Burcam CONVERTIBLE C.I. JET PUMP 3/4HP 115/230V User Manual

|

WWW.BURCAM.COM |

|

|

2190 Boul. Dagenais West |

TEL: 514.337.4415 |

LAVAL (QUEBEC) |

FAX: 514.337.4029 |

CANADA |

|

H7L 5X9 |

info@burcam.com |

Your pump has been carefully packaged at the factory to prevent damage during shipping. However, occasional damage may occur due to rough handling. Carefully inspect your pump for damages that could cause failures. Report any damage to your carrier or your point of purchase.

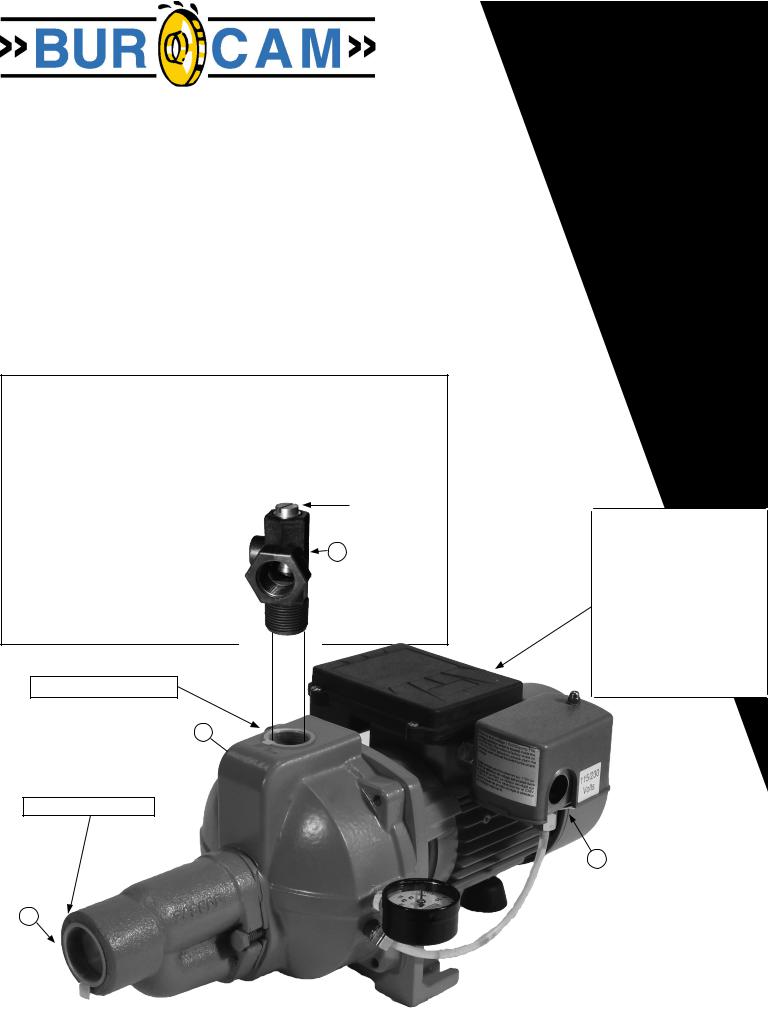

Use the included flow control valve to connect your pump to your home plumbing distribution pipe system. Install this valve to the pump discharge and close the valve completely by turning the top screw clockwise. Then, turn the screw counter-clockwise for one turn only and proceed to the following priming process of the pump.

Follow all these inside step by step instructions to install your pump. Use teflon tape on all threads. (1) Install the pump discharge fittings as illustrated. (2) Fill the suction line with water and connect it to the suction inlet. (3) Remove the priming plug and fill the pump body with water. (4) Screw the plug to the priming inlet. (5) Turn the power on. The pump should deliver water to the plumbing line within 30

seconds. If not, unplug the pump and repeat the process at step 3.

After priming the pump, you can adjust the flow |

1 |

control valve to obtain the best performance of |

the pump. Remember that when you open this valve, you reduce the suction capacity. This valve is used to balance the discharge flow with the suction requirement. The deeper your suction distance, the more closed the valve should be for optimum performance.

Discharge connection

Priming plug

on the side. 3-4

INSTALLATION INSTRUCTIONS

MODELS

503321/503721

AND OTHER PRODUCTS 503327 503727 503328 503728 503331 503731 ETC.

JET PUMP

Please read these instructions carefully. Failure to comply to instructions and designed operation of this system, may void the warranty.

FACTORY SET VOLTAGE 115 V CONNECTION VOLTAGE CHANGING:

Before changing the voltage connection:

A) Ensure the power to the pump is disconnected.

B)Open motor junction box cover.

C)Please select the up knob position for 115V or down knob position for 230V.

D)Connect to appropriate voltage.

E)Close motor junction box.

Suction connection

5

2

© 2011 BUR-CAM Printed in Canada 510068

Safety Instructions:

This fine pump that you have just purchased is designed from the latest in material and workmanship. Before installation and operation, we recommend the following procedures:

|

CHECK WITH YOUR LOCAL ELECTRICAL AND PLUMBING CODES TO ENSURE YOU COMPLY |

|

A |

||

WITH THE REGULATIONS. THESE CODES HAVE BEEN DESIGNED WITH YOUR SAFETY IN MIND. |

||

|

BE SURE YOU COMPLY WITH THEM. |

|

|

WE RECOMMEND THAT A SEPARATE CIRCUIT BE LEAD FROM THE HOME ELECTRICAL |

|

B |

||

DISTRIBUTION PANEL PROPERLY PROTECTED WITH A FUSE OR A CIRCUIT |

||

|

BREAKER. WE ALSO RECOMMEND THAT A GROUND FAULT CIRCUIT BE USED. |

|

|

CONSULT A LICENSED ELECTRICIAN FOR ALL WIRING. |

|

|

THE GROUND TERMINAL ON THE THREE PRONG PLUGS SHOULD NEVER BE REMOVED. THEY |

|

C |

||

ARE SUPPLIED AND DESIGNED FOR YOUR PROTECTION. |

||

|

NEVER MAKE ADJUSTMENTS TO ANY ELECTRICAL APPLIANCE OR PRODUCT WITH THE |

|

D |

||

POWER CONNECTED. DO NOT ONLY UNSCREW THE FUSE OR TRIP THE BREAKER, REMOVE |

||

|

THE POWER PLUG FROM THE RECEPTACLE. |

Monthly Mandatory check-up:

1.Inspect the pump for any obvious condition that necessitates cleaning, correction, adjustement or repair.

2.Clear the surrounding of any paper, leaves or other debris.

3.Assure that the pump is secure for proper operation.

4.Assure that there is adequate clearance from any combustible materials or stucture. Stored materials must be kept away from

the pump. Shelves or cabinet structures must not be in close proximity over the pump.

5.Assure that the motor is securely plugged into a proper GFCI electrical outlet

6.Test the GFCI outlet by pressing its test switch. This should prove that the outlet is energized and will trip off to protect against a ground fault. Be sure to reset the GFCI by pressing its reset switch.

7.Observe that the plumbing can carry the water safely into the residence.

Material required for drilled well application (indoor use only)

Shallow well pump installation

Desired length of polyethylene 1” pipe, 100 PSI, CSA or UL approved, to link up from pumping level to pump.

1 1” foot valve (750756 or 750752P).

1 well seal, as per well casing diameter

(750929 6” x 1”).

1 1” well seal elbow (750860).

2 1” male adaptors (750865 or 750871).

8 1” stainless steel clamps (750885).

Teflon tape.

Tank installation

Desired length of 1” braided hose (750919) to link up from pump to tank. Keep tank as close as possible from pump.

1 tank T (650651).

1 drain valve (650659).

2 1” female adaptor.

1 1” male adaptor (750865 or 750871).

3 1” stainless steel clamps (750885).

Teflon tape.

2

Deep well pump installation

Desired length of polyethylene 1” and 1 1/4” pipe, 100 PSI, CSA or UL approved, to link up from pumping level

to pump.

1 1” foot valve (750756 or 750752P).

1 well seal, as per well casing diameter

(750926 6” x 1 1/4” x 1”).

1 1” well seal elbow (750860).

1 1 1/4” well seal elbow (750861).

1 1 1/4” venturi adaptor (750864).

2 1” male adaptors (750865 or 750871).

1 1 1/4” male adaptor (750872).

8 1” stainless steel clamps (750885).

8 1 1/4” stainless steel clamps (750886).

Teflon tape.

Tools

Screwdrivers, hacksaw to cut pipe, knife to assist in pipe cutting, round file to smooth pipe ends, pipe wrench, adjustable wrench to tighten fittings, propane torch and welding material.

FOR INFORMATION TEL: 514.337.4415 FAX: 514.337.4029

APPLICATIONS

•This pump is designed for shallow well installation for water level up to 25 feet, with injector screwed on pump body; or for deep well installation for water level up to 85 feet, with 2 pipes and injector down in

the well.

•CAPACITY AT 20 PSI .

|

SHALLOW WELL |

|

DEEP WELL |

||||

|

1/2 HP |

3/4 HP |

|

1/2 HP |

3/4 HP |

||

5’ |

900 |

950 |

|

|

|

|

|

10’ |

800 |

850 |

30’ |

500 |

525 |

||

15’ |

650 |

700 |

40’ |

400 |

425 |

||

20’ |

450 |

500 |

50’ |

300 |

325 |

||

25’ |

300 |

350 |

80’ |

150 |

175 |

||

|

US GPH |

|

US GPH |

||||

|

|

|

FRICTION LOSS IN PIPE |

|

|

||

|

|

|

NOT INCLUDED. |

|

|

|

|

FEATURES

•High performance noryl impeller..

•Industrial motor totally enclosed, fan cooled.

•Full time connected run capacitor, to eliminate starting wear vs regular motor.

•Thermal and overload protection.

•Built for a continuous use.

•1/2 HP, 115/230 VCA, 60 Hz, 8.6 A/4.3 A.

•3/4 HP, 115/230 VCA, 60 Hz, 8.9 A/4.5 A.

(at start : 15 A/7.5 A)

Your ejector is factory pre-assembled with the venturi

510066.2, for an optimum performance when the pumping level is between 25’ to 60’ (7.5 meters to 18 meters) depth, in reference to the pump position.

So, this is a deep well application mode. The ejector is positioned into the well and is connected to the pump using 2 pipes (see page 5).

If the pumping level is deeper than 60’ (18 meters) in reference to the pump position, it is mandatory to unscrew the pre-assembled venturi and to replace it by the venturi 510066.3, also as a deep well mode application with the ejector positioned into the well.

|

|

|

|

|

|

|

|

Factory |

|

|

||

|

|

|

|

|

|

|

|

pre assembled, for |

||||

For deep well |

|

|

|

|

deep well application |

|||||||

|

|

|

|

mode, 25' à 60'. |

|

|

||||||

application mode, |

|

For shallow |

||||||||||

|

|

|

|

|||||||||

60’ and deeper. |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

well application |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mode. |

510066.3 |

|

|

|

|

510066.2 |

|

|

510066.1 |

||||

9/32" |

|

21/64" |

|

31/64" |

||||||||

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.1mm |

8.3mm |

12.2mm |

|

|||||||||

In the case of a pumping level lower than 25’ (7.5

meters), unscrew the pre-assembled venturi and replace it by the venturi 510066.1. Then screw the ejector to the pump body. This becomes a shallow well mode application where only one pipe is required

to pump water (see page 4).

|

INSTALLATION STEPS |

|

|

We recommend that you install your pump in a clean and dry location where there is adequate room |

|

STEP 1 |

||

for servicing at a later date. Protection from freezing temperatures and good ventilation should be |

||

|

considered as well, to provide the pump an environment for long life. Locating the pump as close as |

|

|

possible to the water source will reduce friction losses encountered in the suction pipe. |

|

|

Friction losses in the suction pipe must be taken into consideration when the horizontal offset is greater |

|

|

than 50 feet. The suction pipes should be increased from 1” to 1 1/4”. This will reduce friction losses and |

|

|

allow the pump to give maximum performance. |

|

|

A new well should be checked to determine that it is free from sand. Sand will damage the seal and the |

|

|

impeller. Have your well driller clean the well before your installation. |

|

|

Never run the pump dry. Damage to the seal may occur. Fill pump body and suction pipe with water |

|

|

before turning on the power. |

THE RUN OF HORIZONTAL PIPE FROM THE TOP OF YOUR WELL INTO THE HOUSE, WHERE YOUR PUMP WILL BE LOCATED, MUST BE INSTALLED IN A TRENCH, BELOW THE FROST LEVEL

OF YOUR AREA. |

3 |

|

FOR INFORMATION TEL: 514.337.4415 FAX: 514.337.4029

DEEP WELL APPLICATION

SEE DIAGRAM ON PAGE 9

|

Locate your injector body in your package. Using teflon tape, screw the 1 1/4” venturi adaptor |

|

STEP 2 |

||

over the injector venturi (black tube), into the 1 1/4” opening of injector body. Install the 1” |

||

|

||

|

male thread adaptor in the 1” opening in injector body. Securely tighten both adaptors with |

|

|

pipe wrench. |

STEP 3 STEP 4

STEP 5

With teflon tape on threads, install a 1” nipple into the 1” foot valve, then screw this assembly into the 1” bottom opening of the injector.

Cut the desired length of 1” and 1 1/4” poly pipes to run from the top of the well to the pumping level. Smooth the pipe cuttings with your round file. (Check that no cut-out parts are left inside of pipe. This may block pump injector or impeller). Slide 2 stainless steel clamps over one end of each pipe and use torch to soften pipe. Fix the 1” and 1 1/4” pipes respectively on the 1” adaptor and 1 1/4” venturi adaptor. Tighten clamps with screwdriver when cool.

For security against leaks, we suggest to install 2 stainless steel clamps on each adaptor.

Insert both well seal elbows thru their opening of the seal. Slide 2 stainless steel clamps over the free ends of the previously cut pipes and soften pipes with your torch. Attach pipes to the well seal elbows (ends protruding at bottom of well seal). Tighten clamps with screwdriver when cool.

To facilitate servicing at a later date, you may use a pitless adaptor and a sealed well cap instead of an elbow and a well seal as describe in steps 3 and 4.

STEP 6 STEP 7

STEP 8

Install the well seal and the injector piping assembly into your well casing. Tight down the well seal bolts using your adjustable wrench.

Install your pump in the house, on a sound foundation, as close as possible to the basement wall. Locate the openings in the front of the pump body. Thread respectively 1” and 1 1/4” adaptors into corresponding openings using teflon tape. Do not over tighten.

Cut the desired length of pipes from pump |

location to the well seal |

and |

connect |

both ends using the previous way, with |

stainless steel clamps |

and |

torch. |

Do not fill in your trench to the house until you have checked for any leaks in your connections or trouble in your water system.

CONTINUE ON PAGE 6 FOR TANKS

AND ON PAGE 7 FOR ELECTRICAL INSTALLATION STEPS.

4

FOR INFORMATION TEL: 514.337.4415 FAX: 514.337.4029

Loading...

Loading...