Page 1

installation, start-up and

service instructions

SINGLE PA CKA GE RO OFT OP

ELECTRIC COOLING/GAS HEATING UNITS

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . .1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

I. Step 1 — Provide Unit Support. . . . . . . . . . . . . .1

II. Step 2 — Rig and Place Unit . . . . . . . . . . . . . . . .3

III. Step 3 — Field Fabricate Ductwork. . . . . . . . . . .7

IV. Step 4 — Make Unit Duct Connections . . . . . . .7

V. Step 5 — Install Flue Hood and Wind

Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

VI. Step 6 — Trap Condensate Drain . . . . . . . . . . . .8

VII. Step 7 — Install Gas Piping. . . . . . . . . . . . . . . . .8

VIII. Step 8 — Make Electrical Connections . . . . . . .8

IX. Step 9 — Make Outdoor-Air Inl et

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

X. Step 10 — Install Outdoor -Air Hood . . . . . . . . .11

XI. Step 11 — Install All Accessories. . . . . . . . . . .13

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-25

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-34

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . 35-37

START-UP CHECKLIST. . . . . . . . . . . . . . . . . . . . . . . .CL-1

Page

581A

Sizes 155-240

Cancels: II 581A-155-2 II 581A-155-3

6/15/99

WARNING:

1. Improper installation, adjustment, alteration,

service, or maintenance can cause property

damage, personal injury, or loss of life. Refer to

the User’s Information Manual provided with

this unit for more details.

2. Do not store or use gasoline or other flammable

vapor s and l iq uids in t he vici nity of this or a ny

other appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any

phone in your buildi ng.

3. IMMEDIATELY call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

4. If you cannot reach your gas supplier, call the

fire department.

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform the basic maintenance

functions of cleaning coils and filters and replacing filters.

All ot he r oper ati ons s hou ld be pe rfor med by tr ain ed se rvi ce

personnel. When working on air-conditioning equipment,

observe precautions in the literature, tags and labels

attached to the unit, and other safety precautions that may

apply.

Follow all sa fe ty codes. Wear safet y gl a sse s an d w o rk g lov e s.

Use quenching cloth for unbrazing operations. Have fire

extinguishers available for all brazing operations.

WARNING: Before performing service or maintenance operations on unit, turn off mail power s wi tch to

unit. electrical shock cou l d cause personal inju ry.

WARNING: Disconnect gas piping from unit when

pressure testing at pressure greater than 0.5 psig.

Pressures greater than 0.5 psig will cause gas valve

damage resulting in hazardous condition. If gas valve

is subjected to pressure greater than 0.5 psig, it must

be replaced before use. When pressure testing fieldsupplied gas piping at pre ssures of 0.5 ps ig or less, a

unit connected to such piping must be isolated by closing the manual gas valve(s).

IMPORTANT: Units have high ambient operating limits. If

limits are exceeded, the units will automatically lock the

compressor out of operation. Manual res et will be required to

resta r t th e compre ss o r.

INSTALLATION

I. STEP 1 — PROVIDE UNIT SUPPORT

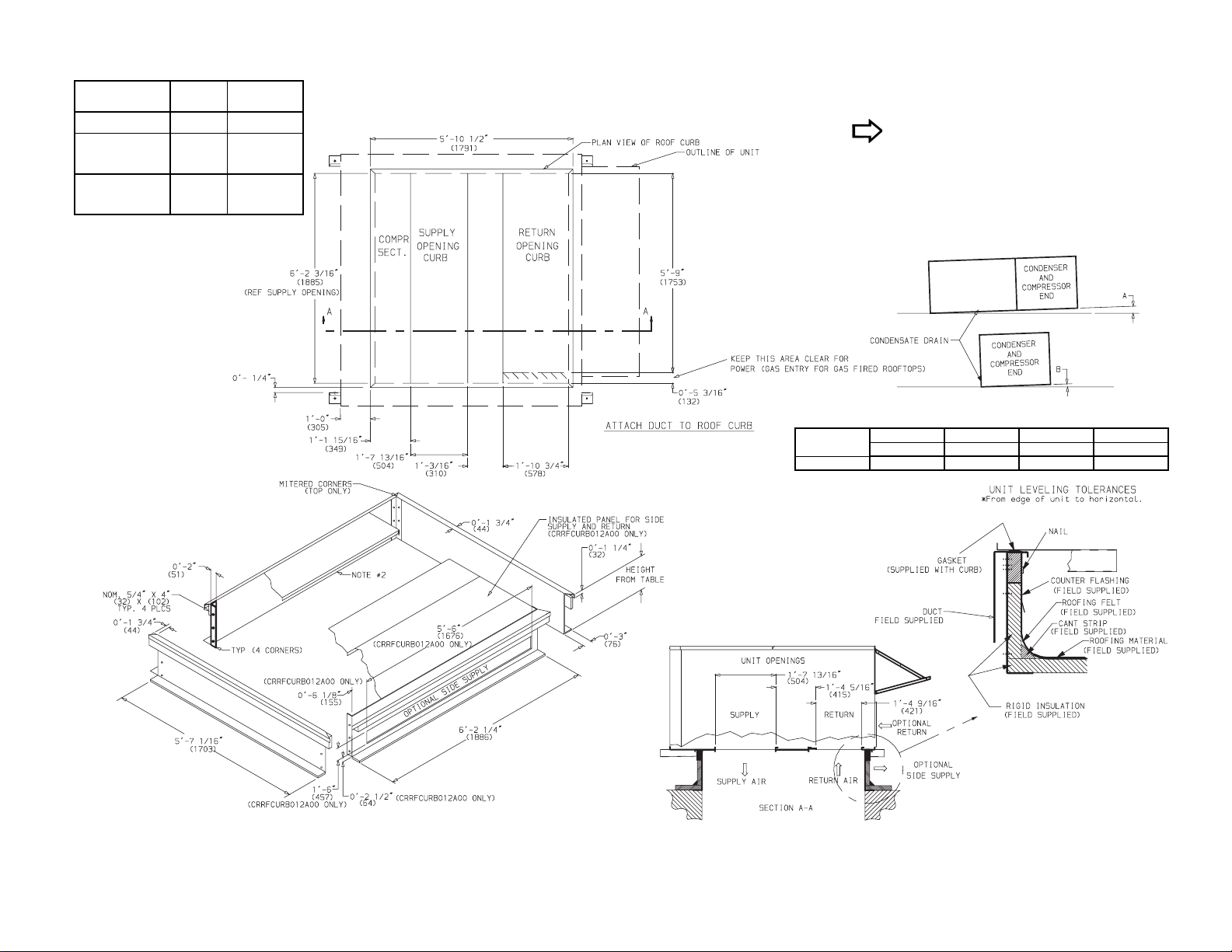

A. Roof Curb

Assemble or install accessory roof curb or horizontal supply

roof curb in accordance with instructions shipped with this

accessory. See Fig. 1 and 2. Install insulation, cant strips,

roofing, and counter flashing as shown. Ductwork can be

installed to roof curb or horizontal supply roof curb before

unit is set in place.

(Instructions continued on page 3.)

Page 2

—2—

PKG. NO. REF.

CRRFCURB010A00

CRRFCURB011A00

CRRFCURB012A00

CURB

HEIGHT

ft-in. (mm)

1-2

(305)

2-0

(610)

2-0

(610)

DESCRIPTION

Standard Curb

14” High

Standard Curb

for Units

Requiring High

Installation

Side Supply

and Return

Curb for High

Installation

NOTES:

1. Roof curb accessory is shipped disassembled.

2. Insulated panels: 1 in. thick neoprene coated 1

3. Dimensions in ( ) are in millimeters.

1

/2 lb density.

4. Direction of airflow.

5. Roof curb: 16 ga. (VA03-56) stl.

To pre vent the hazard of stagnant water build-up in the drain

NOTE:

pan of the indoor section, unit can only be pitched as shown.

Dimensions (degrees and inches)

UNIT

ALL

AB

DEG.IN.DEG.IN.

.28 .45 .28 .43

Fig. 1 — Roof Curb Details

Page 3

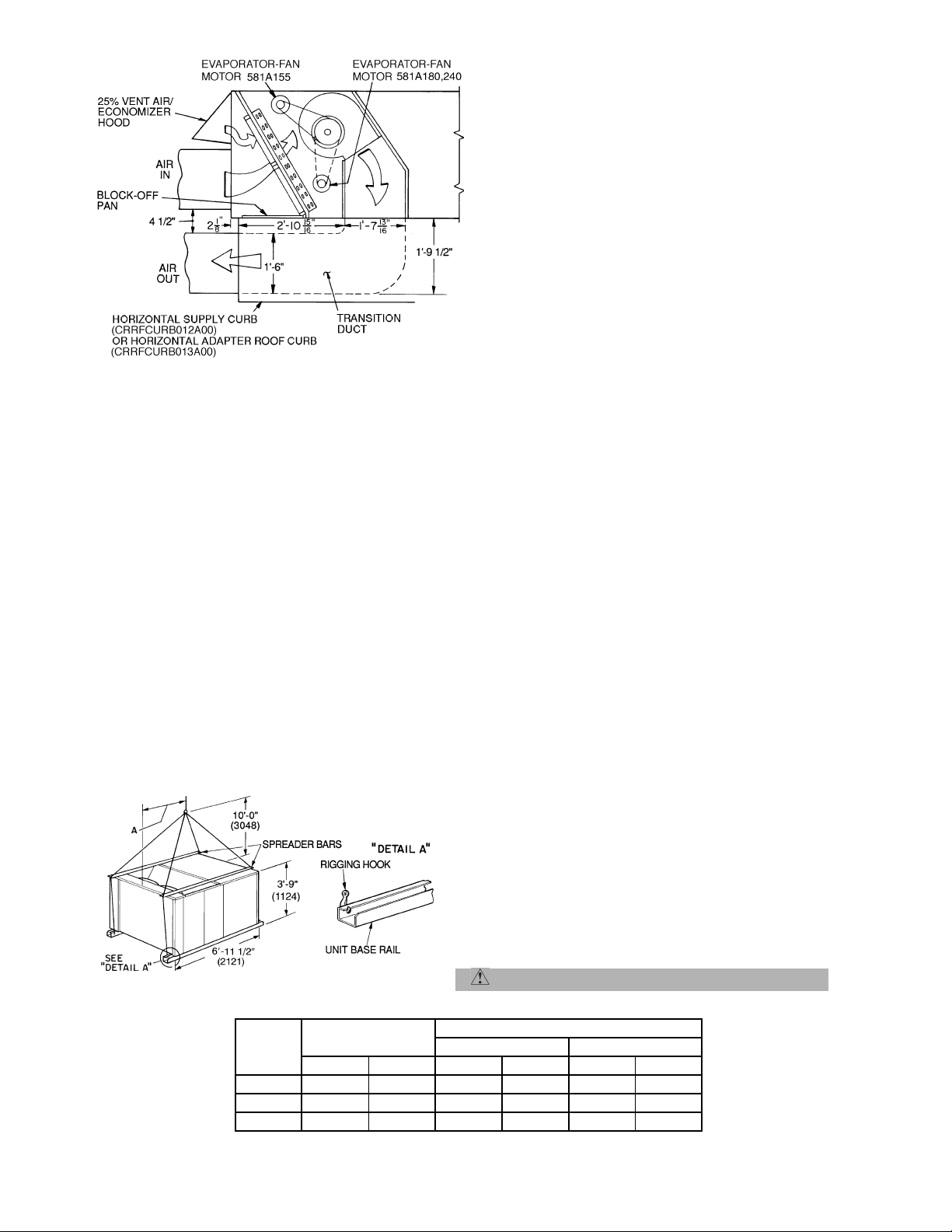

For preassembled horizontal adapter roof curb part no.

NOTE:

(CRRFCURB013A00), the accessor y kit includes a factory-designed,

high-static, regain transition duct. For horizontal curb part no.

CRRFCURB012A00, a field-supplied transition duct is required.

Fig. 2 — Horizontal Adapter Roof Curbs

and Roof Curbs

IMPORTANT: Curb or adapt er roof cur b must be lev el. Th is is

necessary to per mit unit drain to function properly. Unit leveling tolerance is ±

1

/16 in. per linear ft in any direction. Refer

to Accessory Roof Curb or Horizontal Supply Roof Curb

Installation Instructions for additional information as

required.

When accessory roof curb or horizontal supply roof curb is

used, unit may be installed on class A, B, or C roof covering

material.

IMPORTANT: The gasketing of the unit to the roof curb or

adapter roof curb is critical for a watertight seal. Install gasket with the roof curb or adapter as shown in Fig. 1. Improperly applied gasket can also result in air leaks and poor unit

performance.

B. Alternate Unit Support

When a curb or adapter cannot be used, install unit on a

noncombustible surface. Support unit with sleepers, using

unit curb support area. If sleepers cannot be used, support

long sides of unit with a minimum of 3 equally spaced 4-in. x

4-in. pads on each side.

II. STEP 2 — RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

tran sportat i on agency.

Do not drop unit; keep upright. Spreader bars are not

required if top crating is left on unit. Use spreader bars over

unit to prev ent sling or cabl e damage. Rollers may be used to

move unit across a roof. Level by usi n g unit frame as a reference; lev eling toler a n ce is ±

1

/16 in. per linear ft in any direction. See Fig. 3 for additional information. Unit operating

weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails as

shown in Fig. 3. Refer to ri ggi ng inst ruct ions on unit.

A. Positioning

Maintain clearance, per Fig. 4 and 5, around and above unit

to provide minimum distance from combustible materials,

proper airflow, and service access.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air. For proper unit operation, ade quate combustion a nd ventilation air must be provided in accordance with Section 5.3

(Air for Combustion and Ventilation) of the National Fuel

Gas Code, ANSI Z223.1 (American National Standards

Institute) .

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least 4 ft

from any opening through which combustion products could

enter the building, and at least 4 ft from any adjacent building. When unit is located adjacent to public walkways, flue

assembly must be at leas t 7 ft above grade.

B. Roof Mount

Check building codes for weight distribution requirements.

Unit operating weight is shown in Table 1.

Instructions continued on page 8.

UNIT

581A

155

180

240

NOTES:

1. Dimensions in ( ) are in millimeters.

2. Refer to Fig. 4 and 5 for unit operating weights.

3. Remove boards at ends of unit and runners prior to rigging.

4. Rig by inser ting hook s in to uni t ba se rails as show n. Use c or n er pos t from

packaging to protect coil from damag e. Use bumper boards for spreader

bars on all units.

5. Weights do not include opti onal economi zer. Add 110 lb (50 kg) for econo mizer weight.

6. Weights given are for aluminum evaporator and condenser coil plate fins.

7. Add 75 lb (34 kg) for crating on 581A155 and 180 units. Add 135 lb (61 kg)

for crating on 581A240 units.

8. Add 150 lb (68 kg) for copper condens er coi l. Add 280 lb (127 kg ) for

copper condenser and evaporator coils.

CAUTION:

MAXIMUM SHIPPING

WEIGHT

lb kg ft-in. mm ft-in. mm

1725 782 6-11

1800 816 6-11

1900 862 6-11

AB

1

/

2

1

/

2

1

/

2

All panels must be in place when rigging.

DIMENSIONS

2121 4-0 1219

2121 3-2 964

2121 3-4 1016

Fig. 3 — Rigging Details

—3—

Page 4

—4—

STD UNIT

UNIT

WEIGHT

581A

Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg ft-in. mm ft-in. mm ft-in. mm

155 1725 782 110 50 427 194 390 177 438 199 470 213 3-3 991 3-5 1051 1-10 559

180 1800 816 110 50 417 189 399 181 481 218 503 228 3-2 961 3-6 1070 1-10 559

ECONO-

MIZER

WEIGHT

CORNERACORNERBCORNERCCORNER

NOTES:

1. Refer to print for roof curb accessory dimensions.

2. Dimensions in ( ) are in millimeters.

D

DIM A DIM B DIM C

3. Center of Gravity.

4. Direction of airflow.

5. Ductwork to be attached to accessory roof curb only.

6. Minimum clearance:

• Rear: 7 ft- 0 in. (2134) for coil removal. This dim ension can be reduced

to 4 ft-0 in. (1219) if conditions permit coil removal from the top.

• 4 ft-0 in. (1219) to combustible surfaces, all four sides (includes between

units).

• Left side: 4 ft-0 in.(1219) for proper condenser coil airflow.

• Front: 4 ft-0 in. (1219) for control box access.

• Right side: 4 ft-0 in. (1219) for proper operation of damper and power

exhaust if so equipped.

• Top: 6 ft-0 in. (1829) to assure proper condenser fan operation.

• Bottom: 14 in. (356) to combustible surfaces (when not using curb).

• Control box side: 3 ft-0 in. (914) to ungrounded surfaces, non-combustible.

• Control box side: 3 ft-6 in. (1067) to block or concrete walls, or other

grounded surfaces.

POWER EXHAUST/

BAROMETRIC RELIEF

(ACCESSORY ONLY)

• Local codes or jurisdiction may prevail.

7. With the exception of clearance for the condenser coil and the damper/

power exhaust as stated in Note no. 6, a removable fence or barricade

requires no clearance.

8. Dimensions are from outsi de of corner post. Allow 0 ft-

side for top cover drip edge.

5

/16 in. (8) on each

581A180 ONLY

Fig. 4 — Base Unit Dimensions; 581A155 and 180

POWER EXHAUST/

BAROMETRIC RELIEF

(ACCESSORY ONLY)

FIELD

SUPPLIED

Page 5

—5—

UNIT STD. UNIT WEIGHT

581A240

NOTES:

1. Refer to print for roof curb accessory dimensions.

2. Dimensions in ( ) are in millimeters.

3. Center of Gravity.

4. Direction of airflow.

5. Ductwork to be attached to accessory roof curb only.

6. Minimum clearance:

• Rear: 7 ft-0 in. (2134) for coil removal. This dimensio n can be reduced to

4 ft-0 in. (1219) if conditions permit coil removal from the top.

• 4 ft-0 in. (1219) to combustible surfaces, all four sides (includes between

units).

• Left side: 4 ft-0 in.(1219) for proper condenser coil airflow.

• Front: 4 ft-0 in. (1219) for control box access.

• Right side: 4 ft-0 in. (1219) for proper operation of damper and power

exhaust if so equipped.

• Top: 6 ft-0 in. (1829) to assure proper condenser fan operation.

• Bottom: 14 in. (356) to combustible surfaces (when not using curb).

• Control box side: 3 ft-0 in. (914) to ungrounded surfaces, non-combustible.

• Control box side: 3 ft-6 in. (1067) to block or concrete walls, or other

grounded surfaces.

• Local codes or jurisdiction may prevail.

7. With the exception of clearance for the condenser coil and the damper/power

exhaust as stated in Note no. 6, a removable fence or barricade requires no

clearance.

8. Dimensions are fr om outside of cor ner post. Allow 0 ft -

side for top cover drip edge.

1900 lbs (862 kg) 110 lbs (50 kg)

ECONOMIZER

WEIGHT

5

/16 in. (8) on each

Fig. 5 — Base Unit Dimensions; 581A240

Page 6

T able 1 — Physical Data

UNIT 581A 155 180 240

NOMINAL CAPACITY (tons)

OPERATING WEIGHT (lb)

Unit

Al/Al*

Al/Cu*

Cu/Cu*

Economizer

Roof Curb†

COMPRESSOR

Quantity

Number of Refrigerant Circuits

Crankcase Heater Watts

Oil (oz) (Ckt 1, Ckt 2)

REFRIGERANT TYPE

Expansion Device

Operating Charge (lb oz)

Circuit 1**

Circuit 2

CONDENSER COIL

Rows...Fins/in.

Total Face Area (sq ft)

CONDENSER FAN

Nominal Cfm

Quantity...Diameter (in.)

Motor Hp...Rpm

Watts Input (Total)

EVAPORATOR COIL

Rows...Fins/in.

Total Face Area (sq ft)

EVAPORATOR FAN

Quantity...Size (in.)

Type Drive

Nominal Cfm

Std Motor Hp

Opt Motor Hp

Motor Nominal Rpm

Std Maximum Continuous Bhp

Opt Maximum Continuous Bhp

Motor Frame Size

Fan Rpm Range Low-Medium Static

Motor Bearing Type

Maximum Allowable Rpm

Motor Pulley Pitch Dia. Low-Medium Static

Nominal Motor Shaft Diameter (in.)

Fan Pulley Pitch Diameter (in.) Low-Medium Static

Nominal Fan Shaft Diameter (in.)

Belt, Quantity...Type... Length (in.) Low-Medium Static

Pulley Center Line Distance (in.)

Speed Change per Full Turn of

Movable Pulley Flange (Rpm)

Movable Pulley Maximum

Full Turns From Closed Position

Factory Speed

Factory Speed Setting (Rpm) Low-Medium Static

FURNACE SECTION

Rollout Switch Cutout Temp (F) ll

Burner Orifice Diameter (in...drill size)

Natural Gas

Thermostat Heat Anticipator Setting

Stage 1 (amps)

Stage 2 (amps)

Gas Input (Btuh)Stage 1

Efficiency (Steady State) (%)

Temperature Rise Range

Manifold Pressure (in. wg)

Natural Gas

Gas Valve Quantity

GasValvePressure Range (in. wg)

Stage 2

(psig)

High Static

High Static

High Static

High Static

Low-Medium Static

High Static

High Static

0.98 0.8 0.98 0.8 0.98 0.8

0.44 0.44 0.44 0.44 0.44 0.44

Field Gas C onnection Size (in.-FPT)

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

LOW-PRESSURE SWITCH (psig)

Cutout

Reset (Auto.)

FREEZE PROTECTION THERMOSTAT (F)

Opens

Closes

OUTDOOR-AIR INLET SCREENS

Quantity...Size (in.)

RETURN-AIR FILTERS

Quantity...Size (in.)

LEGEND

Al —

Bhp —

Cu —

TXV —

Aluminum

Brake Horsepower

Copper

Thermostatic Expansion Valve

12 15 20

1725 1800 1900

1875 1950 2050

2005 2080 2180

110 110 110

200 200 200

22 2

22 2

70 70 70

60,66 85,60 110,110

20.7 19.5 18.5

11.9 13.45 13.3

Cross-Hatched

1

/2...1050

2...10 X 10 2...12 x 12 2...12 x 12

3

4...15 4...15 4...15

10,500 10,500 14,200

3...22 3...22 2...30

/8-in. Copper Tubes, Aluminum Lanced, Aluminum Pre-Coated, or Copper Plate Fins

21.7 21.7 21.7

1100 1100 3400

Cross-Hatched 3/8-in. Copper Tubes, Aluminum Lanced or Copper Plate Fins, Face Split

4...15 4...15 4...15

17.5 17.5 17.5

Belt Belt Belt

5200 6000 8000

2.9 5 7.5

3.7

1725 1745 1745

R-22

TXV

Propeller Type

1

/2...1050 1...1075

Centrifugal Type

3.13 6.13 9.47 (208 v)

4.38

56H 184T 213T

834-1064 873-1021 1002-1151

1161-1426 1025-1200 1193-1369

Ball Ball Ball

1550 1550 1550

3.1/4.1 4.9/5.9 5.4/6.6

3.7/4.7 4.9/5.9 5.4/6.6

7

/

8

6.0 9.4 9.4

5.2 8.0 7.9

3

1

/

16

1...BX...42 1...BX...50 1...BX...54

1...BX...42 1...BX...48 1...B X...50

13.5-15.5 13.3-14.8 14.6-15.4

11/

8

17/

16

58 37 37

67 44 44

4†† 4†† 4††

3.5 3.5 3.5

978 965 1095

1327 1134 1303

190 190 190

0.1285...30/ 0.136...29 0.1285...30/ 0.136...29 0.1285...30/ 0.136...29

172,000/230,000 206,000/275,000 206,000/275,000

225,000/300,000 270,000/360,000 270,000/360,000

81 81 81

15-45/30-60 15-45/20-50 15-45/20-50

3.3 3.3 3.3

11 1

5.5-13.5 5.5-13.5 5.5-13.5

.235-.487 .235-.487 .235-.487

3

/

4

*Evaporator coil fin material/condenser coil fin material.

†Weight of 14-in. roof curb.

**Circuit 1 uses the lower portion of condenser coil and lower portion of evaporator coils, and

Circuit 2 uses the upper portion of both coils.

††Pulley has 6 turns. Due to belt and pulley, moveable pulley cannot be set to 0 to 1 turns open.

llRollout switch is manual reset.

3

/

4

426

320

27

44

30 ± 5

45 ± 5

Cleanable

2...20 x 25 x 1

1...20 x 20 x 1

Throwaway

4...20 x 20 x 2

4...16 x 20 x 2

(230 and 460 v)

13/

8

17/

16

3

/

4

10.33

—6—

Page 7

III. STEP 3 — FIELD FABRICATE DUCTWORK

On vertical units, secure all ducts to roof curb and building

structure. Do not connect ductwork to unit. Use flexible duct

connectors between unit and ducts as required. Adequately

insulate and weatherproof all ductwork located outdoors,

joints, and roof openings with counter flashing and mastic in

accordance with applicable codes. Insulate ducts passing

through unconditioned space, and use vapor barrier in accordance wit h the latest issue of SMACNA (Sheet Meta l and Air

Conditioning Contractors National Association) and ACCA

(Air Conditioning Contractors of America) minimum installation standards for heating and air conditioning systems.

Ducts passing through an unconditioned space must be insulated and covered with a vapor barrier.

A minimum clearance to combustibles of 1 in. for the first

24 in. of ductwork is required for all units with electric heat.

Cabinet return-air static shall not exceed –0.35 in. wg with

economizer or –0.45 in. wg without economizer.

IV. STEP 4 — MAKE UNIT DUCT CONNECTIONS

Unit is shipped for thru-the-bottom duct connections. Ductwork openings are shown in Fig. 1, 4, and 5. Duct

connections are shown in Fig. 6. Field-fabricated concentric

ductwork may be connected as shown in Fig. 7 and 8. Attach

all ductwork to roof curb and roof curb basepans. Refer to

installation instructions shipped with accessory roof curb for

more information.

WARNING: For vertical supply and return units,

tools or parts coul d drop into ductwork a nd cause an

injury. Install a 90 degree turn in the return ductwork

between the unit and the conditioned space. If a

90 degree elbow cannot be installed, then a grille of

sufficient strength and density should be installed to

prevent objects from falling into the conditioned space.

V. STEP 5 — INSTALL FLUE HOOD AND WIND BAFFLE

Flue hood, screen, and wind baffle are shipped secured

under main control box. To install, secure flue hood and

screen to access panel with screws provided. See Fig. 9. The

wind baffle is then installed over the flue hood.

NOTE: When properly installed, flue hood will line up with

combustion fan housing. See Fig. 10.

Do not drill in this area; damage to basepan may result in water

NOTE:

leak.

Fig. 6 — Air Distribution — Thru-the-Bottom

(581A180, 240 Unit Shown)

Do not drill in this area; damage to basepan may result in water

NOTE:

leak.

Fig. 7 — Concentric Duct Air Distribution

(581A180, 240 Unit Shown)

Dimensions A, A’, B and

NOTE:

B’ are obtained from field-supplied ceiling diffuser.

Shaded areas indicate block-off pans.

Fig. 8 — Concentric Duct Details

INLET

WIND

BAFFLE

LOUVERS

FLUE

SCREEN

Fig. 9 — Flue Hood Location

—7—

Page 8

INDUCED DRAFT

3/4" FPT DRAIN

CONNECTION

1-3/8"

DRAIN HOLE

INDOOR MOTOR ACCESS

FILTER

ACCESS

MOTOR

All field wiring must comply with NEC and local requirements. Insulate low-voltage wires for highest voltage contained within condui t when low-volta ge control wir es are run

in the same conduit as high-voltage wires .

COMBUSTION

FAN HOUSING

MAIN BURNER

SECTION

HEAT EXCHANGER

SECTION

Fig. 10 — Combustion Fan Housing Location

VI. STEP 6 — TRAP CONDENSATE DRAIN

See Fig. 4, 5, and 11 fore drain location. Plug is provided in

drain hole and must be removed when unit is operating. One

3

/4 in. half coupling is provided inside unit evaporat or section

for condensate drain connection. An 8

nipple and a 2 in. x

standard

3

/4 in. diameter elbow to provide a straight path

3

/4 in. diamet er pi pe ni ppl e are co uple d to

1

/2 in. x 3/4 in. diameter

down through holes in unit base rails (see Fig. 11 and 12). A

trap at least 4 inc hes deep must be used.

VII. STEP 7 — INSTALL GAS PIPING

The gas supply pipe enters the unit through the 1

diameter knockout provided. The gas connection to the unit

is made to th e

3

/4 in. FPT gas inlet on the gas manifold. Unit

1

/2 in.

is equipped for use with natural gas. Installation must conform with local building codes or, in the absence of local

codes, wi th the National Fuel Gas code, ANSI Z223.1.

Install field-supplied manual gas shutoff valve with a

1

/8 in.

NPT pressure tap for test gage connection at unit. Field gas

piping must include sediment trap and union. See Fig. 13.

Install sedim ent trap in riser leading to heating section. This

drip leg functions as a trap for dirt and condensate. Install

trap where condensate cannot freeze. Install this sediment

trap b y connecti ng a piping tee to riser lead ing to he ating

section, so that straight-through section of tee is vertical.

Then, connect capped n ipple in to lower end of t ee. Extend

capped nipple below level of gas contr ols.

Fig. 11 — Condensate Drain Details

(581A155 Shown)

Fig. 12 — Condensate Drain Piping Detai ls

WARNING: Do not pressure test gas supply while

connected to unit. Always disconnect union before

servicing.

IMPORTANT: Natural gas pressure at unit gas connection

must not be less than 5.5 in. wg or greater than 13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas

connection.

VIII. STEP 8 — MAKE ELECTRICAL CONNECTIONS

A. Field Power Supply

Unit is factory wired for voltage shown on unit nam epl ate.

When installing units, provide a disconnect per NEC

(National Electrical Code) requirements of adequate size

(Table 2).

Fig. 13 — Field Gas Piping

—8—

Page 9

Route power and ground lines through control box end panel

or unit basepa n (s ee Fig. 4 and 5) to connections as shown on

unit wiring diag ram and Fig. 14.

CAUTION: The correct power phasing is critical in

the operation of the scroll compressors. An incorrect

phasing will cause the compressor to rotate in the

wrong direction. This may lead to premature compressor failure.

WARNING: The unit must be electrically grounded

in accordance with local codes and NEC ANSI/NFPA

70 (National Fire Protection Association).

Field wiring must conform to temperature limitations for

type “T” wire. All field wiring must comply with NEC and

local requirements.

Transformer no. 1 is wired for 230-v unit. If 208/230-v unit is

to be run with 208-v power supply, the transformer must be

rewired as follows:

1. Remove cap from red ( 208 v ) wi re.

2. Remove cap from orange ( 230 v ) spliced wire.

3. Replace oran ge wir e wi th red wire.

4. Recap both wires.

IMPORTANT: BE CERTAIN UNUSED WIRES ARE

CAPPED. Failure to do so may damage the transformers.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, voltages between phases must be balanced within 2%.

Unit failure as a result of operation on improper line voltage

or excessive phase imbalance constitutes abuse and may

cause damage to electrical components. Such operation

would invalidate any warrant y.

B. Field Control Wiring

The unit must have a separate electrical service with a fieldsupplied , w at e rp ro o f, fuse d di sconnect sw i tc h mou nted at, or

within sight fr o m , th e unit. R ef e r to the u n i t r a ti n g plate fo r

maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing. Be sure disconnect switch

does not obst ruct unit rating plate.

The field-supplied disconnect switchbox may be mounted on

the unit over the high-voltage inlet hole in the control corner

panel.

Connect ground lead to chassis ground connection when

using separate ground wire. The unit has a terminal block

for fie l d power connect ions. Inst all conduit conne ctors in side

panel power supply knockout openings indicated in Fig. 4

and 5. Route power lines through connector to unit control

box.

Install a Bryant approved accessory thermostat assembly

according to the installation instructions included with the

accessory. Locate thermostat assembly on a solid wall in the

conditioned s pace to sense average temperature.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals through conduit in unit to lowvoltage connections as shown on unit label wiring diagram

and in Fig. 15.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AW G insulated wire (35 C Minimum).

All wire larger than no. 18 AWG cannot be directly connected

at the thermostat and will require a junction box and splice

at the thermostat.

Set heat antic i pator settings as follows:

VOLT AGE W1 W2

208/230

460

0.98 0.44

0.80 0.44

The room thermostat heat anticipator must be properly

adjusted to ensure proper heating performance. Set the heat

anticipator to settings based on the table above, by using an

ammeter to determine the exact setting for stages 1 and 2.

Failure to make a proper heat anticipator adjustment may

result in improper operation, discomfort to the occupants of

the conditioned space, and inefficient energy utilization;

however, the required setting m ay be changed slightly to provide a greater de gr ee of comfort for a particular installation.

Refer to Accessory Remote Control Panel instructions if

required.

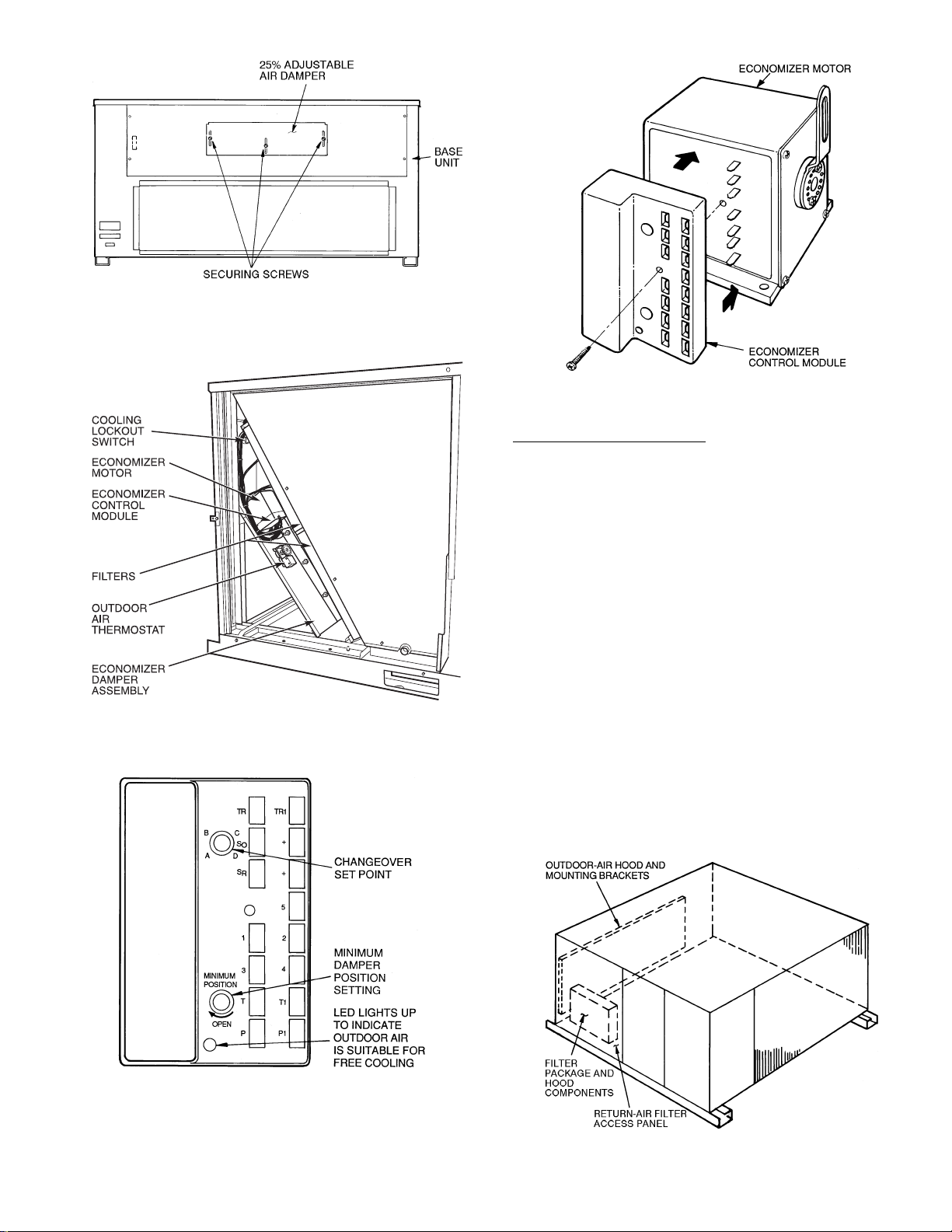

STEP 9 — MAKE OUTDOOR-AIR INLET ADJUSTMENTS

A. Manual Outdoor-Air Damper

All units (except those equipped with a factory-installed

economizer) have a manual outdoor-air damper to provide

ventilation air.

Damper can be preset to admit up to 25% outdoor air into

return-air compartment. To adjust, loosen securing screws

and move damper to desired setting. Retighten screws to

secure damper (Fig. 16).

B. Optional Economizer

Economizer Mot or C ontrol Module (See Fig . 17-19)

The economizer control location is shown Fig. 17. For maxi-

mum benefit of outdoor air, set economizer motor control

module to the “D” setting (Fig. 18). The economizer motor

control module is located on the economizer motor. See

Fig. 19.

The maximum wire size for TB1 is 2/0.

NOTE:

EQUIP —

GND —

NEC —

TB —

LEGEND

Equipment

Ground

National Electrical Code

T erminal Board

Fig. 14 — Field Power Wiring Connections

Fig. 15 — Field Control Therm ostat Wiring

—9—

Page 10

Table 2 — Electrical Data

NOMINAL

UNIT

VOLTAGE

581A

(Standard

(Optional

LEGEND

FLA —

HACR —

IFM —

LRA —

MCA —

MOCP —

NEC —

OFM —

RLA —

*Fuse or HACR circuit breaker.

NOTES

1. In compliance with NEC requirements for multimotor and combination load equipment (refer

to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or

HACR breaker. Canadian units may be fuse or circuit breaker.

2.

Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is greater than 2%.

the following formula to determine the percent voltage imbalance.

% Voltage Imbalance

= 100 x

(3 Ph, 60

Hz)

208/230 187 253 20.7 156 19.3 123 3 0.5 1.7 2.9

015

IFM)

015

IFM)

017

025

460 414 508 10 70 10 62 3 0.5 0.8 2.9 4.2

208/230 187 253 20.7 156 19.3 123 3 0.5 1.7 3.7

460 414 508 10 70 10 62 3 0.5 0.8 3.7 4.8

208/230 187 253 32.1 195 20.7 156 3 0.5 1.7 5.0

460 414 508 16.4 95 10 70 3 0.5 0.8 5.0 7.9

208/230 187 253 42 239 33.6 225 2 1 6.6 7.5

460 414 508 19.2 125 17.3 114 2 1 3.3 7.5 13.0

Full Load Amps

Heating, Air Conditioning and

Refrigeration

Indoor (Evaporator) Fan Motor

Locked Rotor Amps

Minimum Circuit Amps

Maximum Overcurrent Protection

National Electrical Code

Outdoor (Condenser) Fan Motor

Rated Load Amps

:

max voltage deviation from average voltage

average voltage

VOLTAGE

RANGE

Min Max RLA LRA RLA LRA Qty Hp FLA (ea) Hp FLA FLA LRA FLA MCA MOCP*

COMPRESSOR

No. 1 No. 2

Use

7

457

POWER

EXHAUST

—

2.3—6.0

—

2.3—6.0

—

2.3—6.0

—

2.3—6.0

OFM IFM

8.8/

8.4—4.6—18.8

11.0/

10.5—4.6—18.8

15.8/

15.8—4.6—18.8

25.0/

25.0—4.6—18.8

EXAMPLE: Supply voltage is 460-3-60.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

=

= 457

Determine maximum deviation from average voltage.

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

= 1.53%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT:

utility company immediately.

452 + 464 + 455

3

1371

3

If the supply voltage phase imbalance is more than 2%, contact y our local electric

COMBUSTION

FAN MOTOR

0.57

0.57

0.30

0.30

0.57

0.57

0.30

0.30

0.57

0.57

0.30

0.30

0.57

0.57

0.30

0.30

59/59

64/63

29

31

61/61

66/65

30

32

82/82

86/86

41

43

124/124

129/129

61

63

POWER

SUPPLY

110/110

110/110

150/150

150/150

70/70

80/80

35

40

80/80

80/80

35

40

50

50

80

80

—10—

Page 11

Fig. 16 — 25% Outdoor-Air Sect ion Details

Fig. 17 — Economizer Damper Assembl y-End View

Fig. 19 — Economizer Motor Control

Module Location

Damper Vent Position Setting

1. Set fan switch at ON position (continuous fan operation) and close night switch if used.

2. Set system selecto r swit ch at OFF position.

3. Turn damper adjustment knob located on control

module clockwise slowly until dampers assume

desired v e n t p os iti on. Do not manually operate econo-

mizer motor, since damage to motor will res ult.

X. STEP 10 — INSTALL OUTDOOR-AIR HOOD

The outdoor-air hood is common to 25% air ventilation and

econ omizer. If eco nomizer is used , all elec trica l connec tions

have been made and adjusted at the factory. Assemble and

install hood in the field.

NOTE: The hood top panel, upper and lower filter retainers,

hood drain pan, baffle (sizes 180 and 240), and filter support

bracket are secured opposite the condenser end of the unit.

The screens, hood side panels, remaining section of filter

support bracket, seal strip, and other hardware are in a

package located inside the return-air filter access panel

(Fig. 20).

1. Attach seal strip to upper filter retainer. See Fig. 21.

2. Assemble hood top panel, side panels, upper filter

retainer, and drain pan (see Fig. 22 ).

LEGEND

LED —

Light- Emitti ng Diode

Fig. 18 — Economizer Motor Control Mod ule

(Part Number W7459A)

Fig. 20 — Outdoor-Air Hood Component Locati on

—11—

Page 12

3. Secure lower filter retainer and long section of filter

support bracket to unit. See Fig. 22. Leave screws

loose on 180 and 240 units.

4. Slide baffle (sizes 180 and 240) behind lower filter

retainer and tighten screws.

5. Loosen sheet metal screws for top panel of base unitlocated above outdoor-air inlet opening, and remove

screws for hood side panels locat ed on the sides of the

outdoor-air inlet opening.

6. Match notches in hood top panel with unit top panel

screws. Insert hood flange between top panel flange

and unit. Tighten screws.

7. Hold hood side panel flanges flat against unit, and

install screws removed in Step 5.

Fig. 21 — Seal Strip Location

BAFFLE (180 AND 240 SIZES ONLY)

LOWER FILTER

RETAINER

FILTER SUPPORT

BRACKET

8. Insert outd oor-air inlet screens and spacer i n channel

created by lower filter retainer and filter support

bracket.

9. Attach remaining short section of filter support

bracket.

A. Enthalpy Control Installation

NOTE: The accessory outdoor-air enthalpy sensor must be

installed BEF OR E th e economizer hoods ar e installed on the

unit or hoods will have to be removed.

1. Remove and discard the factory-installed jumper

assembly containing the 800-ohm resistor on the

economizer control module (between terminals S

and +). See Fig. 18.

2. Remove black wire assembly containing the 620-ohm

resistor from between economizer control module terminal S

and the outdoor-air thermostat (O A T ). Place

O

this wire assembly (containing the 620-ohm resistor)

between economizer control module terminals S

and

R

+, replacing the jumper removed in Step 1. See

Fig. 18.

3. Disconnect the blue wire from the OAT.

4. Remove OAT from the outside of the economizer. See

Fig. 17.

5. Mount the enthalpy sensor (Fig. 23) to the economizer on the outside of the unit (in the same location

from which the OAT was removed) using the 2 screws

provided. See Fig. 17.

6. Reconnect the blue wire removed in Step 3 to the

enthalpy sen sor terminal +.

7. Cut the violet wire provided to desired length and

terminate with quick-connect terminal provided.

Route the violet wire from the enthalpy sensor terminal S, through the snap bushing, and to the economizer control module terminal S

. See Fig. 18.

O

8. Set changeover set point to the desired location. See

Fig. 24.

NOTE: For maximum benefit of outdoor air, set the enthalpy

control to the “A” setting. At this setting, when the relative

humidity is 50% and the outdoor air is below 74 F, the relay

contacts on the sens or will be closed.

9. Reinstall economizer hoods if removed.

IMPORTANT: Be sure all seal strips and RTV sealant are

intact. A watertight seal to inside of unit must be

maintained.

R

HOOD SIDE

HOOD TOP

PANEL

HOOD DRAIN PAN

UPPER FILTER RETAINER

The outdoor air hood comes with a baffle which is used on

NOTE:

sizes 180 and 240 only. Discard baffle for size 155 units.

PANELS (2)

FILTER SUPPORT

BRACKET

Fig. 22 — Outdoor-Air Hood Details

BAFFLE

(180 AND

240

ONLY)

LOWER

FILTER

RETAINER

Fig. 23 — Outdoor-Air and Return-Air

Enthalpy Sensor

—12—

Page 13

CONTROL

CURVE

RH —

A

B

C

D

CONTROL

POINT

(Appro x Deg)

AT 50% RH

73

68

63

58

Relative Humidity

Fig. 24 — Psychrometric Chart for Solid-State

Enth a lpy Control

B. Differential Enthalpy Control

NOTE: The accessory outdoor-air enthalpy sensor must be

installed BEF OR E the economizer hoods are installed on the

unit or hoods will have to be removed.

1. Remove and discard the factory-installed jumper

assembly containing the 800-ohm resistor on the

economizer control module (between terminals S

and +). See Fig. 18.

2. Disconnect black wire from economizer control module terminal S

and blue wire from the OAT (outdoor -

O

air thermostat).

3. Remove OAT and black wire assembly containing the

620-ohm resistor from the outside of the economizer

(see Fig. 17).

4. Mount the outdoor-air enthalpy sensor (first sensor)

to the economizer on the outside of the unit (in the

same location from which the OAT was removed)

using the 2 screw s pr ov ided. See Fig. 17.

5. Reconnect the blue wire removed in Step 2 to the

enthalpy sensor terminal +.

6. Cut the violet wire provided to desired length and

terminate with quick-connect terminal provided.

Route the viole t wi re from the enthalpy sensor ter minal S, through the snap bushing, and to the economizer control module terminal S

.

O

7. Mount the second enthalpy sensor in the return-air

duct (return-air sensor).

8. Route the blue wire (pr ov i ded) from term inal + on the

return-air enthalpy sensor to the economizer control

module terminal +.

9. Route the violet wire (provided) from terminal S on

the return-air enthalpy sensor to the economizer control module term inal S

.

R

10. Turn changeover set point dial clockwise past the “D”

setting, or the control will not operate on a differential. See Fig . 18.

11. Reinstall economizer hood if removed.

IMPORTANT: Be sure all seal strips and RTV sealant are

intact. A watertight seal to inside of unit must be

maintained.

XI. STEP 11 — INSTALL ALL ACCESSORIES

After all the factory-installed options have been adjusted,

install all field-installed accessories. Refer to the accessory

installation ins tructions included with each accessory.

A. Motormaster® I Control Installation (581A155 and 180

Only)

Install Field -Fabricated Wind Baffles

Wind baffles must be field-fabricated for all units to ensure

proper cooling cycle operation at low ambient temperatures.

See Fig. 25 for baffle details. Use 20-gage, galvanized sheet

metal, or similar corrosion-resistant metal for baffles. Use

field-su pp l ied screws to att ac h baf fl e s t o un i t. Sc r ews should

1

be

/4-in. diameter and 5/8-in. long. Drill required screw holes

for mounting baffles.

CAUTION: To avoid damage to the refrigerant coils

and electrical components, use recommended screw

sizes only. Use care when drilling holes.

Install Mot ormaster I Control s

Only one Motormaster I control is required per unit. The

Motormaster I control must be used in conjunction with the

Accessory 0° F Low Ambient Kit (purchas ed separately). The

Motormaster I device controls outdoor fan no. 1 while outdoor fans no. 2 and 3 are sequenced off by the Accessory 0° F

Low Ambient Kit.

Accessory 0° F Low Ambient Kit — Install the Ac cessory 0° F

Low Ambient Kit per instruction supplied with accessory.

R

Dimensions in ( ) are in mm.

NOTE:

Fig. 25 — Wind Baffle Details

—13—

Page 14

Sensor Assembly — Install the sensor assembly in the location shown in Fig. 26.

Motor Mount — To ensure proper fan height, replace the

existing motor mount with the new motor mount provided

with accessory.

Trans f ormer (460-v Unit s Only) — On 460 volt units, a transformer is required. The transformer is provided with the

accessory and must be field-installed.

Motormaste r® I Co n tr ol — Recomm ende d mounting location

is on the inside of the panel to the left of the control box. The

control should be mounted on the inside of the panel, vertically, with leads protruding from bottom of extrusion.

B. Motormaster III Control Installation (581A240)

Install Field -Fabricated Wind Baffles

Wind baffles must be field-fabricated for all units to ensure

proper cooling cycle operation at low ambient temperatures.

See Fig. 25 for baffle details. Use 20-gage, galvanized sheet

metal, or similar corrosion-resistant metal for baffles. Use

field-supplied screws to attach baffles to unit. Screws should

1

be

/4-in. diameter and 5/8-in. long. Drill require d screw hole s

for mounting baffles.

Replace Outdoor Motor

Replace outdoor-fan motor no. 1 with motor included in

accessory kit. Existing motor is not Motormaster III

compatible.

Install Motor ma st er III Cont ro ls

Only one Motorma st e r III cont rol is requ ire d per uni t.

Sensor — Install the sensor for thermistor input control in

the location shown in Fig. 26. Connect sensor leads to the

purple and grey control signal leads on the Motormaster III

cont ro l .

Signal Selection Switch — Remove the cover of the Motormaster III control. Set the switch to accept the thermistor

sensor input signal. Set the frequency to match the unit

power supply (60 Hz).

Motormaste r III Co ntrol — Recommended mounting location

is beneath the control box, mounted to the partition that separates the control box section from the indoor section.

NOTE: If unit power is supplied through the roof curb and

basepan of the unit, mount the Motormaster III control on

the corner post adjacent to the conduit running from the

basepan to the bottom of the control box.

CAUTION: To avoid damage to the refrigerant

coils and electrical components, use recommended

screw sizes only. Use care when drilling holes.

MOTORMASTER

SENSOR

LOCATION

HAIRPIN END

NOTES:

1. All sensors are located on the eighth hairpin up from the bottom.

2. Field installed tubing insulation is required to be installed over the

TXV (thermostatic expansion valve) bulb and capillary tube for

proper operation at low ambients. Tubing insulation is only required

on the po rtio n of suctio n line lo cated betw een indo or and ou tdoor

sectio n.

Fig. 26 — Motormaster I and M o to rmaster III Sensor

Locations

START-UP

Use the following information and Start-Up Checklist on

page CL-1 to check out unit PRIOR to start-up.

I. UNIT PREPARA TION

Check that unit has been installed in accordance with these

installation ins tructions and all applicable cod es.

II. SERVICE VALVES

Ensure that the liquid line service valve is open. Damage to

the compres sor could result i f it i s left closed.

III. COMPRESSOR MOUNTING

Compressors are internally spring mounte d. D o not loosen or

remove compressor holddown bolts.

IV. REFRIGERANT SERVICE PORTS

Each re frigeran t system h as a tot al of 3 Sch rader-type service gage ports. One port is located on the suction line, one

on the compressor discharge line, and one on the liquid line.

In addition Schrader-type valves are located underneath the

low-pressure switches. Be sure that caps on the ports are

tight.

V. COMPRESSOR ROTATION

It is important to be certain the compressors are rotating in

the proper direction. To determine whether or not compressors are rotat ing in the proper direction:

1. Connect service gages to suction and discharge pressure fitti n gs.

2. Energize the compressor.

3. The su ction pressu re should drop a nd the dischar ge

pressure should rise, as is norm a l o n an y sta rt -up.

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

1. Note that the evaporator fan is probably also rota ting

in the wrong direction.

2. Tu rn off power to the unit.

3. Reverse any two of the incoming power leads.

4. Tu rn on powe r to the com pr essor.

The suct ion and disc harge pr essur e levels sh ould now move

to their normal start-up levels.

—14—

Page 15

NOTE: When compressors are rotating in the wrong direction, the unit will have increased noise levels and will not

provide heating and coolin g.

After a few minutes of reverse operation, the scroll compressor internal overload protection will open, which will activate the unit’s lockout and requires a manual reset. Reset is

accomplished by turning the thermostat on and of f.

VI. INTERNAL WIRING

Check all electrical connections in unit contro l box es ; tighten

as required.

VII. CRANKCASE HEATER( S)

Crankcase heater(s) is energized as long as there is power to

the unit and the compressor is not operating.

IMPORTANT: Unit power must be on for 24 hours prior to

start-up. Otherwise, damage to compressor may result.

VIII. EVAPORATOR FAN

Fan belt and variable pulleys are factory-installed. Remove

tape from the fan pulley. See Tables 3-10 for Fan Performance Data. Be sure that fans rotate in the proper direction.

See Table 11 for air quantity limits. See Table 12 for Evaporator Fan Motor Specifications. See Table 13 for static pressure information for accessories and options. See T able 14 for

fan rpm at various mo tor pulley settings. To al ter fan perfor-

T able 3 — Fan Performance — 581A155225 (Low Heat Units with Stan dard Indoor Fan Motor)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

Bhp —

FIOP —

Watts —

*Stand ard low -med iu m stat ic dri ve rang e is 83 4 to 1064 r pm. A lter na te

high-static drive range is 1161 to 1426. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 3.13. The maxi-

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

753 915 1.05 838 1066 1.23 945 1278 1.47 1044 1500 1.73 1138 1731 1.99

755 991 1.14 865 1198 1.38 968 1414 1.63 1063 1639 1.89 1154 1873 2.15

788 1129 1.30 894 1341 1.54 992 1562 1.80 1084 1791 2.06 1172 2029 2. 33

822 1280 1.47 923 1497 1.72 1017 1722 1.98 1106 1956 2.25 1191 2196 2.53

857 1443 1.66 953 1666 1.92 1044 1896 2.18 1130 2133 2.45 1212 2377 2.73

891 1620 1.86 984 1847 2.12 1071 2082 2.39 1154 2323 2.67 1234 2572 2.96

927 1810 2.08 1015 20 43 2.35 1099 2282 2.62 1180 252 8 2.91 — — —

962 2014 2.32 1047 22 52 2.59 1129 2496 2.87 — — — — — —

998 2233 2.57 1080 24 76 2.85 — — — — — — — — —

1035 2466 2.84 — — — — — — — — — — — —

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1226 1971 2.27 1311 2218 2.55 1391 2474 2.85

1240 2116 2.43 1322 2366 2.72 1401 2623 3.02 — — — — — —

1255 2274 2.61 1335 2526 2.91 — — — — — — — — —

1272 2444 2.81 1350 2700 3.10 — — — — — — — — —

1291 2628 3.02 — — — — — — — — — — — —

———————————————

———————————————

———————————————

———————————————

———————————————

LEGEND

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

mum continuous watts is 2700. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

0.20.40.60.81.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.21.41.61.82.0

mance, see Evaporator Fan Performance Adjustment section

on page 26.

NOTE: A 3

1

/2-in. bolt and threaded plate are included in the

installer’s packet. They can be added to the motor support

channel belo w the m otor mounting plate to aid in raising the

fan motor.

IX. CONDENSER FANS AND MOTORS

Condenser fans and motors are factory set. Refer to Condenser-Fan Adjustment section (page 27) as required. Be

sure that fa ns rotate in the proper di rection.

X. RETURN-AIR FILTERS

Check that correct filters are installed in filter tracks (see

Table 1). Do not operate unit without return-air filters.

XI. OUTDOOR-AIR INLET SCREENS

Outdoor-air inlet screens must be in place before operating

unit.

XII. ACCESSORY ECONOMIZER ADJUSTMENT

Remove fil ter access panel. Ch eck that outdoor-air damper is

closed and return-air damper is open.

Economizer operation and adjustment are described in Base

Unit Operation section on page 24, and in Economizer

Adjustment section on page 28.

——————

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—15—

Page 16

Table 4 — Fan Performance — 581A155225 (Low Heat Units with Optional Indoor Fan Motor)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

Bhp —

FIOP —

Watts —

*Stand ard low -med iu m stat ic dri ve rang e is 83 4 to 1064 r pm. A lter na te

high-static drive range is 1161 to 1426. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the optional motor is 4.38. The maxi-

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

753 942 1.08 838 1091 1.25 945 1298 1.49 1044 1 513 1.74 1138 1737 2.00

755 1020 1.17 865 1223 1.41 968 1433 1.65 1063 1652 1.90 1154 1878 2. 16

788 1159 1.33 894 1366 1.57 992 1581 1.82 1084 1803 2.07 1172 2032 2. 34

822 1311 1.51 923 1522 1.75 1017 1740 2.00 1106 1966 2.26 1191 2197 2.53

857 1474 1.70 953 1690 1.94 1044 1912 2.20 1130 2141 2.46 1212 2376 2.73

891 1650 1.90 984 1871 2.15 1071 2097 2.41 1154 2329 2.68 1234 2567 2.95

927 1840 2.12 1015 20 65 2.37 1099 2295 2.64 1180 253 0 2.91 1257 277 1 3.19

962 2042 2.35 1047 22 72 2.61 1129 2506 2.88 1207 274 5 3.16 1281 298 9 3.44

998 2259 2.60 1080 24 92 2.87 1159 2730 3.14 1234 297 3 3.42 1307 322 1 3.70

1035 2489 2.86 1114 2727 3.14 1189 2969 3.41 1262 3215 3.70 1333 3466 3.99

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1226 1968 2.26 1311 2206 2.54 1391 2451 2.82 1468 2702 3.11 1543 2959 3.40

1240 2111 2.43 1322 2351 2.70 1401 2598 2.99 1476 2850 3.28 1549 3108 3.57

1255 2267 2.61 1335 2509 2.89 1412 2757 3.17 1486 3011 3.46 — — —

1272 2436 2.80 1350 2680 3.08 1425 2929 3.37 1497 3185 3.66 — — —

1291 2616 3.01 1366 2863 3.29 1440 3115 3.58 1510 3372 3.88 — — —

1310 2810 3.23 1384 3059 3.52 1456 3314 3.81 1525 3573 4.11 — — —

1332 3018 3.47 1403 3269 3.76 1473 3526 4.05 — — — — — —

1354 3238 3.72 1424 3492 4.02 1491 3751 4.31 — — — — — —

1377 3473 3.99 1445 3730 4.29 — — — — — — — — —

1401 3722 4.28 — — — — — — — — — — — —

LEGEND

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

mum continuous watts is 3775. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

0.20.40.60.81.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.21.41.61.82.0

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—16—

Page 17

T able 5 — Fan Performance — 581A180270 (Low Heat Units)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

4500

4800

5100

5700

6000

6300

6600

6900

7200

7500

CFM

4500

4800

5100

5700

6000

6300

6600

6900

7200

7500

CFM

4500

4800

5100

5700

6000

6300

6600

6900

7200

7500

Bhp —

FIOP —

Watts —

*Stand ard low -med iu m stat ic dri ve rang e is 87 3 to 1021 r pm. A lter na te

high-static drive range is 1025 to 1200. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 6.13. The maxi-

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

753 1307 1.53 761 1330 1.56 840 1572 1.84 912 1822 2.14 980 2080 2.44

747 1384 1.62 790 1515 1.78 866 1765 2.07 936 2023 2.37 1002 2289 2.68

741 1465 1.72 820 1718 2.01 893 1977 2.32 961 2243 2.63 1025 2516 2.95

810 1911 2.24 882 2182 2.56 950 2459 2.88 1014 2741 3.21 1075 3029 3.55

844 2164 2.54 914 2444 2.87 980 2730 3.20 1042 3021 3.54 1100 3317 3.89

879 2439 2.86 947 2729 3.20 1010 3023 3.55 1070 3322 3.90 1127 3626 4.25

915 2737 3.21 980 3035 3.56 1041 3338 3.91 1099 3645 4.28 1155 3957 4.64

950 3057 3.59 1013 3364 3.95 1072 3675 4.31 1129 3991 4.68 1183 4311 5.06

986 3401 3.99 1047 3717 4.36 1104 4037 4.74 1159 4361 5.11 1211 4689 5.50

1022 3770 4.42 1081 4095 4.80 1136 4423 5.19 1189 4755 5.58 1241 5091 5.97

Rpm W atts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1044 2345 2.75 1105 2619 3.07 1163 2899 3.40 1218 3187 3.74 1271 3481 4.08

1065 2561 3.00 1124 2841 3.33 1180 3127 3.67 1235 3420 4.01 1287 3720 4.36

1086 2795 3.28 1144 3082 3.61 1199 3375 3.96 1252 3674 4.31 1304 3979 4.67

1132 3324 3.90 1187 3624 4.25 1240 3929 4.61 1291 4241 4.97 1341 4558 5.35

1157 3619 4.24 1210 3925 4.60 1262 4239 4.97 1312 4557 5.34 1361 4880 5.72

1182 3935 4.62 1234 4249 4.98 1285 4569 5.36 1334 4894 5.74 — — —

1208 4274 5.01 1259 4595 5.39 1309 4922 5.77 — — — — — —

1235 4636 5.44 1285 4964 5.82 — — — — — — — — —

1262 5021 5.82 — — — — — — — — — — — —

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1322 3781 4.43 1372 4088 4.79 1419 4400 5.16 1466 4719 5.53 1511 5042 5.91

1337 4025 4.72 1386 4337 5.09 1433 4655 5.46 1479 4978 5.84 — — —

1353 4290 5.03 1401 4607 5.40 1448 4930 5.78 — — — — — —

1388 4881 5.72 — — — — — — — — — — — —

———————————————

———————————————

———————————————

———————————————

———————————————

———————————————

LEGEND

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

mum continuous watts is 5180. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

0.2 0.4 0.6 0.8 1.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.2 1.4 1.6 1.8 2.0

— — —— — —— — —— — —— — —

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

2.22.42.62.83.0

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—17—

Page 18

T able 6 — Fan Performance — 581A240270 (Low Heat Units)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

CFM

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

CFM

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

LEGEND

Bhp —

FIOP —

Watts —

*Stan dard low-medium static drive range is 1002 to 1151 rpm. Al ternate

high-static drive range is 1193 to 1369. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 9.47 (for 208-v

units) and 10 .33 ( f or 23 0 an d 460- v u ni ts) . T he maxi m um co nt inu ou s

watts is 7915 (for 208-v units) and 8640 (for 230 and 460-v units).

Do not adjust motor rpm such that motor maximum bhp and/or watts

is exceeded at the maximum operating cfm.

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

824 2607 3.09 894 2844 3.37 961 3085 3.66 1023 3330 3.95 1083 3578 4.24

881 3030 3.59 947 3266 3.88 1009 3507 4.16 1069 3751 4.45 1126 3998 4.74

939 3488 4.14 1001 3725 4.42 1060 3965 4.70 1116 4208 4.99 1170 4454 5.28

998 3982 4.72 1055 4218 5.00 1111 4458 5.29 1165 4701 5.58 1217 4946 5.87

1056 4512 5.35 1111 4748 5.63 1164 4988 5.92 1215 5230 6.20 1264 5474 6.49

1116 5077 6.02 1167 5314 6.30 1218 5553 6.59 1266 5795 6.87 1314 6039 7.16

1175 5678 6.74 1224 5915 7.02 1272 6154 7.30 1319 6395 7.59 1364 6639 7.88

1235 6315 7.49 1282 6552 7.77 1327 6791 8.06 1372 7033 8.34 1415 7276 8.63

1295 6988 8.29 1340 7225 8.57 1383 7465 8.86 1426 7706 9.14 1468 7949 9.43

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1141 3829 4.5 4 1196 4082 4.84 12 49 43 37 5. 1 5 1301 4596 5 .4 5 1351 4856 5.76

1181 4247 5.0 4 1234 4499 5.34 12 85 47 53 5. 6 4 1334 5009 5 .9 4 1383 5267 6.25

1223 4702 5.5 8 1274 4953 5.88 13 23 52 05 6. 1 8 1371 5460 6 .4 8 1417 5716 6.78

1267 5194 6.1 6 1316 5443 6.46 13 63 56 94 6. 7 6 1409 5947 7 .0 6 1454 6202 7.36

1313 5721 6.7 9 1359 5970 7.08 14 05 62 20 7. 3 8 1449 6472 7 .6 8 1493 6726 7.98

1360 6285 7.4 6 1405 6533 7.75 14 49 67 83 8. 0 5 1491 7034 8 .3 4 1533 7286 8.64

1408 6885 8.1 7 1451 7132 8.46 14 94 73 81 8. 7 6 1535 7631 9 .0 5 — — —

1458 7521 8.9 2 1499 7768 9.22 15 40 80 16 9. 5 1 — — — — — —

1508 8193 9.7 2 1549 8440 10. 01 — — — — — — — — —

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1399 5118 6.07 1446 5381 6.38 1492 5647 6.70 1537 5914 7.02 — — —

1429 5527 6.56 1475 5789 6.87 1520 6052 7.18 — — — — — —

1462 5974 7.09 1507 6234 7.40 1550 6495 7.71 — — — — — —

1498 6459 7.66 1540 6717 7.97 — — — — — — — — —

1535 6981 8.28 — — — — — — — — — — — —

———————————————

———————————————

———————————————

———————————————

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

0.2 0.4 0.6 0.8 1.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.2 1.4 1.6 1.8 2.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

2.2 2.4 2.6 2.8 3.0

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—18—

Page 19

Ta ble 7 — Fan Performance — 581A155300 (High Heat Units with Standard Indoor Fan Motor

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

Bhp —

FIOP —

Watts —

*Stand ard low -med iu m stat ic dri ve rang e is 83 4 to 1064 r pm. A lter na te

high-static drive range is 1161 to 1426. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 3.13. The maxi-

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

753 915 1.05 844 1077 1.24 949 128 7 1.48 1047 1507 1.73 1139 1735 2.00

764 1006 1.16 872 1211 1.39 972 1425 1.64 1067 1648 1.90 1156 1880 2.16

798 1147 1.32 901 1357 1.56 997 1576 1.81 1089 1803 2.07 1175 2038 2.34

832 1301 1.50 931 1516 1.74 1024 1 739 2.00 1112 1970 2.27 1195 2209 2.54

868 1467 1.69 962 1688 1.94 1051 1 916 2.20 1136 2151 2.47 1217 2393 2.75

903 1648 1.89 994 1873 2.15 1079 2 106 2.42 1161 2345 2.70 1240 2590 2.98

939 1842 2.12 1026 2073 2.38 1109 2309 2.66 1188 2553 2.9 — — —

976 2050 2.36 1059 2286 2.63 1139 2528 2.91 — — — — — —

1012 2273 2.61 1093 2514 2.89 — — — — — — — — —

1049 2511 2.89 — — — — — — — — — — — —

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1227 1973 2.27 1310 2218 2.55 1390 2471 2.84

1241 2120 2.44 1323 2368 2.72 1400 2623 3.02 — — — — — —

1258 2281 2.62 1337 2531 2.91 — — — — — — — — —

1275 2454 2.82 — — — — — — — — — — — —

1295 2642 3.04 — — — — — — — — — — — —

———————————————

———————————————

———————————————

———————————————

———————————————

LEGEND

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

mum continuous watts is 2700. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

0.2 0.4 0.6 0.8 1.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.21.41.61.82.0

——

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—

———

—19—

Page 20

T able 8 — Fan Performance — 581A155300 (High Heat Units wit h Optional Indoor Fan Motor)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

CFM

3750

4000

4250

4500

4750

5000

5250

5500

5750

6000

LEGEND

Bhp —

FIOP —

Watts —

*Stand ard low -med iu m stat ic dri ve rang e is 83 4 to 1064 r pm. A lter na te

high-static drive range is 1161 to 1426. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the optional motor is 4.38. The maxi-

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

753 942 1.08 844 1101 1.27 949 1306 1.50 1047 1520 1.75 1139 1 741 2.00

764 1035 1.19 872 1236 1.42 972 1444 1.66 1067 1661 1.91 1156 1885 2. 17

798 1177 1.35 901 1382 1.59 997 1594 1.83 1089 1814 2.09 1175 2041 2.35

832 1331 1.53 931 1540 1.77 1024 1757 2.02 1112 1980 2.28 1195 2209 2.54

868 1498 1.72 962 1711 1.97 1051 1932 2.22 1136 2158 2.48 1217 2390 2.75

903 1677 1.93 994 1896 2.18 1079 2120 2.44 1161 2350 2.70 1240 2585 2.97

939 1871 2.15 1026 20 93 2.41 1109 2321 2.67 1188 255 4 2.94 1264 279 3 3.21

976 2077 2.39 1059 23 04 2.65 1139 2536 2.92 1215 277 3 3.19 1289 301 5 3.47

1012 2298 2.64 1093 2529 2.91 1170 2765 3.18 1244 3005 3.46 1315 3250 3.74

1049 2533 2.91 1127 2768 3.18 1201 3008 3.46 1273 3252 3.74 1342 3500 4.03

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1227 1970 2.27 1310 2206 2.54 1390 2448 2.82 1467 2696 3.10 1541 2951 3.39

1241 2116 2.43 1323 2353 2.71 1400 2597 2.99 1475 2847 3.27 1548 3102 3.57

1258 2274 2.62 1337 2513 2.89 1413 2759 3.17 1486 3010 3.46 — — —

1275 2445 2.81 1352 2687 3.09 1426 2934 3.37 1498 3187 3.67 — — —

1295 2629 3.02 1369 2873 3.30 1442 3122 3.59 1511 3377 3.88 — — —

1315 2826 3.25 1388 3073 3.53 1458 3324 3.82 1527 3581 4.12 — — —

1337 3037 3.49 1408 3286 3.78 1477 3540 4.07 — — — — — —

1360 3262 3.75 1429 3513 4.04 1496 3769 4.34 — — — — — —

1384 3500 4.03 1452 3755 4.32 — — — — — — — — —

1410 3753 4.32 — — — — — — — — — — — —

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

mum continuous watts is 3775. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

0.20.40.60.81.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.21.41.61.82.0

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—20—

Page 21

T able 9 — Fan Perform ance — 581A180360 (High Heat Units)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

4500

4800

5100

5700

6000

6300

6600

6900

7200

7500

CFM

4500

4800

5100

5700

6000

6300

6600

6900

7200

7500

CFM

4500

4800

5100

5700

6000

6300

6600

6900

7200

7500

Bhp —

FIOP —

Watts —

*Stand ard low -med iu m stat ic dri ve rang e is 87 3 to 1021 r pm. A lter na te

high-static drive range is 1025 to 1200. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 6.13. The maxi-

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

753 1307 1.53 786 1404 1.65 861 1644 1.93 932 1893 2.22 997 215 0 2.52

747 1384 1.62 818 1603 1.88 890 1852 2.17 958 2108 2.47 1022 2 373 2.78

775 1571 1.84 850 1822 2.14 920 2079 2.44 986 2344 2.75 1048 2 616 3.07

849 2054 2.41 918 2323 2.73 982 2598 3.05 1044 2879 3.38 1102 3166 3. 71

886 2329 2.73 952 2607 3.06 1015 2891 3.39 1074 3180 3.73 1130 3474 4.08

924 2628 3.08 987 2915 3.42 1047 3207 3.76 1105 3504 4.11 1160 3807 4.46

962 2951 3.46 1023 32 46 3.81 1081 3547 4.16 1136 385 3 4.52 1190 416 3 4.88

1000 3298 3.87 1059 3603 4.23 1115 3912 4.59 1168 4225 4.96 1220 4543 5.33

1038 3672 4.31 1095 3986 4.67 1149 4303 5.05 1201 4625 5.42 1251 4950 5.81

1077 4072 4.78 1131 4394 5.15 1184 4720 5.54 1234 5050 5.92 — — —

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1060 2414 2.83 1119 2685 3.15 1175 2964 3.48 1230 3250 3.81 1282 3542 4.15

1082 2644 3.10 1140 2922 3.43 1195 3207 3.76 1248 3498 4.10 1299 3795 4.45

1106 2894 3.39 1163 3178 3.73 1216 3470 4.07 1268 3767 4.42 1319 4071 4.77

1157 3459 4.06 1211 3757 4.41 1262 4061 4.76 1312 4371 5.13 1360 4686 5.50

1184 3774 4.43 1236 4080 4.79 1287 4391 5.15 1335 4707 5.52 1382 5029 5.90

1212 4114 4.83 1263 4427 5.19 1312 4745 5.57 1359 5067 5.94 — — —

1241 4478 5.25 1290 4798 5.63 1338 5122 6.01 — — — — — —

1270 4866 5.71 — — — — — — — — — — — —

———————————————

———————————————

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1332 3841 4.50 1381 4145 4.86 1428 4456 5.23 1473 4772 5.60 1518 5095 5.98

1349 4100 4.81 1397 4409 5.17 1443 4725 5.54 1488 5046 5.92 — — —

1367 4380 5.14 1414 4695 5.51 1460 5016 5.88 — — — — — —

1407 5007 5.87 — — — — — — — — — — — —

———————————————

———————————————

———————————————

———————————————

———————————————

———————————————

LEGEND

Brake Horsepower

Factory-Installed Option

Input Watts to Motor

mum continuous watts is 5180. Do not adjust motor rpm such that

motor maximum bhp and/or watts is exceeded at the maximum

operating cfm.

0.2040.60.81.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.21.41.61.82.0

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

2.22.42.62.83.0

2. Static pressure losses (i.e., economizer) must be added to external

static pre s su r e be for e ent ering Fan Performa nc e tabl e.

3. Interpolation is permissible. Do not extrapolate.

4. Fan performance is based on wet coils, clean filters, and

casing losses. See Table 13 for accessory/FIOP static pressure

information.

5. Extensive mo tor and drive testing on these units ensures that the full

bhp an d watts rang e of the motor can be util ized with confiden ce.

Using your fan motors up to the watts or bhp rating shown will not

result in nuisance tripping or premature motor failure. Unit warranty

will not be affected.

6. U se of a field- supplied mo tor may affect wir ing size. Co ntact your

Bryant representative for details.

—21—

Page 22

T able 10 — Fan Performance — 581A240360 (High Heat Units)

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

CFM

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

CFM

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

CFM

6,000

6,500

7,000

7,500

8,000

8,500

9,000

9,500

10,000

Bhp —

FIOP —

Watts —

*Stan dard low-medium static drive range is 1002 to 1151 rpm. Al ternate

high-static drive range is 1193 to 1369. Other rpms require a fieldsupplied drive.

NOTES:

1. Maximum continuous bhp for the standard motor is 9.47 (for 208-v

units) and 10 .33 ( f or 23 0 an d 460- v u ni ts) . T he maxi m um co nt inu ou s

watts is 7915 (for 208 and 575-v units) and 8640 (for 230 and 460-v

units). Do not adjust motor rpm such that motor maximum bhp and/

or wat ts is exceeded at the maximum operating cfm.

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

868 2752 3.26 934 2987 3.54 997 3227 3.83 1058 3470 4.12 1115 3716 4.41

929 3201 3.80 991 3436 4.08 1051 3675 4.36 1108 3917 4.65 1162 4163 4.94

991 3687 4.37 1049 3923 4.65 1105 4161 4.94 1159 4403 5.22 1211 4647 5.51

1054 4211 5.00 1109 4447 5.28 1161 4686 5.56 1213 4926 5.84 1262 5170 6.13

1117 4773 5.66 1168 5009 5.94 1218 5247 6.22 1267 5488 6.51 1314 5731 6.80

1180 5373 6.37 1229 5609 6.65 1277 5847 6.94 1323 6088 7.22 1368 6331 7.51

1244 6011 7.13 1290 6247 7.41 1335 6485 7.69 1380 6726 7.98 1423 6968 8.27

1308 6687 7.93 1352 6924 8.21 1395 7162 8.50 1437 7402 8.78 1479 7644 9.07

1372 7401 8.78 1414 7638 9.06 1455 7876 9.34 1496 8117 9.63 1535 8358 9.92

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1171 3965 4. 7 0 1224 421 6 5.00 1 27 6 4 46 9 5.30 1326 4726 5.61 137 4 4 98 3 5.91

1215 4410 5. 2 3 1266 465 9 5.53 1 31 6 4 91 1 5.83 1364 5165 6.13 141 1 5 42 1 6.43

1262 4894 5. 8 1 1311 514 2 6.10 1 35 8 5 39 2 6.40 1404 5645 6.70 144 9 5 89 9 7.00

1310 5415 6. 4 2 1357 566 3 6.72 1 40 3 5 91 2 7.01 1447 6164 7.31 149 0 6 41 6 7.61

1360 5976 7. 0 9 1405 622 2 7.38 1 44 9 6 47 1 7.68 1492 6721 7.97 153 3 6 97 3 8.27

1412 6575 7. 8 0 1455 682 1 8.09 1 49 7 7 06 8 8.39 1538 7318 8.68 — — —

1465 7212 8. 5 6 1506 745 7 8.85 1 54 7 7 70 5 9.14 — — — — — —

151978889.36————————————

———————————————

Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp Rpm Watts Bhp

1422 5243 6.22 1468 5505 6.53 1513 5768 6.84

1456 5679 6.74 1501 5938 7.04 1544 6199 7.35 — — — — — —

1493 6155 7.30 1536 6412 7.61 — — — — — — — — —

1533 6670 7.91 — — — — — — — — — — — —

———————————————

———————————————

———————————————

———————————————

———————————————

LEGEND