Page 1

Type 1060

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Electrical positioner repeater

Elektrischer Stellungsrückmelder

Dispositif électrique de quittance de

position

Address / Adresse

Germany / Deutschland / Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

www.burkert.com

Manuals and data sheets on the Internet : www.burkert.com

Bedienungsanleitungen und Datenblätter im Internet: www.buerkert.de

Instructions de service et fiches techniques sur Internet: www.buerkert.fr

en / de / fr

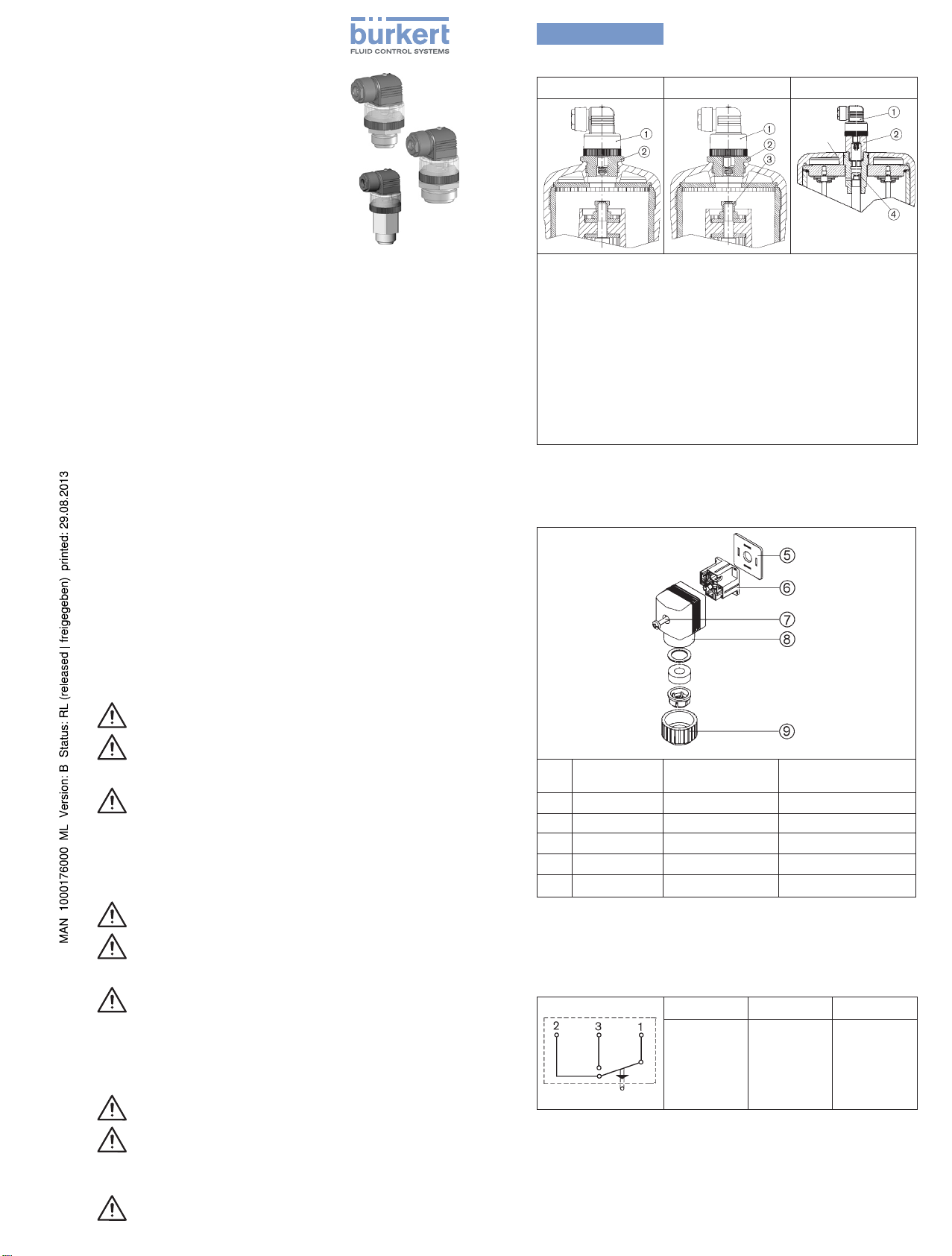

Actuators / Antriebe / Mécanisme de commande

D -50 to/bis/á F -80 G-100, H -125 K-175, L -225

Actuator

Antrieb

commande

Parts required / erforderliche Teile / pièces nécessaires:

① Electrical position repeater with appliance socket

Elektrischer Stellungsrückmelder mit Gerätesteckdose

Dispositif électrique de quittance de position avec

prise de courant sur l‘appareil

② Adapter / Adaptateur

③ Threaded sleeve (only for Types 2030,2031)

Gewindebuchse (nur für Typ 2030, 2031)

Douille filetée (seulement pour type 2030, 2031)

④ Spindle cap / Spindelabdeckkappe / Capuchon de tige

Fig./Bild 1: Actuators / Antriebe / Mécanisme de commande

Electrical Connection / Elektrischer Anschluss / Raccord

électrique

© 2012 Bürkert Werke GmbH

Operating Instructions 1205/01_EU-ml _00809739 / Original DE

SYMBOLS

→

designates a procedure which you must carry out.

Warning of serious or fatal injuries:

DANGER!

In case of imminent danger.

WARNING!

In case of potential danger.

Warning of minor or moderately severe injuries:

CAUTION!

DARSTELLUNGSMITTEL

→

markiert einen Arbeitsschritt den Sie ausführen müssen.

Warnung vor schweren oder tödlichen Verletzungen:

GEFAHR!

Bei unmittelbarer Gefahr.

WARNUNG!

Bei möglicher Gefahr.

Warnung vor leichten oder mittelschweren Verletzungen:

VORSICHT!

SYMBOLES

→

identifie une opération que vous devez effectuer.

Mise en garde contre les blessures graves ou mortelles :

DANGER!

En cas de danger imminent

AVERTISSEMENT!

En cas de danger possible.

Mise en garde contre les blessures légères ou moyennement

graves :

ATTENTION!

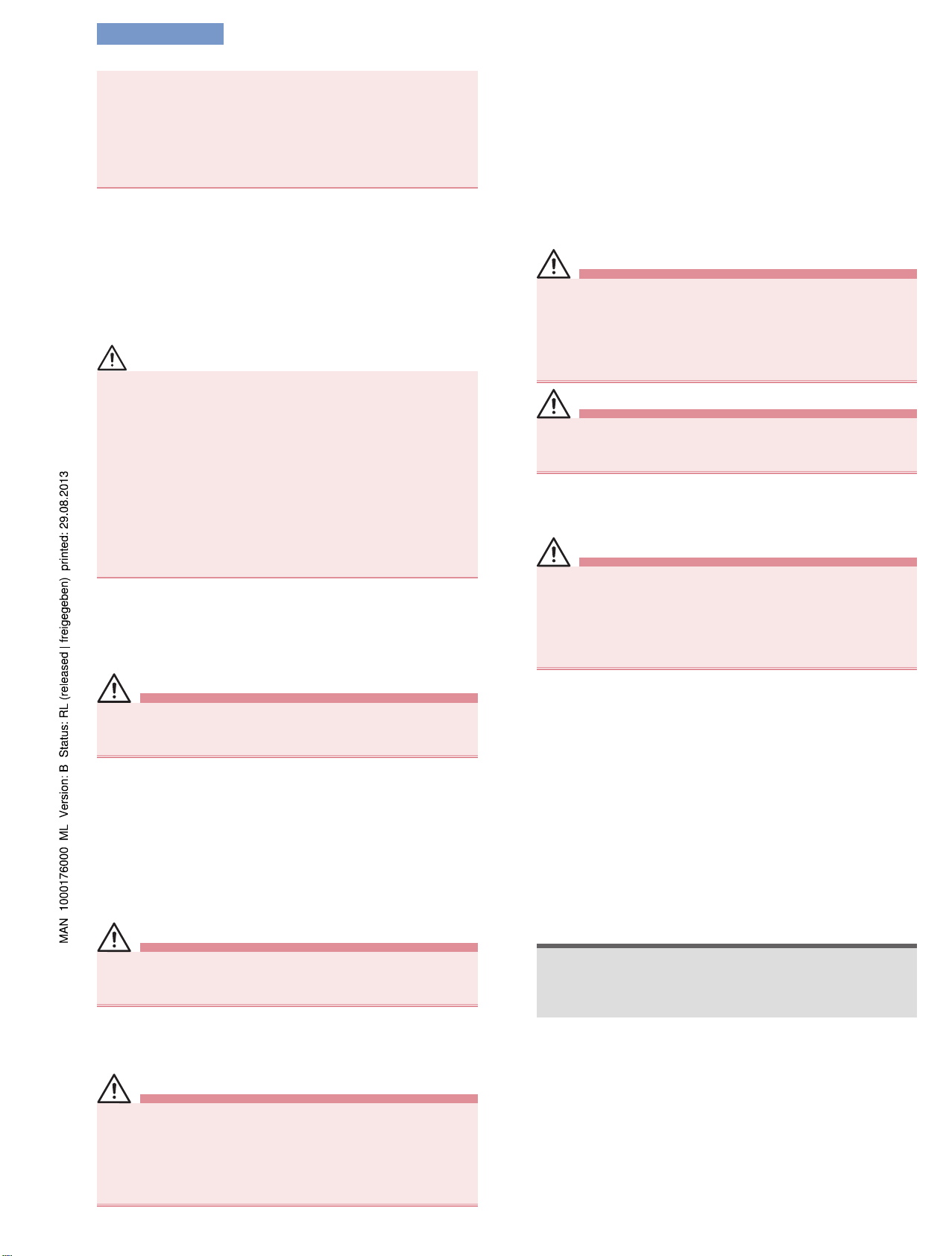

Pos. Designation

of parts

⑤

Flat seal Flachdichtung

⑥

Contact insert Kontakteinsatz Insert de contact

⑦

Cap screw Zylinderschraube Vis à tête cylindrique

⑧

Cap Kappe Capuchon

⑨

Coupling nut Überwurfmutter Ècrou d'accouplement

Teilebezeichnung Désignation des

pièces

Joint plat

Fig./Bild 2: Electrical connection / elekrischer Anschluss /

raccord électrique

Electrical connection scheme / elektrisches

Anschlussschema / schéma électrique

Assignment Belegung Affectation

1. Input

2. Break

contact

3. Make

contact

1. Eingang

2. Öffner

3. Schließer

1. Entrée

2. Contact

de repos

3. Contact

de travail

Fig./Bild 3: Electrical connection scheme / elektrisches

Anschlussschema / schéma électrique

Page 2

english

1. OPERATING INSTRUCTIONS

The operating instructions contain important information.

• Read the instructions carefully and follow the safety instructions

in particular.

• Keep the instructions in a location where they are available to

every user.

• The liability and warranty for Type 1060 are void if the operating

instructions are not followed.

Type 1060

→ Screw transparent hood off the actuator cover.

→ Unscrew position indicator using Allen key (size 8).

→ Type 2030, 2031: Screw threaded bushing ③(seeFig.1)

onto the actuator spindle (size 14).

→ Then interrupt the control air supply.

→ Screw adapter ② instead of the transparent hood onto the

actuator (see Fig. 1).

→ Screw electr. position feedback ① into adapter ② (see Fig. 1).

2. INTENDED USE

Operate the electrical position feedback type 1060 only when in

perfect condition and pay attention to correct storage, transportation,

installation and operation.

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any contingencies and events which may arise during installation, operation

and maintenance.

WARNING!

Danger – high pressure!

• Before loosening lines or valves, turn off the pressure and vent

the lines.

To prevent injury, ensure the following:

• Do not use type 1060 in potentially explosive areas.

• Do not make any internal or external changes to type 1060.

Secure device from unintentional actuation.

• Only trained technicians may perform installation and maintenance work.

• After an interruption in the power supply, ensure that the process is restarted in a controlled manner.

• Observe the general regulations of technology.

4. INSTALLATION AND START-UP

4.1. Actuator D-50 to F-80

Tasks before Installation

DANGER!

Risk of injury from high pressure!

• Before converting the devices, switch off the pressure and

vent the lines.

→ Interrupt the control air supply and flow of medium.

→ Screw transparent hood off the actuator cover.

→ Unscrew position indicator using Allen key (size 5).

→ Screw adapter ② instead of the transparent hood onto the

actuator (see Fig. 1).

→ Screw electr. position feedback ① into adapter ② (see Fig. 1).

4.2. Actuator G-100, H-125

Tasks before Installation

DANGER!

Risk of injury from high pressure!

• Before converting the devices, switch off the pressure and

vent the lines.

→ Interrupt the flow of medium.

→ Empty the valve housing.

→ Move actuator into upper piston position.

DANGER!

Control function B and I:

Risk of injury when unscrewing the transparent hood!

Transparent hood must not be under pressure when unscrewed.

• Before unscrewing the transparent hood, pressurize only

lower piston chamber with compressed air via lower control

air connection.

4.3. Actuator K-175, L-225

Tasks before Installation

WARNING!

Risk of injury and malfunction caused by parts jumping out

or slipping!

The actuators contain pretensioned springs which can jump out

or slip if not opened properly.

• The actuators K-175 / L-225 may be opened by the manufacturer or responsible sales office only.

DANGER!

Risk of injury from high pressure!

• Before converting the devices, switch off the pressure and

vent the lines.

→ Interrupt the flow of medium.

→ Empty the valve housing.

→ Move actuator into upper piston position.

DANGER!

Control function A and I:

Risk of injury when unscrewing the transparent hood!

Transparent hood must not be under pressure when unscrewed.

• Before unscrewing the transparent hood, pressurize only

lower piston chamber with compressed air via lower control

air connection.

→ Screw transparent hood off the actuator cover.

→ Unscrew position indicator (yellow screw cap) by hand.

→ Screw spindle cover cap④ (see Fig. 1) instead of the position

indicator onto the end of the spindle (size 14).

→ Then interrupt the control air supply.

4.4. Installation and start-up

→ Screw adapter ② instead of the transparent hood onto the

actuator (see Fig. 1).

→ Screw electr. position feedback ① into adapter ② (see Fig. 1).

5. ELECTRICAL CONNECTION (for all actuators)

→ Loosen cylinder head screw ⑦ (see Fig. 2) on device socket

and remove socket.

NOTE!

Bent plug tabs will prevent the contact insert from being

reinstalled properly, thereby resulting in functional failure!

• Carefully remove the contact insert and make certain the plug

tabs are not bent.

→ Loosen screw in the contact insert ⑥,takeoutcontactinsert

(seeFig.2).

→ Feed cable through union nut ⑨.

→ Connect according to the circuit (see Fig. 3).

→ Max. connected loads: 5 A at 250 V AC

0.25 A at 250 V DC.

→ Insert contact insert ⑥ into cap ⑧ and screw on (see Fig. 2).

→ Screw on device socket with cylinder head screw ⑦, ensuring

that the flat seal is securely positioned

⑤(seeFig.2).

→ Check the valve for function and leaks.

Page 3

deutsch

I. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung enthält wichtige Informationen.

• Die Anleitung sorgfältig lesen und besonders die Hinweise zur

Sicherheit beachten.

• Die Anleitung so aufbewahren, dass sie jedem Benutzer zur

Verfügung steht.

• Die Haftung und Gewährleistung für Typ 1060 entfällt, wenn die

Anweisungen der Bedienungsanleitung nicht beachtet werden.

II. BESTIMMUNGSGEMÄSSER GEBRAUCH

Den elektrischen Stellungsrückmelder Typ 1060 nur in einwandfreiem

Zustand betreiben und auf sachgerechte Lagerung, Transport,

Installation und Bedienung achten.

III. GRUNDLEGENDE SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine Zufälligkeiten und

Ereignisse, die bei Montage, Betrieb und Wartung auftreten können.

WARNUNG!

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen oder Ventilen den Druck abschalten und Leitungen entleeren.

Zum Schutz vor Verletzungen beachten:

• Typ 1060 nicht in explosionsgefährdeten Bereichen einsetzen.

• An Typ 1060 keine inneren oder äußeren Veränderungen

vornehmen. Gerät vor unbeabsichtigter Betätigung sichern.

• Nur geschultes Fachpersonal darf Installations- und

Instandhaltungsarbeiten ausführen.

• Nach Unterbrechung der elektrischen Versorgung für einen

kontrollierten Wiederanlauf des Prozesses sorgen.

• Die allgemeinen Regeln der Technik einhalten.

IV. EINBAU UND INBETRIEBNAHME

IV.I. Antrieb D-50 bis F-80

Arbeiten vor dem Einbau

GEFAHR!

Verletzungsgefahr durch hohen Druck!

• Vor Umbau der Geräte Druck abschalten, Leitungen entlüften.

→ Zufuhr der Steuerluft und des Mediumstromes unterbrechen.

→ Klarsichthaube vom Antriebsdeckel abschrauben.

→ Stellungsanzeige mit Innensechskantschlüssel (SW5)

abschrauben.

→ Adapter ② anstelle der Klarsichthaube auf Antrieb schrauben

(s. Bild 1).

→ Elektr. Stellungsrückmelder ① in Adapter ② schrauben (s. Bild 1).

IV.II. Antrieb G-100, H-125

Arbeiten vor dem Einbau

GEFAHR!

Verletzungsgefahr durch hohen Druck!

• Vor Umbau der Geräte Druck abschalten, Leitungen entlüften.

→ Zufuhr des Mediumstromes unterbrechen.

→ Ventilgehäuse entleeren.

→ Antrieb in obere Kolbenposition bringen.

GEFAHR!

Steuerfunktion B und I:

Verletzungsgefahr beim Abschrauben der Klarsichthaube!

Klarsichthaube darf beim Abschrauben nicht unter Druck stehen.

• Vor Abschrauben der Klarsichthaube nur unteren Kolbenraum

über unteren Steuerluftanschluss mit Druckluft beaufschlagen.

Typ 1060

→ Typ 2030, 2031: Gewindebuchse ③(s.Bild1) auf die

Antriebsspindel schrauben (SW14).

→ Danach Zufuhr der Steuerluft unterbrechen.

→ Adapter ② anstelle der Klarsichthaube auf Antrieb schrauben

(s. Bild 1).

→ Elektr. Stellungsrückmelder ① in Adapter ② schrauben (s. Bild 1).

IV.III. Antrieb K-175, L-225

Arbeiten vor dem Einbau

WARNUNG!

Verletzungsgefahr und Funktionsausfall durch herausspringende oder verrutschte Teile!

Die Antriebe enthalten vorgespannte Federn, die bei unsachgemäßer Öffnung herausspringen oder verrutschen können.

• Die Antriebe K-175 / L-225 dürfen nur vom Hersteller oder von

der zuständigen Vertriebsniederlassung geöffnet werden.

GEFAHR!

Verletzungsgefahr durch hohen Druck!

• Vor Umbau der Geräte Druck abschalten, Leitungen entlüften.

→ Zufuhr des Mediumstromes unterbrechen.

→ Ventilgehäuse entleeren.

→ Antrieb in obere Kolbenposition bringen.

GEFAHR!

Steuerfunktion A und I:

Verletzungsgefahr beim Abschrauben der Klarsichthaube!

Klarsichthaube darf beim Abschrauben nicht unter Druck stehen.

• Vor Abschrauben der Klarsichthaube nur unteren Kolbenraum

über unteren Steuerluftanschluss mit Druckluft beaufschlagen.

→ Klarsichthaube vom Antriebsdeckel abschrauben.

→ Stellungsanzeige (gelbe Schraubkappe) von Hand

abschrauben.

→ Spindelabdeckkappe④ (s. Bild 1) anstelle der Stellungsan-

zeige auf Spindelende aufschrauben (SW14).

→ Danach Zufuhr der Steuerluft unterbrechen.

IV.IV. Einbau und Inbetriebnahme

→ Adapter ② anstelle der Klarsichthaube auf Antrieb schrauben

(s. Bild 1).

→ Elektr. Stellungsrückmelder ① in Adapter ② schrauben (s. Bild 1).

V. ELEKTRISCHER ANSCHLUSS (für alle Antriebe)

→ Zylinderschraube ⑦ (s. Bild 2) an Gerätesteckdose lösen,

diese abnehmen.

HINWEIS!

Funktionsausfall durch verbogene Steckerfahnen, die den

Wiedereinbau des Kontakteinsatzes verhindern!

• Den Kontakteinsatz vorsichtig herausnehmen und darauf

achten, dass die Steckerfahnen nicht verbogen werden.

→ Schraube im Kontakteinsatz ⑥ lösen, Kontakteinsatz heraus-

nehmen (s. Bild 2).

→ Kabel durch Überwurfmutter ⑨ führen.

→ Anschluss entsprechend der Schaltung vornehmen (s. Bild 3).

→ Max. Anschlusswerte: 5 A bei 250 V AC

0,25 A bei 250 V DC.

→ Kontakteinsatz ⑥ in Kappe ⑧ einsetzen und anschrauben

(s. Bild 2).

→ Gerätesteckdose mit Zylinderschraube ⑦ anschrauben, dabei

auf sicheren Sitz der Flachdichtung ⑤ achten (s. Bild 2).

→ Ventil auf Funktion und Dichtheit prüfen.

→ Klarsichthaube vom Antriebsdeckel abschrauben.

→ Stellungsanzeige mit Innensechskantschlüssel (SW8)

abschrauben.

Page 4

français

1. INSTRUCTIONS DE SERVICE

Les instructions de service contiennent des informations

importantes.

• Lire attentivement les instructions et tenir particulièrement

compte des consignes de sécurité.

• Conserver les instructions afin qu'elles soient accessibles à tous

les utilisateurs.

• La responsabilité et la garantie légale concernant le type 1060

sont exclues en cas de non-respect des instructions de service.

2. UTILISATION CONFORME

Utiliser l’indicateur de position électrique du type 1060 uniquement

en parfait état et veiller à ce que le stockage, le transport, l’installation

et l’utilisation s’effectuent dans les règles.

Type 1060

→ Dévisser le capot transparent du couvercle d’entraînement.

→ Dévisser l’indicateur de position avec une clé à six pans creux

(clé de 8).

→ Types 2030, 2031 : visser la douille filetée ③(voirFig.1) sur

la broche d’entraînement (clé de 14).

→ Ensuite, interrompre l’arrivée de l’air de commande.

→ Visser l’adaptateur ② sur l’entraînement à la place du capot

transparent (voir Fig. 1).

→ Visser l’indicateur de position électrique ① dans l’adaptateur ②

(voir Fig. 1).

4.3. Entraînements K-175, L-225

Interventions avant le montage

AVERTISSEMENT !

3. CONSIGNES DE SÉCURITÉ FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte des hasards et

des événements pouvant survenir lors du montage, de l’exploitation

et de l’entretien.

AVERTISSEMENT !

Danger dû à la haute pression !

• Avant de desserrer les conduites et les vannes, couper la

pression et purger l'air des conduites.

Pour prévenir les blessures, veuillez tenir compte de ce qui suit :

• Ne pas utiliser le type 1060 dans les zones présentant des

risques d'explosion.

• Ne pas apporter de modifications internes ou externes à

l'appareil du type 1060. Protéger l'appareil contre toute mise en

marche involontaire.

• Seul du personnel qualifié peut effectuer l'installation et la

maintenance.

• Garantir un redémarrage contrôlé du process après la coupure

de l'alimentation électrique.

• Respecter les règles générales de la technique.

4. MONTAGE ET MISE EN SERVICE

4.1. Entraînements D-50 à F-80

Interventions avant le montage

DANGER !

Risque de blessures dû à la haute pression !

• Avant de procéder à la transformation des appareils, couper la

pression et purger l'air des conduites.

→ Interrompre l’arrivée d’air de commande et du flux de fluide.

→ Dévisser le capot transparent du couvercle d’entraînement.

→ Dévisser l’indicateur de position avec une clé à six pans creux

(clé de 5).

→ Visser l’adaptateur ② sur l’entraînement à la place du capot

transparent (voir Fig. 1).

→ Visser l’indicateur de position électrique ① dans l’adaptateur ②

(voir Fig. 1).

4.2. Entraînement G-100, H-125

Interventions avant le montage

DANGER !

Risque de blessures dû à la haute pression !

• Avant de procéder à la transformation des appareils, couper la

pression et purger l'air des conduites.

→ Interrompre l’arrivée du flux de fluide.

→ Effectuer une purge d’air du corps de vanne.

→ Amener l’entraînement dans la position de piston supérieure.

DANGER !

Fonctions de commande B et I :

risque de blessures lors du dévissage du capot transparent !

Le capot transparent ne doit pas être sous pression lors du

dévissage.

• Avant de dévisser le capot transparent, appliquer de l'air

comprimé uniquement à la chambre de piston inférieure

par le raccord d'air de commande inférieur.

Risque de blessures et de pannes dû à la sortie ou au

glissement des pièces !

Les entraînements contiennent des ressorts précontraints susceptibles de sortir ou de glisser en cas d'ouverture non conforme.

• Les entraînements K-175 / L-225 doivent être ouverts uniquement par le fabricant ou par la filiale de distribution compétente.

DANGER !

Risque de blessures dû à la haute pression !

• Avant de procéder à la transformation des appareils, couper la

pression et purger l'air des conduites.

→ Interrompre l’arrivée du flux de fluide.

→ Effectuer une purge d’air du corps de vanne.

→ Amener l’entraînement dans la position de piston supérieure.

DANGER !

Fonctions de commande A et I :

risque de blessures lors du dévissage du capot transparent !

Le capot transparent ne doit pas être sous pression lors du

dévissage.

• Avant de dévisser le capot transparent, appliquer de l'air

comprimé uniquement à la chambre de piston inférieure

par le raccord d'air de commande inférieur.

→ Dévisser le capot transparent du couvercle d’entraînement.

→ Dévisser l’indicateur de position (capuchon fileté jaune) à la main.

→ Visser le capuchon de protection de broche④ (voir Fig. 1) sur

l’extrémité de la broche à la place de l’indicateur de position

(clé de 14).

→ Ensuite, interrompre l’arrivée de l’air de commande.

4.4. Montage et mise en service

→ Visser l’adaptateur ② sur l’entraînement à la place du capot

transparent (voir Fig. 1).

→ Visser l’indicateur de position électrique ① dans l’adaptateur ②

(voir Fig. 1).

5. RACCORDEMENT ÉLECTRIQUE (pour tous les

entraînements)

→ Desserrer la vis à tête cylindrique ⑦ (voir Fig. 2) sur la prise de

l’appareil, retirer celle-ci.

REMARQUE !

Panne due à des barrettes de raccordement tordues,

empêchant le remontage de l'insert de contact !

• Retirer l'insert de contact avec précaution et veiller à ne pas

tordre les barrettes de raccordement.

→ Desserrer la vis dans l’insert de contact ⑥,retirercelui-ci(voir

Fig.2).

→ Faire passer le câble à travers l’écrou-raccord ⑨.

→ Effectuer le raccordement conformément au schéma électrique

(voir Fig. 3).

→ Valeurs de raccordement maxi : 5 A à 250 V AC

0,25 A à 250 V DC.

→ Mettre l’insert de contact ⑥ en place dans le capuchon ⑧ et

le visser (voir Fig. 2).

→ Visser la prise de l’appareil avec la vis à tête cylindrique ⑦ en

veillant à la bonne assise du joint plat

⑤(voirFig.2).

→ Contrôler le fonctionnement et l’étanchéité de la vanne.

Loading...

Loading...