutsch

29

Page 30

Optische Stellungsanzeige

Gelb = Ventil offen

Antrieb

Schlüsselfläche für Gabelschlüssel

(sechskant)

Ventilgehäuse

Bild 4: Antrieb demontieren

Typ 2000 INOX

Montage

8.3.2. Ventilgehäuse in Rohrleitung

einbauen

Bei Schweißgehäusen:

→ Ventilgehäuse in Rohrleitungssystem einschweißen.

→ Graphitdichtung prüfen und bei Bedarf erneuern.

Graphitdichtung

Bild 5: Graphitdichtung

Bei anderen Gehäuseausführungen:

→ Ventilgehäuse mit Rohrleitung verbinden.

30

deutsch

Page 31

Typ 2000 INOX

Montage

8.3.3. Antrieb auf Ventilgehäuse montieren

GEFAHR!

Explosionsgefahr durch falsche Schmierstoffe!

Ungeeigneter Schmierstoff kann das Medium verunreinigen. Bei

Sauerstoffanwendungen besteht dadurch Explosionsgefahr.

• Bei spezifischen Anwendungen wie z. B. Sauerstoff - oder Analyseanwendungen nur entsprechend zugelassene Schmierstoffe

verwenden.

WARNUNG!

Verletzungsgefahr durch beschädigte Geräte!

Durch Montagearbeiten mit falschem Werkzeug kann das Gerät

beschädigt werden. Ebenso bei falschem Anziehdrehmoment.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

• Anziehdrehmoment beachten (40 ± 3 Nm)

→ Rohrgewinde vor Wiedereinbau des Antriebes einfetten

(z. B. mit Klüberpaste UH1 96-402 der Fa. Klüber).

→ Bei Steuerfunktion A: Steuerluftanschluss mit Druckluft (5,5 bar)

beaufschlagen, damit der Pendelteller vom Ventilsitz abhebt und

beim Einschrauben nicht beschädigt wird.

→ Antrieb in das Ventilgehäuse einschrauben.

Anziehdrehmoment ( 40 ± 3 Nm) beachten!

Sollte die Position der Steuerluftanschlusses für die

Montage des Schlauches ungünstig sein, kann dieser

durch Verdrehen des Antriebs um 360° stufenlos ausgerichtet werden.

8.4. Pneumatischer Anschluss

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr durch ungeeignete Anschlussschläuche!

Schläuche die dem Druck- und Temperaturbereich nicht standhalten, können zu gefährlichen Situationen führen.

• Nur Schläuche verwenden, die für den angegeben Druck- und

Temperaturbereich zugelassen sind.

• Die Datenblattangaben der Schlauchhersteller beachten.

deutsch

31

Page 32

Typ 2000 INOX

Inbetriebnahme

8.4.1. Steuerluftanschlüsse

Als Steuerluftanschluss ist der separat bestellbare

45°-Winkelanschluss zu empfehlen!

Hier sollte die freibewegliche Schlauchlänge min.

250 mm betragen.

Bei einer kürzeren Schlauchlänge wird die

Bestell-Nr.

903383

Haltbarkeit und Funktion der Steckkupplung

beeinträchtigt!

Bei der Verwendung eines geraden Steuerluftanschlusses sollte die freibewegliche Schlauchlänge min. 400 mm betragen.

Bei einer kürzeren Schlauchlänge wird die

Haltbarkeit und Funktion der Steckkupplung

beeinträchtigt!

Quetschgefahr!

• Aufgrund der Quetschgefahr darf ein

90°-Steuerluftanschluss nicht verwendet

werden!

9. INBETRIEBNAHME

9.1. Sicherheitshinweise

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen, sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Die Sicherheitshinweise und die bestimmungsgemäße Verwendung müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Gerät

in Betrieb nehmen.

32

deutsch

Page 33

Typ 2000 INOX

Wartung, Reinigung

10. WARTUNG, REINIGUNG

10.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr bei unsachgemäßen Wartungsarbeiten!

• Die Wartung darf nur autorisiertes Fachpersonal mit geeignetem

Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Wartung einen kontrollierten Wiederanlauf

gewährleisten.

• Zum Ein- und Ausschrauben von Ventilgehäuse oder Antrieb

einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden

und Anzugsmomente beachten.

10.2. Wartungsarbeiten

10.2.1. Antrieb

Der Antrieb des Schrägsitzventils ist wartungsfrei.

10.2.2. Schrägsitzventil

Verschleißteile die der natürlichen Abnutzung unterliegen:

• Pendelteller

• Graphitdichtung

Bei Undichtheiten das jeweilige Verschleißteil gegen ein entspre-

chendes Ersatzteil austauschen (siehe Kapitel „13. Ersatzteile“).

10.3. Reinigung

Zur Reinigung der Geräteoberfläche können handelsübliche Reinigungsmittel verwendet werden.

HINWEIS!

Vermeidung von Schäden durch Reinigungsmittel.

• Die Verträglichkeit der Mittel mit den Gehäusewerkstoffen und

Dichtungen vor der Reinigung prüfen.

deutsch

33

Page 34

Typ 2000 INOX

Instandhaltung

10.4. Empfohlene Hilfsstoffe

In dieser Anleitung werden für den einwandfreien Betrieb, die

Wartung und die Reparatur des Gerätes folgende Hilfsstoffe

empfohlen:

Art des

Hilfsstoffs

Schmierpaste Klüberpaste

Klebstoff Loctite 640 Marketing Loctite,

Produktbezeichnung

UH1 96-402

Hersteller und Internetadresse

Klüber Lubrication München KG,

www.klueber.de

Henkel AG & Co.KGaA,

www.loctite.de

11. INSTANDHALTUNG

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen

und Schäden am Gerät und dessen Umgebung verursachen

• Nur Originalzubehör sowie Originalersatzteile der Firma Bürkert

verwenden.

11.1. Austausch des Ventilsatzes

Der Ventilsatz beinhaltet:

• Den Pendelteller:

bestehend aus - Dichtungshalter

- Sitzdichtung

- Zentrierung

• Die Graphitdichtung

Diese ist auch separat bestellbar

Für den Austausch des Ventilsatzes muss zunächst, wie

nachfolgend beschrieben, der Antrieb vom Ventilgehäuse

demontiert werden.

34

deutsch

Page 35

Typ 2000 INOX

Instandhaltung

11.1.1. Antrieb vom Ventilgehäuse

demontieren

GEFAHR!

Verletzungsgefahr durch Mediumsautritt und Druckentladung!

Der Ausbau des unter Druck stehenden Gerätes ist wegen plötzlicher Druckentladung und Mediumsaustritt gefährlich.

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entlüften.

WARNUNG!

Verletzungsgefahr durch beschädigte Geräte!

Durch Montagearbeiten mit falschem Werkzeug kann das Gerät

beschädigt werden.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

Steuerfunktion A:

→ Steuerluftanschluss mit Druckluft (5,5 bar) beaufschlagen, damit

der Pendelteller vom Ventilsitz abhebt und nicht beschädigt wird.

Steuerfunktion B:

Bei Steuerfunktion B muss für die Demontage keine Druckluft

angelegt werden.

HINWEIS!

Beschädigung der Sitzdichtung bzw. der Sitzkontur!

• Das Ventil muss sich bei der Demontage des Antriebs in geöffneter Stellung befinden.

→ Antrieb bei offener Ventilstellung mit Gabelschlüssel (SW 22) vom

Ventilgehäuse lösen (siehe „Bild 6“).

Optische Stellungsanzeige

Gelb = Ventil offen

Antrieb

Schlüsselfläche für Gabelschlüssel

(sechskant)

Ventilgehäuse

Bild 6: Antrieb demontieren

deutsch

35

Page 36

Typ 2000 INOX

Instandhaltung

11.1.2. Ventilsatz tauschen

Pendelteller

Graphitdichtung

Spindel

Schlüsselfläche

Dichtungshalter

Sitzdichtung

Zentrierung

WARNUNG!

Verletzungsgefahr durch beschädigte Geräte!

Durch Montagearbeiten mit falschem Werkzeug kann das Gerät

beschädigt werden.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

Durch ein zu großes Anziehdrehmoment, kann das Spindelgewinde beschädigt werden.

• Anziehdrehmoment beachten (40 ± 3 Nm)

Vorgehensweise:

→ Spindel an der Schlüsselfläche mit Gabelschlüssel (SW 7)

gegenhalten.

→ Zentrierung mit einem passenden Gabelschlüssel (SW 5,5)

vorsichtig lösen, um das Spindelgewinde nicht zu beschädigen.

→ Zentrierung abschrauben.

→ Dichtungshalter mit Sitzdichtung abziehen.

→ Neuen Dichtungshalter und neue Sitzdichtung auf die Spindel

stecken.

→ Klebstoff (Loctite 640) auf Spindelgewinde auftragen.

→ Zentrierung aufschrauben und mit einem passenden Gabel-

schlüssel (SW 5,5) anziehen.

Anziehdrehmoment ( 40 ± 3 Nm) beachten!

Bild 7: Ventilsatz

36

deutsch

Page 37

Typ 2000 INOX

Instandhaltung

11.1.3. Antrieb auf Ventilgehäuse montieren

WARNUNG!

Verletzungsgefahr durch ungewolltes Einschalten der Anlage

und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

GEFAHR!

Explosionsgefahr durch falsche Schmierstoffe!

Ungeeigneter Schmierstoff kann das Medium verunreinigen. Bei

Sauerstoffanwendungen besteht dadurch Explosionsgefahr.

• Bei spezifischen Anwendungen wie z. B. Sauerstoff - oder Analyseanwendungen nur entsprechend zugelassene Schmierstoffe

verwenden.

→ Rohrgewinde vor Wiedereinbau des Antriebes einfetten

(z. B. mit Klüberpaste UH1 96-402 der Fa. Klüber).

→ Graphitdichtung prüfen und bei Bedarf erneuern.

Graphitdichtung

→ Bei Steuerfunktion A: Steuerluftanschluss mit Druckluft (5,5 bar)

beaufschlagen, damit der Pendelteller vom Ventilsitz abhebt und

beim Einschrauben nicht beschädigt wird.

WARNUNG!

Verletzungsgefahr durch beschädigte Geräte!

Durch Montagearbeiten mit falschem Werkzeug kann das Gerät

beschädigt werden.

• Zur Demontage des Antriebs vom Ventilgehäuse einen Gabelschlüssel, keinesfalls eine Rohrzange verwenden.

Durch ein zu großes Anziehdrehmoment, kann das Spindelgewinde beschädigt werden.

• Anziehdrehmoment beachten (40 ± 3 Nm)

→ Antrieb in das Ventilgehäuse einschrauben.

Anziehdrehmoment ( 40 ± 3 Nm) beachten!

Sollte die Position der Steuerluftanschlusses für die

Montage des Schlauches ungünstig sein, kann dieser

durch Verdrehen des Antriebs um 360° stufenlos ausgerichtet werden.

Bild 8: Graphitdichtung

deutsch

37

Page 38

Typ 2000 INOX

Störungen

12. STÖRUNGEN

Störung Beseitigung

Antrieb schaltet

nicht.

Steuerdruck zu gering.

→ Siehe Druckangabe auf dem Typschild.

Mediumsdruck zu hoch.

→ Siehe Druckangabe auf dem Typschild.

Durchflussrichtung vertauscht.

→ Siehe Kennzeichnung auf dem Typschild.

Ventil ist nicht

dicht.

Schmutz zwischen Dichtung und Ventilsitz.

→ Schmutzfänger einbauen.

Sitzdichtung verschlissen.

→ Neuen Pendelteller einbauen.

Sitzdichtung beschädigt, z.B. durch Fremdkörper, Span oder Ähnliches.

→ Neuen Pendelteller einbauen.

Durchflussrichtung vertauscht.

→ Siehe Kennzeichnung auf dem Typschild.

Steuerdruck zu gering.

→ Siehe Druckangabe auf dem Typschild.

Mediumsdruck zu hoch.

→ Siehe Druckangabe auf dem Typschild.

Ventil leckt an

der Entlüftungsbohrung.

Spindelabdichtung verschlissen.

→ Antrieb austauschen.

13. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen

und Schäden am Gerät und dessen Umgebung verursachen

• Nur Originalzubehör sowie Originalersatzteile der Firma Bürkert

verwenden.

Als Ersatzeilsatz für das Schrägsitzventil Typ 2000 INOX ist der Ventilsatz unter der Bestell-Nr. 220053 erhältlich. Dieser beinhaltet:

• Den Pendelteller:

bestehend aus - Dichtungshalter

- Sitzdichtung

- Zentrierung

• Die Graphitdichtung

Diese ist auch separat bestellbar

Tab. 1: Störungen

38

deutsch

Page 39

Typ 2000 INOX

Transport, Lagerung, Entsorgung

Bild 9: Ventilsatz

Graphitdichtung

Dichtungshalter

Sitzdichtung

Zentrierung

14. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -20 … +65 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

deutsch

39

Page 40

Typ 2000 INOX

40

deutsch

Page 41

Type 2000 INOX

Sommaire

1. MANUEL ............................................................................................................42

1.1. Symboles..........................................................................................42

1.2. Définition du terme appareil .........................................................42

2. UTILISATION CONFORME.......................................................................43

2.1. Limitations ........................................................................................43

3. CONSIGNES DE SÉCURITÉ FONDAMENTALES ......................... 43

4. INDICATIONS GÉNÉRALES .................................................................... 44

4.1. Adresse ............................................................................................44

4.2. Garantie légale ................................................................................44

4.3. Informations sur Internet ...............................................................44

5. DESCRIPTION DU PRODUIT ................................................................. 45

5.1. Description générale .....................................................................45

5.2. Propriétés .........................................................................................45

6. CARACTÉRISTIQUES TECHNIQUES ................................................45

6.1. Conformité .......................................................................................45

6.2. Normes .............................................................................................45

6.3. Conditions d'exploitation ..............................................................45

6.4. Caractéristiques techniques générales ....................................47

7. STRUCTURE ET MODE DE FONCTIONNEMENT ........................48

7.1. Structure ..........................................................................................48

7.2. Fonction ............................................................................................48

8. MONTAGE

8.1. Consignes de sécurité ..................................................................48

8.2. Avant le montage ............................................................................49

8.3. Montage ...........................................................................................49

8.4. Raccordement pneumatique .......................................................51

9. MISE EN SERVICE .......................................................................................52

9.1. Consignes de sécurité ..................................................................52

10. MAINTENANCE, NETTOYAGE ............................................................. 53

10.1. Consignes de sécurité ................................................................53

10.2. Travaux de maintenance .............................................................53

10.3. Nettoyage ......................................................................................53

10.4. Produits auxiliaires recommandés ............................................54

11. MAINTENANCE

11.1. Remplacement du jeu de vannes .............................................54

12. PANNES

13. PIÈCES DE RECHANGE .........................................................................58

14. TRANSPORT, STOCKAGE, ÉLIMINATION ..................................... 59

........................................................................................................ 48

........................................................................................... 54

..........................................................................................................58

français

41

Page 42

Type 2000 INOX

Manuel

1. MANUEL

Le manuel décrit le cycle de vie complet de l'appareil. Conservez ce

manuel de sorte qu'il soit accessible à tout utilisateur et à disposition

de tout nouveau propriétaire.

Le manuel contient des informations importantes sur la

sécurité !

Le non-respect de ces consignes peut entraîner des situations

dangereuses.

• Le manuel doit être lu et compris.

1.1. Symboles

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement

dangereuse !

• Risque de blessures graves, voire la mort en cas de

non-respect.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures moyennes ou

légères.

REMARQUE !

Met en garde contre des dommages matériels !

• L'appareil ou l'installation peut être endommagé(e) en cas de

non-respect.

désigne des informations complémentaires importantes, des

conseils et des recommandations.

renvoie à des informations dans ce manuel ou dans d'autres

documentations.

→ identifie une opération que vous devez effectuer.

1.2. Définition du terme appareil

Le terme « appareil » utilisé dans ces instructions désigne toujours la

vanne à siège incliné type 2000 INOX.

42

français

Page 43

Type 2000 INOX

Utilisation conforme

2. UTILISATION CONFORME

L'utilisation non conforme de la vanne à siège incliné

type 2000 INOX (désignée ci-après par « appareil ») peut

présenter des dangers pour les personnes, les installations

proches et l'environnement.

• L'appareil a été conçu pour la commande du débit de fluides

liquides et gazeux.

• Lors de l'utilisation, il convient de respecter les données et

conditions d'utilisation et d'exploitation admissibles spécifiées

dans le manuel et dans les documents contractuels. Celles-ci

sont décrites au chapitre « 6. Caractéristiques techniques ».

• L'appareil peut être utilisé uniquement en association avec les

appareils et composants étrangers recommandés et homologués par Bürkert.

• Les conditions pour l'utilisation sûre et parfaite sont un transport, un stockage et une installation dans les règles ainsi qu'une

utilisation et une maintenance parfaites.

• Veillez à ce que l'utilisation de l'appareil soit toujours conforme.

2.1. Limitations

Lors de l'exportation du système/de l'appareil, veuillez respecter les

limitations éventuelles existantes.

3. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte

• des hasards et des événements pouvant survenir lors du montage,

de l'exploitation et de l'entretien des appareils.

• des prescriptions de sécurité locales que l'exploitant est tenu de

faire respecter entre autres par le personnel chargé du montage.

Danger dû à la haute pression !

• Avant de desserrer les conduites ou les vannes, couper la pression et purger l'air des conduites.

Risque de pincement dû à un raccord pneumatique en mouvement !

• Lors de l'ouverture et de la fermeture de l'appareil, ne pas entrer

en contact avec le raccord pneumatique en mouvement.

• Ne pas mettre la main dans la zone immédiatement au-dessus

et en-dessous du raccord d'air de commande.

Risque de coup de bélier pour l'arrivée du flux au-dessus du

siège !

• En cas d'arrivée du flux au-dessus du siège de la vanne à siège

incliné, ne pas l'utiliser pour les substances liquides en raison du

risque de coup de bélier.

Risque de brûlures/d'incendie en fonctionnement continu dû

à des surfaces d'appareil brûlantes !

• Ne pas toucher l'appareil à mains nues.

• Tenir l'appareil éloigné des matières et fluides facilement

inflammables.

français

43

Page 44

Type 2000 INOX

Indications générales

Situations dangereuses d'ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• Alimenter les raccords de fluides seulement avec les fluides

transportés énumérés au chapitre « Caractéristiques techniques ».

• Ne pas utiliser le type 2000 INOX dans des zones présentant

des risques d'explosion.

• Ne pas soumettre le boîtier à des contraintes mécaniques

(par ex. en déposant des objets sur le boîtier ou en l'utilisant

comme marche).

• L'actionnement par inadvertance de l'installation ne doit pas être

possible.

• Seul du personnel qualifié peut effectuer l'installation et la

maintenance.

• Après une interruption de l'alimentation électrique ou pneumatique, un redémarrage défini ou contrôlé du processus doit être

garanti.

• L'appareil doit être utilisé uniquement en parfait état et en respectant le manuel.

• Les règles générales de la technique sont d'application pour

planifier l'utilisation et utiliser l'appareil.

La vanne à siège incliné type 2000 INOX a été développée

dans le respect des règles reconnues en matière de

sécurité et correspond à l'état actuel de la technique. Néanmoins, des risques peuvent se présenter.

4. INDICATIONS GÉNÉRALES

4.1. Adresse

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages du manuel imprimé.

Également sur internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie légale est l'utilisation

conforme de l'appareil dans le respect des conditions d'utilisation

spécifiées.

4.3. Informations sur Internet

Vous trouverez sur Internet les manuels et fiches techniques relatives

au type 2000 INOX : www.buerkert.fr

44

français

Page 45

Type 2000 INOX

Description du produit

5. DESCRIPTION DU PRODUIT

5.1. Description générale

La vanne à siège incliné 2/2 voies type 2000 INOX convient aux fluides

liquides et gazeux.

Au moyen de gaz neutres ou d'air (fluides de commande), elle commande le débit substances, comme l'eau, l'alcool, l'huile, le carburant,

le liquide hydraulique, la solution saline, la lessive, le solvant organique

et la vapeur (fluides transportés).

5.2. Propriétés

• Étanchéité élevée.

• Valeurs de débit élevées.

• Raccord d'air de commande central et rotatif en continu sur 360°.

• Affichage optique de position

• Demande peu d'entretien

5.2.1. Limitations

La vanne à siège incliné ne doit pas être utilisée pour des substances

liquides en cas d'arrivée du flux au-dessus du siège en raison du risque

de coup de bélier !

6. CARACTÉRISTIQUES TECHNIQUES

6.1. Conformité

La vanne à siège incliné type 2000 INOX répond aux directives CE

conformément à la déclaration de conformité CE.

6.2. Normes

Les normes utilisées, avec lesquelles la conformité avec les directives

CE sont prouvées, figurent dans l'attestation CE de type et/ou la

déclaration de conformité CE.

6.3. Conditions d'exploitation

6.3.1. Températures admissibles

Température ambiante : 0 °C … 60 °C

Température du fluide : 0 °C … +180 °C

La vanne à siège incliné peut passer en autoclave.

À cet usage, il convient de retirer le raccord d'air de

commande.

L'association de la température maximale du fluide et de la température ambiante maximale est indiquée dans le diagramme dans

la « Fig. 1 » :

français

45

Page 46

Type 2000 INOX

Caractéristiques techniques

100

90

80

70

60

50

40

Température ambiante [°C]

140 150 160 170

Température du fluide [°C]

Fig. 1 : Association température du fluide / température ambiante

180 190

6.3.2. Plages de pression

AVERTISSEMENT !

Sortie de fluide et risque d'éclatement.

Un dépassement de la pression du fluide et de commande admissible peut entraîner des défauts d'étanchéité et l'éclatement de

conduites ou de l'appareil.

Pour la fonction de commande B, une pression de commande trop

faible peut entraîner des défauts d'étanchéité.

• Ne pas dépasser la pression du fluide, ni la pression de

commande.

• Pour la fonction de commande B, respecter la pression de commande minimale de 4 bar.

Les informations de pression spécifiques au produit sont indiquées

sur la plaque signalétique.

Pression de commande minimale avec la fonction de

commande B : 4 bar

6.3.3. Fluides

AVERTISSEMENT !

Risque de blessure en raison de l'éclatement de conduites

suite à un coup de bélier !

Si la vanne est utilisée pour des fluides liquides en cas d'arrivée

du flux au-dessus du siège, un coup de bélier peut provoquer

l'éclatement des conduites et de l'appareil.

• Ne pas utiliser des vannes avec arrivée du flux au-dessus du

siège pour les fluides liquides !

Fluide de commande : gaz neutres, air

Fluides transportés : eau, les alcools, huiles, carburants,

liquides hydrauliques, solutions salines,

lessives, solvants organiques, vapeur, air,

gaz neutres

46

français

Page 47

Type 2000 INOX

Caractéristiques techniques

6.4. Caractéristiques techniques

générales

6.4.1. Informations sur la plaque signalétique

Exemple :

Type, fonction, diamètre nominal,

matériau du joint, matériau du boîtier

Sens de débit

(1 et 2 = identification des raccords

sur le boîtier de vanne)

Flow 1 2

2000 A 10,0 PTFE VA

G3/8 P med 16 bar

Pilot 5,5 - 10 bar

Made in Germany

00182076

W1X LU

Numéro d'identification

Code-fabricant

Plage de pression de commande admissible

Type de raccord,

pression max. admissible du fluide

6.4.2. Matériaux

Boîtier de vanne acier inoxydable 316L

Actionneur acier inoxydable 1.4404

Éléments d'étanchéité FKM