Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

Type 1094 Standard

Electronic Controller for Vapor Recovery

Elektronische Steuerung für Gasrückführung

Régulateur èlectronique pour la récupération des

vapeurs d’essence

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2004 Bürkert Werke GmbH & Co. KG

Operating Instructions 0507/01_EU-ML_00804775

Page 3

Electronic Control for Vapour Recovery Type 1094 Standard

1 GENERAL INFORMATION ........................................................................................................................... 3

1.1 Symbol used .................................................................................................................................3

1.2 Safety instructions .......................................................................................................................3

1.3 Correct usage ................................................................................................................................3

1.4 Protection against damage through electrostatic charge ..................................................4

1.5 Scope of delivery .........................................................................................................................4

1.6 Guarantee provisions ..................................................................................................................4

2 SYSTEM DESCRIPTION ...............................................................................................................................5

2.1 General description of the area of use ....................................................................................5

2.2 Method of operation of the controller .......................................................................................5

2.3 Principle of operation of a petrol pump with vapour recovery ............................................6

3 TECHNICAL DESCRIPTION .........................................................................................................................7

3.1 General technical data .................................................................................................................7

3.2 Electrical data ................................................................................................................................7

3.3 Inputs ...............................................................................................................................................7

3.4 Outputs ...........................................................................................................................................8

english

4 COMMISSIONING AND INSTALLATION ............................................................................................ 9

4.1 Additional important documentation .........................................................................................9

4.2 Electrical connections ..................................................................................................................9

5 OPERATION AND FUNCTION ..................................................................................................................11

5.1 Display elements ........................................................................................................................ 11

5.2 Setting and operation of the controller ................................................................................. 11

5.3 Calibration of the controller ..................................................................................................... 11

5.4 Puls rate and frequency input ................................................................................................. 11

5.5 K-factor for the suction rate ..................................................................................................... 12

5.6 Pump after-run time ................................................................................................................... 12

5.7 Petrol pump operation .............................................................................................................. 12

1094 - 1

Page 4

6 MAINTENANCE AND TROUBLE-SHOOTING ...................................................................................12

6.1 Maintenance ................................................................................................................................ 12

6.2 Faults ........................................................................................................................................... 12

english

2 - 1094

Page 5

1 GENERAL INFORMATION

1.1 Symbol used

The following symbols are used in these operation instructions:

marks a working step that you must carry out.

ATTENTION!

NOTE

Indicates information that must be followed. Failure to do this could

endanger your health or the functionality of the device

Indicates important additional information, tips and recommendations.

1.2 Safety instructions

To ensure that the device functions correctly and will have a long service life, please

comply with the information in these operating instructions as well as the operating

conditions and the permissible ranges that are specified in the data sheet.

• When planning the application and the operation of the device, observe the general technical rules!

• The device may not be used in areas endangered by explosion with the characteristics of Zones 0 or 1.

• Take suitable measures to exclude any unintentional operation or impermissible

impairment!

• Installation and maintenance work may only be carried out by specialists and with

suitable tools!

• Observe the valid regulations for the prevention of accidents and for the safety of

electrical devices during the operation and maintenance of the device!

• Always switch of the electrical power before carrying out any work on the system!

• Only use the device in its original configuration!

• If these instructions are ignored or if impermissible interventions are made to the

device, no liability will be accepted from our side, and the guarantee on the device

and its accessories will also become invalid!

english

1.3 Correct usage

This device is only intended for the electronic control of a proportional valve for vapour recovery on fuel pumps. Any other use, or any use going beyond this will be considered to be improper usage. Bürkert will thereby accept no liability for any resulting

damage. The risk will be borne by the user alone.

1094 - 3

Page 6

1.4 Protection against damage through electrostatic charge

The device contains electronic components that are react sensitively to electrostatic discharge (ESD). Contact with electrostatically charged persons or objects will endanger these components. In the worst case, they will be immediately destroyed or

will fail after commissioning.

Observe the requirements according to EN 100 015 - 1 in order

to minimise or avoid the possibility of damage through sudden

electrostatic discharge. You should also ensure that the electronic components do not come into contact with nearby supply

voltages.

english

CAUTION WHEN

HANDLING!

ELECTROSTATI-

CALLY SENSITIVE

COMPONENTS /

MODULES

1.5 Scope of delivery

Immediately after receipt of the consignment, ensure that the contents have not been

damaged, and that they agree with the scope of delivery quoted on the enclosed

packaging slip.

In case of a discrepancy, please contact our Customer Service immediately:

Bürkert Steuer- und Regelungstechnik

or your local Bürkert distribution centre.

Kundencenter

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

Fax: 07940-10448

E-mail: info@de.buerkert.com

1.6 Guarantee provisions

This document contains no agreement to provide a guarantee. We would refer you

here to our General Selling and Business Conditions. The precondition for the guarantee is the correct usage of the device under compliance with the specified application conditions.

ATTENTION!

4 - 1094

The guarantee only applies to the freedom of the Type 1094

Standard electronic controller and its components from faults. No

liability will be accepted, however, for consequential damage of

any kind that could arise from the failure or malfunctioning of the

device.

Page 7

2 SYSTEM DESCRIPTION

2.1 General description ot the area of use

When refuelling a vehicle, the petrol flowing into the fuel tank displaces an equal

volume of petrol vapour out of the tank. In order to prevent this petrol vapour from

escaping into the atmosphere, it must be sucked away.

In the solution offered by Bürkert, this suction process takes place by means of

underpressure via a proportional valve mounted in front of the reservoir tank of the

fuel pump. A suction pump transports the petrol vapour out of the vehicle tank and

presses it into the reservoir tank of the petrol pump.

To avoid excessive pressure in the reservoir tank, the volumetric pressure between the

petrol being delivered and the returned petrol vapour must be balanced.

The amount of petrol filled into the vehicle tank is measured using a calibrated piston

meter in the petrol pump, is converted into pulsed signals by the petrol pump computer and is reported to the controller.

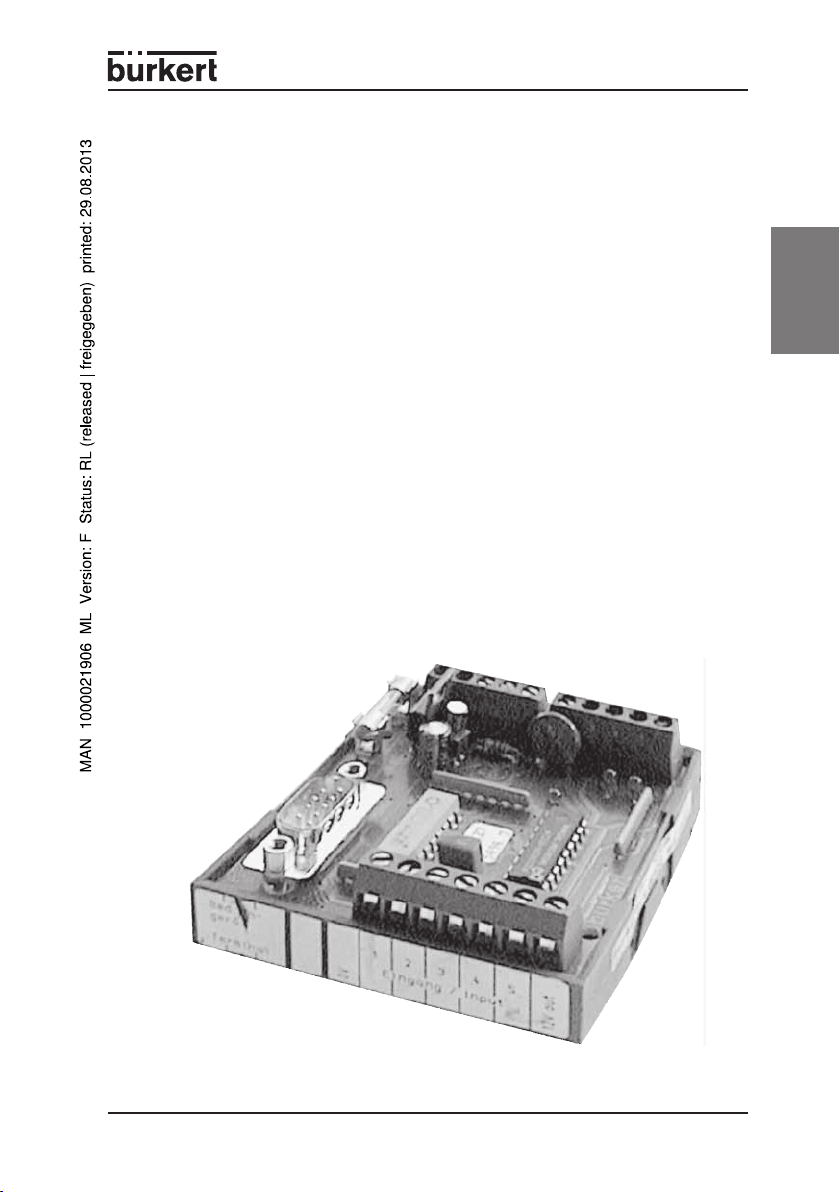

2.2 Method of operation of the controller

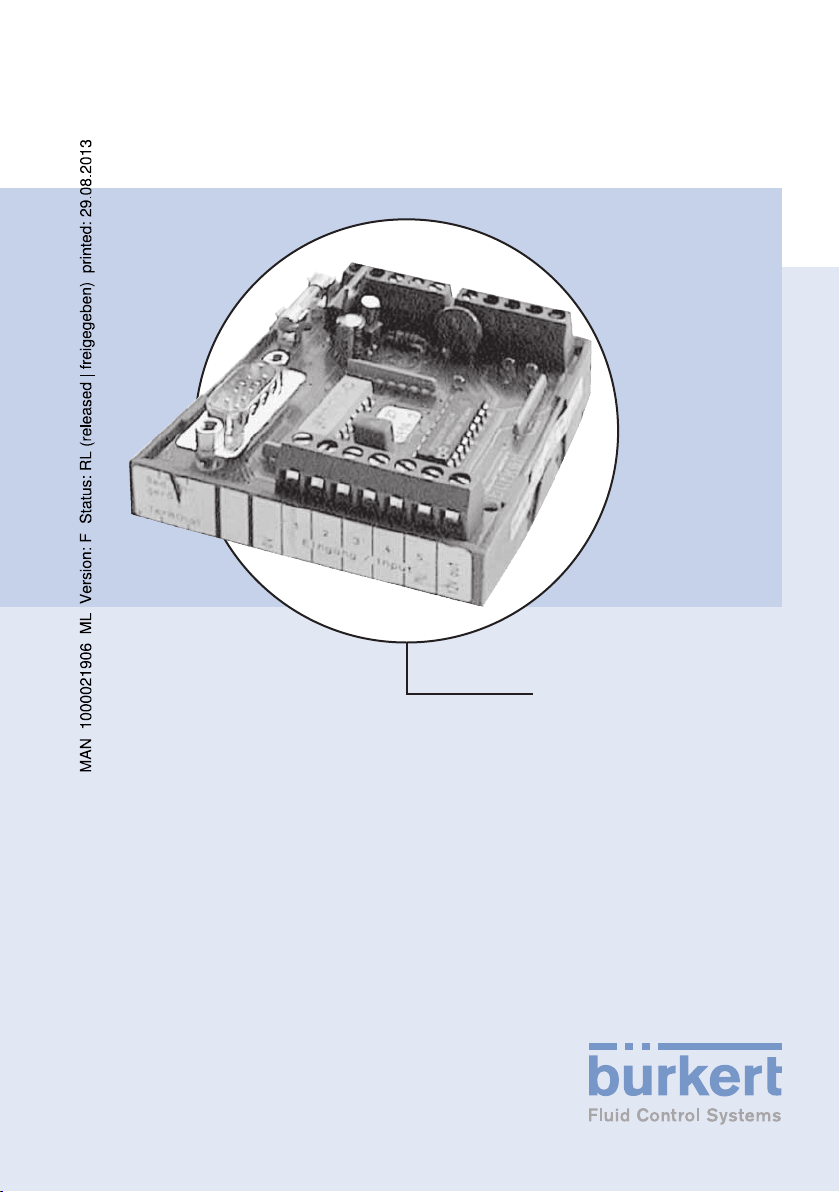

The controller shown on Figure 1 evaluates the pulsed signals from the petrol pump

computer and, by means of electrical PWM control signals, controls the area of flow

of a control valve (explosion-protected proportional valve of Type 2832) and thereby

the flow rate of the returned petrol vapour.

english

Figure 1: Electronic controller Type 1094 Standard

1094 - 5

Page 8

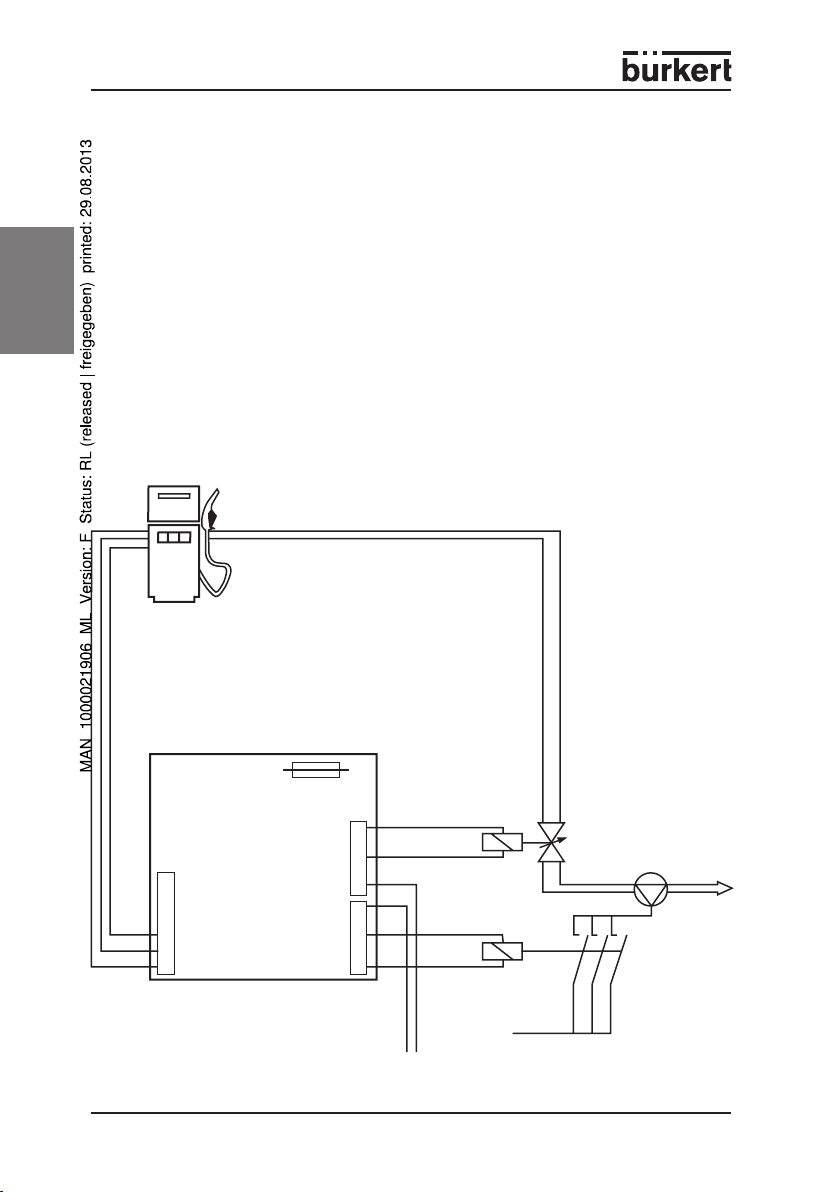

2.3 Principle of operation of a petrol pump with vapour recovery

The valve flow - gas flow characteristic of a pump installation is originally non-linear. In

order to ensure an even suction over the complete control range, a linear characteristic is needed. To do this, various points on the characteristic are automatically stored

in the controller memory when dimensioning the installation with the control unit. The

number of points depends on the characteristic, and will be automatically determined

by the control unit. The correction of the characteristic also takes place automatically

through linear interpolation between these points.

At the start of the refuelling process, the quantity of petrol tanked will be calculated in

the controller from the measured pulse rate. Taking the linearised characteristic and

english

the K-factor of the suction rate into account, the set-value for the valve flow can now

be determined, and the proportional valve can be controlled for the suction of the

petrol vapour. Together with the control of the proportional valve, the vacuum pump

will also be put into operation to generate an underpressure. At the end of the refuelling procedure, the petrol pump computer no longer generates any pulses and the

proportional valve for the vapour recovery will be closed. The vacuum pump will also

be switched off with an after-run time delay.

Suction line

one or more pulse generator

lines from the pulse generator/

petrol pump computer

Proportional

valve

Control electronics

24 V DC

power supply

(Type 1610)

Figure 2: Functional diagram for a petrol pump with vapour recovery

6 - 1094

(Type 2332)

24 V DC contactor/

relay for switching the

pump motor

Power supply for the vacuum pump

Vacuum pump

To the

ground

tank

Page 9

3 TECHNICAL DESCRIPTION

3.1 General technical data

Ambient temperature -25 °C ... +85 °C

Dimensions 68 x 76 x 35 mm

Housing Open housing for mounting on mounting rails according

Protection class IP 20

Order No. 060 651

3.2 Electrical data

Supply voltage

Voltage level 24 V DC ± 10 %

Ripple < 5 %

Current comsumption < 30 mA (without valve current)

3.3 Inputs

Frequency input of the controller

High level impulse 2.5 V ... 25 V

Low level impulse -1.0 V ... +1.0 V

Input impedance

Max. input current 5 mA

Min. pulse width 400 µs

Rate of measurement 1 measurement/sec

Resolution 1 Hz

Measurement range 0 ... 51 l/min

to DIN EN 50 022 / DIN EN 50 035 / DIN EN 50 045

< 300 mA (with valve current)

Ω

> 10 k

english

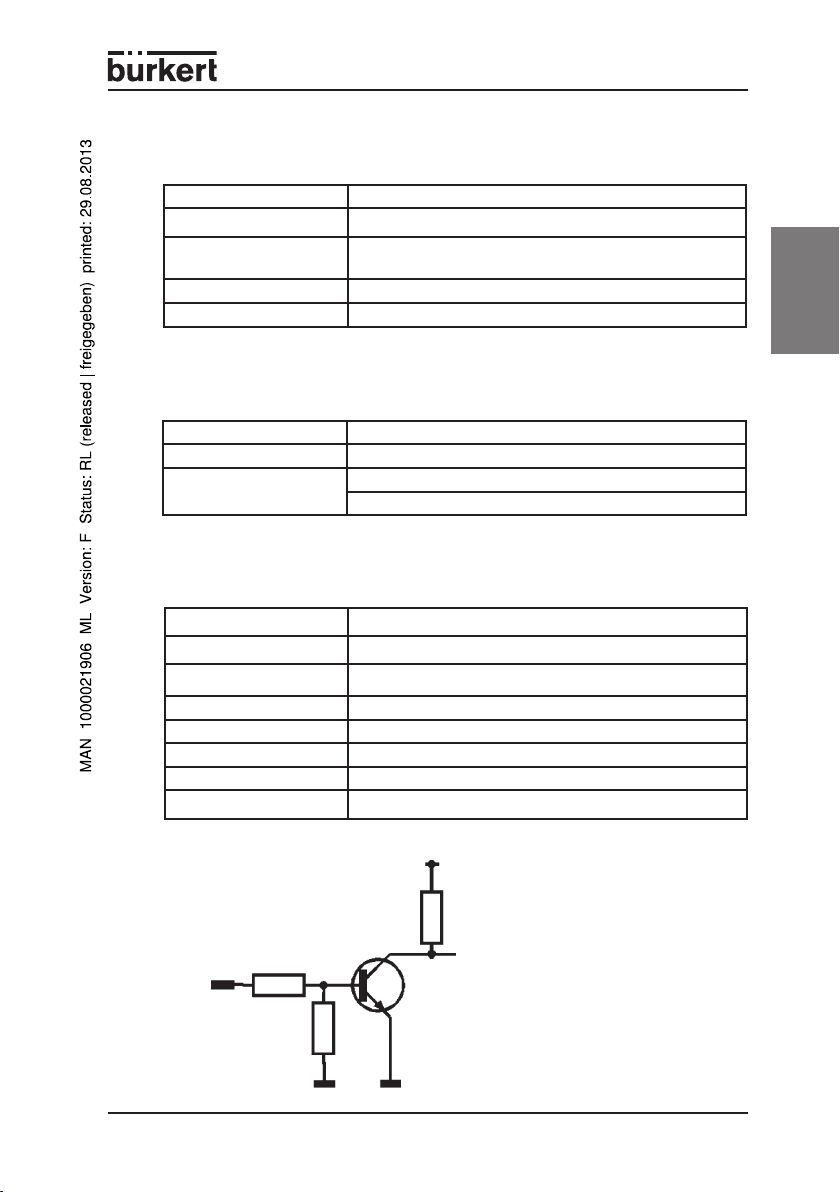

Input 1

Figure 3.

Frequency input of

the controller

VDD

to the

CPU

The volumetric flow of the

tanked petrol is measured by

the piston meter, is converted

into a frequency-proportional

pulsed signal by the petrol pump

computer and is sent to the

frequency input of the controller

(Figure 3).

In the controller, this pulsed signal will be processed to obtain

the actual value of the volumetric

flow of the petrol.

1094 - 7

Page 10

3.4 Outputs

english

Output for the proportional valve

Output transistor Positiv-switching transistor

Load current 0 to 250 mA

Output voltage 24 V DC

Clock frequency 270 Hz

Number of outputs One valve output each for + and -

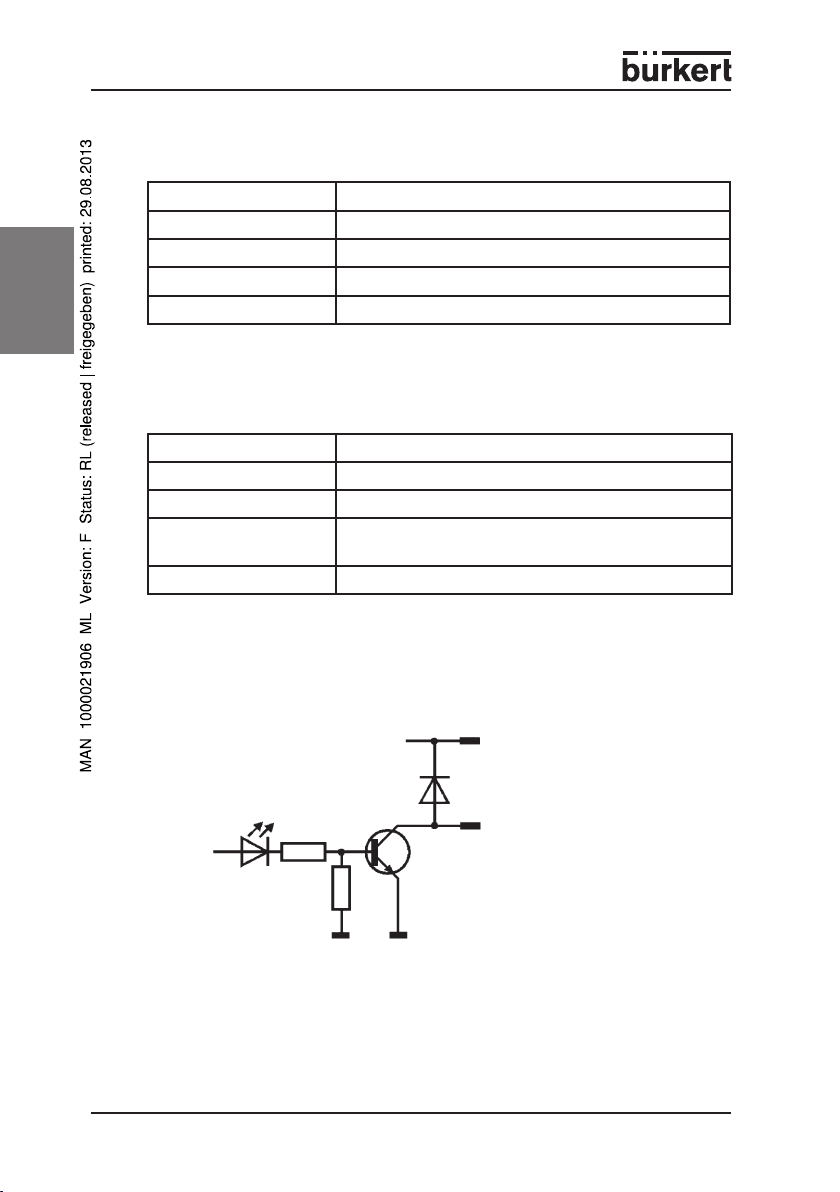

To regulate the Type 2832 proportional vlave, the controller outputs a current-regulated PWM signal via a transistor.

Output for the control of the vaccum pump motor

Output transistor „Open-Collector“ transistor output

Load current 100 mA

Output voltage 24 V DC

Special freatures Freewheeling diode, after-run time adjustable (in con-

nection with the manual control unit Type MKNE-1094)

Number of outputs One pump output each for + (24 V) and – (GND)

The „open-collector“ output shown in Figure 4 is used for the control of a relay/contactor for switching the vacuum pump motor.

The „open-collector“ output is switched active by the controller as long as the proportional valve is open.

2.2 k

10 k

Ω

BC 337 or similar

Ω

from CPU

(Port Bx)

Figure 4: "Open-Collector" transistor output to the pump controller

8 - 1094

+ 24 V

Output

Page 11

4 COMMISSIONING AND INSTALLATION

4.1 Additional important documentation

ATTENTION!

NOTE

Have the following documentation at hand for the commissioning of the controller:

• Data sheet/operating instructions for the piston meter/petrol pump computer of

the petrol pump

• Data sheet/operating instructions for the proportional valve Type 2832 von Bürkert

• Data sheet/operating instructions for the vacuum pump - required for setting-up

the correction factor

• Operating instructions for the Type MKNE-1094 manual control unit from Bürkert

In order to connect the individual petrol pump components to the

Type 1094 controller, you will require the respective interface conditions, such as voltage level, clock rate, impedances, currents, etc.

These can be found in the data sheets and/or the operating instructions for the individual components.

You can obtain the complete documentation for the petrol pump

from the supplier or manufacturer of the petrol pump.

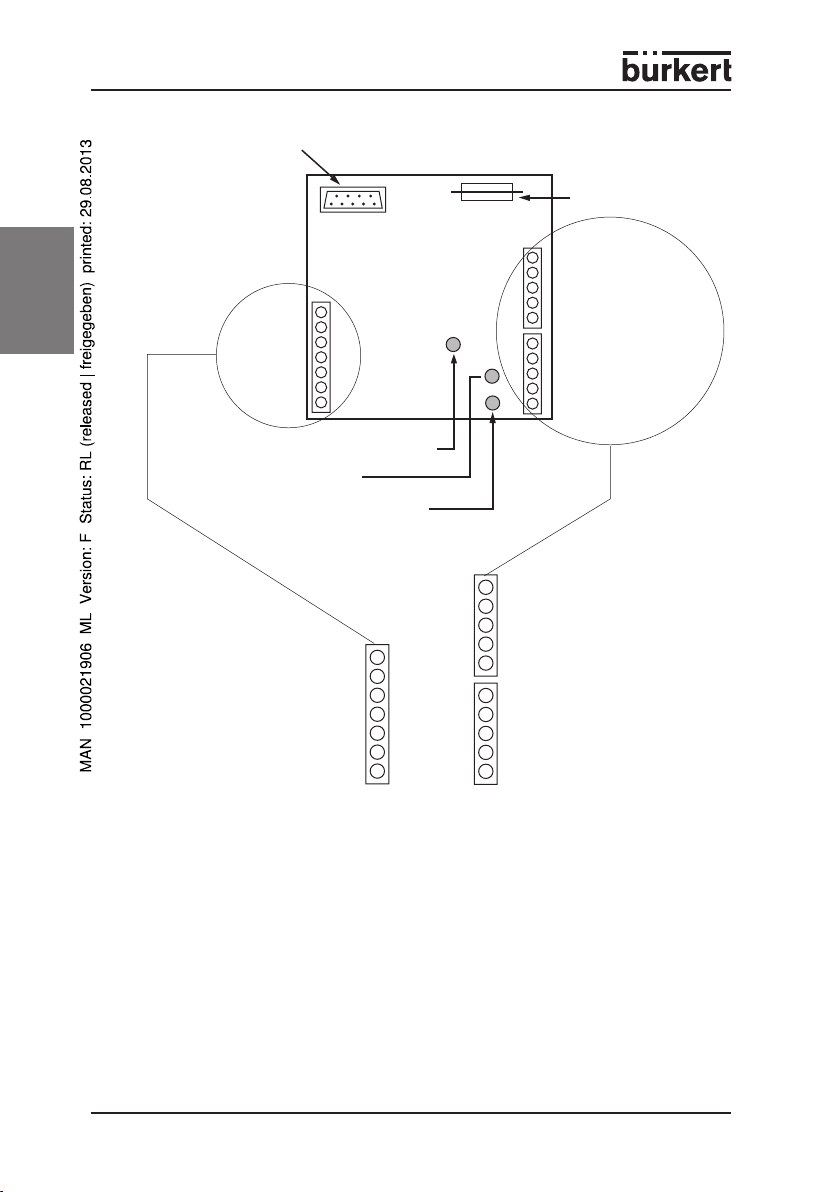

4.2 Electrical connections

Before the commissioning of the controller, carefully connect all the required ports

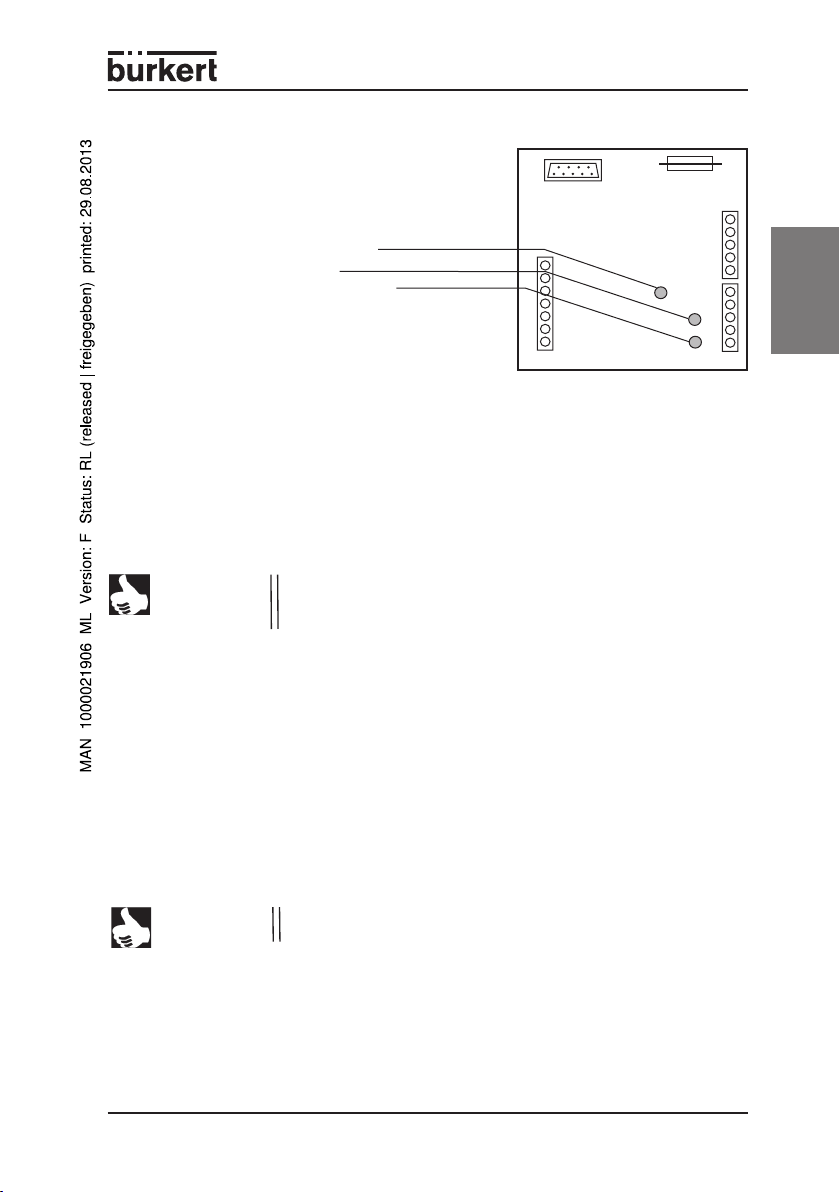

(see Figure 5).

Make the following connections to the controller.

• 24 V DC operating voltage

• Output signal for the Type 2832 proportional valve

• Output signal for relay or contactor for the vacuum pump

• Frequency input signal from the petrol pump computer

english

NOTE

The operation and calibration of the controller takes place exclusively via the external

Type MKNE-1094e manual control unit, which is connected to the controller using a

9-pole SUB-D plug.

In the case of controllers for the two-sided operation of the petrol pump, a separate

SUB-D plug is provided for each side of the petrol pump (Side A and Side B).

Wires/cables

There are no special requirements for the wire connections to be

used within the petrol pump, as the currents and/or power to be

transmitted are very small.

All cables that are used should be fitted with cable lugs.

1094 - 9

Page 12

Connection of the control unit

(9-pole SUB-D plug)

Wire fuse 0.4 A M

Electronic controller

Type 1094 Standard

english

LED red = active

Inputs

LED "Proportional valve active"

LED "Pump active"

LED "Operating voltage on"

Proportional valve (+)

Proportional valve (-)

Protective contacts PE

Frequency input (GND)

Frequency output 1 (+)

not used

not used

not used

not used

Voltage output (+ 12 V) *

* The voltage input and voltage output are looped through here.

Figure 5: Electrical connections

Protective contacts PE

Operational voltage (GND)

Operational voltage (+ 24 V)

Output to the pump (+ 24 V)

Output to the pump (-)

not used

Voltage input (+ 12 V) *

Outputs

10 - 1094

Page 13

5 OPERATION AND FUNCTION

5.1 Display elements

The controller has 3 red LEDs

For the display of

• „Proportional valve active“

• „Pump motor active“

• „Supply voltage connected“

5.2 Setting and operation of the controller

In order to set up the controller in a petrol pump, all the components, signal lines and

the gas gauge from the calibration case must be correctly connected.

The operation and calibration of the controller takes place exclusively using the external Type MKNE-1094 manual control unit, which is connected to the controller using

a 9-pole SUB-D plug.

NOTE

The settings that are possible with the manual control unit are described in detail in

the Type MKNE-1094 operating instructions.

In the case of controllers for the two-sided operation of the petrol

pump, a separate SUB-D plug is provided for each side of the petrol

pump (Side A and Side B).

english

5.3 Calibration of the controller

The electronic vapour recovery controller is program-controlled and has to be adapted (calibrated) to the real petrol pump process before being used for the first time.

The calibration is carried out with the separate (external) MKNE-1094manual control

unit. There is a separate set of operating instructions for this external manual control

unit. Carefully read through these operating instructions and selection the mode of

operation relevant to your application.

NOTE

Bevore the calibration, the pulse rate, the K-factor and the pump

after-run time must be determined and be entered.

5.4 Pulsrate and frequency input

The pulse rate output from the petrol pump computer will be defined by the petrol

pump manufacturer. The output pulse rate can be set up on the controller with the

Type MKNE-1094 manual control unit.

1094 - 11

Page 14

5.5 K-factor for the suction rate

The K-factor for the suction rate corrects the difference in the flow characteristics of

air and petrol vapour. This correction is necessary as the suction system will be initially

measured with atmospheric air, and will later be operated with petrol vapour.

The K-factor is an installation-specific variable. It is determined as the quotient of the

volumetric flow rate of air to the volumetric flow rate of petrol vapour.

Further information regarding the determination of the K-factor can be found in the

operating instructions for the Type MKNE-1094 manual unit (under the chapter „Introduction to the Technology of Vapour Recovery“ and the paragraphs „Information

regarding the volumetric flow rate...“ and „Determination of the correction factor“).

english

5.6 Pump after-run time

The pump after-run time is the delay time for the vacuum pump, and lies between the

end of the refuelling procedure (the closing of the proportional valve) and the switching-off of the vacuum pump. As a result of the after-run time of the pump, any petrol

vapour still remaining in the piping will be sucked out.

5.7 Petrol pump operation

During the calibration, the controller automatically registers the non-linear valve current gas flow characteristic of the complete petrol pump installation, stores the characteristic points, and automatically carries out a linearisation of these characteristics

through linear interpolation. The control of the sucked-in petrol vapour quantity takes

place using the linearised characteristic.

After the calibration, the petrol vapour displaced while filling the tank will be automatically sucked in via the suction line on the pump pistol.

NOTE

The mode of operation of a petrol pump is described in detail in the

chapter "System description".

6 MAINTENANCE AND TROUBLE-SHOOTING

6.1 Maintenance

The electronic controller for vapour recovery is maintenance-free when operated in

accordance with the instructions given in this manual.

6.2 Faults

Fault Cause Correction

Unit does not function

("Operating voltage on" LED = dark)

12 - 1094

No operating

voltage

Fuse defective /

blown

Check the electrical

power supply

Replace the fuse

(wire fuse, 0.4 A

slow-blow)

Page 15

Elektronische Steuerung für Gasrückführung Typ 1094 Standard

1 ALLGEMEINE HINWEISE ...........................................................................................................................15

1.1 Darstellungsmittel ..................................................................................................................... 15

1.2 Sicherheitshinweise ................................................................................................................. 15

1.3 Bestimmungsgemäßer Gebrauch .......................................................................................... 15

1.4 Schutz gegen Beschädigung durch elektrostatische Aufladung .................................. 16

1.5 Lieferumfang .............................................................................................................................. 16

1.6 Garantiebestimmungen ........................................................................................................... 16

2 SYSTEMBESCHREIBUNG ........................................................................................................................17

2.1 Allgemeine Beschreibung des Einsatzbereiches ............................................................... 17

2.2 Arbeitsweise der Steuerung .................................................................................................... 17

2.3 Funktionsweise einer Zapfsäule mit Gasrückführung .......................................................18

3 TECHNISCHE BESCHREIBUNG .............................................................................................................19

3.1 Allgemeine technische Daten .................................................................................................19

3.2 Elektrische Daten ....................................................................................................................... 19

3.3 Eingänge ...................................................................................................................................... 19

3.4 Ausgänge ..................................................................................................................................... 20

deutsch

4 INBETRIEBNAHME UND MONTAGE .................................................................................................21

4.1 Weitere wichtige Unterlagen ................................................................................................... 21

4.2 Elektrische Anschlüsse ............................................................................................................. 21

5 BEDIENUNG UND FUNKTION .................................................................................................................23

5.1 Anzeigeelemente ........................................................................................................................ 23

5.2 Einstellung und Bedienung der Steuerung .......................................................................... 23

5.3 Kalibrierung der Steuerung ...................................................................................................... 23

5.4 Pulsrate und Frequenzeingang ............................................................................................... 23

5.5 K-Faktor für die Saugrate ......................................................................................................... 24

5.6 Pumpennachlaufzeit .................................................................................................................. 24

5.7 Zapfsäulenbetrieb ...................................................................................................................... 24

1094 - 13

Page 16

6 WARTUNG UND FEHLERBEHEBUNG .................................................................................................24

6.1 Wartung ....................................................................................................................................... 24

6.2 Störungen ................................................................................................................................... 24

deutsch

14 - 1094

Page 17

1 ALLGEMEINE HINWEISE

1.1 Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit

oder die Funktionsfähigkeit des Gerätes gefährdet ist.

kennzeichnet wichtige Zusatzinformationen,

Tipps und Empfehlungen.

1.2 Sicherheitshinweise

Bitte beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten, die im Datenblatt spezifiziert sind, damit das Gerät

einwandfrei funktioniert und lange einsatzfähig bleibt:

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der Technik!

• Das Gerät darf nicht im Ex-Bereich der Zone 0 oder 1 eingesetzt werden.

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung auszuschließen!

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen!

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für

elektrische Geräte während des Betriebs und der Wartung des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Verwenden Sie das Gerät nur in seiner Originalkonfiguration!

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät

entfällt jegliche Haftung unsererseits, ebenso erlischt die Garantie auf Geräte und

Zubehörteile!

deutsch

1.3 Bestimmungsgemäßer Gebrauch

Das Gerät ist ausschließlich für die elektronische Steuerung eines Proportionalventils

für die Gasrückführung an Zapfsäulen bestimmt. Eine andere oder darüber hinausgehende Benutzung gilt als nicht bestimmungsgemäß. Für hieraus resultierende Schäden haftet Bürkert nicht. Das Risiko trägt allein der Anwender.

1094 - 15

Page 18

1.4 Schutz gegen Beschädigung durch elektrostatische Aufladung

Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische Entladung (ESD) empfindlich reagieren. Berührung

mit elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

Beachten Sie die Anforderungen nach EN 100 015 - 1, um die

Möglichkeit eines Schadens durch schlagartige elektrostatische

Entladung zu minimieren bzw. zu vermeiden. Achten Sie ebenso

darauf, dass Sie elektronische Bauelemente nicht bei anliegender

Versorgungsspannung berühren.

Bürkert Steuer- und Regelungstechnik

Kundencenter

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

Fax: 07940-10448

E-mail: info@de.buerkert.com

VORSICHT BEI

HANDHABUNG !

ELEKTROSTATISCH

GEFÄHRDETE

BAUELEMENTE /

BAUGRUPPEN

1.5 Lieferumfang

deutsch

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, dass der Inhalt nicht beschädigt ist und mit dem auf dem beigelegten Packzettel angegebenen Lieferumfang

übereinstimmt.

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an unseren Kundenservice:

oder an Ihr Bürkert-Vertriebs-Center.

ACHTUNG

1.6 Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf unsere

allgemeinen Verkaufs- und Geschäftsbedingungen. Voraussetzung für die Garantie ist

der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten

Einsatzbedingungen.

ACHTUNG!

16 - 1094

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit der

elektronischen Steuerung Typ 1094 Standard und ihrer Bauteile.

Es wird jedoch keine Haftung übernommen für Folgeschäden

jeglicher Art, die durch Ausfall oder Fehlfunktion des Gerätes

entstehen könnten.

Page 19

2 SYSTEMBESCHREIBUNG

2.1 Allgemeine Beschreibung des Einsatzbereiches

Beim Betanken eines Fahrzeuges wird von dem in den Tank strömenden Benzin eine

volumengleiche Menge Benzindampf aus dem Tank verdrängt. Um das Entweichen

dieses Benzindampfes in die Atmosphäre zu verhindern, muss er abgesaugt werden.

Dieser Absaugvorgang erfolgt bei der von Bürkert angebotenen Lösung per Unterdruck über ein vorgeschaltetes Proportionalventil in den Vorratstank der Zapfsäule.

Eine Absaugpumpe fördert den Benzindampf aus dem Fahrzeugtank und drückt ihn in

den Vorratstank der Zapfsäule.

Um einen Überdruck im Vorratstank zu vermeiden, muss die Volumenbilanz zwischen

gezapftem Benzin und rückgesaugtem Benzindampf ausgeglichen sein.

Die in den Fahrzeugtank eingefüllte Benzinmenge wird über einen geeichten Kolbenzähler der Zapfsäule gemessen, vom Zapfsäulenrechner in Taktsignale umgerechnet

und an die Steuerung gemeldet.

2.2 Arbeitsweise der Steuerung

Die in Bild 1 dargestellte Steuerung wertet die Taktsignale des Zapfsäulenrechners

aus und steuert über elektrische PWM-Stellsignale die Durchflussöffnung eines

Regelventils (explosionsgeschütztes Proportionalventil Typ 2832) und somit den

Volumenstrom des rückgesaugten Benzindampfes.

Bild 1: Elektronische Steuerung Typ 1094 Standard

deutsch

1094 - 17

Page 20

2.3 Funktionsweise einer Zapfsäule mit Gasrückführung

Die Ventilstrom-Gasfluss-Kennlinie einer Zapfanlage ist ursprünglich nichtlinear. Um

eine gleichmäßige Absaugung im gesamten Ansteuerbereich zu sichern, wird eine

lineare Kennlinie benötigt. Dazu werden beim Einmessen der Anlage mit der Bedieneinheit verschiedene Punkte der Kennlinie automatisch im Speicher der Steuerung

abgelegt. Die Anzahl dieser Punkte ist kennlinienabhängig und wird automatisch von

der Bedieneinheit festgelegt. Die Kennlinienkorrektur erfolgt ebenfalls automatisch

durch lineare Interpolation zwischen diesen Punkten.

Mit Beginn des Zapfvorgangs wird in der Steuerung aus der gemessenen Pulsrate

die gezapfte Benzinmenge berechnet. Unter Einbeziehung der linearisierten Kennlinie und des K-Faktors der Saugrate kann nunmehr der Sollwert für den Ventilstrom

ermittelt und das Proportionalventil zum Absaugen des Benzindampfes angesteuert

werden. Mit dem Ansteuern des Proportionalventils wird auch die Vakuumpumpe zur

Erzeugung eines Unterdruckes in Betrieb genommen. Nach Beendigung des Zapfvorgangs gibt der Zapfsäulenrechner keine Impulse mehr aus und das Proportionalventil

für die Gasrückführung wird geschlossen. Nach Ablauf der Nachlaufzeit wird auch die

Vakuumpumpe abgeschaltet.

deutsch

Saugleitung

Ein oder mehrere

Impulsgeberleitungen vom

Pulsgeber / Zapfsäulenrechner

Ansteuerelektronik

24 V DC-Schütz/

24 V DC

Stromversorgung

(Typ 1610)

Bild 2: Funktionsschema einer Zapfsäule mit Gasrückführung

18 - 1094

Relais zum Schalten

des Pumpenmotors

Proportional

ventil

(Typ 2332)

Vakuumpumpe

zum

Erdtank

Stromversorgung für Vakuumpumpe

Page 21

3 TECHNISCHE BESCHREIBUNG

3.1 Allgemeine technische Daten

Umgebungstemperatur -25 °C ... +85 °C

Abmessungen 68 x 76 x 35 mm

Gehäuse offenes Gehäuse zur Montage auf Tragschienen nach

Schutzart IP 20

Bestell-Nr. 060 651

DIN EN 50 022 / DIN EN 50 035 / DIN EN 50 045

3.2 Elektrische Daten

Versorgungsspannung

Pegel 24 V DC ± 10 %

Restwelligkeit < 5 %

Stromaufnahme < 30 mA (ohne Ventilstrom)

< 300 mA (mit Ventilstrom)

3.3 Eingänge

Frequenzeingang der Steuerung

High-Pegel Impuls 2,5 V ... 25 V

Low-Pegel Impuls -1,0 V ... +1,0 V

Eingangswiderstand

max. Eingangsstrom 5 mA

min. Pulsdauer 400 µs

Messrate 1 Messung/sec

Auflösung 1 Hz

Messbereich 0 ... 51 l/min

> 10 k

deutsch

Ω

Eingang 1

Bild 3:

Frequenzeingang

der Steuerung

VDD

zur

CPU

Der Volumenstrom des gezapften Benzins wird vom

Kolbenzähler gemessen, vom

Zapfsäulenrechner in ein frequenzproportionales Taktsignal

umgewandelt und auf den

Frequenzeingang der Steuerung

geschaltet (Bild 3).

In der Steuerung wird dieses

Taktsignal als Istwert des

Benzin-Volumenstroms verarbeitet.

1094 - 19

Page 22

3.4 Ausgänge

Ausgang für das Proportionalventil

Ausgangstransistor plus-schaltender Transistor

Laststrom 0 bis 250 mA

Ausgangsspannung 24 V DC

Taktfrequenz 270 Hz

Anzahl der Ausgänge je ein Ventilausgang für + und -

Zum Stellen des Proportionalventils Typ 2832 gibt die Steuerung über einen Transistor stromgeregelte PWM-Signale aus.

Ausgang für die Steuerung des Motors der Vakuumpumpe

deutsch

Der in Bild 4 dargestellte „Open-Collector“-Ausgang dient zur Steuerung eines Relais/ Schütz zum Schalten des Motors der Vakuumpumpe.

Der „Open-Collector“- Ausgang wird von der Steuerung aktiv geschaltet, solange das

Proportionalventil geöffnet ist.

von CPU

(Port Bx)

Bild 4: "Open-Collector" Transistorausgang zur Pumpensteuerung

Ausgangstransistor „Open-Collector“ Transistorausgang

Laststrom 100 mA

Ausgangsspannung 24 V DC

Besonderheiten Freilaufdiode, Nachlaufzeit einstellbar (in Verbindung

Anzahl der Ausgänge je ein Pumpenausgang für + (24 V) und – (GND)

2,2 k

10 k

mit dem Handbediengerät Typ MKNE-1094)

+ 24 V

Ω

BC 337 o. ä.

Ausgang

Ω

20 - 1094

Page 23

4 INBETRIEBNAHME UND MONTAGE

4.1 Weitere wichtige Unterlagen

ACHTUNG!

HINWEIS

Legen Sie für die Inbetriebnahme der Steuerung folgende Unterlagen bereit:

• Datenblatt/Bedienungsanleitung des Kolbenzählers/Zapfsäulenrechners der

Zapfsäule

• Datenblatt/Bedienungsanleitung des Proportionalventils Typ 2832 von Bürkert

• Datenblatt/Bedienungsanleitung der Vakuumpumpe - erforderlich für die

Einstellung des Korrekturfaktors

• Bedienungsanleitung für das Handbediengerät Typ MKNE-1094 von Bürkert

Zum Anschluss der einzelnen Zapfsäulenkomponenten an die

Steuerung Typ 1094 benötigen Sie die jeweiligen Schnittstellenbedingungen wie Pegel, Taktraten, Widerstände, Ströme usw.

Diese entnehmen Sie den Datenblättern und/oder Betriebsanleitungen für die Einzelkomponenten.

Die Gesamtdokumentation zur Zapfsäule erhalten Sie beim Lieferanten oder Hersteller der Zapfsäule.

4.2 Elektrische Anschlüsse

Schließen Sie vor Inbetriebnahme der Steuerung alle erforderlichen Anschlüsse

sorgfältig an (siehe Bild 5).

Es sind folgende Verbindungen zur Steuerung herzustellen.

• Betriebsspannung 24 V DC

• Ausgangssignal für Proportionalventil Typ 2832

• Ausgangssignal für Relais oder Schütz der Vakuumpumpe

• Frequenzeingangssignal vom Zapfsäulenrechner

deutsch

HINWEIS

Die Bedienung und Kalibrierung der Steuerung erfolgt ausschließlich über das externe

Handbediengerät Typ MKNE-1094, welches über einen 9-poligen SUB-D-Stecker

mit der Steuerung verbunden wird.

Bei Steuerungen für den doppelseitigen Zapfsäulenbetrieb ist für jede Zapfsäulenseite (Seite A und Seite B) ein separater SUB-D-Stecker vorgesehen.

Drähte/Kabel

Für die zu verwendenden Drahtverbindungen innerhalb der Zapfsäule bestehen keine besonderungen Forderungen, da die zu übertragenden Ströme bzw. Leistungen sehr klein sind.

Alle verwendeten Kabel sollten mit Aderendhülsen versehen

sein.

1094 - 21

Page 24

Anschluss der Bedieneinheit

(9-poliger SUB_D_Stecker)

Feinsicherung 0,4 A M

Elektronische Steuerung

Typ 1094 Standard

deutsch

Spannungsausgang (+ 12 V) *

* Spannungseingang und Spannungsausgang werden hier durchgeschleift.

Bild 5: Elektrische Anschlüsse

Eingänge

LED "Proportionalventil aktiv"

LED "Pumpe aktiv"

LED "Betriebsspannung ein"

Frequenzeingang (GND)

Frequenzeingang 1 (+)

nicht belegt

nicht belegt

nicht belegt

nicht belegt

LED rot = aktiv

Ausgänge

Proportionalventil (+)

Proportionalventil (-)

Schutzkontakte PE

Schutzkontakte PE

Betriebsspannung (GND)

Betriebsspannung (+ 24 V)

Ausgang zur Pumpe (+ 24 V)

Ausgang zur Pumpe (-)

nicht belegt

Spannungseingang (+ 12 V) *

22 - 1094

Page 25

5 BEDIENUNG UND FUNKTION

5.1 Anzeigeelemente

Die Steuerung besitzt 3 rote LEDs

zur Anzeige von

• „Proportionalventil aktiv“

• „Pumpenmotor aktiv“

• „Versorgungsspannung angeschlossen“

5.2 Einstellung und Bedienung der Steuerung

Zur Einstellung der Steuerung in einer Zapfsäule müssen alle Bauteile, Signalleitungen und die Gasuhr aus dem Kalibrierkoffer vorschriftsmäßig angeschlossen sein.

Die Bedienung und Kalibrierung der Steuerung erfolgt ausschließlich über das externe

Handbediengerät Typ MKNE-1094, welches über einen 9-poligen SUB-D-Stecker

mit der Steuerung verbunden wird.

deutsch

HINWEIS

Die mit dem Handbediengerät möglichen Einstellungen sind in der Bedienungsanleitung Typ MKNE-1094 ausführlich beschrieben.

Bei Steuerungen für den doppelseitigen Zapfsäulenbetrieb ist für

jede Zapfsäulenseite (Seite A und Seite B) ein separater SUB-DStecker vorgesehen.

5.3 Kalibrierung der Steuerung

Die elektronische Gasrückführsteuerung ist programmgesteuert und muss vor ihrem

Ersteinsatz an den realen Zapfsäulenprozess angepasst (kalibriert) werden. Die Kalibrierung erfolgt mit dem separaten (externen) Handbediengerät MKNE-1094.

Zu diesem externen Handbediengerät gehört eine separate Bedienungsanleitung.

Lesen Sie diese Bedienungsanleitung sorgfältig durch und wählen Sie die für Ihren

Anwendungsfall zutreffende Betriebsweise.

HINWEIS

Vor der Kalibrierung müssen die Pulsrate, der K-Faktor und die

Pumpennachlaufzeit bestimmt und eingegeben werden.

5.4 Pulsrate und Frequenzeingang

Die vom Zapfsäulenrechner ausgegebene Pulsrate wird vom Zapfsäulenhersteller

festgelegt. Die angegebene Pulsrate kann mit dem Handbediengerät Typ MKNE1094 an der Steuerung eingestellt werden.

1094 - 23

Page 26

5.5 K-Faktor für die Saugrate

Der K-Faktor für die Saugrate korrigiert den Unterschied der Durchflusseigenschaften

von Luft und Benzindampf. Diese Korrektur ist erforderlich, da das Absaugsystem

vorerst mit Atmosphärenluft eingemessen und später mit Benzindampf betrieben wird.

Der K-Faktor ist eine anlagenspezifische Größe. Er wird als Quotient der Volumenrate

Luft zur Volumenrate Benzindampf ermittelt.

Weitere Hinweise zur Bestimmung des K-Faktors siehe Bedienungsanleitung Handgerät Typ MKNE-1094 (unter Kapitel "Einführung in die Technik der Gasrückführung"

die Absätze "Hinweise zur Volumenrate..." und "Bestimmen des Korrekturfaktors").

5.6 Pumpennachlaufzeit

Die Pumpennachlaufzeit ist die Verzögerungszeit der Vakuumpumpe, die zwischen

dem Ende des Zapfvorgangs (Schließen des Proportionalventils) und dem Abschalten der Vakuumpumpe liegt. Durch das Nachlaufen der Pumpe wird der noch in den

Rohrleitungen befindliche Benzindampf abgesaugt.

deutsch

5.7 Zapfsäulenbetrieb

Während der Kalibrierung erfasst die Steuerung automatisch die nichtlineare Ventilstrom-Gasfluss-Kennlinie der gesamten Zapfsäulenanlage, speichert charakteristische

Punkte und nimmt automatisch eine Linearisierung dieser Kennlinie durch lineare

Interpolation vor. Die Steuerung der abgesaugten Benzindampfmenge erfolgt unter

Verwendung der linearisierten Kennlinie.

Nach erfolgter Kalibrierung wird der beim Befüllen eines Tanks verdrängte Benzindampf über die Saugleitung an der Zapfpistole automatisch abgesaugt.

HINWEIS

Die Funktionsweise einer Zapfsäule ist im Kapitel "Systembeschreibung " ausführlich dargestellt.

6 WARTUNG UND FEHLERBEHEBUNG

6.1 Wartung

Die Elektronische Ansteuerung für Gasrückführung ist bei Betrieb entsprechend den

in dieser Anleitung angegebenen Anweisungen wartungsfrei.

6.2 Störungen

Störung Ursache Abhilfe

Gerät ohne Funktion

( LED "Betriebspannung ein" = dunkel)

24 - 1094

Betriebsspannung

fehlt

Sicherung defekt Sicherung ersetzen

Stromversorung

überprüfen

(Feinsicherung 0,4 A

mittelträge)

Page 27

Régulateur électronique pour la récupération des vapeurs d‘es-

sence type 1094 standard

1 RECOMMANDATIONS GENERALES ...................................................................................................27

1.1 Symboles utilisés ....................................................................................................................... 27

1.2 Prescriptions de sécurité ......................................................................................................... 27

1.3 Utilisation conforme ................................................................................................................... 27

1.4 Protection contre la charge électrostatique ........................................................................ 28

1.5 Etendue de fourniture ...............................................................................................................28

1.6 Dispositions de garantie ........................................................................................................... 28

2 DESCRIPTION GENERALE .......................................................................................................................29

2.1 Description générale du domaine d‘application ................................................................. 29

2.2 Mode opératoire de la commande ......................................................................................... 29

2.3 Mode opératoire d‘une colonne de distribution avec récupération des vapeurs

d‘essence .................................................................................................................................... 30

3 DESCRIPTION TECHNIQUE .....................................................................................................................31

3.1 Caractéristiques techniques générales ................................................................................ 31

3.2 Caractéristiques électriques ................................................................................................... 31

3.3 Entrées ......................................................................................................................................... 31

3.4 Sorties .......................................................................................................................................... 32

français

4 MISE EN SERVICE ET MONTAGE .......................................................................................................33

4.1 Autres documents importants ................................................................................................. 33

4.2 Branchements électriques ....................................................................................................... 33

5 UTILISATION ET FONCTIONNEMENT .................................................................................................35

5.1 Eléments d‘affichage ................................................................................................................. 35

5.2 Réglage et utilisation de la commande ................................................................................. 35

5.3 Etalonnage de la commande ................................................................................................... 35

5.4 Fréquence d‘impulsion et entrée en fréquence .................................................................. 35

5.5 Facteur K de débit d‘aspiration ..............................................................................................36

5.6 Temporisation de la pompe ..................................................................................................... 36

5.7 Exploitation de la colonne de distribution ............................................................................36

1094 - 25

Page 28

6 ENTRETIEN DEPANNAGE ..........................................................................................................................37

6.1 Entretien ....................................................................................................................................... 37

6.2 Dérangements ............................................................................................................................ 37

fran çais

26 - 1094

Page 29

1 RECOMMANDATIONS GENERALES

1.1 Symboles utilisés

Les symboles utilisés dans cette notice d'instructions sont les suivants:

désigne une opération à exécuter.

ATTENTION!

REMARQUE

désigne une mise en garde dont l‘inobservation pourrait mettre en

danger votre santé ou l‘intégrité de l‘appareil.

désigne des informations supplémentaires, conseils et recommandations importantes

1.2 Prescriptions de sécurite

Afin d‘assurer le bon fonctionnement et la durabilité de cet appareil, veuillez observer

les recommandations de la présente notice, ainsi que les conditions de service et les

caractéristiques admissibles figurant dans la fiche technique.

• Lors de la planification et de l‘exploitation de l‘appareil, observez les règles générales de la technique!

• L‘appareil ne doit pas être utilisé dans une atmosphère déflagrante de zone 0 ou 1.

• Prenez les mesures appropriées de manière à éviter toute manipulation involontaire

ou intervention abusive!

• L‘installation et les interventions d‘entretien doivent uniquement être exécutées par

le personnel spécialisé et disposant de l‘outillage adéquat!

• Observez les prescriptions de prévention des accidents et de sécurité applicables

aux appareils électriques durant l‘exploitation, la maintenance et la réparation de

l‘appareil!

• Avant toute intervention dans le système, coupez toujours la tension!

• Utilisez toujours l‘appareil dans la configuration originale pour laquelle il a été

prévu!

• Nous déclinons toute responsabilité en cas d‘inobservation de ces recommandations et d‘intervention non autorisée à l‘intérieur de l‘appareil. Il en résulterait par

ailleurs l‘annulation de la garantie sur l‘appareil et les accessoires.

français

1.3 Utilisation conforme

Cet appareil est prévu exclusivement pour le pilotage d‘une vanne proportionnelle

destinée à la récupération des vapeurs d‘essence sur une colonne de distribution.

Toute autre utilisation ou sortant du cadre prévu est considérée comme une utilisation

non conforme. Bürkert décline toute responsabilité pour les dommages qui pourraient

s‘ensuivre. Les risques seraient exclusivement à la charge de l‘utilisateur.

1094 - 27

Page 30

1.4 Protection contre la charge électrostatique

L‘appareil contient des composants électroniques sensibles réagissant à la charge électrostatique (ESD). Tout contact avec des

personnes ou des objets présentant une charge électrostatique

est susceptible de les endommager. Dans les cas extrêmes, ces

ATTENTION

MANIPULER AVEC

PRECAUTION

COMPOSANTS/

MODULES SENSI-

BLES A LA CHARGE

ELECTROSTATIQUE

composants pourraient s‘en trouver immédiatement détériorés,

ou être détruits lors de la prochaine mise sous tension.

Observez les prescriptions stipulées dans la norme

EN 100 015 - 1 de manière à éviter ou à réduire au minimum les

probabilités d‘une détérioration par une décharge électrostatique impulsive. Assurez-vous également de ne pas toucher les

composants électroniques lorsqu‘ils se trouvent sous tension.

1.5 Etendue de fourniture

Immédiatement après la réception de l‘envoi, contrôlez que son contenu n‘a pas été

endommagé et qu‘il concorde avec l‘étendue de fourniture spécifiée sur le bon de

livraison.

En cas de différence, adressez-vous immédiatement à notre service après-vente

fran çais

ou à votre centre de vente Bürkert

Bürkert Steuer- und Regelungstechnik

Kundencenter

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

Fax: 07940-10448

E-mail: info@de.buerkert.com

1.6 Dispositions de garantie

Ce document ne constitue aucun assentiment de garantie. Nous vous renvoyons à

cet effet à nos conditions générales de vente et commerciales. La condition préalable

au consentement de la garantie est l‘utilisation conforme de l‘appareil pour l‘usage

auquel il est destiné, compte tenu de l‘observation des conditions de service

spécifiées.

ATTENTION!

28 - 1094

Les prestations de garantie ne couvrent que les défauts du régulateur électronique type 1094 standard et de ses composants. En

revanche, nous déclinons toute responsabilité pour des dégâts

consécutifs de toute nature susceptibles de survenir par suite de

défaillance ou défaut de fonctionnement de l‘appareil.

Page 31

2 DESCRIPTION GENERALE

2.1 Description générale du domaine d'application

Lors du ravitaillement en carburant d‘un véhicule, le flux d‘essence pénétrant dans le

réservoir expulse une certaine quantité de vapeurs d‘essence. Ces vapeurs doivent

être aspirées afin d‘empêcher qu‘elles ne s‘échappent dans l‘atmosphère.

Dans la solution proposée par Bürkert, ce processus d‘aspiration s‘effectue par dépression via une vanne proportionnelle située en amont dans le réservoir de stockage

de la colonne. Une pompe d‘aspiration aspire les vapeurs d‘essence hors du réservoir

du véhicule et les refoule vers le réservoir de stockage.

Afin de prévenir une surpression dans le réservoir de stockage, le bilan volumique

entre l‘essence prélevée et la vapeur d‘essence réaspirée doit être équilibré.

La quantité d‘essence introduite dans le réservoir du véhicule est mesurée par un

compteur à pistons étalonné de la colonne, convertie en signaux pulsés par l‘ordinateur de la colonne et transmis à la commande.

2.2 Mode opératoire de la commande

La commande représentée sur la fig. 1 interprète les signaux transmis par l‘ordinateur

de la colonne, et par l‘intermédiaire de signaux de réglage électriques MIC contrôle

l‘ouverture de passage d‘une vanne de régulation (vanne proportionnelle antidéflagrante type 2832), et par conséquent le débit volumique des vapeurs d‘essence

réaspirées.

français

Figure 1: Commandé électronique type 1094 standard

1094 - 29

Page 32

2.3 Mode opératoire d‘une colonne de distribution avec récupération

des vapeurs d‘essence

D‘origine, la caractéristique courant de vanne-débit de gaz dans une colonne de

distribution n‘est pas linéaire. Afin d‘assurer une aspiration régulière des gaz dans tout

le domaine contrôlé, on a besoin d‘une caractéristique linéaire. A cet effet, lors de la

mesure de l‘installation avec l‘unité de commande, différents points de la caractéristique sont automatiquement enregistrés dans la mémoire de la commande. Le nombre

de ces points est spécifique à la caractéristique, et est automatiquement déterminé

par l‘unité de commande. La correction de la caractéristique s‘effectue également de

façon automatique par interpolation linéaire entre ces points.

Dès le début du ravitaillement, la commande calcule la quantité d‘essence prélevée en

fonction des impulsions mesurées. En tenant compte de la caractéristique linéarisée

et du facteur K du débit d‘aspiration, il est à présent possible de déterminer la valeur

de consigne du courant de vanne pilotant la vanne proportionnelle pour l‘aspiration

des vapeurs d‘essence. Le pilotage de la vanne proportionnelle provoque également

la mise en service de la pompe à vide pour engendrer la dépression. Lorsque le

ravitaillement est terminé, l‘ordinateur de la colonne ne délivre plus d‘impulsions, de

sorte que la vanne proportionnelle de récupération des vapeurs est fermée. Après une

certaine temporisation, la pompe à vide est arrêtée.

Conduite d'aspiration

fran çais

Une ou plusieurs lignes du capteur

d‘impulsions venant du capteur /

de l‘ordinateur de colonne

Electronique

de commande

Figure 2:

Schéma de principe d‘une

colonne de distribution avec

récupération des vapeurs d‘essence

30 - 1094

Alimentation

(type 1610)

24 V DC

Vanne proportionnelle

(type 2332)

Contacteur / relais

24 V DC de commande de la motopompe

Alimentation de la pompe à vide

Pompe à vide

Vers

réservoir

Page 33

3 DESCRIPTIF TECHNIQUE

3.1 Caractéristiques techniques générales

Température ambiante -25 °C ... +85 °C

Dimensions 68 x 76 x 35 mm

Boîtier Boîtier ouvert à monter sur rail de support selon

Degré de protection IP 20

N° de commande 060 651

DIN EN 50 022 / DIN EN 50 035 / DIN EN 50 045

3.2 Caractéristiques èlectriques

Tension d'alimentation

Niveau 24 V DC ± 10 %

Ondulation résiduelle < 5 %

Courant absorbé < 30 mA (sans courant de vanne)

< 300 mA (avec courant de vanne)

3.3 Entrées

Entrées en fréquence de la commande

Impulsion de haut niveau 2,5 V ... 25 V

Impulsion de bas niveau -1,0 V ... +1,0 V

Résistance d'entrée

Courant max. d'entrée 5 mA

Durée min. d'impulsion 400 µs

Rythme de mesure 1 mesure/s

Résolution 1 Hz

Plage de mesure 0 ... 51 l/min

> 10 k

Ω

français

Entrée 1

Figure 3:

Entrée en fréquence

de la commande

VDD

vers

CPU

Le débit volumique de l‘essence

prélevée est mesuré par le

compteur à pistons, converti par

l‘ordinateur de la colonne en un

signal pulsé proportionnel à la

fréquence et transmis à l‘entrée

en fréquence de la commande

(fig. 3).

Dans la commande, ce signal

est traité pour former la valeur

réelle du débit d‘essence.

1094 - 31

Page 34

3.4 Sorties

fran çais

Sortie pour la vanne proportionelle

Transistor de sortie Transistor à commutation positive

Courant de charge 0 ... 250 mA

Tension de sortie 24 V DC

Fréquence du signal 270 Hz

Nombre de sorties une sortie vanne pour + et -

Pour positionner la vanne proportionnelle type 2832, la commande délivre des signaux

MIC modulés en courant via un transistor.

Sortie pour commande de la motopompe à vide

Transistor de sortie Sortie transistor à collecteur ouvert

Courant de charge 100 mA

Tension de sortie 24 V DC

Particularités Diode de roue libre, temporisation réglable (avec l'unité

de commande manuelle type MKNE-1094)

Nombre de sorties Une sortie pompe pour + (24 V) et - (GND)

La sortie à collecteur ouvert représentée en fig. 4 sert à la commande du relais/contacteur pour la commande de la motopompe à vide.

La sortie à collecteur ouvert est activée par la commande aussi longtemps que la

vanne proportionnelle reste ouverte.

+ 24 V

2,2 k

De CPU

Ω

(port Bx)

Ω

10 k

Figure 4: Sortie du transistor à collecteur ouvert pour commande de la pompe

32 - 1094

BC 337 ou autre

Sortie

Page 35

4 MISE EN SERVICE ET MONTAGE

4.1 Autres documents importants

ATTENTION!

REMARQUE

Pour la mise en service de la commande, préparez la documentation suivante:

• Fiche technique/instructions de service du compteur à pistons/ordinateur de la

colonne de distribution

• Fiche technique/instructions de service de la vanne proportionnelle type 2832

de Bürkert

• Fiche technique/instructions de service de la pompe à vide - nécessaire pour le

réglage du facteur de correction

• Instructions de service de l‘unité de commande manuelle type MKNE-1094 de

Bürkert

Pour le branchement des différents composants de la colonne de

distribution à la commande type 1094, les conditions respectives

d‘interface, telles que niveaux, fréquences, résistances, courants,

etc., doivent être respectées. Ces valeurs peuvent être trouvées

dans les fiches techniques et/ou les instructions de service pour

les composants individuels.

La documentation générale relative à la colonne de distribution

peut être obtenue auprés du constructeur ou du fournisseur de la

colonne.

4.2 Branchements électriques

Avant la mise en service, branchez soigneusement toutes les connexions néces-

saires de la commande (voir fig. 5).

Les connexions suivantes soivent être ètablies:

• Tension de service 24 V DC

• Signal de sortie pour vanne proportionnelle type 2832

• Signal sortie pour relais ou contacteur de la pompe à vide

• Signal d'entrée en fréquence de l'ordinateur de colonne

français

REMARQUE

L‘utilisation et l‘étalonnage de la commande s‘effectuent exclusivement par l‘intermédiaire de l‘unité de commande manuelle type MKNE-1094, qui peut être reliée à la

commande au moyen d‘une fiche SUB-D à 9 pôles.

Pour les commandes d‘exploitation à double colonne, prévoir une fiche SUB-D séparée pour chaque côté (côté A et côté B).

Fils/câbles

Les connexions filaires à utiliser à l‘intérieur de la colonne de distribution ne sont soumises à aucune exigence particulière, car les

courants et puissances en jeu sont très faibles.

Tous les câbles à utiliser doivent être munis d‘embouts de fils.

1094 - 33

Page 36

Branchement de l'unité de commande

(fiche SUB-D à 9 pôles)

Commande èlectronique

type 1094 standard

Microfusible 0,4 A M

fran çais

LED rouge = actif

Entrées

LED "Vanne proportionnelle active"

LED "Pompe active"

LED "Tension en service en"

Entrée en fréquence (GND)

Entrée en fréquence 1 (+)

libre

libre

libre

libre

Entrée tension (+ 12 V) *

* L'entrée et la sortie en tension sont ici rebouclées

Figure 5: Branchements électriques

Sorties

Vanne proportionnelle (+)

Vanne proportionnelle (-)

Contact de protection PE

Contact de protection PE

Tension de service (GND)

Tension de service (+ 24 V)

Sortie vers pompe (+ 24 V)

Sortie vers pompe (-)

libre

Entrée tension (+ 12 V) *

34 - 1094

Page 37

5 UTILISATION ET FONCTIONNEMENT

5.1 Eléments d'affichage

La commande possède 3 LED rouges

pour les affichages suivants

• „Vanne proportionnelle active“

• „Moteur pompe actif“

• „Tension d'alimentation branchée“

5.2 Réglage et utilisation de la commande

Pour le réglage de la commande dans une colonne de distribution, tous les composants, lignes de signaux et compteur d‘essence doivent être branchés conformément

aux prescriptions.

L‘utilisation et l‘étalonnage de la commande s‘effectuent exclusivement par l‘intermédiaire de l‘unité de commande manuelle type MKNE-1094, qui peut être reliée à la

commande au moyen d‘une fiche SUB-D à 9 pôles.

REMARQUE

Les réglages possibles avec l‘unité de commande manuelle sont décrits de manière

exhaustive dans les instructions de service du type MKNE-1094.

Pour les commandes d‘exploitation à double colonne, prévoir une

fiche SUB-D séparée pour chaque côté (côté A et côté B).

5.3 Etalonnage de la commande

La commande électronique de récupération des vapeurs d‘essence est pilotée par

programme, et doit être adaptée aux processus effectifs de la colonne (étalonnage)

avant la première utilisation. L‘étalonnage s‘effectue par l‘intermédiaire de l‘unité de

commande manuelle séparée (externe) type MKNE-1094.

Cette unité de commande est accompagnée d‘instructions de service séparées. Lisez

attentivement ces instructions et sélectionnez le mode opératoire correspondant à

l‘application concernée.

REMARQUE

Avant de procéder à l‘étalonnage, les valeurs de fréquence d‘impulsion, de facteur K et de temporisation de la pompe doivent être

définies et introduites.

5.4 Fréquence d'impulsion et entrée en fréquence

La fréquence d‘impulsion délivrée par l‘ordinateur de la colonne de distribution est

déterminée par le constructeur de la colonne. La fréquence indiquée peut être réglée

sur la commande au moyen de l‘unité de commande manuelle type MKNE-1094.

français

1094 - 35

Page 38

5.5 Facteur K de débit d'aspiration

Le facteur K de débit d‘aspiration a pour but de corriger la différence entre les propriétés d‘écoulement de l‘air et des vapeurs d‘essence. Cette correction est nécessaire, car le système d‘aspiration est configuré préalablement en fonction de l‘air atmosphérique, et est destiné à fonctionner ultérieurement avec des vapeurs d‘essence.

Le facteur K est un paramètre spécifique à l‘installation. Il est déterminé par le quotient des débits volumiques de l‘air et des vapeurs d‘essence.

Pour d‘autres informations sur la détermination du facteur K, se reporter aux

instructions de service de l‘unité de commande manuelle type MKNE-1094

(au chapitre „Introduction à la technique de récupération des vapeurs d‘essence“,

paragraphes „Indications relatives au débit volumique...“ et „Détermination du facteur

de correction“.

5.6 Temporisation de la pompe

La temporisation de la pompe est le temps durant lequel la pompe à vide continue de

fonctionner entre la fin du ravitaillement (fermeture de la vanne proportionnelle) et l‘arrêt. Cette temporisation permet d‘aspirer la quantité résiduelle de vapeurs d‘essence

dans les flexibles.

5.7 Exploitation de la colonne de distribution

fran çais

Durant l‘étalonnage, la commande saisit automatiquement la caractéristique courant

de vanne-débit de gaz de toute l‘installation, enregistre les points caractéristiques et

procède automatiquement à la linéarisation de cette caractéristique par interpolation

linéaire. La commande du débit de vapeurs d‘essence aspirées s‘effectue sur la base

de cette caractéristique linéarisée.

Après l‘étalonnage, les vapeurs d‘essence refoulées lors du ravitaillement sont automatiquement aspirées à travers la conduite d‘aspiration du pistolet de distribution.

REMARQUE

36 - 1094

Le mode opératoire d‘une colonne de distribution est expliqué de

manière détaillée au chapitre „Description du système“.

Page 39

6 ENTRETIEN ET DEPANNAGE

6.1 Entretien

La commande électronique de récupération des vapeurs d‘essence exploitée conformément aux présentes instructions ne nécessite aucun entretien.

6.2 Dérangements

Dérangement Cause Mesure correctrice

L'appareil ne fonctionne pas

( LED "Tension de service en" = noire)

Tension de service absente

Fusible grillé Remplacer le fusible

Vérifier l'alimentation

èlectrique

(microfusible 0,4 A,

moyen)

français

1094 - 37

Page 40

Bürkert Company Locations

Contact addresses / Kontaktadressen

Germany / Deutschland / Allemange

Bürkert Fluid Control System

Sales Centre

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the internet at:

Die Kontaktadressen finden Sie im Internet unter:

Les adresses se trouvent sur internet sous :

www.burkert.com

Page 41

The smart choice

of Fluid Control Systems

www.buerkert.com

Loading...

Loading...