Page 1

FACTORY AUTHORIZED SERVICE

COFFEE BREWERS

MODELS F-35, F-20, F-15

MODELS ABOVE SERIAL NUMBER*

F·35 57581

F·20 30872

F·15 30179

f(J:\666L ~ ~~ ~:~~

(Stainless)

LISTED r'pproved bYe'"''

F-S

F-WG

(Woodgrain)

OPERATING & SERVICE MANUAL

CONTENTS

Electrician's Insrtallation Instructions 2

Plumber's Installation Instructions 2

Initial Operation Instructions 3

Coffee Brewing Directions 3

CleaningTips 3

WARNING

DISCARD GLASS DECANTER IF

• CRACKED

• SCRATCHED

• BOILED DRY

• HEATED WHEN EMPTY

• USED ON HIGH FLAME OR OPEN

ELECTRIC ELEMENTS.

FAILURE TO DO SO MAY RESULT

IN BODILY INJURY.

10023.0000E 1/94 © 1981 BUNN-O-MATIC CORPORATION

Trouble ShootingGuide 4

Component Replacement Instructions 8

Schematic Wiring Diagrams 10

Replacement Parts 11

Warranty Back Cover

Page 2

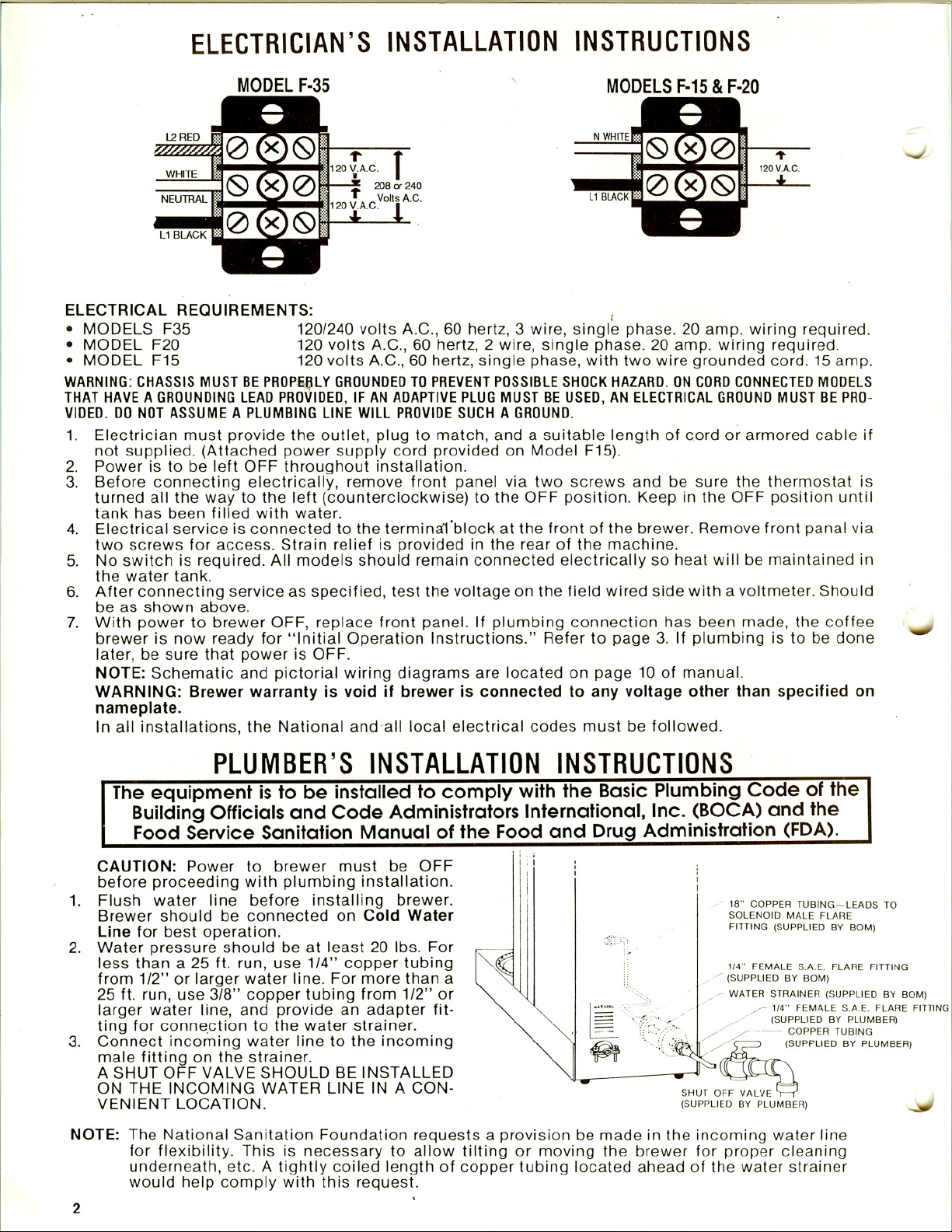

El ECT RICIAN'S INS TAL lA TION INS T RUCTION S

MODEL f·35

MODELS f·15

& f·20

ELECTRICAL REQUIREMENTS: 1

• MODELS F35 120/240 volts A.C., 60 hertz, 3 wire, single phase. 20 amp. wiring required.

• MODEL F20 120 volts A.C., 60 hertz, 2 wire, single phase. 20 amp. wiring required.

• MODEL F15 120 volts A.C., 60 hertz, single phase, with two wire grounded cord. 15 amp.

WARNING: CHASSIS MUST BE PROPEBL Y GROUNDED TO PREVENT POSSIBLE SHOCK HAZARD. ON CORD CONNECTED MODELS

THAT HAVE A GROUNDING LEAD PROVIDED, IF AN ADAPTIVE PLUG MUST BE USED, AN ELECTRICAL GROUND MUST BE PRO-

VIDED. DO NOT ASSUME A PLUMBING LINE WILL PROVIDE SUCH A GROUND.

1. Electrician must provide the outlet, plug to match, and a suitable length of cord or armored cable if

not supplied. (Attached power supply cord provided on Model F15).

2. Power is to be left OFF throughout installation.

3. Before connecting electrically, remove front panel via two screws and be sure the thermostat is

turned all the way to the left (counterclockwise) to the OFF position. Keep in the OFF position until

tank has been filled with water.

4. Electrical service is connected to the termina"1"block at the front of the brewer. Remove front panal via

two screws for access. Strain relief is provided in the rear of the machine.

5. No switch is required. All models should remain connected electrically so heat will be maintained in

the water tank.

6. After connecting service as specified, test the voltage on the field wired side with a voltmeter. Should

be as shown above.

7. With power to brewer OFF, replace front panel. If plumbing connection has been made, the coffee '.......,)

brewer is now ready for "Initial Operation Instructions." Refer to page 3. If plumbing is to be done

later, be sure that power is OFF.

NOTE: Schematic and pictorial wiring diagrams are located on page 10 of manual.

WARNING: Brewer warranty is void if brewer is connected to any voltage other than specified on

nameplate ..

In all installations, the National and-all local electrical codes must be followed.

PLUMBER'S INSTAllATION INSTRUCTIONS

Theequipment isto be installed to comply with the Basic Plumbing Code of the

Building Officials and Code Administrators International, Inc. (BOCA) and the

Food Service Sanitation Manual of the Food and Drug Administration (FDA).

i ;

CAUTION: Power to brewer must be OFF

before proceeding with plumbing installation.

1. Flush water line before installing brewer.

Brewer should be connected on Cold Water

Line for best operation.

2. Water pressure should be at least 20 Ibs. For

less than a 25 ft. run, use 1/4" copper tubing

from 1/2" or larger water line_ For more than a

25 ft. run, use 3/8" copper tubing from 1/2" or

larger water line, and provide an adapter fit-

ting for conne.ction to the water strainer.

3. Connect incoming water line to the incoming

male fitting on the strainer.

A SHUT OFF VALVE SHOULD BE INSTALLED

ON THE INCOMING WATER LINE IN A CON-

VENIENT LOCATION.

NOTE: The National Sanitation Foundation requests a provision be made in the incoming water line

for flexibility. This is necessary to allow tilting or moving the brewer for proper cleaning

underneath, etc. A tightly coiled length of copper tubing located ahead of the water strainer

would help comply with this request.

2

I: 1

18" COPPER TUBING-LEADS TO

SOLENOID MALE FLARE

FITTING (SUPPLIED BY BOM)

1/4" FEMALE SAE. FLARE FITTING

/ / (SUPPLIED BY BOM)

/~ WATER STRAINER (SUPPLIED BY BOM)

='::':':''-' " // (SUPPLIED BY PLUMBER)

== ", :""'. /. --,-, COPPER TUBING

U .."..··.-; "'~''- -' . ,/- 1/4" FEMALE SAE. FLARE FITTING

~ .J·t:, ~~UPPLIED BY PLUMBER)

SHuro~ , J(SUPPLIED BY PLUMBER) ~

Page 3

INITIAL OPERATION INSTRUCTIONS

/

2.

3.

\-t

4.5.

IMPORTANT: • Brewer must be level or slightly lower f'n front to siphon properly.

1.

NOTE: Be sure thermostat is in OFF position.

Turn power to brewer ON.

Place brewing funnel in proper position for brewing. Place a decanter containing a little water on

center warmer and turn ON-OFF toggle switch to the ON position. This switch must be ON to operate

a brew cycle. _

Deflect the start switch. This will start a brew cycle and allow water to flow into the tank. Water will

run approximately two minutes before timed cycle ends. Repeat this cycle three additional times;

water should overflow tank into the decanter on center warmer during the fourth cycle.

Turn power to brewer OFF. Remove front panel via two screws. Adjust timer to deliver desired amount

of water. To increase amount of water, increase time of water flow by turning timer dial slightly

clockwise. To decrease amount of water, decrease time of water flow by turning timer dial slightly

counterclockwise.

6. Turn control thermostat knob fully clockwise to the ON position. Turn power to brewer ON and allow

approximately 10 to 20 minutes for water in tank to heat. (F-35 approximately 10 minutes-F-20 ap-

proximately 15 minutes-F-15 approximately 20 minutes.) When the water reaches brewing

temperature, the contronhermostat will click off and the heating noise will stop. On initial heat up,

normal water expansion will occur in the water tank. Water may drip from the funnel due to this ex-

pansion, but will not occur thereafter.

7. Turn on-off switch to the ON position. Place empty decanter on center warmer under the funnel and

deflect start switch. Run a partial cycle to remove expanded water from the tank. Now run a full cycle

to check for proper timer setting and to cycle control thermostat.

8. When control thermostat clicks off and heating noise stops, run a cycle to check for proper

temperature setting. With an accurate thermometer, take the temperature of the water at the point

below the funnel opening and at the time when the decanter is about half full. Recommended

temperature of the water is approximately

level) thermostat may have to be readjusted to prevent boiling.

9. If water volume and temperature are correct, replace front panel. Coffee brewer is now ready for brew-

ing coffee.

• Electrician's and Plumber's instructions are provided on page 2. These instructions

should be carefully followed before proceeding with initial operation instructions.

• Be sure all electrical and plumbing connections are tight.

1950 F. Due to higher altitude locations (5,000 ft. above sea

COFFEE BREWING DIRECTIONS

FAST, CLEAN, CONVENIENT -BUNN® DISPOSABLE PAPER FILTERS

Drop Bunn filter into funnel.

1. Place Bunn filter in funnel and add desired amount of coffee.

2. Level the bed of coffee and insert funnel in hood guides.

3. Place empty decanter on center warmer under funnel.

4. Turn on-off toggle switch to the "ON" position, deflect start switch and brew a pot of coffee.

IMPORTANT! Use Bunn Filters for Bunn Coffee Brewers. There is a differ'ence.

Pour in fresh coffee.

Slide funnel into head and brew.

Simply throw out grounds.

CLEANING TIPS

1. For cleaning all metal surfaces, use any reputable stainless steel cleansing compound.

2. Sprayhead should be checked and cleaned regularly. (At least once a week.) Sprayhead holes must be

kept open.

3. To prevent "LIMING" problems in the water tube and air tube, remove sprayhead and insert deliming

spring all the way into the tank through both tubes. When inserted into tank properly, no mora than

two inches of the spring should be visible. Saw back and forth five or six times. This will keep tubes

open and clear of lime. In hard water areas this should be done every day; this takes less than a

minute.

3

Page 4

FACTORY AUTHORIZED SERVICE

TROUBLE SHOOTING GUIDE

MODELS F·35, F·20, F·15

and relay, relay and

Be sure water shut

No Power. 2.

Timer.

Loose connection 5.

Solenoid valve.

Should hear two clicks

With On-Off switch

Start switch.

If start switch does

Be sure contact

Check voltage at

(A)

(A)

Cord set and plug

Incoming water lines

Plug and socket con-

Contact points.

If relay does not

On-Off toggle switch.

Switch continuity.

Relay.

Check paddle arm on

(A) Voltage at solenoid

If voltage is

If voltage is not

to solenoid.

would indicate that the

not make and break

switch.

when the start switch

and check for water

side of the solenoid valve.

Installation Instructions"

the micro switch arm

switch is released,

timer, and terminals

If not, check switchcontinuity .

for correct voltage.

deenergizes when start

refer to step 7.

paddle arm is not re-setting and is holding

down. Replace Timer.

contact, replace start

been checked, replacerelay.If relay energizes

at line pressureon the outgoing

start a brew cycle

SYMPTOM

6.

this would indicate a

switch.

warmer should heat.

when micro switch arm

(B)

8.

at terminals and water

solenoid valve.

off valve is open.

nections are tight.

8.(A)

7.

in the ON position,

points are clean.

energize when start

switch is depressed,

defective relay. If

steps 1 thru 5 have

present on the inlet

side of the solenoid,

leased. If not, this

indicator lamp shouldcontact, replace On-Off

light and center

outgoing side, replace

present at terminals

refer to steps 2 thru 7.

(B) If voltage is present

is depressed and re-

at line pressure is

but not present on the

WHAT TO CHECK

POSSIBLE CAUSE

1.

7.

nections between harness

2.

terminal block. Refer

to "Electrician's

1.No Water. 1.

3.

3.If On-Off switch does

not make and break

4.

4.

5.Be sure these con-

6.

REMEDY

is depressed, but

and water shut off valve.

4

Page 5

FACTORY AUTHORIZED SERVICE

NO HOT

WATER

Control 1.

Excessive Lime. 2.Tank and tank lid 2.

Solenoid valve

Brewer must be

Turn knob counter-

Water should flow from

STEAMING

(A)

Knob Setting.

Not Siphoning

Be sure spring is in

If lime build up is

Insert deliming

thermostat.

holes.

and air tube all the

back and forth five

are cleaned from valveseat. If vaIve seat

(C)

decrease, replace control

and tank lid assembly.

(B) Clean sprayhead

spring in water tube

way into tank and saw

is worn or multilated,replace solenoid valve.

properly

'0551 BLE CAUSE WHAT TO CHECK

1. Tank heater

2. Limit Thermostat or

Control Thermostat.

1.

1.

2.Solenoid valve

1.

1.

1.

Thermostat clockwise for lower

2.

lower in front to

sprayhead for approx-

excessive, delime tank

level or slightly

siphon properly.

place and any particles

1. Voltage at tank heater

2. With control thermostat

or six times.

terminals with control

thermostat knob in the

fully clockwise position.

Voltage should be:

Model F35

240 volts A.C.

Models F20 and F15

120 volts A.C.

knob in the fully clockwise

position, check the

voltage between the

white (or red) wire on

the tank heater terminal

and the incoming

terminal (black wire)

on the limit thermostat,

then the outgoing (blue

wire) terminal on the

limit thermostat. Voltage

should be: Models

F15 and F20, 120 volts

A.C. Model F35,

240 volts A.C.

REMEDY

1. If correct voltage is

present at the tank

heater terminals and

water in tank is not being

heated, replace tank

heater.

If voltage is not present

at tank heater termina Is,

refer to step 2.

If incorrect voltage

is present on tank

heater terminals, refer

to "Electrician's

Installation Instructions."

2. (A) If voltage is present

on incoming terminal

(black wire) on the limit

thermostat, but not on the

outgoing terminal, (blue

wire) replace limit

thermostat.

(B) If voltage is present

on both terminals on the

limit thermostat, but not

across tank heater

terminals, replace control

thermostat.

(C) If voltage is not

present on the incoming

terminal on the limit

thermostat, refer to "No

Power" Section.

of water does not

setting. If temperature

WATER KEEPS

RUNNING

(BREWER WON'T

SHUT OFF

ELECTRICALLY) .

1. Solenoid Valve

1. Refer to "Dripping"

section, step 2.

1. Refer to "Dripping"

section, step 2.

5

Page 6

be at least 2 minutes

Timer.

Timer.

Start Switch.

Flow valve.

Clean flow valve of

Timer.

Paddle arm on timer.

Solenoid Valve.

Flow valve.

Timer dial indicator

Solenoid valve

Clean solenoid of

Adjust timer for a

Flow valve assembly.

Not siphoning

If paddle arm on timer

Water pressure should be

Timer consistency.

Switch continuity.

Refer to "Dripping"

Refer to "Dripping"

Low water pressure.

Water pressure at

Flow valve assembly.

with micro switch

below 20 PSI.

or clock.

arm, then resets.

not make and breakcontact, switch should

the line do not reduce

partially or inter-

be replaced.

mittently clog orifice.Replace if necessary.

15 seconds).

any particles that maypartially clog orifice.Replace if necessary.

may partially clogorifices: Replace

sure other appliances in

water pressure to brewer

if necessary.

SYMPTOM

POSSIBLE CAUSE

WHAT TO CHECKREMEDY

3.

1.

2.

2.If start switch does

1.

1.

1.

2.

2.

1.

1.

1.

2.

3.

3.

timer should be

1.

1.

4.

4.

2.Clean flow valve, of

at least 20 PSI. Be

replace timer.

section, Step 1.

slips or doesn't move,

any particles that

3. If times are irregular,

higher setting.

replaced.

section, step 1.

,

Check to see if

and makes contact

slowly moves around

paddle arm on timer

any particles that may

OVERFLOWING

DECANTER

WARMER PLATES

RED HOT-OR

SOLENOID COIL

SMOKING-OR

WATER IN TANK

HEATS EXCESSIVELY

FAST.

6

1. Receiving decanter

machine.

block.

with a watch or clock.

sistency several times

(B) Check timer con-

cator set too high.

section, step 2.

3.

2.

not completely

empty when brew

1.

cycle is started.

2. Timer.

3. Solenoid valve.

1. Brewer wired to

wrong voltage.

FACTORY AUTHORIZED SERVICE

If times are

(A) Timer dial indi-

(A)

1.

Refer to "Dripping"

Personnel operating

Readjust timer

Voltage at terminal

Always start brew

Refer to "Dripping"

Refer to "Electrician's

for correct voltage andcorrect as necessary.

decanter empty.

2.

3.

Installation Instructions"

cycle with receiving

for a lower setting.

(B)

section, step 2.

irregular, timer

should be replaced.

11.

11.

Page 7

r

,

properly.

Vibration.

If brewer is on a

Brewer connected

Brewer should be

Filter and coffee

Water hammer.

This is not the fault

If switch does not make

FiIters. 1.Check if Bunn Filters

Filter should be

FiIters. 1.

Bad harness

Check connections

Be sure all connections

Warmer-defective. 1.

Warmer On-Off Switch.

Not siphoning

Check if Bunn Filters

Adiust control thermo-

Adjust as necessary.

Incoming water line.

Missing sprayhead.

Check for sprayhead.

InstaII sprayhead.

Refer to "Dripping"

Refer to "Dripping"

Improper loading

Water temperature

Check water temperature.

Not siphoning

Refer to "Dripping"

Refer to "Dripping"

Improper loading

60 cycle vibration.

Check tightness of

Tighten nut on top of

High water pressure.

If water' pressure is

Missing sprayhead.

Check for sprayhead.

Install sprayhead.

Voltage at warmer

If voltage is present

Incoming plumbing.

Number of sprayhead

Water pressure on

A 6-hole sprayhead

counter.

see that neither

CYCLE HAS

be level.

of the brewer. It

an air chamber to the

counter, check to

and coffee bed shouldbe level.

and coffee bed should

can usually be corrected

bottom pan norcopper tubing to

pressure regulatorand adjust to 50 PSI.

by rearranging someplumbing or adding

incoming water line.

replace warmer.

brewer is touching

SYMPTOM

POSSIBLE CAUSE

1.Bunn Filters should

WHAT TO CHECKREMEDY

2.

and break when turned

2.

2.

to hot water.

1.

1.

1.

2.

3.

4.Filter and coffee

2.

3.

3.

4.

4.Filters should be

in funnel.

3.

solenoid valve.

4.

5.

5.

5.

5.

switch.

2.

5.

5.

1.

1.Bunn Filters should

2.

in funnel.

1.

centered in funnel

4.

3.

4.

3.

over 90 PSI install

1.

1.

stat knob clockwise

should be used.

3.Wrong sprayhead.

3.

centered in funnel

always be used.

3.

between harness and

Refer to "Initial Operation

on terminals, but

warmer will not heat,

2.If voltage is not

always be used.

sectiOfl, step 1.

are tight.

to a higher setting.

section, step 1.section, step 1.

on and off, replace

section, step 1.

2.

connected to Cold

terminals. Should

are being used.

water line.

FACTORY AUTHORIZED SERVICE

7

Page 8

COMPONENT' REPLACEMENT INSTRUCTIONS

CAUTION: DISCONNECT COFFEE BREWER FROM POWER SOURCE PRIOR TO REMOVING ANY COM.

NOTE: If water tank is full of water, turn control thermostat knob clockwise to desired setting. Refer to

PONENTS.

Access to electrical components is gained by removing front access panel.

CONTROL THERMOSTAT

1. To gain access, remove top lid via 4 screws and remove front panel.

2. Remove mounting screws and disconnect wires, remove old thermostat bulb

by pulling firmly upward on the capillary.

TANK 3. On the new thermostat, slide the red capillary grommet to the red mark on the

LID capillary.

4. Insert the bulb through the hole in the tank lid and press the grommet firmly

and evenly so that the groove in the grommet fits into the tank lid.

"Initial Operation Instructions" steps 6, 7 and 8. If water tank is not full of water, turn control

thermostat knob fully counterclockwise until tank is filled.

NOTE:

TANK HEATER

1. To gain acicess, remove top lid via 4 screws.

2. Remove sprayhead and sprayhead nut from water tube below the

hood.

3. Loosen compression fitting on air vent tube in hood.

4. Disconnect leads to tank heater terminals and limit thermostat

terminal.

5. Remove thermostat bulb from tank lid assembly. Refer to "Control

Thermostat Replacement" step 2 above. Take care not to damage

thermostat capillary or bulb.

6. Remove 8 nuts holding tank lid to tank and lift out tank lid.

7. Remove 2 nuts holding tank heater to tank lid and remove tank

heater.

8. When replacing tank heater, be sure to use new copper washers.

Nuts should be securely tightened to assure water proof seal.

When replacing thermostat bulb in tank lid assembly, refer to "Control Thermostat Replacement"

steps 3 and 4 above.

TIMER

1. To gain access, remove front panel.

2. Disconnect plug and socket connector and disconnect the 2 leads on the solenoid terminals.

3. Disconnect timer from bracket via 2 screws and remove.

RELAY

1. To gain access, remove front panel.

2. Disconnect plug and socket connector from harness plug and socket connector from timer.

3. Disconnect relay from bracket via 2 screws and remove.

8

Page 9

•

solenoidter-

Disconnect f Iare

from

tochassis

Remove 2 screws (D)

Shut off water supply

Disconnect leads (A)

(B&C)

To gain access

I

~

from

to brewer.

II

~,

which hold solenoid

l ,--.\\ II It' "-I I

SOLENOID VALVE

solenoid valve.

2.

.

P~3~~\

valve

SOLENOID

bracket.

1.

remove front panel.

3.

FLOW VALVE

1. To gain access remove top cover via

screw(s) on top.

2. Loosen flare nuts (B and C)and free short

piece of water line from flow valve (D).

3. Remove flow valve (D).

NOTE: When installing new flow valve into solenoid, be sure direction of arrow is away from solenoid.

REPLACING ON-OFF SURFACE HEATER ELEMENTS

1. Remove lower warmer cover plate and heat spreader by

unscrewing center sheet metal screw. DO NOT REMOVE

SMALL SCREWS HOLDING EDGE OF SAUCER.

2. To remove the lower warmer, lift element, bringing down-

curved ends out through curved slot in saucer assembly.

3. Disconnect blue and white spade-clipped wires from element

terminals. These are interchangeable when replacing element.

4. To install new element, bring spade-clipped wires up through

curved slot, reconnect them, and place element in original

position. Be sure heat spreader is replaced between element

and cover plate.

LOWER WARMER ASSEMBLY

5. Warmer elements on the top of the brewer are not as shown at

left. Remove 3 screws holding saucer and remove element.

FACTORY AUTHORIZED SERVICE

9

Page 10

SCHEMATIC WIRING DIAGRAM F15 & 20

L1

LIMIT THERMOSTAT

BLK

TH~~::;.: ...:~ BLK

WHI

BLK r....~···~

120 VOLTS A C

2 WIRE

SINGLE PHASE

60 HZ

SW.

50W

~

'KEEP WARM' HEATER

BAN P3

BLU P1

BLU

1..L1 BLU

lit .u-

· ·..P3

--«

P1, P2, & P3 ARE PINS OF

A POLARIZED THREE·PIN

.. CONNECTOR.

&

F151320W

F20 1800W

f--'VVV' .

TANK HEATER

100W

--{}-'VV'.

TOP REAR WARMER

100W WHI

-u-~

TOP FRONT WARMER

130W

~

LOWER WARMER

P1

GREEN

=!-

P2

N

<, BLU

BLK

WHI ~~ WHI

SCHEMATIC WIRING DIAGRAM F35

L1

LIMIT THERMOSTAT

BLK

T~£~:.;:::.:.~4 BLK

WHI

BLK

120/240 VOLTS A C

3 WIRE

SINGLE PHASE

60HZ

SW. &

50W

~

'KEEP WARM' HEATER

BRN P3

BLU P1

---lliJ!.

BLK 1..L 1 BLU

~~

BLK · ·..P3 BLK

P1, P2, & P3 ARE PINS OF

A POLARIZED THREE·PIN

«

CONNECTOR.

GREEN

~

3500W

f-J'A/'V

TANK HEATER

100W

--{}-'VV'.

TOP REAR WARMER

WOW WHI

----.r- ~

TOP FRONT WARMER

130W

~

LOWER WARMER

P1

<, BLU

P2

WHI ~~ WHI

WH

WH

WH

WH

L2

N

RED

RED

10

Page 11

REPLACEMENt PARTS

01637.0000 Cordset, 5',16/3, HSJO, NEMA 5-15P (model 15)

00658.0000 Decal, Decanter & Funnel Safety

00831.0000 Decal, Electrical

01188.0000 Deliming Spring

20528.1175 Flow Regulator (.175)

00445.0000 Flow Regulator Adapter

20526.0175 Flow Regulator Diaphragm (.175)

01155.0000 Flow Regulator Gasket

04002.0000 Foot

02028.0000 Funnel Assy, Complete W/Black Handle

02028.0002 Funnel Assy, Complete W/Orange Handle

20247.0000 Funnel Basket

20244.0000 Funnel Handle, Black

20244.0001 Funnel Handle, Orange

01031.0000 Funnel Tip Kit

20245.0000 Funnel, Stainless

02074.0000 Funnel, Wide Pouchpack

00460.0000 Tank Lid Inlet Fitting Assy

01201.0000 Tank Lid IInlet Fitting Gasket

01540.0000 Tank Lid IInlet Fitting Washer

04635.0000 Leg, Chrome (3" Set of 2)

04680.0002 Limit Thermostat

04646.0000 Momentary Switch

04645.0000 On/Off Switch, Lighted

10940.1000 Shipping Carton, Complete

01085.0000 Solenoid Valve

01079.0000 Solenoid Valve Base

01066.0000 Solenoid Valve Bonnet Wrench

01101.0000 Solenoid Valve Coil

01111.0000 Solenoid Valve Repair Kit

01075.0000 Sprayhead Fitting Nut

05515.0000 Sprayhead Tube Gasket

05551.0000 Sprayhead Tube Kit

01082.0000 Sprayhead, 6-Hole

02795.0000 Sprayhead, Plastic

00736.0000 Sprayhead, Pouch pack

05518.0000 Syphon Hub

04236.0000 Tank Heater (1320W) (model 15)

04636.0000 Tank Heater (1800W) (model 20)

04637.0000 Tank Heater (3500W) (model 35)

04626.0000 Tank Keep Warm Heater (50W)

05541.0000 Tank Lid

04221.0000 Tank Lid Gasket

04131.0000 Tank W/Keep Warm Heater Assy

01106.0000 Terminal Block (model 15&20)

07038.0000 Terminal Block (model 35)

07073.0000 Thermostat Grommet

04314.0001 Thermostat

02235.0000 Timer

03695.0000 Warmer Assy 130W (Lower)

03625.0000 Warmer Assy WOW (Upper)

03655.0000 Warmer Dish, Porcelain

01227.0000 Warmer Element (1 OOW)

01142.0000 Warmer Element (130W)

05212.0000 Warmer Retainer Plate

01183.0000 Water Strainer

01839.0000 Wiring Harness (model 15&20)

01841.0000 Wiring Harness (model 35)

FACTORY AUTHORIZED SERVICE

I~

I

i

Page 12

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY _

Bunn-O-Matic Corp. (UBunn") warrants the equipment manufactured by it to be commercially free from defects in material ""-

and workmanship existing atthe time of manufacture and appearing within one year from the date of installation. This warranty

does not apply to any equipment, component or part that was not manufactured by Bunn or that, in Bunn's judgement, has

been affected by misuse, neglect, alteration, improper installation or operation, improper maintenance or repair, damage or

casualty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUOING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Bunn are not authorized to make modifications

to this warranty or to make additional warranties that are binding on Bunn. Accordingly, statements by such individuals,

whether oral or written, do not constitute warranties and should not be relied upon.

The Buyer shall give Bunn prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601

or by writing to Post Office Box 3227, Springfield, Illinois, 62708-3227. If requested by Bunn, the Buyer shall ship the defective

equipment prepaid to an authorize,.d Bunn service location. If Bunn determines, in its sole discretion, that the equipment does

not conform to the warranty, Bunn- shall repair the equipment with no charge for parts during the one year warranty period

and no charge for labor by a Bunn Authorized Service Representative during the one year warranty period. If Bunn determines

that repair is not feasible, Buim shall, at its sole option, replace the equipment or refund the purchase price for the equipment.

THE BUYER'S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF THIS

EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AS SPECIFIED HEREIN, TO

REPAIR OR, AT BUNN'S SOLE OPTION, REPLACEMENT OR REFUND. Bunn shall not be liable for any other damage or loss,

including, but not limited to, lost profits, lost sales, loss of use of equipment, claims of Buyer's customers, cost of capital, cost

of down time, cost of substitute equipment, facilities or services, or any other special, incidental or consequential damages.

www.pamasco.com

r~~~--c

fPAMASCC4D

Seudu&tta

*Printed on recycled paper. Consider the environment. Please recycle.

Loading...

Loading...