Page 1

BUNN

®

Y

R

U

AUTION

J

C

IN

L

A

.

N

D

R

O

D

A

S

N

Z

R

A

A

E

S

S

H

P

R

T

E

C

G

E

J

N

I

B

R

F

E

O

.

P

P

G

N

E

P

N

G

I

E

I

O

K

N

E

H

E

R

F

P

O

O

O

F

T

E

U

T

O

U

H

C

R

O

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORA TION OF

CANADA LTD.

280 INDUSTRIAL PARKWAY SOUTH

AURORA, ONTARIO. L4G 3T9

PHONE: (905) 841-2866 FAX: (905) 841-2775

10218.7000 3/00 ©1994 Bunn-O-Matic Corporation

Page 2

CONTENTS

Introduction .............................................................................. 2

Warranty ................................................................................... 2

User Notices.............................................................................. 3

Electrical Requirements ............................................................ 4

Operating Controls ....................................................................4

Initial Set-Up ............................................................................. 4

Cleaning .................................................................................... 5

Coffee Grinding ......................................................................... 5

Adjustments ..............................................................................6

Troubleshooting ........................................................................ 7

Service .................................................................................... 10

Wiring Diagram .......................................................................20

INTRODUCTION

This equipment will store up-to six pounds of whole bean coffee in each of two hoppers and grind it to a preset grind and amount into

an awaiting funnel and filter from most commercial drip coffee brewers. The equipment is only for indoor use on a sturdy counter or shelf.

Adequate space must be available above the grinder to raise the lids when adding beans. Use only with whole bean coffee.

The grind is preset at the factory to fine specifications as set forth by the United States Department of Commerce and

adopted by the Coffee Brewing Center of the Pan American Coffee Bureau. Adjustments may be made to alter both the

amount and grind from the factory setting.

BUNN-O-MATIC COMMERCIAL GRINDER WARRANTY

Bunn-O-Matic Corp. (“Bunn”) warrants the equipment manufactured by it to be commercially free from defects in material and workmanship existing at the time of manufacture and appearing within one year from the date of installation. In

addition, Bunn warrants that the grinding burrs will grind coffee to meet original factory screen sieve analysis for three years

from date of installation or for 30,000 pounds of coffee, whichever comes first. This warranty does not apply to any equipment, component or part that was not manufactured by Bunn or that, in Bunn’s judgement, has been affected by misuse,

neglect, alteration, improper installation or operation, improper maintenance or repair, damage or casualty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn are not authorized to make modifications to this warranty or to make additional

warranties that are binding on Bunn. Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and

should not be relied upon.

The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (905) 841-2866 or

by writing to 280 Industrial Parkway South, Aurora, Ontario L4G 3T9. If requested by Bunn, the Buyer shall ship the

defective equipment prepaid to an authorized Bunn service location. If Bunn determines, in its sole discretion, that the

equipment does not conform to the warranty, Bunn shall repair the equipment with no charge for parts during the one year

warranty period and no charge for labor by a Bunn Authorized Service Representative during the one year warranty period.

If Bunn determines that repair is not feasible, Bunn shall, at its sole option, replace the equipment or refund the purchase

price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE

OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS SPECIFIED HEREIN, TO REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND. Bunn shall not be liable for

any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer’s

customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any other special, inciden-

tal or consequential damages.

2

Page 3

USER NOTICES

Carefully read and follow all notices on the grinder and in this manual. They were written for your protection. All notices on the

grinder are to be kept in good condition. Replace any unreadable or damaged labels.

WARNING

Use only on a properly protected circuit

capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

An extension cord, when used, must be shorter

than 20 feet if 16-gage 3-conductor wire, or

shorter than 10 feet if 18-gage 3-conductor wire.

CAUTION

PERSONAL INJURY

HAZARD.

KEEP FINGERS AND

FOREIGN OBJECTS

OUT OF HOPPER

OR CHUTE OPENING.

#05876.7999

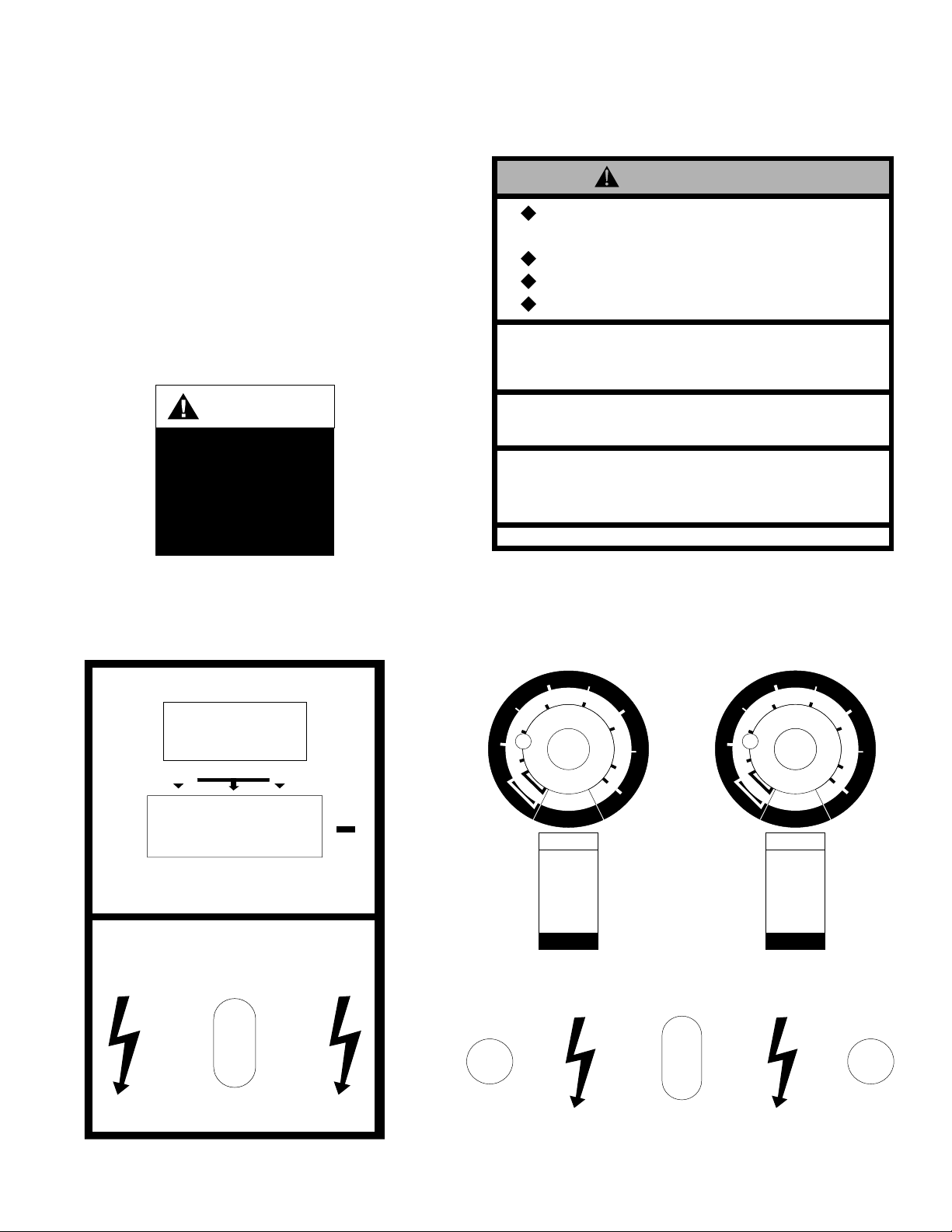

DISPENSE TIME (Seconds)

DISPLAY

Increase Decrease

+

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE, OR SHOCK HAZARD

READ THE ENTIRE OPERATING MANUAL

INCLUDING THE LIMIT OF WARRANTY AND

LIABILITY BEFORE BUYING OR USING THIS PRODUCT

20545-0000 7/90 © 1990 Bunn-O-Matic Corporation

#20545.7000

DISPENSE TIME

3.2

(SECONDS)

20

15

10

6

H

I

H

G

L

O

W

HIGH

3

25

11

30

32

4

22

20

15

10

6

3.2

.4.4

H

I

H

G

L

O

W

HIGH

3

25

30

32

4

Readout will be displayed for 5 minutes.

Timer can only be adjusted

while readout is displayed.

WARNING

HAZARDOUS VOLTAGE

UNPLUG GRINDER

BEFORE REMOVING!

#05942.0000

LEFT

LOW

RIGHT

LOW

WARNING

HAZARDOUS VOLTAGE

UNPLUG GRINDER

BEFORE REMOVING

#25763.0000

3

Page 4

ELECTRICAL REQUIREMENTS

This grinder has an attached cordset and requires 2-wire, grounded service rated 120 volts ac,

15 amp, single phase, 60 Hz.

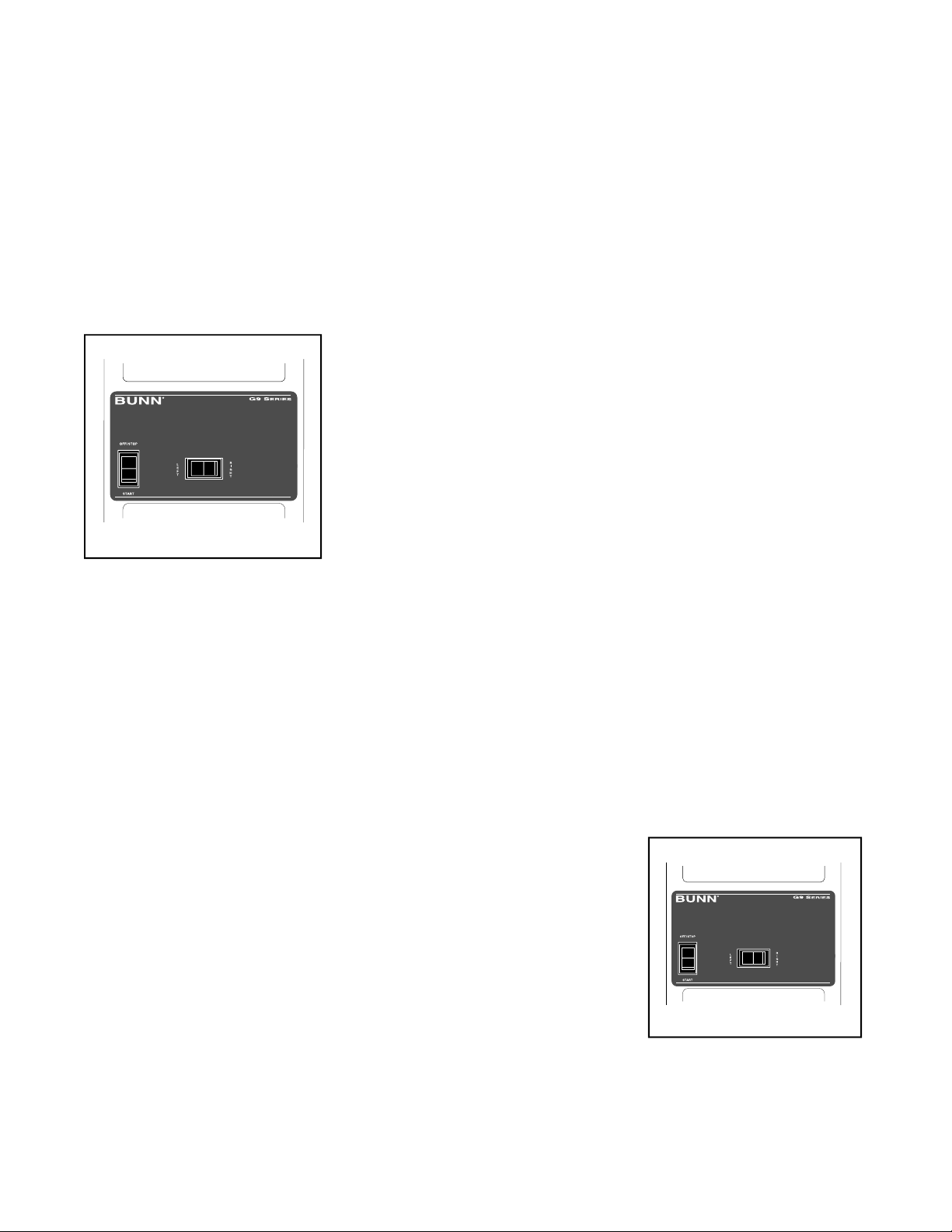

OPERATING CONTROLS

Off/On/Start Switch

OFF - (upper position) Switching to this position stops all operation of the grinder.

ON - (middle position) The switch will return to this position after a grind cycle has begun and

will remain in this position after grinding has ceased.

START - (lower, momentary position) Pressing the switch initiates

a timed grind cycle.

Hopper Selector Switch

Left - Switching to this position allows beans to be dispensed

from the left hopper.

Right - Switching to this position allows beans to be dispensed

from the right hopper.

P633

Dispense Timer

The dispense timer controls the amount of beans that will leave the hopper in a grind cycle. The

timer can be adjusted to dispense a different amount from each hopper. The scale is from 0.4 to

150.0 seconds. Refer to the Adjustments section for timer setting chart (page 7).

INITIAL SET-UP

1. Open the top lid. Clear all foreign objects and shipping material from

the hopper compartment and the entrance to the grind chamber.

2. Remove the lower front inspection panel.

3. Plug-in the grinder.

4. Select either the right or left hopper with the selector switch. Do

not press the start switch.

5. If grinder has an analog timer, proceed to step 6. If grinder has a

digital timer, momentarily press the center (DISPLAY) button on

the dispense timer panel. The readout will indicate the present

timer setting in seconds and will remain displayed for five minutes.

6. Adjust the timer setting to obtain the desired amount of coffee for the selected hopper.

7. Repeat steps 4 thru 6 for the other hopper.

8. Fill the hopper compartments with whole bean coffee. (Capacity 6 pounds each). The grinder is

now ready for use.

P633

4

Page 5

CLEANING

The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all

surfaces on Bunn-O-Matic equipment. Care should be taken not to scratch the hopper or windows with any

abrasive material. Regular cleaning will keep your grinder looking new for years.

COFFEE GRINDING

P598P597 P599 P600 P601

STEP 1 STEP 2 STEP 3 STEP 4 STEPS 5 & 6

1. Visually inspect the desired hopper for an ample supply of whole bean coffee.

2. Place a paper filter into the brew funnel. The filter must not be folded-over or tilted to one side.

3. Insert the funnel into the funnel rails and push until it stops.

4. Momentarily press the start switch. The grinding action will stop automatically after the preset amount of

ground coffee is dispensed into the funnel.

5. Remove the funnel from the grinder and level the bed of grounds by gently shaking.

6. The loaded funnel is now ready for use in any commercial drip coffee brewer according to the manufacturer’s

instructions.

5

Page 6

ADJUSTMENTS

The grind can be set from very fine to very coarse. The amount may be adjusted for use in most commercial coffee brewers. The following procedures should be used to make adjustments. A change in the burr adjustment will also change the amount dispensed. Any adjustment of the burrs should be followed by an adjustment

of the timer.

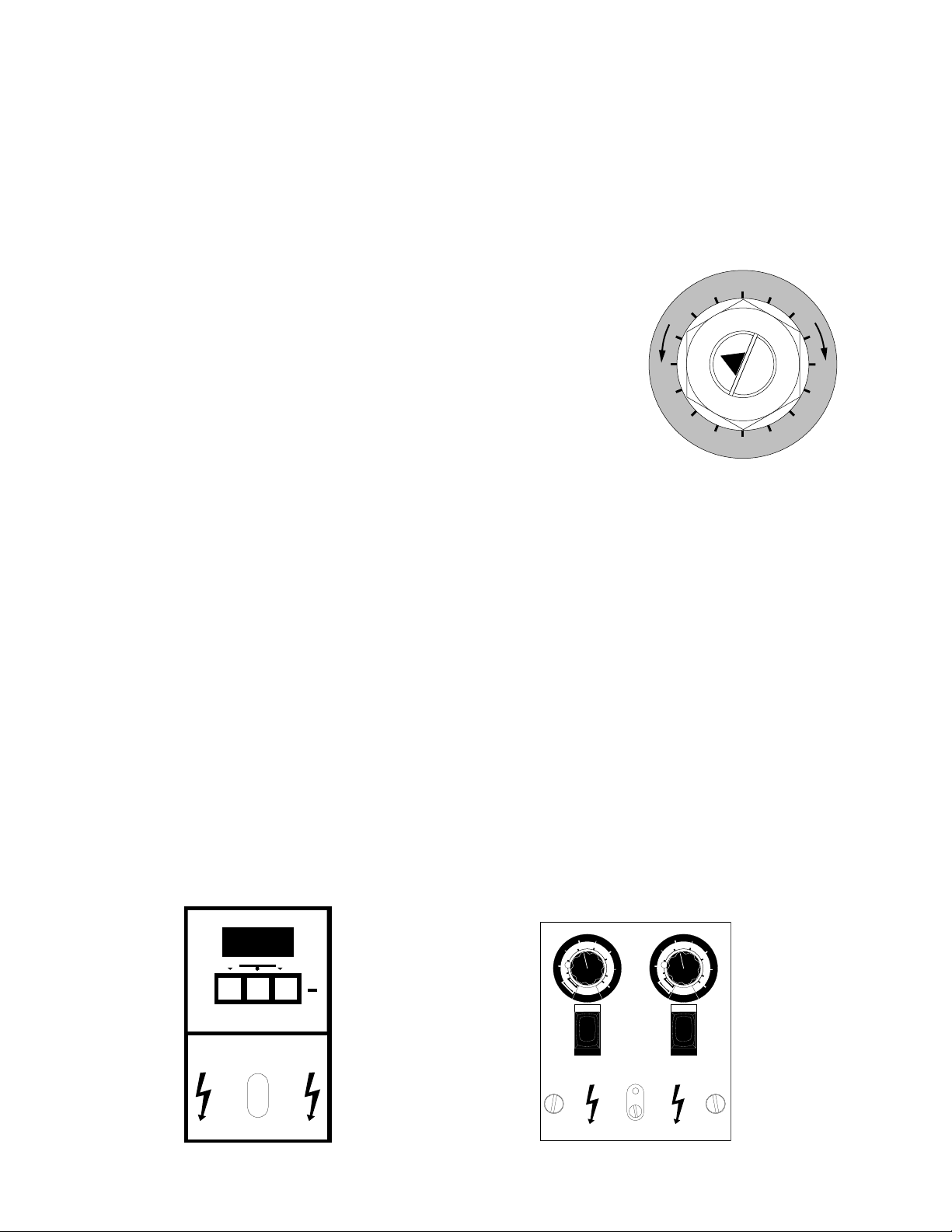

Burr Adjustment

1. Unplug the grinder and empty all beans from the hoppers.

2. Plug-in the grinder, momentarily press the off/on/start switch to the

“START” (lower) position (with either hopper selected) and release, run a

few grind cycles until all of the coffee in the grind chamber is used-up.

O

C

3. Remove the upper front inspection panel.

4. Loosen the burr adjustment screw from its locked position.

5. Hand loosen the adjustment locking nut around the screw approximately

one turn.

6. Press the off/on/start switch to the “START” (lower) position and release,

slowly turn the adjusting screw in a clockwise direction until a metallic

whine is heard due to the rubbing of the grinding burrs. (It may be neces-

sary to start more than one grind cycle to obtain this sound.)

7. Make a mark with a pen on the decal to note the position of the arrow on the grind adjustment screw.

8. The following settings approximately correspond to the CBC recognized grinds. All are referenced from the

arrow position noted in #7.

-

F

I

E

N

S

R

A

B

E

N

U

N

P581

P581

FINE GRIND: Rotate the adjusting screw 7 hash marks in a counterclockwise direction.

DRIP GRIND: Rotate the adjusting screw 8 hash marks in a counterclockwise direction.

REGULAR (COARSE) GRIND: Rotate the adjusting screw 12 hash marks in a counterclockwise direction.

9. Hold the adjusting screw in its set position with a screwdriver while tightening the lock nut to a snug

position by hand. Slightly loosen the adjusting screw and retighten it to its prior position. The lock nut

should now be tight against the burr housing front cover.

Timer Adjustment

1. Unplug the grinder and remove the lower front inspection panel.

2. Determine the grind setting. (The factory setting is fine, to determine other settings, refer to the

previous section.)

3. Use the table on the next page to find approximate timer setting for the grind and amount of coffee desired.

DISPENSE TIME (Seconds)

I 0.0

DISPLAY

Increase Decrease

+

Readout will be displayed for 5 minutes.

Timer can only be adjusted

while readout is displayed.

WARNING

HAZARDOUS VOLTAGE

DISPENSE TIME

20

15

3

25

10

6

30

3.2

32

4

H

I

H

G

L

O

W

HIGH

LEFT

LOW

WARNING

HAZARDOUS VOLTAGE

(SECONDS)

11

RIGHT

22

20

15

3

25

10

6

30

3.2

.4.4

32

4

H

I

H

G

L

O

W

HIGH

LOW

UNPLUG GRINDER

BEFORE REMOVING!

DIGITAL TIMER

UNPLUG GRINDER

BEFORE REMOVING

ANALOG TIMER

P595

6

Page 7

ADJUSTMENTS (cont.)

4. Plug-in the grinder. Select either the right or left hopper with the selector switch. Do not press

the start switch.

5. If grinder has an analog timer, proceed to step 6. If grinder has a digital timer, momentarily press the center

(DISPLAY) button on the dispense timer panel. The readout will indicate the present timer setting in seconds and will remain displayed for five minutes.

6. Adjust the timer setting to obtain the desired amount of coffee for the selected hopper.

7. Verify the setting by weighing a few samples. Use the following table as an approximate guide only.

8. Repeat steps 4 thru 7 for the other hopper.

APPROXIMATE TIMER SETTINGS IN SECONDS

Weight Fine Drip Regular

(ounces) (7*) (8*) (12*)

1.5 0.5 0.5 0.5

1.75 0.7 0.6 0.6

2.0 1.0 0.8 0.8

2.25 1.4 1.4 1.2

2.5 1.9 1.8 1.6

2.75 2.4 2.2 2.0

3.0 2.9 2.7 2.5

3.25 3.3 3.1 2.9

4.0 4.8 4.4 4.0

6.0 8.6 7.9 7.5

8.0 12.0 11.5 10.9

10.0 15.7 15.1 14.1

12.0 19.6 18.5 17.5

14.0 23.5 22.0 20.9

16.0 27.0 25.3 24.3

*Hash mark settings. Refer to

Adjustment-Burr

section.

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified

service personnel.

• All electronic components have 120 volt ac and low voltage dc potential on their terminals. Shorting

of terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If an intermittent condition is encountered, the cause will likely be a switch contact or a

loose connection at a terminal or crimp.

• Make certain that all electrical connections are tight and isolated.

WARNING

• Exercise extreme caution when servicing electrical equipment.

• Turn power OFF when servicing, except when electrical tests are specified.

• Follow recommended service procedures.

• Replace all protective shields or safety notices.

7

Page 8

TROUBLESHOOTING (cont.)

Problem

Grinder will not start.

Probable Cause

1. No power or incorrect voltage

2. Off/On/Start switch

3. Timer

4. Relay

5. Motor overload protector

Remedy

(A) Plug-in the grinder.

(B) Check the voltage at the wall

outlet with a voltmeter. It must

be 120 volts ac.

(A) Momentarily press the Off/On/

Start switch to the “START” (lower)

position.

(B) Refer to

switch for testing procedures. See

page 11.

Refer to

testing procedures. See page 17.

Refer to

procedures. See page 14.

Remove the cover plate located on

the right side of the housing. Press

the red “Reset” button. Listen

carefully for a “click”. This resets the

motor protection circuit and indicates that an overload may have

been encountered by the motor. (An

overload can occur when something

other than coffee is inserted into the

hopper for grinding.) Refer to

Service

procedures. See page 12.

Service

Service

Service

Motor for disassembly

- Off/On/Start

- Timer for

- Relay for testing

Grinder will not shut off.

6. Motor

1. Off/On/Start switch

2. Timer

8

Refer to

procedures. See page 12.

(A) Place the switch in the “OFF/

STOP” position.

(B) Refer to

Switch for testing procedures. See

page 11.

Refer to

procedures. See page 17.

Service

Service

Service

- Motor for testing

- Off/On/Start

- Timer for testing

Page 9

Probable Cause

Remedy

3. Relay

1. Hoppers

2. Bottoms of hoppers

Refer to

Service

- Relay for testing

procedures. See page 14.

Begin each grind cycle by visually

inspecting the hoppers for ample

supplies of whole bean coffee.

Foreign materials must not block the

openings at the bottom of the hoppers.

Refer to

Service

- Off/On/Start switch

for testing procedures. See page 11j0 -1.92 TD0.00A) Che bloo ss. thngs at slid. Slgn s themove freelyloo visowhole sloo travelmple

9

Page 10

SERVICE

This section provides procedures for testing and

replacing various major components used in this

grinder should service become necessary. Refer to

Troubleshooting

cause of any problem.

WARNING - Inspection, testing, and repair of electri-

cal equipment should be performed only by qualified

service personnel. The grinder should be unplugged

when servicing, except when electrical tests are required and the test procedure specifically states to

plug-in the grinder.

Component Access

WARNING - Unplug the grinder before the removal of

any panel or the replacement of any component.

All components are accessible by the removal

of the upper and lower front inspection panels, hopper assembly, and rear panel.

for assistance in determining the

WARNING

Use only on a properly protected circuit

capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

An extension cord, when used, must be shorter

than 20 feet if 16-gage 3-conductor wire, or

shorter than 10 feet if 18-gage 3-conductor wire.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE, OR SHOCK HAZARD

READ THE ENTIRE OPERATING MANUAL

INCLUDING THE LIMIT OF WARRANTY AND

LIABILITY BEFORE BUYING OR USING THIS PRODUCT

20545-0000 7/90 © 1990 Bunn-O-Matic Corporation

NOTICE

For connection to Bunn-Omatic

Coffee Brewer Models:

Dual, OT, Single, & System III only.

(24 volt N.E.C. Class 2 circuit only.)

BUNN

N

O

I

A

T

R

O

P

C

R

O

C

T

I

A

M

-

N

O

-

N

U

B

Y

B

E

D

R

T

U

C

A

U

F

N

A

M

.

A

S

U

.

.

,

O

S

N

I

I

I

L

L

,

L

D

E

F

I

G

N

I

P

R

S

N

/

S

L

D

O

E

M

T

S

T

A

W

P

M

A

.C

.

A

S

L

T

O

V

Z

R

T

E

H

E

R

I

W

E

S

H

A

P

:

T

S

N

T

E

A

P

G

N

I

W

O

L

L

O

F

E

T

H

O

F

E

R

O

M

O

R

E

O

N

R

E

N

D

U

E

D

R

E

C

V

O

IN

G

D

N

P

E

B

E

Y

M

A

S

N

T

E

A

T

P

E

R

H

O

T

E

R

M

O

R

O

N

O

E

The rear panel is attached with eight 8-32 slot-

ted head screws.

P604

The upper front inspection panel is attached with

two 6-32 slotted head screws.

CAUTION

PERSONAL INJURY

HAZARD.

KEEP FINGERS AND

FOREIGN OBJECTS

OUT OF HOPPER

OR CHUTE OPENING.

The lower front inspection panel is attached with

two 6-32 slotted head screws.

P602

P603

P605

The hopper assembly is attached with four 632 slotted head screws with locking nuts located on

the sides of the housing near the center and rear.

Removal of the hopper will also require disconnection of the solenoid wires from the grinder wiring harness.

Contents

Off/On/Start Switch............................................. 11

Motor.................................................................. 12

Relay .................................................................. 14

Slide Plate(s) ...................................................... 15

Snubber .............................................................. 16

Solenoid(s) ......................................................... 16

Timer .................................................................. 17

10

Page 11

SERVICE (cont.)

Off/On/Start Switch

If continuity is present as described, proceed

to #6.

If continuity is not present as described, re

place the switch.

6. Check for continuity across the right terminals

when the switch is placed in the “START” (lower)

position only.

If continuity is present as described, the

Off/On/Start switch is operating properly.

If continuity is not present as described,

replace the switch.

Location:

The Off/On/Start switch is located to the left side

on the front of the housing above the upper front

inspection panel.

Test Procedure:

1. Unplug the grinder.

2. Remove the black wire from the switch.

3. Check for continuity across the black wire from the

Off/On/Start switch and the left blade of the cordset

connector (see illustration below).

CORDSET CONNECTOR

Looking Straight-on

Black

Removal and Replacement:

1. Remove all wires from the switch terminals.

2. Compress the clips inside the front wrapper and

gently push the switch through the opening.

3. Push the new switch into the opening and spread

the clips to retain the switch in the hood.

4. Refer to the following illustration when reconnecting the wires.

If continuity is present as described, proceed

to #4.

If continuity is not present as described, refer

to the

Wiring Diagrams

and check the grinder

wiring harness.

4. Remove the remaining wires from the switch.

5. Check for continuity across the left terminals when

the switch is placed in both the “ON” (center) and

“START” (lower) positions.

11

Page 12

SERVICE (cont.)

Motor

P607

Location:

The motor is located in the upper wrapper.

Test Procedure:

1. Remove the cover plate located on the right side

of the housing. Press the red “Reset” button visible through the opening. Listen carefully for a

“click”. This resets the motor protection circuit

and may indicate that something other than coffee was inserted into the hopper for grinding.

If the grinder remains unable to start, proceed

to #2.

If the grinder stops operating shortly after start-

ing, refer to the removal and replacement steps to

gain access to the grind chamber. Remove any foreign materials that may be found.

2. Unplug the grinder.

3. Remove the electrical access panel at the rear

of the motor.

4. Check the voltage across terminals L1 & L2 of the

motor with a voltmeter when the Off/On/Start

switch is pressed to the “START” (lower) position

and released. Plug-in the grinder. The indication

must be 120 volts ac.

5. Unplug the grinder

If voltage is not present as described, refer to

the

Wiring Diagrams,

and check the grinder wiring

harness.

Removal and Replacement - MOTOR

1. Remove all wires from the solenoids and lift the

hopper assy out of the grinder housing.

2. Remove all wires from the Off/On/Start switch,

motor, and motor mounting plate.

3. The entire wiring harness must be fed into the

bottom of the grinder housing through the hole

in the motor mounting plate.

4. Remove both 6-32 screws beneath the upper

front inspection panel.

5. Remove the six 10-32, slotted, hex head screws

on top of the motor mounting plate.

6. Slowly slide the assembly out the rear of the

grinder housing. The mounting plate may have

to be raised to gain clearance for the motor hardware and wiring harness bushing.

7. Remove the four 5/16"-18 bolts and nuts to separate the motor from the mounting plate.

8. Mount the new motor and tighten the four bolts

and nuts. They should be tightened approximately one full turn past snug.

9. Slide the motor mounting plate into the rear of

the grinder housing.

10. Feed the wiring harness into the top of the housing through the hole in the motor plate.

11. Reinstall the six 10-32 hex head screws through

the motor plate and the two 6-32 slotted head

screws through the housing.

12. Reattach the green wire to the 10-32 stud on

the motor mounting plate.

13. Refer to the

Off/On/Start switch

section when

reconnecting the switch wires.

14. Refer to the

Solenoid

section when reconnect-

ing the solenoid wires.

15. Refer to the following illustration when reconnecting the wires.

If voltage is present as described and the grinder

remains unable to start, replace the motor.

12

Page 13

SERVICE (cont.)

Motor (cont.)

WHI/ BLU to Snubber

WHI/BLU to Relay

WHI/BLK to Cordset

WHI/BLK to Snubber

GRN to Chasis Ground

YEL to Snubber

Removal and Replacement - GRIND CHAMBER

1. Remove the two 1/4"-20 screws holding the front

cover to the burr housing. Carefully remove the

burr housing front cover. Inspect the adjusting

screw to see if the thrust plug is worn.

Replace if excessively worn or damaged.

2. Carefully remove the rotor cup, shear plate, and

burr rotor from the grinder. Inspect the shear

plate and burrs for wear.

Replace if excessively worn or damaged.

3 Remove and inspect the stationary burr for wear.

Replace if excessively worn or damaged.

4. Inspect the grind chamber and remove any foreign materials. The burrs will not properly seat

in the chamber if any material or coffee particles

remain.

5. Reinstall the stationary burr, burr rotor, shear

plate, rotor cup, and dial plate to the burr housing.

6. Refer to the

Adjustments

section to vary the

grind dispensed.

P621

13

Page 14

SERVICE (cont.)

Relay

Grinders with Digital Timer

N

E

P

S

I

D

e

s

a

e

r

c

n

I

+

Timer can only be adjusted

Readout will be displayed for 5 minutes.

while readout is displayed.

W

R

A

Z

A

H

P

N

U

F

E

B

S

I

D

3

0

2

2

5

2

5

1

0

3

0

1

2

3

4

1

6

2

.

3

H

G

I

H

4

.

W

O

L

H

G

I

H

T

F

E

L

F

F

O

N

O

W

O

L

A

W

D

R

A

Z

A

H

P

N

U

O

F

E

B

the

Wiring Diagrams

and check the grinder wiring

harness.

4. Remove the white/red and white/blue wires from

the relay contacts.

5. Check for continuity across the relay contacts

when the Off/On/Start switch is pressed to the

“START” (lower) position and released. Plug-in

)

s

d

n

o

c

e

S

(

E

M

I

T

E

S

e

s

a

e

r

c

e

D

Y

A

L

P

S

I

D

G

E

G

A

IN

T

N

L

O

R

V

A

S

U

O

D

R

E

D

G

N

I

N

I

R

V

G

O

G

M

U

E

L

R

E

R

O

the grinder. Continuity must be present for the

approximate setting on the timer.

6. Unplug the grinder.

If continuity is present as described, reconnect

the white/red and white/blue wires, the relay is operating properly.

If continuity is not present as described, replace

the relay.

Removal and Replacement

1. Remove all wires from the relay terminals.

3

E

0

2

2

IM

5

2

T

5

E

1

)

S

S

N

D

E

N

P

0

O

3

C

E

0

S

1

(

2

3

4

1

6

2

.

3

H

G

I

H

4

.

W

O

L

H

G

I

H

F

F

O

N

O

T

H

G

I

R

W

O

L

E

G

G

A

IN

T

L

N

O

R

V

S

U

O

R

E

D

G

N

I

N

I

R

V

G

O

G

M

U

E

L

R

E

R

2. Remove the 6-32 screw fastening the relay to

the timer bracket.

3. Mount the new relay to the timer bracket and

tighten the screw.

4. Refer to the following illustration when recon-

necting the wires.

Grinders with Analog Timer

P609

Location:

The relay is located on the timer bracket in the

grinder base. The bracket can be removed by loosening the two 8-32 slotted head screws beneath the timer

dial.

Test Procedure:

1. Unplug the grinder.

2. Check the voltage across the red/black and

white/green wires of the relay coil with a volt-

meter when the Off/On/Start switch is pressed

to the “START” (lower) position and released.

Plug-in the grinder. The indication must be 120

volts ac for the approximate setting on the timer.

3. Unplug the grinder.

If voltage is present as described, reconnect the

red/black and white/green wires to the relay coil, and

proceed to #4.

If voltage is not present as described, refer to

WHI/BLU to

Motor L1

RED/BLK to

Timer P4-7

WHI/RED to

Timer P4-6

WHI/GRN to

Timer P4-3

P610

14

Page 15

SERVICE (cont.)

Slide Plate(s)

Location:

The slide plates are located on the solenoid

mounting plate immediately beneath the hopper openings.

The slide plates must always remain flat for

proper operation.

Test Procedure:

With the solenoid mounting plate attached to

the hopper, push the solenoid plunger into the coil.

The slide plate must move freely in the assembly and

snap closed when the plunger is released. Repeat for

the other slide plate.

If the slide plates move as described, they are

operating correctly.

If the slide plates do not move as described, the

problem may be in any one or more of the linkage

pieces, springs, slide plates, and/or the solenoid

mounting plate. Disassemble the solenoid mounting

plate assembly and inspect all components for free

movement.

Replace if excessively worn or damaged.

Removal and Replacement:

1. Remove the hopper from the grinder.

2. Remove six slotted head screws holding the

solenoid mounting panel to the hopper.

3. The slide plate with attached linkage can be lifted

off the pivot pin and removed with the solenoid

plunger.

4. Refer to the illustration above when reassembling the components.

5. Inspect the slide plates after reassembly.

They must move freely.

15

Page 16

SERVICE (cont.)

Snubber

Solenoid(s)

Location:

The snubber is located at the back of the motor

attached to the right side of the wiring harness.

Removal and Replacement:

1. Remove the snubber wires from the motor terminals.

2. Cut the ties holding the snubber to the wiring

harness.

3. Refer to the following illustration when reconnecting the wires.

4. Fasten the snubber to the wiring harness using

new ties.

Location:

The solenoids are located on the mounting plate

immediately beneath the hoppers.

Test Procedure:

1. Unplug the grinder.

2. Check the voltage across the left or right solenoid coil terminals with a voltmeter when the

Off/On/Start switch is momentarily pressed to

the “START” (lower) position and released (hopper selector switch must be corresponding to

the suspect solenoid). Plug-in the grinder. The

indication must be 120 volts ac.

3. Unplug the grinder.

If voltage is present as described, proceed to #4.

If voltage is not present as described, refer to

the

Wiring Diagram

ness.

and check the grinder wiring har-

4. Separate the connectors on the white/brown

wires of the solenoids from the connectors on

the grinder wiring harness. (White/orange and

red/black to the left solenoid and white/yellow

and red/black to the right solenoid.)

5. Check for continuity across the white/brown

wires on the suspect solenoid coil.

16

Page 17

SERVICE (cont.)

Solenoid(s) (cont.)

If continuity is present as described, reconnect

the white/brown wires to the grinder wiring harness,

and proceed to #6.

If continuity is not present as described, replace

the solenoid.

6. Check the solenoid for coil action when the con-

trol switch is momentarily pressed to the

“START” (lower) position and released. Plug-in

the grinder. Listen carefully in the vicinity of the

solenoid for a “clicking” sound as the coil magnet attracts and after a period of time, repels the

plunger.

7. Unplug the grinder.

RED/BLK to

Right Solenoid

RED/BLK to

Timer P4-7

WHI/ORN to

Timer P4-4

Timer

Left

WHI/YEL to

Timer P4-5

RED/BLK to

Left Solenoid

Right

P612

If the sound is heard as described and the

plunger remains unable to move or move freely, refer

to the slide plate section.

If the sound is not heard as described, replace

the solenoid

Removal and Replacement:

1. Remove the hopper assy from the grinder.

2. Remove the four 8-32 slotted-head screws hold-

ing the solenoid coil to the solenoid panel.

3. Feed the white/brown wires through the hole in

the solenoid mounting plate and loosely install

the new solenoid coil.

4. Look through the collector on the bottom of the

assy and adjust the slide plate travel distance

when installing the solenoid coil.

5. Push the solenoid plunger into the solenoid coil

with your hand while moving the coil forward

or backward in its mounting holes.

6. Securely tighten the mounting screws when the

slide plate appears to have no metal showing in

the front or back of the hopper hole.

7. Refer to the following illustration when recon-

necting the wires.

DISPENSE TIME (Seconds)

Decrease

DISPLAY

.

s

e

t

u

n

i

m

5

r

Increase

d

o

f

e

t

d

s

e

u

j

.

y

d

d

a

l

a

e

p

y

s

e

i

a

l

b

d

p

y

s

l

e

i

n

b

d

+

l

o

l

s

i

i

n

w

t

a

t

u

c

u

o

r

o

d

e

E

d

a

m

a

e

i

G

r

e

T

A

R

le

i

T

h

L

w

O

V

S

U

WARNING

O

D

R

A

Z

A

H

UNPLUG GRINDER

BEFORE REMOVING

Digital Timer

3

E

0

2

2

IM

5

2

T

5

E

1

S

N

E

NDS)

P

0

3

IS

0

D

1

(SECO

2

3

4

1

6

3

2

.

3

H

0

2

G

2

I

H

5

4

2

.

W

5

O

1

L

H

G

I

0

H

3

0

1

2

3

F

F

O

4

1

6

2

.

N

3

H

O

G

T

I

H

H

G

4

I

.

R

W

O

L

W

O

L

H

G

I

H

T

F

E

L

F

F

O

E

N

G

O

A

T

L

O

W

V

O

L

S

U

WARNING

O

D

R

A

Z

A

H

UNPLUG GRINDER

BEFORE REMOVING

Analog Timer

P613

Location:

The timer is located in the grinder base.

Test Procedure:

1. Unplug the grinder.

2. Check the voltage across contacts 1 & 2 of the

larger connector on the timer board with a voltmeter whenever the grinder is plugged-in. Plugin the grinder. The indication must be 120 volts

ac.

3. Unplug the grinder.

17

Page 18

SERVICE (cont.)

Timer (cont.)

4. Check the voltage across contacts 2 & 6 of the

larger connector on the timer board with a voltmeter when the control switch is in any position

except “OFF” (center). Plug-in the grinder. The indication must be 120 volts ac.

5. Unplug the grinder.

If voltage is present as described, proceed to

#6.

If voltage is not present as described, refer to

the

Wiring Diagram

ness.

6. Check the voltage across contacts 3 & 7 of the

larger connector on the timer board with a voltmeter after the Off/On/Start switch has been momentarily pressed to “START” (lower) position and

released. Plug-in the grinder. The indication must

be 120 volts ac.

7. Unplug the grinder.

and check the grinder wiring har-

has been momentarily pressed to the right

“START” (lower) position and released. Plug-in

the grinder. The indication must be 120 volts ac

and should remain for the approximate timer

setting.

11. Unplug the grinder.

If voltage is present as described, the timer is

operating properly.

If voltage is not present as described, replace

the timer.

Removal and Replacement:

1. Separate the grinder wiring harness connectors

from the timer circuit board.

2. Remove the relay from the timer bracket.

3. Attach the relay to the new timer bracket.

4. Refer to the following illustration when reattaching the connectors.

5. Refer to the

ume dispensed.

Adjustments

section to reset the vol-

If voltage is present as described, proceed to

#8.

If voltage is not present as described, replace

the timer.

8. Check the voltage across contacts 4 & 7 of the

larger connector on the timer board with a voltmeter after the hopper selector switch is set to

the left position and the Off/On/Start switch has

been momentarily pressed to the “START”

(lower) position and released. Plug-in the

grinder. The indication must be 120 volts ac and

should remain for the approximate timer setting.

9. Unplug the grinder.

If voltage is present as described, proceed to

#10.

If voltage is not present as described, replace

the timer.

10. Check the voltage across contacts 5 & 7 of the

larger connector on the timer board with a voltmeter after the hopper selector switch is set to

the right position and the Off/On/Start switch

18

Page 19

SERVICE (cont.)

Timer (cont.)

(P1-8) BLU to Off/On/Start Switch,

Selector Switch

(P1-6) ORA to Selector Switch

BLK to Cordset

BLK to Off/On/Start Switch

WHI/BLK to Cordset

WHI/GRN to Relay Coil

WHI/ORN to Left Solenoid

WHI/YEL to Right Solenoid

WHI/RED to Off/On/Start Switch

WHI/RED to Relay Contact

RED/BLK to Relay Coil

RED/BLK to Left Solenoid

BLK to Off/On/Start Switch

WHI/BLK to Cordset

WHI/GRN to Relay Coil

WHI/ORN to Left Solenoid

1

P4

8

Digital Timer

1

P4

(P1-2) VIO to Off/On/Start Switch

(P1-1) YEL to Selector Switch

P1

8

1

P2

1

3

1

P3

11

(P1-8) BLU to Off/On/Start Switch,

8

P1

1

(P1-6) ORA to Selector Switch

Selector Switch

(P1-2) VIO to Off/On/Start Switch

(P1-1) YEL to Selector Switch

WHI/YEL to Right Solenoid

WHI/RED to Off/On/Start Switch

WHI/RED to Relay Contact

RED/BLK to Relay Coil

RED/BLK to Left Solenoid

8

Analog Timer

P614

19

Page 20

L1 N

BLK

YEL

VIO

GRY

TAN

ORA

BLU

WHI/RED

WHI/BLK

WHI/GRN

WHI/ORA

WHI/YEL

RED/BLK

RT

SOL

1

WHI/BLU

SOL

YEL

LT

2

SNUBBER

WHI/BLK

K1

120 VOLTS AC

2 WIRE

SINGLE PHASE

60 HZ

WHI/RED WHI/BLK

10756.0000G 3/97 © 1993 BUNN-O-MATIC CORPORATION

K1 N.O.

WHI/BLU

M

L2L1

20

Loading...

Loading...