Page 1

PTB 02 ATEX 2173 X

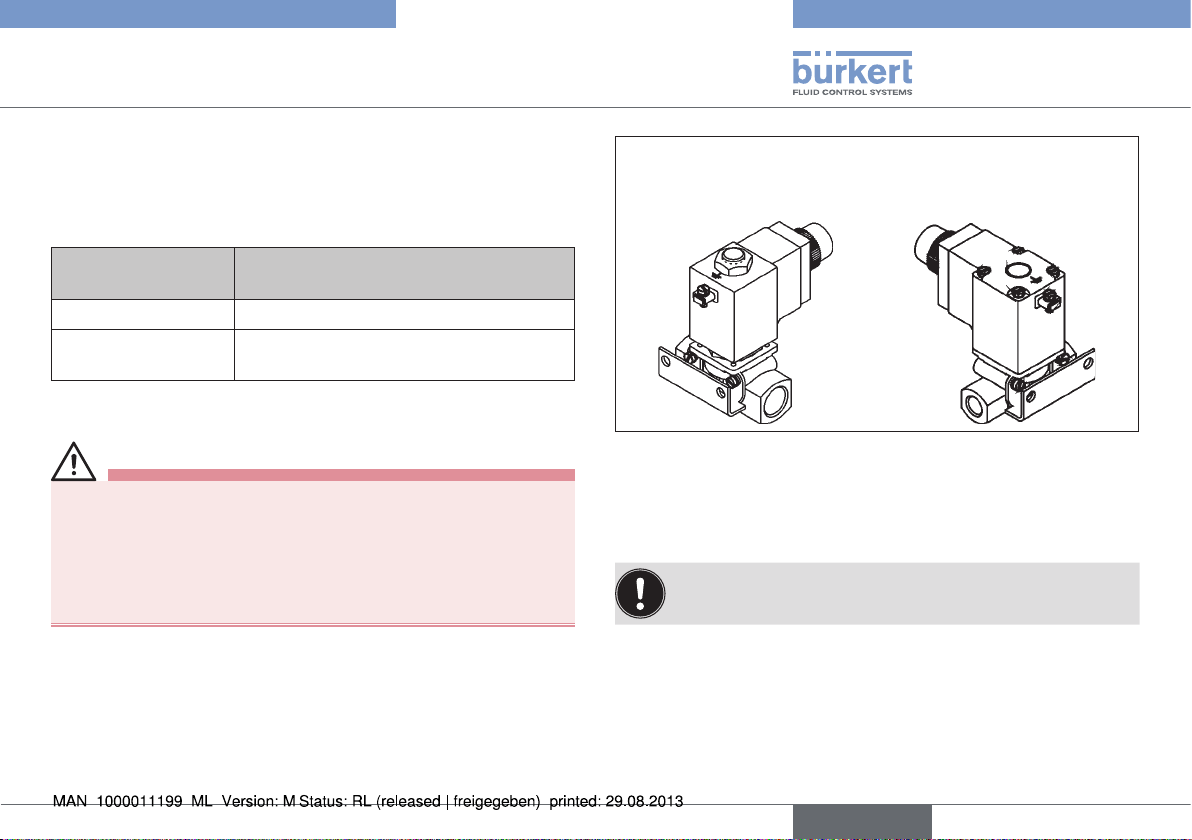

Device with II 2G EX m / II 2G EX em approval

Geräte mit II 2G EX m / II 2G EX em Zulassung

Appareils avec mode de protection II 2G EX m / II 2G EX em

Exapmple / Beispiel / Exemple

Type 0742

Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2002-2011 Bürkert Werke GmbH

Operating Instructions 1106/09_EU-ML_00804440 / Original DE

Page 3

PTB 02 ATEX 2173 X

Table of Contents

1. OPERATING INSTRUCTIONS ...................................................................4

1.1. Symbols ..............................................................................................4

2. AUTHORIZED USE .........................................................................................5

2.1. Restrictions ........................................................................................5

2.2. EX approval .......................................................................................5

3. BASIC SAFETY INSTRUCTIONS .............................................................6

4. GENERAL INFORMATION ...........................................................................7

4.1. Contact Addresses .......................................................................... 7

4.2. Warranty ............................................................................................. 7

4.3. Information on the Internet ............................................................. 7

5. APPLICATION CONDITIONS OF THE DEVICES .............................7

5.1. Short-circuit protection ................................................................... 7

5.2. Operation only with associated valve ..........................................8

5.3. Ignition protection type ................................................................... 8

5.4. Dimensions ........................................................................................ 8

5.5. Protection class ................................................................................8

5.6. Individual assembly ..........................................................................8

5.7. Operating temperature range ........................................................ 8

5.8. Maximum permitted ambient temperature .................................. 9

5.9. Application in petrol pumps ...........................................................9

5.10. Model with a terminal box ..........................................................10

6. TECHNICAL DATA ........................................................................................ 10

6.1. Conformity .......................................................................................10

6.2. Standards .........................................................................................10

6.3. Licenses ...........................................................................................10

6.4. Operating Conditions ....................................................................11

6.5. Electrical Data .................................................................................12

6.6. Electrical connection .....................................................................12

7. ASSEMBLY .......................................................................................................13

7.1. Safety instructions .........................................................................13

7.2. Installation of type 0742 ...............................................................14

8. START-UP .........................................................................................................14

8.1. Safety instructions .........................................................................14

8.2. Start-Up ............................................................................................14

9. MAINTENANCE, TROUBLESHOOTING ............................................ 15

9.1. Safety instructions .........................................................................15

9.2. Maintenance Work .........................................................................15

9.3. Troubleshooting ..............................................................................15

10. TRANSPORT, STORAGE, DISPOSAL .............................................. 16

english

3

Page 4

PTB 02 ATEX 2173 X

Operating Instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

The operating instructions contain important safety

information!

Failure to observe these instructions may result in hazardous

situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a medium or minor

injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the

device or the equipment.

Indicates important additional information, tips and

recommendations.

Refers to information in these operating instructions or in

other documentation.

→ designates a procedure which you must carry out.

4

english

Page 5

PTB 02 ATEX 2173 X

Authorized use

2. AUTHORIZED USE

Unauthorized use of the device Type 0742 may be dangerous

to people, nearby equipment and the environment.

• The device is used is used exclusively as a solenoid valve for media

permitted according to the data sheet and for use in Explosion group

II, Category 2G and Temperature class T4 (T3 at +55 °C) or T5

(see specifications on the

• The device may be used only for the applications designated in

chapter "5. Application conditions of the devices" and in conjunction with third-party devices and components recommended

and authorized by Bürkert. Use according to the authorized data,

service and operating conditions specified in the contract documents and operating instructions.

• The applied protection class is encapsulation EX "m" for coils with

cable connection or encapsulation with increased safety EX "em"

for coils with terminal box.

• The faultless and reliable operation of the system assumes correct transportation, correct storage and installation as well as

careful operation and maintenance. Any other use is regarded as

unauthorized. Bürkert is not liable for any resulting damage. The

user alone bears the risk.

• Only use the device for its intended purpose.

approval plate).

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

2.2. EX approval

The EX approval is only valid if the modules and components authorized by Bürkert are used as described in these operating instructions.

Type 0742 may be used only in combination with the additional components released by Bürkert, otherwise the EX approval will be voided!

If any unauthorized changes are made to the device, modules or components, the EX approval will also be voided.

Temperature classes and electrical data see chapter

"6. Technical Data".

english

5

Page 6

3. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

• Contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

Danger of explosion!

• The device is part of a closed system and must not be removed

during operation.

Risk of electric shock!

Acute risk of injury from hazardous body voltage! Risk of damaging

the device by short-circuit!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations

for electrical equipment!

Danger – high pressure!

When reaching into the system, there is an acute risk of injury.

• Before dismounting pneumatic lines and valves, turn off the

pressure and vent the lines.

• During the installation, make certain the flow direction is correct.

• Observe applicable accident prevention and safety regulations

for pressurized devices.

PTB 02 ATEX 2173 X

Basic safety instructions

Danger of explosion caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged

devices or persons, there is a danger of explosion in the EX area.

• Using suitable measures, ensure that no electrostatic charges

can occur in the EX area.

• Clean the device surface by gently wiping it with a damp or antistatic cloth only.

General Hazardous Situations.

To prevent injuries:

• Ensure that the system cannot be activated unintentionally.

• Installation and maintenance work may be carried out only by

authorized technicians with the appropriate tools.

• After an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

• The device may be operated only when in perfect condition and

in consideration of the operating instructions.

• The general rules of technology must be observed for application

planning and operation of the device.

Failure to observe this operating manual and its operating

instructions as well as unauthorized tampering with the device

release us from any liability and also invalidate the warranty

covering the devices and accessories!

6

english

Page 7

PTB 02 ATEX 2173 X

General information

4. GENERAL INFORMATION

4.1. Contact Addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed

operating instructions.

And also on the Internet at: www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance

with the specified application conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type 0742 can be found

on the Internet at: www.burkert.com

5. APPLICATION CONDITIONS OF

THE DEVICES

5.1. Short-circuit protection

To protect against short-circuits, either a fuse (max. 3 x Ib in accordance

with IEC 60127-2-1) must be connected upstream of each magnet

according to the rated current of the magnet, or a motor protection

switch with short-circuit and thermal quick release (set to rated current).

If rated currents of the magnet are very low, the fuse with the lowest

current value is adequate in accordance with the stated IEC standard.

This fuse may be housed in the associated supply unit or must be

connected separately upstream. The rated voltage of the fuse must be

equal to or greater than the indicated nominal voltage of the magnet.

The breaking capacity of the fuse insert must be equal to or greater

than the maximum short-circuit current accepted at the installation

location (usually 1500 A).

The operator must guarantee short-circuit protection for models A and

L of the electromagnet. The fuse is installed in the terminal box of the

device for model K of the electromagnet.

For a more detailed description of models A, L and K see

chapter "6. Technical Data".

english

7

Page 8

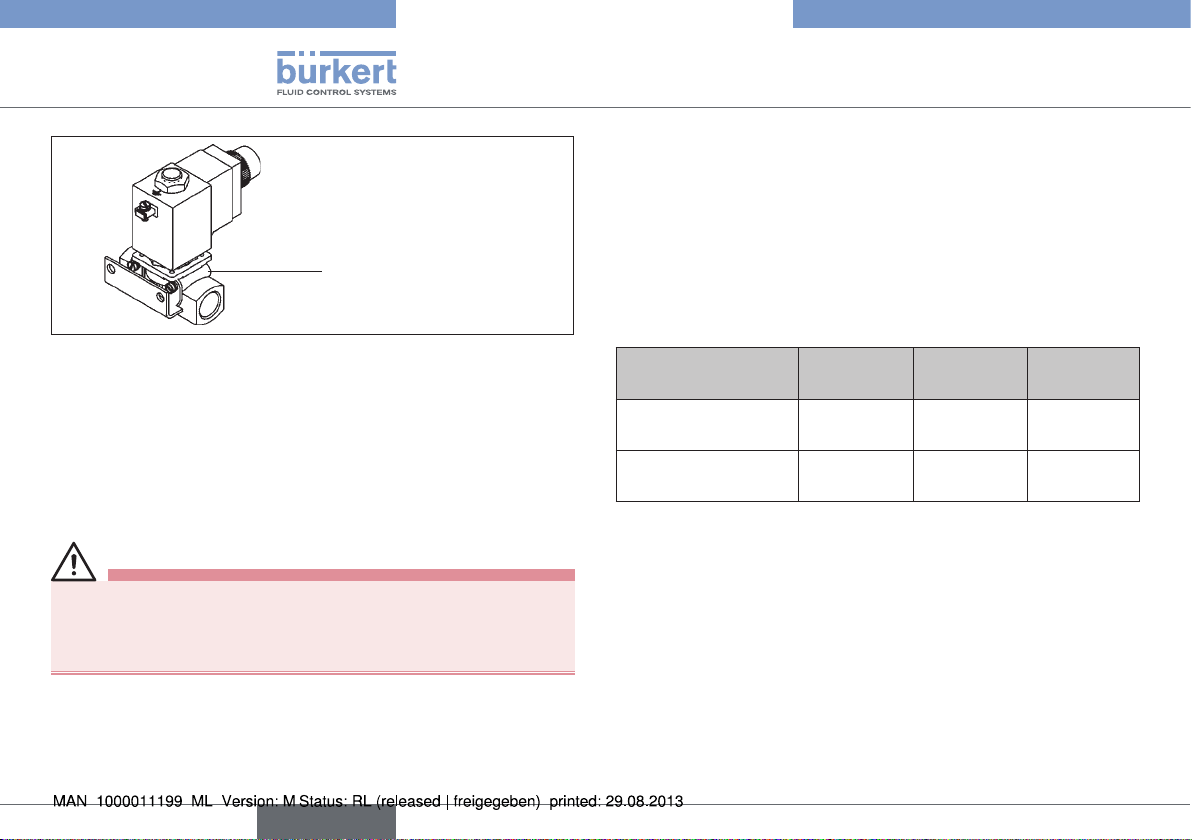

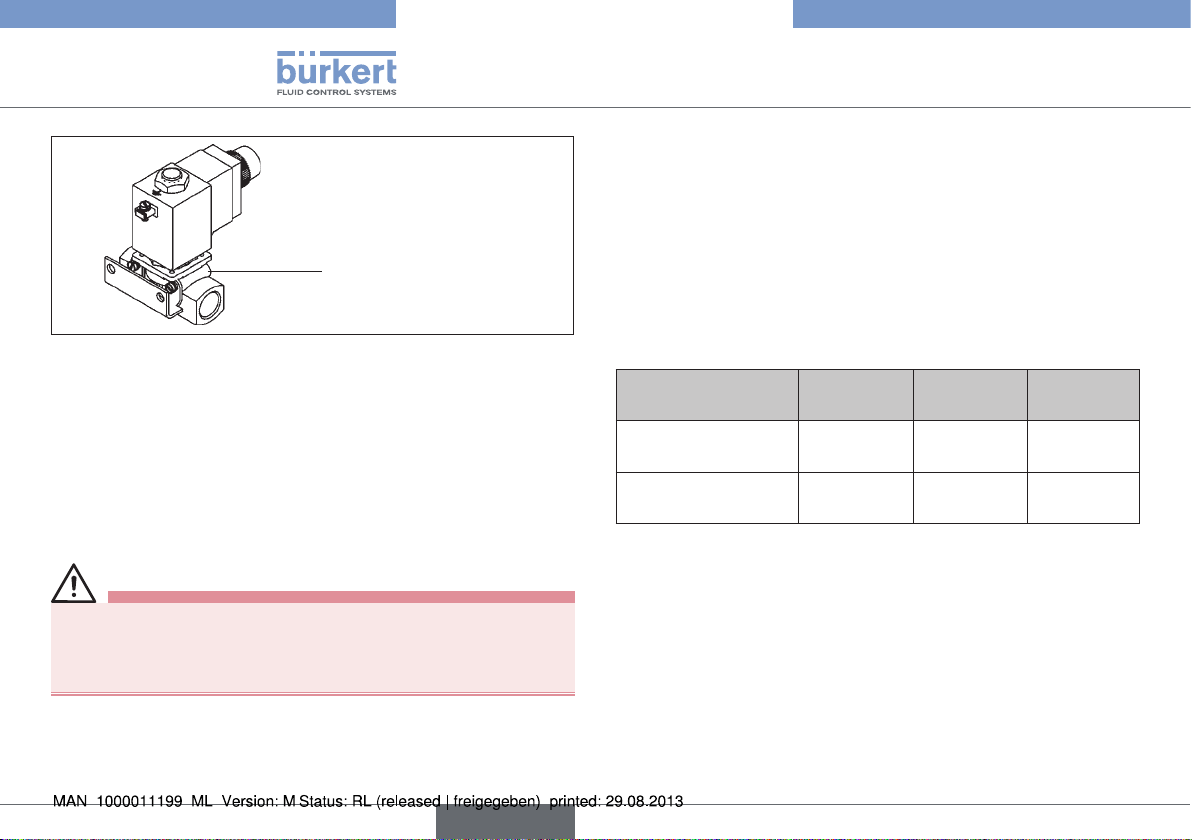

Fuse

...A

PTB 02 ATEX 2173 X

Application conditions of the devices

5.3. Ignition protection type

• For model with installed rubber hose line (A): EX m II T4 (T3 at

+55 °C) or T5 in accordance with EN 60079-0, EN 60079-18.

• For model with terminal box (L and K): EX em II T4 (T3 at +55 °C)

or T5 in accordance with EN 60079-0, EN 60079-7 and

EN 60079-18.

5.4. Dimensions

5.2. Operation only with associated

valve

The solenoid coils type 74. / 75. may be operated as a complete device

only with associated valve body which satisfies the following requirements:

• Materials for individual and block assembly:

Metal (brass, aluminum, stainless steel) or plastic (e.g. polyamide

PA 6 GV).

DANGER!

Danger of explosion!

• If devices are used in gasoline pumps to control gasoline as

Category 2, a valve body made of metal (brass, aluminum or stainless steel) must be used.

Minimum dimensions of the valve bodies:

• 40 mm x 40 mm x 10 mm (L x W x H)

A larger valve body with better heat conductivity may be attached

at any time.

8

english

Connection type Length

(mm)

Electrical

connection A

Electrical

connection L and K

106 40 58

121 60 113

Width

(mm)

Height

(mm)

5.5. Protection class

IP65 in accordance with EN 60529.

5.6. Individual assembly

The solenoid coils type 74. / 75. are suitable for individual assembly only.

5.7. Operating temperature range

For each type observe the operating temperature range specified in

the Electrical Data.

Page 9

PTB 02 ATEX 2173 X

Application conditions of the devices

5.8. Maximum permitted ambient

temperature

Please observe the maximum permitted ambient temperature indicated

for each type under application conditions of the coil!

Design Maximum permitted ambient

temperature

74. -40 ... +40 °C

75. -40 ... +50 °C

(-40 ... +55 °C when T3)

5.9. Application in petrol pumps

DANGER!

Risk of explosion by opening the device!

• The device is a closed system. It must not be removed!

Danger of explosion!

• If devices are used in gasoline pumps to control gasoline as

Category 2, a valve body made of metal (brass, aluminum or

stainless steel) must be used.

The devices may also be used to control gasoline in Category 2 if there

is no air and no oxygen in the closed system.

This also applies to starting and switching off the system.

Model with over-

stretched coil

The solenoid coils are mounted on the fitting using either 4 cylinder

head screws M4 x 58 (flange model) or a central attachment

M14 x 1.5 (overstretched model).

The solenoid coils may be removed by the manufacturer

only!

The valves always represent a closed system.

Block-screwed

model

english

9

Page 10

PTB 02 ATEX 2173 X

Technical Data

5.10. Model with a terminal box

DANGER!

Danger of explosion!

• Only specified cables and lines may be used.

• The operator must ensure an adequate strain relief.

• Lines with an outer diameter from 6 mm to 13 mm may be used.

Observe the maximum thermal load of the installed cables and lines.

• The inserted seal must be adjusted to the diameter of the cable /

line.

• The rated cross-section of the cables / line cores must be at least

0.75 mm² and must not exceed 2.5 mm².

• Screws for attaching the cover of the terminal box must be tightened to a torque of 100 Ncm (± 5 %).

The solenoid coils can be designed with a terminal box (optionally with /

without fuse) (fuse according to separate type-examination certificate).

The attachment of a terminal box changes the ignition protection type

of these solenoid coils.

Identification with attached terminal box:

II 2G EX em II T3, T4 or T5

The label on the cover:

Do not open unless isolated from power supply! is intended to

prevent the cover from being opened unintentionally.

6. TECHNICAL DATA

6.1. Conformity

The device conforms to the EC directives according to the EC

Declaration of Conformity.

6.2. Standards

The conformity with EC guidelines is guaranteed in accordance with

standards:

• EN 60079-0, EN 60079-7, EN 60079-18.

6.3. Licenses

The EC type-examination certificate PTB 02 ATEX 2173 X was

issued by the

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig (Germany)

which also audits production (CE 102).

The EC type-examination certificate can be found on the Internet at:

www.burkert.com

10

english

Page 11

PTB 02 ATEX 2173 X

Technical Data

6.4. Operating Conditions

WARNING!

Danger of explosion!

It is highly risky to exceed the technical data indicated on the

rating plate!

• Never exceed the technical data indicated on the rating plate.

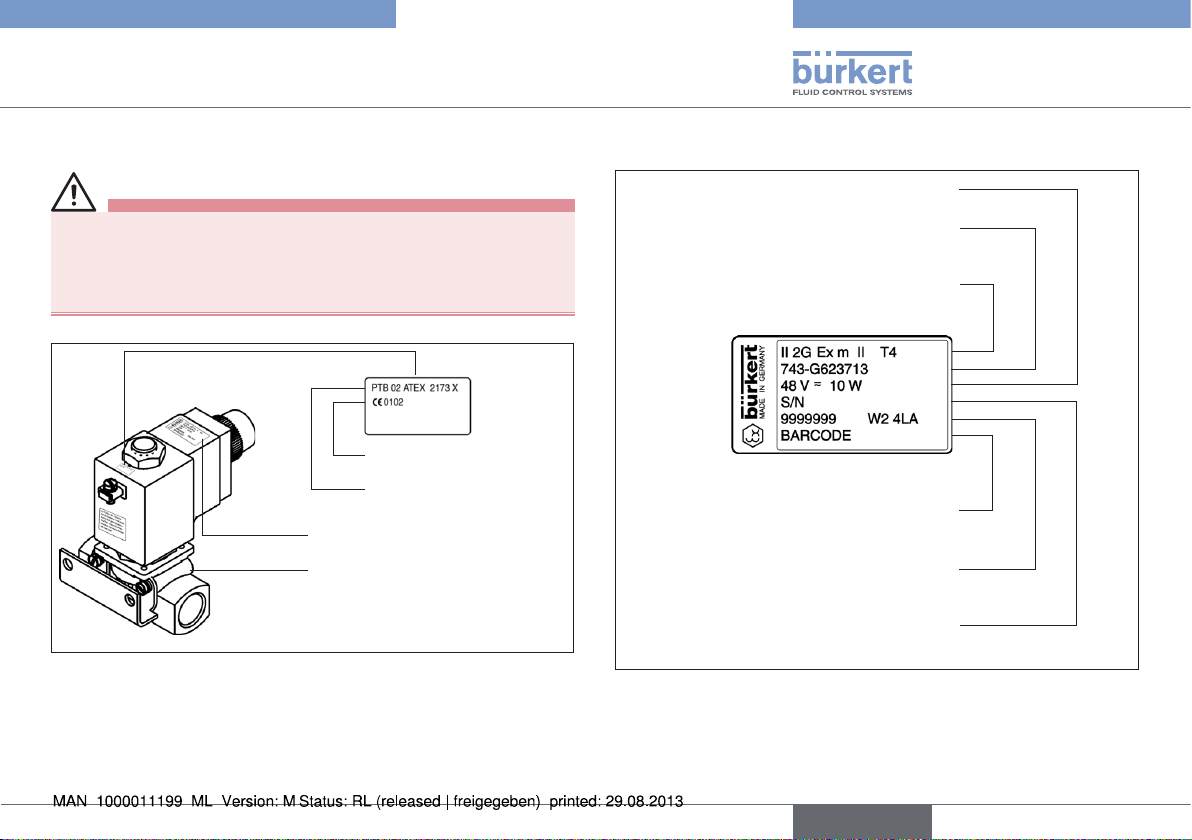

CE identification

PTB approval number

Rating plate

Fuse

... A

Fig. 1: Location of the rating plate

6.4.1. Rating plate

Voltage (± 10 %) - power

Coil type - connection size for fluid

part coil size

Protection class / temperature class

Place for barcode

Identification number of the coil

Serial number of the coil

Fig. 2: Description on the rating plate

english

11

Page 12

PTB 02 ATEX 2173 X

Technical Data

6.5. Electrical Data

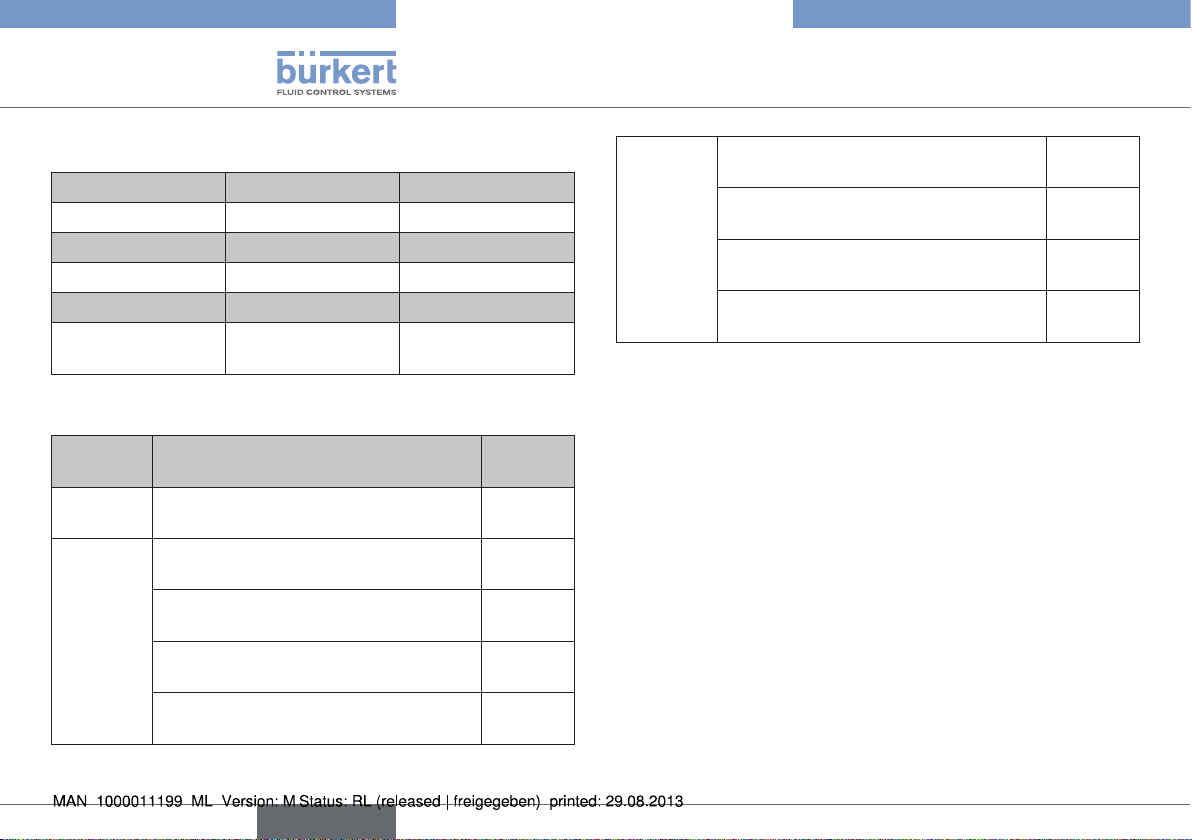

Type

Temperature class

Current type

Nominal voltage

Rated current

Power limit in

equilibrium

74. 75.

T4 T3 or T5

AC/DC AC/DC

12 ... 240 V 12 ... 240 V

1,00 ... 0,028 A 0,63 ... 0,028 A

10 W 7 W

6.6. Electrical connection

Identifi-

cation

A *

L

Permanently installed rubber hose line of

type H05 RN-F3G0,75

** Terminal box with cable gland

M20 x 1.5 without fuse

Terminal box with threaded nipple

M20 x 1.5 without fuse

Terminal box with threaded nipple

NPT 1/2 without fuse

Terminal box with threaded nipple G 1/2

without fuse

Design Internal

code

Not

specified

JA02

JA08

JA09

JA10

** Terminal box with cable gland

M20 x 1.5 and fuse

Terminal box with threaded nipple

K ***

* The connection line of the electromagnet type 7. must be permanently

installed in such a way that it is adequately protected from mechanical

damage.

** Cable gland according to separate type-examination certificate.

*** Fuse according to separate type-examination certificate.

M20 x 1.5 and fuse

Terminal box with threaded nipple

NPT 1/2 and fuse

Terminal box with threaded nipple G 1/2

and fuse

JA01

JA05

JA06

JA07

12

english

Page 13

PTB 02 ATEX 2173 X

Assembly

7. ASSEMBLY

7.1. Safety instructions

DANGER!

Danger of explosion!

The device is a closed system. It must not be removed.

The following safety instructions must be observed:

• The surface of the device may become electrostatically charged.

In potentially explosive areas the surface of the devices may be

cleaned with a damp or an anti-static cloth only.

• Only specified cables and lines may be used.

• The operator must ensure an adequate strain relief.

• Lines with an outer diameter of 6 mm - 13 mm can be used.

Observe the maximum thermal load of the installed cables and

lines.

• The inserted seal must be adjusted to the diameter of the cable

/ line.

The rated cross-section of the cables / line cores must be at

least 0.75 mm² and must not exceed 2.5 mm².

• Screws for attaching the cover of the terminal box must be

tightened to a torque of 100 Ncm (± 5 %).

DANGER!

Risk of electric shock!

Acute risk of injury from hazardous body voltage! Risk of damaging

the device by short-circuit!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

• Live terminals in the terminal box may cause an electric shock,

short-circuit or explosion. Switch off the power supply. Only then

open the terminal box.

• The connection lines of the electromagnets must be permanently

installed in such a way that they are adequately protected from

mechanical damage.

• Observe applicable accident prevention and safety regulations

for electrical equipment!

WARNING!

Danger – high pressure!

When reaching into the system, there is an acute risk of injury.

• Before dismounting pneumatic lines and valves, turn off the

pressure and vent the lines.

• During the installation, make certain the flow direction is correct.

• Observe applicable accident prevention and safety regulations

for pressurized devices.

english

13

Page 14

PTB 02 ATEX 2173 X

Start-Up

7.2. Installation of type 0742

Any installation position.

Preferably with magnet system face up.

1. Clean pipelines.

2. Any installation position

→ Preferential direction with actuator face up.

3. Connect dirt trap upstream

→ Observe direction of flow!

4. Seal

→ PTFE.

5. Screw in pipelines

→ Observe direction of flow!

6. Install / remove.

NOTE!

Information for devices with connecting cable:

Connecting cable and coil are encapsulated. They must not be

removed!

Always connect protective conductor!

7. Connect to power supply.

8. START-UP

8.1. Safety instructions

WARNING!

Risk of injury from improper operation!

Improper operation may result in injuries as well as damage to the

device and the area around it.

• Before start-up, ensure that the operating personnel are familiar

with and completely understand the contents of the operating

instructions.

• Observe the safety instructions and intended use.

• Only adequately trained personnel may start up the equipment/

the device.

8.2. Start-Up

Before starting up the device, ensure that:

• the device has been installed correctly,

• the connection has been made properly,

• the device is not damaged,

• all screws have been tightened.

14

english

Page 15

PTB 02 ATEX 2173 X

Maintenance, Troubleshooting

9. MAINTENANCE,

TROUBLESHOOTING

9.1. Safety instructions

WARNING!

Danger of explosion caused by electrostatic charge!

If there is a sudden discharge from electrostatically charged

devices or persons, there is a danger of explosion in the EX area.

• Using suitable measures, ensure that no electrostatic charges

can occur in the EX area.

• Clean the device surface by gently wiping it with a damp or antistatic cloth only.

Risk of injury from improper servicing, repairs and

maintenance!

• The device may be serviced and maintained by authorized technicians only and with the appropriate tools!

• The unit may be repaired by the manufacturer only!

• When repairing or servicing the system, the valve must not be

opened and the protective conductor connection must not be

disconnected!

9.2. Maintenance Work

The devices are maintenance-free when operated under the conditions described in this manual.

9.3. Troubleshooting

If malfunctions occur, ensure that:

• the device has been installed correctly,

• the connection has been made properly,

• the device is not damaged,

• all screws have been tightened,

• the voltage and pressure have been switched on,

• the pipelines are free.

english

15

Page 16

10. TRANSPORT, STORAGE,

DISPOSAL

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against wet and dirt in

shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage

temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: -40 … +55 °C.

Damage to the environment caused by device components

contaminated with media.

• Ensure the device and packaging are disposed of in an environmentally sound manner.

• Observe applicable regulations relating to refuse disposal and

the environment.

PTB 02 ATEX 2173 X

Transport, Storage, Disposal

16

english

Page 17

PTB 02 ATEX 2173 X

Inhaltsverzeichnis

1. DIE BEDIENUNGSANLEITUNG ............................................................ 18

1.1. Darstellungsmittel ...........................................................................18

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ...................................19

2.1. Beschränkungen ............................................................................19

2.2. EX Zulassung ..................................................................................19

3. GRUNDLEGENDE SICHERHEITSHINWEISE ................................. 20

4. ALLGEMEINE HINWEISE .......................................................................... 21

4.1. Kontaktadresse ...............................................................................21

4.2. Gewährleistung...............................................................................21

4.3. Informationen im Internet ..............................................................21

5. EINSATZBEDINGUNGEN DER GERÄTE........................................... 21

5.1. Kurzschlussschutz ..........................................................................21

5.2. Betrieb nur mit zugehörigem Ventil ............................................22

5.3. Zündschutzart .................................................................................22

5.4. Abmessungen .................................................................................22

5.5. Schutzart ..........................................................................................22

5.6. Einzelmontage .................................................................................22

5.7. Einsatztemperaturbereich .............................................................22

5.8. Maximal zulässiger Umgebungstemperatur .............................23

5.9. Einsatz in Tanksäulen.....................................................................23

5.10. Ausführung mit einem Klemmenkasten ...................................24

6. TECHNISCHE DATEN ................................................................................24

6.1. Konformität .......................................................................................24

6.2. Normen .............................................................................................24

6.3. Zulassungen ....................................................................................24

6.4. Betriebsbedingungen ....................................................................25

6.5. Elektrische Daten ...........................................................................26

6.6. Elektrischer Anschluss ..................................................................26

7. MONTAGE ........................................................................................................27

7.1. Sicherheitshinweise .......................................................................27

7.2. Montage des Typs 0742 ..............................................................28

8. INBETRIEBNAHME ...................................................................................... 28

8.1. Sicherheitshinweise .......................................................................28

8.2. Inbetriebnahme ...............................................................................28

9. WARTUNG, FEHLERBEHEBUNG .........................................................29

9.1. Sicherheitshinweise .......................................................................29

9.2. Wartungsarbeiten ...........................................................................29

9.3. Fehlerbehebung ..............................................................................29

10. TRANSPORT, LAGERUNG, VERPACKUNG .................................. 30

deutsch

17

Page 18

PTB 02 ATEX 2173 X

Die Bedienungsanleitung

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus

des Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für jeden

Benutzer gut zugänglich ist und jedem neuen Eigentümer des Gerätes

wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur

Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen Situationen

führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung drohen schwere Verletzungen oder Tod.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage beschädigt

werden.

Bezeichnet wichtige Zusatzinformationen, Tipps und

Empfehlungen.

Verweist auf Informationen in dieser Bedienungsanleitung

oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

18

deutsch

Page 19

PTB 02 ATEX 2173 X

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Gerätes Typ 0742

können Gefahren für Personen, Anlagen in der Umgebung und

die Umwelt entstehen.

• Das Gerät dient ausschließlich als Magnetventil für die laut Datenblatt zulässigen Medien und für den Einsatz in Explosionsgruppe

II, Kategorie 2G und Temperaturklasse T4 (T3 bei +55 °C) oder

T5 (siehe Angaben auf dem

• Das Gerät darf nur für die im Kapitel „5. Einsatzbedingungen

der Geräte“ vorgesehenen Einsatzfälle und in Verbindung mit

von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten und

-komponenten verwendet werden. Für den Einsatz die in den

Vertragsdokumenten und der Bedienungsanleitung spezifizierten

zulässigen Daten, Betriebs- und Einsatzbedingungen beachten.

• Die angewandte Schutzart ist die Vergusskapselung EX „m“ für

Spulen mit Kabelanschluss oder die Vergusskapselung mit erhöhter Sicherheit EX „em“ für Spulen mit Klemmenkasten.

• Der einwandfreie und sichere Betrieb des Systems setzt

sachgemäßen Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und Instandhaltung voraus.

Eine andere oder darüber hinausgehende Benutzung gilt als nicht

bestimmungsgemäß. Für hieraus resultierende Schäden haftet

Bürkert nicht. Das Risiko trägt allein der Anwender.

• Das Gerät nur bestimmungsgemäß einsetzen.

Zulassungsschild).

2.1. Beschränkungen

Bei der Ausfuhr des Systems/Gerätes gegebenenfalls bestehende

Beschränkungen beachten.

2.2. EX Zulassung

Die EX Zulassung ist nur gültig, wenn die von Bürkert zugelassenen

Module und Komponenten so verwendet werden, wie es in dieser

Bedienungsanleitung beschrieben ist.

Der Typ 0742 darf nur in Kombination mit den von Bürkert freigegebenen Zusatzkomponenten eingesetzt werden, andernfalls erlischt die

EX Zulassung!

Bei unzulässigen Veränderungen am Gerät, Modulen oder Komponenten, erlischt die EX Zulassung ebenfalls.

Temperaturklassen und elektrische Daten siehe Kapitel

„6. Technische Daten“.

deutsch

19

Page 20

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich ist.

Explosionsgefahr!

• Das Gerät ist Teil eines geschlossenen Systems und darf nicht

während des Betriebs demontiert werden.

Gefahr durch elektrische Spannung!

Akute Verletzungsgefahr durch gefährliche Körperspannung!

Gefahr der Beschädigung des Gerätes durch Kurzschluss!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung abschalten

und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

Gefahr durch hohen Druck!

Bei Eingriffen in das System besteht akute Verletzungsgefahr.

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten

und die Leitungen entlüften.

• Beim Einbau die Durchflussrichtung beachten.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für druckbeaufschlagte Geräte einhalten.

PTB 02 ATEX 2173 X

Grundlegende Sicherheitshinweise

Explosionsgefahr durch elektrostatische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im EX-Bereich Explosionsgefahr.

• Durch geeignete Maßnahmen sicherstellen, dass es im EX Bereich zu keinen elektrostatischen Aufladungen kommen kann.

• Die Geräteoberfläche nur durch leichtes Abwischen mit einem

feuchten oder antistatischen Tuch reinigen.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden kann.

• Installations- und Instandhaltungsarbeiten dürfen nur von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt

werden.

• Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf des

Prozesses zu gewährleisten.

• Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung

der Bedienungsanleitung betrieben werden.

• Für die Einsatzplanung und den Betrieb des Gerätes müssen die

allgemeinen Regeln der Technik eingehalten werden.

Bei Nichtbeachtung dieser Bedienungsanleitung und ihrer

Hinweise sowie bei unzulässigen Eingriffen in das Gerät entfällt

jegliche Haftung unsererseits, ebenso erlischt die Gewährleistung auf Geräte und Zubehörteile!

20

deutsch

Page 21

PTB 02 ATEX 2173 X

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Kontaktadresse

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der gedruckten

Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der spezifizierten

Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 0742 finden Sie im

Internet unter: www.buerkert.de

5. EINSATZBEDINGUNGEN DER

GERÄTE

5.1. Kurzschlussschutz

Jedem Magneten muss als Kurzschlussschutz eine seinem Bemessungsstrom entsprechende Sicherung (max. 3 x Ib nach IEC 601272-1) bzw. ein Motorschutzschalter mit Kurzschluss- und thermischer

Schnellauslösung (Einstellung auf Bemessungsstrom) vorgeschaltet

werden. Bei sehr kleinen Bemessungsströmen des Magneten ist die

Sicherung mit dem kleinsten Stromwert nach der genannten IEC-Norm

ausreichend. Diese Sicherung darf im zugehörigen Versorgungsgerät

untergebracht sein oder muss separat vorgeschaltet werden. Die

Sicherungs-Bemessungsspannung muss gleich oder größer als die

angegebene Nennspannung des Magneten sein. Das Ausschaltvermögen des Sicherungseinsatzes muss gleich oder größer als der

maximal anzunehmende Kurzschlussstrom am Einbauort (üblicherweise

1500 A) sein.

Bei der Ausführung A und L des Elektromagneten muss der Kurzschlussschutz durch den Betreiber gewährleistet werden. Bei Ausführung K des Elektromagneten ist die Sicherung im Klemmenkasten

des Gerätes eingebaut.

Nähere Beschreibung der Ausführungen A, L und K siehe

Kapitel „6. Technische Daten“.

deutsch

21

Page 22

Sicherung / Fuse

...A

5.2. Betrieb nur mit zugehörigem

Ventil

Die Magnetspulen Typ 74. / 75. dürfen nur mit zugehörigem Ventilkörper als Komplettgerät betrieben werden, der folgenden Forderungen

entspricht:

• Werkstoffe bei Einzel- und Blockmontage:

Metall (Messing, Aluminium, Edelstahl) oder Kunststoff (z. B.

Polyamid PA 6 GV).

GEFAHR!

Explosionsgefahr!

• Bei Einsatz der Geräte in Tanksäulen zur Steuerung von Benzin als

Kategorie 2 muss ein Ventilkörper aus Metall (Messing, Aluminium

oder Edelstahl) verwendet werden.

Mindestbemessungen der Ventilkörper:

• 40 mm x 40 mm x 10 mm (L x B x H)

Ein größerer Ventilkörper mit besserer Wärmeleitfähigkeit darf

jeder Zeit angebaut werden.

PTB 02 ATEX 2173 X

Einsatzbedingungen der Geräte

5.3. Zündschutzart

• Bei Ausführung mit eingebauter Gummischlauchleitung (A):

EX m II T4 (T3 bei +55 °C) bzw. T5 nach EN 60079-0,

EN 60079-18.

• Bei Ausführung mit Klemmenkasten (L und K): EX em II T4

(T3 bei +55 °C) bzw. T5 nach EN 60079-0, EN 60079-7 und

EN 60079-18.

5.4. Abmessungen

Anschlussart Länge

Elektrischer

Anschluss A

Elektrischer

Anschluss L und K

(mm)

106 40 58

121 60 113

Breite

(mm)

Höhe

(mm)

5.5. Schutzart

IP65 nach EN 60529.

5.6. Einzelmontage

Die Magnetspulen Typ 74. / 75. sind nur zur Einzelmontage geeignet.

5.7. Einsatztemperaturbereich

Für jeden Typ den bei den Elektrischen Daten aufgeführten Einsatztemperaturbereich beachten.

22

deutsch

Page 23

PTB 02 ATEX 2173 X

Einsatzbedingungen der Geräte

5.8. Maximal zulässiger

Umgebungstemperatur

Bitte beachten Sie für jeden Typ den unter Einsatzbedingungen der

Spule angegeben, maximal zulässigen Umgebungstemperatur!

Ausführung Maximal zulässiger

Umgebungstemperatur

74. -40 ... +40 °C

75. -40 ... +50 °C

(-40 ... +55 °C, wenn T3)

5.9. Einsatz in Tanksäulen

GEFAHR!

Explosionsgefahr durch Öffnen des Gerätes!

• Das Gerät ist ein geschlossenes System. Es darf nicht demontiert

werden!

Explosionsgefahr!

• Bei Einsatz der Geräte in Tanksäulen zur Steuerung von Benzin als

Kategorie 2 muss ein Ventilkörper aus Metall (Messing, Aluminium

oder Edelstahl) verwendet werden.

Die Geräte dürfen auch zur Steuerung von Benzin in Kategorie 2 eingesetzt werden, wenn in dem geschlossenen System keine Luft und

kein Sauerstoff vorhanden ist.

Dies gilt auch beim Anfahren und Abschalten des Systems.

Ausführung mit

übergestreckter

Spule

Die Magnetspulen werden entweder mit 4 Zylinderschrauben

M4 x 58 (Flanschausführung) oder Zentralbefestigung M14 x 1,5

(Übersteckausführung) auf die Armatur montiert.

Die Magnetspulen dürfen nur vom Hersteller demontiert

werden!

Die Ventile stellen immer ein geschlossenes System dar.

Blockverschraubte

Ausführung

deutsch

23

Page 24

PTB 02 ATEX 2173 X

Technische Daten

5.10. Ausführung mit einem

Klemmenkasten

GEFAHR!

Explosionsgefahr!

• Nur festgelegte Kabel und Leitungen dürfen eingeführt werden.

• Betreiber muss eine entsprechende Zugentlastung gewährleisten.

• Es können Leitungen mit Außendurchmesser von 6 mm bis 13 mm

verwendet werden. Die maximale thermische Belastung der eingeführten Kabel bzw. Leitungen beachten.

• Die eingelegte Dichtung muss dem Durchmesser des Kabels /

der Leitung angepasst werden.

• Der Bemessungsquerschnitt der Kabel / Leitungsadern muss mindestens 0,75 mm² betragen und darf 2,5 mm² nicht überschreiten.

• Schrauben zur Befestigung des Deckels des Klemmenkastens

müssen mit einem Drehmoment von 100 Ncm (± 5 %) angezogen

werden.

Die Magnetspulen können mit einem Klemmenkasten (wahlweise mit /

ohne Sicherung) ausgeführt werden (Sicherung nach getrennter Baumusterprüfbescheinigung). Durch den Anbau eines Klemmenkastens

ändert sich die Zündschutzart dieser Magnetspulen.

Kennzeichnung mit angebautem Klemmenkasten:

II 2G EX em II T3, T4 oder T5

Als Schutz gegen unbeabsichtiges Öffnen des Deckels trägt dieser

die Aufschrift:

Nur spannungsfrei öffnen!

6. TECHNISCHE DATEN

6.1. Konformität

Das Gerät ist konform zu den EG-Richtlinien entsprechend der

EG-Konformitätserklärung.

6.2. Normen

Durch folgende Normen wird die Konformität mit den EG-Richtlinien

erfüllt:

• EN 60079-0, EN 60079-7, EN 60079-18.

6.3. Zulassungen

Die EG-Baumusterprüfbescheinigung PTB 02 ATEX 2173 X wurde

von der

PTB (Physikalisch Technische Bundesanstalt)

Bundesallee 100

38116 Braunschweig

ausgestellt, die auch die Fertigung auditiert (CE 102).

Die EG-Baumusterprüfbescheinigung finden Sie im Internet unter:

www.buerkert.de

24

deutsch

Page 25

PTB 02 ATEX 2173 X

Technische Daten

6.4. Betriebsbedingungen

WARNUNG!

Explosionsgefahr!

Überschreitung der auf dem Typenschild angegebenen technischen

Daten führt zu hohem Risiko!

• Auf dem Typenschild angegebenen technischen Daten keinesfalls überschreiten.

CE - Kennzeichnung

PTB - Zulassungsnummer

Typenschild

Sicherung / Fuse

... A

Bild 1: Lage des Typenschildes

6.4.1. Typenschild

Spannung (± 10 %) - Leistung

Spulentyp - Anschlussgröße für

Fluidteil - Spulengröße

Schutzart / Temperaturklasse

Platz für Barcode

Identnummer der Spule

Seriennummer der Spule

Bild 2: Beschreibung des Typenschildes

deutsch

25

Page 26

PTB 02 ATEX 2173 X

Technische Daten

6.5. Elektrische Daten

Typ

Temperaturklasse

Stromart

Nennspannung

Bemessungsstrom

Grenzleistung im

Beharrungszustand

74. 75.

T4 T3 oder T5

AC/DC AC/DC

12 ... 240 V 12 ... 240 V

1,00 ... 0,028 A 0,63 ... 0,028 A

10 W 7 W

6.6. Elektrischer Anschluss

Kenn-

zeichnung

A *

L

Fest eingebaute Gummischlauchleitung

des Typs H05 RN-F3G0,75

** Klemmenkasten mit Kabelverschraubung M20 x 1,5 ohne Sicherung

Klemmenkasten mit Gewindenippel M20 x

1,5 ohne Sicherung

Klemmenkasten mit Gewindenippel NPT

1/2 ohne Sicherung

Klemmenkasten mit Gewindenippel G 1/2

ohne Sicherung

Ausführung Interner

Code

ohne

Angabe

JA02

JA08

JA09

JA10

** Klemenkasten mit Kabelverschraubung

M20 x 1,5 und Sicherung

Klemmenkasten mit Gewindenippel M20 x

K ***

* Die Anschlussleitung des Elektromagneten Typ 7. muss fest und so verlegt

werden, dass sie vor mechanischen Beschädigungen hinreichend geschützt

ist.

** Kabelverschraubung nach getrennter Baumusterprüfbescheinigung.

*** Sicherung nach getrennter Baumusterprüfbescheinigung.

1,5 und Sicherung

Klemmenkasten mit Gewindenippel NPT

1/2 und Sicherung

Klemmenkasten mit Gewindenippel G 1/2

und Sicherung

JA01

JA05

JA06

JA07

26

deutsch

Page 27

PTB 02 ATEX 2173 X

Montage

7. MONTAGE

7.1. Sicherheitshinweise

GEFAHR!

Explosionsgefahr!

Das Gerät ist ein geschlossenes System. Es darf nicht demontiert

werden.

Folgende Sicherheitshinweise sind einzuhalten:

• Die Oberfläche des Gerätes kann sich elektrostatisch aufladen. In

explosionsgefährdeten Bereichen darf die Oberfläche der Geräte

nur mit einem feuchten oder antistatischen Tuch gereinigt werden.

• Nur festgelegte Kabel und Leitungen dürfen eingeführt werden.

• Betreiber muss eine entsprechende Zugentlastung gewährleisten.

• Leitungen mit Außendurchmesser von 6 mm ... 13 mm können

verwendet werden. Die maximale thermische Belastung der eingeführten Kabel bzw. Leitungen beachten.

• Die eingelegte Dichtung muss dem Durchmesser des Kabels /

der Leitung angepasst werden.

Der Bemessungsquerschnitt der Kabel / Leitungsadern

muss mindestens 0,75 mm² betragen und darf 2,5 mm² nicht

überschreiten.

• Die Schrauben zur Befestigung des Deckels des Klemmenkastens

müssen mit einem Drehmoment von 100 Ncm (± 5 %) angezogen

werden.

GEFAHR!

Gefahr durch elektrische Spannung!

Akute Verletzungsgefahr durch gefährliche Körperspannung!

Gefahr der Beschädigung des Gerätes durch Kurzschluss!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung abschalten

und vor Wiedereinschalten sichern!

• Spannungsführende Klemmen im Klemmenkasten können Stromschlag, Kurzschluss oder Explosion verursachen. Spannung

abschalten. Erst dann den Klemmenkasten öffnen.

• Die Anschlussleitungen der Elektromagneten müssen fest und

so verlegt werden, dass sie vor mechanischen Beschädigungen

hinreichend geschützt sind.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für elektrische Geräte beachten!

WARNUNG!

Gefahr durch hohen Druck!

Bei Eingriffen in das System besteht akute Verletzungsgefahr.

• Vor dem Lösen von Leitungen und Ventilen den Druck abschalten und die Leitungen entlüften.

• Beim Einbau die Durchflussrichtung beachten.

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen

für druckbeaufschlagte Geräte einhalten.

deutsch

27

Page 28

PTB 02 ATEX 2173 X

Inbetriebnahme

7.2. Montage des Typs 0742

Einbaulage beliebig.

Vorzugsweise mit Magnetsystem oben.

1. Rohrleitungen reinigen.

2. Einbaulage beliebig

→ Vorzugsrichtung mit Antrieb oben.

3. Schmutzfänger vorschalten

→ Durchflussrichtung beachten!

4. Abdichtung

→ PTFE.

5. Rohrleitungen einschrauben

→ Durchflussrichtung beachten!

6. Montieren / Demontieren.

HINWEIS!

Hinweis für Geräte mit Anschlusskabel:

Anschlusskabel und Spule sind vergossen. Sie dürfen nicht

demontiert werden!

Schutzleiter immer anschließen!

7. Elektrisch anschließen.

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

WARNUNG!

Verletzungsgefahr bei unsachgemäßem Betrieb!

Nicht sachgemäßer Betrieb kann zu Verletzungen, sowie Schäden

am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass der Inhalt

der Bedienungsanleitung dem Bedienungspersonal bekannt ist

und vollständig verstanden wurde.

• Die Sicherheitshinweise und die bestimmungsgemäße Verwendung müssen beachtet werden.

• Nur ausreichend geschultes Personal darf die Anlage/das Gerät

in Betrieb nehmen.

8.2. Inbetriebnahme

Vor Inbetriebnahme sicherstellen, dass:

• das Gerät vorschriftsmäßig installiert wurde,

• der Anschluss ordnungsgemäß ausgeführt wurde,

• das Gerät nicht beschädigt ist,

• alle Schrauben fest angezogen sind.

28

deutsch

Page 29

PTB 02 ATEX 2173 X

Wartung, Fehlerbehebung

9. WARTUNG,

FEHLERBEHEBUNG

9.1. Sicherheitshinweise

WARNUNG!

Explosionsgefahr durch elektrostatische Aufladung!

Bei plötzlicher Entladung elektrostatisch aufgeladener Geräte oder

Personen besteht im EX-Bereich Explosionsgefahr.

• Durch geeignete Maßnahmen sicherstellen, dass es im EXBereich zu keinen elektrostatischen Aufladungen kommen kann.

• Die Geräteoberfläche nur durch leichtes Abwischen mit einem

feuchten oder antistatischen Tuch reinigen.

Verletzungsgefahr bei unsachgemäßen Wartungs-, Reparatur

und Instandhaltungsarbeiten!

• Die Wartungs- und Instandhaltungsarbeiten am Gerät dürfen nur

autorisiertes Fachpersonal mit geeignetem Werkzeug durchführen!

• Reparaturen am Gerät dürfen nur vom Hersteller durchgeführt

werden!

• Bei Repatatur- oder Wartungsarbeiten an der Anlage darf das

Ventil nicht geöffnet und die Schutzleiterverbindung nicht getrennt

werden!

9.2. Wartungsarbeiten

Die Geräte sind beim Betrieb unter den in dieser Anleitung beschriebenen Bedingungen wartungsfrei.

9.3. Fehlerbehebung

Bei Störungen sicherstellen, dass:

• das Gerät vorschriftsmäßig installiert wurde,

• der Anschluss ordnungsgemäß ausgeführt wurde,

• das Gerät nicht beschädigt ist,

• alle Schrauben fest angezogen sind,

• Spannung und Druck anliegen,

• die Rohrleitungen frei sind.

deutsch

29

Page 30

10. TRANSPORT, LAGERUNG,

VERPACKUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den Transport

beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten

Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -40 … +55 °C.

Umweltschäden durch von Medien kontaminierte Geräteteile.

• Gerät und Verpackung umweltgerecht entsorgen!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen

einhalten.

PTB 02 ATEX 2173 X

Transport, Lagerung, Verpackung

30

deutsch

Page 31

PTB 02 ATEX 2173 X

Table des matières

1. LES INSTRUCTIONS DE SERVICE .....................................................32

1.1. Symboles..........................................................................................32

2. UTILISATION CONFORME.......................................................................33

2.1. Limitations ........................................................................................33

2.2. Homologation EX ...........................................................................33

3. CONSIGNES DE SÉCURITÉ FONDAMENTALES .........................34

4. INDICATIONS GÉNÉRALES .................................................................... 35

4.1. Adresses ..........................................................................................35

4.2. Garantie légale ................................................................................35

4.3. Informations sur Internet ...............................................................35

5. CONDITIONS D’UTILISATION DE L’APPAREIL ............................. 35

5.1. Protection contre les courts-circuits .........................................35

5.2. Exploitation avec vanne correspondante ..................................36

5.3. Type de protection à l’allumage ..................................................36

5.4. Dimensions ......................................................................................36

5.5. Type de protection .........................................................................36

5.6. Montage individuel .........................................................................36

5.7. Plage de température d’utilisation ..............................................36

5.8. Température ambiante maximale autorisée ..............................37

5.9. Utilisation dans les pompes à essence .....................................37

5.10. Modèle avec coffret à bornes ...................................................38

6. CARACTÉRISTIQUES TECHNIQUES ................................................ 38

6.1. Conformité .......................................................................................38

6.2. Normes .............................................................................................38

6.3. Homologations ................................................................................38

6.4. Conditions d’exploitation ..............................................................39

6.5. Caractéristiques électriques ........................................................40

6.6. Raccordement électrique .............................................................40

7. MONTAGE ........................................................................................................41

7.1. Consignes de sécurité ..................................................................41

7.2. Montage du type 0742 .................................................................42

8. MISE EN SERVICE ....................................................................................... 42

8.1. Consignes de sécurité ..................................................................42

8.2. Mise en service ...............................................................................42

9. MAINTENANCE, DÉPANNAGE .............................................................. 43

9.1. Consignes de sécurité ..................................................................43

9.2. Travaux d’entretien .........................................................................43

9.3. Dépannage ......................................................................................43

10. TRANSPORT, STOCKAGE, ÉLIMINATION .....................................44

français

31

Page 32

PTB 02 ATEX 2173 X

Les instructions de service

1. LES INSTRUCTIONS DE

SERVICE

Les instructions de service décrivent le cycle de vie complet de l’appareil. Conservez ces instructions de sorte qu’elles soient accessibles

à tout utilisateur et à disposition de tout nouveau propriétaire.

Les instructions de service contiennent des informations

importantes sur la sécurité !

Le non-respect de ces consignes peut entraîner des situations

dangereuses.

• Les instructions de service doivent être lues et comprises.

1.1. Symboles

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement dangereuse !

• Risque de blessures graves, voire la mort en cas de non-respect.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou de

moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

• L’appareil ou l’installation peut être endommagé(e) en cas de

non-respect.

Désigne des informations supplémentaires importantes, des

conseils et des recommandations d’importance.

Renvoie à des informations dans ces instructions de service

ou dans d’autres documentations.

→ identifie une opération que vous devez effectuer.

32

français

Page 33

PTB 02 ATEX 2173 X

Utilisation conforme

2. UTILISATION CONFORME

L’utilisation non conforme de l’appareil du type 0742 peut présenter des dangers pour les personnes, les installations proches

et l’environnement.

• L’appareil sert exclusivement d’électrovanne pour les fluides autorisés par la fiche technique et pour l’utilisation dans les groupes

d’explosion II, catégorie 2G et classe de température T4 (T3 dans

+55 °C) ou T5 (voir les données sur la

• L’appareil peut être employé uniquement pour les cas individuels

prévus dans le chapitre « 5. Conditions d’utilisation de l’appareil »

et en association avec les appareils et composants étrangers

recommandés et homologués par Bürkert. Lors de l’utilisation,

il convient de respecter les données et conditions d’utilisation

et d’exploitation admissibles spécifiées dans les instructions de

service et dans les documents contractuels.

• Le type de protection employé est l’encapsulage EX « m » pour

bobines avec raccordement câble ou l’encapsulage avec sécurité

augmentée EX « m » pour bobines avec coffret à bornes.

• L’exploitation impeccable et sûre du système suppose un transport

conforme, un stockage et une installation conformes ainsi qu’une

utilisation et une maintenance soigneuses. Toute autre utilisation

est considérée comme non conforme. Bürkert n’est pas responsable des dommages en résultant. L’utilisateur est seul à en

supporter le risque.

• L’appareil doit être utilisé seulement de façon conforme.

plaque d’homologation).

2.1. Limitations

Lors de l’exportation du système / de l’appareil, veuillez respecter les

limitations éventuelles existantes.

2.2. Homologation EX

L’homologation EX n’est valable que si vous utilisez les modules et

composants homologués par Bürkert tel que cela est décrit dans ces

instructions de service.

Le type 0742 ne doit être utilisé qu’avec les composants supplémentaires autorisés par Bürkert, sinon l’homologation EX devient caduque.

En cas de modification non autorisée de l’appareil, des modules ou des

composants, l’homologation EX devient également caduque.

Classes de températures et données électriques, voir le

chapitre « 6. Caractéristiques techniques ».

français

33

Page 34

3. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte

• Des hasards et des événements pouvant survenir lors du montage,

de l’exploitation et de l’entretien des appareils.

• Des prescriptions de sécurité locales que l’exploitant est tenu de

faire respecter par le personnel chargé du montage.

Risque d’explosion !

• L’appareil fait partie d’un système clos et ne peut pas être démonté

pendant l’exploitation.

Danger présenté par la tension électrique !

Danger important de blessures par tensions dangereuses au niveau

du corps ! Danger d’endommagement de l’appareil par court-circuit !

• Avant d’intervenir dans l’appareil ou l’installation, couper la tension

et empêcher toute remise sous tension par inadvertance !

• Veuillez respecter les réglementations en vigueur pour les appareils

électriques en matière de prévention des accidents ainsi qu’en

matière de sécurité !

Danger dû à la haute pression !

Il y a risque important de blessures lors d’interventions sur le système.

• Avant de desserrer les conduites et les vannes, coupez la pression

et assurez l’échappement de l’air des conduites.

• Lors du montage, respectez le sens du débit.

• Veuillez respecter les réglementations en vigueur pour les appareils

sous pression en matière de prévention des accidents ainsi qu’en

matière de sécurité.

PTB 02 ATEX 2173 X

Consignes de sécurité fondamentales

Risque d’explosion dû à la charge électrostatique !

Il y a risque d’explosion en cas de décharge soudaine d’appareils

ou de personnes chargés d’électricité statique dans des zones

présentant des risques d’explosion.

• Assurez-vous par des mesures appropriées, qu’il ne peut y avoir

de charges électrostatiques dans de telles zones présentant

des risques d’explosion.

• Ne nettoyer la surface de l’appareil que par un essuyage léger

avec un chiffon humide ou antistatique.

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respecter ce qui suit :

• L’installation ne peut pas être actionnée par inadvertance.

• Les travaux d’installation et de maintenance doivent être effectués

uniquement par des techniciens qualifiés et habilités disposant de

l’outillage approprié.

• Après une interruption de l’alimentation électrique ou pneumatique,

un redémarrage défini ou contrôlé du processus doit être garanti.

• L’appareil doit être utilisé uniquement en parfait état et en respectant les instructions de service.

• Les règles générales de la technique sont d’application pour planifier

l’utilisation et utiliser l’appareil.

Le non-respect de ces instructions de service avec ses

consignes ainsi que les interventions non autorisées sur l’appareil

excluent toute responsabilité de notre part et entraînent la nullité

de la garantie légale concernant les appareils et les accessoires !

34

français

Page 35

PTB 02 ATEX 2173 X

Indications générales

4. INDICATIONS GÉNÉRALES

4.1. Adresses

Allemagne

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail : info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages des instructions de

service imprimées.

Egalement sur internet sous : www.burkert.com

4.2. Garantie légale

La condition pour bénéficier de la garantie légale est l’utilisation

conforme de l’appareil dans le respect des conditions d’utilisation

spécifiées.

4.3. Informations sur Internet

Vous trouverez les instructions de service et les fiches techniques

concernant le type 0742 sur Internet sous www.buerkert.fr

5. CONDITIONS D’UTILISATION

DE L’APPAREIL

5.1. Protection contre les

courts-circuits

Pour assurer la protection contre les courts-circuits, il convient de

placer en amont de chaque aimant un fusible correspondant à son

courant évalué (maxi 3 x Ib selon CEI 60127-2-1) ou un disjoncteur-protecteur à déclenchement rapide thermique et de court-circuit (réglage

sur le courant évalué). Selon la norme CEI citée, le fusible à la valeur

de courant le plus faible suffit lorsque les courants mesurés de l’aimant

sont très faibles. Ce fusible peut être logé dans l’appareil d’alimentation

correspondant ou placé séparément en amont. La tension mesurée du

fusible doit être identique ou supérieure à la tension nominale indiquée

de l’aimant. La puissance de coupure du fusible doit être identique ou

supérieure au courant de court-circuit maximal possible sur le lieu de

montage (habituellement 1500 A).

Avec les modèles d’électro-aimants A et L, la protection court-circuit

doit être garantie par l’exploitant. Avec le modèle d’électro-aimant K,

la sécurité est montée dans le coffret à bornes de l’appareil.

Pour une description plus complète des modèles A, L et K,

voir le chapitre « 6. Caractéristiques techniques ».

français

35

Page 36

Sécurité / Fusible

...A

PTB 02 ATEX 2173 X

Conditions d’utilisation de l’appareil

5.3. Type de protection à l’allumage

• Avec les modèles avec flexible en caoutchouc (A) : EX m II T4 (T3

dans +55 °C) ou T5 selon EN 60079-0, EN 60079-18.

• Avec les modèles avec coffret à bornes (L et K) : EX em II T4 (T3

dans +55 °C) ou T5 selon EN 60079-0, EN 60079-7 et

EN 60079-18.

5.4. Dimensions

5.2. Exploitation avec vanne

correspondante

Les bobines magnétiques de type 74. / 75. ne doivent être exploitées

comme appareil complet qu’avec le corps de vanne adapté, qui remplit

les exigences suivantes :

• Matériaux en montage unique ou en bloc :

Métal (laiton, aluminium, inox) ou plastique (par ex. Polyamide PA

6 GV).

DANGER !

Risque d’explosion !

• Lors de l’utilisation des appareils dans des pompes à essence

pour la commande d’essence de catégorie 2, un corps de vanne

en métal (laiton, aluminium, inox) doit être employé.

Dimensionnements du corps de vanne :

• 40 mm x 40 mm x 10 mm (L x l x h)

Il est possible d’utiliser à tout moment un corps de soupape plus

grand avec une meilleure conductibilité thermique.

36

Type de

raccordement

Raccordement

électrique A

Raccordements

électriques L et K

Longueur

(mm)

106 40 58

121 60 113

Largeur

(mm)

Hauteur

(mm)

5.5. Type de protection

IP65 selon EN 60529.

5.6. Montage individuel

Seules les bobines magnétiques de type 74. / 75. sont adaptées au

montage individuel.

5.7. Plage de température d’utilisation

Respecter la plage de température d’utilisation indiquée dans les

données électriques pour chaque type.

français

Page 37

PTB 02 ATEX 2173 X

Conditions d’utilisation de l’appareil

5.8. Température ambiante maximale

autorisée

Veuillez respecter la température maximale ambiante autorisée pour

chaque type donné de conditions d’utilisation de la bobine !

Version Température ambiante maximale

autorisée

74. -40 ... +40 °C

75. -40 ... +50 °C

(-40 ... +55 °C lorsque T3)

5.9. Utilisation dans les pompes à

essence

DANGER !

Danger d’explosion en ouvrant l’appareil !

• L’appareil est un système clos. Il ne doit pas être démonté !

Risque d’explosion !

• Lors de l’utilisation des appareils dans des pompes à essence

pour la commande d’essence de catégorie 2, un corps de vanne

en métal (laiton, aluminium, inox) doit être employé.

Les appareils doivent être également utilisés pour la commande

d’essence de catégorie 2 quand aucun air ou oxygène n’est présent

dans le système clos.

Cela est également valable lors du démarrage ou de l’arrêt du

système.

Modèle avec

bobine en

hyperextension

Les bobines magnétiques sont montées soit avec 4 vis à tête cylindrique

M4 x 58 (modèle à bride) ou fixation centrale M14 x 1,5 (modèle en

hyperextension) sur la robinetterie.

Les bobines magnétiques ne doivent être démontées que

par le constructeur !

Les vannes représentent toujours un système clos.

Modèle en bloc

vissé

français

37

Page 38

PTB 02 ATEX 2173 X

Caractéristiques techniques

5.10. Modèle avec coffret à bornes

DANGER !

Risque d’explosion !

• Seuls des câbles et des conduites fixés doivent être installés.

• L’exploitant doit garantir une décharge de traction correspondante.

• Des conduites avec diamètre extérieur de 6 mm à 13 mm peuvent

être utilisées. Respecter la contrainte thermique maximale du câble

ou de la conduite utilisée.

• Le joint inséré doit être adapté au diamètre du câble / de la

conduite utilisés.

• La section de base pour le calcul de l’âme du câble / de la conduite

doit être de 0,75 mm² minimum et ne doit pas dépasser 2,5 mm².

• Les vis pour la fixation du couvercle du coffret à bornes doivent

être serrées avec un couple de serrage de 100 Ncm (± 5 %).

Les bobines magnétiques peuvent être effectuées avec un coffret à

bornes (au choix avec / sans fusible) (sécurité selon certificat d’essai

de modèle séparé). Du fait du montage d’un coffret à bornes, le type

de protection à l’allumage de ces bobines magnétiques est modifié.

Désignation avec coffret à bornes monté :

II 2G EX em II T3, T4 ou T5

Comme protection contre une ouverture involontaire du couvercle,

celui-ci porte la mention :

N’ouvrir que hors tension !

6. CARACTÉRISTIQUES

TECHNIQUES

6.1. Conformité

L’appareil est conforme aux directives CE conformément à la déclaration

de conformité CE.

6.2. Normes

La conformité avec les directives CE est satisfaite par les normes

suivantes :

• EN 60079-0, EN 60079-7, EN 60079-18.

6.3. Homologations

Le certificat d’essai de modèle type PTB 02 ATEX 2173 X a été

établi par le

PTB (office fédéral physico-technique)

Bundesallee 100

38116 Braunschweig

qui effectue également l’audit de production (CE 102).

Le certificat d’essai de modèle CE se trouve sur Internet sous :

www.buerkert.fr

38

français

Page 39

PTB 02 ATEX 2173 X

Caractéristiques techniques

6.4. Conditions d’exploitation

AVERTISSEMENT !

Risque d’explosion !

Un dépassement des données techniques données sur la plaque

signalétique entraîne un risque élevé !

• Ne dépasser en aucun cas les données techniques données sur

la plaque signalétique.

Label CE

N° d’homologation PTB

Plaque signalétique

Sécurité / Fusible

... A

Fig. 1 : Position de la plaque signalétique

6.4.1. Plaque signalétique

Tension (± 10 %) - Puissance

Type de bobine - grandeur de raccor-

dement pour partie fluide - taille de bobine

Type de protection / classe de température

Emplacement pour code-barres

Numéro d’identification de la bobine

Numéro de série de la bobine

Fig. 2 : Description de la plaque signalétique

français

39

Page 40

PTB 02 ATEX 2173 X

Caractéristiques techniques

6.5. Caractéristiques électriques

Type

Classe de

température

Type de courant

Tension nominale

Courant évalué

Puissance limite

en état stable

74. 75.

T4 T3 ou T5

AC/DC AC/DC

12 ... 240 V 12 ... 240 V

1,00 ... 0,028 A 0,63 ... 0,028 A

10 W 7 W

6.6. Raccordement électrique

Identi-

fication

A *

L

Flexible en caoutchouc monté fixé du

type H05 RN-F3G0,75

** Coffret à bornes avec passe-câble à

vis M20 x 1,5 sans fusible

Coffret à bornes avec raccord à vis

M20 x 1,5 sans fusible

Coffret à bornes avec raccord à vis

NPT 1/2 sans fusible

Coffret à bornes avec raccord à vis

G 1/2 sans fusible

Version Code

interne

sans

indication

JA02

JA08

JA09

JA10

** Coffret à bornes avec passe-câble à

vis M20 x 1,5 et fusible

Coffret à bornes avec raccord à vis

K ***

* Le câble de raccordement de l’électro-aimant de type 7. doit être disposé fixé

et de telle façon qu’il soit suffisamment protégé des dommages mécaniques.

** Passe-câble à vis selon le certificat d’essai de modèle séparé.

*** Sécurité selon le certificat d’essai de modèle séparé.

M20 x 1,5 et fusible

Coffret à bornes avec raccord à vis

NPT 1/2 et fusible

Coffret à bornes avec raccord à vis

G 1/2 et fusible

JA01

JA05

JA06

JA07

40

français

Page 41

PTB 02 ATEX 2173 X

Montage

7. MONTAGE

7.1. Consignes de sécurité

DANGER !

Risque d’explosion !

L’appareil est un système clos. Il ne doit pas être démonté.

Les indications de sécurité suivantes doivent être respectées :

• La surface de l’appareil peut se charger d’électricité statique.

Dans les zones présentant des risques d’explosion, la surface

de l’appareil ne doit être nettoyée qu’avec un chiffon humide ou

antistatique.

• Seuls des câbles et des conduites fixés doivent être installés.

• L’exploitant doit garantir une décharge de traction correspondante.

• Seules les conduites avec un diamètre extérieur de 6 mm ... 13 mm

peuvent être utilisées. Respecter la contrainte thermique maximale

du câble ou de la conduite utilisée.

• Le joint inséré doit être adapté au diamètre du câble / de la

conduite.

La section de base pour le calcul de l’âme du câble / de la

conduite doit être de 0,75 mm² minimum et ne doit pas dépasser 2,5 mm².

• Les vis pour la fixation du couvercle du coffret à bornes doivent

être serrées avec un couple de serrage de 100 Ncm (± 5 %).

DANGER !

Danger présenté par la tension électrique !

Danger important de blessures par tensions dangereuses au niveau

du corps ! Danger d’endommagement de l’appareil par court-circuit !

• Avant d’intervenir dans l’appareil ou l’installation, couper la tension

et empêcher toute remise sous tension par inadvertance !

• Les bornes conductrices de tension du coffret à bornes peuvent

entraîner des chocs électriques, des court-circuits ou des explosions. Couper la tension. Seulement alors, ouvrir le coffret à bornes.

• Les câbles de raccordement des électro-aimants doivent être

disposés fixés et de telle façon qu’ils soient suffisamment protégés

des dommages mécaniques.

• Veuillez respecter les réglementations en vigueur pour les appareils

électriques en matière de prévention des accidents ainsi qu’en

matière de sécurité !

AVERTISSEMENT !

Danger dû à la haute pression !

Il y a risque important de blessures lors d’interventions sur le

système.

• Avant de desserrer les conduites et les vannes, coupez la pression et assurez l’échappement de l’air des conduites.

• Lors du montage, respectez le sens du débit.

• Veuillez respecter les réglementations en vigueur pour les appareils sous pression en matière de prévention des accidents ainsi

qu’en matière de sécurité.

français

41

Page 42

PTB 02 ATEX 2173 X

Mise en service

7.2. Montage du type 0742

Emplacement de montage libre.

De préférence avec le système magnétique en haut.

1. Nettoyer les tuyauteries.

2. Emplacement de montage libre

→ Orientation préférentielle avec l’entraînement en haut.

3. Intercaler un collecteur d’impuretés

→ Respectez le sens du débit !

4. Etanchéification

→ PTFE.

5. Vissez les tuyauteries

→ Respectez le sens du débit !

6. Monter / démonter.

REMARQUE !

Indication pour les appareils avec câble de raccordement :

Le câble de raccordement et la bobine sont moulés. Ils ne doivent

pas être démontés !

Raccordez toujours le conducteur de protection !

7. Raccordez à l’électricité.

8. MISE EN SERVICE

8.1. Consignes de sécurité

AVERTISSEMENT !

Risque de blessures dû à une exploitation non conforme !

Une utilisation non conforme peut entraîner des blessures et

endommager l’appareil et son environnement.

• Avant la mise en service, il faut s’assurer que le contenu des

instructions de service est connu et parfaitement compris par

les opérateurs.

• Respectez les consignes de sécurité et l’utilisation conforme.

• L’appareil / l’installation doit être mis(e) en service uniquement

par un personnel suffisamment formé.

8.2. Mise en service

Avant la mise en service, s’assurer que :

• l’appareil a été installé dans les règles,

• le raccordement a été correctement effectué,

• l’appareil n’est pas endommagé,

• toutes les vis sont bien serrées.

42

français

Page 43

PTB 02 ATEX 2173 X

Maintenance, dépannage

9. MAINTENANCE, DÉPANNAGE

9.1. Consignes de sécurité

AVERTISSEMENT !

Risque d’explosion dû à la charge électrostatique !

Il y a risque d’explosion en cas de décharge soudaine d’appareils

ou de personnes chargés d’électricité statique dans des zones

présentant des risques d’explosion.

• Assurez-vous par des mesures appropriées, qu’il ne peut y avoir

de charges électrostatiques dans de telles zones présentant

des risques d’explosion.

• Ne nettoyer la surface de l’appareil que par un essuyage léger

avec un chiffon humide ou antistatique.

Risque de blessures lors de travaux de maintenance, réparation et d’entretien non conformes !

• Les travaux de maintenance et d’entretien sur l’appareil ne doivent

être effectués que par un personnel autorisé et qualifié avec des