Page 1

DUAL® SH

CAUTION

DISCARD DE

CANTER

IF:

. CRACKED

. SCRATCHED

. BOILED DRY

. HEATED WH

EN EMPTY

. USED ON HI

GH FLAME

. OR EXPOSED

ELECTRIC

ELEMENTS

FAILURE TO

COMPLY RIS

KS INJURY

PN: 658

1985 BUNN-O-MATIC

CORPORATION

FUNNEL CON

TENTS

ARE HOT

WITH SMART FUNNEL

®

E

C

R

G

R

!

O

U

T

L

O

IN

N

E

S

E

N

N

N

R

A

O

E

R

P

P

W

Y

A

M

O

N

O

P

A

W

C

F

M

Y

!

O

O

N

L

R

A

A

F

F

V

T

O

O

C

T

M

E

N

E

N

E

R

N

M

O

E

E

C

R

C

S

O

I

A

F

D

L

E

P

B

E

R

R

E

T

N

A

C

E

D

D

R

A

C

S

CAUTION

I

D

:

!

D

IF

E

D

Y

K

E

T

C

P

H

A

C

M

R

Y

E

T

E

C

R

A

M

.

N

D

R

A

C

E

I

L

C

D

H

R

F

S

E

T

.

W

L

H

I

C

D

G

O

E

I

E

L

B

H

T

.

E

A

N

D

E

O

E

H

S

D

.

E

O

S

P

U

X

S

Y

.

E

T

R

N

R

U

E

O

N

J

M

.

O

I

N

E

T

I

S

L

A

T

R

E

S

O

N

P

K

R

E

S

O

I

T

C

R

N

C

I

T

O

Y

A

L

C

M

T

-

P

O

L

-

O

N

M

E

N

H

O

U

N

E

B

C

N

5

R

8

U

9

O

1

F

A

T

E

R

U

IL

A

F

8

5

6

:

N

P

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

29877.0000 12/03 ©2001 Bunn-O-Matic Corporation

www.bunnomatic.com

Page 2

BUNN-O-MATIC COMMERCIAL PRODUCT WARRANTY

Bunn-O-Matic Corp. (“BUNN”) warrants equipment manufactured by it as follows:

1) All equipment other than as specified below: 2 years parts and 1 year labor.

2) Electronic circuit and/or control boards: parts and labor for 3 years.

3) Compressors on refrigeration equipment: 5 years parts and 1 year labor.

4) Grinding burrs on coffee grinding equipment to grind coffee to meet original factory screen sieve analysis: parts

and labor for 3 years or 30,000 pounds of coffee, whichever comes first.

These warranty periods run from the date of installation BUNN warrants that the equipment manufactured by it will

be commercially free of defects in material and workmanship existing at the time of manufacture and appearing

within the applicable warranty period. This warranty does not apply to any equipment, component or part that was

not manufactured by BUNN or that, in BUNN’s judgment, has been affected by misuse, neglect, alteration, improper

installation or operation, improper maintenance or repair, damage or casualty. This warranty is conditioned on the

Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601

or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the

defective equipment prepaid to an authorized BUNN service location; and 3) receiving prior authorization from

BUNN that the defective equipment is under warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRITTEN OR ORAL,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF EITHER

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of BUNN are

not authorized to make modifications to this warranty or to make additional warranties that are binding on BUNN.

Accordingly, statements by such individuals, whether oral or written, do not constitute warranties and should not

be relied upon.

If BUNN determines in its sole discretion that the equipment does not conform to the warranty, BUNN, at its

exclusive option while the equipment is under warranty, shall either 1) provide at no charge replacement parts and/

or labor (during the applicable parts and labor warranty periods specified above) to repair the defective

components, provided that this repair is done by a BUNN Authorized Service Representative; or 2) shall replace

the equipment or refund the purchase price for the equipment.

THE BUYER’S REMEDY AGAINST BUNN FOR THE BREACH OF ANY OBLIGATION ARISING OUT OF THE SALE OF

THIS EQUIPMENT, WHETHER DERIVED FROM WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT BUNN’S

SOLE OPTION AS SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall BUNN be liable for any other damage or loss, including, but not limited to, lost profits, lost sales,

loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of down time, cost of substitute

equipment, facilities or services, or any other special, incidental or consequential damages.

INTRODUCTION

The brewer incorporates a wireless interface system that allows the DBC Grinder to load certain information

into the "programming tag" located inside the handle of the funnel. This information includes what flavor of coffee

is being ground and what batch size will be brewed (small, medium, or large). Once the correct flavor name and

amount of coffee is ground, the funnel is loaded into the brewer. The information from the funnel handle is then

transferred into the brewer. The brewer then takes this information and dispenses the amount of water preset in

the brewer for that particular flavor of coffee and batch size. The brewer can also be programmed to adjust different

functions of the brewing process, such as brew temperature, brew volumes, bypass percentages, pulse brew, etc.

This allows the operator to program a certain "recipe" for each coffee flavor to be brewed.

Page 2

29877 040802

Page 3

TABLE OF CONTENTS

User Notices .............................................................................................................................. 4

Electrical and Plumbing Requirements ...................................................................................... 5

Operating Controls..................................................................................................................... 6

Initial Setup ............................................................................................................................... 7

Coffee Brewing .......................................................................................................................... 7

Cleaning..................................................................................................................................... 7

Glossary .................................................................................................................................... 8

PROGRAMMING .......................................................................................... 9

Programming Switches ............................................................................................................. 9

Programming the Brewer ........................................................................................................ 10

PROGRAM FUNCTIONS (LEVEL 1) Brew Lockout ................................................. 10

PROGRAM FUNCTIONS (LEVEL 2) .......................................................................................... 11

Set New Recipe (using a Smart Funnel® and G9-2T DBC Grinder)........................... 12

Set Brew Volumes .......................................................................................................... 12

Set By-Pass Percentages ................................................................................................ 13

Set Pulse Brew Times ..................................................................................................... 13

Set Preinfusion Times..................................................................................................... 13

Set Drip Times ................................................................................................................ 14

Set New Recipe (using a Recipe Card) ........................................................... 15

Set New Recipe (no Smart Funnel® nor G9-2T DBC Grinder) ................................. 16

Review Recipes/Modify Recipes/Set up No Name Coffee ..................................... 17

Set Brew Volumes .......................................................................................................... 18

Set Bypass Percentages ................................................................................................. 19

Set Pulse Brew Times ..................................................................................................... 20

By Example .............................................................................................................. 22

Enter Times ............................................................................................................. 23

Set Preinfusion Times..................................................................................................... 24

Set Drip Times ................................................................................................................ 25

Copy Settings ......................................................................................... 26

Enable Ads ............................................................................................ 27

Set Temp (Brewing Temperature) ........................................................................................ 27

Set Ready (Ready Temperature) .......................................................................................... 27

Refill (Adjust Sensitivity) ..................................................................................................... 28

Spray Oz/M (Read sprayhead flow rate) ............................................................................... 28

Bypass Oz/M (Read bypass flow rate) .................................................................................. 28

Calibrate Flow ........................................................................................ 29

Calibrate Sprayhead Flow ............................................................................................... 29

Calibrate Bypass Flow ..................................................................................................... 30

Brew Counters (View/Reset) ................................................................................................ 31

Funnel Detect......................................................................................... 31

Server Detect ......................................................................................... 32

Service Tools ......................................................................................... 32

Test Outputs (Components) ........................................................................................... 33

Test Switches ................................................................................................................. 33

Test Servers....................................................................................................................34

Test Frequency ............................................................................................................... 34

Factory Defaults (Reset) ...................................................................................................... 35

Troubleshooting ...................................................................................................................... 36

Schematic (Wiring Diagram) ................................................................................................... 47

Page 3

29877 121302

Page 4

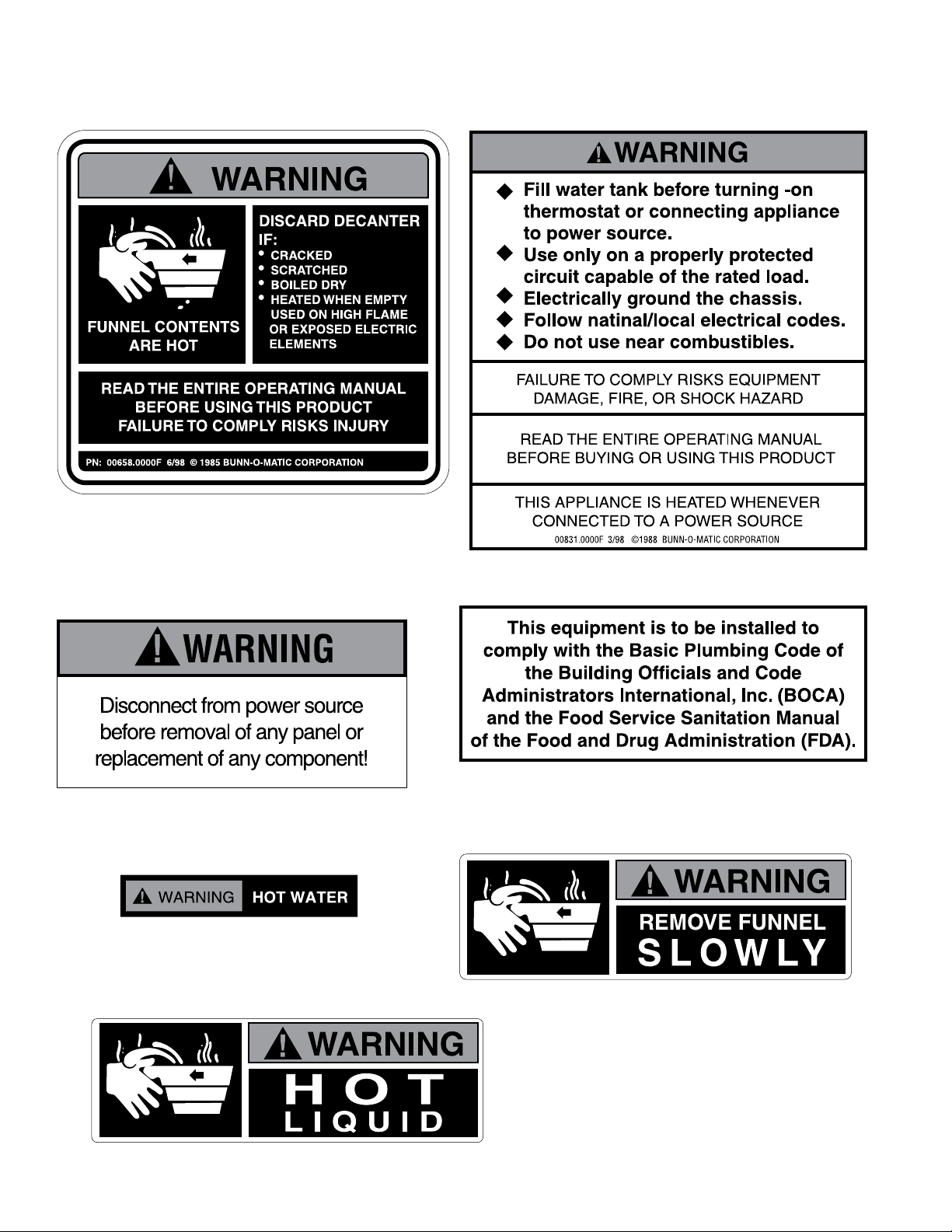

USER NOTICES

The notices on this brewer should be kept in good condition. Replace unreadable or damaged labels.

00658.0000

10044.0000

20201.5600

00831.0000

00656.0000

03409.0000

Page 4

03408.0000

29877 040201

Page 5

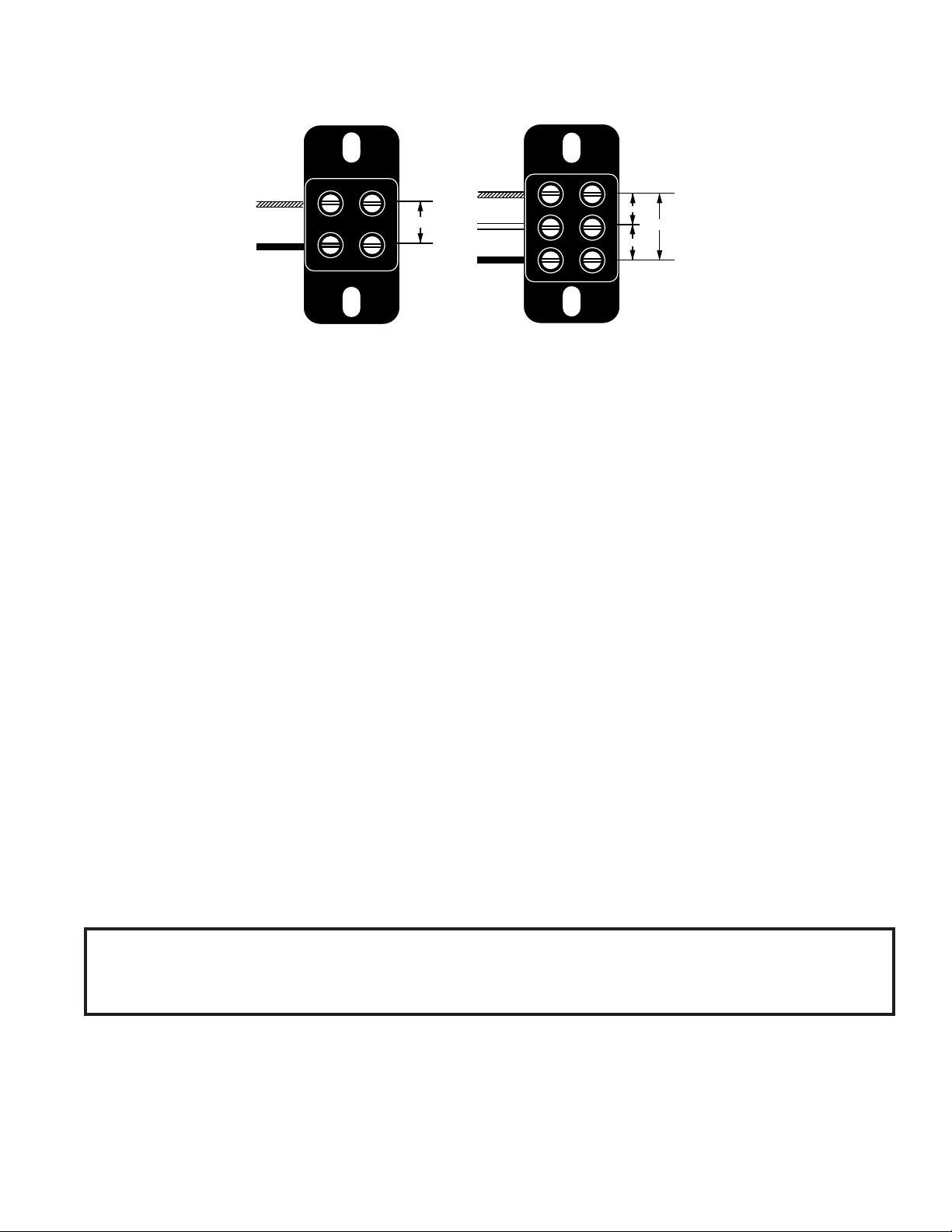

ELECTRICAL REQUIREMENTS

CAUTION - The brewer must be disconnected from the power source until specified in

Initial Set-Up.

L2 RED

200 or 240V A.C.

L1 BLACK

Requires 2-wire, grounded

service rated 200, 230 or 240

volts ac, 30 amp, single phase

50 or 60 Hz.

L2 RED

WHITE

NEUTRAL

L1 BLACK

120V A.C.

208 or 240V A.C.

120V A.C.120V A.C.

Requires 3-wire, grounded service rated 120/208 or 120/240

volts ac, 30 amp, single phase,

60 Hz.

ELECTRICAL HOOK-UP

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service as specified.

2. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3. Remove the front panel beneath the sprayheads.

4. Feed the cord through the strain relief and connect it to the terminal block.

5. Connect the brewer to the power source and verify the voltage at the terminal block before proceeding. Replace

the front panel.

6. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked up, the brewer is ready for

Initial Set-Up

.

PLUMBING REQUIREMENTS

This brewer must be connected to a cold water system with operating pressure between 20 and 90 psi (138

and 620 kPa) from a 1⁄2" or larger supply line. A shut-off valve should be installed in the line before the brewer. Install

a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345 kPa). The water

inlet fitting is 1⁄4" flare or female quick connect.

NOTE – Bunn-O-Matic recommends 1⁄4" copper tubing for installations of less than 25 feet and 3⁄8" for more than

25 feet from the 1⁄2" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer

to clean the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The

size and shape of the hole made in the supply line by this type of device may restrict water flow.

This equipment must be installed to comply with the Basic Plumbing Code of the

Building Officials and Code Administrators International, Inc. (BOCA)

and the Food Service Sanitation Manual of the Food and Drug Administration (FDA).

PLUMBING HOOK-UP

1. Flush the water line and securely attach it to the flare fitting located on bottom of brewer.

2. Turn on the water supply.

Page 5

29877 120203

Page 6

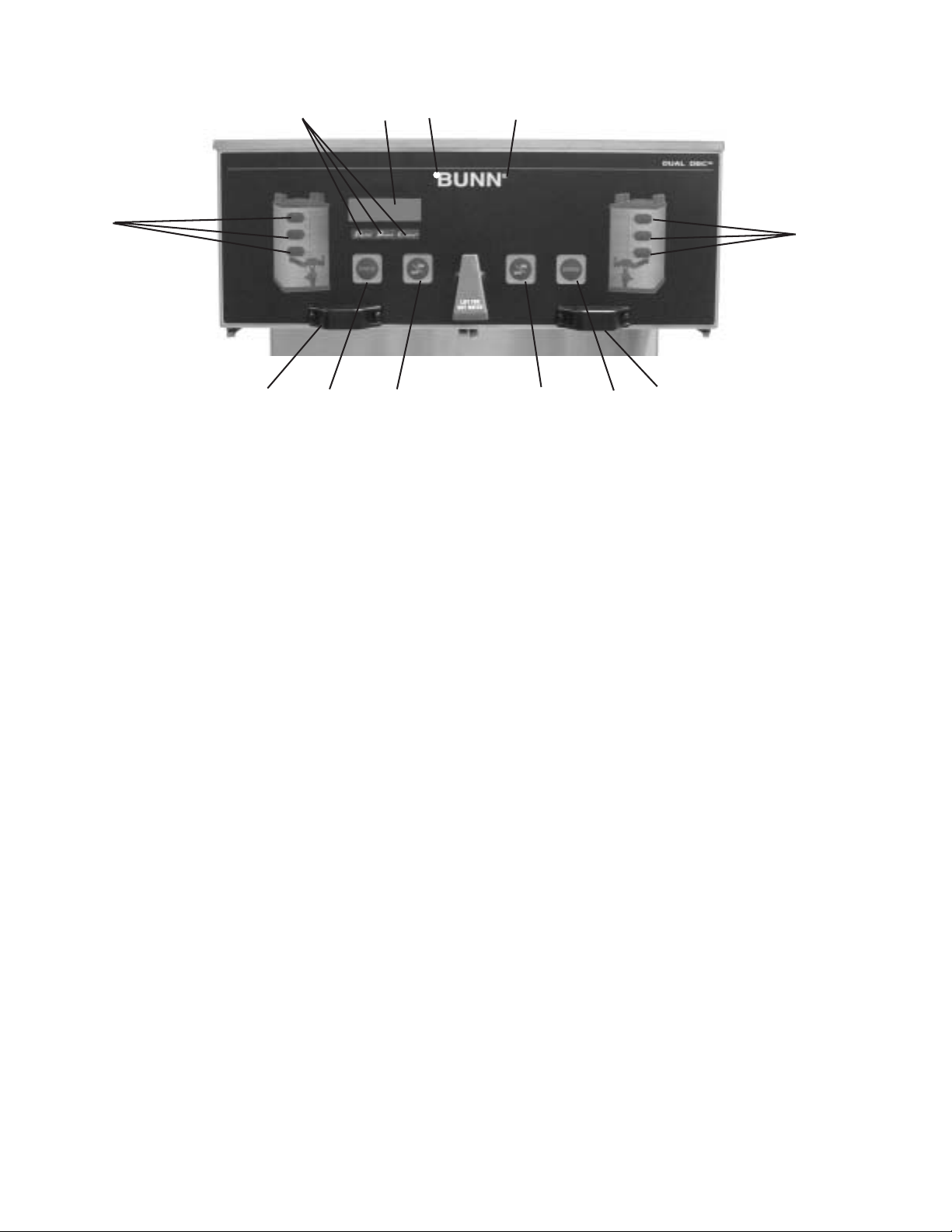

OPERATING CONTROLS

h

f

e

d

a

g

c

b

b

g

c

a

OPERATING CONTROLS

(a) BATCH SELECTOR PADS

Pressing the pad corresponding to the Small, Medium, or Large batch selects the amount of coffee to be

brewed. Pressing a different pad after a brew cycle has been initiated does not change the brew batch in progress.

Light indicates the selected batch to brew.

(b) ON/OFF PAD

Pressing the ON/OFF pad alternately turns the brewing side on and off. Pressing this pad during the brew cycle

will interrupt the brew cycle, stopping the flow of water. Pressing this pad during the programming of the brewer

will exit the setup and return to the main screen.

(c) BREW PAD

Momentarily pressing and releasing this pad begins a brew cycle.

(d) ® PAD

Pressing and holding the ® pad allows entry to the programming menus. Pressing and releasing the pad steps

through each function screen during programming.

(e) FUNCTION SCREEN

This is the display which shows the various functions of the brewer and allows the programming to be

accomplished.

(f) FUNCTION SCREEN PADS

These are the hidden pads which are used to program the brewer.

(g) FUNNEL SENSING COILS

These are used to "receive" information from the Smart Funnel® handle (coffee name and batch size), and also

from RECIPE CARDS.

(h) SCROLL BACKWARDS

The upper left corner of the B in BUNN® can be used to scroll backwards through the function list.

Page 6

29877 040802

Page 7

INITIAL SETUP

CAUTION – The brewer must be disconnected from the power source throughout the initial setup, except when

specified in the instructions.

1. Insert an empty funnel into the funnel rails of one of the brew stations.

2. Place an empty server under the funnel.

3. Connect the brewer to the power source. Water will begin flowing into the tank and stop when the tank is filled

to its capacity. Display will show PLEASE WAIT...TANK FILLING until tank is filled with water.

4. Wait approximately twenty minutes for the water in the tank to heat to the proper temperature. Display will show

READY TO BREW...WATER TEMP: XXX˚ when tank is at operating temperature.

5. Place a small vessel beneath the faucet and open the faucet handle. Release it when you hear the tank refilling.

6. Water volumes have been preset at the factory. Refer to adjustments for the

Set Brew Volumes

section of this

manual should the volume need to be increased or decreased.

7. The brewer is now ready for use in accordance with the coffee brewing instructions.

COFFEE BREWING

1. Select the desired batch size on the grinder. It is not necessary to select a size on the brewer.

2. Insert a BUNN® filter into the funnel.

3. Grind the selected amount of fresh coffee into the Smart Funnel® using the G9-2T DBC with Smart Funnel

operation and level the grounds by gently shaking.

4. Slide the funnel into the funnel rails. The brewer will read the size ground through the chip in the funnel handle

and will automatically select the correct size to brew. If the grounds are not obtained through a grinder

compatible with a Smart Funnel®, a batch size must be chosen on the brewer.

5. Place an empty server under the funnel.

®

6 Momentarily press and release the pad. If the brewer has the funnel lock option and if it is activated, once

a brew cycle has been started the funnel is locked in place. There may be certain situations in which the brew

cycle will not begin when is pressed:

a) BREW TEMPERATURE TOO LOW - wait until heated or cancel BREW LOCKOUT option. (Page 10)

b) FUNNEL NOT IN PLACE (or using a standard brew funnel) - cancel FUNNEL DETECT option. (Page 31)

c) CHECK FUNNEL - remove funnel, empty previously brewed grounds and grind a new batch into the funnel.

d) SERVER NOT IN PLACE - place Soft Heat® Server, or cancel SERVER DETECT option. (Page 32)

7. If none of the above messages are displayed, the display will read NOW BREWING and the time remaining in

the brew cycle. Arrows will point to the side which is brewing. If both sides are brewing simultaneously, the

arrows will alternate from left to right on the display.

8. Following the BREW will be a countdown of drip time DRIPPING which shows the time remaining until the

funnel lock will release. Discard the grounds and filter only after visible dripping stops.

CLEANING

1. The use of a damp cloth rinsed in any mild, nonabrasive, liquid detergent is recommended for cleaning all

surfaces on Bunn-O-Matic equipment.

2. Check and clean the sprayhead. The sprayhead holes must always remain open.

NOTE – In hard water areas, this may need to be done daily. It will help prevent liming problems in the brewer and

takes less than a minute.

Page 7

29877 080301

Page 8

GLOSSARY

AD CARD: An assembly consisting of a computer chip and an instruction label. Used for loading advertising

messages into the brewer.

BREW LOCKOUT: The inability to initiate a brew if the water temperature is less than the ready temperature

programmed into the brewer.

BYPASS: The process of diverting a portion of the brew water to the outside of the paper filter so that it does not

pass through the coffee grounds. This process is sometimes used to optimize the flavor of the finished

brew.

CHIP: A computer chip containing either recipes for specific coffee flavors or advertising messages which are

read by the sensing coils on the brewer. One chip is embedded in each Smart Funnel® handle to carry the

coffee flavor name and batch size ground from the grinder to the brewer.

DRIP TIME: The length of time from when the water spray over the grounds ends, to the time that no water drips

from the funnel tip.

FACTORY DEFAULTS: The factory preset brew settings that were installed into the brewer's memory.

FIRST ON-TIME: During a pulse brew or preinfusion, this is the time set for the initial flow of water over the

grounds.

FUNNEL DETECT: Sets the inability to initiate a brew cycle if the funnel is not properly inserted into the funnel

rails.

FUNNEL SENSING COIL: A sensor on the front hood of the brewer, which reads what name and batch size of

coffee was ground into the funnel and allows for the brewer to automatically set itself to what is read from

the funnel handle.

LAST ON-TIME: During a pulse brew, this is the time set for the second on-time, and each alternating on-time for

the remainder of the brew cycle.

MAIN SCREEN: The term used to describe the screen that is displayed when the brewer is not in use. This screen

is also displayed after exiting the programming mode.

NO-NAME COFFEE: The term for the recipe used by the brewer when there is no coffee name stored in the funnel.

The brewer can contain separate No-Name recipes for the left and right brewing positions.

OFF-TIME: During a pulse brew or preinfusion, this is the time set for the length of time that the water is not

spraying over the grounds.

PREINFUSION: The process of beginning a brewing cycle with an initial spray of water onto the grounds followed

by a pause in the spray. After the programmed pause, the spray continues without interruption until the end

of the brewing cycle.

PULSE BREW: The process which allows the brew water to start, then stop, repeatedly, over the grounds in order

to derive the best flavor from the coffee. Pulse brew is also used in some instances to prevent a funnel

overflow.

RECIPE: Set of brewing parameters stored in the brewer. The parameters are unique for each coffee name and

include brew ounces, pulse brew, percent bypass, preinfusion and drip time.

RECIPE CARD: An assembly consisting of a computer chip and an instruction label. Used for loading a recipe into

the brewer and the companion BrewWISE Grinder.

SERVER DETECT: Sets the inability to initiate a brew cycle if the server is not properly placed on the stand below

the brew funnel.

SOFT HEAT®: The type of server and brewer which are used as part of the Smart Funnel® system. The server is

placed on the brewer, and is connected through the receptacles on the brewer. The server contains a

temperature-controlled heater which maintains the coffee at a constant temperature.

Page 8

29877 120203

Page 9

PROGRAMMING

Using the menu-driven display on the front of the brewer, the operator has the ability to alter or modify

various brewing parameters such as brew temperatures, brew volumes, bypass percentages, etc. This allows for

the precise brewing of various flavors of coffee.

Programming of the brewer is achieved by entering a certain function. Then, by the use of hidden programming

switches, the operator can customize the brewing process to their specifications.

PROGRAMMING SWITCHES

To access the programming mode, and to scroll through the different function screens, hidden programming

switches are used. There are five of these switches that will be used for the setup of the brewer.

2

P2289

3 4 5

1. ® symbol (upper right of the BUNN logo)

This is used to access the programming mode and is also used to scroll forward through the function list.

1

2. Upper left corner of the "B" in the BUNN logo

This is used to scroll backwards through the function list.

3. "Digital" (lower left under the display)

This is used to select options that appear on the display during programming.

4. "Brewer" (center under the display)

This is used to select options that appear on the display during programming.

5. "Control" (lower right under the display)

This is used to select options that appear on the display during programming.

Page 9

29877 080301

Page 10

PROGRAMMING THE BREWER

The programming of the brewer is divided into two levels. There is one function in Level 1. All other functions

are accessed in Level 2.

The following function screens are in order of appearance. Each screen will have instructions on how to access,

and the procedures to program the various functions of the brewer.

IMPORTANT PROGRAMMING NOTES

- READ CAREFULLY -

To exit the programming mode at any time, press and release either of the pads located on the front switch

panel. The display will return to the MAIN SCREEN.

If none of the five programming switches are pressed within one minute during the setup of the brewer, the

programming of the function screen that is being set will be exited and the display will return to the MAIN SCREEN.

Always remember to place a container and funnel under the sprayhead when operating the brewer during the

set-up of PULSE BREW - SET BY EXAMPLE, CALIBRATE FLOW and testing the brew and bypass valves in SERVICE

TOOLS/TEST OUTPUTS.

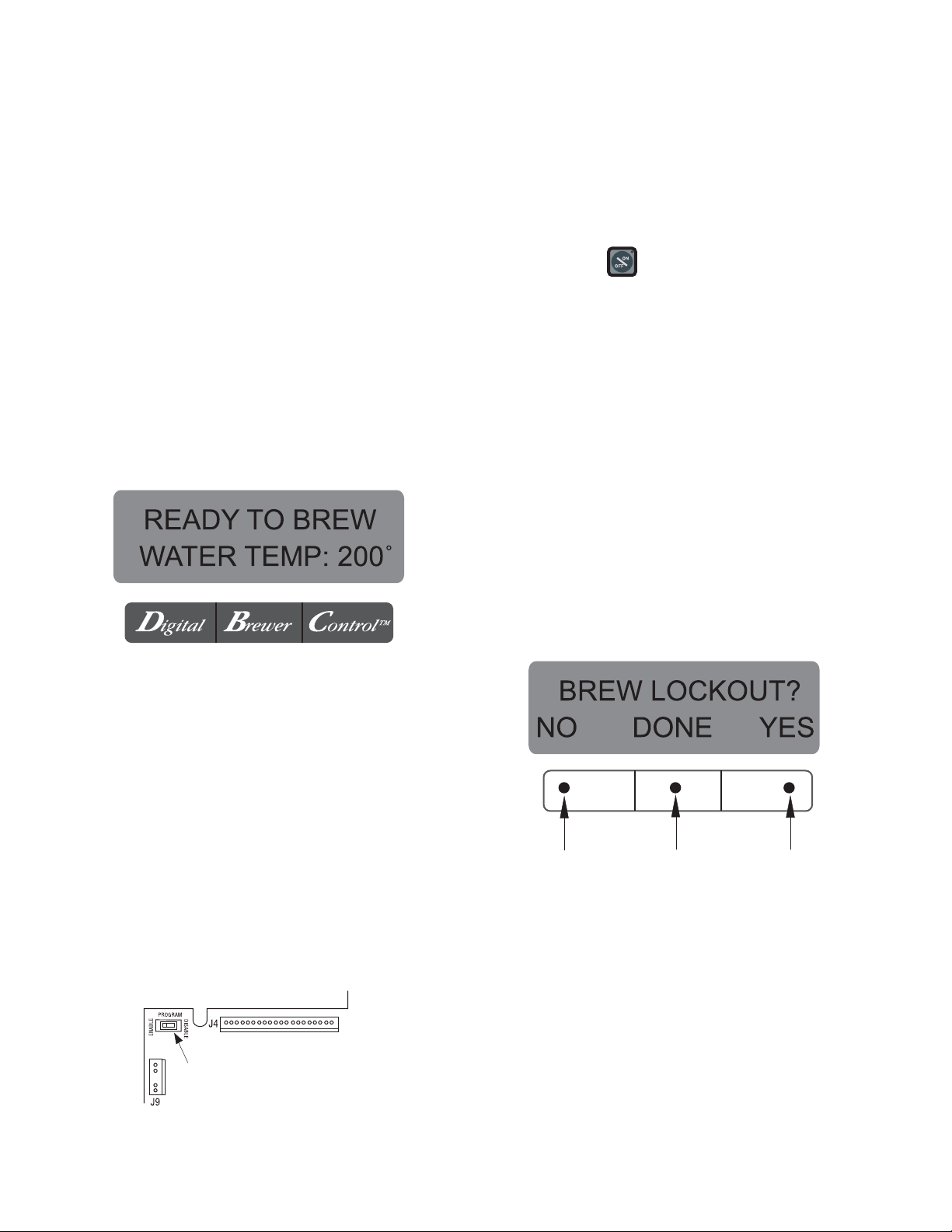

MAIN SCREEN

This screen will be shown when the brewer is

ready for use. The screen displays the water temperature in the tank. When the water in the tank reaches the

correct set temperature, the display will change from

HEATING to READY TO BREW.

PROGRAMMING LOCKOUT SWITCH (mounted on

main control board)

This switch can be set to prevent access to the

programming levels of the brewer. Once all the correct

brew settings are programmed, the operator can set

the switch to the "DISABLE" position to prohibit anyone from changing the settings.

PROGRAMMING

SWITCH

P2424

PROGRAM FUNCTIONS - LEVEL 1

BREW LOCKOUT

This function allows the operator to prevent or

allow brewing if the water temperature is less than the

set READY temperature.

To access this function screen press and hold the

® symbol. Release the ® when the display reads:

Press here

for NO

The YES or NO should be flashing. Select YES to

prevent brewing if the water temperature is below the

set READY temperature. Select NO to permit brewing

at any water temperature.

When finished, press and release DONE. This will

exit this function screen and return to the MAIN

SCREEN on the display.

Press here

for DONE

Press here

for YES

Page 10

29877 080301

Page 11

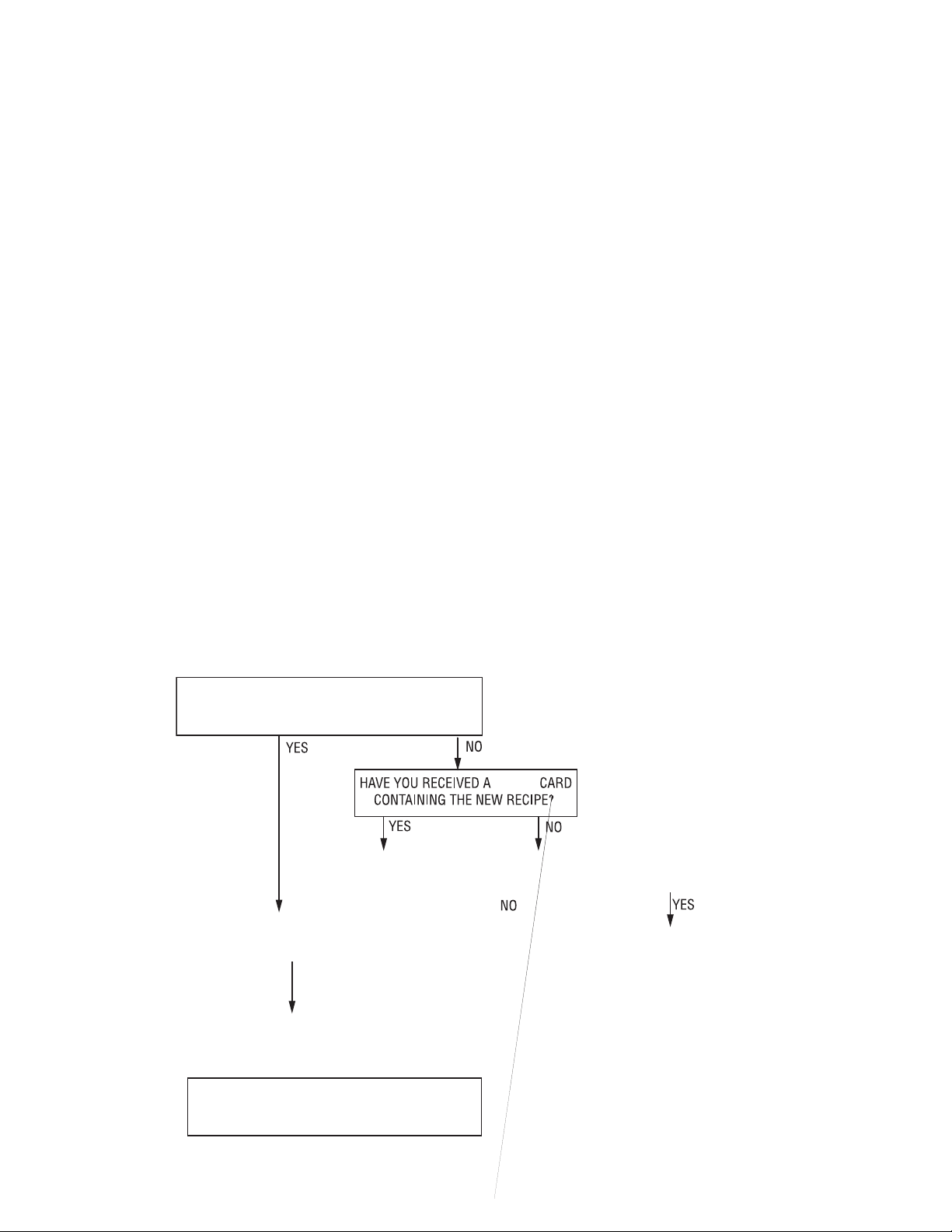

PROGRAMMING THE BREWER (cont.)

PROGRAM FUNCTIONS - LEVEL 2

There are three methods of programming the

various brewing parameters of the Dual

®

Smart Funnel

Brewer.

®

SH with

METHOD 1:

Using a Smart Funnel

®

and a G9-2T DBC Grinder:

Certain coffee NAMES are stored in the G9-2T

DBC's memory. When a particular name of coffee is

ground into the Smart Funnel®, that name and the

batch size selected are transferred from the grinder to

the programming chip located in the funnel's handle.

The funnel is then inserted into the brewer's left side

funnel rails. The sensor coil on the brewer reads the

information contained in the handle. This then allows

the operator to set the BREW VOLUMES, BYPASS

PERCENTAGES, PULSE BREW TIMES, PREINFUSION

TIMES and DRIP-OUT TIMES for that particular coffee

NAME. Each coffee NAME can be set individually to

provide optimum brewing quality.

METHOD 2:

Using a RECIPE CARD to enter all of the brew

settings at one time:

If using a coffee name not in the G9-2T DBC's

memory, the customer can obtain a RECIPE CARD

from the factory with all the information needed to set

up that particular coffee flavor. This includes the

COFFEE NAME, BREW VOLUMES, BYPASS PER-

CENTAGES, PULSE BREW TIMES, PREINFUSION

TIMES, and DRIP-OUT TIMES.

METHOD 3:

Not using a Smart Funnel® and/or a G9-2T DBC

Grinder:

This allows the operator to enter ONE set of

brewing parameters for each side, in the event a Smart

Funnel® and/or a G9-2T DBC is not used with the Dual

SH Brewer. This is referred to as a NO NAME coffee

flavor. If the brewer does not read the information in

the funnel's handle, it automatically selects the NO

NAME brewing parameters set up prior to brewing.

This includes the BREW VOLUMES, BYPASS PER-

CENTAGES, PULSE BREW TIMES, PREINFUSION

TIMES and DRIP-OUT TIMES for the three batch sizes.

®

Page 11

29877 121302

Page 12

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

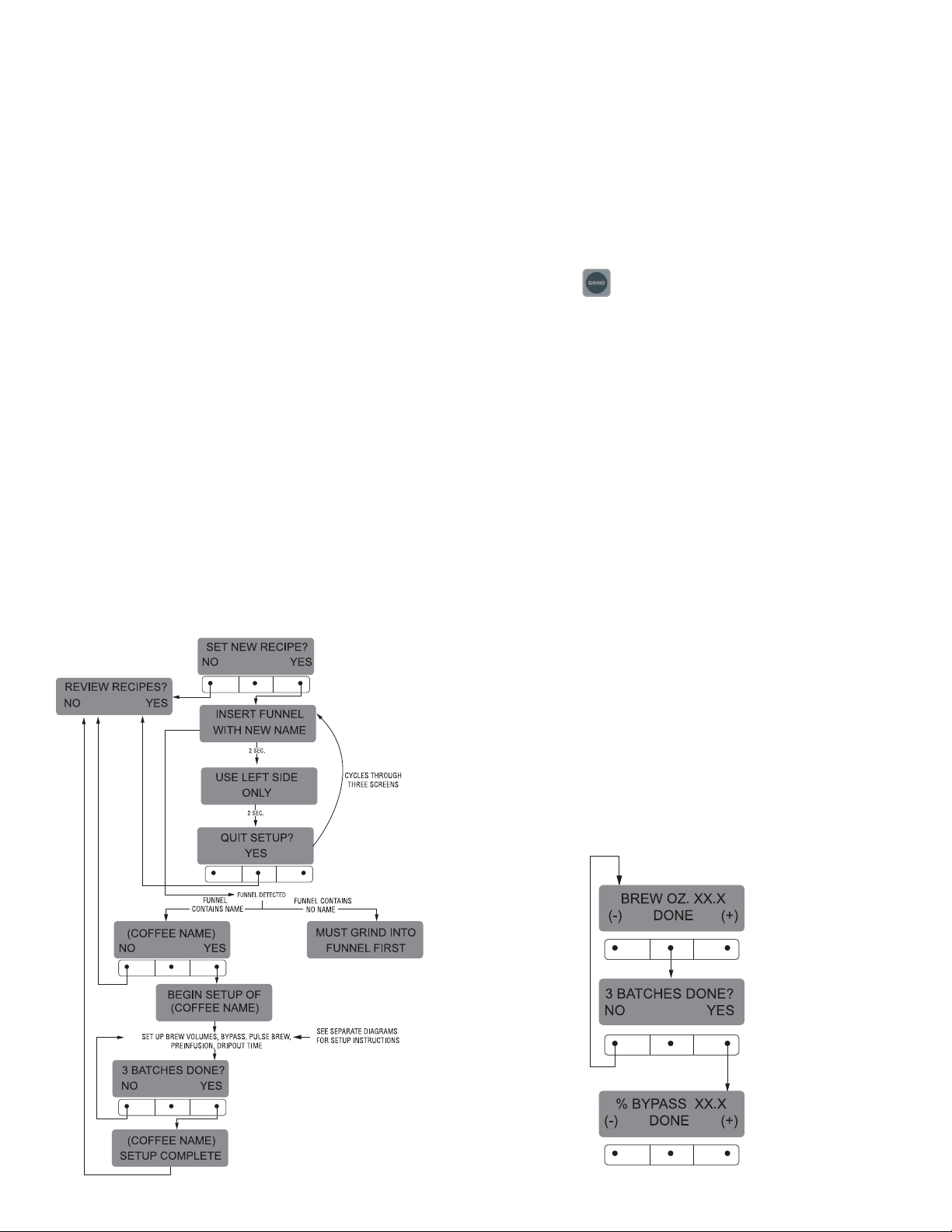

SET NEW RECIPE

Using a Smart Funnel® and a G9-2T DBC Grinder:

This function allows the operator to set BREW

VOLUMES, BYPASS PERCENTAGES, PULSE BREW

TIMES, PREINFUSION TIMES and DRIP-OUT TIMES

for each coffee name preset in the grinder's memory.

Certain coffee NAMES are stored in the G9-2T

DBC's memory. When a particular name of coffee is

®

ground into the Smart Funnel

, that name and the

batch size selected are transferred from the grinder to

the programming chip located in the funnel handle.

The funnel is then inserted into the brewer's left side

funnel rails. The sensor coil on the brewer reads the

information contained in the handle. The name of the

coffee flavor will then appear on the display. This then

allows the operator to set the BREW VOLUMES,

BYPASS PERCENTAGES, PULSE BREW TIMES, PREINFUSION TIMES and DRIP-OUT TIMES for that

particular coffee NAME. It also allows the operator to

set other brewing parameters, such as BREW TEM-

PERATURE, READY TEMPERATURE, BREW LOCKOUTS, etc. Each coffee NAME can be set individually

to provide optimum brewing quality.

Procedure for Setting the Recipe:

NOTE: Before beginning setup, place a server beneath

the left brew funnel.

1. Insert the funnel into the grinder and select a batch

size to grind. It is not necessary to have coffee

beans in the hopper(s) in order to program the

brewer. The coffee name is pre-selected and stored

in the grinder's memory for the side being ground.

2. Press the

pad. When the grinder stops grind-

ing, remove the funnel.

3. On the brewer, press and hold the ® pad until the

display reads SET NEW RECIPE. Release the ®

pad.

4. Press and release YES. The display should read

INSERT FUNNEL WITH NEW NAME, then USE

LEFT SIDE ONLY, and finally, QUIT SETUP? These

three displays will repeatedly cycle.

5. Insert the funnel into the rails on the left side of

the brewer. The display should read the NAME of

the coffee that was ground into the funnel, along

with a NO and YES. If the NAME on the display is

correct, press YES.

6. If, for some reason, the name of the coffee from

the grinder did not load properly into the funnel, or

if a grind has not yet been done, the display will

read MUST GRIND INTO FUNNEL FIRST. It will be

necessary to grind another batch following steps

1 and 2.

7. If the grind is acknowledged by the brewer, the

display will read BEGIN SETUP OF (COFFEE NAME).

Then the screen will display BREW OZ. and a batch

light will be blinking. (Refer to page 18 for description of BREW OZ. function).

P2299

Page 12

P2415

29877 121302

Page 13

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET NEW RECIPES (cont.)

8. Using (-) and (+), set the amount of brew water, in

ounces, to be dispensed for that particular batch

size.

9. When finished, press another batch size and repeat step #8 for that size. Continue setting all batch

sizes.

10. When finished setting all batch sizes, press and

release DONE. The display should read 3 BATCH

SIZES DONE?

11. If the three batch sizes are not correct, press and

release NO to return to the BREW OUNCES setup

screen and repeat steps 8 through 10. If the three

batch sizes are correct, press YES. This will advance to the % BYPASS function. (Refer to page

19 for description of % BYPASS function.)

17. If setting pulse brew by ENTER TIMES (entering

known times) press NO. The display should read

ENTER TIMES. Press and release YES and proceed with the setup instructions for

PULSE BREW - ENTER TIMES,

page 23. After SET

SETTING

PULSE BREW has been accomplished, the next

function will be SET PREINFUSION. (Refer to page

24 for description of SET PREINFUSION function.

P2416

12. Using (-) and (+) set the amount of bypass water

(percentage) to be dispensed around the grounds

for that particular batch size.

13. When finished, press another batch size and repeat step #12 for each batch to be set.

14. When finished setting each batch size, press DONE.

The display should read 3 BATCHES DONE?

15. If the three batch sizes are not correct, press and

release NO to return to the % BYPASS setup

screen and repeat steps 12 through 15. If they are

correct, press YES. This will advance to SET PULSE

BREW. (Refer to page 20 for description of SET

PULSE BREW function.

16. To SET PULSE BREW, if setting pulse brew BY

EXAMPLE (brewing into a funnel) press YES and

proceed with the setup instructions for

PULSE BREW - BY EXAMPLE,

on page 22.

SETTING

P2417

18. To SET PREINFUSION press YES in the SET PRE-

INFUSION screen to proceed. The display should

now read ON TIME and a batch light will be

blinking.

19. Using (-) and (+), set the amount of time the brew

water will initially presoak the grounds for that

particular batch size.

20. When finished, press another batch size and repeat until all three batch sizes are set.

21. When finished, press DONE. The display should

now read OFF TIME and a batch light will be

blinking.

Page 13

29877 090401

Page 14

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET NEW RECIPES (cont.)

22. Using (-) and (+), set the amount of time the brew

cycle will delay (after the presoak cycle shuts off)

before resuming brewing.

23. When finished, press another batch size and repeat until all three batch sizes are set.

24. When finished setting all batch sizes, press DONE.

The display will show the ON and OFF TIMES that

were entered for a particular batch size. After a 5

second delay, the display should read 3 BATCHES

DONE.

25. If the three batches are not complete, press NO in

order to return to SET PREINFUSION, and repeat

steps 19 through 24.

26. If the three batches are correct, press YES. This will

advance to the next function, SET DRIP TIME.

(Refer to page 25 for description of SET DRIP

TIME function.)

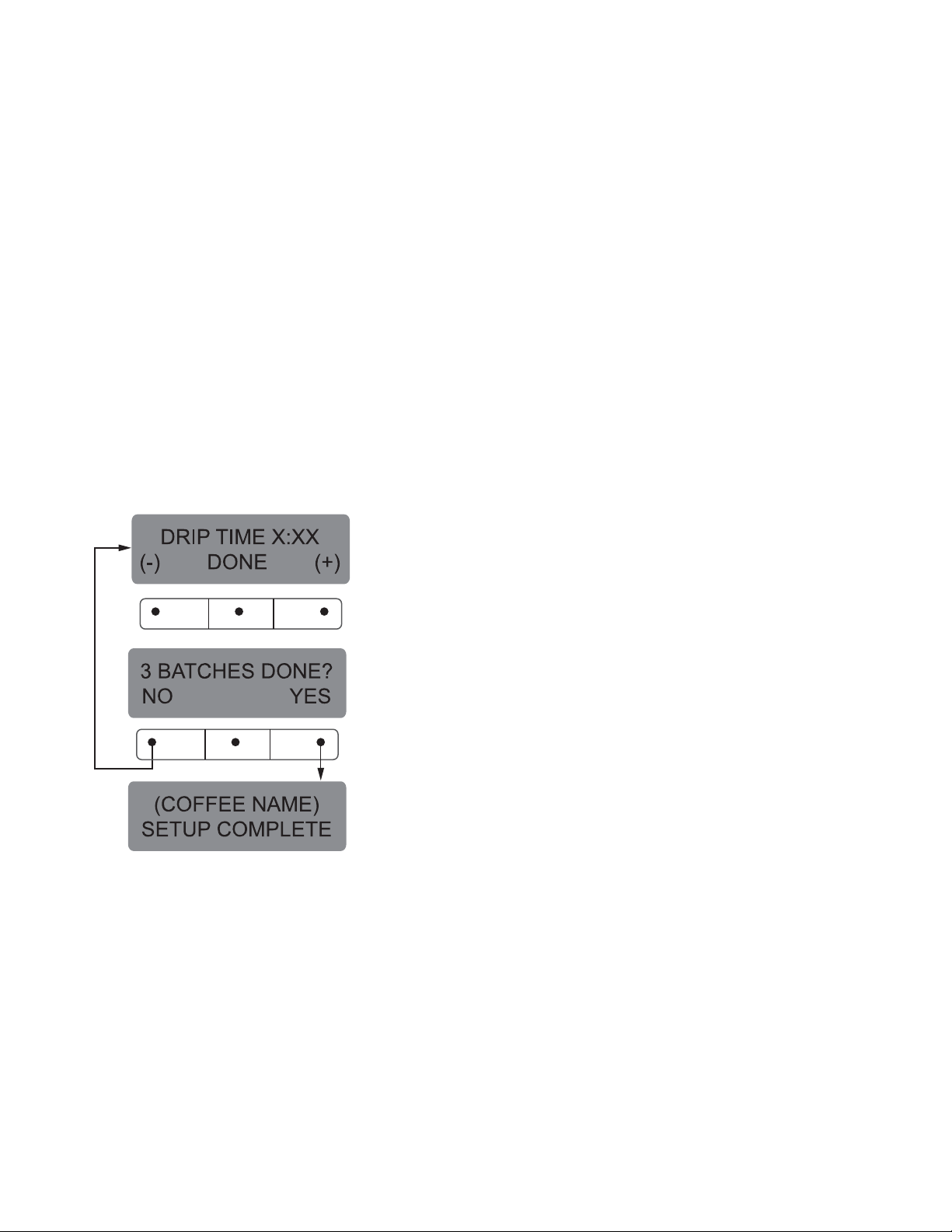

27. The display should now read DRIP TIME, along

with either the word OFF, or a time will be showing.

A batch light should also be blinking.

28. Using (-) and (+), set the amount of time from

when the brew spray ends to when the funnel is

emptied of hot liquid for that batch size.

NOTE: Set to OFF to prevent funnel locks from engag-

ing (to disable this function), for a particular batch

size. To set to OFF, continue to press and release (-)

until OFF appears on the screen.

29. When finished, press another batch size and repeat step 28 until all three sizes are set.

30. When finished setting all batch sizes press DONE.

The display should read 3 BATCHES DONE?.

31. If the three batch sizes are not correct, press NO to

return to the DRIP TIME setup screen and repeat

steps 28 through 30.

32. If the three batch sizes are correct, press YES. The

screen should show the name of the coffee being

programmed (modified) along with SETUP COM-

PLETE.

32. After a 5 second delay, the display will advance to

the next coffee name in the brewer's memory. If no

other coffee names are present, the display will

read THAT WAS THE LAST RECIPE, and return to

the REVIEW RECIPES screen.

P2418

Page 14

29877 080301

Page 15

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET NEW RECIPE

Using a RECIPE CARD to load coffee names and brew

®

settings into the Dual

The G9-2T DBC's memory contains certain coffee

names. If the operator uses a coffee name that is not

already stored in the grinder's memory, a RECIPE

CARD can be obtained from the factory. The RECIPE

CARD would include all the information needed to set

up that particular coffee name. The information from

the RECIPE CARD is loaded into the grinder's memory,

then into the brewer's memory by holding the chip

area up to the equipment's sensing coil. This information can include the coffee name, BREW VOLUMES,

BYPASS PERCENTAGES, PULSE BREW TIMES, PREINFUSION TIMES and DRIP-OUT TIMES for that

particular coffee NAME. These can all be loaded in

seconds.

Contact Bunn-O-Matic Corporation for the avail-

ability of RECIPE CARDS.

SH DBC with Smart Funnel®:

6. If the brewing information is not correct, or it is

desired to exit the setup before the settings are

loaded into the brewer's memory, press QUIT. The

display will read (COFFEE NAME) NOT SAVED.

The display will then return to the MAIN SCREEN.

READY TO BREW

WATER TEMP: 200º

POSITION CARD UNDER THE

LEFT SIDE SENSOR COIL

CARD CONTAINS

RECIPIE FOR

NOTE: Instructions to program the brewer and grinder

are printed on the RECIPE CARD, along with the coffee

name that is being programmed.

Procedure to program the coffee name:

1. Remove the funnels (if present) from the left and

right funnel rails.

2. Position the RECIPE CARD vertically, so that the

top end of the chip is beneath the left side funnel

sensing coil.

3. After a short pause the display will read CARD

CONTAINS RECIPE FOR then will change to (COF-

FEE NAME) SHOW QUIT SAVE. All brewing pa-

rameters for that coffee flavor are now transferred

from the CARD to the brewer.

4. To show (view) this information, press and release

SHOW. The display will scroll through all of the

brew settings for all three batch sizes. The display

will then return to CARD CONTAINS RECIPE FOR

then will change to (COFFEE NAME) SHOW QUIT

SAVE.

5. If all brew settings are correct, press SAVE. The

display will read (COFFEE NAME) SETUP COM-

PLETE. All brew settings for that name are now

stored in the brewer's memory.

(COFFEE NAME)

SHOW QUIT SAVE

SCROLLS THROUGH ALL

OF THE BREW SETTINGS

FOR THE THREE BATCH

SIZES FOR THAT COFFEE

FLAVOR

(COFFEE NAME)

NOT SAVED

(COFFEE NAME)

SETUP COMPLETE

P2300

Page 15

29877 121302

Page 16

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET NEW RECIPE:

®

If not using a Smart Funnel

or a G9-2T DBC Grinder, the brewer will function as

a standard Bunn

®

Dual® Brewer:

It is possible to operate the brewer without using

a Smart Funnel® and/or a G9-2T DBC Grinder. If a

standard funnel, or if a non-DBC grinder is used the

brewer will automatically select a NO NAME coffee

flavor when the pad is pressed. This means that

no name was read from the funnel's handle.

There are two NO NAME coffee programs that can

be set in the brewer. They are referred to as NO NAME

LEFT and NO NAME RIGHT. The left and right sides of

the brewer can be set up independently of each other.

This includes BREW VOLUMES, BYPASS PERCENT-

AGES, PULSE BREW TIMES, PREINFUSION TIMES

and DRIP-OUT TIMES. The brewer will perform in the

same capacity as a standard Bunn Dual® Brewer.

The instructions for programming the NO NAME

settings are on the following pages. The same steps

are followed for setting the recipe as those that are

used to MODIFY A RECIPE, beginning on page 18.

Note that when the display reads NO NAME LEFT,

that is when MODIFY should be pressed in order to set

the parameters for the NO NAME LEFT coffee.

Otherwise, press NEXT to display NO NAME RIGHT.

At this point, MODIFY should be pressed in order to set

the parameters for the NO NAME RIGHT coffee.

(with a sensor coil) and/

P2419

NOTE: Before beginning setup, insert a funnel into the

left and right side funnel rails, and place a Soft Heat

Server beneath each brew funnel.

®

Page 16

29877 080301

Page 17

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

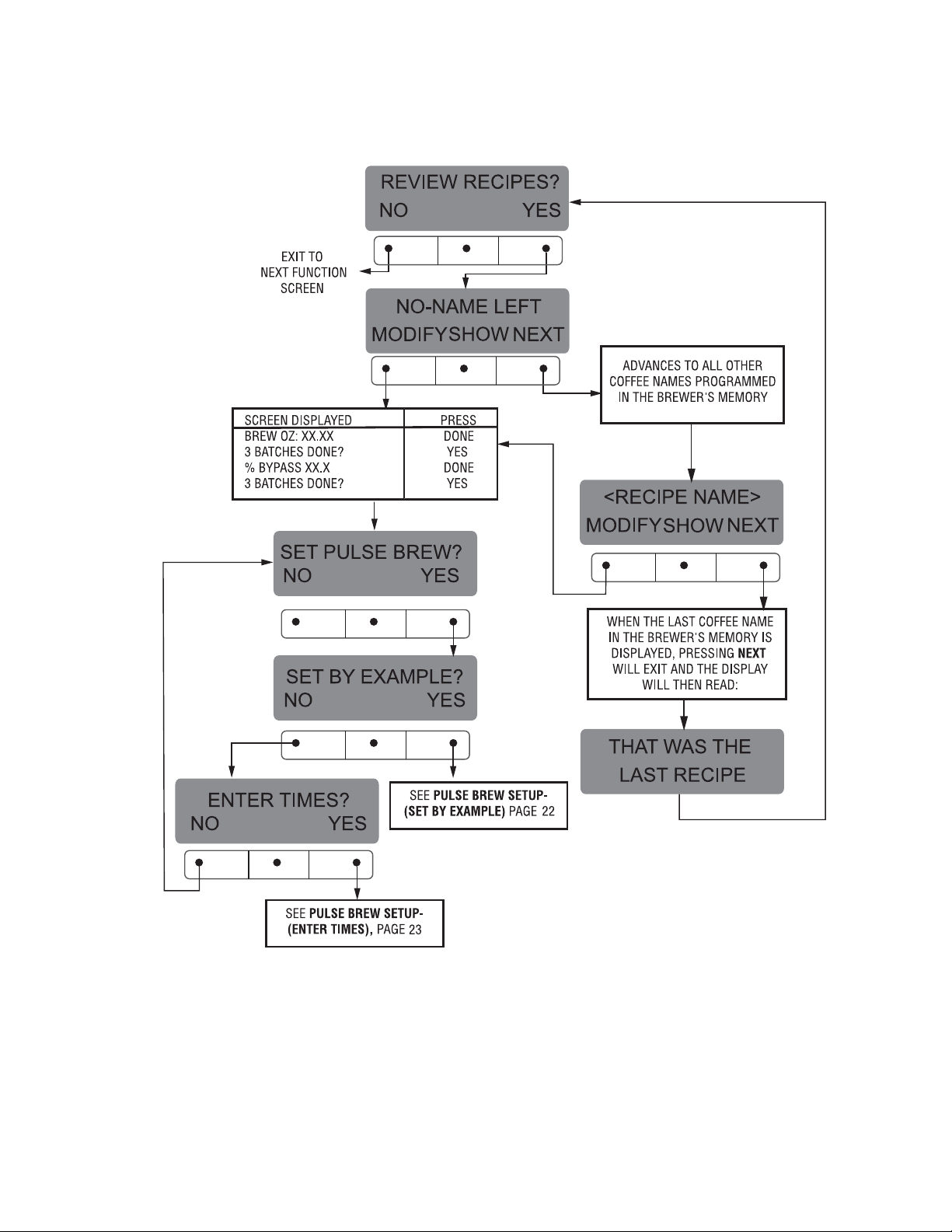

REVIEW RECIPES/MODIFY RECIPES/SET UP NO

NAME COFFEE FLAVORS:

This function has three parts. It allows the operator to view the brew settings for the various coffee

names programmed into the brewer.

It also allows the operator to modify (change) any

of the BREW VOLUMES, BYPASS PERCENTAGES,

PULSE BREW TIMES, PRE-INFUSION TIMES and

DRIP-OUT TIMES for a particular coffee name pro-

grammed into the brewer.

Finally, this function is used to set up the two NO

NAME coffee BREW VOLUMES, BYPASS PERCENTAGES, PULSE BREW TIMES, PRE-INFUSION TIMES

and DRIP-OUT TIMES.

Procedure for reviewing recipes:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ®. Press the ®

until the display reads REVIEW RECIPES.

Page 17

29877 080301

Page 18

BREW OZ (SETTING OR ADJUSTING BREW VOLUMES)

This function allows adjustment of the brew vol-

umes for each batch. The indicator signifies volume in

ounces per batch.

Procedure for modifying recipes - brew ounces:

Range: 10.0 oz to 400 oz for all three batch sizes

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Press the

® until the display reads REVIEW RECIPES.

2. Press YES to proceed. The display should now

read NO-NAME LEFT, along with MODIFY, SHOW

and NEXT.

3. Press and release NEXT to advance to the desired

coffee name to be modified.

4. Press and release MODIFY. The display should

read BREW OZ: and a batch light will be blinking.

Press and release the batch size to be modified.

Page 18

Page 19

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

% BYPASS

This function allows adjustment of the amount of

water that bypasses the grounds. The number signifies the percentage of the brew volume which does not

flow over the coffee grounds.

Modifying recipes - bypass percentages:

Range: 0% to 90% for all three batch sizes

NOTE: If the brewer is already in the % BYPASS

screen, it is not necessary to follow steps 1 through 6

in this section, but proceed directly to step 7.

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Press the

® until the display reads REVIEW RECIPES.

2. Press YES to proceed. The display should now

read NO-NAME LEFT, along with MODIFY, SHOW

and NEXT.

3. Press and release NEXT to advance to the desired

coffee name to be modified.

Page 19

29877 080301

Page 20

Page 21

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET PULSE BREW (cont.)

Page 21

29877 080301

Page 22

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

Setting Pulse Brew - BY EXAMPLE:

1. This display should read CONTAINER READY?

Place a container under the left side sprayhead.

Place a brew funnel containing a filter and grounds

on top of the container so that the spray and coffee bed can be viewed. (See Fig. 1)

2. Choose the batch size to be set by pressing the

pad next to the indicator light on the left brew side.

The batch size indicator selected will be flashing.

3. If everything is in place, press YES in the CON-

TAINER READY? screen. The display should read

PRESS BREW TO START 1ST ON TIME.(a)

4. Press and release the pad. The brew water

will start to flow into the funnel and the water level

will rise.(b)

5. Watch the flow of water. When it reaches the de-

sired level in the funnel, press and release the

pad again to end the 1ST ON TIME.(c)

6. The spray will stop and the brew funnel will start

to empty. When the water level in the funnel drains

P2288

FIG. 1

to the desired level, press again to end the

OFF-TIME. This also begins the spray of water for

the final setting.(d)

7. The brew water will begin again and the water level

in the funnel will rise. Watch the flow of water.

When it reaches the desired level, press to

end the LAST ON TIME.(e)

8. The display should now show the 1st, off and last

times for the batch size just programmed. After a

5 second delay, the display will read 3 BATCHES

DONE? (f and g)

9. If other batches need to be modified, press NO.

The display will go back to SET BY EXAMPLE.

Press YES, then press a different batch size pad

and repeat steps 1 through 8. Repeat until all the

desired batch sizes are set for the left side. (g)

10. When finished press YES in 3 BATCHES DONE?.

The display will then read SET PREINFUSION.

Another alternative is to press and release either

of the pads located on the front panel of the

brewer to exit SET PULSE BREW and return to

the MAIN SCREEN.

NOTE: Pressing ® before reaching the final setting

screen exits the setup and retains the old values.

Page 22

Page 23

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

Setting Pulse Brew - ENTER TIMES:

NOTE: No water should flow from the brewer during

this set-up process.

1. This display should read 1ST ON TIME X:XX.

Choose the batch size to be set by pressing the

pad next to the indicator light on the left brew side.

The batch size indicator selected will be flashing.

2. Adjust the 1ST ON TIME using (-) and (+). When

finished, press DONE. (a)

3. The display will now read OFF TIME X:XX. Adjust

the OFF TIME using (-) and (+). When finished,

press DONE.(b)

4. The display will now read LAST ON TIME X:XX.

Adjust the LAST ON TIME using (-) and (+). When

finished, press DONE.(c)

5. The display will show the three times just entered

for that batch size. After a 5 second delay, the display will read 3 BATCHES DONE?(d and e)

Page 23

29877 080301

Page 24

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SET PREINFUSION

This function allows the operator to set an initial

soaking of the grounds and a delay time, before the

complete brew cycle starts.

Procedure for Modifying preinfusion times:

Range: On time - off to 4 minutes

Off time - off to 4 minutes for all three batch

sizes

NOTE: If the brewer is already in the SET PREINFUSION

screen, it is not necessary to follow steps 1 through 9

in this section, but proceed directly to step 10.

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Press the

® until the display reads REVIEW RECIPES.

2. Press YES to proceed. The display should now

read NO-NAME LEFT, along with MODIFY, SHOW

and NEXT.

3. Press and release NEXT to advance to the desired

coffee name to be modified.

4. Press and release MODIFY. The display should

read BREW OZ.

5. Press and release DONE. The display should read

3 BATCHES DONE?.

6. Press and release YES. The display should now

read % BYPASS.

7. Press and release DONE. The display should read

3 BATCHES DONE?.

8. Press and release YES. The display should now

read SET PULSE BREW.

9. Press and release NO. The display should now

read SET PREINFUSION.

10. Press YES to proceed. The display should now

read ON TIME and a batch light will be blinking.

11. Using (-) and (+), set the amount of time the brew

water will initially presoak the grounds for that

particular batch size.

12. When finished, press another batch size and repeat until all three batch sizes are set.

13. When finished, press DONE. The display should

now read OFF TIME and a batch light will be

blinking.

14. Using (-) and (+), set the amount of time the brew

cycle will delay (after the presoak cycle shuts off)

before resuming brewing.

15. When finished, press another batch size and repeat until all three batch sizes are set.

16. When finished, press DONE. The display will show

the ON and OFF TIMES that were entered for each

particular batch size.

17. After a 5 second delay, the display should read 3

BATCHES DONE?. If the three batches are not

complete, press NO in order to return to SET

PREINFUSION, and repeat steps 10 through 14.

18. If the three batches are done, press YES. This will

advance to the next function, SET DRIP TIME.

Another alternative is to press and release either of

the pads located on the front panel of the

brewer to exit SET PREINFUSION and return to the

MAIN SCREEN.

Page 24

29877 080301

Page 25

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

DRIP TIME (now displayed on "non" funnel lock units

as well)

This function allows the setting or modification of

the funnel locks to stay engaged after the end of a

brew cycle. This ensures that the funnel cannot be

removed until after the liquid has emptied out of the

funnel.

Procedure to modify drip times:

Range: OFF to 10 minutes for all three batch sizes.

NOTE: If the brewer is already in the DRIP TIMES

screen, it is not necessary to follow steps 1 through 10

in this section, but proceed directly to step 11.

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Press the

® until the display reads REVIEW RECIPES.

2. Press YES to proceed. The display should now

read NO-NAME LEFT, along with MODIFY, SHOW

and NEXT.

3. Press and release NEXT to advance to the desired

coffee name to be modified.

4. Press and release MODIFY. The display should

read BREW OZ.

5. Press and release DONE. The display should read

3 BATCHES DONE?.

6. Press and release YES. The display should now

read % BYPASS.

7. Press and release DONE. The display should read

3 BATCHES DONE?.

8. Press and release YES. The display should now

read SET PULSE BREW.

9. Press and release NO. The display should now

read SET PREINFUSION.

10. Press and release NO. The display should now

read DRIP TIME, along with either the word OFF,

or a time will be showing. A batch light should also

be blinking.

11. Using the (-) and (+), set the amount of time from

when the brew solenoid shuts off to when drip-out

occurs for that batch size.

NOTE: Set to OFF to prevent funnel locks from engag-

ing (to disable this function), for a particular batch

size. To set to OFF, press and release (-) until OFF is

displayed.

Page 25

P2297

29877 080301

Page 26

COPY SETTINGS (NO NAME COFFEE SETTINGS ONLY)

This function is used to transfer all the brew

settings from a NO NAME coffee flavor programmed

on one side of the brewer to the other side. A NO NAME

coffee is a flavor that is not in the grinder's memory or

is what appears if a Smart Funnel® is not used.

For example, once the left side's 3 batch sizes are

programmed (brew volumes, bypass percentages,

pulse brew times, pre-infusion times, and drip-out

times) for a particular NO NAME coffee, all the data can

be transferred from the left side of the brewer to the

right side in one step. The data can also be transferred

from right to left, if the right side had been the initial

set-up side. This results in less set-up time.

If two different NO NAME setups are required, one

on the left, the other on the right side, it is not

recommended that this function be used.

Procedure to copy settings:

1. Press and hold the ® pad until the display reads

SET RECIPES. Release the ® pad. Continue to

press and release the ® pad until the display reads

COPY SETTINGS.

Page 26

Page 27

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

ENABLE ADS?

This function allows the operator to choose whether

or not to display the advertising message that was

entered into the brewer with an AD CARD. This message will be displayed when the brewer is not in use.

P2301

Procedure to Enable/Disable Ads:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ®. Press and

release the ® until the display reads ENABLE ADS.

The YES or NO will be flashing to indicate the

current selection.

2. Press and release the NO pad to disable this

function (no ads will be displayed on the screen),

or;

3. Press and release the YES pad to enable this

function (ads will be displayed on screen).

4. When finished, press and release DONE to save the

new setting, exit the ENABLE ADS function and

advance to the next function screen, SET TEMP.

Another alternative is to press and release either of

the pads located on the front switch panel to

exit the ENABLE ADS function and return to the

MAIN SCREEN.

SET TEMP - Range: 185˚F (85˚C) to 205˚F (96˚C)

This function allows the operator to set the brew

water temperature in the tank. It also sets the hot water

faucet dispense temperature.

P2302

Procedure to set brew temperature:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release button. Press and

release the ® until the display reads SET TEMP.

Page 27

29877 080301

Page 28

P2306

Procedure to adjust the flow rate setting:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ®. Press and

release the ® pad until the display reads BYPASS

OZ/M. The number represents what the brewer

thinks is the flow rate of the bypass valve in ounces

per minute.

2. If the actual flow rate of the bypass valve is known,

but is different than the number on the display, use

the (-) and (+) pads to enter the correct flow rate

in ounces per minute.

3. When finished, press and release the DONE pad.

This saves the new setting and advances to the

next function screen, CALIBRATE FLOW. Another

alternative is to press and release either of the

pads located on the front switch panel to exit the

BYPASS OZ/M function and return to the MAIN

SCREEN.

Page 28

29877 080301

Page 29

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

CALIBRATE FLOW

This function allows the operator to enter the

actual flow rate of the sprayhead and the bypass for

each side of the brewer by dispensing both separately

for one minute. The volumes are then entered in

ounces per minute (OZ/M).

Procedures to calibrate the sprayhead flow rate:

1. Place a container, accurately graduated in ounces,

and with a minimum capacity of 60 ounces, be-

neath the funnel on the side of the brewer to be

calibrated.

2. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Press and

release the ® pad until the display reads CALI-

BRATE FLOW ?.

3. Press and release YES to advance to the SPRAY

HEAD CAL? function screen. (Pressing NO in the

CALIBRATE FLOW screen will advance to the next

function screen, BREW COUNTERS).

4. Press and release the YES pad. The display should

read CONTAINER READY? If the container is un-

der the funnel, press YES. The display should read

CALIBRATE SPRAY .. PRESS BREW TO START.

5. Press and release the pad on the side to be

calibrated. The display should read CALIBRATE

SPRAY .. 60 SEC TO FINISH. The 60 second timer

on the display will count down to zero. When the

counter reaches zero, the display will change to

LEFT or RIGHT OZ., along with a number signify-

ing ounces per minute.

6. Measure the amount of water in the container and

using the (-) or (+) pads, adjust the amount on the

display to match the amount in the container. Then

press DONE.

7. The display should now read NEW L or R SPRY

FLOW, along with the correct flow rate of the

sprayhead in ounces per minute. After about 5

seconds, the display will return to the CALIBRATE

FLOW screen.

8. To exit the CALIBRATE FLOW program, press NO

to advance to the next function screen, or press

and release the pad located on the front

P2608

switch panel to exit the CALIBRATE FLOW func-

tion and return to the MAIN SCREEN.

9. Repeat steps 1 - 8 when calibrating the other side.

Page 29

29877 121302

Page 30

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

CALIBRATE FLOW (cont.)

Procedures to calibrate the bypass flow rate:

1. Place a container, accurately graduated in ounces,

and with a minimum capacity of 60 ounces, below

the funnel on the brewer to be calibrated.

2. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Press and

release the ® pad until the display reads CALI-

BRATE FLOW?.

3. Press and release YES to advance to the SPRAY

HEAD CAL? function screen. (Pressing NO in the

CALIBRATE FLOW screen will advance to the next

function screen, BREW COUNTERS).

4. Press and release NO to advance to the BYPASS

CALIBRATION screen.

5. Press and release the YES pad. The display should

read CONTAINER READY? If the container is under the funnel, press YES. The display should read

CALIBRATE BYPASS .. PRESS BREW TO START.

6. Press and release the pad on the side to be

calibrated. The display should read CALIBRATE

BYPASS .. 60 SEC TO FINISH. The 60 second

timer on the display will count down to zero. When

the counter reaches zero, the display will change to

LEFT or RIGHT OZ., along with a number signify-

ing ounces per minute.

7. Measure the amount of water in the container, and

using (-) or (+), adjust the amount on the display

to match the amount in the container. Then press

DONE.

8. The display should now read NEW L or R BYPS

FLOW, along with the correct flow rate of the

bypass in ounces per minute. After about 5 seconds, the display will return to the CALIBRATE

FLOW screen.

9. To exit the CALIBRATE FLOW function, press and

release NO to advance to the next function screen,

or press and release the pad located on the

front switch panel to exit the CALIBRATE FLOW

function and return to the MAIN SCREEN.

10. Repeat steps 1 - 9 when calibrating the other side.

Page 30

P2609

29877 121302

Page 31

BREW COUNTERS

This function allows the operator to track the

number of brew cycles completed on the left side, the

right side, and the total of both combined. There are

three resettable counters, and one life counter that is

not resettable.

Page 31

Page 32

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SERVER DETECT

This function allows the operator to prevent the

®

start of a brew cycle if a Soft Heat

server is not

positioned correctly on the brewer.

SERVER DETECT ?

P2310

Procedures to set server detect:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ®. Press and

release the ® pad until the display reads SERVER

DETECT.

2. The NO or YES flashes to indicate the current

selection.

3. Select YES to prevent brewing if the Soft Heat

server is not correctly positioned on the brewer

beneath the funnel.

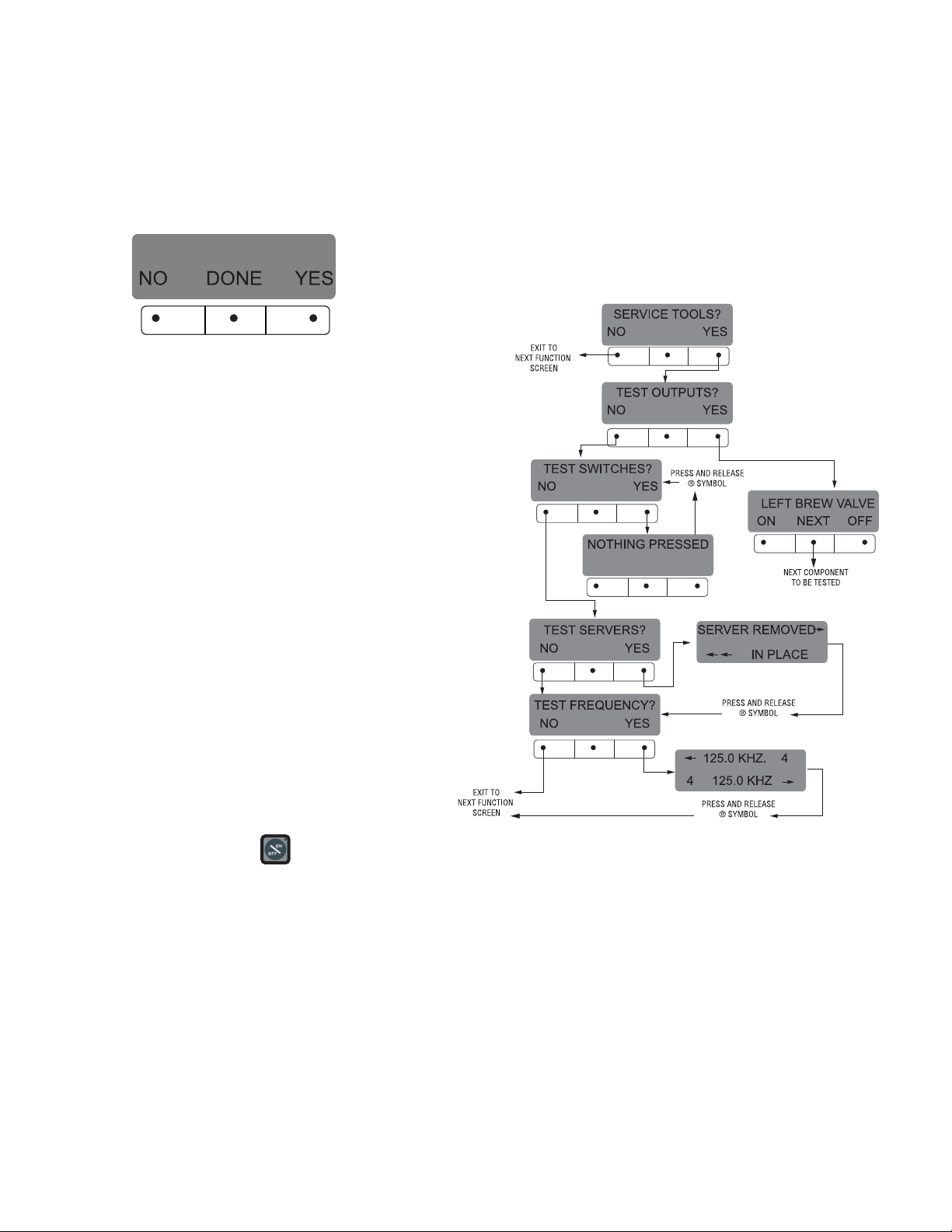

SERVICE TOOLS

This function allows the testing of individual components and the ability to check switches for proper

function. This function also tests the Soft Heat® server's

status on the brewer (in place or removed), and the

funnel sensor coil's frequency (diagnostic tool for

troubleshooting purposes only).

®

NOTE: If YES is selected and a brew cycle is attempted

with a server not properly placed, the display will read

SERVER NOT IN PLACE.

4. Select NO to allow brewing without a Soft Heat

server in place. This is selected when brewing into

a container other than a Soft Heat® Server.

5. When finished, press and release DONE. This will

save the new setting, exit the function screen and

advance to SERVICE TOOLS. Another alternative

is to press either of the pads located on the

front switch panel to exit the SERVER DETECT

function and return to the MAIN SCREEN.

®

P2311

Page 32

29877 121302

Page 33

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SERVICE TOOLS (cont.)

Testing individual components (outputs):

This will allow the operator to test the operation of

individual components and outputs of the brewer. The

components that can be individually tested are as

follows:

12. Press NEXT to advance to the next component to

be tested.

13. To test LEFT FUNNEL LOCK, press ON. If the

funnel lock is functional, the lock will come down

to hold the funnel in place.

14. Press OFF to retract the funnel lock.

15. Press NEXT to advance to the next component to

be tested.

16. To test LEFT SERVER, press ON. If the server and

the sensor are functional, the light on the lower

right corner of the server will illuminate.

17. Press OFF to end testing of server.

18. Press NEXT to advance to the next component to

be tested.

19. Follow steps 7 through 15 to test the right side

components.

20. To test REFILL VALVE, press ON. If the refill valve

is functional, the sound of the valve operating will

be heard.

21. Press OFF to end testing of refill valve.

22. Press NEXT to advance to the next component to

be tested.

23. To test TANK HEATERS, connect a voltmeter across

each of the tank heaters to check for voltage.

24. Press ON. The correct voltage should be present at

the heater terminals.

25. Press OFF to end testing of the tank heaters.

Page 33

NOTE: The tank heater will automatically turn off if left

on too long.

26. After testing the tank heater, press NEXT to ad-

vance to the next test.

27. The HEATER CONTACTOR is used only on certain

models. Check the machine schematic to see if the

contactor is present. Connect a voltmeter across a

tank heater that is operated by the contactor and

press ON to check that correct voltage is present.

Press OFF and confirm the voltage is zero.

28. Press NEXT to return to TEST OUTPUTS.

29. To exit SERVICE TOOLS, press and release either

of the pads located on the front switch panel.

This will return to the MAIN SCREEN.

Procedure to test switches:

This function allows the operator to test the opera-

tion of the individual switches on the front panel.

1. Place brew funnels into rails on both sides of

brewer.

29877 121302

Page 34

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

SERVICE TOOLS (cont.)

2. Place a Soft Heat® server beneath each brew

funnel.

3. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Continue

pressing and releasing the ® pad until SERVICE

TOOLS appears.

4. Press YES to run tests on various components and

outputs within the brewer. (Pressing NO will exit

this function and advance to the next function

screen.)

5. The display should read TEST OUTPUTS.

6. In TEST OUTPUTS screen, press NO. This advances to TEST SWITCHES.

7. Pressing NO in this screen will advance to the next

function. Press YES in the TEST SWITCHES screen

to test the switches. The display will read NOTH-

ING PRESSED.

8. From this screen, press any of the switches on the

front of the brewer. While the switch is pressed,

the display shows the name of that switch. If the

name does not appear, or if it remains after the

switch has been released, the switch is defective.

Each switch can be tested in this manner.

9. After all switches have been tested, press and

release either of the ® buttons located on the front

switch panel. This will exit TEST SWITCHES and

return to the MAIN SCREEN.

Procedures to test servers:

This function allows the operator to test the opera-

tion of the Soft Heat® servers. It will also show if the

server is correctly placed on the brewer stand.

1. Place brew funnels into rails on both sides of

brewer.

2. Place a Soft Heat® server beneath each brew

funnel.

3. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Continue

pressing and releasing the ® pad until SERVICE

TOOLS appears.

4. Pressing NO will exit this function and advance to

the next function screen. Press YES to run tests on

various components and outputs within the brewer.

5. The display should read TEST OUTPUTS

Page 34

6. In TEST OUTPUTS screen, press NO. This advances to TEST SWITCHES. Press and release NO

once more. The display should now read TEST

SERVERS

7. Press YES in the TEST SERVERS screen to show

if a server is in place. The display should read IN

PLACE with arrows pointing to the left and right

8. Lift and pull both Soft Heat servers forward about

2 inches so that the two contacts on each server do

not touch the two contacts on the brewer.

9. The display should then read SERVER REMOVED

with arrows pointing to the left and right.

10. After the servers have been tested, press and

release either of the pads located on the front

switch panel. This will exit TEST SERVERS and

return to the MAIN SCREEN.

Procedures to test coil frequency:

1. Place brew funnels into rails on both sides of

brewer.

2. Place a Soft Heat® server beneath each brew

funnel.

3. Press and hold the ® pad until the display reads

SET NEW RECIPES. Release the ® pad. Continue

pressing and releasing the ® pad until SERVICE

TOOLS appears.

4. Pressing NO will exit this function and advance to

the next function screen. Press YES to run tests on

various components and outputs within the brewer.

5. The display should read TEST OUTPUTS.

6. In TEST OUTPUTS screen, press NO. Continue to

press and release NO until the display reads TEST

FREQUENCY.

7. Press and release YES. The display will show the

frequency of the sensor coil circuits. This is for

diagnostic service use when troubleshooting this

circuit.

8. After the coils have been tested, press and release

either of the pads located on the front switch

panel. This will exit the TEST FREQUENCY function and return to the MAIN SCREEN.

NOTE: If the operator wishes to test more than one

function in the SERVICE TOOLS section (outputs,

switches, servers, or coil frequency), it is not

necessary to exit the program. Use the flow chart

for SERVICE TOOLS to navigate to a particular

function.

29877 121302

Page 35

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

FACTORY DEFAULTS

This function allows the operator to erase all of the

previously entered recipes and ad messages. Factoryset default values will replace all previous settings.

P2312

FACTORY DEFAULT VALUES

Brew Lockout YES

BREW VOLUMES:

Small Batch 64 oz.

Medium Batch 128 oz.

Large Batch 192 oz.

BYPASS PERCENTAGE:

Small Batch 0%

Medium Batch 20%

Large Batch 20%

PULSE BREW TIMES:

Small Batch 40 (1st on) - 10 (off) - 5 (last on)

Medium Batch OFF

Large Batch OFF

PREINFUSION TIMES:

Small Batch OFF

Medium Batch OFF

Large Batch OFF

Procedure to set factory defaults:

1. Press and hold the ® pad until SET NEW RECIPES

appears. Release the ® pad. Press and release ®

until the display reads FACTORY DEFAULTS.

2. Pressing NO in this screen will revert to the MAIN

SCREEN. Press YES to replace the defaults. This

advances to WILL REPLACE ALL BREWING SET-

TINGS. This screen will alternate with ARE YOU

SURE?.

3. Pressing NO in the confirmation screen will revert

to MAIN SCREEN, without resetting the brewing

setups to the defaults. Press YES to load the

defaults. This will then revert to the MAIN SCREEN,

and the factory default values will replace all

previously entered values. It will NOT reset the

summation Brew counter.

DRIP OUT TIMES:

Small Batch 1:00

Medium Batch 1:30

Large Batch 2:00

ENABLE ADS YES

BREW TEMPERATURE 200˚F (93˚C)

READY TEMPERATURE 195˚F (91˚C)

REFILL 155

SPRAY (OZ/MINUTE) 39.2

BYPASS (OZ/MINUTE) 24.1

FUNNEL DETECT YES

SERVER DETECT YES

Page 35

29877 121302

Page 36

TROUBLESHOOTING

A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems

encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic

Technical Service Department.

• Inspection, testing, and repair of electrical equipment should be performed only by qualified service

personnel.

• All electronic components have 120 - 240 volt ac and low voltage dc potential on their terminals.

Shorting of terminals or the application of external voltages may result in board failure.

• Intermittent operation of electronic circuit boards is unlikely. Board failure will normally be

permanent. If an intermittent condition is encountered, the cause will likely be a switch contact or

a loose connection at a terminal or crimp.

• Solenoid removal requires interrupting the water supply to the valve. Damage may result if

solenoids are energized for more than ten minutes without a supply of water.

• The use of two wrenches is recommended whenever plumbing fittings are tightened or loosened.

This will help avoid twists and kinks in the tubing.

• Make certain that all plumbing connections are sealed and electrical connections tight and isolated.

• This brewer is heated at all times. Keep away from combustibles.

WARNING

• Exercise extreme caution when servicing electrical equipment.

• Disconnect the brewer from the power source when servicing, except when electrical tests are

specified.

• Follow recommended service procedures.

• Replace all protective shields or safety notices.

Screen Displayed

Possible Cause

1. Overflow cup is full of water.

1. Soft Heat

®

Server not correctly

positioned on base.

2. Not using a Soft Heat® Server, and

the SERVER DETECT function is ac-

tivated (on).

Troubleshooting Procedures

Empty cup

Position the server so that the connector pins on the server make contact with connector on the brewer.

Disable the SERVER DETECT function. See page 32 for procedure.

Page 36

29877 121302

Page 37

TROUBLESHOOTING (cont.)

Screen Displayed

Possible Cause Troubleshooting Procedures

1. SMART FUNNEL not fully inserted

into the funnel rails.

Position the funnel so that the sensor is directly beneath the sensor

coil on the brewer.

2. Not using a SMART FUNNEL, and

the FUNNEL DETECT function is ac-

Disable the FUNNEL DETECT func-

tion. See page 32 for procedure.

tivated (on).

1. Water temperature in the tank

does not meet the SET READY TEM-

(a) Wait for the brewer to heat to the

proper temperature.

PERATURE.

(b) Disable the BREW LOCKOUT

function. See page 10 for procedure.

1. Brew funnel was not removed

after the previous brew cycle was

Remove funnel, check contents, and

insert back into the funnel rails.

finished.

OR

1. Brew funnel was moved out of

position after the brew cycle was

started.

Press BREW to start a brew cycle

without removing the funnel.

To resume brewing, correctly position the funnel and press BREW

again. The brew cycle will resume

from the point it was interrupted.

OR

Press ON/OFF to terminate the cycle.

Page 37

29877 121302

Page 38

TROUBLESHOOTING (cont.)

Screen Displayed

1. Soft Heat® Server was moved out

of position after the brew cycle was

started.

1. ON/OFF switch was pressed after

the brew cycle was started.

Troubleshooting ProceduresPossible Cause

To resume brewing, correctly position the Soft Heat® Server and press

BREW again. The brew cycle resumes from the point it was interrupted.

OR

Press ON/OFF to terminate the brew

cycle.

To resume brewing, press BREW

again. The brew cycle resumes form

the point it was interrupted.

1. Tank Heater failure

2. Triac Failure

3. Control Board/Thermistor failure

OR

Press ON/OFF to terminate the brew

cycle.

Service Required

Service Required

Service Required

Page 38

29877 090401

Page 39

TROUBLESHOOTING (cont.)

Screen Displayed

1. Water shut off to brewer

2. Inlet Solenoid Valve failure

3. Control Board Failure

1. Temperature Sensor Probe wire(s)

broken or not making connection.

Troubleshooting ProceduresPossible Cause

Check water supply shut-off

Service required

Service required

Check wire and connection of both

black and white wires of temperature probe.

1. Temperature Sensor Probe wire(s)

shorted to housing, or to each other.

Check to confirm that wire(s) are not

pinched between two surfaces or

connected to each other.

Page 39

29877 090401

Page 40

TROUBLESHOOTING (cont.)

Problem

Equipment will not operate.

Brew cycle will not start.

Possible Cause