Page 1

Operating Instructions

Interface RS 232 and

Interface RS 485 / Profibus

for

Digital Industrial Controller Type 1110

and

Digital Batch Controller Type 1115

1

Page 2

Contents

1 Block diagram of functions ...................................................... 2

2 Notices concerning use and safety.......................................... 3

3 System description .................................................................... 4

3.1 Introduction ................................................................................ 4

3.2 Switch configuration ................................................................. 4

3.3 Connector pin assignment........................................................ 5

3.4 Installation.................................................................................. 5

4 Profibus....................................................................................... 6

4.1 Objects for Digital Industrial Controller Type 1110 ................ 6

4.2 Error list operating errors ......................................................... 14

4.3 Objects for Digital Batch Controller Type 1115 ...................... 15

4.4 Error list operating errors ......................................................... 19

5 RS 232-Protocol ......................................................................... 20

5.1 Transmission format .................................................................. 20

5.2 Transmission protocol ............................................................... 20

6 Configuration of the interfaces ................................................ 22

2

Page 3

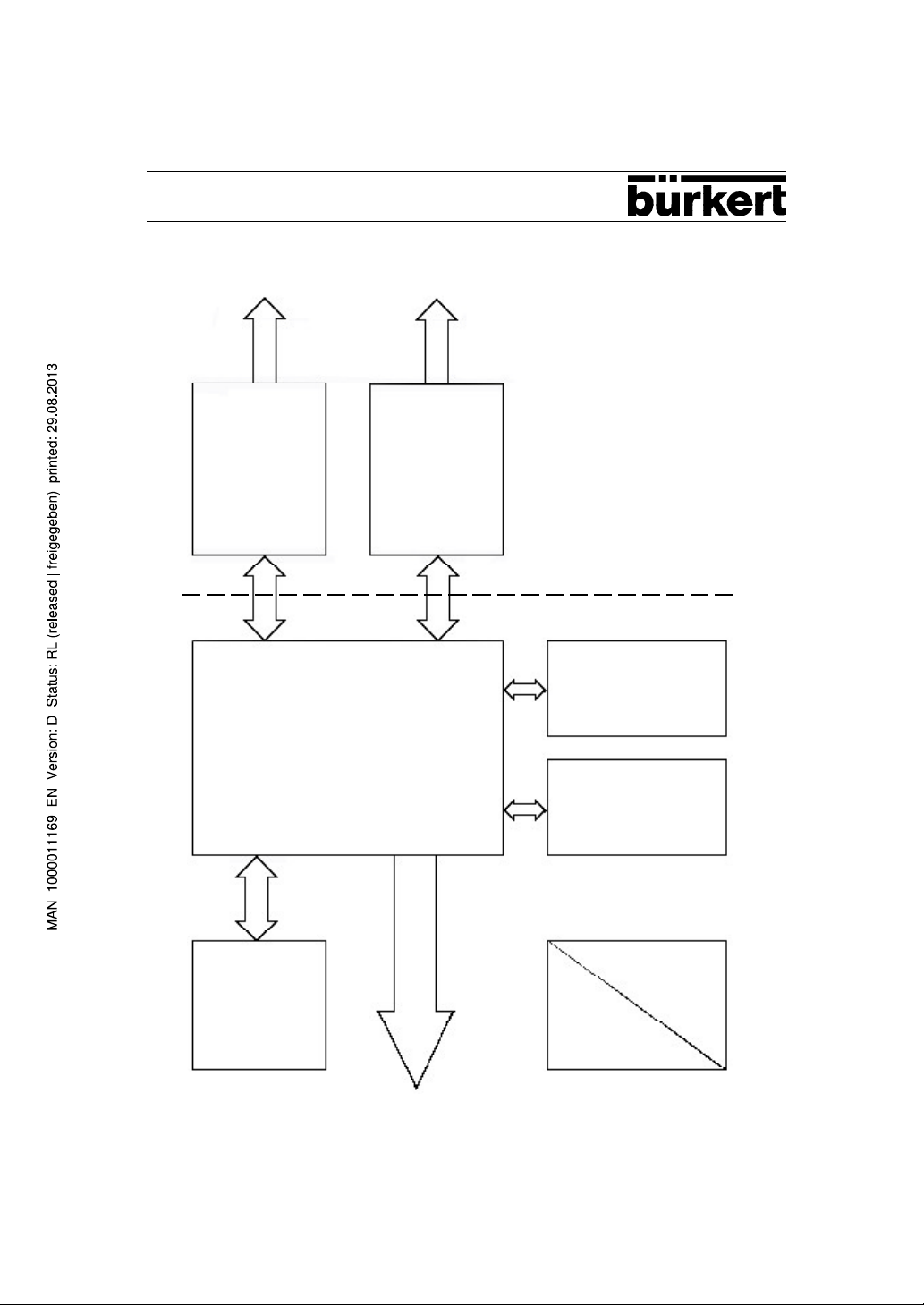

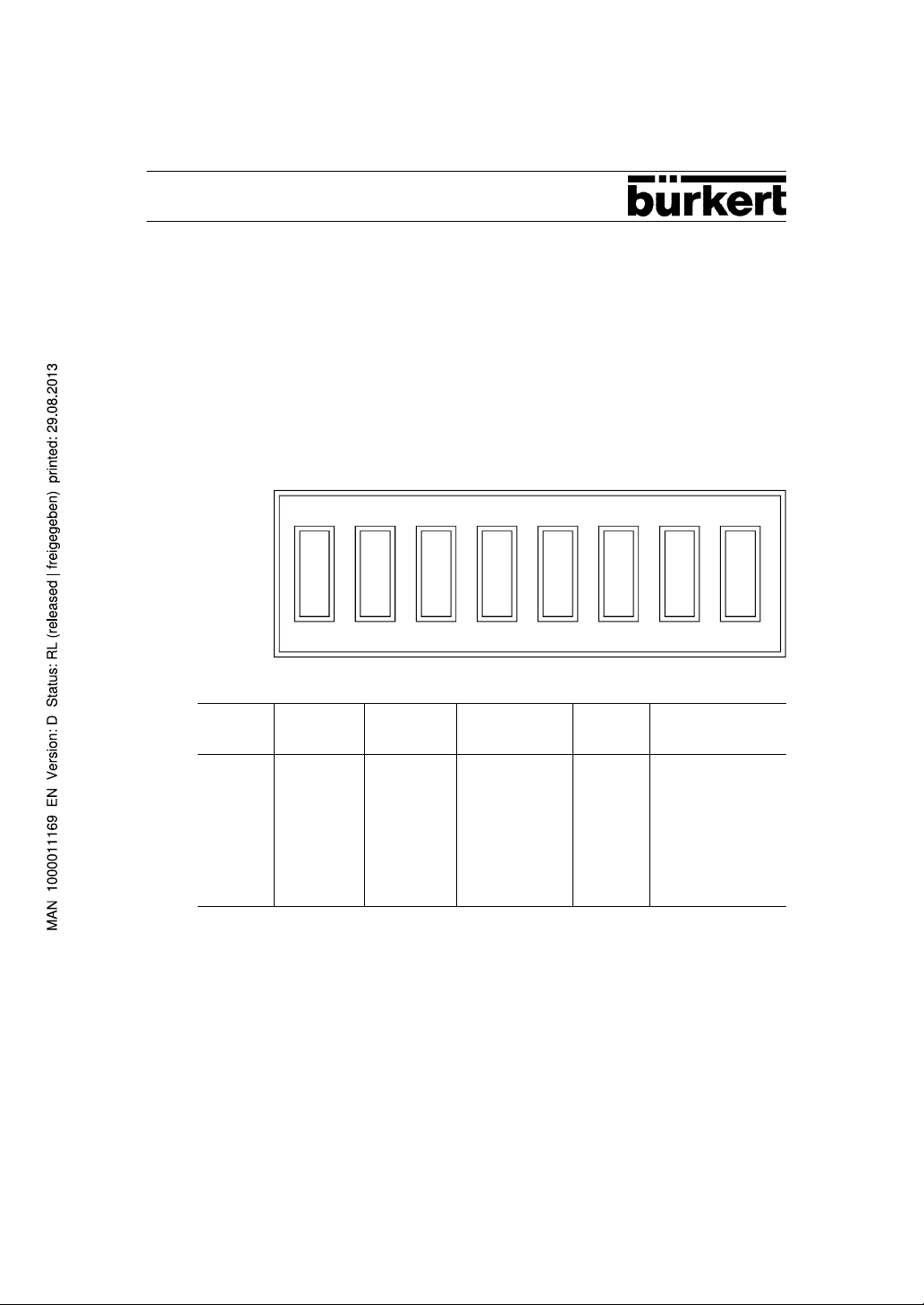

1 Block diagram of functions

Driver RS 232 Driver RS 485

Interface card RS 232, RS 485 / Profibus

CPU 80C51FQA

galvanic separation

OT-PROM 64 Kbit

Clock 12/16 MHz

RAM 32 Kbit

DC

DC

3

Page 4

2 Notices concerning use and safety

In order to ensure a perfect functioning and a long working life of the interface card

when using this card, the user is requested to follow this operating instructions and the

operating instructions of the digital units to be used with this card (e.g. Digital Industrial

Controller

Type 1110 or Digital Batch Controller Type 1115) as well as to maintain the operating

conditions and to observe the allowed specifications according to the data sheet.

Installation and maintenance personnel must be trained and qualified for this work.

All possibilites of unauthorized operation with the resulting impairment of the process are

to be ruled out through precautionary measures. For maintenance purposes, safe

electrical disconnectors and media technical shut off devices are to be provided. Should

the unit equipped with the interface card be part of a complex automation system, then

the automation system must be provided with a defined and controlled restart process

as specified in the instructions for starting up again following an interruption.

When operating the device or carrying out service and repair work on the equipment, the

regulations in force for the prevention of accidents and the safety of electrical

equipment must be observed.

Commissioning, start-up and repairs may only be carried out through authorized

specialists.

4

Page 5

3 System description

3.1 Introduction

The Digital Industrial Controller 1110 as well as the Digital Batch Controller 1115 can be

equipped with a digital interface.

Using the additional card required for this purpose, either a point-to-point connection can

be erected through RS 232 or, by using additional equipment, a network can be built

through

RS 485/Profibus.

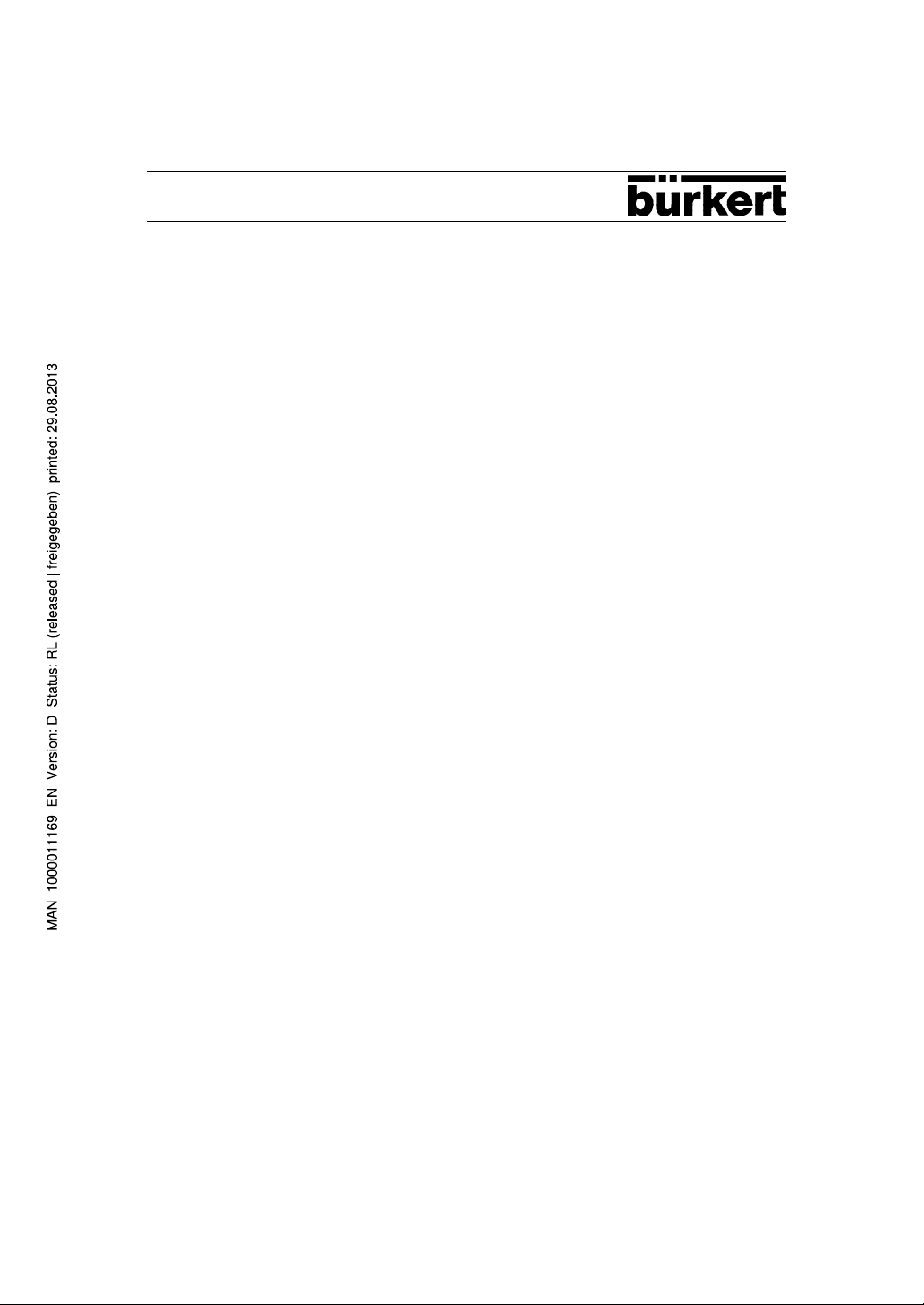

3.2 Switch configuration

ON

1 2 3 4 5 6 7 8

RS 232 RS 485 RS 485 Profibus Profibus

add. equipment add. equipment

1 OFF OFF ON OFF ON

2 OFF OFF ON OFF ON

3 OFF ON ON ON ON

4 OFF ON ON ON ON

5 ON OFF OFF OFF OFF

6 ON OFF OFF OFF OFF

7 OFF ON ON ON ON

8 OFF OFF OFF ON ON

5

Page 6

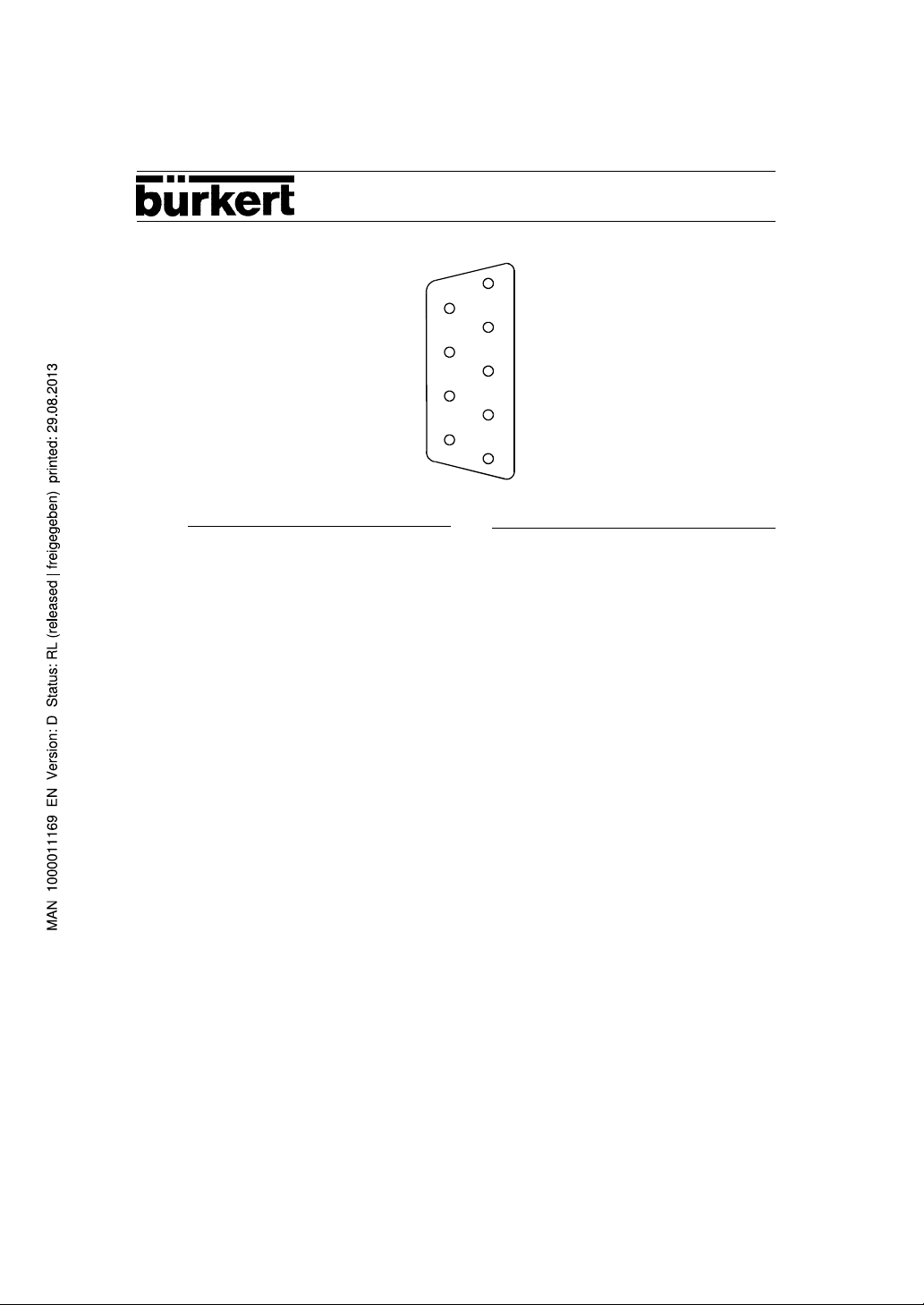

3.3 Connector pin assignment D sub-connector 9 terminal/female

9

5

6

1

RS 232 RS 485 / Profibus

2 TxD 3 reception/transmission data

positive

3 RxD 8 reception/transmission data

negative

5 GND 5 GND

3.4 Installation

The maximum bus baud rate is 500 KBaud.

The following performance lengths can be achieved:

1200 m 9.6 / 19.2 / 93.75 KBaud

600 m 187.5 KBaud

200 m 500 KBaud

twisted double-wiring, shielded Notice:

standard wiring diameter 0.22 mm

doubled wiring length at 0.5 mm

2

2

for additional information refer to the

Profibus standard DIN 19245

To operate, remove equipment from the mains supply. Remove plastic inset from back of

equipment and insert interface card.

After reconnecting to mains supply, the following settings are necessary in serial menu

supplements:

1. address

(for Profibus, the baud rate adjusts automatically)

2. additionally for RS 232/485:

parity / odd / even / none

baud rate 4800 / 9600

6

Page 7

4. Profibus

Profibus is standardized according to DIN 19 245.

We support the following features:

Get OV (long)

Read

Write.

FMS features supported are therefore:

80 30 00 00 00 00

Our equipment is slave.

We provide the following communication references:

Index Typ SAP

2 MSZY 3

3 MSAZ 4

4 MSZY 5

5 MSAZ 6

6 MSZY 7

7 MSAZ 8

8 MSZY 9

9 MSAZ 10

(Master Slave Cyclic / Acyclic)

4.1 List of the objects for the Digital Industrial Controller Type 1110

Structure of the masks

Within a mask, the variable required for the configuration from among the following will

be represented. Sequence: 1st variable = LSB

LSB represented.

1- is required in the configuration

0- is not required in the configuration

20 UINT16 Mask process values

21 UINT8 Hardware unit

22 FLP X1 measurable value channel 1

23 FLP X2 measurable value channel 2

24 FLP W1 set point main controller or single controller

25 FLP Yh correcting variable main controller at cascade

26 FLP W2 set point support controller at cascade

27 FLP Y2h correcting variable heating/continuous

28 FLP Y2k correcting variable cooling

29 FLP Xdh control offset main controller

7

Page 8

30 FLP Xd2 control offset support/single controller

31 UINT8 Relay position output relay

0: non-active

1: active

Bit 0 = position relay 1

Bit 1 = position relay 2

Bit 2 = alarm relay 2

Bit 3 = alarm relay 2

valve`s

32 UINT8 Reading-in condition of binary input (please follow Index 182/181)

33 UINT8 Reading-in condition of binary input (please follow Index 183/184)

34 UINT8 Condition of set point ramp

35 UINT8 Condition of set point tracking (SPT)

36 UINT8 Condition of main controller (only with cascade controller)

37 UINT8 Condition of support controller

Pulse valve: Not the current relay condition, but rather the

switching condition is set.

0: off

1: on

0: off

1: on

0: manual

1: automatic

2: manual

3: manual

0: manual

1: automatic

2: manual

3: manual

8

Page 9

38 UINT8 Controller errors

x x x x x x x x

39 UINT16 Input errors

x x x x x x x x x

2

2

0 : EEPROM-data configuration OK

1 : EEPROM-data configuration defect

0 : EEPROM-data parametration OK

1 : EEPROM-data parametration defect

0 : EEPROM-data former condition OK

1 : EEPROM-data former condition defect

0 : EEPROM-data calibration data OK

1 : EEPROM-data calibration data defect

0 : no error at the binary input

1 : error at the binary input

0 : no error at the analogue output

1 : error at the analogue output

0 : no error at input 1

1 : error at input 1

0 : no error at input 2

1 : error at binary input 2

0 : no error at the thermocouple input

1 : error at the thermocouple input

0 : no error at the PT100 input

1 : error at the PT100 input

0 : no error at the first standard signal U input 1

1 : error at the first standard signal U input 1

0 : no error at the first standard signal I input 1

1 : error at the first standard signal I input 1

0 : no error at the first frequency input

1 : error at the first frequency input

0 : no error at the second frequency input

1 : error at the second frequency input

0 : no error at the second standard signal U input

1 : error at the second standard signal U input 2

0 : no error at the second standard signal I input

1 : error at the second standard signal I input 2

0 : no NTC error

1 : NTC error */

40 UINT8 Operating errors

refer to error list 3.2

41 UINT8 Configuration/parametration

0: reserve

1: process

2: configuration

3: parametration

9

Page 10

42 UINT8 Remote / local switching

0: local

1: remote

43 UINT16 Alteration 1

44 UINT16 Alteration 2

45 UINT8 Address / station address of the unit

49 UINT8 PT 100 Type (connection type)

The contents of the following indices can be automatically

altered by the internal processor; i.e. meaningless user

parametrations will be automatically corrected.

Index Bit Index Bit

57 0 81 6

56 1 92 7

85 2 91 8

84 3 101 9

58 4 125 10

82 5 170 11

The contents of the following indices can be automatically

altered by the internal processor; i.e. meaningless user

parametrations will be automatically corrected.

Index Bit Index Bit

61 0 171 5

63 1 76 6

66 2 166 7

145 3 181 8

156 4

0: 3 conductors

1: 4 conductors

50 UINT16 Mask configuration 1st input

51 UINT8 Type 1st input

10

0: 0 - 10 V

1: 0 - 20 mA

2: 4 -2 0 mA

3: frequency

4: Pt 100

5: thermocouple J

6: thermocouple K

7: thermocouple T

8: thermocouple R

9: thermocouple S

Page 11

52 UINT8 Vst reference junction compensation ext / int at thermocouple

0: internal

1 external

53 UINT8 Rad evolving a root

54 UINT16 Fre final value frequency input

55 FLP Fg1 limit frequency filter

56 FLP X1u minimum value 1st input (lower scale value)

57 FLP X1o maximum value 1st input (upper scale value)

58 FLP Xvu minimum value ratio input (lower scale value)

59 FLP Xvo maximum value ratio input (upper scale value)

60 UINT16 Mask configuration limit of correcting variable

61 FLP Yu lower limit main controller

62 FLP Yo upper limit main controller

63 FLP Y2hu lower limit heating/continuous

64 FLP Y2ho upper limit heating/continuous

65 FLP Y2ku lower limit cooling

66 FLP Y2ko upper limit cooling

70 UINT16 Mask structure / configuration 2nd input

71 UINT8 Structure of the controller

72 UINT8 Type 2nd input

0: no

1: yes

0: standard controller

1: external set point

2: ratio controller

3: disturbance-variable compensation

4: reserve

5: cascade controller

0: 0 - 10 V

1: 0 - 20 mA

2: 4 -2 0 mA

3: frequency

73 UINT8 Evolving a root

0: off

1: on

74 UINT16 Fre2 final value frequency input

75 FLP Fg2 limiting frequency filter

76 FLP X2u minimum value 2. input (lower scale value)

77 FLP X2o maximum value 2. input (upper scale value)

11

Page 12

80 UINT16 Mask configuration alarm function

81 FLP X1- lower alarm limit actual value

82 FLP X1+ upper alarm limit actual value

83 FLP A1 Hy alarm hysteresis actual value

84 FLP A1Q- lower alarm limit absolute value ratio regulation

85 FLP A1Q+ upper alarm limit absolute value ratio regulation

86 FLP A1QH hysteresis absolute value ratio regulation

87 UINT8 Mode alarm function

90 UINT16 Mask configuration set point limits

91 FLP W1u lowest set point limit

92 FLP W1o upper set point limit

100 UINT16 Mask configuration set point ramp

102 FLP D gradient (standard: W/min)

103 UINT8 Pon ramp at alteration of set point

110 UINT16 Mask configuration Set Point Tracking

111 FLP SPTE final value set point tracking (read only!)

112 FLP SPTD gradient set point tracking

113 UINT8 SPT on / off

120 UINT16 Mask configuration disturbance-variable compensation

121 FLP kps amplification

122 FLP Tds derivative-action time

123 FLP Ts delay time

124 FLP Xsd insensitiveness

125 FLP X0 operating point

0: absolute alarm

1: band alarm

0: off

1: on

0: off

1: on

140 UINT16 Mask configuration main controller

141 FLP kp1 amplification

142 FLP Tn reset time

143 FLP Tv derivative-action time

144 FLP Ratio derivative-action time / delay time

145 FLP Y0 operating point

146 FLP Xtb insensitiveness

12

Page 13

150 UINT16 Mask configuration support / single controller

151 FLP kp1 amplification heating / continuous

152 FLP kp2 amplification cooling

153 FLP Tn reset time

154 FLP Tv derivative-action time

155 FLP Ratio derivative-action time / delay time

156 FLP Y0 operating point

157 FLP Xtb insensitiveness

158 UINT8 direction of effect

0: positive direction of effect

1: inverted direction of effect

160 UINT16 Mask configuration output

161 UINT8 Function output

0: reserve

1: 2-point

2: 3-point

3: 3-point step (without external feedback)

4: continuous

5: position (with external feedback)

162 UINT8 Type continuous output

0: 0 - 10 V

1: 0 - 20 mA

2: 4 - 20 mA

163 UINT8 Pulse valve yes / no (with 2 point output)

0: no pulse valve

1: pulse valve

164 FLP Ty motor running time

165 FLP Xsh hysteresis

166 FLP Xsd insensitiveness

167 FLP T+ cycle time heating

168 FLP T- cycle time cooling

169 FLP Gt gear lot

170 FLP Olp overlapping range

171 FLP Ys safety value

180 UINT16 Mask configuration binary input / output

181 UINT8 Function binary input

0: no (no function)

1: alarm

2: manual / automatic

3: external / internal W (if index 71 = 1)

4: safety value

182 UINT8 Effect binary input

0: normal

1: inverted

13

Page 14

183 UINT8 Function binary output

0: no (no function)

1: alarm

2: manual / automatic

3: feeler break

184 UINT8 Effect binary output

190 UINT16 Mask code

191 UINT16 Code priority 1 (configuration)

192 UINT16 Code priority 2 (parametration)

193 UINT16 Code priority 3 (process operation)

200 UINT16 Mask configuration other

201 UINT8 Language

202 UINT8 Representation 2nd line

203 UINT8 Resolution bar graph

0: normal

1: inverted

0: German

1: English

2: French

0: actual value

1: bar graph

14

Page 15

4.2 Error list operating errors

Index 40

1: Acknowledged

2: Access OK

3: Data base not up to date

4: Value outside of value range

5: Value cannot be described in current condition

6: Another enquiry is still in progress

7: Main controller cannot be operated

8: Main controller contains wrong value

9: Support / single controller cannot be operated

10: Support / single controller contains wrong value

11: W main controller / single controller cannot be operated

12: W main controller / single controller contains wrong value

13: W support controller cannot be operated

14: W support controller contains wrong value

15: Yh main controller cannot be operated

16: Yh main controller contains wrong value

17: Y2h support / single controller cannot be operated

18: Y2h support / single controller contains wrong value

19: Y2k support / single controller cannot be operated

20: Y2k support / single controller contains wrong value

21: Y2h 3-point step cannnot be operated

22: Y2h 3-point step contains wrong value

23: Set point ramp cannot be operated

24: Set point ramp contains wrong value

25: Parametration is not possible

26: Configuration is not possible

27: Parametration is not possible → not part of process operation

28: Parametration is not possible → LOCAL in configuration

29: Configuration is not possible → not part of process operation

15

Page 16

4.3 List of the objects for Digital Batch Controller Type 1115

20 UINT16 Mask process values

21 UINT8 Hardware unit

22 FLP Actual volume 1

23 FLP Actual volume 2

24 FLP Actual volume 1 + 2

25 FLP Residual volume 1

26 FLP Residual volume 2

27 FLP Residual volume 1 + 2

28 FLP Required volume 1

29 FLP Required volume 2

30 FLP Required volume 1 + 2

31 FLP Exact limit 1

32 FLP Exact limit 2

33 FLP Throughput 1

34 FLP Throughput 2

35 FLP Throughput 1 + 2

36 FLP Total volume 1

37 FLP Total volume 2

38 FLP Total volume 1+2

39 UINT8 Condition 1

0: Channel turned off

1: Filling procedure stopped

2: Approximate proportioning

3: Exact proportioning

4: Runoff

5: Filling procedure completed

6: Channel placed back

40 UINT8 Condition 2

41 UINT8 Total condition

42 UINT8 Starting time in hours

43 UINT8 Starting time in minutes

44 UINT8 Starting time in seconds

45 UIN16 Remaining proportionings

16

0: Channel turned off

1: Filling procedure stopped

2: Approximate proportioning

3: Exact proportioning

4: Runoff

5: Filling procedure completed

6: Channel placed back

0: Process at standstill

1: Process in progress

2: Process will be placed back

3: Manual proportioning

Page 17

46 UINT8 Remaining time in hours

47 UINT8 Remaining time in minutes

48 UINT8 Remaining time in seconds

49 UINT8 Configuration on / off

50 UINT8 Error output

51 UINT8 Batch errors

52 UINT8 Batch warning

53 UINT8 Operating error (refer to 4.4)

54 UINT8 Remote / local mode

60 UINT8 Address

61 UINT8 Version - internal

62 UINT8 Error - access

70 UINT16 Mask configuration 1st input

71 UINT8 Type 1st input

0: EEprom - data configuration defective

1: EEprom - data parametration defective

0: calibration defective

1: standard signal output defective

2: feeler channel 1 defective

3: feeler channel 2 defective

4: process data defective

5: power failure

0: local

1: remote

internal indices only

for the manufacturer

0: input not in use

1: frequency

2: 0 - 20 mA

3: 4 - 20 mA

4: 0 - 10 V

72 UINT8 Evolving the root

0: off

1: on

73 UINT8 Standard type

0: manual

1: teach IN

74 FLP k-factor

75 FLP maximum flow

17

Page 18

80 UINT16 Mask configuration 2nd input

81 UINT8 Type 2nd input

0: input not in use

1: frequency

2: 0 - 20 mA

3: 4 - 20 mA

4: 0 - 10 V

82 UINT8 Evolving the root

83 UINT8 Standard type

84 FLP k-factor

85 FLP maximum flow

90 UINT16 Mask configuration hunting

91 UINT8 Hunting correction

92 UINT16 Maximum hunting time

100 UINT16 Mask configuration valve

101 UINT8 Valve type

110 UINT16 Mask configuration output

111 UINT8 Type output

0: off

1: on

0: manual

1: teach in

0: no

1: yes

0: standard

1: pulse

0: input not in use

1: frequency

2: 0 - 20 mA

3: 4 - 20 mA

4: 0 - 10 V

112 UINT8 Process sizes

113 FLP Maximum flow

18

0: throughput channel 1

1: throughput channel 2

2: throughput channel 1 + 2

3: actual value channel 1

4: actual value channel 2

5: actual value channel 1+ 2

Page 19

120 UINT16 Mask configuration binary output

121 UINT8 Type binary output

0: off

1: EOB

2: delay

122 UINT8 Effect of binary output

130 UINT16 Mask configuration code

131 UINT16 Code priority 1

132 UINT16 Code priority 2

133 UINT16 Code priority 3

140 UINT16 Mask total volume

141 UINT8 Total volume delete (during parametration)

150 UINT16 Mask configuration automatic

151 UINT8 Mode type

152 UINT8 Limits automatic

153 UINT16 Required proportioning

154 UINT8 Proportioning duration - hours

155 UINT8 Proportioning duration - minutes

156 UINT8 Proportioning duration - seconds

0: low - active

1: high - active

0: no

1: total volume channel 1

2: total volume channel 2

3: total

0: manual

1: automatic

0: no limits

1: limits regarding number of proportionings

2: limits regarding time

160 UINT16 Mask configuration starting delay

161 UINT8 Starting delay - hours

162 UINT8 Starting delay - minutes

163 UINT8 Starting delay - seconds

170 UINT16 Mask configuration operation

171 UINT8 Mode type

0: internal

1: external

2: global

19

Page 20

172 UINT8 Effect

180 UINT16 Mask configuration language

181 UINT8 Language

4.4 Error list operating errors

Batch controller-errors from the monitor

1: acknowledged

2: access OK

3: data base not up to date

4: value outside of value range

5: value cannot be described in current condition

6: another enquiry is still in progress

7: start cannot be operated

8: stop cannot be operated

9: reset cannot be operated

10: required channel 1 > cannot be operated

11: required channel 1 > corrected to limit

12: required channel 2 > cannot be operated

13: required channel 2 > corrected to limit

0: normal

1: inverted

0: German

1: English

2: French

20

14: exact channel 1 > cannot be operated

15: exact channel 1 > corrected to limit

16: exact channel 2 > cannot be operated

17: exact channel 2 > corrected to limit

18: condition k1 cannot be operated

19: reserve

20: condition k2 cannot be operated

21: reserve

22: reserve

23: reserve

24: reserve

25: parametration not possible

26: configuration not possible

27: parametration not possible → not part of process operation

28: parametration not possible → LOCAL in configuration

29: configuration not possible → not part of process operation

Page 21

5. RS 232 - Protocol

5.1 Transmission format

8 Bit ASCII

1 Startbit

1 Stopbit

1 Paritybit (if "odd" or "even")

The data is transmitted in IEEE format.

S. E. E. E. E. E. E. E. Value = (-1)S * 2

E. M. M. M. M. M. M. M. S = Sign

M. M. M. M. M. M. M. M. E = Exponent

M. M. M. M. M. M. M. M. M = Mantissa

hex 40 40 00 00 = 1 · 2 · 1,5

A parity check will be carried out ("odd", "even", "none")

In addition, a block check will be carried out.

All bytes are added onto one byte without considering the overflow.

The LSByte of the "block check" symbol is transmitted as the second to last symbol

(before the ETX).

Each block begins with an STX (HEX 2) and ends with an ETX (HEX 3).

STX and ETX are not components of the "block check".

5.2 Transmission protocol

Following each write access the unit answers with ACK (HEX 6) whenever the access

has

been carried out correctly.

The unit answers with NAK (HEX 15) whenever the access could not be carried out

even

through the block was correctly received.

In the event of a transmission error, no answer is given.

(E-127)

* 1.Mantissa

If an STX is received within a telegram, then this will result in a new start being carried

out and the former content being lost.

An access is built as follows:

1. Byte address: address of the station MSByte

2. Byte address: address of the station LSByte

3. Byte index: object index MSByte

4. Byte index: object index LSByte

5. Byte value: value MSByte

6. - 13. byte: value according to value length

21

Page 22

During the writing, the value to be written is transmitted in "Wert".

During the reading, the value is not included while going out. When coming back, the

complete "Buffer" is transmitted along with the value.

Example of 5.1: Transmission format

Write Required Value Address 5, Index 24, Value 3

02 3035 3138 3430 3420 30 30 30 30 3536 30

STX 05 24 3 block check ETX

Read Required Value Address 5, Index 24

Enquiry: 02 3035 3138 4345 03

Answer:02 3035 3138 3430 3430 30 30 30 30 3536 30

The indices of the individual values correspond to those of the profibus protocoll.

PC Programme

You will find further details in the file "Read .me".

Each interface card contains a disk with which you can build a RS 485 / profibus net

or a RS 232 connection.

The programme is structured in menu technique and is therefore easy to handle.

The programme is started with "PROFIBUS" and/or "RS232".

For exchanging data, two rudimentary programmes are available on the disk.

These allow reading and writing transactions to be carried out:

a) RS 232.exe

b) Profibus. exe

22

Page 23

6 Configuration of the interfaces

When the interface card (RS 232 or RS 485 / Profibus) has been installed, then appears

in the menu item "Add. Menu" of the digital unit (e.g. Digital Industrial Controller Type 1110

or

Digital Batch Controller Type 1115) the menu item "Serial" (after the menu item

"Language").

Menu for configuring Menu for configuring

the serial interface RS 232 the serial interface RS 485 /

Profibus

Add. Menu

Language

Serial

End

Add. Menu

Language

Serial

End

Mode

remote

local

Baud rate

Bd: 9600

Bd: 4800

Parity check

Par: even

Par: none

Address

Adr:

PAr: odd

Mode

local

Address

Adr:

remote

SELECT

ENTER

23

Page 24

Further information concerning the menus

Mode

local In the local mode, only data from digital units can be requested through the serial

remote In the remote mode , data can be transmitted in both directions through the

Baud rate

Bd: 4800 The baud rate equals 4800 baud.

BD: 9600 The baud rate equals 9600 baud.

Parity check

Par: none No parity check will be carried out.

Par: even A check and/or an alteration will be carried out on an even parity.

interface. External data cannot be transmitted to the units.

The digital units can only be configurated and parametrated and the required

value can only be adjusted (at the controller) by using the unit`s keyboard and

not through the serial interface.

serial interface.

The digital unit can be configured and parametrated and the required value can

be adjusted using the serial interface.

In this case, the parametration and alteration of the required value cannot be

carried out through the unit`s keyboard.

If the operator mode is accessed through the remote mode by using the unit

keyboard, then the main configuration menu does not appear as usual, but rather

a menu item appears which permits the setting of the interface mode.

The configuration can be carried after the mode has been switched from remote

to local .

This parameter can only be set by using the interface RS 232.

Par: odd A check and/or an alteration will be carried out on an odd parity.

This parameter can only be set by using the interface RS 232.

Address

Adr: Address of the interface card

24

Address range with RS 232: 1 ... 32

Address range with RS 485 / Profibus: 0 .. 127.

Page 25

Operating Instructions 0507/02_EU-EN_00000000

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com Bürkert Company Locations

Steuer- und Regeltechnik

Christian-Bürkert-Str. 13-17

74653 Ingelfingen

T elefon (0 79 40) 10-111

T elefax (0 79 40) 10-448

www.buerkert.com

info@de.buerkert.com

Australia: Seven Hills NSW 2147, Ph. (02) 1300 888 868

Austria: 1150 Wien, Ph. (01) 894 13 33

Belgium: B-2110 Wijnegem, Ph. (03) 325 89 00

Brazil: 04715-005 São Paulo - SP, Ph. (011) 51 82 00 11

Canada: Oakville, Ontario L6L 6M5, Ph. (905) 847 55 66

China: Shanghai, Ph. (8621) 58 68 21 19

Czech Republic: 60200 Brno, Ph. (543) 25 25 05

Denmark: 2730 Herlev , Ph. (44) 50 75 00

Estonia: EE-12915 Tallin, Ph. (372)644 06 98

Finland: FI-00370 Helsinki, Ph. (09) 54 97 06 00

France: 67220 T riembach au V al, Ph. (0388) 58 91 11

Hong Kong: Kwai Chung NT, Ph. 24 80 12 02

India: Chennai 600 028, Ph.(044)52 30 34 56

Italy: 20060 Cassina De ‘Pecchi (Mi), Ph. (02) 95 90 71

Japan: Tokyo 166-0004, Ph.(03) 53 05 36 10

Korea: Seoul 153-811, Ph. (02) 34 62 55 92

INTERNATIONAL

Berlin, Ph. (0 30) 67 97 17-0

Frankfurt, Ph. (0 61 03) 9 41 40

Hannover, Ph. (05 11) 902 76-0

Dresden, Ph. (03 59 52) 36-300

Dortmund, Ph. (0 23 73) 96 81-0

München, Ph. (0 89) 8 29 22 80

Stuttgart, Ph. (07 11) 451 10-0

Malaysia: 11960 Penang, Ph. (04) 64 350 08

Netherlands: NL-3542 DP Utrecht, Ph. (0346) 58 10 10

Norway: 2013 Skjetten, Ph. (63) 84 44 10

Philippines: Paranaque City , Ph. (02) 776 43 84

Poland: PL-02-904 Warszawa, Ph. (022) 840 60 10

Portugal: Sales office in Spain, Ph. (21) 21 28 490

Singapore: Singapore 408933, Ph. 68 44 22 33

South Africa: Millenium Business Park, Ph. (011) 574 60 00

Spain: 08970 Sant Joan Despi, Barcelona, Ph. (93) 477 79 80

Sweden: 21120 Malmö, Ph. (040) 664 51 00

Switzerland: 6331 Hünenberg ZG, Ph. (041) 785 66 66

T aiwan: T aiw an 115, Ph. (02) 26 53 78 68

T urkey: TR-Yenisehir-lzmir, Ph. (0232) 459 53 95

United Kingdom: Stroud, Glos, GL5 2QF, Ph. (01453)731353

USA: Irvine, CA 92614, Ph. (949) 223 31 00

Loading...

Loading...