Page 1

INSTRUCTIONS

AND

PARTS MANUAL

MODULAR DRIVE

SYSTEM

Please record your equipment identication information below for future reference. This information can be

found on your machine nameplate.

Model Number:

Serial Number:

Date of Purchase:

Whenever you request replacement parts or information on this equipment, always supply the information

you have recorded above.

LIT-MDS-IPM-0215

Bug-O Systems is guided by honesty, integrity and

ethics in service to our customers and in all we do.

A DIVISION OF WELD TOOLING CORPORATION

280 TECHNOLOGY DRIVE CANONSBURG, PENNSYLVANIA 15317-9564 USA

PHONE: 412-331-1776 http://www.bugo.com FAX: 412-331- 0383

Page 2

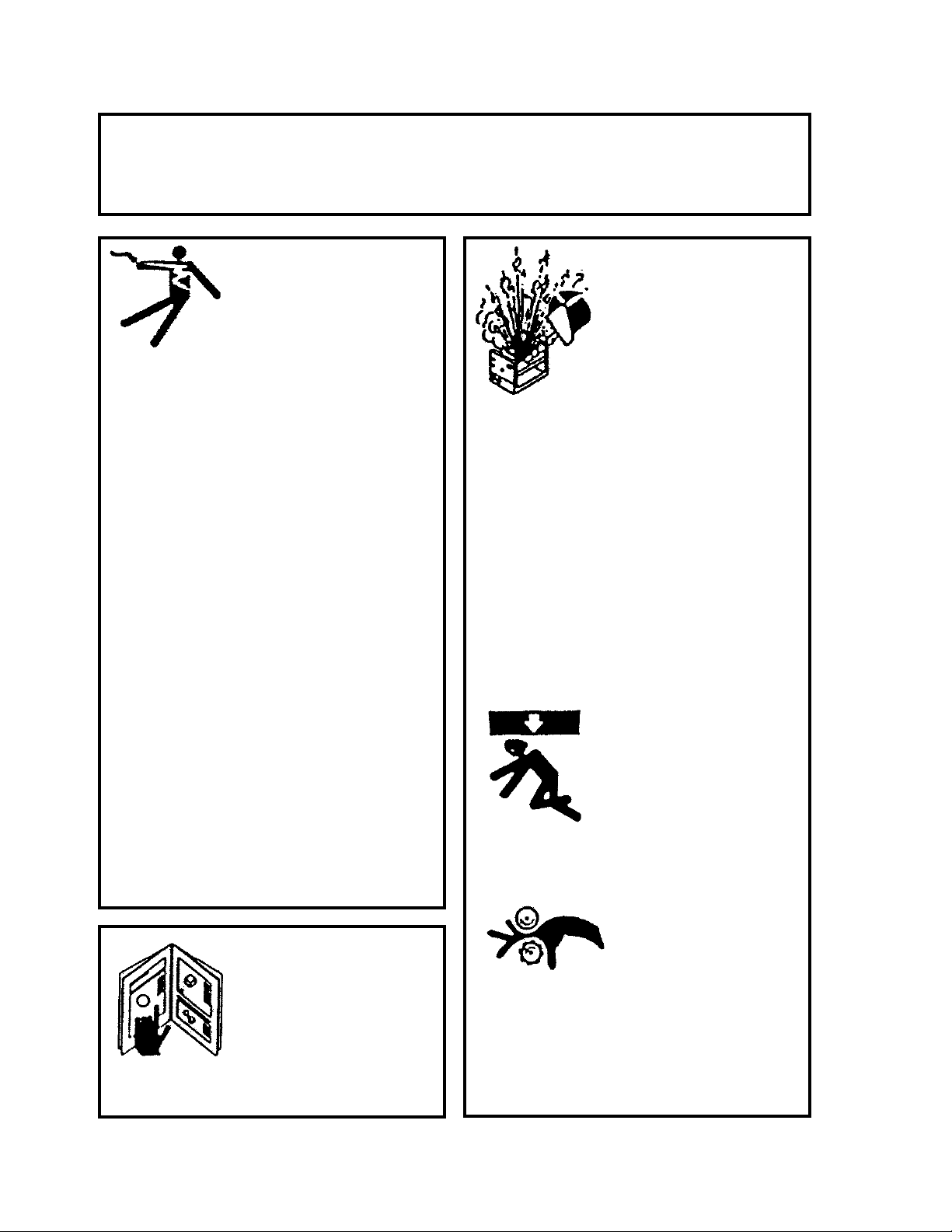

SAFETY

1) The equipment is not waterproof.

Using the unit in a wet environ-

ment may result in serious injury.

Do not touch equipment when wet

or standing in a wet location.

2) The unused connectors have

power on them. Always keep the

unused connectors covered with

the supplied protective panels.

Operation of the machine without

the protective panels may result in

injury.

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY

QUALIFIED INDIVIDUALS.

EQUIPMENT DAMAGE

ELECTRIC SHOCK can kill.

1) Do not plug in the power cord without

rst verifying the equipment is OFF

and the cord input voltage is the same

as required by the machine or serious

damage may result.

2) Always verity both the pinion and

wheels are fully engaged before apply ing power or equipment damage may

occur.

POSSIBLE.

3) Never open the equipment without

rst unplugging the power cord or

serious injury may result.

4) Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

5) Never remove or bypass the equip ment power cord ground. Verify the

equipment is grounded in accor-

dance with all applicable local and

national electrical safety codes. If

none exist, use International Electric

Code (IEC) 950.

READ INSTRUCTIONS.

3) Do not leave the equipment

unattended.

4) Remove from the work site and store in

a safe location when not in use.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or

walk underneath equipment.

MOVING PARTS can

cause serious injury.

1) Never try to stop the pinion from mov ing except by removing power or by

using the STOP control.

Read the instruction manual before

installing and using the equipment.

2

2) Do not remove any protective panels,

covers or guards and operate equip ment.

Page 3

HIGH FREQUENCY WARNINGS

SPECIAL PRECAUTIONS ARE REQUIRED WHEN USING PLASMA,

TIG OR ANY WELDING PROCESS THAT USES HIGH FREQUENCY TO

WARNING: HIGH FREQUENCY CAN EFFECT MACHINE

OPERATION AND THEREFORE, WELD QUALITY.

Read the precautions below before installing and using the equipment.

PRECAUTIONS:

1) Some plasma or welding cables are strong sources of high frequency interference.

NEVER lay a plasma or welding cable across the controls of the machine.

2) Always physically separate the plasma or welding cable leads from the machine

cables. For example, the plasma or welding cable leads should NEVER be bundled

with a pendant cable or the machine power cord. Maximize the separation between

any machine cables and the plasma or welding cables.

STRIKE AN ARC.

3) Strictly follow the grounding procedures specied for the plasma or welding unit.

NOTE: Some plasma and welding units produce exceptionally large amounts of high

frequency noise. They may require a grounding rod be driven into the earth within six

feet (2 meters) of the plasma or welding unit to become compatible with an automatic

cutting or welding process.

4) If the high frequency is produced using a spark gap, adjust the points so the gap is as

small as possible. The larger the gap, the higher the voltage and the higher the

interference.

5) Some plasma or welding units will inject high frequency interference into the AC

power line. Use separate power line branches whenever possible to power the

plasma or welding source and the machine. Do not plug them into the same outlet box.

6) High frequency noise may enter the machine through the plasma or welding supply

remote contactor leads. Some plasma and welding sources can produce noise spikes

of up to several thousand volts. These sources are not compatible with automated

cutting and welding equipment. It is recommended that the remote contactor leads on

these plasma or welding sources not be connected to the machine. An alternate

solution is to purchase a separate remote contactor isolation box.

3

Page 4

MODULAR DRIVE SYSTEM

INSTRUCTIONS AND PARTS MANUAL

TABLE OF CONTENTS

PAGE

5.............. Introduction / Standard Features

6.............. Additional Features

7.............. Setup

8.............. Master Drive Unit / Technical Data / Dimensions

9 ........... MPD-1000 Master Drive Unit / Exploded View / Parts List

10 ......... Master Drive Unit / Wiring Diagram

11 ......... AC Power Wiring Diagram / Electrical Component Chart

12 ......... Signal Wiring / Parts List

13............ Modules / Technical Data / Dimensions

14 ......... MDS-1002 Straight Module

15-16 ... MDS-1003 Stitch Module

17 ......... MDS-1004 Programmable Module

18-19 ... MDS-1005 / MDS-1005-DIAL / Weaver Control Modules

20 ......... MDS-1005 / MDS-1005-DIAL / Weaver Control Module Replacement Parts

21 ......... Digital Readout Calibration

22............ WPD-1000 Linear Weaver / Introduction / Features

23 ......... Linear Weaver / Technical Data / Dimensions

24-25 ... Linear Weaver / Setup

26 ......... WPD-1100 Linear Weaver / Exploded View

27 ......... WPD-1100 Linear Weaver / Parts List

28............ WPD-2100 Pendulum Weaver II / Introduction / Features

29-30 ... Pendulum Weaver II / Installation / Setup and Alignment

31 ......... Pendulum Weaver II / Technical Data / Dimensions

32 ......... WPD-2100 Pendulum Weaver II / Exploded View / Parts List

33 ......... WPD-2120 Pendulum Weaver II / Electronics / Exploded View / Parts List

34 ......... WPD-2115 Pendulum Gear Box / Exploded View

35............ Weaver Unit / Wiring Diagram

36............ Carriages

37............ Detailed Setup

38............ MDS-1055 Universal Limit Kit

39............ MDS-1060-_ Remote Control Cable

39............ CAS-__ Automatic Height Control

40............ Accessories

41............ Aluminum Rigid Rail

42............ Semi Flex Rail

43............ Hi-Flex Rail

44............ Standard Magnet Assemblies

45-46 ...... Vacuum Support Kit

47-56 ...... Troubleshooting Guide

57............ Warranty

4

Page 5

INTRODUCTION

The Modular Drive System is the only product in the industry that allows the user to custom congure one

machine for various applications. The system consists of drives, plug-in control modules and carriages

that are easily assembled. The modular design allows the operator to quickly upgrade or recongure the

machine for straight line cutting and welding, stitch welding or weave welding. The system will run in any

position using Aluminum Rigid Rail, Aluminum Semi-Flex Rail [with a minimum radius of 15' (4.57 m)], Bent

Rigid Rail or Hi-Flex Rail [with a minimum radius of 40" (1 m)].

The straight line cutting and welding conguration consists of a carriage, master drive, racking group and

control module. The optional MDS-1060-10 Remote Control Cable can be used to remote the control

module.

A number of straight line control modules are available. The MDS-1002 Straight Line Module provides

simple direction and speed control for continuous cutting or welding. The MDS-1003 Stitch Module provides

a straight line and stitch welding mode with skip time, weld time and crater/puddle buildup time. The MDS1004 Programmable Stitch Module provides digital display of all stitch welding parameters. The MDS-1004

Stitch Module has closed position feedback so all distances are set in inches or mm as opposed to time and

are repeatable. The MDS-1055 Universal Limit Kit adds cycler, stop at limit and rapid return functions to the

MDS-1002 and MDS-1003 modules. The MDS-1004 Programmable Module has built in stop at limit and

rapid return modes. For more features, see the appropriate pages on each of the modules.

The Master Drive is rated at 60 lbs (27 kg) vertical load. (International Robotics Standards Rating)** The

machine is equipped with overload protection.

STANDARD FEATURES

The Master Drive Unit incorporates the following standard internal features:

• High torque, low inertia motor for precise stops and starts.

• Dedicated fail-safe brake with three times the stopping and holding power of the motor.

• Motor overload protection which turns off the motor and engages the brake when excessive load is

placed on the machine.

• Closed loop speed control for adjustable and repeatable control of critical welding or cutting parameters.

• Closed loop position control to prevent position creep when the machine stops to perform an operation

such as crater ll at the end of a stitch weld.

**The International Robotics Standards Rating requires a minimum of 2:1 continuous-duty safety margin on

all power train and electronics components.

5

Page 6

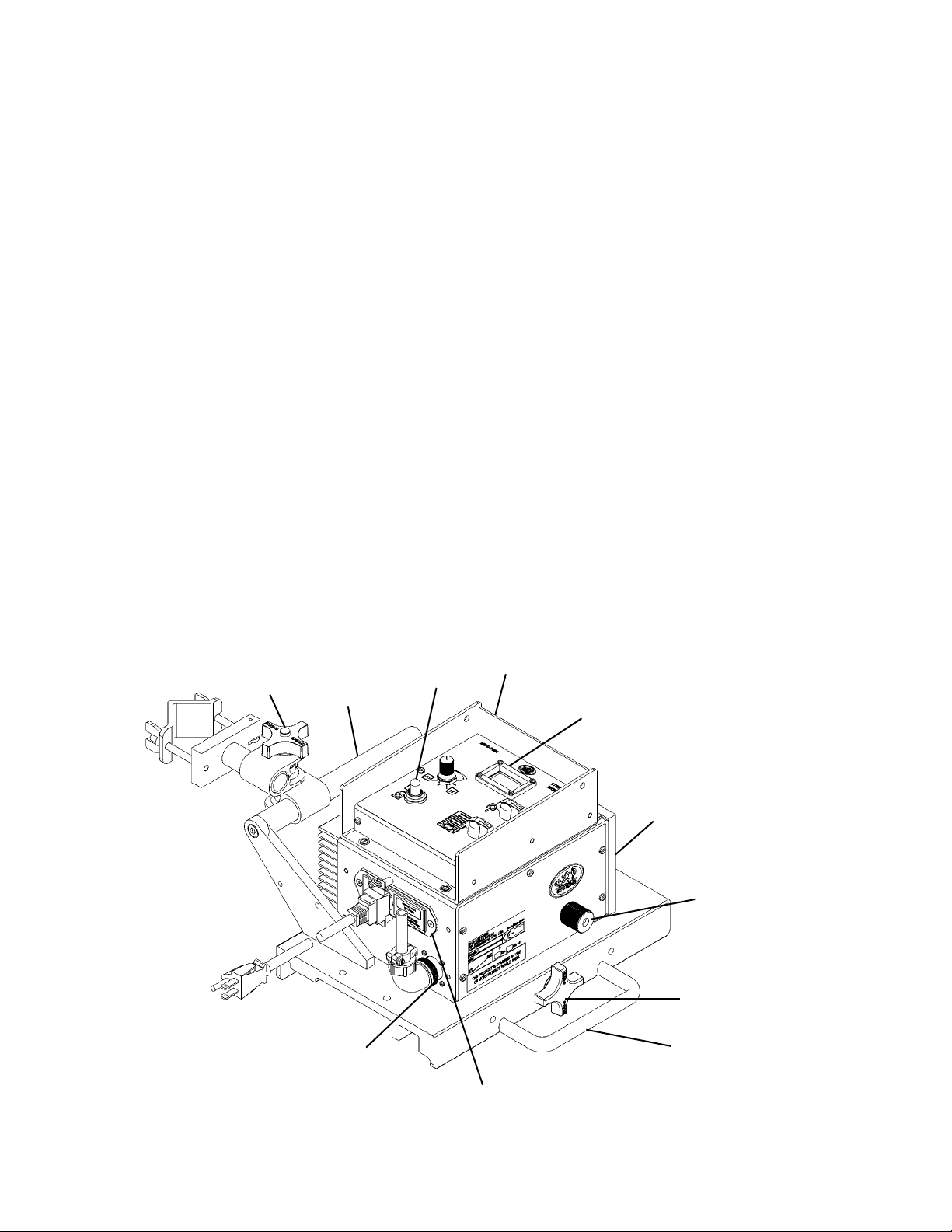

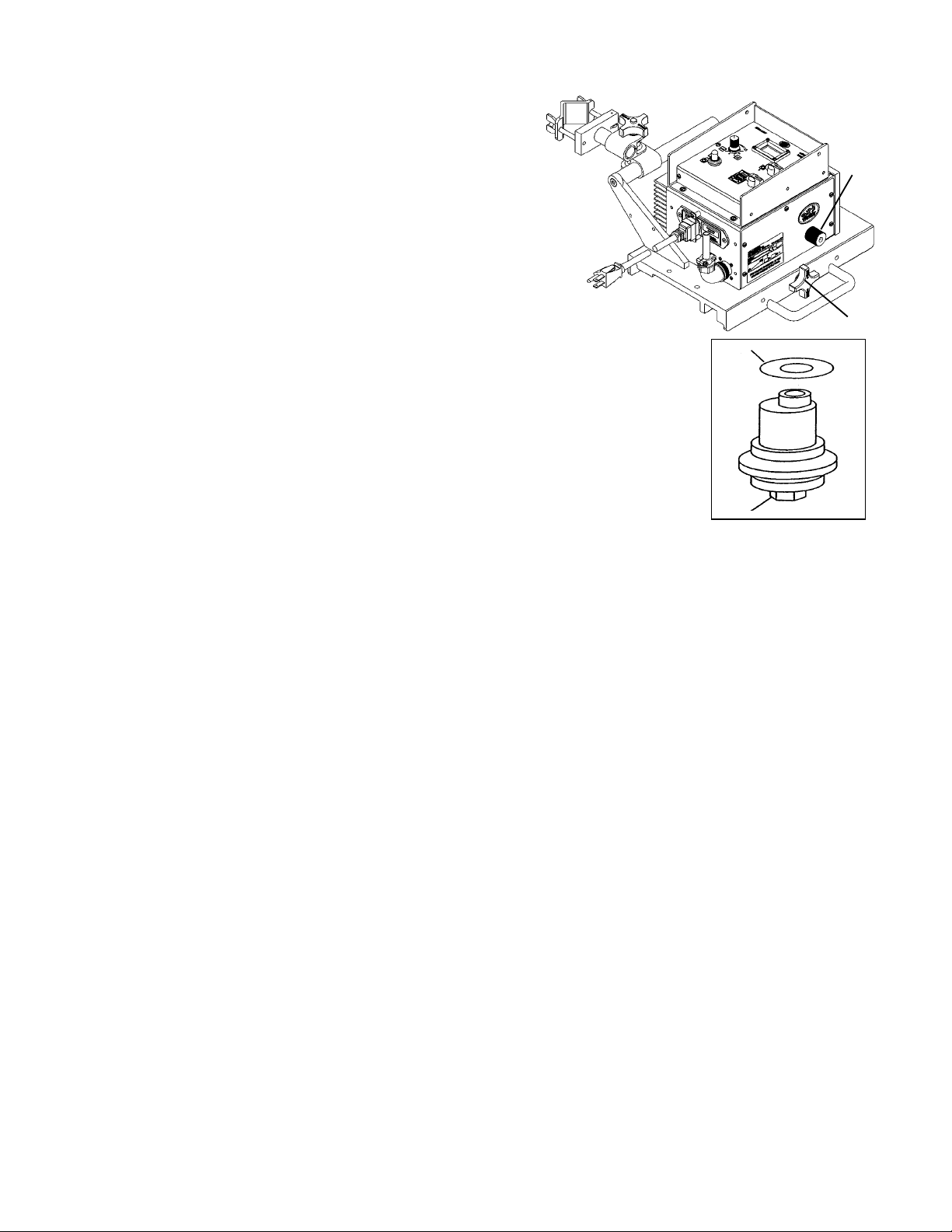

ADDITIONAL FEATURES

1. Control Module that is easily remoted or changed.

2. Master Power Drive Module that is recongurable by the user, for different applications, by

adding or changing mating modules and accessories.

3. Clutch, to enable rapid manual repositioning of the carriage anywhere on the track.

4. Wheel engagement knob, which enables placement of the releasable carriage anywhere on

the track.

5. Optional cable mounting bar with anchor clamp to keep the welding cables and contact wires

away from the work surface.

6. Contactor ON/OFF switch.

7. Power Entry Box with:

a) Input Power Fuse

b) Machine ON/OFF Switch

c) Power Cord Mating Connector

8. Standard Carrying Handle.

9. Digital speed readout for more repeatable welding/cutting.

10. Optional Carrying Handle and Mounting Bar.

11. Remote Weld Contactor Receptacle.

5

10

6

1

9

2

3

4

11

7

6

8

Page 7

SETUP

1) WHEEL ADJUSTMENT AND ALIGNMENT

Always check for proper carriage wheel adjustment before

using the machine. Turn the wheel engagement knob (A)

on the side of the carriage until the wheels are fully moved

towards the center of the carriage (engaged). Then rotate

the master drive clutch knob (B) fully counter clockwise to

disengage the drive pinion. Slide the carriage onto the end of

a track. The wheels should slide into the track V-grooves and

the carriage will move smoothly along the track if the wheels

are properly aligned.

B

A

The wheels along one side of the carriage have stainless steel shim washers (C) underneath. These wheels are adjustable. Readjust these wheels (if

necessary) by rotating the hex bolt (D) with a 1/2" wrench.

Grasp the sides of the carriage. The wheels are too loose if it is possible to

move the carriage from side to side or up and down. Use a nger to keep one

of the adjustable wheels from rotating as the carriage is manually pushed

along the track. The wheels are adjusted too tight if rm nger pressure is not

enough to prevent wheel rotation. Repeat the process for the other adjustable

wheel.

2) POSITIONING THE MACHINE ON THE TRACK

Position the rail using magnet plates or vacuum cups. Wipe the track grooves free of weld splatter and other

debris. This will prevent binding and premature rail and wheel wear. Lubricate the rack using a dry spray, if

desired, for extended track life.

Turn the wheel engagement knob (A) on the side of the carriage fully counter clockwise to disengage the

wheels. Then rotate the Master Drive clutch knob (B) fully counter clockwise to disengage the drive pinion.

The carriage can now be placed anywhere on the track. Turn the wheel engagement knob (A) clockwise

to engage the wheels rmly in the V-grooves. Verify all four wheels are in the grooves. Manually move the

carriage along the track to verify the motion is smooth and the wheel alignment is correct. Rotate the Master

Drive clutch knob (B) fully clockwise while gently rocking the machine forward and backward to fully engage

the drive pinion. The rocking motion is necessary to help insure proper gear mesh.

C

D

3) REMOTE CONTACTOR WIRING

Connect the remote weld contactor to the welding source as shown below:

Pins A and B ................. connection for Output #1

Pins C and D ................ connection for Output #2

4) GUN AND TORCH SETUP

For welding, insert the welding gun into the all-position clamp on the rack. Adjust the clamp, the clamp block

and the rack to position the gun for welding. Connect the weld contactor connector to the rear of the main

drive unit. Route the welding cable and weld contactor wires through the cable anchor clamp.

For cutting, insert the cutting torch into the torchholder on the rack. Adjust the torchholder, the clamp block

and the rack to position the torch for cutting. Connect the hose assembly to the manifold and the cutting

torch. The manifold acts as a strain relief on the supply hoses as well as a quick shut-off valve for the gases.

Once the torch valves are adjusted, the manifold eliminates the need for continuous adjustments and keeps

the supply lines from dragging the torch out of position.

5) MACHINE OPERATION

Turn the main power ON at the power entry box. Set parameters on control module in use.

7

Page 8

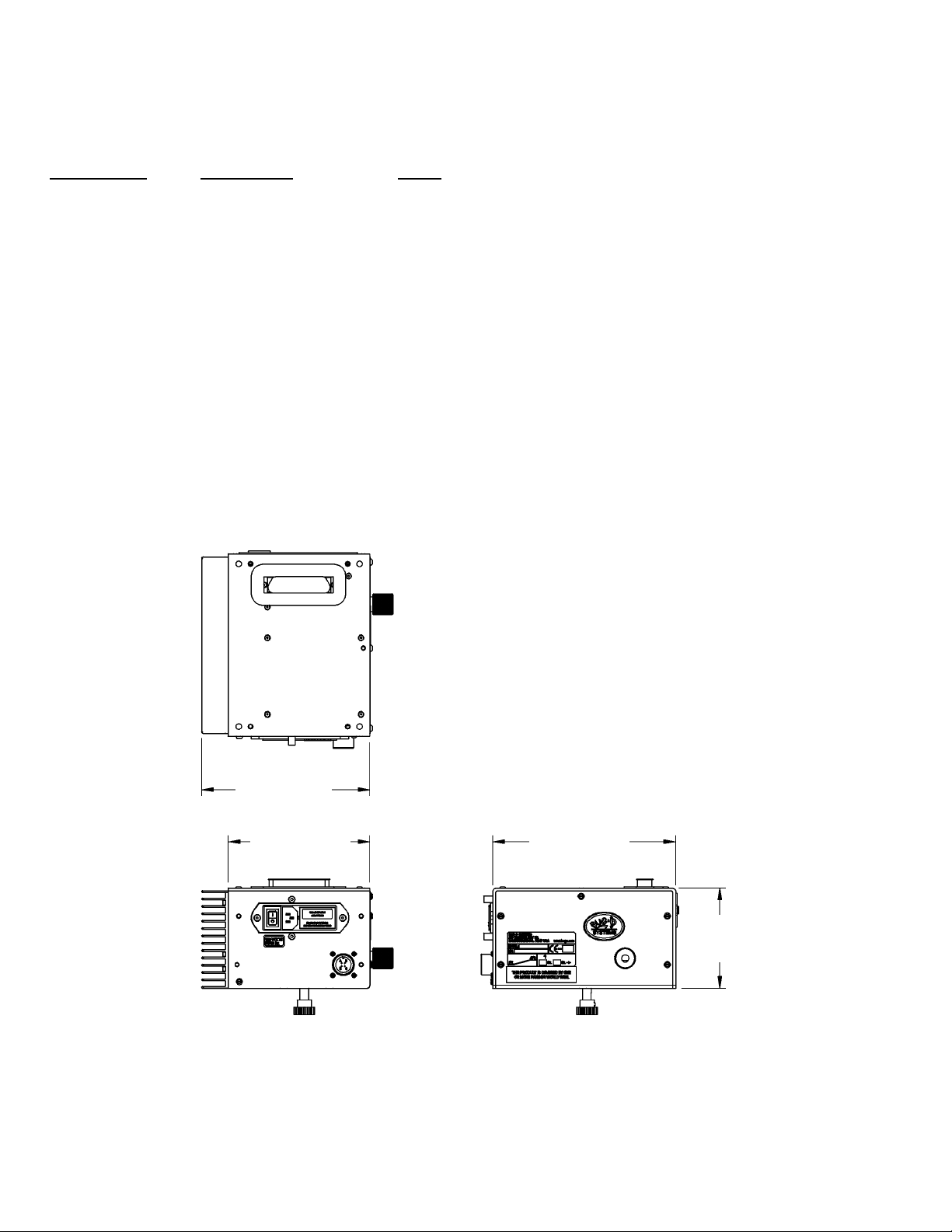

MASTER DRIVE UNIT / TECHNICAL DATA

Power Requirements:

Part Number Voltage / Hz Amps

MPD-1000 120 VAC/50-60 Hz 2A

MPD-1002 240 VAC/50-60 Hz 3A

MPD-1004 42 VAC/50-60 Hz 6A

Dimensions: 7.75" L x 6.00" W x 4.25" H

(197 x 152 x 108 mm)

Load Capacity: Vertical - 60 lbs (27 kg) [International Robotics Standards Rating]**

Horizontal - 100 lbs (45 kg)

Speed Range: 2-120 in/min (51-3048 mm/min)

Net Weight: 10 lbs (4.5 kg)

Shipping Weight: 13 lbs (5.9 kg)

DIMENSIONS

7.13

(181 mm)

6.00

(152 mm)

7.75

(197 mm)

4.25

(108 mm)

** The Master Drive is rated at 60 lbs (27 kg) vertical load. The International Robotics Standards

Rating requires a minimum of 2:1 continuous-duty safety margin on all power train and electronics

components. The machine is equipped with overload protection.

CAUTION: The Speed Control Card in the Master Drive is NOT interchangeable

with the speed card in the Linear or Pendulum Weavers.

8

Page 9

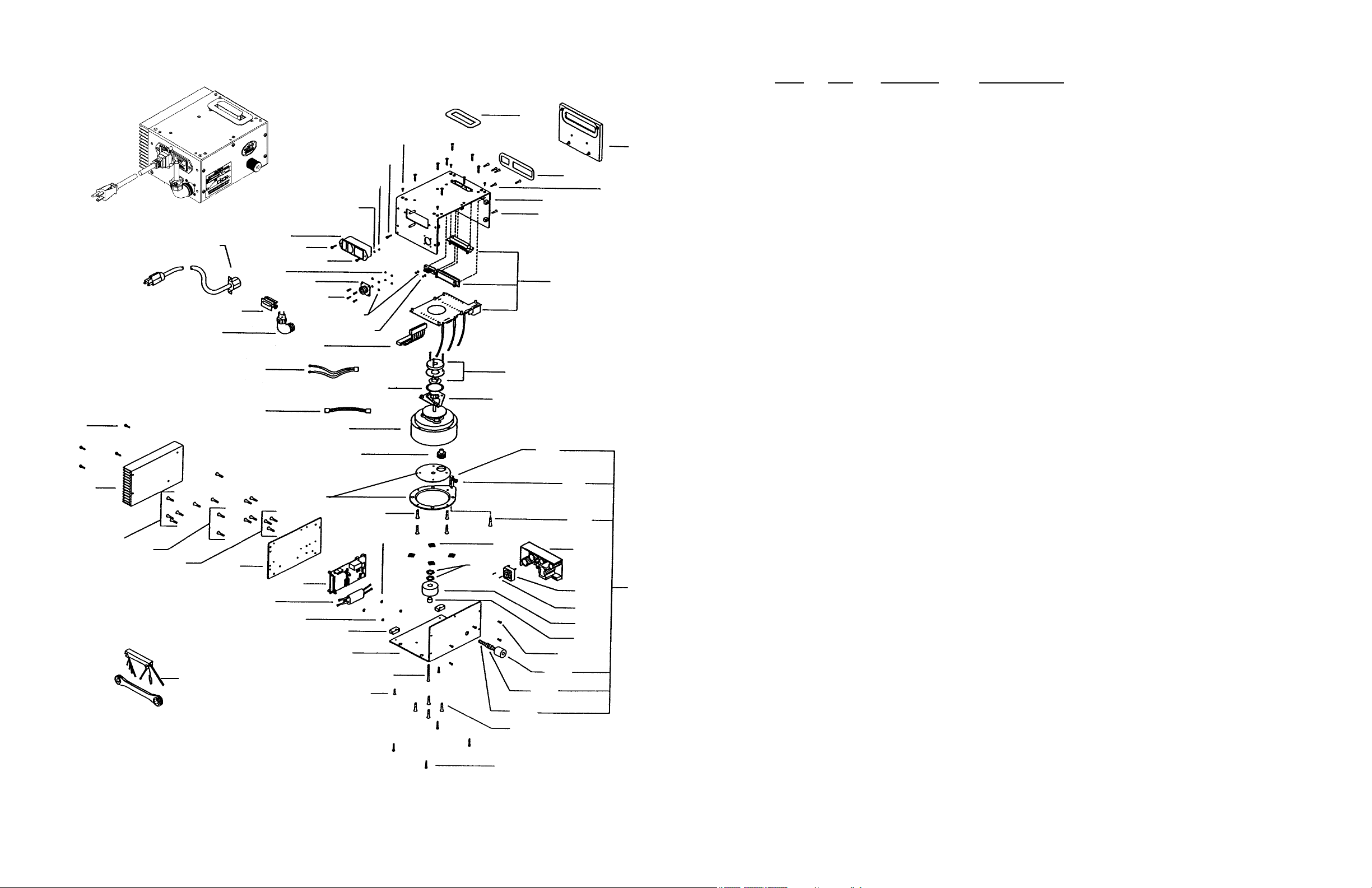

MPD-1000 MASTER DRIVE UNIT / EXPLODED VIEW / PARTS LIST

45

20

6

15

54

38

40

24

14

41

49

15

11

1

39

12

28

4

53

14

55

2

30

19

13

54

27

26

17

11

52

29

16

36

37

13

8

7

23

11

10

21

42

48

9

3

22

10

32

44

51

33

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-1034 Panel Connector, 4-T, Male

2 1 WPD-1013 Rubber Ring Gasket

3 1 BUG-9444 Tool Kit

4 4 FAS-0104 Pan Hd Screw 4-40 x 318 Lg

43

46

11

5 2 FAS-0107 Pan Hd Screw 4-40 x 3/4 Lg

6 6 FAS-0114 Pan Hd Screw 6-32 x 3/8 Lg

7 4 FAS-0504 Soc Hd Cap Scr 4-40 x 3/8 Lg

8 4 FAS-0557 Soc Hd Cap Scr 1/4-20 x 3/4 Lg

9 3 FAS-0902 Fit Hd Soc Scr 4-40 x 1/4 Lg

10 19 FAS-0905 Fit Hd Soc Scr 4-40 x 1/2 Lg

11 11 FAS-0914 Fit Hd Soc Scr 6-32 x 3/8 Lg

12 1 FAS-0915 Fit Hd Soc Scr 6-32 x 1/2 Lg

13 8 FAS-0923 Fit Hd Soc Scr 8-32 x 5/16 Lg

14 6 FAS-1305 Hex Nut 4-40

15 3 FAS-1310 Hex Nut 6-32

16 2 FAS-1325 Hex Nut 8-32 Nylon

17 1 FAS-2823 Fit Hd Sit Scr 8-32 x 1 1/2 Lg

18 1 GOF-3012 Spacer 1/2 OD x 5/16 Lg

19 1 GOF-3014 Pinion

20 4 MDS-1019 Snap Rivet, Black

*21 1 BUG-9454 V-Lock Cord 120VAC

22 1 MPD-1006 Side Panel

23 1 MPD-1007 Heat Sink

24 1 MPD-1008 Filter

25 1 MPD-1009 Fan Assembly

26 1 MPD-1011 Base Panel

27 2 MPD-1012 Mounting Block

28 1 MPD-1090 Matched Clutch Plts

**29 1 BUG-2593 Glide Flat

30 1 MPD-1015 Gear Motor (60:1)

31 1 MPD-1016 Clutch Assembly (Includes items 32 through 37)

35

32 1 BUG-1216 Ball Joint

33 1 BUG-1857 Knob

34 1 FAS-0945 Fit Hd Soc Scr 10-32 x 1/2 Lg

34

35 1 FAS-1341 Hex Jam Nut 10-32

36 2 FAS-1390 Hex Nut 3/8-16

37 1 MPD-1017 3/8-16 Threaded Stud

50

38 1 MPD-1018 Wiring Harness-Speed Board to Motor

39 1 MPD-1019 Wiring Harness-Interconnect to Speed Bd/Control

40 1 MPD-1020 Wiring Harness-Interconnect to Speed Bd/Power

25

5

47

18

6

31

41 1 MPD-1025 Power Entry Module

* 42 1 MPD-1067 Fuse 6A

43 1 MPD-1029 Connector Cover Plate

44 1 MPD-1031 Cover Panel (Includes item #20)

45 1 MPD-1038 Gasket for 50-Pin Connector

46 1 MPD-1039 Gasket for 50-Pin/3-Pin Connector

47 1 MPD-1042 Inductor, Potted-with Connectors

48 1 MUG-1617 Cable Connector, 4-T, Female, Elbow

*49 1 PCB-1000 Speed Board

* 50 1 PCB-1005-120 Power Supply Assembly 165W 120VAC

51 1 PCB-1010 Interconnect Board

52 1 PCB-1012 Position Card

53 6 WAS-0201 #4 Internal Star Lockwasher

54 3 WAS-0211 #6 Internal Star Lockwasher

55 1 WPD-1012 Brake Assembly

* See Electrical Component Chart for 240 VAC and 42 VAC Part Numbers

**Included in Item 28.

CAUTION: The Speed Control Card in the Master Drive is NOT interchangeable with the speed card in the Linear or Pendulum Weavers.

9

Page 10

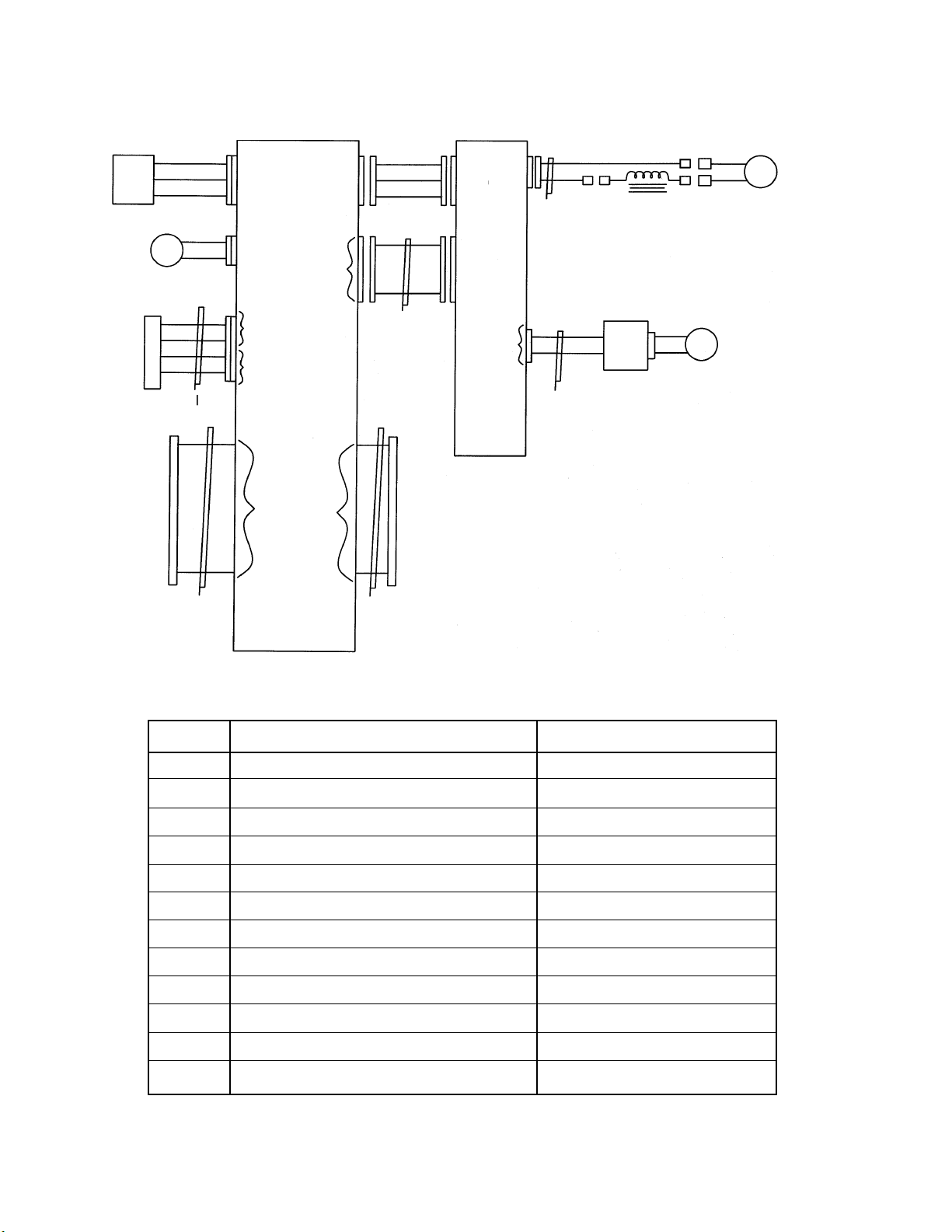

MASTER DRIVE WIRING DIAGRAM MPD-1000/ MPD-1002/ MPD-1004

120V AND 240V WIRING ONLY

SEE FIGURE 1 FOR 42V WIRING

10

NOTES:

Encoder card and brake are mounted on the motor.

18 pin connectors are not wired 1:1.

The Connector on one end is ipped.

For example, Pin 1 goes to connector 18.

Most signals on the 50 pin connector come in one 50 pin connector

and exit on the other 50 pin connector.

Pinouts for connectors can be determined from screen print.

Page 11

AC POWER WIRING DIAGRAM

PEM

BLK

J1

PC

RED

*F2

FUSE BOX

42 VAC

F1

BLK BLU

RED

GRN

RED

RED BLK

BLK

RFI

115 VAC

240 VAC

GRN

AC

POWER

OUT

&

BLK

BLU

BLU

PS PS

DC OUT

RED

DC OUT

ELECTRICAL COMPONENT CHART

MPD-1000 MPD-1002 MPD-1004

ITEM DESCRIPTION 120 VAC 240 VAC 42 VAC

F1,F2* Fuses (2) MPD-1067 6A (2) MPD-1067 6A (2) MPD-1067 6A

PC Power Cord MPD-1030 MPD-1032 MPD-1034

PS Power Supply PCB-1005-120 PCB-1005-240 PCB-1005-42

J1 Connector w/Pins MPD-1021 MPD-1021 MPD-1021

PEM Power Entry Module MPD-1025 MPD-1025 MPD-1025

RFI Filter Module MPD-1008 MPD-1008 MPD-1008

*F2 replaced with bus wire on 120 VAC

PART NO.

11

Page 12

SIGNAL WIRING

PS

A

B

C

D

FROM

CONTROL

MODULE

WHT/RED

WHT/BLK

WHT/OR

RED

F

BLK

PUR

PUR

YEL

YEL

CI

50 LINE

RIBBON

+ 15 V

GND

- 15 V

FAN +

FAN -

1

CONTACT

2

3

4

CONTACT

INPUTS

INTERCONNECT

+ 15 V

GND

- 15 V

SPEED

CARD

SIGNALS

A

B

OUTPUTS

PCB 1

WHT/RED

WHT/BLK

WHT/OR

C2

18 LINE

C3

50 LINE

RIBBON

MOTOR

OUT

POSITION

IN AND

BRAKE

OUT

SPEED

CONTROL

PCB 2

TO

OSCILLATOR

OR

ACCESSORIES

BLK

RED

C4

10 LINE

RIBBON

CK

CHOKE

PCB 3

POSITION

M

GEAR

MOTOR

B

BRAKE

12

PARTS LIST

ITEM DESCRIPTION PART NO.

B Brake Assembly WPD-1012

Cl Contactor Cable Assembly MPD-1036

C2 DC Power Cable Assembly MPD-1020

C3 Speed Card Cable Assembly MPD-1019

C4 Motor Wiring MPD-1018

CK Inductor Pot Assembly (Choke) MPD-1042

F Fan Assembly MPD-1009

M Gear Motor MPD-1015

PCB1 Interconnect Card PCB-1010

PCB2 Tractor Speed Card PCB-1000

PCB3 Position Sensor Card PCB-1012

PS Power Supply (see AC Wiring Diagram)

Page 13

MODULES / TECHNICAL DATA

MDS-1002 STRAIGHT LINE MODULE

MDS-1003 STITCH MODULE

MDS-1004 PROGRAMMABLE MODULE

MDS-1005 WEAVER CONTROL MODULE

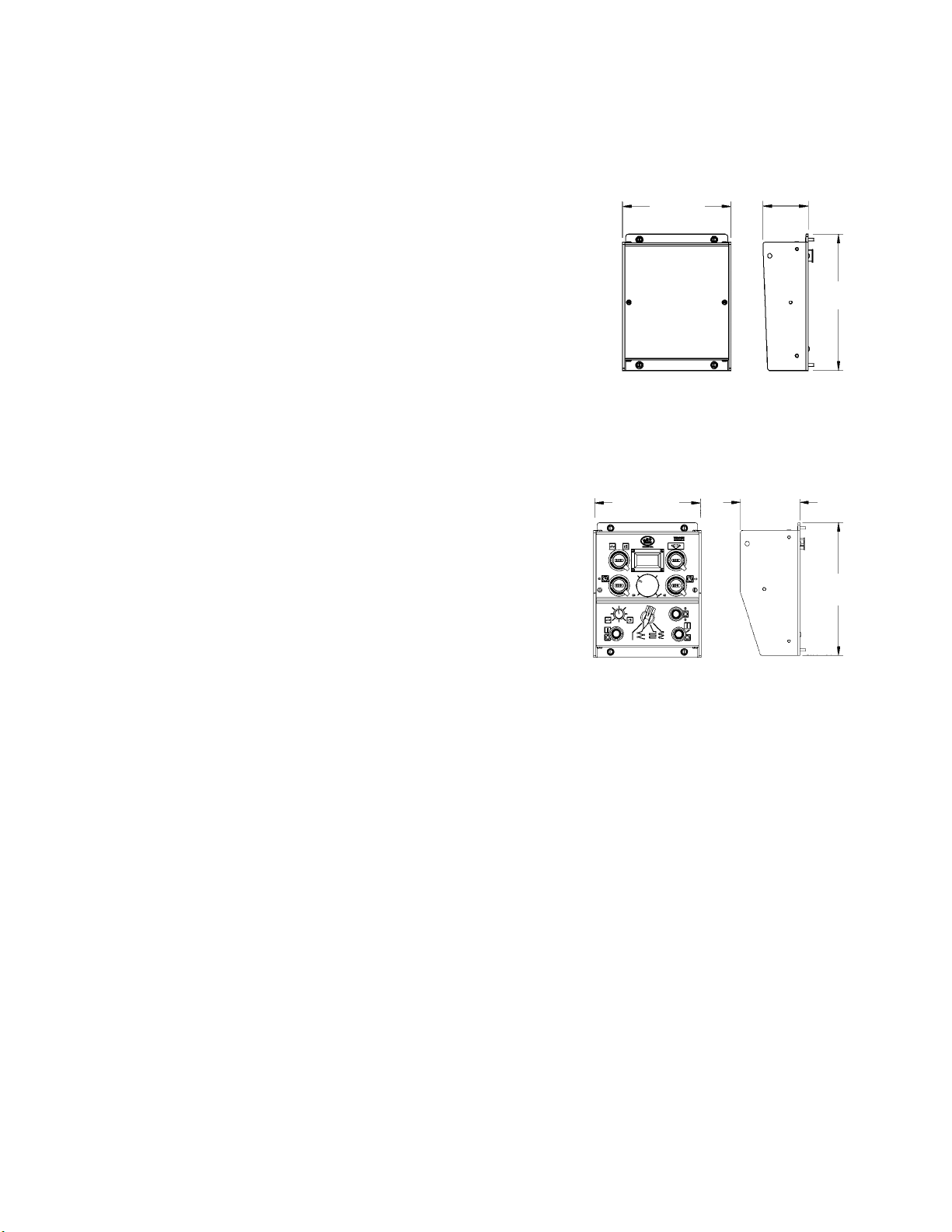

Dimensions: 7.50" L x 6.00" W x 2.50" H

(191 x 152 x 64 mm)

Net Weight: 1.75 lbs (0.8 kg)

Shipping Weight: 3.0 lbs (1.4 kg)

MDS-1005-DIAL WEAVER CONTROL MODULE

Dimensions: 7.50" L x 6.00" W x 3.38" H

(191 x 152 x 86 mm)

Net Weight: 3 lbs (1.4 kg)

Shipping Weight: 8 lbs ( 3.63 kg)

DIMENSIONS

6.00"

(152 mm)

MDS-1002

MDS-1003

MDS-1004

MDS-1005

Dial Weaver Control Module

6.00"

(152 mm)

2.50"

(64 mm)

7.50"

(191 mm)

3.38"

(86 mm)

7.50"

(191 mm)

13

Page 14

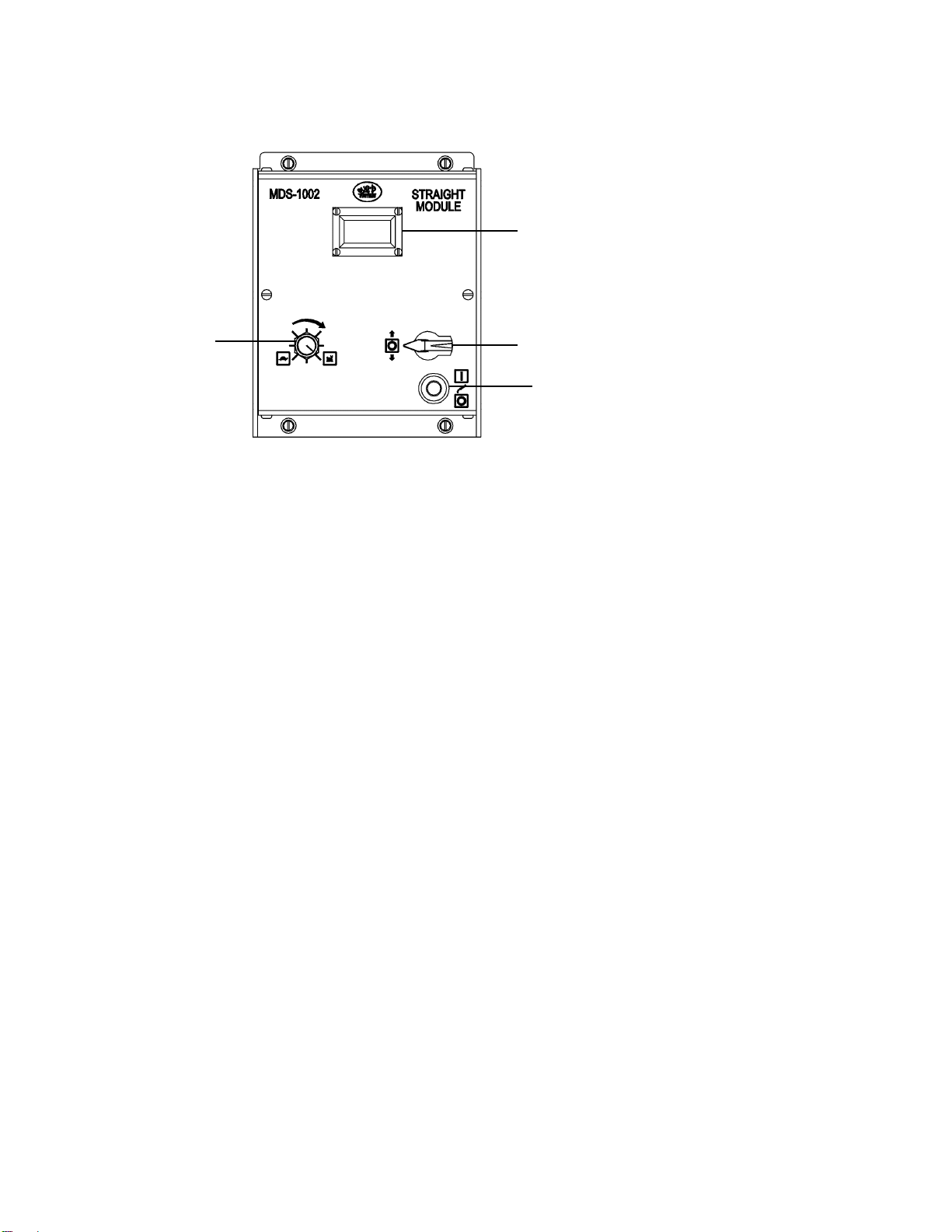

MDS-1002 STRAIGHT MODULE

The MDS-1002 Straight Module provides direction and speed control for continuous cutting or welding.

DIGITAL READOUT

SPEED CONTROL

CARRIAGE TRAVEL SWITCH

WELD CONTACT

(PLASMA)

SPEED CONTROL: Sets the tractor speed from 2-120 in/min (5.1-304.8 cm/min).

CARRIAGE TRAVEL SWITCH: Provides FORWARD/STOP/REVERSE direction control.

Stop at limit in direction of travel & Cycle between limits can be controlled

with the installation of the MDS-1055 Universal Limit Kit. (Ref to pg. 38)

DIGITAL READOUT: The display is dual function.

a) PRESET SPEED - Displayed when the CARRIAGE TRAVEL SWITCH is OFF or motion

is halted by a motor overload condition.

b) MEASURED SPEED - Displayed when power is applied to the motor.

(This will be the same as the Preset Speed.)

Factory settings of 120 Volt machines are set to in/min, 240 and 42 Volt machines are set cm/min.

WELD CONTACT: Opens/closes a pair of independent 1 Amp contacts (pins A & B and C & D) at the weld

contactor receptacle.

NOTE: A safety interlock will automatically open the weld contacts if the motor overload protection halts ma-

chine motion. Clear the overload by turning the carriage travel switch to OFF. Resetting the overload

fault will not cause the contacts to automatically reclose. Use the weld contact switch to restart the

welder plasma unit after clearing the overload.

REPLACEMENT POTS AND SWITCHES

CARRIAGE TRAVEL:

Switch and Spacer MDS-1112

Black Pointer Knob BUG-9694

SPEED CONTROL:

10 K Ω Pot, 3-3/4 turn PCB-1026

Black Knob MDS-1018

Knob Seal Nut MDS-1046

WELD CONTACT:

Switch and Spacer MDS-1115

Toggle Switch Boot MDS-1047

14

Page 15

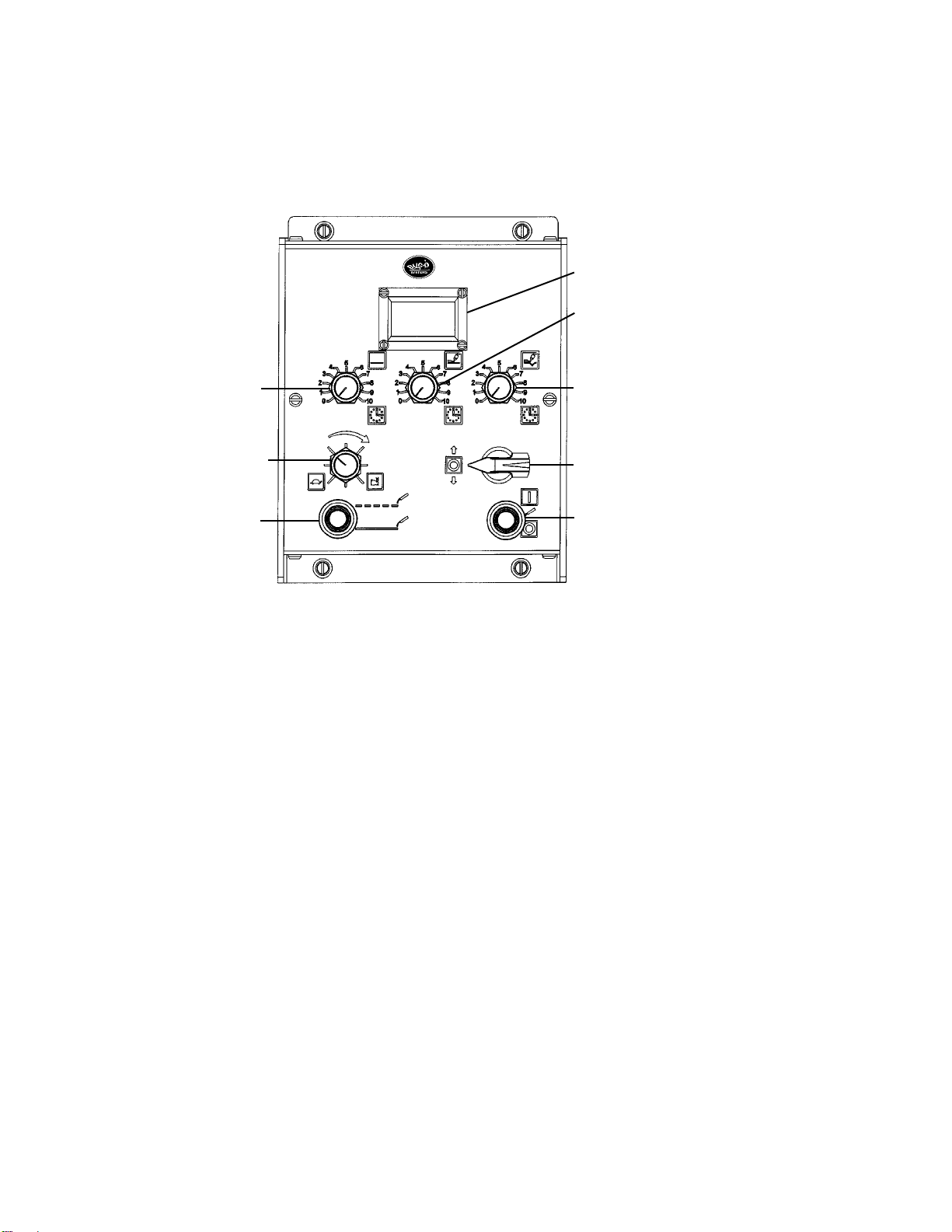

MDS-1003 STITCH MODULE

The MDS-1003 Stitch Module provides direction and speed control for continuous welding and cutting. In

addition, a stitch welding mode is provided, with adjustments for skip time (welder off), weld on time and

puddle buildup/crater ll time.

MDS-1003

SKIP TIME

SPEED CONTROL

MODE

STITCH MODULE

DIGITAL READOUT

WELD TIME

PUDDLE BUILDUP/CRATER FILL TIME

CARRIAGE TRAVEL SWITCH

WELD CONTACT

(PLASMA)

SPEED CONTROL: Sets the tractor weld speed from 2-120 in/min (5.1-304.8 cm/min).

CARRIAGE TRAVEL SWITCH: Provides FORWARD/STOP/REVERSE direction control.

DIGITAL READOUT: The display is dual function.

a) PRESET SPEED - Displayed when the CARRIAGE TRAVEL SWITCH is OFF

or motion is halted by a motor overload condition.

b) MEASURED SPEED - Displayed when power is applied to the motor. (This will

be the same as the Preset Speed.)

Factory settings of 120 Volt machines are set to in/min, 240 and 42 Volt machines are set cm/min.

WELD CONTACT: Opens/closes a pair of independent 1 Amp contacts (pins A & B and C & D) at the

weld contactor receptacle. In STITCH mode, this switch acts as a weld contact enable and the stitch module cycles the contacts on and off.

NOTE: A safety interlock will automatically open the weld contacts if the motor overload protection halts

machine motion. Clear the overload by turning the carriage travel switch to OFF. Resetting the

overload fault will not cause the contacts to automatically reclose. Use the weld contact switch to

restart the welder after clearing the overload.

15

Page 16

MDS-1003 STITCH MODULE, CONT’D.

STITCH/CONTINUOUS: Selects between cyclic (Stitch) welding and continuous welding or cutting.

a) CONTINUOUS - Selects continuous welding or cutting.

b) STITCH - Selects the cyclic (Stitch) welding mode. This mode consists of four continuously repeated steps.

1) The machine stops moving for the selected time to perform Puddle

Buildup. (PIERCE WHEN PLASMA CUTTING)

2) The machine welds at the selected welding speed for the time selected

using the Weld Time control.

3) The machine stops moving for the selected time to perform Crater Fill.

4) The machine turns off the welder and moves at maximum speed to

where the next weld needs performed. This location is determined by

setting a Skip Time control.

WELD TIME: This control functions only when the mode switch is set to Stitch. Weld time sets a weld

length time from 1-50 seconds. This corresponds to a weld length of approximately 0.03-100 inches (0.82540 mm). NOTE: The operator must manually enable the weld contactor by turning on the Weld Contact

or the welder will never cycle on and off.

SKIP TIME: This control functions only when the mode switch is set to Stitch. Skip time sets how long the

machine travels between welds (0.3-15 seconds). This corresponds with a skip length of approximately 0.630 inches (15-762 mm). The machine always moves between welds at maximum speed.

PUDDLE BUILDUP / CRATER FILL TIME: This control functions only when the mode switch is set to

Stitch. Puddle Buildup/Crater Fill Time sets the time the machine is stopped at the beginning and end of

every weld (0-1.5 sec).

REPLACEMENT POTS AND SWITCHES

WELD CONTACT: CARRIAGE TRAVEL SWITCH:

Switch and Spacer MDS-1116 Switch and Spacer MDS-1112

Toggle Switch Boot MDS-1047 Black Pointer Knob BUG-9694

PUDDLE BUILDUP/CRATER FILL TIME: WELD TIME:

500K Ω Pot, 3/4 turn MDS-1053 500K Ω Pot, 3/4 turn MDS-1053

Black Knob MDS-1018 Black Knob MDS-1018

Knob Seal Nut MDS-1046 Knob Seal Nut MDS-1046

SKIP TIME: SPEED CONTROL:

500K Ω Pot, 3/4 turn MDS-1053 10K Ω Pot, 3 turn PCB-1026

Black Knob MDS-1018 Black Knob MDS-1018

Knob Seal Nut MDS-1046 Shaft Seal Nut MDS-1046

MODE:

Switch and Spacer MDS-1115

Toggle Switch Boot MDS-1047

16

Page 17

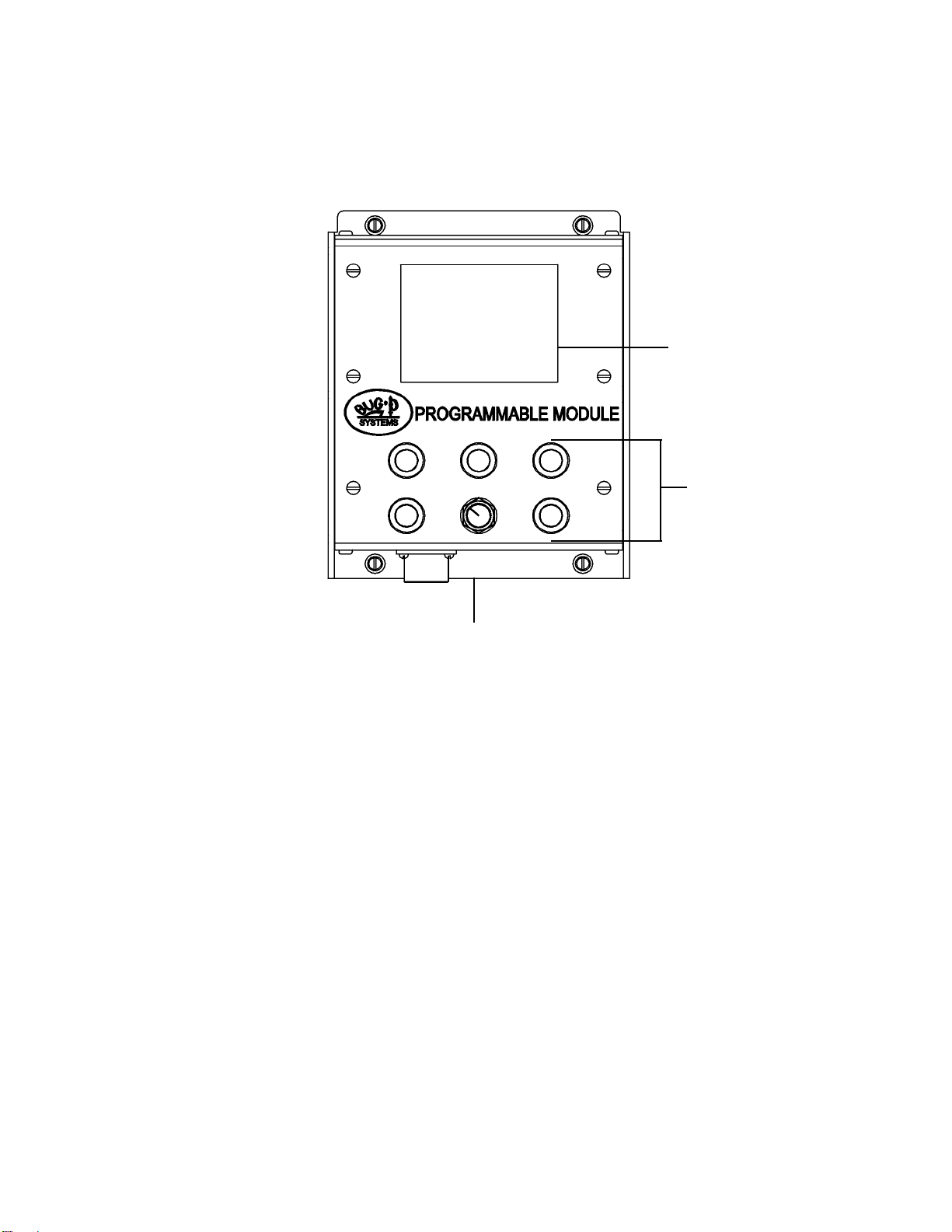

MDS-1004 PROGRAMMABLE MODULE

The MDS-1004 PROGRAMMABLE MODULE provides stitch controls for welding or cutting with the Modular

Drive System. All stitching parameters are set and displayed on a graphic screen. This allows each setting

to be set exactly the same every time. See MDS-1004 Manual for detailed instructions.

Display

Controls

Extra Contactor Output

FEATURES

• Each stitch setting is displayed while being set. This allows each setting to be exactly set each time

a job is set up.

• Closed loop encoder feedback is employed to ensure the traveled distances match the set distances.

• The module provides an extra contactor output. This output and the output on the Modular Drive can

be disabled or enabled independently.

• The module will stop the machine or return it to start after a preset number of welds. This eliminates

the need for external limit switches.

• This unit can return past the start location to allow for work piece changes. One button will start the

whole welding procedure.

• Stitch welds stopped in mid-job can be restarted without interrupting the weld pattern.

• Puddle-buildup and Crater-ll timers are independent.

17

Page 18

WEAVER CONTROL MODULES

MDS-1005 WEAVER CONTROL MODULE

The MDS-1005 Weaver Control Module provides weave welding control functions.

MDS-1005

WEAVE SPEED

DWELL LEFT

STEERING

CONTROL

TRACTOR SPEED

CONTROL

MODE SELECTOR

SWITCH

START/STOP

WEAVE

MODULE

WEAVE

AMPLITUDE

DIGITAL

READOUT

DWELL RIGHT

CARRIAGE TRAVEL

SWITCH

WELD CONTACT

MDS-1005-DIAL WEAVER CONTROL MODULE

The MDS-1005 Dial Weaver Control Module provides weave welding control functions with 3 turn digital dial

pots for the weave speed, weave amplitude, dwell left and right. The addition of the dial pots allows for precise and repeatable setting of all parameters. The dial pots also enable repeatable parameter settings from

machine to machine. All dials vary from 0-300 which corresponds to the setting the parameter from 0 to its

MAX value. For example, a 300 setting for weave amplitude corresponds to 2" of weave amplitude which is

its max value. The DIGITAL READOUT provided for the tractor speed displays in either inches per minute or

centimeters per minute directly.

18

WEAVE SPEED

DWELL LEFT

STEERING

CONTROL

TRACTOR SPEED

CONTROL

MODE SELECTOR

SWITCH

START/STOP

WEAVE

AMPLITUDE

DIGITAL

READOUT

DWELL RIGHT

CARRIAGE TRAVEL

SWITCH

WELD CONTACT

Page 19

WEAVER CONTROL MODULES, CONT’D.

AMPLITUDE (WEAVE): Continuously adjustable up to a 2" (51 mm) maximum weaver stroke.

CARRIAGE TRAVEL SWITCH: Provides FORWARD/STOP/REVERSE direction control.

DIGITAL READOUT: Three tractor display modes exist.

a) PRESET SPEED - Displayed when the CARRIAGE TRAVEL SWITCH is OFF or motion is

halted by a motor overload condition.

b) CONTINUOUSLY MEASURED SPEED - Displayed when the MODE SELECTOR SWITCH

setting is RUN or NO WEAVE. (This will be the same as the Preset Speed.)

c) SAMPLED SPEED - The tractor motion alternates between moving at the Preset Speed and

stopping when the MODE SELECTOR SWITCH is set to STEP or STOP ON DWELL. This

is referred to as “stepping” the tractor. To avoid having the display continuously uctuate

between the zero speed and the actual speed, the readout measures the travel speed near

the end of each tractor step. This speed is then displayed until another sample is taken at

the end of the next tractor step. This provides a stable display of the measured travel speed.

(This will be the same as the Preset Speed.)

Factory settings of 120 Volt machines are set to in/min, 240 and 42 Volt machines are set cm/min.

LEFT AND RIGHT DWELL: The left and right dwell controls have a 0-3 second adjustment range.

MODE SELECTOR SWITCH: Four welding modes are available.

1) RUN - In this mode, power to the drive unit is always on

and the machine travels continuously both during weave

and dwell. Weave speed and dwell time both affect the

weave pattern.

2) STEP - The unit travels only during dwell and stops during

the weaver cross stroke. Changing weave speed does not

effect the weld pattern-dwell time does.

3) TRACTOR STOP ON DWELL - The tractor travels during

the weave stroke; the tractor and weaver stop during dwell.

4) NO WEAVE - In this mode oscillation is stopped. Only the

tractor is powered. This mode is used for stringer passes.

SPEED CONTROL (TRACTOR): Sets the tractor speed from 2-120 in/min (5.1-304.8 cm/min).

START/STOP: This enables/disables all tractor and weaver motion.

STEERING: The three-turn steering knob has a +/- 2" (51 mm) range.

WEAVE SPEED CONTROL: Sets the weave speed from 0-100 in/min (0-254 cm/min).

WELD CONTACT: Opens/closes a pair of independent 1 Amp contacts (pins A & B and C & D) at the weld

contactor receptacle.

NOTE: A safety interlock will automatically open the weld contacts if the motor overload

protection halts machine motion. Clear the overload by turning the carriage travel

switch to off. Resetting the overload fault will not cause the contacts to automatically

reclose. Use the weld contact switch to restart the welder after clearing the overload.

1

2

3

4

19

Page 20

MDS-1005 / MDS-1005-DIAL WEAVER CONTROL MODULE REPLACEMENT PARTS

REPLACEMENT POTS AND SWITCHES MDS-1005 MDS-1005-DIAL

WELD CONTACT:

CARRIAGE TRAVEL SWITCH:

DWELL RIGHT:

AMPLITUDE:

WEAVE SPEED:

STEERING CONTROL:

DWELL LEFT:

TRACTOR SPEED CONTROL:

MODE SELECTOR SWITCH:

START/STOP:

Switch and Spacer MDS-1114

Toggle Switch Boot MDS-1047

Switch and Spacer MDS-1117

Toggle Switch Boot MDS-1047

500K Ω Pot MDS-1053

Black Knob MDS-1018

Knob Seal Nut MDS-1046

50K Ω Pot, 3 turn MDS-1079

Knob, Digital Dial BUG-3297

Dial Spacer BUG-3302

10K Ω Pot MDS-1052 MDS-1078 (3 turn)

Black Knob MDS-1018

Knob Seal Nut MDS-1046

Knob, Digital Dial BUG-3297

Dial Spacer BUG-3302

10K Ω Pot MDS-1052 MDS-1078 (3 turn)

Black Knob MDS-1018

Knob Seal Nut MDS-1046

Knob, Digital Dial BUG-3297

Dial Spacer BUG-3302

10K Ω Pot, 3 turn PCB-1027

Black Knob BUG-5757

Knob Seal Nut BUG-5759

500K Ω Pot MDS-1053

Black Knob MDS-1018

Knob Seal Nut MDS-1046

50K Ω Pot, 3 turn MDS-1079

Knob, Digital Dial BUG-3297

Dial Spacer BUG-3302

10K Ω Pot, 3 turn PCB-1024

Knob MDS-1044

Shaft Seal Nut BUG-5759

Switch and Spacer MDS-1113

Black Pointer Knob BUG-9694

Switch and Spacer MDS-1115

Toggle Switch Boot MDS-1047

20

Page 21

DIGITAL READOUT CALIBRATION

Internal Control Module adjustments enable the user to change between cm/min and in/min. The display can

also be recalibrated, if required, to give an accurate speed readout.

STEP 1: Remove endplate.

STEP 2: Set Switch 1 & 2:

SW 1 SW 2

in/min Down Down

cm/min Up Down

STEP 3: Apply power to the Modular Drive.

Maximize the tractor speed using

the Control Module front panel. Do

not change this speed for the rest

of the procedure.

STEP 4: Calculate the speed of the

machine by measuring

how far it moves in a

certain amount of time.

STEP 5: Set the speed display to

the measured speed using

a small slotted screwdriver.

STEP 6: Verify accuracy of speed

display to actual speed

and repeat steps 4 & 5 as

needed.

STEP 7: Reinstall endplate.

21

Page 22

WPD-1100 LINEAR WEAVER

INTRODUCTION

The Linear Weaver and Weaver Control Module add weave welding capability to the Modular Drive System.

The Linear Weaver bolts onto the front of the carriage and the Weaver Control Module plugs into the top of the

Master Drive Unit. The optional MDS-1060 Remote Control Cable can be used to remote the Control Module.

FEATURES

The Linear Weaver and Weaver Control Module incorporate the following standard features:

• High torque, low inertia motor for precise stops and starts.

• High speed Linear Weaver for weaving, with independent control of right and left dwell times.

• High motor gearing which prevents the crossarm from moving when the unit is turned off.

• Closed loop speed control for adjustable and repeatable control of critical welding or cutting parameters.

• Closed loop position control to prevent drift from the center weld position.

• Clutch, to enable rapid installation or replacement of the weaver cross arm.

• Gun mounting group with adjustable racking block for accurate positioning of the gun.

• Contactor ON/OFF switch.

The gure below shows how the Linear Weaver and Weaver Control Module connect to the carriage and

Master Drive Unit.

GUN MOUNTING

GROUP

LINEAR WEAVER

CROSS ARM

LINEAR WEAVER

WEAVER

CONTROL

MODULE

WEAVER CLUTCH

(KNOB ADJUSTMENT)

CARRIAGE

22

MASTER DRIVE UNIT

Page 23

TECHNICAL DATA

WPD-1100 LINEAR WEAVER

Power Receives power from Master Drive.

Requirements: Uses 70 additional watts.

Dimensions: 7.25" L x 5.50" W x 5.37" H (184 x 140 x 137 mm)

Net Weight: 13.5 lbs (6.0 kg)

Shipping Weight: 16.5 lbs (7.5 kg)

Speed: 2-110 in/min (51-2794 mm/min)

Cycles: 2.5 cycles per second at 1/8" (3mm) stroke

1.6 cycles per second at 1/4" (6mm) stroke

1.0 cycles per second at 1/2" (12mm) stroke

0.7 cycles per second at 1.0" (25mm) stroke

(at maximum speed and 0 dwell)

Load Capacity: 10 lbs (4.5 kg)

DIMENSIONS

9.74

(247.4 mm)

7.25

(184 mm)

(432 mm)

17.0

5.37

(137 mm)

5.50

(140 mm)

23

Page 24

LINEAR WEAVER SETUP

1) WEAVER CONTROL MODULE AND LINEAR WEAVER INSTALLATION

The Weaver Control Module plugs into the top of the Master Drive Unit. Use a at head screw driver to

rmly secure the four corners of the module.

Place the Linear Weaver on a at surface, connector side up. Remove connector cover plate from MPD-1000.

Loosen, but do not remove, the bolts that hold the Master Drive Module to the carriage. Plug the Master Drive

Module into the Linear Weaver. The connectors should t together easily and do not need forced. Attach

the Linear Weaver to the carriage using the two weaver mounting bolts. DO NOT SUBSTITUTE LONGER

BOLTS. Retighten the bolts that hold the Master Drive Unit to the carriage.

2) CROSSARM WHEEL ADJUSTMENT AND ALIGNMENT

Always check the crossarm wheel adjustment before using the machine. The

wheels are too loose and need adjustment if the crossarm can move up and

down. Normal gear backlash will permit crossarm side to side movement of

approximately 0.02" (0.5 mm).

If the wheels need adjustment, remove the left and right weaver end covers. The

two top wheels are adjustable. Loosen the hex bolt (A) until the adjustable bushing

(B) can be rotated. Correct the wheel alignment by rotating adjustable bushing (B).

Check for proper alignment by using a nger to keep one of the wheels from

rotating while manually moving the crossarm. The wheels are adjusted too tight if

rm nger pressure is not enough to prevent wheel rotation. Once aligned, hold the

adjustment bushing (B) still while tightening the hex bolt (A). Recheck alignment.

B

A

3) REALIGNING THE CROSSARM

(includes crossarm INSTALLATION and REMOVAL)

Rotate the clutch knob (C) fully counterclockwise. This

disengages the drive pinion from the rack. Remove

the two socket head screws from the crossarm (D). The

crossarm may be removed from or installed into the

Linear Weaver at this time.

Turn on the AC power. Rotate the four-turn steering

control knob and the weave speed knob on the Weaver

Control Module fully clockwise. Turn the start/stop

switch to START. Set the mode selector switch to NO

WEAVE. Align the crossarm (D) so that 1 7/8" (48 mm)

of the crossarm protrudes from the left side of the Linear

Weaver. To insure proper gear mesh, gently rock the

crossarm back and forth about 1/16" (2 mm) while

engaging the pinion using the clutch knob (C).

Set the weave amplitude to maximum. Use the steering knob on the control module to move the crossarm to

both the extreme left and the extreme right. Perform measurements to determine if The crossarm is installed

too far left or too far right. Repeat the crossarm realigning procedure changing the 1 7/8" (48 mm) dimension

as required. Reinstall the two crossarm screws.

CAUTION: IMPROPER GEAR

MESH MAY CAUSE PINION, RACK,

OR LINEAR WEAVER DAMAGE.

D

LEFT SIDE

C

24

Page 25

LINEAR WEAVER SETUP, CONT’D.

4) REMOTE CONTACTOR WIRING

Connect the remote weld contactor on the Master Drive to the welding source as shown below.

Pins A and B ...................connection for Output #1

Pins C and D ...................connection for Output #2

5) GUN AND SETUP

For welding, insert the welding gun into the all-position clamp on the rack. Adjust the clamp, the clamp

block and the rack to position the gun for welding. Connect the weld contactor connector to the rear of the

Master Drive Unit. Route the welding cable and weld contactor wires through the cable anchor clamp. Turn

on the AC power. Use the steering knob on the control module to move the crossarm to both the extreme

left and then the extreme right. Turn on the oscillator, at the same time, with the controls set to maximum

weave width. Readjust the crossarm or the gun if the racking xture hits the case during operation.

6) MACHINE OPERATION

Turn the main power ON at the power entry box. Set the following parameters using the MDS-1005

Control Module (Ref. pg. 18 for illustration):

Weld Mode Selector Switch

Tractor Speed Control

Steering Control

Weave Amplitude

Weave Speed

Left and Right Dwells

The Start/Stop control will turn on the weaver. To start welding, push the weld contactor switch “ON” (momentarily) which will turn on the wire feeder/weld current. Use the carriage travel switch to select a forward

or reverse carriage travel direction.

CAUTION: The Speed Control Card in the Linear Weaver is NOT interchangeable with the speed card in

the Master Drive or Pendulum Weaver.

25

Page 26

WPD-1100 LINEAR WEAVER / EXPLODED VIEW

4

2

9

5

8

12

53

11

49

55

20

11

31

31

32

11

52

23

18

12

51

19

25

50

11

26

52

54

18

25

16

42

56

21

6,58

57

34

16

7,58

17

24

17

28

3

17

37

35

30

39

10

BUG-5933

___ Coil (Not Shown)

17

29

38

36

22

13

27

45

15

15

46

47

44

15

48

17

17

14

43

40

26

33

1

41

Page 27

WPD-1100 LINEAR WEAVER / PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 BUG-1590-KM Gear Motor (80:1)

2 1 BUG-1853 Machine Rack 7 1/2" (191 mm) Lg

3 4 BUG-2593 Glide Flat

4 1 BUG-5455 Gun Mounting Group

5 1 BUG-5462 Right Angle Clamp

6 2 CWO-4021 Adj Leg & Wheel Assembly

7 2 CWO-4020 Fixed Leg & Wheel Assembly

8 1 WPD-1178 Post w/Fasteners

9 1 WPD-1150 Cross Arm

10 1 BUG-9447 Wrench

11 8 FAS-0114 Pan Hd Scr 6-32 x 3/8 Lg

12 6 FAS-0124 Pan Hd Scr 8-32 x 3/8 Lg

13 1 WPD-1028 Pinion, 3/4 PD, 24 Teeth

14 2 FAS-0557 Soc Hd Cap Scr 1/4-20 x 3/4 Lg

15 4 FAS-0815 Flt Hd Slt Scr 6-32 x 1/2 Lg

16 10 FAS-0905 Flt Hd Soc Scr 4-40 x 1/2 Lg

17 10 FAS-0925 Flt Hd Soc Scr 8-32 x 1/2 Lg

18 4 FAS-1305 Hex Nut 4-40

19 1 FAS-1325 Hex Nut 8-32 Nylon

20 1 FAS-2121 Pan Hd Scr 8-32 x 1 1/4 Lg

21 2 MDS-1034 Spacer Washer .125 ID x .255 OD x .06 Thk

22 1 MPD-1013 Clutch Plate

23 1 MPD-1042 Inductor, Potted w/Connectors

24 1 PCB-1001 Speed Board

25 4 WAS-0201 # 4 Internal Star Lockwasher

26 1 WPD-1001 Ground Harness

27 1 WPD-1002 Weaver Base Plate Assembly**

28 1 WPD-1103 Dust Plate

29 1 WPD-1004 Motor Mount Plate

30 1 WPD-1106 Oscillator Mount Plate

31 2 WPD-1110 Side Panel

32 1 WPD-1020 Cover Panel

33 1 WPD-1022 Wiring Harness-Speed Board to Motor

34 1 WPD-1023 Connector, 50-Pin, M

35 1 WPD-1025 Pot/Gear Assembly (Includes items 36 thru 41)

36 1 BUG-5235 Flexible Coupling

37 1 BUG-5596 Gear, 72 Teeth

38 1 SFX-1218 Flange Bearing

39 1 WPD-1026 Shaft .250 Dia x .675 Lg

40 1 WPD-1027 Pot Mounting Bracket

41 1 WPD-1037 Potentiometer w/Wiring

42 1 WPD-1029 Encoder/Speed Board Wiring Harness

43 1 WPD-1030 Pinion/Encoder Assembly (Includes items 44 thru 48)

44 1 BUG-6059 Encoder

45 2 FAS-0904 Flt Hd Soc Scr 4-40 x 3/8 Lg

46 1 WPD-1031 Pinion Assembly

47 1 WPD-1033 Encoder Spacer

48 1 WPD-1034 Encoder Card

49 1 WPD-1035 Clutch Assembly (Includes items 50 thru 55)

50 2 FAS-1340 Hex Nut 10-32

51 1 SFX-1224 Sleeve

52 2 WAS-0230 #10 Washer

53 1 WPD-1038 Thumb Screw Knob with 1.75" Stud

54 1 WPD-1166 Clutch Linkage

55 1 WPD-1043 Black Nylon Spacer .118" Thick

56 1 STOF-0804 Spacer, 3/8"OD, 1/4"ID, 3/8" Long, Alum

57 1 WPD-1167 10-32 Shoulder Bolt, 3/8" Long

58 4 WAS-0240 1/4 Flat Washer

**(Includes (2) BUG-5933 Helicoils 1/4 x 20 x 1/4 Lg - Not Shown)

27

Page 28

WPD-2100 PENDULUM WEAVER II

INTRODUCTION

The Pendulum Weaver and Weaver Control Module add a pendulum-type weaving motion to the Modular

Drive System. The Pendulum Weaver is particularly useful for weaving llet welds in a corner joint. The weaver

motor box is mounted to the front of the carriage using standard racks and rackholders.

FEATURES

• High torque, low inertia motor for precise starts and stops.

• Heavy duty planetary gear box with powerful output shaft for rotating

welding gun and attachments for the gun.

• High speed pendulum motion with independent control of right and left dwell times.

• High motor gearing ratio, that prevents the welding gun from moving by

backdriving the gear train when power is off.

• Closed loop speed control for adjustable and repeatable control of critical

welding or cutting parameters.

• Closed loop position control to prevent drift from the center position.

• Gun mounting group with adjustable racking block for accurate positioning of the gun.

• Weld Contactor ON/OFF switch.

28

Page 29

PENDULUM WEAVER II SETUP

INSTALLATION

The Weaver Control Module plugs into the Master Drive Unit. Use a at blade screwdriver to rmly secure

the four corners of the module.

Remove connector cover plate from MPD-1000. Plug the Pendulum Weaver Electronics box into the front

end of the Master Drive Unit. Secure the box to the drive unit by using the four captive screws on the electronics box.

Bolt the mounting plate onto the front of the carriage, below the electronics box, and bolt the rackholder onto

the mounting plate. Insert the 14" (355 mm) rack through it.

Several different arrangements can be used to mount the gearbox on the rack and to position the welding

gun. One recommended assembly method is shown below: bolt the racks, gearbox, and clamps together as

shown in the diagram.

Finally connect the gearbox to the electronics box using the cable supplied, with 6-pin connectors on each end.

29

Page 30

SETUP AND ALIGNMENT

Attach the rail parallel to the weld joint, with magnet bars or vacuum cups. Position the drive carriage on the

rail - see Modular Drive instructions if necessary.

Insert the welding gun into the clamp on the pendulum weaver. Adjust the racks and clamps to align the

welding gun tip with the weld joint, and tighten rmly in place.

IMPORTANT!

When the welding gun is clamped in place with the nozzle pointing into the weld groove, the centerline of

the wire must pass through the axis of the gearbox output shaft, as shown in Figure A, which is a view looking along the shaft. Figure B shows the side view of the same.

For a llet weld, the nozzle will be at a 45

0

angle as shown in Figure C, and will swing equally in both directions.

30

Figure A

Figure C

Figure B

CAUTION: The Speed Control Card in the Pendulum

Weaver is NOT interchangeable with the speed

card in the Master Drive or Linear Weaver.

Page 31

TECHNICAL DATA

WPD-2100 PENDULUM WEAVER II

Power Uses 70 watts,

Requirements: received from Master Drive Unit.

Dimensions:

Electronics Box: 6.0"W x 4.38"H x 2.38"L (152 x 111 x 60.3 mm)

Gearbox: 3.31"W x 4.10"H x 5.66"L (84 x 104 x 144 mm)

Net Weight: 12.88 lbs (5.84 kg)

Speed:* 0 - 200 ipm (0-5080 mm/m)

Cycles:* 3.7 cycles per second at 1/8" (3 mm) stroke

3.0 cycles per second at 1/4"(6 mm) stroke

2.0 cycles per second at 1/2" (12 mm) stroke

1.3 cycles per second at 1.0"(25 mm) stroke

(at maximum speed and 0 dwell)

Stroke:* 2"(51 mm)

Steering:* 4"(101 mm) to 2" (51 mm), each side of center

Dwell Time: 0 - 3 seconds, left and right

Load Capacity: 10 lbs (4.5 kg)

*all measured at a 6" (152mm) radius

DIMENSIONS

6.00"

(152 mm)

4.38"

(111 mm)

2.38"

(60.3mm)

Electronics Box

4.10"

(104 mm)

19.00"

(483 mm)

5.66"

(144 mm)

3.31"

(84 mm)

7.25"

(184 mm)

7.50"

(191 mm)

14.00"

(356 mm)

31

Page 32

WPD-2100 PENDULUM WEAVER II / EXPLODED VIEW / PARTS LIST

1

12

13

16

17

14

4

5

11

15

2

7

10

8

7

9

6

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 MUG-1634-3 Power Cable, 3' (914 mm)

2 1 MDS-1029 Mounting Plate w/Screws

3 1 WPD-2110 Pendulum Gear Box (Includes items 4, 5, 6)

4 1 WPD-2115 Gear Box

5 1 WPD-2041 Clamp Block

6 1 WPD-2050 Gun Mounting Group (Includes items 7 thru 10)

7 2 BUG-2234 Adjustable Clamping Lever

8 1 WPD-2044 Shaft Adaptor w/Collar

9 1 WPD-2052 Gun Clamp

10 1 WPD-2053 Link

11 1 WPD-2120 Pendulum Weaver Electronics Box

12 1 WPD-2040 Pendulum Mounting Group (Includes items 13 thru 17)

13 1 BUG-1796 Machined Rack 14" (355 mm)

14 1 BUG-1853 Machined Rack 7-1/2" (191 mm)

15 1 BUG-5462 Right Angle Clamp

16 1 MDS-1031 3.5" (89 mm) Rackholder w/Long Handle

17 1 UNI-1036 Rackrider w/Post

3

32

Page 33

WPD-2120 PENDULUM WEAVER II / ELECTRONICS / EXPLODED VIEW

1

17

15

16

14

18

5

2

9

2

10

5

13

6

12

3

4

8

7

4

11

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 4 FAS-0104 Pan Hd Scr 4-40 x 3/8 Lg

2 8 FAS-0114 Pan Hd Scr 6-32 x 3/8 Lg

3 1 FAS-0225 Rnd Hd Scr 8-32 x 1/2 Lg

4 10 FAS-0905 Flt Hd Soc Scr 4-40 x 1/2 Lg

5 8 FAS-1305 Hex Nut 4-40

6 2 FAS-1320 Hex Nut 8-32

7 2 FAS-1322 Hex Nut 8-32 Nylock

8 2 FAS-2127 Pan Hd Scr 8-32 x 2 3/4 Lg

9 2 MDS-1034 Spacer Washer .125 ID x .255 OD x .06 Thick

10 1 PCB-1009 Speed Board for Pendulum Weaver

11 1 PCB-1021 Capacitor Card

12 1 WAS-0221 #8 Internal Star Lockwasher

13 1 WPD-1001 Ground Harness

14 1 WPD-1023 Connector, 50-Pin, Male

15 1 WPD-2005 Wiring Harness

16 1 WPD-2006 Wiring Harness-Capacitor Bd to Speed Bd

17 1 WPD-2011 Front Panel

18 1 WPD-2012 Rear Panel

33

Page 34

WPD-2115 PENDULUM GEAR BOX / EXPLODED VIEW / PARTS LIST

2

21

12

2

13

22

9

6

2

10

14

4

PARTS LIST

18

19

20

5

8

34

17

3

7

11

23

1

2

16

15

ITEM QTY PART NO. DESCRIPTION

1 3 FAS-0104 4-40 x 3/8 Pan Head, Black

2 12 FAS-0124 8/32 x 3/8 Pan Hd, Di-Chrome

3 3 FAS-1305 Hex Nut 4-40

4 4 MET-0053 Pan Hd. Phillips M4 x .7 x 10

5 4 MET-0063 Pan Hd. Phillips M5 x .7 x 10

6 6 MET-1033 Flt Hd Phil M2.5 x 10

7 3 WAS-0201 #4 Internal Star Lockwasher

8 1 WPD-1037 Pot w/Wiring

9 1 WPD-2027 Motor Mounting Plate

10 1 WPD-2028 Pot Mounting Plate w/Inserts

11 1 WPD-2123 Rear End Plate

12 1 WPD-2124 Output End Plate

13 1 WPD-2125 Enclosure Exclusion

14 1 WPD-2130 125:1 Gear Reduction Unit

15 1 WPD-2131 Timing Belt, 3MM Pitch

16 1 WPD-2132 Timing Pulley, 60 Grooves

17 1 WPD-2133 Timing Pulley, 22 Grooves

18 1 WPD-2134 Pulley, 14 Teeth, 32 Pitch

19 1 WPD-2135 Drive Belt, 32 Pitch

20 1 WPD-2136 Pulley, 72 Teeth, 32 Pitch

21 1 WPD-2137 Flanged Clip Bearing 12 MM ID

22 1 WPD-2140 Motor w/Wires

23 1 WPD-2141 Wiring Harness

Page 35

WPD-1100 LINEAR WEAVER, WPD-2100 PENDULUM WEAVER WIRING DIAGRAM***

Notes:

* The encoder section outlined is for the WPD-1000 Linear Weaver only.

** The PC Card to lter power is only used in WPD-2000 Series Pendulum Weavers.

***Wiring diagram will also work for older WPD-1000 and WPD-2000 Weavers.

35

Page 36

CARRIAGES

The MPD-1065 Releasable 12" (305 mm) and FMD-1105 12" (305 mm) Hi Flex Carriages can be

placed anywhere on the track by using the knob located on the side of the carriage, which engages

or disengages the wheels from the rail. The MPD-1055 18" (457 mm) Carriage provides an extended

deck for mounting accessories, wire feeder, etc. The pinion from the drive unit engages the rack on

the rail, providing positive drive in all positions. On each carriage, one set of wheels is adjustable to

allow for smooth, accurate travel. All wheels contain permanently lubricated, sealed bearings and

their steel components are plated to resist corrosion.

FOR HI-FLEX RAIL

FMD-1105 12" HI FLEX CARRIAGE

100 lb (45 kg) Carrying Capacity

The Hi-Flex Carriage can be placed anywhere along the track using the quick release knob on the

side of the carriage to engage/disengage the wheels from the track. Use with BUG-O Hi-Flex Rails.

FMD-1105 HI-FLEX CARRIAGE / PARTS LIST / EXPLODED VIEW

FOR ALUMINIUM RIGID RAIL AND SEMI-FLEX RAIL

MPD-1065 RELEASABLE CARRIAGE 12" (305 mm)

100 lb (45 kg) Carrying Capacity

PARTS LIST / EXPLODED VIEW

ITEM QTY PART NO. DESCRIPTION

1 2 BUG-1984 External Adj Leg & Wheel Assembly

2 2 FAS-0545 Soc Hd Cap Scr 10-32 x 1/2 Lg

3 2 MPD-1045 Fixed Leg & Wheel Assembly

4 1 MPD-1049 Handle, Black

5 1 MPD-1059 Knob Screw (Included w/carriage)

6 1 MPD-1066 Carriage

5

6

1

2

ITEM QTY PART NO. DESCRIPTION

1 4 BUG-2841 Washer 5/8" O.D. X 5/16" I.D. Teon

2 2 FAS-0659 Soc Hd Shr 5/16-18 X 1"

3 2 FMD-1093 Standoff .875 Dia. .688 Lg.

4 1 MPD-1035 Handle W / Cable Anchor

5 4 FAS-0956 Screw, Flat Hd Cap 5/16-24 x 5/8

6 1 FMD-1022 Carriage For Flex Rail

*A 1 FMD-1068 Fixed Wheel Mounting Block

*B 1 FMD-1069 Adj. Wheel Mounting Block

*C 1 FMD-1081 Bearing Block

*D 8 FAS-0386 Screw, Hex Hd Cap

5/16-24 x 5/8

*E 8 BUG-2012 Bearing

*F 8 CON-1029 Washer, 5/16 x 0.015

*G 2 FMD-1083 Dowel Pin, 1/2 x 2"

*H 1 FMD-1071 Threaded Shaft

*J 2 BUG-2848 Cam Spacer

*K 1 FMD-1072 Knob

*L 1 FMD-1026 Carriage Base

*Part of Item 6 (FMD-1022)

*H

*F

*D

5

*A

4

3

MPD-1055 CARRIAGE 18" (457 mm)

150 lb (68 kg) Carrying Capacity

PARTS LIST / EXPLODED VIEW

4

*L

2

1

4

ITEM QTY PART NO. DESCRIPTION

1 3 BUG -1984 External Adj Leg & Wheel Assembly

2 3 BUG-2956 Fixed Leg & Wheel Assembly

3 4 FAS-0545 Soc Hd Cap Scr 10-32 x 1/2 Lg

4 2 MPD-1049 Handle, Black

5 1 MPD-1055-PNT Carriage 18" (457 mm), Painted

5

1

3

36

*K

*J

*C

*G

*B

*E

4

2

Page 37

DETAILED SETUP

1. Install Rail

The Tube Carriage is designed for use with Bent Rigid Rail (BRR) or Ring Rail. The exact outside diameter (OD) of the work piece, including coating, must be known when ordering rail. Minimum pipe OD is

9 inches (229 mm). Rail is custom bent for each OD and features adjustable feet to accommodate pipe

ovality and deviations in coating thickness.

2. Secure Carriage on Rail

A. Select the correct pair of holes on each side of the carriage for the rail diameter being used (see chart,

below). If the wheels are not attached to the correct set of holes, remove the wheel brackets and bolt

them in selected holes. Tighten the bolts until the brackets are snug but still free to rotate.

B. Loosen the adjustment knob to separate the two halves of the split carriage. Loosen and turn the clutch

knob counterclockwise to put the drive in the declutched position.

C. Place the carriage on the ring rail with the wheels in the rail grooves. Close the cam handle and move

the carriage back and forth a few inches. The wheels on their mounting brackets will align themselves

correctly with the rail grooves.

D. Verify that wheels are properly aligned, then tighten the wheel mounting bolts to lock them in position.

Rotate the clutch knob clockwise to engage the drive pinion with the rack.

E. Verify that pinion is properly engaged in rack. The correct wheel position will provide a minimum of 1/8"

(3.175 mm) engagement between the drive pinion and the gear rack.

A

B

C

E

F

Pipe OD

Carriage

Wheel

Hole Set

D

BRR-1210

Rail ID

in mm in mm

A 20 - 25 500 - 635 9 - 21 230 - 530

B 23 - 35 585 - 890 12 - 31 300 - 790

C 30 - 44 760 - 1120 18 - 40 455 - 1015

D 41 - 60 1040 - 1525 29 - 54 735 - 1375

E 75 - 174 1905 - 4420 64 - 170 1625 - 4320

F at rail at rail

Notes: 1. Chart values are for reference only

2. Pinion height may need to be adjusted for some rail or pipe sizes.

3. Position and Clamp Welding Gun

Secure welding gun in the all-position clamp located on the end of the height control mechanism. Arrange

cables so that they do not interfere with the movement of the machine and secure in the cable anchor at

the back of the machine.

37

Page 38

MDS-1055 UNIVERSAL LIMIT KIT

The MDS-1055 Universal Limit Kit is an accessory that installs between the Master Drive Unit and any of the

three control modules: the *MDS-1002 Straightline, the MDS-1003 Stitch and the MDS-1005 Weaver Control

Module. This limit kit adds the ability to CYCLE between limits, STOP AT LIMIT, or RAPID RETURN. All existing functions of the control modules are maintained.

CYCLE MODES:

a) CYCLE - Cycles between two limits. Limit contact does not turn off the weld contactor.

b) STOP AT LIMIT - Limit contact in the direction of travel set by the control module Carriage Travel

Switch will stop motion and turn off the weld contactor. The Carriage Travel Switch will reverse

the travel direction and start motion away from the contacted limit. The weld contactor will not

automatically turn back on when the machine exits a limit.

c) RAPID RETURN - The machine will run at the preset welding speed in the direction set by the

Carriage Travel Switch on the control module until it hits a limit. When this limit is hit, the machine

will turn off the weld contactor, reverse direction, and travel at full speed to the opposite limit. Upon

reaching the limit, the machine stops.

*FMD-1055 For use on Hi-Flex Rail Only.

MASTER

DRIVE UNIT

TO REAR

LIMIT

CONTROL

MODULE

UNIVERSAL

LIMIT KIT

TO FRONT

LIMIT

CARRIAGE

38

Page 39

MDS-1060-_ REMOTE CONTROL CABLE

MDS-1060-10 10' (3 m) REMOTE CONTROL CABLE

MDS-1060-25 25' (7.6 m) REMOTE CONTROL CABLE

MOUNTS TO

MASTER DRIVE

MOUNTS TO

CONTROL MODULE

The optional Remote Control Cable allows the operator

to perform work in conned areas where it is difcult to

reach the controls. To use the remote cable, detach the

control module from the master drive. Fasten the Master

Drive Adaptor Plate to the drive unit using the four 8-32 x

3/8 long captive screws provided with the remote cable.

Attach the Control Module Adaptor Plate to the control

module using the control module’s captive screws. The

Master Drive Unit is now ready for remote control.

CAS-20__ AUTOMATIC HEIGHT CONTROL

CAS-2050 AUTOMATIC HEIGHT CONTROL / Linear Weaver

The CAS-2050 is an Automatic Height Control (AHC) for the Linear Weaver (WPD-1100) that controls

the welding tip to work distance and maintains a constant weld current, helping to provide uniform weld

penetration. The CAS-2050 senses the actual weld current, compares this value to the set point, and raises

or lowers the welding gun accordingly.

CAS-2060 AUTOMATIC HEIGHT CONTROL / Pendulum Weaver

The CAS-2060 is an Automatic Height Control (AHC) for the Pendulum Weaver (WPD-2100) that controls

the welding tip to work distance and maintains a constant weld current, helping to provide uniform weld

penetration. AHC senses the actual weld current, compares this value to the set point, and raises or lowers

the welding gun accordingly. It features a built-in time delay after the arc is struck, and automatically shuts

off when the current drops too low (generally below 60 amps).

CAS-2050

AUTOMATIC HEIGHT CONTROL / Linear Weaver

AUTOMATIC HEIGHT CONTROL / Pendulum Weaver

CAS-2060

39

Page 40

MODULAR DRIVE ACCESSORIES

FOR STRAIGHT LINE CUTTING:

MDS-3025

2-Hose

Quick-Acting

Manifold

MDS-1050

Machined

Rack

Cutting Group

CIR-1010-3

Twin Hose

Assembly

32" (813 mm)

FOR STRAIGHT LINE AND STITCH WELDING:

MDS-9898

3-Hose

Quick-Acting

Manifold

MUG-1119-32

3-Hose

Assembly

32" (813 mm)

MDS-1040

Machined Rack

Welding Group

FOR ALL APPLICATIONS:

MPD-1065

Releasable

Carriage

12"

(305 mm)

MPD-1055

Carriage

18"

(457 mm)

BUG-2205

Carriage

Trailer with

Hitch

MDS-1045

Extended

Mounting

Plate

40

FMD-1105 Drive Carriage

with cable anchor for MDS

Master Drive or Universal

Bug-O-Matic on High-Flex Rail

MPD-1035

Handle with

Cable Anchor

FMD-1090 Long Trailer

For use w/ FMD-1100

• Used to carry accessories,

wire feeder, etc.

FMD-1150 Hi-Flex Carriage

for DC-III Drive

FMD-1095 Short Trailer

For use w/ FMD-1100

• Used to carry accessories,

wire feeder, etc.

FMD-1100 Drive Carriage

• Used when oscillation is

not required

Page 41

ALUMINUM RIGID RAIL

ALUMINUM RIGID RAIL is a high quality alloy, rigid section made to the machine tool tolerance shown in

the sectional view below. The carriage drive pinion meshes with a machined gear rack that is mounted on

the rail. The wheels of the carriage travel in opposed grooves at either side of the rail, locking the carriage

to the rail. Heavy duty [H.D.] aluminum four-legged rigid rail is supplied in two lengths: ARR-1080 [93-1/2"

(2.37 m)] called 8' (2.37 m) rail and ARR-1085 [46-1/2" (1.18 m)] called 4' (1.18 m) rail - see insert below.

Extra heavy duty aluminum four-legged rigid rail: ARR-1250 [93-1/2' (2-37 m)] called 8' (2.37 m) rail and

ARR-1200 [46-1/2" (1.18 m)] called 4' (1.18 m) rail, is also available.

NOTE: 8' Rails accept up to 8 supports, 4' Rails accept up to 4 supports.

RAIL FOR LONGER SPANS:

When unsupported rail paths longer than 93-1/2" (2.37 m) nominal 8' (2.37 m) rail are required, multiple

sections of standard rail are mounted on plate, channel or box sections.

ARR-1080 / H.D. ALUMINUM RIGID RAIL 8' (2.37 m)

A

C

D

B

A 2.75" (70mm)

3

B 4.0" (102 mm)

C .375" (9.5 mm)

D .875" (22 mm)

1

7

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 1 ARR-1006 Rack

2 2 ARR-1027 Splice Bar

3 2 ARR-1028 Carriage Soft

4 1 ARR-1081 Rail-Extrusion

5 2 FAS-0375 Hex Hd Cap Scr 5/16-18 x 1/2

6 2 FAS-1370 Hex Nut 5/16-1 8

7 16 FAS-1445 S.T. Pan Hd Scr 10-32 x 1/2

5

4

2

6

41

Page 42

SEMI-FLEX RAIL

MIN. RADIUS

15' (4.6 m)

SEMI-FLEX RAIL can be bent inside or

outside to a minimum radius of 15' (4.6 m)

or 30' (9.1 m) diameter without permanent

deformation.

8'

(2.37 m)

8'

(2.37 m)

AFR-3000 SEMI-FLEX RAIL replaces the old AFR-1000, 1010, 1020 and the later AFR-2000 rails. All the

rack-mounting holes on the AFR-3000 Semi-Flex Rail are slotted so that the rack can slide along the rail.

The length of the slots has been increased so that the rails can now be leapfrogged around a complete

circle. The tension of the screws holding the rack on the rail is adjusted so that the rack can be moved along

the rail with the AFR-2001 Rack-Adjusting Tool.

NOTE: Use at least four attachments (magnets or vacuum cups) on each SEMI-FLEX RAIL.

AFR-3000 / SEMI-FLEX RAIL

A

C

D

4

2

B

A 2.75" (70mm)

B 4.0" (102 mm)

C .33" (8.5 mm)

D .500" (12.7 mm)

6

5

1

CAUTION: Bending beyond the recommended 15'-0" (4.6 m) radius may put

a permanent bend in the rail and break off some of the rack screws.

7

9

3

PARTS LIST

ITEM QTY PART NO. DESCRIPTION

1 16 AFR-1015 Spacer Washer

2 1 AFR-2001 Rack Adjusting Tool

3 1 AFR-3002 Splice Plate

4 1 AFR-3006 Rack

5 1 AFR-3009 Extrusion, Punched

6 2 FAS-0855 Flt Hd Soc Scr 1/4-20 x 1/2

7 2 FAS-0955 Flt Hd Soc Scr 1/4-20 x 1/2

8 16 FAS-1446-HW S.T. Slotted Hex w/Washer 10-32 x 5/8

9 16 WAS-0230 #10 Washer

8

42

Page 43

HI-FLEX RAIL

The FMD Hi-Flex Rail can ex from a straight to a 30" (760 mm) radius inside or outside. The rail is made

from a tempered, wear resistant, stainless steel with a steel rack. It is designed for use with the FMD Hi-Flex

Carriage. The rail comes in 57.7" (1.47 m) lengths and can be held in place with magnets or vacuum cups.

An optional stiffener can be installed behind the rail for heavy duty, straight line applications.

R 30"

(760 mm)

FMD-1050 Hi-Flex Rail

Without Magnet

Assemblies

3.995"

(102 mm)

.080"

(2 mm)

.250"

(6.4 mm)

FMD-2155 Hi-Flex Rail

with 8 Permanent magnets

FMD-2170 Hi-Flex Rail

with 8 Rare Earth On/Off magnets

57.722" (1.47 m) Actual Length

R 30"

(760 mm)

FMD Hi-Flex Rail can

ex inside or outside

to a minimum radius

of 30" (760 mm).

5

1

6

ITEM QTY PART NO. DESCRIPTION

1 4 FAS-0376 Hex Hd Cap Scr 5/16-18 x 5/8"

2 4 FAS-1370 Hex Nut 5/16-18

3 196 FAS-1444 Phil Pan Hd Scr 10-32 x 3/8"

4 1 FMD-1051 Track 5' 17-4 Stainless .077

5 98 FMD-1052 Rack Section, 3 Teeth

6 1 FMD-1053 Flex Rail Splice Plate

7 4 WAS-0250 5/16 Sae Washer

4

3

7

2

43

Page 44

STANDARD MAGNET ASSEMBLIES

MAGNET PLATE ASSEMBLIES mount ARR rail quickly and conveniently right on the work surface.

Magnets cannot exert maximum pull on dirty material. Remove excessive paint, scale and rust from the area

on which the magnets will be placed.

KEEP MAGNETS CLEAN - before positioning, wipe off magnetic particles which adhere to the poles.

For MAXIMUM HOLDING POWER on swivel magnets, press down on top of each side of magnet.... then

rotate until it holds rmly. The magnet will retain its magnetism indenitely - to preserve the magnet casing,

keep torch 4" (101 mm) away from magnets when burning/welding. Use various thicknesses of keepers to

decrease the magnetic pull when required.

R.E. On/Off Magnets

The New, Bug-O/ Mag-switch, Switchable On/Off

Rare-Earth magnet assembly provides for quick

rail positioning without ghting the magnet. The

lighter weight, at just 1.7 lb. (.77 kg), less than all

other magnet assemblies, improves handling. 200

lb (90 kg) holding capacity.

*All XXX-2010-HH are “High Heat” models and

are rated at 180°C (356°F) for high temperature

applications.

For Aluminum Rigid Rail

R.E. On/Off Magnet

ARM-2010

ARM-2010-HH*

Holding Power

250 lb. (113 kg)

Swivel Magnet w/ Release

ARM-2325

Holding Power

250 lbs. (113 kg)

Magnet Plate, Short

ARM-2248

Holding Power

200 lbs. (91 kg)

Spacer

ARM-2015

Use with

ARM-2010 only

Swivel Magnets

Magnet bar, swivel with release; recommended

for all applications, combines maximum strength

and versatility. This assembly holds up to 250

lbs. (113 kg) on a at, clean steel surface.

Short Swivel Magnets

Magnet bar, short; compact for positioning in

hard-to-reach or restricted areas. This assembly

holds up to 200 lbs. (91 kg) on a at, clean steel

surface.

Fixed Magnet w/ Release

ARM-2265

Holding Power

200 lbs. (91 kg)

For Semi-Flex Rail

R.E. On/Off Magnet

AFR-2010

AFR-2010-HH*

Holding Power

250 lb. (113 kg)

For Hi-Flex Rail

R.E. On/Off Magnet, Hi-Flex

FMD-2010

FMD-2010-HH*

Holding Power

250 lb. (113 kg)

44

Hi-Flex Magnet w/ Release

FMD-2325

Holding Power

250 lbs. (113 kg)

Spacer Bar

FMD-2015

Use with

FMD-2010 only

Fixed Magnet w/ Release

ARM-2465

Holding Power

200 lbs. (91 kg)

Swivel Magnet w/ Release

ARM-2425

Holding Power

250 lbs. (113 kg)

Page 45

VACUUM SUPPORT KIT

The standard Vacuum Support Kit, ARV-1080 consists

of four (4) bars (with 8 cups) and associated hose and

ttings. Some applications may require additional ARV1036 Vacuum Support Bar assemblies.

ARV-1051

ARV-2020 Vacuum Pump Kit 120V

ARV-1036

ARV-2030 Vacuum Pump Kit 240V

ARV-1036 VACUUM SUPPORT BAR / EXPLODED VIEW / PARTS LIST

VACUUM CUPS are used for mounting the rail to

the work piece when magnet bars will not hold.

8

EXAMPLE: Stainless steel or nonferrous surfaces.

The surface must be smooth and nonporous.

1

Each vacuum bar is tted with two (2) cups and will

exert a maximum pull of 100 lbs. (45 kg).

3

4

ITEM QTY PART NO. DESCRIPTION

1 2 ARR-9008 Spacer Tube

2 2 ARV-1034 Choke Nipple

3 2 ARV-1107 3/8 Hose Barb x 1/4 NPT-M

4 2 ARV-1109 Protective Cap

5 1 ARV-1111 Support Bar

6 2 ARV-1116 Vacuum Cup (Silicone)

7 2 FAS-0252 Rnd Hd Scr 1/4-20 x 1/4

8 2 FAS-2372 Hex Hd Cap Scr 5/16-18 x 1-1/4

NOTE: Keep ame or arc at least 4"(101 mm) away from vacuum cups.

Vacuum cups can be used on preheated material to 6000 F (3150 C).

Each vacuum cup exerts a maximum pull of 50 lbs. (22.6 kg).

4

3

5

7

2

6

45

Page 46

VACUUM SUPPORT KIT, CONT’D.

VACUUM PUMP / EXPLODED VIEW / PARTS LIST

ARV-2020 VACUUM PUMP KIT, 120VAC 60HZ/1PH

ARV-2030 VACUUM PUMP KIT, 240 VAC 50 HZ/1PH

1

2

3

The VACUUM PUMP KITS are 1/6 HP units

that provide 15" (381 mm) Hg on continuous

duty. The ARV-2020/2030 Pump will support

17

18

20

30 vacuum cups.

A Repair Kit ARV-1029 is available for the

ARV-2020 and ARV-2030 pumps. The kit con-

19

tains (4) vanes, (1) body gasket, lter felts for

the mufer, oiler lter, and oiler wick, a cover

gasket and separator felt for the oiler lter.

15

16

14

ITEM QTY PART NO. DESCRIPTION

1 1 ARV-2017 1/4'' Brass Vacuum Relief Valve

2 1 ARV-2014 Vacuum Gage

3 1 ARV-2018 1/4'' NPT Union Cross, Female

4 2 ARV-2012 1/4'' NPT Nipple

5 1 ARV-2016 1/4'' NPT Brass Check Valve, F

6 2 ARV-1107 3/8'' Hose Barb x 1/4'' NPT-M

7 2 ARV-1005 11/16'' x .112 Thk Clamp

8 1 ARV-1004-P Hose 3/8'' ID x 11/16'' OD

9 1 ARV-1012 Female Quick Connector

10 1 ARV-2019 Pump

11 1 ARV-1999 Foot Support w/Fasteners

12 1 ARV-2021 120 VAC Power Cord w/Switch

*

†

240 VAC Replacement Power Components

13 1 ARV-2013 Handle

14 1 ARV-2011 Body

15 4 ARV-2010 Vane

16 1 ARV-2009 Shroud

17 2 ARV-2003 End Cap

18 2 ARV-2004 Felt

19 2 ARV-2005 O-ring

20 2 ARV-2002 End Cap Assembly (Includes parts 17, 18, 19)

21 1 ARV-2001 Filter/Mufer

22 1 ARV-2006 Mufer Box

23 1 ARV-2007 Gasket

24 1 ARV-2008 End Plate

†

240 VAC requires the items below

* 1 BUG-9233 Label, 240 VAC

* 1 BUG-9593 240 VAC Twist Plug

* 1 BUG-9594 240 VAC Connector Body

* 1 ARV-2021 120 VAC Power Cord w/Switch

* Not Shown

4

5

6

21

7

8

22

23

24

12

7

6

9

10

13

11

46

Page 47

MODULAR DRIVE SYSTEM TROUBLESHOOTING GUIDE

The Modular Drive System allows the user to mix and match components to custom build a machine for

an application. The resulting ability to replace and remove individual components while troubleshooting

signicantly reduces the time and effort required to troubleshoot the system. The recommended troubleshooting procedure is as follows:

1) Verify that there are no loose electrical or mechanical connections.

2) Verify that the welding power source is properly grounded and its ground clamp is attached to

the workpiece.

3) Ensure the High Frequency Warnings in the front of this IPM are not being violated.

4) When possible, swap out each component in the system one at a time with a known good

component. For example, replace the Control Module on a defective machine with the Control

Module from a working machine. Often, this will pinpoint the defective component quickly. If the

defective component is a Weaver Drive or a Master Drive, troubleshoot the drive to a circuit

board level using step 5 and/or 6 below.

5) Remove all attached components. This includes the Remote Control Cable and Universal Limit

Kit. All attached components are removed to limit the number of components affecting the operation

and complexity of the system. Assemble a base system composed of a Control Module and

a Master Drive. Test the base system. If the base system does not work, troubleshoot the base

system to a circuit board level using the Base System Test Procedure. If possible, test the

Control Module by swapping it with a known good Module.

6) If the system had a Weaver Drive, install it and retest the system. If the system does not work,

troubleshoot the system to a circuit board level using the Base System Test Procedure.