Page 1

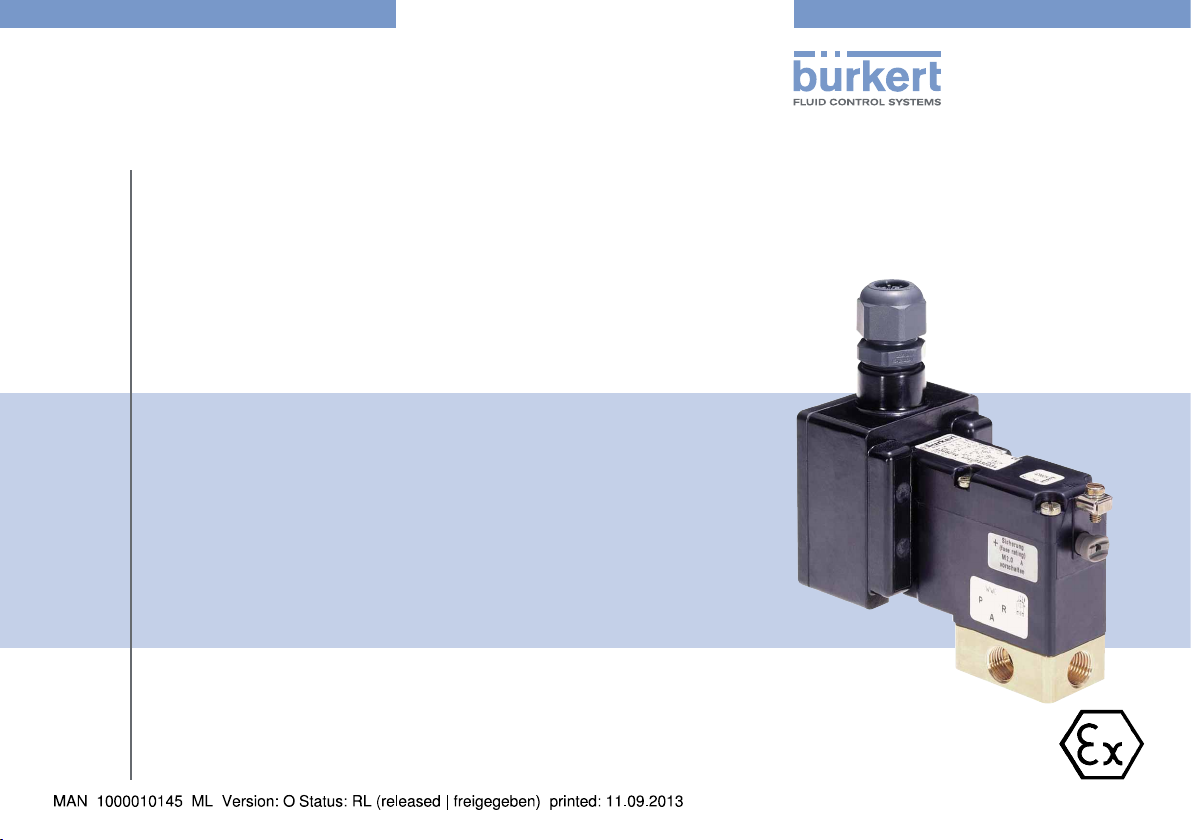

PTB 03 ATEX 1030 X

Device with II 2G/D Ex approval

Geräte mit II 2G/D Ex Zulassung

Appareils avec mode de protection II 2G/D Ex

Example/Beispiel/Exemple

Coil type 0780 with valve body type 0330

Spule Typ 0780 mit Gehäuse Typ 0330

Bobine type 0780 avec le corps type 0330

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2008 - 2013 Bürkert Werke GmbH

Operating Instructions 1309/12_EU-ML_00804717 / Original DE

Page 3

PTB 03 ATEX 1030 X

Device with II 2G/D Ex certification

1. THE OPERATING INSTRUCTIONS .........................................................4

1.1. Symbols ..............................................................................................4

2. INTENDED USE ................................................................................................5

2.1. Restrictions ........................................................................................5

2.2. Ex-Approval ....................................................................................... 5

2.3. Special instructions in explosion-risk areas ............................... 6

3. GENERAL SAFETY INSTRUCTIONS .....................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Contact Address ..............................................................................7

4.2. Warranty .............................................................................................7

4.3. Information on the Internet ............................................................. 7

5. APPLICATION CONDITIONS .....................................................................8

5.1. Special conditions ...........................................................................8

6. TECHNICAL DATA / SAFE OPERATION ..............................................9

6.1. Conformity .........................................................................................9

6.2. Standards ........................................................................................... 9

6.3. Operating Conditions ...................................................................... 9

6.4. General Technical Data ................................................................11

7.4. Disassembly ....................................................................................14

8. START-UP .........................................................................................................14

8.1. Safety Instructions .........................................................................14

9. MAINTENANCE, REPAIR, TROUBLESHOOTING .........................15

9.1. Maintenance and repair ................................................................15

9.2. Troubleshooting ..............................................................................15

10. ACCESSORIES ...........................................................................................15

10.1. Spare parts ....................................................................................15

11. TRANSPORT, STORAGE, DISPOSAL .............................................. 16

7. ASSEMBLY AND DISASSEMBLY .........................................................12

7.1. Safety Instructions .........................................................................12

7.2. Installation of valve .........................................................................13

7.3. Electrical connection .....................................................................13

english

3

Page 4

PTB 03 ATEX 1030 X

The Operating Instructions

1. THE OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous situations. The operating instructions must be read and understood.

• Carefully read the operating instructions before using the device.

• In particular observe the chapter entitled “Intended Use”, and

“General Safety Instructions” as well as the chapter entitled

„Application Conditions“.

1.1. Symbols

In the instructions, the following symbols are used to identify important

information:

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe the warning may result in moderately serious

or minor injuries.

NOTE!

Warns of damage to property!

Important tips and recommendations.

Refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Page 5

PTB 03 ATEX 1030 X

Intended Use

2. INTENDED USE

Incorrect use may be a hazard to people, nearby equipment

and the environment.

• The device serves exclusively as a solenoid valve for the media

stated in the data sheet and for use in Explosion Group IIC,

Category 2G and Temperature Class T4 or T5 (see data on the

- Ex approval plate).

• The device may be used only in category 2D with the temperatures

T135 °C and/or 100 °C as well as for the designated application

cases specified in chapter “5. Application Conditions” and in conjunction with third-party devices and components recommended

and authorized by Bürkert.

• The applied ignition protection types are the pressure-resistant

casing “d” with increased safety “e”. The safety fuse incorporated in version PD29 is executed in ignition protection type

encapsulation “m”. The proximity switch, which can be optionally

incorporated in all versions, is executed in ignition protection

type intrinsic safety “ia”.

The composition of the ignition protection code follows the ignition protection types of the components used in each case.

• Correct transportation, correct storage and installation and careful

use and maintenance are essential for reliable and problem-free

operation.

Any other use is considered improper use. Bürkert is not liable

for any resulting damage. The user alone bears the risk.

• Use the device only as intended.

2.1. Restrictions

If exporting the device, observe any existing restrictions.

2.2. Ex-Approval

The Ex approval is only valid if you use the modules and components

authorised by Bürkets in such a way as described in this operating

manual.

The coil type 0770/0780 may only be used in combination with additional components that have been approved by Bürkert. Otherwise, the

Ex approval will expire!

If you make any unauthorized changes to the device, the modules or

the components, the Ex approval will also expire.

The EC Qualification Test Certificate PTB 03 ATEX 1030 X and the

IECEx Certificate of Conformity IECEx PTB 05.0026X has been

drawn up by the:

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig

who also audited the manufacture (CE0102).

The EC type approval test certificate can be found on the Internet at:

www.burkert.com

english

5

Page 6

PTB 03 ATEX 1030 X

General Safety Instructions

2.3. Special instructions in explosion-risk

areas

WARNING!

Danger caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged devices

or persons, there is a danger of explosion in the explosion-risk area.

• Take appropriate measures to prevent electrostatic charges in

explosion-risk areas.

• Clean the device surface by gently wiping it with a damp or

antistatic cloth only.

Additional special conditions can be found under “5.1” of

these operating instructions.

3. GENERAL SAFETY INSTRUCTIONS

These safety instructions do not take into account

• any contingencies or events which may occur during the installation,

operation and maintenance of the devices.

• local safety regulations, the observance of which is the responsibility

of the operator, also with respect to the installation personnel.

Danger of explosion!

• The device is a sealed system. It must not be opened

Danger of electrostatic charge!

Acute risk of injury from hazardous structure-borne voltage!

Risk of damage to the device due to short circuit!

• Before starting work, switch off the power supply and secure to

prevent it being switched on again!

• Observe the applicable accident prevention and safety regulations for electrical devices!

Danger - high pressure!

• There is a serious risk of injury when reaching into the

equipment.

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

• Observe the currently valid accident prevention and safety

regulations!

6

english

Page 7

PTB 03 ATEX 1030 X

General Information

4. GENERAL INFORMATION

Danger of explosion caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged

devices or persons, there is a danger of explosion in the Ex area.

• Take appropriate measures to prevent electrostatic charges in

the Ex area.

• Clean the device surface by gently wiping it with a damp or

antistatic cloth.

General hazardous situations.

To prevent injury, ensure that:

• That the system cannot be activated unintentionally.

• That no unauthorized changes are performed on the system.

• Only expert and instructed personnel with appropriate tools

carry out any work on the system.

• The device may be operated only when in perfect condition and

in consideration of the operating instructions.

• The general rules of technology apply to application planning

and operation.

4.1. Contact Address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet under: www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3. Information on the Internet

The operating manual and the data sheets can be found on the Internet

under: www.burkert.com

english

7

Page 8

5. APPLICATION CONDITIONS

5.1. Special conditions

5.1.1. Short-circuit protection

Each electromagnet shall be provided on the line with a short-circuit

protection in the form of a fuse designed to meet the magnet starting

current (max. 3 x I

motor overload trip instantaneous short-circuit and thermal release

(Adjustment to match the pull-in current).

• At very low pull-in currents of the solenoid the fuse with the lowest

current value is adequate according to the stated IEC standard.

This fuse may be mounted in the associated supply unit or must

be connected in series separately.

• The rated voltage of the fuse must be equal to or larger than the

quoted nominal voltage of the magnet.

• The switch-off capability of the fuse cartridge must be equal to or

greater than the maximum theoretical short-circuit current at the

installation location (normally 1500 A).

• In the case of versions PD30 of the solenoid, short-circuit protection must be assured by the operator.

• In the case of version PD29 of the solenoid, the fuse is installed in

the terminal box of the device.

More detailed descriptions are to be found in the section

“6. Technical data / Safe operation”.

in accordance with IEC 60127-2-1) or a

rating

PTB 03 ATEX 1030 X

Application Conditions

Fuse ... A

5.1.2. Operation with associated valve body

The solenoid coils Type 77. / 78. may only be operated with a valve

body satisfying the following requirements.

For the valve body, the following materials may be used:

• metal (brass, aluminium, stainless steel) or

• plastics (e,g, polyamide PA 6 GV ...)

5.1.3. Manual operation / approximity switch

The solenoid armature can be manually operated via the push

button. The push button may be locked by depressing and turning

by 90°.

As an alternative to manual operation, the solenoid can be equipped

with a proximity switch. The internal code for this version is CF 15.

8

english

Page 9

PTB 03 ATEX 1030 X

Technical data / Safe operation

5.1.4. Model with a terminal box

DANGER!

Risk of explosion!

• Only permanently laid cables and wiring may be inserted.

• The operator must provide suitable stress relief.

• Wires with an outside diameter of 6 to 13 mm may be used.

Observe the maximum thermal loading of the cables or wires to

be inserted.

• The inserted break-off seal must be matched to the diameter of

the cable or wire.

• The rated cross-section of the cable or wire strands must be at

least 0.75 mm² and may not exceed 2.5 mm².

• The screws for fixing the cover of the terminal box must be tightened with a torque of 1 Nm (± 5 %).

The solenoid coils may also be executed with a terminal box, with

or without fuse/contactor (to separate Design Type Inspection Certificate) as desired.

For protection against inadvertent opening of the cover, the latter

bears the marking:

Open only when the voltage is switched off!

6. TECHNICAL DATA / SAFE

OPERATION

6.1. Conformity

The coil type 0770/0780 is compliant with the EC Directives according

to the EC Declaration of Conformity.

6.2. Standards

Refer to the EC type approval test certificate and/or the EC Declaration

of conformity for the applicable standards verifying conformity with the

EC directives.

6.3. Operating Conditions

DANGER!

Risk of explosion by excedance technical data!

Exceeding the technical data indicated on the type label increases

the explosion risk!

• Never exceed the technical data indicated on the type label!

6.3.1. Maximum permissible ambient

temperature range

Please observe the maximum permissible ambient temperature range

given under Operating conditions of the coils for each type!

Version Maximum permissible ambient temperature

range

07xx -30 °C ... +55 °C

english

9

Page 10

PTB 03 ATEX 1030 X

Technical data / Safe operation

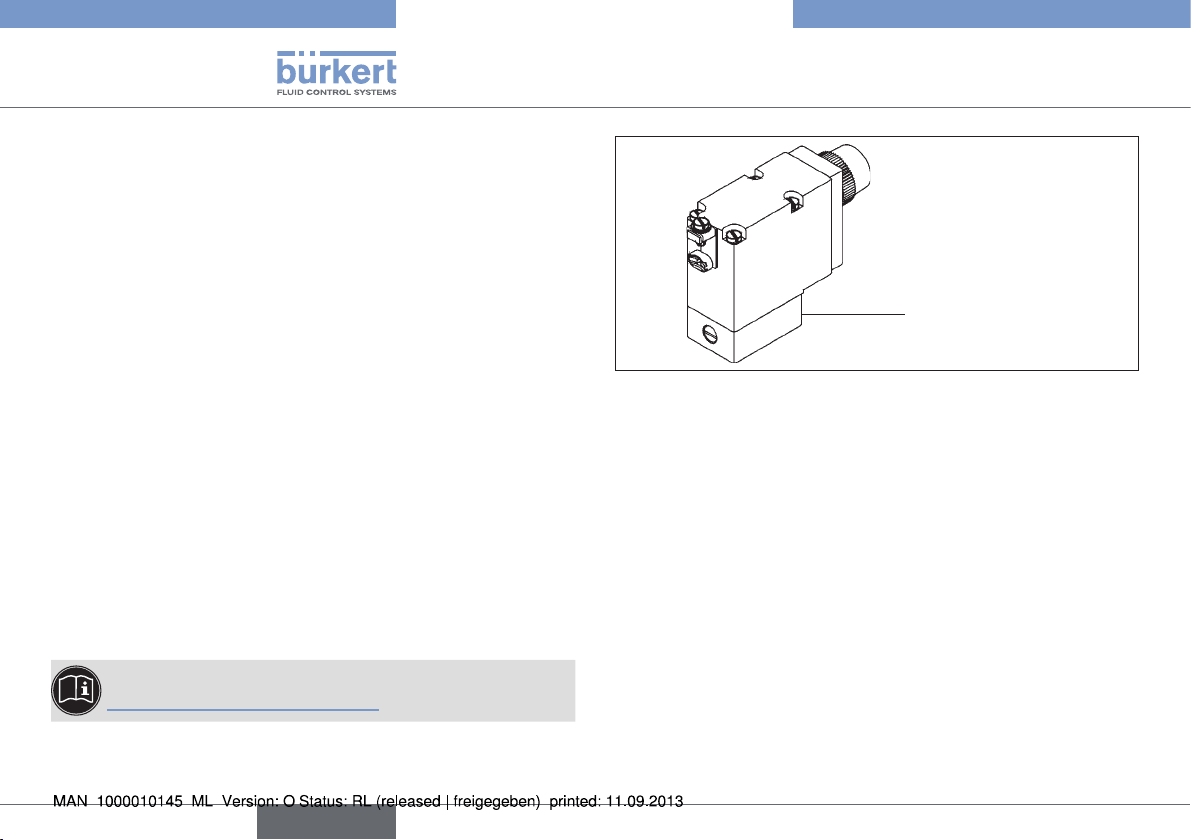

6.3.2. Type of protection

IP65 to EN 60529 (DIN VDE 0470 Part 1)

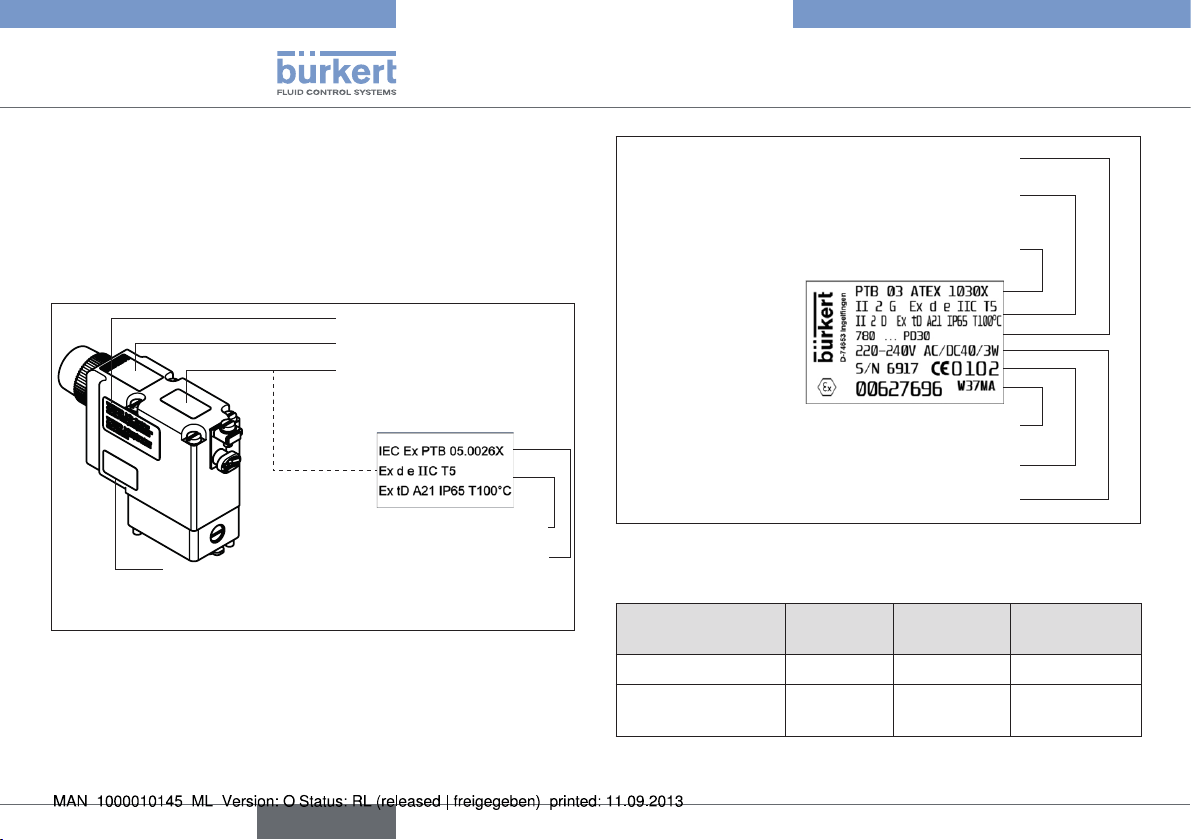

6.3.3. Location and description of the type

label

Warning notices

Type label coil

Type label IEC Ex

Protection class - Temperature class

Fuse

...A

IEC EX Approval number

Fig. 1: Location of the type label

Type and design

Protection class, Temperature class

PTB approval number

Id. number of the coil, Date of manufacture

Serial number of the coil, Inspection body

Voltage (± 10 %), Current type, Power consumption

Fig. 2: Description of the type label

6.3.4. Dimensions

Connection type Length

(mm)

Width

(mm)

Height

(mm)

Molded-in cable 96 32 56

Terminal box with/

123 60 113

without safety fuse

10

english

Page 11

PTB 03 ATEX 1030 X

Technical data / Safe operation

6.3.5. Type of explosion protection

The composition of the explosion protection code follows the explosion

protection types of the components used in each case:

Solenoid with or without

terminal box

Solenoid with terminal

box and fuse

Solenoid without terminal

box with proximity switch

Solenoid with terminal

box, fuse and proximity

switch

II 2 G Ex d e IIC T4 resp. T5

II 2 D Ex tD A21 IP 65 T135 °C resp.

T100 °C

II 2 G Ex d e mb IIC T4

II 2 D Ex tD A21 IP65 T135 °C

II 2 G Ex d e ia IIC T4 resp. T5

II 2 D Ex tD A21 IP65 T135 °C resp.

T100 °C

II 2 G Ex d e ia mb IIC T4

II 2 D Ex tD A21 IP65 T135 °C

6.4. General Technical Data

6.4.1. Electrical Data

Type

Temperature class

Type of current

Rated voltage

Voltage tolerance

Rated current

Pick-up current

Pick-up power

Power consumption for

holding in equilibrium

Max. number of

switching actuations ca

6.4.2. Electrical connection

Version

code

PD30* * Permanently installed rubber sheathed

cable of Type H05 RN-F3G0.75

77. - ... - ... - . 78. - ... - ... - .

T4 T5

Universal Universal

24 ... 240 V 24 ... 240 V

+10 % / -10 % +10 % / -10 %

0,085 ... 0,014 A 0,085 ... 0,014 A

01,66 ... 0,166 A 01,66 ... 0,166 A

40 W 40 W

3 W 3W

20 / min 10 / min

Execution Internal

Code

****JWxx

english

11

Page 12

PTB 03 ATEX 1030 X

Assembly and disassembly

Version

code

** Terminal box with cable bushing M20

Execution Internal

Code

JA02

x 1.5, without fuse

PD30

Terminal box with threaded nipple M20 x

1.5, without fuse

Terminal box with threaded nipple NPT

JA08

JA09

1/2, without fuse

Terminal box with threaded nipple G 1/2,

JA10

without fuse

** Terminal box with cable bushing M20 x

JA01

1.5 and fuse

PD29 ***

Terminal box with threaded nipple M20 x

1.5 and fuse

Terminal box with threaded nipple NPT

JA05

JA06

1/2 and fuse

Terminal box with threaded nipple G 1/2

JA07

and fuse

* The connecting cable of solenoid Type 07xx must be laid permanently

such that it is adequately protected from mechanical damage

** Cable bushing to separate Design Inspection Certificate

*** Fuse protection PD29 to separate type approval test certificate

**** Different cable lengths

7. ASSEMBLY AND DISASSEMBLY

7.1. Safety Instructions

DANGER!

Danger of explosion!

The device is a sealed system. The unit must not be dismantled!

The following safety regulations must be observed:

• The surface of the device may develop an electrostatic charge.

In areas with an explosion hazard, the surface of the units may

only be cleaned with a damp cloth.

• Only permanently laid cables and wiring may be inserted.

• The operator must provide suitable stress relief.

• Wires with an outside diameter of 6 to 13 mm may be used.

Observe the maximum thermal loading of the cables or wires to

be inserted.

• The inserted break-off seal must be matched to the diameter of

the cable or wire.

• The rated cross-section of the cable or wire strands must be at

least 0.75 mm² and may not exceed 2.5 mm².

• The screws for fixing the cover of the terminal box must be tightened with a torque of 1 Nm (±5%).

• The connection nut (clamping nut) of the cable gland on the terminal box must be tightened with a torque of 1.5 Nm (± 5 %).

12

english

Page 13

PTB 03 ATEX 1030 X

Assembly and disassembly

DANGER!

Danger of high voltage!

Acute risk of injury from hazardous structure-borne voltage!

Risk of damage to the device due to short circuit!

• Before starting work, switch off the power supply and secure to

prevent it being switched on again!

• Live terminals in the terminal box can cause electric shock, short

circuit or explosion. Switch off the power supply before opening the terminal box.

• The connecting cables to the electromagnets must be secure,

and be laid so that they are adequately protected from mechanical damage.

• Observe the applicable accident prevention and safety regulations for electrical devices!

WARNING!

Danger - high pressure!

Interventions in the pneumatic system represent an acute risk of

injury.

• First switch off pressure before disconnecting lines and valves.

• Observe the flow direction during installation.

• Observe the applicable accident prevention and safety regulations for pneumatic systems.

7.2. Installation of valve

The solenoid valve can be mounted in any position.

Preferably with solenoid system mounted at the top.

Procedure:

→ Clean pipelines.

→ Connect a dirt trap upstream.

→ Seal pipeline connections with PTFE tape.

→ Screws in pipelines.

Make certain the direction of flow is correct!

→ Check valve for leakage.

7.3. Electrical connection

DANGER!

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the electrical power

supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

If the protective conductor contact between coil and body is

missing, there is danger of electrical shock!

• Always connect protective conductor.

• Check electrical continuity between coil and body.

english

13

Page 14

Start-up

PTB 03 ATEX 1030 X

The connection cable is encapsulated with the coil and

cannot be removed.

→ Attach the electrical connection.

7.4. Disassembly

DANGER!

Risk of electric shock!

There is a serious risk of injury when reaching into the equipment.

• Only trained electrical engineers may work on the electrical

system.

• Before starting work, always switch off the power supply and

safeguard to prevent re-activation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

Procedure:

→ Disconnect the power connection.

→ Disconnect the valve body from the pipeline.

NOTE!

Malfunctions as a result of contamination!

• In case of new installation, remove old PTFE tape from the connections. Residues or parts of the tape must not get into the pipeline.

8. START-UP

8.1. Safety Instructions

WARNING!

Danger due to improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• In particular observe the safety instructions and intended use.

• The device may be started by adequately trained personnel only.

Before commissioning, ensure that:

• The device has been correctly installed,

• The connections have been correctly made,

• The device is not damaged,

• All bolts are securely tightened.

14

english

Page 15

PTB 03 ATEX 1030 X

Maintenance, Repair, Troubleshooting

9. MAINTENANCE, REPAIR,

TROUBLESHOOTING

9.1. Maintenance and repair

DANGER!

Danger due to improper maintenance, repair and inspection

work!

• The maintenance and inspection work on the device may be carried

out by authorized technicians only and with the appropriate tools!

• Repairs on the device may only be carried out by the

manufacturer!

• When performing repair or maintenance work on the system, the

valve may not be opened and the protective-conductor connection

may not be disconnected!

9.2. Troubleshooting

In the event of faults, make sure that:

• the device has been installed according to the specifications,

• the connection has been established properly,

• the device is not damaged,

• all screws have been tightened,

• the voltage and pressure have been switched on,

• the pipelines are free.

10. ACCESSORIES

CAUTION!

Risk of injury and / or damage by the use of incorrect parts!

Incorrect accessories and unsuitable parts may cause injuries and

damage the device and the surrounding area.

• Use only original accessories and original spare supplied by

Bürkert.

10.1. Spare parts

For electromagnet models with terminal boxes, fuses of the Type 1058

with approval PTB 01 ATEX 2064 U can be used in Temperature

Class T4.

Fuse

Type 1058

0.063 A 153717

0.080 A 153745

0.100 A 153718

0.125 A 153719

0.160 A 153720

0.200 A 153731

0.315 A 153733

0.400 A 153734

0.500 A 153735

0.630 A 153736

0.800 A 153737

Order

No.

english

15

Page 16

PTB 03 ATEX 1030X

Transport, Storage, Disposal

Fuse

Type 1058

1.000 A 153738

1.250 A 153739

1.600 A 153746

2.000 A 153740

3.150 A 153742

Order

No.

11. TRANSPORT, STORAGE, DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -40 … +60 °C.

Damage to the environment caused by device components

contaminated with media.

• Ensure the device and packaging are disposed of in an environmentally sound manner.

• Observe applicable regulations relating to refuse disposal and

the environment.

16

english

Page 17

PTB 03 ATEX 1030 X

Geräte mit II 2G/D Ex Zulassung

1. BEDIENUNGSANLEITUNG ...................................................................... 18

1.1. Darstellungsmittel ...........................................................................18

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ................................... 19

2.1. Beschränkungen ............................................................................19

2.2. Ex-Zulassung ...................................................................................19

2.3. Besondere Hinweise im Ex-Bereich ..........................................20

3. ALLGEMEINE SICHERHEITSHINWEISE...........................................20

4. ALLGEMEINE HINWEISE .......................................................................... 21

4.1. Kontaktadressen .............................................................................21

4.2. Gewährleistung...............................................................................21

4.3. Informationen im Internet ..............................................................21

5. EINSATZBEDINGUNGEN ......................................................................... 22

5.1. Besondere Bedingungen .............................................................22

6. TECHNISCHE DATEN / SICHERER BETRIEB...............................23

6.1. Konformität .......................................................................................23

6.2. Normen .............................................................................................23

6.3. Betriebsbedingungen ....................................................................23

6.4. Allgemeine Technische Daten .....................................................25

7.4. Demontage ......................................................................................28

8. INBETRIEBNAHME ...................................................................................... 28

9. WARTUNG, REPARATUR, FEHLERBEHEBUNG ........................... 29

9.1. Wartung und Reparatur ................................................................29

9.2. Fehlerbehebung ..............................................................................29

10. ERSATZTEILE ............................................................................................... 29

10.1. Zubehör ..........................................................................................29

11. TRANSPORT, LAGERUNG, ENTSORGUNG ................................. 30

7. MONTAGE UND DEMONTAGE .............................................................. 26

7.1. Sicherheitshinweise .......................................................................26

7.2. Installation des Ventils ...................................................................27

7.3. Elektrischer Anschluss ..................................................................27

deutsch

17

Page 18

PTB 03 ATEX 1030 X

Bedienungsanleitung

1. BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Geräts. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Geräts

wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen

führen. Die Anleitung muss gelesen und verstanden werden.

• Lesen Sie die Bedienungsanleitung vor dem Einsatz des Geräts

sorgfältig durch.

• Beachten Sie vor allem die Kapitel „Bestimmungsgemäße

Verwendung“, und „Allgemeine Sicherheitshinweise“ sowie das

Kapitel „Einsatzbedingungen“.

1.1. Darstellungsmittel

Für die Kennzeichnung wichtiger Informationen werden in der Anleitung

folgende Darstellungsmittel verwendet:

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann Gerät oder Anlage beschädigt werden.

Bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

Verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

18

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

deutsch

Page 19

PTB 03 ATEX 1030 X

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz können Gefahren für

Personen, Anlagen in der Umgebung und die Umwelt entstehen.

• Das Gerät dient ausschließlich als Magnetventil für die Iaut Datenblatt zulässigen Medien und für den Einsatz in Explosionsgruppe

IIC, Kategorie 2G und Temperaturklasse T4 oder T5 (siehe Angaben auf dem

• Das Gerät darf nur für den Einsatz in Kategorie 2D mit den Temperaturen T135 °C bzw. 100 °C sowie für die im Kapitel „5. Einsatzbedingungen“ vorgesehenen Einsatzfällen und in Verbindung

mit von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten

und -komponenten verwendet werden.

• Die angewendeten Zündschutzarten sind die Druckfeste Kapselung „d“ mit Erhöhter Sicherheit „e“. Die Sicherung, die bei

Ausführung PD29 eingebaut ist, ist in Zündschutzart Vergusskapselung „m“ ausgeführt. Der Näherungsschalter, der optional bei

allen Ausführungen eingebaut werden kann, ist in Zündschutzart

Eigensicherheit „ia“ ausgeführt. Die Zusammensetzung des Zündschutzartenkennzeichens richtet sich nach den Zündschutzarten

der jeweils verwendeten Komponenten.

• Voraussetzungen für den sicheren und einwandfreien Betrieb sind

sachgemäßer Transport, sachgemäße Lagerung und Installation

sowie sorgfältige Bedienung und Instanthaltung.

Eine andere oder darüber hinausgehende Benutzung gilt als nicht

bestimmungsgemäß. Für hieraus resultierende Schäden haftet

Bürkert nicht. Das Risiko trägt allein der Anwender.

• Das Gerät nur bestimmungsgemäß einsetzen.

- Zulassungsschild).

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Geräts gegebenenfalls

bestehende Beschränkungen.

2.2. Ex-Zulassung

Die Ex-Zulassung ist nur gültig, wenn Sie die von Bürkert zugelassenen

Module und Komponenten so verwenden, wie es in dieser Bedienungsanleitung beschrieben ist.

Die Magnetspule Typ 0770/0780 darf nur in Kombination mit den

von Bürkert freigegebenen Zusatzkomponenten eingesetzt werden,

andernfalls erlischt die Ex-Zulassung!

Nehmen Sie unzulässige Veränderungen am Gerät, den Modulen oder

Komponenten vor, erlischt die Ex-Zulassung ebenfalls.

Die EG-Baumusterprüfbescheinigung PTB 03 ATEX 1030 und das

IECEx Certificate of Conformity IECEx PTB 05.0026X wurde von

der:

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100,

38116 Braunschweig

ausgestellt, die auch die Fertigung auditiert (CE 102).

Die EG-Baumusterprüfbescheinigung finden Sie im Internet unter:

www.buerkert.de

deutsch

19

Page 20

PTB 03 ATEX 1030 X

Allgemeine Sicherheitshinweise

2.3. Besondere Hinweise im Ex-Bereich

WARNUNG!

Gefahr durch elektrostatische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im Ex-Bereich Explosionsgefahr.

• Durch geeignete Maßnahmen sicherstellen, dass es im ExBereich zu keinen elektrostatischen Aufladungen kommen kann.

• Die Geräteoberfläche nur durch leichtes Abwischen mit einem

feuchten oder antistatischen Tuch reinigen.

Weitere Besondere Bedingungen finden Sie unter „5.1“ in

dieser Bedienungsanleitung.

3. ALLGEMEINE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung,

auch in Bezug auf Montagepersonal, der Betreiber verantwortlich ist.

Explosionsgefahr!

• Das Gerät ist Teil eines geschlossenen Systems und darf nicht

während des Betriebs demontiert werden.

Gefahr durch elektrische Spannung!

Akute Verletzungsgefahr durch gefährliche Korperspannung!

Gefahr der Beschädigung des Geräts durch Kurzschluss!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

Gefahr durch hohen Druck!

Bei Eingriffen in das System besteht akute Verletzungsgefahr.

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten

und die Leitungen entlüften.

• Beim Einbau die Durchflussrichtung beachten.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für druckbeaufschlagte Geräte einhalten.

20

deutsch

Page 21

PTB 03 ATEX 1030 X

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

Explosionsgefahr durch elektrostatische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im Ex-Bereich Explosionsgefahr.

• Durch geeignete Maßnahmen sicherstellen, dass es im ExBereich zu keinen elektrostatischen Aufladungen kommen kann.

• Geräteoberfläche nur durch leichtes Abwischen mit einem

feuchten oder antistatischen Tuch reinigen.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Am System dürfen keine unerlaubten Änderungen vorgenommen

werden.

• Arbeiten am System dürfen nur durch fachkundiges und unterwiesenes Personal mit geeignetem Werkzeug ausgeführt werden.

• Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung betrieben werden.

• Für die Einsatzplanung und den Betrieb müssen die allgemeinen

Regeln der Technik eingehalten werden.

4.1. Kontaktadressen

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Geräts unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter finden Sie im Internet unter:

www.buerkert.de

deutsch

21

Page 22

5. EINSATZBEDINGUNGEN

5.1. Besondere Bedingungen

5.1.1. Kurzschlussschutz

Jedem Magneten muss als Kurzschlussschutz eine seinem Anzugsstrom

entsprechende Sicherung (max. 3 x I

ein Motorschutzschalter mit Kurzschluss- und thermischer Schnellauslösung (Einstellung auf Anzugsstrom) vorgeschaltet werden.

• Bei sehr kleinen Anzugsströmen des Magneten ist die Sicherung

mit dem kleinsten Stromwert nach der genannten IEC-Norm ausreichend. Diese Sicherung darf im zugehörigen Versorgungsgerät

untergebracht sein oder muss separat vorgeschaltet werden.

• Die Sicherungs-Bemessungsspannung muss gleich oder größer

als die angegebene Nennspannung des Magneten sein.

• Das Ausschaltvermögen des Sicherungseinsatzes muss gleich

oder größer als der maximal anzunehmende Kurzschlussstrom am

Einbauort (üblicherweise 1500 A) sein.

• Bei der Ausführung PD30 des Elektromagneten muss der Kurzschlussschutz durch den Betreiber gewährleistet werden.

• Bei Ausführung PD29 des Elektromagneten ist die Sicherung im

Klemmkasten des Geräts eingebaut.

Nähere Beschreibung der Ausführungen finden Sie im

Kapitel „6. Technische Daten / Sicherer Betrieb“.

nach IEC 60127-2-1) bzw.

Nenn

PTB 03 ATEX 1030 X

Einsatzbedingungen

Sicherung ... A

5.1.2. Betrieb nur mit zugehörigem Ventil

Die Magnetspulen Typ 77. / 78. dürfen nur mit zugehörigem Ventilkörper betrieben werden.

Als Ventilkörper können folgende Werkstoffe verwendet werden:

• Metall (Messing, Aluminium, Edelstahl),

• Kunststoff (z.B. Polyamid PA 6 GV ...).

5.1.3. Handbetätigung / Näherungsschalter

Der Magnetanker kann über den Tastknopf manuell betätigt werden.

Durch Eindrücken und Verdrehen um 90° wird der Tastknopf

arretiert.

Alternativ zur Handbetätigung kann der Elektromagnet mit einem

Näherungsschalter ausgerüstet werden. Der interne Code für diese

Ausführung ist CF 15.

22

deutsch

Page 23

PTB 03 ATEX 1030 X

Technische Daten / Sicherer Betrieb

5.1.4. Ausführung mit einem

Klemmenkasten

GEFAHR!

Explosionsgefahr!

• Nur festgelegte Kabel und Leitungen dürfen eingeführt werden.

• Der Betreiber muss eine entsprechende Zugentlastung

gewährleisten.

• Es können Leitungen mit Außendurchmesser von 6 mm bis 13

mm verwendet werden. Die maximale thermische Belastung der

eingeführten Kabel bzw. Leitungen beachten.

• Die eingelegte, ausbrechbare Dichtung muss dem Durchmesser

des Kabel / Leitung angepasst werden.

• Der Bemessungsquerschnitt der Kabel / Leitungsadern muss mindestens 0,75 mm² betragen und darf 2,5 mm² nicht überschreiten.

• Die Schrauben zur Befestigung des Deckels des Klemmenkastens müssen mit einem Anziehdrehmoment von 1 Nm (± 5 %)

angezogen werden.

Die Magnetspulen dürfen auch mit einem Klemmenkasten (wahlweise

mit / ohne Sicherung) ausgeführt werden (Sicherung nach getrennter

Baumusterprüfbescheinigung).

Als Schutz gegen unbeabsichtiges Öffnen des Deckels trägt dieser

die Aufschrift:

Nur spannungsfrei öffnen!

6. TECHNISCHE DATEN / SICHERER

BETRIEB

6.1. Konformität

Die Magnetspule Typ 0770/0780 ist konform zu den EG-Richtlinien

entsprechend der EG-Konformitätserklärung.

6.2. Normen

Die angewandten Normen, mit denen die Konformität mit den EG-Richtlinien nachgewiesen wird, sind in der EG-Baumusterprüfbescheinigung

und/oder der EG-Konformitätserklärung nachzulesen.

6.3. Betriebsbedingungen

GEFAHR!

Explosionsgefahr durch Überschreitung technischen Daten!

Überschreitung der auf dem Typschild angegebenen technischen

Daten führt zu hohem Risiko!

• Auf dem Typschild angegebenen technischen Daten keinesfalls

überschreiten!

6.3.1. Maximal zulässiger

Umgebungstemperaturbereich

Bitte beachten Sie für jeden Typ den unter Einsatzbedingungen der

Spule angegeben, maximal zulässigen Umgebungstemperaturbereich!

Ausführung Maximal zulässiger

Umgebungstemperaturbereich

07xx -30 °C ... +55 °C

deutsch

23

Page 24

PTB 03 ATEX 1030 X

Technische Daten / Sicherer Betrieb

6.3.2. Schutzart

IP65 nach EN 60529 (DIN VDE 0470 Teil 1)

6.3.3. Lage und Beschreibung des

Typschildes

Warnhinweis

Typschild Spule

Typschild IEC Ex

Schutzart - Temperaturklasse

Sicherungswert / Fuse

...A

IEC EX Zulassungsnummer

Bild 1: Lage des Typschildes

Typ und Ausführung

Schutzart, Temperaturklasse

PTB Zulassungsnummer

Identnummer der Spule, Herstellerdatum

Seriennummer der Spule, Überwachungsstelle

Spannung (± 10 %), Stromart, Leistung

Bild 2: Beschreibung des Typschildes

6.3.4. Abmessungen

Anschlussart Länge

(mm)

Eingepresstes

96 32 56

Kabel

Klemmenkasten

123 60 113

mit/ohne Sicherung

Breite

(mm)

Höhe

(mm)

24

deutsch

Page 25

PTB 03 ATEX 1030 X

Technische Daten / Sicherer Betrieb

6.3.5. Zündschutzarten

Die Zusammensetzung des Zündschutzartenkennzeichens richtet sich

nach den Zündschutzarten der jeweils verwendeten Komponenten:

Elektromagnet

mit oder ohne

Klemmenkasten

Elektromagnet mit

Klemmenkasten

und Sicherung

Elektromagnet

ohne Klemmenkasten mit

Näherungsschalter

Elektromagnet

mit Klemmenkasten und

Sicherung sowie

Näherungsschalter

II 2 G Ex d e IIC T4 bzw. T5

II 2 D Ex tD A21 IP 65 T135 °C bzw.

T100 °C

II 2 G Ex d e mb IIC T4

II 2 D Ex tD A21 IP65 T135 °C

II 2 G Ex d e ia IIC T4 bzw. T5

II 2 D Ex tD A21 IP65 T135 °C bzw. T100 °C

II 2 G Ex d e ia mb IIC T4

II 2 D Ex tD A21 IP65 T135 °C

6.4. Allgemeine Technische Daten

6.4.1. Elektrische Daten

Typ

Temperaturklasse

Stromart

Nennspannung

Spannungstoleranz

Bemessungsstrom

Anzugsstrom

Anzugsleistung

Grenzleistung im

Beharrungszustand

Max. Schalthäu-

figkeit ca.

6.4.2. Elektrischer Anschluss

Ausfüh-

rungscode

PD30*

* Fest eingebaute Gummischlauchleitung des Typs H05 RN-F3G0,75

77. - ... - ... - . 78. - ... - ... - .

T4 T5

Allstrom Allstrom

24 ... 240 V 24 ... 240 V

+10 % / -10 % +10 % / -10 %

0,085 ... 0,014 A 0,085 ... 0,014 A

01,66 ... 0,166 A 01,66 ... 0,166 A

40 W 40 W

3 W 3 W

20 / min 10 / min

Ausführung Interner

Code

****JWxx

deutsch

25

Page 26

PTB 03 ATEX 1030 X

Montage und Demontage

Ausfüh-

rungscode

** Klemmenkasten mit Kabelver-

Ausführung Interner

Code

JA02

schraubung M20 x 1,5 ohne Sicherung

PD30

Klemmenkasten mit Gewindenippel

M20 x 1,5 ohne Sicherung

Klemmenkasten mit Gewindenippel

JA08

JA09

NPT 1/2 ohne Sicherung

Klemmenkasten mit Gewindenippel G

JA10

1/2 ohne Sicherung

** Klemmenkasten mit Kabelver-

JA01

schraubung M20 x 1,5 und Sicherung

PD29 ***

Klemmenkasten mit Gewindenippel

M20 x 1,5 und Sicherung

Klemmenkasten mit Gewindenippel

JA05

JA06

NPT 1/2 und Sicherung

Klemmenkasten mit Gewindenippel G

JA07

1/2 und Sicherung

* Die Anschlussleitung des Elektromagneten Typ 07xx muss fest und so

verlegt werden, dass sie vor mechanischen Beschädigungen hinreichend

geschützt ist

** Kabelverschraubung nach getrennter Baumusterprüfbescheinigung

*** Sicherung PD29 nach getrennter Baumusterprüfbescheinigung

**** Unterschiedliche Kabellängen

7. MONTAGE UND DEMONTAGE

7.1. Sicherheitshinweise

GEFAHR!

Explosionsgefahr!

Das Gerät ist ein geschlossenes System. Es darf nicht demontiert

werden. Folgende Sicherheitsfestlegungen sind einzuhalten:

• Die Oberfläche des Geräts kann sich elektrostatisch aufladen. In

explosionsgefährdeten Bereichen darf die Oberfläche der Geräte

nur mit einem feuchten oder antistatischen Tuch gereinigt werden.

• Nur festgelegte Kabel und Leitungen dürfen eingeführt werden.

• Der Betreiber muss eine entsprechende Zugentlastung

gewährleisten.

• Leitungen mit Außendurchmesser von 6 mm ... 13 mm können

verwendet werden. Die maximale thermische Belastung der

eingeführten Kabel bzw. Leitungen beachten.

• Die eingelegte, ausbrechbare Dichtung muss dem Durchmesser

des Kabels / Leitung angepasst werden.

• Der Bemessungsquerschnitt der Kabel / Leitungsadern muss mindestens 0,75 mm² betragen und darf 2,5 mm² nicht überschreiten.

• Die Schrauben zur Befestigung des Deckels des Klemmenkastens müssen mit einem Anziehdrehmoment von 1 Nm (± 5 %)

angezogen werden.

• Die Überwurfmutter (Druckschraube) der Kabelverschraubung am

Klemmenkasten muss mit einem Anzugsdrehmoment von 1,5 Nm

(± 5 %) angezogen werden.

26

deutsch

Page 27

PTB 03 ATEX 1030 X

Montage und Demontage

GEFAHR!

Gefahr durch elektrische Spannung!

Akute Verletzungsgefahr durch gefährliche Korperspannung!

Gefahr der Beschädigung des Gerätes durch Kurzschluss!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung abschalten und vor Wiedereinschalten sichern!

• Spannungsführende Klemmen im Klemmenkasten können Stromschlag, Kurzschluss oder Explosion verursachen. Spannung

abschalten. Erst dann den Klemmkasten öffnen.

• Die Anschlussleitungen der Elektromagneten müssen fest und

so verlegt werden, dass sie vor mechanischen Beschädigungen

hinreichend geschützt sind.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

WARNUNG!

Gefahr durch hohen Druck!

Bei Eingriffen in das System besteht akute Verletzungsgefahr.

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten

und die Leitungen entlüften.

• Beim Einbau die Durchflussrichtung beachten.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für druckbeaufschlagte Geräte einhalten.

7.2. Installation des Ventils

Die Einbaulage des Magnetventils ist beliebig.

Vorzugsweise mit Magnetsystem oben.

Vorgehensweise:

→ Rohrleitungen reinigen.

→ Schmutzfänger vorschalten.

→ Anschlüsse der Rohrleitung mit PTFE-Band abdichten.

→ Rohrleitungen einschrauben.

Durchflussrichtung beachten!

→ Ventil auf Dichtheit prüfen.

7.3. Elektrischer Anschluss

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das System die elektrische Spannung abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

Bei fehlendem Schutzleiterkontakt zwischen Spule und

Gehäuse besteht die Gefahr des Stromschlags!

• Schutzleiter immer anschließen.

• Elektrischer Durchgang zwischen Spule und Gehäuse prüfen.

deutsch

27

Page 28

PTB 03 ATEX 1030 X

Inbetriebnahme

Das Anschlusskabel ist mit der Spule vergossen und kann

nicht demontiert werden.

→ Elektrischer Anschluss anbringen.

7.4. Demontage

GEFAHR!

Gefahr durch elektrische Spannung!

Bei Eingriffen in die Anlage besteht akute Verletzungsgefahr.

• Arbeiten am elektrischen System dürfen nur von ausgebildeten

Elektrofachkräften durchgeführt werden.

• Vor Beginn der Arbeiten in jedem Fall die Spannung abschalten

und diese vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

Vorgehensweise:

→ Elektrische Verbindung trennen.

→ Ventilgehäuse von der Rohrleitung trennen.

HINWEIS!

Funktionsstörungen durch Verschmutzung!

• Bei Neuinstallation altes PTFE-Band an den Anschlüssen entfernen. Reste oder Teile des Bandes dürfen nicht in die Rohrleitung

gelangen.

8. INBETRIEBNAHME

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen, sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Die Sicherheitshinweise und die bestimmungsgemäße Verwendung müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Gerät

in Betrieb nehmen.

Stellen Sie vor Inbetriebnahme sicher, dass:

• das Gerät vorschriftmäßig installiert wurde,

• der Anschluss ordnungsgemäß ausgeführt wurde,

• das Gerät nicht beschädigt ist,

• alle Schrauben fest angezogen sind.

28

deutsch

Page 29

PTB 03 ATEX 1030 X

Wartung, Reparatur, Fehlerbehebung

9. WARTUNG, REPARATUR,

FEHLERBEHEBUNG

9.1. Wartung und Reparatur

GEFAHR!

Gefahr durch unsachgemäße Wartungs-, Reparatur- und

Instandhaltungsarbeiten!

• Die Wartungs- und Instandhaltungsarbeiten am Gerät dürfen nur

autorisiertes Fachpersonal mit geeignetem Werkzeug durchführen!

• Reparaturen am Gerät dürfen nur vom Hersteller durchgeführt werden!

• Bei Repatatur- oder Wartungsarbeiten an der Anlage darf das

Ventil nicht geöffnet und die Schutzleiterverbindung nicht getrennt

werden!

9.2. Fehlerbehebung

Stellen Sie bei Störungen sicher, dass:

• das Gerät vorschriftmäßig installiert wurde,

• der Anschluss ordnungsgemäß ausgeführt wurde,

• das Gerät nicht beschädigt ist,

• alle Schrauben fest angezogen sind,

• Spannung und Druck anliegen,

• die Rohrleitungen frei sind.

10. ERSATZTEILE

VORSICHT!

Verletzungsgefahr, Sachschäden durch falsche Teile!

Falsches Zubehör und ungeeignete Ersatzteile können Verletzungen

und Schäden am Gerät und dessen Umgebung verursachen.

• Nur Originalzubehör sowie Originalersatzteile der Firma Bürkert

verwenden.

10.1. Zubehör

Bei Ausführung der Geräte mit Klemmenkasten kann in Temperaturklasse T4, die Sicherung des Typs 1058 mit Zulassung PTB 01 ATEX

2064 U eingesetzt werden.

Sicherung

Typ 1058

0,063 A 153717

0,080 A 153745

0,100 A 153718

0,125 A 153719

0,160 A 153720

0,200 A 153731

0,315 A 153733

0,400 A 153734

0,500 A 153735

0,630 A 153736

0,800 A 153737

Bestellnummer

deutsch

29

Page 30

PTB 03 ATEX 1030 X

Transport, Lagerung, Entsorgung

Sicherung

Typ 1058

1,000 A 153738

1,250 A 153739

1,600 A 153746

2,000 A 153740

3,150 A 153742

Bestellnummer

11. TRANSPORT, LAGERUNG,

ENTSORGUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur: –40 … +60 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

30

deutsch

Page 31

PTB 03 ATEX 1030 X

Appareils avec mode de protection II 2G/D Ex

1. À PROPOS DE CE MANUEL ................................................................... 32

1.1. Symboles..........................................................................................32

2. UTILISATION CONFORME.......................................................................33

2.1. Limitations ........................................................................................33

2.2. Homologation Ex ............................................................................33

2.3. Remarques particulières dans une zone présentant des

risques d’explosion .................................................................................34

3. CONSIGNES DE SÉCURITÉ FONDAMENTALES ......................... 34

4. INDICATIONS GÉNÉRALES .................................................................... 35

4.1. Adresses ..........................................................................................35

4.2. Garantie légale ................................................................................35

4.3. Informations sur Internet ...............................................................35

5. CONDITIONS D‘EMPLOI DES APPAREILS ..................................... 36

5.1. Conditions particulières ................................................................36

6. CARACTÉRISTIQUES TECHNIQUES / FONCTIONNEMENT

EN TOUTE SÉCURITÉ ...................................................................................... 37

6.1. Conformité .......................................................................................37

6.2. Normes .............................................................................................37

6.3. Conditions d‘exploitation ..............................................................37

6.4. Caractéristiques techniques générales ....................................39

7.2. Installation de la vanne ..................................................................41

7.3. Raccordement électrique .............................................................41

7.4. Démontage ......................................................................................42

8. MISE EN SERVICE .......................................................................................42

9. ENTRETIEN, RÉPARATION, DÉPANNAGE ....................................... 43

9.1. Entretien et réparation ...................................................................43

9.2. Dépannage ......................................................................................43

10. ACCESSOIRES ...........................................................................................43

10.1. Pièces de rechange.....................................................................43

11. TRANSPORT, STOCKAGE, ÉLIMINATION ..................................... 44

7. MONTAGE ET DÉMONTAGE ..................................................................40

7.1. Consignes de sécurité ..................................................................40

français

31

Page 32

PTB 03 ATEX 1030 X

À propos de ce manuel

1. À PROPOS DE CE MANUEL

Ce manuel décrit le cycle de vie complet de l‘appareil. Conservez ce

manuel de sorte qu‘il soit accessible à tout utilisateur et à disposition

de tout nouveau propriétaire.

Les instructions de service contiennent des informations

importantes sur la sécurité.

Le non-respect de ces consignes peut entraîner des situations

dangereuses. Les instructions de service doivent être lues et

comprises.

• Lisez attentivement les instructions de service avant d’utiliser

l’appareil.

• Faites particulièrement attention aux chapitres « Utilisation

conforme », et « Consignes de sécurité fondamentales » ainsi

que les « Conditions d‘emploi des appareils ».

1.1. Symboles

Les moyens de représentation suivants sont utilisés dans le manuel

pour identifier les informations importantes :

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement dangereuse !

• Risque de blessures graves, voire la mort en cas de non-respect.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou de

moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

Conseils et recommandations importants.

Renvoie à des informations dans ces instructions de service

ou dans d’autres documentations.

32

→ identifie une opération que vous devez effectuer.

français

Page 33

PTB 03 ATEX 1030 X

Utilisation conforme

2. UTILISATION CONFORME

L’utilisation non conforme peut présenter des dangers pour

les personnes, les installations proches et l’environnement.

• L‘appareil sert exclusivement d‘électrovanne pour les fluides autorisés d‘après la fiche technique et pour l‘emploi dans un groupe

déflagrant IIC, catégorie 2G et classe de température T4 ou T5

(voir indications sur la plaque d‘homologation

• L’appareil doit être utilisé uniquement en catégorie 2D aux températures T135 °C resp. 100 °C ainsi que dans les cas prévus au

chapitre « 5. Conditions d‘emploi des appareils » et en association

avec des appareils et composants d’autres marques recommandés

et homologués par Bürkert.

• Les types de protection à l’allumage utilisés sont le coffret blindé

antidéflagrant « d » avec sécurité accrue « e ». La sécurité installée dans la version PD29 est du type de protection à l’allumage

par encapsulage « m ». Le détecteur de proximité pouvant être

monté en option sur toutes les versions est du type de protection

à l’allumage à sécurité intrinsèque « ia ». L’identification du type

de protection à l’allumage est basée sur les types de protection

à l’allumage des composants utilisés.

• Les conditions pour l’utilisation sûre et parfaite sont un transport, un

stockage et une installation dans les règles ainsi qu’une utilisation

et maintenance parfaites.

Toute autre utilisation ou toute utilisation allant au-delà est considérée

comme non conforme. Bürkert décline toute responsabilité pour

les dommages qui en résultent. L’utilisateur est seul à en supporter

le risque.

• Veillez à ce que l’utilisation de l’appareil soit toujours conforme.

).

2.1. Limitations

Lors de l‘exportation du système / de l’appareil, veuillez respecter les

limitations éventuelles existantes.

2.2. Homologation Ex

L‘homologation Ex n‘est valable que si vous utilisez les modules et

composants homologués par Bürkert tel que cela est décrit dans ces

instructions de service.

La soupape à languette peut être utilisée uniquement avec les composants supplémentaires autorisés par Bürkert, sinon l‘homologation

Ex devient caduque !

L‘homologation Ex devient également caduque si vous apportez

des modifications non autorisées à l‘appareil, aux modules ou aux

composants.

Le certificat d’examen CE de type PTB 03 ATEX 1030 X et le certificat de conformité IECEx PTB 05.0026X ont été établis par :

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100,

38116 Braunschweig

qui effectue également l‘audit de production (CE 0102).

Vous trouverez le certificat d’essai de modèle type CE sur Internet

sous : www.burkert.fr

français

33

Page 34

PTB 03 ATEX 1030 X

Consignes de sécurité fondamentales

2.3. Remarques particulières dans

une zone présentant des risques

d’explosion

AVERTISSEMENT !

Risque dû à la charge électrostatique.

Il y a risque d’explosion en cas de décharge soudaine d’appareils

ou de personnes chargés d’électricité statique dans des zones

présentant des risques d’explosion.

• Par des mesures appropriées, assurez-vous qu’il ne peut y avoir

de charges électrostatiques dans de telles zones.

• Nettoyer la surface de l’appareil uniquement en l’essuyant légèrement avec un chiffon humide ou antistatique.

Vous trouverez d‘autres conditions particulières au chapitre

« 5.1 » de ce manuel d‘utilisation.

3. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte :

• des hasards et des événements pouvant survenir lors du montage, de

l‘exploitation et de l‘entretien des appareils.

• des prescriptions de sécurité locales que l‘exploitant est tenu de faire

respecter par le personnel chargé du montage.

Risque d‘explosion.

• La soupape à languette fait partie d‘un système fermé et ne peut

pas être démontée pendant l‘exploitation.

Danger par tension électrique.

Risque de blessure grave en raison d’une tension corporelle

dangereuse!

• Avant de commencer une intervention, couper la tension et

assurer une protection contre la remise en marche de l’appareil!

• Respecter les règles de prévention des accidents et de sécurité

en vigueur pour les appareils électriques!

Danger dû à la haute pression.

Il y a risque important de blessures lors d’interventions sur le

système.

• Couper d’abord la pression, puis détacher les câbles et les

vannes.

• Respecter les règles de prévention des accidents et de sécurité

en vigueur pour les appareils pneumatiques.

34

français

Page 35

PTB 03 ATEX 1030 X

Indications générales

4. INDICATIONS GÉNÉRALES

Risque d‘explosion dû à la charge électrostatique.

Il y a risque d‘explosion en cas de décharge soudaine d‘appareils

ou de personnes chargés d‘électricité statique dans des zones

présentant des risques d‘explosion.

• Par des mesures appropriées, assurez-vous qu‘il ne peut y avoir

de charges électrostatiques dans de telles zones.

• Nettoyez la surface de la soupape à languette uniquement en

essuyant légèrement avec un chiffon ou antistatique humide.

Situations dangereuses d‘ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• L’actionnement par inadvertance de l’installation ne doit pas être

possible.

• Aucune modification non autorisée ne doit être apportée au

système.

• Les travaux sur le système doivent être exécutés uniquement

par du personnel qualifié et formé disposant de l’outillage

approprié.

• L’appareil doit être utilisé uniquement en parfait état et en respectant le manuel d’utilisation.

• Les règles générales de la technique sont d’application pour

planifier l’utilisation et utiliser l’appareil.

4.1. Adresses

Allemagne

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail : info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages de ces instructions de

service imprimées.

Egalement sur internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie est l‘utilisation conforme de

l‘appareil dans le respect des conditions d‘utilisation spécifiée.

4.3. Informations sur Internet

Vous trouverez les instructions de service et la fiche technique sur

Internet à l‘adresse : www.buerkert.fr

français

35

Page 36

5. CONDITIONS D‘EMPLOI DES

APPAREILS

5.1. Conditions particulières

5.1.1. Protection contre les courts-circuits

Un fusible correspondant au courant d‘actionnement (max. 3 x I

selon CEI 60127-2-1) ou un disjoncteur de court-circuit et thermique

à déclenchement rapide (réglage sur courant de démarrage) doit être

monté en amont de chaque aimant.

• Selon la norme CEI citée, le fusible au valeur de courant le plus faible

suffit lorsque les courants évalués de l’aimant sont très faibles. Ce

fusible peut être placé dans l’appareil d’alimentation s’y rattachant

ou doit être branché séparément en amont.

• La tension de calcul du fusible doit être égale ou supérieure à la

tension nominale indiquée de l’aiment.

• Le pouvoir de coupure de la cartouche doit être égal ou supérieur

au courant de court-circuit supposé au lieu de montage (habituellement 1500 A).

• Dans les versions PD30 de l‘électro-aimant, la protection contre les

courts-circuits doit être assurée par l‘exploitant.

• Dans la version PD29 de l‘électro-aimant, le fusible est monté dans

la boîte de connexions de l‘appareil.

Vous trouverez une description plus détaillée des versions au

chapitre « 6. Caractéristiques techniques / fonctionnement

en toute sécurité ».

rating

PTB 03 ATEX 1030 X

Conditions d‘emploi des appareils

Fusible ... A

5.1.2. Fonctionnement avec corps de

soupape s‘y rattachant

Les bobines magnétiques des type 77. / 78. ne doivent être mise en

œuvre qu‘avec le corps de vanne s‘y rattachant.

On peut utiliser comme corps de vanne les matières suivantes :

• métal (p. ex. laiton, acier spécial...) ou

• matière plastique (e. ex. polyamide, PVC, PTFE)

5.1.3. Commande manuelle / détecteur de

proximité

L’induit de l’aimant peut être manœuvré à la main par le bouton-poussoir.

En pressant et tournant de 90°, le bouton-poussoir est bloqué.

Alternativement à la commande manuelle, l’électro-aimant peut être

équipé d’un détecteur de proximité. Le code interne pour cette version

est CF 15.

36

français

Page 37

Caractéristiques techniques /

fonctionnement en toute sécurité

PTB 03 ATEX 1030 X

5.1.4. Exécution avec boîte à bornes

DANGER !

Risque d‘explosion.

• Uniquement des câbles et des lignes déterminés doivent être

introduits.

• L‘exploitant doit assurer une décharge de traction correspondante.

• Des lignes ayant un diamètre extérieur de 6 mm à 13 mm peuvent

être utilisées. Tenir compte de la charge thermique maximale es

câbles ou des lignes introduits.

• Le joint qui peut s‘arracher doit être adapté au diamètre du câble/

de la ligne.

• La section de référence des conducteurs du câble/de la ligne doit

mesurer au moins 0,75 mm² et ne doit pas dépasser 2,5 mm².

• Les vis pour fixer le couvercle de la boîte de connexions doivent

être serrées à un couple de 1 Nm (±5 %).

Les bobines magnétiques peuvent être aussi réalisées avec une boîte

de connexions (au choix avec ou sans fusible) - (fusible conforme au

certificat d‘essai de type séparé).

Comme protection contre toute ouverture involontaire du couvercle,

ce dernier porte l‘inscription :

À n‘ouvrir qu‘en absence de tension!

6. CARACTÉRISTIQUES TECHNIQUES

/ FONCTIONNEMENT EN TOUTE

SÉCURITÉ

6.1. Conformité

Les bobines magnétiques des type 0770/0780 est conforme aux

directives CE sur la base de la déclaration de conformité CE.

6.2. Normes

Les normes utilisées, avec lesquelles la conformité avec les directives

CE sont prouvées, figurent dans l’attestation CE de type et/ou la

déclaration de conformité CE.

6.3. Conditions d‘exploitation

AVERTISSEMENT !

Risque d‘explosion.

Le non-respect des caractéristiques techniques visées sur la

plaque signalétique induit des risques graves!

• Toujours respecter les caractéristiques techniques figurant sur

la plaque signalétique!

6.3.1. Plage de température de service

Tenir compte pour chaque type de la plage de température de service

figurant dans les conditions d’emploi des appareils.

Version Plage de température ambiante maximale

admissible

07xx -30 °C ... +55 °C

français

37

Page 38

PTB 03 ATEX 1030 X

Caractéristiques techniques /

fonctionnement en toute sécurité

6.3.2. Mode de protection

IP65 selon EN 60529 (DIN VDE 0470 partie 1)

6.3.3. Emplacement et la description de la

plaque signalétique

Mise en garde

Plaque signalétique bobine

Plaque signalétique IEC Ex

Type de protection / classe de température

Fusible / Fuse

...A

N° d’homologation IEC Ex

Fig. 1 : Emplacement de la plaque signalétique

Type et version

Type de protection, Classe de température

N° d’homologation PTB

N° ID de la bobine, Date fabricant

N° de série de la bobine, Organisme de surveillance

Tension (± 10 %), Type de courant, Puissance

Fig. 2 : Description de la plaque signalétique

6.3.4. Dimensions

Mode de

raccordement

Longueur

(mm)

Largeur

(mm)

Hauteur

(mm)

Câble serti 96 32 56

Boîte à bornes

123 60 113

avec/sans fusible

38

français

Page 39

Caractéristiques techniques /

fonctionnement en toute sécurité

PTB 03 ATEX 1030 X

6.3.5. Protection „e“

La composition des signes distinctifs de protection allumage

s’oriente sur les modes de protection allumage des composants

respectivement utilisés :

Electro-aimant avec ou

sans coffret à bornes

Electro-aimant avec

coffret à bornes et

fusible

Electro-aimant sans

coffret à bornes, avec

détecteur de proximité

Electro-aimant avec

coffret à bornes,

fusible et détecteur de

proximité

II 2 G Ex d e IIC T4 resp. T5

II 2 D Ex tD A21 IP 65 T135 °C resp.

T100 °C

II 2 G Ex d e mb IIC T4

II 2 D Ex tD A21 IP65 T135 °C

II 2 G Ex d e ia IIC T4 resp. T5

II 2 D Ex tD A21 IP65 T135 °C resp.

T100 °C

II 2 G Ex d e ia mb IIC T4

II 2 D Ex tD A21 IP65 T135 °C

6.4. Caractéristiques techniques

générales

6.4.1. Caractéristiques électriques

Type

Classe de température

Type de courant

Tension nominale

Tolérance de tension

Courant de calcul

Courant

d‘actionnement

Puissance d´attraction

Puissance de maintien

en régime établi

Régime de charge max.

env.

6.4.2. Raccordement électrique

Code

d’exécution

PD30*

* Conduite flexible en caoutchouc

montée fixe du type H05 RN-F3G0,75

77. - ... - ... - . 78. - ... - ... - .

T4 T5

tous courants tous courants

24 ... 240 V 24 ... 240 V

+10 % / -10 % +10 % / -10 %

0,085 ... 0,014 A 0,085 ... 0,014 A

01,66 ... 0,166 A 01,66 ... 0,166 A

40 W 40 W

3 W 3W

20 / min 10 / min

Version Code interne

****JWxx

français

39

Page 40

PTB 03 ATEX 1030 X

Montage et Démontage

Code

d’exécution

** Boîte de connexions avec passe

Version Interner

Code

JA02

câble à vis M20 x 1,5 sans fusible

PD30

Boîte de connexions avec raccord

fileté M20 x 1,5 sans fusible

Boîte de connexions avec raccord

JA08

JA09

fileté NPT 1/2, sans fusible

Boîte de connexions avec raccord

JA10

fileté G 1/2, sans fusible

** Boîte de connexions avec passe

JA01

câble à vis M20 x 1,5 et fusible

PD29 ***

Boîte de connexions avec raccord

fileté M20 x 1,5 et fusible

Boîte de connexions avec raccord

JA05

JA06

fileté NPT 1/2 et fusible

Boîte de connexions avec raccord

JA07

fileté G 1/2 et fusible

* La ligne de raccordement de l‘électro-aimant Type 7..- doit être posée

fixe et de manière à ce qu‘elle soit suffisamment à l‘abri de détériorations

mécaniques.

** Passe câble à vis selon certificat d‘essai de type séparé

*** Fusible PD29 selon le certificat d’essai de modèle type CE séparé

**** Différentes longueurs de câble

7. MONTAGE ET DÉMONTAGE

7.1. Consignes de sécurité

DANGER !

Danger d‘explosion.

L’appareil est un système fermé. L‘appareil ne doit pas être

démonté. Il faut respecter les prescriptions de sécurité suivantes :

• La surface de l’appareil peut emmagasiner une charge électrostatique. Dans les zones à risques de déflagration, la surface des

appareils ne doit être nettoyée qu’avec un linge humide.

• Uniquement des câbles et des lignes déterminés doivent être

introduits.

• L‘exploitant doit assurer une décharge de traction correspondante.

• Des lignes ayant un diamètre extérieur de 6 mm à 13 mm peuvent

être utilisées. Tenir compte de la charge thermique maximale es

câbles ou des lignes introduits.

• Le joint qui peut s‘arracher doit être adapté au diamètre du câble/

de la ligne.

• La section de référence des conducteurs du câble/de la ligne

doit mesurer au moins 0,75 mm² et ne doit pas dépasser

2,5 mm².

• Les vis pour fixer le couvercle de la boîte de connexions doivent

être serrées à un couple de 1 Nm (±5 %).

• L’écrou-raccord (vis de pression) du passe-câbles sur le coffret

à bornes doit être serré à un couple de 1,5 Nm (± 5 %).

40

français

Page 41

PTB 03 ATEX 1030 X

Montage et Démontage

DANGER !

Danger par tension électrique.

Risque de blessure grave en raison d’une tension corporelle

dangereuse.

• Les bornes conductrices de tension de la boîte de bornes

peuvent causer des décharges électriques, des courts-circuits

ou des explosions. Il convient de toujours couper la tension

avant d’ouvrir la boîte de bornes.

• Avant de commencer une intervention, couper la tension et

assurer une protection contre la remise en marche de l’appareil.

• Les lignes de raccordement des électro-aimants doivent solides

et posées de manière à être suffisamment protégées contre des

dommages d’origine mécanique.

• Respecter les règles de prévention des accidents et de sécurité

en vigueur pour les appareils électriques.

DANGER !

Danger dû à la haute pression.

Il y a risque important de blessures lors d’interventions sur le

système.

• Les interventions sur le système pneumatique ne peuvent être

réalisées que par un personnel spécialisé et formé à cet effet, et

à l’aide des outils appropriés.

• Couper d’abord la pression, puis détacher les câbles et les

vannes.

• Respecter les règles de prévention des accidents et de sécurité

en vigueur pour les appareils pneumatiques.

7.2. Installation de la vanne

La position de montage de l’électrovanne est indifférente.

De préférence avec le système magnétique en haut.

Procédure à suivre :

→ Nettoyer les tuyauteries.

→ Monter le panier en amont.

→ Étancher les raccords de la tuyauterie avec une bande PTFE.

→ Visser les tuyauteries.

Respecter le sens du débit !

→ Contrôler l’étanchéité de la vanne.

7.3. Raccordement électrique

DANGER !

Risque de choc électrique.

• Avant d’intervenir dans le système, couper la tension et empêcher

toute remise sous tension par inadvertance.

• Veuillez respecter les réglementations en vigueur pour les appareils

électriques en matière de prévention des accidents ainsi qu’en

matière de sécurité.

Il y a risque de choc électrique en l’absence d’un contact du