Page 1

installation, start-up and

service instructions

SINGLE PACKAGE ROOFTOP

GAS HEATING/ELECTRIC COOLING UNITS

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

I. Step 1 — Provide Unit Support. . . . . . . . . . . . . . . . . 1

II. Step 2 — Rig and Place Unit. . . . . . . . . . . . . . . . . . . 4

III. Step 3 — Field Fabricate Ductwork . . . . . . . . . . . . 11

IV. Step 4 — Make Unit Duct Connections . . . . . . . . . 11

V. Step 5 — Install Flue Hood and Wind Baffle . . . . . 11

VI. Step 6 — Trap Condensate Drain . . . . . . . . . . . . . . 11

VII. Step 7 — Orifice Change. . . . . . . . . . . . . . . . . . . . . 12

VIII. Step 8 — Install Gas Piping . . . . . . . . . . . . . . . . . . 13

IX. Step 9 — Make Electrical Connections . . . . . . . . . 13

X. Step 10 — Make Outdoor-Air Inlet Adjustments . . 15

XI. Step 11 — Install Outdoor-Air Hood. . . . . . . . . . . . 15

XII. Step 12 — Install All Accessories . . . . . . . . . . . . . 16

XIII. Step 13 — Adjust Factory-Installed Options. . . . . 18

XIV. Step 14 — Install Control Accessory for Optional

Perfect Humidity™ Dehumidification Package . . 24

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26-34

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34-42

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . .43-47

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . CL-1

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equ ipment can

be hazardous due to system pressure and electrical components. Only trained and qualified service personnel should

install, repair , or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters. All

other operations should be performed by trained se rvice personnel. When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to the

unit, and other safety pre c au ti ons th at ma y a ppl y.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for unbrazing operations. Have fire extinguishers available for all brazing operations.

WARNING: Before performing service or maintenance operations on unit, turn off main power switch to

unit and install lockout tag to disconnect switch. Electrical shock could cause personal injury.

580F

Dura

Cancels: II 580F-180-2 II 580F-180-3

WAR NING:

1. Improper installation, adjustment, alteration, service, or maintenance can cause property damage,

personal injury, or loss of life. Refer to the User’s

Information Manual provided with this unit for

more details.

2. Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any

phone in your building.

3. IMMEDIATELY call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s

instructions.

4. If you cannot reach your gas sup plier, call the fire

department.

WAR NING: Disconnect gas piping from unit when

pressure testing at p ressure greater than 0.5 psig. Pressures greater than 0.5 psig will cause gas valve damage

resulting in hazardous condition. If gas valve is subjected

to pressure greater than 0.5 psig, it must be replaced

before use. When pressure testing field-supplied gas piping at pressures of 0.5 psig or less, a unit connected to

such piping must be isolated by closing th e manual gas

valve(s).

IMPORTANT: Units have high ambient operating limits. If

limits are exceeded, the units will au tomatically lock the compressor out of operation. Manual reset will be required to

restart the compressor.

INSTALLATION

I. STEP 1 — PROVIDE UNIT SUPPORT

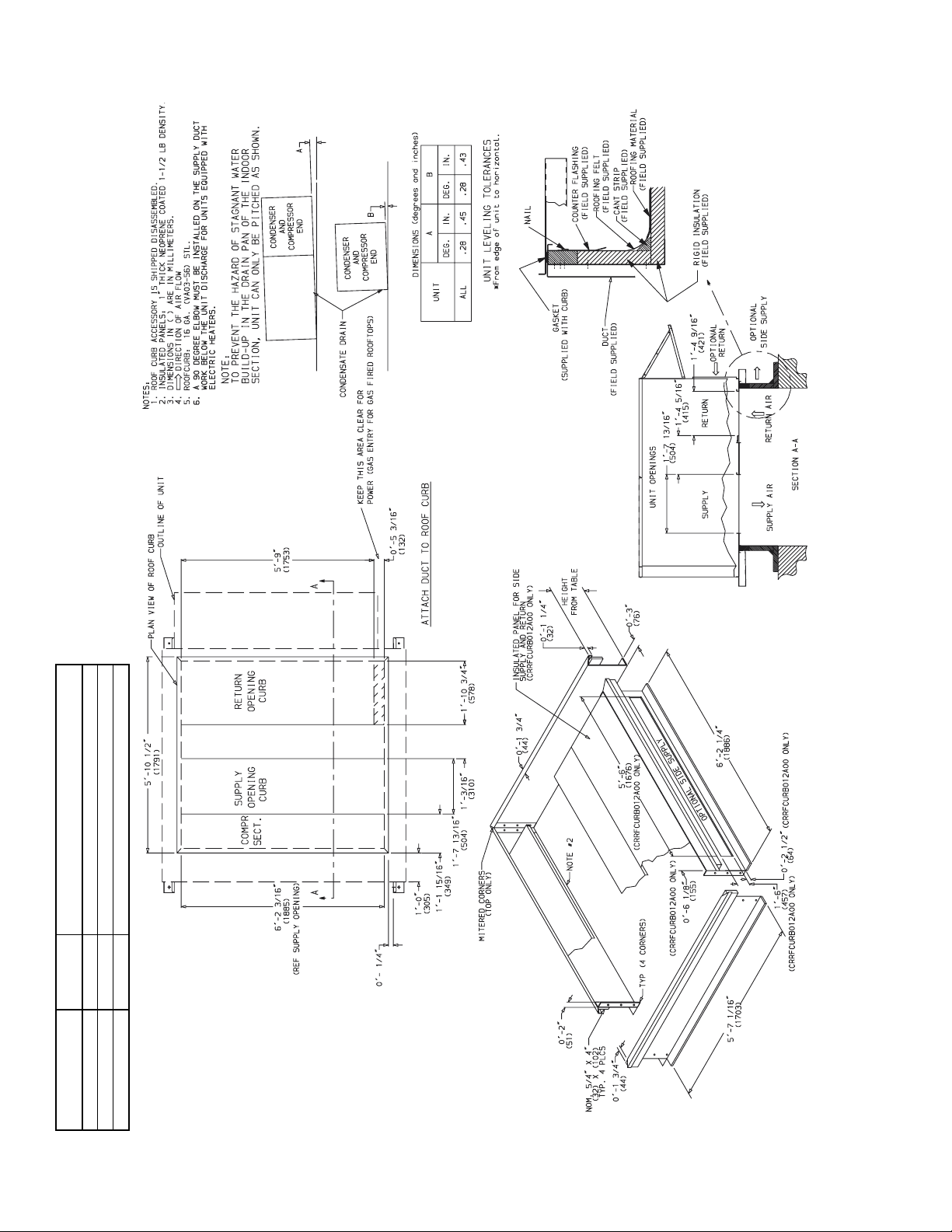

A. Roof Curb

Assemble or install accessory roof curb or horizontal adapter

roof curb in accordance with instructions shipped with this

accessory. See Fig. 1A, 1B, and 2. Install insulation, cant

strips, roofing, and counter flashing as shown. Ductwork can

be installed to roof curb or horizontal adapter roof curb before

unit is set in place. Curb or adapter roof curb shoul d be level.

This is necessary to permit unit drain to function properly.

Unit leveling tolerance is ±

tion. Refer to Accessory Roof Curb or Horizontal Adapter Roof

Curb Installation Instructions for additional information as

required. When accessory roof curb or horizontal adapter roof

curb is used, unit may be installed on class A, B, or C roof covering material.

1

/16 in. per linear ft in any direc-

Instructions continued on page 4.

Pac

Series

Sizes 180-300

15 to 25 Tons

3/15/06

Page 2

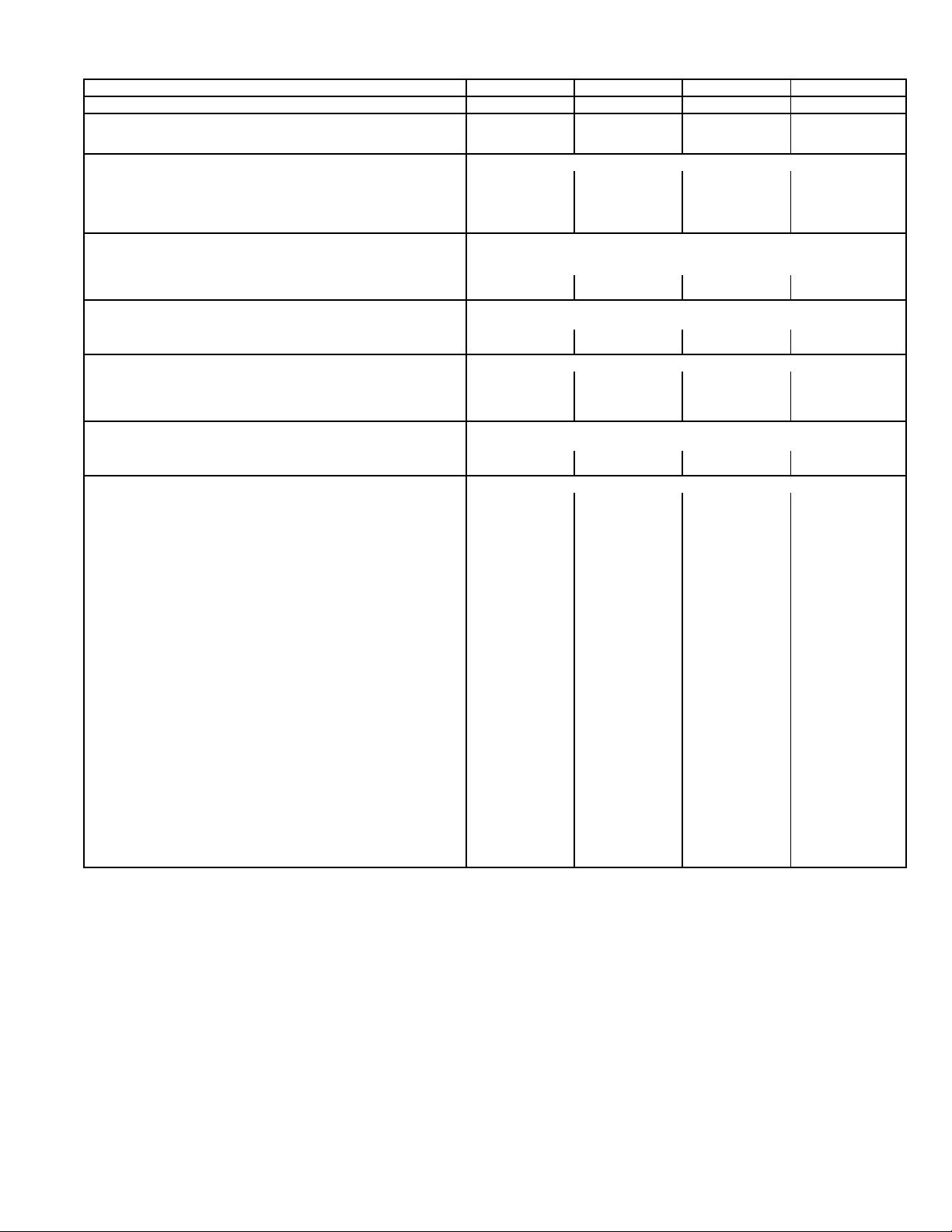

DESCRIPTION

CURB

HEIGHT

Fig. 1A — Roof Curb Details — 580F180-240

PKG. NO. REF.

CRRFCURB012A00 2′-0″ (610) Side Supply and Return Curb for High Installation

CRRFCURB010A00 1′− 2″ (305) Standard Curb 14″ High

CRRFCURB011A00 2′-0″ (610) Standard Curb for Units Requiring High Installation

—2—

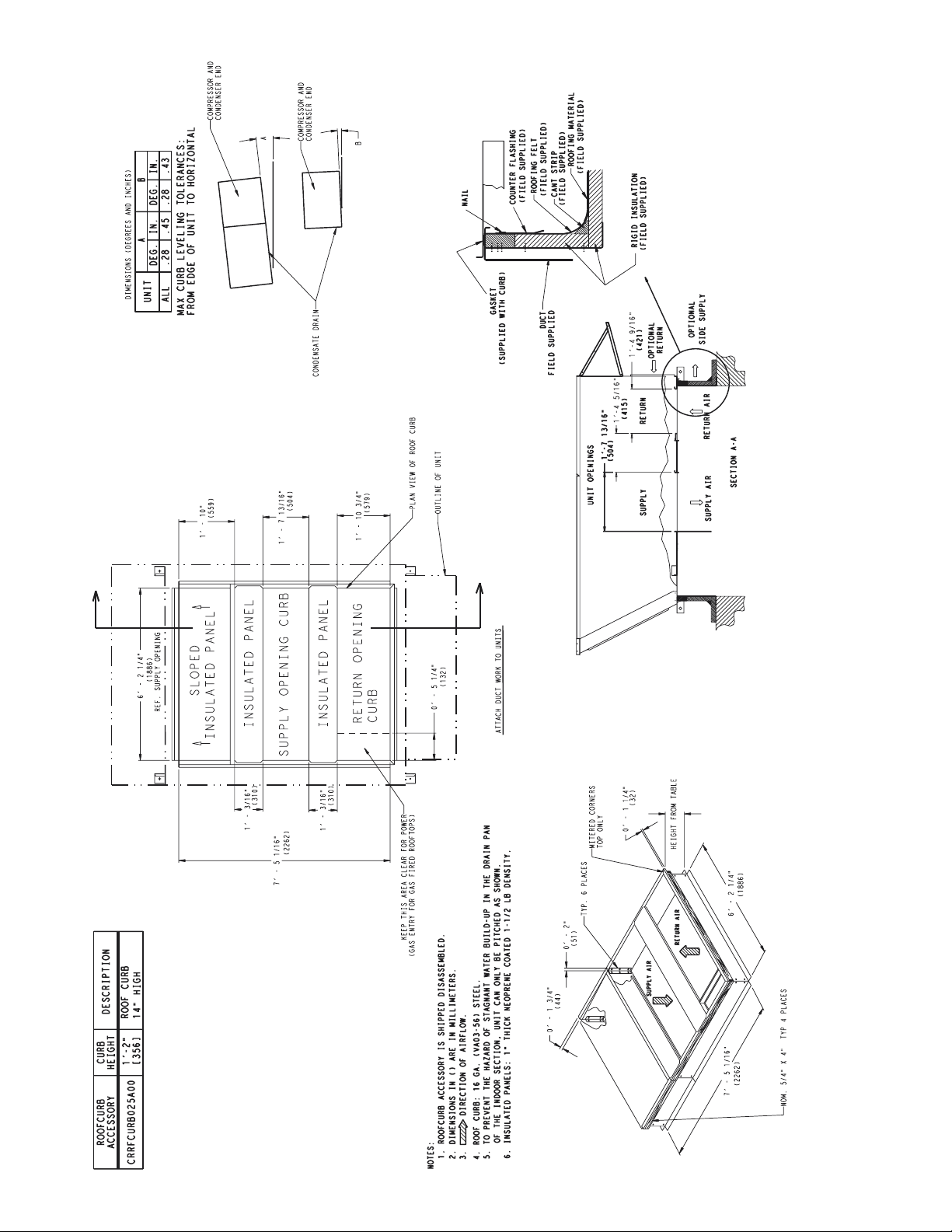

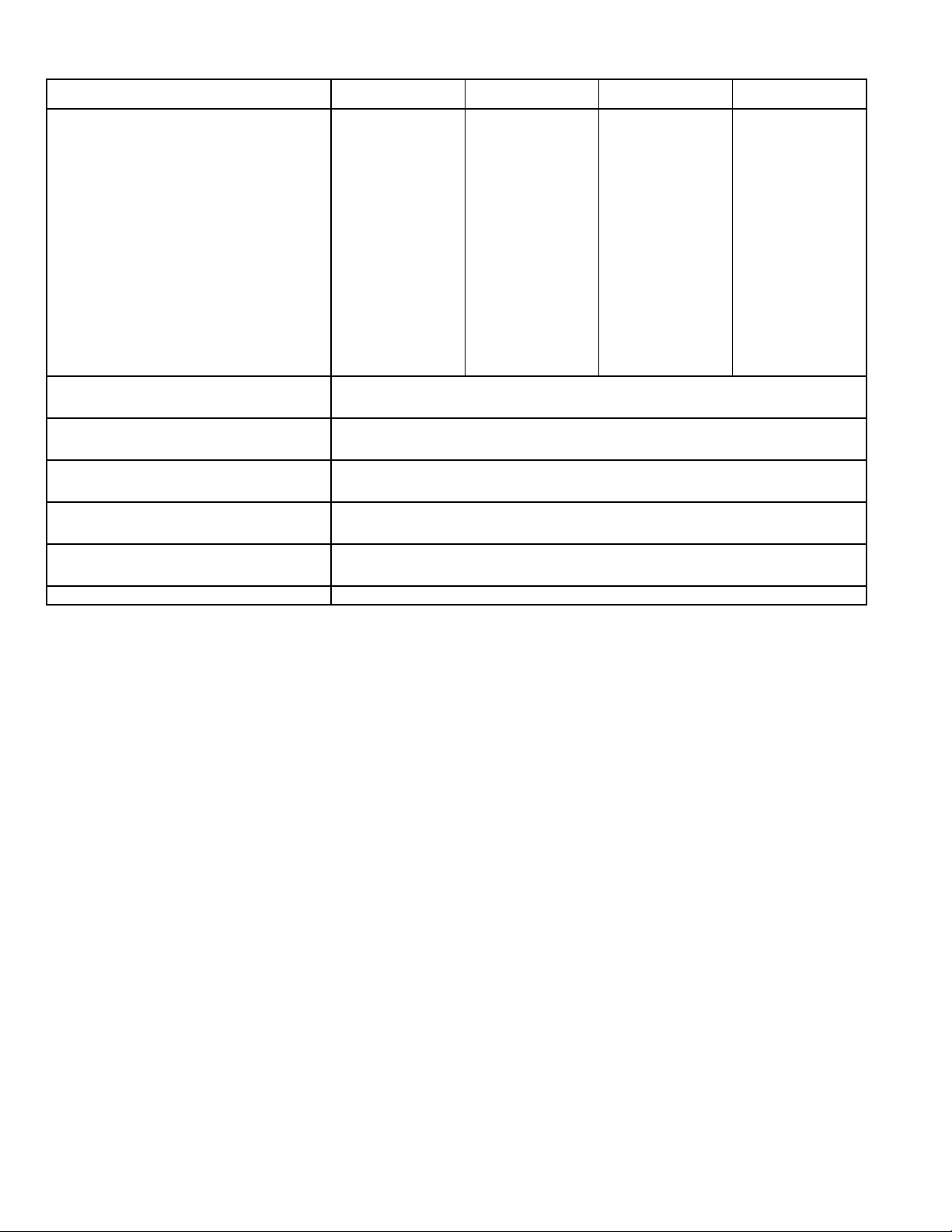

Page 3

A

A

Fig. 1B — Roof Curb Details — 580F300

—3—

Page 4

3 1/2"

2" X 1/4

SUPPORT TYP.

STITCH WELDED

FULLY INSULATED

SUPPLY PLENUM

1" INSULATION

1 1/2 # DENSITY,

STICK PINNED & GLUED

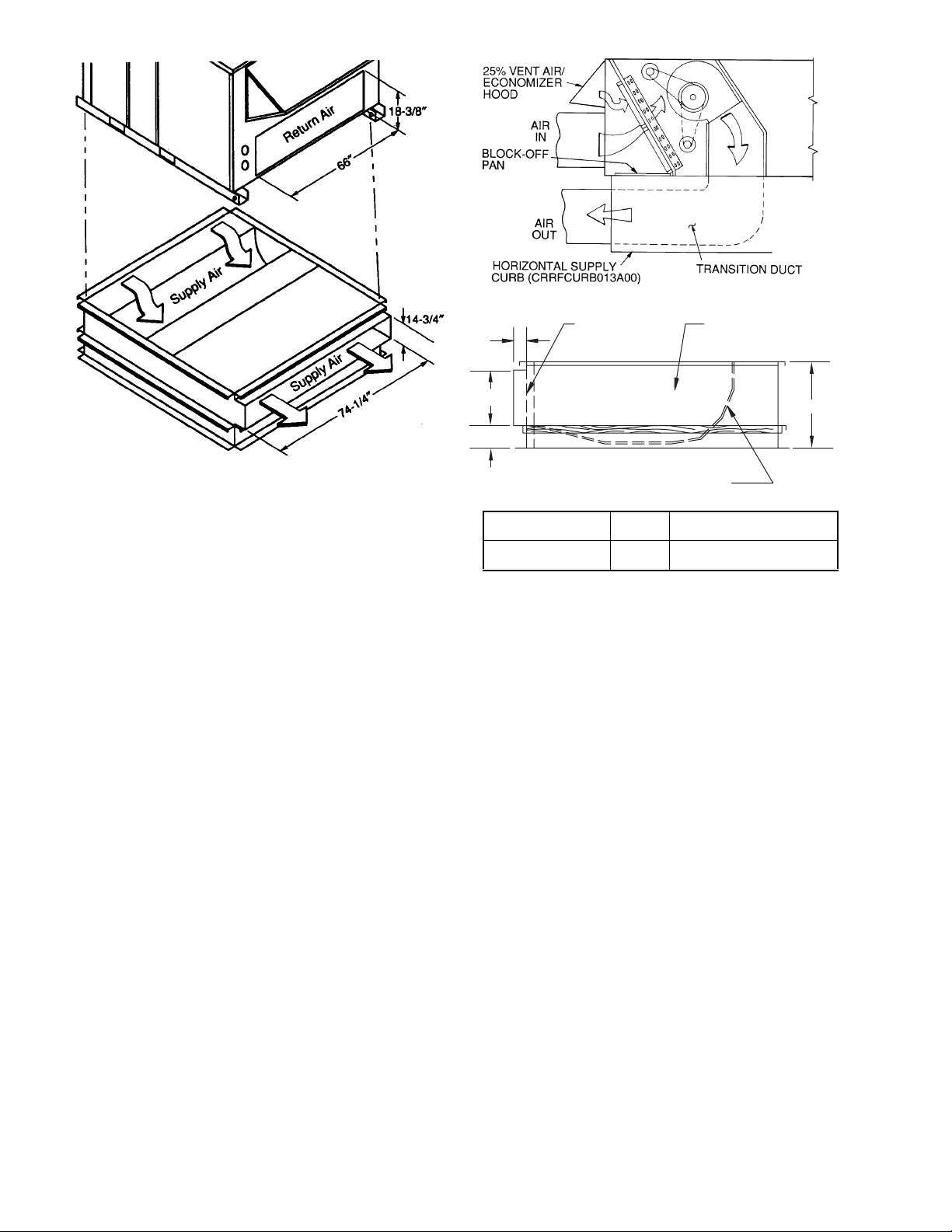

NOTE: CRRFCURB013A00 is a fully factory preassembled horizontal

adapter and includes an insulated transition duct. The pressure drop

through the adapter curb is negligible.

For horizontal return applications: The power exhaust and barometric

relief dampers must be installed in the return air duct.

Fig. 2 — Horizontal Supply/Return Adapter Installation (580F180-240)

IMPORTANT: The gasketing of the unit to the roof curb or

adapter roof curb is critical for a watertight seal. Install

gasket with the roof curb or adapter as shown in Fig. 1A and

1B. Improperly applied gasket can also result in air leaks

and poor unit performance.

B. Alternate Unit Support

When the curb or ada pter cannot be used, install unit on a

noncombustible surface. Support unit with sleepers, using

unit curb support area. If sleepers cannot be used, support

long sides of unit with a minimum of 3 equally spaced 4-in. x

4-in. pads on each side.

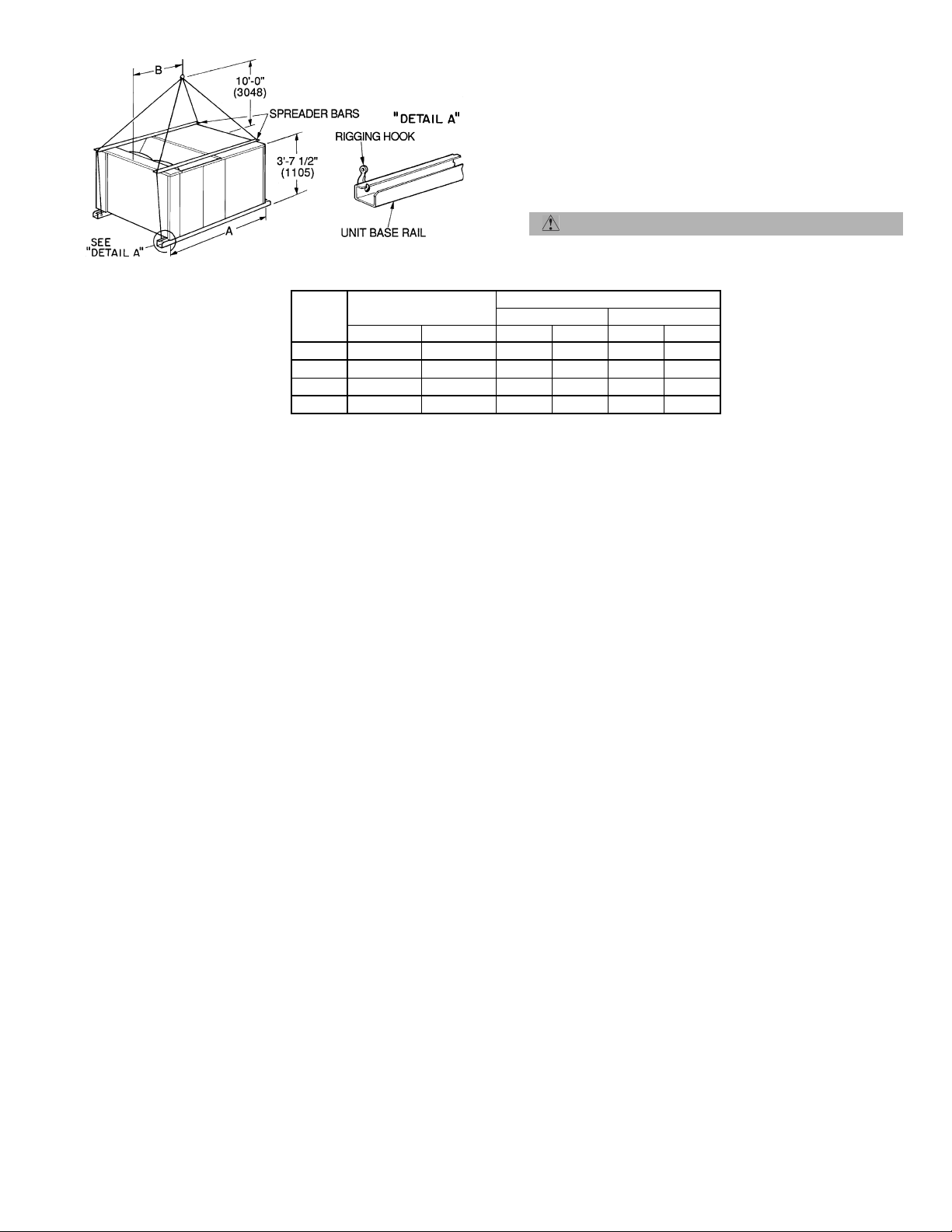

II. STEP 2 — RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with

transportation agency.

Do not drop unit; keep upr ight. Use sprea der bars over unit

to prevent sling or cable damage. Rollers may be used to

move unit across a roof. Level by using unit frame a s a reference; leveling tolerance is ±

1

/16 in. per linear ft in any direction. See Fig. 3 for additional information. Unit operating

weight is shown in Table 1.

Four lifting holes are provided in ends of unit base rails as

shown in Fig. 3. Refer to rigging instructions on unit.

NOTE: On 58 0F300 unit s, the lower forklift braces mus t be

removed prior to setting unit on roof curb.

14 3/4"

6"

ACCESSORY

PACKAGE NO.

CRRFCURB013A00

12" WIDE STANDING

SEAM PANELS

CURB

HEIGHT

1′-11″

(584)

DESCRIPTION

Pre-Assembled, Roof Curb,

Horizontal Adapter

23"

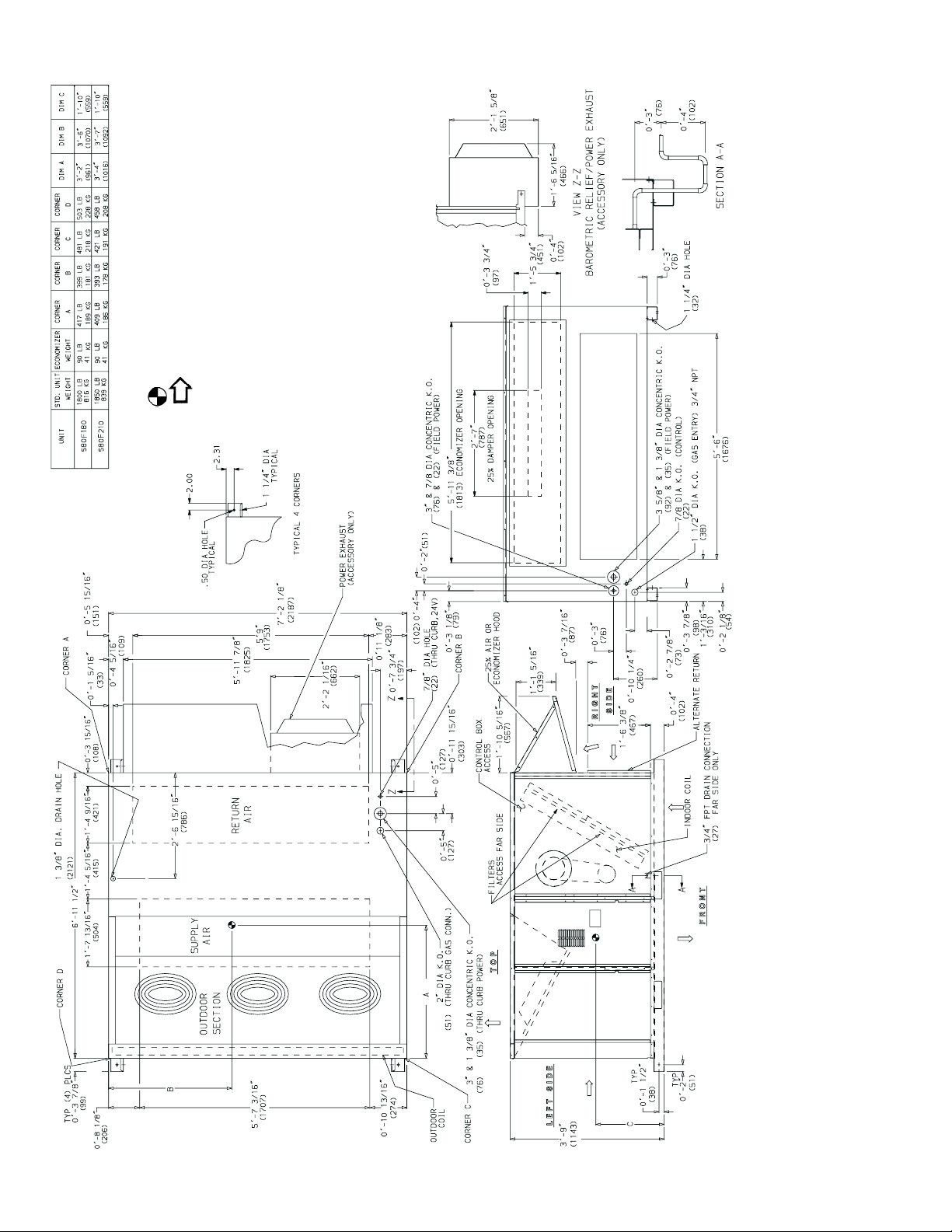

A. Positioning

Maintain clearance, per Fig. 4-6, around and above unit to

provide minimum distance from combustible materials,

proper airflow, and service access.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated air .

For proper unit operation, adequate combustion and ventilation air must be provided in accordance with Section 5.3 (Air

for Combustion and Ventilation) of the National Fuel Gas

Code, ANSI Z223.1 (American National Standards Institute).

Although unit is weatherproof, guard against water from

higher level runoff and overhangs.

Locate mechanical draft system flue assembly at least 4 ft

from any opening through which combustion products could

enter the buil ding, and at le ast 4 ft fr om any adj acen t buil ding. When unit is located adjacent t o public walkways, flue

assembly must be at least 7 ft above grade.

B. Roof Mount

Check building codes for weight distribution requirements.

Unit operating weight is shown in Table 1.

Instructions continued on page 11.

—4—

Page 5

NOTES:

1. Dimensions in ( ) are in millimeters.

2. Refer to Fig. 4-6 for unit operating weights.

3. Remove boards at ends of unit and runners prior to rigging.

4. Rig by inserting hooks into unit base rails as shown. Use corner

post from packaging to protect coil from damage. Use bumper

boards for spreader bars on all units.

5. Weights do not include optional EconoMi$erIV. Add 90 lb (41 kg)

for EconoMi$erIV weight.

6. Weights given are for aluminum evaporator and condenser coil

plate fins.

CAUTION: All panels must be in place when rigging.

UNIT

580F

MAXIMUM

SHIPPING WEIGHT

lb kg ft-in. mm ft-in. mm

180 1875 850 6-11

210 1925 873 6-11

240 2085 923 6-11

300 2445 1109 6-11

Fig. 3 — Rigging Details

DIMENSIONS

AB

1

/22121 4-0 1219

1

/22121 3-2 964

1

/22121 3-4 1016

1

/22121 3-4 1016

—5—

Page 6

″ (8) on each side for

16

/

5

so equipped.

• Top: 6′-0″ (1829) to assure proper condenser fan operation.

surfaces.

• Bottom: 14″ (356) to combustible surfaces (when not using curb).

• Control box side: 3′-0″ (914) to ungrounded surfaces, non-combustible.

• Control box side: 3′-6″ (1067) to block or concrete walls, or other grounded

• Local codes or jurisdiction may prevail.

exhaust as stated in Note #6, a removable fence or barricade requires no clear-

ance.

top cover drip edge.

7. With the exception of clearance for the condenser coil and the damper/power

8. Dimensions are from outside of corner post. Allow 0′-

(1219) if conditions permit coil removal from the top.

• Rear: 7′-0″ (2134) for coil removal. This dimension can be reduced to 4′-0″

• 4′-0″ (1219) to combustible surfaces, all four sides (includes between units).

• Left side: 4′-0″ (1219) for proper condenser coil airflow.

• Front: 4′-0″ (1219) for control box access.

1. Refer to print for roof curb accessory dimensions.

2. Dimensions in [ ] are in millimeters.

3. Center of gravity.

4. Direction of airflow.

5. Ductwork to be attached to accessory roof curb only.

NOTES:

6. Minimum clearance:

• Right side: 4′-0″ (1219) for proper operation of damper and power exhaust if

Fig. 4 — Base Unit Dimensions — 580F180, 210

—6—

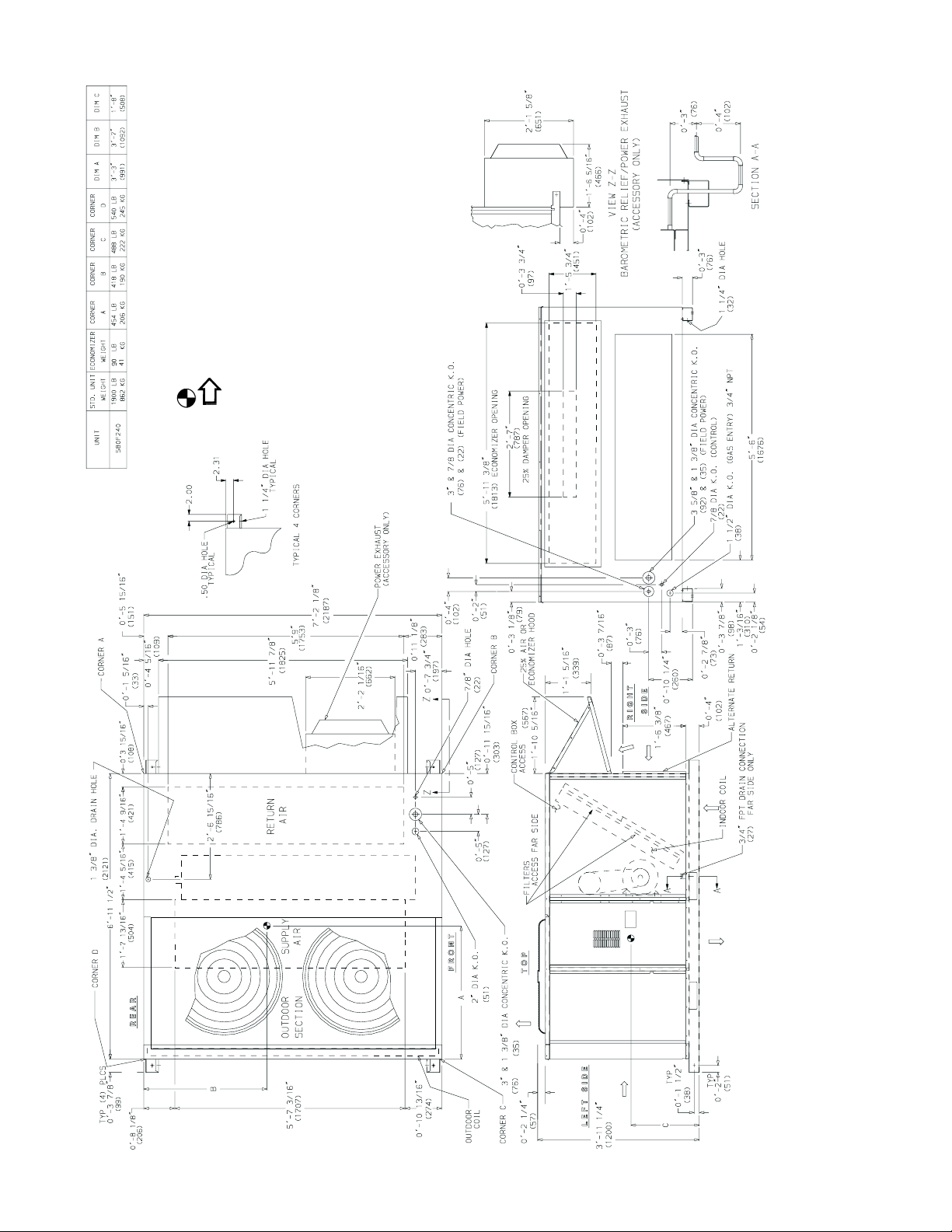

Page 7

″ (8) on each side for

16

/

5

NOTES:

so equipped.

• Top : 6′-0″ (1829) to assure proper condenser fan operation.

surfaces.

• Bottom: 14″ (356) to combustible surfaces (when not using curb).

• Control box side: 3′-0″ (914) to ungrounded surfaces, non-combustible.

• Control box side: 3′-6″ (1067) to block or concrete walls, or other grounded

• Local codes or jurisdiction may prevail.

exhaust as stated in Note #6, a removable fence or barricade requires no clear-

ance.

top cover drip edge.

7. With the exception of clearance for the condenser coil and the damper/power

8. Dimensions are from outside of corner post. Allow 0′-

(1219) if conditions permit coil removal from the top.

• Rear: 7′-0″ (2134) for coil removal. This dimension can be reduced to 4′-0″

• 4′-0″ (1219) to combustible surfaces, all four sides (includes between units).

• Left side: 4′-0″ (1219) for proper condenser coil airflow.

• Front: 4′-0″ (1219) for control box access.

1. Refer to print for roof curb accessory dimensions.

2. Dimensions in [ ] are in millimeters.

3. Center of gravity.

4. Direction of airflow.

5. Ductwork to be attached to accessory roof curb only.

6. Minimum clearance:

• Right side: 4′-0″ (1219) for proper operation of damper and power exhaust if

Fig. 5 — Base Unit Dimensions — 580F240

—7—

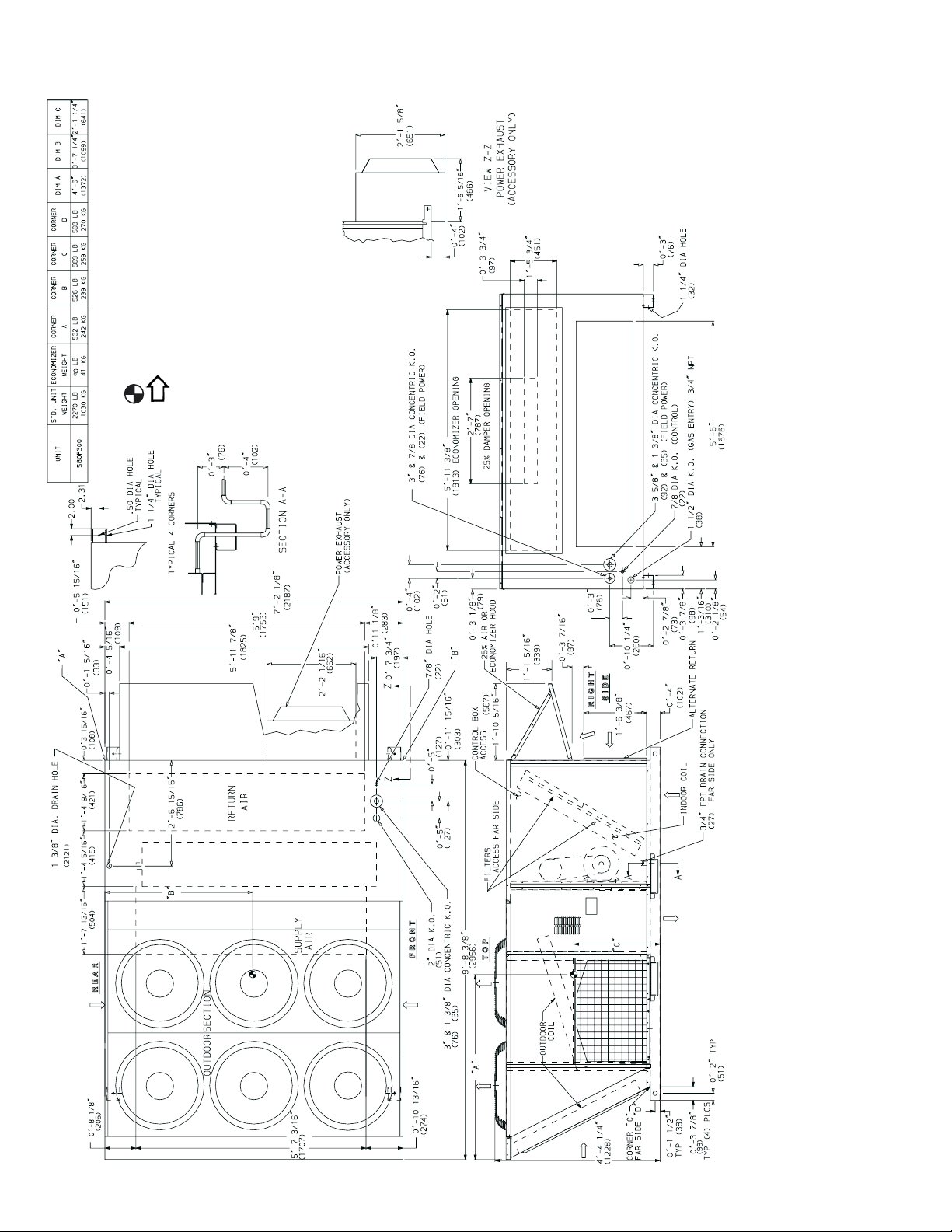

Page 8

″ (8) on eac h side for top cover

16

/

5

ditions permit coil removal from the top.

•Rear: 7′-0″ (2134) for coil re moval. This dimension can be reduced t o 4′-0″ (1219) if con-

•4′-0″ (1219) to combustible surfaces, all four sides (includes between units).

•Left side: 4′-0″ (1219) for proper condenser coil airflow.

• Right side: 4′-0″ (1219) for proper operation of damper and power exhaust if so eq uipped.

•Top: 6′-0″ (182 9) to assure proper condenser fan operation.

•Front: 4′-0″ (1219) for control box access.

• Bottom: 14″ (356) to combustible surfaces (when not using curb).

1. Refer to print for roof curb accessory dimensions.

2. Dim ensions in ( ) are in millimeters.

3. Center of Gravity.

4. Direction of airflow.

5. Ductwork to be attached to accessory roof curb only.

NOTES:

6. Minimum clearance:

• Con trol box side: 3′-0″ (914) to ungrounded surfaces, non-c ombustible.

drip edge.

• Con trol box side: 3′-6″ (1067) t o block or concrete walls, or other gro unded surfaces.

• Local codes or jurisdiction may prevail.

stated in Note #6, a removable fence or barricade requ ires no clearance.

9. The lower forklift brace must be removed prior to setting unit on roof curb.

7. With the exception of clearance for the condenser coil and the damper/power exhaust as

8. Dimensions are from outside of corner post. Allow 0′-

Fig. 6 — Base Unit Dimensions — 580F300

—8—

Page 9

Table 1 — Physical Data

UNIT 580F 180 210 240 300

NOMINAL CAPACITY (tons) 15 18 20 25

OPERATING WEIGHT 1800 1850 1900 2270

EconoMi$erIV 90 90 90 90

Perfect Humidity™ Dehumidification Package 40 40 40 40

COMPRESSOR/MANUFACTURER Scroll, Copeland

Quantity...Model (Ckt 1, Ckt 2)

Capacity Stages (%) 60, 40 55, 45 55, 45 50, 50

Number of Refrigerant Circuits 222 2

Oil (oz) (Ckt 1, Ckt 2) 85, 60 106, 81 106,106 136, 106

REFRIGERANT TYPE R-22

Expansion Device TXV

Operating Charge (lb-oz)

Circuit 1† 19-8 19-8 19-11 26-13

Circuit 2 13-8 19-2 13-14 25-10

CONDENSER COIL Cross-Hatched

Rows...Fins/in. 4...15 4...15 4...15 3...15 (2 coils)

Total Face Area (sq ft) 21.7 21.7 21.7 43.4

CONDENSER FAN Propeller Type

Nominal Cfm 10,500 10,500 14,200 21,000

Quantity...Diameter (in.) 3...22 3...22 2...30 6...22

Motor Hp...Rpm

Watts Input (Total) 1100 1100 3400 2200

EVAPORATOR COIL Cross-Hatched

Rows...Fins/in. 4...15 4...15 4...15 4...15

Total Face Area (sq ft) 17.5 17.5 17.5 17.5

EVAPORATOR FAN Centrifugal Type

Quantity...Size (in.) 2...12 x 12 2...12 x 12 2...12 x 12 2...12 x 12

Type D riv e Belt Belt Belt Belt

Nominal Cfm 6000 7200 8000 10,000

Motor Hp 557.510

Motor Nominal Rpm 1745 1745 1745 1740

Maximum Continuous Bhp 6.13 5.90

Motor Frame Size 184T 184T 213T 215T

Nominal Rpm High/Low ——— —

Fan Rpm Range Low-Medium Static 873-1021 910-1095 1002-1151 1066-1283

Motor Bearing Type Ball Ball Ball Ball

High Static 1025-1200 1069-1287 1193-1369 1332-1550

Maximum Allowable Rpm 1550 1550 1550 1550

Motor Pulley Pitch Diameter Low-Medium Static 4.9/5.9 4.9/5.9 5.4/6.6 4.9/5.9

Min/Max (in.) High Static 4.9/5.9 4.9/5.9 5.4/6.6 4.9/5.9

Nominal Motor Shaft Diameter (in.) 1

Fan Pulley Pitch Diameter (in.) Low-Medium Static 9.4 9.4 9.4 8.0

High Static 8.0 8.0 7.9 6.4

Nominal Fan Shaft Diameter (in.) 1

Belt, Quantity...Type...Length (in.) Low-Medium Static 1...BX...50 1...BX...50 1...BX...53 2...BX...50

High Static 1...BX...48 1...BX...48 1...BX...50 2...BX...47

Pulley Center Line Distance (in.) 13.3-14.8 13.3-14.8 14.6-15.4 14.6-15.4

Speed Change per Full Turn of

Movable Pulley Flange (rpm)

Low-Medium Static 37 37 37 36

High Static 44 34 44 45

Movable Pulley Maximum Full Turns

From Closed Position 6** 6†† 6** 6††

Factory Pulley Setting 3.5 3.5 3.5 3.5

Factory Speed Setting (rpm) Low-Medium Static 965 1002 1120 1182

Fan Shaft Diameter at Pulley (in.) 1

High Static 1134 1178 1328 1470

LEGEND

Bhp — Brake Horsepower

TXV — Thermostatic Expansion Valve

*The ZRU140KC compressor is a tandem compressor, consisting of a ZR72KC (25% total

capacity) and a ZR68KC (24% total capacity).

†Circuit 1 uses the lower portion of the condenser coil and lower portion of the evaporator coils;

and Circuit 2 uses the upper portion of both coils.

**Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to 1

open.

††Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to

open.

***Rollout switch is manual reset.

†††A Liquid Propane kit is available as an accessory.

¶The 580F300 unit requires 2-in. industrial-grade filters capable of handling face velocities up to

625 ft/min (such as American Air Filter no. 5700 or equivalent).

NOTE: The 580F units have a low-pressure switch (standard) located on the suction side.

1...ZR94KC,

1...ZR72KC

1

/2...1050

1

/

8

7

/

16

7

/

16

1...ZR108KC,

1...ZR94KC

3

Aluminum Pre-Coated, or Copper Plate Fins

/8-in. Copper Tubes, Aluminum Lanced,

1

/2...1050 1...1075

3

/8-in. Copper Tubes, Aluminum Lanced or

Copper Plate Fins, Face Split

1...ZR125KC,

1...ZR108KC

8.7 [208/230 v]

9.5 [460 v]

1

/2 turns

1

/2 turns

17/

17/

11/

8

16

16

13/

17/

17/

8

16

16

1...ZRU140KC,*

1...ZR144KC

1

/2...1050

10.2 [208/230 v]

11.8 [460 v]

13/

8

17/

16

17/

16

—9—

Page 10

Table 1 — Physical Data (cont)

UNIT 580F

FURNACE SECTION

Rollout Switch Cutout Temp (F)*** 190 190 190 190

(Low Heat/High Heat)

180

(Low Heat/High Heat)

210

(Low Heat/High Heat)

240

(Low Heat/High Heat)

300

Burner Orifice Diameter (in. ...drill size)

Natural Gas Std 0.1285...30/0.136...29 0.1285...30/0.136...29 0.1285...30/0.136...29 0.1285...30/0.136...29

Thermostat Heat Anticipator Setting (amps)

208/230 v Stage 1 0.98 0.98 0.98 0.98

460 v Stage 1 0.80 0.80 0.80 0.80

Stage 2 0.44 0.44 0.44 0.44

Stage 2 0.44 0.44 0.44 0.44

Gas Input Stage 1 206,000/270,000 206,000/270,000 206,000/270,000 206,000/270,000

Stage 2 275,000/360,000 275,000/360,000 275,000/360,000 275,000/360,000

Efficiency (Steady-State) (%) 81 81 81 81

Temperature Rise Range 15-45/20-50 15-45/20-50 15-45/20-50 15-45/20-50

Manifold Pressure (in. wg)

Natural Gas Std 3.3 3.3 3.3 3.3

Liquid Propane††† Alt 3.3 3.3 3.3 3.3

Gas Valve Quantity 1111

Gas Valve Pressure Range

in. wg 5.5-13.5 5.5-13.5 5.5-13.5 5.5-13.5

psig 0.235-0.487 0.235-0.487 0.235-0.487 0.235-0.487

Field Gas Connection Size (in.-FPT)

3

/

4

3

/

4

3

/

4

3

/

4

HIGH-PRESSURE SWITCH (psig)

Cutout 426

Reset (Auto) 320

LOW-PRESSURE SWITCH (psig)

Cutout 27

Reset (Auto) 44

FREEZE PROTECTION THERMOSTAT (F)

Opens 30 ± 5

Closes 45 ± 5

OUTDOOR-AIR INLET SCREENS Cleanable

Quantity...Size (in.) 2...20 x 25 x 1

1...20 x 20 x 1

RETURN-AIR FILTERS Throwaway¶

Quantity...Size (in.) 4...20 x 20 x 2

1

POWER EXHAUST

/2 Hp, 208/230-460 v Motor Direct Drive, Propeller-Fan (Factory-Wired for 460 v)

4...16 x 20 x 2

LEGEND

Bhp — Brake Horsepower

TXV — Thermostatic Expansion Valve

*The ZRU140KC compressor is a tandem compressor, consisting of a ZR72KC (25% total capac-

ity) and a ZR68KC (24% total capacity).

†Circuit 1 uses the lower portion of the condenser coil and lower portion of the evaporator coils;

and Circuit 2 uses the upper portion of both coils.

**Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to 1

open.

††Pulley has 6 turns. Due to belt and pulley size, movable pulley cannot be set to 0 to

1

/2 turns

1

/2 turns

open.

***Rollout switch is manual reset.

†††A Liquid Propane kit is available as an accessory.

¶The 580F300 unit requires 2-in. industrial-grade filters capable of handling face velocities up to

625 ft/min (such as American Air Filter no. 5700 or equivalent).

NOTE: The 580F units have a low-pressure switch (standard) located on the suction side.

—10—

Page 11

III. STEP 3 — FIELD FABRICATE DUCTWORK

Secure all ducts to building structure. Use flexible duct connectors between unit and ducts as required. Insulate and

weatherproof all external ductwork, joints, and roof openings

with counter flashing and m asti c i n acc ordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

IV. STEP 4 — MAKE UNIT DUCT CONNECTIONS

Unit is shipped for thru-the-bottom duct connections. Ductwork openings are shown in Fig. 1 and 4-6. Duct connections

are shown in Fig. 7. Field-fabricated concentric ductwork

may be connected as shown in Fig. 8 and 9. Attach all ductwork to roof curb and roof curb basepans.

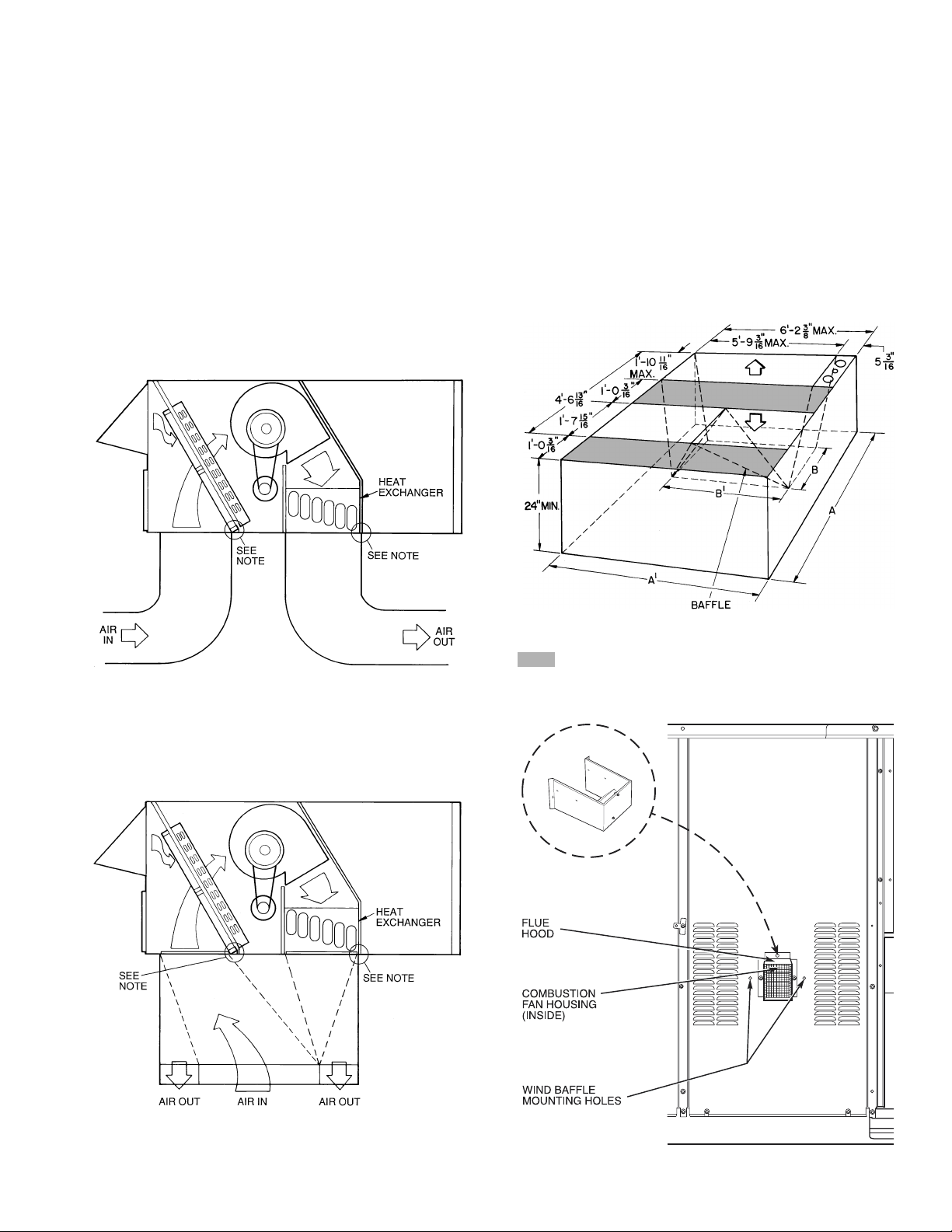

V. STEP 5 — INSTALL FLUE HOOD AND WIND BAFFLE

Flue hood and wind baffle are shipped secured under main

control box. To install, secure flue hood to access panel. See

Fig. 10. The wind baffle is then installed over the flue hood.

NOTE: Whe n properly insta lled, flue hoo d will line up with

combustion fan housing. See Fig. 11.

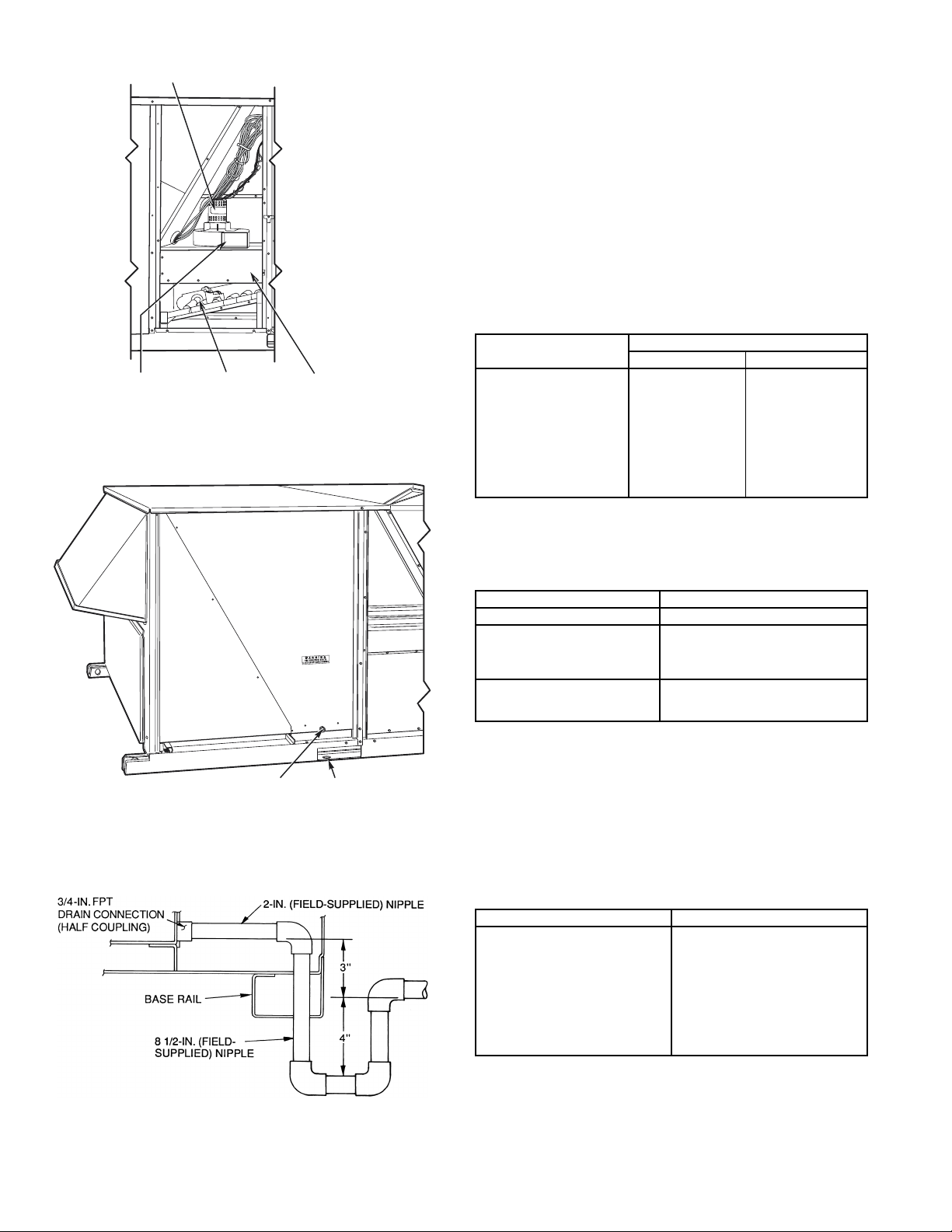

VI. STEP 6 — TRAP CONDENSATE DRAIN

See Fig. 12 for drain location. One

3

/4-in. half coupling is provided inside unit evaporator section for condensate drain

connection. An 8

diameter pipe nipple, coupled to standard

1

/2-in. x 3/4-in. diameter and 2-in. x 3/4-in.

3

/4-in. diameter

elbows, provide a straight path down through hole in unit

base rails (see Fig. 13). A trap at least 4-in. de ep must be

used.

NOTE: Do not drill in this area; damage to basepan may result in water

leak.

Fig. 7 — Air Distribution — Thru-the-Bottom

NOTE: Dimensions A, A′, B, and B′ are obtained from field-supplied

ceiling diffuser.

Shaded areas indicate block-off panels.

Fig. 9 — Concentric Duct Details

WIND

BAFFLE

NOTE: Do not drill in this area; damage to basepan may result in water

leak.

Fig. 8 — Concentric Duct Air Distribution

Fig. 10 — Flue Hood Location

—11—

Page 12

INDUCED DRAFT

MOTOR

VII. STEP 7 — ORIFICE CHANGE

This unit is factory assembled for heating operation using

natural gas at an elevation from sea level to 2000 ft. This

unit uses orifice type LH32RFn nn, wher e “nnn” i ndicates th e

orifice size based on drill size diameter in thousands of an

inch.

A. High Elevation (Above 2000 ft)

Use accessory high altitude kit when installing this unit at

an elevation of 2000 to 7000 ft. For elevations above 7000 ft,

refer to Table 2 to identify the correct orifice size for the

elevation. See Table 3 for the nu mber of orifi ces re quired for

each unit size. Purc hase the se orifi ces f rom your lo cal Bryant

dealer. Fo llow in structions in acc essory I nstallati on Ins tructions to install the correct orif ices.

Table 2 — Altitude Compensation*

COMBUSTION

FAN HOUSING

MAIN BURNER

SECTION

HEAT EXCHANGER

SECTION

Fig. 11 — Combustion Fan Housing Location

3/4" FPT DRAIN

CONNECTION

1-3/8"

DRAIN HOLE

Fig. 12 — Condensate Drain Details (580F180 Shown)

ELEVATION (ft)

0-1,999 30 29

2,000 30 29

3,000 31 30

4,000 31 30

5,000 31 30

6,000 31 30

7,000 32 31

8,000 32 31

9,000 33 31

10,000 35 32

*As the height above sea level increases, there is less oxygen per cubic

foot of air. Therefore, heat input rate should be reduced at higher altitudes. Includes a 4% input reduction per each 1000 ft.

†Orifices available through your Bryant dealer.

NATURAL GAS ORIFICE†

Low Heat High Heat

Table 3 — Orifice Quantity

UNIT ORIFICE QUANTITY

580F180 Low Heat 5

580F210 Low Heat,

580F240 Low Heat,

580F300 Low Heat,

580F180 High Heat

580F210 High Heat,

580F240 High Heat,

580F300 High Heat

6

7

B. Conversion To LP (Liquid Propane) Gas

Use accessory LP gas conversion kit when converting this unit

for use with LP fuel usage for elevations up to 7000 ft. For

elevations above 7000 ft, refer to Table 4 to identify the correct

orifice size for the elevation. See Table 3 for the number of

orifices required for each unit size. Purchase these orifices

from your local Bryant deale r. Follow instructions in acce ssory

Installation Instructions to install the corre ct orific es.

Table 4 — LP Gas Conversion*

Fig. 13 — Condensate Drain Piping Details

ELEVATION (ft) LP GAS ORIFICE†

0-1,999 36

2,000 37

3,000 38

4,000 38

5,000 39

6,000 40

7,000 41

8,000 41

9,000 42

10,000 43

*As the height above sea level increases, there is less oxygen per

cubic foot of air. Therefore, heat input rate should be reduced at higher

altitudes. Includes a 4% input reduction per each 1000 ft.

†Orifices available through your Bryant dealer.

—12—

Page 13

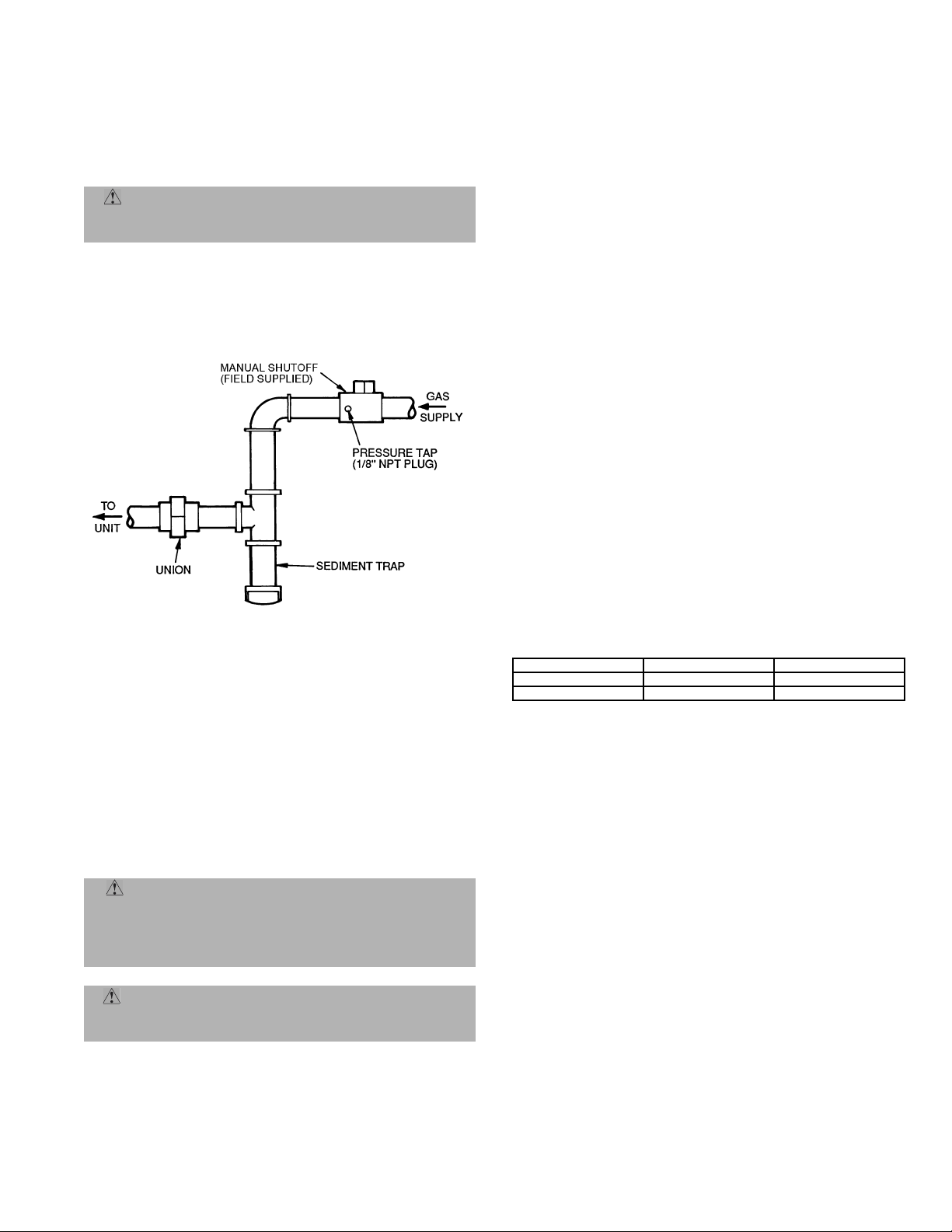

VIII. STEP 8 — INSTALL GAS PIPING

Unit is equipped for use with natural gas. Installation must

conform with local bu ilding codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1.

Install field-supplied manual gas shutoff valve with a

1

/8-in.

NPT pressure tap for test gage co nnection at unit. Field gas

piping must include sediment trap and union. See Fig. 14.

WARNING: Do not pressure test gas supply while

connected to unit. Always disconnect union before

servicing.

IMPORTANT: Natural gas pressure at unit gas connection

must not be less than 5.5 in. wg or greater than 13.5 in. wg.

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas

connection.

Fig. 14 — Field Gas Piping

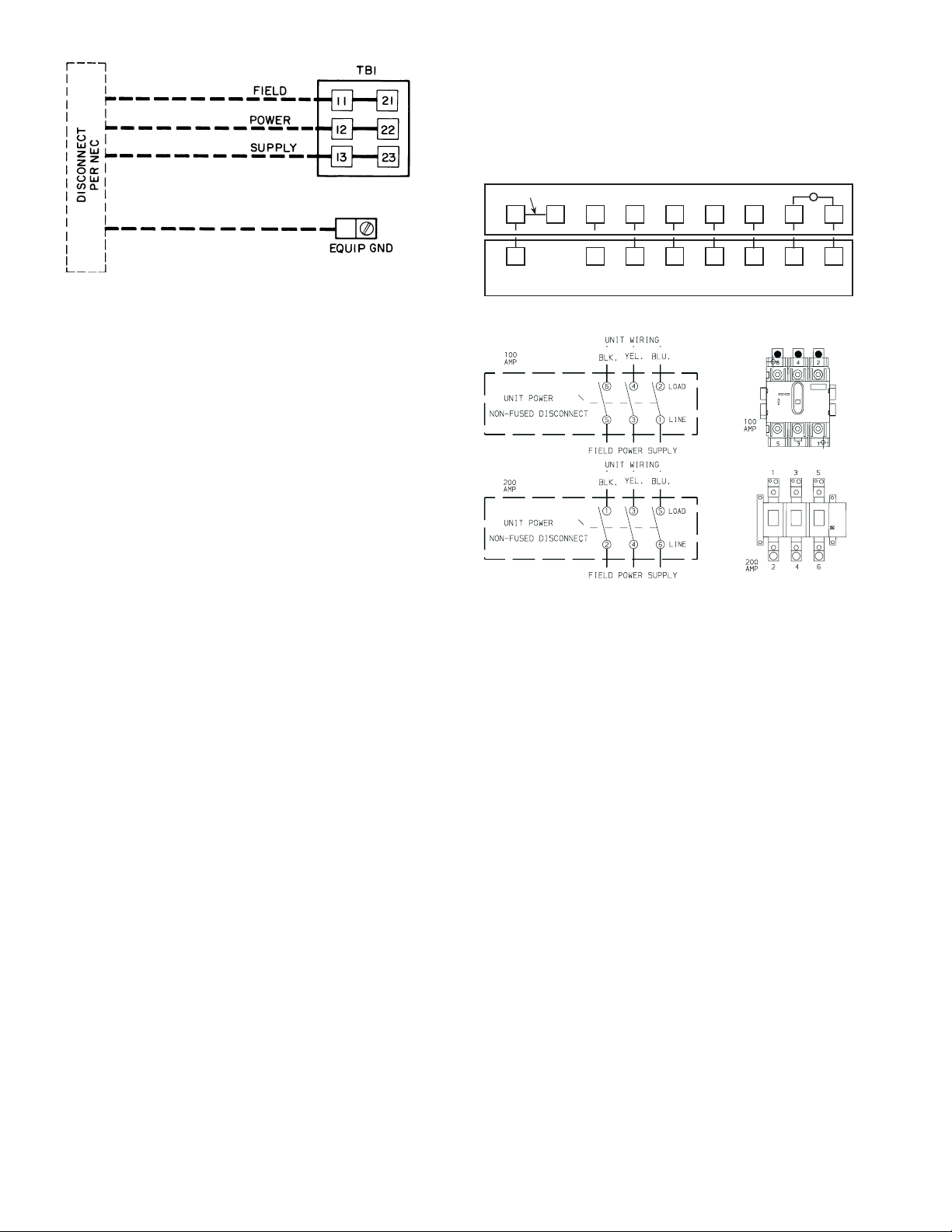

IX. STEP 9 — MAKE ELECTRICAL CONNECTIONS

A. Field Power Supply

Unit is factory wired for voltage shown on unit nameplate.

When installing units, provide a disconnect per NEC

(National Electrical Code) requirements of adequate size

(Table 5).

All field wiring must comply with NEC and local

requirements.

Route power and ground lines through control box end

panel or unit basepan (see Fig. 4-6) to connections as shown

on unit wiring diagram and Fig. 15.

CAUTION: The correct power phasing is critical in

the operation of the scroll compressors. An incorrect

phasing will cause the compressor to rotate in the

wrong direction. This may lead to premature compressor failure.

WARNING: The unit must be electrically grounded

in accordance with local codes and NEC ANSI/ NF PA 70

(National Fire Protection Association).

Field wiring must conform to temperature limitations for

type ‘‘T’’ wire. All field wiring must comply with NEC and

local require ments.

Transformer no. 1 is wi r ed for 230 -v unit. If 2 08/230-v unit is

to be run with 208-v power supply, the transfo rmer must be

rewired as follows:

1. Remove cap from red (208 v) wire.

2. Remove cap from orange (230 v) spliced wire.

3. Replace orange wire with red wire.

4. Recap both wires.

IMPORTANT: BE CERTAIN UNUSED WIRES ARE

CAPPED. Failure to do so may damage the transformers.

Operating voltage to compressor must be within voltage

range indicated on unit nameplate. On 3-phase units, voltages between phases must be balanced within 2%.

Unit failure as a res ult of ope ra tio n o n imp ro per line volt age

or excessive phase imbalance constitutes abuse and may

cause damage to electrical components.

B. Field Control Wiring

Install a Bryant-approv ed acces sory ther mosta t assemb ly (or

light commercial Thermidistat™ device for units equipped

with Perfect Humidity™ option) according to the installation

instructions included with accessory. Locate thermostat

assembly on a solid interior wall in the conditioned space to

sense average temperature.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals through conduit in uni t to lowvoltage connections as shown on unit label wiring diagram

and in Fig. 16.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gage) insulated wire (35 C minimum). For 50 to 75 ft,

use no. 16 AWG insulated wire (35 C minimum). For over

75 ft, use no. 14 AWG insulated wire (35 C minimum). All

wire larger than no. 18 AWG cannot be directly connected a t

the thermos tat and wi ll req uire a j unction box and s plice a t

the thermostat.

Set heat anticipator settings as follows:

VOLTAGE W1 W2

208/230 0.98 0.44

460 0.80 0.44

Settings may be changed slightly to provide a greater degree

of comfort for a particular installation.

C. Optional Non-Fused Disconnect

On units with the optional non-fused disconnect, incoming

power will be wired into the disconnect switch. Refer to

Fig. 17 for wiring for 100 and 200 amp disconnect switches.

Units with an MOCP (maximum overcurrent protection)

under 100 will use the 100 amp disconnect switch. Units

with an MOCP over 100 will use the 200 amp disconnect

switch. Refer to the applicable disconnect wiring diagram.

To prevent breakage during shipping, the disconnect handle

and shaft are shipped and packaged inside the unit control

box. Install the disconnec t handle before unit operation. To

install the handle and shaft, perform the following procedure:

1. Open the co nt ro l b ox do or and r e mo ve t he handle and

shaft from shipping location.

2. Loosen the Allen bolt located on the disconnect

switch. The bolt is locat ed on the sq uare hole a nd is

used to hold the shaft in place. The shaft cannot be

inserted until the Allen bo lt is moved.

3. Insert the disconnect shaft into the square hole on

the disconnect switch. The end of the shaft is specially cut and the shaft can only be inserted in the

correct orientation.

—13—

Page 14

D. Optional Convenience Outlet

On units with optional convenience outlet, a 115-v GFI

(ground fault interrupt) convenience outl et rece ptacle is pr ovided for field wiring. Field wiring should be run thro ugh th e

7

/8-in. knockout provided in the basepan near the return air

opening.

THERMOSTAT ASSEMBLY

REMOVABLE JUMPER

RC

RH

Y1 Y2

W1

W2

GC

L

X

LEGEND

EQUIP — Equipment

GND — Ground

NEC — National Electrical Code

TB — Te rm i n al B o a r d

NOTE: The maximum wire size for TB1 is 2/0.

Fig. 15 — Field Power Wiring Connections

4. Tighten the Allen bolt to lock the shaft into position.

5. Close the control box door.

6. Attach the handle to the external access door with

the two screws provided. When the handle is in the

ON position, the handle will be vertical. When

the handle is in the OFF position, the handle will be

horizontal.

7. Turn the handle to the OFF position and close the

door. The handle should fit over the end of the sha ft

when the door is closed.

8. The handle must be in the OFF position to open the

control box door.

R

RED

Y1

BLU

PNK

W1Y2

ORN

W2

VIO

C

BRN

X

WHT

G

BLK

Fig. 16 — Field Control Thermostat Wiring

6T3 4T2 2T1 LOAD

5L3 3L2 1L1 LINE

NOTE: The disconnect takes the place of TB-1 as shown on the unit

wiring diagram label and the component arrangement label.

Fig. 17 — Optional Non-Fused Disconnect Wiring

—14—

Page 15

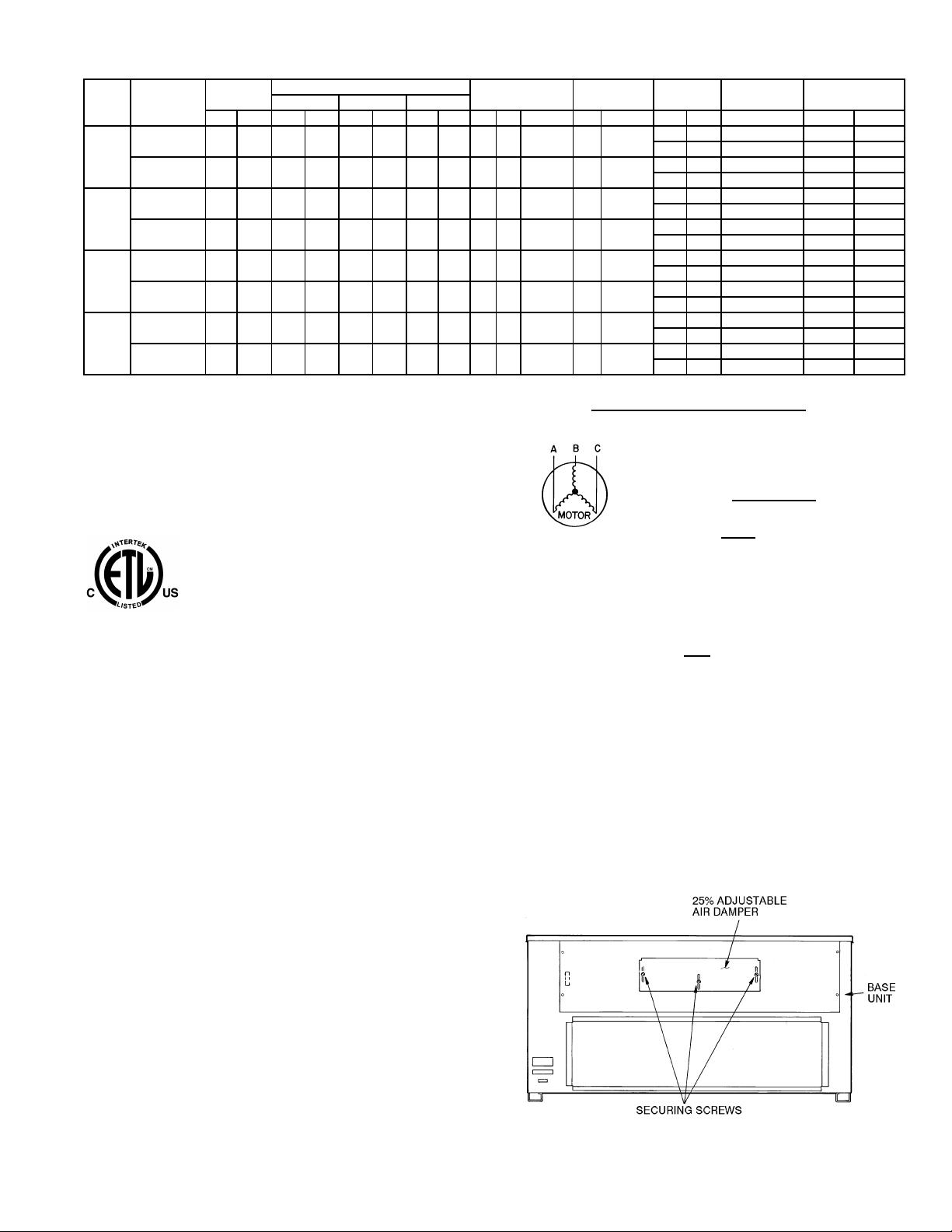

Table 5 — Electrical Data

UNIT

580F

LEGEND

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

IFM — Indoor (Evaporator) Fan Motor

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection

NEC — National Electrical Code

OFM — Outdoor (Condenser) Fan Motor

RLA — Rated Load Amps

*Fuse or HACR circuit breaker.

NOTES:

1. In compliance with NEC requirements for multimotor and combination load

2. Unbalanced 3-Phase Supply Voltage

NOMINAL

VOLTAGE

(3 Ph, 60 Hz)

208/230 187 253 32.1 195 — — 20.7 156 3 0.5 1.7 5.0 15.8/15.8

180

210

240

300

equipment (refer to NEC Articles 430 and 440), the overcurrent protective

device for the unit shall be fuse or HACR breaker. Canadian units may be

fuse or circuit breaker.

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%.

imbalance.

460 414 508 16.4 95 — — 10 70 3 0.5 0.8 5.0 7.9

208/230 187 253 30.1 225 — — 28.8 195 3 0.5 1.7 5.0 15.8/15.8

460 414 508 15.5 114 — — 14.7 95 3 0.5 0.8 5.0 7.9

208/230 187 253 42 239 — — 33.6 225 2 1 6.6 7.5 25.0/25.0

460 414 508 19.2 125 — — 17.3 114 2 1 3.3 7.5 13.0

208/230 187.2 253 20.7 156 20.7 156 47.1 245 6 0.5 1.7 10.0 28.0/28.0

460 414 508 10 75 10 75 19.6 125 6 0.5 0.8 10.0 14.6

VO LTAG E

RANGE

Min Max RLA LRA RLA LRA RLA LRA Qty Hp FLA (ea) Hp FLA FLA LRA FLA MCA MOCP*

Use the following formula to determine the percent voltage

COMPRESSOR

No. 1 No. 1A No. 2

OFM IFM

% Voltage Imbalance

= 100 x

EXAMPLE: Supply voltage is 460-3-60.

Determine maximum deviation from average voltage.

Maximum deviation is 7 v.

Determine percent voltage imbalance.

% Voltage Imbalance = 100 x

This amount of phase imbalance is satisfactory as it is below the maximum

allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility company immediately.

max voltage deviation from average voltage

(AB) 457 – 452 = 5 v

(BC) 464 – 457 = 7 v

(AC) 457 – 455 = 2 v

POWER

EXHAUST

— — 0.57 82/82 110/110

4.6 18.8 0.57 86/86 110/110

— — 0.30 41 50

2.3 6.0 0.30 43 50

— — 0.57 87/87 110/110

4.6 18.8 0.57 92/92 110/110

— — 0.30 44 50

2.3 6.0 0.30 47 60

— — 0.57 124/124 150/150

4.6 18.8 0.57 129/129 150/150

— — 0.30 61 80

2.3 6.0 0.30 63 80

— — 0.57 138/138 175/175

4.6 18.8 0.57 143/143 150/175

— — 0.30 64 80

2.3 6 0.30 66 80

average voltage

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

= 1.53%

=

= 457

7

457

COMBUSTION

FAN MOTOR

452 + 464 + 455

3

1371

3

POWER

SUPPLY

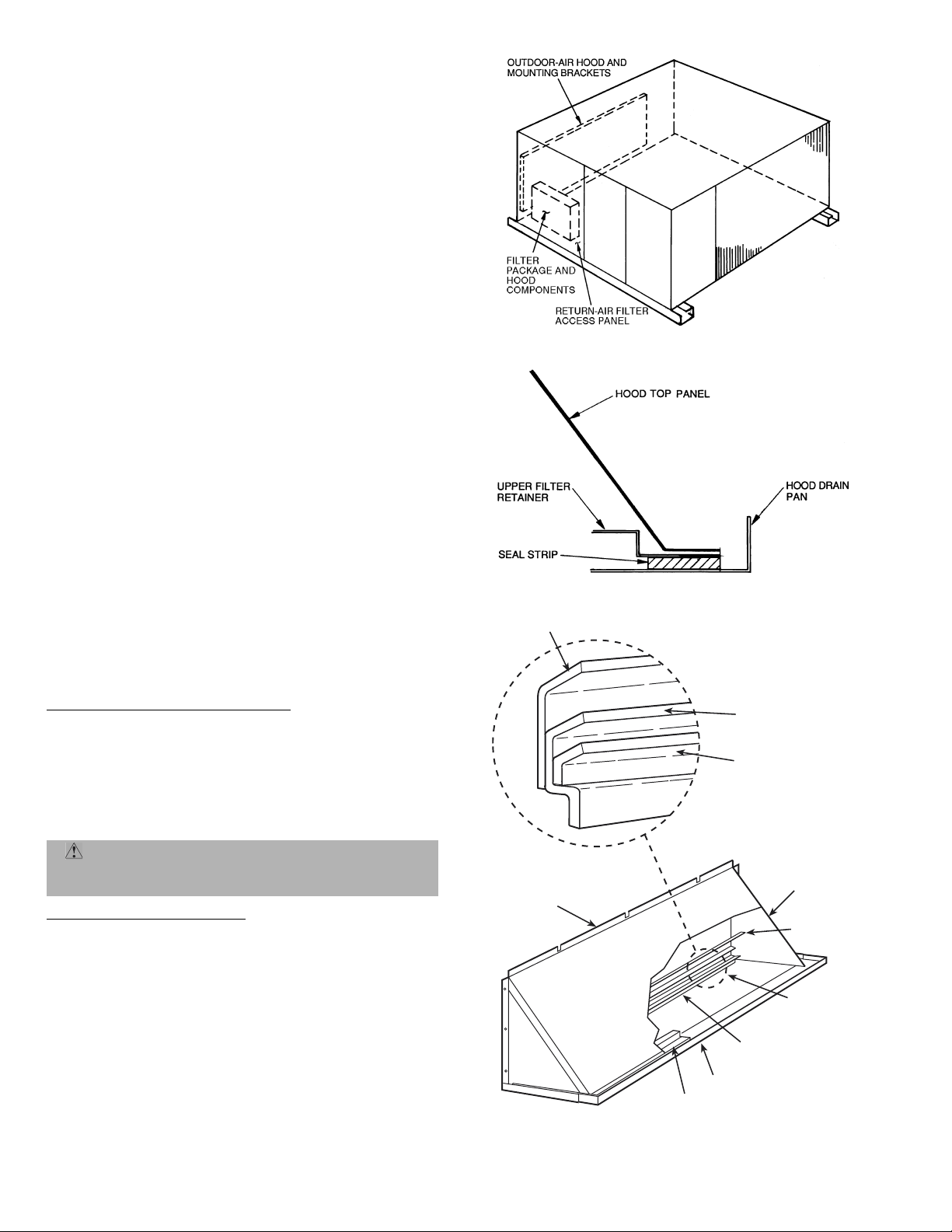

X. STEP 10 — MAKE OUTDOOR-AIR INLET ADJUSTMENTS

A. Manual Outdoor-Air Damper

All units (except those equipped with a factory-installed

EconoMi$erIV ) h ave a ma nual out door-air damper to provide

ventilation air.

Damper can be preset to admit up to 25% outdoor air into

return-air compartment. To adjust, loosen securing screws

and move damper to desired setting, then retighten screws

to secure damper (Fig. 18).

XI. STEP 11 — INSTALL OUTDOOR-AIR HOOD

The outdoor-air hood is common to 25% air ventilation and

EconoMi$erIV. If EconoMi$erIV is factory installed, all

electrical connections have been made and adjusted at the

factory. Assemble and install hood in the field.

Fig. 18 — Standard 25% Outdoor-Air Section Details

—15—

Page 16

IMPORTANT: If the unit is equipped with the optional

EconoMi$erIV component, move the outdoor-air temperature sensor prior to installing the outdoor-air hood. See the

Optional EconoMi$erIV section for more inform ation.

NOTE: The hood top panel, upper and lower filter retainers,

hood drain pan, baffle (size 300), and filter support bracket

are secured opposite the condenser end of the unit. The

screens, hood side panels, remaining section of filter support

bracket, seal strip, and hardware are in a package located

inside the return-air filter access panel (Fig. 19).

1. Attach seal strip to upper filter retainer. See Fig. 20.

2. Assemble hood top panel, side panels, upper filter

retainer, and drain pan (see Fig. 21).

3. Secure lower filter retainer and support bracket to

unit. See Fig. 21. Leave screws loose on size 300 units.

4. Slide baffle (size 300) behind lower filter retainer and

tighten screws.

5. Loosen sheet metal screws for top pa nel of base unit

located above o utdoor-air inlet opening, and remove

screws for hood side panels located on the sides of the

outdoor-air inlet opening.

6. Match notches in hood top panel to unit top panel

screws. Inser t hood flange betw een top panel flan ge

and unit. Tighten screws.

7. Hold hood side panel flanges flat against unit, and

install screws removed in Step 5.

8. Insert outdoor-air inlet screens and spacer in channel

created by lower filter retainer and filter support

bracket.

9. Attach remaining section of filter support bracket.

XII. STEP 12 — INSTALL ALL ACCESSORIES

After all the factory-installed options have been adjusted,

install all field-installed accessories. Refer to the accessory

installation instructions included with each accessory.

A. Motormaster® I Control (–20 F) Installation (580F180

and 210 Only)

Install Field-Fabricated Wind Baffles

Wind baffles must be field-fabricated for all units to ensure

proper cooling cycle operation at low ambient temperatures.

See Fig. 22 for baffle details. Use 20-gage, galvanized sheet

metal, or similar corrosion-resistant metal for baffles. Use

field-supplied screws to attach baffles to uni t. Scre ws shou ld

1

be

/4-in. diameter and 5/8-in. long. Drill required screw holes

for mounting baffles.

Fig. 19 — Outdoor-Air Hood Component Location

Fig. 20 — Seal Strip Location

BAFFLE

LOWER FILTER

RETAINER

FILTER SUPPORT

BRACKET

CAUTION: To avoid damage to the refrigerant

coils and electrical components, use recommended

screw sizes only. Use care when drilling holes.

Install Motormaster I Controls

One Motormaster I control is required on size 180 and 210

units. The Motormaster I control must be used in conjunction

with the accessory fan motor sequencing kit and winter start

kit (purchased separately). The Motormaster I device controls

outdoor fan no. 1 while outdoor fans no. 2 and 3 are sequenced

off by the accessory fan motor sequencing kit.

Accessory Fan Motor Sequencing Kit — Install the access ory

fan motor sequencing kit per instruction supplied with accessory (purchased separately).

Winter Start Time Delay Relay Kit — Install the kit per

the instructions supplied with the accessory (purchased

separately).

Sensor Assembl y — Install the sensor assembly in the location shown in Fig. 23.

HOOD SIDE

HOOD TOP

PANEL

HOOD DRAIN PAN

UPPER FILTER RETAINER

NOTE: The outdoor-air hood comes with a baffle which is used on

size 300 units only, discard baffle for size 180-240 units.

PANELS (2)

FILTER SUPPORT

BRACKET

Fig. 21 — Outdoor-Air Hood Details

—16—

BAFFLE

(300 ONLY)

LOWER

FILTER

RETAINER

Page 17

Motor Mount — To ensure proper fan height, replace the

existing motor mount with the new motor m ount provided

with accessory .

Transformer (460-v Units Only) — On 460-v units, a transformer is required. The transformer is provided with the

accessory and must be field-installed.

Motormaster® I Control — Recommended mounting location

is on the inside of the panel to the left of the con trol box. The

control should be mounted on the inside of the panel, vertically, with leads protruding from bottom of extrusion.

B. Motormaster V Control Installation (580F240 and 300)

Install Field-Fabricated Wind Baffles

Wind baffles must be field-fabricated for all units to ensure

proper cooling cycle operation at low ambient temperatures.

See Fig. 22 for baffle details. Use 20-gage, galvanized sheet

metal, or similar corrosion-resistant metal for baffles. Use

field-supplied screws to attach baffles to unit. Screws should

1

be

/4-in. diameter and 5/8-in. long. Drill required screw holes

for mounting baffles.

CAUTION: To avoid damage to the ref rigerant coils

and electrical components, use recommended screw

sizes only. Use care when drilling holes.

Install Motormaster V Controls

The Motormaster V control is a m otor speed control device

which adjusts condenser fan motor speed in response to

declining liquid refrigerant pressure. A properly applied

Motormaster V control extends the operating range of airconditioning systems and permits operation at lower outdoor

ambient te mp eratures.

The minimum ambient temperatures at which the unit will

operate are:

TEMPERATURE OPERATING LIMITS — F°

Standard

Unit

40 25 –20

Unit with

Low Ambient Kit

Unit with

MMV Control

NOTE: Dimensions in ( ) are in mm.

Fig. 22 — Wind Baffle Details

To operate down to the ambient temperatures listed,

Motormaster V controls (Fig. 24) must be added. Fieldfabricated and installed wind baffles are also required for all

units (see Fig. 22) . The M oto rma st er V con tr ol pe rmi ts op er a tion of the unit to an ambient temperature of –20 F. The control regulates the speed of 3-phase fan motors that are

compatible with the control. These motors are factory

installed.

See Table 6 for the Motormaster V control accessory package

usage. Table 7 shows applicable voltages and motors.

Replacement of motor or fan blade IS NOT REQUIRED

ON CURRENT PRODUCTION UNITS since the control is

compatible with the factory-installed fan motors. Only field

wiring control is re quired.

Install the Motormaste r V control per inst ructions supplied

with accessory .

Table 6 — Motormaster V Control Package Usage

UNIT VOLTAGE ITEM DESCRIPTION

580F180-300

208/230 CRLOWAMB015A00

460 CRLOWAMB016A00

Table 7 — Applicable Voltages and Motors

VOLTAGE COMPATIBLE MOTO R

208/230-3-60 HD52AK654

460-3-60 HD52AK654

SENSOR

LOCATION

HAIRPIN END

580F180 580F210

NOTE: All sensors are located on the eighth hairpin up from the

bottom.

SENSOR

LOCATION

HAIRPIN END

Fig. 23 — Motormaster I Sensor Locations

—17—

Page 18

FROM FUSE BLOCK

BLK

YEL

BLU

ECONOMI$ERIV

SUPPLY AIR

TEMPERATURE SENSOR

LOCATION

B

13B

13C

12 13A

2

256

TO PRESSURE

TRANSDUCER

2

3

1

TO MOTOR(S)

Fig. 24 — Motormaster® V Control

XIII. STEP 13 — ADJUST FACTORY-INSTALLED OPTIONS

A. Optional EconoMi$erIV

See Fig. 25 and 26 for EconoMi$erIV component locations.

NOTE: These instructions are for installing the optional

EconoMi$erIV only. Refer to the accessory EconoMi$erIV or

EconoMi$er2 installation instructions when fie ld installing an

EconoMi$erIV or EconoMi$er2 accessory.

To complete installation of the optional EconoMi$erI V, perform the following procedure.

1. Remove the EconoMi$erIV hood. Refer to Step 11 —

Install Outdoor-Air Hood on page 15 for information

on removing and installing the outd oor-air hood.

2. Relocate outdoor air temperature sensor from shipping position to operation po sition on Ec onoMi$erIV.

See Fig. 25.

IMPORTANT: Failure to relocate the sensor will result in the

EconoMi$erIV not ope r ating properly.

3. Re-install economizer hood.

OUTDOOR AIR

TEMPERATURE SENSOR

(INSTALLED OPERATION

POSITION)

LOW TEMPERATURE

COMPRESSOR

LOCKOUT SWITCH

SCREWS

ECONOMI$ERIV

FRAME

TOP

SCREWS

Fig. 25 — EconoMi$erIV Component Locations —

End View

ACTUATOR

CONTROLLER

FLANGE

AND SCREWS

(HIDDEN)

1

TR

R

T

c

a

V

4

2

M

O

C

4

2

_

c

a

V

T

O

H

H

X

E

+

t

e

S

V

0

2

1

V

2

1

1

N

5

N

n

H

i

X

M

E

s

o

P

4

n

P1

e

p

P

O

3

V

C

1

D

x

a

1

EF

T

M

T

V

0

1

EF

V

2

V

C

D

V

t

C

e

D

S

V

1

0

Q

1

A

Q

A

V

2

+

e

O

e

r

S

C

F

l

o

O

o

S

C

B

D

+

R

S

A

R

S

Fig. 26 — EconoMi$erIV Assembled in Unit —

Side View

4. Install all EconoMi$erIV accessories. EconoMi$erIV

wiring is shown in Fig. 27.

Outdoor air leakage is shown in Table 8. Return air pressure

drop is shown in Tabl e 9.

Table 8 — Outdoor Air Damper Leakage

DAMPER STATIC PRESSURE (in. wg)

0.2 0.4 0.6 0.8 1.0 1.2

LEAKAGE (cfm) 35 53 65 75 90 102

Table 9 — Return Air Pressure Drop (in. wg)

CFM

4500 5000 5400 6000 7200 7500 9000 10,000 11,250

0.040 0.050 0.060 0.070 0.090 0.100 0.110 0.120 0.140

B. EconoMi$erIV Standard Sensors

Outdoor Air Temperature (OAT) Sensor

The outdoor air temperature sensor (HH57AC074) is a 10 to

20 mA device used to me asure the outdoor-air tempera ture.

The outdoor-air tempera ture is used t o determine whe n the

EconoMi$erIV can be used for free cooling. The sensor must

be field-relo cated. See Fig. 25. The operat ing range of temperature measurement is 40 to 100 F.

Supply Air Temperature (SAT) Sensor

The supply air temperature sensor is a 3 K thermistor

located at the inlet of the indoor fan. See Fig. 26. This sensor

is factory installed. The operating range of temperature

measurement is 0° to 158 F. See Tabl e 10 for sensor temper ature/resistance values.

The temperature sensor looks like an eyele t terminal with

wires running to it. The sensor is located in the “crimp end”

and is sealed from moisture.

Low Temperature Compressor Lockout Switch

The EconoMi$erIV is equipped with an ambient tempera-

ture lockout switch located in the outdoor air stream which

is used to lockout the co mpresso rs belo w a 42 F ambie nt te mperature. See Fig. 25.

—18—

Page 19

LEGEND

DCV — Demand Controlled Ventilation

IAQ — Indoor Air Quality

LALS— Low Temperature Compressor

Lockout Switch

OAT — Outdoor-Air Temperature

POT — Potentiometer

Potentiometer Default Settings:

Power Exhaust Middle

Minimum Pos. Fully Closed

DCV Max. Middle

DCV Set Middle

Enthalpy C Setting

Fig. 27 — EconoMi$erIV Wiring

NOTES:

1. 620 ohm, 1 watt 5% resistor should be removed only when using differential

enthalpy or dry bulb.

2. If a separate field-supplied 24 v transformer is used for the IAQ sensor power

supply, it cannot have the secondary of the transformer grounded.

3. For field-installed remote minimum position POT, remove black wire jumper

between P and P1 and set control minimum position POT to the minimum

position.

Table 10 — Supply Air Sensor Temperature/

Resistance Values

TEMPERATURE (F) RESISTANCE (ohms)

–58 200,250

–40 100,680

–22 53,010

–4 29,091

14 16,590

32 9,795

50 5,970

68 3,747

77 3,000

86 2,416

104 1,597

122 1,080

140 746

158 525

176 376

185 321

194 274

212 203

230 153

248 116

257 102

266 89

284 70

302 55

C. EconoMi$erIV Control Modes

Determine the EconoMi$erIV control mode before set up of the

control. Some modes of operation may require different sensors.

Refer to Table 11. The EconoMi$erIV is supplied from the factory with a supply air temperature sensor, a low temperature

compressor lockout switch, and an outdoor air temperature

sensor . This allows for operation of the EconoMi$erIV with outdoor air dry bulb changeover control. Additional accessories

can be added to allow for different types of changeover control

and operation of the EconoMi$erIV and unit.

Outdoor Dry Bulb Changeover

The standard controller is shippe d from the factory config-

ured for outdoor dry bulb changeover control. The outdoor

air and su pply air temperature sensors are included as standard. For this control mode, the outdoor temperature is compared to an adjustable set point selected on the control. If the

outdoor-air temperature is above the set point, the

EconoMi$erIV will adjust the outdoor-air dampers to minimum position. If the outdoor-air temperature is below the set

point, the position of the outdoor-air dampers will be controlled to provid e fr ee co o lin g us ing out do or ai r. When in this

mode, the LED next to the free cooling set point potentiometer will be on. The changeover temp erature set poi nt is controlled by the free cooling set poi nt potentiomete r located on

the control. See Fig. 28. The scal e on the p otentio meter i s A,

B, C, and D. See Fig. 29 for the corresponding temp erature

changeover values.

—19—

Page 20

Table 11 — EconoMi$erIV Sensor Usage

ECONOMI$ERIV WITH OUTDOOR AIR

APPLICATION

DRY BULB SENSOR

Accessories Required Accessories Required

Outdoor Air Dry Bulb None. The outdoor air dry bulb sensor is factory installed. CRTEMPSN002A00*

Differential Dry Bulb CRTEMPSN002A00* (2) CRTEMPSN002A00*

Single Enthalpy HH57AC078 None. The single enthalpy sensor is factory installed.

Differential Enthalpy

for DCV Control using a

CO

2

Wall-Mounted CO

for DCV Control using a

CO

2

Duct-Mounted CO2 Sensor

*CRENTDIF004A00 and CRTEMPSN002A00 accessories are used on many different base units. As such, these kits may contain parts that will not be needed for

installation.

†CGCDXSEN004A00 is an accessory CO

**CGCDXASP001A00 is an accessory aspirator box required for duct-mounted applications.

Sensor

2

sensor.

2

HH57AC078

and

CRENTDIF004A00*

CGCDXSEN004A00

CGCDXSEN004A00†

and

CGCDXASP001A00**

ECONOMI$ERIV WITH SINGLE

ENTHALPY SENSOR

CRENTDIF004A00*

Differential Dry Bulb Control

For differential dry bulb control the standard outdoor dry

bulb sensor is used in conjunction with an additional accessory return air sensor (part number CRTEMPSN002A00).

The accessory sensor must be mounted in the return

airstream. See Fig. 30.

In this mode of operation, the outdoor-air temperature is

compared to the return-air temperature and the lower temperature airstream is used for cooling. When using this mode

of changeover control, turn the free cooling/enthalpy set point

potentiometer fully clockwise to the D setting. See Fig. 28.

1

R

T

R

T

ac

V

4

2

OM

C

4

2

_

c

Va

T

H

O

X

H

E

t

+

e

S

V

0

2

2V 1

1

N

1

N

5

n

i

XH

M

E

s

o

P

1

P

4

n

e

P

p

O

V

3

C

D

x

1

T

1

a

F

M

E

T

V

0

1

F

E

V

2

V

C

D

V

C

et

D

S

V

0

Q1

A

Q

A

2V 1

+

O

e

e

S

r

C

F

l

O

o

o

S

C

B

D

+

R

S

A

R

S

Fig. 28 — EconoMi$erIV Controller Potentiometer

and LED Locations

19

LED ON

mA

18

17

16

15

14

13

12

11

10

9

40

LED OFF

45

D

LED ON

C

LED OFF

50

60

55

LED ON

B

LED OFF

70

75

65

LED ON

A

LED OFF

100

90

95

85

80

DEGREES FAHRENHEIT

Fig. 29 — Outside Air Temperature

Changeover Set Points

IAQ

SENSOR

RETURN AIR

TEMPERATURE

OR ENTHALPY

SENSOR

Fig. 30 — Return Air Temperature or Enthalpy

Sensor Mounting Location

Outdoor Enthalpy Changeover

For enthalpy control, accessory enthalpy sensor (part num-

ber HH57AC078) is required. Replace the standard outdoor

dry bulb temperature sensor with the accessory enthalpy

sensor in the same mounting location. See Fig. 25. When the

outdoor air enthalpy rises above the outdoor enthalpy

changeover set point, the outdoor-air damper moves to its

minimum position. The outdoor enthalpy changeover set

point is set with the ou tdoor enthalpy set poi nt potentiometer on the EconoMi$er IV controller. The set points are A, B,

C, and D. See Fig. 31. The factory-installed 620-ohm jumper

must be in place across terminals SR and SR+ on the

EconoMi$erIV controller. See Fig. 25 and 32.

Differential Ent halpy Control

For differential enthalpy control, the EconoMi$er IV cont rolle r

uses two enthalpy sensors (HH57AC078 and

CRENTDIF004A00), one in the outside air and one in the

return airstream on the EconoMi$erIV frame. The

EconoMi$erIV controller compares t he outdoor air enthalp y to

the return air entha lpy to dete rmine Econo Mi$erIV use. The

controller s elects the lower enthal py air (return or outdoor)

—20—

Page 21

for cooling. For example, when the outdoor air has a lower

enthalpy than the return air and is below the set point, the

EconoMi$erIV opens to bring in outdoor air for free c ooling.

Replace the standard outside air dry bulb temperature sensor with the ac ces sory enth alpy senso r in t he same mou nting

location. See Fig. 25. Mount the return air enthalpy sensor

in the return airstream. See Fig. 30. The outdoor enthalpy

changeover set point is set with the outdoor enthalpy set

point potentiomete r on the EconoMi$erIV c ontroller. W hen

using this mode of changeover control, turn the enthalpy set

point potentiometer fully clockwise to the D setting.

NOTE: Remove 620-ohm resistor if differential enthalpy sensor is installed.

Indoor Air Quality (IAQ) Sensor Input

The IAQ input can be used for demand control ventilation

control based on the level of CO

measured in the space or

2

return air duct.

Mount the accessory IAQ sensor according to manufacturer

specifications. The IAQ sensor should be wired to the AQ and

AQ1 terminals of the controller. Adjust the DCV potentiometers to correspond to the DCV voltage output of the indoor air

quality sensor at the user-determined set point. See Fig. 33.

If a separate field-supplied transformer is used to power the

IAQ sensor, the sensor must not be grounded or the

EconoMi$erIV control board will be damaged.

Exhaust Set Point Adjustment

The exhaust set point will determine w hen the exhaust fan

runs based on dam p er position (if acce ssory power exha ust is

installed). The set point is modified with the Exhaust Fan

Set Point (EXH SET) potentiometer. See Fig. 28. The set

point represents the damper position above which the

exhaust fan will be turned on. When there is a call for

exhaust, the E con o Mi $er I V co ntro ller provides a 45 ± 15 sec ond delay before exhaust fan activation to allow the dampers

to open. This delay allows the damper to reach the appropriate position to avoid unnecessary fan overload.

Minimum Position C o ntrol

There is a minimum damper position potentiometer on the

EconoMi$erIV controller. See Fig. 28. The minimum damper

position maintains the minimum airflow into the building

during the occupied period.

When using demand ventilation, the minimum damper position represents the minimum ventilation position for VOC

(volatile organic compound) ventilation requirements. The

maximum demand ventilation position is used for fully occupied ventilation.

When demand ventilation control is not being used, the minimum position potentiometer should be used to set the occupied ventilation position. The maximum demand ventilation

position should be turned fully clock wi se.

Adjust the minimum position potentiometer to allow the

minimum amount of outdoor air, as required by local codes,

to enter the building. Make minimum position adjustments

with at least 10° F temperature difference between the outdoor and return-air temperatures.

CONTROL

CURVE

4

1

2

1

A

B

C

D

8

1

6

1

CONTROL POINT

APPROX. °F (°C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

LPY

HA

26

NT

E

4

2

2

2

0

2

40

(4)

35

(2)

—

85

(29)90(32)95(35)

46

4

4

42

40

IR

8

3

Y A

6

DR

3

D

N

U

4

3

PO

R

32

E

P

TU

30

B

28

60

(16)

55

(13)

B

50

C

(10)

45

D

(7)

70

(21)

0

0

1

65

(18)

A

80

(27)

75

(24)

0

9

80

70

0

6

50

0

4

TIVE HUM

RELA

0

3

100

(38)

IDITY (

20

105

110

(41)

(43)

)

%

0

1

B

C

D

35

40

45

50

55

60

65

70

75

(2)

(4)

(7)

(10)

(13)

(16)

(18)

(21)

APPROXIMATE DRY BULB TEMPERATURE— °F (°C)

(24)

80

(27)

Fig. 31 — Enthalpy Changeover Set Points

—21—

A

85

(29)90(32)95(35)

100

(38)

105

(41)

110

(43)

HIGH LIMIT

CURVE

Page 22

TR1

N1

P1

T1

AQ1

SO+

SR+

EXH

2V 10V

EXH

Open

2V 10V

DCV

2V 10V

Free

Cool

B

A

Min

Pos

DCV

Max

DCV

C

D

Set

Set

N

P

T

AQ

SO

SR

TR

24

24 Vac

Vac

COM

HOT

_

+

12

5

4

3

EF1

EF

Fig. 32 — EconoMi$erIV Controller

CO SENSOR MAX RANGE SETTING

2

6000

5000

4000

3000

2000

1000

RANGE CONFIGURATION (ppm)

0

2345678

DAMPER VOLTAGE FOR MAX VENTILATION RATE

800 ppm

900 ppm

1000 ppm

1100 ppm

Fig. 33 — CO2 Sensor Maximum Range Setting

To determine the minimum position setting, perform the

following proced ur e :

1. Calculate the appropriate mixed-air temperature

using the following formula:

(T

T

OA

x

O

= Outdoor-Air Temperature

O

)+ (TR x

100 100

RA

) = T

M

OA = Percent of Outdoor Air

T

= Return-Air Temperature

R

RA = Percent of Return Air

= Mixed-Air Temperature

T

M

As an example, if local codes require 10% outdoor air

during occupied conditions, outdoor-air temperature

is 60 F, and return-air temperature is 75 F.

(60 x .10) + (75 x .90) = 73.5 F

2. Disconnect the supply-air sensor from terminals T and

T1.

3. Ensure that the factory-installed jumper is i n place

across terminals P and P1. If remote damper positioning is being used, make sure that the terminals

are wired accor din g to Fig. 27 and that t he mi nimu m

position potentiometer is turned fully clockwise.

4. Connect 24 vac across terminals TR and TR1.

5. Carefully adjust the minimum position potentiometer

until the measured mixed-air temperature matches

the calculated value.

6. Reconnect the supply air sensor to terminals T and T1.

Remote control of the EconoMi$erIV damper is desirable when

requiring additional temporary ventilation. If a field-supplied

remote potentiometer (H oneywel l part num ber S963B1 128) is

wired to the EconoMi$ erIV controller, the minimum position

of the damper can be controlled from a remote location.

To control the minimum damper position remotely, remove

the factory-install ed jumper on the P and P1 terminals on

the EconoMi$erIV controller. Wire the field-supplied potentiometer to the P and P1 terminal s on the EconoMi $erIV controller. See Fig. 30.

Damper Movement

Damper movement from full open to full closed (or vice

versa) takes 21/2 minutes.

Thermostats

The EconoMi$erIV control works with conventional thermo-

stats that have a Y1 (cool stage 1), Y2 (cool stage 2), W1

(heat stage 1), W2 (heat stage 2), and G (fan). The

EconoMi$erIV control does not support space temperature

sensors. Connections are made at the thermostat terminal

connection board located in the main control box.

Occupancy Control

The factory default configuration for the EconoMi$erIV con-

trol is occupied mode. Occupied status is provided by the red

jumper from terminal TB2-9 to terminal TB2-10. When

unoccupied mode is desired, install a field-supplied timeclock

function in place of the jumper between terminals TB2-9 and

TB2-10. See Fig. 27. Whe n t he tim e clock c ont ac ts ar e cl os ed,

the EconoMi$erIV control will be in occupied mode. When

the timeclock contacts are open (removing the 24-v signal

from terminal N), the Econo Mi$erIV will be in unoccupied

mode.

Demand Controlled V enti lation (DCV)

When using the EconoMi$erIV for demand controlled venti-

lation, there are some equipment selection criteria which

should be considered. When selecting the heat capacity and

cool capacity of the equipment, the maximum ventilation

rate must be evaluated for design conditio ns. The maximum

damper position must be calculated to provide the desired

fresh air.

Typically the maximum ventilation rate will be ab out 5 to

10% more than the typical cfm required per person, using

normal outside air design criteria.

A proportional anticipatory strategy should be taken with

the following conditions: a zone with a large area, varied

occupancy, and equipment that cannot exceed the requ ired

ventilation rate at design con dition s. Exceeding th e requ ired

ventilation rate means the equipment can co ndition air a t a

maximum ventilation rate that is gre ater than the requ ired

ventilation rate for maximum occupancy. A proportionalanticipatory strategy will cause the fresh air supplied to

increase as the room CO

set point has not been reached. By the time the CO

CO

2

level increases even though the

2

level reaches the set point, the damper will be at maximum

ventilation and should maintain the set point.

In order to have the CO

sensor control the economizer damper

2

in this manner, first determine the damper voltage output for

minimum or base ventilation. Base ve ntilation is t he ventilation required to remove contaminants during unoccupied

periods. The following equation may be used to determine the

2

—22—

Page 23

percent of outside-air entering the building for a given damper

position. For best results there should be a t least a 10 degre e

difference in outside and return-air temperatures.

OA

(TO x

T

= Outdoor-Air Temperature

O

)+ (TR x

100 100

RA

) = T

M

OA = Percent of Outdoor Air

TR = Return-Air Temperature

RA = Percent of Return Air

TM = Mixed-Air Temperature

Once base ventilation has been determined, set the mini-

mum damper position potentiometer to the correct position.

The same equation can be used to determine the occupied or

maximum ventilation rate to the building. For example, an

output of 3.6 volts t o the ac tuat o r pro vide s a ba se ve ntil at io n

rate of 5% and an output of 6.7 volts provides the maximum

ventilation rate of 20% (or bas e plu s 15 cfm pe r pers on). Use

Fig. 33 to determine the maximum setting of the CO2 sensor.

For example, a 1100 ppm set point relates to a 15 cfm per

person design. Use the 1100 ppm curve on Fig. 33 to find the

point when the CO

sensor output will be 6.7 volts. Line up

2

the point on the graph with the left side of the chart to determine that the range configuration for the CO

sensor sho uld

2

be 1800 ppm. T he EconoMi$erIV control ler will output the

6.7 volts fro m the CO

sensor to the actuator when the CO

2

concentration in the spac e is a t 1100 ppm . The D CV set point

may be left at 2 volts since the CO

sensor voltage wi ll be

2

ignored by the Econo Mi$erIV controller until it rises above

the 3.6 volt setting of the minimum position potentiometer.

Once the fully occupied damper position has been determined, set the maximu m da mpe r de ma nd con t ro l ve nt il atio n

potentiometer to this position. Do not set to the maximum

position as this can result in over-ventilation to the space

and potential high-humidity levels.

CO

Sensor Configurati on

2

The CO2 sensor has preset standard voltage settings that

can be selected anytime afte r the sensor is powere d up. See

Table 12 .

Use setting 1 or 2 for Bryant equipment. See Table 12.

1. Press Clear and Mode buttons. Hold at least 5 seconds until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to select the preset number.

See Table 12.

4. Press Enter to lock in the selection.

5. Press Mode to exit and resume normal operation.

The custom settings of the CO

sensor can be changed any-

2

time after the s ensor is energiz ed. Follow the s teps belo w to

change the non-standard settings:

1. Press Clear and Mode buttons. Hold at least 5 seconds until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to toggle to the NONSTD

menu and press Enter.

4. Use the Up/Down button to toggle through each of

the nine variables, starting with Altitude, until the

desired setting is reached.

5. Press Mode to move through the variables.

6. Press Enter to lock in the selection, then press Mode

to continue to the next variable.

Dehumidification of Fresh Air with DCV Control

2

Information from ASHRAE indicates that the largest humidity load on any zone is the fresh air introduced. For some

applications, a field-supplied energy recovery unit can be

added to reduce the moisture content of the fresh air being

brought into the building when the enthalpy is high. In most

cases, the normal heating and cooling processes are more

than adequate to remove the humidity loads for most commercial applications.

If normal roof top heating and cooling operation is not adequate for the outdoor humidity level, an energy recovery unit

and/or a dehumidification option should be considered.

Tab l e 1 2 — CO

SETTING EQUIPMENT OUTPUT

1

Interface w/Standard

2 Proportional Any

Building Control System

3 Exponential Any

4

5 Proportional 20

Economizer

6 Exponential 15

7 Exponential 20

8 Health & Safety Proportional —

Parking/Air Intakes/

9

Loading Docks

LEGEND

ppm — Parts Per Million

Proportional Any

Proportional 15

Proportional —

Sensor Standard Settings

2

VENTILATION

RATE

(cfm/Person)

ANALOG

OUTPUT

0-10V

4-20 mA

2-10V

7-20 mA

0-10V

4-20 mA

0-10V

4-20 mA

0-10V

4-20 mA

0-10V

4-20 mA

0-10V

4-20 mA

0-10V

4-20 mA

0-10V

4-20 mA

—23—

CO

CONTROL RANGE

2

(ppm)

0-2000 1000 50

0-2000 1000 50

0-2000 1100 50

0-1100 1100 50

0- 900 900 50

0-1100 1100 50

0- 900 900 50

0-9999 5000 500

0-2000 700 50

OPTIONAL

RELAY SETPOINT

(ppm)

RELAY

HYSTERESIS

(ppm)

Page 24

XIV. STEP 14 — INSTALL HUMIDISTAT FOR OPTIONAL

PERFECT HUMIDITY™ DEHUMIDIFICATION PACKAGE

Perfect Humidity dehumidification package operation can be

controlled by field installation of a Bryant-approved

humidistat. To install the humidistat perform the following

procedure:

1. Locate humidistat on a solid interior wall in the

conditioned space. Location should be in a well ventilated area to sense aver age humidity.

2. Route thermostat cable or equivalent single leads of

colored wire from humidistat terminals through conduit in unit to the low voltage connection on the

2-pole terminal strip (TB3) as shown in Fig. 34 and

Fig. 35. See Fig. 36 for operation diagram.

Fig. 35 — Typical Perfect Humidity

Dehumidification Package Control Box

LEGEND

CB — Circuit Breaker

LLSV — Liquid Line Solenoid Valve

LPS — Low-Pressure Switch

TB — Terminal Block

TRAN — Transformer

Fig. 34 — Typical Wiring Perfect Humidity Dehumidification Package Humidistat (460 V Unit Shown)

—24—

Page 25

Fig. 36 — Perfect Humidity™ Dehumidification Package Operation Diagram (Single Circuit Shown)

—25—

Page 26

START-UP

Use the following information and Start-Up Checklist on

page CL-1 to check out unit PRIOR to start-up.

I. UNIT PREPARATION

Check that unit has been installed in accordance with these

installation instructions and all applicable codes.

II. COMPRESSOR MOUNTING

Compressors are internally spring mounted. Do not loosen or

remove compressor holddown bolts.

III. GAS PIPING

Check gas piping for leaks.

WARNING: Disconnect gas piping from unit when

leak testing at pressure greater than

1

sures greater than

/2 psig will cause gas valve damage

1

/2 psig. Pres-

resulting in hazardous condition. If gas valve is subjected to pressure greater than

1

/2 psig, it must be

replaced before use. When pressure testing fieldsupplied gas piping at pressures of

1

/2 psig or less, a

unit connected to such piping must be isolated by manually closing the gas valve .

IV. REFRIGERANT SERVICE PORTS

Each refrigerant system has a total of 3 Schrader-type

service gage ports. One port is lo cated on the suction line,

one on the compre ssor discha rge line, and one on the liqui d

line. In addition, Schrader-type valves are located underneath the low-pressure switches. Be sure that caps on the

ports are tight.

V. COMPRESSOR ROTATION

It is important to be c ertain the c ompressors are rotating in

the proper direction. To determine whether or not co mpressors are rotating in the proper direction:

1. Connect service gages to suct ion and discharge pressure fittings.

2. Energize the compressor .

3. The suction pr essure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pressure does not rise to normal levels:

1. Note that the evaporator fan is probably also rotating

in the wrong direction.

2. Turn off power to the unit.

3. Reverse any two of the in coming power leads.

4. Turn on power to the compressor.

The suction and discharge pressure levels should now move

to their normal start-up levels.

NOTE: When compre ssors are rotatin g in the wrong direction, the unit will have increased noise levels and will not

provide heating and cooling.

After a few minutes o f re vers e o per ation , th e s cro ll co m pressor internal overload protection will open, which will

activate the unit’s lockout and requires a manual reset.

Reset is accomplished by turning the thermostat on and off.

VI. INTERNAL WIRING

Check all electrical conne c tion s in unit c o ntrol b oxe s; tig hte n

as required.

VII. CRANKCASE HEATER

Crankcase heater(s) is energized as long as there is power to

the unit and the compressor is not operating.

IMPORTANT: Unit power must be on for 24 hours prior to

start-up. Otherwise, damage to compressor may result.

VIII. EVAPORATOR FAN

Fan belt and variable pulleys are factory-installed. See

Tables 13-20 for fan performance data. Be sure that fans

rotate in the proper direction. See Table 21 for air quantity

limits. See Table 22 for static pressure information for accessories and options. See Table 23 for fan rpm at various motor

pulley settings. See Tables 24 and 25 for evaporator fan

motor data. To alter fan performance, see Evaporator Fan

Performance Adjustment section on page 35.

NOTE: A 3

1

/2-in. bolt and threaded plate are included in the

installer’s packet. They can be added to the motor support

channel below the motor mounting plate to aid in raising the

fan motor.

IX. CONDENSER-FANS AND MOTORS

Condenser fans and motors are factory set. Refer to

Condenser-Fan Adjustment section on page 36 as required.

Be sure that fans rotate in the proper direction.

X. RETURN-AIR FILTERS