Page 1

INSTRUCTIONS

AND

PARTS MANUAL

PROGRAMMABLE

GANTRY SYSTEM

Please record your equipment identication information below for future reference. This information can be found

on your machine nameplate.

Model Number

Serial Number

Date of Purchase

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above.

LIT-PGS-IPM-0314

Bug-O Systems is guided by honesty, integrity and

ethics in service to our customers and in all we do.

A DIVISION OF WELD TOOLING CORPORATION

280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA 15317-9564 USA

PHONE: 412-331-1776 http://www.bugo.com FAX: 412- 331- 0383

Page 2

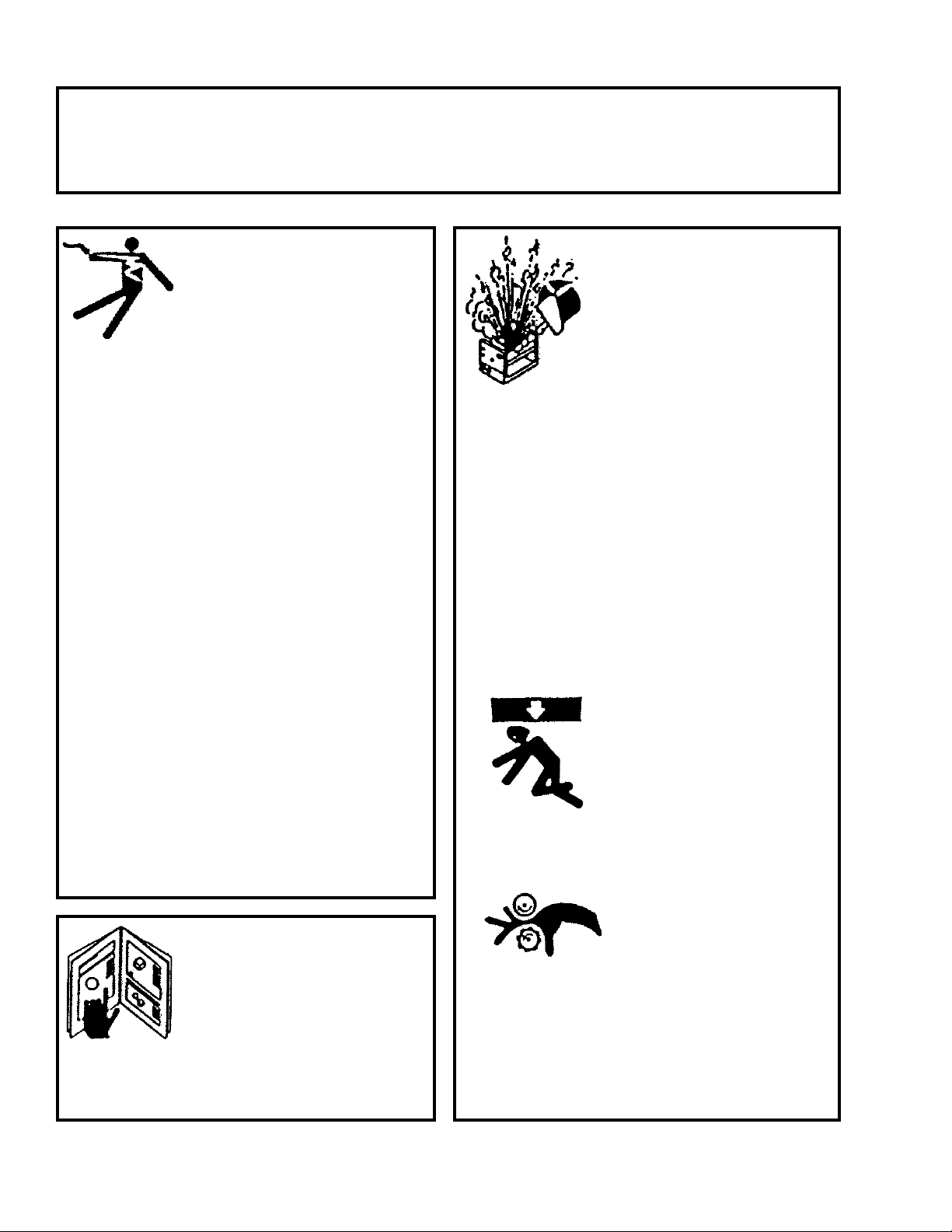

SAFETY

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY

QUALIFIED INDIVIDUALS.

ELECTRIC SHOCK can kill.

1) The equipment is not waterproof. Using

the unit in a wet environment may result

in serious injury. Do not touch equipment

when wet or standing in a wet location.

2) The unused connectors have power on

them. Always keep the unused connec tors covered with the supplied protective

panels. Operation of the machine without

the protective panels may result in injury.

3) Never open the equipment without rst

unplugging the power cord or serious

injury may result.

4) Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

5) Never remove or bypass the equipment

power cord ground. Verify the equipment

is grounded in accordance with all appli cable local and national electrical safety

codes. If none exist, use International

Electric Code (IEC) 950.

EQUIPMENT DAMAGE

POSSIBLE.

1) Do not plug in the power cord without rst

verifying the equipment is OFF and the

cord input voltage is the same as required

by the machine or serious damage may

result.

2) Always verity both the pinion and wheels

are fully engaged before applying power

or equipment damage may occur.

3) Do not leave the equipment unattended.

4) Remove from the work site and store in

a safe location when not in use.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or

walk underneath equipment.

MOVING PARTS can

cause serious injury.

READ INSTRUCTIONS.

1) Never try to stop the pinion from moving

except by removing power or by using the

STOP control.

Read the instruction manual before

installing and using the equipment.

2) Do not remove any protective panels,

covers or guards and operate equipment.

2

Page 3

HIGH FREQUENCY WARNINGS

SPECIAL PRECAUTIONS ARE REQUIRED WHEN USING PLASMA,

TIG OR ANY WELDING PROCESS THAT USES HIGH FREQUENCY TO

STRIKE AN ARC.

WARNING: HIGH FREQUENCY CAN EFFECT MACHINE

OPERATION AND THEREFORE, WELD QUALITY.

Read the precautions below before installing and using the equipment.

PRECAUTIONS:

1) Some plasma or welding cables are strong sources of high frequency interference.

NEVER lay a plasma or welding cable across the controls of the machine.

2) Always physically separate the plasma or welding cable leads from the machine

cables. For example, the plasma or welding cable leads should NEVER be bundled

with a pendant cable or the machine power cord. Maximize the separation between

any machine cables and the plasma or welding cables.

3) Strictly follow the grounding procedures specied for the plasma or welding unit.

NOTE: Some plasma and welding units produce exceptionally large amounts of high

frequency noise. They may require a grounding rod be driven into the earth within six

feet (2 meters) of the plasma or welding unit to become compatible with an automatic

cutting or welding process.

4) If the high frequency is produced using a spark gap, adjust the points so the gap is as

small as possible. The larger the gap, the higher the voltage and the higher the inter ference.

5) Some plasma or welding units will inject high frequency interference into the AC

power line. Use separate power line branches whenever possible to power the

plasma or welding source and the machine. Do not plug them into the same outlet

box.

6) High frequency noise may enter the machine through the plasma or welding supply

remote contactor leads. Some plasma and welding sources can produce noise spikes

of up to several thousand volts. These sources are not compatible with automated

cutting and welding equipment. It is recommended that the remote contactor leads on

these plasma or welding sources not be connected to the machine. An alternate

solution is to purchase a separate remote contactor isolation box.

3

Page 4

PROGRAMMABLE GANTRY SYSTEM

INSTRUCTIONS AND PARTS MANUAL

TABLE OF CONTENTS PAGE

PAGE

5.............. Setup and Operating Instructions

6,7........... Introduction: Program Control Description and Operation

7.............. Shape Programming

8.............. Segment Type and Quadrant Chart #1

9-11 ......... Programming Data Requirements

12............ Setting Measurement Units: Metric or Inches

13-14 ...... Shape Programming Examples

15............ Hand Held Pendant

16............ PGS-1000 Programmable Gantry System / Exploded View

17............ Programmable Gantry System / Parts List / Technical Data

18............ MUG-1680 Control Box Functions

19............ MUG-1680 Control Box Wiring Diagram

20............ MUG-1680 Control Box Electrical Component Chart

21............ MUG-1590-E Drive Unit / Parts List

22............ MUG-1595 Encoder Assembly / Parts List

23............ Drive Unit / Encoder Assembly Wiring Diagram

24............ Pendant Cable Wiring

25............ Plasma Cutting

26............ Aluminum Rigid Rail

27............ PRS-1010 Power Racker Introduction / Technical Data

28............ PRS-1050 Motorized Block Assembly / Parts List

29............ Power Racker Wiring Diagram / Electrical Component Chart

30............ Accessories

31-32 ...... Suggested Bed Designs for Burning Table

33............ Operation Checklist and Troubleshooting

34............ Keypad Character / Map Direct and Shifted Characters

35............ Program Diagnostics for Gantry

36............ Warranty

------CAUTION------

DO NOT LEAVE EQUIPMENT

UNATTENDED WITH POWER ON.

BE CERTAIN POWER IS OFF WHEN

4

NOT IN USE!

Page 5

SETUP

The GANTRY is shipped in major assemblies, ready to assemble on your burning table. It is very important to

construct the burning table carefully; two suggested bed designs are shown on pages 31 and 32. Whichever design is

used, it is critical that:

1. The ARR-1080 Rails are mounted on strong supports, independent of the burning bed. By using a 6" (150 mm)

beam, the rails may be mounted in a straight line, by using the ARR-1050 mounting system, even though the steel

may not be perfectly straight. USE A TRANSIT when setting the rails to ensure they are both LEVEL AND

STRAIGHT.

2. After the rails are installed and checked, put the carriages one at the time on the rails. The LEFT carriage is the

one with the Controls.

3. Insert the 2 vertical columns (MUG-1053) into the column bases (MUG-1050). Place the Crossing Rail on the

columns, and bolt on loosely. With the drives disengaged, square up the gantry, level the crossing rail, and then

tighten the Crossing Rail clamps. Slide the cross drive on to the rail.

4. Connect the cables between various components, referring to diagrams on page 16.

5. Rotate the clutches on the 3 drive units to engage the pinions with the racks. The machine can now be plugged in

and run.

OPERATING INSTRUCTIONS

1. Check that the cross-beam is square to the main track. Adjust the torch position, and connect the required gas

hoses or plasma trigger connection.

2. Plug the machine into the power line of correct voltage, and push the RESET button.

3. Push the red STOP/PAUSE button and use the toggle switches to move the machine and cross drive to the

starting position. Press the RESET button to make this the starting point.

4. Set the speed knob for correct speed. Speed can be checked by moving the machine manually using the toggle

switches.

5. It the required shape has not been programmed, refer to Shape Programming, and enter the program. If the

shape has been programmed, turn on the preheat gases, set the torch height and ignite the torch.

6. When the work piece is heated enough, press the black RUN button. The solenoid will turn on the cutting oxygen,

the machine will start moving along the programmed shape, and at the end of the shape it will stop and turn off

the, solenoid. Manually turn off the preheat gases. The machine is now ready for the next cut. Note: For Plasma

Cutting, see page 25.

5

Page 6

INTRODUCTION

This is a 2-axis gantry that has 2 synchronized drives running on parallel tracks, and a second axis drive carrying a

cutting torch that runs on a cross beam. It can be used for ame or plasma cutting, or welding, of a variety of shapes

programmed and stored in memory.

PROGRAM CONTROL DESCRIPTION

The machine has 20 storage areas in memory for different programmed shapes, numbered 0 to 19. At any time, one of

these shape numbers is the current one, and will stay current even when power is shut off and turned back on, until the

shape number is changed by the operator.

All programming is done with the hand-held terminal provided; this may be plugged into the connector on the rear of the

machine or unplugged at any time. The terminal is not needed to run the machine once programmed; it is recommended

it be disconnected when cutting.

Shapes are built up only from the segments provided: circular arcs and straight lines, square or inclined, by selecting

type and quadrant for each segment. A shape can have up to 50 segments. Some other operations, like solenoid On/

Off, time delay, or repeat another shape a number of times, also count as one segment each if used.

OPERATION

When rst plugged in, the position of the machine becomes the reference Start (Home) position. Now there are 3

options (the pendant terminal is not needed for the rst two).

1. MOVE

To change the Start position, push and release the STOP/PAUSE button, move the machine manually to the

required position using the manual X and Y jog switches, and push the RESET button.

2. RUN

Push the RUN button to cut a shape.

3. PROGRAM using the Hand Held Terminal

The Programming operation is selected by pressing keys A, B, C, D, E.

A: ALL SEGMENTS; data entry for new shape consists of Total number of segments

Data for each: Type (arc, x/y line or slope)

Quadrant 1-4

Size (radius, or x/y dimension) See Shape programming for details.

For example, a 2 inch diameter circle could be 4 Segments:

1. 2 1 100 Counterclockwise arc quadrant 1 1.00 inch rad

2. 2 2 100 Counterclockwise arc quadrant 2 1.00 inch rad

3. 2 3 100 Counterclockwise arc quadrant 3 1.00 inch rad

4. 2 4 100 Counterclockwise arc quadrant 4 1.00 inch rad

The data should be tabulated on paper from a diagram before entering.

B: PROGRAM SEGMENT

Press B on terminal to re-program a single segment. This is useful if there is an error in data for just one

segment, so the whole shape does not have to be re-entered.

C: CHANGE Shape Number

Press C on terminal to change the current shape number. Enter the new shape number. The program

switches to the new number in memory, and to whatever shape is stored there.

6

Page 7

OPERATION, CONT’D.

D: DISPLAY Shape Data

Press D to display the data for the current shape. The terminal display shows Total No. of segments, and

data for each segment one by one each time you press Enter.

E: END of segment Slowdown.

Press E to set Deceleration value for the shape, when the machine approaches the end of each segment.

This is useful when the shape has sharp corners, to prevent overshoot. 99 is maximum slowdown, 0 is no

slowdown.

IMPORTANT:

1. Once the HOLD button is pressed, computer control is halted until the RUN or the RESET button is pressed.

Therefore the programming cannot be done with the handheld terminal in this state; the RESET button should

be pressed rst.

2. After pushing A and programming a new shape, End of segment Slowdown will still have the old value unless

reprogrammed. To set-new value, push E.

SHAPE PROGRAMMING

1. Draw the required shape on paper to some scale.

2. Refer to the Segment Chart (Chart #1) and divide the shape into straight line and arc segments.

3. Decide on the operation sequence and mark any other operations such as turning torch on or off, or delay.

4. Number all the segments in sequence, including other operations if any, and make a table with required data.

Example for a clockwise circle starting from the top:

(Dimensions described for metric version)

Seg. No. Type Quadrant Dimensions

1. 1 1 300 (30 mm)

2. 1 4 300

3. 1 3 300

4. 1 2 300

5. With the machine powered up and pendant plugged in, select which shape number this will be.

Push C : display reads Shape No.

Push 3 for No. 3, press Enter key (backward arrow) .The program is now in Shape No. 3

6 . Push A : display reads “Total segments?”

Push 4 for 4 segments and Enter.

Display reads “1. Type?” waiting for Segment 1 data.

7. Push 1 for type, clockwise arc. (Refer to Chart #1).

Display reads “Quadrant?”

Push 1 for quadrant 1.

Display reads “mm x 10”

Push 3, 0, 0, Enter, for 300, which is 30.0 mm.

Segment 1 has now been entered, display reads “2. Type?”, asking for data for segment 2.

8. Repeat above steps to enter data for all segments, in sequence. Display will read “Ready” after all segments

are entered.

The shape program is now stored in memory as shape No. 3, and the machine is ready to cut the shape.

7

Page 8

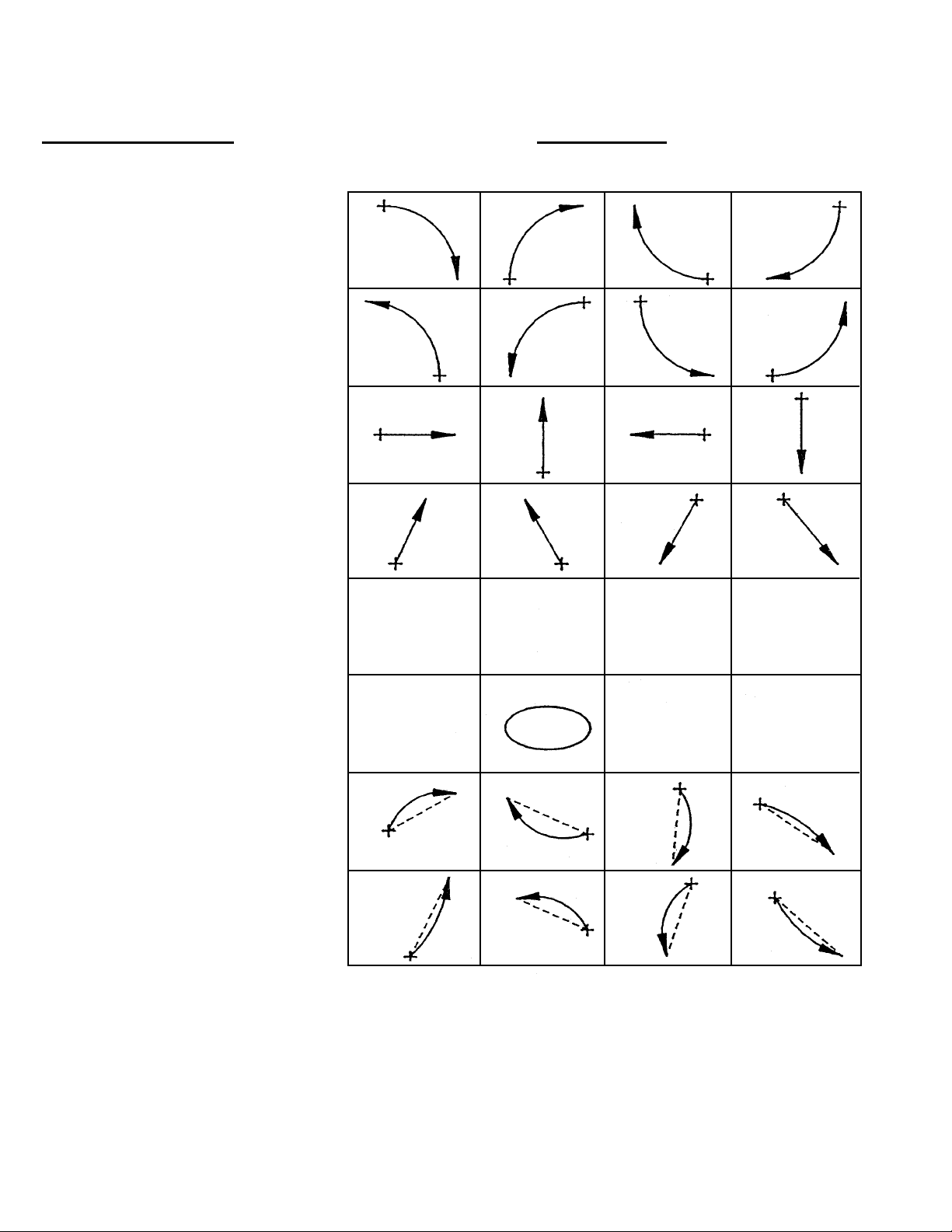

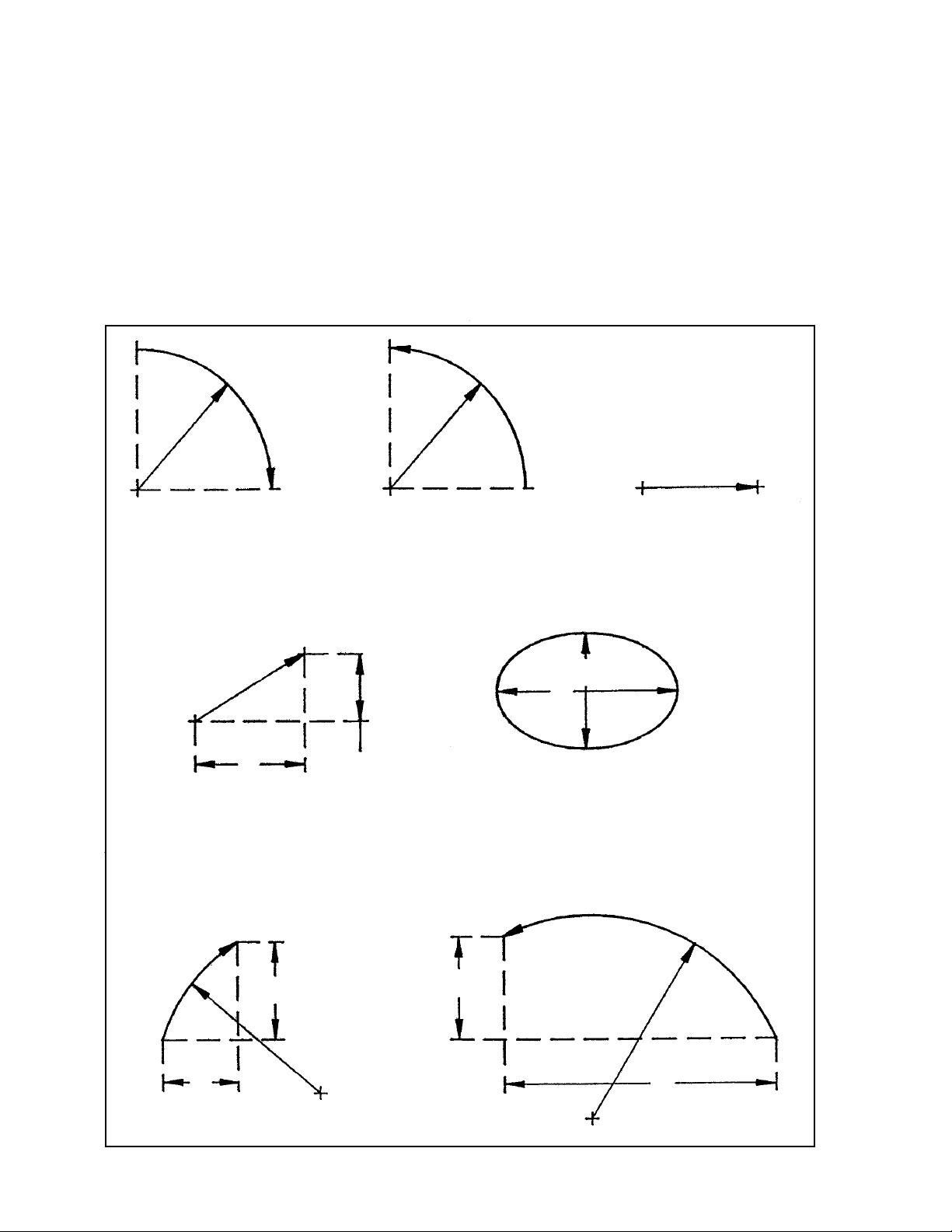

SEGMENT TYPE AND QUADRANT CHART

SEGMENT TYPES: QUADRANT:

#1 #2 #3 #4

1. CLOCKWISE 900 ARC

0

2. COUNTERCLOCKWISE 90

3. X OR Y AXIS LINE

ARC

4. OBLIQUE LINE

5. FUNCTIONS

6. FUNCTIONS

7. CLOCKWISE PARTIAL ARC

8. COUNTERCLOCKWISE

PARTIAL ARC

WELD/OXY

ON

REPEAT

ANOTHER

SHAPE

WELD/OXY

OFF

WAIT FOR

START BUTTON

AUXILIARY

MODES

TIME

DELAY

PERCENT

SPEED

CHART #1

8

Page 9

PROGRAMMING DATA REQUIREMENTS

To program a complete new shape (press “A”):

Count the number of segments or operations and enter the total.

For each segment (refer to DIMENSIONS REQUIRED Chart #2, Page 10)

Enter TYPE : Select from 1 through 8

QUADRANT: 1,2,3 or 4; refer to Chart #1.

SIZE: One or more dimensions per segment as described below; 100 per inch or 10 per mm

(Depending on machine version); or for time, 100 per second of delay.

Eg. 150 = 1.5", or for metric 375 = 37.5 mm

NOTE: Maximum distance per segment is 72" (1829 mm)

DETAILED DESCRIPTION OF TYPES

Type 1. Clockwise, 900 arc segments.

Quadrant determined by which quarter of a full circle makes the arc. (See Chart #1).

Dimensions required: Radius only.

Type 2. Counterclockwise , 900 arc segments.

Quadrant determined by which quarter of a full circle makes the arc. (See Chart #1).

Dimensions required: Radius only.

Type 3. Line along X or Y axis.

Quadrant determined by direction of movement. (See Chart #1) (East: 1, North: 2, West: 3, South:4).

Dimensions required: Length only.

Type 4. Angled straight line.

Quadrant determined by direction of movement. (See Chart #1) (NE: 1, NW: 2, SW: 3, SE: 4 ).

Dimensions required: (1) X-dimension; movement along X axis

(2) Y-dimension; movement along Y axis

Type 5. Functions or other operations.

Quadrant by selecting function. (See Chart #1)

1. Weld/oxygen ON: turn ON weld contact-relay or cutting oxygen solenoid.

Dimensions required: None.

2. Weld/oxygen OFF.

Dimensions required: None.

3. Pause: Machine stops and waits until START/RUN button is pushed again.

Dimensions required: None.

4. Delay: Machine stops and holds position for a programmed time period, up to 99.99 seconds.

Dimensions required: time in .01 second units.

(eg. 2.5 seconds = 250)

Type 6. Special functions.

Determine quadrant by selecting function.

1. Repeat: Another complete shape will be repeated the specied number of times.

Shape No. of the repeated shape MUST BE LOWER than the Shape No. of the current

shape being programmed. Therefore it CANNOT BE USED IN SHAPE No. 0.

Data required: (1) Shape No. to be repeated

(2) Number of times.

2. Ellipse: This is provided for making a complete true ellipse, always starting from the left

(West extremity) and moving clockwise.

Dimensions required: (1) diameter along X-axis.

(2) diameter along Y-axis.

9

Page 10

PROGRAMMING DATA REQUIREMENTS, CONT’D.

Type 7. Clockwise arc, must be less than 1800.

Quadrant determined by direction of end point of arc relative to the start point. (See Chart #2).

Dimensions required:

(1) X-dimension; offset along X-axis from start to end point.

(2) Y-dimension; offset along Y-axis from start to end point.

(3) Radius of arc.

Type 8. Counterclockwise arc, must be less than 1800.

Quadrant determined by direction of end point of arc relative to the start point. (See Chart #2).

Dimensions required:

(1) X-dimension; offset along X-axis from start to end point.

(2) Y-dimension; offset along Y-axis from start to end point.

(3) Radius of arc.

R R

L

1

X

4

Y

2

3

X

Y

6-2

10

X

R

7

Y

Y

R

X

8

CHART #2

Page 11

PROGRAMMING DATA REQUIREMENTS, CONT’D.

AUXILIARY MODES: TYPE 6, QUADRANT 3

This function allows the 2 internal Solid State Relay outputs to be independently turned ON and OFF, providing

control of 2 output signals; and also to switch the machine between Rapid Traverse mode and Set Speed.

The machine is shipped with OUTPUT (1) wired to the amphenol connector for the external relay or solenoid,

using pins A and C. By default, this Output turns ON when the Start button is pressed to run a shape, and

turns OFF at the end of the shape. Both the contact relay and cutting solenoid use only Output (1).

OUTPUT (2) is present across pins A and D on the amphenol connector, but is not used by the standard relay

box - a custom box has to be made to use this output. By default the output is OFF when a shape is started,

until specically turned ON by the Solenoid/Weld ON command Type 5, Quad 1.

Subsequently while running, the Type 5 ON and OFF commands turn both Outputs On and Off together, and

both turn Off at the end.

When programming Type 6 Quad 3, a Mode Number is required to be entered. The 8 auxiliary modes, numbered

0 through 7, allow the setting of a mode with any combination of Outputs On or Off, and choice of Set Speed

by the speed knob, or maximum speed regardless of setting. The combinations are listed in the table below:

AUXILIARY MODES CHART

Mode

No.

Output 1 Output 2 Speed

0 Off Off Set

1 Off On Set

2 Off Off Hi

3 Off On Hi

4 On Off Set

5 On On Set

6 On Off Hi

7 On On Hi

11

Page 12

PROGRAMMING DATA REQUIREMENTS, CONT’D.

SET % SPEED, FRACTION OF SET SPEED: Type 6, Quadrant 4

Selecting Type 6-4 allows the speed to change to a fraction of the set speed. Display will read “Speed %”,

and data entry is accepted from 1 to 99. Entering 0 or just return will make the speed 100%, which is the

same as set speed.

When the program reaches a Type 6-3 segment while running, the speed will change to the percent

entered, and continue at this setting until there is a later Type 6-3 segment which changes it to another %

setting or back to 100%.

NOTE: If Type 6-3 has been set for HI (rapid traverse) then this setting will cut down the HI speed to the

same %.

Settings below 10 % are not recommended.

SETTING MEASUREMENT UNITS: METRIC OR INCHES

The machine is factory set in inch or metric units before shipping, and is not meant to be switched between

the two systems on a regular basis. However if the machine happens to be set in a unit system not wanted

by the user, the setting can be changed to suit.

To set the machine for programming in mm or inches:

First with power on, push the RESET button on the machine. Next, on the keypad of the handheld terminal,

note the blank “Shift” key. (Refer to Hand Held Pendant diagram if necessary, page 34).

Press the Shift Key, then “9”, and the display should read: “English/metric, 0/1”

Then Push 1 to select metric dimensions, 0 to select inches. Any shapes in the machine should be

reprogrammed; the machine will not convert numbers already entered.

12

Page 13

SHAPE PROGRAMMING EXAMPLES

EXAMPLE: OBROUND SHAPE

3.0"

A

B C

6.0"

CUTTING PATH:

START

F

4.0"

A-B-C-D-E-F-A

E

10.0"

TOTAL NO. OF SEGMENTS = 6

SEG NO TYPE QUADRANT SIZE COMMENT

AB 1 1 2 300 CW Arc, 3.00" rad

BC 2 3 1 400 X-axis line, 3.00"

CD 3 1 1 300 CW Arc

DE 4 1 4 300 CW Arc

EF 5 3 3 400 X-axis Line

FA 6 1 3 300 CW Arc

AB: Type 1 species Clockwise Arc

Quadrant No. is 2

Size 300 species Radius = 3.00" (Metric: 300 = 30.0 mm)

13

Page 14

SHAPE PROGRAMMING EXAMPLES, CONT’D.

Type 6 Quadrant 1.

The shape shown has a rectangular tooth form repeated six times. The required shape is numbered Shape

2, and the four segment repeated tooth is Shape 1 so that it can be called for by Shape 2. (A Repeat in a

program must call for a lower number shape).

Shape No. 2:

13"

6

Start

1

5

4

8"

2

Shape No.

3

1:

2

4

1

Shape # 1

Segment Type Quad. Dimension

1. 3 1 100

2. 3 2 200

3. 3 1 100

4. 3 4 200

Shape #2

Segment Type Quad. Dimension

1. 3 4 800

2. 6 1 1

6

3. 3 1 100

4. 3 2 600

5. 2 1 200

6. 3 3 1100

(Repeat #1)

(6 times)

3

14

Page 15

HAND HELD PENDANT

This is a hand held terminal with keypad and display, which plugs into the control panel. Press

keys A, B, C, D, or E for the function desired, as described in the Programming instructions

on pages 6, 7 & 8. Use the digit keys to enter move distances or other dimensions; push the

Enter button to store the numeric value entered. The Backspace (BKSP) key deletes the last

digit before pushing the Enter button, in case a correction is required.

15

Page 16

PGS-1000 PROGRAMMABLE GANTRY SYSTEM

10

2

11

9

12

1

10

11

9

13

1

5

16

14

17

15

17

4

7

8

13

10

11

3

9

6

to

16

Page 17

PGS-1000-8,-10,-12 PROGRAMMABLE GANTRY SYSTEM PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 2 BUG-2785 Carriage, 36"

2 1 BUG-2975 Cable Mounting Assembly

3 1 BUG-5250 Carriage, 12"

4 1 BUG-5285 H. D. Cutting Group (optional)

5 1 BUG-6050 Hand Held Pendant

6 2 MUG-1050 Column Base

7 2 MUG-1053 Column

8 1 MUG-1410-8 Face Rail Assembly 8 ft.

-10 Face Rail Assembly 10 ft.

-12 Face Rail Assembly 12 ft.

9 3 MUG-1590-E Drive Unit (100:1) 4-80 ipm

10 3 MUG-1595 Encoder

11 3 MUG-1621-1.5 Cable 18"

12 1 MUG-1633-3 Shielded Cable 3' (X1)

13 2 MUG-1633-12 Shielded Cable 12'(X2, Y)

-14 Shielded Cable 14' (X2,Y)

-16 Shielded Cable 16' (X2,Y)

14 1 MUG-1678 Cable Carrier (8', 10' or 12') ft

15 1 MUG-1680 XXY Gantry Control Box 120 VAC

MUG-1682 same as above except 240 VAC

16 1 MUG-1685 Cable Carrier Mount

17 1 ARR-1080 H.D. Rigid Rail, 8' (ordered separately)

TECHNICAL DATA

Gantry Control Box MUG-1680 120 VAC/50-60 Hz/1

Power Requirements: MUG-1682 240 VAC/50-60 Hz/1

Travel Speed: 4-80 in/min (100-2000 mm/min)

Maximum Segment

Dimension: 72" (1800 mm) Within Limits of Travel

Minimum Dimension

Increment: Inches: 0.01" Metric: 0.1 mm

Delay Increment: 0.01 seconds

Maximum Delay 99.99 seconds

17

Page 18

MUG-1680 CONTROL BOX FUNCTIONS

2

1

4

3

7

6

5

8

PANEL CONTROLS:

9

1. SPEED

2. START / RUN

3. STOP / PAUSE

4. RESET

5. PILOT LIGHT

6. POWER ON/OFF SWITCH

7. CIRCUIT BREAKER

8. MANUAL JOG Y DRIVE

9. MANUAL JOG X-X DRIVES

18

Page 19

MUG-1680 CONTROL BOX WIRING DIAGRAM

RED

103

BLK

103

RED

BLK

103

RED

BLK

RED

BLK

BLK

RED

RED

BLK

YEL

MC 1

WHT

BLU

X 1

E

F

X 1

D

A

B

C

CN 3

GY

PK

YEL

103

SW 5

PK

7

9

8

6

5

3

2

4

BLU

1

PK

TAN

GY

10

TAN

WHT

10

9

8

BLU

F

A

7

BLK

WHT

Y

10

9

BLU

F

A

SW 6

OR

8

E

Y

D

B

C

CN 5

BRN

OR

103

7

6

5

3

2

4

1

TAN

BLU

BRN

TAN

OR

CM

TAN

BLU

TAN

YEL

GY

BRN

0- VOLT

YEL

WHT

BLU

PK

WHT

YEL

OR

WHT

PUR

223

E

X 2

D

B

C

CN 4

BLU

PUR

YEL

103

6

5

3

2

4

1

MC 3

PUR

BLU

BLU

TAN

TAN

WHT

CB

BLK

BLK

VT

PL

LF

GRN

PC

WHT

WHT

TB 1

SW 1

BLK

T1

GY

GY

BLK

BLU + YEL

RED

RED

BLU + YEL

BLK

WHT

TB 2

T2

GY

BLK

GY

BLK

BLU + YEL

RED

RED

BLU + YEL

BLU

RED

SW 2

GRN

START

BLU

BLU/WHT

YEL

P

SW 3

STOP

RESET

DLF

CN 2

CN 1

SW 4

WHT/BLK

OR

YEL

BLU

BLU

WHT/BLK

WHT/BLK

BRN

BLK

RED

10

8

1

B

A

104

GRN

A

D

1

C

D

E

F

B

C

19

Page 20

MUG-1680 CONTROL BOX ELECTRICAL COMPONENT CHART

ITEM DESCRIPTION

120 VAC 240 VAC 42 VAC

PC Power Cord BUG-9445 GOF-3115 BUG-9442

CB Circuit Breaker BUG-2931 BUG-2923 ARM-2278

1.0 A 0.7 A 3.0 A

PL Pilot Light BUG-1415 BUG-1428 BUG-1427

VT Volt Trap BUG-1393 BUG-1563 BUG-1393

T1,T2 Transformer BUG-5218 BUG-5231 BUG-5232

P Potentiometer BUG-9686

SW1 Toggle SW (Power) ARM-2279

SW2 PB Switch (Start) SWT-1113

SW3 PB Switch (Stop) SWT-1112

SW4 PB Switch (Reset) SWT-1111

SW5 Toggle SW (X Dir) MUG-1199

SW6 Toggle SW (Y Dir) MUG-1199

LF Line Filter BUG-6069

CM Control Module MUG-1670-XXY

MUG-1680 MUG-1682 MUG-1684

MC1, 2, 3 Motor Control Board BUG-1770

TB1, TB2 Terminal Block BUG-6028

CN 1 Connector (AUX) MUG-1156

CN2 Connector (Pendant) BUG-9902

CN3 Connector (X1) BUG-9909

CN4 Connector (X2) BUG-9909

CN5 Connector (Y) BUG-9909

DLF Data Line Filter SEO-4118

Encoder / Motor MUG-1686

Wiring Harness

Speed Board MUG-1687

Wiring Harness

Panel Controls MUG-1688

Wiring Harness

Toggle Switch MUG-1689

Wiring Harness

20

Page 21

MUG-1590-E DRIVE UNIT / PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-1595 Gear Motor (100:1)

2 1 BUG-2988 Left Side Panel

3 1 BUG-5112 Front End Plate

4 1 BUG-5114 Swivel Plate

5 1 BUG-5120 Cam Clutch Assy (Includes Items 6-11)

6 1 BUG-2767 Wing Nut

7 1 BUG-5113 Cam & Tube Assy

8 1 BUG-5116 Stud

9 1 BUG-5119 Knob w/ Fastener

10 1 BUG-5122 Delrin Washer

11 1 WAS-0240 1/4 SAE Washer

12 4 BUG-5121 Stand Off

13 1 BUG-5128 Pinion, Long Shaft

14 1 BUG-5131 Sleeve

15 1 BUG-9614 Needle Bearing

16 1 BUG-9635 Flange Bearing 3/8"

17 1 BUG-9909 Panel Connector, 6-T, Male

18 8 FAS-0114 Pan Hd Scr 6-32 x 3/8 Lg.

19 4 FAS-0124 Pan Hd Scr 8-32 x 3/8 Lg.

20 8 FAS-0204 Rnd Hd Scr 4-40 x 318 Lg.

21 1 FAS-0654 Soc Hd Shr Scr 5/6 x 3/8 x 1/4-20

22 8 FAS-1305 Hex Nut 4-40

23 4 FAS-2824 Fit Hd Slt Scr 8-32 x 1-3/4 Lg.

24 1 GOF-3019 Handle w/Nuts

25 1 MUG-1156 Panel Connector, 4-T, Female

26 1 MUG-1586 Cover

17

20,22

24

12

4

26

25

20,22

5

6.750

(171 mm)

6

11

7.125

(181 mm)

9

2

1

10

6.563

(167 mm)

7

18

3

23 15

13

8 16

14

19 21

21

Page 22

MUG-1595 ENCODER ASSEMBLY

12

4.000 REF

3.750 REF

5.500 REF

1

5

4

9, 6, 8

13

10

2

11

22

.250 REF

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-6059 Encoder

2 1 BUG-6044 Flexible Coupling

3 1 BUG-6047 Pinion w/ Shaft

4 2 FAS-0115 Pan Hd Scr. 6-32 x 1/2

5 1 FAS-0124 Pan Hd Scr. 8-32 x 3/8

6 4 FAS-0204 Rnd Hd Scr. 4-40 x 3/8

7 2 FAS-0227 Rnd Hd Scr. 8-32 x 3/4

8 4 FAS-1305 4-40 Hex Nut

9 1 MUG-1156 Socket Connector

10 1 MUG-1592 Bracket

11 1 MUG-1593 Pod

12 1 MUG-1594 Plate

13 1 MUG-1596 Enclosure

14 2 SFX-1218 Flange Bearing

* 1 CBP-1598 Connector Cable

7

14

3

Page 23

DRIVE UNIT / ENCODER ASSEMBLY WIRING DIAGRAM

MUG-1633-

Shielded cable

BUG-9909

Panel

Connector

6-T, M

PK

BLU

RED

MOTOR

BLK

RED

BLK

MUG-1156

Panel Connector

4-T, F

WHT

D

A

C

B

MUG-1621-1.5

Cable 18"

YEL

MUG-1595 Encoder Assembly

MUG-1156

Panel Connector

4-T, F

A

D

B

C

WHT

YEL

RED

BLK

CAP-1105 M

Capacitor 1.0 mF

5

4

3

2

1

+5 V

GND

BUG-6039

Encoder

23

Page 24

PENDANT CABLE WIRING

BUG-6050

Hand Held Terminal

A ____ Black: Circuit Com.

B ____ Yellow: TX (Transmit)

BUG-9906

Cable Connector, 6-T, M

BLK

(SHIELD)

F

RED

BRN

OR

YEL

E

(Front View)

A

B

C

D

C ____ Orange: RX (Receive) 9600 Baud

D ____ Brown: Signal Ground

E ____ Red: Power (5 V)

F ____ Shield Drain Wire, Bare, Touching Foil Shielding

NOTE: Other wires should be trimmed and unable to touch terminal pins.

24

Page 25

PLASMA CUTTING

The Programmable Gantry System can be used successfully for plasma cutting; however it is important to

take certain precautions to avoid interference and protect the control circuits. (These comments also apply

to TIG welding or any process that uses high frequency to strike an arc.) An external relay box is available

separately or in the welding kit to provide the contact signal to the plasma source.

PRECAUTIONS:

1. NEVER lay the plasma gun cable across the top of the machine. The further away from the machine

it can be routed and supported, the better.

2. See that all grounding procedures specied for the plasma source are followed diligently.

3. If the high frequency is produced using a spark gap, adjust the points so that the gap is as small as

possible. The larger the gap, the higher the voltage and stronger the interference.

4. We strongly recommend you disconnect the Hand Held Terminal (programming pendant) when

running the machine. Any length of wire acts as an antenna to receive HF radiation, and though the

cable is shielded, it is possible for some induced voltage to leak through.

5. Use separate power line branches whenever possible to power the plasma source and the machine.

Do not plug them into the same outlet box.

6. Though there is an internal power line lter, an external protective device will always help. Computer

equipment line protection boxes are readily available at low cost, with surge suppression and line

ltering circuitry. The machine can be plugged into the power line through one of these boxes.

25

Page 26

ALUMINUM RIGID RAIL

ALUMINUM RIGID RAIL is a high quality alloy, rigid section made to the machine tool tolerance shown in

the sectional view below. The carriage drive pinion meshes with a machined gear rack that is mounted on

the rail. The wheels of the carriage travel in opposed grooves at either side of the rail, locking the carriage

to the rail. Heavy duty [H.D.] aluminum four-legged rigid rail is supplied in two lengths: ARR-1080 [93-1/2"

(2.37 m)] called 8' (2.37 m) rail and ARR-1085 [46-1/2" (1.18 m)] called 4' (1.18 m) rail - see insert below.

Extra heavy duty aluminum four-legged rigid rail: ARR-1250 [93-1/2" (2.37 m)] called 8' (2.37 m) rail and

ARR-1200 [46-1/2" (1.18 m)] called 4' (1.18 m) rail, is also available.

RAIL FOR LONGER SPANS:

When unsupported rail paths longer than 93-1/2" (2.37 m) nominal 8' (2.37 m) rail are required, multiple

sections of standard rail are mounted on plate, channel or box sections.

ARR-1080 / H.D. ALUMINUM RIGID RAIL 8' (2.37 m)

A

C

B

A 2.75" (70 mm)

B 4.0" (102 mm)

C .375" (9.5 mm)

D .875" (22 mm)

D

5

3

4

1

2

6

7

26

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 ARR-1006 Rack

2 2 ARR-1027 Splice Bar

3 2 ARR-1028 Carriage Bolt

4 1 ARR-1081 Rail Extrusion

5 2 FAS-0375 Hex Hd Cap Scr 5/16-18 x 1/2

6 2 FAS-1370 Hex Nut 5/16-18

7 16 FAS-1445 S.T. Pan Hd Scr 10-32 x 1/2

Page 27

PRS-1010 POWER RACKER

The POWER RACKER is a compact, motorized drive that enables the operator to position the process tool

using a handheld pendant. It consists of a Control Box, Pendant Control and Motorized Block. The Power

Racker also includes a 15" Heavy Duty Tube Rack and Right Angle Clamp which can used in conjunction

with a BUG-2708 Clamp for welding, or a BUG-5188 Torchholder for cutting applications.

TECHNICAL DATA:

PRS-1010

Power Racker

120 VAC / 60 Hz

PENDANT

CONTROL

PRS-1012

Power Racker

240 VAC / 60 Hz

CONTROL BOX

MOTORIZED

BLOCK

7.435"

(189mm)

3"

(76mm)

1.624"

(41mm)

15"

(381mm)

27

Page 28

PRS-1050 MOTORIZED BLOCK ASSEMBLY

ABOD

OD

RED

BLK

MOTOR

13

10

11

3,4

9

7

1

2

8

5

12

6

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-1034 Panel Connector, 4-T, M

2 10 FAS-0112 Pan Hd Scr. 6-32 x 1/4

3 4 FAS-0204 Rnd Hd Scr. 4-40 x 3/8

4 4 FAS-1305 Hex Nut 4-40

5 8 FAS-1412 S.T. Pan Hd Screw “F”

6 3 PRS-1027 Soc Hd Cap Scr. 3 mm.5p, 35 L

7 1 PRS-1025-P Motor

8 1 PRS-1026 Pinion

9 1 PRS-1040 Cover

10 1 PRS-1041 End Plate

11 1 PRS-1042 End Plate

12 2 PRS-1048 Bearing

13 1 PRS-1049 Racker Block

28

Page 29

POWER RACKER WIRING DIAGRAM

PRS-1070

PENDANT CONTROL

BLK 8V

SW

P

OR F/R

BLU OV

BRN SP

PC

PRS-1100

CONTROL BOX 120 VAC

CB

BLK

GRN

C

WH

B

C

R

A

F

E

D

CN1

VT

CN2

A

D

B

C

RED

BLU

CN3

COM

NC

R

NO

T

TAN

BLU

TAN

BLU

RED

TAN

BLU

TAN

WHT/BLU

A

B

F

E

C

D

YEL

BLU

BRN

MCB

POWER RACKER ELECTRICAL COMPONENT CHART

ITEM DESCRIPTION

120 VAC 240 VAC 42 VAC

CB Circuit Breaker BUG-2923 BUG-2952 BUG-2933

PC Power Cord BUG-9445 GOF-3115 BUG-9442

R Relay BUG-1383 BUG-1551 BUG-9636

T Transformer BUG-5001 BUG-5002 BUG-5003

VT Volt Trap BUG-1393 BUG-1563 BUG-1393

C Cable MUG-1625

CN1 Cable Connector 6-T, M BUG-9906

CN2 Panel Connector, 6-T, F BUG-9902

CN3 Panel Connector 4-T, F MUG-1156

MCB Speed Control CAS-1770

P Potentiometer BUG-9686

SW Toggle Switch (For-Off-Rev) MUG-1199

PRS-1081 PRS-1083 PRS-1085

29

Page 30

ACCESSORIES

BUG-5275

H.D. Cutting Group

BUG-5285

H.D. Welding Group

BUG-2708

Clamp with

7/8" Rod

MUG-1695

Contact Relay 120 VAC

MUG-1697

Contact Relay 240 VAC

BUG-5188

Torchholder

Assembly

*MUG-1690

Q. A. Manifold

w/ Solenoid 120 VAC

30

*MUG-1692-_

Q. A. Manifold

w/ Solenoid 240 VAC

* Includes 3-Hose Assembly

Page 31

SUGGESTED BED DESIGNS FOR BURNING TABLE

The construction of your burning table is very important. The table must be rigid and strong. 6" (150

mm) WF Beams are recommended for rail supports, so that even if they are not straight, the ARR-O

rails 4" wide (102 mm) may be mounted in a straight line. A transit is recommended for set-up, but

piano-wire can be used. The bolting holes in the rail are uniformly spaced, but rather than laying-out

the holes, position the rail on its supports and transfer the holes. Make sure that the rails on each

side start at the same place!

Actual Length

1/4" x 6" Bars

Centerline to Centerline

Distance. Maximum Work

Width plus 24"

(Material Length

Plus 5'0" or more)

Side Rails should be

3-4" below burning bed

Note:

1. Rail should be mounted on separate supports - not connected to burning bed

- so the rail alignment will not be disturbed during loading and unloading.

2. Rail must be straight and at - parallel to cutting table.

6" Wide Flange at

12 1b/FT

ARR-O Rail

Legs Grouted in

Concrete

31

Page 32

SUGGESTED BED DESIGNS FOR BURNING TABLE, CONT’D.

AT 12 1B/FT

6" WIDE FLANGE

3-4"

THAN RAIL BASE

SHOULD BE 3-1" HIGHER

BURNING BED

32

(Check Quote For Actual Length)

MATERIAL LENGTH PLUS APPROX. 5'

1/4" X 6" BARS

4"

L

P + 24"

Maximum Width

Page 33

OPERATION CHECKLIST AND TROUBLE SHOOTING

1. Plug in the machine and turn on the Power Switch. Use the X and Y direction toggle switches to jog the GANTRY

in all 4 directions in turn. This overrides any speed command from the computer control. If the drives run in

corresponding direction, and the speed can be varied with the Speed Pot, this indicates:

a) the speed control boards are OK

b) the controller circuit is supplying the required voltages

If only one motor does not run then it is likely that the motor’s speed control is faulty. If both X and Y motors do not

operate properly then there may be a bad component on the control module that prevents proper voltages to be

supplied to the toggle switches.

A bad connection in the speed signal line to the speed board may also run the motor in one direction only at full

speed.

Manual control must function correctly before checking the computer control.

2. Attach the Handheld Pendant and push the Reset button. The display should read “Reset OK”. Push D on the

keypad and push “RETURN” until the display shows the Shape No. and data for all segments. If the display functions

this indicates:

a) the communication line is functioning

b) the computer is operating its program

If the message “Reset OK” comes up but pushing D or any other key has no effect, there could be a false signal

coming in from the STOP button, due to a wire short or damaged switch.

3. Disconnect the Handheld Terminal and power up.

Toggle the X and Y switches in all 4 directions after pushing Reset. When the switch is let go, the machine should

go back to its original position.

This conrms the computer is running its program, and also interfacing correctly with encoders and the speed

signal outputs to the speed boards.

If one motor returns to home and not the other, then the computer may not be receiving the encoder signals

properly from that axis - encoder pick up gear or coupling may be loose or the pins in the encoder plug may not be

making good connection.

If a motor returns home from one direction but not from the other, the speed control may be faulty and drive only

in one direction.

33

Page 34

KEYPAD CHARACTER / MAP DIRECT AND SHIFTED CHARACTERS

Shift Key, then “9”

E.g. to type U for units, press

SHIFTED CHARACTER SET

Shift Key

34

V: Version Number

T: Test drives & encoders, function

R: set Ratio SE4-P; DO NOT USE

U: set Units, inch or metric

Page 35

PROGRAMMED DIAGNOSTICS FOR GANTRY

These diagnostics are included in the control module for Programmable Gantries since version XXY01.

See character map of keypad for shifted keys to use these commands.

Press “T” for Test

The display should show “D-E-F?”

Next press “D” to check Drives

E for Encoders

F to Finish; get back to main menu

After selecting either D or E, for Drive or Encoder, the display will show

“Axis No.”

Press 1 for Axis 1: main drive, 2: for Axis 2: cross drive (or 3 for 2nd X- drive on a Gantry).

If drive was selected, the axis selected should run:

1 second forward (display shows “F”)

1 second back (display shows “B”)

The drive should move regardless of whether encoder pulses are counted, at the speed set by the speed pot.

If Encoder was selected, the encoder count of the corresponding encoder (1 or 2) should scroll up continuously in the

display. Press any key to stop.

Rotating the encoder in either direction will increase or decrease the displayed count, if the computer is successfully

counting the pulses from it. The encoder can be rotated manually if disengaged, or by using the joystick to move in the

desired direction.

Note: the count is in hexadecimal notation (number base 16) (10H=16 decimal, 400H =1024 decimal).

Press “V” for Version.

The display will show the program version number; e.g. SH005 or XXYOI, etc.

Applicable to new program versions only.

35

Page 36

WARRANTY

MODEL ____________________________

Limited 3-Year Warranty

For a period ending one (1) year from the date of invoice, Manufacturer warrants that any new machine or part is free from defects in materials and workmanship and Manufacturer agrees to repair or

replace at its option, any defective part or machine. HOWEVER, if the invoiced customer registers

the Product Warranty by returning the Warranty Registration Card supplied with the product within

90 days of the invoice date, or by registering on-line at www.bugo.com, Manufacturer will extend the

warranty period an additional two (2) years which will provide three (3) total years from the date of

original invoice to customer. This warranty does not apply to machines which, after Manufacture’s

inspection are determined by Manufacturer to have been damaged due to neglect, abuse, overloading, accident or improper usage. All shipping and handling charges will be paid by the customer.

The foregoing express warranty is exclusive and Manufacturer makes no representation or warranty

(either express or implied) other than as set forth expressly in the preceding sentence. Specifically,

Manufacturer makes no express or implied warranty of merchantability or fitness for any particular

purpose with respect to any goods. Manufacturer shall not be subject to any other obligations or liabilities whatsoever with respect to machines or parts furnished by Manufacturer.

Manufacturer shall not in any event be liable to Distributor or any customer for any loss of profits, incidental or consequential damages or special damages of any kind. Distributor’s or customer’s sole

and exclusive remedy against Manufacturer for any breach of warranty, negligence, strict liability or

any other claim relating to goods delivered pursuant hereto shall be for repair or replacement (at

Manufacturer’s option) of the machines or parts affected by such breach.

SERIAL NO. ________________________

DATE PURCHASED: _________________

WHERE PURCHASED:________________

Distributor’s Warranty:

In no event shall Manufacturer be liable to Distributor or to any customer thereof for any warranties,

representations or promises, express or implied, extended by Distributor without the advance written consent of Manufacturer, including but not limited to any and all warranties of merchantability or

fitness for a particular purpose and all warranties, representations or promises which exceed or are

different from the express limited warranty set forth above. Distributor agrees to indemnify and hold

Manufacturer harmless from any claim by a customer based upon any express or implied warranty

by Distributor which exceeds or differs from Manufacturer’s express limited warranty set forth above.

HOW TO OBTAIN SERVICE:

IF YOU THINK THIS MACHINE IS NOT OPERATING PROPERLY, RE-READ THE INSTRUCTION

MANUAL CAREFULLY, THEN CALL YOUR AUTHORIZED BUG-O DEALER/DISTRIBUTOR. IF

THEY CANNOT GIVE YOU THE NECESSARY SERVICE, WRITE OR PHONE US TO TELL US

EXACTLY WHAT DIFFICULTY YOU HAVE EXPERIENCED. BE SURE TO MENTION THE MODEL

AND SERIAL NUMBERS.

36

Loading...

Loading...