Bryant 575Jx08G/H Series Installation, Start-up And Service Instructions Manual

575J*08G/H

HEAT PUMP CONDENSING UNITS, 60 Hz,

SINGLE CIRCUIT, 2--STAGE WITH DIGITAL SCROLL COMPRESSOR

AND PURON

R

(R--410A) REFRIGERANT -- SIZE 08

Installation, Start--Up and

Service Instructions

CONTENTS

SAFETY CONSIDERATIONS 2....................

Rated Indoor Airflow (cfm) 3.....................

INSTALLATION 5 -- 14...........................

Jobsite Survey 5................................

Step 1 -- Plan for Unit Location 5..................

Step 2 -- Complete Pre--Installation Checks 6.........

Step3–PrepareUnitMounting Support 6...........

Step 4 -- Rig and Mount the Unit 6.................

Step 5 -- Complete Refrigerant Piping Connections 6...

Step 6 -- Install Accessories 9.....................

Step 7 -- Complete Electrical Connections 9..........

Step 8 -- Wind Baffles for Low Ambient Control 14...

PRE-START-UP 15...............................

System Checks 15..............................

Turn On Crankcase Heaters 15....................

Preliminary Charge 15...........................

START--UP 15 -- 18..............................

575J--08G/H Units 15............................

SERVICE 21 - 32................................

Refrigeration System 21.........................

Compressor Oil 21..............................

Servicing Systems on Roofs

with Synthetic Materials 21.......................

Liquid Line Filter Driers 21.......................

Filed Refrigerant Access Ports 21..................

Outdoor Coil Metering Devices 21.................

Refrigerant System Pressure Access Ports 22.........

Compressor Protection 22........................

Crankcase Heater 22............................

Commercial Defrost Board 22.....................

Comfort Alert Diagnostic Module 28...............

Lubrication 30.................................

Outdoor Coil Maintenance and

Cleaning Recommendations 30....................

Service Parts 32................................

Fastener Torque Values 32........................

TROUBLESHOOTING 33.........................

OPERATING SEQUENCE 19......................

Indoor (Supply) Fan 19..........................

Cooling Unit Without Economizer 19...............

Cooling Unit With Economizer 19.................

Heating 19....................................

Defrost Cycle 19...............................

Supplemental Heating/Emergency Heating 20........

Cooling and Heating Shutdown 20.................

ROUTINE SYSTEM MAINTENANCE 20............

Quarterly Inspection

(and 30 days after initial start) 20..................

APPENDIX A

R

Air Conditioner and Heat Pump with Puron

Quick Reference Guide 34........................

APPENDIX B

Wiring Diagram List 34..........................

APPENDIX C

Low Ambient Option — Factory Installed 34.........

START--UP CHECKLIST 39 -- 40...................

–

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for

information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual

instructions package

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloths for brazing operations and

have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions attached to

the unit. Consult local building codes and appropriate

national electrical codes (in USA, ANSI/NFPA70,

National Electrical Code (NEC); in Canada, CSA C22.1)

for special requirements.

It is important to recognize safety information. This is the

575J*08G/H

safety--alert symbol

unit and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety-alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or

death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify

unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

. When you see this symbol on the

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, turn off main power switch to unit and install

lock(s) and lockout tag(s). Ensure electrical service to

rooftop unit agrees with voltage and amperage listed

on the unit rating plate. Unit may have more than one

power switch.

!

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

R

Puron

higher pressures than standard R--22 systems. Do not

use R--22 service equipment or components on Puron

refrigerant equipment.

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could cause personal

injury or death.

Relieve pressure and recover all refrigerant before

system repair or final unit disposal.

Wear safety glasses and gloves when handling

refrigerants. Keep torches and other ignitions sources

away from refrigerants and oils.

(R--410A) refrigerant systems operate at

!

WARNING

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts and servicing

575J units.

2

Rated Indoor Airflow (cfm)

The table to the right lists the rated indoor airflow used

for the AHRI efficiency rating for the units covered in this

document.

Model Number Full Load Airflow (cfm)

575J*08G/H --- 524J*08H 2625

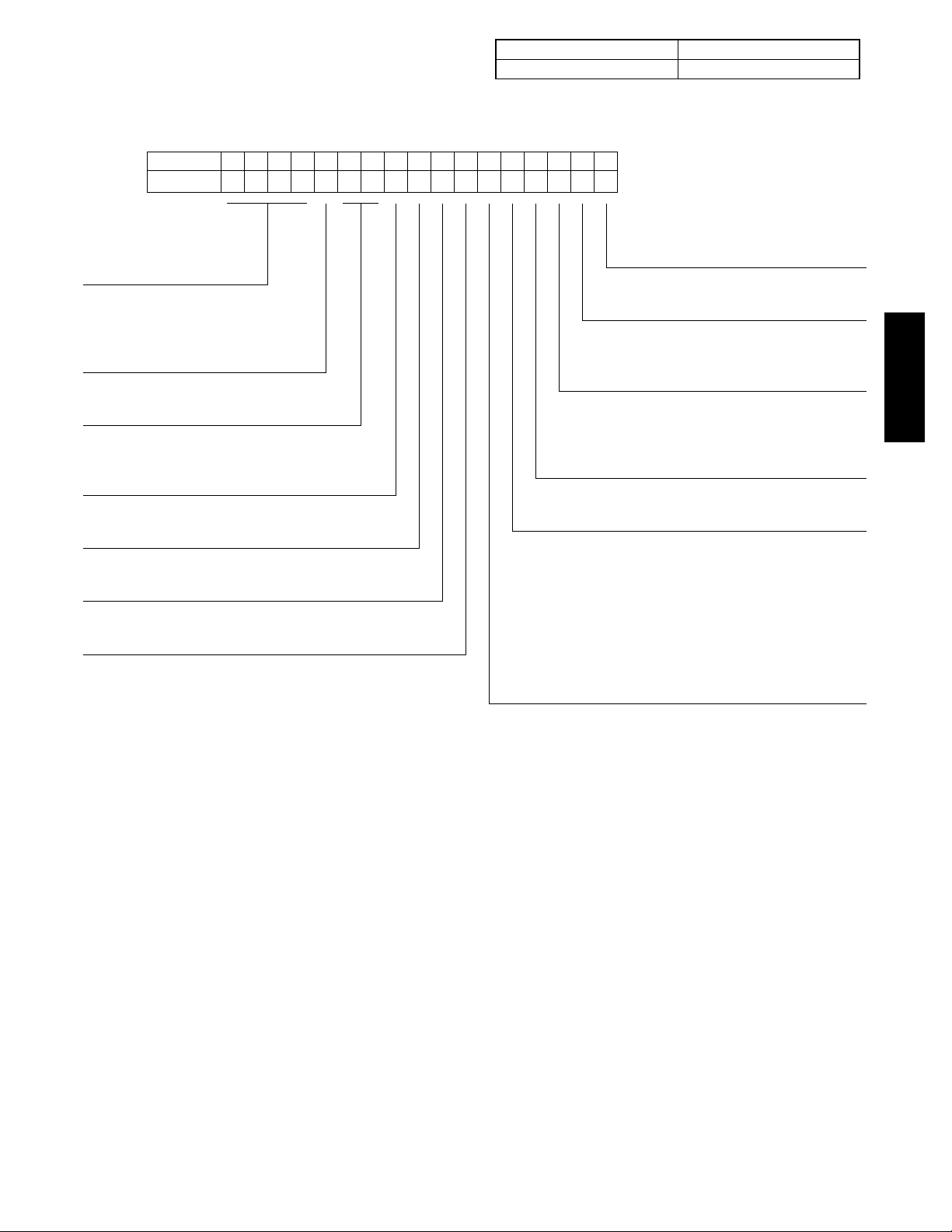

Position

Example

Model Type

575J = Bryant Heat Pump

Condensing Unit with

®

R–410A Refrigerant

Puron

Voltage

E = 460/3/60

P = 208/ 230/3/60

T = 575/3/60

Nominal Tonnage

08 = 7.5 Tons

Refrigerant Circuit

G = Single Circuit, Dual Stage

H = Single Circuit, Dual Stage w/ Low Ambient Controller

Factory Assigned

0 = Not Used

Factory Assigned

0 = Not Used

Factory Assigned

0 = Not Used

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

575JE08G000A00A0A

Fig. 1 -- Model Number Nomenclature

Packaging

A = Standard

B = LTL

Base Unit Controls

0 = Electro-Mechanical Controls

Electrical Options

A = None

C = Non-Fused Disconnect

Service Options

0 = None

1 = Unpowered Convenience Outlet

2 = Powered Convenience Outlet

Not Used

0 = Not Used

Coil Options (RTPF)

A = Cu/Al

B = Precoat (Cu/Al)

C = E-Coat (Cu/Al)

E = Cu/Cu

M = Cu/Al with Louvered Hail Guard

N = Precoat (Cu/Al) with Louvered Hail Guard

P = E-Coat (Cu/Al) with Louvered Hail Guard

R = Cu/Cu with Louvered Hail Guard

575J*08G/H

C14309

3

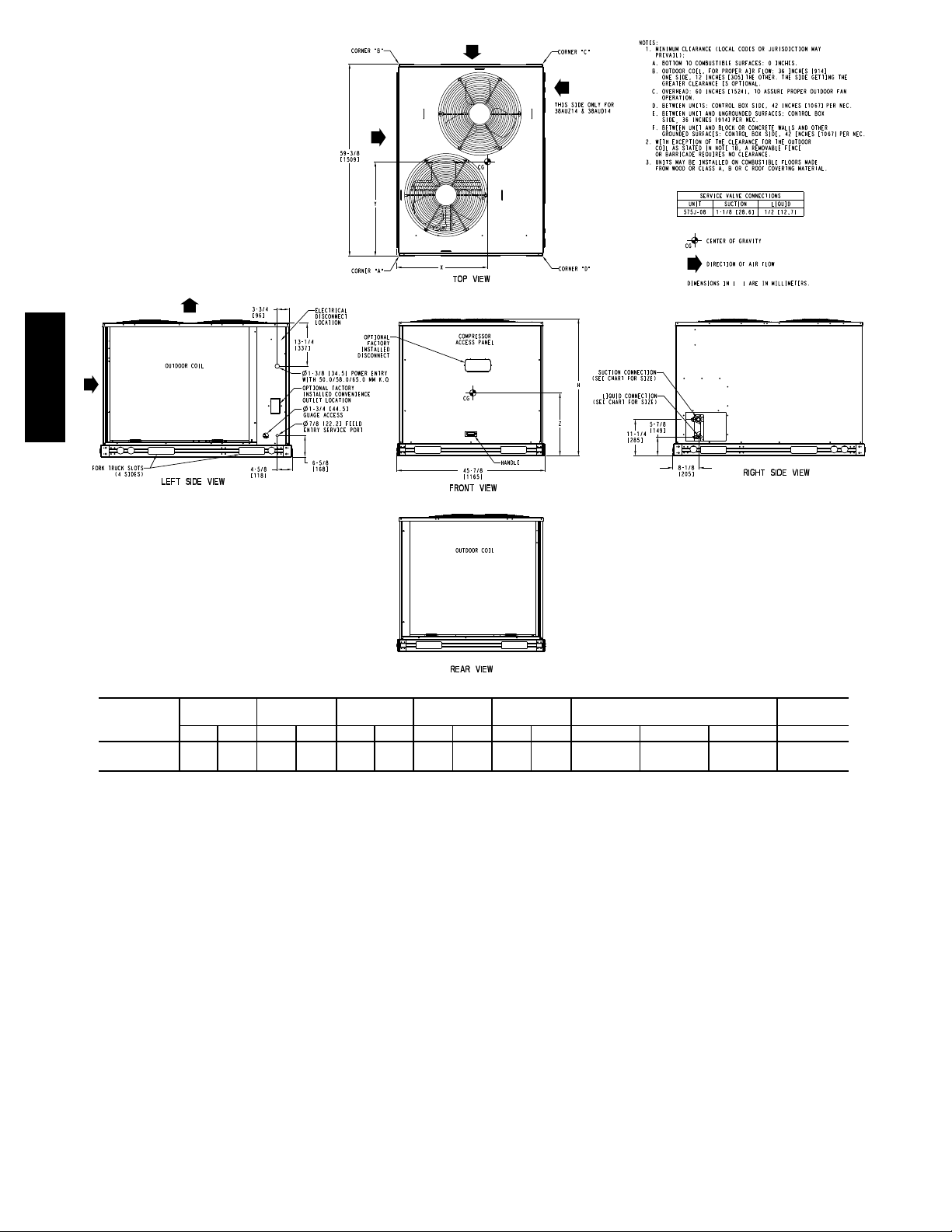

575J*08G/H

UNIT

575J*08G/H

Standard

Weight

Corner

A

Corner

B

Corner

C

Corner

D

Center of Gravity

Unit Height

lbs. kg. lbs. kg. lbs. kg. lbs. kg. lbs. kg. X Y Z H

470 213 156 71 106 48 86 39 120 54

21

[533]

24

[610]

23

[584]

50-3/8

[1280]

Fig. 2 -- 575J*08G/H Unit Dimensions

C14310

4

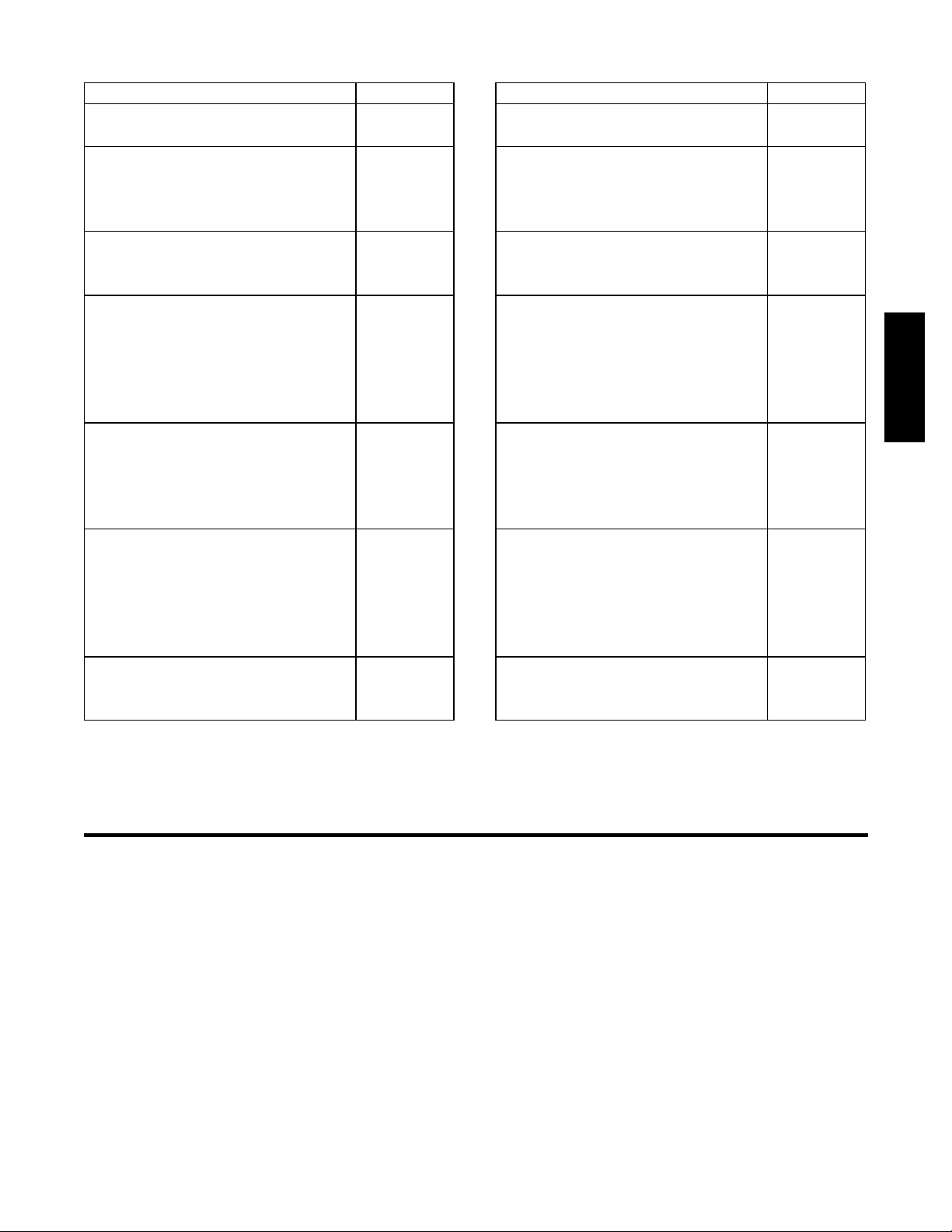

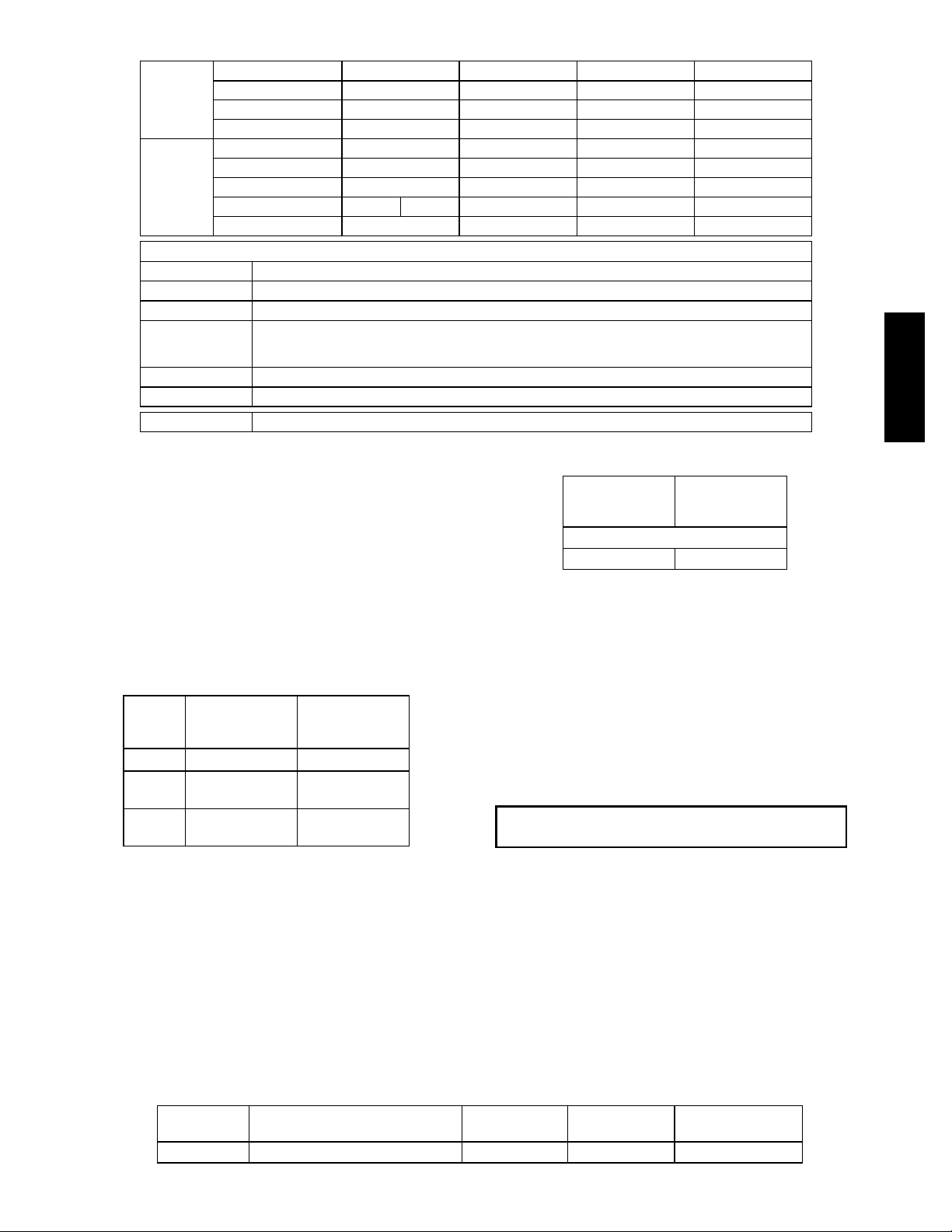

Table 1 – Physical Data

575J*08G/H — 60 Hz English

Table 2 – Physical Data

575J*08G/H — 60 Hz SI

NOMINAL CAPACITY (tons) 7.5

OPERATING WEIGHTS (lb)

Round Tube/Plate Fin Coil (Cu/Al) 470

REFRIGERANT TYPE

RTPF Operating Charge, Typical (lb)

RTPF Shipping Charge (lb) 9.0

Metering Device Acutrol

COMPRESSOR

Qty...Type 1...Digital Scroll

Oil Charge (oz) 60

CONDENSER FANS

Qty...Rpm 2...1100

Motor Hp

Diameter 22

Nominal Airflow (Cfm Total) 6000

Watts (Total) 610

RTPF CONDENSER COIL

Material (Tube/Fin) Cu / Al

Coil Type RTPF

Rows/Fins per inch (FPI) 2/17

Face Area (sq ft total) 23.0

CONTROLS

Pressurestat Settings (psig)

High Cutout 630 10

Cut-in 505 20

Low Cutout 27 3

Cut-in 44 5

PIPING CONNECTIONS (in. ODS)

Qty...Suction 1...11/

Qty...Liquid 1...1/

LEGEND

RTPF — Round Tube/Plate Fin

ODS — Outside Diameter Sweat (socket)

‡

Unit is factory-supplied with par tial charge only.

†

Typical operating charge with 25 ft of interconnecting piping.

‡

†

R-410A

24.0

1

/

4

NOMINAL CAPACITY (kW) 26.4

OPERATING WEIGHTS (lb)

Round Tube/Plate Fin Coil (Cu/Al) 213

REFRIGERANT TYPE

RTPF Operating Charge, Typical (kg)

RTPF Shipping Charge (kg) 4.1

Metering Device Acutrol

COMPRESSOR

Qty...Type 1...Digital Scroll

Oil Charge (liters) 1.8

CONDENSER FANS

Qty...r/s 2...18

Motor Hp NEMA

Diameter (mm) 560

Nominal Airflow (L/s) 2832

Watts (Total) 610

RTPF CONDENSER COIL

Material (Tube/Fin) Cu / Al

Coil Type RTPF

Rows/Fins per Meter (Fins/m) 2 / 670

Face Area (sq m total) 2.1

CONTROLS

Pressurestat Settings (kPa)

High Cutout 4347 70

Cut-in 3482 138

Low Cutout 186 21

Cut-in 303 35

PIPING CONNECTIONS (in. ODS)

8

2

Qty...Suction 1...11/

Qty...Liquid 1...1/

LEGEND

RTPF — Round Tube/Plate Fin

NEMA — National Electrical Manufacturers Association

ODS — Outside Diameter Sweat (socket)

‡

Unit is factory-supplied with par tial charge only.

†

Typical operating charge with 25 ft of interconnecting piping.

‡

†

R-410A

10.9

1

/

4

575J*08G/H

8

2

.INSTALLATION

Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes and the NEC (National

Electrical Code) ANSI/NFPA 70 for special installation requirements.

2. Determine unit location (from project plans) or select

unit location.

3. Check for possible overhead obstructions which may

interfere with unit lifting or rigging.

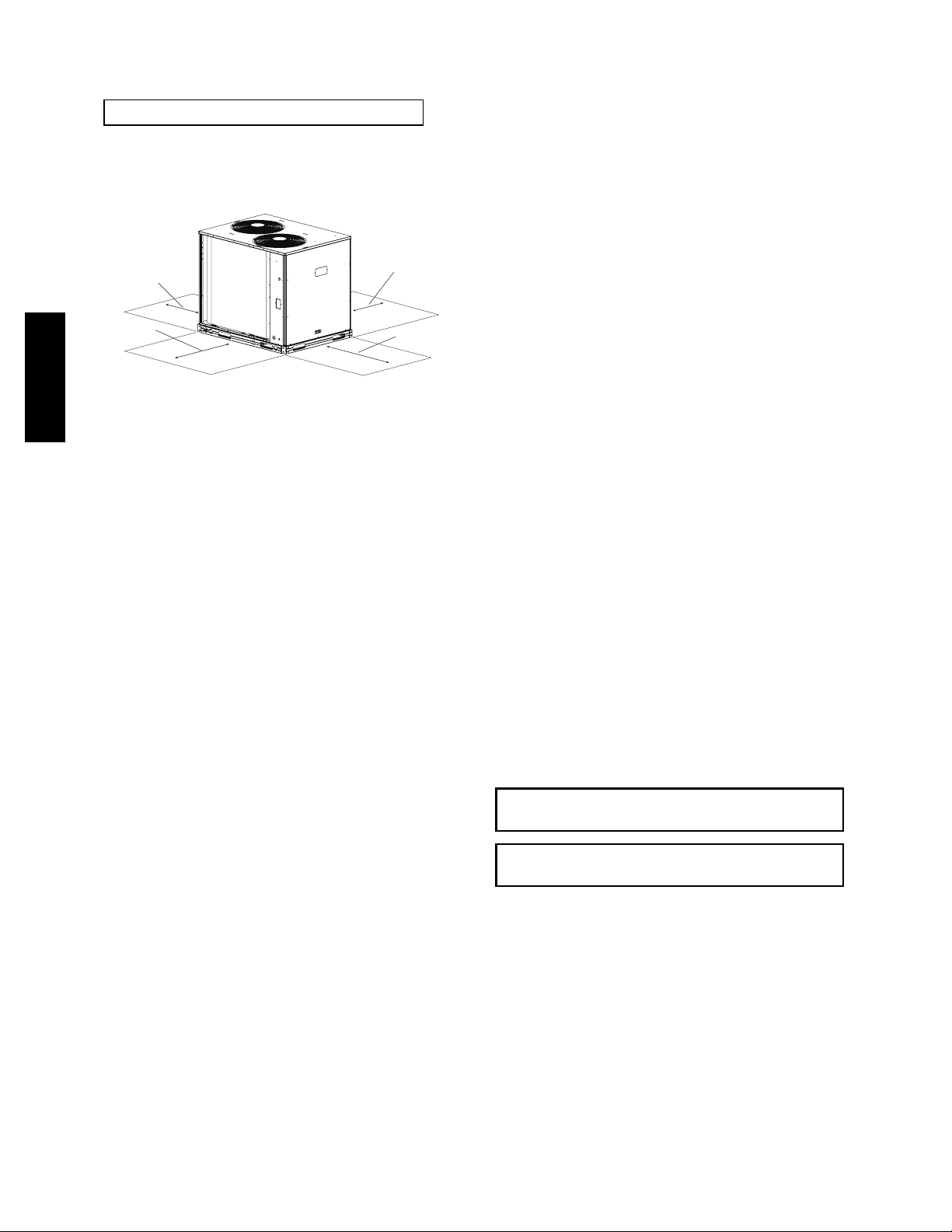

Step 1 — Plan for Unit Location

Select a location for the unit and its support system (pad,

rails or other) that provides for the minimum clearances

required for safety. This includes the clearance to

combustible surfaces, unit performance and service access

below, around and above unit as specified in unit

drawings. See Fig. 3.

Select a unit mounting system that provides adequate

height to allow for removal and disposal of frost and ice

that will form during the heating-defrost mode.

NOTE: Consider also the effect of adjacent units on

airflow performance and control box safety clearance.

Do not install the outdoor unit in an area where fresh air

supply to the outdoor coil may be restricted or when

recirculation from the condenser fan discharge is possible.

Do not locate the unit in a well or next to high walls.

Evaluate the path and required line length for

interconnecting refrigeration piping, including vapor riser

requirements and liquid line lift; a heat pump system will

5

have one of each type in opposite modes. Relocate

sections to minimize the length of interconnecting tubing.

Step 3 — Prepare Unit Mounting Support

Slab Mount —

DO NOT BURY REFRIGERATION LINES.

Although unit is weatherproof, avoid locations that permit

water from higher level runoff and overhangs to fall onto

the unit.

RIGHT:

REAR:

Min 18” (457 mm)

requried for service

LEFT:

Min 18” (457 mm)

requried for service

Note: Observe requirements for 39” (914 mm) operating clearance

on either Left or Rear coil opening.

Min 18” (457 mm)

requried for service

575J*08G/H

Fig. 3 -- Service Clearance Dimensional Drawing

Step 2 — Complete Pre-Installation Checks

Check Unit Electric Characteristic —

Confirm before installation of unit that voltage, amperage

and circuit protection requirements listed on unit data

plate agree with power supply provided.

Un--crate Unit —

Remove unit packaging except for the top skid assembly,

which should be left in place until after the unit is rigged

into its final location.

Inspect Shipment —

File a claim with shipping company if the shipment is

damaged or incomplete.

Consider System Requirements —

FRONT:

42” (1067 mm)

C11035

Provide a level concrete slab that extends a minimum of 6

in. (150 mm) beyond unit cabinet. Install a gravel apron in

front of condenser coil air inlet to prevent grass and

foliage from obstructing airflow.

Step 4 — Rig and Mount the Unit

Rigging —

These units are designed for overhead rigging. Refer to

the rigging label for preferred rigging method. Spreader

bars are required. Use the wooden top skid, when rigging,

to prevent rigging straps from damaging the unit. All

panels must be in place when rigging. As further

protection for coil faces, plywood sheets may be placed

against the sides of the unit, behind cables. Run cables to

a central suspension point so that the angle from the

horizontal is not less than 45 degrees. Raise and set the

unit down carefully.

If it is necessary to roll the unit into position, mount the

unit on longitudinal rails, using a minimum of 3 rollers.

Apply force to the rails, not the unit. If the unit is to be

skidded into position, place it on a large pad and drag it

by the pad. Do not apply any force to the unit.

Raise from above to lift the unit from the rails or pad

when unit is in its final position.

After the unit is in position, remove all shipping materials

and top crating.

Step 5 — Complete Refrigerant Piping

Connections

Refrigerant lines must be carefully designed and

constructed to ensure equipment reliability and efficiency.

Line length, pressure drop, compressor oil return, and

vertical separation are several of the design criteria that

must be evaluated. See Table 3.

S Consult local building codes and National Electrical

Code (NEC, U.S.A.) for special installation

requirements.

S Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit. See Fig. 2 for unit

dimensions and weight distribution data.

S Locate the unit so that the outdoor coil (condenser)

airflow is unrestricted on all sides and above.

S The unit may be mounted on a level pad directly on the

base channels or mounted on raised pads at support

points. See Tables 1 and 2 for unit operating weights.

See Fig. 2 for weight distribution based on

recommended support points.

NOTE: If vibration isolators are required for a particular

installation, use the data in Fig. 2 to make the proper

selection.

IMPORTANT: Do not bury refrigerant piping

underground.

IMPORTANT: A refrigerant receiver is not

provided with the unit. Do not install a receiver.

Check Vertical Separation —

If there is any vertical separation between the indoor and

outdoor units, check to ensure that the separation is within

allowable limits. Relocate equipment if necessary.

Provide Safety Relief —

If local codes dictate an additional safety relief device,

purchase locally and install locally. Installation will

require the recovery of the factory shipping charge before

the factory tubing can be cut and the supplemental relief

device is installed.

6

Table 3 – 575J*08G/H Piping Recommendations

Model &

Nominal

capacity

Legend:

Linear Line Linear tubing length, feet

Equivalent Line Equivalent tubing length, including effects of refrigeration specialties devices

Liquid Line size Tubing size, inches OD.

Max Lift

Vapor Line size Tube size, inches OD

Charge Charge Quantity, lbs.

NOTE: For applications with linear length greater than 100 ft (30.5 m), contact your local Bryant representative.

Linear Line (ft) 0 --- 2 5 25 --- 50 50--- 75 75--- 100

Linear Line (m) 0 --- 8 8 --- 1 5 8 --- 15 15 --- 23

Equiv. Line (ft) 0 --- 3 8 38 --- 75 75 --- 113 113--- 150

Equiv. Line (m) 0 --- 12 12 --- 23 12 --- 23 23 --- 34

Liquid Line size

Max Lift Cool 25 50 75 100

Max Lift Heat 25 50 50 60

Vapor Line size

575J*08G/H

Charge (lbs) 23.9 26.0 27.9 29.8

Cool

Heat

Maximum liquid lift at maximum permitted pressure drop

S Indoor unit ABOVE outdoor unit

S Indoor unit BELOW outdoor unit

1

/2”

7

/8” 11/8” 11/8” 11/8” 11/8”

1

/2”

1

/2”

1

/2”

575J*08G/H

Refrigerant Line Sizing —

Consider the length of the piping required between the

outdoor and indoor units. The maximum allowable line

length is 100 ft (30.5 m). See Table 3. Refrigerant vapor

piping should be insulated.

Risers in Heat Pump Piping Systems —

Elevation differences between the outdoor unit and the

indoor unit in heat pump systems will create two riser line

conditions – one in the liquid line in one mode and one in

the vapor line in the opposite mode. See the following

table to identify which lines are risers in this installation.

575J Unit

Mode

Cooling Liquid

Heating

BELOW

ID Unit

Riser in Riser in

Vapor

(Discharge Gas)

575J Unit

ABOVE

ID Unit

Vapor

(Suction Gas)

Liquid

Liquid Line Riser: Refer to Pipe Sizing Table, Table 3;

observe Max Lift limits for liquid line according to unit

mode, equivalent line length and pipe size.

VaporLineRiser:Refer to Table 4 for maximum pipe

size in single pipe vapor risers. All pipe size

recommendations in Pipe Sizing Table, Table 3, satisfy

these maximum vapor line sizes. If this installation is

re--using existing piping, check the vapor line sizes

against these maximum values; replace riser sections with

these pipe sizes if necessary.

Table 4 – Maximum Vapor Line Sizes

575J Unit

BELOW

ID Unit

Max Diameter, Single Pipe (in.)

1-3/

8

575J Unit

ABOVE

ID Unit

1-5/

8

Install Filter Drier and Moisture Indicator —

Every unit MUST have a bi-directional filter drier in the

liquid line. Locate the filter drier(s) at the indoor unit, close

to the indoor coil’s thermal expansion valve (TXV) inlets.

575J units include one Puron-duty filter drier, shipped in

cartons attached to the unit basepan. Remove the filter

drier and prepare to install in the liquid line at the indoor

coil. Do not remove connection fitting plugs until ready to

connect and braze the filter drier into the liquid line

position. See Table 5.

IMPORTANT: A refrigerant receiver is not

provided with the unit. Do not install a receiver.

Installation of liquid line moisture indicating sightglass is

recommended. Locate the sightglass(es) between the

outlet of the filter drier and the TXV inlet.

Refer to Table 5 for recommendations on refrigeration

specialties.

Select the filter drier for maximum unit capacity and

minimum pressure drop. Complete the refrigerant piping

from the indoor unit to the outdoor unit before opening

the liquid and vapor service valves at the outdoor unit.

LIQUID LINE

SIZE (in.)

1

/

2

Table 5 – Refrigerant Specialties Part Numbers

LIQUID LINE

SOLENOID VALVE (LLSV)

EF680035 plus EF680039 biflow kit EF680037 KM680004 KH43LG089

SOLENOID

COIL

7

SIGHT

GLASS

FILTER

DRIER

Install Liquid Line Solenoid Valves —

A

It is recommended that a bi-directional solenoid valve be

placed in the main liquid line (see Fig. 4) between the

outdoor unit and the indoor coil. Locate the solenoid valve

at the end of the liquid line, near the outdoor unit

connections, with flow direction arrow pointed at the

outdoor unit. Refer to Table 5. (A liquid line solenoid

valve is required when the liquid line length exceeds 75 ft

[23 m].) This valve prevents refrigerant migration (which

causes oil dilution) to the compressor during the off cycle,

at low outdoor ambient temperatures. Wire the solenoid

according to the unit label diagram.

!

CAUTION

1

The stub tube connections include

/4-in SAE service fittings

with Schrader valve cores (see Fig. 5). Before making any

brazed connections to the unit service valves, remove both

Schrader valve caps and cores and save for re-installation.

Connect a source for nitrogen to one of these service fittings

during tube brazing to prevent the formation of copper

oxides inside the tubes at brazed joints.

Field Service

Factory

High-Flow

ccess Port

Access Port

(Schrader core)

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Failure to use a solenoid valve relay (SVR) PNO

HN61PC005 may cause overload of Comfort Alert

575J*08G/H

Diagnostic Module (CADM) and compressor alarm

lock out.

CAPACITY CONTROL LIQUID LINE SOLENOID

VALVE -- 575J units are single--stage only designs. DO

NOT USE a capacity control liquid line solenoid valve on

the indoor coil.

8 DIAMS

MIN

EQUALIZER LINE

SIGHT GLASS

A LOCATION

TXV

INDOOR

COIL CKT

AIRFLOW

TXV

SENSING

BULB

15 DIAMS

MIN

10

DIAMS

FILTER DRIER

A LOCATION

Fig. 5 -- Typical Piping Connection Assembly

When connecting the field tubing to the 575J service

valves, wrap the valves in wet rags to prevent overheating

Pressure-test all joints from outdoor unit connections over

to the indoor coil, using nitrogen as pressure and with

soap-and-bubbles.

When pressure-testing is completed, remove the nitrogen

source at the outdoor unit service valves and re-install the

two Schrader valve cores. Torque the cores to 2-3 in-lbs

(23-34 N-cm).

Where vapor line is exposed to outdoor air, line must be

insulated. See Table 7 for insulation requirements.

Table 7 – Insulation for Vapor Line Exposed

Service Valve

with Stem Cap

Sweat

Connection

C10203

to Outdoor Conditions

LEGEND

TXV — Thermostatic Expansion Valve

C11036

Fig. 4 -- Location of Sight Glass and Filter Drier

Table 6 – Minimum Outdoor Air Operating Temperature

UNIT

575J*08G/H 100 35 (1.7) –20 (–28.9)

* Applies to Cooling mode of operation only.

† Wind baffles (f ield-su pplied and field-installed) are recommended for all

units with low ambient head pressure control. Refer to Low Ambient

Control Installation Instructions (shipped with accessory) for details.

%

COMPRESSOR

CAPACITY

MINIMUM OUTDOOR

TEMP — F (C)*

Standard Unit

Head Pressure

Control

†

Make Piping Connections —

Piping connections at the 575J unit are ball valves with

stub tube extensions. Do not open the unit service valves

LENGTH OF EXPOSED

VAPOR LINE*

ft m in. mm

10 3

25 8

35 11

50 15

* Recommended vapor line insulation for piping exposed to outdoor

conditions to prevent loss of heating during heating cycle. When vapor

line goes through interior spaces, insulation should be selected to prevent condensation on cooling cycle. Heating capacity should be reduced 1000 Btuh (295 W) if over 35 ft (11 m) of vapor line with

mm) insu lation is exposed to outdoor con ditions.

† Closed cell foam insulation with a thermal conductivity of: 0.28 Btu S

2

in./ft

S h S F (0.04 W/m S C).

INSULATION THICKNESS

3

/

8

1

/

2

3

/

4

3

/

4

Evacuation/Dehydration —

Evacuate and dehydrate the connected refrigeration

system(s) (excluding the 5757J unit) to 500 microns using

a two-stage vacuum pump attached to the service ports

outside the 575J service valves, following description in

GTAC II, Module 4, System Dehydration.

10

13

19

19

†

3

/4in. (19

until all interconnecting tube brazing as been completed.

8

!

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal

injury, death and/or equipment damage.

R

Puron

higher pressures than standard R--22 systems. Do not

use R--22 service equipment or components on Puron

refrigerant equipment.

IMPORTANT: Charge in Cooling mode only!

Preliminary Charge —

Before starting the unit, charge R-410A liquid refrigerant

into the high side of the 575J circuit through the liquid

service valve. The amount of refrigerant added must be at

least 80% of the operating charge listed in Table 3 for

LINEAR line length LESS the factory charge quantity (if

factory shipping charge has not been removed). See the

following example.

Allow high and low side pressures to equalize. If pressures

do not equalize readily, charge R-410A vapor (using

special service manifold with expansion device) into the

vapor line service port for the low side of system to assure

charge in the evaporator. Refer to GTAC II, Module 5,

Charging, Recover, Recycling, and Reclamation for liquid

charging procedures.

Example:

575J*08G/H

60-ft (18.3 m) linear line length

Equivalent line length 90-ft (27.4 m)

Liquid Lift: 20-ft (6.1 m)

Select line sizes from Table 3:

Liquid

Vapor 1-

Charge 27.9 lbs (at 75-ft linear length)

80% of Operating Charge:

0.80 x 27.9 = 22.3 lbs

Factory Shipping Charge: 9 lbs

Field-charge quantity: 22.3 lbs – 9.0 lbs = 13.3 lbs

For linear line lengths longer than 100 ft (30.5 m), contact

your local Bryant representative for system charge value.

(R--410A) refrigerant systems operate at

1

/2in

1

/8in.

Step 6 — Install Accessories

Accessories requiring modifications to unit wiring should

be completed now. These accessories may include Winter

Start controls, Low Ambient controls, phase monitor,

Compressor LOCout. Refer to the instructions shipped

with the accessory.

Step 7 — Complete Electrical Connections

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Do not use gas piping as an electrical ground. Unit

cabinet must have an uninterrupted, unbroken electrical

ground to minimize the possibility of personal injury if

an electrical fault should occur. This ground may consist

of electrical wire connected to unit ground lug in control

compartment, or conduit approved for electrical ground

when installed in accordance with NEC (National

Electrical Code); ANSI/NFPA 70, latest edition (in

Canada, Canadian Electrical Code CSA [Canadian

Standards Association] C22.1), and local electrical

codes.

NOTE: Field-supplied wiring shall conform with the

limitations of minimum 63F(33C) rise.

Field Power Supply —

If equipped with optional Powered Convenience Outlet:

The power source leads to the convenience outlet’s

transformer primary are not factory connected. Installer

must connect these leads according to required operation

of the convenience outlet. If an always-energized

convenience outlet operation is desired, connect the

source leads to the line side of the unit-mounted

disconnect. (Check with local codes to ensure this method

is acceptable in your area.) If a de-energize via unit

disconnect switch operation of the convenience outlet is

desired, connect the source leads to the load side of the

unit disconnect. On a unit without a unit-mounted

disconnect, connect the source leads to compressor

contactor C and indoor fan contactor IFC pressure lugs

with unit field power leads.

Refer to Fig. 11 for power transformer connections and the

discussion on connecting the convenience outlet on page 11.

Field power wires are connected to the unit at line-side

pressure lugs on compressor contactor C and TB1 (see

wiring diagram label for control box component

arrangement) or at factory-installed option non-fused

disconnect switch. Max wire size is #4 AWG (copper only).

NOTE: TEST LEADS - Unit may be equipped with short

leads (pigtails) on the field line connection points on

contactor C or optional disconnect switch. These leads are

for factory run-test purposes only; remove and discard

before connecting field power wires to unit connection

points. Make field power connections directly to line

connection pressure lugs only.

575J*08G/H

9

!

WARNING

FIRE HAZARD

Failure to follow this warning could result in

intermittent operation or performance satisfaction.

Do not connect aluminum wire between disconnect

switch and condensing unit. Use only copper wire.

(See Fig. 6.)

ELECTRIC

DISCONNECT

SWITCH

COPPER

WIRE ONLY

ALUMINUM

575J*08G/H

WIRE

Fig. 6 -- Disconnect Switch and Unit

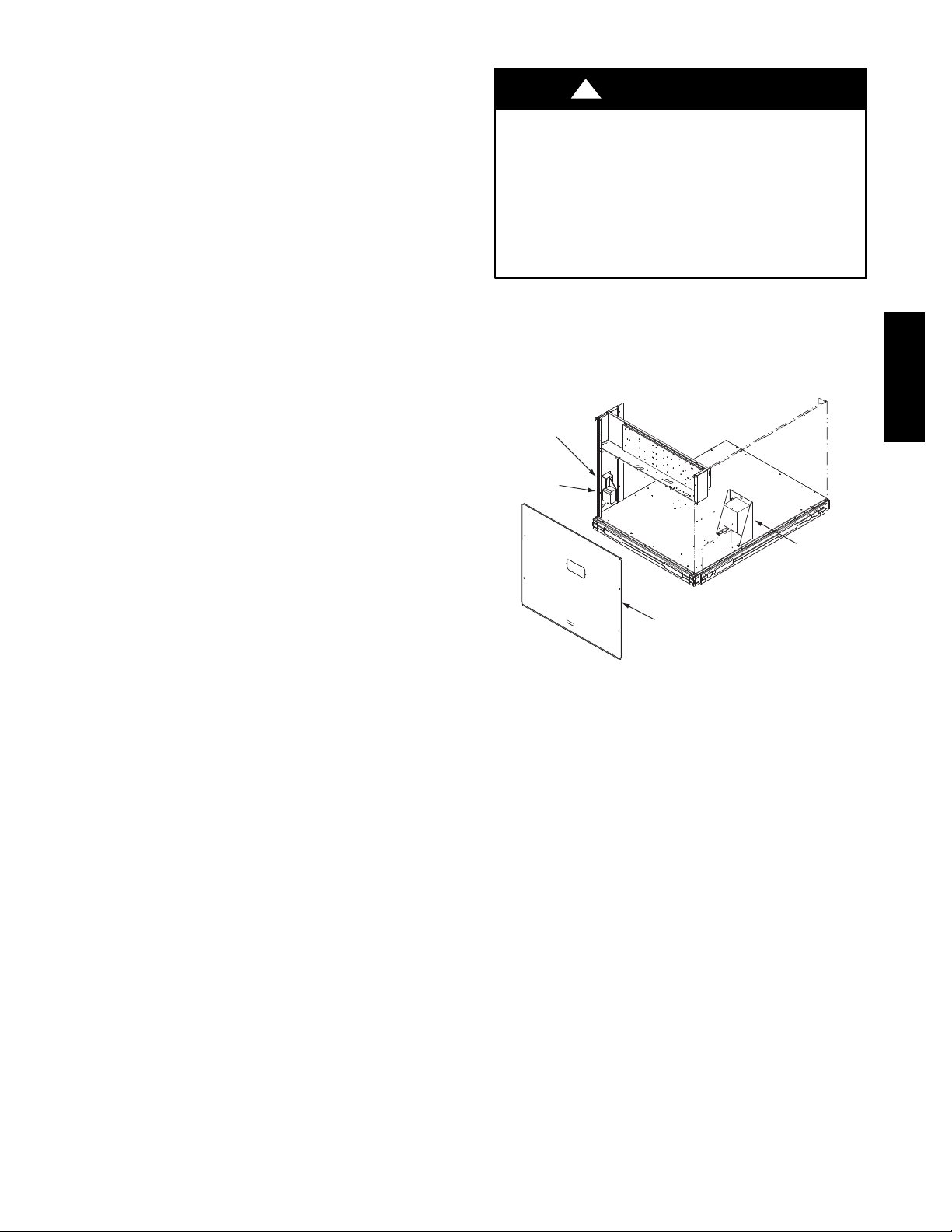

Units with Factory-Installed Non--Fused Disconnect —

The factory-installed option non--fused disconnect (NFD)

switch is located in a weatherproof enclosure located

under the main control box.The manual switch handle and

shaft are shipped in the disconnect enclosure. Assemble the

shaft and handle to the switch at this point. Discard the

factory test leads (see Fig. 7).

Units Without Disconnect Option

CTB1

11 1 3

Disconnect

per

NEC

L1

L2 L3

208/230-3-60

460-3-60

575-3-60

A93033

C12284

Fig. 8 -- Location of Non--Fused Disconnect Enclosure

To field install the NFD shaft and handle:

1. Remove the unit front pane (see Fig. 2).

2. Remove (3) hex screws on the NFD enclosure -- (2) on

the face of the cover and (1) on the left side cover.

3. Remove the front cover of the NFD enclosure.

4. Make sure the NFD shipped from the factory is at

OFF position (the arrow on the black handle knob is

at OFF).

5. Insert the shaft with the cross pin on the top of the shaft

in the horizontal position.

6. Measure from the tip of the shaft to the top surface of

the black pointer; the measurement should be 3.75 --

3.88 in. (95 -- 99 mm).

7. Tighten the locking screw to secure the shaft to the

NFD.

8. Turn the handle to the OFF position with red arrow

pointing at OFF.

9. Install the handle on to the painted cover horizontally

with the red arrow pointing to the left.

10. Secure the handle to the painted cover with (2) screws

and lock washers supplied.

11. Engaging the shaft into the handle socket, re--install

(3) hex screws on the NFD enclosure.

12. Re--install the unit front panel.

Units With Disconnect Option

L1

L2

L3

2

4

6

Optional

Disconnect

Switch

1

3

5

Factory

Wiring

Disconnect factory test leads; discard.

C10204

Fig. 7 -- Power Wiring Connections

Connect field power supply conductors to LINE side

terminals when the switch enclosure cover is removed to

attach the handle.

C12279

Fig. 9 -- Handle and Shaft Assembly for NFD

10

UnitsWithout Factory-Installed

Non--Fused Disconnect —

Convenience Outlets

When installing units, provide a disconnect switch per

NEC (National Electrical Code) of adequate size.

Disconnect sizing data is provided on the unit informative

plate. Locate on unit cabinet or within sight of the unit per

national or local codes. Do not cover unit informative

plate if mounting the disconnect on the unit cabinet.

All Units -

All field wiring must comply with NEC and all local

codes. Size wire based on MCA (Minimum Circuit Amps)

on the unit informative plate. See Fig. 7 and the unit label

diagram for power wiring connections to the unit power

terminal blocks and equipment ground. Maximum wire

size is #2 ga AWG (copper only) per pole on contactors.

Provide a ground-fault and short-circuit over-current

protection device (fuse or breaker) per NEC Article 440

(or local codes). Refer to unit informative data plate for

MOCP (Maximum Over-current Protection) device size.

All field wiring must comply with the NEC and local

requirements.

All units except 208/230-v units are factory wired for the

voltage shown on the nameplate. If the 208/230-v unit is

to be connected to a 208-v power supply, the control

transformer must be rewired by moving the black wire

with the

connection and moving it to the 208-v

-in. female spade connector from the 230-v

-in. male

terminal on the primary side of the transformer. Refer to

unit label diagram for line-side information. Field power

wires will be connected line--side pressure lugs on the

power terminal block or at factory--installed option

non--fused disconnect.

NOTE: Check all factory and field electrical connections

for tightness.

Affix the crankcase heater warning sticker to the unit

disconnect switch.

Voltage and Current Balance —

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate. See

Table 8. On 3-phase units, voltages between phases must

be balanced within 2% and the current within 10%. Use

the formula shown in the legend for Table 8, Note 4 (see

page 14) to determine the percent of voltage imbalance.

Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to

electrical components. Such operation would invalidate

any applicable Bryant warranty.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Units with convenience outlet circuits may use

multiple disconnects. Check convenience outlet for

power status before opining unit for service. Locate its

disconnect switch, if appropriate, and open it. Tag--out

this switch, if necessary.

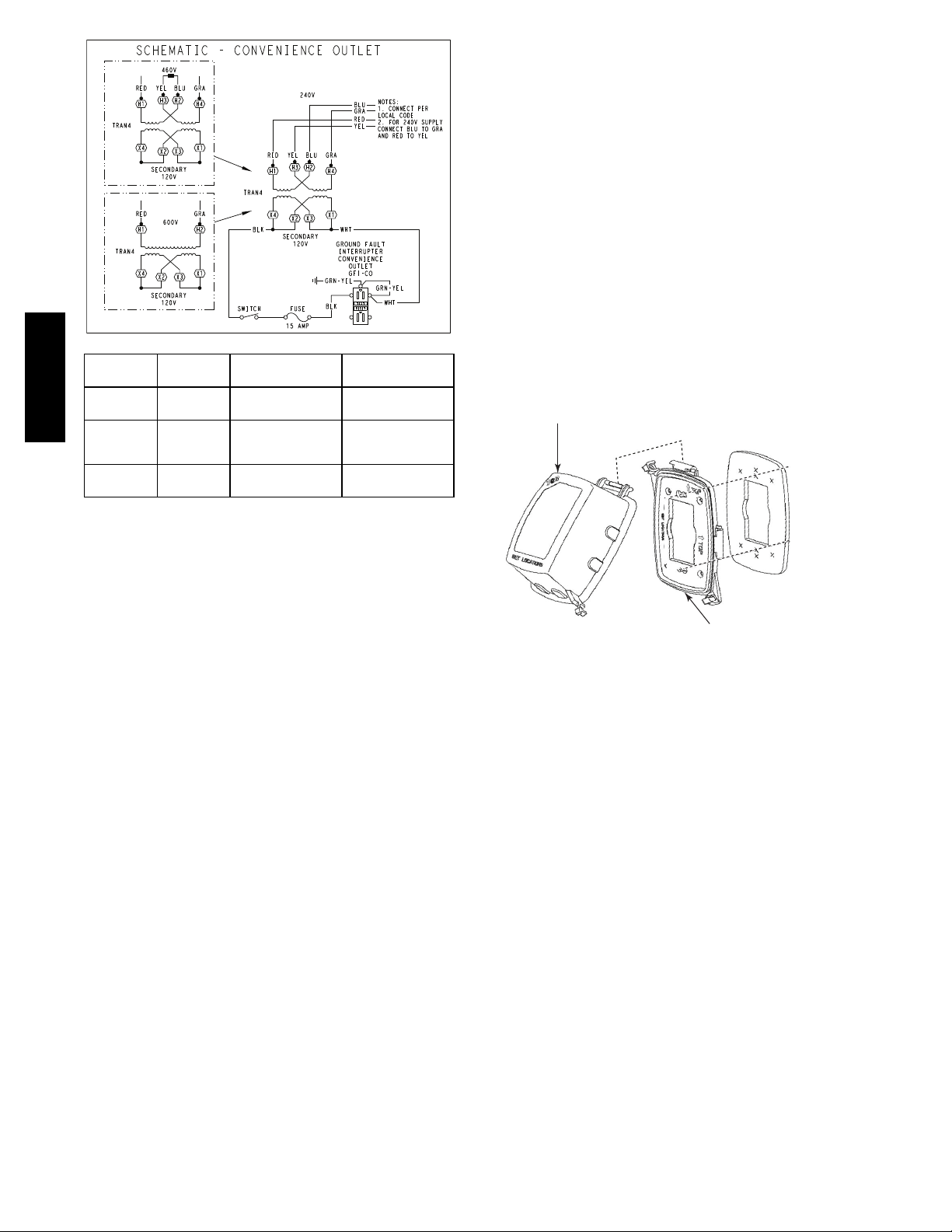

Two types of convenience outlets are offered on 575J

models: Non-powered and unit-powered. Both types provide

a 125-volt GFCI (ground-fault circuit-interrupter) duplex

receptacle rated at 15-A behind a hinged waterproof access

cover, located on the end panel of the unit. See Fig. 10.

Convenience

Outlet

GFCI

Pwd-CO

Fuse

Switch

Pwd-CO

Transformer

Control Box

Access Panel

C11038

Fig. 10 -- Convenience Outlet Location

Non-powered type: This type requires the field

installation of a general-purpose 125-volt 15-A circuit

powered from a source elsewhere in the building. Observe

national and local codes when selecting wire size, fuse or

breaker requirements and disconnect switch size and

location. Route 125-v power supply conductors into the

bottom of the utility box containing the duplex receptacle.

Unit-powered type: A unit-mounted transformer is

factory-installed to stepdown the main power supply

voltage to the unit to 115-v at the duplex receptacle. This

option also includes a manual switch with fuse, located in

a utility box and mounted on a bracket behind the

convenience outlet; access is through the unit’s control

box access panel. See Fig. 10.

The primary leads to the convenience outlet transformer are

not factory-connected. Selection of primary power source is

a customer-option. If local codes permit, the transformer

primary leads can be connected at the line-side terminals on

the unit-mounted non-fused disconnect or HACR breaker

switch; this will provide service power to the unit when the

unit disconnect switch or HACR switch is open. Other

connection methods will result in the convenience outlet

circuit being de-energized when the unit disconnect or

HACR switch is open. See Fig. 11.

11

575J*08G/H

The weatherproof cover kit is shipped in the unit’s control

box. The kit includes the hinged cover, a backing plate

and gasket.

DISCONNECT ALL POWER TO UNIT AND

CONVENIENCE OUTLET.

Remove the blank cover plate at the convenience outlet;

discard the blank cover.

UNIT

VOLTAGE

208,

575J*08G/H

230

460 480

575 600

CONNECT

AS

240

PRIMARY

CONNECTIONS

L1: RED + YEL

L2: BLU + GRA

L1: RED

Splice BLU + YEL

L2: GRA

L1: RED

L2: GRA

TRANSFORMER

TERMINALS

H2 + H3

Fig. 11 -- Powered Convenience Outlet Wiring

Duty Cycle: The unit-powered convenience outlet has a

duty cycle limitation. The transformer is intended to

provide power on an intermittent basis for service tools,

lamps, etc; it is not intended to provide 15-amps loading

for continuous duty loads (such as electric heaters for

overnight use). Observe a 50% limit on circuit loading

above 8-amps (i.e., limit loads exceeding 8-amps to 30

minutes of operation every hour).

H1 + H3

H2 + H4

H1

H4

H1

H2

C10206

Loosen the two screws at the GFCI duplex outlet, until

1

approximately

/2in (13 mm) under screw heads are

exposed. Press the gasket over the screw heads. Slip the

backing plate over the screw heads at the keyhole slots

and align with the gasket; tighten the two screws until

snug (do not overtighten).

Mount the weatherproof cover to the backing plate as

shown in Fig. 12. Remove two slot fillers in the bottom of

the cover to permit service tool cords to exit the cover.

Check for full closing and latching.

COVER – WHILE-IN-USE

WEATHERPROOF

RECEPTACLE

NOT INCLUDED

BASE PLATE FOR

GFCI RECEPTACLE

C09022

Fig. 12 -- Weatherproof Cover Installation

Test the GFCI receptacle by pressing the TEST button on

the face of the receptacle to trip and open the receptacle.

Check for proper grounding wires and power line phasing

if the GFCI receptacle does not trip as required. Press the

RESET button to clear the tripped condition.

Fuse on power type: The factory fuse is a Bussman

“Fusetron” T-15, non-renewable screw-in (Edison base)

type plug fuse.

Using unit-mounted convenience outlets: Units with

unit-mounded convenience outlet circuits will often

require that two disconnects be opened to de-energize all

power to the unit. Treat all units as electrically energized

until the convenience outlet power is also checked and

de-energization is confirmed. Observe National Electrical

Code Article 210, Branch Circuits, for use of convenience

outlets.

Installing Weatherproof Cover

A weatherproof while--in--use cover for the factory

installed convenience outlets is now required by UL

standards. This cover cannot be factory mounted due its

depth; it must be installed at unit installation. For

shipment, the convenience outlet is covered with a blank

cover plate.

NOTE: Check all factory and field electrical connections

for tightness.

Field Control Wiring —

575J unit control voltage is 24 v. See Fig. 17 for typical field

control connections and the unit’s label diagram for

field-supplied wiring details. Route control wires to the 575J

unit through the opening in unit’s end panel to the

connections terminal board in the unit’s control box.

Remainder of the system controls connection will vary

according to the specific construction details of the indoor

section. Fig. 13 depicts typical connections to a Bryant

524J fan coil unit. Plan for field connections carefully and

install control wiring correctly per the project plan.

Additional components and supplemental transformer

accessory may be required.

The 575J unit requires an external temperature control

device. This device can be a thermostat (field-supplied)

or a thermostat emulation device provided as part of a

third--party Building Management System).

12

Loading...

Loading...