Page 1

SLCA-7

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To ensure you have the latest revision of the Operating Manual, or to view the Illustrated Parts

Catalog, Programming Manual, or Service Manual, please visit the Bunn-O-Matic website, at

www.bunn.com. This is absolutely FREE, and the quickest way to obtain the latest catalog and

manual updates. For Technical Service, contact Bunn-O-Matic Corporation at 1-800-286-6070.

39328.0003D 10/13 ©2013 Bunn-O-Matic Corporation

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) Airpots, thermal carafes, decanters, GPR servers, iced tea/coffee dispensers, MCP/MCA pod brewers thermal servers

and Thermofresh servers (mechanical and digital)- 1 year parts and 1 year labor.

2) All other equipment - 2 years parts and 1 year labor plus added warranties as specified below:

a) Electronic circuit and/or control boards - parts and labor for 3 years.

b) Compressors on refrigeration equipment - 5 years parts and 1 year labor.

c) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis - parts

and labor for 4 years or 40,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be

commercially free of defects in material and workmanship existing at the time of manufacture and appearing within the

applicable warranty period. This warranty does not apply to any equipment, component or part that was not manufactured

by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper installation or operation,

improper maintenance or repair, non periodic cleaning and descaling, equipment failures related to poor water quality,

damage or casualty. In addition, the warranty does not apply to replacement of items subject to normal use including but

not limited to user replaceable parts such as seals and gaskets. This warranty is conditioned on the Buyer 1) giving BUNN

prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office

Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an

authorized BUNN service location; and 3) receiving prior authorization from BUNN that the defective equipment is under

warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make

modifications to this warranty or to make additional warranties that are binding on BUNN. Accordingly, statements by such

individuals, whether oral or written, do not constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the

applicable parts and labor warranty periods specified above) to repair the defective components, provided that this repair

is done by a BUNN Authorized Service Representative; or 2) shall replace the equipment or refund the purchase price for

the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION

AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of

use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities

or services, or any other special, incidental or consequential damages.

392, A Partner You Can Count On, Air Infusion, AutoPOD, AXIOM, BrewLOGIC, BrewMETER, Brew Better Not Bitter, BrewWISE, BrewWIZARD, BUNN Espress, BUNN Family Gourmet, BUNN Gourmet, BUNN Pour-O-Matic, BUNN, BUNN with

the stylized red line, BUNNlink, Bunn-OMatic, Bunn-O-Matic, BUNNserve, BUNNSERVE with the stylized wrench design,

Cool Froth, DBC, Dr. Brew stylized Dr. design, Dual, Easy Pour, EasyClear, EasyGard, FlavorGard, Gourmet Ice, Gourmet

Juice, High Intensity, iMIX, Infusion Series, Intellisteam, My Café, Phase Brew, PowerLogic, Quality Beverage Equipment

Worldwide, Respect Earth, Respect Earth with the stylized leaf and coffee cherry design, Safety-Fresh, savemycoffee.com,

Scale-Pro, Silver Series, Single, Smart Funnel, Smart Hopper, SmartWAVE, Soft Heat, SplashGard, The Mark of Quality

in Beverage Equipment Worldwide, ThermoFresh, Titan, trifecta, Velocity Brew, Air Brew, Beverage Bar Creator, Beverage

Profit Calculator, Brew better, not bitter., BUNNSource, Coffee At Its Best, Cyclonic Heating System, Daypart, Digital Brewer Control, Element, Milk Texturing Fusion, Nothing Brews Like a BUNN, Pouring Profits, Signature Series, Sure Tamp, Tea

At Its Best, The Horizontal Red Line, Ultra are either trademarks or registered trademarks of Bunn-O-Matic Corporation.

The commercial trifecta® brewer housing configuration is a trademark of Bunn-O-Matic Corporation.

2

39328.3 070913

Page 3

INTRODUCTION

This equipment dispenses hot beverages or soups on demand from powdered product. It is indoor use only on

a sturdy counter or shelf.

TABLE OF CONTENTS

Introduction ............................................................................................................................................3

User Notices ...........................................................................................................................................4

Initial Set-up ...........................................................................................................................................5

Electrical Requirements ..........................................................................................................................5

Electrical Hook-up ................................................................................................................................... 5

Plumbing Requirements .........................................................................................................................5

Plumbing Hook-up .................................................................................................................................. 5

Operating Controls .................................................................................................................................. 6

Installing Pump Tubing ........................................................................................................................... 8

Initial Fill & Heat ...................................................................................................................................... 9

Liquid Level Control ................................................................................................................................ 9

Rinse Alarm Feature ................................................................................................................................ 9

Programming The Dispenser ................................................................................................................10

Program Mode ................................................................................................................................ 10

Priming The Concentrate Lines ............................................................................................................. 13

Draining The Hot Water Tank ................................................................................................................14

Operating The Dispenser ....................................................................................................................... 14

Cleaning And Preventive Maintenance ..................................................................................................15

Daily Rinsing ................................................................................................................................... 15

Daily Parts Washing ........................................................................................................................15

Weekly Sanitizing ............................................................................................................................15

Weekly Parts Washing .................................................................................................................... 16

Preventive Maintenance ........................................................................................................................17

Replacing The Pump Tubing .................................................................................................................17

Calibrating The Dispenser .....................................................................................................................18

Troubleshooting Guide .......................................................................................................................... 20

Field Calibration of the Concentrate Pumps ..........................................................................................21

Calibrating of the Concentrate Pumps ............................................................................................. 21

Calibration the Dispenser Flow Rate ................................................................................................22

Field Calibrating the Empty Product Warning ..................................................................................22

Field Adjustment of Powder Hoppers .............................................................................................. 23

Electrical Wiring Schematics ................................................................................................................. 24

3

39328.3 012113

Page 4

USER NOTICES

RINSE ALARM

The notices on this dispenser should be kept in good condition. Replace unreadable or damaged labels.

As directed in the International Plumbing Code of the

International Code Council and the Food Code

Manual of the Food and Drug Administration (FDA),

this equipment must be installed with adequate

backflow prevention to comply with federal, state

and local codes. For models installed outside the

U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

00656.0001

00986.0000

00824.0002

37881.0000

11646.0002

PLACE

CUP

HERE

39474.0000

If all LED’S on control panel are flashing, and LED display shows

“RINSE”, a rinse function is required to clear.

1. Place minimum 32 ounce container under dispense nozzles.

2. Place top switch in “RINSE” position.

3. Press any dispense switch on front door. Rinse will automatically

dispense for 15 seconds, then stop

4. Place top switch in “NORMAL” position.

5. Discard rinse water and close door.

Center container under dispense point.

Keep hands away.

All nozzles dispense HOT LIQUID.

To stop rinse, press STOP button on door.

Centre el recipiente debajo del punto de distribución.

Mantenga alejadas las manos.

Todas las toberas distribuyen LÍQUIDO CALIENTE.

Para detener el enjuague, pulse el botón STOP de

la puerta.

Si destellan todos los LED del panel de control y en la pantalla de LED

aparece “RINSE” (ENJUAGAR), se requiere aplicar la función de enjuague

para borrar la alarma.

1. Coloque un recipiente de 1 l (32 onzas) como mínimo debajo de las

toberas de distribución

2. Coloque el conmutador superior en la posición “RINSE”.

3. Pulse cualquier interruptor de distribución de la puerta delantera. Se

distribuye automáticamente el enjuague durante 15 segundos y luego se

detiene.

4. Coloque el conmutador superior en la posición “NORMAL”.

5. Deseche el agua de enjuague y cierre la puerta.

ADVERTENCIA

ALARMA DE ENJUAGUE

39591.0000

4

39328.3 012113

Page 5

INITIAL SET-UP

1. Apply the four non-skid pads from the parts box to the bottom of the legs.

2. Remove the drip tray assembly and drip tray bracket from the parts box.

3. Place a set of key holes in the drip tray bracket over the lower two screws in the panel below the hopper access door; push down gently and tighten screws.

ELECTRICAL REQUIREMENTS

CAUTION - The dispenser must be disconnected from the power source until specified in Electrical Hook-Up.

The dispenser can be wired to a 120V, 2 wire with ground.

Refer to the dispenser’s dataplate for exact voltage requirements.

ELECTRICAL HOOK-UP

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specified.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. Connect the dispenser to the power source.

4. Place the main power switch in the "ON" position.

5. If plumbing is to be hooked-up later be sure the dispenser is disconnected from the power source. If plumb-

ing has been hooked-up, the dispenser is ready for Initial Fill & Heat.

PLUMBING REQUIREMENTS

This dispenser must be connected to a cold water system with operating pressure between 20 and 100 psi (138

and 690 kPa). This water source must be capable of producing a minimum flow rate of 4.5 fl. oz. (133.1 ml) per

second. A shut-off valve should be installed in the line before the dispenser. Install a regulator in the line when

pressure is greater than 100 psi (690 kPa) to reduce it to 50 psi (345 kPa). The water inlet fitting is .25" (9.52

mm) flare.

NOTE - At least 18 inches (457 mm) of an FDA approved flexible beverage tubing, such as reinforced braided

polyethylene or silicone, before the dispenser will facilitate movement to clean the countertop. Bunn-O-Matic

does not recommend the use of a saddle valve to install the dispenser. The size and shape of the hole made in

the supply line by this type of device may restrict water flow.

As directed in the International Plumbing Code of the International Code Council and the Food

Code Manual of the Food and Drug Administration (FDA), this equipment must be installed with

adequate backflow prevention to comply with federal, state and local codes. For models installed

outside the U.S.A., you must comply with the applicable Plumbing /Sanitation Code for your area.

NOTE - If a backflow prevented is required by code, a shock arrestor should be installed between backflow preventer

and dispenser. Installing the shock arrestor as close to the dispenser as possible will provide the best results.

NOTE - Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed

and maintained in accordance with federal, state and local codes.

PLUMBING HOOK-UP

1. Flush the water line and securely attach it to the flare fitting on the bottom of the dispenser.

2. Turn-on the water supply.

5

39328.3 012113

Page 6

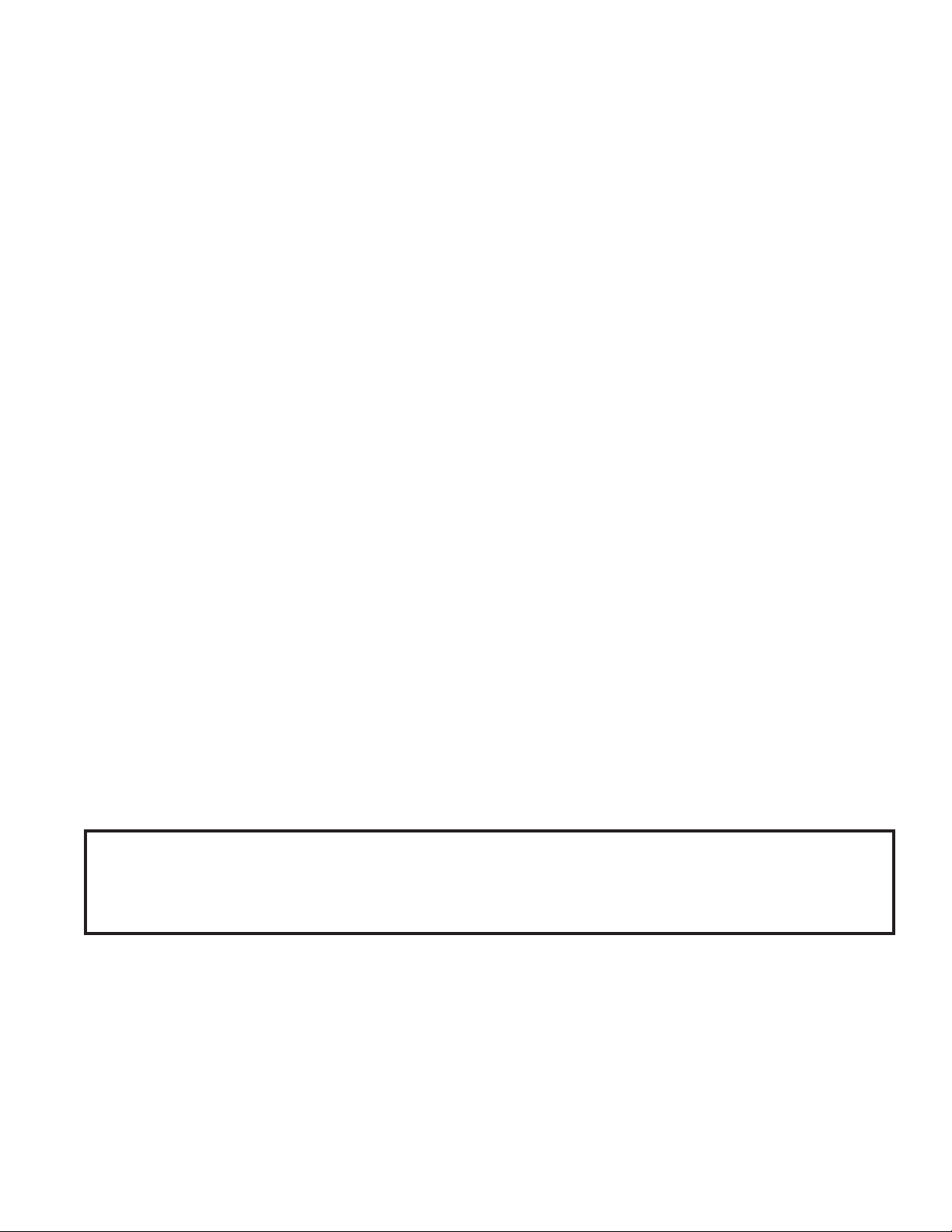

OPERATING CONTROLS AND INTERFACE

1. Cup Size Buttons: Momentarily pushed to select beverage size to dispense.

2. Stop Button: Momentary pushed to stop dispensing.

3. Decaf Button: Momentarily pushed to select Decaffeinated coffee.

4. Dispense Buttons: Momentarily pushed to dispense selected beverage.

5. Decaf refill LED: Illuminates when left (Decaf) concentrate can needs replaced.

6. Coffee (Hot Chocolate) refill LED: Illuminates when right (Regular) concentrate can needs replaced.

7. Main Power Switch: Removes AC power to tank heater and control circuits.

8. Function Selector Switch: Allows the user to select different dispensing functions (Located behind the

splash guard panel)

a. Rinse: Dispenses hot water only- Flushes the powder and coffee mixing chambers and dispense lines

and tips.

b. Prime: Dispenses concentrates only – Primes concentrate pumps.

c. Normal: Normal dispense mode – Dispenses mixed product.

9. Mode Selector Switch: Allows the user to select different operating modes.

a. Run: Normal operating position.

b. Night: Anti-pilfering mode that disables dispensing, but keeps heater and chiller operational.

WARNING – The NIGHT Mode does not remove AC power from the dispenser. Disconnect power source before

servicing the dispenser.

c. Program: Enables programming and set up of the dispenser.

10. Programming Switches: Used in conjunction with the LED display to program and calibrate the dispenser to

customer specific requirements.

a. Menu: used to scroll to the next menu screen.

b. (+): used to increase the display value.

c. (-): used to decrease the display value.

11. LED Display: Displays programming menus and fault messages.

7

6

39328.3 012113

Page 7

OPERATING CONTROLS (Continued)

5 3 1 2 6 1

SMALL

DECAF

CAPPUCCINO

LATTE

STOP

MOCHA

CAPPUCCINO

MOCHA LATTE

LARGE

HOT CHOCOLATE

BLACK COFFEE

ESPRESSO

4

11 8 9

10

7

39328.3 012113

Page 8

INSTALLING PUMP TUBING

1. Loosen the thumbscrews securing the tubing retainer plates to the pump bodies and set the retainer plates

aside.

2. Depress the tension screws and remove them from the notch in the pump body, releasing the spring tension

on the pump bands.

3. Apply lubricant (BUNN-O-Matic part no. M2531.0001) to the middle section of the new pump tubing.

4. Insert the free end of the pump tubes over the elbow fittings in the bottom of the product section as far as

possible.

5. Carefully wrap the new tubing around the rotors, making sure that the elbows end up parallel to the rotor

face.

6. Depress the tension screws and insert it in the notch in the pump body, reapplying spring tension on the

pump bands.

7. Replace the tubing retainer plates and tighten the thumbscrews.

8. Open the product containers and screw pump tube connector to coffee container fitting.

Note: Replacement Tube Kits can be purchased from BUNN-O-MATIC. Order part no. 37500.0206

9. Prime the pumps. Refer to Priming the Concentrate Lines section.

Thumbscrew

Remove Retaining Plate

Tension

Screw

Release Spring Tension

Tension Screw

Tube Clamp

Pump Tubing Installed

2.0”

Lubricate between arrows

Lubricate New Tube

2.0”

8

39328.3 012113

Page 9

INITIAL FILL & HEAT

1. Turn on the water supply and connect the dispenser to the power source.

2. Water will automatically flow into the tank to the proper level and then shut-off. This will take less than ten

minutes.

3. A tank full of cold water will take approximately fifty minutes for the water to heat at 120 volts, approximately

15 minutes at 240 volts.

4. Fill the hoppers with the dry product to be dispensed. Hot chocolate in the left hopper, powder milk product

in the right hopper.

5. The LED display on the control panel behind the door splash panel will alternately display the tank water

temperature and the cold shoe temperature.

LIQUID LEVEL CONTROL

The system automatically maintains the hot water tank’s level by energizing the refill solenoid when the water

level drops below the liquid level probe. If the system has not successfully refilled in 15 minutes, a refill error

occurs. When a refill error occurs, the refill solenoid is de-energized. Once the cause of the refill error has been

investigated and cured, the system can be reset by both disconnecting (for at least 5 seconds) and then reconnecting the power to the machine.

RINSE ALARM FEATURE

Periodic rinsing of the mix chambers and dispense tips is essential for proper maintenance and optimum performance of the dispenser. The dispenser is shipped from the factory with the rinse timer enabled.

The rinse timer automatically keeps track of the time since the dispenser was last run through a rinse sequence.

If the dispenser detects that a rinse sequence has not been run for the desired time, all LEDs’ on the membrane

switch on the front door will flash, and "RINSE" will be displayed on the LED display behind the door splash

panel.

Rinse Procedure:

1. Open the front door and place the Normal/Program/Rinse switch in the RINSE position.

2. Place a large container under the dispense nozzle. Press any dispense button on the front door. The LED

display above the programming buttons will begin counting down from 8. The rinse will terminate when the

display reaches “0”.

3. Return the Normal/Program/Rinse switch to the NORMAL position, and close the front door.

EMPTY PRODUCT WARNING

The dispenser will automatically illuminate the LED next to the Decaf or Hot Chocolate button when the Decaf

or Regular coffee BIB is empty, respectively. The Refill message is triggered when conductance sensor reading

drops below the minimum setting. The factory set minimum is 450 and should be correct for many locations.

However, in some areas the hardness of the local water supply will affect this reading. It is recommended that

the Empty Product Threshold be calibrated upon installation for proper operation of the Empty Product Warning.

See "Field Calibrating the Empty Product Warning" in the Calibration section of this manual.

9

39328.3 101513

Page 10

SLCA-7 PROGRAMMING

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

Program Mode: Used to change or enter new set-up values.

To enter the Program Mode, Set the RUN/NIGHT/PROGRAM Switch to the PROGRAM position, the unit will

display “__PPP” to indicate it is in the Program Mode. Use the MENU switch to scroll to the next display. Use

the Increase (+) and Decrease (-) switch to adjust the values.

LED DISPLAY PROGRAM MODE DESCRIPTION

10

MENU (-) (+)

20

30

MENU (-) (+)

40

1 9 0

1 8 0

1 5 5

r u n

Tank Temperature

Set Tank Ready Temperature

Refill Threshold

Left hopper motor

Default = 190°F

Default = 180°F

Set tank refill threshold

Default = 155

Press any beverage dispense switch,

left hopper motor will run for 10 seconds.

Left hopper motor

40

50

50

7 6

r u n

8 3

Right hopper motor

Right hopper motor

10

Set left hopper auger power level

Default = 76

Press any beverage dispense switch,

right hopper motor will run for 10

seconds.

Set right hopper auger power level

Default = 83

39328.3 012113

Page 11

PROGRAMMING (Continued)

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

LED DISPLAY PROGRAM MODE DESCRIPTION

60

MENU (-) (+)

70

MENU (-) (+)

80

MENU (-) (+)

90

3 0

3 0

1 0

1 0

Left Dispense Ratio

Right Dispense Ratio

Left Espresso Ration

Right Espresso Ration

Set Decaf Coffee Ratio

Default = 30:1

Set Regular Coffee Ratio

Default = 30:1

Set Left Espresso Ration

Default = 10:1

Set Right Espresso Ration

Default = 10:1

01

11

21

MENU (-) (+)

4 5 0

1 0

1.

5.

1 0

Empty Product Threshold

Small Cup Dispense Time

Large Cup Dispense Time

Set Conductance Threshold

Default = 450

Set Small Cup Dispense time Default=

11.0 seconds

Set Large Cup Dispense time Default=

15.0 seconds

11

39328.3 012113

Page 12

PROGRAMMING (Continued)

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

LED DISPLAY PROGRAM MODE DESCRIPTION

31

MENU (-) (+)

41

51

61

MENU (-) (+)

8

1.

0.

5

2 4

0

1

Powder Whipper Delay Off

Powder Auger Motor Delay on

Rinse Alarm Timer

Power Up Delay

Set Powder Whipper Motor Delay Off

time

Default = 1.8 seconds

Set Powder Auger Motor Delay On

time

Default = .5 seconds

Displays hours for Rinse Alarm

Default = 24 hours

Displays Time In Minutes Tank Heater

Activation Will Be Delayed After Power Up

Default = 1 minute

71

MENU (-) (+)

81

MENU (-) (+)

9

1

0

2

##

0 4. 3

0 8.

L

#

6

O

Cup Count

Small Cup Espresso Dispense

Time

Large Cup Espresso Dispense

Time

BIB Cabinet Vent Fan Speed

Shows Total Number Of Cups Dispensed, Or Individual Beverage Count

When Dispense Button Is Pressed

Set Small Cup Espresso Dispense

Time

Default = 4.3 seconds

Set Large Cup Espresso Dispense

Time

Default = 8.6 seconds

Set BIB Cabinet Vent Fan Speed To

LO or HI

Default = LO

MENU (-) (+)

12

39328.3 012113

Page 13

PRIMING THE CONCENTRATE LINES

1. Open the dispenser door.

2. Select Prime on the Function Selector Switch and Run on the Mode Selector Switch.

3. Close the dispenser door.

4. Place a container under the dispense tip.

5. Activate the appropriate dispense button, "Small" cup button for Left Pump, "Large" cup button for Right

Pump, until concentrate flows from the dispense nozzle. Priming may take 10 to 20 seconds.

6. Open the dispenser door; select Normal on the Function Selector Switch.

Note: Concentrate may continue to drip out of dispense tip. The user may wish to Rinse (refer to Rinsing) the

dispenser to clean out the remaining concentrate.

2

6

13

39328.3 012113

Page 14

DRAINING THE HOT WATER TANK

CAUTION - The dispenser must be disconnected from the power source throughout these steps

1. Disconnect the dispenser from the power source.

2. Open front door and place Main Power Switch in the OFF position and let the water in the tank cool before

draining.

3. Shut off and disconnect the incoming water supply.

4. Remove the drip tray and access panels below the door.

5. Pull the clamped end of the silicone tube out of the dispenser and direct it into a drain or a container large

enough to hold the volume of water in the tank, 4.0 gallons.

6. Make certain the shut off clamp is locked tightly on the tube, and then remove the snap type clamp and plug

from end of tube.

7. Carefully release the shut off clamp to let the water drain from the tank.

NOTE - The dispenser must be refilled using the INITIAL FILL & HEAT steps before reconnecting to the power

source.

OPERATING THE DISPENSER

Set the Function Selector Switch to NORMAL and the Mode Selector Switch to RUN

1. Place a cup on the drip tray beneath the center dispense nozzle.

2. In area marked “1” of the control panel:

a. Select desired beverage size, small or large cup. This selection is mandatory for dispensing.

3. In the area marked “2” of the control panel:

a. REGULAR coffee is the default, and no selection is required for REGULAR coffee. Press the DECAF but-

ton if a decaffeinated beverage is desired.

b. Press the button to dispense the desired beverage. Dispensing is portion controlled, and will automati-

cally stop when correct amount of beverage has been dispensed.

4. Pressing the STOP button in the center of the control panel will stop dispensing.

14

39328.3 012113

Page 15

CLEANING & PREVENTATIVE MAINTENANCE

General Cleaning and Sanitizing Procedures Note: The BUNN¨ SLCA-7 dispenser incorporates a “user select-

able” rinse reminder feature, which flashes the LED’s on the front panel when it is time to rinse.

Daily: RINSING

1. Open the front door and place the Normal/Program/Rinse switch in the RINSE position.

2. Place a ½ gal (2 liter) container under the dispense nozzle. Press any dispense button on the front door. The

LED display above the programming switches will begin counting down from “8”. The rinse will terminate

when the display reaches “0”.

3. Return the Normal/Program/Rinse switch to the NORMAL position, and close the front door.

Daily: PARTS WASHING

1. Remove and wash the drip tray and drip tray cover in a mild detergent solution. Rinse thoroughly.

2. Wipe the splash panel, dispense nozzles, door, and cabinet with a clean damp cloth.

Weekly: SANITIZING

1. Open the dispenser door.

2. Select PRIME on the Function Selector Switch and RUN on the Mode Selector Switch.

3. Remove the bag connector from the product BIB and disassemble or prop open the internal valve to allow

flow of product through the connector.

NOTE: Cutting the mating fittings from an empty bag makes an excellent “free flowing” connector for this purpose.

4. Place the bag connector into a one-gallon (3.8 liter) container of warm soapy tap water 140°F (60°C).

5. Place an empty container under dispense tip and activate the corresponding pump until the clean soapy water

is dispensed from the dispense tip.

6. Repeat steps 4 and 5 with warm tap water 140°F (60°C) to rinse the soapy water from the pump tubing.

Continue dispensing until the water is clear, and no soapy water is being dispensed.

7. Prepare 2.5 gallons (9.46L) of sanitizing solution by dissolving 1 packet of Kay 5 sanitizer into 2.5 gallons

(9.46L) of 120°F (48.9°C) water to ensure 100 ppm of available chlorine.

8. Again, repeat steps 4 and 5 with the sanitizing solution. Once sanitizing solution is visible, continue to dispense

for 1 minute. Release handle and allow solution to sit for 5 minutes.

9. After soaking for 5 minutes, activate the dispense switch a second time, this time for 2 minutes. After 2

minutes, release the dispense switch.

10. Repeat step 6 to flush out the sanitizing solution from the pump tubing.

11. Remove the mating connector from the bag connector.

12. Reattach the bag connector to product box.

13. Select NORMAL on the Function Selector Switch and RUN on the Mode Selector Switch.

14. Activate the dispenser until concentrate/water mixture appears. Then dispense 12 ounce (354.9 ml) glass of

concentrate/water mixture and discard.

15. Repeat steps 1 through 14 for other dispense head.

16. Wipe internal and external surfaces with a clean, damp cloth.

15

39328.3 012113

Page 16

Weekly: Parts Washing and Sanitizing

1. Remove elbows from

both hoppers.

6. Remove mixing

chambers by pulling

straight out.

2. Remove elbows from

middle and right mixing chambers, twisting slightly to help

release.

7. Remove middle and

right frother disk

from shaft by pulling

straight out.

3. Remove dispense

hose from left whipping chamber by

sliding it to the right.

8. Remove left frother

from shaft by pulling

straight out.

4. Remove upper mixing bowl from left

chamber by pulling

out and up.

9. Rotate tab on mixing chamber base

further counter clock

wise, and remover

from shaft by pulling

straight out.

NOTE: Insure O-ring and

shaft seal are in place

during re-assembly.

5. Rotate tab at bottom

of mixing chamber

bases counter clock

wise to release base.

10. Remove dispense

hoses from dispense

nozzle assembly.

11. Clean all parts removed in warm soapy

water. Use Bunn P/N

33685.0000 cleaning brush provided

to clean bores and

orifices. Rinse in cold

water.

12. Prepare one-gallon

(3.8 liter) of sanitizing solution with at

least 100 ppm of

available chlorine in

120°F (48.9°C) water.Soak all cleaned

parts in sanitizing solution for 5 minutes,

then rinse thoroughly

in cold water, and

dr y.

13. Rinse cleaning

brush, dip in sanitizing solution, and

brush the bore of

each of four dispense nozzles.

NOTE: Repeat this procedure for each nozzle

separately.

16

14. When reassembling parts, be sure

to align arrow on

frother disk with

flat on whipper motor shaft, and rotate

tab on whipper base

clock wise to the

vertical position to

lock mixing chamber.

15. When reassembling

left frother, be sure

to align raised bar

on top of frother

shaft with the flat

on whipper motor

shaft.

39328.3 012113

Page 17

PREVENTIVE MAINTENANCE

Bunn-O-Matic® Corporation recommends that preventive maintenance be performed at regular intervals. Maintenance should be performed by a qualified service technician. For Technical Service, contact Bunn-O-Matic®

Corporation at 1-800-286-6070.

NOTE: Replacement parts or service caused by failure to perform required maintenance is not covered by

warranty.

REPLACING THE PUMP TUBING

The pumps and tubing used in the dispenser are designed to give maximum performance and long life. However,

the tubes are a wear item and must be replaced periodically. How long the tube last is dependent on usage and

properties of the concentrate. Excessive wear will reduce the output of the pumps resulting in a weak mixed

beverage. Bunn-O-Matic recommends replacing the Pump Tubing a minimum of once every 6 months or

sooner if warranted.

Refer to the Tube Replacement Instruction inside the Cabinet door.

Note: To avoid concentrate spills, rinse the pump tubing with warm tap water prior to removing the tubes, (Refer

to steps 1 - 4 of the Weekly Sanitizing instructions).

1. Disconnect pump tube connector from product box by turning connector counterclockwise. Repeat for other

pump and product box.

2. Remove product box from product shelf, and remove product shelf from machine by sliding forward.

3. Refer to INSTALLING PUMP TUBING, page 8.

17

39328.3 012113

Page 18

MENU (-) (+)

CALIBRATING THE DISPENSER

MENU (-) (+)

CALIBRATION MODE: The SLCA-7 is calibrated at the factory and does not normally need to be re-calibrated.

To enter the Calibration Mode, Set the RUN/NIGHT/PROGRAM Switch to the PROGRAM position and then hold

the MENU switch down for 10 seconds.

LED DISPLAY CALIBRATION MODE DESCRIPTION

1C

MENU (-) (+)

1C

2C

MENU (-) (+)

2C

r u n

3.

4 0

r u n

4

3.

0

Left Pump Cal.

Left Pump Cal.

Right Pump Cal.

Right Pump Cal.

Set PRIME-NORMAL-RINSE switch

to PRIME position.

Press the SMALL button, left pump

will run for 100 counts

Enter ml collected from the 100 count

test above.

Default = 43.0 ml

Set PRIME-NORMAL-RINSE switch

to PRIME position.

Press the LARGE button, left pump

will run for 100 counts

Enter ml collected from the 100 count

test above.

Default = 43.0 ml

3C

MENU (-) (+)

3C 41

MENU (-) (+)

r u n

.4

Left Coffee Water Rate

Left Coffee Water Rate

18

Set PRIME-NORMAL-RINSE switch

to RINSE position

Press the SMALL button, left pump

dilution water will run for 20 seconds.

Enter Liters collected from 20 sec.

test above

Default = .414

39328.3 012113

Page 19

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

MENU (-) (+)

CALIBRATING THE DISPENSER (Continued)

LED DISPLAY CALIBRATION MODE DESCRIPTION

4C

4C

MENU (-) (+)

5C

6C

r u n

41.4

E 0 0

-

- -

Right Coffee Water Rate

Right Coffee Water Rate

Displays fault

Reset Factory Defaults

Set PRIME-NORMAL-RINSE switch

to RINSE position

Press the LARGE button, right pump

dilution water will run for 20 seconds.

Enter Liters collected from 20 sec.

test above

Default = .414

Use the (+) or (-) button to scroll forward or backward through faults.

Resets all set up values to the Factory

Default Setting.

Hold both Increase (+) and Decrease

(-) buttons for 10 seconds

Displays Software Version #-

PC

0 XX

Exits to home view after 3 sec.

19

39328.3 012113

Page 20

TROUBLESHOOTING GUIDE

MENU (-) (+)

MENU (-) (+)

Error Codes

When an error has occurred, all Door LED’s will be flashing. Open the Door to access the LED Display and record the Error Code. Refer to the list of Error Codes below to identify the problem. A troubleshooting guide is

provided to suggest probable causes and remedies for the most likely problems encountered. If the problem

remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department.

LED DISPLAY ERROR DESCRIPTION/TROUBLESHOOTING

CE

CE

MENU (-) (+)

CE

CE

MENU (-) (+)

0 0 1

0 0 2

0 0 3

0 0 4

Left (Decaf) Pump Failure

Right (Regular) Pump Failure

Heating Time Too Long

Fill Time Too Long

Left Motor or RPM Sensor Failure.

Check Motor and RPM sensor wires

for shorts or open connections

Right Motor or RPM Sensor Failure.

Check Motor and RPM sensor wires

for shorts or open connections

Tank Heater ON Continuous For More

Than 1.5 Hour. Check heater wires

for open connections.

Fill Valve ON Continuous For More

Than 15 minutes. Water Turned OFF.

Refill Valve disconnected. Faulty

Valve.

CE

MENU (-) (+)

CE

MENU (-) (+)

0

0 1 0

0 7

Tank Temp Sensor Failed

Overflow Switch Fault

20

Sensor Reading Out Of Range (High

or Low). Faulty Sensor wiring.

Water In Overflow Cup. Check liquid

level probe in tank lid for lime builup.

Check level probe wiring for open circuit.

39328.3 012113

Page 21

Field Calibration of the Concentrate Pumps, Dispenser Flow Rates,

and Hopper Powder Throw

The factory set default values for the Pump & Dispenser Flow Rates are very accurate and typically do not need

to be field calibrated. However, if the mix ratio accuracy is ever in question, this procedure can be used to recalibrate the unit in the field. Equipment Required:

50 or 100 ml graduated cylinder, with 1 ml graduations.

1000 ml graduated container.

NOTE: You can calibrate either the Concentrate Pump, Dispenser Flow Rate and set the Hopper Throw Rate independently. Simply scroll through the menu screen to the desired section and perform only those steps. (Refer

to Calibrating the Dispenser)

Calibrating the Concentrate Pumps.

Decaf Coffee - Concentrate Pump Calibration

1. Open the door of the dispenser and select PROGRAM on the Mode Selector Switch.

2. Depress and Hold the MENU switch for approximately 10 sec. The unit will display “C1 run” when it has

entered the Calibration Mode.

3. Select PRIME on the Function Selector Switch.

4. Remove the elbow from the Left (Decaf) Coffee Mixing Chamber and place a container under the mixing

chamber outlet. Press the SMALL cup button. The dispenser will display a 100 count down and then shut

the pump OFF automatically. Release the dispense switch.

5. Stop priming and allow the tip to stop dripping. Discard the concentrate collected.

6. Place a 50 ml graduated cylinder under the Left (Decaf) Coffee Mixing Chamber outlet.

7. Press the SMALL cup button. The dispenser will display a 100 count down and then shut the pump OFF

automatically. Release the dispense switch.

8. Keep the graduated cylinder under dispense tip until all the concentrate has dripped out.

9. Measure the volume of concentrate collected in the graduated cylinder.

The acceptable range for the volume of concentrate collected is 40 - 48 ml

10. If the amount collected is not within the acceptable range, empty the graduated cylinder and repeat STEPS

6 – 9.

11. If the amount collected is still not within range, replace the pump tubing with a new Tube Kit, (refer to the

Tube Replacement Instructions).

12. When satisfied with the volume of concentrate collected, press the MENU switch. The current Calibration

volume “C1 XX” will be displayed.

13. Use the (-) / (+) keys to adjust number displayed to the amount measured in STEP 9.

Regular Coffee - Concentrate Pump Calibration

Depress the MENU button to display the Regular Concentrate Pump calibration menu “C2 run”. Repeat STEPS

3 – 13 above for the right side “Regular” pump, using the LARGE cup button.

(Continued)

21

39328.3 012113

Page 22

Calibrating the Dispenser Flow Rates

Decaf Coffee - Dispenser Flow Rate Calibration

1. Select RINSE on the Function Selector Switch, and PROGRAM of the Mode Selector Switch. Depress and

Hold the MENU switch for approximately 10 sec. The unit will display “C1 run” when it has entered the Calibration Mode

2. Press the MENU button to display the Decaf Coffee Flow Rate calibration menu “C3 run”

3. Reconnect the elbow to the Left (Decaf) Coffee Mixing Chamber outlet. Place a container under Dispense Tip

and depress the SMALL cup button. A steady stream of water comes out the tip (20 seconds).

4. Allow the tip to stop dripping. Discard the water collected

5. Place a 1000 ml graduated container under Dispense Tip.

6. Press the DECAF dispense button. The dispenser will display a 20 second count down timer and then stop

dispensing automatically.

7. Keep the graduated container under dispense tip until all the water stops dripping.

8. Measure the volume of water collected in the graduated container.

The acceptable range for the volume of water collected is .39 - .43 liters

9. If the amount of water collected is not within the acceptable range, empty the graduated container and repeat

STEPS 5 – 8.

10. If the amount collected is still not within range, inspect the dispense valves, tubing and mix chamber for

lime, kinks or other obstructions.

11. When satisfied with the volume of water collected, press the MENU switch. The current Water Calibration

volume “C3 XX” will be displayed.

12. Use the (-) / (+) keys to adjust number displayed to the amount measured in STEP 8.

Regular Coffee - Dispenser Flow Rate Calibration

Depress the MENU button to display the Regular Coffee Flow Rate calibration menu “C4 run”.

Repeat STEPS 3 – 12 above for the right side Regular dispense valve, using the LARGE cup button.

Field Calibrating the Empty Product Warning

The dispenser will automatically illuminate the LED next to the Decaf or Hot Chocolate button when the Decaf or

Regular coffee BIB is empty. The Refill message is triggered when the conductance sensor reading drops below

the minimum setting. The factory set minimum is 450 and should be correct for many locations. However, in

some areas the harness of the local water supply will affect this reading. If the Refill message doesn’t come on

when the container is empty, or the message comes on too early and there is still concentrate in the container,

use the following procedure to find the correct Empty Product Threshold.

Calibrating The Empty Product Threshold

1. Remove the coffee concentrate BIB(s) from the Unit

2. Open the dispenser door to access the digital programming module with LED

3. Place a large container under the dispenser tip.

4. Place the NORMAL/PROGRAM/RINSE switch into the RINSE position

5. Press any dispense button on the door. The unit will automatically rinse for eight seconds. Repeat until the

water exiting the coffee nozzle is running clear.

6. Place the NORMAL/PROGRAM/RINSE switch into the RUN position.

7. Press the LARGE and the BLACK COFFEE button. Observe the numbers display on the LED panel, the

conductance reading will be displayed. (NOTE: It is typical for this number to fluctuate (+/-25) about the

nominal value.) This is the conductance of the water in your area. Record this reading.

8. Repeat steps six and seven, only pressing LARGE, DECAF and BLACK COFFEE button. Record this reading.

22

39328.3 101513

Page 23

9. Install the coffee BIB’s into the unit, and prime the pumps. Dispense several cups of both regular coffee and

Decaf coffee. If either one or both the DECAF and HOT CHOCOLATE LED illuminates during this process

and dispensing is disabled, the EMPTY PRODUCT WARNING can be reset by priming the appropriate pump

momentarily.

10. After several cups of both coffees have been dispensing, dispense both a REGULAR coffee and a DECAF

coffee. Observe the conductivity reading for each, and record.

11. Take the average of the largest reading from steps seven and eight with the lowest reading from step ten,

and enter this new value in the Empty BIB threshold position, “P10 XXX”, see Programming the dispenser.

Example, if the conductance readings with water from steps six and seven are 225 and 250, and the conductance readings with coffee from step ten is 355 and 370, you would average 250 and 355, and enter “302”

for the empty BIB threshold in “P10 XXX”.

Field Adjustment of Powder Hoppers

The powder throw for the powder products is pre-set from the factory. It can be checked and adjusted in the

field using this calibration procedure.

Adjusting the Hopper Throw Weight

1. Open the dispenser door to access the digital programming module with LED.

2. Remove the mixing chamber below the hopper outlet elbow.

3. Select PROGRAM on the Function Selector Switch, and NORMAL for the Mode Selector Switch.

4. Press the MENU button to display the Left Hopper Motor calibration menu “04 run”

5. Hold a container under the hopper outlet elbows, and press any beverage button on the front door.

6. The left hopper will run automatically for 10 second, and then stop.

7. Weight the contents of the container. Divide by 10 to determine grams or ounce per second of throw.

8. Press the MENU button to increment the display to menu “O4 XXX”. The number displayed is the power

level drive of the hopper motor. The power level can be increased or decreased by pressing (-) or (+) button.

Each increment is equal to approximately a 1% increase or decrease in hopper motor speed.

9. Press the MENU button to display the Right Hopper Motor calibration menu “05 run”.

10. Repeat steps 5 – 8 to measure and adjust the right hopper throw weight.

11. Replace the powder-mixing chamber, and return the Function Selector Switch to the RUN position.

23

39328.3 101513

Page 24

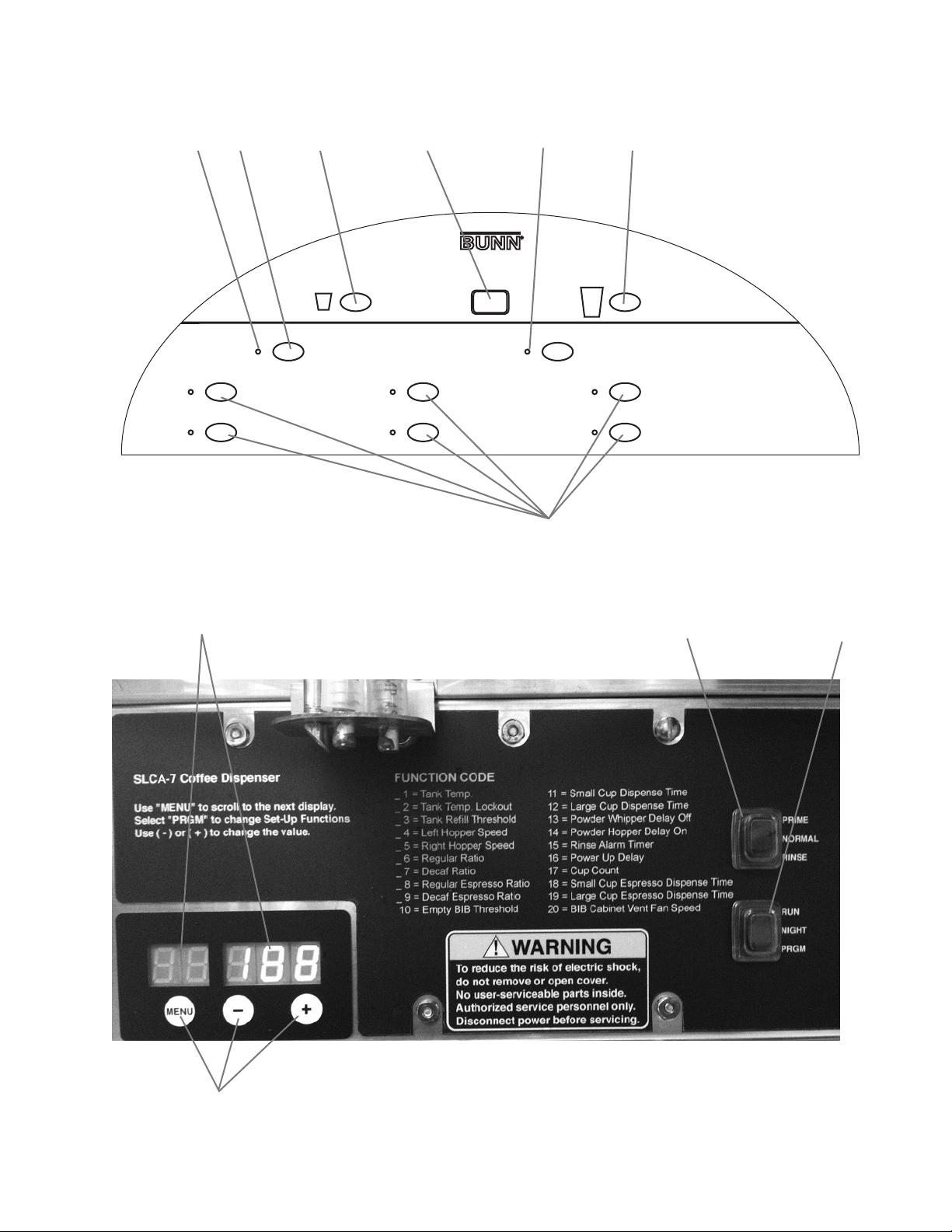

ELECTRICAL WIRING DIAGRAM SLCA-7

SCHEMATIC WIRING DIAGRAM SLCA-7

RED

RED

RED

RED

RED

LEFT

+

M

(1)

HOPPER

-

RIGHT

+

M

HOPPER (2)

-

LEFT RPM

SENSOR

-

LEFT

M

PUMP (3)

+

RIGHT RPM

SENSOR

-

RIGHT

M

PUMP (4)

+

POWDER WHIPPER (1)

LEFT COFFEE WHIPPER (3)

RIGHT COFFEE WHIPPER (4)

SWITCHES:

A1 SMALL CUP

A2 STOP

A3 LARGE CUP

A4 DECAF

A5 NOT USED

A6 HOT CHOCOLATE

A7 NOT USED

A8 CAPPUCINO

A9 MOCHA CAPPUCINO

A10 BLACK COFFEE

A11 LATTE

A12 MOCHA LATTE

A13 ESPRESSO

MEMBRANE SWITCH

LED INDICATORS:

L1 DECAF

L2 HOT CHOCOLATE

L3 NOT USED

L4 CAPPUCINO

L5 MOKA CAPPUCINO

L6 BLACK COFFEE

L7 LATTE

L8 MOKA LATTE

L9 ESPRESSO

+ SOL -

POWDER

+ SOL -

LEFT COFFEE

+ SOL -

RIGHT COFFEE

+ SOL -

INLET VALVE

BRN/WHI

GRN

WHI/RED

GRN

1

3

BRN/BLK

BRN/WHI

1

3

WHI/RED

RED/BLK

BRN/WHI

ORN

YEL

GRY

WHI/BLU

WHI/BLK

TAN

WHI/BLU

WHI/BLK

RED

GRN

L1L2L3L4L5L7 L6L9 L8

- M +

- M +

- M +

A2 A1

A4 A3

A6

L1 L2

WHI

230 VAC

CONNECTION

BLK

WHI/VIO

LIMIT

THERMOSTAT

BRN/WHI

BLK/WHI

ORG

GRN

BLU

WHI

BLK

RED/WHI

BLU/WHI

GRN/WHI

RED/BLK

ORG/BLK

GRN/BLK

BLU/BLK

WHI/BLK

BLK/RED

RED/GRN

RED

WHI/RED

BRN/WHI

WHI/BLU

WHI/BLU

WHI/RED

WHI/RED

WHI/BLK

BRN/WHI

RED/BLK

3

WHI

BLK

1

BLK

COM

RED

1

GRY

5

J3

ORN

YEL

8

1

GRN

GRN

ORN

5

YEL

BLU

BLK

10

J1

GRN

RED

15

VIO

GRN

GRN

20

1

J14

5

1

5

J2

10

15

20

ORN

YEL

GRN

BLU

GRN

MEMBRANE

SWITCH

SWITCH TAIL

SHEILD LAYER

A9

A11A10

A12A8

A13

LED TAIL

4

WHI

BLK

2

2

7

3

1

6

4

10

5

8

MENU

(-)

(+)

BLU/RED

ORG/RED

L1

120 VAC

CONNECTION

TANK HEATER

BLU

N.O.

1

J6

5

1

J15

4

1

J5

4

1

J11

3

1

5

J4

MAIN CONTROL BOARD

10

1

5

J13

10

12

1

5

J16

10

14

BLK

BLK

BLK

BLK

WHI

WHI

RED

RED

GRY

WHI/ORN

PNK

ORN

GRN

BLKBLK

RED

WHI

WHI/RED

WHI/BLK

RED

VIO

VIO

BLK

WHI/VIO

RED

VIO

GRY

WHI/BLK

WHI/GRY

N

WHI/VIO

WHI

L2

GROUND

120/208-240 VAC

CONNECTION

N

L1 L2

BLK

WHI

WHI/VIO

WHI

OVERFLOW

PROTECTION SWITCH

BLK

RED

RED

+V

+V

M

BLOWER FAN

GRY

WHI

BLK

1

WHI

POWER SUPPLY

-V

24VDC, 180 WATTS

-V

GROUND

N/L2

L1

BLK

WHI

PROBE

TANK

t°

230 VAC CONNECTION

BLK

RED

WHI

RED

BLOWER FAN

WHI

M

- M +

FAN

PRIME

NORMAL

LEFT

CONDUCTANCE

RIGHT

CONDUCTANCE

RINSE

PROGRAM

NIGHT

RUN

39318.0008 03 07/12 ©2012 BUNN-O-MATIC CORPORATION

120/208-240 VOLTS AC

3 WIRE + GROUND

or

120 or 230 VOLTS AC

2 WIRE + GROUND

SINGLE PHASE

60 HZ

24

39328.3 012113

Loading...

Loading...