BUG-O Systems Modular Drive System User Manual

INSTRUCTIONS

AND

PARTS MANUAL

MODULAR DRIVE

SYSTEM

A DIVISION OF WELD TOOLING CORPORATION

280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA 15317-9564 USA

PHONE: 412-331-1776 http://www.bugo.com FAX: 412-331- 0383

Please record your equipment identication information below for future reference. This information can be

found on your machine nameplate.

Model Number:

Serial Number:

Date of Purchase:

Whenever you request replacement parts or information on this equipment, always supply the information

you have recorded above.

LIT-MDS-IPM-0215

Bug-O Systems is guided by honesty, integrity and

ethics in service to our customers and in all we do.

2

SAFETY

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY

QUALIFIED INDIVIDUALS.

EQUIPMENT DAMAGE

POSSIBLE.

ELECTRIC SHOCK can kill.

1) The equipment is not waterproof.

Using the unit in a wet environ-

ment may result in serious injury.

Do not touch equipment when wet

or standing in a wet location.

2) The unused connectors have

power on them. Always keep the

unused connectors covered with

the supplied protective panels.

Operation of the machine without

the protective panels may result in

injury.

3) Never open the equipment without

rst unplugging the power cord or

serious injury may result.

4) Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

5) Never remove or bypass the equip-

ment power cord ground. Verify the

equipment is grounded in accor-

dance with all applicable local and

national electrical safety codes. If

none exist, use International Electric

Code (IEC) 950.

READ INSTRUCTIONS.

Read the instruction manual before

installing and using the equipment.

1) Do not plug in the power cord without

rst verifying the equipment is OFF

and the cord input voltage is the same

as required by the machine or serious

damage may result.

2) Always verity both the pinion and

wheels are fully engaged before apply-

ing power or equipment damage may

occur.

3) Do not leave the equipment

unattended.

4) Remove from the work site and store in

a safe location when not in use.

1) Never try to stop the pinion from mov-

ing except by removing power or by

using the STOP control.

2) Do not remove any protective panels,

covers or guards and operate equip-

ment.

MOVING PARTS can

cause serious injury.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or

walk underneath equipment.

3

PRECAUTIONS:

1) Some plasma or welding cables are strong sources of high frequency interference.

NEVER lay a plasma or welding cable across the controls of the machine.

2) Always physically separate the plasma or welding cable leads from the machine

cables. For example, the plasma or welding cable leads should NEVER be bundled

with a pendant cable or the machine power cord. Maximize the separation between

any machine cables and the plasma or welding cables.

3) Strictly follow the grounding procedures specied for the plasma or welding unit.

NOTE: Some plasma and welding units produce exceptionally large amounts of high

frequency noise. They may require a grounding rod be driven into the earth within six

feet (2 meters) of the plasma or welding unit to become compatible with an automatic

cutting or welding process.

4) If the high frequency is produced using a spark gap, adjust the points so the gap is as

small as possible. The larger the gap, the higher the voltage and the higher the

interference.

5) Some plasma or welding units will inject high frequency interference into the AC

power line. Use separate power line branches whenever possible to power the

plasma or welding source and the machine. Do not plug them into the same outlet box.

6) High frequency noise may enter the machine through the plasma or welding supply

remote contactor leads. Some plasma and welding sources can produce noise spikes

of up to several thousand volts. These sources are not compatible with automated

cutting and welding equipment. It is recommended that the remote contactor leads on

these plasma or welding sources not be connected to the machine. An alternate

solution is to purchase a separate remote contactor isolation box.

HIGH FREQUENCY WARNINGS

WARNING: HIGH FREQUENCY CAN EFFECT MACHINE

OPERATION AND THEREFORE, WELD QUALITY.

SPECIAL PRECAUTIONS ARE REQUIRED WHEN USING PLASMA,

TIG OR ANY WELDING PROCESS THAT USES HIGH FREQUENCY TO

STRIKE AN ARC.

Read the precautions below before installing and using the equipment.

4

5.............. Introduction / Standard Features

6.............. Additional Features

7.............. Setup

8.............. Master Drive Unit / Technical Data / Dimensions

9 ........... MPD-1000 Master Drive Unit / Exploded View / Parts List

10 ......... Master Drive Unit / Wiring Diagram

11 ......... AC Power Wiring Diagram / Electrical Component Chart

12 ......... Signal Wiring / Parts List

13............ Modules / Technical Data / Dimensions

14 ......... MDS-1002 Straight Module

15-16 ... MDS-1003 Stitch Module

17 ......... MDS-1004 Programmable Module

18-19 ... MDS-1005 / MDS-1005-DIAL / Weaver Control Modules

20 ......... MDS-1005 / MDS-1005-DIAL / Weaver Control Module Replacement Parts

21 ......... Digital Readout Calibration

22............ WPD-1000 Linear Weaver / Introduction / Features

23 ......... Linear Weaver / Technical Data / Dimensions

24-25 ... Linear Weaver / Setup

26 ......... WPD-1100 Linear Weaver / Exploded View

27 ......... WPD-1100 Linear Weaver / Parts List

28............ WPD-2100 Pendulum Weaver II / Introduction / Features

29-30 ... Pendulum Weaver II / Installation / Setup and Alignment

31 ......... Pendulum Weaver II / Technical Data / Dimensions

32 ......... WPD-2100 Pendulum Weaver II / Exploded View / Parts List

33 ......... WPD-2120 Pendulum Weaver II / Electronics / Exploded View / Parts List

34 ......... WPD-2115 Pendulum Gear Box / Exploded View

35............ Weaver Unit / Wiring Diagram

36............ Carriages

37............ Detailed Setup

38............ MDS-1055 Universal Limit Kit

39............ MDS-1060-_ Remote Control Cable

39............ CAS-__ Automatic Height Control

40............ Accessories

41............ Aluminum Rigid Rail

42............ Semi Flex Rail

43............ Hi-Flex Rail

44............ Standard Magnet Assemblies

45-46 ...... Vacuum Support Kit

47-56 ...... Troubleshooting Guide

57............ Warranty

TABLE OF CONTENTS

MODULAR DRIVE SYSTEM

INSTRUCTIONS AND PARTS MANUAL

PAGE

5

The Modular Drive System is the only product in the industry that allows the user to custom congure one

machine for various applications. The system consists of drives, plug-in control modules and carriages

that are easily assembled. The modular design allows the operator to quickly upgrade or recongure the

machine for straight line cutting and welding, stitch welding or weave welding. The system will run in any

position using Aluminum Rigid Rail, Aluminum Semi-Flex Rail [with a minimum radius of 15' (4.57 m)], Bent

Rigid Rail or Hi-Flex Rail [with a minimum radius of 40" (1 m)].

The straight line cutting and welding conguration consists of a carriage, master drive, racking group and

control module. The optional MDS-1060-10 Remote Control Cable can be used to remote the control

module.

A number of straight line control modules are available. The MDS-1002 Straight Line Module provides

simple direction and speed control for continuous cutting or welding. The MDS-1003 Stitch Module provides

a straight line and stitch welding mode with skip time, weld time and crater/puddle buildup time. The MDS-

1004 Programmable Stitch Module provides digital display of all stitch welding parameters. The MDS-1004

Stitch Module has closed position feedback so all distances are set in inches or mm as opposed to time and

are repeatable. The MDS-1055 Universal Limit Kit adds cycler, stop at limit and rapid return functions to the

MDS-1002 and MDS-1003 modules. The MDS-1004 Programmable Module has built in stop at limit and

rapid return modes. For more features, see the appropriate pages on each of the modules.

The Master Drive is rated at 60 lbs (27 kg) vertical load. (International Robotics Standards Rating)** The

machine is equipped with overload protection.

STANDARD FEATURES

The Master Drive Unit incorporates the following standard internal features:

• High torque, low inertia motor for precise stops and starts.

• Dedicated fail-safe brake with three times the stopping and holding power of the motor.

• Motor overload protection which turns off the motor and engages the brake when excessive load is

placed on the machine.

• Closed loop speed control for adjustable and repeatable control of critical welding or cutting parameters.

• Closed loop position control to prevent position creep when the machine stops to perform an operation

such as crater ll at the end of a stitch weld.

**The International Robotics Standards Rating requires a minimum of 2:1 continuous-duty safety margin on

all power train and electronics components.

INTRODUCTION

6

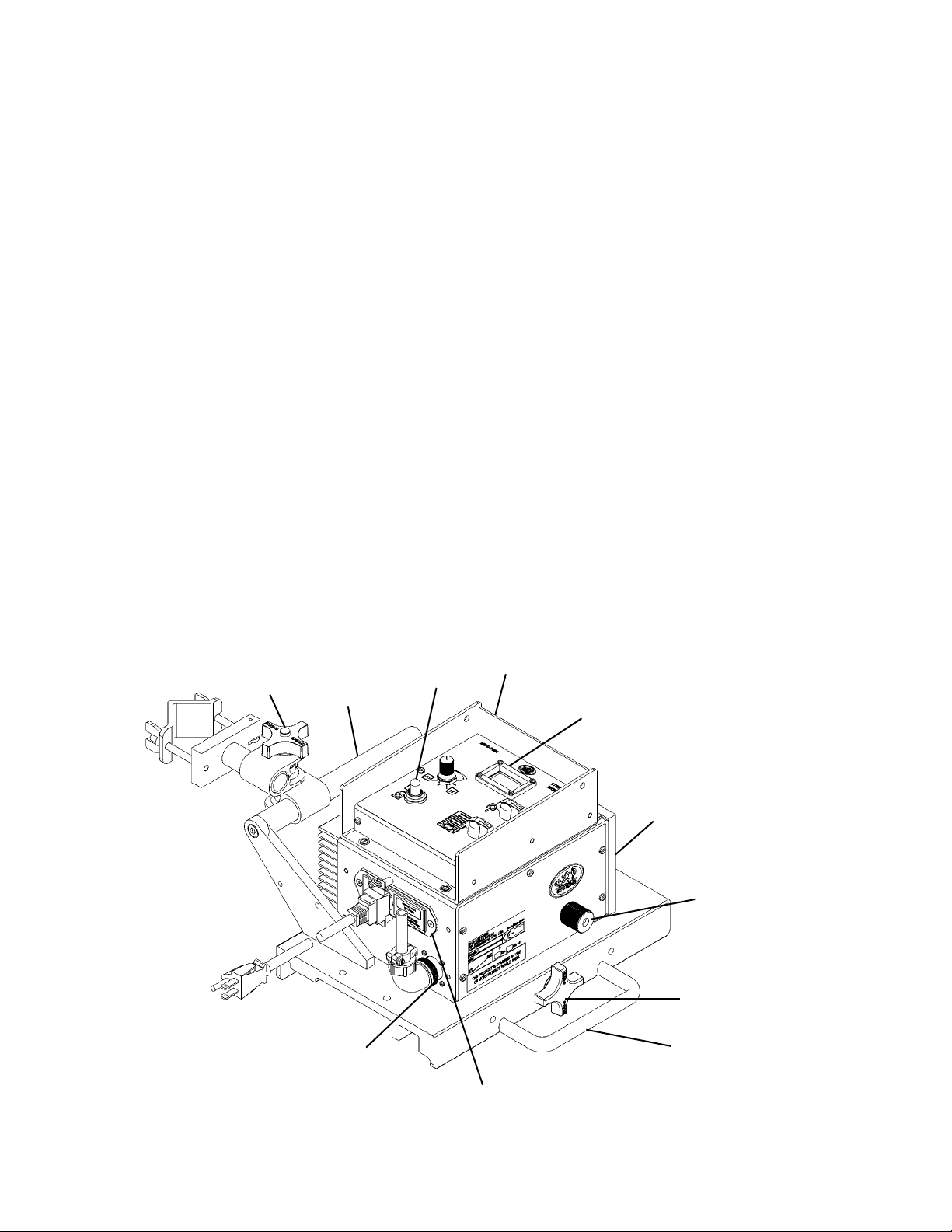

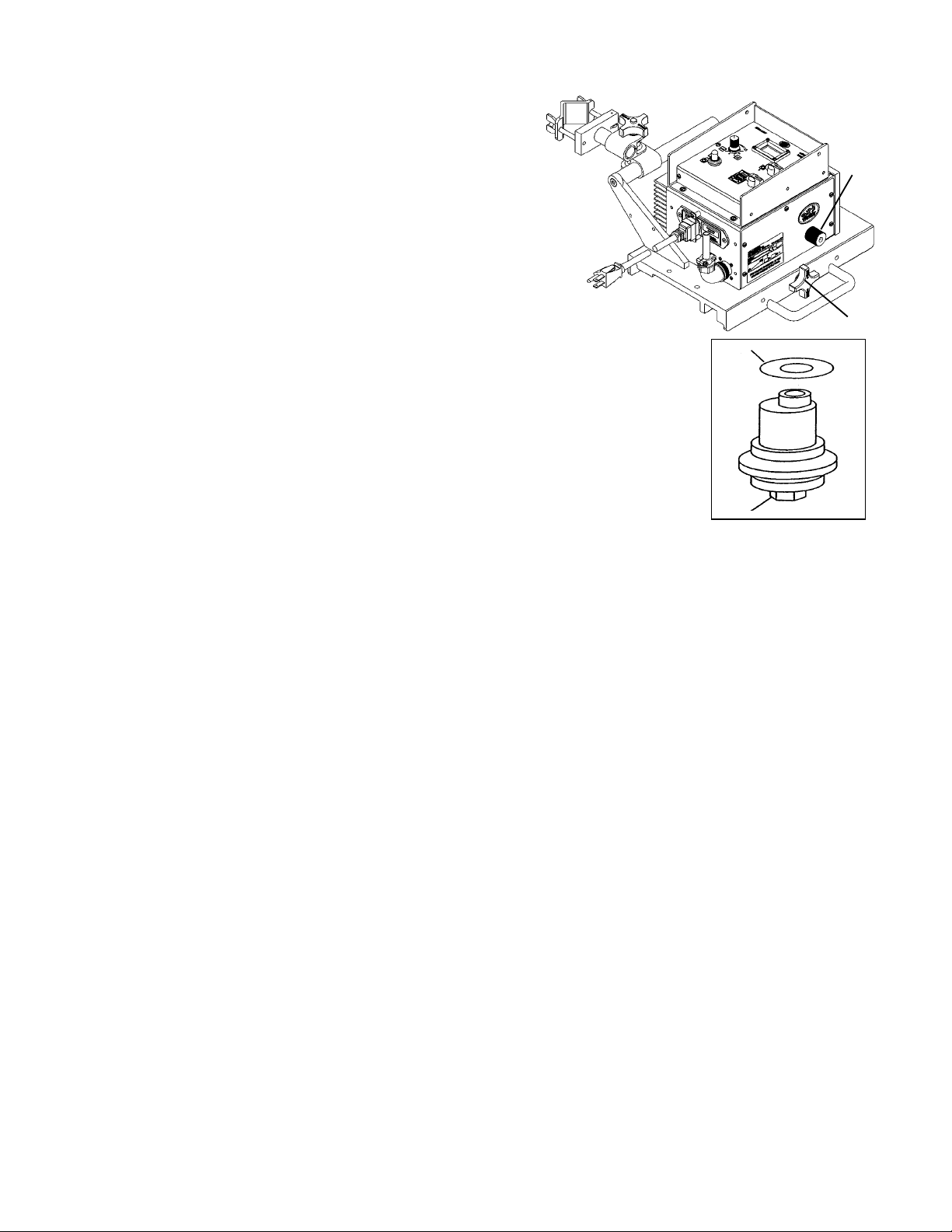

1. Control Module that is easily remoted or changed.

2. Master Power Drive Module that is recongurable by the user, for different applications, by

adding or changing mating modules and accessories.

3. Clutch, to enable rapid manual repositioning of the carriage anywhere on the track.

4. Wheel engagement knob, which enables placement of the releasable carriage anywhere on

the track.

5. Optional cable mounting bar with anchor clamp to keep the welding cables and contact wires

away from the work surface.

6. Contactor ON/OFF switch.

7. Power Entry Box with:

a) Input Power Fuse

b) Machine ON/OFF Switch

c) Power Cord Mating Connector

8. Standard Carrying Handle.

9. Digital speed readout for more repeatable welding/cutting.

10. Optional Carrying Handle and Mounting Bar.

11. Remote Weld Contactor Receptacle.

ADDITIONAL FEATURES

5

10

6

1

9

2

3

4

8

11

7

7

1) WHEEL ADJUSTMENT AND ALIGNMENT

Always check for proper carriage wheel adjustment before

using the machine. Turn the wheel engagement knob (A)

on the side of the carriage until the wheels are fully moved

towards the center of the carriage (engaged). Then rotate

the master drive clutch knob (B) fully counter clockwise to

disengage the drive pinion. Slide the carriage onto the end of

a track. The wheels should slide into the track V-grooves and

the carriage will move smoothly along the track if the wheels

are properly aligned.

The wheels along one side of the carriage have stainless steel shim wash-

ers (C) underneath. These wheels are adjustable. Readjust these wheels (if

necessary) by rotating the hex bolt (D) with a 1/2" wrench.

Grasp the sides of the carriage. The wheels are too loose if it is possible to

move the carriage from side to side or up and down. Use a nger to keep one

of the adjustable wheels from rotating as the carriage is manually pushed

along the track. The wheels are adjusted too tight if rm nger pressure is not

enough to prevent wheel rotation. Repeat the process for the other adjustable

wheel.

2) POSITIONING THE MACHINE ON THE TRACK

Position the rail using magnet plates or vacuum cups. Wipe the track grooves free of weld splatter and other

debris. This will prevent binding and premature rail and wheel wear. Lubricate the rack using a dry spray, if

desired, for extended track life.

Turn the wheel engagement knob (A) on the side of the carriage fully counter clockwise to disengage the

wheels. Then rotate the Master Drive clutch knob (B) fully counter clockwise to disengage the drive pinion.

The carriage can now be placed anywhere on the track. Turn the wheel engagement knob (A) clockwise

to engage the wheels rmly in the V-grooves. Verify all four wheels are in the grooves. Manually move the

carriage along the track to verify the motion is smooth and the wheel alignment is correct. Rotate the Master

Drive clutch knob (B) fully clockwise while gently rocking the machine forward and backward to fully engage

the drive pinion. The rocking motion is necessary to help insure proper gear mesh.

SETUP

C

D

B

A

3) REMOTE CONTACTOR WIRING

Connect the remote weld contactor to the welding source as shown below:

Pins A and B ................. connection for Output #1

Pins C and D ................ connection for Output #2

5) MACHINE OPERATION

Turn the main power ON at the power entry box. Set parameters on control module in use.

4) GUN AND TORCH SETUP

For welding, insert the welding gun into the all-position clamp on the rack. Adjust the clamp, the clamp block

and the rack to position the gun for welding. Connect the weld contactor connector to the rear of the main

drive unit. Route the welding cable and weld contactor wires through the cable anchor clamp.

For cutting, insert the cutting torch into the torchholder on the rack. Adjust the torchholder, the clamp block

and the rack to position the torch for cutting. Connect the hose assembly to the manifold and the cutting

torch. The manifold acts as a strain relief on the supply hoses as well as a quick shut-off valve for the gases.

Once the torch valves are adjusted, the manifold eliminates the need for continuous adjustments and keeps

the supply lines from dragging the torch out of position.

8

CAUTION: The Speed Control Card in the Master Drive is NOT interchangeable

with the speed card in the Linear or Pendulum Weavers.

Power Requirements:

Part Number Voltage / Hz Amps

MPD-1000 120 VAC/50-60 Hz 2A

MPD-1002 240 VAC/50-60 Hz 3A

MPD-1004 42 VAC/50-60 Hz 6A

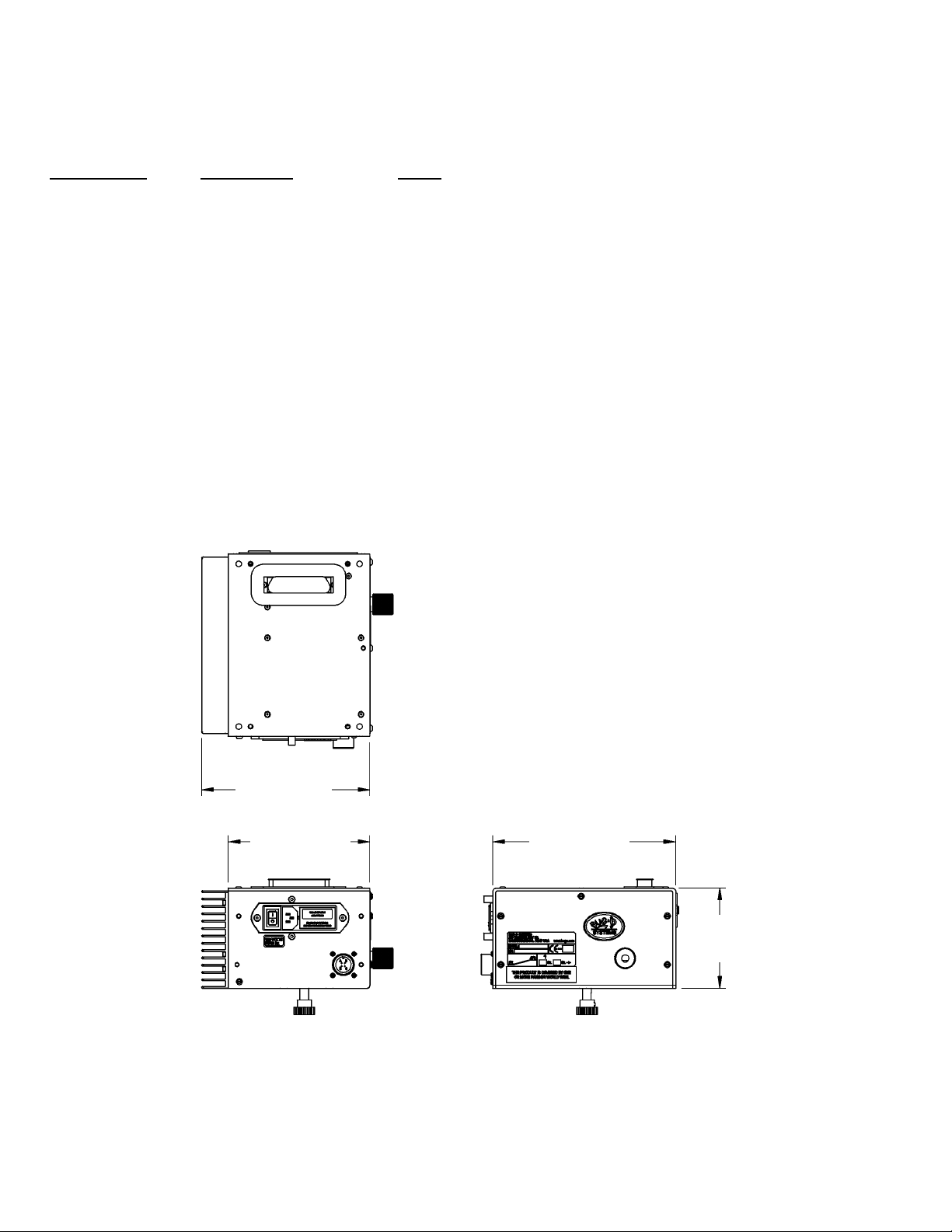

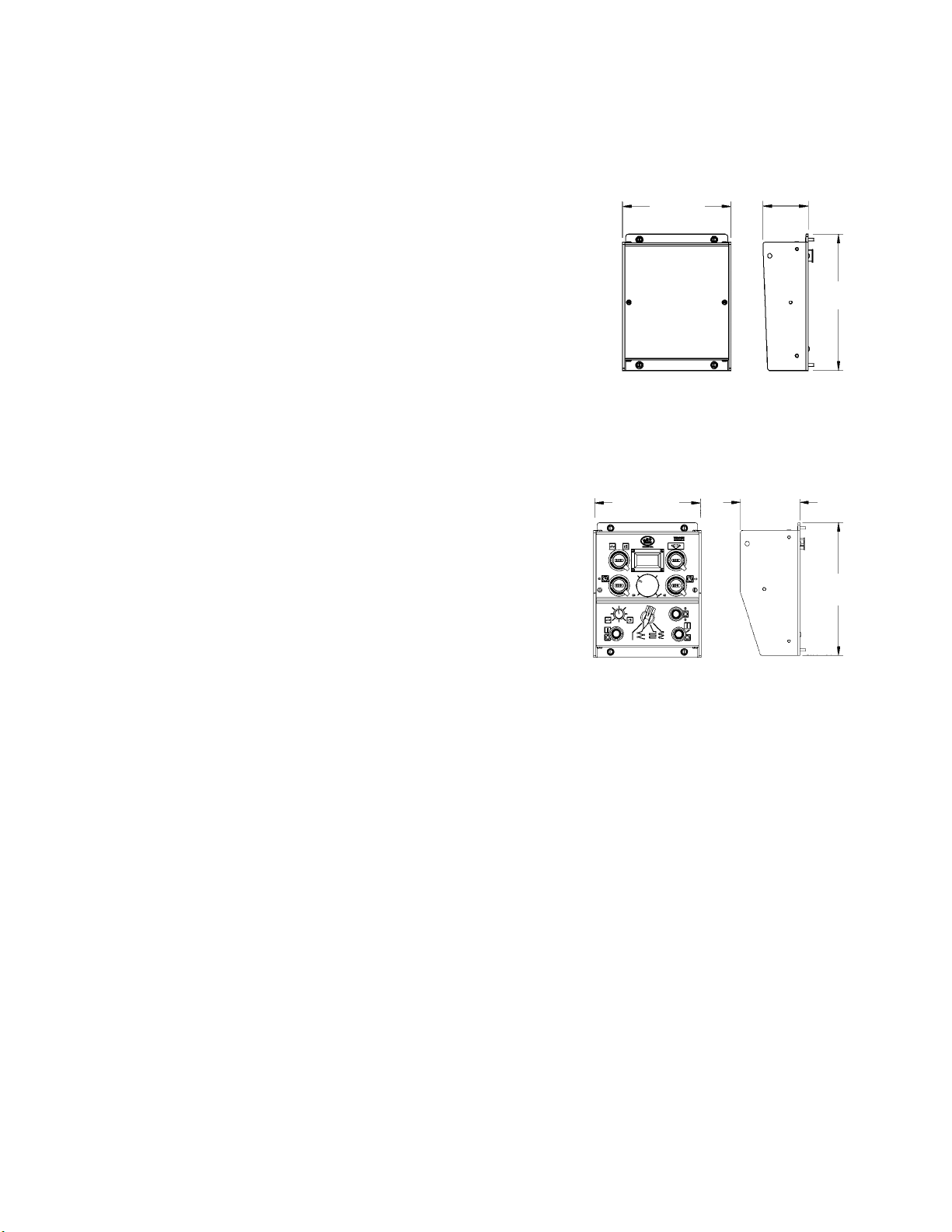

Dimensions: 7.75" L x 6.00" W x 4.25" H

(197 x 152 x 108 mm)

Load Capacity: Vertical - 60 lbs (27 kg) [International Robotics Standards Rating]**

Horizontal - 100 lbs (45 kg)

Speed Range: 2-120 in/min (51-3048 mm/min)

Net Weight: 10 lbs (4.5 kg)

Shipping Weight: 13 lbs (5.9 kg)

MASTER DRIVE UNIT / TECHNICAL DATA

** The Master Drive is rated at 60 lbs (27 kg) vertical load. The International Robotics Standards

Rating requires a minimum of 2:1 continuous-duty safety margin on all power train and electronics

components. The machine is equipped with overload protection.

DIMENSIONS

7.13

(181 mm)

7.75

(197 mm)

4.25

(108 mm)

6.00

(152 mm)

9

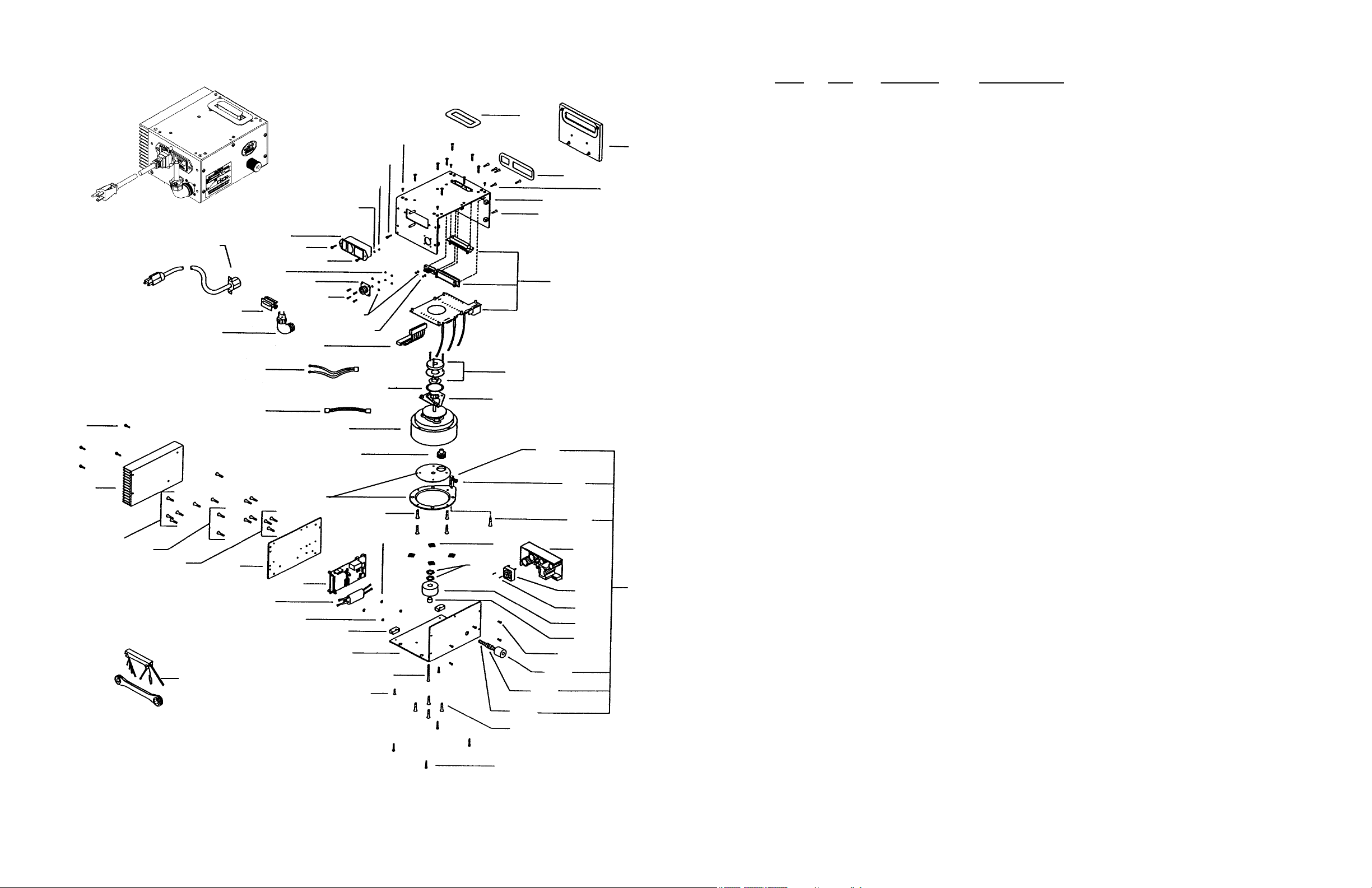

MPD-1000 MASTER DRIVE UNIT / EXPLODED VIEW / PARTS LIST

20

6

15

54

41

11

12

14

1

21

45

46

11

44

10

43

51

55

52

2

39

14

53

4

38

40

30

19

28

13

54

32

35

34

29

50

16

31

25

5

47

18

6

33

36

37

13

11

17

26

27

15

24

49

22

9

10

3

11

23

7

48

42

8

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-1034 Panel Connector, 4-T, Male

2 1 WPD-1013 Rubber Ring Gasket

3 1 BUG-9444 Tool Kit

4 4 FAS-0104 Pan Hd Screw 4-40 x 318 Lg

5 2 FAS-0107 Pan Hd Screw 4-40 x 3/4 Lg

6 6 FAS-0114 Pan Hd Screw 6-32 x 3/8 Lg

7 4 FAS-0504 Soc Hd Cap Scr 4-40 x 3/8 Lg

8 4 FAS-0557 Soc Hd Cap Scr 1/4-20 x 3/4 Lg

9 3 FAS-0902 Fit Hd Soc Scr 4-40 x 1/4 Lg

10 19 FAS-0905 Fit Hd Soc Scr 4-40 x 1/2 Lg

11 11 FAS-0914 Fit Hd Soc Scr 6-32 x 3/8 Lg

12 1 FAS-0915 Fit Hd Soc Scr 6-32 x 1/2 Lg

13 8 FAS-0923 Fit Hd Soc Scr 8-32 x 5/16 Lg

14 6 FAS-1305 Hex Nut 4-40

15 3 FAS-1310 Hex Nut 6-32

16 2 FAS-1325 Hex Nut 8-32 Nylon

17 1 FAS-2823 Fit Hd Sit Scr 8-32 x 1 1/2 Lg

18 1 GOF-3012 Spacer 1/2 OD x 5/16 Lg

19 1 GOF-3014 Pinion

20 4 MDS-1019 Snap Rivet, Black

*21 1 BUG-9454 V-Lock Cord 120VAC

22 1 MPD-1006 Side Panel

23 1 MPD-1007 Heat Sink

24 1 MPD-1008 Filter

25 1 MPD-1009 Fan Assembly

26 1 MPD-1011 Base Panel

27 2 MPD-1012 Mounting Block

28 1 MPD-1090 Matched Clutch Plts

**29 1 BUG-2593 Glide Flat

30 1 MPD-1015 Gear Motor (60:1)

31 1 MPD-1016 Clutch Assembly (Includes items 32 through 37)

32 1 BUG-1216 Ball Joint

33 1 BUG-1857 Knob

34 1 FAS-0945 Fit Hd Soc Scr 10-32 x 1/2 Lg

35 1 FAS-1341 Hex Jam Nut 10-32

36 2 FAS-1390 Hex Nut 3/8-16

37 1 MPD-1017 3/8-16 Threaded Stud

38 1 MPD-1018 Wiring Harness-Speed Board to Motor

39 1 MPD-1019 Wiring Harness-Interconnect to Speed Bd/Control

40 1 MPD-1020 Wiring Harness-Interconnect to Speed Bd/Power

41 1 MPD-1025 Power Entry Module

* 42 1 MPD-1067 Fuse 6A

43 1 MPD-1029 Connector Cover Plate

44 1 MPD-1031 Cover Panel (Includes item #20)

45 1 MPD-1038 Gasket for 50-Pin Connector

46 1 MPD-1039 Gasket for 50-Pin/3-Pin Connector

47 1 MPD-1042 Inductor, Potted-with Connectors

48 1 MUG-1617 Cable Connector, 4-T, Female, Elbow

*49 1 PCB-1000 Speed Board

* 50 1 PCB-1005-120 Power Supply Assembly 165W 120VAC

51 1 PCB-1010 Interconnect Board

52 1 PCB-1012 Position Card

53 6 WAS-0201 #4 Internal Star Lockwasher

54 3 WAS-0211 #6 Internal Star Lockwasher

55 1 WPD-1012 Brake Assembly

* See Electrical Component Chart for 240 VAC and 42 VAC Part Numbers

**Included in Item 28.

CAUTION: The Speed Control Card in the Master Drive is NOT interchangeable with the speed card in the Linear or Pendulum Weavers.

10

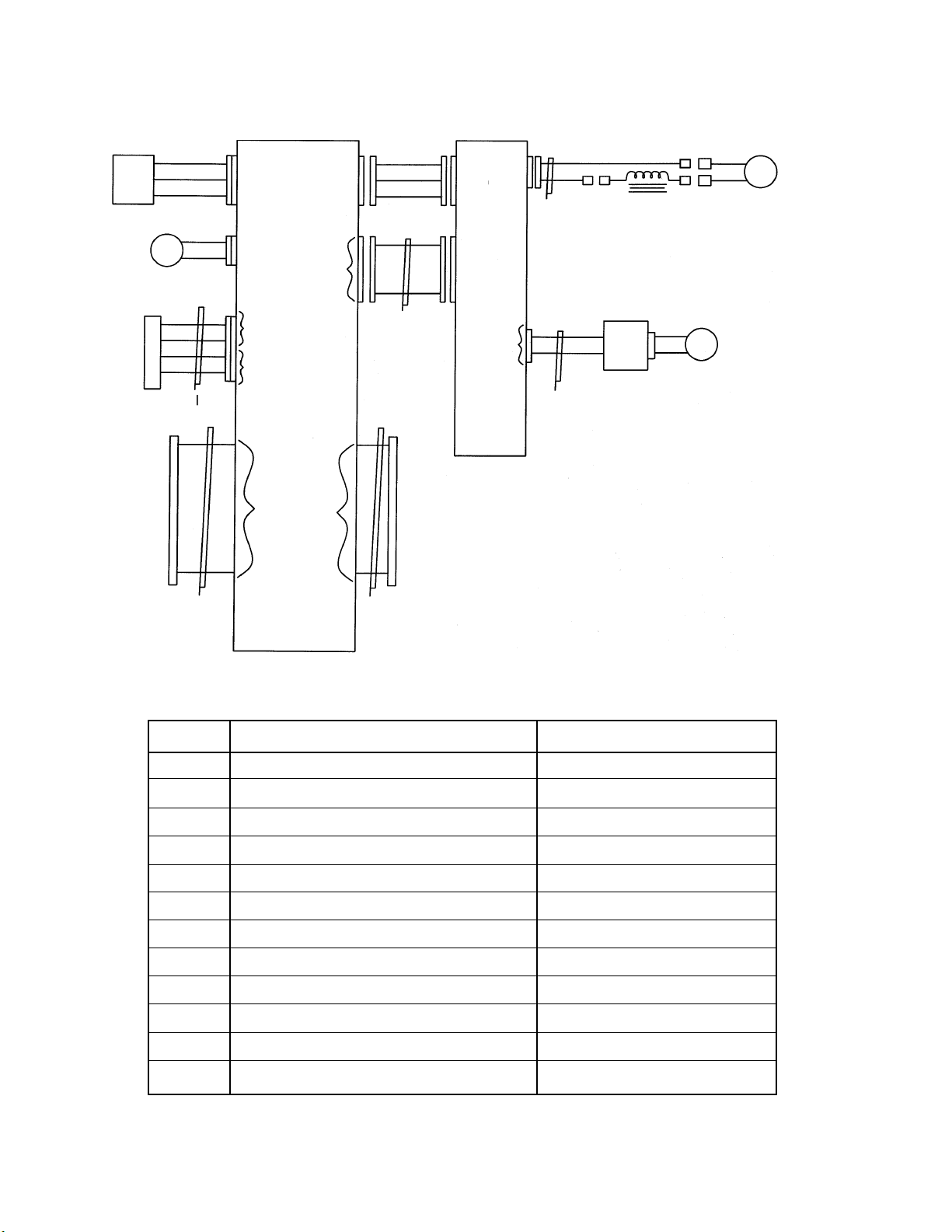

MASTER DRIVE WIRING DIAGRAM MPD-1000/ MPD-1002/ MPD-1004

NOTES:

Encoder card and brake are mounted on the motor.

18 pin connectors are not wired 1:1.

The Connector on one end is ipped.

For example, Pin 1 goes to connector 18.

Most signals on the 50 pin connector come in one 50 pin connector

and exit on the other 50 pin connector.

Pinouts for connectors can be determined from screen print.

120V AND 240V WIRING ONLY

SEE FIGURE 1 FOR 42V WIRING

11

AC POWER WIRING DIAGRAM

PEM

BLK

RFI

RED

GRN

GRN

PC

J1

AC

POWER

OUT

BLK

RED

RED BLK

115 VAC

&

240 VAC

BLK

RED

42 VAC

BLK BLU

RED

BLU

PS PS

BLU

DC OUT

DC OUT

ELECTRICAL COMPONENT CHART

MPD-1000 MPD-1002 MPD-1004

ITEM DESCRIPTION 120 VAC 240 VAC 42 VAC

F1,F2* Fuses (2) MPD-1067 6A (2) MPD-1067 6A (2) MPD-1067 6A

PC Power Cord MPD-1030 MPD-1032 MPD-1034

PS Power Supply PCB-1005-120 PCB-1005-240 PCB-1005-42

J1 Connector w/Pins MPD-1021 MPD-1021 MPD-1021

PEM Power Entry Module MPD-1025 MPD-1025 MPD-1025

RFI Filter Module MPD-1008 MPD-1008 MPD-1008

PART NO.

FUSE BOX

F1

*F2

*F2 replaced with bus wire on 120 VAC

12

SIGNAL WIRING

PS

WHT/RED

WHT/BLK

WHT/OR

WHT/RED

WHT/BLK

WHT/OR

+ 15 V

GND

- 15 V

+ 15 V

GND

- 15 V

F

RED

BLK

CONTACT

A

PUR

PUR

YEL

YEL

A

B

C

D

1

2

3

4

CI

CONTACT

B

MOTOR

OUT

CK

CHOKE

GEAR

MOTOR

M

RED

BLK

INPUTS

OUTPUTS

FROM

CONTROL

MODULE

50 LINE

RIBBON

INTERCONNECT

PCB 1

50 LINE

RIBBON

TO

OSCILLATOR

OR

ACCESSORIES

POSITION

IN AND

BRAKE

OUT

SPEED

CONTROL

PCB 2

18 LINE

C3

C4

PCB 3

10 LINE

RIBBON

B

POSITION

BRAKE

FAN +

FAN -

SPEED

CARD

SIGNALS

C2

ITEM DESCRIPTION PART NO.

B Brake Assembly WPD-1012

Cl Contactor Cable Assembly MPD-1036

C2 DC Power Cable Assembly MPD-1020

C3 Speed Card Cable Assembly MPD-1019

C4 Motor Wiring MPD-1018

CK Inductor Pot Assembly (Choke) MPD-1042

F Fan Assembly MPD-1009

M Gear Motor MPD-1015

PCB1 Interconnect Card PCB-1010

PCB2 Tractor Speed Card PCB-1000

PCB3 Position Sensor Card PCB-1012

PS Power Supply (see AC Wiring Diagram)

PARTS LIST

13

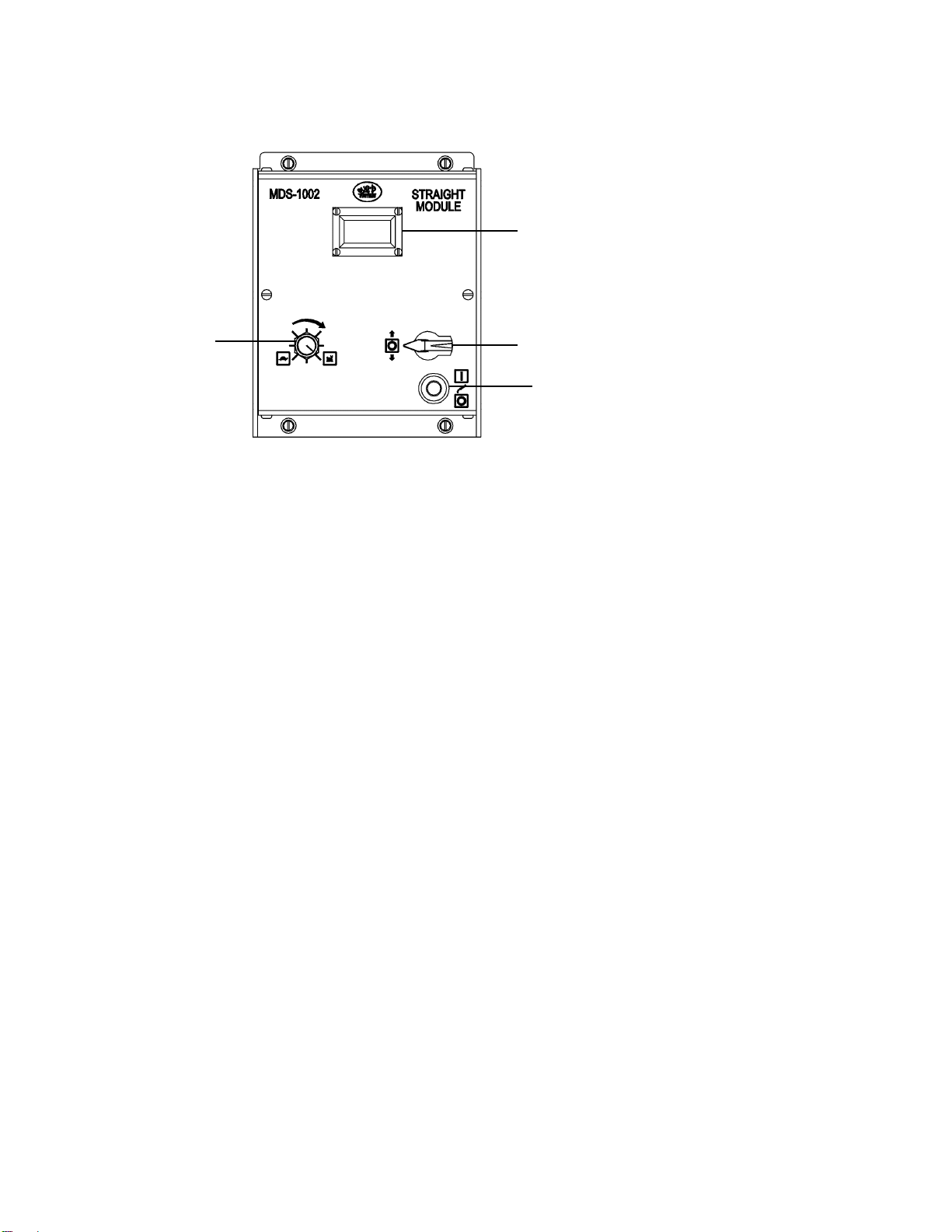

MDS-1002 STRAIGHT LINE MODULE

MDS-1003 STITCH MODULE

MDS-1004 PROGRAMMABLE MODULE

MDS-1005 WEAVER CONTROL MODULE

Dimensions: 7.50" L x 6.00" W x 2.50" H

(191 x 152 x 64 mm)

Net Weight: 1.75 lbs (0.8 kg)

Shipping Weight: 3.0 lbs (1.4 kg)

MODULES / TECHNICAL DATA

DIMENSIONS

2.50"

(64 mm)

MDS-1002

MDS-1003

MDS-1004

MDS-1005

6.00"

(152 mm)

7.50"

(191 mm)

6.00"

(152 mm)

3.38"

(86 mm)

7.50"

(191 mm)

MDS-1005-DIAL WEAVER CONTROL MODULE

Dimensions: 7.50" L x 6.00" W x 3.38" H

(191 x 152 x 86 mm)

Net Weight: 3 lbs (1.4 kg)

Shipping Weight: 8 lbs ( 3.63 kg)

Dial Weaver Control Module

14

SPEED CONTROL: Sets the tractor speed from 2-120 in/min (5.1-304.8 cm/min).

CARRIAGE TRAVEL SWITCH: Provides FORWARD/STOP/REVERSE direction control.

Stop at limit in direction of travel & Cycle between limits can be controlled

with the installation of the MDS-1055 Universal Limit Kit. (Ref to pg. 38)

DIGITAL READOUT: The display is dual function.

a) PRESET SPEED - Displayed when the CARRIAGE TRAVEL SWITCH is OFF or motion

is halted by a motor overload condition.

b) MEASURED SPEED - Displayed when power is applied to the motor.

(This will be the same as the Preset Speed.)

Factory settings of 120 Volt machines are set to in/min, 240 and 42 Volt machines are set cm/min.

WELD CONTACT: Opens/closes a pair of independent 1 Amp contacts (pins A & B and C & D) at the weld

contactor receptacle.

NOTE: A safety interlock will automatically open the weld contacts if the motor overload protection halts ma-

chine motion. Clear the overload by turning the carriage travel switch to OFF. Resetting the overload

fault will not cause the contacts to automatically reclose. Use the weld contact switch to restart the

welder plasma unit after clearing the overload.

REPLACEMENT POTS AND SWITCHES

CARRIAGE TRAVEL:

Switch and Spacer MDS-1112

Black Pointer Knob BUG-9694

SPEED CONTROL:

10 K Ω Pot, 3-3/4 turn PCB-1026

Black Knob MDS-1018

Knob Seal Nut MDS-1046

WELD CONTACT:

Switch and Spacer MDS-1115

Toggle Switch Boot MDS-1047

MDS-1002 STRAIGHT MODULE

The MDS-1002 Straight Module provides direction and speed control for continuous cutting or welding.

CARRIAGE TRAVEL SWITCH

WELD CONTACT

(PLASMA)

DIGITAL READOUT

SPEED CONTROL

15

SPEED CONTROL: Sets the tractor weld speed from 2-120 in/min (5.1-304.8 cm/min).

CARRIAGE TRAVEL SWITCH: Provides FORWARD/STOP/REVERSE direction control.

DIGITAL READOUT: The display is dual function.

a) PRESET SPEED - Displayed when the CARRIAGE TRAVEL SWITCH is OFF

or motion is halted by a motor overload condition.

b) MEASURED SPEED - Displayed when power is applied to the motor. (This will

be the same as the Preset Speed.)

Factory settings of 120 Volt machines are set to in/min, 240 and 42 Volt machines are set cm/min.

WELD CONTACT: Opens/closes a pair of independent 1 Amp contacts (pins A & B and C & D) at the

weld contactor receptacle. In STITCH mode, this switch acts as a weld contact en-

able and the stitch module cycles the contacts on and off.

NOTE: A safety interlock will automatically open the weld contacts if the motor overload protection halts

machine motion. Clear the overload by turning the carriage travel switch to OFF. Resetting the

overload fault will not cause the contacts to automatically reclose. Use the weld contact switch to

restart the welder after clearing the overload.

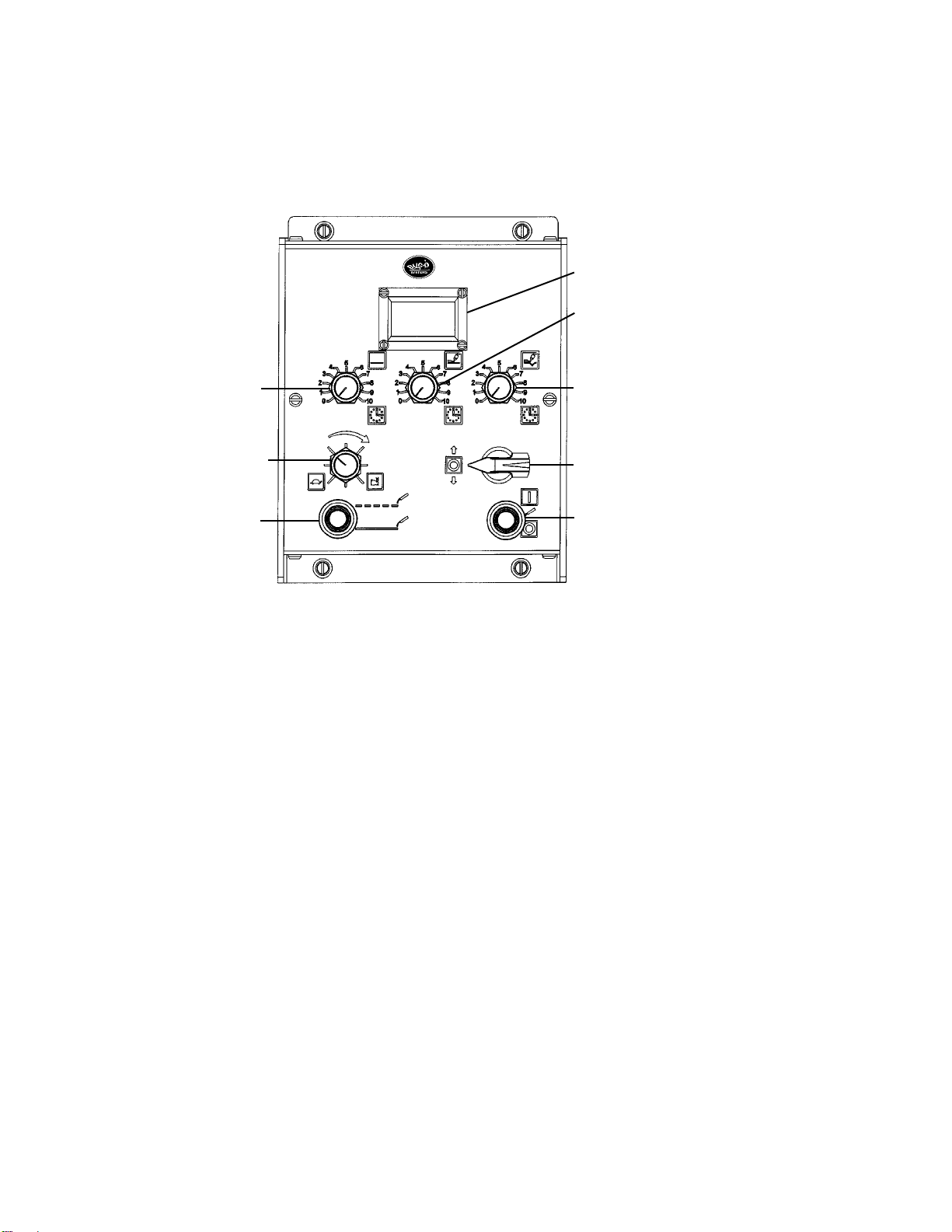

MDS-1003 STITCH MODULE

The MDS-1003 Stitch Module provides direction and speed control for continuous welding and cutting. In

addition, a stitch welding mode is provided, with adjustments for skip time (welder off), weld on time and

puddle buildup/crater ll time.

DIGITAL READOUT

WELD TIME

PUDDLE BUILDUP/CRATER FILL TIME

WELD CONTACT

(PLASMA)

CARRIAGE TRAVEL SWITCH

SKIP TIME

SPEED CONTROL

MODE

MDS-1003

STITCH MODULE

16

STITCH/CONTINUOUS: Selects between cyclic (Stitch) welding and continuous welding or cutting.

a) CONTINUOUS - Selects continuous welding or cutting.

b) STITCH - Selects the cyclic (Stitch) welding mode. This mode consists of four continuously repeated steps.

1) The machine stops moving for the selected time to perform Puddle

Buildup. (PIERCE WHEN PLASMA CUTTING)

2) The machine welds at the selected welding speed for the time selected

using the Weld Time control.

3) The machine stops moving for the selected time to perform Crater Fill.

4) The machine turns off the welder and moves at maximum speed to

where the next weld needs performed. This location is determined by

setting a Skip Time control.

WELD TIME: This control functions only when the mode switch is set to Stitch. Weld time sets a weld

length time from 1-50 seconds. This corresponds to a weld length of approximately 0.03-100 inches (0.8-

2540 mm). NOTE: The operator must manually enable the weld contactor by turning on the Weld Contact

or the welder will never cycle on and off.

SKIP TIME: This control functions only when the mode switch is set to Stitch. Skip time sets how long the

machine travels between welds (0.3-15 seconds). This corresponds with a skip length of approximately 0.6-

30 inches (15-762 mm). The machine always moves between welds at maximum speed.

PUDDLE BUILDUP / CRATER FILL TIME: This control functions only when the mode switch is set to

Stitch. Puddle Buildup/Crater Fill Time sets the time the machine is stopped at the beginning and end of

every weld (0-1.5 sec).

REPLACEMENT POTS AND SWITCHES

WELD CONTACT: CARRIAGE TRAVEL SWITCH:

Switch and Spacer MDS-1116 Switch and Spacer MDS-1112

Toggle Switch Boot MDS-1047 Black Pointer Knob BUG-9694

PUDDLE BUILDUP/CRATER FILL TIME: WELD TIME:

500K Ω Pot, 3/4 turn MDS-1053 500K Ω Pot, 3/4 turn MDS-1053

Black Knob MDS-1018 Black Knob MDS-1018

Knob Seal Nut MDS-1046 Knob Seal Nut MDS-1046

SKIP TIME: SPEED CONTROL:

500K Ω Pot, 3/4 turn MDS-1053 10K Ω Pot, 3 turn PCB-1026

Black Knob MDS-1018 Black Knob MDS-1018

Knob Seal Nut MDS-1046 Shaft Seal Nut MDS-1046

MODE:

Switch and Spacer MDS-1115

Toggle Switch Boot MDS-1047

MDS-1003 STITCH MODULE, CONT’D.

17

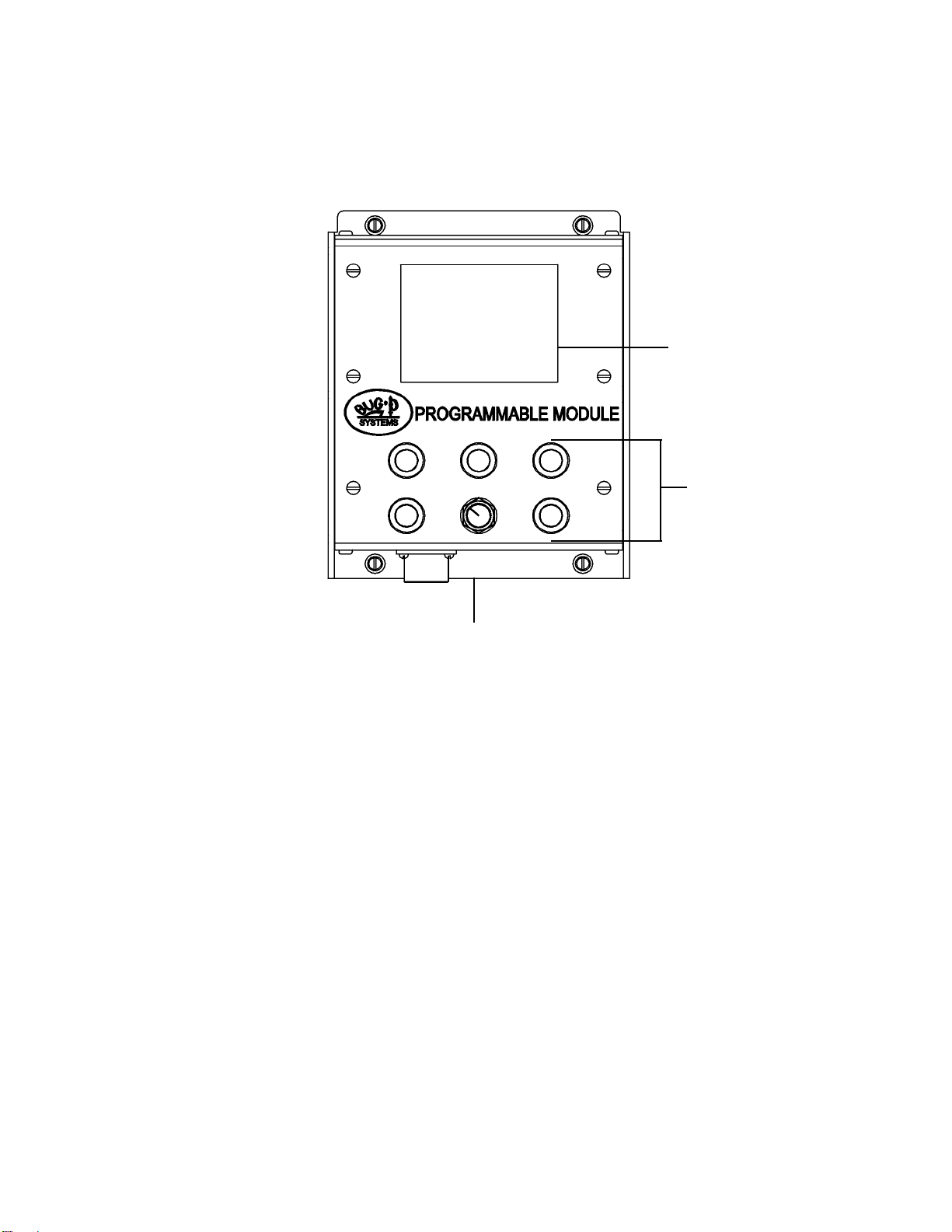

MDS-1004 PROGRAMMABLE MODULE

The MDS-1004 PROGRAMMABLE MODULE provides stitch controls for welding or cutting with the Modular

Drive System. All stitching parameters are set and displayed on a graphic screen. This allows each setting

to be set exactly the same every time. See MDS-1004 Manual for detailed instructions.

FEATURES

• Each stitch setting is displayed while being set. This allows each setting to be exactly set each time

a job is set up.

• Closed loop encoder feedback is employed to ensure the traveled distances match the set distances.

• The module provides an extra contactor output. This output and the output on the Modular Drive can

be disabled or enabled independently.

• The module will stop the machine or return it to start after a preset number of welds. This eliminates

the need for external limit switches.

• This unit can return past the start location to allow for work piece changes. One button will start the

whole welding procedure.

• Stitch welds stopped in mid-job can be restarted without interrupting the weld pattern.

• Puddle-buildup and Crater-ll timers are independent.

Display

Controls

Extra Contactor Output

18

MDS-1005 WEAVER CONTROL MODULE

The MDS-1005 Weaver Control Module provides weave welding control functions.

TRACTOR SPEED

CONTROL

MODE SELECTOR

SWITCH

START/STOP

DWELL LEFT

STEERING

CONTROL

WEAVE SPEED

DIGITAL

READOUT

WEAVE

AMPLITUDE

DWELL RIGHT

CARRIAGE TRAVEL

SWITCH

WELD CONTACT

MDS-1005

WEAVE

MODULE

MDS-1005-DIAL WEAVER CONTROL MODULE

TRACTOR SPEED

CONTROL

MODE SELECTOR

SWITCH

START/STOP

DWELL LEFT

STEERING

CONTROL

WEAVE SPEED

DIGITAL

READOUT

WEAVE

AMPLITUDE

DWELL RIGHT

CARRIAGE TRAVEL

SWITCH

WELD CONTACT

WEAVER CONTROL MODULES

The MDS-1005 Dial Weaver Control Module provides weave welding control functions with 3 turn digital dial

pots for the weave speed, weave amplitude, dwell left and right. The addition of the dial pots allows for pre-

cise and repeatable setting of all parameters. The dial pots also enable repeatable parameter settings from

machine to machine. All dials vary from 0-300 which corresponds to the setting the parameter from 0 to its

MAX value. For example, a 300 setting for weave amplitude corresponds to 2" of weave amplitude which is

its max value. The DIGITAL READOUT provided for the tractor speed displays in either inches per minute or

centimeters per minute directly.

Loading...

Loading...