Page 1

INSTRUCTIONS

AND

PARTS MANUAL

TRAC-BUG

Please record your equipment identication information below for future reference.

This information can be found on your machine nameplate.

Model Number:_________________________________________

Serial Number:_________________________________________

Date of Purchase:_______________________________________

Whenever you request replacement parts or information on this equipment, always

supply the information you have recorded above.

LIT-TRB-IPM-1014

Bug-O Systems is guided by honesty, integrity and

ethics in service to our customers and in all we do.

A DIVISION OF WELD TOOLING CORPORATION

280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA, 15317-9564 USA

PHONE: 412-331-1776 http://www.bugo.com FAX: 412-331-0383

Page 2

SAFETY

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR

DEATH. KEEP CHILDREN AWAY. BE SURE THAT ALL INSTALLATION,

OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

ELECTRIC SHOCK can kill.

1. The equipment is not waterproof. Using the

unit in a wet environment may result in

serious injury. Do not touch the equipment

when wet or standing in a wet location.

2.Never open the equipment without rst

unplugging the power cord or serious

injury may result.

3.Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC) 950.

4.Never remove or bypass the equipment

power cord ground. Verify the equipment

is grounded in accordance with all

applicable local and national electrical

safety codes. If none exist, use

International Electrical Code (IEC) 950.

READ INSTRUCTIONS.

Read the instruction manual before

installing and using the equipment.

EQUIPMENT DAMAGE

POSSIBLE.

1. Do not plug in the power cord without

rst verifying the equipment is OFF and

the cord input voltage is the same as

required by the machine or serious

damage may result.

2. Do not leave the equipment unattended.

Remove from the work site and store in

a safe location when not in use.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or

walk underneath equipment.

MOVING PARTS can

cause serious injury.

1.Never try to stop the pinion from moving

except by removing power or by using

the STOP control.

2. Do not remove any protective panels,

covers or guards and operate equipment.

CAUTION

DO NOT LEAVE EQUIPMENT UNATTENDED

WHEN NOT IN USE!

Remove from work site and store in a safe location.

3

Page 3

TRAC-BUG

INSTRUCTION AND PARTS MANUAL

TABLE OF CONTENTS

PAGE

5.......... Operating Instructions / Set-Up

6.......... Trac-Bug / Oxy-fuel / Technical Data

7.......... Trac-Bug / Oxy-fuel / Exploded View / Parts List

8.......... Trac-Bug / Plasma / Technical Data

9.......... Trac-Bug / Plasma / Exploded View / Parts List

10........ TRB-1010 Base Assembly / Exploded View / Parts List

11 ........ TRB-1020 Cover Assembly / Exploded View / Parts List

12........ TRB-1030 Rear Plate Assembly / Exploded View / Parts List

13........ TRB-1040 Clutch Assembly / Exploded View / Parts List

14........ TRB-1050 Drive Section / Exploded View / Parts List

15........ Trac-Bug Wiring Diagram / Electrical Component Chart

16........ Trac-Bug Track

17........ TRB-1160 Radius Kit Installation / Exploded View / Parts List

18........ TRB-1153 Radius Riser Assembly / Exploded View / Parts List

19........ TRB-1155 Radius Arm Attachment / Exploded View / Parts List

20........ Troubleshooting Guide

21........ Warranty

THIS PRODUCT IS COVERED BY ONE OR

MORE PATENTS WORLD WIDE.

4

Page 4

OPERATING INSTRUCTIONS / SET-UP

1. TRACK SET-UP

The TRAC-BUG will run on any 6" centerline, “V” groove friction track.

To position track, simply set it parallel to the cut line of the work piece.

For most applications, such as straight or bevel cutting, the rail should be

set within 6" to 10" of the cut line. Snapping a chalk line will aid in

set-up. Rails can be joined for long cuts.

2. TORCH SET-UP

Insert the torch into the torch holder on the rack. Adjust the torch holder,

the clamp and the rack to set the torch to the desired position. Connect

the Twin Hose Assembly to the Quick Action Manifold and to the

cutting torch. The manifold provides strain relief for the supply hoses

and quick shut off of the gas supply to the torch. Once the torch is

adjusted, the manifold eliminates the need to readjust the valves after

each cut and prevents the supply hoses from dragging the torch out

of position.

3. MACHINE SET-UP

The TRAC-BUG can be positioned anywhere along the track and in

either direction. Be sure the wheels are seated into the “V” of the track.

Disengage the clutch on the rear of the unit to allow free rolling along

track. Rack torch support to position torch over cut line and roll the unit

back and forth to conrm alignment with the cut line. Reengage clutch.

4. MACHINE OPERATION

Set Toggle Switch to the center “STOP” position. Connect power cord

to the appropriate voltage supply. Throw Toggle Switch to either

direction to verify power to the unit. Adjust travel speed using the Speed

Control. The Circuit Breaker protects the unit from overload or

electrical faults.

CAUTION: IF CIRCUIT BREAKER OPENS, FIND AND CORRECT THE

PROBLEM BEFORE RESETTING.

5

Page 5

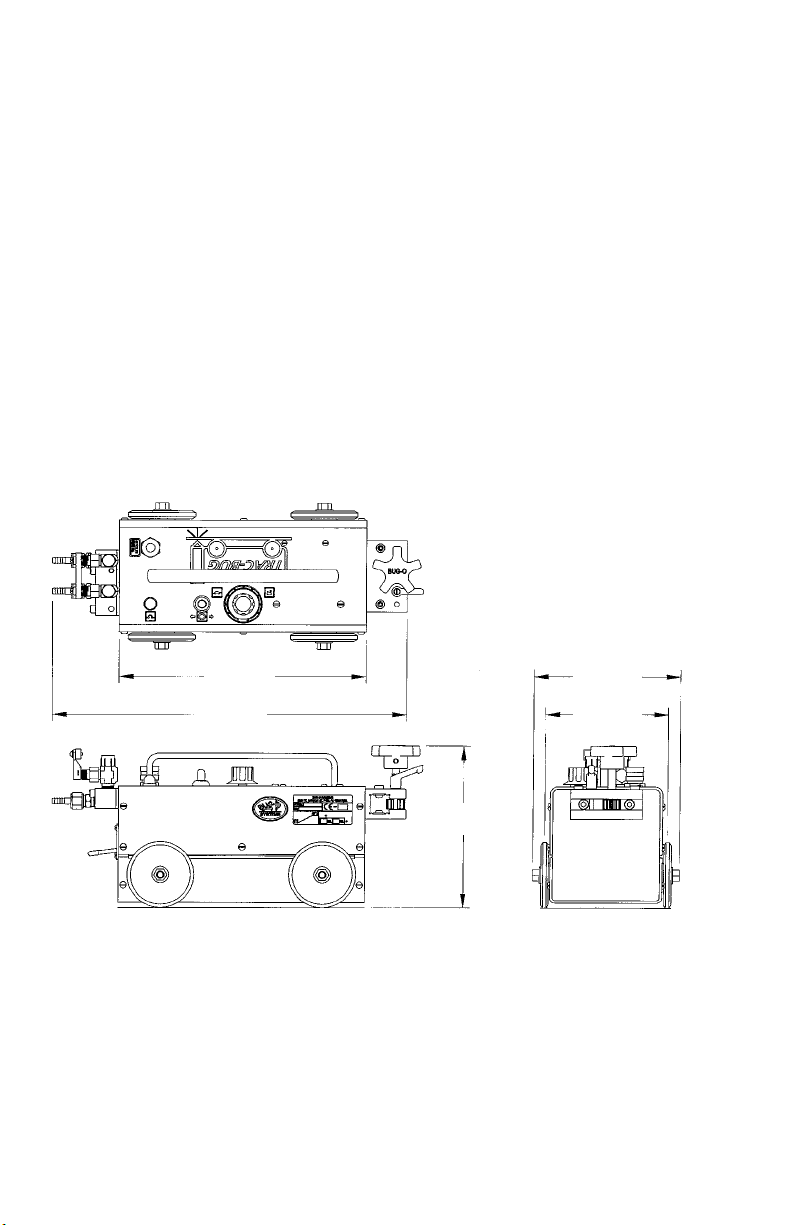

TRAC-BUG / OXY-FUEL

TECHNICAL DATA

Power requirement: 60 watts at rated voltage.

TRB-1000 TRAC-BUG for Oxy-fuel 120 VAC/50-60/1

TRB-1002 TRAC-BUG for Oxy-fuel 240 VAC/50-60/1

TRB-1004 TRAC-BUG for Oxy-fuel 42 VAC/50-60/1

Travel Speed: Innitely variable from 4-72 ipm (100-1800 mm/min)

Net Weight: 33 lbs. (15 kg)

Shipping Weight: 38 lbs. (17 kg)

Dimensions: See below.

12.00"

(305 mm)

17.25"

(439 mm)

8.00"

(204 mm)

7.25"

(185 mm)

6.00"

(152 mm)

6

Page 6

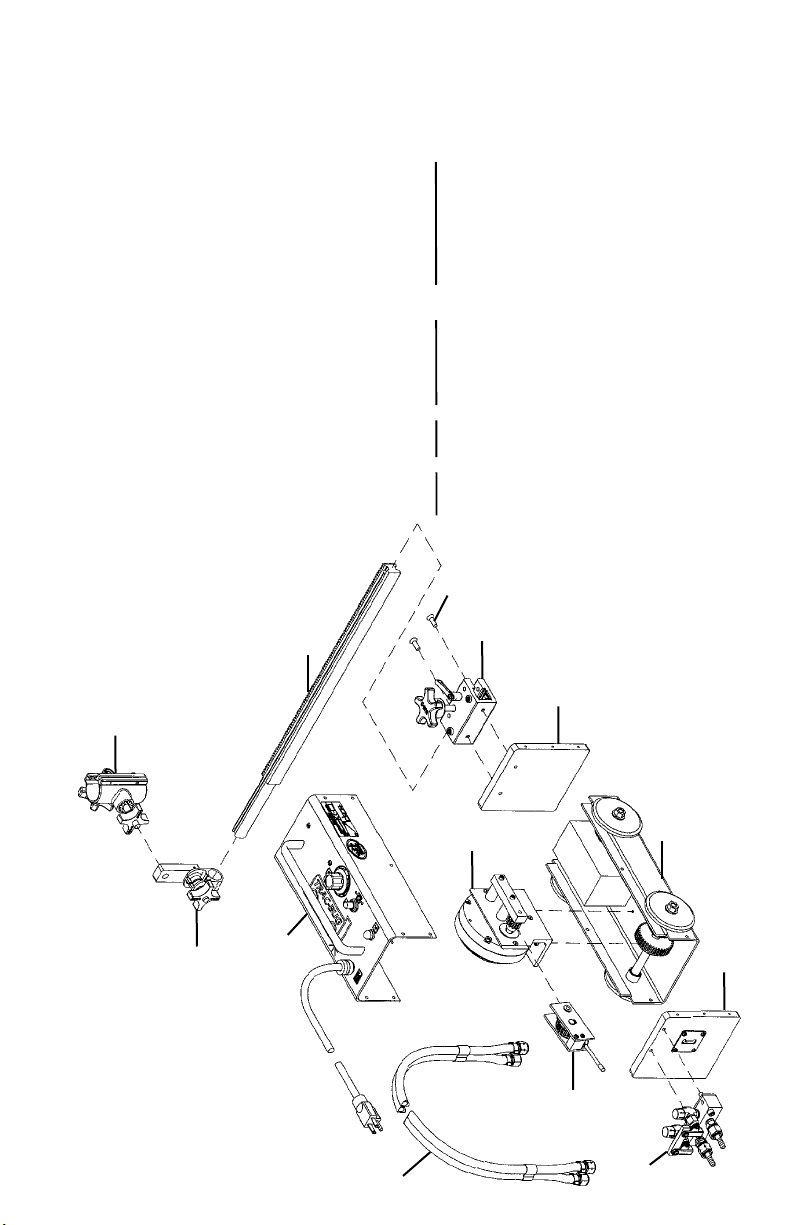

TRAC-BUG / OXY-FUEL

PARTS LIST / TRAC-BUG OXY-FUEL

2 1 BUG-5451 Rack Holder

1 1 BUG-2915 Torch Holder

ITEM QTY PART NO. DESCRIPTION

10 1 TRB-1030 Rear Plate Assembly (page 12)

9 1 TRB-102_ Cover Assembly (page 11)

8 1 TRB-1010 Base Assembly (page 10)

7 1 PAN-1015 Rack 22-5/8"

6 1 MDS-3025 2 Hose Q & A Manifold

5 2 FAS-0957 Flt Hd Soc Scr 1/4-20 x 3/4"

4 1 CIR-1010-3 Twin Hose Assembly

3 1 BUG-9035 Universal Extender

11 1 TRB-1031 Front Plate

14 14 FAS-0124 Flt Hd Scr 8-32 x 3/8"

13 1 TRB-1050 Drive Section (page 14)

12 1 TRB-1040 Clutch Assembly (page 13)

5

7

2

11

1

13

3

9

8

10

12

4

6

7

Page 7

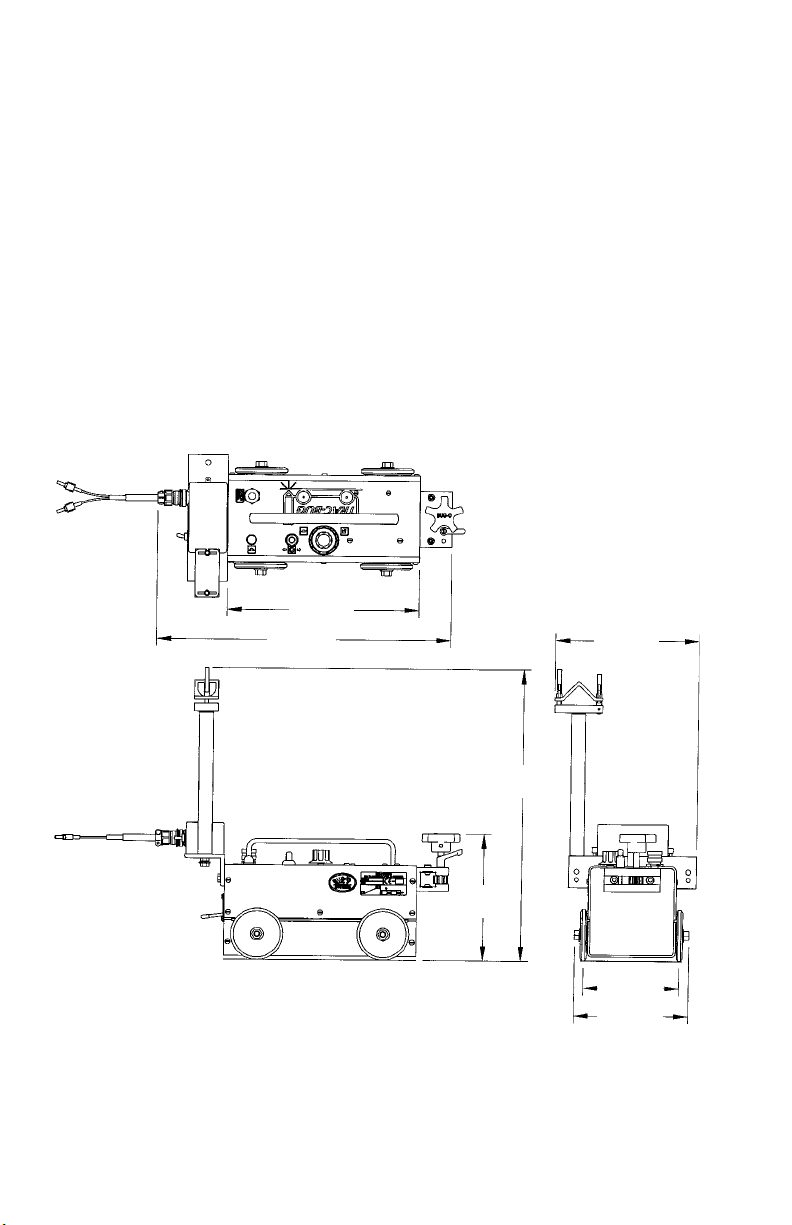

TRAC-BUG / PLASMA

TECHNICAL DATA

Power requirement: 60 watts at rated voltage.

TRB-1500 TRAC-BUG for Plasma 120 VAC/50-60/1

TRB-1502 TRAC-BUG for Plasma 240 VAC/50-60/1

TRB-1504 TRAC-BUG for Plasma 42 VAC/50-60/1

Travel Speed: Innitely variable from 4-72 ipm (100-1800 mm/min)

Net Weight: 33 lbs. (15 kg)

Shipping Weight: 38 lbs. (17 kg)

Dimensions: See below.

12.00"

(305 mm)

18.38"

(467 mm)

9.00"

(229 mm)

18.00"

(470 mm)

8.00"

(204 mm)

6.00"

(152 mm)

7.25"

(185 mm)

8

Page 8

TRAC-BUG / PLASMA

6

5

PARTS LIST / TRAC-BUG PLASMA

ITEM QTY PART NO. DESCRIPTION

3 1 BUG-9035 Universal Extender

2 1 BUG-5451 Rack Holder

1 1 BUG-2915 Torch Holder

6 1 PAN-1015 Rack 22-5/8"

5 2 FAS-0957 Flt Hd Soc Scr 1/4-20 x 3/4"

4 1 BUG-5485 Contactor Box

9 1 TRB-1030 Rear Plate Assembly (page 12)

8 1 TRB-102_ Cover Assembly (page 11)

7 1 TRB-1010 Base Assembly (page 10)

13 14 FAS-0124 Flt Hd Scr 8-32 x 3/8"

12 1 TRB-1050 Drive Section (page 14)

11 1 TRB-1040 Clutch Assembly (page 13)

10 1 TRB-1031 Front Plate

2

1

10

7

12

3

8

9

11

4

9

Page 9

TRB-1010 BASE ASSEMBLY

9

7

10

6

4

3

1

5

11

2

8

10

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 4 TRB-1032 Teon Washer

2 4 FAS-1390 3/8-16 Hex Nut

3 4 TRB-1009 Press Bearing

4 1 TRB-1011 Base Panel

5 4 TRB-1014 Steel Wheel

6 2 TRB-1016 Axle

7 2 TRB-1017 Timing Pulley

8 1 TRB-1018 Driven Gear

9 1 TRB-1019 Drive Belt

10 1 TRB-1026 10# Weight

11 4 WAS-0260 3/8" Washer

Page 10

TRB-1020 COVER ASSEMBLY

TRB-1020 120 VAC

TRB-1022 240 VAC

TRB-1024 42 VAC

5

16

12

14

7

4

8

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

* 1 1 BUG-1393 Volt Trap 120 VAC

2 1 CAS-1770 Motor Control Board

3 1 BUG-2255 Toggle Switch

* 4 1 BUG-2923 Circuit Breaker .7 amp

5 1 BUG-2924 Reset Button Seal

* 6 1 BUG-5001 Transformer 120 VAC

* 7 1 BUG-9445 Power Cord 120 VAC

8 1 BUG-9446 Cord Grip

9 1 BUG-9686 Potentiometer Control

10 2 FAS-0114 Pan Hd Scr 6-32 x 3/8"

11 2 FAS-0124 Pan Hd Scr 8-32 x 3/8"

12 2 FAS-0235 Rd Hd Scr 10-24 x 1/2"

13 2 FAS-1320 8-32 Hex Nut

14 1 BUG-5758 Seal, Toggle Switch

15 1 TRB-1021 TRB Cover Panel

16 1 TRB-1025 Handle, 9" Centers

* See Electrical Component Chart on page 15 for 240 VAC and 42 VAC part numbers.

9

3

10

11

15

1

2

6

13

Page 11

TRB-1030 REAR PLATE ASSEMBLY

1

6

3

7

7

4

5

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 4 FAS-0112 Pan Hd Scr 6-33 x 1/4"

2 1 FAS-0217 Rnd Hd Scr 6-32 X 3

3 1 TRB-1027 Clutch Spring

4 1 TRB-1028 Clutch Plate

5 1 TRB-1029 Rear Plate

6 1 FAS-1310 Hex Nut 6-32

7 2 WAS-0210 #6 SAE Flat

12 13

Page 12

TRB-1040 CLUTCH ASSEMBLY

1

3

5

2

8

11

9

10

7

3

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 FAS-0634 Soc Hd Shd 1/4" x 3/8" x 10-24

2 4 FAS-0112 Pan Hd Slt 6-32 x 1/4"

3 2 MUG-1579 Retaining Ring For 3/8" Shaft

4 1 SFX-1216 Bearing Flg 1/4" ID x 3/8" OD x 3/16" LG

5 1 TRB-1035 Clutch Lever

6 1 TRB-1041 Inner Side Plate

7 1 TRB-1042 Outer Side Plate

8 1 TRB-1043 Spacer Block

9 1 TRB-1044 Bearing Flg 3/8" ID x 1/2" OD x 1/4" LG

10 1 TRB-1046 3/8" Diameter Shaft

11 1 TRB-1047 Idler Gear Assembly

4

6

Page 13

TRB-1050 DRIVE SECTION

4

2

9

1

4

5

6

4

7

4

8

3

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-1550 Gear Motor 150:1

2 1 BUG-5122 Delrin Washer

3 2 FAS-0527 Soc Hd Cap Scr 8-32 x 3/4"

4 7 FAS-0925 Flt Hd Soc Scr 8-23 x 1/2"

5 1 SFX-1271 Dowel Pin .250" Dia. x .875"

6 1 TRB-1036 Motor Mount Angle

7 2 TRB-1037 Spacer .625" OD x 1.141" LG

8 1 TRB-1038 Clutch Bar

9 1 TRB-1039 Drive Pinion

14 11

Page 14

TRAC-BUG WIRING DIAGRAM

7

6

BLU

WHT/BLU

WHT/BLU

2

3

4

1

ORG

BLU

YEL

TAN

BLU

TAN

RED

BLU

CAS-1770

5

8

M

ELECTRICAL COMPONENT CHART

ITEM DESCRIPTION VOLTAGE

120 VAC 240 VAC 42 VAC

1 Power Cord BUG-9445 GOF-3115 BUG-9442

2 Circuit Breaker BUG-2923 BUG-2952 BUG-2933

3 Transformer BUG-5001 BUG-5002 BUG-5003

4 Volt Trap BUG-1393 BUG-1563 BUG-1393

5 Speed Control CAS-1770

6 Potentiometer w/knob BUG-9686

7 Toggle Sw., F-O-R BUG-2255

8 Gear Motor BUG-1550

15

Page 15

TRAC-BUG TRACK

TRB-1250 FRICTION TRACK 71" (1.8 m)

The TRB-1250 Friction Track is made of steel. The design allows the user

to join multiple sections together for long cuts. This track can only be used

for down-hand applications. The track sections weight 16 lbs. (7.3 kg) each.

7.00"

(178 mm)

6.00"

(152 mm)

.313"

(8 mm)

71.00"

(1800 mm)

16

Page 16

TRB-1160 RADIUS KIT INSTALLATION

The TRB-1160 Radius Kit enables the Trac-Bug to be quickly changed from

a straight line to a circle cutting machine.

Bolt TRB-1153 to the drive unit with the two bolts supplied.

Bolt TRB-1156 to the drive unit with the two bolts supplied. Insert magnet pivot

and rod to machine.

3

4

2

1

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 TRB-1153 Radius Riser Assembly

2 1 TRB-1156 Radius Block Assembly

3 1 GOF-3128 Rod

4 1 TRB-1165 Magnet Pivot Assembly

5 1 TRB-1155 Radius Arm Attachment (includes items 2, 3 and 4)

NOTE: TRB-1160 can be installed on 2012 models and later. Models from 2011

and earlier require additional machining. Consult the factory for instruction.

17

Page 17

TRB-1153 RADIUS RISER ASSEMBLY

1

5

4

3

Note: Thread lock both FAS-0654

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 2 FAS-0557 Soc Hd Cap 1/4-20 x 3/4

2 1 TRB-1154 Radius Riser Block

3 2 BUG-2841 Washer 5/8 OD x 5/16 ID

4 2 BUG-2012 Bearing

5 2 FAS-0654 Soc Hd Shr 5/16 x 3/8 x 1/4-20

2

18

Page 18

TRB-1155 RADIUS ARM ATTACHMENT

3

6

1

4

5

Note: Maintain approx. 1/8" gap

between GOF-3138 & BUG-9012

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 GOF-3128 Rod

2 1 TRB-1156 Radius Block Assembly

*3 1 GOF-3137 Pivot Point

*4 1 BUG-9012 Locking Collar

*5 2 BUG-2034 Teon Washer 3/4 OD x 3/8 ID x 1/16

*6 1 FAS-0359 Hex Hd Cap Scr 1/4-20 x 1"

*7 1 GOF-3138 Offset Link

*8 1 TRB-1159 Radius Arm Spacer

*9 1 TRB-1158 Sleeve

*10 1 GOF-3133 Magnet

2

7

8

9

10

*Items are part of TRB-1165 Magnet Pivot Assembly

19

Page 19

TROUBLESHOOTING GUIDE

PROBLEM CAUSE REMEDY

Does not run, No power to Check power line supply voltage.

indicator light off. machine. Plug in line cord rmly.

Does not run, Wiring shorts. Disconnect machine and

indicator light off. examine internally;

rewire at fault.

Circuit breaker

tripped. If none found, throw direction

switch to “OFF”, reset breaker

and plug in:

Shorted motor. If breaker does not trip, replace

drive unit.

Faulty speed If breaker trips again, replace

control board. control board.

(OR)

Burned out

transformer. Replace transformer.

Does not run, Bad connection. Check wining connections,

indicator light on. 12 VAC should appear

across secondary of transformer.

Tighten terminal screws on speed

control board.

Faulty speed If DC Volts = 0 across leads to

control board. motor; replace control board.

Unit runs, Faulty speed Replace control board.

but no control control board. (Check connection rst).

over speed.

NOTE: Make sure unit is plugged into correct voltage,

(120 VAC, 240 VAC, 42 VAC) corresponding to Model No. rating.

12 VAC should appear across secondary of transformer in all

TRAC-BUG Units.

20

Page 20

WARRANTY

Limited 3-Year

Warranty

For a period ending one (1) year from the date of invoice, Manufacturer warrants

that any new machine or part is free from defects in materials and workmanship and

Manufacturer agrees to repair or replace at its option, any defective part or machine.

HOWEVER, if the invoiced customer registers the Product Warranty by returning the

Warranty Registration Card supplied with the product within 90 days of the invoice

date, or by registering on-line at www.bugo.com, Manufacturer will extend the warranty period an additional two (2) years which will provide three (3) total years from

the date of original invoice to customer. This warranty does not apply to machines

which, after Manufacture’s inspection are determined by Manufacturer to have been

damaged due to neglect, abuse, overloading, accident or improper usage. All shipping and handling charges will be paid by the customer.

The foregoing express warranty is exclusive and Manufacturer makes no representation or warranty (either express or implied) other than as set forth expressly in

the preceding sentence. Specifically, Manufacturer makes no express or implied

warranty of merchantability or fitness for any particular purpose with respect to any

goods. Manufacturer shall not be subject to any other obligations or liabilities whatsoever with respect to machines or parts furnished by Manufacturer.

Manufacturer shall not in any event be liable to Distributor or any customer for any

loss of profits, incidental or consequential damages or special damages of any kind.

Distributor’s or customer’s sole and exclusive remedy against Manufacturer for any

breach of warranty, negligence, strict liability or any other claim relating to goods delivered pursuant hereto shall be for repair or replacement (at Manufacturer’s option)

of the machines or parts affected by such breach.

Model _____________________________

Serial No. __________________________

Date Purchased: ____________________

Where Purchased: ___________________

Distributor’s Warranty:

In no event shall Manufacturer be liable to Distributor or to any customer thereof for

any warranties, representations or promises, express or implied, extended by Distributor without the advance written consent of Manufacturer, including but not limited

to any and all warranties of merchantability or fitness for a particular purpose and

all warranties, representations or promises which exceed or are different from the

express limited warranty set forth above. Distributor agrees to indemnify and hold

Manufacturer harmless from any claim by a customer based upon any express or

implied warranty by Distributor which exceeds or differs from Manufacturer’s express

limited warranty set forth above.

HOW TO OBTAIN SERVICE:

If you think this machine is not operating properly, re-read the instruction manual

carefully, then call your Authorized BUG-O dealer/distributor. If they cannot give

you the necessary service, write or phone us to tell us exactly what difculty

you have experienced. BE SURE to mention the MODEL and SERIAL numbers.

21

Page 21

NOTES:

22

Loading...

Loading...