Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

Type 1110

Digital Industrial Controller

Digitaler Industrieregler

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

© 2002 Bürkert Werke GmbH & Co. KG

Operating Instructions 0507/10_EU-ML_00801137

Page 3

DIGITAL INDUSTRIAL CONTROLLER

CONTENTS:

1 GENERAL SAFETY INSTRUCTIONS .......................................................................... 3

2 CHARACTERISTICS AND POSSIBILITIES OF USE

(OVERVIEW) .............................................................................................................................. 4

3 INSTALLING THE CONTROLLER .................................................................................. 6

4 CONNECTIONS ....................................................................................................................... 6

4.1 Pin assignments ........................................................................................................................ 6

4.2 Supply voltages ......................................................................................................................... 7

4.2.1 115/230 V and 24/48 V Changeover

4.2.2 24V DC/AC Converter for operation at 24 V DC

................................................................................

........................................................

4.3 Signal inputs ............................................................................................................................... 9

4.4 Signal outputs ........................................................................................................................... 11

5 CONTROLLER STRUCTURES...................................................................................... 13

5.1 Overall Structure of the Digital Industrial regulator ................................................. 13

5.2 Controller for single control loop ......................................................................................15

5.2.1 Single control loop

5.2.2 Standard controller structure

..................................................................................................................

.............................................................................................

15

15

5.3 Controller with additional functions for feed forward control ............................... 17

5.3.1 Single control loop with feed forward control

5.3.2 Feed forward controller structure

.....................................................................................

.............................................................

17

17

5.4 Controller with additional functions for follow-up control ...................................... 19

5.4.1 Servo-control (external set-point input)

5.4.2 External setpoint controller structure

........................................................................

.............................................................................

19

19

5.5 Controller with additional functions for ratio control ................................................21

5.5.1 Ratio control

5.5.2 Ratio controller structure

..............................................................................................................................

.....................................................................................................

21

22

5.6 Controller with additional functions for cascade control ....................................... 23

5.6.1 Cascade control

5.6.2 Cascade controller structure

......................................................................................................................

.............................................................................................

23

24

5.7 Explanations of the controller structures' function blocks .................................... 26

english

8

8

1110 - 1

Page 4

DIGITAL INDUSTRIAL CONTROLLER

6 OPERATION ............................................................................................................................. 38

6.1 Operating levels....................................................................................................................... 38

6.2 Operator controls and indicators ..................................................................................... 39

6.3 Process operation .................................................................................................................. 40

english

6.4 Setting numeric values

6.5 Configuration ............................................................................................................................ 43

6.5.1 Operation during configuration

6.5.2 Main menu of the configuration level

6.5.3 Configuration menus

6.5.4 Meanings of the symbols in the configuration menus

6.6 Parameter definition .............................................................................................................. 68

6.6.1 Operation during parameter definition

6.6.2 Parameter definition menus

7 SELF-OPTIMISATION ......................................................................................................... 72

......................................................................................................... 42

.............................................................................................................

.........................................................................................

.............................................................................

...........................................

..........................................................................

...............................................................................................

43

44

46

54

68

68

7.1 Stability and control quality ................................................................................................ 72

7.2 Principle of self-optimisation by adaption ....................................................................72

7.3 Principle of self-optimisation by tuning ......................................................................... 72

7.4 Operating principle of the tuning and adaption modules ...................................... 74

7.5 Notes on using the tuning and adaption module ..................................................... 75

7.6 Operating the tuning and adaption functions ............................................................. 79

8 ERROR MESSAGES AND WARNINGS .................................................................... 81

9 ANNEX ........................................................................................................................................ 84

9.1 Characteristics of PID controllers ....................................................................................84

9.2 Rules for adjusting PID controllers ................................................................................. 88

9.3 List of abbreviations ............................................................................................................... 91

9.4 Index ............................................................................................................................................. 92

9.5 Userconfiguration .................................................................................................................... 93

2 - 1110

Page 5

DIGITAL INDUSTRIAL CONTROLLER

1 GENERAL SAFETY INSTRUCTIONS

To ensure that the device functions correctly, and will have a long service life, please

comply with the information in these Operating Instructions, as well as in the

application conditions and the additional data given in the data sheet:

• When planning the application of the device, and during its operation, observe

the general technical rules!

• Installation and maintenance work should only be carried out by specialist staff

using the correct tools!

• Observe the relevant accident prevention and safety regulations for electrical

equipment during the operation and maintenance of the unit!

• If the controller is part of a complex automation system, a defined and controlled

re-start must be carried out following an interruption of operation.

• Always switch off the voltage before carrying out work on the device!

english

• Take suitable measures to prevent unintentional operation or impermissible

impairment.

• If these instructions are ignored, no liability will be accepted from our side, and

the guarantee on the device and on accessory parts will become invalid!

1110 - 3

Page 6

DIGITAL INDUSTRIAL CONTROLLER

2 CHARACTERISTICS AND POSSIBILITIES OF USE

(OVERVIEW)

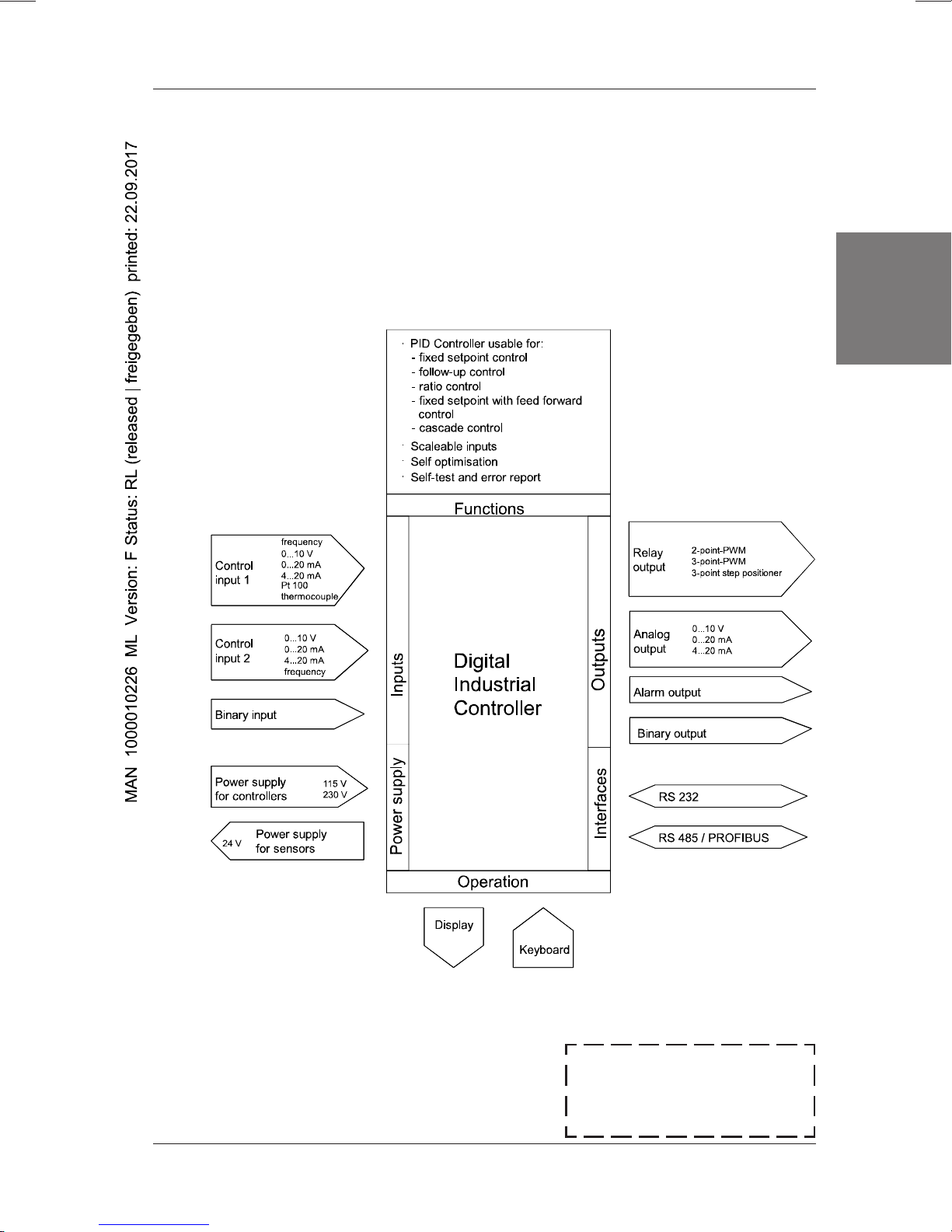

The digital industrial controller is designed as a PID controller for controlling tasks in

the process control technology. It represents a new controller generation based on a

microprocessor.

english

Either standard

scaleable controller inputs or resistance thermometers and thermocouples can be

connected.

Outputs for continuous standard signals or relay outputs can now be used as

controller outputs.

In addition, outputs for error reports and a binary input and output for additional

functions are available.

RS 232 or RS 485 / PROFIBUS serial interfaces are available as connection

options.

The following control tasks can be realised with the controller:

• Fixed setpoint control (single control loop)

• Fixed setpoint with feed forward control

• Follow-up control (external set-value)

• Ratio control

• Cascade control

The controller is characterised by user-friendly operation and has a backlit, easily

legible LCD plain language display.

The following operator actions can be carried out with menu support in various

operator control levels:

current/voltage

and frequency-analog signals can be applied to the

4 - 1110

• Configuration (defining the controller structure),

• Parameter definition (setting controller parameters),

• Process operation (manual interventions).

Configuration and parameter definition data is stored in an EEPROM to protect

against power failures.

NOTE

The digital industrial regulator complies with the 73/23/EWG

Low Voltage Regulations and the EMC 89/2338/EWG

Regulations.

Page 7

DIGITAL INDUSTRIAL CONTROLLER

Unauthorized operation of the individual operator control levels can be rendered

impossible by a free choice of user codes. Regardless of this, a permanently

programmed and invariable master code exists which allows access to all levels.

This 4-digit master code can be found on the bottom margin of this page. It

can be cut out and stored separately from the instruction manual.

Self-optimization algorithms (for self-adjustment and adaption) are implemented in

the controller and ensure automatic adaption of the controller’s parameters to the

process in the closed control loop.

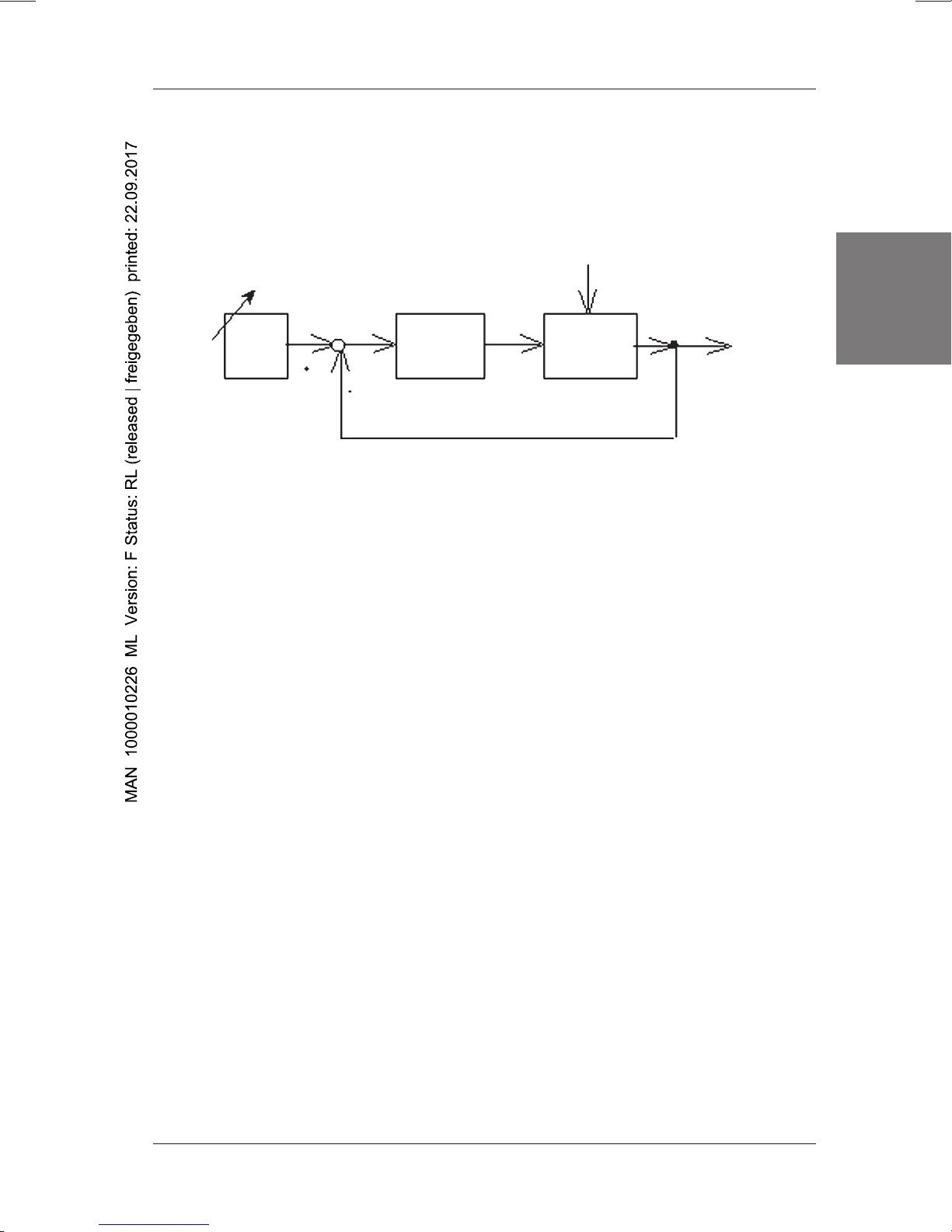

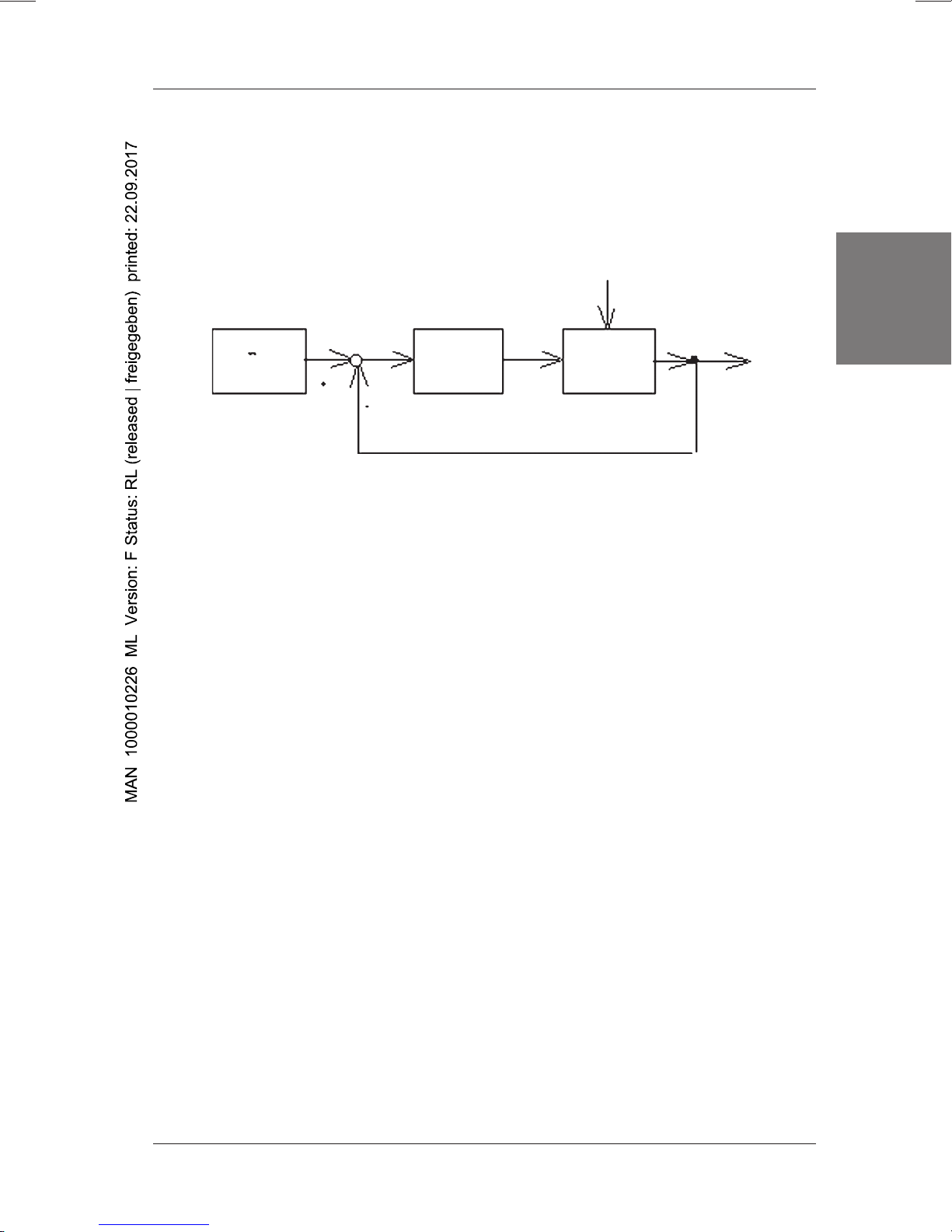

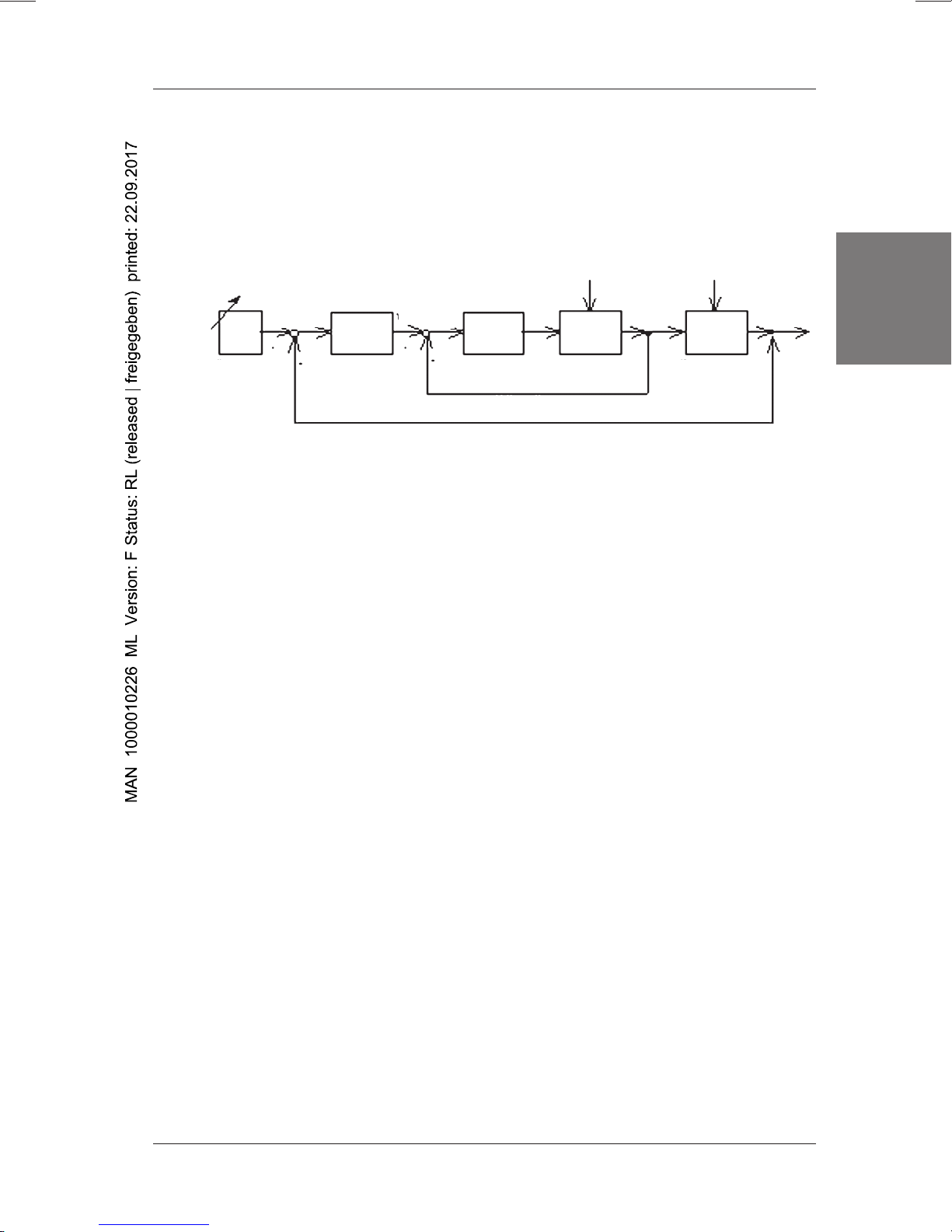

Figure 1 shows an overview of the controller.

english

Figure 1: Overview diagram

✂

Mastercode for digital

industrial controller:

8575

1110 - 5

Page 8

DIGITAL INDUSTRIAL CONTROLLER

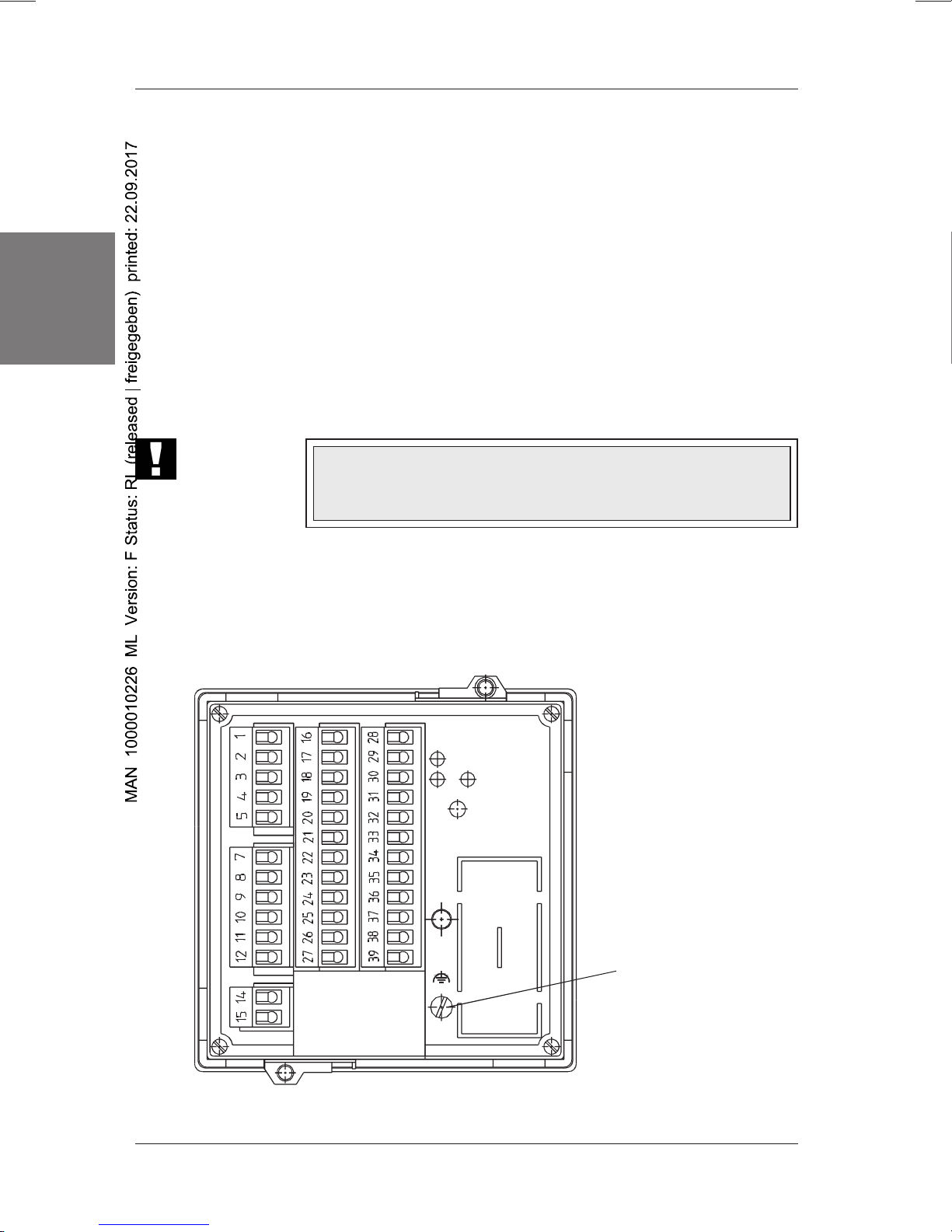

3 INSTALLING THE CONTROLLER

The controller was conceived for installation in switch panels. On the controller,

first of all remove the retaining elements engaged on both sides by swivelling in

anticlockwise direction. Insert the controller, including the enclosed rubber seal, into

the insertion opening from the front. Then again engage the two retaining elements

in the bolts on the sides of the housing and screw in the threaded pin inside from the

rear.

Switch panel insertion opening (W x H): 92 x 92 mm2 (+0,8 mm)

Outer controller dimensions (W x H x D): 96 x 96 x 173 mm

english

Controller weight: 960 g

Degree of protection: IP 65 (front when using the

Operating temperature: 0 bis +50 °C

Storage temperature: -20 bis +60 °C

ATTENTION!

4 CONNECTIONS

4.1 Pin assignments

3

enclosed seal)

To ensure the electromagnetic compatibility (EMC) the screw

terminal TE (Technical Earth) must be connected to the earth

potential by a cable that is as short as possible (30 cm, 2.5 mm2)

Figure 2: Rear side of controller

6 - 1110

TE connection

(Technical Earth)

Page 9

Relay 3

(Alarm)

Relay 3

(Alarm)

Relay 1

(Output)

DIGITAL INDUSTRIAL CONTROLLER

Controller input 2 Controller input 1

Position acknowledgement

Binary

output

Controller output

Standard signal

Current

Standard signal

Voltage

Relay 2

(Output)

Binary

input

Power

supply

Fig. 3: Allocation of the terminal strip

NOTE When connecting the sensor lines:

• Lay the lines separate from the power lines (lines in which large

currents flow) and high frequency lines. Never under any

circumstances use multi-pole cables to carry both power and

sensor lines.

• When using screened cables, only connect the screen at one

end. Never under any circumstances connect the screen to both

the protective conductor and the earth of the regulator input.

Resistance

thermometer

PT100

Thermo

couples

english

4.2 Supply voltages

Power supply for the Connect to terminals 14

controller: and 15.

Model 1: 115 / 230V 50 ... 60 Hz

Model 2: 12 / 24V 50 ... 60 Hz

Power supply for 24 V DC Accessible on terminals 23

transducers: and 24.

ATTENTION!

To ensure the electro-magnetic compatibility (EMC), the screw

terminal TE (Technical Earth) must be connected to the earth

potential with a short cable (30 cm, 2.5 mm2).

1110 - 7

Page 10

DIGITAL INDUSTRIAL CONTROLLER

4.2.1 115/230 V and 24/48 V Changeover

By means of a jumper inside the unit, the supply voltage can be changed from 230 V

to 115 V, or from 12 V to 24 V respectively. This adaptation must take place before

installing the unit.

Procedure:

Î Insert all connection and supply lines

Î Remove the connecting screw for the Technical Earth

english

Î Remove the optionally-installed interface card (if present)

Î Undo the four screws on the rear plate, and remove the rear plate

Î Pull the unit one third of the way out of the housing

Î The jumper is easily accessible on the power supply printed-circuit board,

positioned immediately in front of one of the relays and identified by the numbers

1-4 on the board.

Î At delivery, the connector is positioned between contacts 2 and 4

Î To change the unit to 115V or 12 V respectively, contacts 1 and 3 must be

bridged with the connector. Proceed identically when changing from 24V to 12V.

Î Finally, push the unit back into the housing, and screw on the rear plate.

NOTE

If the unit is to be set to the lower voltage, please ensure that the

voltage does not exceed the quoted tolerances, and make a note

on the wiring diagram.

4.2.2 24V DC/AC Converter for operation at 24 V DC

The 12/24V AC controller model can also be operated at 24 VDC using an optional

DC/AC converter. Up to 3 controllers can be supplied from a single converter. (Order

number: 19139J)

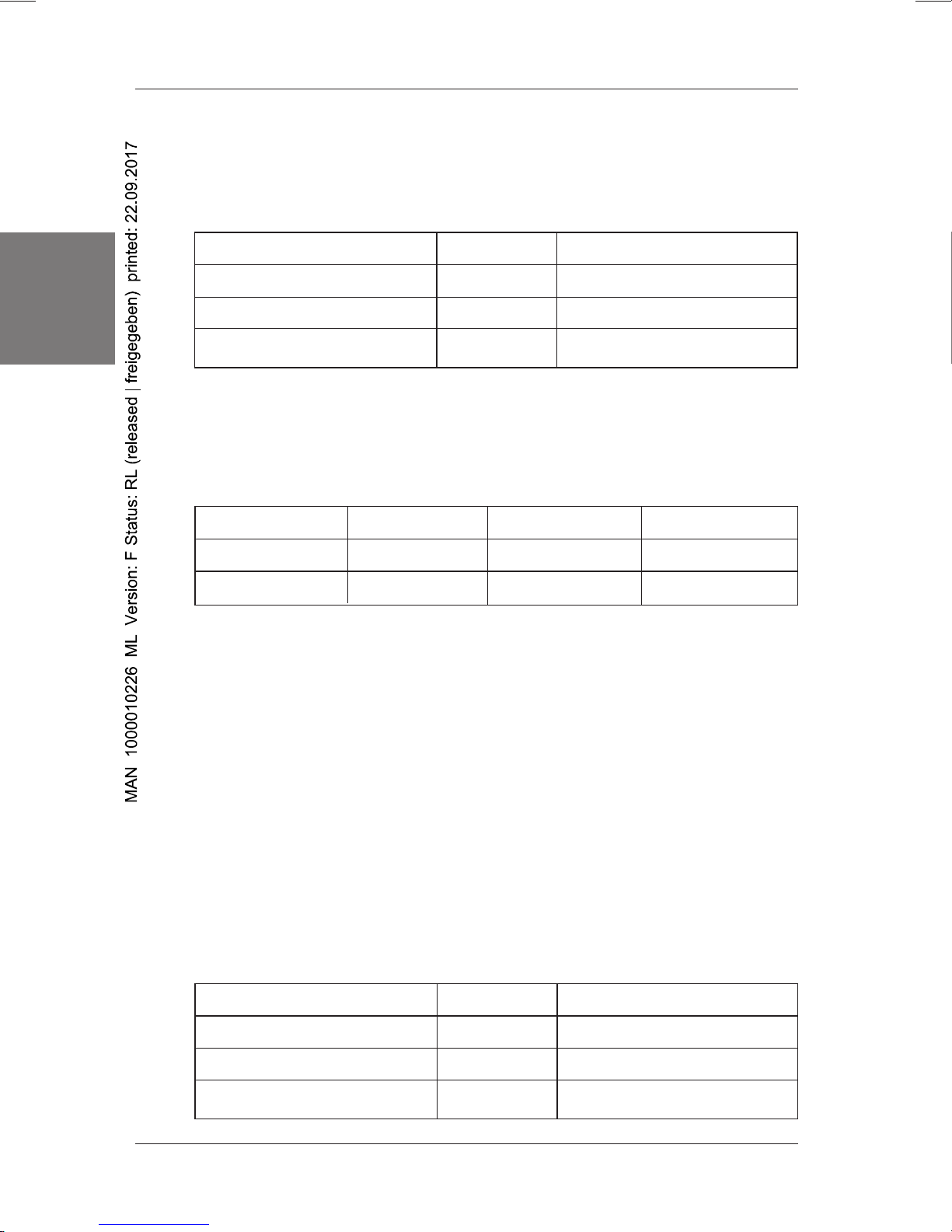

Supply voltage 16V - 26V DC

Output voltage 16V-26V AC (50 Hz)

Efficiency > 95%

Switch-on delay max. 5 secs

Dimensions (WxHxD) 23 x 75 x 110 mm

8 - 1110

3

Page 11

4.3 Signal inputs

All signal inputs are short-circuit proof, are voltage-stable to 41 volts and are

galvanically isolated with regard to the outputs and the supply voltage.

Controller input 1:

The following input configurations are available:

• Input for standard signal (voltage) 0 ... 10 V Terminals 30 and 31

Input resistance: > 400 kΩ

Measuring error: < 0,2 %

Temperature influence: < 0.2 % / 10 degrees

• Input for standard signal (current) 0 (4) ... 20 mA Terminals 29 and 31

Input resistance: < 300 Ω in accordance with DIN IEC 381 (typically 200)

DIGITAL INDUSTRIAL CONTROLLER

english

Measuring error: < 0,2 %

Temperature influence: < 0.2 % / 10 degrees

Nominal temperature: 22 °C

Wire breakage and short-circuit detection within the range from 4 to 20 mA

• Input for frequency-analog signal 5 ... 1000 Hz Terminals 28 and 31

Input resistance: > 10 kΩ

Measuring error: < 0,1 %

Signal types: Sine wave, square wave, delta ( > 300 mVpp)

• Input for connection of Pt 100 resistance Terminals 35, 36, 37, 38

thermometers

(in accordance with DIN 43760 for 3 and 4-wire connection)

Measurement range - 200 to + 850 °C

Measurement current max. 0,5 mA

Measuring error ± 0.2 % ± 2 digits

1110 - 9

Page 12

DIGITAL INDUSTRIAL CONTROLLER

english

NOTE

• Input for connection of thermocouples Terminals 38 and 39

For the following thermocouples, the characteristics are linearised internally:

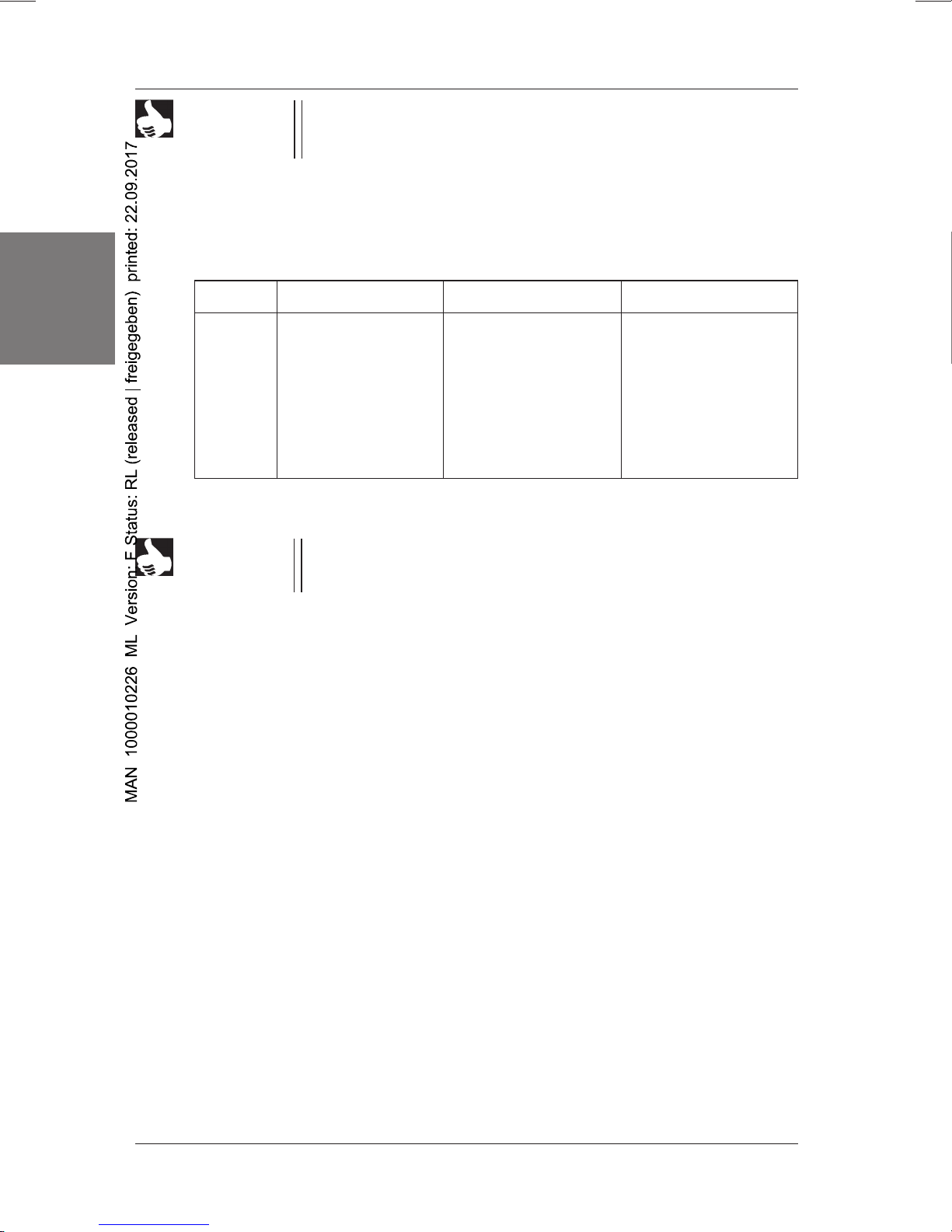

Type Thermocouple pair Measurement range Accuracy

J Fe - CuNi -200 to +1200 °C < ± 0.3 % ± 1 Digit

K NiCr - Ni -200 to +1370 °C < ± 0.3 % ± 1 Digit

T Cu - CnNi 0 to +400 °C < ± 0.3 % ± 2 Digit

R Pt 13Rh - Pt 0 to 1760 °C < ± 0.3 % ± 1 Digit

S Pt 10Rh - Pt 0 to 1760 °C < ± 0.3 % ± 1 Digit

NOTE

If the displayed values are fluctuating, set the limit frequency of the

digital filter to a lower value in the Inputs menu and check the TE

connection.

If the displayed values are fluctuating, set the limit frequency of the

digital filter to a lower value in the Inputs menu and check the TE

connection.

Input impedance: > 1 MΩ

Comparison point compensation:

• internal with integrated NTC thermistor

Comparison point compensation error: 0.5 K ± 1 digit

• external with Pt 100 resistance thermometer

Controller input 2

• Input for standard signal (voltage) 0 ... 10 V Terminals 18 and 19

(same technical data as for controller input 1)

• Input for standard signal (current) 0 (4) ... 20 mA Terminals 17 and 19

(same technical data as for controller input 1)

• Input for frequency-analog signal 5 ... 1000 Hz Terminals 16 and 19

(same technical data as for controller input 1)

Configurable for:

• Feed forward control

• Follow-up control (external setpoint)

• Ratio control

• Cascade control

10 - 1110

Page 13

DIGITAL INDUSTRIAL CONTROLLER

• Input for the connection of a potentiometer Terminals 19, 20 and 27

for position feedback (1 ... 10 kΩ)

for position regulation

• Binary inputs Terminals 25 and 26

Input resistance: > 25 kΩ

Configurable line of action:

Logical value Voltage not inverted inverted

0 0 ... 4,5 V nactive active

1 13 ... 35 V active inactive

Configurable functions:

• Changeover between manual and automatic mode

• Changeover between external and internal setpoint *)

• Triggering alarms

• Safety value output

*) Available only if controller input 2 has been configured for an external setpoint.

english

4.4 Signal outputs

Controller output

The following output configurations are available:

Controller output for continuous signals

• Output for standard signal 0 ... 10 V Terminals 33 and 34

max. load current: 5 mA

Accuracy: 0,5 %

• Output for standard signal 0 (4) ... 20 mA Terminals 32 and 33

max. load resistance: 600 Ω

Accuracy: 0,5 %

Controller outputs for discontinuous signals

2 relays with one potential free changeover contact each:

Relay 1 Terminals 7, 8 and 9

Relay 2 Terminals 10, 11 and 12

1110 - 11

Page 14

DIGITAL INDUSTRIAL CONTROLLER

The following output signals are configurable (cf. Sections 5.7 and 6.5.4):

• 2-point PWM signal (PWM: Pulse width modulation)

• 3-point PWM signal

• 3-point step signal

• 3-point step signal with external feedback (position control)

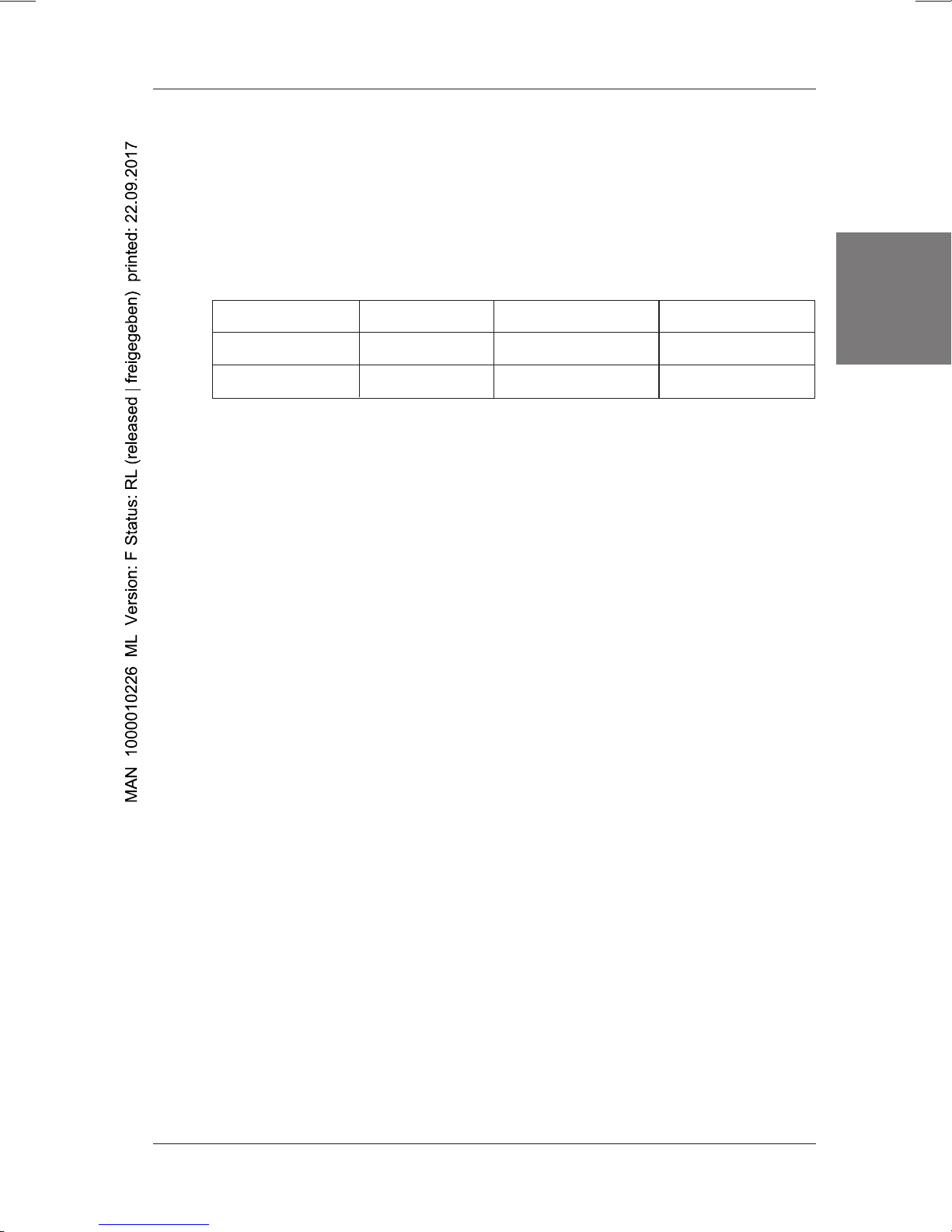

Electrical data of the relay AC DC

Max. switched voltage 250 V 300 V

Max. switched current 5A 5A

english

Max. switched power 1250 VA 100 W at 24V, 30 W at 250V

• Binary output Terminals 21 and 22

max. load current: 20 mA

Configurable line of action (not inverted / inverted):

Logical value Output not inverted inverted

0 high resistance inactive active

1 17.5 ... 24 V active inactive

Configurable functions:

• Signal:

• Signal:

• Signal:

Outputs for alarms

2 relays with one potential free changeover contact and internal connected bose

(see connection diagram):

Relay 3 Terminals 1, 2 and 3

Relay 4 Terminals 3, 4 and 5

Configurable alarms:

• Alarm, absolute

• Alarm, relative

• Alarm, ratio

Alarm has occurred

Error has occurred

MANUALmode

Electrical data of the relay AC DC

Max. switched voltage 250 V 300 V

Max. switched current 5A 5A

Max. switched power 1250 VA 100 W at 24V, 30 W at 250V

12 - 1110

Page 15

DIGITAL INDUSTRIAL CONTROLLER

5 CONTROLLER STRUCTURES

5.1 Overall Structure of the Digital Industrial Controller

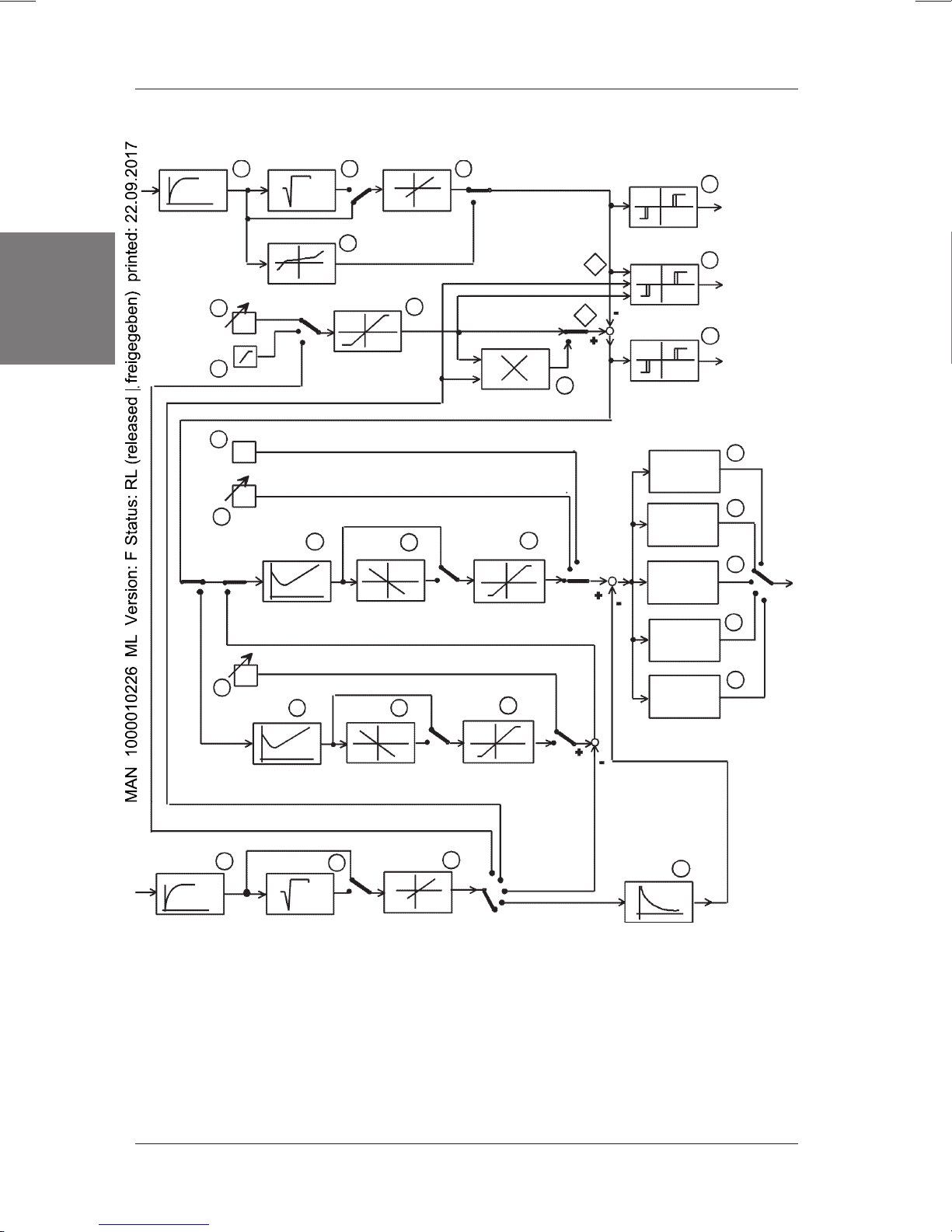

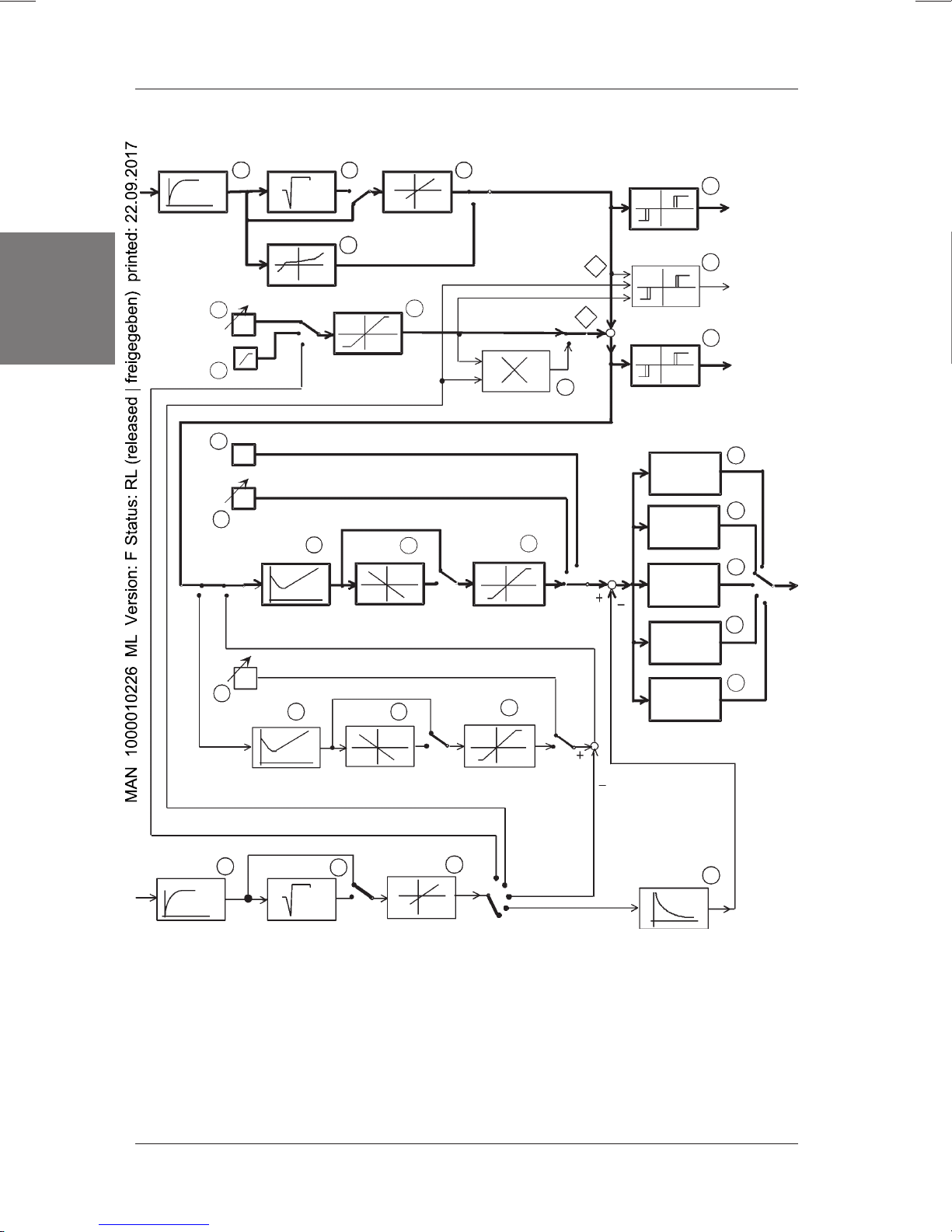

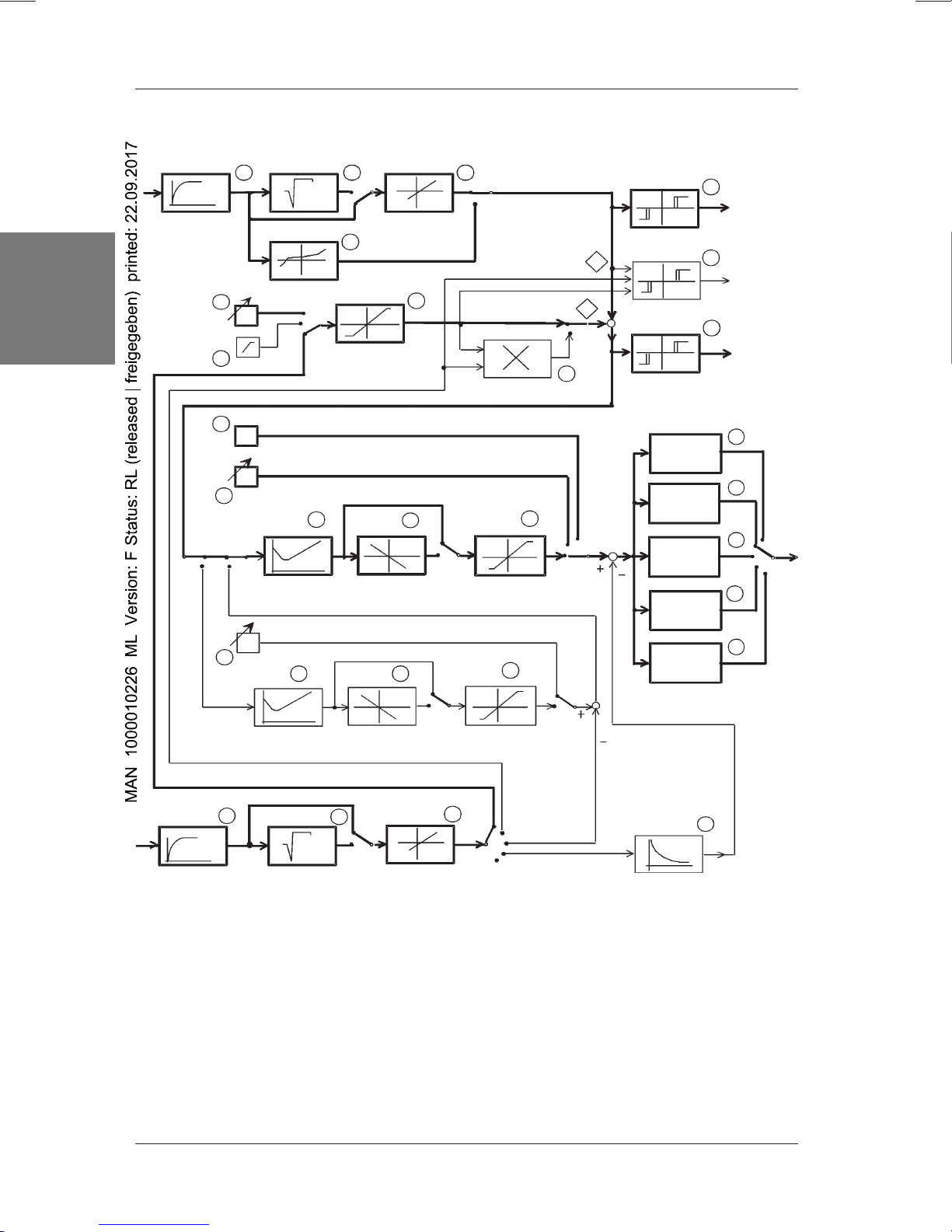

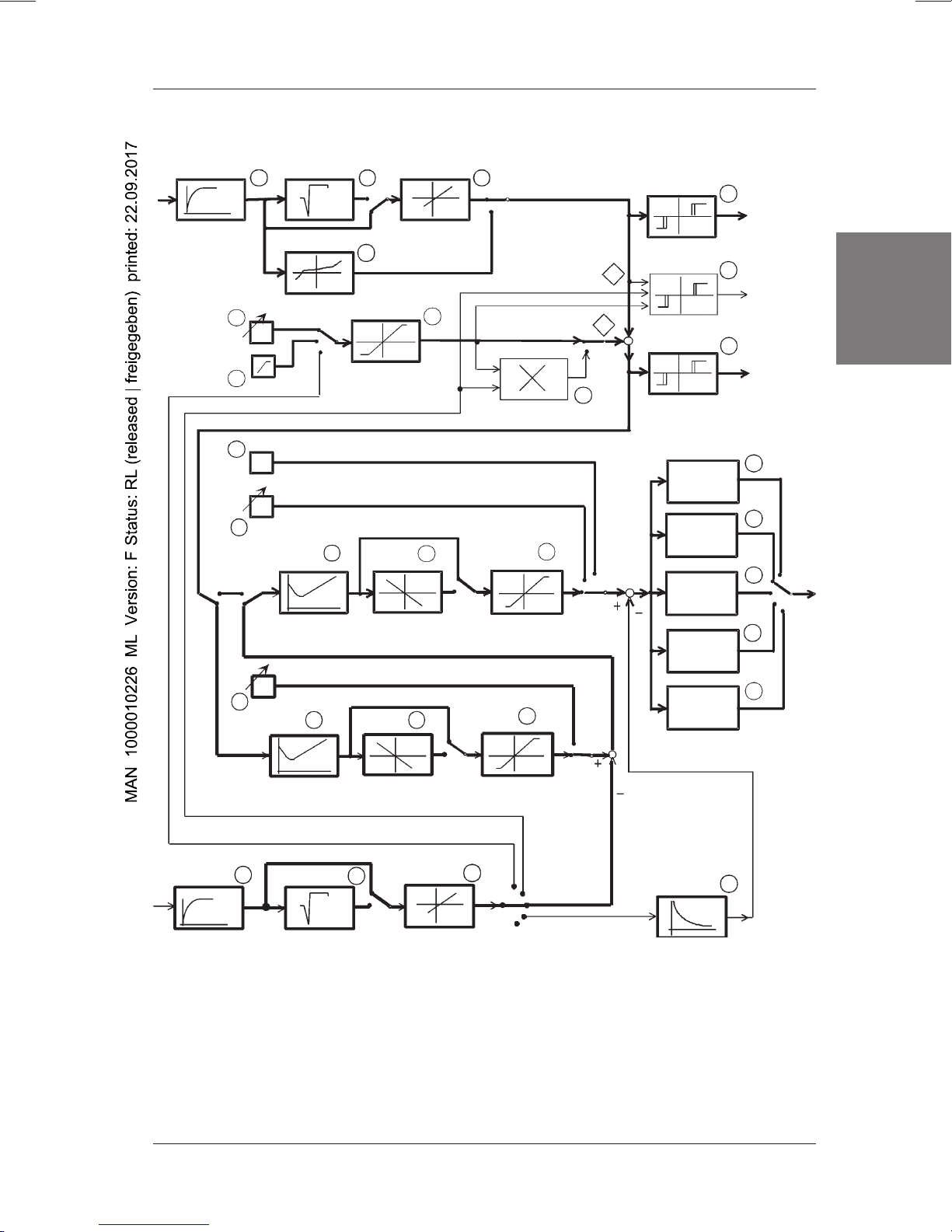

Figure 4 shows the overall structure of the digital industrial controller in the form of a

signal flow chart. In addition to function blocks, it contains function selectors which

are used to set a concrete controller structure when configuring the controller.

The following concrete controller structures can be configured on the basis of the

overall structure:

• Controller for single control loop

(

Standard controller

• Controller with additional functions for feed forward control

(

Feed forward controller

• Controller with additional functions for follow-up control

(

External setpoint controller

• Controller with additional functions for ratio control

(

Ratio controller

• Controller with additional functions for cascade control

(

Cascade controller

The function blocks contained in the overall structure are explained in Section 5.7.

structure)

structure)

structure)

structure)

structure)

english

1110 - 13

Page 16

DIGITAL INDUSTRIAL CONTROLLER

Filter 1

PV1

Input 1

english

Ramp

13

5

6

14

Root extraction Scaling

1

Linearisation

SP1

23

4

Setpoint

limiting

COs

CO

10

Controller 2

7

11

Line of action

Multiplier

CO2

Manipulated

variable limiting

12

27

SP

PV1

Alarm abs.

Alarm ratio

Alarm rel.

Continuous

signal

2-pointPWM signal

3-pointPWM signal

3-pointstep signal

8

Aabs

28

Averh

9

Arel

15

16

17

RA

18

SP2

22

20

29

21

CO1

Controller 1

Input 2

23 24

PV2

Filter 2 Root extraction

Line of action

Scaling

Manipulated

variable limiting

25

ext.SP

off

ratio

cascade

Feed forward

Figure 4: Overall structure of the Digital Industrial Regulator

Refer to Page 122 ff for a description of the function blocks

3-point-step

signal with

ext. p. a.

26

PDT1

Feed forward

control

19

Controller

output

14 - 1110

Page 17

DIGITAL INDUSTRIAL CONTROLLER

5.2 Controller for single control loop

5.2.1 Single control loop

If a control task consists of keeping a quantity (e.g. a temperature) at a fixed setpoint

SP (constant), a fixed setpoint control configuration is used for this purpose. The

control variable PV (temperature) is measured and compared against the setpoint

SP (Figure 5).

Z

Setpoint

generator

SP

PVd

F

R

Controller

CO

Controlled system

PV

F

S

Figure 5: Single control loop

If it deviates from the setpoint as the result of a disturbance Z, for example, the

controller generates a manipulated variable CO according to this deviation, which is

referred to as the system deviation PVd = SP-PV, in such a way that the controlled

variable PV is adapted as exactly as possible to the setpoint.

A PID controller can be used for this purpose. With regard to its parameters, it must

be configured so as to arrive at a control response that does justice to the task in

hand (see Annex).

Example:

Let us look at control of a room’s temperature as an example of a fixed setpoint

control configuration in a single control loop. The aim is to compensate all

disturbances that cause the room temperature to deviate from the temperature

setpoint. The room temperature is compared against the setpoint SP. According to

the system deviation PVd, the controller adjusts the fuel supply until the required

room temperature has been reached.

english

5.2.2

Standard controller

The

standard controller

overall structure appropriately. It is based on PID controller 2. PID controller 1 is not

used. Input 1 is used for the controlled variable PV1, while input 2 is not used. SP1

is the setpoint that has to be set.

structure

structure shown in Figure 6 is obtained by configuring the

1110 - 15

Page 18

DIGITAL INDUSTRIAL CONTROLLER

Filter 1

PV1

Input 1

english

5

Ramp

6

13

14

Root extraction Scaling

213

Linearisation

SP1

4

Setpoint

limiting

COs

CO

10

Controller 2

7

11

Line of action

CO2

Multiplier

12

Manipulated

variable limiting

8

Aabs

Alarm abs.

PV1

28

Averh

SP

27

Alarm ratio

Alarm rel.

Continuous

signal

2-pointPWM signal

3-pointPWM signal

3-pointstep signal

9

Arel

15

16

17

RA

18

SP2

22

20

29

CO1

Controller 1

Line of action

Manipulated

variable limiting

Input 2

PV2

Filter 2

23

Root extraction

24

Scaling

25

ext.SP

off

Figure 6: Structure of the Standard Controller

Description of the functional blocks from Page 122

21

ratio

cascade

Feed forward

3-point-step

signal with

ext. p. a.

PDT1

Feed forward

control

19

Controller

output

26

16 - 1110

Page 19

DIGITAL INDUSTRIAL CONTROLLER

5.3 Controller with additional functions for feed forward control

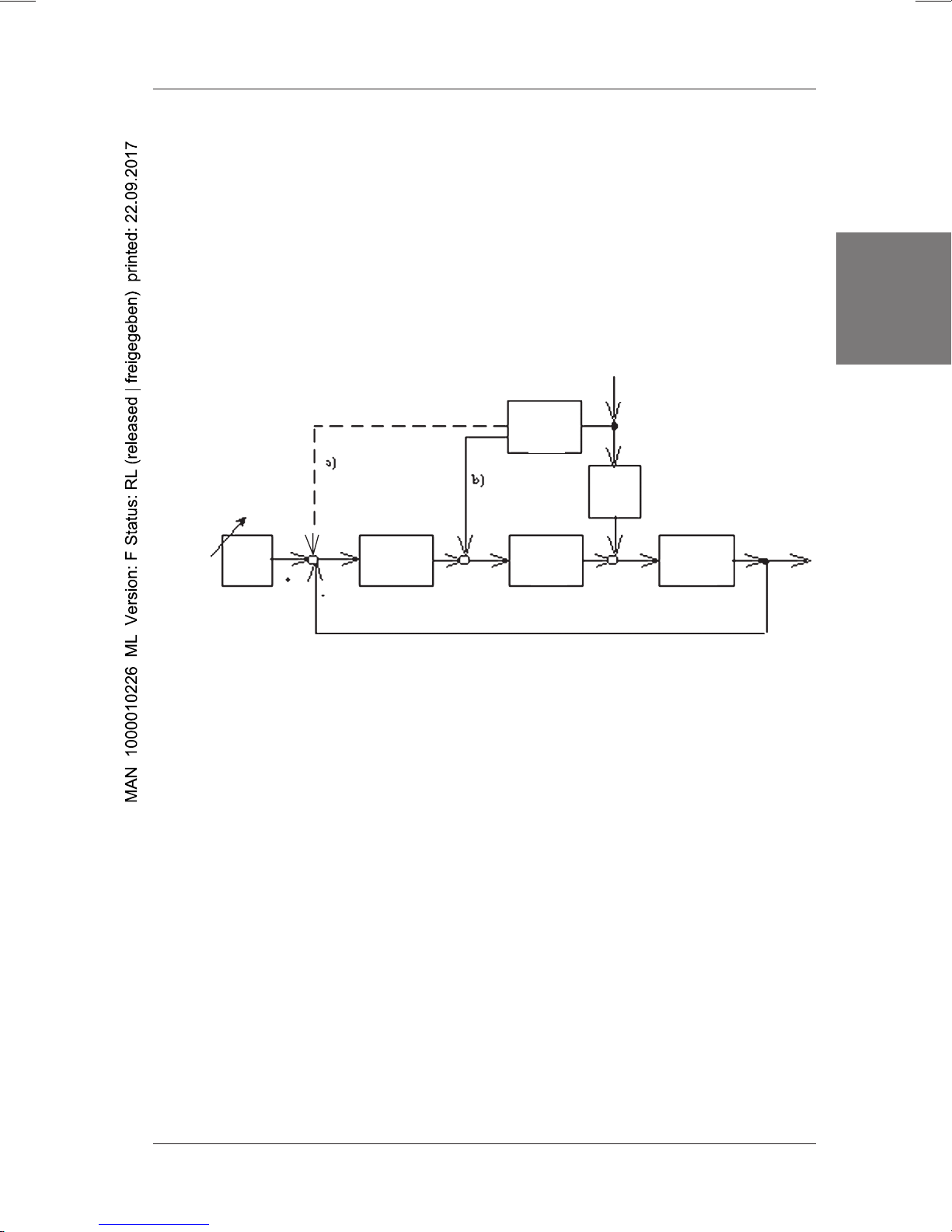

5.3.1 Single control loop with feed forward control

The control response of a single control loop can be improved substantially in most

cases by feed forward control. The precondition for this is that the disturbance

variable can be measured and recorded.

The disturbance can be fed either to the controller's input or output via a

compensator Fk (Fig. 7). In the digital controller, the disturbance is fed forward to the

controller's output. The compensator Fk consists of a PDT-1 element. This element's

P component feeds forward in proportion to the disturbance. The D component feeds

a value that is proportional to changes in the disturbance. Both components can be

chosen freely when configuring or defining the parameters.

english

Z

F

Z

PV

F

S2

Partial controlled

system 2

Setpoint

generator

SP PVd

F

R

Controller

Compensation element

F

K

CO

F

S1

Partial controlled

system 1

Figure 7: Single control loop with feed forward control

a) to the controller’s input

b) to the controller’s output

Example:

Let us take water level control in a steam boiler as an example of fixed setpoint

control with feed forward control. The water level is measured and controlled by way

of the supply of feed water. Here, the outgoing quantity of steam manifests itself in

the form of the principal disturbance. If it is measured and additionally fed forward to

the controller. The controller's response can be improved in this way.

5.3.2

Feed forward controller

The

feed forward

configuring the overall structure accordingly. It is based on PID controller 2.

PID controller 1 is not used. Input 1 is used for the controlled variable PV1, while

input 2 serves to feed the disturbance forward to the controller’s output. SP1 is the

setpoint that has to be set.

structure

controller structure highlighted in Figure 8 is obtained by

1110 - 17

Page 20

DIGITAL INDUSTRIAL CONTROLLER

Filter 1

PV1

Input 1

english

Ramp

Root extraction

1

Linearisation

5

SP1

6

4

Setpoint

limiting

13

COs

CO

14

10

Controller 2

Scaling

2

11

Line of action

3

8

Aabs

Alarm abs.

PV1

7

Multiplier

12

CO2

SP

27

Alarm ratio

Alarm rel.

Continuous

signal

2-pointPWM signal

3-pointPWM signal

Manipulated

variable limiting

3-pointstep signal

28

Averh

9

Arel

15

16

17

RA

18

SP2

22

20

29

CO1

Controller 1

Line of action

Manipulated

variable limiting

Input 2

PV2

23

Filter 2 Root extraction

24

Scaling

25

ext.SP

off

Figure 8: Structure of the feed forward control

Description of the functional blocks from Page 122

21

ratio

cascade

Feed forward

3-point-step

signal with

ext. p. a.

PDT1

Feed forward

control

19

Controller

output

26

18 - 1110

Page 21

DIGITAL INDUSTRIAL CONTROLLER

5.4 Controller with additional functions for follow-up control

5.4.1 Follow-up control (external set-point input)

The purpose of a follow-up control is to slave the controlled variable PV1 as exactly

as possible to another variable, the command variable, which varies in time. Either a

process variable PV2 originating from a system FS2 or a different variable with a

given time progression can be used as the command variable (Figure 9).

Z

SP=

PV2

F

S2

PVd

CO

F

R

F

S

PV1

english

5.4.2

Setpoint

generator

Controller

Controlled system

Figure 9: Follow-up control

The controller of a follow-up control configuration must be designed so as to arrive

at a good response to setpoint changes with a short settling time and wellattenuated stabilisation.

Example:

Let us take a power steering system as an example of a follow-up control. The

command variable PV2 for the angle of the wheel (controlled variable PV1) is

specified by the position of the steering wheel.

External setpoint controller

The

external setpoint

controller structure highlighted in Figure 10 is obtained by

structure

appropriately configuring the overall structure. It is based on PID controller 2. PID

controller 1 is not used. Input 1 is used for the control variable PV1, while the

command variable is applied to input 2 as the external setpoint.

In this controller structure, the binary input can be used to switch between the

external setpoint and the setpoint SP1.

1110 - 19

Page 22

DIGITAL INDUSTRIAL CONTROLLER

Filter 1

PV1

Input 1

english

5

Ramp

6

13

14

22

Root extraction

SP1

COs

CO

Controller 2

SP2

Linearisation

10

20

Scaling

213

4

7

SP

Alarm abs.

PV1

Alarm ratio

Setpoint

limiting

Line of action

Multiplier

11

CO2

Manipulated

variable limiting

29

21

27

Alarm rel.

Continuous

signal

2-point-

12

PWM signal

3-pointPWM signal

3-pointstep signal

3-point-step

signal with

ext. p. a.

8

Aabs

28

Averh

9

Arel

15

16

17

RA

18

19

Controller

output

CO1

Controller 1

Input 2

PV2

23

Filter 2 Root extraction

Line of action

24

Scaling

Manipulated

variable limiting

25

ext.SP

off

Figure 10: Structure for External Set-Point

Description of the functional blocks from Page 122

20 - 1110

ratio

cascade

Feed forward

26

PDT1

Feed forward

control

Page 23

DIGITAL INDUSTRIAL CONTROLLER

5.5 Controller with additional functions for ratio control

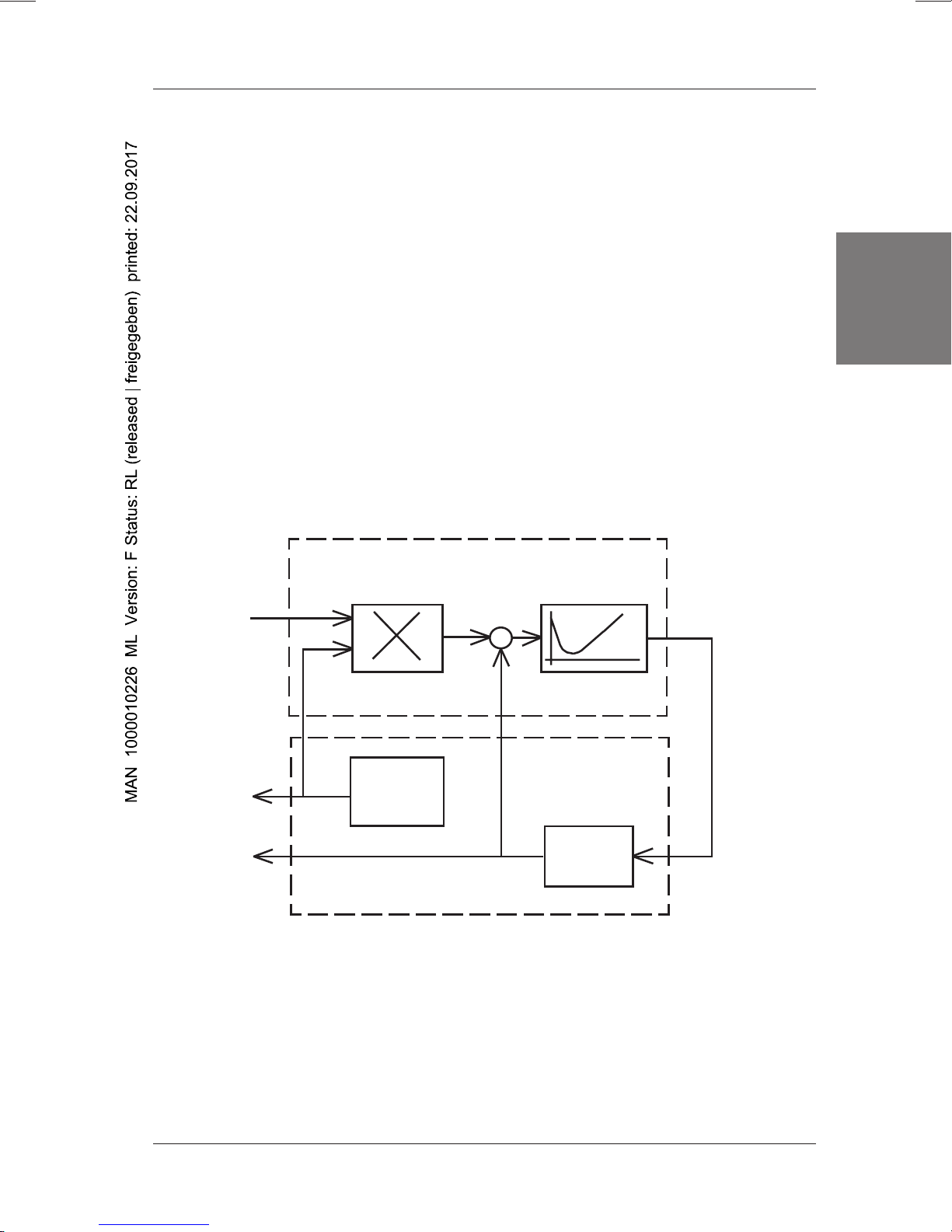

5.5.1 Ratio control

A ratio control is a special type of follow-up control and/or external set-point input.

The task of a ratio control is to cause a controlled variable (PV1) to track another

process variable (PV2) within a specific ratio.

PV1 is described as the dependent variable, and PV2 as the command variable.

In the regulated condition of the ratio control, the following equation applies:

SPr = PV1 / PV2

SPr: ratio set-point

PV1: dependent variable (controlled variable)

PV2: command variable

This gives the internal set-point for the channel X1 that is to be controlled:

PV1set = PV2*SPr

SP = X2*SPr

Controller

Ratio

setpoint

SPr

Command

variable

PV2

Multiplier

Setpoint

SP

Reference

system

PID Controller

PV1

Regulated

variable CO

english

Controlled system

Figure 11: Ratio control

Example:

Let us take mixture control of an acid/alkali flow as an example of a ratio control

system. The internal setpoint SP for the supply of acid (PV1 set) is generated by

multiplying the flow rate of the alkali (command variable PV2) with the ratio setpoint

SPr.

Follow-up

system

1110 - 21

Page 24

DIGITAL INDUSTRIAL CONTROLLER

5.5.2

Ratio controller

Filter 1

PV1

Input 1

english

structure

The

ratio controller

configuring the overall structure. It is based on PID controller 2. PID controller 1 is

not used. Input 1 is used for the control variable PV1 and the process variable PV2

is applied to input 2. SP1 is the ratio setpoint that has to be set.

Root extraction

13

Linearisation

5

SP1

Ramp

6

13

COs

CO

14

Controller 2

structure highlighted in Figure 12 is obtained by appropriately

2

4

Setpoint

limiting

Scaling

7

1110

Line of action

CO2

Multiplier

12

Manipulated

variable limiting

8

Aabs

Alarm abs.

PV1

28

Averh

SP

27

Alarm ratio

Alarm rel.

Continuous

signal

2-pointPWM signal

3-pointPWM signal

3-pointstep signal

9

Arel

15

16

17

18

RA

SP2

22

20

29

21

CO1

Controller 1

Line of action

Manipulated

variable limiting

Input 2

PV2

Filter 2

23

Root extraction

24

Scaling

25

ext.SP

ratio

Figure 12: Ratio controller structure

See Page 25 ff for a description of the function blocks

22 - 1110

cascade

Feed forwardoff

3-point-step

signal with

ext. p. a.

PDT1

Feed forward

control

19

Controller

output

26

Page 25

DIGITAL INDUSTRIAL CONTROLLER

5.6 Controller with additional functions for cascade control

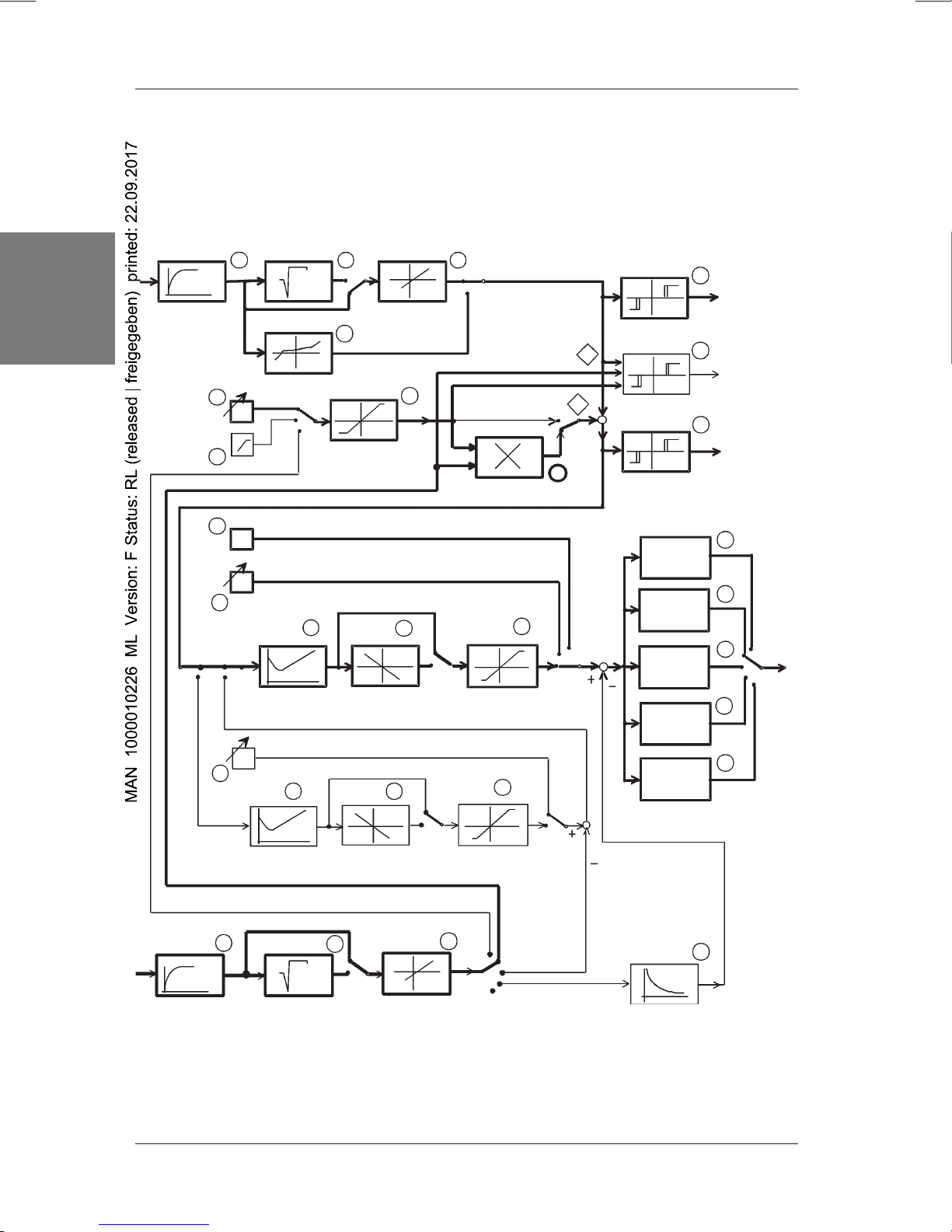

5.6.1 Cascade control

In a cascade control, two control loops are interlinked so that one control loop (the

main control loop) is superimposed on the other (the auxiliary control loop). We

therefore speak of a double control loop (Figure 13).

Z1Z2

CO2

R1

Subsystem 2

Auxiliary control loop

PV2

F

S2

F

R1

Subsystem 1

PV1

Setpoint

generator

SP1

PVd 1

Main controller

CO1

F

R1

Main control loop

PVd2

F

Auxiliary

controller

Figure 13: Cascade control

The controlled system is split into the two subsystems FS1 and FS2. The controlled

variable PV1 is measured on the subsystem FS1 and the auxiliary controlled variable

PV2 is measured on the subsystem FS2.

The auxiliary control loop consists of the auxiliary controller FR2 and the subsystem

FS2. The setpoint for the auxiliary control loop is given by the output variable CO1 of

the main controller FR1, which constitutes the main control loop together with the

auxiliary control loop and the subsystem FS1. The setpoint of the main control loop is

specified as SP1.

A prerequisite for interaction between the two control loops is that the auxiliary

control loop must have a faster time response than the main control loop, i.e. the

essential delays are encountered in the sub-loop FS1. Disturbances Z2 influencing

the subsystem FS2 are balanced out by the faster auxiliary control loop and

disturbances Z1 influencing the subsystem FS1 are balanced out by the main control

loop.

english

Example:

Control of the temperature in a tank heated with hot steam can be mentioned as an

example of a cascade control. A fast auxiliary control loop for control of the

hot steam flow rate is superimposed on the slow temperature control loop with the

main controller FR1.

1110 - 23

Page 26

DIGITAL INDUSTRIAL CONTROLLER

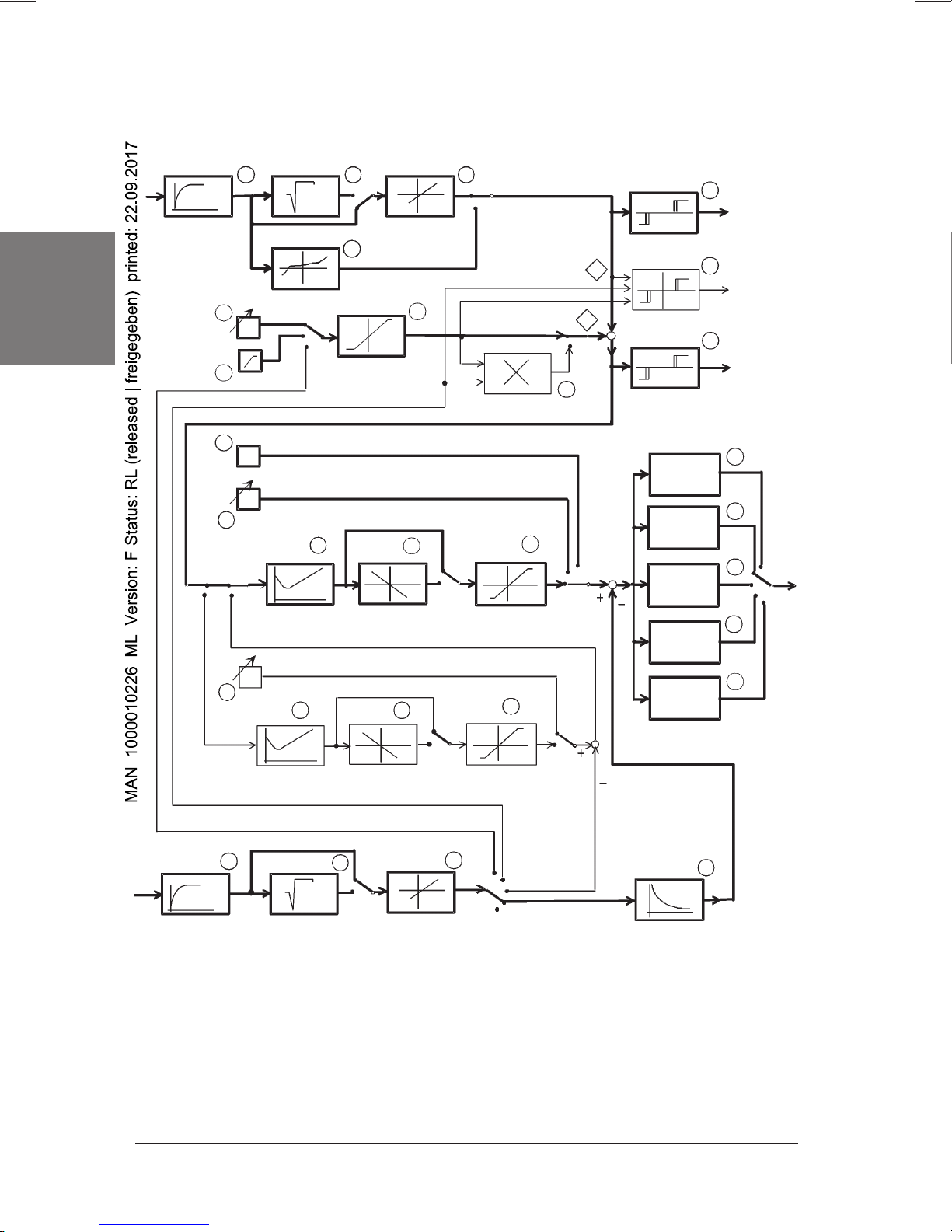

5.6.2

english

Cascade controller

The

cascade controller

appropriately configuring the overall structure.

PID controller 1 is used as the main controller and PID controller 2 as the auxiliary

controller. Input 1 is used for the controlled variable PV1 of the main control loop and

input 2 is used for the auxiliary controlled variable PV2.

SP1 is the setpoint for the main control loop. When the main controller is in AUTO

mode, it specifies the setpoint for the auxiliary control loop. When the main controller

is in MANUAL mode, a setpoint SP2 for the auxiliary control loop can be set on the

keyboard.

structure

structure highlighted in Figure 14 is obtained by

24 - 1110

Page 27

DIGITAL INDUSTRIAL CONTROLLER

PV1

Filter 1

Input 1

5

Ramp

6

13

14

Root extraction Scaling

Linearisation

SP1

213

4

Setpoint

limiting

COs

CO

10

Controller 2

7

11

Line of action

CO2

Multiplier

12

Manipulated

variable limiting

8

Aabs

Alarm abs.

PV1

28

Averh

-

SP

+

27

Alarm ratio

Alarm rel.

Continuous

signal

2-pointPWM signal

3-pointPWM signal

3-pointstep signal

9

Arel

english

15

16

17

RA

18

SP2

22

20

29

21

CO1

Controller 1

Line of action

Manipulated

variable limiting

Input 2

PV2

Filter 2

2423

Root extraction

Scaling

25

ext.SP

off

ratio

cascade

Feed forward

Figure 14: Cascade controller structure

See Page 122 ff for a description of the function blocks.

3-point-step

signal with

ext. p. a.

PDT1

Feed forward

control

19

Controller

output

26

1110 - 25

Page 28

DIGITAL INDUSTRIAL CONTROLLER

5.7 Explanations of the controller structures' function blocks

Functional Block 1: Filter at Input 1

Using the filter, the disturbance signals superimposed on the measured signal can

be damped. The filter is designed as a 1st order low-pass filter.

The limiting frequency of the filter can be set up within the range 0.1 to 20.0 Hz via

the parameters Fg1 (1st input) and Fg2 (2nd input) in Parameter (Filter menu) and

Configure (Input 1 and Input 2 menus).

english

• 0.1 Hz (strong damping, time constant 1.6 seconds)

• 20.0 Hz (weak damping, time constant 0.01 seconds)

ATTENTION!

Adjustable parameters:

Fg1: Limiting frequency (- 3 dB) of the filter at input 1.

Function block 2: Root extraction at input 1

This function serves to extract the square root of the input signal. It is needed

whenever the flow rate is measured as a pressure difference on a nozzle or

diaphragm (effective pressure method).

As, in some cases, the filter constant can have an effect on the

regulation parameters, the settings of the limiting frequency of

the filter should always be carried out before setting the

regulation parameters.

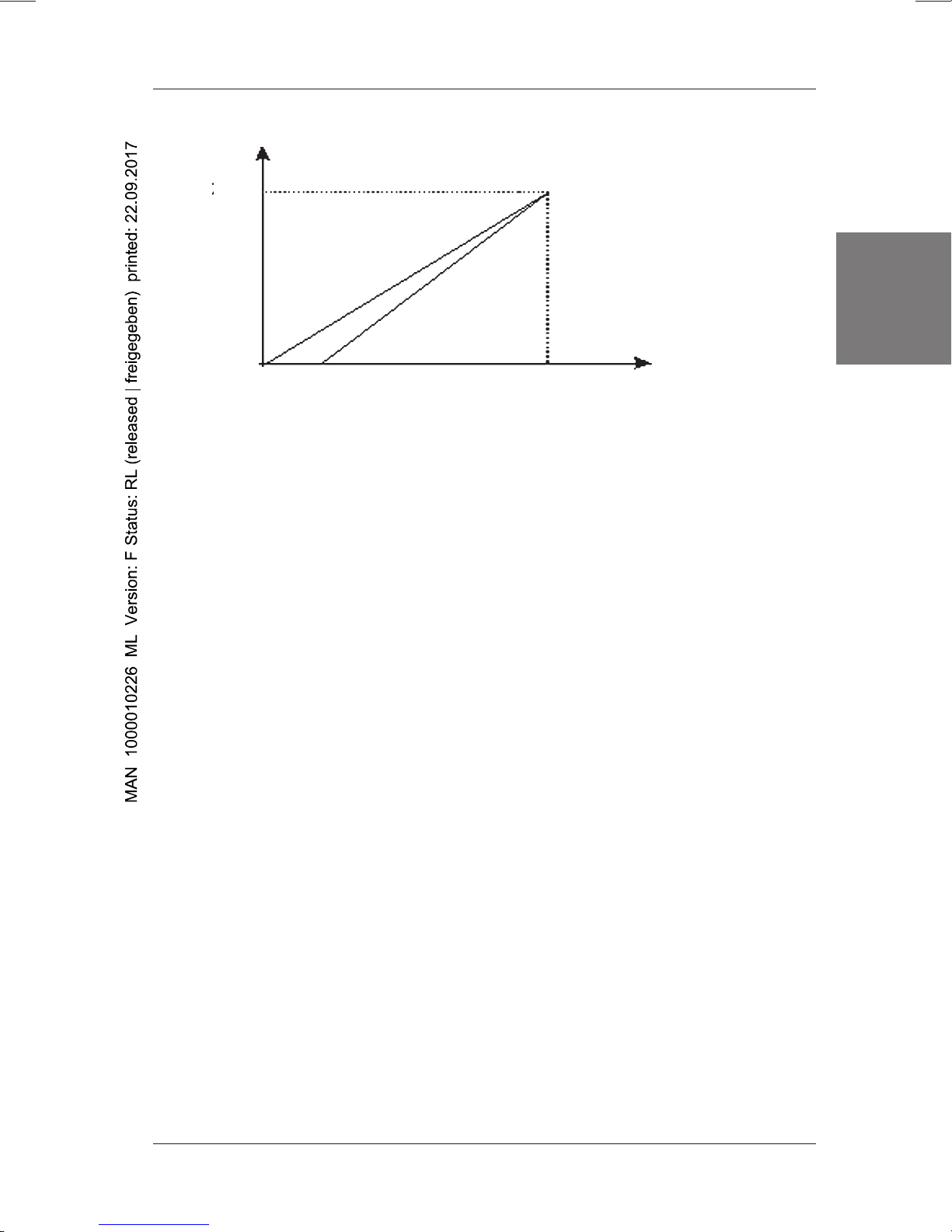

Function block 3: Scaling at input 1

Scaling assigns a numeric value to the measured electrical value that corresponds

to the physical measured quantity (Figure 15).

Adjustable parameters:

PVh: High scaling value, which is assigned to the maximum current,

voltage or frequency value.

PVl: Low scaling value, which is assigned to the minimum current,

voltage or frequency value.

26 - 1110

Page 29

Scaling value

PVh

DIGITAL INDUSTRIAL CONTROLLER

PVl

0

Fmin (0 Hz)

4 mA

20 mA

10 V

Fmax

Standard signal

Frequency-analog signal

Figure 15: Scaling

Function block 4: Linearisation

The characteristics of the various thermocouples and of the Pt 100 are linearised

internally.

Function block 5: Setting the setpoint SP1

Setting the set point using the regulator keyboard

Function block 6: Ramp

english

The set point can be continually increased or decreased using the ramp function.

Options:

Ramp on: Setpoint ramp active. An entered setpoint is initialised by way of the

Ramp off: Setpoint ramp not active.

ramp.

In a cascade control, the setpoint ramp is only available for the main

controller. The ramp is only started when the controller is in

Automatic mode.

1110 - 27

Page 30

DIGITAL INDUSTRIAL CONTROLLER

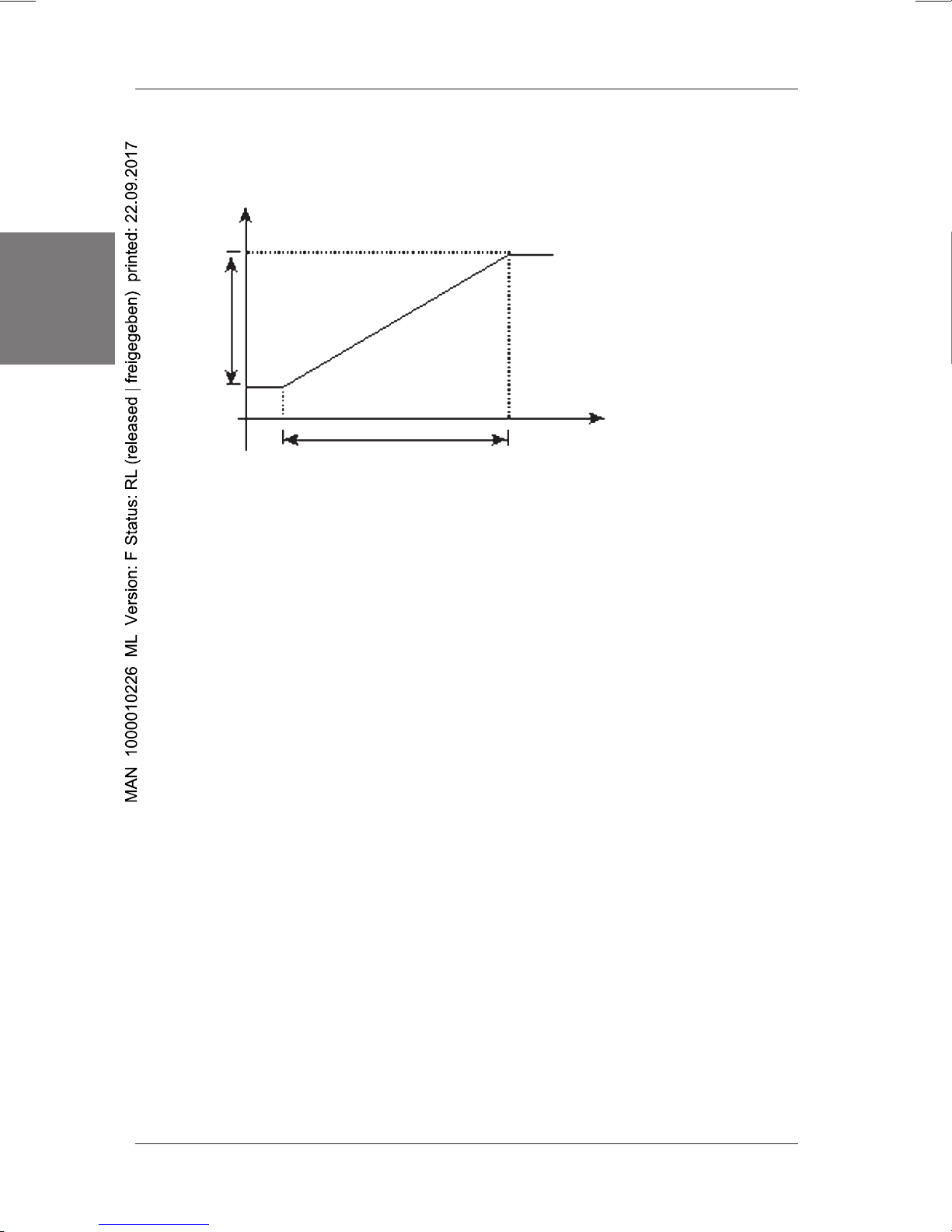

Adjustable parameters:

D: Pitch of the setpoint ramp

SP

english

∆SP

∆t

Figure 16: Ramp function

Function block 7: Setpoint limiting

A low and a high limit can be entered for the setpoint. The setpoint can only be

adjusted within this range.

Adjustable parameters:

SPh: High setpoint limit

SPl: Low setpoint limit

D=∆SP / ∆t

t

Function block 8: Alarm, absolute

With this function, the alarm relay is operated if the controlled variable PV exceeds

an upper limit or falls below a lower limit. The limits can be adjusted within the

scaling range PVl .. PVh, or within the measurement range of the temperature

inputs.

High limit violation: Alarm via relay 3

Low limit violation: Alarm via relay 4

Adjustable parameters:

PV+ : High alarm limit

PV- : Low alarm limit

Hy : Switching hysteresis

28 - 1110

Page 31

DIGITAL INDUSTRIAL CONTROLLER

Function block 9: Alarm, relative

This function actuates the alarm relays when the system deviation exceeds a high

limit or falls below a low limit. In this case, therefore, the limits are referred to the

setpoint (relative). This alarm function is not available when ratio control is

configured.

High limit violation: Alarm via relay 3

Low limit violation: Alarm via relay 4

Adjustable parameters:

PV+ : High alarm limit

PV- : Low alarm limit

Hy : Switching hysteresis

Function block 10: PID controller (2)

This function block is a parameter-definable PID controller that can be used either

as a single controller or as an auxiliary controller within the scope of cascade

control.

english

Adjustable parameters:

Kp: Amplification factor

Tr: Reset time

Td: Derivative action time

CO0: Operating point

Function block 11: Line of action

Here, a function selector can be used to set whether the actuator is to be triggered

with a positive or negative line of action. When a positive line of action is set, the

output signal CO of PID controller 2 increases along with rises in the system

deviation PVd, while it decreases when the line of action is negative.

Options:

Inv. no: positive line of action

Inv. yes:negative line of action

1110 - 29

Page 32

DIGITAL INDUSTRIAL CONTROLLER

Y

CO

Positive line of action

positiver Wirkungssinn

negativer Wirkungssinn

Negative line of action

english

0

xd (Regeldifferenz)

PVd (system deviation)

Figure 17: Line of action with reference to the P controller

Functional block 12: Setting the regulated variables

This function block can be used to define the range within which the controlled

variable CO may vary.

Adjustable parameters:

COh: Maximum value of the controlled variable

COl: Minimum value of the controlled variable

For 3-point PWM signals, the heating / cooling range can be limited separately. If the

variable is at a limit value, the integrator circuit will be active.

Chh: Maximum value of the heating variable (Relay 1)

Chl: Minimum value of the heating variable (Relay 1)

Cch: Maximum value of the cooling variable (Relay 2)

Ccl: Minimum value of the cooling variable (Relay 2)

For a 3-point step output without external feedback, the variable limitation is not

available.

Function block 13: Safety value

Here, you specify the controlled variable that is to be output in the event of a

malfunction occurring or if the binary input is activated (when the „Output safety

value“ function is configured; see Section 6.5.4)

Adjustable parameters:

COs: Safety value of the control variable

30 - 1110

Page 33

DIGITAL INDUSTRIAL CONTROLLER

Function block 14: Manual controlled variable adjustment

This functional block can be activated at the Process Operation level. The manual

variable setting is only possible in the MANUAL operating mode of the unit. The

control element is switched out by the controller, and driven with the last-calculated

set variable. The value can now be changed using the “arrow” keys (See Par. 6.3).

Function block 15: Continuous signal

The controlled variable CO is output as a continuous signal Ra (see Figure 6, for

example). Three standard signals can be selected:

• Standard signal 0...10 V

• Standard signal 0...20 mA

• Standard signal 4...20 mA

Function block 16: 2-point PWM signal

2-point output

english

When using a switching output, such as the 2-point PWM output, the continuous

variable CO, which is calculated by the PID algorithm, must be converted into a

switching signal.

This conversion takes place via a PWM element (PWM: Pulse-Width Modulation).

The relay will be clocked with a changeover period which is proportional to CO. In

this way, a quasi-continuous behaviour is achieved. The period T+ of the PWM

signal must be adapted to the regulated system.

Ra

ton

Relay on

Relay off

0

toff

ton / T+ ~ CO

t

T+

Figure 18: 2-point PWM signal

CO = ton / T+ *100%

ton = CO / 100 % T+

1110 - 31

Page 34

DIGITAL INDUSTRIAL CONTROLLER

Adjustable parameter:

T+: Period of the 2-point PWM signal

Options:

Imp. no: Use of a standard valve.

The 2-point PWM signal is output via relay1

Imp. yes: Use of a pulse valve. 2 relays are used for output in this case.

Relay 1 is energised with the rising edge of the 2-point PWM signal,

english

Function block 17: 3-point PWM signal

3-point Output

while relay 2 is energised with its falling edge. A pulse valve can be

actuated in this way. The valve’s pick-up winding is triggered with

relay 1, while its drop-out winding is triggered with relay 2.

The 3-point PWM output is a combination of two 2-point PWM outputs. One PWM

output controls the output relay 1 (Output relay, heat) dependent on COh, while the

other PWM output controls the output relay 2 (Output, cool) dependent on COk.

Each of the two outputs is subordinated to a PID algorithm within the controller. The

following diagram shows the principle of the controller characteristic for the 3-point

output:

Controlled

100 %

Setpoint SP Actual value PV

variable CO

HeatCool

Characteristic for

P-controller

Figure 19: 3-point output

The Output, Heat period, T+, and the Output, Cool period, T-, can be set separately

of one another.

In addition, the amplification factors for both controllers (heat / cool) can be

separately adjusted. The reset time Tr (I-portion of the controller) and the derivative

action time Td (D-portion of the controller) are the same for both controllers.

32 - 1110

Page 35

DIGITAL INDUSTRIAL CONTROLLER

Overlap area

When using the 3-point PWM Output, the following controller behaviour results in

the area around the set-point, depending on the setting of the overlap area:

Overlap area negative

(Dead range)

Controlled

100 %

Setpoint SP

variable CO

HeatCool

OLP < 0

Characteristic

for P-controller

Actual value PV

Overlap area positive

(overlap)

Figure 20: Overlap area for 3-point PWM signal

Adjustable parameters:

T+: Period for switching relay 1 (heating)

T- : Period for switching relay 2 (cooling)

Olp: Overlap zone (heating and cooling)

100 %

Setpoint SP

OLP > 0

Controlled

variable CO

HeatCool

english

Characteristic

for P-controller

Actual value PV

Funktionsblock 18: 3-Punkt-Schritt-Signal

The 3-point step signal can be used to control motor-driven actuators. In doing so,

TCO is the time needed to move the actuator from one end position to the other.

Adjustable parameters:

Gt: Backlash of the gearbox when shifting from forwards to reverse

Psd: insensitive area (for explanation, refer to Chapter 6.5.4)

TCO: Regulating time (motor running time)

1110 - 33

Page 36

DIGITAL INDUSTRIAL CONTROLLER

Function block 19: 3-point step signal with external position

acknowledgement (Position control)

This signal serves to control motor-driven actuators on which a position

acknowledgement is provided by way of a potentiometer. The resistance value of the

acknowledgement potentiometer must be within the range from 1 kΩ to 10 kΩ.

Adjustable parameters:

Psh: Switching hysteresis

Psd: Insensitivity zone

english

Relay output

SP

PV

Psh

Psd

Figure 21: 3-point step signal

Function block 20: PID controller 1

This function block is a parameter-definable PID controller that is used as a main

controller for cascade control.

Adjustable parameters:

Kp: Proportional action coefficient / Gain

Tr: Reset time

Td: Derivative action time

Pdb: Dead area

CO0: Operating point

34 - 1110

Page 37

DIGITAL INDUSTRIAL CONTROLLER

Function block 21: Manipulated variable limiting

This function block can be used to define the range in which the output variable of

controller 1 may vary.

Adjustable parameters:

COh: Maximum value of the output variable

COl: Minimum value of the output variable

Function block 22: Setting the setpoint SP2

Setting the set-point via the controller keyboard (set-point of the subordinate

controller for cascade regulation).

Function block 23: Filter at input 2

The filter can be used to attenuate interference signals superimposed on the

measured signal. The filter consists of a low pass filter of the first order (see

Functional Block 1).

Adjustable parameters:

Fg2: Limiting frequency (- 3 dB) of the filter at input 2.

Function block 24: Root extraction at input 2

This function serves to extract the root of the measured signal at input 2 (see

Functional Block 2).

english

Function block 25: Scaling at input 2

Function corresponding to function block 3.

Adjustable parameters:

P2h: High scaling value, which is assigned to the maximum current, voltage or

frequency value.

P2l: Low scaling value, which is assigned to the minimum current, voltage or

frequency value:

1110 - 35

Page 38

DIGITAL INDUSTRIAL CONTROLLER

Function block 26: PDT1 element

This function block is the compensator for feed forward control (compare Figure 7).

Adjustable parameters:

Kps: Proportional action coefficient / Gain

Tds: Derivative action time

Ts: Time constant

PV0: Operating point

english

Function block 27: Multiplier

In this function block, the command variable PV1 set for ratio control is generated by

multiplying the process variable PV2 with the ratio setpoint SP1 (cf. Figure 11).

Function block 28: Alarm, ratio

This function serves the purpose of alarming in a ratio control.

In a ratio control, the following alarms are possible as alternatives in addition to an

alarm, absolute, that refers to the controlled variable PV1 (cf. Function block 8):

Alarm, ratio absolute

The alarm relay will be operated if the actual value of the ratio of the regulated variable PV1 to the process variable PV2 exceeds an upper limit or falls below a lower

limit.

Alarm, ratio relative

The alarm relay will be operated if the control system deviation of the ratio exceeds

an upper limit or falls below a lower limit.

In this case, the limit value for an alarm message are therefore related to the ratio

set-point (relative).

Adjustable parameters:

PV+: Upper limit for alarm message (Actual value of Input 1)

PV-: Lower limit for alarm message (Actual value of Input 1)

Pr+: Upper limit for alarm message (Actual value of ratio)

Pr-: Lower limit for alarm message (Actual value of ratio)

Hy: Switching hysterisis

36 - 1110

Page 39

DIGITAL INDUSTRIAL CONTROLLER

Functional Block 29: Direction of action

Here, the structure switches can be set to determine whether the output signal CO1

of PID controller1 (main controller of the cascade regulation) will be used with a

positive or negative direction of action. With a positive direction of action, the output

signal increases with increasing control difference PVd1, with negative direction of

action, it reduces (cf. Functional Block 11).

Options:

Inv. No: positive direction of action

Inv. Yes: negative direction of action

english

1110 - 37

Page 40

DIGITAL INDUSTRIAL CONTROLLER

6 OPERATION

6.1 Operating levels

The controller has two operating modes, MANUAL and AUTOMATIC.

It can be operated either in MANUAL or in AUTOMATIC mode. Operation is broken

down into 3 levels:

• Configuration

In the configuration level, concrete controller structures can be selected and the

english

inputs and outputs can be adapted to connected sensors and actuators.

All parameter definition data can also be entered.

During the course of configuration, the controller is always in MANUAL mode. Once

configuration is completed, the controller assumes the operating mode it was in

before configuration.

• Parameter definition

At the Parametrisation level, the regulator parameters can be entered on the basis

of the selected regulator structure.

No settings can be made that change the regulator structure and/or the input and

output types.

When you switch to the parameter definition level, the controller retains its original

operating mode.

If no key is pressed for 30 sec., parameter definition mode is terminated. All inputs

made up to that time are saved.

• Process operation

The setpoint and value of the controlled variable and the manipulated variable can

be displayed in the process operation level.

The setpoint can be set both in MANUAL and also in AUTOMATIC mode. In the

AUTO operational mode, a self-optimisation process can be initiated by setting the

set-point (for more information, refer to Chapter 7).

The manipulated variable, however, can only be altered in MANUAL mode.

When the controller is switched on, you are first of all in the

From here, you can then switch over to the

levels (see Sections 6.3, 6.5 and 6.6). After switch-on, the unit takes up the

operational mode that it had before being last switched off.

Every operator control level can be protected against unauthorised access by

means of a four-digit

allow hierarchically arranged protection. Entering the code number for the

configuration

parameter definition

levels.

level allows users to use all three levels. The code number for

code number

allows access to the

. Code numbers can be chosen freely. They then

configuration

parameter definition

process operation

or

parameter definition

and

process operation

level.

38 - 1110

Page 41

DIGITAL INDUSTRIAL CONTROLLER

The code number for process operation only allows to carry out operations in the

process operation level. Regardless of any code numbers already entered, access

to all three levels is obtained with the permanently programmed master code, which

should be reserved for selected persons (cf. Section 1).

6.2 Operator controls and indicators

Figure 22 shows the front of the controller.

Display of the manipulated variable of a 3-point controller

H = Heating

C = Cooling

Value of the process variables CO, PV, SP, or F

english

Display of:

Manipulated variable CO

Actual value (PV)

Set-point (SP)

Flow rate (F)

Internal set-point (I)

External set-point (E)

For cascade:

Main controller (1)

Auxiliary controller (2)

displayed

Change numeric value

for each position

Increase manipulated value

Set decimal point position

Select position

Reduce manipulated value

The decimal point position is

valid for several parameters

(see explanation of

parameters). You must

therefore always set the

decimal point in good time.

Y 099H

ALARM

I

0.....9

SELECT

ENTER

➨

Cancel a set numeric value

Selection within the menu

Cascade controller

Changeover of display from

main to auxiliary controller

Proceed to next menu point

Confirm entry

➤

➤

DISPLAY

1110

Output relay 1 “Heat”

Output relay 2 “Cool"

Top alarm relay

Buttom alarm relay

Bar graph (system deviation)

or actual value

Inscription field

LED: AUTOMATIC

Changeover:

MANUAL / AUTOMATIC

Display of:

Manipulated variable CO

Actual value PV

Set-point SP

Flow rate F

(actual value of

Input PV1 for ratio control)

Figure 22: Operator controls and indicators of the controller

There are 6 operator controls (keys) in the bottom half of the front panel. The

meanings of these operator controls depend on the operator control level (see

Sections 6.3, 6.5 and 6.6).

There is an LCD plain language display with 2 lines of 8 characters each in the top

half. The display that appears there also depends on the operator control level in

which you are currently working. The display shown in Figure 22 refers to the

process operation

Press SELECT and ENTER keys for 5 sec: Changeover to Configuration

Press SELECT key for 5 sec: Changeover to Parametrisation

level.

1110 - 39

Page 42

DIGITAL INDUSTRIAL CONTROLLER

➨

1110

6.3 Process operation

In the process operation level, the 6 operator controls have the meanings shown in

Figure 23.

english

Operator control

➤

➤

MANUAL/AUTO key

DISPLAY

DISPLAY key

SELECT

SELECT key

ENTER

Meaning

Switching over the MANUAL and AUTOMATIC modes.

The AUTOMATIC mode is indicated by an LED in the operator

control.

Switch-over to the next process variable

SP: Set-point

PV: Actual value of controlled variable PV1 (or of the Ratio)

CO: Manipulated variable

(Ch and Cc for 3-point PWM signals)

F: Flow rate (actual value of the Input PV1 for ratio control)

• Switching over to the parameter definition level by pressing

the key for more than 5 seconds

• Switching over to the configuration mode by simultaneously

pressing this key and the SELECT key for more than 5 seconds

• Confirm set value

Figure 23: Meanings of operator controls in the process operation level

40 - 1110

ENTER key

0.....9

„Down arrow“ key

0.....9

„Up arrow“ key

• Digit selection when setting numeric values

• Reducing the value of the manipulated variable (in MANUAL

mode), i.e. reducing the voltage or current (in the case of

standard signals) or the pulse width in the case of PWM signals

• Relay 2 on (motor „Reverse“) in the case of 3-step signals

without external feedback

• Modifying a numeric value

• Increasing the value of the manipulated variable (in MANUAL

mode), i.e. increasing the voltage or current (in the case of

standard signals) or the pulse width in the case of PWM

signals

• Relay 1 on (motor „Forwards“) in the case of 3-point step

signals without external feedback

Page 43

DIGITAL INDUSTRIAL CONTROLLER

1110

1110

1110

1110

In the form of a flow chart, Figure 24 shows the meanings of the operator controls in

the

process operation

i.e. MANUAL or AUTOMATIC. Switching to the next process value by pressing the

DISPLAY key and setting the setpoint by pressing the „Up arrow“ and „Down arrow“

keys are possible both in MANUAL and AUTOMATIC mode. The manipulated variable can only be modified in MANUAL mode.

level. It is assumed that the controller is in one of the modes,

ENTER

SELECT

ENTER

DISPLAY

DISPLAY

english

SELECT

ENTER

SELECT

ENTER

ENTER

ENTER

SELECT

ENTER

➤

DISPLAY

0.....9 0.....9

➤

0.....9 0.....9

DISPLAY

➨

0.....9 0.....9

ENTER

➨

➨

➨

0.....9

0.....9

Figure 24: Flow chart of the process operation level

1110 - 41

Page 44

DIGITAL INDUSTRIAL CONTROLLER

1110

1110

6.4 Setting numeric values

Numeric values have to be set when setting a setpoint in the process operation

level, but also when defining parameters and when configuring. This can be done by

means of the „Up arrow“ and „Down arrow“ keys. Figure 25 shows the principle of

setting numeric values with reference to a controller’s reset time Tr.

Pressing the “Arrow down” key will switch one position to the left each time, starting

with the lowest position (Position selection). The position will blink to indicate that it

is selected. By pressing the ,Up arrow“ key, the value in the flashing position can be

altered from 0 to 9 (highest position from -1 to 9). The value set is saved by pressing

english

the ENTER key. If the SELECT key is pressed after entering a numeric value, the

value is cancelled and the original numeric again appears in the display.

You can move the decimal point by one position to the left by pressing the ,Up

arrow“ and ,Down arrow“ keys at the same time. Not all numeric values allow you to

move the decimal point, however.

The parameters can now be set within the pre-defined setting ranges (cf., Par.

6.5.4). If a value is entered which is outside the permitted range, it will be set to the

limit value that would have been exceeded when confirmed by the ENTER key.

1110

➤

➤

DISPLAY

0.....9

SELECT

ENTER

➨

Figure 25: Setting the number values.

Con t

Tr

0

.

.

.

9

-1

rol 1

0

.

.

.

9

0.....9

0.....9

modifying

numeric value

➨

digit selection

0.....9

➨

0.....9

moving

position of

decimal

point

42 - 1110

Page 45

DIGITAL INDUSTRIAL CONTROLLER

1110

6.5 Configuration

6.5.1 Operation during configuration

To switch to the

configuration

level, the SELECT and ENTER keys must be pressed

simultaneously for 5 seconds. During configuration, the controller is in the MANUAL

mode (cf. Figure 24).

The main menu appears in the LCD display panel when you enter the

configuration

level. To exit this level again, you must select the END option in the main menu with

the SELECT key and then press ENTER. The controller then returns to the operating mode it was in before configuration. All settings made during the configuration

will become effective immediately after the Configuration level is quit, and will be

stored in an EEPROM, where they will be unchanged by a loss of voltage.

In the

configuration

Operator control

SELECT

SELECT key

level, operator controls have the meanings shown in Figure 26.

Meaning

• Switching to the next option within a menu

english

• Confirming the menu option concerned and switching to the

ENTER

ENTER key

➨

0.....9

„Down arrow“ key

0.....9

„Up arrow“ key

affiliated sub-menu

• Confirming set numeric values of controller parameters

• Switching to the next parameter

• Position selection when setting a numeric value

• Setting a numeric value

Figure 26: Meanings of operator controls in the configuration level

1110 - 43

Page 46

DIGITAL INDUSTRIAL CONTROLLER

6.5.2 Main menu of the configuration level

In total, the main menu of the configuration level embraces the following options:

Structure: ` Definition of the controller structure

` For cascade control

- Definition of the set-point limits of the main controller

` For ratio control

- Definition of the display range for the ratio value

- Setting the set-value limits

english

Input 1: • Defining the input signal type

- Defining the alarm mode

- Defining the alarm limits for the ratio value

• Decision to include the root function

• Scaling definitions

• Definition of alarm mode and alarm limits

• Dimensioning the input filter

• Setting the setpoint limits

Input 2: • Defining the input signal type

• Decision to include the root function

• Scaling definitions

• Dimensioning the input filter

• In the case of feed forward control: Setting the parameters of the

PDT1 element (function block 26 in Figure 8)

Controller: • Setting controller parameters

Output: • Defining the output signal type

Safety: • Setting the safety value for the manipulated variable.

This manipulated variable is output in the event of an internal

error, an error at the controller input or when the binary input is

active (function: safety).

Adaption: • Selection of various adaption algorithms

Options: • Selection of the language

` Binary input affiliation

` Binary output affiliation

` Setting the ramp

` Defining the set-point tracking

(jolt-free switchover from MANUAL to AUTO)

` Selection of the display layout in row 2

` Input of a security code

When configuring, a specific controller structure must always be defined first using

the Structure menu. The other menus then relate to the selected menu structure.

44 - 1110

Page 47

DIGITAL INDUSTRIAL CONTROLLER

Sub-menu of the main menu option

Standard

External W:

Ratio:

Feed forward:

Cascade

: Standard controller for single control loops;

the 2nd controller input is not used.

Follow-up control with an external setpoint (command variable);

the 2nd controller input is used for external setpoint input.

Ratio control;

the 2nd controller input is used for the process variable PV2.

Fixed setpoint control with feed forward control;

the 2nd controller input is used for feed forward control.

: Cascade control;

the 2nd controller input is used for cascade control.

Structure

english

1110 - 45

Page 48

DIGITAL INDUSTRIAL CONTROLLER

6.5.3 Configuration menus

Figures 28 to 32 show the configuration menus for the 5 possible control structures

in the form of flow charts. These flow charts contain selection blocks and

specification blocks.

Selection blocks:

Here, you can make a selection from a number of possibilities (options). The

individual possibilities are each listed adjacently in a selection block (vertical

lettering). Select an option by pressing the SELECT key. In the selection blocks, this

is indicated by a horizontal arrow. You can confirm an option and switch to the next

block by pressing the ENTER key. This is indicated by vertical arrows next to the

english

connecting lines between the blocks.

Specification blocks:

Here, numeric values must be defined for parameters. The individual parameters in

a specification block are listed one below the other. The numeric values are set with

the „Up arrow“ and „Down arrow“ keys (see Section 6.4). You can confirm set

numeric values and switch to the next parameter by pressing the ENTER key. In the

specification blocks, this is represented by a vertical arrow (see Figure 27). Before

confirming and switching further by pressing the ENTER key, you can cancel a set

value by pressing the SELECT key (cf. Section 6.4).

Key to pressDisplayed arrow

→

↓

Figure 27: Meanings of the arrow in the configuration menu

The informations and symbols contained in the following configuration menus are

explained in section 6.5.4.

SELECT

ENTER

46 - 1110

Page 49

DIGITAL INDUSTRIAL CONTROLLER

english

Figure 28a: Configuration menu for the standard controller structure (Part 1)

SELECT

ENTER

1110 - 47

Page 50

DIGITAL INDUSTRIAL CONTROLLER

StruMenu

Input 1

Controller

Output signal type

Output

Safety

Adap Contr.

Add Menu

End

english

Contin.

Signal type

4-20 mA

0-10 V

0-20 mA

Manipulated

variable limiting

COh:

COl::

Line of action

Inv: no

Inv: yes

Position

Intensitivity

Psd:

Switching

hysteresis

Psh:

Manipulated

variable limiting

COh:

COl::

2-point

Period

T+ :

Manipulated

variable limiting

COh:

COl:

Line of action

Inv: no

Inv: yes

3-point

Period

T+ :

:

T-

Overlap

zone

Olp:

Manipulated

variable limiting

:

Chh

:

Chl

:

Cch

:

Ccl

3-pt step

Backlash

of gearbox

Gt:

Motor

run time

TCO:

Insensitivity

Psd:

Figure 28b: Configuration menu for the standard controller structure (Part 2)

48 - 1110

Pulse

output

Imp: no

Imp: yes

SELECT

SELECT

ENTER

ENTER

Page 51

DIGITAL INDUSTRIAL CONTROLLER

SELECT

ENTER

english

Deutsch

English

Francais

Figure 28c: Configuration menu for the standard controller structure (Part 3)

NOTE The menu point

Serial

only appears if an interface card is plugged

in (Option). For explanation, refer to the Operating Instructions of

the Interface Card.

1110 - 49

Page 52

DIGITAL INDUSTRIAL CONTROLLER

english

Figure 29: Configuration menu for the

(See Figures 28b and 28c for details of the

options)

50 - 1110

external setpoint

Output, Safety value

structure

and

Options

SELECT

ENTER

menu

Page 53

DIGITAL INDUSTRIAL CONTROLLER

english

Figure 30: Configuration menu for the

(see Figures 28b and 28c for details of the

options)

ratio contro

l structure

Output, Safety value

and

Options

1110 - 51

SELECT

ENTER

menu

Page 54

DIGITAL INDUSTRIAL CONTROLLER

english

Figure 31: Configuration menu for the

(See Figures 28b and 28c for details of the

and

Options

menu options)

52 - 1110

feed forward control

structure

Output, Safety value, Adaption

SELECT

ENTER

Page 55

DIGITAL INDUSTRIAL CONTROLLER

english

Figure 32: Configuration menu for the

(See Figures 28b and 28c for details of the

options)

cascade control

Output, Safety value

structure

SELECT

ENTER

and

Options

1110 - 53

menu

Page 56

DIGITAL INDUSTRIAL CONTROLLER

6.5.4 Meanings of the symbols in the configuration menus

Sub-menus to the Structure main menu

Ratio control

Scaling

Prh:

english

Prl:

Alarm mode

Al: abs

Al: rel

Upper scaling value for the actual value of the ratio of control to

process variable. When setting Prh, a decimal point position is

defined, which will then be also valid for Prl, Pr+, Pr-, Srh and Srl.

In addition, the ratio value will be displayed with this decimal point

position. The display range for the ratio value will be set up here. If the

ratio value is outside this range, the area limit (Prh, Prl) that has

been exceeded will be displayed. The set-point and alarm limits can

be set up within this range. The alarm hysterisis also refers to this

range.

Setting range: 0000 ≤ Prh ≤ 9999

Low scaling value for the ratio

Adjustment range: 0000 ≤ Prl ≤ Prh

Absolute alarm; the programmed alarm has a fixed