®

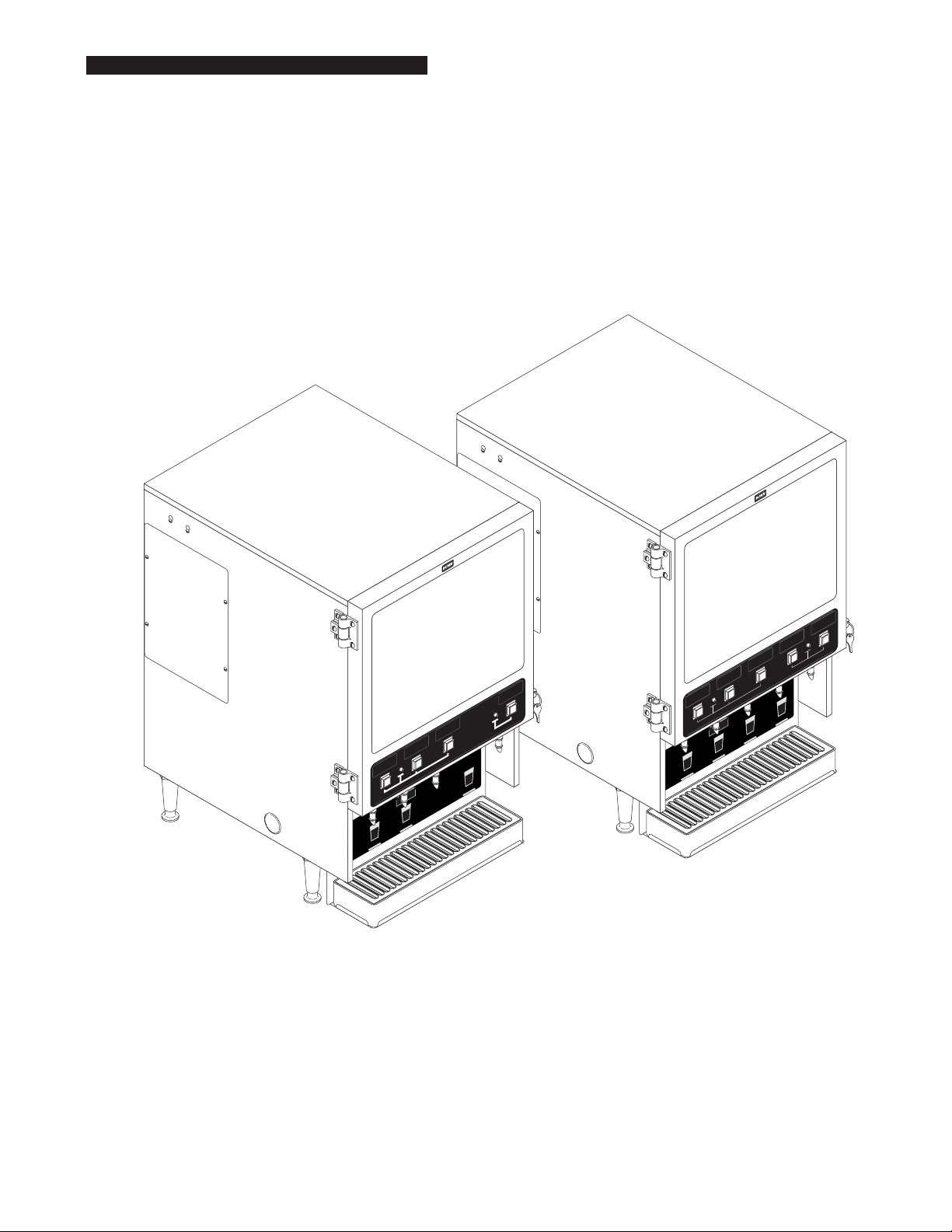

BUNN

FMD-4

FMD-5

RINSE

E

RINSE

CUP HERE

RELEASE BUTT

PLACE

CUP HERE

WARNING

!

H O T

L I Q U I D

ON WHEN CUP IS 2/3 FULL

PLACE

CUP HERE

PUSH and HOLD BUTTON UNTIL CUP IS 2/3 FULL, THEN RELEAS

RINSE

RINSE

PUSH and HOLD BUTTON UNTIL CUP IS 2/3 FULL, THEN RELEASE

WARNING

!

H O T

Q U I D

L I

ON WHEN CUP IS 2/3 FULL

RELEASE BUTT

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

35135.0000 03/03 ©2003 Bunn-O-Matic Corporation

www.bunnomatic.com

INTRODUCTION

This equipment dispenses hot beverages or soups on demand from powdered product. It is for indoor use only on a sturdy counter

or shelf.

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis: parts and labor for 3 years

or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will be commercially

free of defects in material and workmanship existing at the time of manufacture and appearing within the applicable warranty period.

This warranty does not apply to any equipment, component or part that was not manufactured by BUNN or that, in BUNN’s judgment,

has been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, damage or

casualty. This warranty is conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by

telephone at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping

the defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from BUNN that the

defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are not authorized to make modifications to this warranty or to

make additional warranties that are binding on BUNN. Accordingly, statements by such individuals, whether oral or written, do not

constitute warranties and should not be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its exclusive option while the

equipment is under warranty, shall either 1) provide at no charge replacement parts and/or labor (during the applicable parts and labor

warranty periods specified above) to repair the defective components, provided that this repair is done by a BUNN Authorized Service

Representative; or 2) shall replace the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS EQUIPMENT,

WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S SOLE OPTION AS SPECIFIED HEREIN, TO

REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales, loss of use of

equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute equipment, facilities or services, or any

other special, incidental or consequential damages.

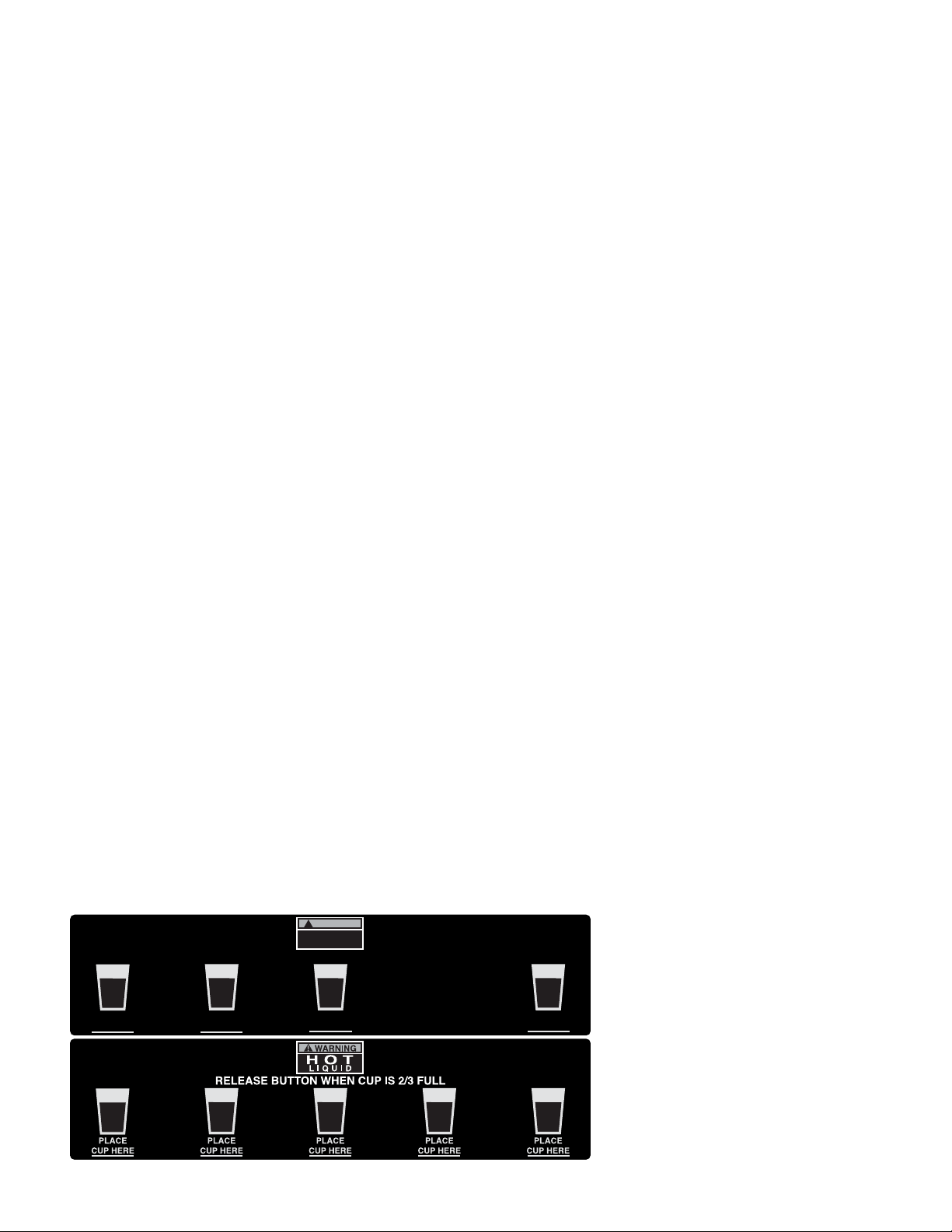

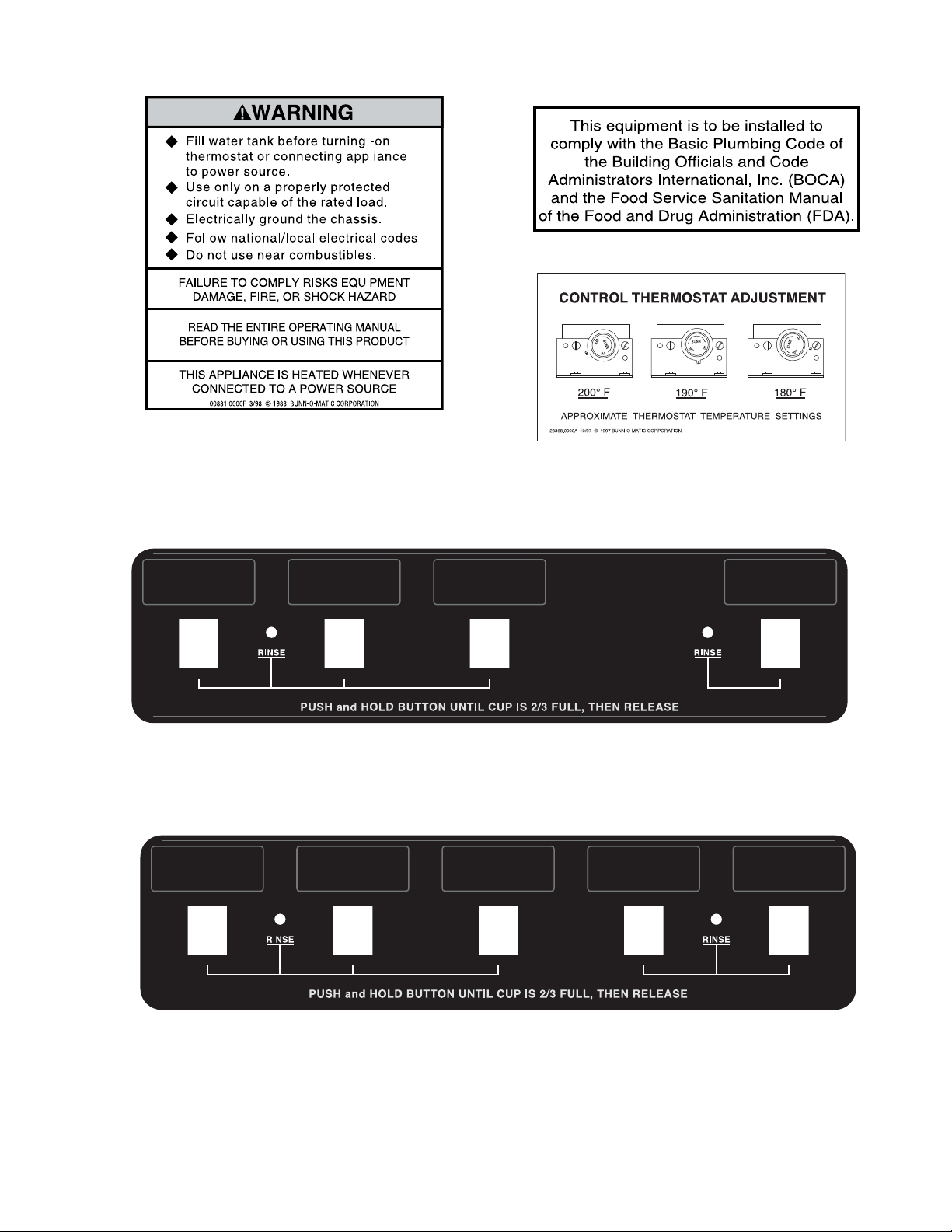

USER NOTICES

Carefully read and follow all notices on the equipment and in this manual. They were written for your protection. All notices are to be

kept in good condition. Replace any unreadable or damaged labels.

!

WARNING

H O T

RELEASE BUTTON WHEN CUP IS 2/3 FULL

L I Q U I D

FMD-4 28328.0008

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

FMD-5 28328.0009

2

35135 012103

USER NOTICES (Cont.)

00831.0000

00656.0000

28368.0000

FMD-4 28964.0004

FMD-5 28964.0003

3

35135 012103

INITIAL SET-UP

1. Locate the drip tray assembly inside the dispenser door.

2. Remove the drip tray and the drip tray cover and set them aside.

ELECTRICAL REQUIREMENTS

CAUTION - The dispenser must be disconnected from the power source until specified in

The 120 volt version of this dispenser has an attached cordset and requires 2-wire, grounded service rated 120

volts ac, 15 amp, single phase, 60 Hz. The mating connector must be a NEMA 5-15R.

The 120/208 and the 120/240 versions of this dispenser has an attched cordset. The mating connector must be

a NEMA 14-20R.

(

Refer to the dispenser’s dataplate for exact voltage requirement.)

Initial Set-Up.

ELECTRICAL HOOK-UP

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specified.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. Open the front door of the dispenser and place the heater switch in the “OFF” (upper position).

4. Connect the dispenser to the power source.

5. If plumbing is to be hooked-up later be sure the dispenser is disconnected from the power source. If plumbing has been hooked-up, the dispenser is ready for

Initial Fill & Heat.

PLUMBING REQUIREMENTS

This dispenser must be connected to a cold water system with operating pressure between 20 and 100 psi

(138 and 690 kPa). This water source must be capable of producing a minimum flow rate of 4.5 fluid ounces

(133.1 ml) per second. A shut-off valve should be installed in the line before the dispenser. Install a regulator in

the line when pressure is greater than 100 psi (690 kPa) to reduce it to 50 psi (345 kPa). The water inlet fitting

is 3⁄8" flare.

NOTE - At least 18 inches of an FDA approved flexible beverage tubing, such as reinforced braided polyethylene

or silicone, before the dispenser will facilitate movement to clean the countertop. It can be purchased direct from

Bunn-O-Matic (part number 00327-0000). Bunn-O-Matic does not recommend the use of a saddle valve to

install the dispenser. The size and shape of the hole made in the supply line by this type of device may restrict

water flow.

This equipment must be installed to comply with the Basic Plumbing Code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the Food and Drug Administration (FDA).

PLUMBING HOOK-UP

1. Flush the water line and securely attach it to the flare fitting on the bottom of the dispenser.

2. Turn-on the water supply.

4

35135 012103

INITIAL FILL & HEAT

CAUTION - The dispenser must be disconnected from the power source throughout the initial set-up, except

when specified in the instructions.

1. Turn-on the water supply and connect the dispenser to the power source.

2. Water will automatically flow into the tank to the proper level and then shut-off. This will take less than five

minutes.

3. When the tank is full of water, open the front door and place the heater switch in the “ON” (lower) position.

A tank full of cold water will take approximately eighty minutes for the water to heat on 120 volt versions or

forty minutes for 120/208 volt versions and 120/240 volt versions.

During this waiting period, complete these dispenser set-up steps:

a. Place the drip tray in front of the dispenser. Set the drip tray cover in place.

b. Place a set of keyholes in the cup locator plate over the screws beneath the hopper access door and push down

gently.

c. Fill the hoppers with the dry product to be dispensed.

LIQUID LEVEL CONTROL

The system automatically maintains the hot water tank’s level by energizing the refill solenoid when the water

level drops below the liquid level probe. If the system has not successfully refilled in 15 minutes, a refill error occurs.

When a refill error occurs, the refill solenoid is de-energized and the left rinse L.E.D. will flash about once every

5 seconds. Once the cause of the refill error has been investigated (see the troubleshooting guide in the Operating

and Service Manual) and cured, the system can be reset by placing the Rinse/Run switch in the programming

(center) position, momentarily.

RINSE TIMERS

The dispenser is shipped from the factory with the rinse timers disabled. To enable the rinse timers, remove

power from the dispenser, remove the lower access panel, and remove the jumper from J1 of the control boards.

Replace the lower access panel, and return power to the dispenser. When enabled, the rinse timers automatically

keep track of the time since the dispenser was last run through a rinse sequence. If the dispenser detects that a

rinse sequence has not been run for 8 hours, the appropriate rinse L.E.D. will flash continually. If, after an additional

4 hours (12 hours total), a rinse sequence has still not been run, the appropriate rinse L.E.D. will light continuously,

and the appropriate hopper drives will be disabled until a rinse sequence has been run.

RUNNING A RINSE SEQUENCE

1. Place the rinse/run switch in the rinse position.

2. Sequentially, or simultaneously, at each of the positions dispense for at least 10 seconds.

3. After the rinse L.E.D. has extinguished, the rinse timer is reset.

4. Return the rinse/run switch to the run position.

DISPENSER USE

1. Simply place a cup on the drip tray beneath the dispensing tip.

2. Press the button and dispense the beverage.

3. Release the button when the cup is approximately 2/3 full and allow the whipper chamber to drain.

NOTE - The whipper chamber must drain at the end of each dispense.

5

35135 012103

COLD BEVERAGE SET-UP (OPTIONAL)

Cold beverages may be dispensed from the left dispense position. Simply place the HOT/COLD switch near the left

whipper chamber in the “COLD” (upper) position.

CLEANING

Refer to the decal on the rear of the dispenser door for cleaning recommendations and proccedures.

The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning all surfaces

on Bunn-O-Matic equipment.

ADJUSTMENTS

The beverage solenoid is preset to dispense approximately 9/10 ounce per second. This amount can be adjusted:

1. Disconnect the dispenser from the power source.

2. Remove product hopper(s).

3. Remove the hole plug(s) in the auger motor mounting panel.

4. Rotate the control at the base of the solenoid clockwise to decrease or counterclockwise to increase the amount

of water.

5. Reinstall plug(s) and hopper(s).

HOPPER MOTOR SPEED PROGRAMING

The hopper dispense rate is preset at the factory. With 22 tooth gear and auger wire the preset dispense rate is

approximately 3 to 5 grams per second. With 30 tooth gear and auger wire the preset dispense rate is approximately

5 to 7 grams per second. The hopper dispense rate can be adjusted to produce a wide range of dispense rates as

follows:

1. Place the rinse/run switch in the center (program) position.

2. Place the increase/decrease switch in the desired (increase or decrease) position.

3. Press and release the dispense switch for the chamber you wish to adjust. Each time the dispense switch is

pressed, the rinse L.E.D. will flash, and the motor speed for that hopper will be increased/decreased by

approximately 2 1/2%.

4. Return the rinse/run switch to the run position after hopper motor speed adjustments are complete.

6

35135 012103

DRAINING THE HOT WATER TANK

CAUTION - The dispenser must be disconnected from the power source throughout these steps.

1. Disconnect the dispenser from the power source.

2. Place the tank heater switch in the “OFF” position.

3. Shut-off and disconnect the incoming water supply.

4. Remove the front, lower access panel.

5. Pull out drain tube to empty into a sink or a container with a minimum of 6-1/2 gallon capacity.

6. Make sure drain clamp is closed. Then, remove drain plug.

7. Direct tube into sink or container and open drain clamp. Continue draining tank until ALL of the water is out.

WARNING: Be very careful with the draining water because it can be very hot.

8. Close drain clamp, insert drain plug, place drain tube back into machine, and replace lower access panel.

NOTE - The dispenser must be refilled using the

source.

INITIAL FILL & HEAT

steps before reconnecting to the power

7

35135 012103

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

• All electronic components have 120 volt ac and low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If an

intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will help

to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This unit is heated at all times. Keep away from combustibles.

WARNING – • Exercise extreme caution when servicing electrical equipment.

• Unplug the dispenser when servicing, except when electrical tests are specified.

• Follow recommended service procedures

• Replace all protective shields or safety notices

PROBLEM

Product will not dispense

PROBABLE CAUSE

1. No water

2. No power or incorrect voltage to

the dispenser

3. Dispense Switch

REMEDY

Water lines and valves to the dispenser must be open.

(A1) Check for 120 volts across the

black and white wires on two wire

120 volt dispensers.

(A2) Check for 120 volts across the

red and white wires and the black

and white wires, 208 volts across

the red and black wires on three wire

120/208 volt dispensers and 240

volts across the red and black wires

on three wire 120/240 volt dispensers.

(B) Check circuit breakers or fuses.

Refer to

Service

- Dispense Switch

for testing procedure. See page 23

4. Dispense Solenoid Valve

8

Refer to

Service

- Dispense Solenoid

Valve for testing procedures. See

page 35

35135 012103

TROUBLESHOOTING (cont.)

PROBLEM

Product will not dispense (cont.)

PROBABLE CAUSE

5. Solenoid Valve (Inlet)

REMEDY

Refer to

Service

- Solenoid Valve

(Inlet) for testing procedures. See

page 37

6. Control Board #1 and Probe

7. Auger Drive

8. Water Strainer

9. Lime build-up

CAUTION - Tank and tank components should be delimed regularly

depending on local water conditions.

Excessive mineral build-up on stainless steel surfaces can initiate corrosive reactions resulting in serious

leaks.

10. Transformer

Refer to

Service

- Control Board and

Probe for testing procedures. See

page 20

Refer to

Service

- Auger Drive. See

page 13 & 15

Remove the strainer and check for

obstructions. Clear or replace.

Inspect the tank assembly for excessive lime deposits. Delime as required.

Refer to

Service

- Transformer for

testing procedures. See page 41

Water is not hot

1. Limit Thermostat

CAUTION - Do not eliminate or bypass limit thermostat. Use only BOM

replacement part #29329.1000

2. Control Thermostat

3. Tank Heater

Refer to

Service

- Limit Thermostat

for testing procedures. See page 31

Refer to

Service

- Control Thermostat for testing procedures. See page

19

Refer to

Service

- Tank Heater for

testing procedures. See page 38

9

35135 012103

TROUBLESHOOTING (cont.)

PROBLEM

PROBABLE CAUSE

REMEDY

Water is not hot (Cont.)

Spitting or excessive steaming

4. Tank Heater Switch

5. Relay (120V versions only)

6. Control Board #2 (120V versions

only)

1. Lime build-up

CAUTION - Tank and tank components should be delimed regularly

depending on local water conditions.

Excessive mineral build-up on stainless steel surfaces can initiate corrosive reactions resulting in serious

leaks.

2. Control Thermostat

Refer to

Service

- Tank Heater Switch

for testing procedures. See page 39

Refer to

Service

- Relay for testing

procedures. See page 40

Refer to

Service

- Control Board #2

for testing procedures. See page 22

Inspect the tank assembly for excessive lime deposits. Delime as required.

Refer to

Service

- Control Thermostat for testing procedures. See

page 19

Dripping from dispense tip

Water flows into tank continuously

1. Lime build-up

CAUTION - Tank and tank components should be delimed regularly

depending on local water conditions.

Excessive mineral build-up on stainless steel surfaces can initiate corrosive reactions resulting in serious

leaks.

2. Dispense Solenoid Valve

1. Control Board #1 and Probe

2. Solenoid Valve (Inlet)

Inspect the tank assembly for excessive lime deposits. Delime as required.

Remove the dispense solenoid valve

and clear any obstructions. Rebuild

or replace the valve if necessary. See

page 35

Refer to

Service -

Control Board and

Probe for testing procedures. See

page 20

Refer to

Service

- Solenoid Valve

(Inlet) for testing procedures. See

page 37

10

35135 012103

TROUBLESHOOTING (cont.)

PROBLEM

PROBABLE CAUSE

REMEDY

Product overflows container

Weak product

1. Dispense Switch

2. Dispense Solenoid Valve

1. Water Temperature

2. Whipper Motor

3. Frother

Refer to

Service -

Dispense Switch

for testing procedures. See page 23

Remove the solenoid valve and clear

any obstructions. Rebuild or replace

the valve if necessary. See page 35

Place an empty container beneath

the dispense tip. Initiate a dispense

cycle and check the water temperature immediately below the dispense

tip with a thermometer. Reading

should be 180°F to 200°F (see thermostat temperature settings decal

in

USER NOTICES

Refer to

Service

on page 3.)

- Whipper Motor for

testing procedure. See page 27

Refer to

Service

- Frother Compo-

nents. See page 26

4. Dispense Solenoid Valve

5. Auger Drive

6. Auger Spring

7. Auger Motor

8. Rinse/Run Switch

9. Rinse Timer

10. Relay (120V versions only)

Refer to

Service

- Dispense Solenoid

Valve for test procedures. See page

35

Refer to

Service

- Auger Drive Com-

ponents. See page 13 & 15

Refer to

Service

- Auger Drive Com-

ponents. See page 13 & 15

Refer to

Service

- Auger Drive Com-

ponents. See page 13 & 15

Refer to

Service -

Rinse/Run Switch

for test procedures. See page 32

Refer to

Operation

- Rinse Timer.

See Page 5

Refer to

Service

- Relay for testing

procedures. See page 40

11. Control Board #2 (120V versions

only)

11

Refer to

Service

- Control Board #2

for testing procedures. See page 22

35135 012103

TROUBLESHOOTING (CONT.)

PROBLEM

Dispenser is making unusual

noises

Excess dust

Display not lit

PROBABLE CAUSE

1. Plumbing Lines

2. Water Supply

3. Tank Heater

1. Fan

1. Lamp

REMEDY

Plumbing lines should not be resting on the counter top.

(A) The dispenser must be connected

to a cold water line

(B) Water pressure to the dispenser

must not exceed 100 psi (690 kPa).

Install a regulator if necessary to

lower the working pressure to approximately 50 psi (345 kPa).

Remove and clean lime off the tank

heater. See page 38

Refer to

Service

- Fan for testing

procedures. See page 25

Refer to

Service

- Lamp, see page 29

for lamp replacement.

2. Lamp Holder

3. Starter - Lamp

4. Ballast

Refer to

Service

- Lamp Holder for

testing procedures. See page 29

Refer to

Service

- Starter for testing

procedures. See page 30

Refer to

Service

- Ballast for testing

procedures. See page 18

12

35135 012103

SERVICE

This section provides procedures for testing and

replacing various major components used in this

dispenser should service become necessary. Refer to

Troubleshooting

cause of any problem.

WARNING - Inspection, testing, and repair of electrical equipment should be performed only by qualified

service personnel. The dispenser should be unplugged when servicing, except when electrical tests

are required and the test procedure specifically states

to plug-in the dispenser.

COMPONENT ACCESS

WARNING - Disconnect the dispenser from the power

source before the removal of any panel or the replacement of any component.

All components are accessible by opening the

door, removal of the door panels, dispenser top covers, hopper(s), hopper support plate, splash guard,

splash panel w/drip tray, lower front access panel and

rear access cover.

Refer to the contents listing for component location.

Auger Drive Components (FMD-4) ....................... 13

Auger Drive Components (FMD-5) ....................... 15

Ballast ...................................................................18

Control Thermostat............................................... 19

Control Board ....................................................... 20

Dispense Switch ...................................................23

Fan........................................................................ 25

Frother ..................................................................26

Increase/Decrease Switch..................................... 28

Lamp Holder .........................................................29

Lamp .................................................................... 29

Lamp Starter and Socket ......................................30

Limit Thermostat .................................................. 31

Rinse/Run Switch .................................................32

Hot/Cold Switch-Optional ..................................... 33

Solenoid (Cold Water - Optional) .......................... 34

Solenoid (Dispense) ............................................. 35

Solenoid (Inlet) ..................................................... 37

Tank Heater ........................................................... 38

Tank Heater Switch ............................................... 39

Tank Heater Relay ................................................. 40

Transformer ..........................................................41

Whipper Motor ..................................................... 27

Wiring Diagram .............................................. 42-45

for assistance in determining the

Contents

AUGER DRIVE COMPONENTS FMD-4

J1

J2

J4

J3

J1

J2

J4

J3

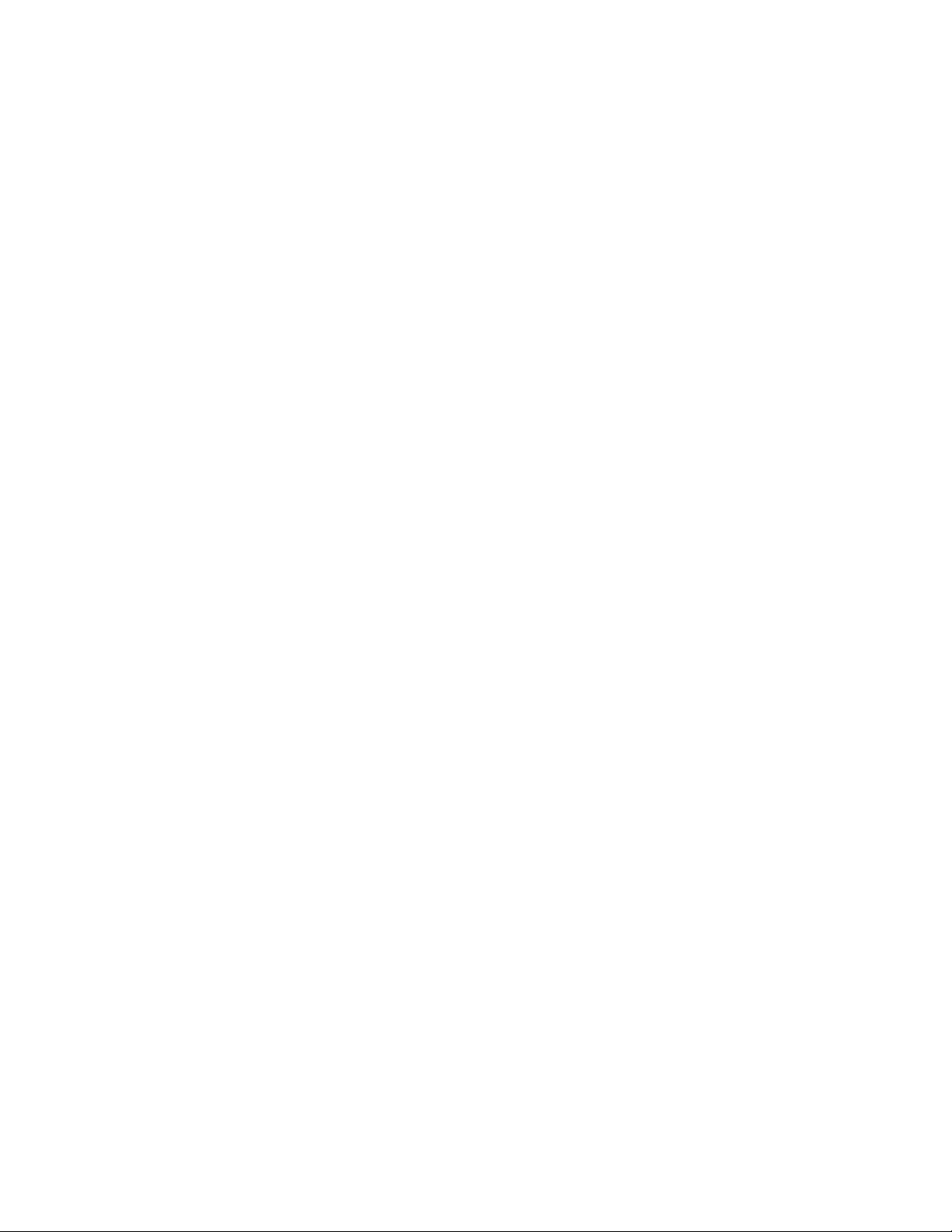

FIG. 1 AUGER DRIVE COMPONENTS

Location

The auger components are located inside the

bottom part of the hopper except for the auger drive

bracket, spacer and retaining clip, which are located

on the outside rear of the hopper base. The auger

motor is located on the lower right rear of the motor

mounting panel. Refer to Fig. 2 for disassembly and

assembly.

Test Procedures - Auger Motor

1. Disconnect the dispenser from the power source.

2. Disconnect the white/red wire and the white wire

from the hopper speed control board.

3. Check the voltage across the white/red wire and

the white wire with a voltmeter. With the rinse/

run switch in the run (lower) position, connect

the dispenser to the power supply. The indication must be :

a) 120 volts ac for two wire 120 volt models.

b) 120 volts ac for three wire 120/208 volt or

120/240 volt models.

4. Disconnect the dispenser from the power sup-

ply.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the wiring diagram and check the dispenser wiring harness.

13

P2635

35135 012103

SERVICE

AUGER DRIVE COMPONENTS - FMD-4 (CONT.)

5. Check the voltage across the positive (red wire)

terminal and the negative (black wire) terminal on

the auger motor with a voltmeter. With the rinse/

run switch in the run (lower) position press and

hold the dispense switch. Connect the dispenser

to the power supply. After a .6 second delay the

indication must be 4.0 to 24.5 volts dc.

If voltage is present as described, the auger motor

drive is operating properly. If auger does not turn,

replace the auger motor.

If voltage is not present as described, replace the

auger hopper drive board.

Removal, Cleaning and Replacement

Hopper & Auger

1. Open the dispenser door and raise the top front

cover.

2. Lift the hopper assy (15) over the pins on hopper

support plate (11) and slide hopper assembly out

the front of the dispenser.

3. Remove hopper lid (1) and empty product.

4. Pull off the ejector elbow (14).

5. Remove retainer clip (10) and washer (9) from the

bottom of the hopper base (8).

6. Remove whipper shaft (3), wiper blade (4) and

wiper drive gear (5) from the hopper base (8).

7. Remove auger wire (13) by pulling it out the front

of the hopper base (8).

8. Remove auger drive bracket (6) by unscrewing left

hand threads from auger drive shaft (12).

9. Slide spacer (7) and auger drive shaft bracket (6)

off of the auger drive shaft (12).

10. Remove auger drive shaft (12) from hopper base

(8).

11. Wash components in a mild solution of dish detergent using a bristle brush when needed.

12. Rinse and dry each item thoroughly.

13. Check for damaged or broken components, replace any if necessary and reassemble hopper

assembly.

14. Install hopper assy (15) in the dispenser by sliding

hopper assy on the hopper support plate (11) until

the slot in the rear of the hopper base (8) seats

against the pins in the hopper support plate (11).

1

2

3

4

6

5

12

13

7

14

8

9

10

15

16 17 18 19 11

FIG. 2 AUGER DRIVE & HOPPER DISASSEMBLY

1. Hopper Lid

2. Hopper

3. Wiper Shaft

4. Wiper Blade

5. Wiper Drive Gear

6. Auger Drive Bracket

7. Spacer

8. Hopper Base

9. Washer

10. Retainer Clip

11. Hopper Support Plate

12. Auger Drive Shaft

13. Auger Wire

14. Ejector Elbow

15. Hopper Assembly

16. Auger Motor Bracket

17. Auger Motor

18. Dust Seal

19. Auger Motor Mounting

panel

P2633

14

35135 012103

SERVICE (cont.)

AUGER DRIVE COMPONENTS - FMD-4 (cont.)

Auger Drive Motor (Refer to Fig. 2)

1. Remove hopper assy (15), and set aside for reassembly.

2. Remove the four #8-32 screws securing the hopper support plate (11), remove plate and set aside

for reassembly.

3. Remove the four #8-32 screws, located inside the

dispenser housing on the lower right front of the

auger motor mounting panel (19), securing auger

motor mounting bracket (16) and auger motor

(17) to the rear of the auger motor mounting panel

(19).

4. Disconnect the wires from the hopper drive board.

5. Remove auger motor mounting bracket (16), auger motor (17) and dust seal (18) as an assembly.

6. Remove dust seal (18) from auger motor (17).

7. Disconnect the wires from the auger motor (17).

8. Remove the four #8-32 screws securing the auger

motor (17) to the auger motor mounting bracket

(16).

9. Remove auger motor (17) and discard.

10. Using four #8-32 screws install new auger motor

(17) on mounting bracket (16).

11. Install dust seal (18) on auger motor shaft and

align notch in seal with motor casting.

12. Reconnect the wires to the terminals on the hopper drive board.

13. Refer to Fig. 3 when reconnecting wires.

14. Using four #8-32 locking screws install auger

motor, dust seal and mounting bracket to the rear

of the auger motor mounting panel (19).

15. Install hopper assy (15).

STATIONS 1 - 4

RED to BRN/WHI from

Control Board #1 J3-3

RED to WHI/RED from

Control Board #1 J3-2

RED to WHI/ORN from

Control Board #1 J3-1

RED to WHI/YEL from

Control Board #2 J3-3

BLK to GRN from

Control Board J3-4

P1639

FIG. 3 AUGER MOTOR TERMINALS

AUGER DRIVE COMPONENTS - FMD-4 & FMD-5

J1

J2

J4

J3

J1

J2

J4

J3

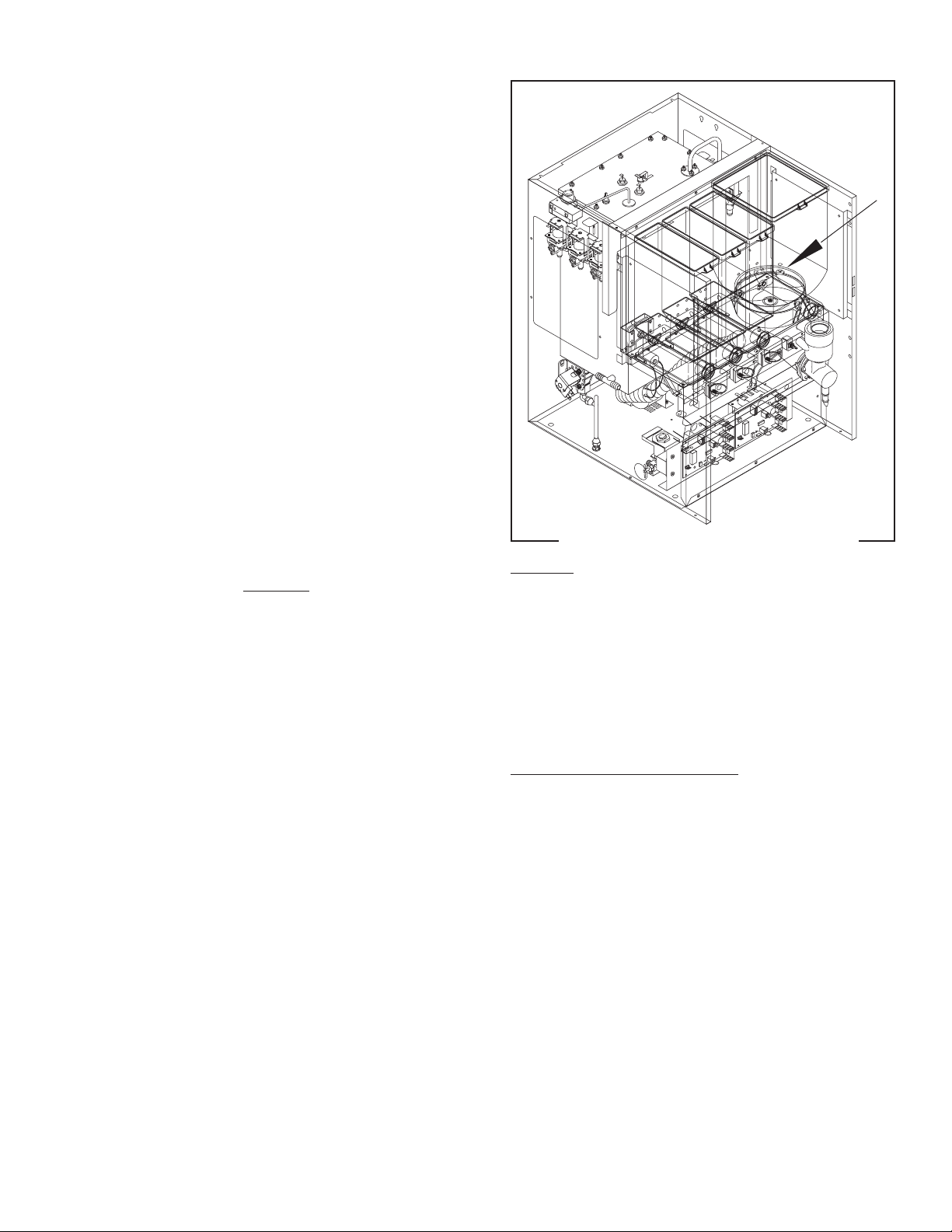

FIG. 4 AUGER DRIVE COMPONENTS

Location

The auger components are located inside the

bottom part of the hopper except for the auger drive

bracket, washer and locknut, which are located on the

outside bottom rear of the hopper. The auger motors

are located on the rear of the auger motor mounting

panel. Refer to Fig. 5 for disassembly and assembly.

Test Procedures - Auger motors

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the motor to be tested.

3. Check the voltage across the positive (white/or-

ange) wire for the right motor, or the positive

(white/red) wire for the left motor and the negative

(green) wire with a voltmeter. With the rinse/run

switch in the run (lower) position press and hold

the appropriate dispense switch. Connect the dis-

penser to the power supply. After a .6 second

delay the indication must be 4.0 to 24.5 volts dc.

15

P2635

35135 012103

SERVICE (cont.)

AUGER DRIVE COMPONENTS - FMD-4 & FMD-5

(cont.)

4. Disconnect the dispenser from the power supply.

1

2

4

If voltage is present as described and the auger does

not turn, replace the auger motor.

If voltage is not present as described, refer to the wiring diagrams and check the dispenser wiring harness.

Removal, Cleaning and Replacement

Hopper & Auger

1. Open the dispenser door and raise the top front

cover.

2. Lift the front edge of hopper assy (20) over the

tab on hopper support plate (19) and slide hopper assembly out the front of the dispenser.

3. Remove hopper lid (1) and empty product.

4. Pull off the ejector elbow (13).

5. Remove agitator disc assy (2) by pulling agitator

support rod (4) towards agitator disc assy and

lifting agitator disc assy from hopper (10).

6. Remove auger (12) by pulling it out the front of

the hopper (10).

7. Remove auger drive shaft (5) by removing the

retaining clip (6) from auger drive shaft.

8. Slide washer (8) and auger drive shaft bracket

(7) off of the auger drive shaft (5).

9. Slide auger drive shaft (5) from auger drive shaft

bushing (3) and remove from hopper (10).

10. Remove locknut (9) from auger drive shaft bushing (3) and remove auger drive shaft bushing

from hopper (10).

11. Wash components in a mild solution of dish detergent using a bristle brush when needed.

12. Rinse and dry each item thoroughly.

13. Check for damaged or broken components, replace any if necessary and reassemble hopper

assy.

14. Install hopper assy (20) in the dispenser by sliding

hopper assy in the guides on the hopper support

plate (19) until the slot in the bottom rear the

hopper seats against the pin (18) in the hopper

support plate.

3

5

8

7

9

6

10

11

14 15 16 12 13

FIG. 5 AUGER DRIVE & HOPPER DISASSEMBLY

1. Hopper Lid

2. Mixing Blade

3. Agitator Disk

4. Auger Drive Shaft

Bushing

5. Auger Drive Shaft

6. Locknut

7. Auger Drive Bracket

8. Hopper

9. Auger Wire

10. Ejector Elbow

11. Hopper Assy

12. Auger Motor Mounting

Panel

13. Hopper Support Plate

14. Auger Motor Bracket

15. Auger Motor

16. Dust Seal

P2634

16

35135 012103

SERVICE (cont.)

AUGER DRIVE COMPONENTS - FMD-4 & FMD-5

(cont.)

STATIONS 1 - 5

Auger Drive Motor (Refer to Fig. 5)

1. Remove all hopper assemblies (20) and set aside

for reassembly.

2. Remove the four #8-32 screws securing the hopper support plate (19), remove plate and set aside

for reassembly.

3. Remove the four #8-32 locking screws, located

inside the dispenser housing on the front of the

auger motor mounting panel (14), securing auger

motor mounting bracket (15) and auger motor

(16) to the rear of the auger motor mounting panel

(14).

4. Disconnect the wires from the auger motor (16) to

be removed.

5. Remove auger motor mounting bracket (15), auger motor (16) and dust seal (17) as an assembly.

6. Remove dust seal (17) from auger motor (16).

7. Remove the four #8-32 screws securing the auger

motor to the auger motor mounting bracket.

8. Remove auger motor and discard.

9. Using four #8-32 screws install new auger motor

(16) on mounting bracket (15).

10. Install dust seal (17) on auger motor shaft.

11. Using four #8-32 locking screws install auger

motor, dust seal and mounting bracket to the rear

of the auger motor mounting panel (14)

12. Reconnect the wires to the terminals on the auger

motor.

13. Install hopper support plate (19) and all hopper

assemblies (20).

14. Refer to Fig. 6 when reconnecting wires.

RED to BRN/WHI from

Control Board #1 J3-3

RED to WHI/RED from

Control Board #1 J3-2

RED to WHI/ORN from

Control Board #1 J3-1

RED to WHI/YEL from

Control Board #2 J3-3

RED to WHI/BLU from

Control Board #2 J3-2

BLK to GRN from

Control Board J3-4

P1639

FIG. 6 AUGER MOTOR TERMINALS

17

35135 012103

SERVICE (cont.)

BALLASTS - FMD-4 & FMD-5

J1

J2

J4

J3

FIG. 7 BALLASTS

Location

Removal and Replacement

1. Loosen the three #8-32 screws securing the component bracket to the dispenser housing base.

2. Pull component bracket out the front of the dispenser far enough so the leads on each ballast can

be disconnected from the main wiring harness and

the door interconnect harness.

3. Remove the two #8-32 screws securing each

ballast to the rear of the component bracket.

4. Remove and discard the ballast.

5. Install new ballast on the rear of the component

bracket and secure each with two #8-32 screws.

6. Refer to Fig. 8 and reconnect the wires.

7. Place the component bracket into position and

tighten the two #8-32 screws securing the component bracket to the dispenser housing base.

J1

J2

J4

J3

BLK to BLK

from Main

Wiring Harness

P2635

BLK to RED from

Main Harness

The front door lamp ballast is located behind the

front access panel on the left front side of the component bracket.

Test Procedure

1. Disconnect the dispenser from the power source.

2. Disconnect the two black lead on the ballast from

the main harness.

3. Check for continuity between the two black leads

on the ballast.

If continuity is present as described the ballast is

operating properly.

If continuity is not present as described, replace the

ballast.

FIG. 8 BALLAST TERMINALS

P1447

18

35135 012103

SERVICE (cont.)

CONTROL THERMOSTAT - FMD-4 & FMD-5

J1

J2

P2635

FIG. 9 CONTROL THERMOSTAT

Location

The control thermostat is located at the upper left

rear of the dispenser housing.

Test Procedure

1. Disconnect the dispenser from the power source.

2. Disconnect the black wire of the control thermostat from the black lead from the limit thermostat.

3. Remove bulb from the tank.

4. Check the voltage across black wire on the control

thermostat and the white or red wire on the tank

heater with the tank heater switch in the “ON”

lower position with a voltmeter. Connect the dispenser to the power source. The indication must

be:

a) 120 volts ac for two wire 120 volt models.

b) 208 volts ac for three wire 120/208 volt models.

c) 240 volts ac for three wire 120/240 volt models.

5. Disconnect the dispenser from the power source.

Removal and Replacement.

1. Remove the thermostat capillary bulb by firmly

pulling-up on the capillary at the tank lid. This will

disengage the grommet from the tank lid.

2. Loosen the two #6-32 screws securing the thermostat to the front tank mounting bracket.

3. Disconnect the wires from the thermostat.

4. Remove thermostat and remove the screws and

spacers from the thermostat.

5. Discard thermostat.

6. Install two spacers and two #6-32 screws on the

new thermostat.

7. Position the thermostat on the botttom side of the

front tank mounting bracket and tighten the two

#6-32 screws.

8. Slide the grommet to the line 4.5" above the bulb

on the new capillary tube.

9. Insert the capillary bulb through the hole in the

tank lid and press the grommet firmly and evenly

so that the groove in the grommet fits into the tank

lid.

10. Carefully bend the capillary tube so that the tube

and bulb inside the tank are in the vertical position

and away from any electrical connections.

11. Refer to Fig. 10 and reconnect the wires.

NOTE - The capillary tube must be clear of any electrical termination and not kinked.

BLK from Limit

Thermostat

If voltage is present as described the control thermostat is operating properly. Reinstall bulb into the tank.

If voltage is not present as described, replace the

thermostat.

19

BLK from Tank

Heater Switch

P1668

FIG. 10 THERMOSTAT TERMINALS

35135 012103

SERVICE (cont.)

CONTROL BOARD

J1

J2

J4

J3

J1

J2

J4

J3

#2

#1

FIG. 11 CONTROL BOARD

P2635

Location:

The Control Boards are located behind the lower

front access cover mounted on the component bracket.

Test Procedure:

Liquid Level Control Circuitry(Control Board #1):

1. Disconnect the dispenser from the power source.

2. Disconnect the six pin connector from J3 of the

control board.

3. Check the voltage across pins 5 & 6 of the six pin

connector on the wiring harness with a voltmeter.

Connect the dispenser to the power source. The

indication must be 24 volts ac.

4. Disconnect the dispenser from the power source.

5. Reconnect the six pin connector of the wiring

harness to J3 of the control board.

6. Disconnect the four pin connector from J4 of

control board #1.

7. Check the voltage across pins 1 & 4 of the four pin

connector on the wiring harness with a voltmeter.

Connect the dispenser to the power source. The

indication must be 120 volts ac for two wire 120

volt models, three wire 120/208 volt models, three

wire 120/240 volt models.

8. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to step 9.

If voltage is not present as described, refer to the

wiring diagram and check the dispenser wiring harness.

9. Reconnect the four pin connector of the wiring

harness to J4 of control board #1.

10. Disconnect the ten pin connector from J2 of

control board #1.

11. Carefully connect a piece of insulated jumper wire

to pin 10 (top right) of J2 on the control board.

Keep the other end of this wire away from any

metal surfaces of the dispenser.

12. Check the voltage across the terminals of the inlet

solenoid valve with a voltmeter. Connect the dispenser to the power source. The indication must

be 120 volts ac for two wire 120 volt models, three

wire 120/208 volt models, three wire 120/240 volt

models after a delay of approximately 10 seconds.

13. Touch the free end of the jumper wire to the

dispenser housing. The indication must be 0.

14. Move the jumper wire away from the housing. The

indication must, again, be 120 volts ac for two wire

120 volt models, three wire 120/208 volt models,

three wire 120/240 volt models after a delay of

approximately 5 seconds.

15. Disconnect the dispenser from the power source

and remove the jumper wire.

If voltage is present as described, proceed to step 5.

If voltage is not present as described, refer to the

wiring diagram and check the dispenser wiring harness.

If voltage is present as described, proceed to step 16.

If the voltage is not present as described, replace

control board #1.

20

35135 012103

SERVICE (cont.)

CONTROL BOARD (CONT.)

16. Reconnect the ten pin connector of the wiring

harness to J2 of control board #1.

17. Gently pull the liquid level probe out of the tank lid

and inspect for corrosion. Replace it if necessary.

18. Place the probe so that neither end is in contact

with any metal surface of the dispenser.

19. Check the voltage across the terminals of the inlet

solenoid valve with a voltmeter. Connect the dispenser to the power source. The indication must

be 120 volts ac for two wire 120 volt models, three

wire 120/208 volt models, three wire 120/240 volt

models after a delay of approximately 10 seconds.

20. Move the probe’s flat end to the dispenser housing. The indication must be 0.

21. Move the probe’s flat end away from the housing.

The indication must, again, be 120 volts ac for two

wire 120 volt models, three wire 120/208 volt

models, three wire 120/240 volt models after a

delay of approximately 5 seconds.

22. Disconnect the dispenser from the power source.

If the voltage is present as described, re-install the

probe. The liquid level control circuitry is operating

properly.

If the voltage is not present as described, check the

pink probe wire and green tank wire for continuity.

Hopper Motor Control Circuitry (Stations 1-3, Control

Board #1 & Stations 4-5, Control Board #2):

1. Disconnect the dispenser from the power source.

2. Disconnect the six pin connector from J3 of the

appropriate control board.

3. Check the voltage across pins 5 & 6 of the six pin

connector on the wiring harness with a voltmeter.

Connect the dispenser to the power source. The

indication must be 24 volts ac.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to step 5.

If voltage is not present as described, refer to the

wiring diagram and check the dispenser wiring harness.

5. Reconnect the six pin connector of the wiring

harness to J3 of the control board.

6. Check that the rinse/run switch is in the run

position.

7. Check the voltage across the red (+) terminal and

the black (-) terminal of the auger motor with a

voltmeter. Connect the dispenser to the power

source. Press and hold the appropriate dispense

switch. After a delay of about .6 seconds, the

indication must be between +4.0 and +24.5 volts

dc.

If the voltage is present as described, the hopper

motor control circuitry is operating properly.

If the voltage is not present as described, replace the

control circuit board.

21

35135 012103

Tank Heater Relay Control Circuitry (Control Board

#2)(120V dispensers only):

1. Disconnect the dispenser from the power source.

2. Disconnect the six pin connector from J3 of control board #2.

3. Check the voltage across pins 5 & 6 of the six pin

connector on the wwiring harness with a voltmeter. Connect the dispenser to the power source.

the indication must be 24 volts ac.

4. disconnect the dispenser from the power source.

If voltage is present as described, proceed to step 5.

If voltage is not present as described, refer to the

wiring diagram and check the dispenser wiring harness.

5. Reconnect the six-pin connector of the wiring

harness to J3 of control board #2.

6. Disconnect the four-pin connector from J4 of

control board #2.

7. Check the voltage across pins 1 & 4 of the four-pin

connector on the wiring harness with a voltmeter.

The indication must be 120 volts ac.

8. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to step 9.

If voltage is not present as described, refer to the

wiring diagram and check the dispenser wiring harness.

9. Reconnect the four-pin connector of the wiring

harness to J4 of control board #2.

10. Check the voltage across the coil terminals of the

tank heater relay with a voltmeter. Connect the

dispenser to the power source. The indication

must be 0 volts ac.

If voltage is absent as described, proceed to step 11.

If voltage is present, replace the control circuit board

#2.

11. Place containers below any three dispenser nozzles.

12. Simultaneously initiate dispenses at each of the

selected dispense stations while monitoring the

voltage across the coil terminals of the tank heater

relay. The indication must be 120V ac.

If voltage is present as described, the control board #2

is functioning correctly.

If voltage is not present as described, replace the

control circuit board #2.

Removal and Replacement:

1. Disconnect the three plugs on the main wiring

harness from the connectors on the control board.

2. Remove the four #6-32 keps nuts securing the

control board to the component bracket.

3. Remove control board and discard.

4. Install new control board on the component bracket

using four #6-32 keps nuts.

5. Reconnect the three plugs on the main harness to

the connectors on the control board.

NOTE: J4 is not connected on Control Board #2 on

120/208 - 240V dispensers.

CONTROL BOARD #1

J3 J1

J3 J1

J1

J2

J4

J1

J2

J3

22

J4

J3

J4 J2

CONTROL BOARD #2

J4 J2

FIG. 12 CONTROL BOARD CONNECTORS

35135 012103

P2637

SERVICE (cont.)

DISPENSE SWITCH(S) - FMD-4 & FMD-5

RINSE

E

ON UNTIL CUP IS 2/3 FULL, THEN RELEAS

RINSE

PUSH and HOLD BUTT

PLACE

CUP HERE

WARNING

!

H O T

L I Q U I D

RELEASE BUTTON WHEN CUP IS 2/3 FULL

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

FMD-4

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Open the dispenser door and remove the bottom

door cover.

3. Disconnect the wires from the door interconnect

wiring harness to the dispense switch to be tested.

4. Check for voltage across the black and red/white

wires for the dispense switch to be teseted from

the door interconnect wiring harness. Connect the

dispenser to the power supply. The indication

must be:

a) 120 volts ac for two wire 120 volt models.

b) 120 volts ac for three wire 120/208 volt or 120/

240 volt models.

5. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #6.

If voltage is not present as described, refer to the wiring diagram and check the dispenser wiring harness.

RINSE

ELEASE

IS 2/3 FULL, THEN R

ON UNTIL CUP

RINSE

PUSH and HOLD BUTT

PLACE

CUP HERE

WARNING

!

H O T

L I Q U I D

PLACE

CUP HERE

RELEASE BUTTON WHEN CUP IS 2/3 FULL

PLACE

CUP HERE

PLACE

CUP HERE

PLACE

CUP HERE

FMD-5

FIG.13 DISPENSE SWITCHES

Location:

The dispense switches are located on the lower

outside of the dispenser door.

6. With a voltmeter, check the voltage across the

remaining two wires of the dispense switch being

tested from the door interconnect wiring harness.

Connect the dispenser to the power source. The

indication must be +5 volts dc.

If voltage is present as described, proceed to #7.

If voltage is not present as described, refer to the

wiring diagram and check the dispenser wiring harness.

P2636

23

35135 012103

SERVICE (cont.)

DISPENSE SWITCHES (cont.)

7. Check for continuity across the terminals (top

right to top left; bottom right to bottom left) of the

dispense switch with the switch in the “ON” position. Continuity must not present when the switch

is in the “OFF” released position.

BLK

RED/WHI

If continuity is present as described, reconnect the

connector to the door interconnect wiring harness,

the switch is operating properly.

If continuity is not present as described, replace the

switch.

Removal and Replacement

1. Open the dispenser door.

2. Remove the six #8-32 screws securing the bot-

tom door cover and remove cover.

3. Disconnect the wires on the dispense switch from

the door interconnect wiring harness.

4. Compress the clips inside the door on the dis-

pense switch and gently push the switch through

the opening

5. Push the new switch into the opening and spread

the clips to hold the switch in the door.

6. Reconnect the wires to the dispense switch from

the door interconnect wiring harness.

7. Reinstall the door bottom cover using six #8-32

screws.

8. Refer to Fig. 14 when reconnecting wires.

STATIONS

-1-

BLK/WHI

RED

ORN

GRN/WHI

BLU

WHI/BLK

-2-

RED/BLK

-3-

ORN/BLK

-4-

GRN/BLK

-5-

BLU/BLK

FIG. 14 DISPENSE SWITCH TERMINALS

P1449

24

35135 012103

SERVICE (cont.)

FAN

Removal and Replacement:

1. Disconnect the vacuum hose from the fan.

2. Remove the two #8-32 locking screws securing

the fan to the dispenser housing base plate.

3. Disconnect the wires from the fan terminals and

discard the fan

4. Refer to Fig. 16 and connect the wires to the new

fan.

5. Install new fan through the rear access hole and

secure to the dispenser housing base plate using

two #8-32 locking screws.

6. Reconnect the vacuum hose to the fan.

BLK from Main Harness

J1

J2

J4

J3

J1

J2

J4

J3

P2635

FIG. 15 FAN

Location:

The fan is located inside the dispenser housing

on the center rear of the dispenser base plate.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the black and white wires from the fan

terminals.

3. Check the voltage across the black and white wires

on the main harness with a voltmeter. Connect the

dispenser to the power source. The indication

must be:

a) 120 volts ac for two wire 120 volts models.

b) 120 volts ac for three wire 120/208 volt or 120/

240 volt models.

If voltage is present as described, replace the fan

If voltage is not present as described, refer to wiring

diagram and check the dispenser wiring harness.

WHI from Main Harness

P1507

FIG. 16 FAN TERMINALS

25

35135 012103

SERVICE (cont.)

FROTHER AND WHIPPER MOTOR - FMD-4 (shown)

& FMD-5

J1

J2

J4

J3

J1

J2

J4

J3

4. Disconnect the dispenser from the power source.

If voltage is present as described, replace the motor.

If voltage is not present as described, refer to the wiring diagrams and check the dispenser wiring harness.

10

7

1

2

4

P2635

FIG. 17 FROTHER AND WHIPPER MOTOR

Location:

The frothers are located behind the dispenser door,

mounted on the front panel inside the whipper chamber.

The whipper motors are located on the back side

of the whipper motor mounting panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the red and white wires (FMD-1 &

FMD-2 left motor) or orange and white wires

(FMD-2 right motor) of the main harness from the

black leads of the motor.

3. Press and hold the dispense switch and check the

voltage across the disconnected harness wires

with a voltmeter. Connect the dispenser to the

power source. The reading must be:

a) 120 volts ac for two wire 120 volt models.

b) 120 volts ac for three wire 120/208 volt or 120/

240 volt models.

11 12 13

9 8 6 5

P2628

FIG. 18 MIXING/WHIPPER CHAMBER

COMPONENTS

1. Steam Collector

2. Mixing Chamber

3. Dispense Tip

4. Whipper Chamber

5. O-Ring

6. Frother

8. Nut

9. Slinger

10. Motor Assy.

11. Fan

12. Vacuum Hose

13. Baffle

7. Receptacle w/Seal

Removal, Cleaning & Replacement (Refer to Fig. 18):

1. Open the dispenser door and raise the top front

cover.

2. Lift the front edge of the each hopper assembly

over the tab on the hopper support panel and

slide each hopper assembly out the front of the

dispenser. Set aside for reassembly.

3. Remove the four #8-32 screws securing the hopper support panel to auger motor mounting panel

and the whipper motor mounting panel. Set aside

for reassembly.

3

26

35135 012103

SERVICE (cont.)

FROTHER AND WHIPPER MOTOR - FMD-4

(shown) & FMD-5 (cont.)

4. Disconnect vacuum hose (12) from fan baffle (13).

5. Remove the steam collector (1) by pulling it forward and at the same time twisting it clockwise.

6. Pull the mixing chamber (2) out of the whipper

chamber (4).

7. Remove the two #4-40 x .25" screws securing the

fan baffle (13) to the whipper motor mounting

panel and remove fan baffle. Set aside for reassembly.

8. Remove dispense tip (3) and twist the whipper

chamber (4) clockwise and pull it off the whipper

chamber receptacle (7).

9. Pull the frother (6) off the motor shaft. Notice the

flat side on the shaft and the matching flat inside

the frother. It is important that these two flats are

lined up when reassembling.

10. Slip the O-ring (5) off the whipper chamber receptacle (7).

11. Slide the receptacle w/seal off of the motor shaft.

12. Slide the slinger (9) off of the motor shaft.

13. Remove the two nuts (8) securing whipper chamber receptacle (7) and whipper motor (10) to the

front panel.

NOTE: To remove the receptacle only rotate clockwise

until the receptacle clears the nuts (8) and slide off

of the motor shaft.

14. Disconnect the black leads on the motor (10) from

the main wiring harness.

15. Remove motor and discard.

16. Install new motor (10) on rear of front panel and

secure with two nuts (8) and connect black leads

on the motor to the main wiring harness. Refer to

Fig. 19 when reconnecting wires

17. Slide slinger (9) onto the motor shaft flush against

the front panel.

18. Wash remaining components in a mild solution of

dish detergent using a bristle brush.

19. Rinse thoroughly and allow to dry before reinstalling in the dispenser.

20. Slide whipper chamber receptacle w/seal (7) and

O-ring (5) on to the motor shaft.

21. Rotate the receptacle w/seal (7) counterclockwise

until it snaps into place on the motor mounting

nuts (8).

22. Push frother (6) onto the motor shaft, making sure

the flat in the frother (6) lines up with the flat on the

motor shaft.

23. Install whipper chamber (4) on the whipper chamber receptacle (7) by twisting counterclockwise

until the tabs on the whipper chamber (4) lock with

the tabs on the whipper chamber receptacle (7).

Be sure dispense port is pointing down.

24. Install dispense tip (3) into the bottom of the

whipper chamber (4).

25. Using two #4-40 screws secure the fan baffle to

the whipper motor mounting panel.

26. Install vacuum hose (12) on fan baffle (13).

27. Install hopper support panel using four #8-32

screws.

28. Slip the mixing chamber (2) onto the mixing

chamber water inlet tube far enough so the mixing

chamber (2) will seat inside the whipper chamber

(4).

29. Install the steam collector (1) onto the mixing

chamber (2) by pushing down and toward the

dispenser while twisting until the flange on the

steam collector lines-up with the slot in the front

panel.

30. Install hopper assembly in the dispenser by sliding

hopper assembly on the hopper support panel

until the slot in the bottom rear of the hopper seats

against the shoulder screw in the hopper support

panel.

BLK to Main Harness WHI

BLK to Main Harness BRN Station #1

BLK to Main Harness RED Station #2

BLK to Main Harness ORN Station #3

BLK to Main Harness YEL Station #4

BLK to Main Harness BLU Station #5

P1221

FIG.19 WHIPPER MOTOR TERMINALS

27

35135 012103

SERVICE (cont.)

INCREASE/DECREASE SWITCH

J1

J2

J4

J3

J1

J2

J4

J3

P2635

FIG. 20 INCREASE/DECREASE SWITCH

Location:

The increase/decrease switch is located on the

lower left front of the whipper motor mounting panel.

Removal and Replacement:

1. Open the dispenser door.

2. Remove the facenut securing the increase/decrease switch to the whipper motor mounting

panel.

3. Remove switch with wires attached from the back

side of the whipper motor mounting panel.

4. Disconnect the wires from the switch and discard

the switch.

5. Refer to Fig. 21 when connecting the wires to the

new switch.

6. Install new switch with wires attached through the

hole in the whipper mounting panel and secure

with facenut.

RED/BLK from Control

Board J2-6

GRN from Control

Board J2-9

WHI/VIO from Control

Board J2-1

P1208

FIG. 21 INCREASE/DECREASE SWITCH

TERMINALS

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the wires from the switch terminals.

3. Check for continuity between the center terminal

and upper terminal with switch in the decrease

position (lower). Check for continuity between the

center terminal and the lower terminal with the

switch in the increase position (upper).

If continuity is present as described, the switch is

operating properly.

If continuity is not present as described, replace the

switch.

28

35135 012103

SERVICE (cont.)

LAMP HOLDERS

1

3

4

6

2

5

RINSE

RINSE

PUSH and HOLD BUTTON UNTIL CUP IS 2/3 FULL, THEN RELEASE

P2638

FIG. 22 LAMP HOLDERS

1. Door Assy

2. Lamp Holders

3. Lamp

Location:

The lamp holders are located on the front of the

upper panel behind the display panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Remove upper door panel (4) and disconnect the

door wiring harness from the leads on the lamp

holders.

3. Remove lamp from lamp holders.

4. Check for continuity on each lead of the lamp

holders.

If continuity is present as described, lamp holders are

operating properly.

If continuity is not present as described replace the

lamp holder.

4. Upper Panel

5. Lower Panel

6. Starter W/Socket

Removal and Replacement:

1. Open dispenser door (1).

2. Remove the six #8-32 screws securing lower door

panel (5) to the door (1) and remove cover.

3. Disconnect the door wiring harness from the door

interconnect wiring harness.

4. Remove three #8-32 screws securing the upper

door panel (4) to the door.

5. Remove the upper door cover (4), lamp (3), lamp

holders (2) and door wiring harness as an assembly.

6. Disconnect the wires from the lamp holder to be

replaced from the door wiring harness.

7. Rotate lamp (3) 90° and remove from lamp holders (2).

8. Remove the #6-32 screw securing the lamp holder

(2) to be removed, remove lamp holder (2) and

discard.

9. Install new lamp holder (2) and secure with a #632 screw.

10. Connect the wires on the new lamp holder to the

door wiring harness.

11. Install lamp (3) into lamp holders (2) and turn 90°

until the pins snap in place.

12. Install upper door panel (4), lamp (3), lamp holders (2) and door wiring harness as an assembly

using three #8-32 screws.

13. Reconnect the plug on the door wiring harness to

the connector on the door interconnect wiring

harness.

14. Install the door lower panel (5) using six #8-32

screws.

LAMP REPLACEMENT (Refer to Fig. 22)

1. Open dispenser door (1).

2. Remove the six #8-32 screws securing lower door

panel (5) to the door (1) and remove cover.

3. Disconnect the door wiring harness from the door

interconnect wiring harness.

4. Remove three #8-32 screws securing the upper

door panel (4) to the door.

5. Remove the upper door cover (4), lamp (3), lamp

holders (2) and door wiring harness as an assembly.

6. Rotate lamp (3) 90° and remove from lamp holders (2).

7. Install lamp (3) into lamp holders (2) and turn 90°

until the pins snap in place.

8. Install upper door panel (4), lamp (3), lamp holders (2) and door wiring harness as an assembly

using three #8-32 screws.

29

35135 012103

SERVICE (cont.)

LAMP REPLACEMENT (Refer to Fig.22)(cont.)

9. Reconnect the plug on the door wiring harness to

the connector on the door interconnect wiring

harness.

10. Install the door lower panel (5) using six #8-32

screws.

LAMP STARTER and SOCKET (Refer to Fig. 22)

Location:

The lamp starter (6) is located inside the door assy

(1) on the top of the door lower panel (5).

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the starter leads from the door wiring

harness.

3. Remove lamp starter from starter socket.

4. Check for continuity on each lead of the starter

socket.

If continuity is present as described the starter socket

is operating properly.

If continuity is not present as described replace the

starter socket.

Removal and Replacement (Refer to Fig.22):

1. Open dispenser door assy (1)

2. Remove the four #8-32 screws securing the door

lower panel (5) to the door assy (1).

3. Disconnect the leads on the starter socket from the

door wiring harness.

4. Remove lower door panel (5) and starter w/socket

(6) as assembly.

5. Compress the spring tabs on the socket and remove socket from the door bottom cover (5).

6. Rotate starter 90° and remove from the starter

socket.

7. Insert new starter (6) into socket and turn 90° until

the pins snap in place.

8. Install new socket by compressing spring tabs on

the socket and pushing the socket up through the

hole in the lower door panel (5) and releasing

spring tabs.

9. Connect the sockets leads to the door wiring

harness.

10. Install door lower panel (5) with starter and starter

socket on door assy (1) using four #8-32 screws.

5. Remove starter (6) from starter socket.

6. Check for continuity across the pins on the bottom

of the starter (6).

If continuity is present as described, replace the starter.

If continuity is not present as described, starter is

operating properly.

Note: If continuity tests are both as described and

lamp does not light, replace the starter.

30

35135 012103

SERVICE (cont.)

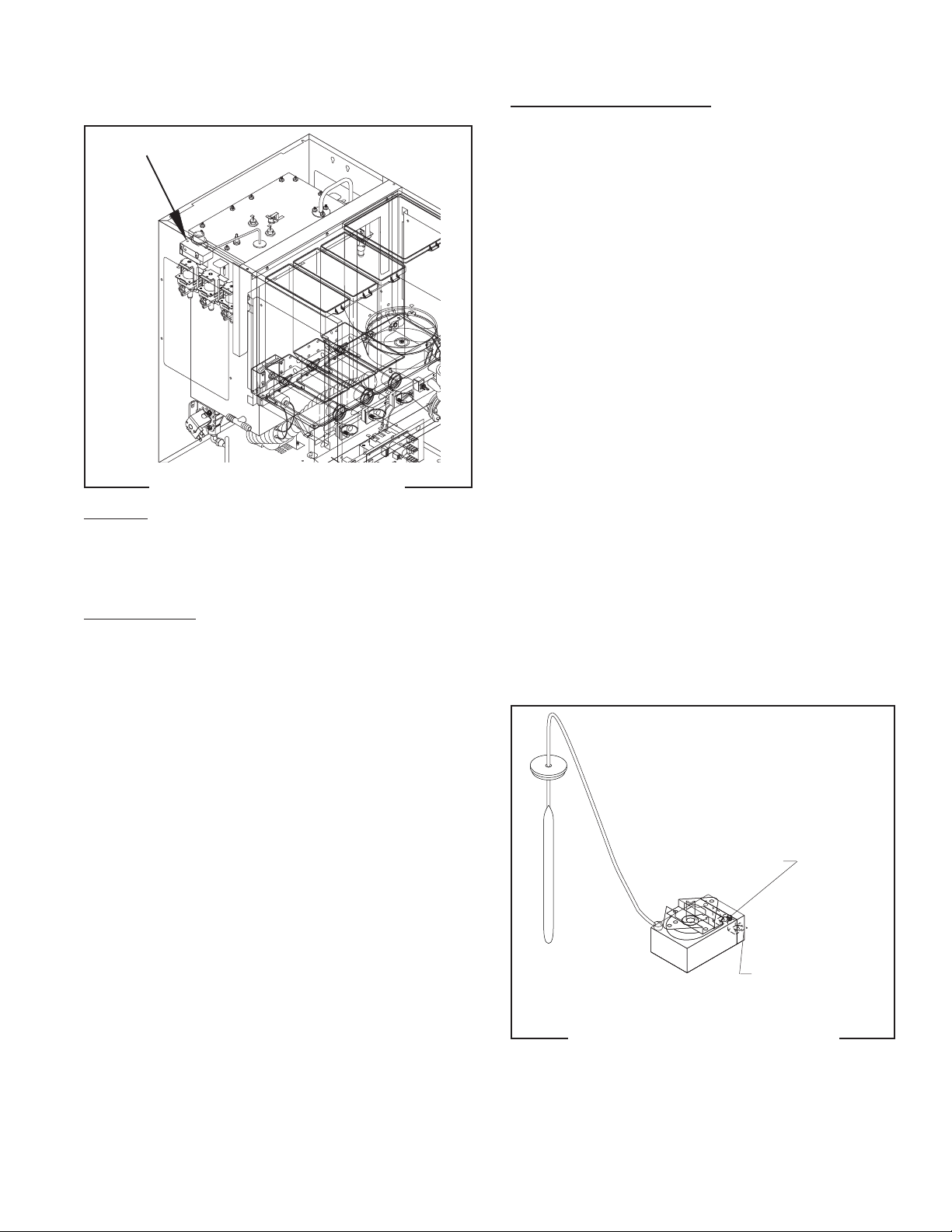

LIMIT THERMOSTAT

FIG. 23 LIMIT THERMOSTAT

Location:

The limit thermostat is located in the center of the

tank lid.

Removal and Replacement:

1. Remove all wires from the limit thermostat terminals.

2. Carefully slide the limit thermostat out from under the retaining clip and remove the limit thermostat.

3. Carefully slide the new limit thermostat into the

retaining clip.

4. Refer to Fig. 24 when reconnecting the wires.

BLK to Tank Heater

BLK to Control

Thermostat

P2635

P1800

FIG. 24 LIMIT THERMOSTAT TERMINALS

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect both black wires from the limit thermostat.

3. Check for continuity across the limit thermostat

terminals.

If continuity is present as described, the limit thermostat is operating properly.

If continuity is not present as described, replace the

limit thermostat.

31

35135 012103

SERVICE (cont.)

RINSE/RUN SWITCH

J1

J2

J4

J3

J1

J2

J4

J3

FIG. 25 RINSE/RUN SWITCH

Location:

The rinse/run switch is located on the lower center

of the whipper motor mounting panel.

P2635

Removal and Replacement:

1. Open the dispenser door.

2. Remove the facenut securing the run/rinse switch

to the whipper motor mounting panel.

3. Remove switch with wires attached from the back

side of the whipper motor mounting panel.

4. Disconnect the wires from the switch and discard the switch.

5. Refer to Fig. 26 when connecting the wires to

the new switch.

6. Install new switch with wires attached through

the hole in the whipper motor mounting panel

and secure with facenut.

BRN/BLK to

Main Harness

GRY to Control

Board J2-2

GRN to Control

Board J2-9

BLK from

Main Harness

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Check for continuity between the center left terminal and left bottom terminal, also between the

center right terminal and the right bottom terminal with the switch in the rinse position (upper).

Check for continuity across the center left terminal and the top left terminal, also between center

right terminal and the top right terminal with the

switch in the run position (lower). Continuity must

not be present when the switch is in the center

position.

If continuity is present as described, the switch is

operating properly.

If continuity is not present as described, replace the

switch.

BRN/BLK to

Main Harness

WHI/GRY to Control

Board J2-3

FIG. 26 RINSE/RUN SWITCH TERMINALS

P1644

32

35135 012103

SERVICE (cont.)

HOT/COLD SWITCH (Optional)

J1

J2

J4

J3

If voltage is present as described, reconnect the four

pin plugs and proceed to #5.

If voltage is not present as described, refer to the

Wiring Diagrams

and check the main wiring harness.

5. Disconnect the wires from the switch terminals.

6. With the switch in the “Cold” (upper) position

check for continuity between the center terminal

and the bottom terminal. With the switch in the

“Hot” (lower) position check for continuity between the center terminal and the upper terminal.

If continuity is present as described, the hot/cold

J1

J2

J4

J3

switch is operating properly.

If continuity is not present as described, replace the

switch.

P2635

FIG. 27 HOT/COLD SWITCH

Location:

The hot/cold switch is located on the left side of

the whipper motor mounting panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Disconnect the four pin plug from the hot/cold

switch and the four pin connector on the main

wiring harness.

3. Press the left dispense switch on the door and,

with a voltmeter, check the voltage across the

white wire (pin 4) and red wire (pin 2) in the four

pin connector on the main wiring harness. Connect the dispenser to the power source. The indication must be:

a) 120 volts ac for two wire 120 volt models, and

three wire 120/208 volt and 120/240 volt models.

b) 240 volts ac for two wire 240 volt models.

4. Disconnect the dispenser from the power source.

Removal and Replacement:

1. Remove all wires from the switch terminals.

2. Remove the mounting nut on the front of the whipper motor mounting panel.

3. Remove the hot/cold switch from the rear of the

front panel and discard.

4. Reconnect the wires to the terminals on the rear

of the new switch.

5. Push new hot/cold switch through the hole on the

left side of the whipper motor mounting panel and

secure with mounting nut.

6. Refer to Fig. 28 when reconnecting the wires.

TAN to Main Harness

RED to Main Harness

WHI/YEL to Cold

Solenoid

P1208

FIG. 28 HOT/COLD SWITCH TERMINALS

33

35135 012103

SERVICE (cont.)

SOLENOID VALVE (COLD WATER - OPTIONAL)

J1

J2

J4

J3

J1

J2

J4

J3

6. Check the solenoid valve for coil action. Connect

the dispenser to the power source. With "HOT/

COLD" switch in the "COLD" (upper) position press

the left dispense switch and listen carefully in the

vicinity of the solenoid valve for a "clicking" sound

as the coil magnet attracts.

7. Disconnect the dispenser from the power source.

If the sound is heard as described and water will not

pass through the solenoid valve, there may be a blockage in the water line before the solenoid valve or, the

solenoid valve may require inspection for wear, and

removal of waterborne particles.

P2635

FIG. 29 COLD WATER SOLENOID VALVE

Location:

The cold water solenoid valve is located on the

left side of the dispenser base just behind the component bracket.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the white and white/yellow wires from

the solenoid valve. With the “HOT/COLD” switch in

the "COLD" (upper) position press the left dis-

pense switch on front of the door.

3. With a voltmeter, check the voltage across the

white and white/yellow wires. Connect the dis-

penser to the power source. The indication must

be:

a) 120 volts ac for two wire 120 volt models, three

wire 120/208 volt, and 120/240 volt models.

b) 240 volts ac for two wire 240 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5

If voltage is not present as described, refer to

Diagrams

and check dispenser wiring harness.

Wiring

5. Check for continuity across the solenoid valve coil

terminals.

If the sound is not heard as described, replace the

solenoid valve.

Removal and Replacement:

1. Loosen the two screws securing the component

bracket to the dispenser base. Lift the component

bracket off of the base and move to the right.

2. Remove the white and white/yellow wires from

the solenoid valve.

3. Turn off the water supply to the dispenser.

4. Disconnect the water lines to and from the solenoid valve.

5. Loosen the two #8-32 screws and washers securing the solenoid mounting bracket to the base.

Remove solenoid bracket and solenoid valve as

an assembly.

6. Remove the two #10-32 screws and lockwashers

securing the solenoid valve to the solenoid bracket.

7. Using two #10-32 screws and lockwashers install

new solenoid valve on solenoid mounting bracket.

8. Install the solenoid valve and bracket on the dispenser base and tighten the two #8-32 screws.

9. Securely fasten the water lines to and from the

solenoid valve.

10. Refer to Fig. 30 when reconnecting the wires.

WHI/YEL to Hot/

Cold Switch

WHI to Main Wiring

Harness

If continuity is present as described, reconnect the

white and white/yellow wires to the solenoid.

If continuity is not present as described, replace the

solenoid valve.

34

P1215

FIG. 30 COLD WATER SOLENOID TERMINALS

35135 012103

SERVICE (cont.)

SOLENOID VALVE (DISPENSE) - FMD-4 & FMD-5

J1

J2

J4

J3

J1

J2

J4

J3

P2635

FIG. 31 DISPENSE SOLENOID VALVE

Location:

The dispense solenoid is located on the upper left

center of the tank.

If voltage is present as described, proceed to #5

If voltage is not present as described, refer to wiring

diagram and check dispenser wiring harness.

5. Check for continuity across the solenoid valve

coil terminals.

If continuity is present as described, reconnect the

wires to the solenoid (see Fig. 32), proceed to #6

If continuity is not present as described, replace the

solenoid valve.

6. Check the solenoid valve for coil action. Connect

the dispenser to the power source. With "RINSE/

RUN” switch in the "RINSE" upper position press

the dispense switch and listen carefully in the

vicinity of the solenoid valve for a "clicking" sound

as the coil magnet attracts.

7. Disconnect the dispenser from the power source.

If the sound is heard as described and water will not

pass through the solenoid valve, there may be a blockage in the water outlet before the solenoid valve or,