Page 1

Type 1062

Electrical on/off position feedback

Elektrischer Auf/Zu-Stellungsrückmelder

Indicateur électrique de position tout ou rien

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2008-2013

Operating Instructions 1311/5_EU-ML 00562584 / Original FR

Page 3

Type 1062

Table of Contents

1. ABOUT THIS MANUAL ................................................................................ 5

1.1. Symbols used ...................................................................................... 5

1.2. Definition of the word "device" ................................................... 5

2. INTENDED USE ...............................................................................................6

2.1. Restraints ............................................................................................... 6

2.2. Ex certification .....................................................................................6

3. BASIC SAFETY INFORMATION .............................................................. 7

4. GENERAL INFORMATION ..........................................................................8

4.1. Manufacturer's address and international contacts ........ 8

4.2. Warranty conditions .......................................................................... 8

4.3. Information on the Internet ...........................................................8

5. DESCRIPTION .................................................................................................. 9

5.1. Area of application ............................................................................ 9

5.2. General description .......................................................................... 9

5.2.1. Construction ...........................................................................9

5.2.2. Principle of operation ...........................................................9

5.3. Description of the name plate on the standard 1062 ....9

5.4. Description of the name plates on the 1062 ATEX ...... 10

5.5. Versions available ........................................................................... 11

6. TECHNICAL DATA ....................................................................................... 11

6.1. Conditions of use ............................................................................ 11

6.2. Conformity of the 1062 ATEX to standards

and directives .................................................................................... 11

6.3. Conformity of the 1062 approved by CSA ......................... 12

6.4. General technical data ................................................................. 12

6.4.1. Mechanical data .................................................................12

6.4.2. General data ........................................................................13

6.4.3. General data specific to the devices approved by

CSA ....................................................................................... 14

6.4.4. Electrical data......................................................................14

7. ASSEMBLY ...................................................................................................... 16

7.1. Safety instructions.......................................................................... 16

7.2. Replacing the top part of an actuator size 40mm ......... 17

7.3. Fitting the position feedback to a pneumatic actuator 1 7

7.4. Fitting the position feedback with stroke

limiter to a pneumatic actuator size 50 to 80mm ......... 19

7.5. Fitting the position feedback with stroke

limiter to a pneumatic actuator size 100 or 125mm .... 23

english

3

Page 4

8. INSTALLATION AND WIRING ................................................................26

8.1. Safety instructions.......................................................................... 26

8.2. Electrical wiring ................................................................................ 27

8.2.1. Wiring a mechanical contact version ............................28

8.2.2. Wiring a version with inductive 2-wire switch ............. 30

8.2.3. Wiring a version with inductive 3-wire switch ............. 31

8.2.4. Wiring a version with two inductive 3-wire switches 31

8.2.5. Wiring a version with double inductive 2-wire

NAMUR switch ...................................................................32

8.2.6. Wiring a version with double inductive 4-wire switch 3 4

9. COMMISSIONING ....................................................................................... 34

9.1. Safety instructions.......................................................................... 34

9.2. Setting the cams ............................................................................. 34

10. MAINTENANCE AND TROUBLESHOOTING ............................... 35

10.1. Safety instructions..........................................................................35

10.2. Cleaning of the transmitter ........................................................ 35

Type 1062

11. SPARE PARTS AND ACCESSORIES .............................................. 36

12. PACKAGING, TRANSPORT .................................................................. 36

13. STORAGE ...................................................................................................... 37

14. DISPOSAL OF THE PRODUCT .......................................................... 37

4

english

Page 5

Type 1062

About this manual

1 ABOUT THIS MANUAL

This manual describes the entire life cycle of the device. Please keep

this manual in a safe place, accessible to all users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to hazardous

situations.

▶ This manual must be read and understood.

1.1 Symbols used

danger

Warns you against an imminent danger.

▶ Failure to observe this warning can result in death or in serious

injury.

Warning

Warns you against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or

even death.

Caution

Warns you against a possible risk.

▶ Failure to observe this warning can result in substantial or minor

injuries.

note

Warns you against material damage.

▶ Failure to observe this warning may result in damage to the

device or system.

indicates additional information, advice or important recommendations for your safety and for the correct operation of

the device.

refers to information contained in this manual or in other

documents.

→ indicates a procedure to be carried out.

1.2 Definition of the word "device"

The word "device" used within this manual refers to the electrical on/

off position feedback type 1062.

english

5

Page 6

Type 1062

Intended use

2 INTENDED USE

Use of the 1062 electrical position feedback that does not

comply with the instructions could present risks to people,

nearby installations and the environment.

▶ The 1062 electrical position feedback, fitted to an on/off valve,

is used to detect the status - open or closed - of this valve.

▶ The position feedback can be fitted to an actuator valve with a

diameter of 40 to 125 mm.

▶ Protect this device against electromagnetic interference, ultra-

violet rays.

▶ Protect a device installed outdoors from the effects of climatic

conditions.

▶ Use this device in compliance with the characteristics and

commissioning and use conditions specified in the contractual

documents and in the user manual.

▶ Requirements for safe and proper operation are proper trans-

port, storage and installation, as well as careful operation and

maintenance.

▶ Only use the device as intended.

2.1 Restraints

Observe any existing restraints when the device is exported.

2.2 Ex certification

Ex certification is only valid if modules and components approved by

Bürkert are used as indicated in this user manual.

The electronic modules can only be combined with the types of

pneumatic valves authorised by Bürkert; if this is not the case, Ex

certification is void.

Any modification to the system or to one of the modules or components not authorised beforehand also voids Ex certification.

6

english

Page 7

Type 1062

Basic safety information

3 BASIC SAFETY

INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during assembly,

use and maintenance of the devices.

• the local safety regulations that the operator must ensure the staff

in charge of assembly and/or maintenance observe.

Risk of explosion.

When the 1062 is used in an ATEX 21 or 22 zone, make sure:

• That the cover of the electrical position feedback is always

screwed shut before operating the valve.

• That you check that the device is not subject to a flow of air and

dust that may result in an accumulation of electrostatic charges.

Otherwise, intall the device in a conductive cover.

• "The NAMUR switches on the 1062 must be powered by a voltage

source of a type certified for use in explosive atmospheres in

groups IIB/IIC and their combination must be compatible from the

instrinsic safety point of view."

Danger due to high pressure in the installation.

▶ Shut down the pneumatic power source and depressurise the

pipes before carrying out work on the device.

Risk of injury due to electrical discharge.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Various dangerous situations

To avoid injury take care:

▶ to prevent any power supply switch-on.

▶ to ensure that installation and maintenance work are carried out

by qualified and skilled staff with the appropriate tools.

▶ to guarantee a set and controlled restarting of the process, after

an electrical and/or pneumatic power supply interruption.

▶ to use the device only if in perfect working order and in compli-

ance with the instructions provided in the user manual.

▶ to observe the general technical rules when locating and using

the device.

• not to use non-Ex certified versions of the 1062 electrical position

feedback in a potentially explosive atmosphere.

english

7

Page 8

Type 1062

General information

4 GENERAL INFORMATION

Various dangerous situations (cont'd)

To avoid injury take care:

• not to use outdoors a device approved by CSA.

• not to use this device in an environment incompatible with the

materials from which it is made.

• not to subject the device to mechanical loads (e.g. by placing

objects on top of it or by using it as a step).

• not to make any external or internal modifications to the device.

note

Elements / Components sensitive to electrostatic discharges

▶ This device contains electronic components sensitive to electro-

static discharges. They may be damaged if they are touched by

an electrostatically charged person or object. In the worst case

scenario, these components are instantly destroyed or go out of

order as soon as they are activated.

▶ To minimise or even avoid all damage due to an electrostatic

discharge, take all the precautions described in the EN 613405-1 and 5-2 standards.

▶ Also ensure that you do not touch any of the live electrical

components.

4.1 Manufacturer's address and

international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the

internet at:

www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of the

1062 in observance of the operating conditions specified in this manual.

4.3 Information on the Internet

You can find the user manuals and the technical data sheets on the

1062 and the INERIS 03ATEX0268 X EC design-examination certificate on the Internet under:

www.burkert.com

8

english

Page 9

Type 1062

Description

5 DESCRIPTION

5.1 Area of application

The electrical position feedback, combined with a pneumatic valve,

is intended to signal the position - open or closed - of this valve.

The position of the valve is given:

• by light(s) and by electrical signal on the mechanical contact

versions, on the inductive 3-wire switch (1 output) or double

inductive 4-wire switch (2 outputs) or double inductive 2-wire

NAMUR switch (2 outputs)

• only by electrical signal on versions with inductive 2-wire switch (1

output).

5.2 General description

5.2.1 Construction

The electrical position feedback is composed of a housing, fitted

with a cable gland, with a transparent cover.

The housing includes:

- a duplication system that adapts to the pneumatic actuator rod

on the valve,

- one or two electronic boards, each fitted with a mechanical

contact limit switch or an inductive switch, with 2 or 3 lights

(except for the 2-wire inductive versions)

- a terminal block for electrical connection.

5.2.2 Principle of operation

The duplication rod fitted with 2 cams moves when the valve opens

or closes: the movement of a cam past the switch associated with it

activates the latter.

When the switch is activated, the light, if there is one, comes on (or

goes off on the NAMUR versions) and an electrical signal is transmitted remotely.

This signal is transmitted in accordance with the NAMUR standard

on one version of the 1062 ATEX.

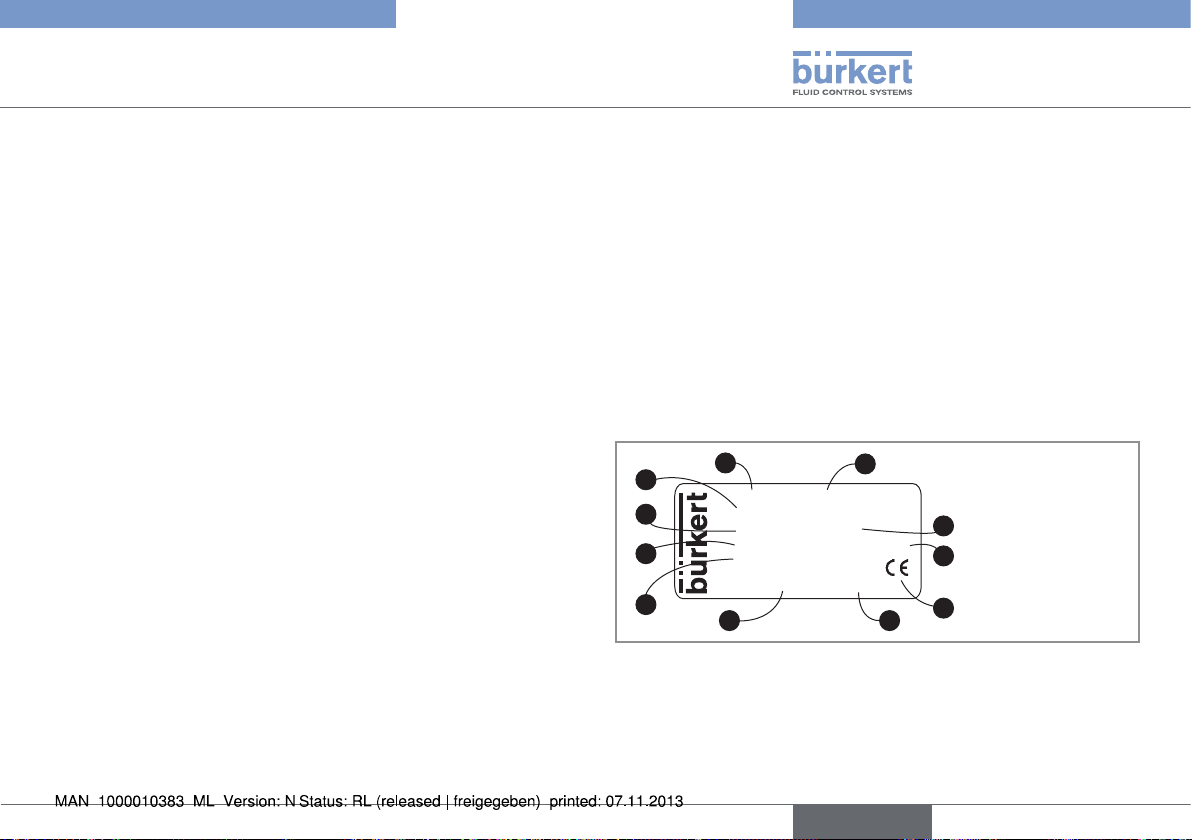

5.3 Description of the name plate on

the standard 1062

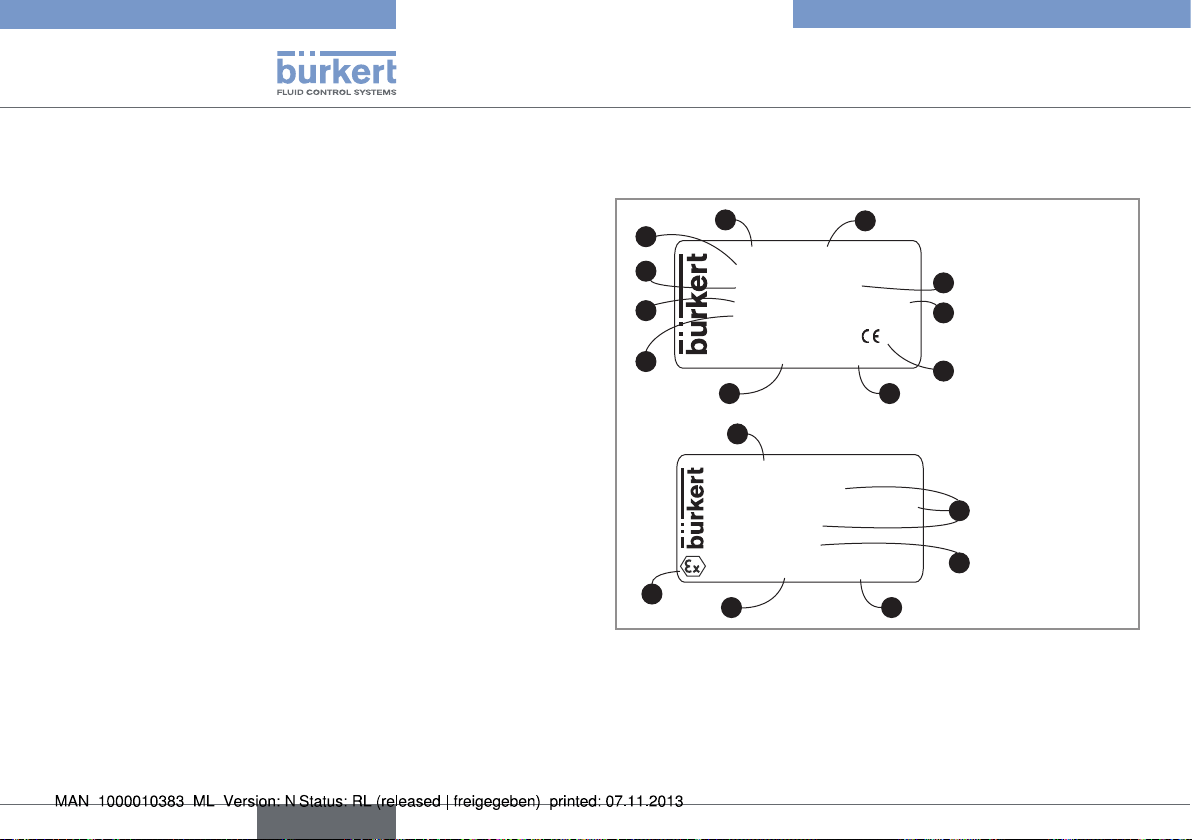

2

1

1062 PROXIMITY SWITCH

3

4

3-WIRE PNP-NO

10-30V DC NO/NC

MAX:200mA ACTUATOR >80

S/N 1199

00560409 W48LP

Made in France

5

6

Fig. 1: Name plate on the 1062 position feedback, standard

version

1. Type of device

2. Characteristics of the limit switch

3. Electrical power supply

11

10

9

8

7

english

9

Page 10

Type 1062

Description

4. Current consumption

5. Serial number

6. Item number

7. Manufacturing code

8. Conformity Marking

9. Available actuator sizes

10. Mode of operation of the 1062

11. Limit switch type

5.4 Description of the name plates

on the 1062 ATEX

2

1

1062 PROXIMITY SWITCH

3

4

5

2-WIRE NAMUR

8V DC NO/NC

MAX:15mA ACTUATOR =40

INERIS 03ATEX0268X/02

Made in France

00560411 W48LP

6

12

II 2 GD EEx Ia IIC

T6, T5 ou T4

Ex iaD21 T85°C, T100°C

ou T135°C

S/N 1000

F67220 TRIEMBACH

00560411 W48LP

13

6

Fig. 2: Name plate on the 1062 position feedback, ATEX version

1. Type of device

2. Characteristics of the limit switch

3. Electrical power supply

4. Current consumption

11

10

9

0102

8

7

15

14

7

10

english

Page 11

Type 1062

Technical data

5. ATEX certification body and certification number

6. Item number

7. Manufacturing code

8. Conformity Marking

9. Actuator size

10. Mode of operation

11. Limit switch type

12. Operating zone

13. ATEX logo

14. Serial number

15. Temperature classification

5.5 Versions available

To find out about the versions of the position feedback available,

consult the technical datasheet for the 1062 on our Internet site

under:

www.burkert.com

6 TECHNICAL DATA

6.1 Conditions of use

Ambient temperature

• version approved by CSA and CE

• version only approved by CE

Air humidity < 80%, non condensated

Protection class acc. to EN 60529 IP65, when wired and

6.2 Conformity of the 1062 ATEX to

standards and directives

The 1062 ATEX electrical position feedback (version with double

inductive 2-wire NAMUR switch) meets the requirements of the

ATEX Directive 94/9/EC on equipment intended for use in potentially explosive atmospheres. The following standards have been

used in the assessment:

• EN 60079-0 (2004)

• EN 60079-11 (2006)

• EN 61241-0 (2006)

• EN 61241-11 (2007)

• 0 to +60 °C

• -20 to +60 °C

cable gland tightened

english

11

Page 12

Type 1062

Technical data

6.3 Conformity of the 1062 approved

by CSA

The devices approved by CSA, with variable key PD01, conform to

the following standards:

• CSA C22.2 n° 61010-1-04

• UL 61010-1

6.4 General technical data

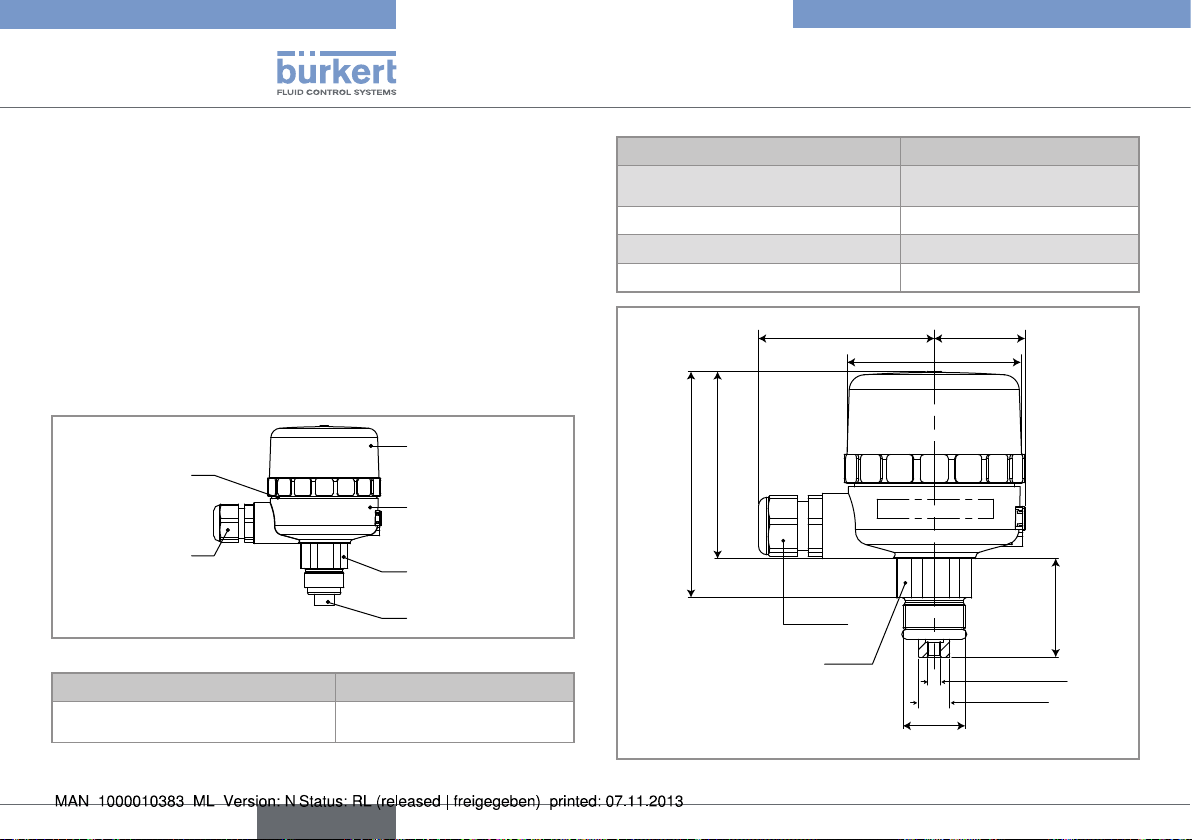

6.4.1 Mechanical data

PC or PSU

EPDM

PA6 or PPS

PA or PVDF

Fig. 3: Materials used in the 1062 position feedback

Component Material

Housing / Cover PA6 / PC or

PPS/PSU

Stainless steel or

brass

Brass

Component Material

Seal between the cover and the

EPDM

housing

Cable gland M16x1,5 PA or PVDF

External threaded part Brass or stainless steel

Internal threaded part Brass

67,5 35

Ø 66

72

87

M16x1,5

SW27

M5 / M6 / M10

12 / 10 / 16

M24x1,5 / M26x1,5 / M36x2

24 - 40

12

Fig. 4: Dimensions of the 1062 position feedback [mm]

english

Page 13

Type 1062

Technical data

6.4.2 General data

Actuator size Ø 40 to 125 mm, depending on the

version

Mechanical contact

version

• type of contact

• statuses detected

- 1062 fitted with

one switch

- 1062 fitted with

two switches

• valve open or closed

indication mode

• colour of the lights

depending on the

status detected

• power up light

• in silver or gold

- valve open or valve closed

- valve open and valve closed

• using lights and electrical signal via

terminal block

• a green light comes on when the valve

opens ("position open" or "position

open and closed" version) and/or a

red light comes on when the valve

closes ("position closed" or "position

open and closed" version)

• orange

Version with inductive

2-wire switch

• statuses detected

- 1062 fitted with

one switch

- 1062 fitted with

two switches

• valve open or closed

indication mode

Version with inductive

3-wire switch

• statuses detected

- 1062 fitted with

one switch

- 1062 fitted with

two switches

• valve open or closed

indication mode

• colour of the lights

depending on the

status detected

• power up light

- valve open or valve closed

- valve open and valve closed

• by electrical signal via terminal block

- valve open or valve closed

- valve open and valve closed

• using lights and electrical signal via

terminal block

• a green light comes on when the valve

opens and a red light comes on when

the valve closes

• orange

english

13

Page 14

Type 1062

Technical data

Version with double

inductive switch (4-wire)

• statuses detected

• valve open or closed

indication mode

• colour of the lights

depending on the

status detected

• power up light

Version with double

inductive 2-wire NAMUR

switch

• statuses detected

• valve open or closed

indication mode

• colour of the lights

depending on the

status detected

• valve open and valve closed

• using lights and electrical signal via

terminal block

• an orange light comes on when the

valve opens and a red light comes on

when the valve closes

• green

• valve open and valve closed

• using lights and electrical signal via

terminal block

• an orange light goes off when the

valve opens and a red light goes off

when the valve closes

6.4.3 General data specific to the devices

approved by CSA

Degree of pollution Degree 2, acc. to EN 61010-1

Installation category Category I, acc. to EN 61010-1

Height above sea level max. 2000 m

Electric power supplied by an SELV (Safety Extra Low

Voltage) source

6.4.4 Electrical data

Connection cable standard, diameter between 5 and

7 mm, max cross-section of the strand

2

1 mm

Mechanical contact

version (per contact)

• Power supply of

devices approved by

CSA and CE

• Power supply

of devices only

approved by CE

• Power consumption

• Allowable load

• Type of output

• 12-30 V AC or

12-48 V DC

• 12-30 V DC or

12-48 V DC/V AC or

48/110 V DC/V AC or

110/250 V DC/V AC

• < 35 mA (48 V DC)

< 8 mA (220 V AC)

• depending on the power supply

voltage and the type of load, inductive

or resistive: see „Table 1“ next page

• contact normally open or normally

closed

14

english

Page 15

Type 1062

Technical data

Version with inductive

2-wire switch (per

switch)

• Power supply

• Power consumption

• Allowable load

• Type of output

Version with inductive

3-wire switch (per

switch)

• Power supply

• Power consumption

• Allowable load

• Type of output

Version with double

inductive 4-wire switch

• Power supply

• Power consumption

• Allowable load

• Type of output

• 10-30 V DC

• ≤ 2 mA

• ≤ 100 mA

• contact normally open or normally

closed

• 10-30 V DC

• ≤ 25 mA

• ≤ 200 mA

• NPN or PNP, normally open or normally closed

• 10-30 V DC

• ≤ 15 mA

• ≤ 150 mA, per output

• PNP, normally open

Version with double

inductive 2-wire

NAMUR switch

• Power supply

• Power consumption

• 8 V DC

• ≤ 1,2 mA (activated) and

> 2,1 mA (not activated)

• Allowable load

• Type of output

Supply voltage

• see table in chap. „8.2.5“

• acc. to NAMUR

Inductive load

[I

]

max

Resistive load

[I

max

]

24 V DC 5 A 5 A

30 V DC 2 A 5 A

50 V DC 0,7 A 1 A

74 V DC 0,25 A 0,6 A

125 V DC 0,03 A 0,4 A

250 V DC 0,02 A 0,25 A

125 V AC 8 A 8 A

250 V AC 8 A 8 A

Table 1: Allowable loads for a mechanical contact version

english

15

Page 16

Type 1062

Assembly

7 ASSEMBLY

7.1 Safety instructions

Risk of explosion.

When the 1062 is used in an ATEX 21 or 22 zone, make sure:

• That the cover of the electrical position feedback is always

screwed shut before operating the valve.

danger

Danger due to high pressure in the installation.

▶ Shut down the pneumatic power source and depressurise the

pipes before carrying out work on the device.

Risk of injury due to electrical discharge.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Warning

Risk of injury due to non-conforming assembly.

▶ The device must only be assembled by qualified and skilled staff

with the appropriate tools.

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶ Avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restarting of the process subse-

quent to the assembly of the device.

16

english

Page 17

Type 1062

Assembly

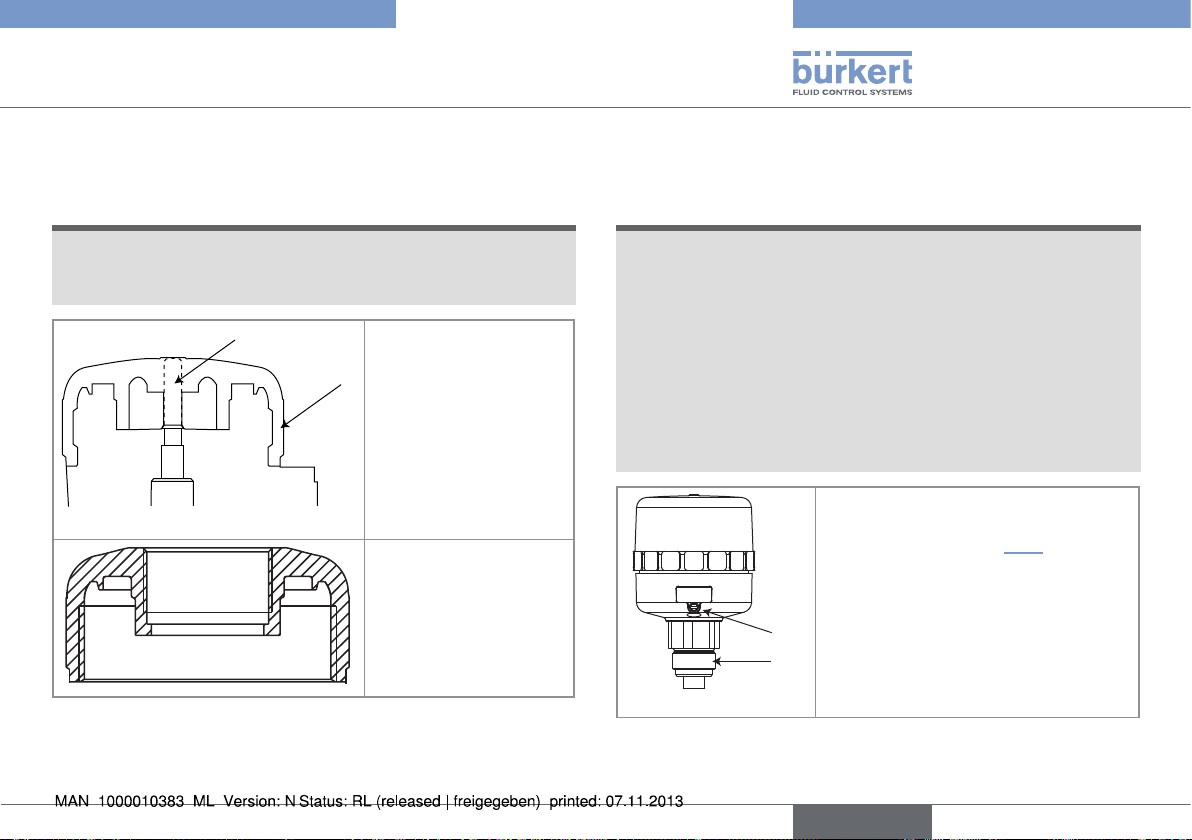

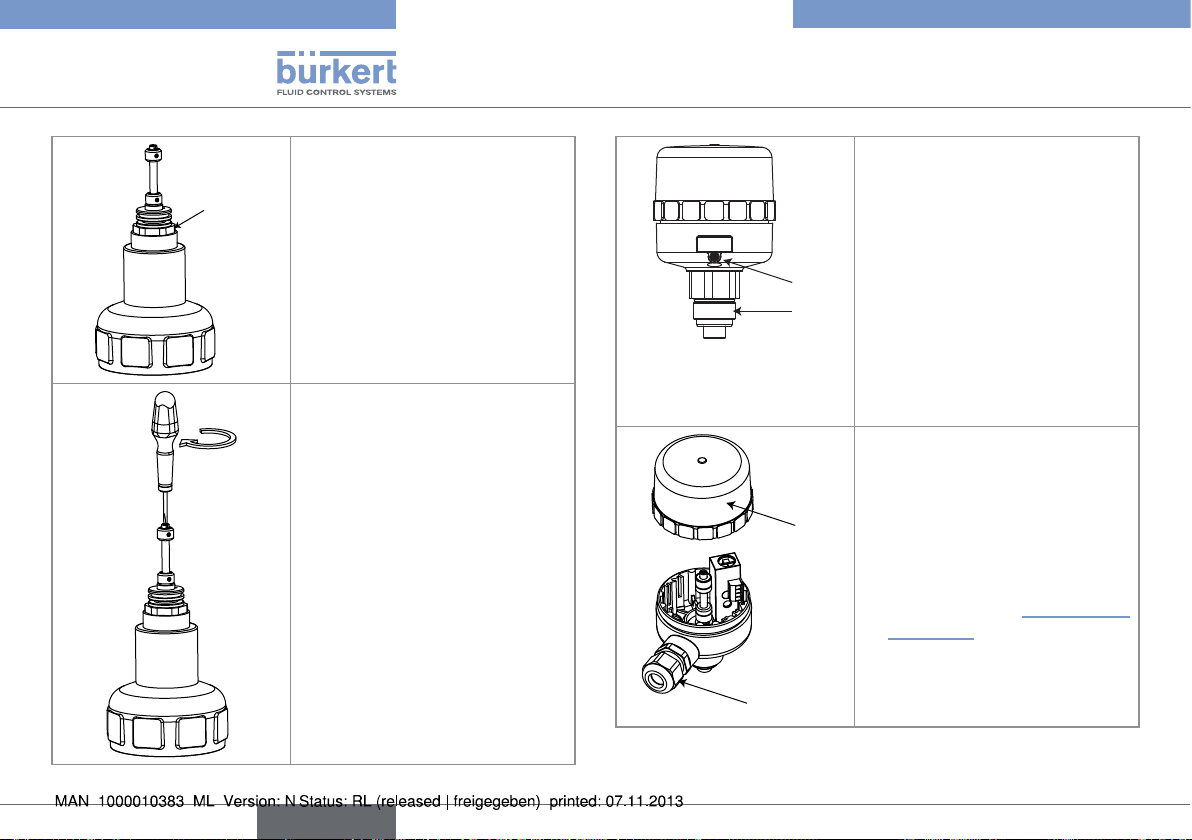

7.2 Replacing the top part of an

actuator size 40mm

note

The tightness of the actuator is not guaranteed when the

cover is removed.

▶ Prevent the projection of fluids into the actuator.

B

→ Remove the top part

of the actuator, "A",

by unscrewing it with

A

the spanner available

in accessories (item

number 639175).

→ Remove the top part

of the actuator rod,

"B", by unscrewing by

hand.

→ Screw the top part of

the actuator supplied

with the 1062 to the

actuator size 40mm,

and tighten it using the

spanner (item number

639175).

Fig. 5: Replacing the top part of the actuator size 40mm

7.3 Fitting the position feedback to a

pneumatic actuator

note

The tightness of the actuator is not guaranteed when the

transparent cap is removed.

▶ Prevent the projection of fluids into the actuator.

The tightness of the position feedback is not guaranteed

when the cover is removed.

▶ Prevent the projection of fluids into the position feedback.

The position feedback may be damaged if a metal component comes into contact with the electronics.

▶ Prevent contact of the electronics with a metal component (a

screwdriver, for example).

→ If the valve is fitted with an actuator

size 40mm, replace the top part of the

actuator. See chap. „7.2“.

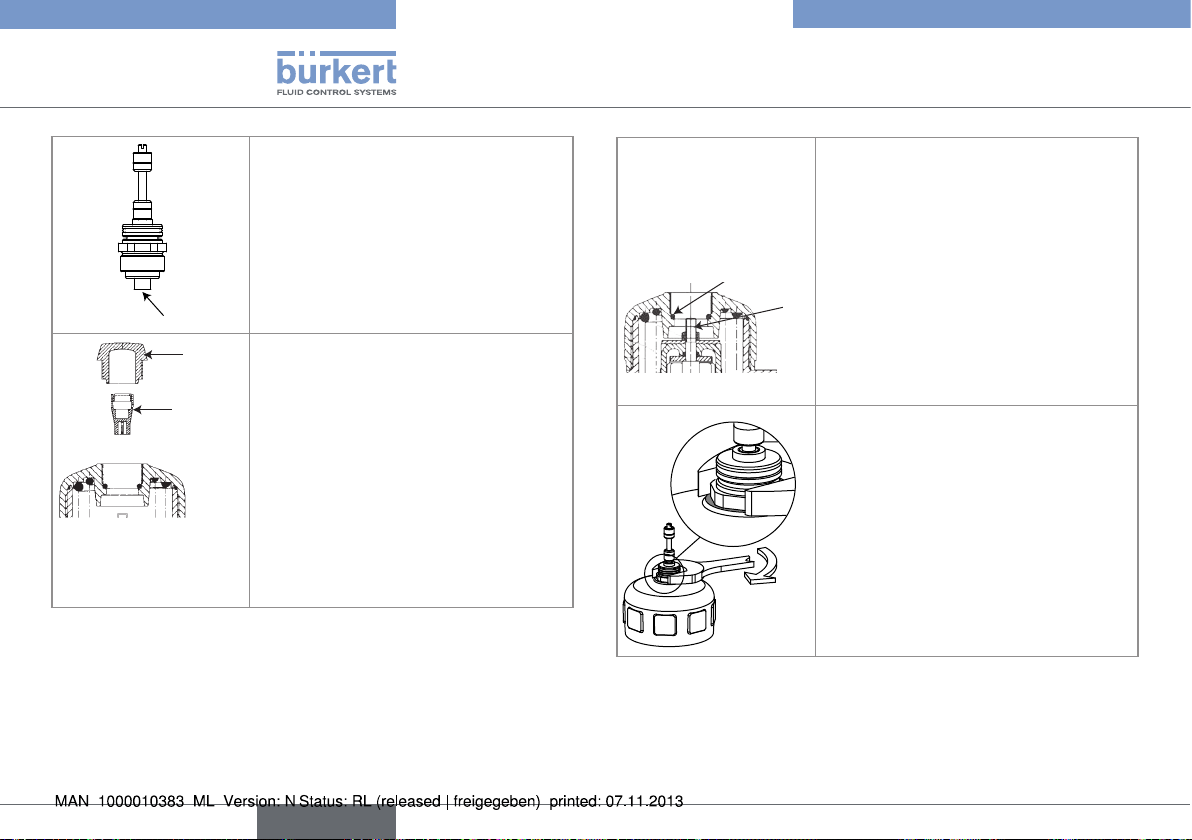

→ Unscrew the cone point set screw "C"

from the 1062 to unlock the duplication system "D" using a hexagonal

C

D

male spanner.

→ Carefully remove the duplication

system "D" from the housing of the

1062.

english

17

Page 18

Type 1062

D

J

E

H

Assembly

→ Check that the seals have been fitted

and that they are undamaged. Replace

them if necessary.

→ Put thread lock into the internal thread

in the duplication rod "E".

→ Check that the seal "H" is fitted and

that it is correctly positioned inside

the actuator.

→ Insert the duplication system "D" into

the actuator.

→ Screw the duplication rod "E" onto

the actuator rod "J".

E

F

G

→ Unscrew the small transparent cap "F"

on the actuator, preferably by hand or

using a suitable tool in order not to

damage it (except for actuators size

40mm).

→ Pump air into the actuator on a valve

which is normally closed (function "A")

or has a double effect (function "I") so

that the actuator rod moves to the top

position.

→ Tighten the adaptor until free contact

is obtained with the top of the

actuator, using a flat No 27 spanner.

→ Unscrew the visual position feedback

"G" using a hexagonal male spanner.

18

english

Page 19

Type 1062

Assembly

→ Fully tighten the duplication rod on

the actuator rod using a screwdriver

with a blade of suitable size.

→ Depressurize the actuator of a valve

which is normally closed (function

"A") or has a double effect (function

"I"): the valve recovers its default

position.

K

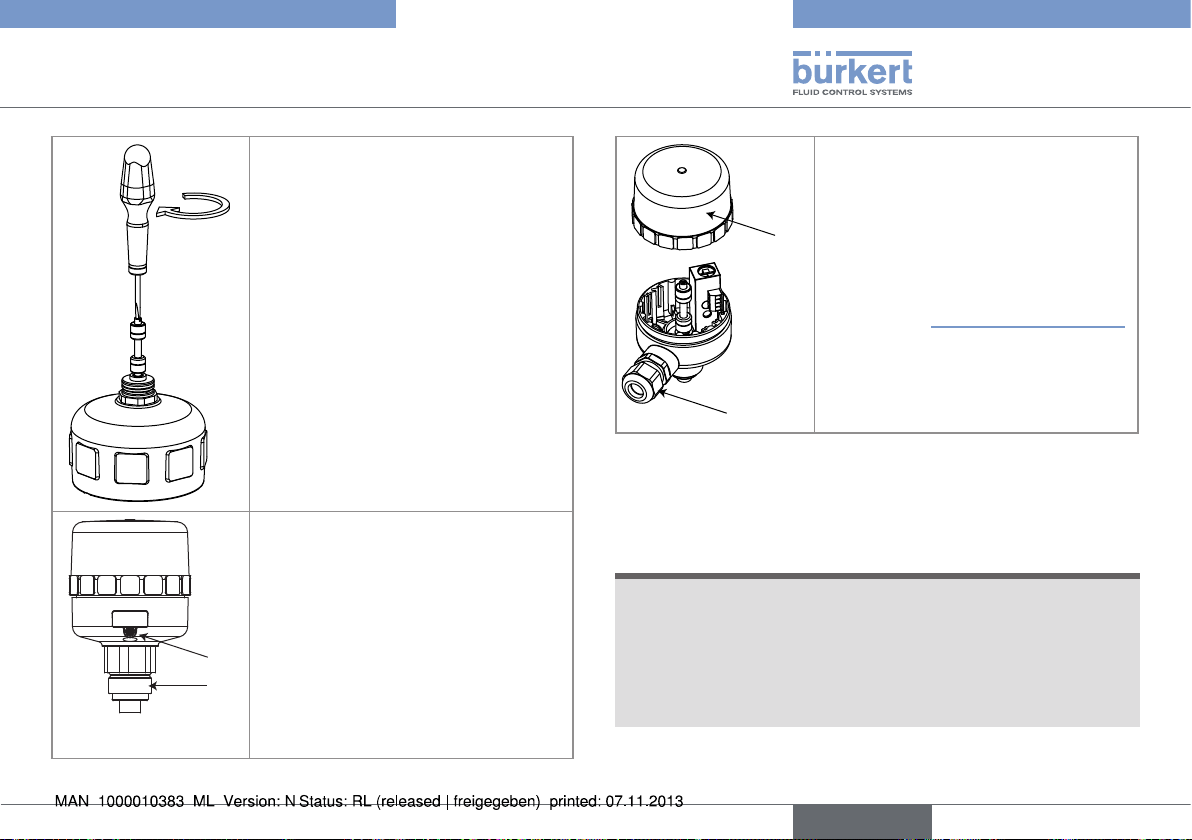

→ Unscrew the cover "K" on the

position feedback.

→ Unscrew the cable gland "L".

→ Thread the cable through the cable

gland.

→ Wire according to the wiring

diagram for your version of the 1062:

See chap. „8 Installation and wiring“.

→ Fasten the cable gland to ensure

tightness of the product.

L

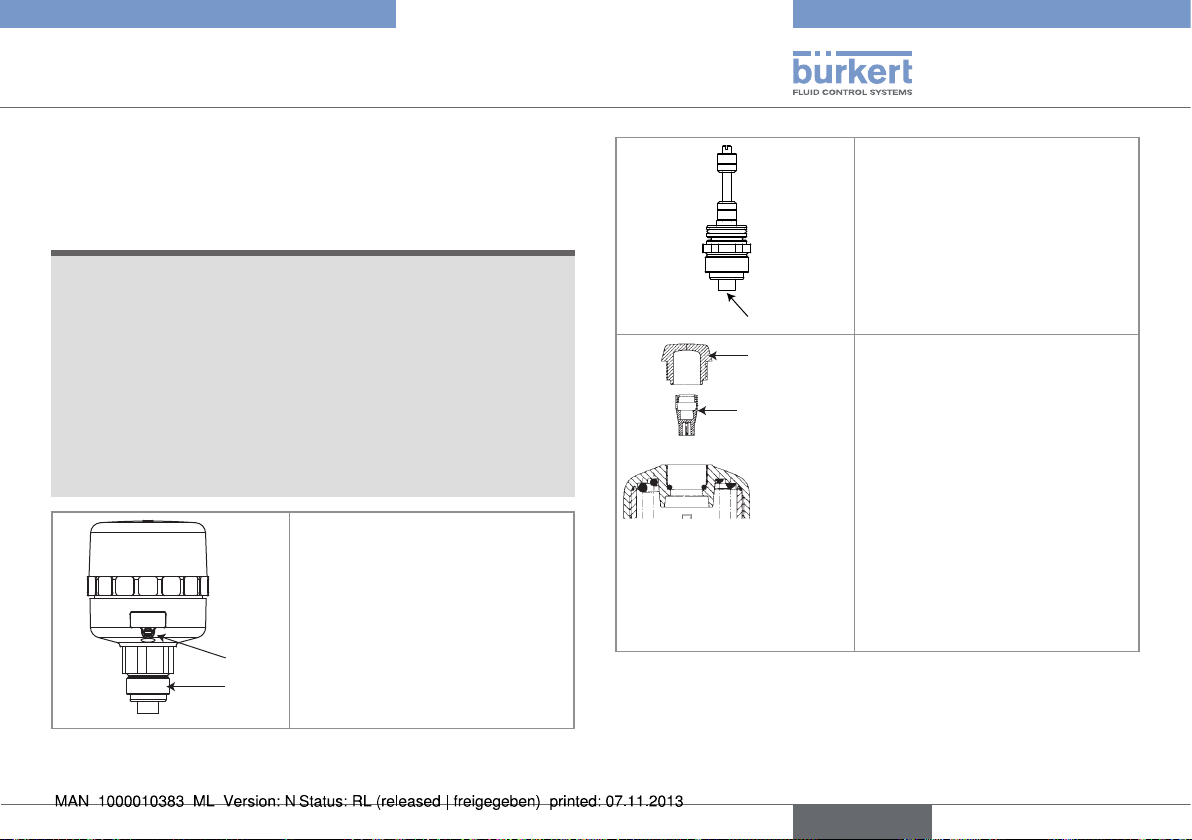

7.4 Fitting the position feedback with

stroke limiter to a pneumatic

→ Insert the position feedback housing

into the duplication system "D"

setting the cable gland in the

direction desired and making sure,

on a mechanical contact version,

that you do not damage the contact

C

D

levers on the switches.

→ Fasten the housing and the dupli-

cation system by tightening the cone

point set screw "C" using a hexagonal male spanner.

note

The tightness of the actuator is not guaranteed when the

transparent cap is removed.

▶ Prevent the projection of fluids into the actuator.

The tightness of the position feedback is not guaranteed

when the cover is removed.

▶ Prevent the projection of fluids into the position feedback.

actuator size 50 to 80mm

english

19

Page 20

Type 1062

Assembly

note

The position feedback may be damaged if a metal component comes into contact with the electronics.

▶ Prevent contact of the electronics with a metal component (a

screwdriver, for example).

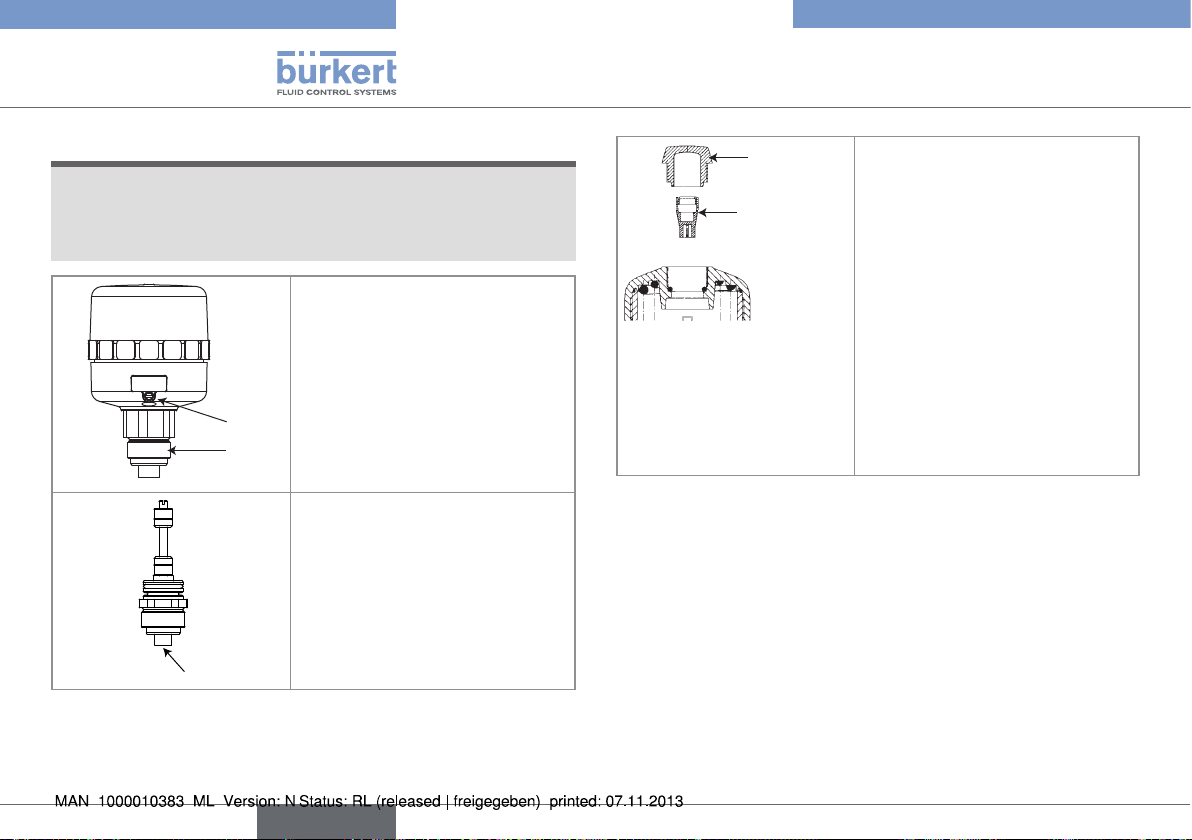

→ Unscrew the cone point set

screw "C" from the 1062 to

unlock the duplication system "D"

using a hexagonal male spanner.

→ Carefully remove the duplication

system "D" from the housing of

C

D

the 1062.

→ Check that the seals have

been fitted and that they are

undamaged. Replace them if

necessary.

→ Put thread lock into the internal

thread in the duplication rod "E".

E

F

G

→ Unscrew the small transparent

cap "F" on the actuator, preferably by hand or using a suitable tool in order not to damage

it (except for actuators size

40mm).

→ Pump air into the actuator on a

valve which is normally closed

(function "A") or has a double

effect (function "I") so that the

actuator rod moves to the top

position.

→ Unscrew the visual position

feedback "G" using a hexagonal

male spanner.

20

english

Page 21

Type 1062

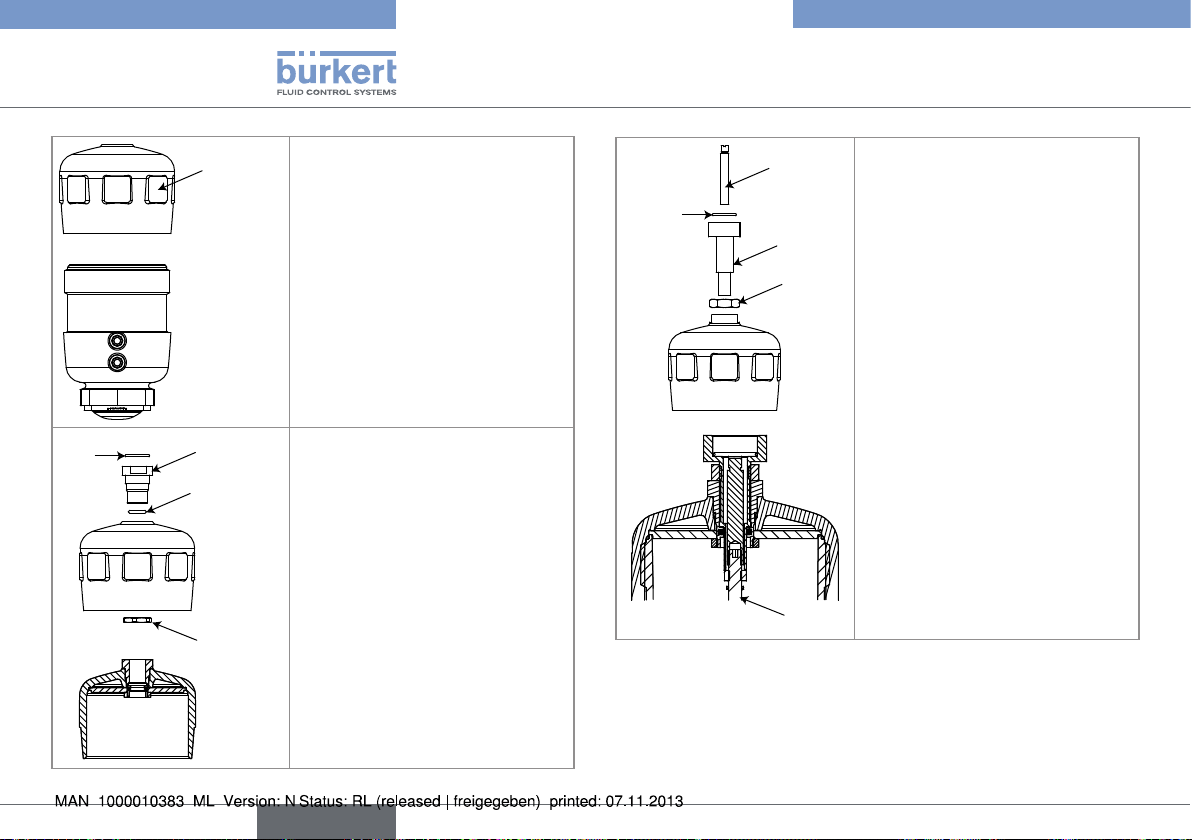

O

H

J

N

K

P

M

Assembly

→ Check that the seal "H" is fitted

and that it is correctly positioned inside the actuator.

P

→ Insert the protection hood "P".

→ Screw the adapter nut "J" in the

top part of the actuator.

→ Screw the connecting pin "K"

with locknut "L" in the adapter

nut "J".

→ Adjust the stroke of the actuator

(by more or less screwing the

connecting pin "K") depending

on the operating mode of the

valve:

- if the valve operates as normally closed (NC), adjust

the stroke by starting valve

closed.

- if the valve operates as normally open (NO), adjust the

stroke by starting valve open.

D

→ Insert the duplication system

"D" into the stroke limiter.

→ Block the locknut "L".

→ Insert the seal "M" in the con-

necting pin "K".

→ Screw the stem "N" on the

stem "O" of the actuator.

english

21

Page 22

Type 1062

Assembly

→ Tighten the duplication

system "D" until free contact

D

is obtained with the top of

the limiter, using a flat No 27

spanner.

C

D

→ Insert the position feedback

housing into the duplication

system "D" setting the

cable gland in the direction

desired and making sure, on

a mechanical contact version,

that you do not damage the

contact levers on the switches.

→ Fasten the housing and the

duplication system by tightening the cone point set screw

→ Fully tighten the duplication

rod on the actuator rod using

a screwdriver with a blade of

suitable size.

→ Depressurize the actuator of a

valve which is normally closed

(function "A") or has a double

effect (function "I"): the valve

recovers its default position.

Q

"C" using a hexagonal male

spanner.

→ Unscrew the cover "Q" on the

position feedback.

→ Unscrew the cable gland "R".

→ Thread the cable through the

cable gland.

→ Wire according to the wiring

diagram for your version of the

1062: See chap. „8 Installation

and wiring“.

→ Fasten the cable gland to

ensure tightness of the product.

R

22

english

Page 23

Type 1062

E

Assembly

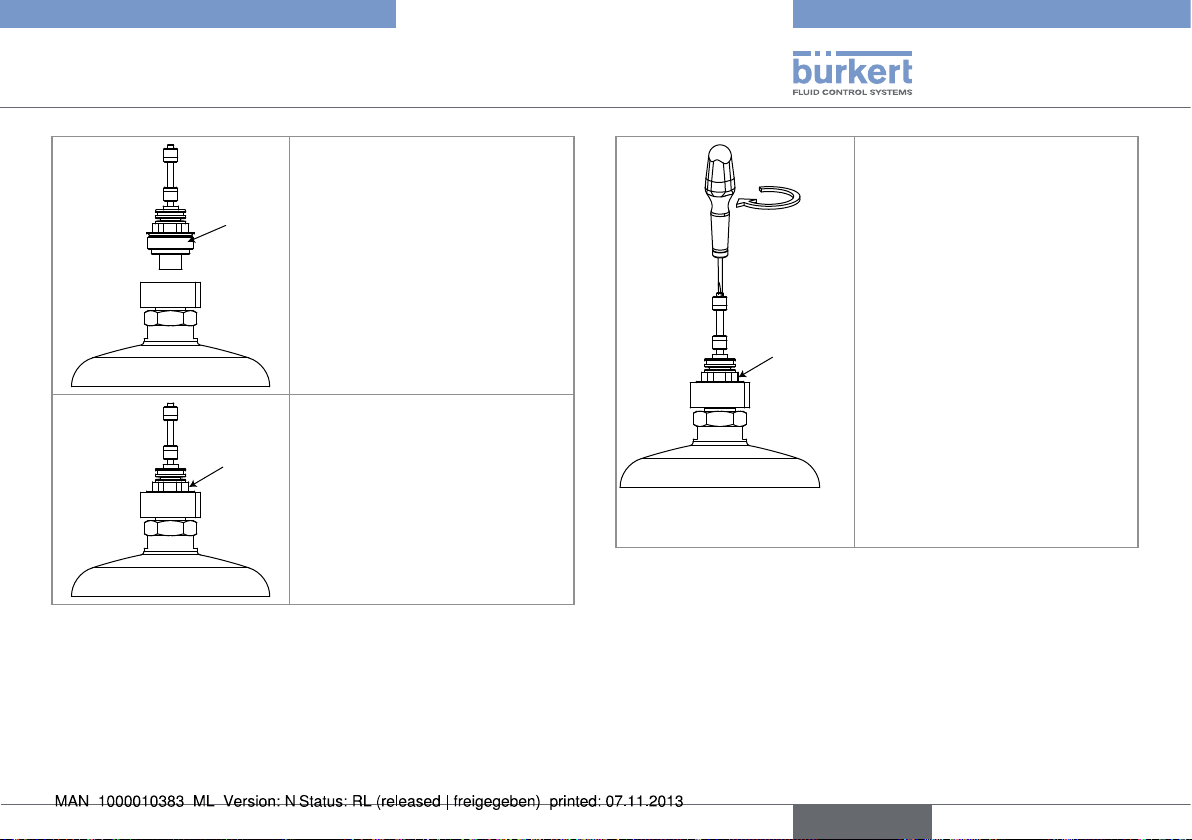

7.5 Fitting the position feedback with

stroke limiter to a pneumatic

actuator size 100 or 125mm

note

The tightness of the actuator is not guaranteed when the

transparent cap is removed.

▶ Prevent the projection of fluids into the actuator.

The tightness of the position feedback is not guaranteed

when the cover is removed.

▶ Prevent the projection of fluids into the position feedback.

The position feedback may be damaged if a metal component comes into contact with the electronics.

▶ Prevent contact of the electronics with a metal component (a

screwdriver, for example).

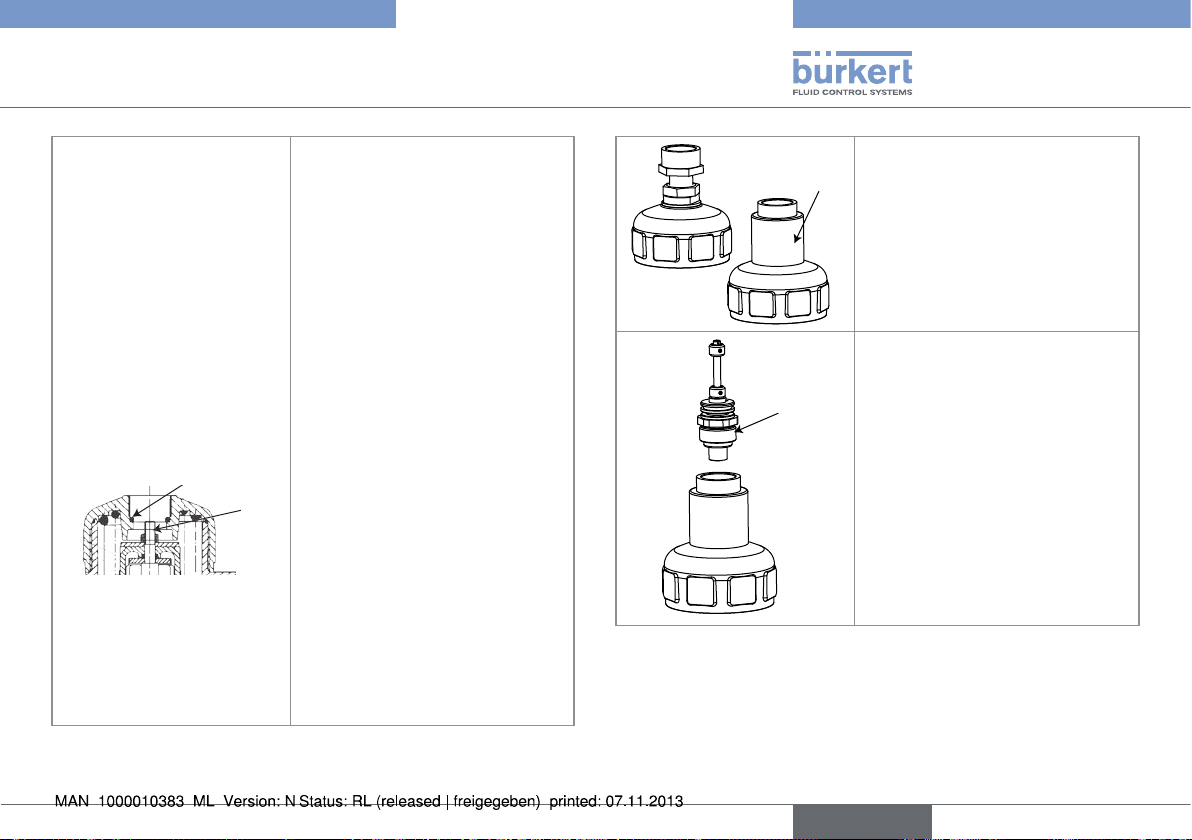

→ Unscrew the cone point set

screw "C" from the 1062 to

unlock the duplication system "D"

using a hexagonal male spanner.

→ Carefully remove the duplication

system "D" from the housing of

C

D

the 1062.

→ Check that the seals have

been fitted and that they are

undamaged. Replace them if

necessary.

→ Put thread lock into the internal

thread in the duplication rod "E".

F

G

→ Unscrew the small transparent

cap "F" on the actuator, preferably by hand or using a suitable tool in order not to damage

it

→ Pump air into the actuator on a

valve which is normally closed

(function "A") or has a double

effect (function "I") so that the

actuator rod moves to the top

position.

→ Unscrew the visual position

feedback "G" using a hexagonal

male spanner.

english

23

Page 24

Type 1062

Assembly

H

M

K

J

actuator, by unscrewing it with

the spanner available in accessories (item number 639172 for

an actuator size 100mm or item

number 639173 for an actuator

size 125mm).

→ Insert the seal "J" into the groove

of the adaptater nut "K".

→ Screw the adaptater nut "K" in

the top part of the actuator.

P

→ Remove the top part "H" of the

Q

N

O

→ Screw the locknut "L" on "K",

inside the top hat of the actuator.

→ Insert the seal "M" into the adap-

tater nut "K".

L

→ Screw back the top part of the

actuator.

R

→ Screw the connecting pin "N"

with the locknut "O" in the

adapter nut "K".

→ Adjust the stroke of the actuator

(by more or less screwing the

connecting pin "N") depending

on the operating mode of the

valve:

- if the valve operates as normally closed (NC), adjust

the stroke by starting valve

closed.

- if the valve operates as normally open (NO), adjust the

stroke by starting valve open.

→ Block the locknut "O".

→ Insert the seal "P" in the con-

necting pin "N".

→ Screw the stem "Q" on the

stem "R" of the actuator.

24

english

Page 25

Type 1062

Assembly

→ Insert the duplication system

"D" into the stroke limiter.

D

→ Fully tighten the duplication

rod on the actuator rod using

a screwdriver with a blade of

suitable size.

→ Depressurize the actuator of a

valve which is normally closed

(function "A") or has a double

effect (function "I"): the valve

recovers its default position.

D

→ Tighten the duplication

system "D" until free contact

D

is obtained with the top of

the limiter, using a flat No 27

spanner.

english

25

Page 26

Type 1062

Installation and wiring

→ Insert the position feedback

housing into the duplication

system "D" setting the

cable gland in the direction

desired and making sure, on

a mechanical contact version,

C

D

that you do not damage the

contact levers on the switches.

→ Fasten the housing and the

duplication system by tightening the cone point set screw

"C" using a hexagonal male

spanner.

→ Unscrew the cover "R" on the

position feedback.

→ Unscrew the cable gland "S".

R

→ Thread the cable through the

cable gland.

8 INSTALLATION AND WIRING

8.1 Safety instructions

Risk of explosion.

When the 1062 is used in an ATEX 21 or 22 zone, make sure:

• That the cover of the electrical position feedback is always

screwed shut before operating the valve.

• That you check that the device is not subject to a flow of air and

dust that may result in an accumulation of electrostatic charges.

Otherwise, intall the device in a conductive cover.

• "The NAMUR switches on the 1062 must be powered by a voltage

source of a type certified for use in explosive atmospheres in

groups IIB/IIC and their combination must be compatible from the

instrinsic safety point of view."

→ Wire according to the wiring

diagram for your version of the

1062: See chap. „8 Installation

and wiring“.

→ Fasten the cable gland to

ensure tightness of the product.

S

26

english

Page 27

Type 1062

Installation and wiring

danger

Danger due to high pressure in the installation.

▶ Shut down the pneumatic power source and depressurise the

pipes before carrying out work on the device.

Risk of injury due to electrical discharge.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Warning

Risk of injury due to nonconforming installation.

▶ Electrical installation can only be carried out by qualified and

skilled staff with the appropriate tools.

▶ Install appropriate safety devices (correctly rated fuse and/or

circuit-breaker).

Risk of injury due to unintentional switch on of power supply

or uncontrolled restarting of the installation.

▶ Take appropriate measures to avoid unintentional activation of

the installation.

▶ Guarantee a set or controlled restarting of the process subse-

quent to the assembly of the device.

8.2 Electrical wiring

danger

Risk of injury due to electrical discharge.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Use a high quality electrical power supply (filtered and

regulated).

note

The tightness of the position feedback is not guaranteed

when the cover is removed.

▶ Prevent the projection of fluids into the position feedback.

The position feedback may be damaged if a metal component comes into contact with the electronics.

▶ Prevent contact of the electronics with a metal component (a

screwdriver, for example).

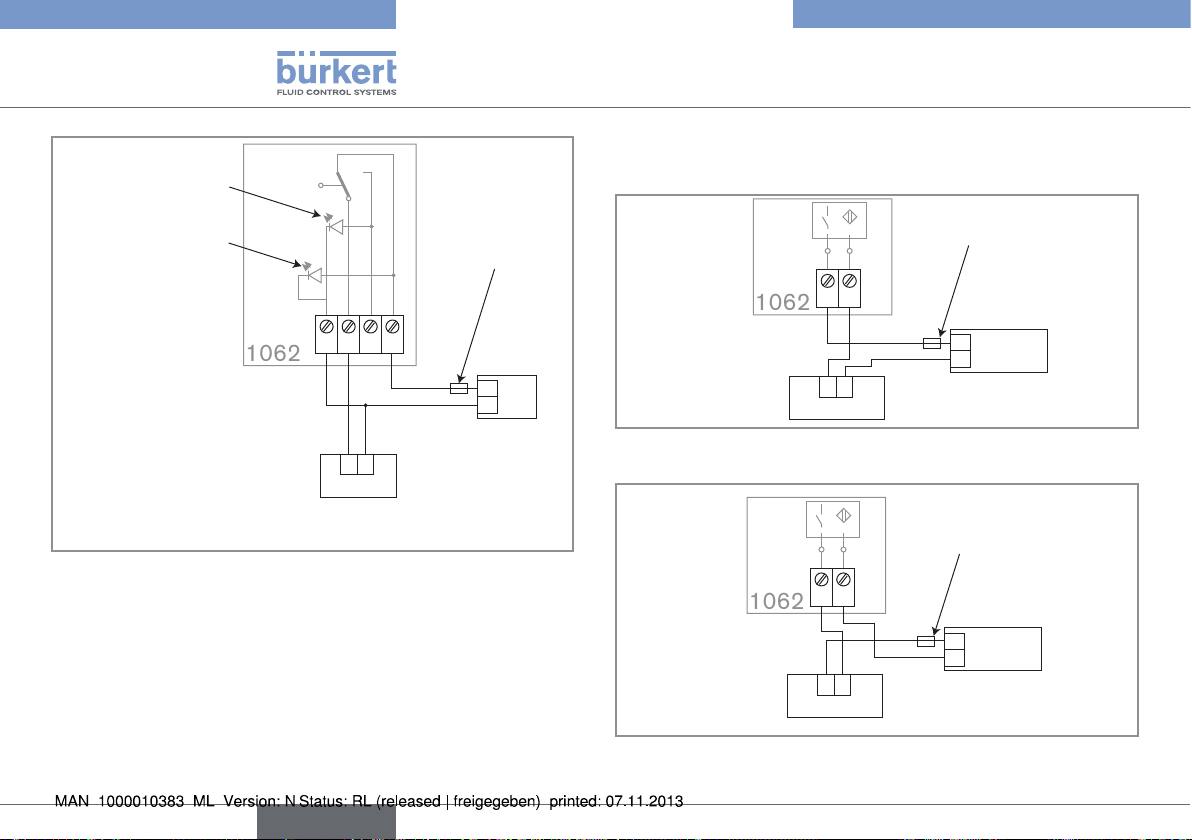

→ Assemble the device as shown in chap. „7 Assembly“ before

wiring it.

→ Carry out the electrical wiring in accordance with chap. „8.2.1“

to „8.2.6“ for your version of the 1062.

→ Once the device has been wired, lock the cable so that it does

not impair the mobility of the duplication rod, by inserting it

english

27

Page 28

Type 1062

1062

Installation and wiring

into the notches provided for this purpose in the bottom of the

housing, as shown in „Fig. 6“ below:

Fig. 6: Final position of the cable

8.2.1 Wiring a mechanical contact version

note

On a mechanical contact version, the used contact is not

voltage free.

• Do not connect the unused contact in order to obviate any danger

of malfunction.

Green light (open

valve detection)

Orange light (volt-

age present)

-

NONC

Load

+

8 A max.

Fig. 7: Wiring of the contact when normally open (NO) on a

mechanical contact version, valve open detection

1)

Use a power supply that matches the data shown on the name plate of the

1062

Fuse suitable for

the max. load

+

Power supply

-

+

-

1)

28

english

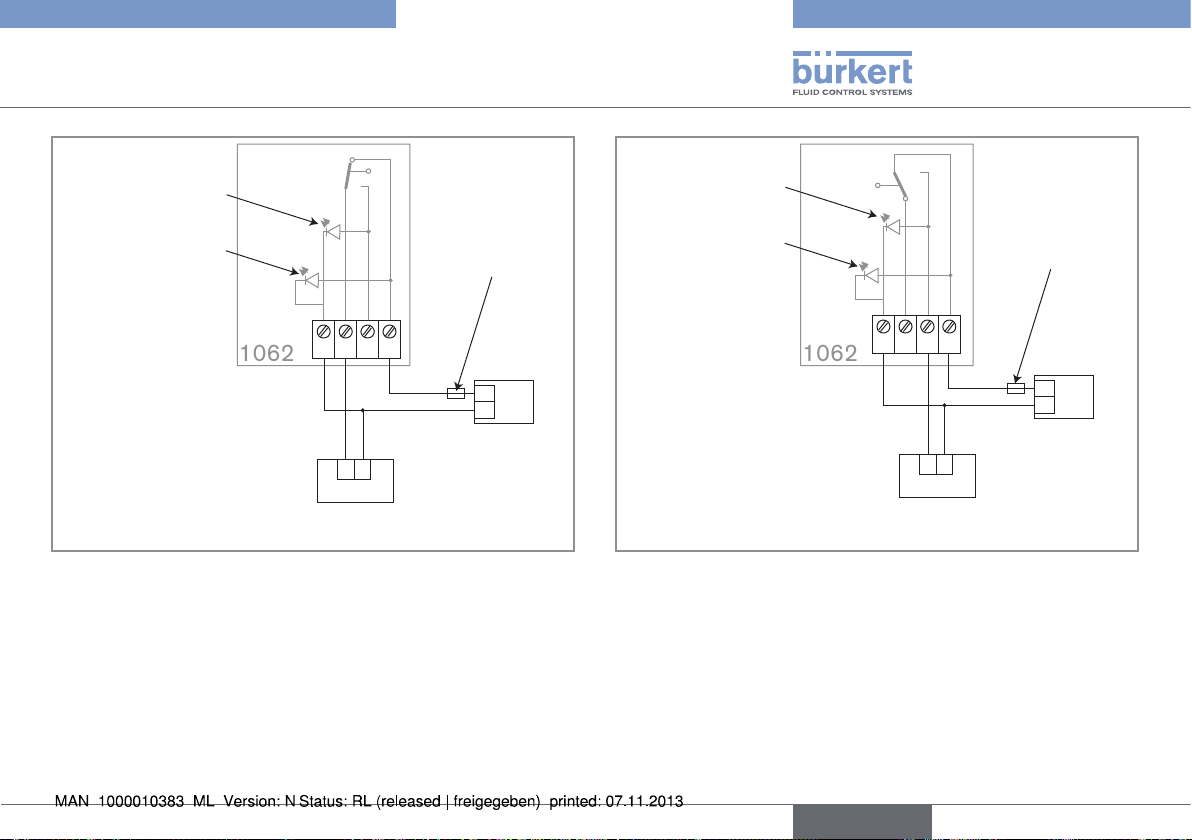

Page 29

Type 1062

1062

1062

Installation and wiring

Green light (open

valve detection)

Orange light (volt-

age present)

-

+

8 A max.

NONC

-

Fuse suitable for

the max. load

+

Power supply

+

-

1)

Load

Fig. 8: Wiring of the contact when normally closed (NC) on a

mechanical contact version, valve open detection

1)

Use a power supply that matches the data shown on the name plate of the

1062

Red light

(valve closed

detection)

Orange light

(voltage present)

-

NONC

+

8 A max.

Fuse suitable for

the max. load

+

Power supply

-

+

-

1)

Load

Fig. 9: Wiring of the contact when normally open (NO) on a

mechanical contact version, valve closed detection

1)

Use a power supply that matches the data shown on the name plate of the

1062

english

29

Page 30

1062

Red light (valve closed

1062

1062

detection)

Orange light (volt-

age present)

-

+

8 A max.

NONC

-

Fuse suitable for

the max. load

+

Power supply

+

-

1)

Load

Fig. 10: Wiring of the contact when normally closed (NC) on a

mechanical contact version, valve closed detection

1)

Use a power supply that matches the data shown on the name plate of the

1062

Type 1062

Installation and wiring

8.2.2 Wiring a version with inductive

2-wire switch

Reaction speed according

to the max. load

-

+

125 mA

Load

-

+

100 mA max.

Fig. 11: Wiring the inductive 2-wire switch in "less common"

mode, open and/or closed valve detection

-

+

125 mA

Load

-

+

100 mA max.

+

10-30 VDC

-

Power supply

Reaction speed according

to the max. load

+

10-30 VDC

-

Power supply

30

Fig. 12: Wiring the inductive 2-wire switch in "more common"

mode, open and/or closed valve detection

english

Page 31

Type 1062

1062

1062

Installation and wiring

8.2.3 Wiring a version with inductive

3-wire switch

Green light (valve open detection) or red

light (valve closed detection)

Orange light

(voltage present)

Reaction speed according

to the max. load

A

+ -

250 mA

Load

-

+

200 mA max.

Fig. 13: Wiring a version with an inductive 3-wire switch in PNP

mode, valve open or valve closed detection

+

10-30 VDC

-

Power supply

8.2.4 Wiring a version with two inductive

3-wire switches

Green light (valve open

detection)

A

+ -

Valve open

switch

-

+

200 mA max.

Load 1

Fig. 14: Wiring a version with two inductive 3-wire switches in

NPN mode, valve open and valve closed detection

Red light (valve closed

detection)

A

+ -

Reaction speed according

to the max. load

500 mA

-

+

200 mA max.

Load 2

Valve closed

switch

Orange light

(voltage present)

+

10-30 VDC

-

Power supply

english

31

Page 32

Type 1062

062

Installation and wiring

Green light (valve open

detection)

Red light (valve closed

detection)

Valve closed

switch

Orange light

(voltage present)

500 mA

+

10-30 VDC

-

1

Valve open

switch

A

+ -

A

+ -

Reaction speed according

to the max. load

Power supply

-

+

200 mA max.

Load 1

-

+

200 mA max.

Load 2

Fig. 15: Wiring a version with two inductive 3-wire switches in

PNP mode, valve open and valve closed detection

8.2.5 Wiring a version with double

inductive 2-wire NAMUR switch

Respect the maximum allowable characteristics of the circuit

established with an inductive NAMUR switch shown in the table

below.

Max. authorised

ambient T°

100 °C II 2G T4 60 200 20 180 350

85 °C II 2G T5 60 200 20 180 350

80 °C II 2G T5 60 200 20 180 350

70 °C II 2G T6 60 200 20 180 350

Category

T° class

Ii [mA] (with

resistive limit)

Pi (mW)

U (V)

Ci (nF)

Li (µH)

32

english

Page 33

Type 1062

Installation and wiring

The following table gives the state of the orange and red LEDs and

the related position of the valve, depending on the use of the S01

and S02 circuits:

Circuits S01 and

S02

Circuits S01 and

S02 are wired and

energized

LEDs Valve position

Open Closed

Orange LED

state (S01)

Red LED

state (S02)

Only circuit S01

wired and energized

Orange LED

state (S01)

Red LED

state (S02)

Only circuit S02

wired and energized

Orange LED

state (S01)

Red LED

state (S02)

: LED OFF

: LED ON

Orange light (valve open

detection)

S01

4

S02

3

UB2

2

S01

1

UB1

S02

Red light (valve closed

detection)

In

+

In

+

Intrinsic safety barrier

Fig. 16: Wiring the 2 outputs of the double inductive 2-wire

switch, valve open detection (output S01) and valve

closed detection (output S02)

english

33

Page 34

Type 1062

Commissioning

8.2.6 Wiring a version with double

inductive 4-wire switch

Orange light (valve open detection)

Green light

(voltage

present)

S01

S02

Fig. 17: Wiring the 2 outputs of a version with a double inductive

4-wire switch, in PNP mode, valve open detection (output

S01) and/or valve closed detection (output S02)

Red light (valve closed detection)

Load 2

150 mA max.

4

S02

3

0V

2

S01

1

V+

+

150 mA max.

Load 1

+

-

Reaction speed

according to the

max. load

500 mA

+

10-30 VDC

-

Power supply

-

9 COMMISSIONING

9.1 Safety instructions

Warning

Danger due to nonconforming commissioning.

Nonconforming commissioning could lead to injuries and damage

the device and its surroundings.

▶ Before commissioning, make sure that the staff in charge have

read and fully understood the contents of the manual.

▶ In particular, observe the safety recommendations and intended

use.

▶ The device/installation must only be commissioned by suitably

trained staff.

▶ Protect the device against electromagnetic interference and

ultraviolet rays.

Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors,

the effects of climatic conditions.

9.2 Setting the cams

Activate the valve to check the correct detection of the open and/or

closed position.

If detection is incorrect, reposition each cam opposite its switch

according to the position of the valve as shown in the photos in „Fig.

17“.

34

english

Page 35

Type 1062

Maintenance and troubleshooting

→ Activate the valve

Target of the valve

open switch

so that it opens

completely.

→ The top cam

should be located

opposite the

target of the valve

open switch.

→ Activate the valve

so that it closes

completely.

→ The bottom cam

should be located

opposite the

target of the valve

Target of the valve

closed switch

Fig. 18: Correct position of the cams in relation to the switches

closed switch.

10 MAINTENANCE AND

TROUBLESHOOTING

10.1 Safety instructions

danger

Danger due to high pressure in the installation.

▶ Shut down the pneumatic power source and depressurise the

pipes before carrying out work on the device.

Risk of injury due to electrical discharge.

▶ Shut down the electrical power source of all the conductors and

isolate it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Warning

Risk of injury due to non-conforming maintenance.

▶ Maintenance must only be carried out by qualified and skilled

staff with the appropriate tools.

▶ Guarantee a set or controlled restarting of the process, after a

power supply interruption.

10.2 Cleaning of the transmitter

The external surface of the electrical position feedback can be

cleaned with a cloth dampened with water or a product compatible

with the materials from which it is made.

english

35

Page 36

Type 1062

Spare parts and accessories

Please feel free to contact your Bürkert supplier for any additional

information.

11 SPARE PARTS AND

ACCESSORIES

Caution

Risk of injury and damage by the use of incorrect parts.

Incorrect accessories or unsuitable replacement parts may cause

injuries and damage the device and the surrounding area.

▶ Use only original accessories and original replacement parts

from Bürkert.

Accessory Item number

Assembly spanner (actuator size 40mm) 639175

Assembly spanner (actuator size 100mm) 639172

Assembly spanner (actuator size 125mm) 639173

15. PACKAGING, TRANSPORT

note

Damage due to transport

Transport may damage an insufficiently protected device.

▶ Transport the device in shock-resistant packaging and away

from humidity and dirt.

▶ Do not expose the device to temperatures outside the storage

temperature range.

▶ Protect the electrical interfaces by using protection caps.

36

english

Page 37

Type 1062

Storage

12 STORAGE

note

Poor storage can damage the device.

▶ Store the device in a dry place away from dust.

▶ Storage temperature of the devices approved by CSA and CE:

0 to +60°C.

▶ Storage temperature of the devices only approved by CE:

-20 to +60°C.

16. DISPOSAL OF THE PRODUCT

→

Dispose of the device and its packaging in an environmentallyfriendly way.

note

Damage to the environment caused by products contaminated by fluids.

▶ Keep to the existing provisions on the subject of waste disposal

and environmental protection.

Please note

Comply with the national and/or local regulations which

concern the area of waste disposal.

english

37

Page 38

Type 1062

38

english

Page 39

Typ 1062

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ..............................................................5

1.1. Darstellungsmittel .............................................................................5

1.2. Begriffsdefinition "Gerät" ............................................................... 5

2. BESTIMMUNGSGEMÄSSE VERWENDUNG .....................................6

2.1. Beschränkungen ................................................................................ 6

2.2. Ex-Zulassung ....................................................................................... 6

3. GRUNDLEGENDE SICHERHEITSHINWEISE ................................... 7

4. ALLGEMEINE HINWEISE ............................................................................ 8

4.1. Herstelleradresse und internationale Kontaktadressen 8

4.2. Gewährleistung ................................................................................... 8

4.3. Informationen im Internet .............................................................. 8

5. BESCHREIBUNG ............................................................................................ 9

5.1. Anwendungsbereich.........................................................................9

5.2. Allgemeine Beschreibung ............................................................. 9

5.2.1. Aufbau ......................................................................................9

5.2.2. Funktionsprinzip .....................................................................9

5.3. Beschreibung des Typschilds des 1062 Standard ....... 10

5.4. Beschreibung der Typschilder des 1062 ATEX .............. 10

5.5. Lieferbare Versionen ..................................................................... 11

6. TECHNISCHE DATEN ............................................................................... 11

6.1. Betriebsbedingungen ................................................................... 11

6.2. Einhaltung der Normen und Richtlinien durch

den 1062 ATEX ................................................................................. 11

6.3. Konformität der 1062 mit CSA-Zulassung ........................ 12

6.4. Allgemeine Technische Daten ................................................. 12

6.4.1. Mechanische Daten ........................................................... 12

6.4.2. Allgemeine Daten ...............................................................13

6.4.3. Spezifische allgemeine Daten der Geräte mit CSA-

Zulassung .............................................................................15

6.4.4. Elektrische Daten ...............................................................15

7. MONTAGE ....................................................................................................... 16

7.1. Sicherheitshinweise ...................................................................... 16

7.2. Auswechseln des oberen Teils eines 40 mm-Antriebs 1 7

7.3. Stellungsrückmelder auf einen pneumatischen

Antrieb montieren ........................................................................... 18

7.4. Stellungsrückmelder mit Hubbegrenzer auf

einen 50 bzw. 80 mm-pneumatischen Antrieb

montieren ............................................................................................ 20

7.5. Stellungsrückmelder mit Hubbegrenzer auf

einen 100- bzw. 125 mm pneumatischen Antrieb

montieren ............................................................................................ 23

deutsch

3

Page 40

Typ 1062

8. INSTALLATION UND VERKABELUNG .............................................. 27

8.1. Sicherheitshinweise ...................................................................... 27

8.2. Elektrische Verkabelung ............................................................. 28

8.2.1. Anschluss einer Version mit mechanischem Kontakt . 29

8.2.2. Anschluss einer Version mit induktivem Endschalter mit 2

Leitungen ......................................................................................................31

8.2.3. Anschluss einer Version mit induktivem Endschalter

mit 3 Leitungen ...................................................................31

8.2.4. Anschluss einer Version mit zwei induktiven Ends-

chaltern mit 3 Leitungen ...................................................32

8.2.5. Anschluss einer Version mit zwei induktiven

NAMUR Endschaltern mit 2 Leitungen .........................33

8.2.6. Anschluss einer Version mit zwei induktiven Ends-

chaltern mit 4 Leitungen ...................................................34

9. INBETRIEBNAHME ..................................................................................... 35

9.1. Sicherheitshinweise ...................................................................... 35

9.2. Einstellung der Schaltnocken .................................................. 35

10. WARTUNG, FEHLERHABUNG ............................................................ 36

10.1. Sicherheitshinweise ...................................................................... 36

10.2. Die Pflege des Gerätes ................................................................ 36

13. LAGERUNG .................................................................................................. 37

14. ENTSORGUNG ........................................................................................... 38

11. ERSATZTEILE, ZUBEHÖR .................................................................... 37

12. VERPACKUNG, TRANSPORT .............................................................37

4

deutsch

Page 41

Typ 1062

Die Bedienungsanleitung

1 DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit.

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen führen.

▶ Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1 Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

▶ Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

▶ Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

▶ Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS

Warnt vor Sachschäden!

▶ Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

1.2 Begriffsdefinition "Gerät"

Der in dieser Anleitung verwendete Begriff "Gerät" steht immer für

den elektrischen Auf/Zu-Stellungsrückmelder Typ 1062.

deutsch

5

Page 42

Typ 1062

Bestimmungsgemässe verwendung

2 BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des elektrischen

Stellungs-Rückmelders Typ 1062 können Gefahren für Personen, Anlagen in der Umgebung und die Umwelt entstehen.

▶ Der elektr. Stellungsrückmelder Typ 1062 wird auf ein Auf-Zu-

Ventil montiert und ermöglicht die Rückmeldung des Zustands

(offen oder geschlossen) dieses Ventils.

▶ Der Stellungsrückmelder kann auf ein Ventil montiert werden,

das durch einen Antrieb von 40 bis 125 mm betätigt wird.

▶ Schützen Sie dieses Gerät vor elektromagnetischen Störungen

und U.V.-Bestrahlung.

▶ Schützen Sie dieses Gerät bei Außenanwendung vor

Witterungseinflüssen.

▶ Für den Einsatz sind die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten, Betriebsund Einsatzbedingungen zu beachten.

▶ Zum sicheren und problemlosen Einsatz des Geräts müssen

Transport, Lagerung und Installation ordnungsgemäß erfolgen,

außerdem müssen Betrieb und Wartung sorgfältig durchgeführt

werden.

▶ Setzen Sie das Gerät nur bestimmungsgemäß ein.

2.1 Beschränkungen

Beachten Sie bei der Ausfuhr des Geräts gegebenenfalls bestehende

Beschränkungen.

2.2 Ex-Zulassung

Die Ex-Zulassung ist nur gültig, wenn die von Bürkert zugelassenen

Module und Komponenten gemäß den Angaben in dieser Bedienungsanleitung eingesetzt werden.

Der Stellungsrückmelder darf nur mit von Bürkert freigegebenen

Pneumatikventiltypen eingesetzt werden; andernfalls erlischt die

Ex-Zulassung.

Nehmen Sie unzulässige Veränderungen am System, den Modulen

oder Komponenten vor, erlischt die Ex-Zulassung ebenfalls.

6

deutsch

Page 43

Typ 1062

Grundlegende Sicherheitshinweise

3 GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf das Montage- und/oder Wartungspersonal, der

Betreiber verantwortlich ist.

Explosionsgefahr!

Wenn der 1062 in einer Atex Zone 21 oder 22 eingesetzt wird,

auf Folgendes achten:

• Den Deckel des elektr. Stellungsrückmelders immer vor dem

Betätigen des Ventils festschrauben.

• Sicherstellen, dass das Gerät keinem Luft- und Staubstrom ausgesetzt wird, der zu einer Ansammlung elektrostatischer Ladung

führen könnte.

• "Die NAMUR-Endschalter des 1062 müssen für eine Verwendung

in explosionsfähigen Atmosphären der Gruppen IIB/IIC mit einer

zertifizierten Spannungsquelle versorgt werden, und ihre Verbindung muss hinsichtlich der Eigensicherheit kompatibel sein."

Gefahr durch hohen Druck in der Anlage!

▶ Vor Eingriffen am Gerät die pneumatische Versorgung unterbre-

chen und den Druck aus den Leitungen ablassen.

Gefahr durch elektrische Spannung!

▶ Schalten Sie vor Beginn der Arbeiten in jedem Fall alle existierenden

am Gerät angeschlossenen Spannungs-Versorgungen ab, und

sichern Sie diese vor unbeabsichtigtem Wiedereinschalten!

▶ Beachten Sie die geltenden Unfallverhütungs- und Sicherheits-

bestimmungen für elektrische Geräte!

Allgemeine Gefahrensituationen!

Zum Schutz vor Verletzungen ist zu beachten:

▶ Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

▶ Installations- und Instandhaltungsarbeiten dürfen nur von autorisier-

tem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

▶ Nach einer Unterbrechung der elektrischen und/oder pneumati-

schen Versorgung ist ein definierter oder kontrollierter Wiederanlauf des Prozesses zu gewährleisten.

▶ Betreiben Sie das Gerät nur in einwandfreiem Zustand und unter

Beachtung der Bedienungsanleitung.

▶ Für die Einsatzplanung und den Betrieb des Gerätes gelten die

allgemeinen Regeln der Technik!

• Die nicht Ex-zertifizierten Versionen des elektr. Stellungsrückmelders

Typ 1062 nicht in explosionsgefährdeten Bereichen einsetzen.

deutsch

7

Page 44

Typ 1062

Allgemeine Hinweise

4 ALLGEMEINE HINWEISE

Allgemeine Gefahrensituationen! (Folge)

Zum Schutz vor Verletzungen ist zu beachten:

• Die Geräte mit CSA-Zulassung nicht im Außenbereich anwenden.

• Dieses Gerät nicht in einer Umgebung verwenden, die mit den

Materialien, aus denen es besteht, inkompatibel ist.

• Belasten Sie das Gehäuse nicht mechanisch (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen oder innerlichen Veränderungen

an den Geräten vor.

HINWEIS

Elektrostatisch gefährdete Bauelemente / Baugruppen!

▶ Das Gerät enthält elektronische Bauelemente, die gegen elekt-

rostatische Entladung (ESD) empfindlich reagieren. Berührung

mit elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

▶ Beachten Sie die Anforderungen nach EN 61340-5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

▶ Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

4.1 Herstelleradresse und

internationale Kontaktadressen

Sie können mit dem Hersteller des Gerätes unter folgender Adresse

Kontakt aufnehmen:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

oder wenden Sie sich an Ihr lokal zuständiges Vertriebsbüro von Bürkert.

Die internationalen Kontaktadressen finden Sie im Internet unter:

www.burkert.com

4.2 Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße

Gebrauch des 1062 unter Beachtung der im vorliegenden Handbuch

spezifizierten Einsatzbedingungen.

4.3 Informationen im Internet

Sie finden im Internet die Bedienungsanleitungen und Datenblätter

zum Typ 1062 sowie die EU-Baumusterprüfung des Typs INERIS

03ATEX0268 X unter:

www.buerkert.de

8

deutsch

Page 45

Typ 1062

Beschreibung

5 BESCHREIBUNG

5.1 Anwendungsbereich

Der elektr. Stellungsrückmelder wird auf ein Pneumatikventil montiert und

ermöglicht die Rückmeldung des Zustands (offen oder geschlossen)

dieses Ventils.

Die Ventilstellung wird

• bei den Versionen mit mechanischem Kontakt, mit induktivem

Endschalter mit 3 Leitungen (1 Ausgang) oder zwei induktiven

Endschalter mit 4 Leitungen (2 Ausgänge) oder zwei induktiven NAMUR-Endschalter mit 2 Leitungen (2 Ausgänge) durch

Signallampe(n) und ein elektrisches Signal angezeigt

• bei den Versionen mit induktivem Endschalter mit 2 Leitungen (1

Ausgang) nur durch ein elektrisches Signal angezeigt.

5.2 Allgemeine Beschreibung

5.2.1 Aufbau

Der elektr. Stellungsrückmelder besteht aus einem Gehäuse, ausgestattet mit einer Kabelverschraubung, und einem Klarsichtdeckel.

Das Gehäuse enthält:

• ein Übertragungssystem, das sich an die Achse des pneumatischen Ventilantriebs anpasst,

• eine oder zwei Elektronikplatinen, jeweils ausgestattet mit einem

Endschalter mit mechanischem Kontakt oder induktivem End-

schalter, mit 2 oder 3 Signallampen (außer bei den induktiven

Versionen mit 2 Leitungen)

• eine Klemmleiste für den elektrischen Anschluss.

5.2.2 Funktionsprinzip

Die mit 2 Schaltnocken ausgestattete Übertragungsachse wird

bewegt, wenn das Ventil geöffnet oder geschlossen wird: bei der

Passage einer Schaltnocke vor dem dazugehörigen Endschalter

wird dieser betätigt.

Wenn der Endschalter betätigt wird, leuchtet die Signallampe

auf (falls vorhanden) (bzw. verlischt bei den NAMUR Versionen)

und über die elektrischen Anschlüsse wird ein elektrisches Signal

übertragen.

Dieses Signal wird bei der Version 1062 ATEX gemäß der NAMUR

Norm übertragen.

deutsch

9

Page 46

Typ 1062

Beschreibung

5.3 Beschreibung des Typschilds

des 1062 Standard

2

1

1062 PROXIMITY SWITCH

3

4

3-WIRE PNP-NO

10-30V DC NO/NC

MAX:200mA ACTUATOR >80

S/N 1199

00560409 W48LP

Made in France

5

6

Bild 1: Typschild des Stellungsrückmelders 1062,

Standardversion

1. Gerätetyp

2. Eigenschaften des Endschalters

3. Stromversorgung

4. Strombedarf

5. Seriennummer

6. Bestellnummer

7. Konstruktionscode

8. Konformitäts-Kennzeichen

9. Mögliche Antriebsgrößen

10. Betriebsart

11. Typ des Endschalters

11

10

9

8

7

5.4 Beschreibung der Typschilder

des 1062 ATEX

2

1

1062 PROXIMITY SWITCH

3

4

5

2-WIRE NAMUR

8V DC NO/NC

MAX:15mA ACTUATOR =40

INERIS 03ATEX0268X/02

Made in France

00560411 W48LP

6

12

II 2 GD EEx Ia IIC

T6, T5 ou T4

Ex iaD21 T85°C, T100°C

ou T135°C

S/N 1000

F67220 TRIEMBACH

00560411 W48LP

13

6

Bild 2: Typschilder des Stellungsrückmelders 1062, ATEX

Version

11

10

9

0102

8

7

15

14

7

10

deutsch

Page 47

Typ 1062

Technische Daten

1. Gerätetyp

2. Eigenschaften des Endschalters

3. Stromversorgung

4. Strombedarf

5. ATEX Zertifizierungsstelle und Zertifizierungsnummer

6. Bestellnummer

7. Konstruktionscode

8. Konformitäts-Kennzeichen

9. Antriebsgröße

10. Betriebsart

11. Typ des Endschalters

12. Einsatzzone

13. ATEX Logo

14. Seriennummer

15. Temperaturklasse

5.5 Lieferbare Versionen

Die verfügbaren Versionen des Stellungsrückmelders können Sie

dem Datenblatt für den Typ 1062 auf unserer Website entnehmen:

www.buerkert.de

6 TECHNISCHE DATEN

6.1 Betriebsbedingungen

Umgebungstemperatur

• Ausführung mit CSA- und

CE-Zulassungen

• Ausführung mit nur CE-Zulassung

Luftfeuchtigkeit < 80%, nicht kondensierend

Schutzart nach EN 60529 IP65, bei verkabeltem

6.2 Einhaltung der Normen und

Richtlinien durch den 1062 ATEX

Der elektr. Stellungsrückmelder Typ 1062 ATEX (NAMUR Version

mit zwei induktiven Endschaltern mit 2 Leitungen) erfüllt die Anforderungen der ATEX Richtlinie 94/9/EG für Geräte und Schutzsysteme

zur bestimmungsgemäßen Verwendung in explosionsgefährdeten

Bereichen. Zur Beurteilung wurden die folgenden Normen verwendet:

• EN 60079-0 (2004)

• EN 60079-11 (2006)

• EN 61241-0 (2006)

• EN 61241-11 (2007)

• 0 bis +60 °C

• -20 bis +60 °C

Gerät und vollständig

festgeschraubter

Kabelverschraubung

deutsch

11

Page 48

Typ 1062

Technische Daten

6.3 Konformität der 1062 mit

CSA-Zulassung

Die Geräte mit CSA-Zulassung, mit variablem Schlüssel PD01,

erfüllen die Anforderungen der Normen:

• CSA C22.2 n° 61010-1-04

• UL 61010-1

6.4 Allgemeine Technische Daten

6.4.1 Mechanische Daten

PC oder PSU

EPDM

PA6 oder PPS

PA oder PVDF

Bild 3: Werkstoffe, aus denen der Stellungsrückmelder 1062

besteht

Element Material

Gehäuse / Deckel PA6 / PC oder PPS/PSU

Edelstahl oder

Messing

Messing

Element Material

Dichtung zwischen Deckel und

EPDM

Gehäuse

Kabelverschraubung M16x1,5 PA oder PVDF

Außengewindestück Messing oder Edelstahl

Innengewindestück Messing

67,5 35

Ø 66

72

87

M16x1,5

SW27

M5 / M6 / M10

12 / 10 / 16

M24x1,5 / M26x1,5 / M36x2

24 - 40

12

Bild 4: Abmessungen des Stellungsrückmelders 1062 [mm]

deutsch

Page 49

Typ 1062

Technische Daten

6.4.2 Allgemeine Daten

Antriebsgröße Ø 40 bis 125 mm, je nach Version

Version mit mechanischem Kontakt

• Kontaktart

• detektierte Zustände

- 1062 mit einem

Endschalter

- 1062 mit zwei

Endschaltern

• Signalisierung des

geöffneten oder

geschlossenen Ventils

• Farben der Signallampen je nach detektiertem Zustand

• BetriebsspannungSignalleuchte

• aus Silber oder Gold

- Ventil offen oder Ventil geschlossen

- Ventil offen und Ventil geschlossen

• durch Signalleuchten und durch elektrisches Signal über Klemmleiste

• eine grüne Signalleuchte leuchtet auf,

wenn das Ventil geöffnet wird (Version

"geöffnete Stellung" oder "geöffnete

und geschlossene Stellung") und/

oder eine rote Signalleuchte leuchtet

auf, wenn das Ventil geschlossen

wird (Version "geschlossene Stellung"

oder "geöffnete und geschlossene

Stellung")

• orange

Version mit induktivem

Endschalter mit 2

Leitungen

• detektierte Zustände

- 1062 mit einem

Endschalter

- 1062 mit zwei

Endschaltern

• Signalisierung des

geöffneten oder

geschlossenen Ventils

- Ventil offen oder Ventil geschlossen

- Ventil offen und Ventil geschlossen

• durch elektrisches Signal über

Klemmleiste

deutsch

13

Page 50

Typ 1062

Technische Daten

Version mit induktivem

Endschalter mit 3

Leitungen

• detektierte Zustände

- 1062 mit einem

Endschalter

- 1062 mit zwei

Endschaltern

• Signalisierung des

geöffneten oder

geschlossenen Ventils

• Farben der Signallampen je nach detektiertem Zustand

• BetriebsspannungSignalleuchte

- Ventil offen oder Ventil geschlossen

- Ventil offen und Ventil geschlossen

• durch Signalleuchten und durch elektrisches Signal über Klemmleiste

• eine grüne Signalleuchte leuchtet auf,

wenn das Ventil geöffnet wird, und eine

rote Signalleuchte leuchtet auf, wenn

das Ventil geschlossen wird

• orange

Version mit zwei induktiven Endschaltern (4

Leitungen)

• detektierte Zustände

• Signalisierung des

geöffneten oder

geschlossenen Ventils

• Farben der Signallampen je nach detektiertem Zustand

• BetriebsspannungSignalleuchte

NAMUR Version mit zwei

induktiven Endschaltern

(2 Leitungen)

• detektierte Zustände

• Signalisierung des

geöffneten oder

geschlossenen Ventils

• Farben der Signallampen je nach detektiertem Zustand

• Ventil offen und Ventil geschlossen

• durch Signalleuchten und durch elektrisches Signal über Klemmleiste

• eine orange Signalleuchte leuchtet auf,

wenn das Ventil geöffnet wird, und eine

rote Signalleuchte leuchtet auf, wenn

das Ventil geschlossen wird

• grün

• Ventil offen und Ventil geschlossen

• durch Signalleuchten und durch elektrisches Signal über Klemmleiste

• eine orange Signalleuchte verlischt,

wenn das Ventil geöffnet wird, und eine

rote Signalleuchte verlischt, wenn das

Ventil geschlossen wird

14

deutsch

Page 51

Typ 1062

Technische Daten

6.4.3 Spezifische allgemeine Daten der

Geräte mit CSA-Zulassung

Verschmutzungsgrad Verschmutzungsgrad 2 nach

EN 61010-1

Einbaukategorie Kategorie I nach EN 61010-1

Max. Höhe 2000 m

Spannungsversorgung durch Schutzkleinspannungsquelle

6.4.4 Elektrische Daten

Versorgungsspannung

Induktive Last

[I

]

max

24 V DC 5 A 5 A

30 V DC 2 A 5 A

50 V DC 0,7 A 1 A

74 V DC 0,25 A 0,6 A

125 V DC 0,03 A 0,4 A

250 V DC 0,02 A 0,25 A

125 V AC 8 A 8 A

250 V AC 8 A 8 A

Tab. 1: Zulässige Last einer Version mit mechanischem Kontakt

Anschlusskabel Standard, Durchmesser zwischen 5 und

7 mm, max. Leiterquerschnitt 1 mm

Ohmsche Last

[I

]

max

2

Version mit mechanischem Kontakt (pro

Kontakt)

• Versorgungsspannung

der Geräte mit CSAund CE-Kennzeichen

• Versorgungsspannung

der Geräte mit nur CEKennzeichen

• Eigenverbrauch

• Zulässige Last

• Ausgangstyp

Version mit induktivem

Endschalter mit 2 Leitungen

(pro Endschalter)

• Stromversorgung

• Eigenverbrauch

• Zulässige Last

• Ausgangstyp

• 12-30 V AC oder

12-48 V DC

• 12-30 V DC oder

12-48 V DC/V AC oder

48/110 V DC/V AC oder

110/250 V DC/V AC

• < 35 mA (48 V DC)

< 8 mA (220 V AC)