BUNN

REPLACEMENT OF ANY COMPONENT!

BEFORE REMOVAL OF ANY PANEL OR

W

A

R

N

IN

G

®

H5M

DISCONNECT FROM POWER SOURCE

WARNING

!

Very Hot Water

Use With Care!

OPERATING & SERVICE MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

10267.0000D 7/00 © 1988 BUNN-O-MATIC CORPORATION

CONTENTS

Introduction ................................................. 2

Warranty ...................................................... 2

User Notices ................................................ 3

Electrical Requirements ............................... 4

Plumbing Requirements .............................. 4

Initial Set-Up................................................ 5

Draining the Dispenser ................................ 5

Cleaning....................................................... 5

Troubleshooting .......................................... 6

Service......................................................... 9

Wiring Schematics..................................... 19

INTRODUCTION

This equipment heats and dispenses water on demand for beverages and cooking purposes. This equipment

is for indoor use, either wall-mounted or on a sturdy counter or shelf.

WARRANTY

Bunn-O-Matic Corp. (“Bunn”) warrants the equipment manufactured by it to be commercially free from defects

in material and workmanship existing at the time of manufacture and appearing within one year from the date of

installation. In addition:

1.) Bunn warrants electronic circuit and/or control boards to be commercially free from defects in material and

workmanship for two years from the date of installation.

2.) Bunn warrants the compressor on refrigeration equipment to be commercially free from defects in material

and workmanship for two years from the date of installation.

3.) Bunn warrants that the grinding burrs on coffee grinding equipment will grind coffee to meet original factory

screen sieve analysis for three years from date of installation or for 30,000 pounds of coffee, whichever comes first.

This warranty does not apply to any equipment, component or part that was not manufactured by Bunn or that,

in Bunn’s judgement, has been affected by misuse, neglect, alteration, improper installation or operation, improper

maintenance or repair, damage or casualty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR

ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn are

not authorized to make modifications to this warranty or to make additional warranties that are binding on Bunn.

Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not

be relied upon.

The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (217)

529-6601 or by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the Buyer

shall ship the defective equipment prepaid to an authorized Bunn service location. If Bunn determines, in its sole

discretion, that the equipment does not conform to the warranty, Bunn shall repair the equipment with no charge

for parts during the warranty period and no charge for labor by a Bunn Authorized Service Representative during

the warranty period. If Bunn determines that repair is not feasible, Bunn shall, at its sole option, replace the

equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE

OF THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS

SPECIFIED HEREIN, TO REPAIR OR, AT BUNN’S SOLE OPTION, REPLACEMENT OR REFUND.

In no event shall Bunn be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

2

10267 071900

3

ELECTRICAL REQUIREMENTS

CON

P

O

N

OFF

Fill

W

!

st l

ffici

ood

Fo

CAUTION - The dispenser must be disconnected from the power source until specified in

Initial Set-Up.

The H5M dispenser requires 2-wire, grounded service rated 120, 208, or 240 volts ac, 20 amp, single phase.

The H5MA, 230V-CE dispenser requires 2-wire, grounded service rated 230 volts ac, 40 amp, single phase, 50/

60Hz

. (Refer to the dispenser’s dataplate for exact voltage requirement.)

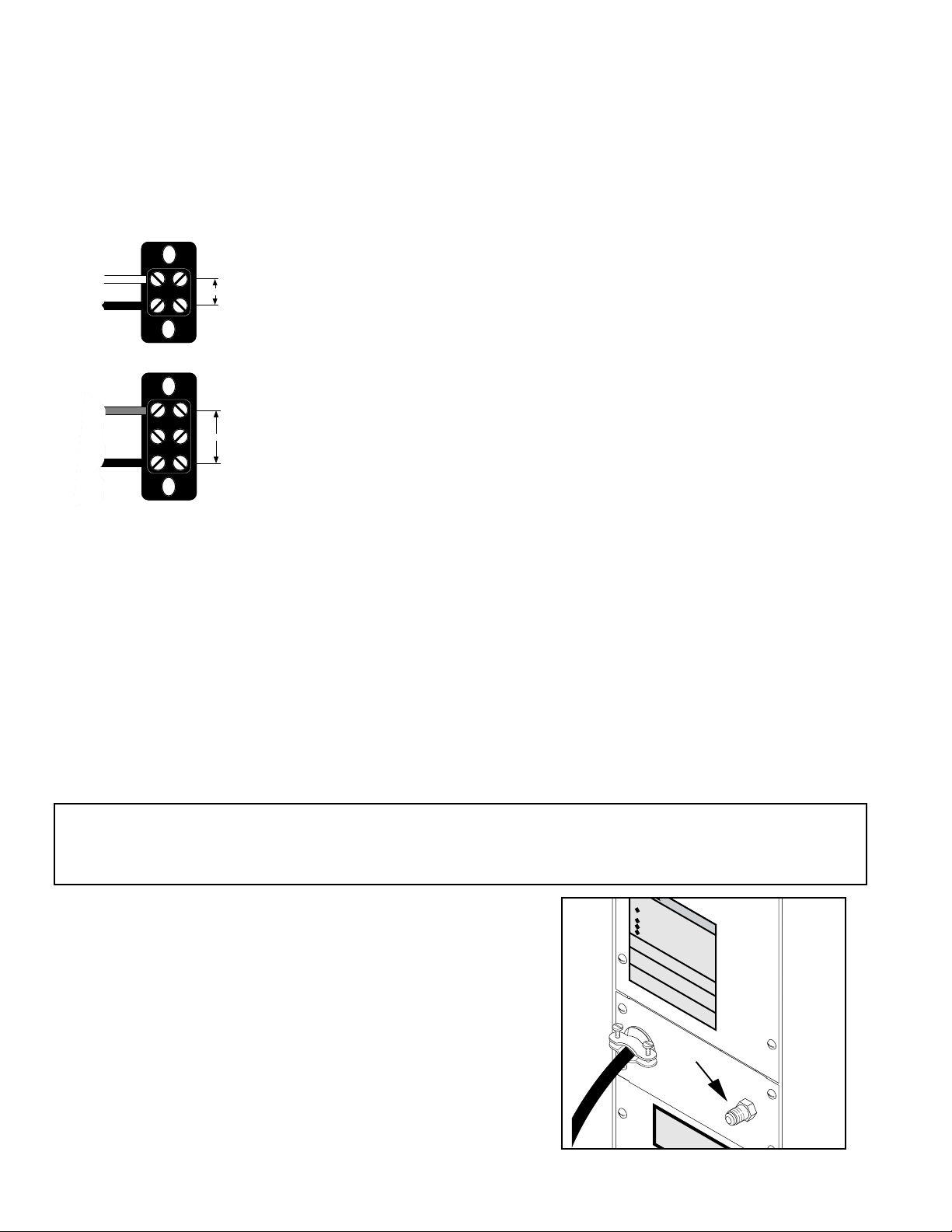

Electrical Hook-Up

CAUTION – Improper electrical installation will damage electronic components.

WHITE

NEUTRAL

L1 BLACK

120V.A.C.

1. An electrician must provide electrical service as specified.

2. Using a voltmeter, check the voltage and color coding of each conductor at

the electrical source.

3. Remove the upper and lower rear panels. Turn the knob of the thermostat to

the “OFF” position (fully counterclockwise).

4. Install a strain relief and the proper electrical wiring to the terminal block.

L2 RED

208 or 240V.A.C.

L1 BLACK

5. Connect the dispenser to the power source and verify the voltage at the terminal block before proceeding. Reinstall both rear panels.

6. If plumbing is to be hooked-up later be sure the dispenser is disconnected from

the power source. If Plumbing has been hooked-up, the dispenser is ready for

Initial Set-Up

.

PLUMBING REQUIREMENTS

This dispenser must be connected to a COLD WATER system with operating pressure between 20 and 90 psi (138

and 620 kPa)from a 1⁄2" or larger supply line. A shut-off valve should be installed in the line before the dispenser.

Install a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345 kPa). The

water inlet fitting is 1⁄4" flare.

NOTE - Bunn-O-Matic recommends 1⁄4" copper tubing for installations of less than 25 feet and 3⁄8" for more than

25 feet from the 1⁄2" water supply line. At least 18 inches of an FDA approved flexible beverage tubing, such as

reinforced braided polyethylene or silicone, before the dispenser will facilitate movement to clean the countertop.

It can be purchased direct from Bunn-O-Matic (part number 00326-0000). Bunn-O-Matic does not recommend

the use of a saddle valve to install the dispenser. The size and shape of the hole made in the supply line by this type

of device may restrict water flow.

This equipment must be installed to comply with the Basic Plumbing Code of the Building Officials

and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the

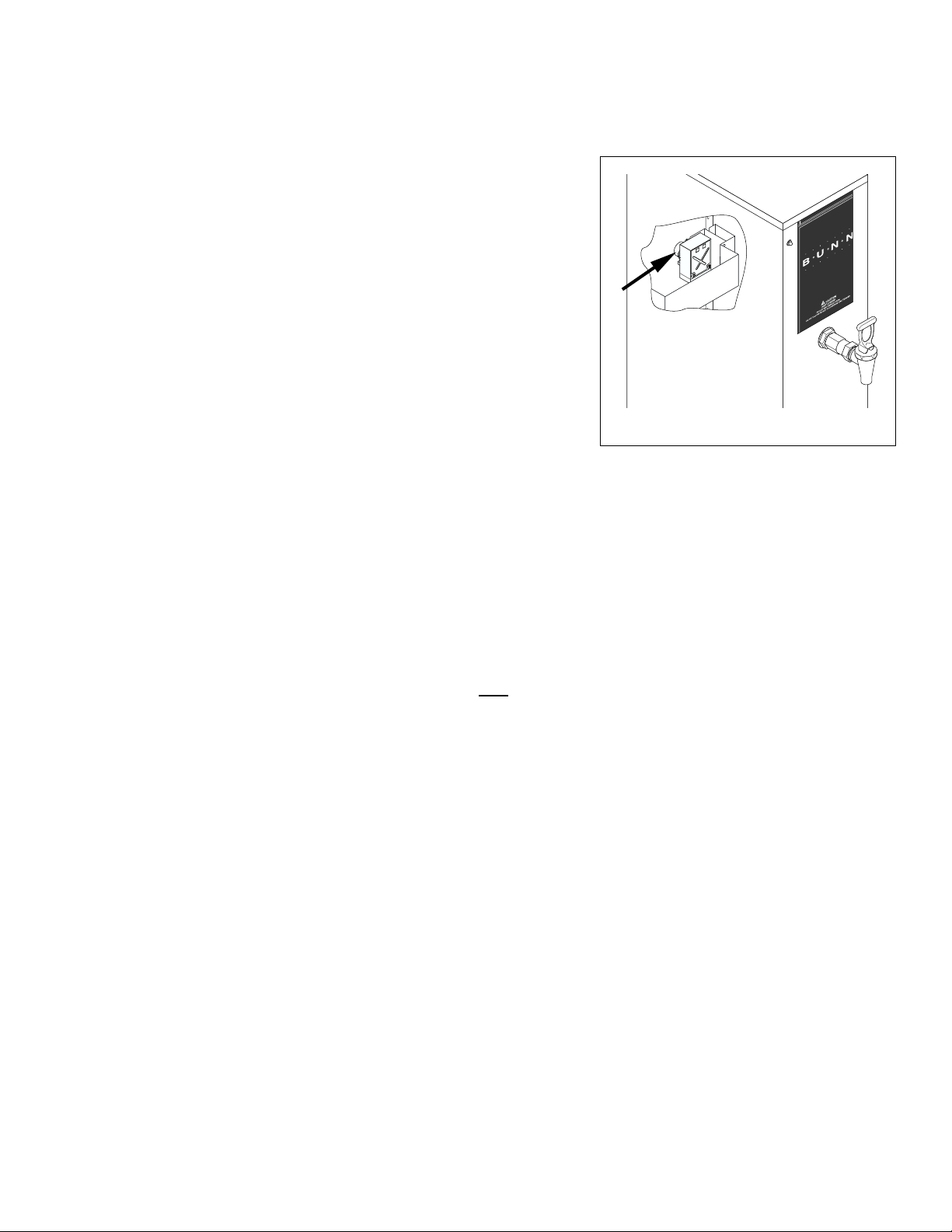

Plumbing Hook-Up

1. Flush the water line and securely attach it to the flare fitting on

Food and Drug Administration (FDA).

water tank before turning -on

thermostat or connecting appliance

ARNING

to power source.

Use only on a properly protected

circuit capable of the rated load.

Electrically ground the chassis.

Follow national/local electrical codes.

Do not use near combustibles.

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE, OR SHOCK HAZARD

R

E

AD

LIAB

IN

TH

C

LU

ILITY B

E E

D

ING

NTIR

EFO

TH

E O

E

R

LIM

E BU

TH

PER

IS A

IT O

AT

YIN

P

IN

F W

C

PLIA

G

O

G

O

NN

M

AR

R

NC

U

EC

R

00831.0000A 5/88 © 1988 BUNN-O-MATIC CORPORATION

SIN

A

E IS H

TED

N

G

TO

TH

EA

A

TED

PO

W

W

H

E

ENE

R SO

U

NECT FROM

OWER SOURCE

BEFORE REMOVING!

AN

UA

TY

L

A

N

IS PR

D

O

DU

CT

VE

RCE

R

the rear of the dispenser.

2. Turn-on the water supply.

This equipment is to be in

comply with the Basic Pl

Administrators

the Building O

and the F

of the

P1770

4

10267 071900

INITIAL SET-UP

CAUTION - The dispenser must be disconnected from the power source throughout the initial set-up, except

when specified in the instructions.

1. Remove the upper rear panel and rotate the control thermostat

knob fully counterclockwise to the “OFF” position and replace

the panel.

2. Connect the dispenser to the power source and turn-on the water

supply.

3. Water will automatically flow into the tank to the proper level

and shut-off. This will take approximately 10 minutes.

4. Disconnect the dispenser from the power source, remove the

upper rear panel and place the control thermostat knob fully

clockwise to the “ON” position, and replace the panel.

5. Connect the dispenser to the power source and wait approximately twenty minutes for the water in the tank to heat.

6. On models with ready indicator, the indicator will glow when the

proper water temperature for use is achieved.

P1781

DRAINING THE DISPENSER

CAUTION - The dispenser must be disconnected from the power source throughout these steps.

1. Disconnect the dispenser from the power source.

2. Shut-off and disconnect the incoming water supply

3. Remove the 4-40 screws at the sides of the top panel.

4. Gently remove one of the grommets from the tank lid.

5. Insert a tube to the bottom of the tank and syphon ALL of the water out. Bunn-O-Matic has a syphon assem-

bly available (#12440.0000) for this purpose.

NOTE - The dispenser must be full using the INITIAL SET-UP steps before reconnecting to the power source.

CLEANING

The use of a damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for cleaning

all surfaces on Bunn-O-Matic equipment.

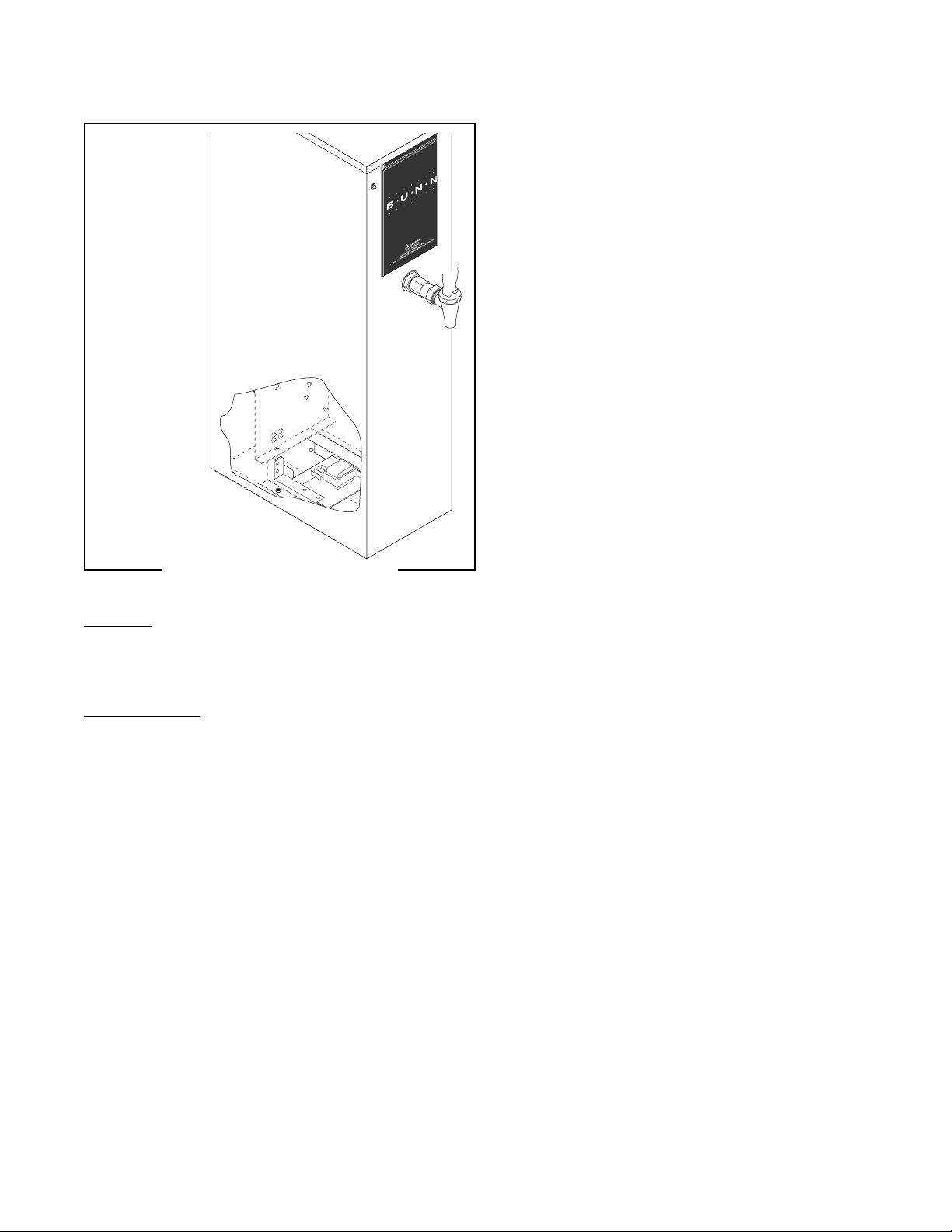

WALL MOUNTED INSTALLATION

If the dispenser is wall mounted, the bottom of the dispenser should be at the same height as a counter or

table top. Use B.O.M. part #12542.0000 for side mounted Wall Bracket Kit or # 13125.0001 for front mounted

Wall Bracket Kit .

SUPPORT FOR LARGE RECEPTACLES

CAUTION: If the dispenser is to be used with larger receptacles such as pitchers or pots, those receptacles must

be adequately supported during dispensing of hot water to avoid spillage of very hot water. This support may be

provided by a table or counter top, or use B.O.M. part #12599.0000 Shelf Kit

5

10267 071900

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel.

• All electronic components have 120 – 240 volt ac and low voltage dc potential on their terminals. Shorting of

terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be permanent. If an

intermittent condition is encountered, the cause will likely be a switch contact or a loose connection at a

terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if solenoids are

energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened. This will

help to avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This dispenser is heated at all times. Keep away from combustibles.

WARNING

• Exercise extreme caution when servicing electrical equipment.

• Disconnect the dispenser from the power source when servicing, except when electrical tests are speci-

fied.

• Follow recommended service procedures

• Replace all protective shields or safety notices

Problem

Equipment will not operate.

Probable Cause

1. No power or incorrect voltage

2. Safety overflow switch

Remedy

(A) Check the terminal block for the correct voltage. It should be:

a.) 100 to 120 volts ac across the black and

white terminals for 100 to 120 volt models,

b.) 200 to 240 volts ac across the red and

black terminals for 200 to 240 volt models

c.) 230 volts ac across the red and black

terminals for 230 volt models.

(B) Check circuit breakers or fuses.

Refer to Service – safety overflow switch

for testing procedures. See page 11.

6

10267 071900

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

Automatic refill will not operate

after drawing hot water.

Water flows into the tank continuously (Dispenser disconnected from power source).

1. No water

2. Water strainer/flow control

3. Safety overflow switch

4. Liquid level system

5. Solenoid valve

1. Solenoid valve

Check plumbing and shut-off valves.

(A) Direction of flow arrow must be pointing towards dispenser.

(B) Remove the strainer/flow control and

check for obstructions. Clear or replace.

Refer to Service – safety overflow switch

for testing procedures. See page 11.

Refer to Service – liquid level board for testing procedures. See page 15.

Refer to Service – solenoid valve for testing procedures. See page 12.

Refer to Service – solenoid valve for testing procedures. See page 12.

Water flows into the tank continuously (Dispenser connected

1. Liquid level system

Refer to Service – liquid level board for testing procedures. See page 15.

to power source).

Water is cold.

1. Control thermostat

Control thermostat must be in the “ON”

position.

2. Safety overflow switch

Refer to Service – safety overflow switch

for testing procedures. See page 11.

3. Limit thermostat

Refer to Service – limit thermostat for testing procedures. See page 10.

CAUTION – Do not eliminate or bypass limit thermostat. Use only B.O.M. replacement part #23717.0001.

4. Tank heater

Refer to Service – tank heater for testing

procedures. See page 13.

5. Temperature control

Refer to Service – control thermostat for

testing procedures. See page 14.

7

10267 011599

TROUBLESHOOTING (cont.)

Problem Probable Cause Remedy

Water boils continuously.

1. Temperature control

Refer to Service – control thermostat for

testing procedures. See page 14.

2. Lime build-up

Inspect the tank assembliy for excess lime

deposits. Delime as required.

CAUTION – Tanks and tank components should be delimed reglarly depending on local water conditions. Excessive mineral build-up on stainless steel surfaces can initiate corrosive reactions resulting in serious leaks.

Dispenser is making unusual

noises.

1. Solenoid valve

2. Plumbing lines

The nut on top of the solenoid valve must

be tight or it will vibrate during operation.

Plumbing lines should not be resting on the

counter top.

3. Water supply

(A) The dispenser must be connected to a

cold water line.

(B) Water pressure to the dispenser must

not be higher than 90 psi (620 kPa). Install

a regulator if necessary to lower the working pressure to approximately 50 psi (345

kPa).

Ready indicator will not light.

(when temperature is within 4°

of its selected setting.)

1. Temperature control

2. Ready Indicator LED

Refer to Service – control thermostat for

testing procedures. See page 14.

Replace the indicator LED.

8

10267 011599

SERVICE

This section provides procedures for testing and

replacing various major components used in this dispenser should service become necessary. Refer to

Troubleshooting for assistance in determining the cause

of any problem.

Component Access

WARNING – Disconnect the dispenser from the power

source before the removal of any panel or the replacement of any component.

The limit thermostat, liquid level probe, tank heater,

and temperature sensor are located at the top of the

dispenser. Access is gained by removing the top lid,

attached with three 4-40 slotted-head screws.

WARNING – Inspection, testing, and repair of electrical

equipment should be performed only by qualified service personnel. Disconnect the dispenser from the

power source when servicing, except when electrical

tests are required and the test procedure specifically

states to connect the dispenser to the power source.

Contactor ............................................................ 17

Limit Thermostat ................................................ 10

Liquid Level Board .............................................. 15

Safety Overflow Switch ....................................... 11

Solenoid Valve .................................................... 12

Tank Heater ........................................................ 13

Control Thermostat............................................. 14

9

101112

SERVICE (cont.)

Solenoid Valve

Location:

The solenoid valve is located inside the rear of the dispenser on the right side near the bottom.

6. Check the solenoid valve for coil action. Connect

the dispenser to the power source. Listen carefully

in the vicinity of the solenoid valve for a “clicking”

sound after approximately 5 seconds, as the coil

magnet attracts the plunger.

7. Disconnect the dispenser from the power source.

If the sound was heard as described and water will not

pass through the solenoid valve, there may be a blockage in the water line before or after the solenoid valve

or the solenoid valve may require inspection for wear

and removal of waterborne particles.

If the sound was not heard as described, replace the

solenoid valve.

Removal and Replacement:

1. Remove all wires from the solenoid valve coil.

2. Turn-off the water supply to the dispenser.

3. Disconnect the water lines to and from the solenoid valve.

4. Remove the two 8-32 slotted-head screws holding

the solenoid valve and mounting bracket to the

component bracket.

5. Lift-out the solenoid valve.

6. Remove the two 10-32 slotted-head screws holding the solenoid valve to its mounting bracket.

7. Securely install the new solenoid valve to its mounting bracket. The direction of flow arrow must be

pointing towards the tank lid.

8. Attach the solenoid valve and mounting bracket to

the component bracket.

9. Securely fasten the water lines to and from the solenoid valve.

10. Reconnect the wires, FIG. 6.

13

SERVICE (cont.)

Thermostat

Location: The mechanical thermostat is located inside

the upper rear panel. To test the thermostat, access

will also be needed to the terminal block located inside

the bottom access panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Check the voltage across the black wire on the thermostat and the white or red wire at the terminal

block with a voltmeter. Connect the dispenser to

BLU/BLK to Limit Thermostat

BLK to Terminal Block

FIG. 10 THERMOSTAT WIRING

14

P1782

SERVICE (cont.)

Liquid Level Board

FIG. 11 LIQUID LEVEL BOARD

Location:

The liquid level board is located inside the lower

panel.

Test Procedure:

1. Disconnect the dispenser from the power source.

2. Remove the blue wire from terminal 1 and the pink

wire from terminal 4 of the circuit board.

3. Check the voltage across terminals 2 and 3 with a

voltmeter. Connect the dispenser to the power

source. Turn the thermostat knob to the “ON” position (fully clockwise). The indication must be:

a.) 100 to 120 volts ac for 100 to 120 volt models,

b.) 200 to 240 volts ac for 200 to 240 volt models,

c.) 230 volts ac for 230 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described, refer to the wiring diagrams and check the wiring harness.

15

SERVICE (cont.)

Liquid Level Board (cont.)

15. Move the probe's flat end to the dispenser housing. The indication must be 0.

16. Move the probe's flat end away from the dispenser

housing. The indication should again be:

a.) 100 to 120 volts ac for 100 to 120 volt models,

b.) 200 to 240 volts ac for 200 to 240 volt models,

c.) 230 volts ac for 230 volt models.

17. Disconnect the dispenser from the power source.

If voltage is present as described, reinstall the probe,

the level control board and level probe are operating

properly.

If voltage is not present as described, check the pink

probe wire.

Removal and Replacement:

1. Remove all wires from the level control board.

2. Remove two #8-32 screws holding level control

board and mounting bracket to the component

bracket.

3. Install the new level control board and mounting

bracket to the component bracket.

4. Refer to FIG. 12 when reconnecting the wires.

BLU to Solenoid (T-1)

BLK to Overflow Safety Switch (T-2)

WHI to Terminal Block (T-3)

PNK to Level Probe (T-4)

P1784

FIG. 12 LIQUID LEVEL BOARD WIRING

16

10267 071900

SERVICE (cont.)

Contactor

FIG. 13 CONTACTOR

Location:

The contactor is located on the component

bracket inside the lower rear panel.

Test Procedures:

1. Disconnect the dispenser from the power source.

2. Disconnect the black wire from the contactor coil

to the limit thermostat and black wire from the red

wire on the main harness on two wire 240V models.

3. Check the voltage across the red wire and black

wire with a voltmeter. The indication must be:

a.) 240 volts ac for 240 volt models,

b.) 230 volts ac for 230 volt models.

4. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #5.

If voltage is not present as described refer to the Wiring Diagrams and check the wiring harness.

5. Check for continuity between the left and right terminals on the contactor coil.

If continuity is present as described, reconnect the

wires and proceed to #6

If continuity is not present as described, replace the

contactor.

6. Check the voltage across the upper left terminal

and the upper right terminal on the contactor with

a voltmeter. Connect the dispenser to the power

source. The indication must be:

a.) 240 volts ac for 240 volt models,

b.) 230 volts ac for 230 volt models.

7. Disconnect the dispenser from the power source.

If voltage is present as described, proceed to #8.

If voltage is not present as described, refer to the wiring diagrams and check the wiring harness.

8. Check for continuity across the terminals on the

left side of the contactor by manually closing the

contacts. Continuity must not present when the

contact is released.

9. Check for continuity across the terminals on the

right side of the contactor by manually closing the

contacts. Continuity must not be present when the

contact is released.

If continuity is present as described, the contactor is

operating properly.

If continuity is not present as described, replace the

17

SERVICE (cont.)

Contactor (cont.)

contactor.

Removal and Replacement:

1. Disconnect all the wires from the contactor.

2. Remove the two #8-32 screws securing the

contactor to the contactor mounting bracket, remove contactor and protective shield. Discard

RED to Terminal Block(L2)

contactor.

3. Install new contactor with shield between mounting bracket and contactor and secure with two #832 screws

4. Refer to Fig. 14 and reconnect the wires.

BLK to left Tank

Heater

RED to Right

Tank Heater

BLK to Terminal

Block (L1)

BLK to Limit

Thermostat

RED from Main Harness

FIG.14 CONTACTOR WIRING

P1725

18

10267 011599

WIRING DIAGRAMS

OPTIONAL

READY INDICATOR

BLK

SCHEMATIC WIRING DIAGRAM H5M

BLK

L1

BLK

BLK BLK

SW&

THERMOSTAT

THERMOSTAT

BLU/BLK

OVERFLOW

PROTECTION SWITCH

REDRED

120 VOLTS A C

2 WIRE

SINGLE PHASE

10243.0000D 1/99 © 1987 BUNN-O-MATIC CORPORATION

SCHEMATIC WIRING DIAGRAM H5M

L1

LIMIT

LIQUID

LEVEL

BOARD

BLK

4312

P

N

K

(PROBE)

GREEN

WHI

TANK HEATER

BLU WHI

SOL

WHI

GREEN

N

L2

BLK RED

OPTIONAL

READY INDICATOR

BLK

SW&

THERMOSTAT

BLK BLK

208 or 240 VOLTS A C

SINGLE PHASE

N.O. N.O.

RED

OVERFLOW

PROTECTION SWITCH

2 WIRE

BLU/BLK

REDRED

BLK

TANK HEATER

LIMIT

THERMOSTAT

BLK

LIQUID

LEVEL

BOARD

4312

P

N

K

(PROBE)

10262.0000C 1/99 © 1987 BUNN-O-MATIC CORPORATION

BLU

RED

BLK BLKBLK

K

SOL

RED

RED

RED

19

10267 011599

WIRING DIAGRAMS

SCHEMATIC WIRING DIAGRAM H5MA, 230V CE

L1

THERMAL

BLK RED-12BLK-12

BLK

BLK BLK

N.O. N.O.

SW&

THERMOSTAT

OVERFLOW

PROTECTION SWITCH

FUSE

THERMOSTAT

BLU/BLK

REDRED

N.C.

230 VOLTS A C

2 WIRE

TANK HEATER

LIMIT

LIQUID

LEVEL

BOARD

BLK

4312

BLU

P

N

K

(PROBE)

GREEN

THERMAL

FUSE

SOL

L2

RED

K

RED

RED

RED

SINGLE PHASE

10262.0001A 11/99 © 1999 BUNN-O-MATIC CORPORATION

20

10267 071900

Loading...

Loading...