Bryant Legacy Line, 582J Series Series Manual

582J

LEGACY LINE™

SINGLE PACKAGED ROOFTOP 14 SEER

GAS HEAT/ELECTRIC COOLING

3 to 5 NOMINAL TONS

Product Data

Copyright 2019 Bryant Corporation Form PDS582J-4-6-06

TABLE OF CONTENTS

PAGE

FEATURES/BENEFITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MODEL NUMBER NOMENCLATURE . . . . . . . . . . . . . . . 4

AHRI CAPACITY RATINGS . . . . . . . . . . . . . . . . . . . . . . . . 5

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPTIONS AND ACCESSORIES . . . . . . . . . . . . . . . . . . . . 11

BASE UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . 15

PA GE

APPLICATION DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . .44

GUIDE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . .47

The Bryant rooftop unit (RTU) was designed by customers for customers. With “no-strip screw” collars, handled access panels, and

more, we’ve made your unit easy to install, easy to maintain and easy to use.

Easy to install:

All Legacy Line™ units are field-convertible to horizontal air flow, which makes it easy to adjust to unexpected job site complications. Lighter units make easy replacement. Bryant 582J rooftops fit on existing Bryant curbs dating back to 1989. Also, our large

control box gives you room to work and room to mount Bryant accessory controls.

Easy to maintain:

Easy access handles by Bryant provide quick and easy access to all normally serviced components. Our “no-strip” screw system has

superior holding power and guides screws into position while preventing the screw from stripping the unit’s metal. Take accurate

pressure readings by reading condenser pressure with panels on. Simply remove the black, composite plug, route your gage line(s)

through the hole, and connect them to the refrigeration service valve(s).

Easy to use:

The newly designed central terminal board by Bryant puts all your connections and troubleshooting points in one convenient place,

standard. Most low voltage connections are made to the same board, which makes it easy to find what you’re looking for and easy

to access it. Bryant rooftops have high and low pressure switches, a filter drier, and 2-in. (51mm) filters standard.

2

FEATURES/BENEFITS

Key features

• Single cooling stage models are available from 3-5 tons.

• SEERs up to 14.1.

• EERs up to 12.0.

• Up to 28% lighter than similar industry units. Lighter rooftop units make for easier replacement jobs.

• Utility connections are the same because 3-5 ton units fit on existing Bryant rooftop curbs. This saves time and money on replacement jobs.

• Standardized components and layout. Standardized components and controls make service and stocking parts easier.

• Scroll compressors on all units. This makes service, stocking parts, replacement, and troubleshooting easier.

• Field-convertible airflow. Being able to convert a unit from vertical airflow to horizontal makes it easy to overcome job site complications.

• Standard Direct Drive - ECM indoor motor with optional belt drive system to meet nearly all applications.

• Provisions for bottom or side condensate drain.

• Capable of thru-the-base or thru-the-curb gas line routing.

• Single-point gas/electrical connection.

• Sloped, composite drain pan sheds water and won’t rust.

• Standardized controls and control box layout. Standardized components and controls make stocking parts and service easier.

• Tool-less filter access door.

• Clean, large, easy to use control box.

• Color-coded wiring.

• Large, laminated wiring and power wiring drawings are affixed to unit, making troubleshooting easy.

• Single, central terminal board for test and wiring connections.

• Fast-access, handled, panels for easy access on normally accessed service panels.

• “No-strip” screw system guides screws into the panel and captures them tightly without stripping the screw, the panel, or the unit.

• Mechanical cooling (115°F to 40°F or 46°C to 4°C) standard on all models. Winter Start Kit allows cooling operation down to

25°F (–4°C) and Motormaster

• High efficiency gas heat with induced-draft flue exhaust design.

• Induced draft motor ensures no flue gas can escape into the indoor air stream.

• Bryant-designed naturally draining heat exchanger, unlike positive pressure heat exchangers, do not need to be periodically, manually drained. This saves labor and maintenance expense.

• 2-in. (51mm) disposable filters on all units.

• Refrigerant filter-drier on each circuit.

• Each circuit is protected with a high pressure and low pressure switch.

• Many factory-installed options ranging from air management economizers, 2 position dampers, plus convenience outlets, disconnect switches and smoke detectors.

• Standard (parts only) Warranty: 15 yr. Stainless steel, 10 yr. aluminized heat exchanger, 5 yr. compressor, 1 yr. parts.

• Factory-installed Perfect Humidity

Motormaster

®

I controller.

®

to –20°F (–29°C).

™

dehumidification system on all sizes with round tube/plate fin condenser coils, includes

3

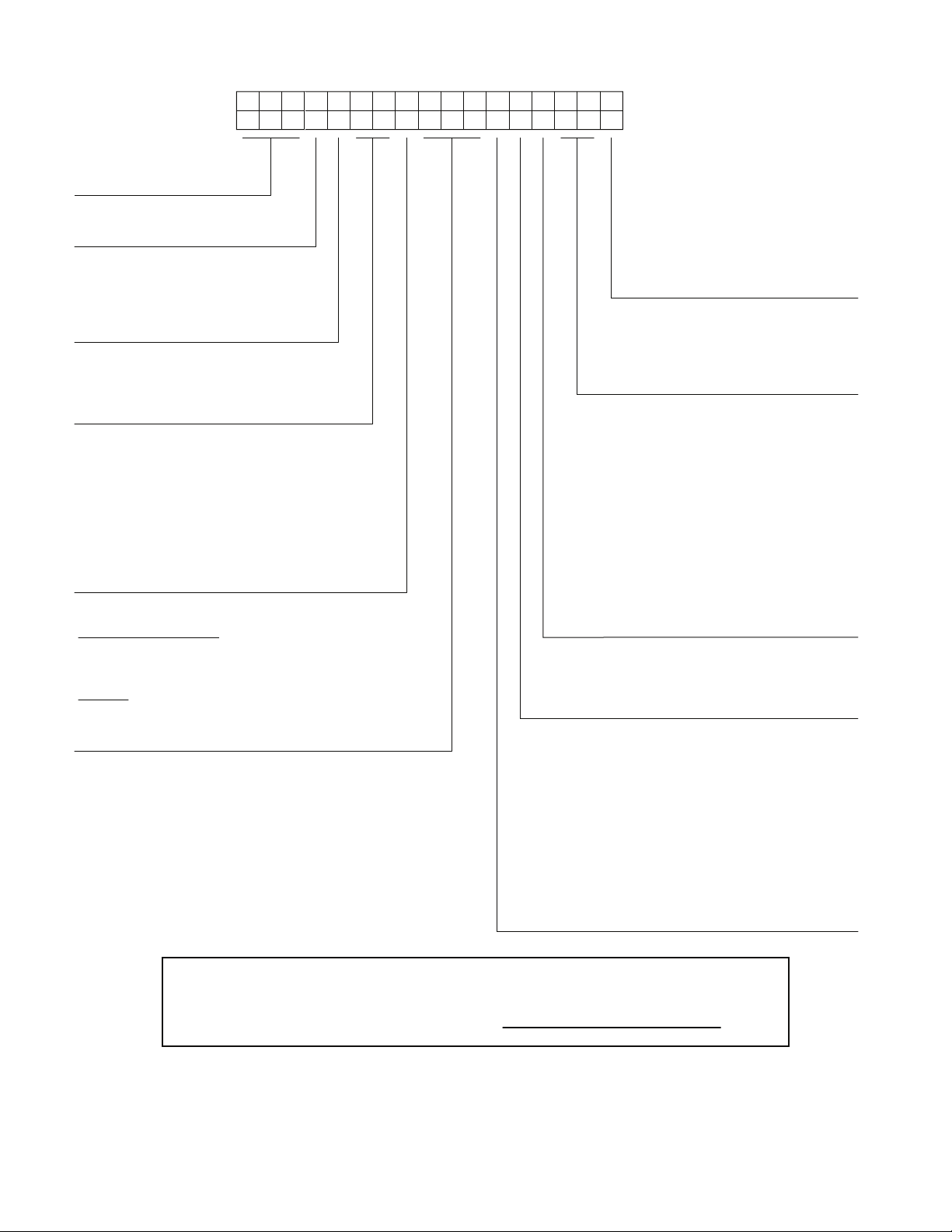

Model

J - Puron

®

(R-410A) Refrigerant

Unit Type

582 - Gas Heat RTU, Legacy Series

Packaging and Control

A = Standard Packaging, electro-mechanical

controls that require W7212 EconoMi$er® IV

B = LTL Packaging

, electro-mechanical

controls that require W7212 EconoMi$er IV

C = Standard Packaging, electro-mechanical

controls that require W7220 EconoMi$er X

F = LTL Packaging, electro-mechanical

controls that require W7220 EconoMi$er X

Cooling Tons

04 - 3 tons

05 - 4 tons

06 - 5 tons

Heat Level Input

Standard / Stainless Steel

072 = 72,000

115 = 115,000

150 = 150,000

Low NOx

060 = 60,000

090 = 90,000

120 = 120,000

Indoor Fan Options

0 = Direct Drive ECM

2 = Medium Static Option

3 = High Static Option

Refrig. System/Gas Heat Options

A = Standard One Stage cooling models/Nat. Gas Heat

B = Standard One Stage cooling models/Low NO

x

Heat

C = Standard One Stage cooling models/SS HX Heat

G = One-Stage cooling models/Alum Heat Exchanger

with Perfect Humidity™

H = One-Stage cooling models/Low NO

x

Heat

with Perfect Humidity

J = One-Stage cooling models/Stainless Steel Exchanger

with Perfect Humidity

Coil Options (RTPF) (Outdoor - Indoor - Hail Guard)

A = Al/Cu - Al/Cu

B = Precoat Al/Cu - Al/Cu

C = E-coat Al/Cu - Al/Cu

D = E-coat Al/Cu - E-coat Al/Cu

E = Cu/Cu - Al/Cu

F = Cu/Cu - Cu/Cu

M = Al/Cu -Al/Cu — Louvered Hail Guard

N = Precoat Al/Cu - Al/Cu — Louvered Hail Guard

P = E-coat Al/Cu - Al/Cu — Louvered Hail Guard

Q = E-coat Al/Cu - E-coat Al/Cu — Louvered Hail Guard

R = Cu/Cu - Al/Cu — Louvered Hail Guard

S = Cu/Cu - Cu/Cu — Louvered Hail Guard

Voltage

E = 460-3-60

J = 208/230-1-60

P = 208/230-3-60

T = 575-3-60

Outdoor Air Options

A = None

B = Temperature Economizer, Barometric Relief,

Standard Leak (W7212 or W7220)

E = Temperature Economizer, Barometric Relief,

Standard Leak w/CO

2

(W7212 or W7220)

H =

Enthalpy

Economizer, Barometric Relief,

Standard Leak (W7212 or W7220)

L =

Enthalpy

Economizer, Barometric Relief,

Standard Leak w/CO

2

(W7212 or W7220)

Q = Motorized 2 Position Damper

U = Temperature

Economizer,

Barometric

Relief,

Ultra Low Leak (W7220)

W =

Enthalpy Economizer,

Barometric

Relief, Ultra Low Leak

(W7220)

Example:

Position:

582JE06A072A0B0A

A

1234567891011 12 13 14 15 16

17

Factory Installed Options

0A = None

NOTE: See the 582J 3 to 5 ton Price Pages

for a complete list of factory installed

options.

Note: On single phase(-J) voltage code) models, the

following are not available as a factory installed option:

- Perfect Humidity

- Coated Coils or Cu Fin Coils

- Louvered Hail Guards

- Economizer or 2 Position Damper

- Powered 115 Volt Convenience Outlet

For California Residents:

For installation in SCAQMD only: This furnace does not meet the SCAQMD Rule 1111 14 ng/J

NOx emission limit, and thus is subject to a mitigation fee of up to $450. This furnace is not

eligible for the Clean Air Furnace Rebate Program: www.CleanAirFurnaceRebate.com.

MODEL NUMBER NOMENCLATURE

\

4

®

C

S

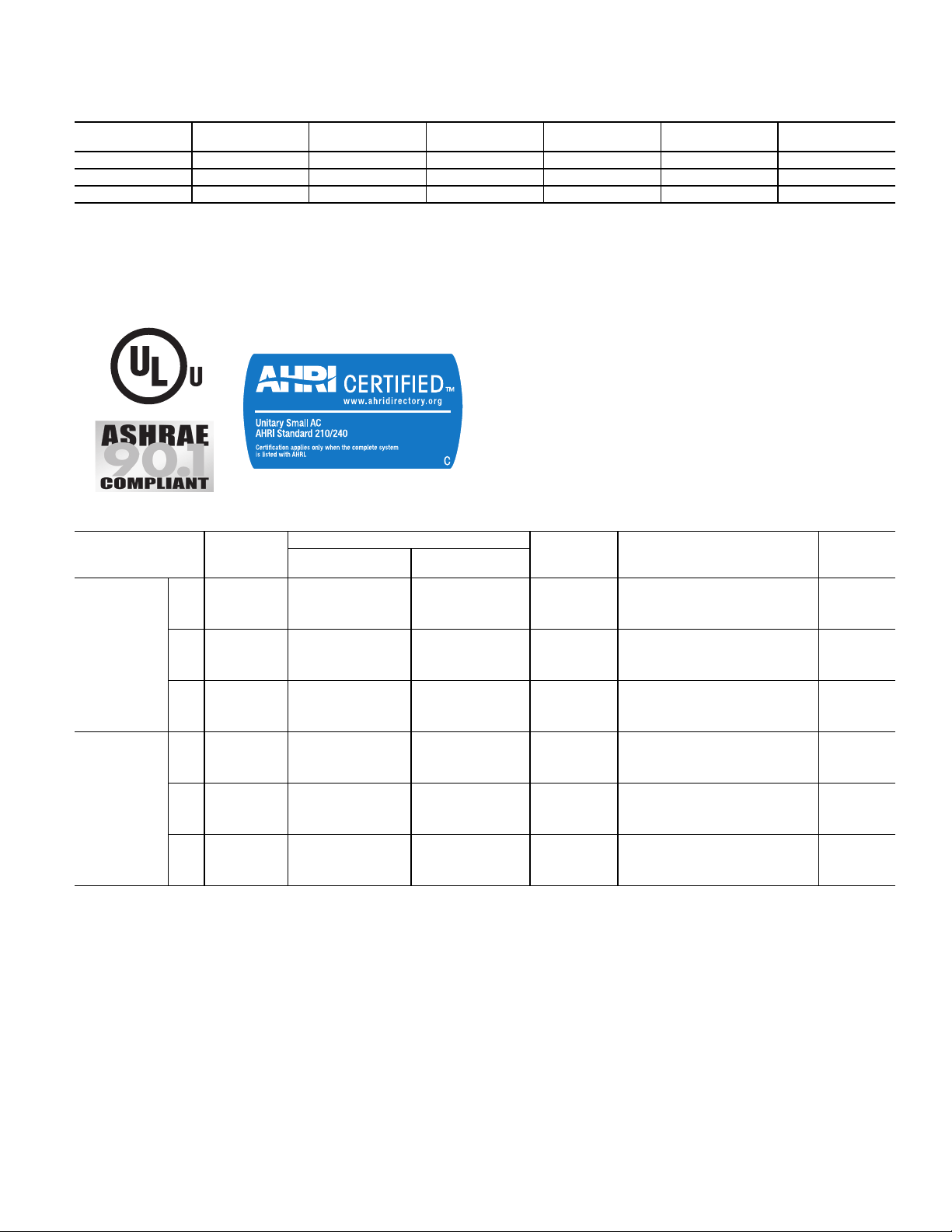

AHRI CAPACITY RATINGS

AHRI COOLING RATING TABLE

UNIT COOLING STAGES

582J*04 1 3 35.4 3.0 14.0 12.00

582J*05 1 4 47.5 4.0 14.0 12.00

582J*06 1 5 58.5 4.9 14.1 12.00

LEGEND NOTES:

AHRI — Air-Conditioning, Heating, and Refrigeration Institute Test

ASHRAE — American Society of Heating, Refrigerating, and Air-Condition-

EER — Energy Efficiency Ratio

SEER — Seasonal Energy Efficiency Ratio

Standard

ing Engineers

NOM. CAPACITY

(TONS)

NET COOLING

CAPACITY (MHBH)

1. Rated in accordance with AHRI Standard 210/240.

2. Ratings are based on:

3. All 582J units comply with ASHRAE 90.1 and Department of Energy

4. All 582J units comply with US Energy Policy Act (2005). To evaluate

TOTAL POWER

(kW)

Cooling Standard: 80°F (27°C) db, 67°F (19°C) wb indoor air temperature and 95°F (35°C) db outdoor air temperature.

(DOE) Energy Standard for minimum SEER and EER requirements.

code compliance requirements, refer to state and local codes.

SEER EER

HEATING RATING TABLE - NATURAL GAS AND PROPANE

582J UNITS GAS HEAT

LOW – 65/53 25-55 82.0% 81.0%

04

SINGLE

PHASE

THREE

PHASE

NOTES:

1. Heat ratings are for natural gas heat exchangers operated at or below

2000 ft (610 m). For information on propane or altitudes above 2000 ft

(610 m), see the Application Data section of this book. Accessory Propane/High Altitude kits are also available.

2. In the USA, the input rating for altitudes above 2000 ft (610 m) must be

de-rated by 4% for each 1000 ft (305 m) above sea level. In Canada, the

input rating must be de-rated by 10% for altitudes of 2000 ft (610) to

4500 ft (1372 m) above sea level.

05

06

04

05

06

MED – 90/73.5 45-85 82.0% 81.2%

HIGH – – – – –

LOW – 65/53 20-55 82.0% 81.0%

MED – 90/73.5 30-65 82.0% 81.2%

HIGH – 130/106 45-80 82.0% 81.0%

LOW – 65/53 15-55 82.0% 81.0%

MED – 90/73.5 25-65 82.0% 81.2%

HIGH – 130/106 35-80 82.0% 81.0%

LOW – 72/59 25-55 82.0% N/A

MED 82/66 115/93 55-85 81.0% N/A

HIGH – – – – –

LOW – 72/59 25-55 82.0% N/A

MED – 115/93 35-65 81.0% N/A

HIGH 120/96 150/120 50-80 80.0% N/A

LOW – 72/59 20-55 82.0% N/A

MED – 115/93 30-65 81.0% N/A

HIGH 120/96 150/120 40-80 80.0% N/A

AL/SS HEAT EXCHANGER

INPUT/OUTPUT

STAGE 1 (MBH)

INPUT/OUTPUT

STAGE 2 (MBH)

TEMP RISE

(DEG F)

THERMAL EFFICIENCY (%) AFUE (%)

5

AHRI CAPACITY RATINGS (cont)

HEATING RATING TABLE – LOW NOX (see note)

582J UNIT GAS HEAT

LOW — 60/49 20–50 82.0% 81.3%

04

SINGLE/THREE PHASE

— – Not applicable. NOTE: Units meet California’s South Coast Air Quality Management District

05

06

MED — 90/73.5 30–60 82.0% 81.5%

HIGH — — — — —

LOW — 60/49 20–50 82.0% 81.3%

MED — 90/73.5 30–60 82.0% 81.5%

HIGH — 120/98 40–70 82.0% 81.3%

LOW — 60/49 15–50 82.0% 81.3%

MED — 90/73.5 25–60 82.0% 81.5%

HIGH — 120/98 35–70 82.0% 81.3%

LOW NO

INPUT/OUTPUT

STAGE 1 (MBH)

HEAT EXCHANGER

X

INPUT/OUTPUT

STAGE 2 (MBH)

(SCQAQMD) Low - NO

less.

TEMP RISE

(DEG F)

emissions requirement of 40 nanograms per joule or

X

THERMAL

EFFICIENCY (%)

AFUE (%)

SOUND PERFORMANCE TABLE

582J UNIT

04 A 1 76 78.2 78.0 74.2 73.3 70.6 66.0 62.4 56.9

05 A 1 81 90.9 84.6 79.5 77.9 76.5 71.1 66.9 62.5

06 A 1 77 87.5 82.5 76.1 73.6 71.3 67.1 64.1 60.0

LEGEND

dB – Decibel

NOTES:

1. Outdoor sound data is measured in accordance with AHRI standard 270.

2. Measurements are expressed in terms of sound power. Do not compare these

values to sound pressure values because sound pressure depends on specific

COOLING

STAGES

A–WEIGHTED 63 125 250 500 1000 2000 4000 8000

OUTDOOR SOUND (dB) AT 60 Hz

environmental factors which normally do match individual applications. Sound

power values are independent of the environment and therefore more accurate.

3. A-weighted sound ratings filter out very high and very low frequencies, to

better approximate the response of the “average” human ear. A-weighted measurement for Bryant units are taken in accordance with AHRI standard 270.

MINIMUM - MAXIMUM AIRFLOW RATINGS–NATURAL GAS AND PROPANE

VOLTAGE UNIT HEAT LEVEL

LOW

SINGLE

PHASE

THREE

PHASE

582J*04

582J*05

582J*06

582J*04

582J*05

582J*06

MED 800 1520 800 1520

HIGH ————

LOW

MED 1050 2280 1050 2280

HIGH 1230 2190 1230 2190

LOW

MED 1050 2730 1050 2730

HIGH 1230 2820 1230 2820

LOW

MED 1010 1570 1010 1570

HIGH ————

LOW

MED 1330 2460 1330 2460

HIGH 1390 2220 1390 2220

LOW

MED 1330 2880 1330 2880

HIGH 1390 2780 1390 2780

COOLING AL HX HEATING SS HX HEATING

MINIMUM MAXIMUM MINIMUM MAXIMUM MINIMUM MAXIMUM

900 1970 900 1970

900 1500

900 2470 900 2470

1200 2000

900 3290 900 3290

1500 2500

990 2190 990 2190

900 1500

990 2190 990 2190

1200 2000

990 2730 990 2730

1500 2500

6

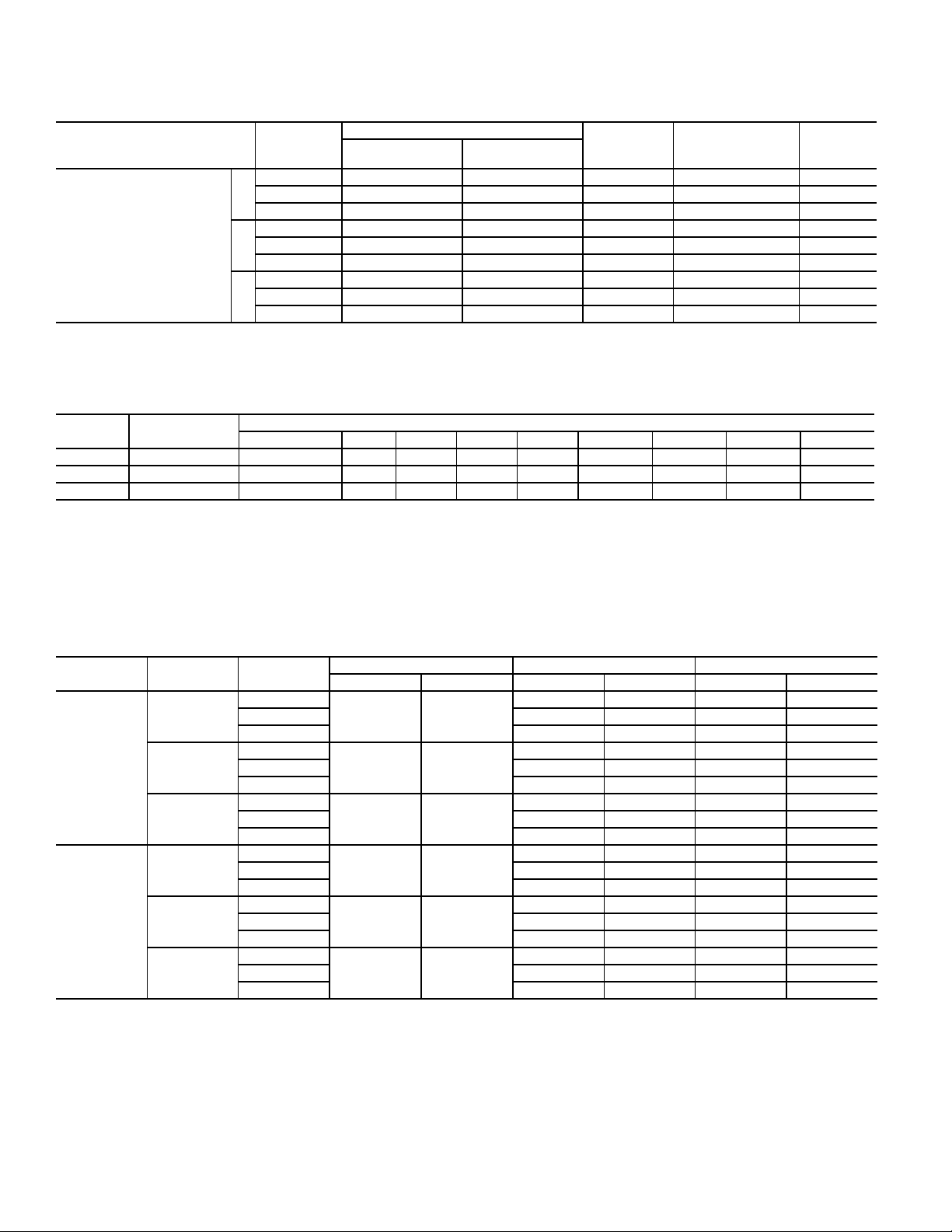

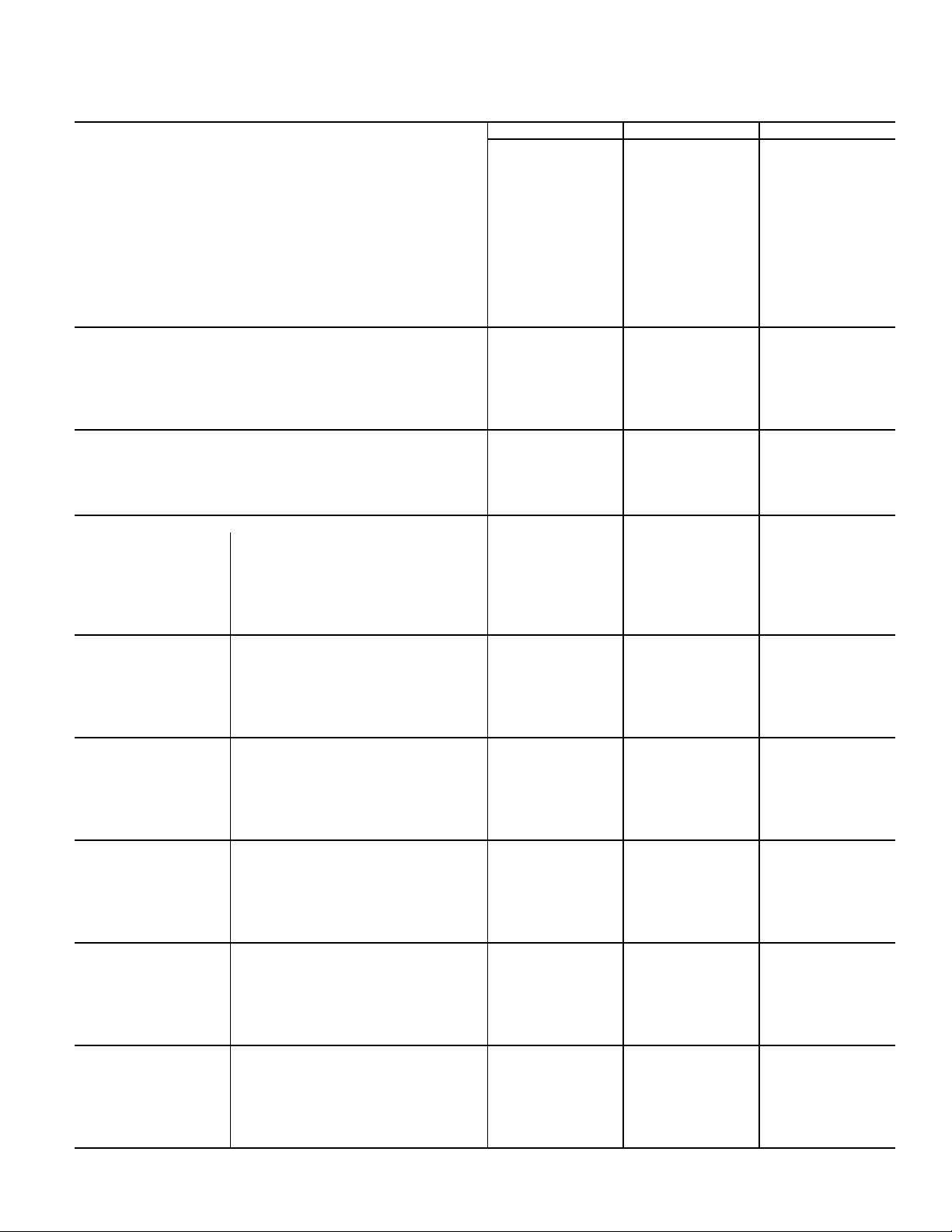

PHYSICAL DATA

REFERIGERATION SYSTEM

®

Puron

®

Puron

Perfect Humidity™ Puron

EVAPORATION COIL

PERFECT HUMIDITY COIL

EVAP. FAN AND MOTOR

STANDARD STATIC

1 PHASE

MEDIUM STATIC

1 PHASE

HIGH STATIC

1 PHASE

STANDARD STATIC

3 PHASE

MEDIUM STATIC

3 PHASE

HIGH STATIC

3 PHASE

PHYSICAL DATA (COOLING) 3-5 TONS

582J*04A/B 582J*05A/B 582J*06A/B

# Circuits / # Comp. / Type 1 / 1 / Scroll 1 / 1 / Scroll 1 / 1 / Scroll

refrig. (R-410A) A 1 phase (lbs-oz) 7-2 10-8 16-0

refrig. (R-410A) A 3 phase (lbs-oz) 7-2 10-8 14-8

®

refrig. (R-410A) charge A (lbs-oz) 10-6 15-5 26-0

oil A/B (oz) 25 42 42

Metering Device Acutrol Acutrol Acutrol

Perfect Humidity Metering Device Acutrol + TXV Acutrol + TXV Acutrol + TXV

High-press. Trip / Reset (psig) 630/505 630/505 630/505

Low-press. Trip / Reset (psig) 54/117 54/117 54/117

Loss of charge Trip/Reset (psig) N/A N/A N/A

Material (Tube/Fin) Cu/Al Cu/Al Cu/Al

Coil Type

Rows / FPI 3 / 15 3 / 15 4 / 15

Total Face Area (ft

Condensate Drain Conn. Size

Material (Tube/Fin) Cu/Al Cu/Al Cu/Al

Coil Type

Rows / FPI 1 / 17 2 / 17 2 / 17

Total Face Area (ft

Motor Qty / Drive Type 1 / Direct 1 / Direct 1 / Direct

Max BHP111

RPM Range 600-1200 600-1200 600-1200

Motor Frame Size 48 48 48

Fan Qty / Type 1 / Centrifugal 1 / Centrifugal 1 / Centrifugal

Fan Diameter (in.) 10 x 10 10 x 10 10 x 10

Motor Qty / Drive Type 1 / Belt 1 / Belt 1 / Belt

Max BHP 1.2 1.2 1.5

RPM Range 770-1175 770-1175 1035-1466

Motor Frame Size 48 48 56

Fan Qty / Type 1 / Centrifugal 1 / Centrifugal 1 / Centrifugal

Fan Diameter (in.) 10 x 10 10 x 10 10 x 10

Motor Qty / Drive Type 1 / Belt 1 / Belt N/A

Max BHP 1.5 1.5 N/A

RPM Range 1035-1466 1035-1466 N/A

Motor Frame Size 56 56 N/A

Fan Qty / Type 1 / Centrifugal 1 / Centrifugal N/A

Fan Diameter (in.) 10 x 10 10 x 10 N/A

Motor Qty / Drive Type 1 / Direct 1 / Direct 1 / Direct

Max BHP111

RPM Range 600-1200 600-1200 600-1200

Motor Frame Size 48 48 48

Fan Qty / Type 1 / Centrifugal 1 / Centrifugal 1 / Centrifugal

Fan Diameter (in.) 10 x 10 10 x 10 11 x 10

Motor Qty / Drive Type 1 / Belt 1 / Belt 1 / Belt

Max BHP 1.7 1.7 2.9

RPM Range 770-1175 920-1303 1035-1466

Motor Frame Size 48 56 56

Fan Qty / Type 1 / Centrifugal 1 / Centrifugal 1 / Centrifugal

Fan Diameter (in.) 10 x 10 10 x 10 10 x 10

Motor Qty / Drive Type 1 / Belt 1 / Belt 1 / Belt

Max BHP 2.9 2.9 2.9

RPM Range 1035-1466 1208-1550 1303-1550

Motor Frame Size 56 56 56

Fan Qty / Type 1 / Centrifugal 1 / Centrifugal 1 / Centrifugal

Fan Diameter (in.) 10 x 10 10 x 10 10 x 10

3

/8-in. RTPF

2

) 5.5 5.5 7.3

2

) 3.9 3.9 5.2

3

/4-in.

3

/8-in. RTPF

3

/8-in. RTPF

3

/4-in.

3

/8-in. RTPF

3

/8-in. RTPF

3

3

/8-in. RTPF

/4-in.

7

PHYSICAL DATA (CONT)

PHYSICAL DATA (COOLING) 3-5 TONS (cont)

582J*04A/B 582J*05A/B 582J*06A/B

COND. COIL

1 phase Material (Tube/Fin) Cu/Al Cu/Al Cu/Al

Coil Type

Rows / FPI 1 / 17 2 / 17 2 / 17

Total Face Area (ft

2

3 phase Material (Tube/Fin)

Coil Type

Rows / FPI 1/17 2/17 2/17

Total Face Area (ft

2

COND. FAN / MOTOR

Qty / Motor Drive Type 1 / Direct 1 / Direct 1 / Direct

Motor HP / RPM 1 / 8 / 825 1 / 4 / 1100 1 / 4 / 1100

Fan diameter (in.) 22 22 22

FILTERS

RA Filter # / Size (in.) 2 / 16 x 25 x 2 2 / 16 x 25 x 2 4 / 16 x 16 x 2

OA inlet screen # / Size (in.) 1 / 20 x 24 x 1 1 / 20 x 24 x 1 1 / 20 x 24 x 1

N/A – Not applicable

3

/8-in. RTPF

3

/8-in. RTPF

3

/8-in. RTPF

) 16.5 16.5 21.3

3

/8-in. RTPF

3

/8-in. RTPF

3

/8-in. RTPF

) 16.5 14.6 18.8

8

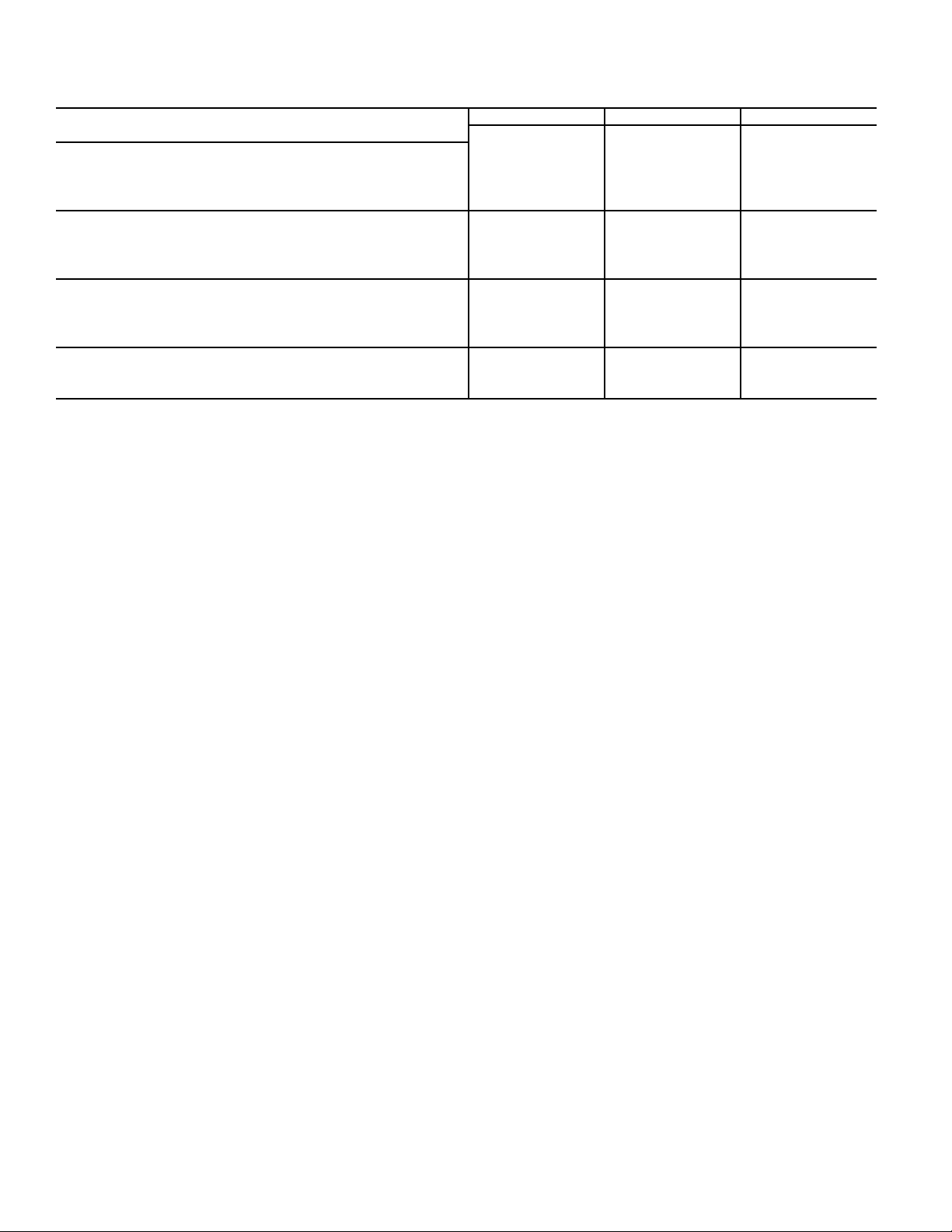

PHYSICAL DATA (HEATING - SINGLE PHASE UNITS) 3-5 TONS

ELECTRICAL

GAS CONNECTION

Nat. gas supply line pressure (in. wg) / (PSIG) 4-13 / 0.18-0.47 4-13 / 0.18-0.47 4-13 / 0.18-0.47

LP gas supply line pressure (in. wg) / (PSIG) 11-13 / 0.40-0.47 11-13 / 0.40-0.47 11-13 / 0.40-0.47

HEAT ANTICIPATOR SETTING (AMPS)

NATURAL GAS HEAT

# of stages / # of burners (total) 1 / 2 1 / 2 1 / 2

LOW

MED

HIGH

LIQUID PROPANE HEAT

LOW

MED

HIGH

LOW NOX GAS HEAT

LOW

MED

HIGH

LEGEND

LP – Liquid propane

— – Not applicable

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) 1 or 2 / 3 1 / 3 1 / 3

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) — 1 or 2 / 3 1 or 2 / 3

Rollout switch opens/closes (°F) — 195 / 115 195 / 115

# of stages / # of burners (total) 1 / 2 1 / 2 1 / 2

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) 1 or 2 / 3 1 / 3 1 / 3

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) — 1 or 2 / 3 1 or 2 / 3

Rollout switch opens/closes (°F) — 195 / 115 195 / 115

# of stages / # of burners (total) 1 / 2 1 / 2 1 / 2

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) 1 / 3 1 / 3 1 / 3

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) — 1 / 3 1 / 3

Rollout switch opens/closes (°F) — 195 / 115 195 / 115

582J*04 582J*05 582J*06

Single Phase Single Phase Single Phase

# of Gas valves 1 1 1

First stage 0.14 0.14 0.14

Second stage 0.14 0.14 0.14

Connection size

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) 25-55 20-55 15-55

Connection size

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) 45-85 30-65 25-65

Connection size —

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) — 45-80 35-80

Connection size

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) 25-55 20-55 15-55

Connection Size

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Temperature Rise (°F) 45-85 30-65 25-65

Connection size —

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) — 45-80 35-80

Connection size

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) 20-50 20-50 15-50

Connection size

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) 30-60 30-60 25-60

Connection size —

1

/2-in. NPT

1

/2-in. NPT

Temperature rise (°F) — 40-70 35-70

9

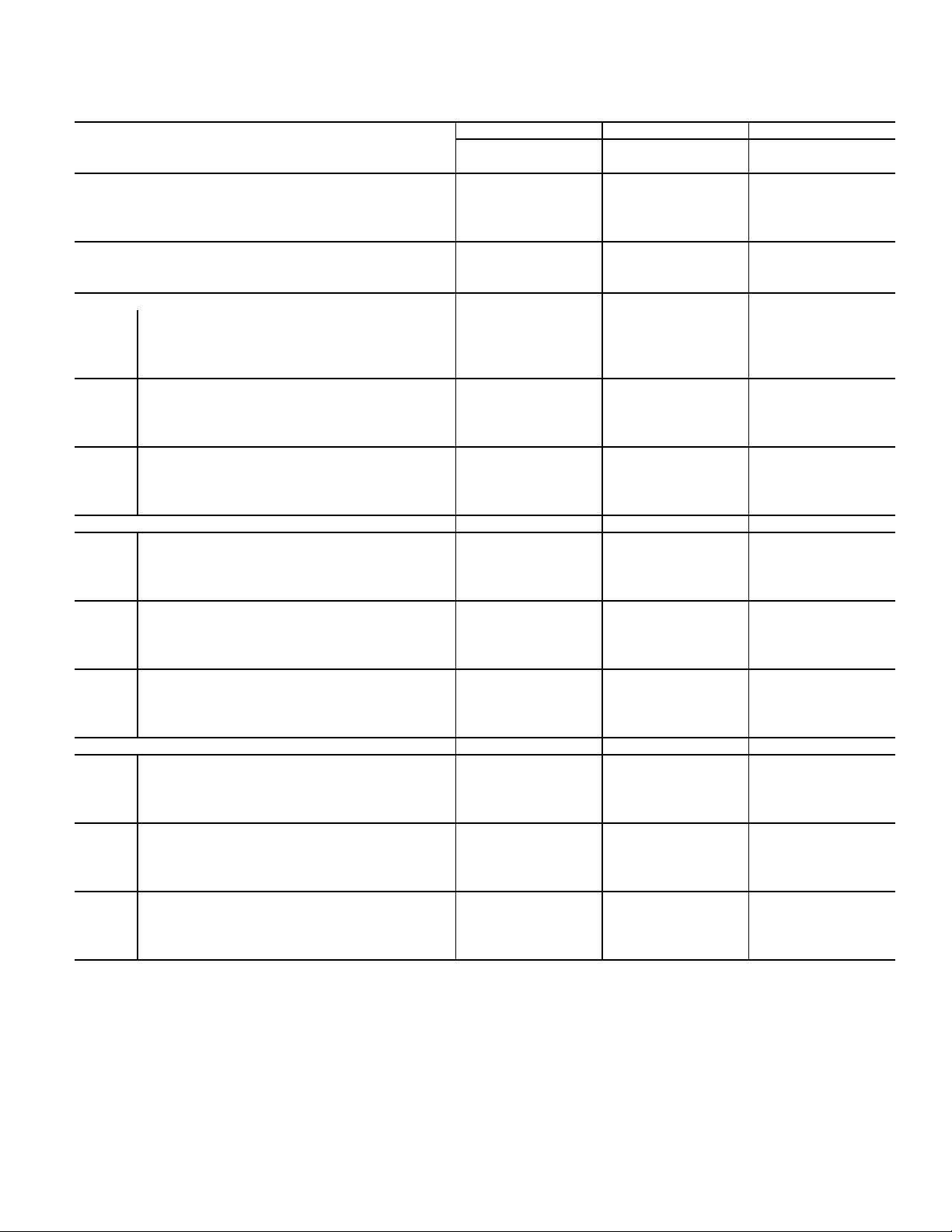

PHYSICAL DATA (CONT)

PHYSICAL DATA (HEATING - THREE PHASE UNITS) 3-5 TONS

ELECTRICAL

GAS CONNECTION

# of Gas valves 1 1 1

Nat. gas supply line pressure (in. wg.) / (PSIG) 4-13 / 0.18-0.47 4-13 / 0.18-0.47 4-13 / 0.18-0.47

LP gas supply line pressure (in. wg.) / (PSIG) 11-13 / 0.40-0.47 11-13 / 0.40-0.47 11-13 / 0.40-0.47

HEAT ANTICIPATOR SETTING (AMPS)

First stage 0.14 0.14 0.14

Second stage 0.14 0.14 0.14

NATURAL GAS HEAT

# of stages / # of burners (total) 1 / 2 1 / 2 1 / 2

LOW

MED

HIGH

LIQUID PROPANE HEAT

LOW

MED

HIGH

LOW NOX GAS HEAT

LOW

MED

HIGH

LEGEND

LP – Liquid propane

— – Not applicable

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) 1 or 2 / 3 1 / 3 1 / 3

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) — 1 or 2 / 3 1 or 2 / 3

Rollout switch opens/closes (°F) — 195 / 115 195 / 115

# of stages / # of burners (total) 1 / 2 1 / 2 1 / 2

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) 1 or 2 / 3 1 / 3 1 / 3

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) — 1 or 2 / 3 1 or 2 / 3

Rollout switch opens/closes (°F) — 195 / 115 195 / 115

# of stages / # of burners (total) 1 / 2 1 / 2 1 / 2

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) 1 / 3 1 / 3 1 / 3

Rollout switch opens/closes (°F) 195 / 115 195 / 115 195 / 115

# of stages / # of burners (total) — 1 / 3 1 / 3

Rollout switch opens/closes (°F) — 195 / 115 195 / 115

Connection size

Temperature rise (°F) 25-55 25-55 20-55

Connection size

Temperature rise (°F) 55-85 35-65 30-65

Connection size —

Temperature rise (°F) — 50-80 40-80

Connection size

Temperature rise (°F) 25-55 25-55 20-55

Connection size

Temperature rise (°F) 55-85 35-65 30-65

Connection size —

Temperature rise (°F) — 50-80 40-80

Connection size

Temperature rise (°F) 20-50 20-50 15-50

Connection size

Temperature rise (°F) 30-60 30-60 25-60

Connection size —

Temperature rise (°F) — 40-70 35-70

582J*04 582J*05 582J*06

Three Phase Three Phase Three Phase

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

1

/2-in. NPT

10

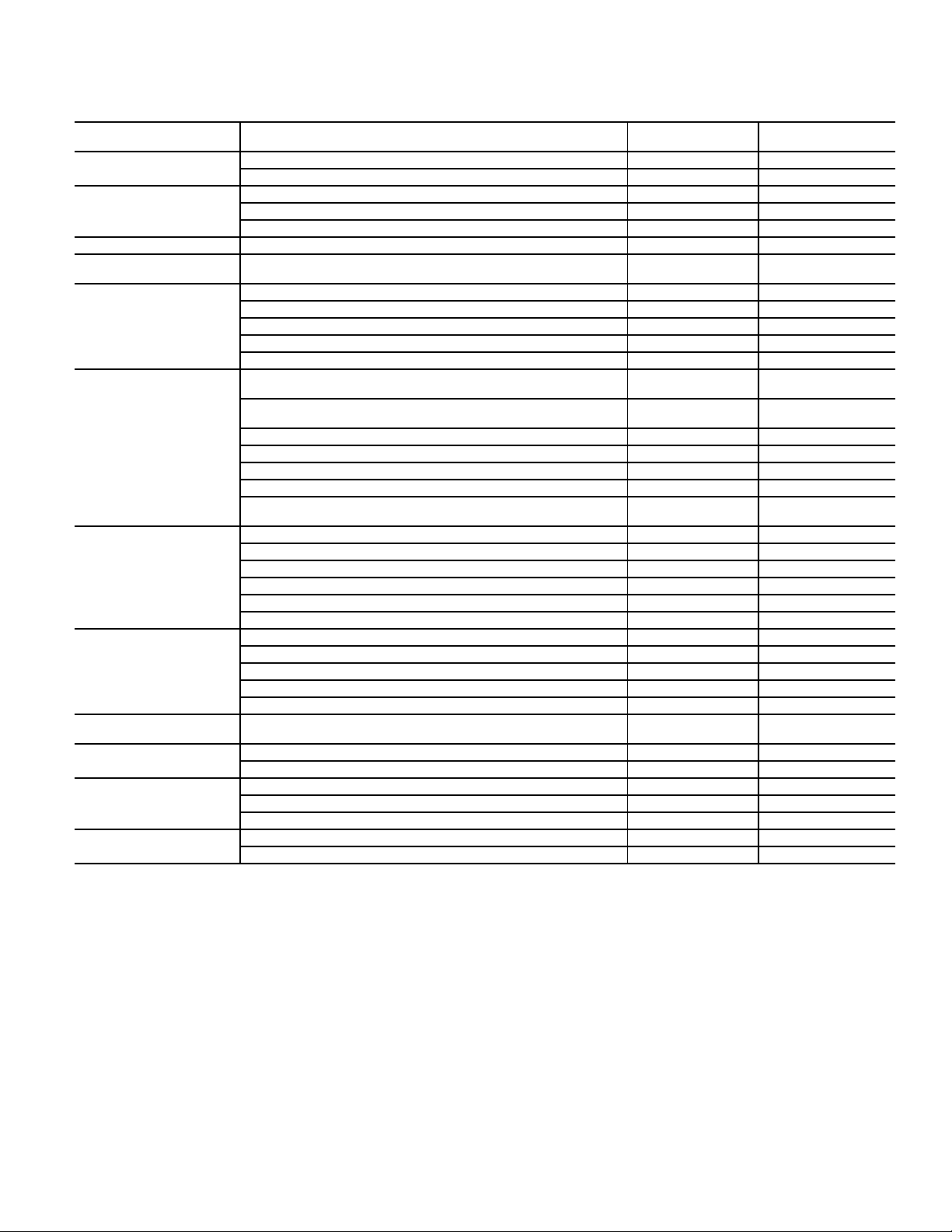

OPTIONS AND ACCESSORIES

CATEGORY ITEM

CABINET

COIL OPTIONS

Thru-the-base electrical or gas-line connections X X

Hinged Access Panels X

Cu/Cu indoor and/or outdoor coils

Pre-coated outdoor coils

Premium, E-coated outdoor coils

5

5

5

HUMIDITY CONTROL Perfect Humidity™ Dehumidification System

CONDENSER

PROTECTION

Condenser coil hail guard (louvered design)

5

5

FACTORY-

INSTALLED OPTION

X

X

X

X

XX

Thermostats, temperature sensors, and subbases X

RTU Open multi-protocol controller X

CONTROLS

Smoke detector (supply and/or return air) X

Time Guard II compressor delay control circuit X

Phase Monitor X

ECONOMIZERS AND

OUTDOOR AIR DAMPERS

EconoMi$er IV for electro-mechnical controls - Non FDD (Standard

air leak damper models)

EconoMi$er2 for DDC controls, complies with FDD (Standard and

Ultra Low Leak air damper models)

Motorized 2-position outdoor air damper

5, 6

5, 7

5

Manual outdoor air damper (25% and 50%) X

Barometric relief

1

XX

XX

XX

XX

Power exhaust X

ECONOMIZER SENSORS

AND IAQ DEVICES

EconoMi$er X for electro-mechanical controls, complies with FDD.

(Standard and Ultra Low Leak air damper models)

Single dry bulb temperature sensors

Differential dry bulb temperature sensors

sensor

2

2

2

sensor

2

2

Single enthalpy sensors

Differential enthalpy sensors

Wall-mounted or duct-mounted CO

Unit-mounted CO

5, 6

2

2

2

XX

XX

XX

X

Propane conversion kit X

Stainless steel heat exchanger X

GAS HEAT

High altitude conversion kit X

Flue Shield X

Flue Discharge Deflector X

INDOOR MOTOR AND

DRIVE

LOW AMBIENT CONTROL

POWER OPTIONS

ROOF CURBS

Multiple motor and drive packages X

Winter start kit

Motormaster

®

head pressure controller

Convenience outlet (powered)

3

3

5

X

Convenience outlet (non-powered) X

Non-fused disconnect

4

X

Roof curb 14-in. (356mm) X

Roof curb 24-in. (610mm) X

NOTES:

1. Included with economizer.

2. Sensors used to optimize economizer performance.

3. See application data for assistance.

4. Available on units with MOCPs of 80 amps or less.

5. Not available as factory-installed option on single phase (208-230/1/60) models. Use field-installed accessory where available.

6. FDD (Fault Detection and Diagnostic) capability per California Title 24 section 120.2.

7. Models with RTU Open DDC controls comply with California Title 24 Fault Detection and Diagnostic (FDD).

FIELD-INSTALLED

ACCESSORY

X

X

X

X

X

11

OPTIONS AND ACCESSORIES (CONT)

Economizer

Economizers save energy, money and improve comfort levels

in the conditioned space. They bring in fresh, outside air for

ventilation; and provide cool outside air to cool your building.

This is also the preferred method of low ambient cooling.

When integrated with CO

sensors, economizers can provide

2

even more savings by coupling the ventilation air to only the

amount required based on space occupancy. Economizers are

available, installed and tested by the factory, with either

enthalpy or temperature dry-bulb inputs. There are also models

for electromechanical and direct digital controllers. Additional

sensors are available as accessories to optimize the economizer.

Economizers include gravity controlled barometric relief that

helps equalize building pressure and ambient air pressures.

This can be a cost effective solution to prevent building pressurization. Economizers are available in Ultra Low Leak and

standard low leak versions.

CO2 sensor

CO2 sensors improve productivity and save money by working

with the economizer to intake the correct amount of outside air

for ventilation. As occupants fill your building, the CO

detects their presence through increasing CO

levels and opens

2

sensor

2

the economizer appropriately.

When the occupants leave, the CO

levels decrease, and the

2

sensor appropriately closes the economizer. This intelligent

control of the ventilation air, called Demand Controlled Ventilation (DCV) reduces the overall load on the rooftop, saving

money.

Smoke detectors

Trust the experts. Smoke detectors make your application safer

and your job easier. Bryant smoke detectors immediately shut

down the rooftop unit when smoke is detected. They are available, installed by the factory, for supply air, return air, or both.

Louvered hail guards

Sleek, louvered panels protect the condenser coil from hail

damage, foreign objects, and incidental contact.

Convenience outlet (powered or un-powered)

Reduce service and/or installation costs by including a convenience outlet in your specification. Bryant will install this service feature at our factory. It provides a convenient, 15 amp,

115v GFCI receptacle with “Wet in Use” cover. The “powered”

option allows the installer to power the outlet from the line side

of the disconnect or load side as required by code. The “unpowered” option is to be powered from a separate 115/120-v

power source.

Non-fused disconnect

This OSHA-compliant, factory-installed safety switch allows a

service technician to locally secure power to the rooftop.

Power exhaust with barometric relief

Superior internal building pressure control. This field-installed

accessory may eliminate the need for costly, external pressure

control fans.

RTU Open, multi-protocol controller

Connect the rooftop to an existing BAS without needing complicated translators or adapter modules using the RTU Open

controller. This new controller speaks the 4 most common

building automation system languages (BACnet

N2, and LonWorks

3

). Use this controller when you have an

1

, Modbus2,

existing BAS.

Time Guard II control circuit

This accessory protects your compressor by preventing shortcycling in the event of some other failure and prevents the compressor from restarting for 30 seconds after stopping. Not

required with RTU Open or authorized commercial thermostats.

Motorized 2-position damper

The new Bryant 2-position, motorized outdoor air damper

admits up to 100% outside air. Using reliable, gear-driven technology, the 2-position damper opens to allow ventilation air and

closes when the rooftop stops, stopping unwanted infiltration.

Manual OA damper

Manual outdoor air dampers are an economical way to bring in

ventilation air. The dampers are available in 25% and 50%

versions.

Optional Perfect Humidity™ dehumidification system

Bryant’s Perfect Humidity dehumidification system is an allinclusive factory-installed option that can be ordered with any

Legacy Line 582J*04-06B rooftop unit.

This system expands the envelope of operation of Bryant’s

Legacy Line rooftop products to provide unprecedented flexibility to meet year-round comfort conditions.

The Perfect Humidity dehumidification system has the industry’s only dual dehumidification mode setting. The Perfect

Humidity system includes two new modes of operation.

The Legacy Line 582J*04-06B rooftop coupled with the Perfect Humidity system is capable of operating in normal design

cooling mode, subcooling mode, and hot gas reheat mode. Normal design cooling mode is when the unit will operate under its

normal sequence of operation by cycling compressors to maintain comfort conditions.

Subcooling mode will operate to satisfy part load type conditions when the space requires combined sensible and a higher

proportion of latent load control. Hot Gas Reheat mode will

operate when outdoor temperatures diminish and the need for

latent capacity is required for sole humidity control. Hot Gas

Reheat mode will provide neutral air for maximum dehumidification operation.

Motormaster® head pressure controller

The Motormaster motor controller is a low ambient, head pressure

controller kit that is designed to maintain the unit’s condenser head

pressure during periods of low ambient cooling operation. This

device should be used as an alternative to economizer free cooling

when economizer usage is either not appropriate or desired. The

Motormaster will either cycle the outdoor fan motors or operate

them at reduced speed to maintain the unit operation, depending

on the model.

12

1. BACnet is a registered trademark of ASHRAE (American Society of

Heating, Refrigerating, and Air-Conditioning Engineers).

2. Modbus is a registered trademark of Schneider Electric.

3. LonWorks is a registered trademark of Echelon Corporation.

Winter start kit

The winter start kit by Bryant extends the low ambient limit of

your rooftop to 25°F (–4°C). The kit bypasses the low pressure

switch, preventing nuisance tripping of the low pressure

switch. Other low ambient precautions may still be prudent.

Propane heating

Convert your gas heat rooftop from standard natural gas operation to propane using this field-installed kit.

High altitude heating

High altitudes have less oxygen, which means heat exchangers

need less fuel. The new gas orifices in this field-installed kit

make the necessary adjustment for high altitude applications.

They restore the optimal fuel to air mixture and maintain

healthy combustion at altitudes above 2000 ft (610m). Kits

may not be required in all areas.

Hinged access panels

Allows access to unit’s major components with specifically

designed hinged access panels. Panels are: filter, control box,

fan motor, and compressor.

Flue discharge deflector

The flue discharge deflector is a useful accessory when flue gas

recirculation is a concern. By venting the flue discharge

upwards, the deflector minimizes the chance for a neighboring

unit to intake the flue exhaust.

Optional stainless steel heat exchanger

The stainless steel heat exchanger option provides the tubular

heat exchanger made out of a minimum 20 gage type 409 stainless steel for applications where the mixed air to the heat

exchanger is expected to drop below 45°F (7°C). Stainless steel

may be specified on applications where the presence of airborne contaminants require its use (applications such as paper

mills) or in areas with very high outdoor humidity that may

result in severe condensation in the heat exchanger during cooling operation.

Flue discharge heat shield

The flue discharge heat shield keeps people from touching the

rooftop unit’s potentially hot flue discharge. This is especially

useful for ground level applications, where more untrained

people could have access to the unit’s exterior.

Alternate motors and drives

Some applications need larger horsepower motors, some need

more airflow, and some need both. Regardless of the case, your

Bryant expert has a factory-installed combination to meet your

application. A wide selection of motors and pulleys (drives) are

available, factory installed, to handle nearly any application.

Thru-the-base connections

Thru-the-base connections, available as either an accessory or

as a factory option, are necessary to ensure proper connection

and seal when routing wire and piping through the rooftop’s

basepan and curb. These couplings eliminate roof penetration

and should be considered for gas lines, main power lines, as

well as control power.

13

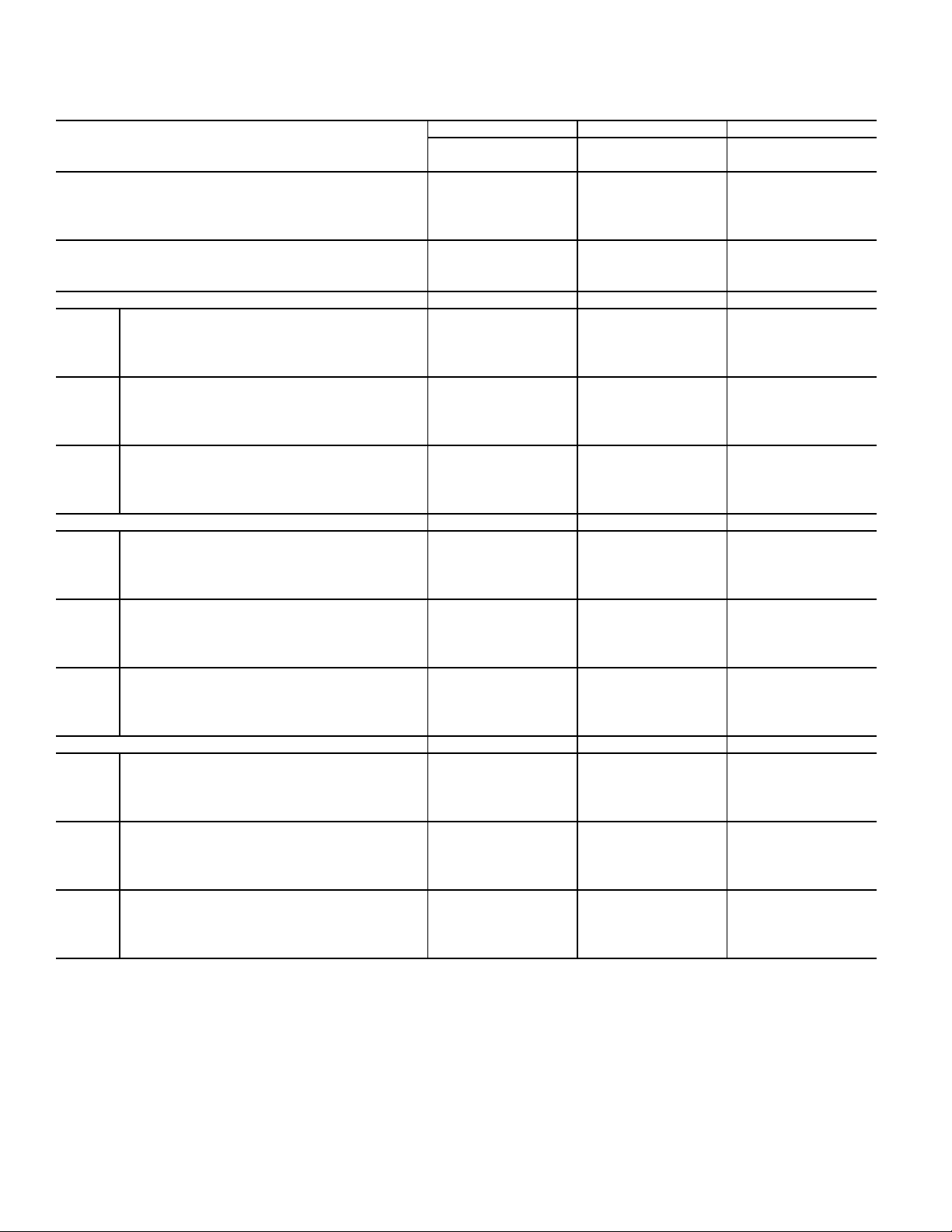

OPTIONS AND ACCESSORIES (CONT)

OPTIONS AND ACCESSORY WEIGHTS

OPTION/ACESSORY WEIGHTS

OPTION/ACCESSORY

Perfect Humidity™

1

Power exhaust - vertical 45 20 45 20 45 20

Power exhaust - horizontal 30 14 30 14 30 14

EconoMi$er (IV, X, or 2) 35 16 35 16 35 16

Two-position damper 39 18 39 18 39 18

Manual dampers 12 5 12 5 12 5

Medium gas heat 12 59494

High gas heat ——178178

Hail guard (louvered) 13 6 13 6 17 8

Cu/Cu Condenser Coil

Cu/Cu Condenser and Evaporator Coils

2

2

Roof curb (14-in. curb) 115 52 115 52 115 52

Roof curb (24-in. curb) 197 89 197 89 197 89

CO

sensor 212121

2

Flue discharge deflector 737373

Optional indoor motor/drive 6 3 6 3 17 8

Motormaster controller 949494

Return smoke detector 737373

Supply smoke detector 7 37373

Non-fused disconnect 5 25252

Powered convenience outlet 36 16 36 16 36 16

Non-powered convenience outlet 424242

Enthalpy sensor 212121

Differential enthalpy sensor 313131

NOTE: Where multiple variations are available, the heaviest combination is listed.

— Not available

1

For Perfect Humidity, add Motormaster® Controller.

2

Where available.

04 05 06

lb kg lb kg lb kg

50 23 50 23 55 25

37 17 74 34 95 43

75 34 112 51 165 75

14

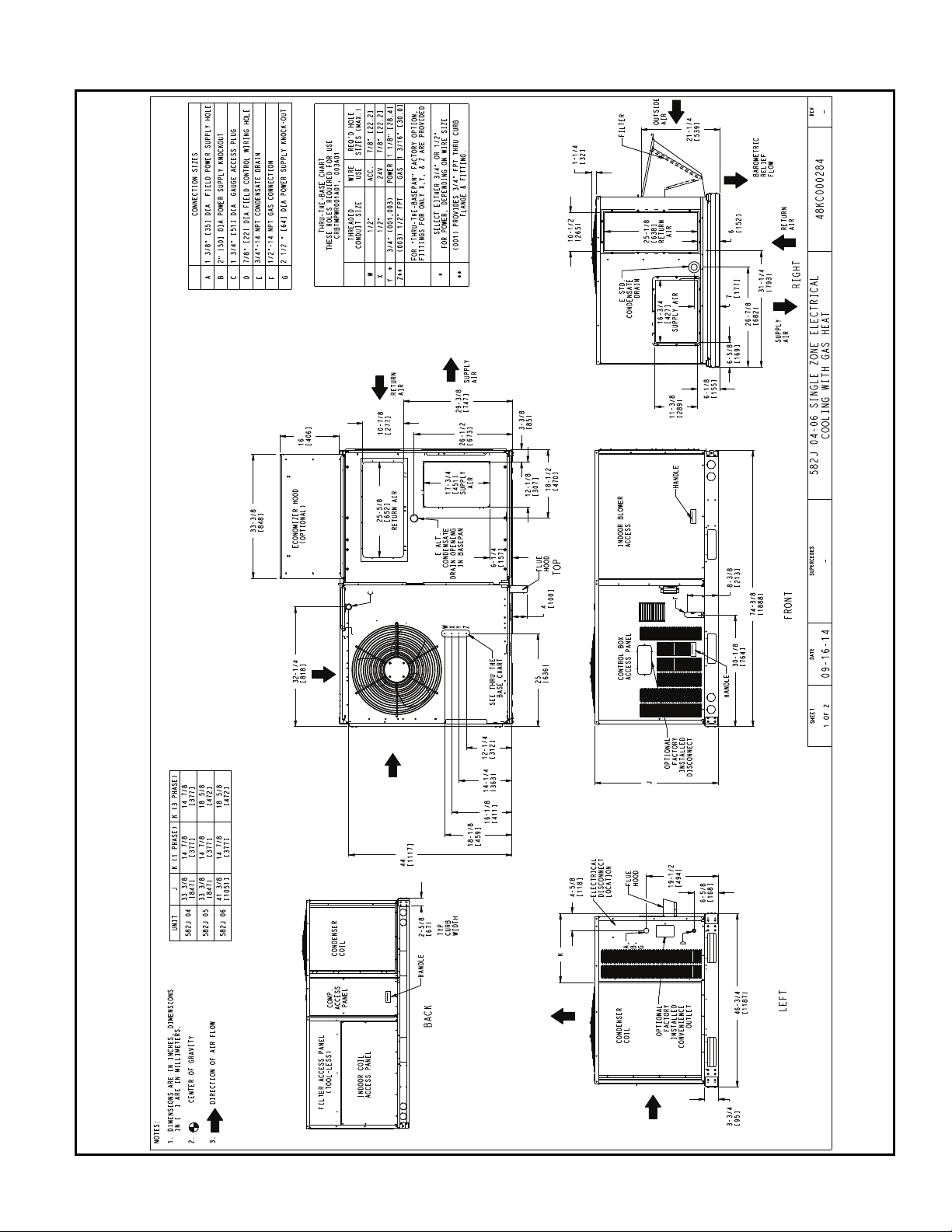

582J*04-06 BASE UNIT DIMENSIONS

BASE UNIT DIMENSIONS

15

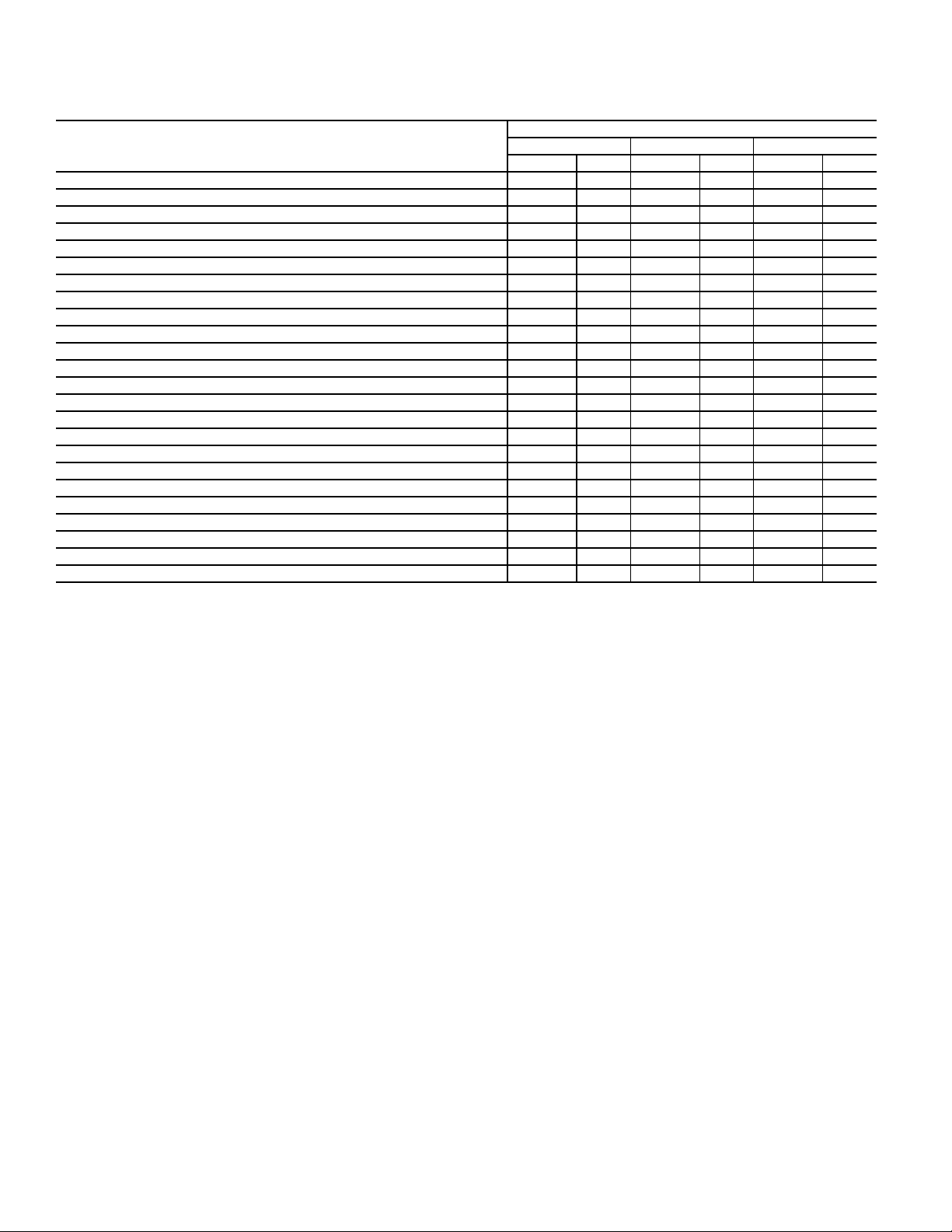

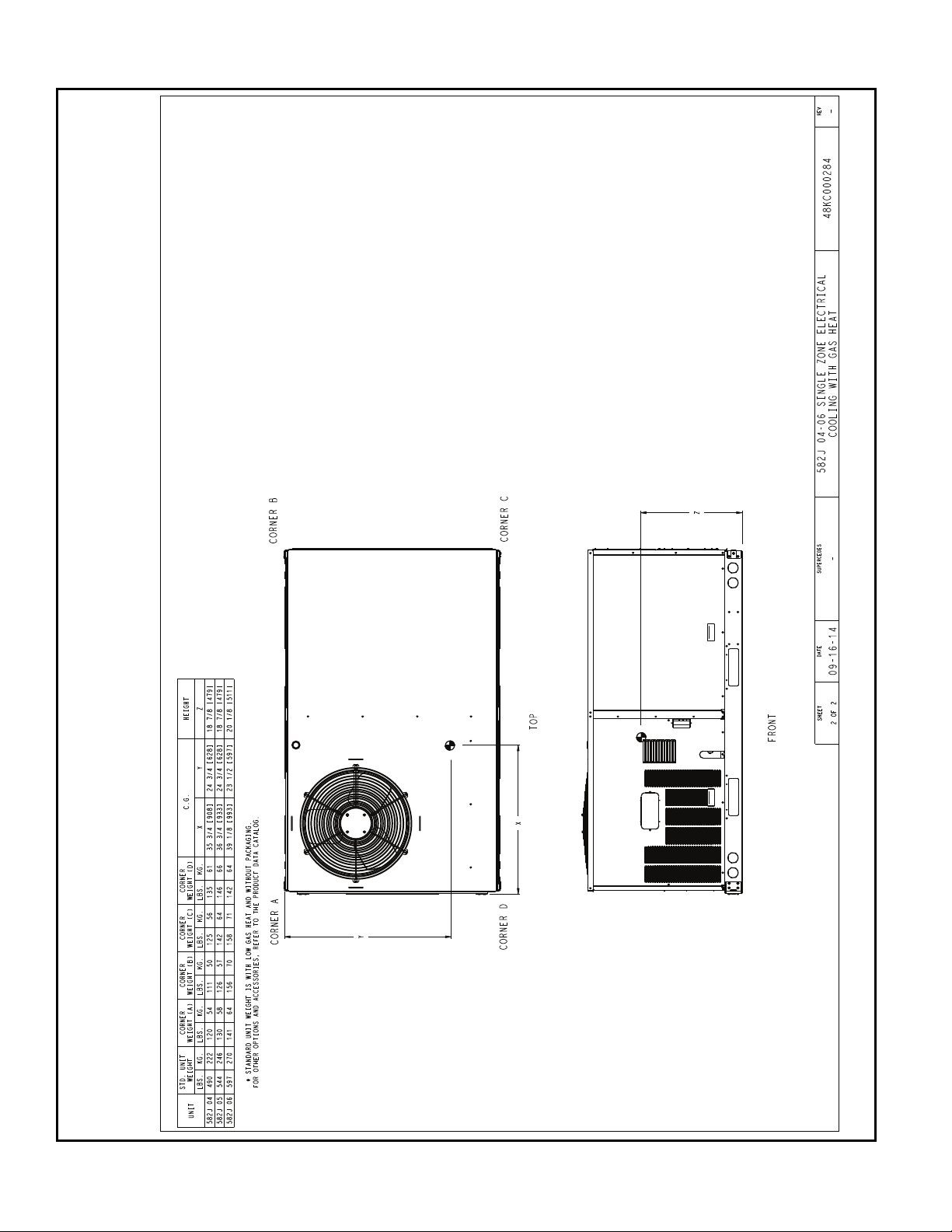

582J*04-06 CORNER WEIGHTS

BASE UNIT DIMENSIONS (CONT)

16

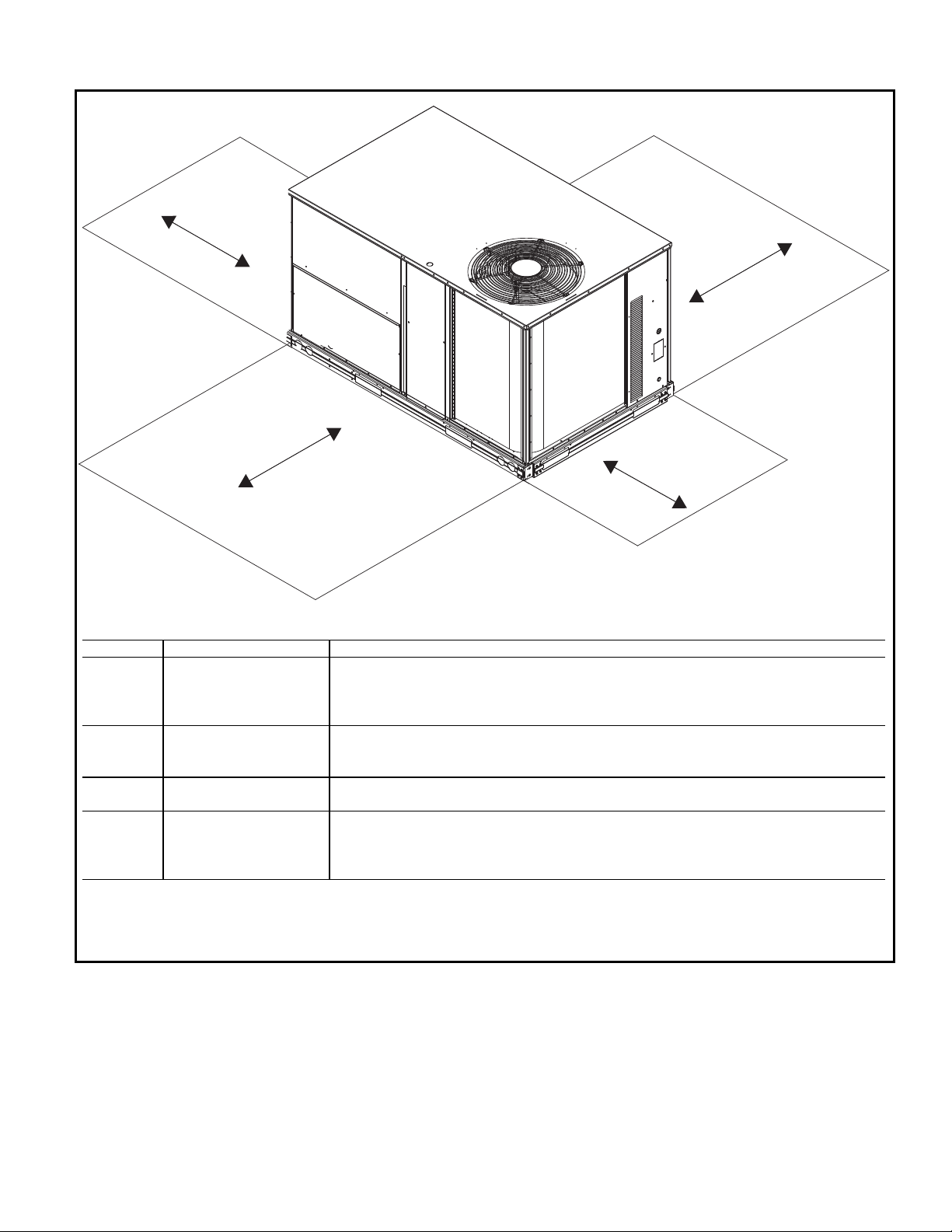

C

B

A

D

NOTE: Unit not designed to have overhead obstruction. Contact Application Engineering for guidance on any application planning overhead obstruction or for vertical clearances.

SERVICE CLEARANCE DIMENSIONS

LOCATION DIMENSION CONDITION

A

48-in. (1219 mm) Unit disconnect is mounted on panel

18-in. (457 mm) No disconnect, convenience outlet option

18-in. (457 mm) Recommended service clearance

12-in. (305 mm) Minimum clearance

B

42-in. (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall)

36-in. (914 mm) Surface behind servicer is electrically non-conductive (e.g., wood, fiberglass)

Special Check sources of flue products within 10 ft (3 m) of unit fresh air intake hood

C

36-in. (914 mm) Side condensate drain is used

18-in. (457 mm) Minimum clearance

D

48-in. (1219 mm) No flue discharge accessory installed, surface is combustible material

42-in. (1067 mm) Surface behind servicer is grounded (e.g., metal, masonry wall, another unit)

36-in. (914 mm) Surface behind servicer is electrically non-conductive (e.g., wood, fiberglass)

Special Check for adjacent units or building fresh air intakes within 10 ft (3 m) of this unit’s flue outlet

17

Loading...

Loading...