Page 1

Operating Instructions

Bedienungsanleitung

Instructions de Service

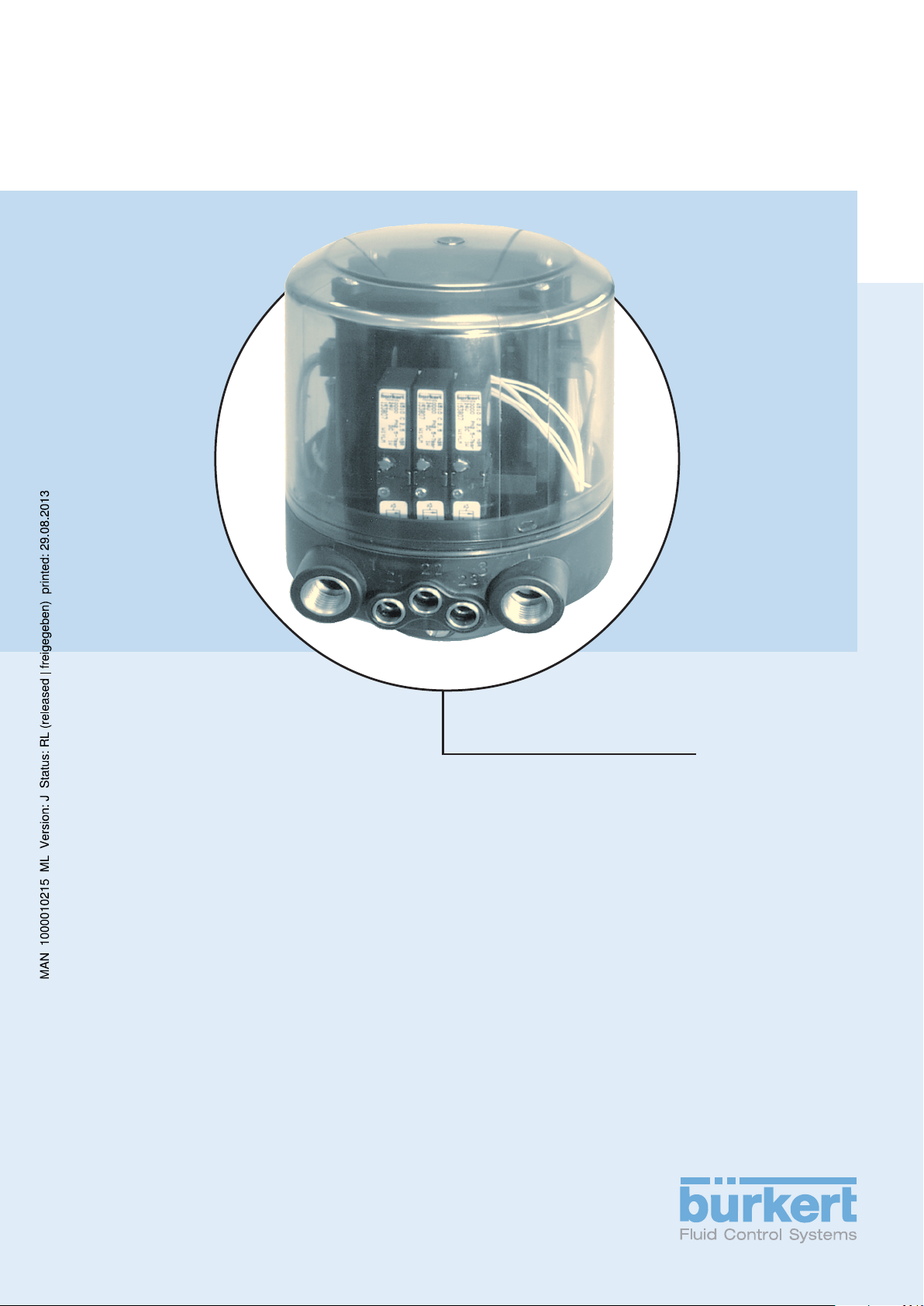

Type 1066

Control Head

Steuerkopf

Tête de commande

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2002 Bürkert Werke GmbH & Co. KG

Operating Instructions 0509/04_EU-ML_00804373

Page 3

C

ONTENTS

Contents of the

Operating Instructions for the

Control Head Type 1066 for Process Valves

GENERAL INFORMATION

Symbols Used................................................................................................................. 4

Intended use ................................................................................................................... 4

Safety instructions ........................................................................................................... 4

Scope of Delivery ............................................................................................................ 5

Guarantee conditions ...................................................................................................... 5

Transport, storage ........................................................................................................... 6

english

Disposal .......................................................................................................................... 6

TECHNICAL DATA

Structure and Function of the Control Head .................................................................... 8

Characteristics ................................................................................................................ 8

Operating conditions ....................................................................................................... 9

Mechanical data .............................................................................................................. 9

Pneumatic data ............................................................................................................... 10

Electrical data .................................................................................................................10

INSTALLATION

Installation of the control head......................................................................................... 12

Flange adaptor ........................................................................................................................ 12

Installation procedure .............................................................................................................. 13

INSTALLATION AND COMMISSIONING

Pneumatic installation ..................................................................................................... 16

Wiring connections on the control head .................................................................................. 16

Electrical installation ....................................................................................................... 17

Control heads without communication .................................................................................... 17

Control heads with communiction ........................................................................................... 19

1066 - 1

Page 4

C

ONTENTS

MAINTENANCE / CLEANING

Maintenance / Cleaning .................................................................................................. 30

REPAIRS

Repairs ........................................................................................................................... 32

Removing and/or replacing the cover ..................................................................................... 32

Changing the printed circuit board .......................................................................................... 33

Replacing the valve group ...................................................................................................... 33

Changing the valve on versions for 24 / 110 / 230 V UC without communication................... 34

english

Changing the proximity switch/micro-switch........................................................................... 35

Spare parts .....................................................................................................................36

Service addresses .......................................................................................................... 36

2 - 1066

Page 5

GENERAL

GENERAL INFORMATION

INFORMATION

Symbol used................................................................................................................................................................................................................................................... 4

Intended use ................................................................................................................................................................................................................................................... 4

Safety instructions.................................................................................................................................................................................................................................. 4

Scope of Delivery.................................................................................................................................................................................................................................... 5

Guarantee conditions........................................................................................................................................................................................................................ 5

Transport, storage................................................................................................................................................................................................................................... 6

Disposal ................................................................................................................................................................................................................................................................ 6

english

1066 - 3

Page 6

GENERAL INFORMATION

Symbols Used

The following symbols are used in these Operating Instructions:

marks a work step that must be carried out.

ATTENTION!

NOTE

Intended use

english

• The control head for process valve type 1066 is used to control pneumatically-activated process

valves and record their switching statuses. Other incidents of use are deemed non-compliant.

• The Technical Data presented in these instructions, on the datasheet and on the type plate must be

checked for consistency before commissioning and complied with during operation of the control head.

• Unauthorized rebuilding or changes to the device are not allowed for safety reasons.

• Shield the control head from interventions by unauthorized persons. To this end the control head can be

secured on the boreholes present on the cover and casing by means of a lead seal and / or cutting

screw.

• The working directions given in these instructions and safety indications must be followed and

complied with at all times. If the operating instructions, safety tips, or safety information are ignored or

not followed in the proper order, the warranty shall be void.

Indicates information which, if not followed, could result in danger to your health or to

the functionality of the machine.

Indicates important additional information, tips and recommendations.

Safety instructions

Follow the instructions of this operating manual, along with the terms of use and permitted data as

specified for process valves on the datasheets and the control head type plate, so that the device can

operate smoothly and have a long service life.

• When planning the application of the device, and during its operation, observe the general technical

rules!

• Installation and maintenance work may only be carried out by specialist staff using the correct tools!

• Use only original replacement parts for necessary repairs, and when changing these parts observe the

directions in these instructions.

• Observe the relevant accident prevention and safety regulations applicable for elekctrical equipment

while operating and maintaining the device!

• Always switch off the electrical power supply before carrying out any works on the system!

• Note that piping or valves must not be removed from a system that is under pressure!

• Take suitable measures to prevent unintentional operation or impermissible impairment.

• Following an interruption of the electrical or pneumatic supply, ensure a defined and controlled re-start

of the process!

4 - 1066

Page 7

GENERAL INFORMATION

NOTE

• Avoid larger mechanical loads on the control head, as these may lead to mechanical impairment or

destruction of the control head. These include walking on the control head, placing heavy objects on it,

heavy impacts, falling hard objects etc.

• Avoid the infiltration of moisture into the control head. When assembling in particular, make sure that all

seals are fitted according to directions and assembly screws, cable screw connections and sealing

plugs are securely tightened. Use only dried control air!

NOTE

• Avoid attaching longer and mechanically rigid attachment parts, since extensions of this type would

produce leverages through which the casing could be destroyed by hand.

NOTE

• Use only highly compatible cleaning products when cleaning the control head and rinse thoroughly with

clear water after these cleaning products have been used. The compatibility of the cleaning product

should be tested where necessary.

NOTE

The control head is designed in protection type IP67. This supposes that all seals

are positioned correctly and that casing and cover are mechanically intact.

With regard to its mechanical resistance, the plastic casing of the control

head is designed for direct attachment of flexible hoses and conduits only.

Cleaning products often contain aggressive components that may become

deposited in small grooves and cavities on the control head, and their prolonged

effect may lead to the desctruction even of high-quality plastics.

A pressure-relief valve is situated on the underside of the control head casing,

serving as rupture protection in the event of an leaky component in the control

head (leakage incident).

english

• When assembling the control head, ensure a minimum distance of 5 mm between the pressure-relief

valve and the neighbouring component so that the pressure-relief valve can disengange without

problems in the event leaking. Otherwise, the cover could literally be "exploded" in the event of leakage

in the control head.

• If these instructions are ignored, no liability will be accepted from our side, and the guarantee on the

device and its accessories will also become invalid!

Scope of Delivery

Immediately after receiving the shipment, ensure that the contents are undamaged and correspond to the

scope of the delivery listed on the enclosed packing note. In case of any discrepancies, please contact

our Call Center:

or your local Bürkert Sales Center immediately.

Guarantee conditions

Bürkert Fluid Control System, Call Center

Chr.-Bürkert-Str. 13-17, D-74653 Ingelfingen

Tel. 07940 - 10 111 / Fax 07940 - 10 91 448

E-Mail: info@de.buerkert.com

This document contains no agreement to provide a guarantee. We would refer you here to our General

Selling and Business Conditions. The precondition for the guarantee is the correct usage of the device

under compliance with the specified application conditions.

ATTENTION!

The guarantee only applies to the freedom from fault of the Head Control of the

process valves. No liability will be accepted, however, for consequential damage of any

kind that could arise from the failure or malfunctioning of the device.

1066 - 5

Page 8

GENERAL INFORMATION

Transport, storage

ATTENTION!

Disposal

english

ATTENTION!

Transport and store the appliance in its original packing only.

Storage in a dry room.

Maximum storage temperature +50 °C

When disposing of the appliance, observe the national standards for refuse disposal.

6 - 1066

Page 9

TECHNICAL DATA

TECHNICAL DATA

Structure and Function of the Control Head ................................................................................................................................................... 8

english

Characteristics............................................................................................................................................................................................................................................. 8

Operating conditions .......................................................................................................................................................................................................................... 9

Mechanical data........................................................................................................................................................................................................................................ 9

Pneumatic data .......................................................................................................................................................................................................................................... 10

Electrical data ............................................................................................................................................................................................................................................... 10

1066 - 7

Page 10

TECHNICAL DATA

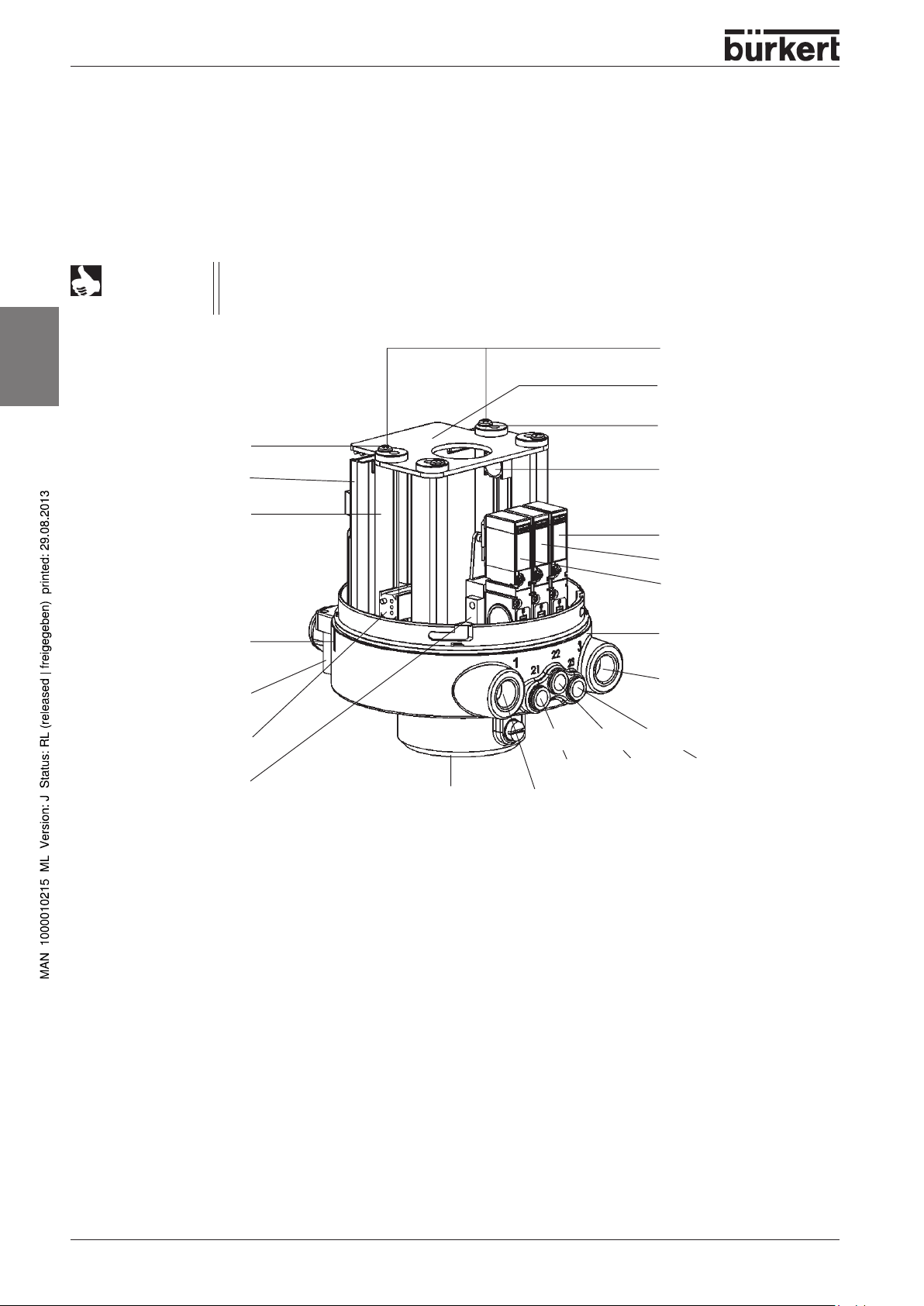

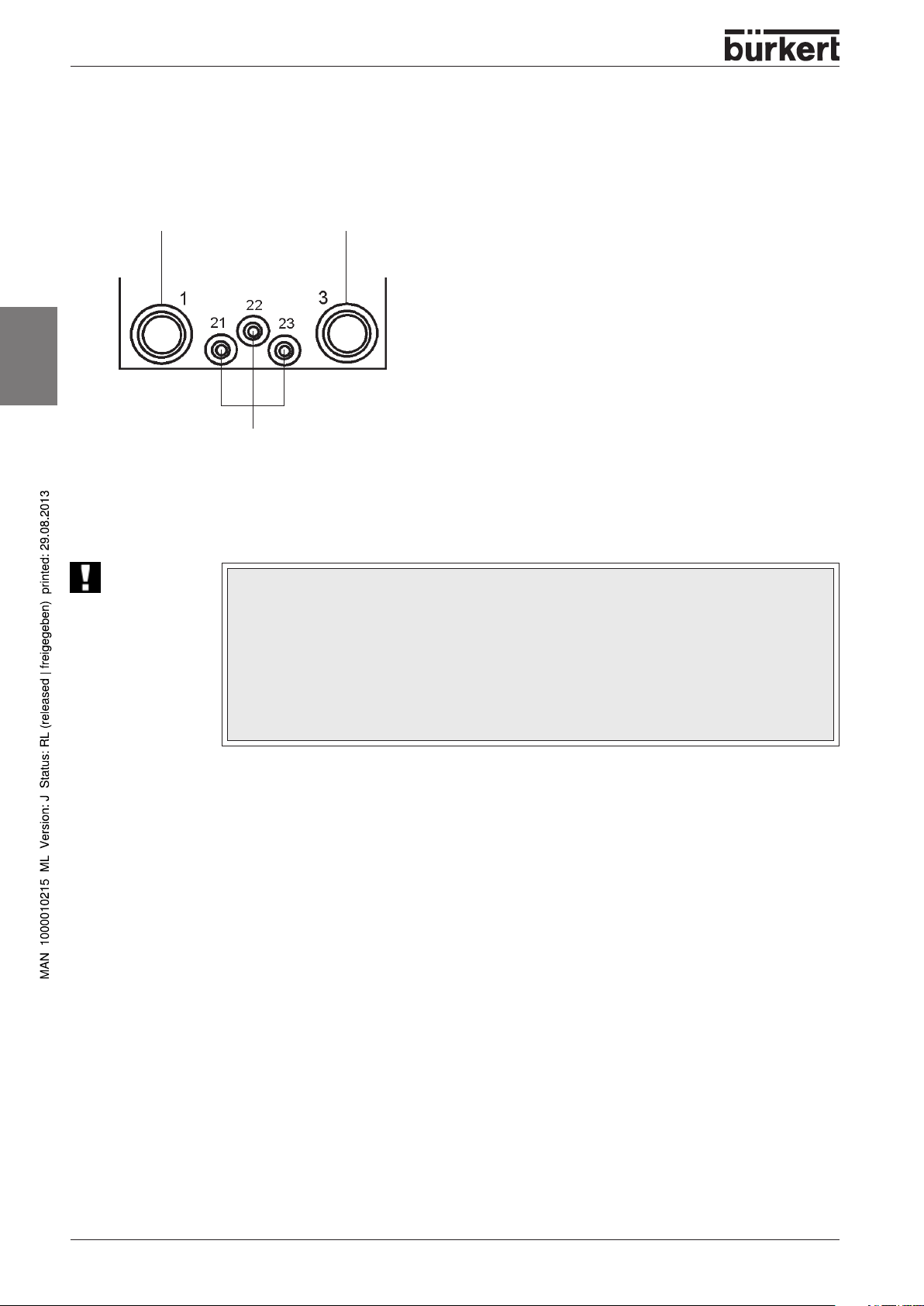

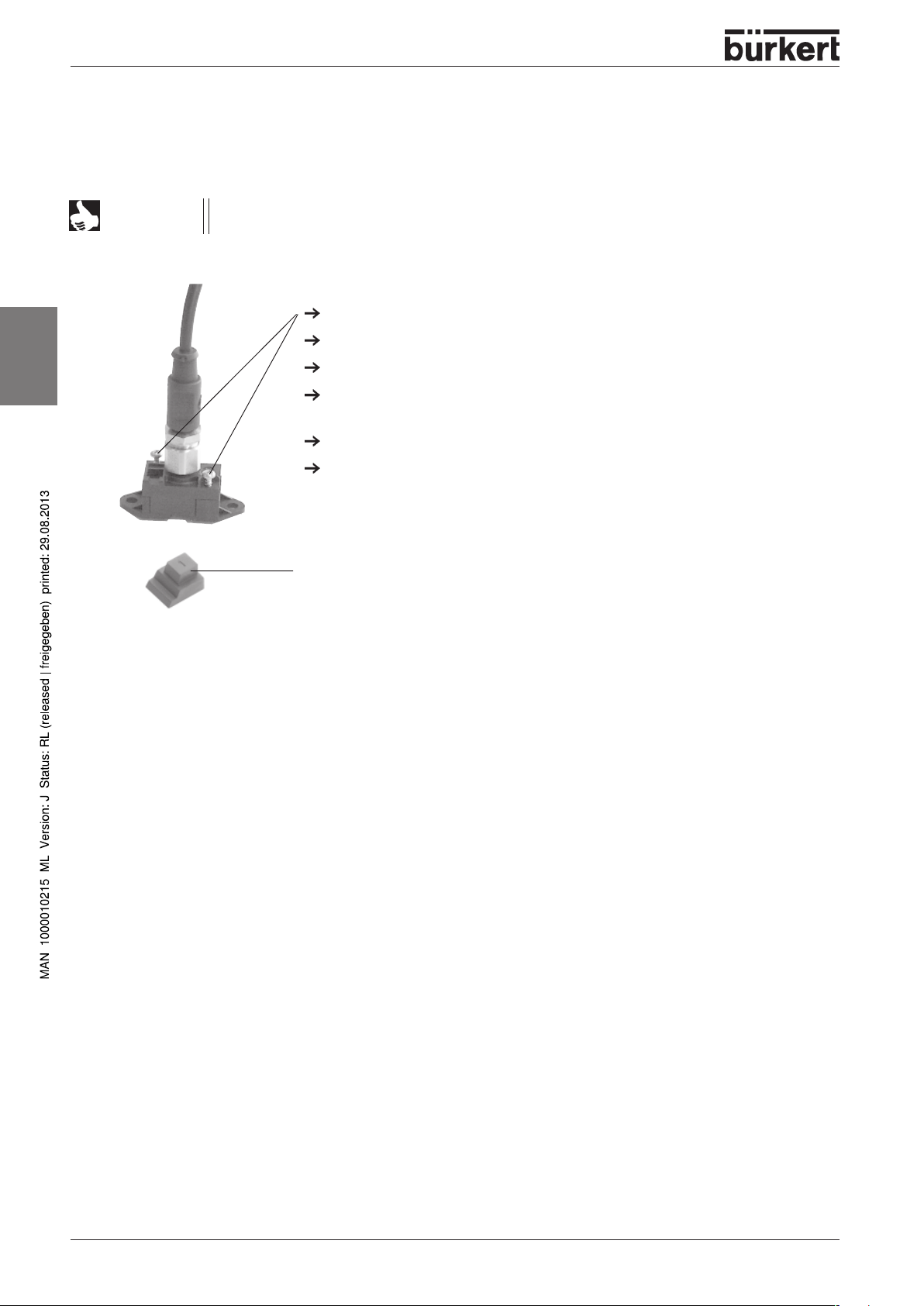

Structure and Function of the Control Head

The Type 1066 control head is used to control pneumatically operated process valves from various

manufacturers. Depending on the configuration, it can be fitted with up to three solenoid valves (pilot

valves) for control of the process valve and with a maximum of three height-adjustable inductive

proximity sensors for position feedback. One of these sensors can also be an external sensor

(Attachment via 3-pole screw clamp on printed circuit board).

english

Column with spindle

mounting the cover

Electrical connection

NOTE

Adjustment of the

proximity sensor 1

Printed card

Marking for

For sealed fieldbus modules, pay attention to the numbering of the proximity switch on the

circuit board / the identification on the device, since deviations from the numbering in the

drawing below are possible.

Adjustment throug

these holes

Cover plate

Adjustment of proximity

sensor 2

Proximity sensor 2

Solenoid valve 3

Solenoid valve 2

Solenoid valve 1

Housing

Exhaust air

Proximity sensor 1

Valve flange

Characteristics

With the Type 1066 control head, there is a de-central solution for driving the process valves in addition to

the intended central solution for valve blocks. The advantages of this solution in the form of the compact

control head

Main areas of application:

unit with the pilot valves and optionally usable field bus interfaces are:

Pneumatic connections

Valve 1

Compressed airInterface to the

process valve

Lower installation outlay.

Simple commissioning.

Short response times due to the short distance between the pilot valve and the

process valve.

Foodstuff industry (e.g. dairies)

Chemical industry

Pharmaceutical industry

Valve 3Valve 2

8 - 1066

Cosmetics industry

Breweries

Page 11

TECHNICAL DATA

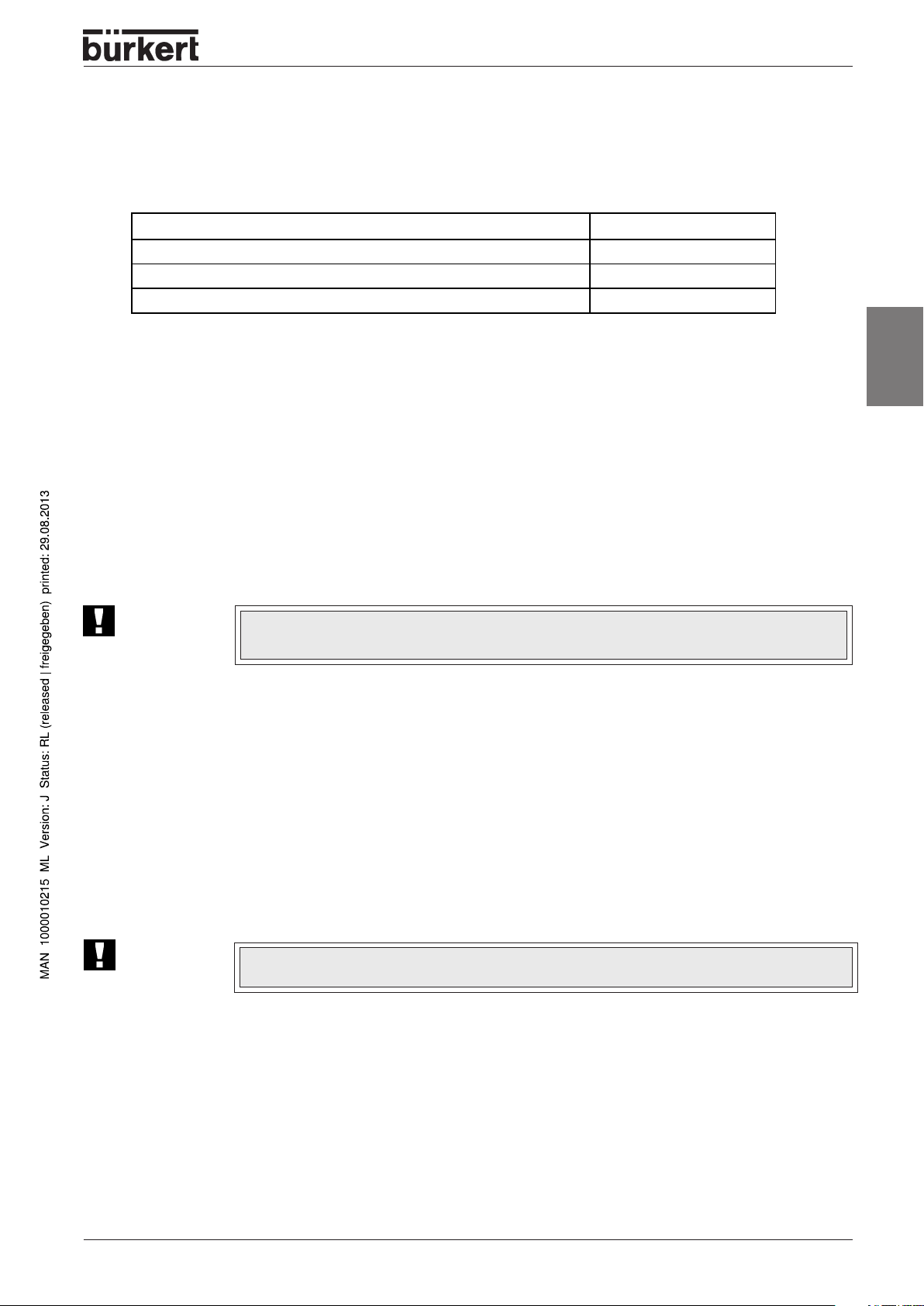

Options

Number of pilot valves

Operating mode / Type of application Number of pilot valves

Single-acting actuators 1

Double-acting actuators 2

Dual-seat valves with integrated air supply to both valve seats 3

Control heads without communication

8-pole screw terminal for 24 V DC

Multipol (8-pole round plug) for 24 V DC

2 x 6 screw terminals for 24 / 110 / 230 V UC

Control heads with communication

Actuator sensor interface (ASI)

DeviceNet

ATTENTION!

The connection to other (higher) bus systems is possible using commercially available

Gateways.

Operating conditions

Media Compressed air, non-oiled; neutral gases

english

Medium temperature -10 ... + 50 °C

Ambient temperature -10 ... + 50 °C

Protection class IP 67

ATTENTION!

The control head is not suitable for use outdoors!

Mechanical data

Weight 0.5 bis 0.65 kg (depending on model)

Housing material Housing PA / PPE

Cover PSU (transparent, blue-grey)

Sealing material NBR

1066 - 9

Page 12

TECHNICAL DATA

Pneumatic data

Port connections Compressed air/Exhaust air G 1/4

Service ports tube hose connection

6/4 mm or 1/4 inch, plug-in

Pressure range 2.5 to 7 bar

Air flow, control valve 110 l/min Type 6510, 40 l/min Type 6106

english

Flow: Q

Measurement at +20 °C, 6 bar pressure at the valve inlet and 1 bar

pressure difference

Response times Type 6510 / Type 6106

Opening 15 / 23 ms Closing 10 / 21 ms

Measurement at valve outlet at 6 bar and +20 °C

Opening: pressure rise 0 to 90 %

Closing: pressure fall 100 to 10 %

Control range min. stroke 2mm max. stroke 73 mm

- value air (l/min)

Nn

Electrical data

Protection class IP 67

Operating voltage

without communication 24 V DC ±10 %

24/110/230 V UC ±10 %

with communication in accordance with the ASI and DeviceNet specification

Max. electrical power loss 5 W for 3 x Type 6510 or 1 x Type 6106

Connections

Control heads

without communication: Multipol (8-pole round plug DIN 45326) for 24 V DC

(8-pole screw terminals) for 24 V DC

2 x 6-pole screw terminals for 24/110/230 V UC

Control heads

with communication:

ASI: Cut-clamp connector and cable fitting

M12 plug and cable fitting

M12 flange plug, 4-pole

DeviceNet: 5-pole M12 plug connection

Solenoid valves

Nominal power 1 W Type 6510 / 3 W Type 6106

Operating mode continuous (ED 100 %)

Proximity switches

Operating voltage 8 to 30 V DC

Output signal max. 100 mA, short-circuit proof

Micro-switch potential-free, max. 1 A switched current

10 - 1066

Page 13

INSTALLATION

INSTALLATION

Installation of the control head............................................................................................................................................................................................. 12

english

Flange adaptor

Installation procedure

........................................................................................................................................................................................................................................ 12

..................................................................................................................................................................................................................... 13

1066 - 11

Page 14

INSTALLATION

Installation of the control head

Flange adaptor

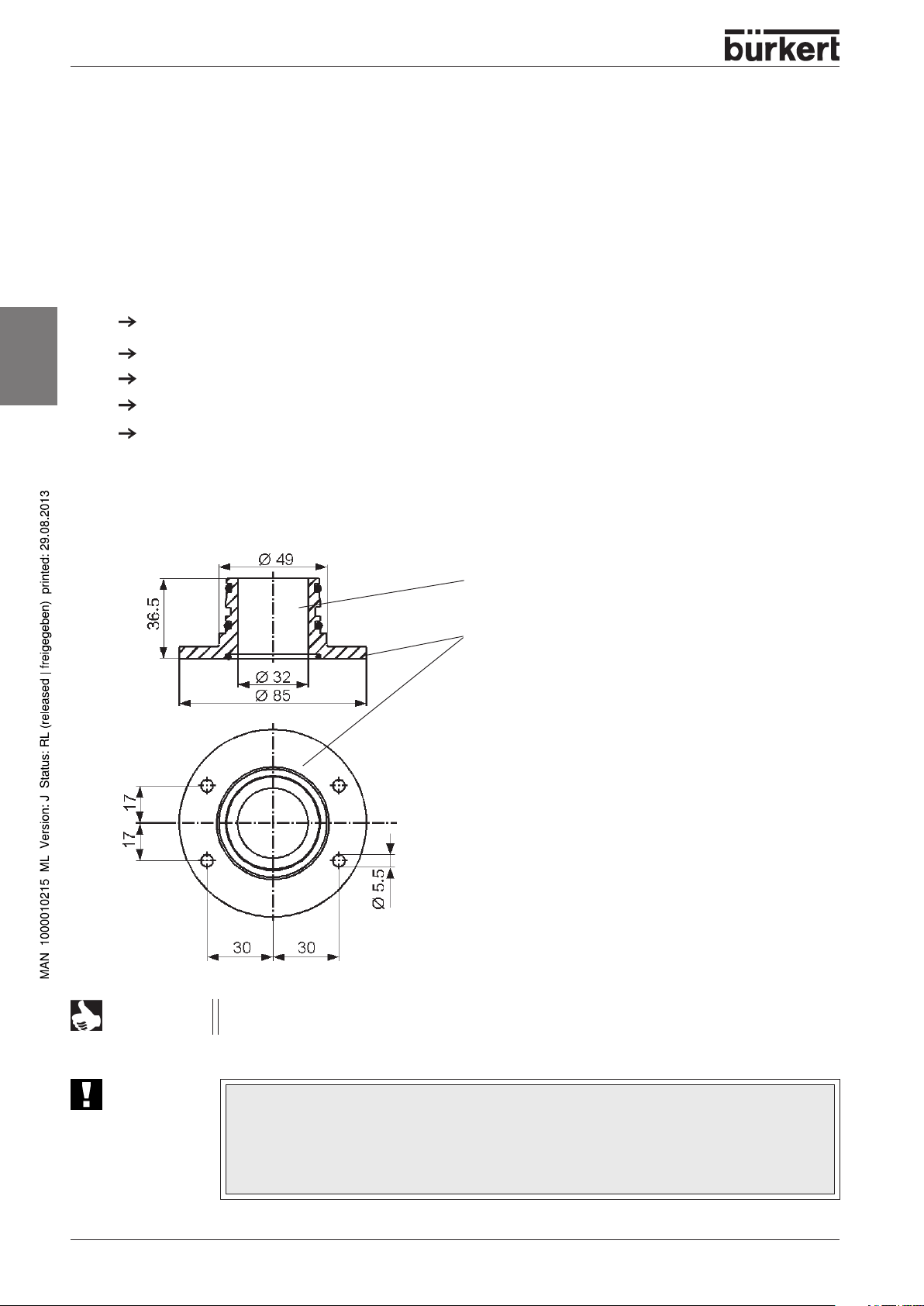

To mount the control head type 1066 on a process valve from a different manufacturer, you need an

adapter with customized flange (flange adapter) and a customized switching knob (see also Data Sheet).

The connecting part for the control head is Bürkert-specific. The flange component must be adapted to

the shape of the process valve. The drawing below shows an application for a special process valve. The

control head can be installed in any position, but preferably with the cover at the top.

When making your own flange, comply exactly with the following parameters:

Dimensions

Number of sealed positions

english

Dimension for the O-ring

Measurement tolerance

Material data

Main dimensions for the flange adapter

Cylindrical adapter part

Custom flange part

NOTE

ATTENTION!

12 - 1066

Please request detailed dimensional drawings if you are manufacturing your own flange

adapter.

A centring device is necessary for the installation of the flange adapter.

maximum permissible deviation is ± 0.1 mm. If this tolerance is exceeded, there is the

danger that the proximity sensors may not function correctly.

Use a special installation sleeve to avoid exceeding this tolerance.

The

Page 15

Installation procedure

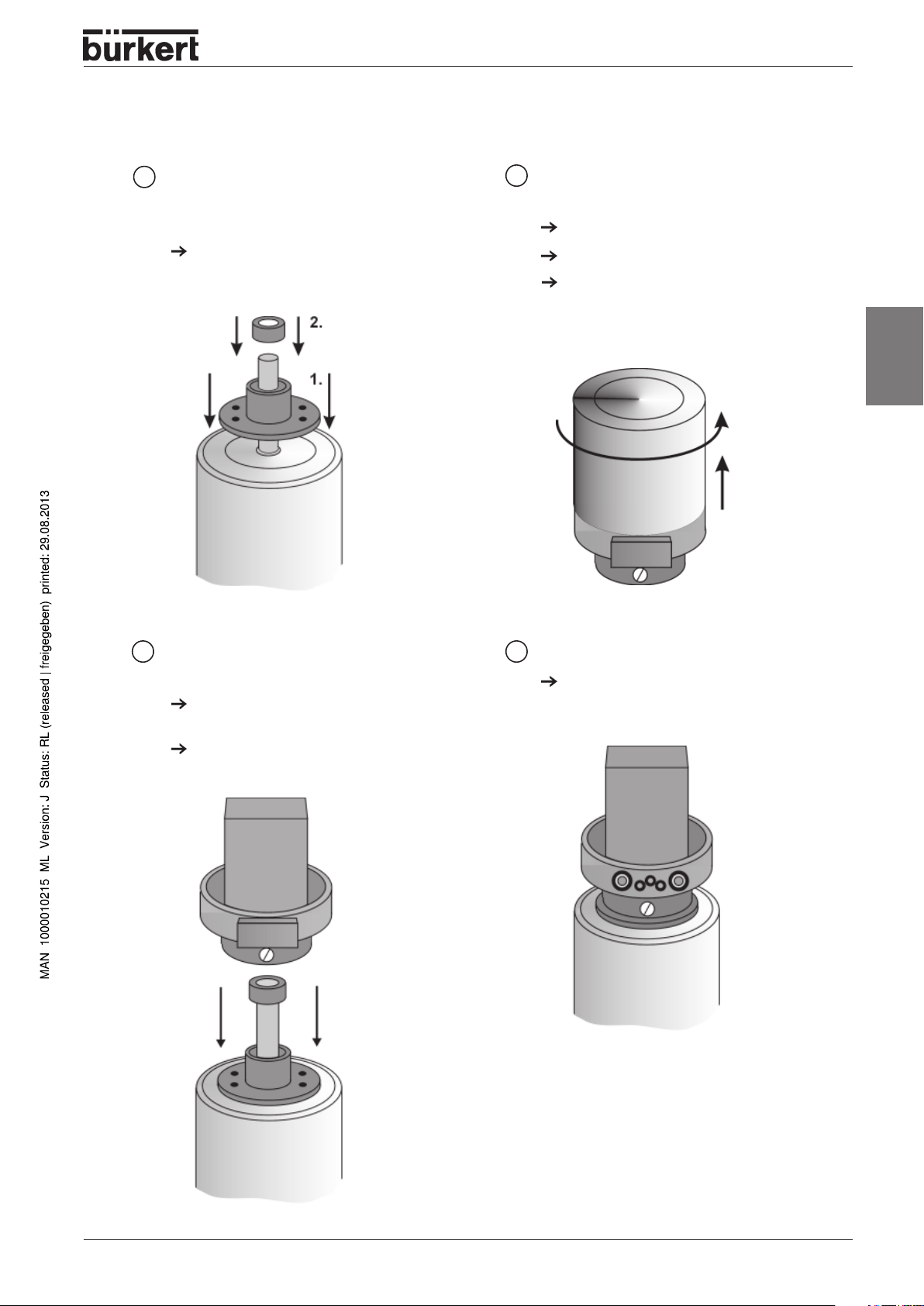

Fix the flange adapter to the

1

process valve/Fix switching knob

to piston rod (customer-specific)

ensure that it is centred

INSTALLATION

Remove the cover from the control

2

head

Loosen the locking screw

Turn the cover to the left to the stop

Pull the cover off upwards

english

Insert the control head onto

3 4

the flange adapter

Position the control head

(control head can be turned through 360°)

Secure the control head using the two

screws on the side

Fit the pneumatic connections

Refer to Pneumatic Installation,

(Installation/Commissioning chapter)

1066 - 13

Page 16

INSTALLATION

english

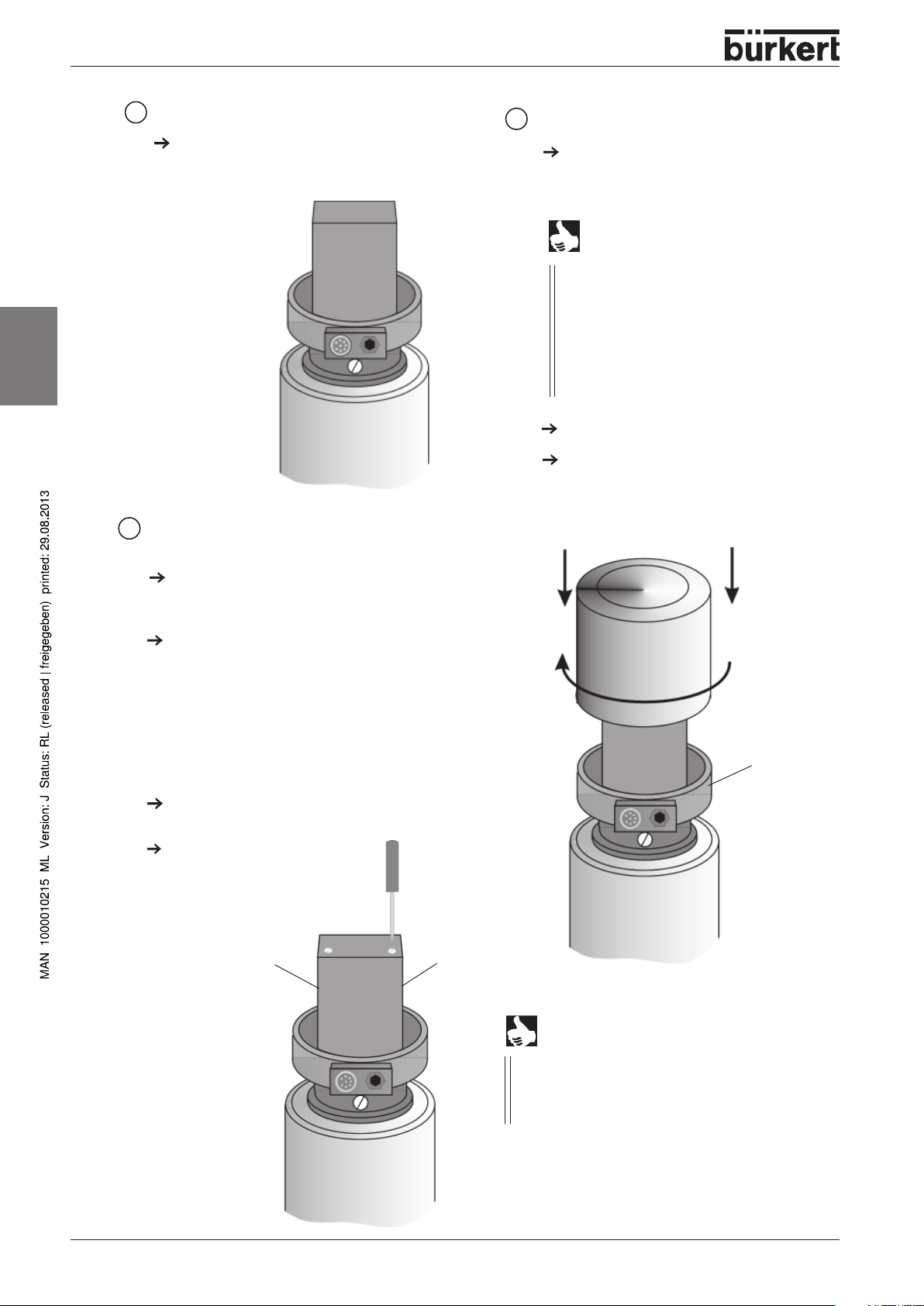

5

Fit the electrical connections

Control heads without and

with communication

(see chapter on electrical installation)

7

Fit the cover

Check the seat of the cover O-ring,

or pull a new O-ring onto the collar of

the cover.

Distributed across the circumference of

the casing are 4 handles that retain the

O ring when the cover is being

removed. Take care to ensure that the

newly-applied O ring is positioned

correctly under the handles and is

resting on the casing without twisting.

Fit the cover.

Turn the cover right until it reaches the

stop.

NOTE

Adjust

6

the proximity sensors

Using a screwdriver, turn the adjusting

screw (spindle) until the optimal position

of the proximity switch has been set up.

The LED mounted on the proximity switch

is an adjustment aid: it lights up when

reaching the corresponding threshold value.

the limit position micro-switches

When using micro-switches, LEDs are not

provided for reasons of cost

Set the position as for the proximity

switches

Using the switching sound

of the micro-switch

(very quiet) as a setting

aid or external electrical

continuity check.

LED

Housing

with cover

collar and

O-ring seat

LED

14 - 1066

NOTE

Secure the cover where necessary to prevent

unauthorised access by inserting a lead seal

and/or self-tapping screw in the holes in the

cover and the housing.

Page 17

INSTALLATION AND COMMISSIONING

INSTALLATION AND

COMMISSIONING

english

Pneumatic installation...................................................................................................................................................................................................................... 16

Wiring connections on the control head

................................................................................................................................................................. 16

Electrical installation .......................................................................................................................................................................................................................... 17

Control heads without communication

8-pole screw terminal for 24 V DC

Multipol (8-pole round plug to DIN 45326) for 24 V DC

2 x 6-pole screw terminals for 24 / 110 / 230 V UC

Control heads with communication

AS-Interface

...................................................................................................................................................................................................................................... 19

Handling the flat cable clamp

Technical data for the ASI circuit board

Programming data

LED status display ASI

Bit allocation

........................................................................................................................................................................................................... 20

............................................................................................................................................................................................ 21

........................................................................................................................................................................................................................... 21

Number of connectable control heads and maximum length of the bus

(ASI standard case and ASI version with extended address range)

..................................................................................................................................................................... 17

....................................................................................................................................................................... 17

............................................................................................................. 18

....................................................................................................................... 18

.............................................................................................................................................................................. 19

............................................................................................................................................................................ 20

............................................................................................................................................... 20

............................................................ 22

DeviceNet

........................................................................................................................................................................................................................................... 24

Explanation of terms

Technical data

...................................................................................................................................................................................................................... 24

Maximum line lengths

Safety setting for bus failure

Electrical connection

Configuration

.......................................................................................................................................................................................................................... 26

LED Status Display

.................................................................................................................................................................................................... 24

................................................................................................................................................................................................. 24

.............................................................................................................................................................................. 25

................................................................................................................................................................................................... 25

...................................................................................................................................................................................................... 28

1066 - 15

Page 18

INSTALLATION AND COMMISSIONING

Pneumatic installation

Wiring connections on the control head

G 1/4 G 1/4

english

Compressed

air

ATTENTION!

Exhaust air

Plug-and-socket connections

for 6/4 mm or 1/4" hose

plug-in

for valves V1, V2 and V3

• Only use calibrated hose lines with 6 mm or ¼ " external diameter.

• Only cut these using a hose cutter (danger of damaging the hose).

• Select the length of the hose so that the control head can be removed with the

screw fitting.

• Take care to ensure a tension-free hose guide well aligned with the plug connector,

since hoses that are plugged in when tensed (contorted) may lead to leakages at

the plug connection.

16 - 1066

Page 19

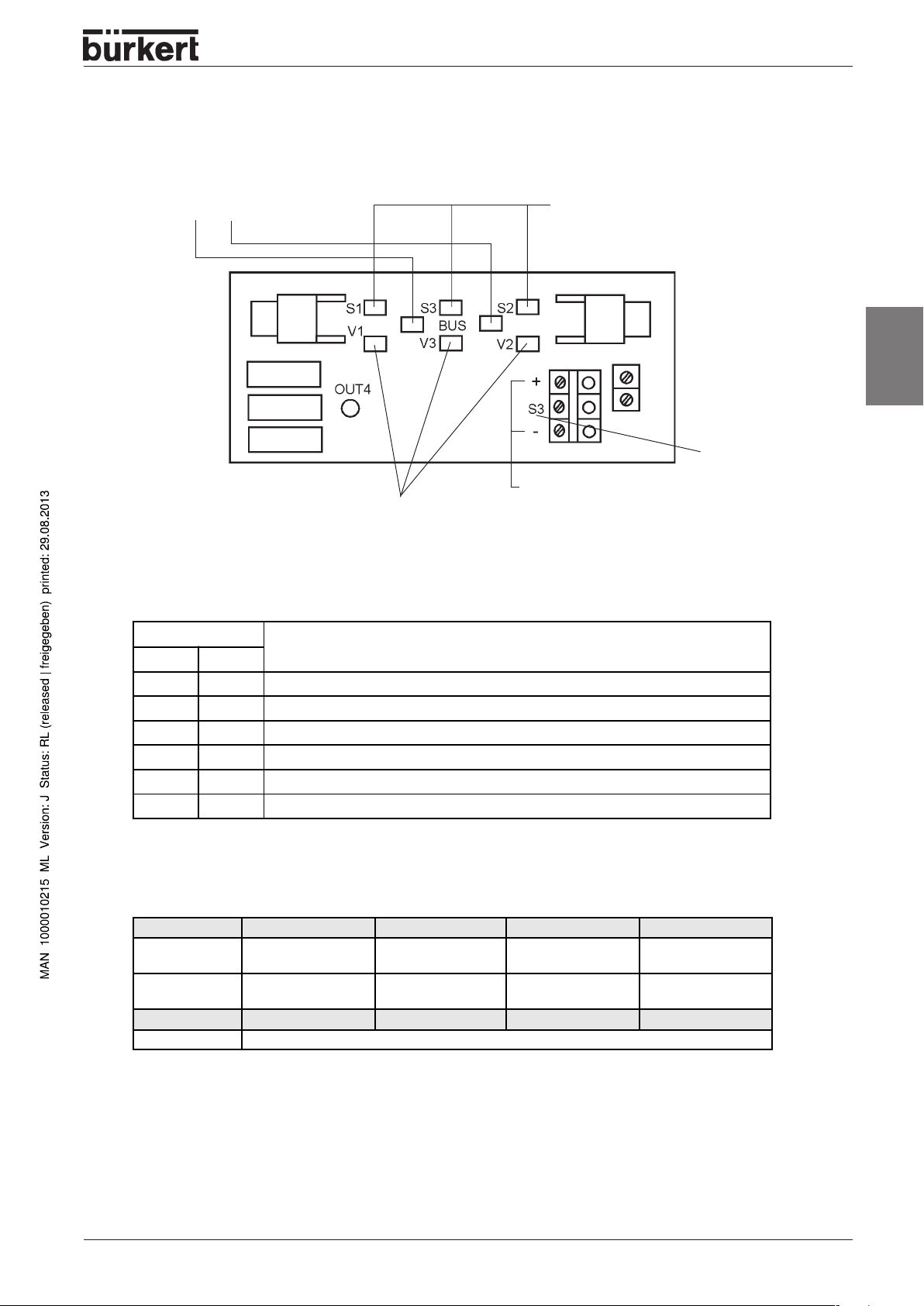

Electrical installation

Control heads without communication

There are different ways of electrically connecting control heads without communication.

On the model for 24 V DC, status per valve is displayed uniformly with an LED in each case.

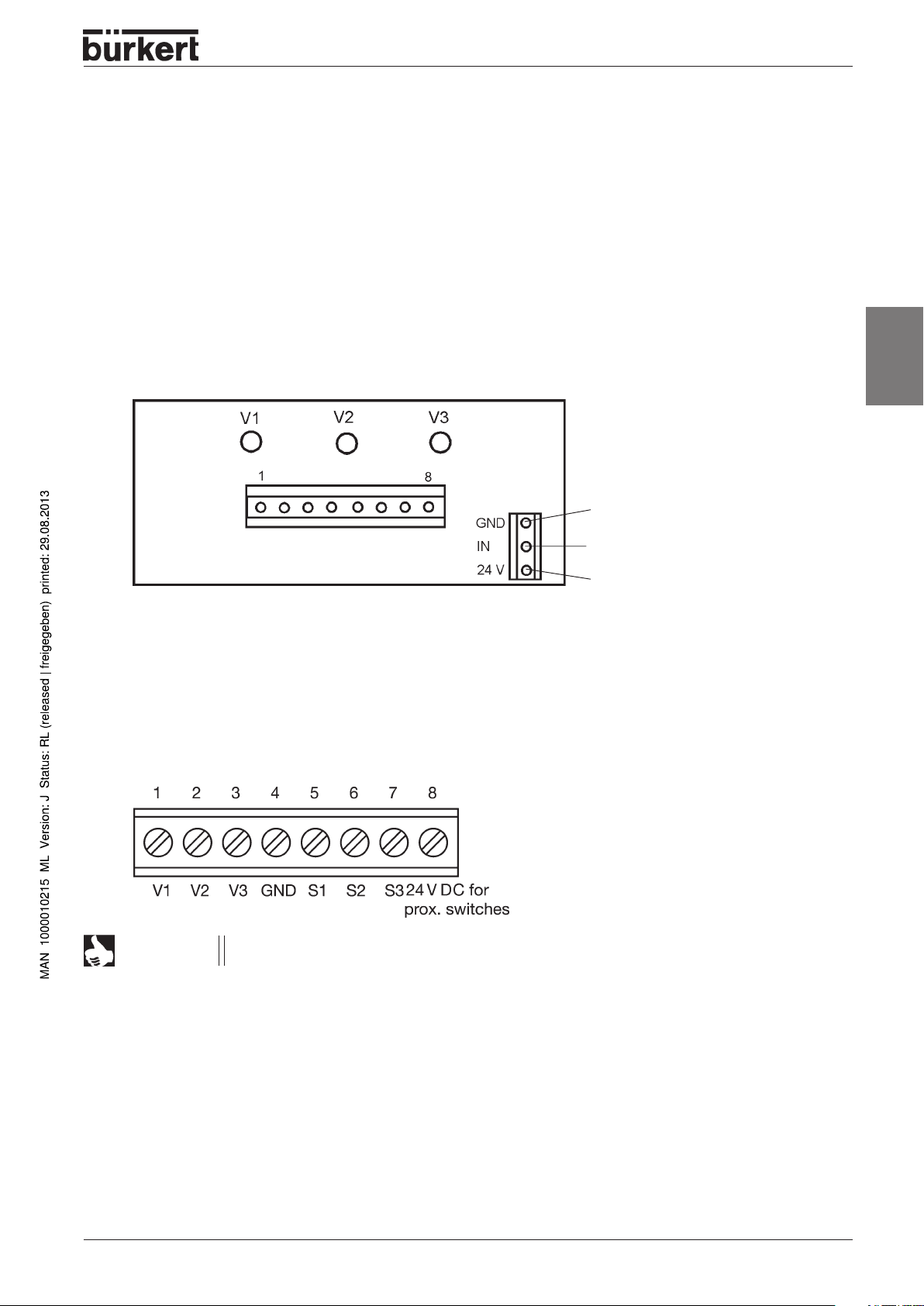

8-pole screw terminal for 24 V DC

(in interior of housing, cable duct with screw fitting for cable)

LED status display 24 V DC

INSTALLATION AND COMMISSIONING

english

Layout of the 8-pole screw terminal

NOTE

The outputs of the proximity switches are pnp-plus switching and are short-circuit proof.

Ground

Switched signal of the external

proximity switch S3

Power supply

V = valve

S = proximity switch (sensor)

1066 - 17

Page 20

INSTALLATION AND COMMISSIONING

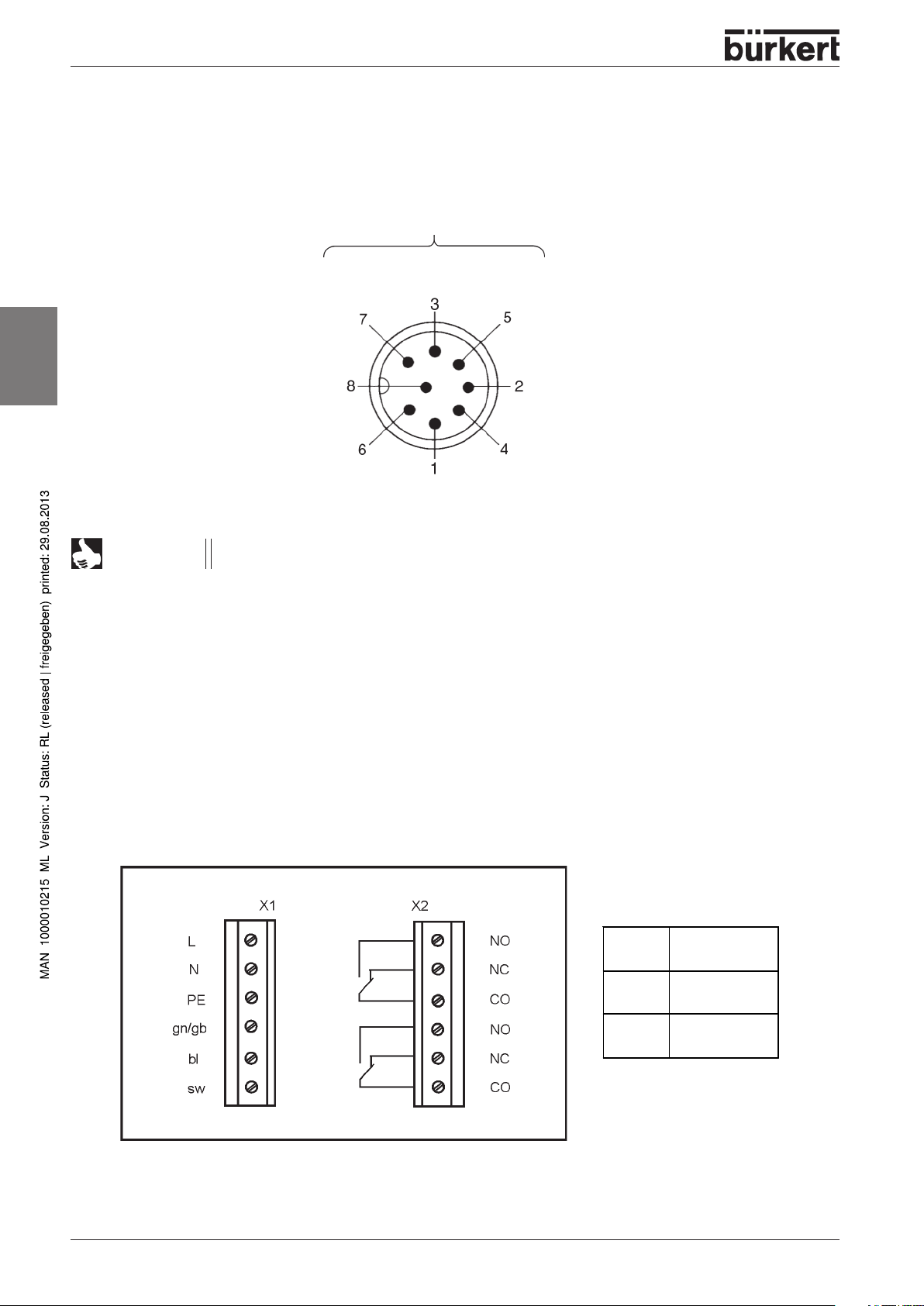

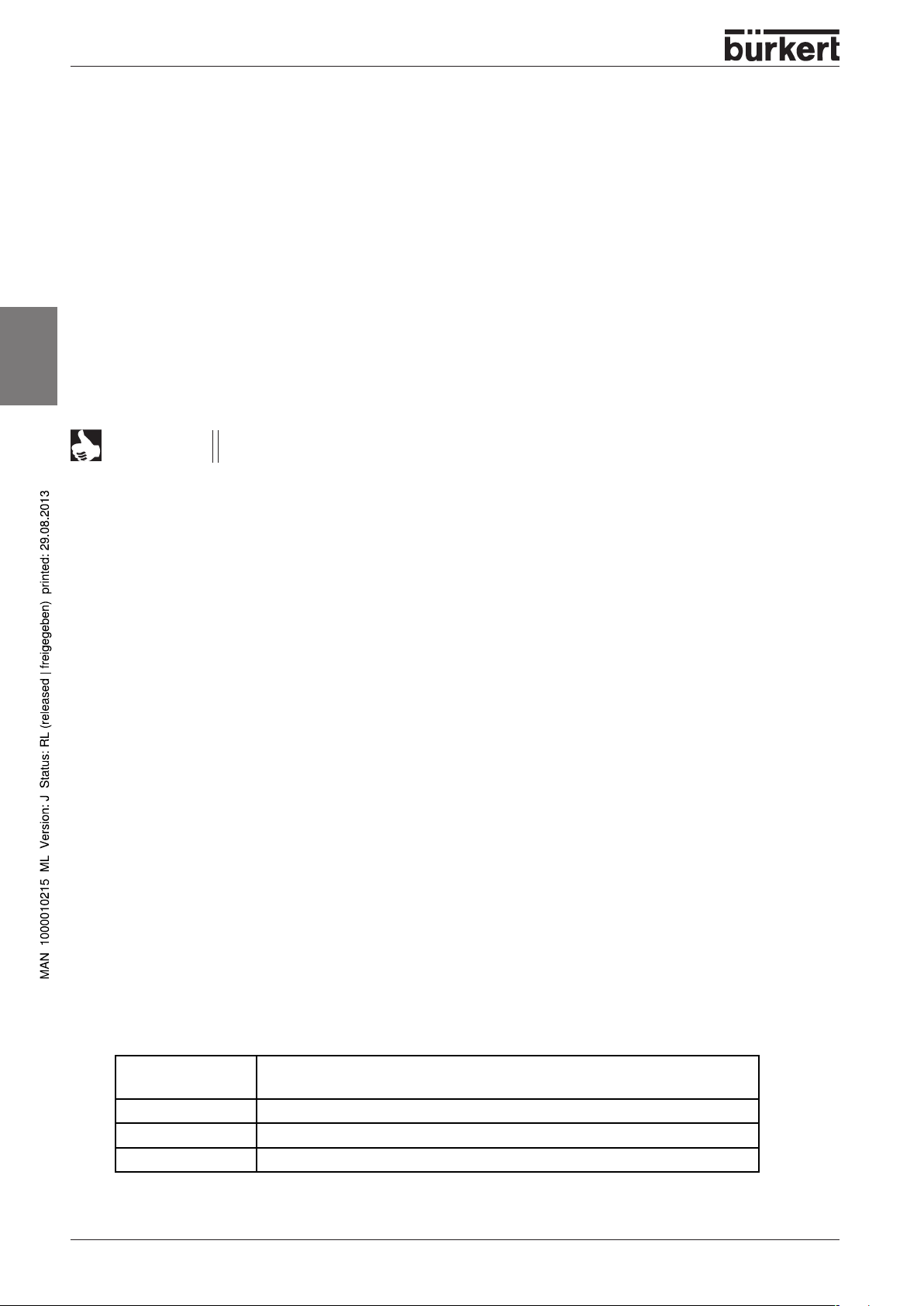

Multipol (8-pole round plug to DIN 45326) for 24 V DC

View of the sensor installed in the head, seen from the front looking at the pins, with the solder

connections below.

Outputs of the proximity switches

pnp-plus switching and are short-circuit proof

english

Proximity switch 2

Valve 3

Proximity

switch 1

24 V DC

(operating voltage for the

proximity switches)

Valve 1

Valve 2

(common earth for valves)

NOTE

The outputs of the proximity switches are pnp-plus switching and are short-circuit proof.

Proximity

switch 3

GND

2 x 6-pole screw terminals for 24 / 110 / 230 V UC

The 2 x 6-pole screw terminal model consists of:

Cable gland with screw fitting for cable

Max. 1 valve (Type 6106, DN1.2)

2 mechanical limit switches with potential-free contacts for position feedback

(No LED status display)

Printed circuit board with 2 x 6-pole screw terminals for 24 / 110 / 230 V UC

gn/gb green/yellow

Switch 1

Valve/Network

Switch 2

bl blue

sw black

18 - 1066

Page 21

INSTALLATION AND COMMISSIONING

Control heads with communication

AS-Interface

ASI (Actuator Sensor Interface) is a field bus system that is used for networking (mainly) binary sensors

and actuators to a master controller.

Bus line

Unscreened pairs (ASI line as ASI format cable) over which both information (data) and energy (power

supplies for the sensors and actuators) are transmitted.

Network topology

Freely selectable within wide limits, i.e., star, tree and line networks are possible. Further details can be

found in the ASWI specification.

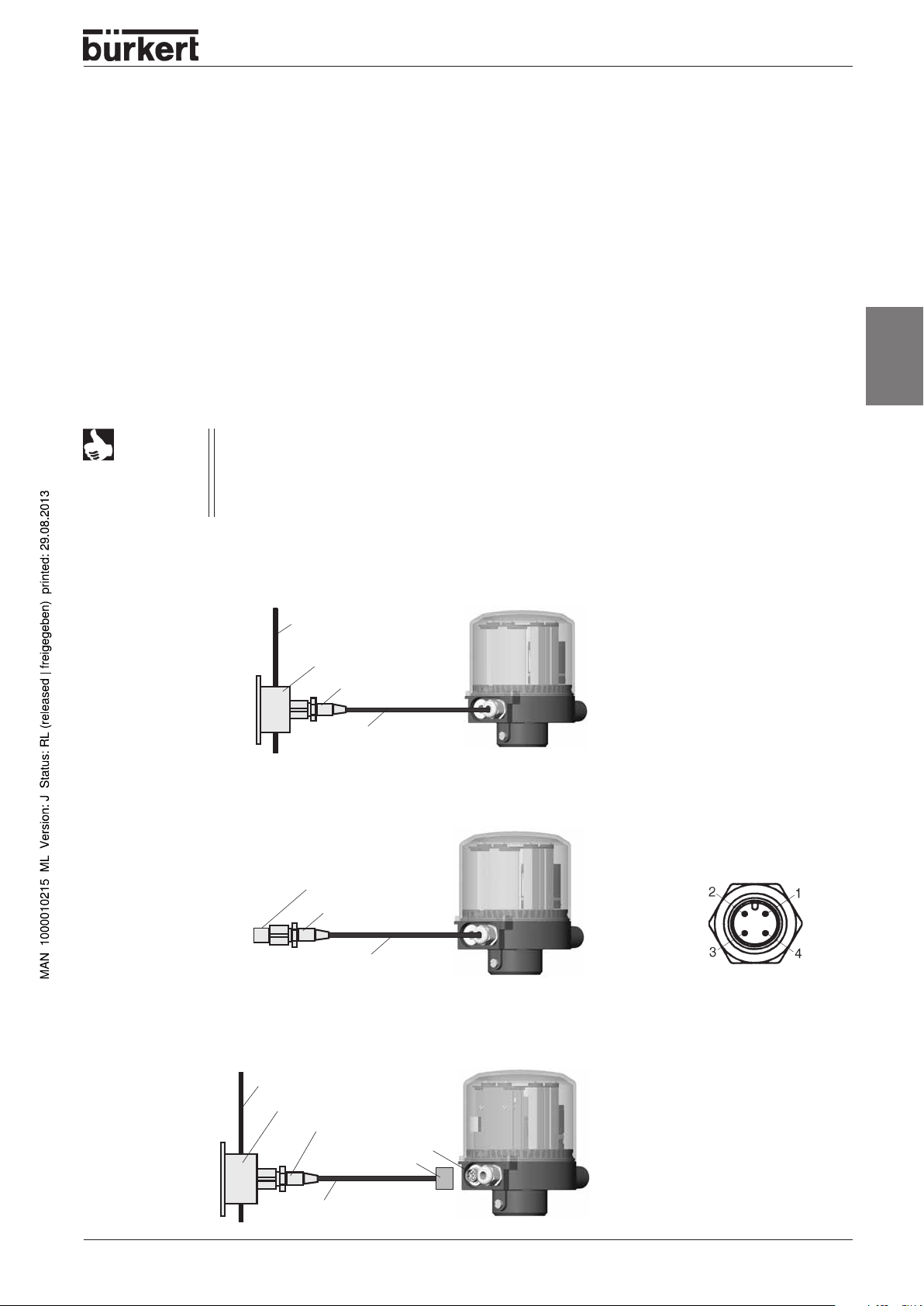

Bus connection variants

NOTE

1. Flat cable clamp on the 1 m round cable

ASI standard connection:

2. 4-pole M12 plug on the 2 m round cable

ASI special connection 1: (on request)

Data for the round cable

The electrical values of the round cable leading directly to the control head deviate slightly

from the ASI specification. When calculating the maximum permissible line length according

to the ASI specification, the length should therefore be set longer by the factor 1.5.

ASI length = 1.5 x real length

ASI format cable

Flat cable clamp

Conductor plug with

moulded cable

Round cable (1 m long, of

which 0.2 m in the control head)

english

4-pole M12 plug for

ASI connection

M12 plug

Conductor plug with

moulded cable

Round cable (1 m long, of

which 0.2 m in the control head)

3. 4-pole M12 plug on the control head, without cable

ASI special connection 2: (on request)

ASI format cable

Flat cable clamp

Conductor plug

M12 flange plug

M12 socket

Round cable (1 m long)

ASI PIN configuration

1 = ASI+

2 = not used

3 = ASI4 = not used

1066 - 19

Page 22

INSTALLATION AND COMMISSIONING

Handling the flat cable clamp

Contact is achieved in the form of a penetration technique using the flat cable clamp for ASI from cables.

Electrical connection is achieved in the process without cutting and skinning the cable.

english

NOTE

Close the second cable aperture using a cable seal if the flat cable terminates in the clamp

(final connection).

Connecting the flat cable clamp with conductor plug and moulded cable

with an ASI flat cable

Loosen both screws on the flat cable clamp.

Separate the upper part of the flat cable clamp from the lower part.

Lay the ASI flat cable in the correct position.

If the flat cable terminates here:

Insert the flat cable seal into the aperture in the correct position.

Place the upper part of the flat cable clamp onto the lower part.

Tighten the screws.

Done!

The electrical connection to the ASI cable has been produced.

Flat cable seal for flat cable clamp

Technical data for the ASI circuit board

Inputs 3 sensors S1 top S3, pnp plus-switching

Supply via the AS interface (24 V +20 % / -10 %), short-circuit proof, current

limited to 60 mA

Switch level High signal ≥ 10 V

Limitation of input current ≥ 6.5 mA, input current Low signal ≥ 1.5 mA

Outputs 3 valves V1 - V3

max. 3 x 1 W

Power reduction after approx. 100 ms, with integrated Watch-Dog function

Programming data

I/O-Code 7 hex (4 outputs and 4 inputs)

ID-Code F hex (see following table for bit allocation); extended ID codes 1 and 2 = F hex

Profile 7.F

20 - 1066

Page 23

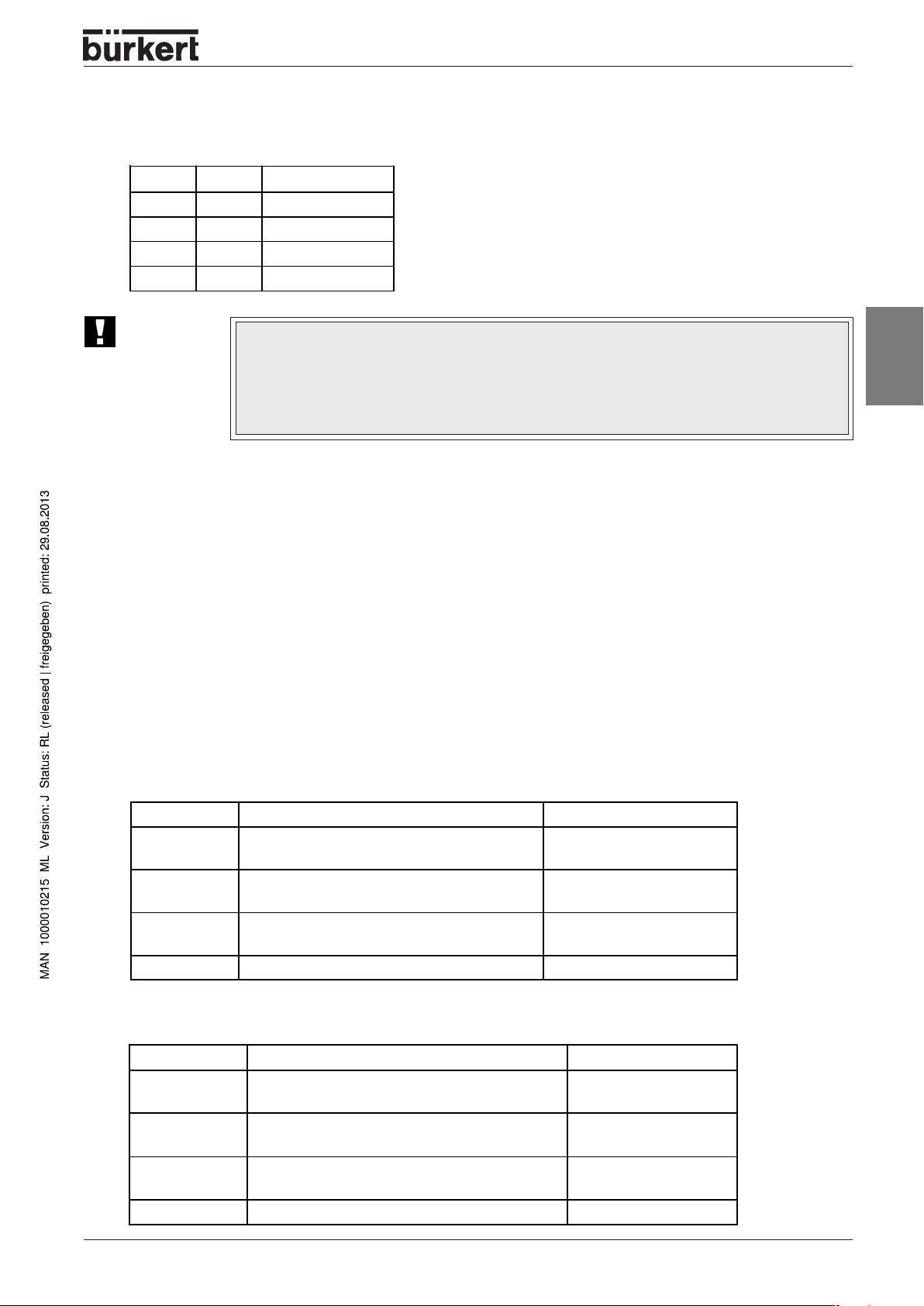

LED status display ASI

Visible part of the ASI printed circuit board

INSTALLATION AND COMMISSIONING

Status display bus

LED green red

LED's for

Valves V1 - V3

LED's for

proximity switches S1 - S3

Power supply for an

external proximity switch

(from the ASI cable)

Overview of ASI LED Status display

LED Bus status

green red

dark dark POWER OFF

dark light No data traffic (expired watch-dog with Slave address not 0)

light dark ok

blinking blinking Peripheral fault (overload in sensor supply)

blinking light Slave address equal to 0

dark blinking RESET

english

Switching signal of

an external proximity

switch

Bit allocation

Data bit D3 D2 D1 D0

Output

LED yellow

Input

Not used

Parameter bit P3 P2 P1 P0

Output

Valve 3

Input

Prox. switch 3

Prox. switch 2

Not used

Output

Valve 2

Input

Output

Valve 1

Input

Prox. switch 1

1066 - 21

Page 24

INSTALLATION AND COMMISSIONING

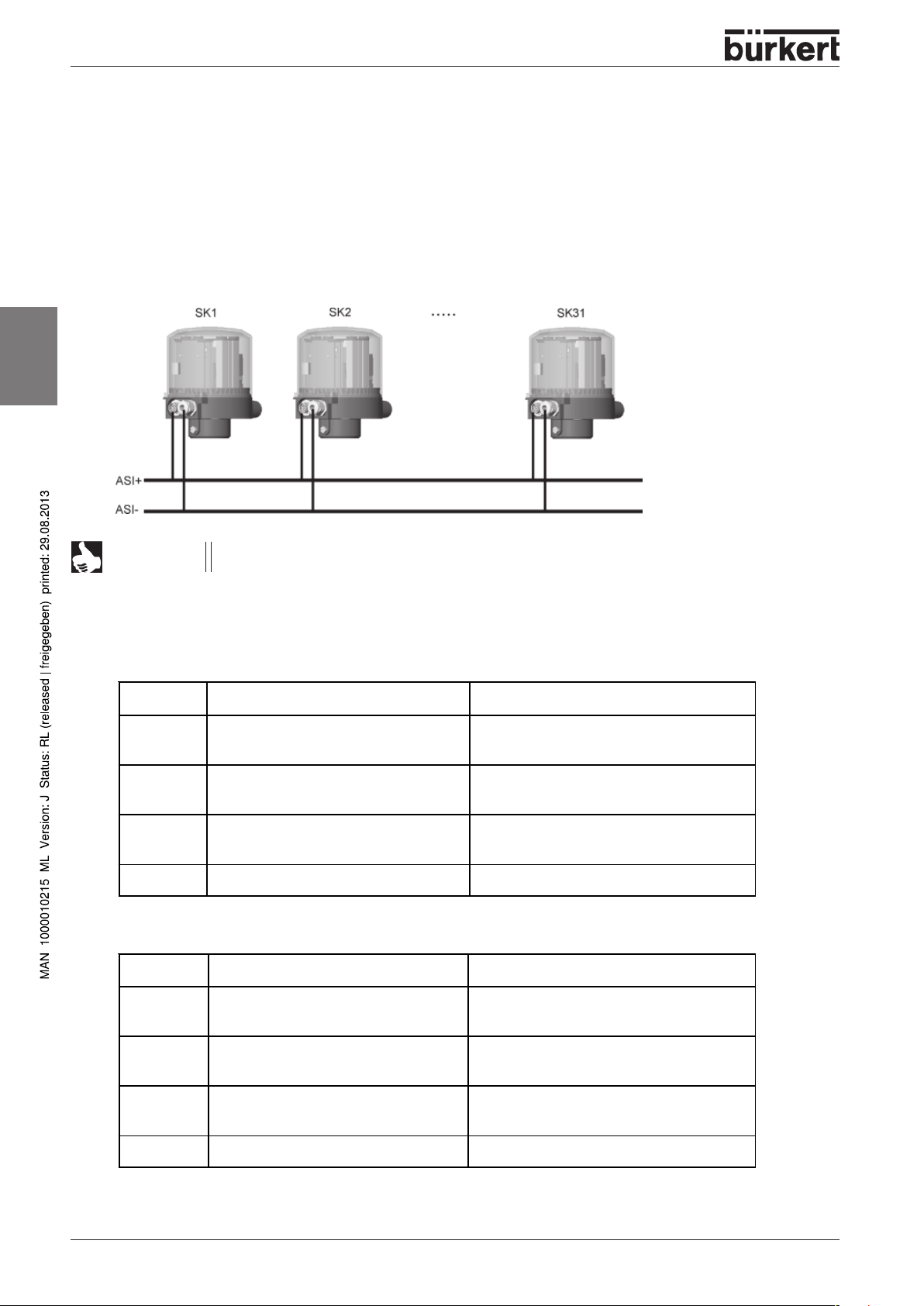

Number of connectable control heads and maximum length of the

bus line

I. ASI standard case

A maximum of 31 control heads can be attached to a bus line in the standard case.

According to ASI specifications the bus cable may be a maximum 100 m long.

english

NOTE

When using other cable diameters, the maximum cable length also changes (refer to ASI

specification).

Process data

Data bits for inputs (sensor and prox. switches):

Bit No. Sensor Value allocation

Bit 0 S1 (sensor 1)

Bit 1 S2 (sensor 2)

Bit 2 S3 (terminal for add. prox. switch)

Bit 3 Not used always 0

Data bits for outputs (actuators and valves):

Bit No. Valve Value allocation

0 Prox. switch 1 OFF

1 Prox. switch 1 ON

0 Prox. switch 2 OFF

1 Prox. switch 2 ON

0 Prox. switch 3 OFF

1 Prox. switch 3 ON

Bit 0 V1 (Valve 1)

Bit 1 V2 (Valve 2)

Bit 2 V3 (Valve 3)

Bit 3 Not used always 0

Parameter bits: not used

22 - 1066

0 Valve 1 OFF

1 Valve 1 ON

0 Valve 2 OFF

1 Valve 2 ON

0 Valve 3 OFF

1 Valve 3 ON

Page 25

INSTALLATION AND COMMISSIONING

II. ASI version with extended address range (A/B Slave)

1 Master can communicate with 62 Slaves with the ASI version with extended address range (A/B Slave).

As in the standard case, the bus cable with extended address range according to ASI specifications my be

a maximum 100 m long.

NOTE

Characteristics of the A/B Slave variant compared with the standard case

• 62 Slaves per Master

• The yellow OUT 4 LED on the ASI circuit board is no longer controllable, since the fourth output bit

used up to now is now used for the addressing.

• Limitations in power supply due to the nominal current of the inductors:

Only 2 solenoid valves can be connected at the same time; the third solenoid valve can only be

hooked up after 100 ms have passed.

ATTENTION!

Differences in the addressing of ASI variants

Parameters ASI Standard device ASI device for A/B Slave addressing

Number Slaves / Master 31 62

Maximum cable lengths also vary when other cable cross sections are used (see ASI

specifications).

If an A/B Slave device is being used as a replacement for a standard device, a

configuration error arises due to the different ID codes!

english

I/O Code 7 hex 7 hex

ID Code F hex A hex

Extended ID1 F hex 7 hex

Extended ID2 F hex E hex

Profile S-7.F.F S-7.A.E

1066 - 23

Page 26

INSTALLATION AND COMMISSIONING

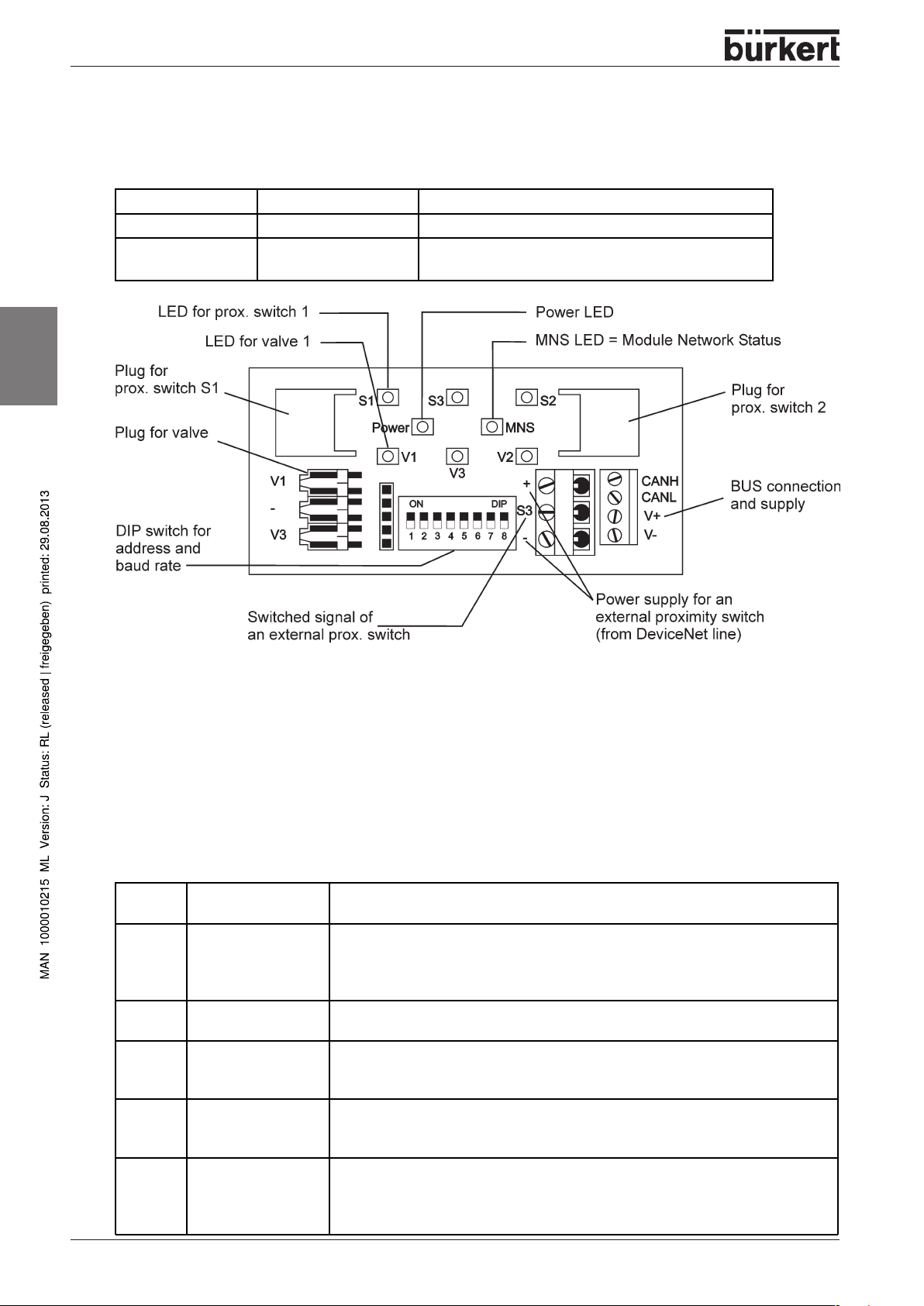

DeviceNet

Explanation of terms

• DeviceNet is a field bus system that is based on the CAN protocol (Controller Area Network). It makes

possible the networking of actuators and sensors (slaves) with a master control unit (master).

• In the DeviceNet, the Type 1066 control head is a slave device according to the Predefined

Master/Slave Connection laid down in the DeviceNet specification. Polled I/O, Bit Strobed I/O and

Change of State 4 (COS) are supported as I/O connection types.

• In DeviceNet, a differentiation is made between cyclic or event-controlled transmitted process messages

of higher priority (I/O Messages) and non-cyclic management messages of lower priority (Explicit Messages).

english

Technical data

• The protocol corresponds to

NOTE

Baud rate

Adresses

Process data

Inputs

Files

A diskette with configuration files (BUE1066.EDS and BUE1066.ICO) is always delivered

with the DeviceNet models. You can also obtain these files over the Internet.

125 kBit/s, 250 kBit/s, 500 kBit/s (via DIP switch);

Factory setting: 125 kBit/s

0 ... 63 (via DIP switch);

Factory setting: 63

2 static input assemblies

(Input: from control head 1066 to DeviceNet Master/Scanner)

1 static Output Assembly

3 sensors (proximity switches) S1 - S3, pnp, plus-switching

Supply via the DeviceNet line (11 to 25 V DC)

Switching level High signal ≥ 5 V

Switching level Low signal ≤ 1.5 V

BUE1066.EDS

BUE1066.ICO

You can also obtain these files over the Internet.

DeviceNet Specification Release 2.0

Maximum line lengths

The maximum total line lengths (sum of main and drop lines) of a network depend on the baud rate.

Total line lengths

Baud rate

125 kBaud 500 m

250 kBaud 250 m

500 kBaud 100 m

1)

According to the DeviceNet specification. When using another cable type, lower maximum values

apply (refer to the DeviceNet specification).

24 - 1066

according to the DeviceNet specification

Maximum total line length when using Thick Cables according to the

DeviceNet specification

1)

Page 27

INSTALLATION AND COMMISSIONING

Drop line lengths

Baud rate Maximum length of a drop line Max. accumulated length in the network

125 kBaud 6 m 156 m

250 kBaud 6 m 78 m

500 kBaud 6 m 39 m

Safety setting for bus failure

In case of a bus failure, the setting of the last data byte of the bus outputs will be retained as long as

power is connected.

Electrical connection

The bus line is a 4-pole cable with an additional screen that must correspond to the DeviceNet

specifications and over which both information (data) and power (power supply for the low-power actuators

and sensors) will be transmitted.

english

Bus connection (round plug M12, 5-pole)

CAN_H

white

Data

lines

Plug viewed from the front looking at the pins (not at the solder side).

The Type 1066 control head has a 5-pole Micro-style M12 round plug. The following pin configuration

corresponds to the DeviceNet specification:

CAN_L

blue

Drain (screen)

not used

Pin Signal Colour

1 Screen not used

2V+ red

3V- black

4CAN_H white

5 CAN_L blue

Vblack

V+

red

Voltage supply

11 ... 25 V DC

max. power 5 W, if all

valves switched

(3 x Type 6510 with 1 W each)

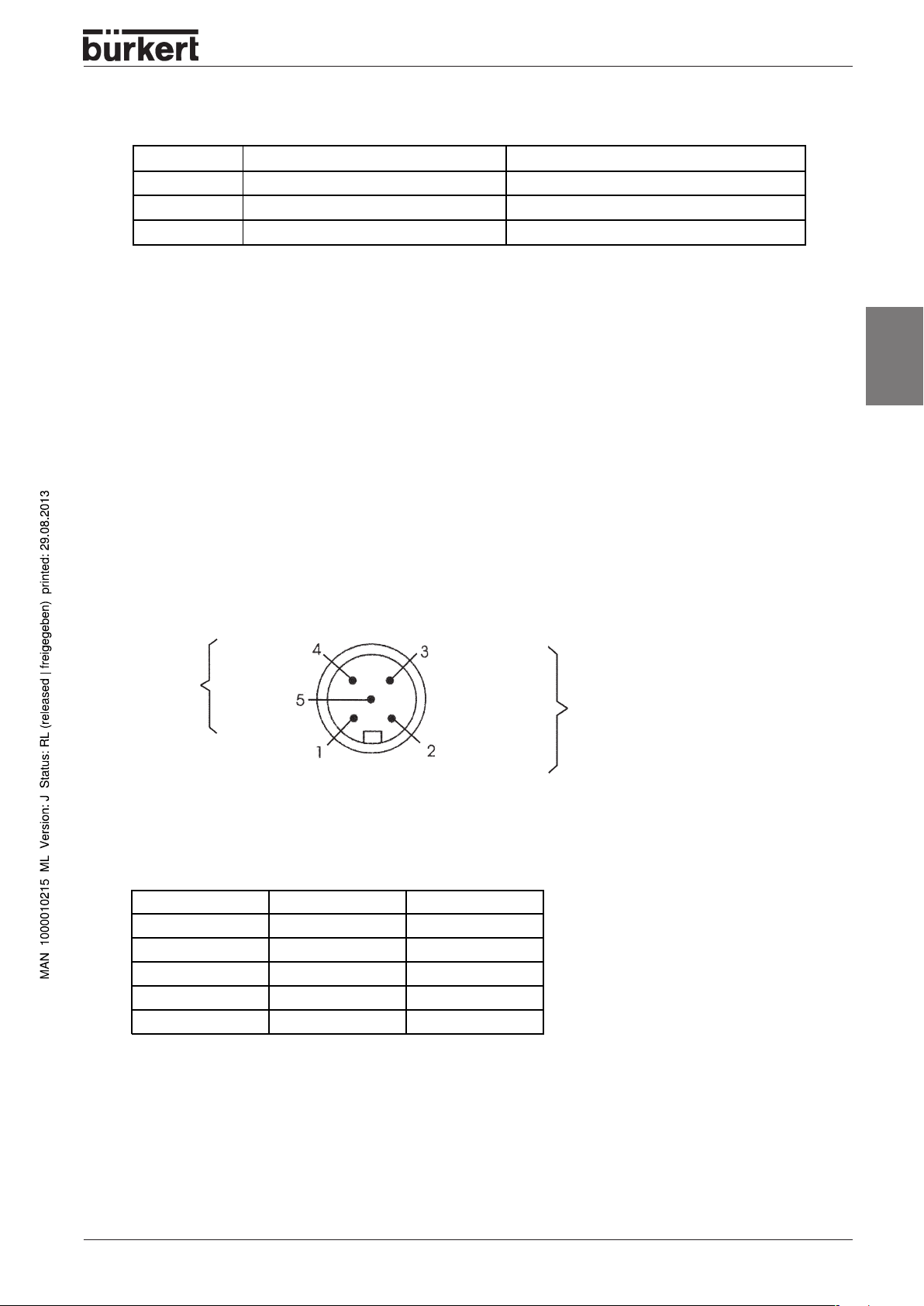

Termination circuit for DeviceNet systems

When installing a DeviceNet system, attention must be paid to the correct termination circuit for the data

lines. This circuit prevents interference arising from signal reflection on the data lines. The main line must

therefore be terminated as both ends, as shown, with resistors of 120 Ω with 1/4 W power rating.

1066 - 25

Page 28

INSTALLATION AND COMMISSIONING

Network topology of a DeviceNet system

Line with a main line (trunk line) and several drop lines.

The main line and the drop lines are made up from identical material (see sketch).

english

ATTENTION!

To avoid reflections, fit terminating resistors at both ends of the trunk line (120

Configuration

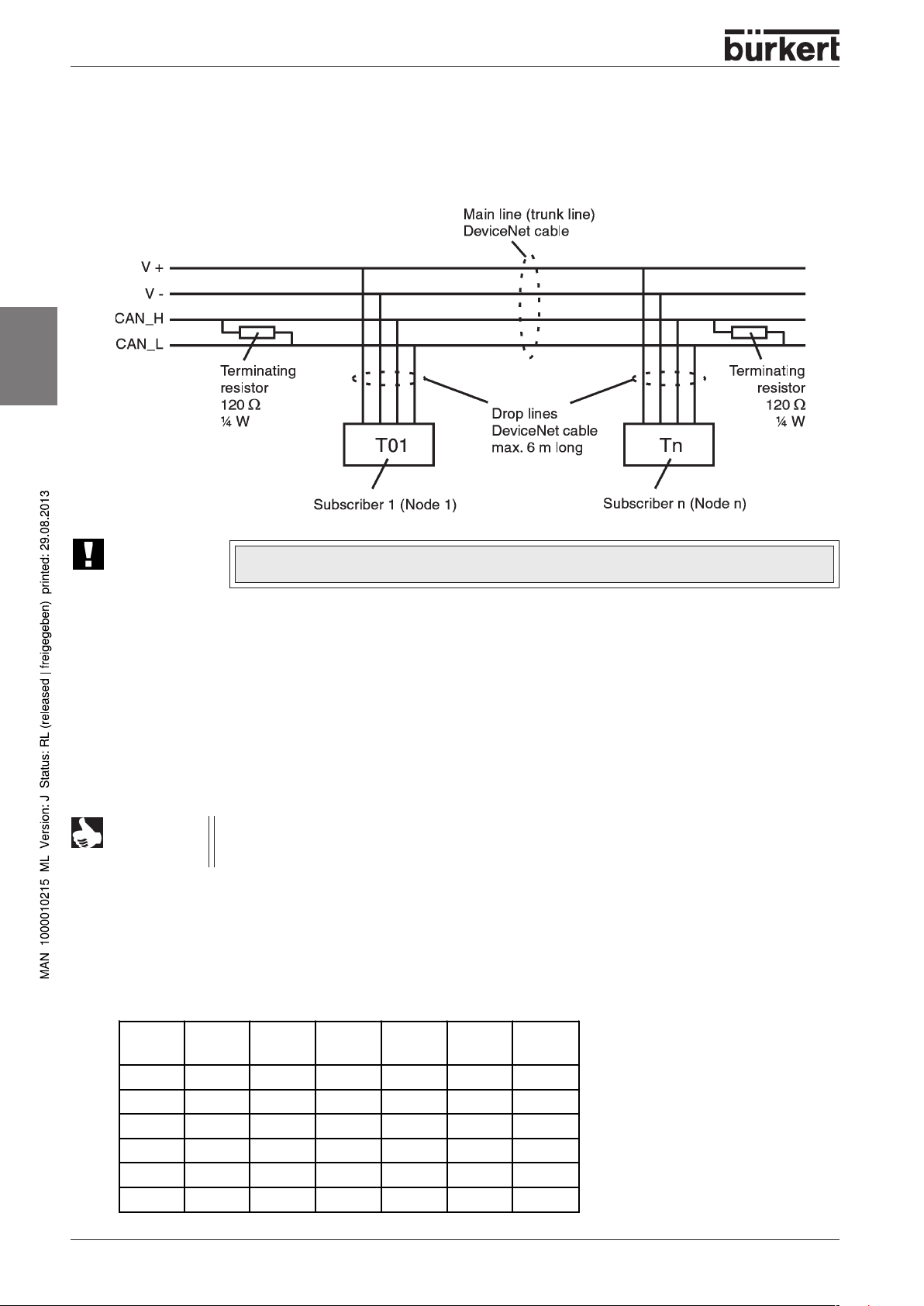

DIP switch

8 DIP switches are fitted for the configuration:

• DIP switches 1 to 6 for the DeviceNet addresses

• DIP switches 7 and 8 for the baud rate

NOTE

Setting the DeviceNet address

MAC ID – Medium Access Control Identifier:

[Example of value allocation at switch DIP1:

DIP 1=off=0 / DIP 1=on=1 / MAC ID=DIP 1*20+DIP 2*21+...+DIP 6*25]

Before the commissioning of the controller with DeviceNet, the

into DeviceNet Configuration Tool. The required files (BUE1066.EDS and BUE1066.ICO)

are available on diskette or over the Internet.

EDS-Datei

ΩΩ

Ω

).

ΩΩ

must be read

[2

26 - 1066

=1]

DIP 2

[21=2]

DIP 1

0

off off off off off off 0

on off off off off off 1

off on off off off off 2

... ... ... ... ... ... ...

offononononon62

on on on on on on 63

DIP 3

[22=4]

DIP 4

[23=8]

DIP 5

[24=16]

DIP 6

[25=32]

MAC

ID

Page 29

Setting the baud rate

Adapting the control head to the baud rate of the network.

DIP 7 DIP 8 Baud rate

off off 125 kBaud

on off 250 kBaud

off on 500 kBaud

on on not allowed

INSTALLATION AND COMMISSIONING

ATTENTION!

Any change to the settings using the DIP switches will only become effective

following a re-start of the device.

A re-start can be carried out by briefly unclamping and the re-clamping the control head

from/to the network or by sending a corresponding Reset Message. It is also possible be

switching the network power supply off and then on again.

Configuration of the Process Data

3 static inputs and 3 static output assemblies are available for the transmission of the process data via an

I/O connection. Selected attributes are gathered together in one object in these assemblies, in order to be

able to be transmitted together as process data via an I/O connection.

The process data can either be accessed cyclically in the connection variants "Polled I/O" and "Bit-strobed

I/O" with "Change of State" when the input values change, or non-cyclically via Explicit Messages.

The access path for non-cyclic access is: class 4

instance 1

attribute 3

With the

cyclic write access to the output data with

Get_Attribute_Single

service, non-cyclic read access can be obtained to the input data, and non-

Set_Attribute_Single.

english

1 Data Byte for inputs (sensors and/or proximity switches):

Bit Sensor Value allocation

Bit 0 S1 (Prox.switch 1)

Bit 1 S2 (Prox. switch 2)

Bit 2 S3 (Terminal for additional prox. switch)

Bit 3 ... Bit 7 Not used 0 always

1 Data Byte for inputs (sensors and/or proximity switches):

Bit Sensor Value allocation

Bit 0 S1 (Valve 1)

Bit 1 S2 (Valve 2)

Bit 2 S3 (Valve 3)

Bit 3 ... Bit 7 Not used 0 always

0 Prox. switch 1 OFF

1 Prox. switch 1 ON

0 Prox. switch 2 OFF

1 Prox. switch 2 ON

0 Prox. switch 3 OFF

1 Prox. switch 3 ON

0 Valve 1 OFF

1 Valve 1 ON

0 Valve 2 OFF

1 Valve 2 ON

0 Valve 3 OFF

1 Valve 3 ON

1066 - 27

Page 30

INSTALLATION AND COMMISSIONING

LED Status Display

The device status will be indicated by 2 LEDs ("Power" and "MNS").

Name of the LED Type / Colour Function

POWER Single-colour, green LED lit up: device has electrical power

MNS

Tw o- c ol o u r,

red / green

english

Corresponds to MNS-LED according to DeviceNet

specification (MNS Module Network Status)

Status of the MNS LED

Once electrical power has been applied (connection of the network line), the following functional tests of

the two-coloured MNS LED are carried out:

• LED lights up green for a short time (ca. ¼ s).

• LED lights up red for a short time (ca. ¼ s).

• LED dark.

Once the functional tests have been completed, the MNS LED can indicate the device status as shown in

the table below.

LED

state

Dark

Green

Green

blinking

Red

blinking

Red Critical fault

Device status Explanation / Correction of problem

- No power supply to device.

No power /

not online

On-line, connection

to Master exists

On-line, no

connection to

Master

Connection

time-out

- Device has not yet finished the duplicate MAC ID Test (test lasts approx. 2s).

- Connect additional devices if the device is the only network participant.

- Replace the device.

- Normal operational status with connection made to Master.

- Normal operational status without connection made to Master.

- One or more connections are in the Time-Out state.

- Make new connection via the master to ensure that the I/O data will by

transmitted cyclically.

- Another device with the same MAC ID in the network > change MAC ID and

restart.

- BUS OFF as a result of communication problems.

- Check the baud rate: replace the device if necessary.

28 - 1066

Page 31

MAINTENANCE / CLEANING

MAINTENANCE / CLEANING

Maintenance / Cleaning ................................................................................................................................................................................................................ 30

english

1066 - 29

Page 32

MAINTENANCE / CLEANING

Maintenance / Cleaning

When used correctly, the Type 1066 control head works without maintenance and without problems.

Repairs may only be carried out by authorised personnel using suitable tools.

Control heads operating in facilities may become contaminated by leaking medium and other influences.

In this event the facilities must be cleaned with suitable cleaning products and finally rinsed thoroughly

with water.

english

ATTENTION!

Before using cleaning materials,

the materials of the housing and the cover. ON cases of soiling, or following the use of

acidic or alkaline cleaning agents, always rinse thoroughly rinse off the control head with

clear water. In doing this, pay special attention that threaded holes and depressions are

clean and drained.

always check the compatibility of these agents with

30 - 1066

Page 33

REPAIRS

REPAIRS

english

Repairs ................................................................................................................................................................................................................................................................... 32

Removing and/or replacing the cover

Changing the printed circuit board

Replacing the valve group

Changing the valve on versions for 24 / 110 / 230 V UC without communication

Changing the proximity switch / micro-switch

....................................................................................................................................................................................................... 33

....................................................................................................................................................................... 32

................................................................................................................................................................................. 33

............................................ 34

................................................................................................................................................ 35

Spare Parts....................................................................................................................................................................................................................................................... 36

Service Addresses ................................................................................................................................................................................................................................ 36

1066 - 31

Page 34

REPAIRS

Repairs

In case of the failure of certain components or modules, the control head can be repaired.

english

ATTENTION!

• Only use original spare parts for the repair work (refer to Spare Parts Table).

• Repairs may only be carried out by authorised specialists using suitable tools.

• Comply with the valid accident prevention regulations and the safety regulations.

• Ensure that the device is free of pressure and of electrical power before carrying out

any work.

• Check that the parameters of the spare parts agree with those given on the rating

plate of the control head being repaired.

Removing and/or replacing the cover

Removing the cover from the control head

Loosen the locking screw

Turn the cover to the left until it reaches the stop

Remove the cover by pulling upwards!

Fitting the cover

Check the seat of the cover O-ring, or pull

a new O-ring onto the collar of the cover.

NOTE

Distributed across the circumference

of the casing are 4 handles that

retain the O ring when the cover is

being removed.

Take care to ensure that the newlyapplied O ring is positioned correctly

under the handles and is resting on

the casing without twisting.

NOTE

Fit the cover.

Turn the cover right until it reaches the

stop.

Secure the cover where necessary to

prevent unauthorised access by

inserting a lead seal and/or a selftapping screw in the holes in the cover

and the housing.

Housing with

cover collar and

O-ring seat

32 - 1066

Page 35

Changing the printed circuit board

Proceed as follows:

Remove the cover.

Before disconnecting, mark the electrical connections so that it will

bepossible to reconnect them without error.

Disconnect all electrical connections from the printed circuit board

(plug and / or screw connections).

Loosen the four screws (Torx 10) with which the cover plate is secured.

Remove the cover plate.

Remove all circuit boards (no screw fittings).

Insert the new circuit boards.

ATTENTION!

Replace the cover plate.

ATTENTION!

Ensure the correct fit of the printed circuit boards into

the housing projections!

Ensure the correct fit of the circuit board an the screw

heads in the projections and/or the cut-outs in the

cover plate!

REPAIRS

Plate for

24 V DC

without communication

english

Replacement

ASI module, moulded

Screw down the cover plate (Torx 10; tightening torque 0.7 Nm).

Reconnect the electrical connections according to the markings made

earlier.

Refit the cover.

Replacing the valve group

The valve group consists of a connection plate with 1, 2 or 3 flanged

valves of the type 6510

housing.

NOTE

For 24 V DC without communication, ASI and

DeviceNet, only a change of the whole valve group

is permitted.

Proceed as follows:

Remove the cover.

Before disconnecting from the circuit board, mark the electrical

connections so that it will be possible to reconnect them without

error.

Disconnect all electrical connections from the printed circuit

board (screw connections).

Loosen the 2 screws (Torx 20) with which the valve group is

secured.

Remove the valve group complete with its O-rings.

Fit the new valve group complete with its O-rings.

Screw down the valve group (Torx 20; tightening torque 1.5 Nm).

Reconnect the electrical connections according to the markings made earlier.

Refit the cover, ensuring that the O-rings are correctly seated.

and the O-rings for the fluidic flange to the

Replacement

DeviceNet, moulded

Valve group, optionally

with 1, 2 or 3 valves

- 24 V DC without

communication

- ASI (24 V DC)

- DeviceNet (9 V DC)

1066 - 33

Page 36

REPAIRS

Changing the valve on versions for 24 / 110 / 230 V UC without

communication

english

For the verion for 24/110/230 V UC without communication only

paying attention to operating voltage. The valve connection plate remains in the control head.

valve model 6106

is exchanged while

Proceed as follows:

Remove the cover.

Unscrew the screws on the appliance socket.

Pull the appliance socket from the valve.

Note the mounting position of the tag connectors and the manual

override.

Loosen the 2 fixing screws on the valve body.

Remove the coil bobbin.

Loosen the 2 fixing screws on the valve body.

Remove the valve body complete with its O-rings.

Fit the new valve body together with its O-rings on the correct side

(manual override to the left)

Retighten the screws alternately and evenly

(tightening torque 0.5 Nm).

Fit the new coil bobbin on the correct side

(long tag connector to the left).

Valve

Type 6106

Alternately and evenly tighten the coil screws

(tightening torque 0.15 Nm).

Mount the appliance socket on the valve.

Secure the socket with a screw

(tightening torque 1 Nm).

Refit the cover.

34 - 1066

Page 37

Changing the proximity switch / micro-switch

Proceed as follows:

REPAIRS

Remove the cover.

Before disconnecting from the circuit board, mark the

electrical connections so that it will be possible to reconnect

them without error.

Disconnect all electrical connections to the proximity switch /

micro-switch from the printed circuit board (plug connections).

Loosen the four screws (Torx 10) with which the cover plate is

secured.

Remove the cover plate.

Note the positions of the proximity switch and the trigger of

the micro-switch.

Lift out the proximity switch / micro-switch with the adjusting

screw and the connecting cable.

Unscrew the old adjusting screws for re-use.

Screw the adjusting screws into the threaded holes on the

new proximity switch / micro-switch.

Only when there is a proximity switch:

Remove the O ring from the old proximity switch and insert it

into the clearance of the new proximity switch. (This O ring is

used to muffle vibration and prevents the proximity switch

from sliding out.)

Clearance for

O ring

Inductive proximity switch with

LED and moulded-on wire and

plug (the plug is not depicted in

the sketch)

english

Mount the new proximity switch with the adjusting screw in

the guide column.

ATTENTION!

Re-fit the cover plate.

ATTENTION!

Firmly screw down the cover plate

(Torx 10; tightening torque 0,7 Nm).

Reconnect the electrical connections to the proximity switch /

micro-switch according to the note made earlier.

Adjust the position of the proximity switch / micro-switch:

- Using a screwdriver, turn the adjusting screw (spindle)

until the optimal position of the proximity switch has been

set up.

Ensure the correct seating of the proximity switch / micro-switch in the guides

and depressions on the body.

Ensure the correct seating of the printed circuit

board and the screw heads in the projections

and cut-outs of the cover plate.

LED

LED

- The LED mounted on the proximity switch is an adjustment

aid: it lights up when reaching the corresponding threshold

value.

Refit the cover.

1066 - 35

Page 38

REPAIRS

Spare Parts

Position Spare part Order No.

english

1 ASI replacement module, sealed

2 Conductor plug straight, moulded cable, 1 m long, V 4A-M12 locking device

3 Flat cable clamp with bush, M12 outlet made of VA, gold contacts

4 Flat cable seal for clamp (if cable terminates here)

5 24 V DC board without communication

6 24 / 110 / 230 V UC board without communication

7 Inductive proximity switch (sensor)

8 Stop position microswitch complete

9 Adjusting screw for proximity switch / microswitch (1 item)

10 Shoulder screw M5 for securing the control head (10-pack)

11 Cover for control head (1 item)

12 O rings for cover (10-pack)

13 without communication, valve group with 1 valve, 24 V DC

14 without communication, valve group with 2 valves, 24 V DC

15 without communication, valve group with 3 valves, 24 V DC

16 with ASI communication, valve group with 1 valve, 24 V DC

17 with ASI communication, valve group with 2 valves, 24 V DC

18 with ASI communication, valve group with 3 valves, 24 V DC

19 with DeviceNet communication, valve group with 1 valve, 9 V DC

20 with DeviceNet communication, valve group with 2 valves, 9 V DC

21 with DeviceNet communication, valve group with 3 valves, 9 V DC

22 Single valve type 6106, 24 V UC

23 Single valve type 6106, 110 V UC

24 Single valve type 6106, 230 V UC

799 189

799 647

799 646

799 795

799 188

799 137

798 546

648 004

798 064

798 074

798 073

798 072

193 375

193 376

193 377

193 375

193 376

193 377

198 195

198 196

198 197

141 073

142 490

141 387

Positions 13 to 24 complete with O rings and fixing screws.

Service Addresses

Bürkert Werke GmbH & Co. KG Bürkert GmbH & Co. KG

Fluid Control System DC Dresden

Christian-Bürkert-Straße 13 - 17 Christian-Bürkert-Straße 2

74653 Ingelfingen 01900 Großröhrsdorf

Telephone: (0 79 40) 10 - 111 Telephone: (03 59 52) 36 - 300

Fax: (0 79 40) 10 - 448 Fax: (03 59 52) 36 - 551

36 - 1066

Page 39

Inhaltsverzeichnis

der Betriebsanleitung

Steuerkopf für Prozessventile Typ 1066

ALLGEMEINE HINWEISE

Darstellungsmittel ........................................................................................................... 40

Bestimmungsgemäße Verwendung ................................................................................ 40

Sicherheitshinweise........................................................................................................ 40

Lieferumfang ................................................................................................................... 41

Garantiebestimmungen ................................................................................................... 41

INHALT

Transport und Lagerung .................................................................................................. 42

Entsorgung......................................................................................................................42

TECHNISCHE DATEN

Aufbau und Funktion des Steuerkopfes .......................................................................... 44

Merkmale ........................................................................................................................44

Betriebsbedingungen...................................................................................................... 45

Mechanische Daten ........................................................................................................ 45

Pneumatische Daten....................................................................................................... 46

Elektrische Daten ............................................................................................................ 46

MONTAGE

Montage des Steuerkopfes ............................................................................................. 48

Flanschadapter ....................................................................................................................... 48

Montageablauf......................................................................................................................... 49

deutsch

INSTALLATION INBETRIEBNAHME

Pneumatische Installation ............................................................................................... 52

Anschlussbelegung am Steuerkopf ........................................................................................ 52

Elektrische Installation .................................................................................................... 53

Steuerköpfe ohne Kommunikation .......................................................................................... 53

Steuerköpfe mit Kommunikation ............................................................................................. 55

1066 - 37

Page 40

INHALT

WARTUNG / REINIGUNG

Wartung / Reinigung ....................................................................................................... 66

REPARATUR

Reparaturen .................................................................................................................... 68

Deckel abnehmen bzw. aufstecken ........................................................................................ 68

Wechsel der Leiterkarte.......................................................................................................... 69

Wechsel der Ventilgruppe ....................................................................................................... 69

Wechsel des Ventils bei Versionen für 24/110/230 V UC ohne Kommunikation ...................... 70

Wechsel Näherungsschalter / Mikroschalter .......................................................................... 70

Ersatzteile ....................................................................................................................... 72

Serviceanschriften .......................................................................................................... 72

deutsch

38 - 1066

Page 41

ALLGEMEINE HINWEISE

ALLGEMEINE

HINWEISE

Darstellungsmittel............................................................................................................................................................................................................................... 40

deutsch

Bestimmungsgemäße Verwendung .................................................................................. 40

Sicherheitshinweise ....................................................................................................................................................................................................................... 40

Lieferumfang............................................................................................................................................................................................................................................... 41

Garantiebestimmungen ............................................................................................................................................................................................................. 41

Transport und Lagerung............................................................................................................................................................................................................ 42

Entsorgung.................................................................................................................................................................................................................................................... 42

1066 - 39

Page 42

ALLGEMEINE HINWEISE

Darstellungsmittel

In dieser Betriebsanleitung werden folgende Darstellungsmittel verwendet:

markiert einen Arbeitsschritt, den Sie ausführen müssen.

ACHTUNG!

HINWEIS

kennzeichnet Hinweise, bei deren Nichtbeachtung Ihre Gesundheit oder die Funktionsfähigkeit des Gerätes gefährdet ist.

kennzeichnet wichtige Zusatzinformationen, Tipps und Empfehlungen.

Bestimmungsgemäße Verwendung

• Der Steuerkopf für Prozessventile Typ 1066 dient zur Ansteuerung pneumatisch betätigter Prozessventile und zur Erfassung von deren Schaltzuständen. Andere Einsatzfälle gelten als nicht

bestimmungsgemäß.

deutsch

• Die in dieser Anleitung, im Datenblatt sowie auf dem Typschild aufgeführten Technischen Daten sind

vor der Inbetriebnahme auf Übereinstimmung zu prüfen und während des Betriebes des Steuerkopfes

einzuhalten.

• Eigenmächtige Umbauten und Veränderungen am Steuerkopf sind aus Sicherheitsgründen verboten.

• Schützen Sie den Steuerkopf vor Eingriffen Unbefugter. Dazu kann der Steuerkopf mit einer Plombe

und / oder einer Schneidschraube an den an Deckel und Gehäuse vorhandenen Bohrungen gesichert

werden.

• Die in dieser Anleitung gegebenen Arbeitsanweisungen und Sicherheitshinweise sind unter allen Umständen zu beachten und einzuhalten. Bei Nichtbeachtung dieser Arbeitsanweisungen und deren Reihenfolge sowie der Sicherheitshinweise oder der Sicherheitskennzeichnung erlischt der Haftungsanspruch.

Sicherheitshinweise

Beachten Sie die Hinweise dieser Betriebsanleitung sowie die Einsatzbedingungen und zulässigen Daten,

die in den Datenblättern und auf dem Typschild des Steuerkopfes für Prozessventile spezifiziert sind,

damit das Gerät einwandfrei funktioniert und lange einsatzfähig bleibt.

• Halten Sie sich bei der Einsatzplanung und dem Betrieb des Gerätes an die allgemeinen Regeln der

Technik!

• Installation und Wartungsarbeiten dürfen nur durch Fachpersonal und mit geeignetem Werkzeug erfolgen!

• Verwenden Sie für erforderliche Reparaturen nur Originalersatzteile und beachten Sie beim Wechseln

dieser Teile die Hinweise dieser Anleitung.

• Beachten Sie die geltenden Unfallverhütungs- und Sicherheitsbestimmungen während des Betriebes

und der Wartung des Gerätes!

• Schalten Sie vor Eingriffen in das System in jedem Fall die Spannung ab!

• Beachten Sie, dass in Systemen, die unter Druck stehen, Leitungen und Ventile nicht gelöst werden

dürfen!

• Treffen Sie geeignete Maßnahmen, um unbeabsichtigtes Betätigen oder unzulässige Beeinträchtigung auszuschließen!

• Gewährleisten Sie nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung einen

definierten und kontrollierten Wiederanlauf des Prozesses!

40 - 1066

Page 43

ALLGEMEINE HINWEISE

HINWEIS

• Vermeiden Sie höhere mechanische Belastungen des Steuerkopfes, die zur mechanischen Beeinträchtigung oder Zerstörung des Steuerkopfes führen können. Dazu gehören Begehen, Ablegen schwerer

Gegenstände, harte Schläge, herabfallende harte Gegenstände u.a.

• Vermeiden Sie das Eindringen von Feuchte in den Steuerkopf. Achten Sie insbesondere bei der Montage auf den ordnungsgemäßen Einbau aller Dichtungen, auf fest angezogene Montageschrauben, Kabelverschraubungen und Dichtstopfen. Verwenden Sie nur getrocknete Steuerluft!

HINWEIS

• Vermeiden Sie den Anschluss längerer und mechanisch starrer Anschlussteile, da mit solch einer Verlängerung Hebelkräfte erzeugbar wären, mit denen das Gehäuse von Hand zerstört werden könnte.

HINWEIS

• Verwenden Sie zur Reinigung des Steuerkopfes nur gut verträgliche Reinigungsmittel und spülen Sie

nach Einsatz dieser Reinigungsmittel gründlich mit klarem Wasser nach. Die Verträglichkeit des

Reinigungsmittels sollte gegebenenfalls getestet werden.

Der Steuerkopf ist in der Schutzart IP67 ausgelegt. Das setzt einen guten Sitz aller

Dichtungen und die mechanische Unversehrtheit von Gehäuse und Deckel voraus.

Das Kunststoffgehäuse des Steuerkopfes ist bezüglich seiner mechanischen

Festigkeit nur für den unmittelbaren Anschluss von flexiblen Schläuchen und

Leitungen ausgelegt.

Reinigungsmittel enthalten oftmals aggressive Bestandteile, die sich in kleinen

Rillen und Vertiefungen am Steuerkopf absetzen können und deren Dauereinwirkung zur Zerstörung auch hochwertiger Kunststoffe führen kann.

deutsch

HINWEIS

• Sichern Sie bei der Montage des Steuerkopfes einen Mindestabstand von 5 mm zwischen dem Überdruckventil und dem nächsten Bauteil, damit das Überdruckventil im Leckagefall problemlos auslösen

kann. Anderenfalls könnte bei Leckage im Steuerkopf der Deckel regelrecht „abgesprengt“ werden.

• Bei Nichtbeachtung dieser Hinweise und unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung

unsererseits, ebenso erlischt die Garantie auf Geräte und Zubehörteile!

Lieferumfang

Überzeugen Sie sich unmittelbar nach Erhalt der Sendung, dass der Inhalt nicht beschädigt ist und mit

dem auf dem beigelegten Packzettel angegebenen Lieferumfang übereinstimmt.

Bei Unstimmigkeiten wenden Sie sich bitte umgehend an unser Call-Center:

oder an Ihr Bürkert Vertriebs-Center.

Auf der Gehäuseunterseite des Steuerkopfes befindet sich ein Überdruckventil als

Berstschutz für den Fall eines undichten Bauelements im Steuerkopf (Leckagefall).

Bürkert Fluid Control System, Call-Center

Chr.-Bürkert-Str. 13-17, D-74653 Ingelfingen

Tel. 07940 - 10 111 / Fax 07940 - 10 91 448

E-Mail: info@de.buerkert.com

Garantiebestimmungen

Diese Druckschrift enthält keine Garantiezusagen. Wir verweisen hierzu auf unsere allgemeinen Verkaufsund Geschäftsbedingungen. Voraussetzung für die Garantie ist der bestimmungsgemäße Gebrauch des

Gerätes unter Beachtung der spezifizierten Einsatzbedingungen.

ACHTUNG!

Die Gewährleistung erstreckt sich nur auf die Fehlerfreiheit des Steuerkopfes für

Prozessventile. Es wird jedoch keine Haftung übernommen für Folgeschäden jeglicher

Art, die durch Ausfall oder Fehlfunktion des Gerätes entstehen könnten.

1066 - 41

Page 44

ALLGEMEINE HINWEISE

Transport und Lagerung

ACHTUNG!

Lagerung in einem trockenen Raum.

Maximale Lagertemperatur +50 °C

Entsorgung

ACHTUNG!

deutsch

Transportieren und lagern Sie das Gerät nur in der Originalverpackung.

Beachten Sie bei der Entsorgung des Gerätes die nationalen Abfallbeseitigungsvorschriften.

42 - 1066

Page 45

TECHNISCHE DATEN

TECHNISCHE DATEN

Aufbau und Funktion des Steuerkopfes ............................................................................................................................................................... 44

Merkmale ............................................................................................................................................................................................................................................................. 44

deutsch

Betriebsbedingungen ....................................................................................................................................................................................................................... 45

Mechanische Daten ............................................................................................................................................................................................................................ 45

Pneumatische Daten ......................................................................................................................................................................................................................... 46

Elektrische Daten.................................................................................................................................................................................................................................... 46

1066 - 43

Page 46

TECHNISCHE DATEN

Aufbau und Funktion

Der Steuerkopf Typ 1066 dient zur Ansteuerung von pneumatisch betätigten Prozessventilen unterschiedlicher Hersteller. Er ist je nach Konfiguration mit bis zu drei Magnetventilen (Pilotventilen) zur Prozessventilansteuerung bestückbar und mit maximal drei höhenverstellbaren induktiven Näherungsschaltern

(Sensoren) zur Stellungsrückmeldung ausrüstbar. Einer dieser Sensoren kann auch ein externer Sensor

sein (Anschluss über 3-polige Schraubklemme auf Leiterplatte).

HINWEIS

Näherungsschalter 1

deutsch

Beachten Sie bei den vergossenen Feldbusmodulen die Nummerierung der Näherungsschalter auf der Platine bzw. die Kennzeichnung am Gerät, da Abweichungen zur Nummerierung in der untenstehenden Zeichnung möglich sind.

Justierung

Leiterkarte

Säule mit Spindel

Markierung für

Deckelmontage

Elektr. Anschlüsse

Justierung durch diese Bohrungen

Abdeckplatte

Justierung Näherungsschalter 2

Näherungsschalter 2

Magnetventil 3

Magnetventil 2

Magnetventil 1

Gehäuse

Abluft

Näherungsschalter 1

Ventilflansch

Merkmale

Mit dem Steuerkopf Typ 1066 existiert neben den für den eher zentralen Einsatz vorgesehenen Ventilinseln eine dezentrale Lösung zur Ansteuerung von Prozessventilen. Die Vorteile dieser Lösung in Form

der kompakten Einheit

Feldbusschnittstellen sind:

Haupteinsatzgebiete:

Pneumatische Anschlüsse

Ventil 3Ventil 2Ventil 1

Schnittstelle zum

Prozessventil

Steuerkopf

Geringer Installationsaufwand.

Einfache Inbetriebnahme.

Kurze Schaltzeiten auf Grund kurzer Wege zwischen Pilotventil und Prozessventil.

Lebensmittelindustrie (z. B. Molkereien)

Chemische Industrie