Page 1

installation, start-up

and service instructions

COMMERCIAL AIR-COOLED

SPLIT SYSTEM HEAT PUMP

Cancels: II 575A-90-1 II 575A-90-2

575A

Size 090

71⁄2Tons

12/1/95

IMPORTANT — READ BEFORE INSTALLING

1. Read and become familiar with these installation instructions before installing this unit.

2. Be sure the installation conforms to all applicable local

and national codes.

3. These instructionscontainimportant information for the

proper maintenance and repair of this equipment. Retain these instructions for future use.

CONTENTS

Page

SAFETY CONSIDERATIONS .......................1

INSTALLATION .................................1-8

I. Complete Pre-Installation Checks ............1

II. Rig and Mount the Unit .....................3

III. Complete Refrigerant Piping Connections .....4

IV. Make Electrical Connections ................6

START-UP ....................................8-11

I. Preliminary Checks ........................8

II. Evacuate and Dehydrate ....................8

III. Refrigerant and Oil Charge ..................8

IV. Refrigerant Service Ports ...................9

V. Sequence of Operation .....................9

VI. Checking Cooling and Heating Control

Operation ...............................10

VII. Malfunction ..............................10

SERVICE ....................................11,12

I. Cleaning ................................11

II. Lubrication ..............................12

III. Outdoor Fan Adjustment ...................12

IV. Compressor Removal .....................12

TROUBLESHOOTING CHART ...................13,14

START-UP CHECKLIST .....................CL-1,CL-2

SAFETY CONSIDERATIONS

Installing and servicing air-conditioning equipment can be hazardous due to system pressure and electrical components. Only

trained and qualified service personnel should install or service air-conditioning equipment.

When working on air-conditioning equipment, observe precautions in literature and on tags and labels attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire extinguisher available. Read these instructions thoroughly. Consult local building codes and National Electrical Code (NEC)

for special installation requirements.

The 575A090 outdoor unit is approved for use only with the

524A-H090 indoor unit. Use only approved indoor unit.

The 575A090 unit is Underwriters’Laboratories (UL) and UL

Canada approved for use with the 524A-H090 indoor unit only.

I. COMPLETE PREINSTALLATION CHECKS

A. Uncrate Unit (See Fig. 1)

Remove unit packaging except for the top skid assembly and

wood bumpers, which should be left in place until after unit

is rigged into place.

B. Inspect Shipment

File claim with shipping company if shipment is damaged or

incomplete.

C. Consider System Requirements

• Consult local building codes and NEC for special installation requirements.

• Allow sufficient space for airflow clearance, wiring, refrigerant piping, and servicing unit. See Fig. 2.

• Locate unit so that outdoor unit airflow is unrestricted on

all sides and above. Refer to Fig. 2.

• Unit may be mounted on a level pad directly on base rails

or mounted on raised pads at support points. See Fig. 2 for

weight distribution based on recommended support points.

• Provide for condensate drainage and defrost water disposal beneath unit.

• Areas with high snowfall may need elevated mounting for

adequate airflow.

NOTE: If vibration isolators are required for a particular installation, use corner weight information in Fig. 2 to make

proper selection.

WARNING:

ways turn off main power to system. There may be more

than one disconnect switch. Electrical shock can cause

personal injury.

The 575A090 unit uses a semi-hermetic compressor. See

Table 1 for physical data.

Before installing or servicing system, al-

INSTALLATION

Fig. 1 — 575A090 Unit

Page 2

UNIT

575A

UNIT W/

ALUMINUM-FIN

COIL

UNIT W/

COPPER-FIN

COIL

WEIGHT (WITH ALUMINUM-FIN COIL) WEIGHT (WITH COPPER-FIN COIL)

Std Unit Corner W Corner X Corner Y Corner Z Std Unit Corner W Corner X Corner Y Corner Z

Dim. A Dim. B Dim. A Dim. B Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg

1

⁄

2

9

18-43⁄

4

090

18-89

[508.0]

18-59

[431.8]

18-9

[546.0]

9

540 245 132 60 100 45 133 60 175 80 608 276 160 73 117 53 142 64 189 86

[425]

NOTES:

1. Dimensions in [ ] are in millimeters.

2. Center of Gravity. See chart for dimensions.

3. Direction of airflow.

4. Minimum clearance (local codes or jurisdiction may prevail):

a. Bottom to combustible surfaces, 0 in. (0 mm)

b. Outdoor coil, for proper airflow, 36 in. (914 mm) one side, 12 in.

(305 mm) the other. The side getting the greater clearance is optional.

c. Overhead, 60 in. (1524 mm) to assure proper outdoor-fan operation.

d. Between units, control box side, 42 in. (1067 mm) per National

Electrical Code (NEC).

e. Between unit and ungrounded surfaces, control box side, 36 in.

(914 mm) per NEC.

f. Between unit and block or concrete walls and other grounded surfaces,

control box side, 42 in. (1067 mm) per NEC.

5. With the exception of the clearance for the outdoor coil as stated in

note 4b, a removable fence or barricade requires no clearance.

6. Units may be installed on combustible floors made from wood or Class A,

B, or C roof covering material.

7. Vertical center of gravity is approximately 40% of total unit height.

Fig. 2 — Dimensions

—2—

ELECTRICAL CONNECTIONS

CONNECTION SIZES

3

AA 1

⁄89 Dia. [35] Field Power Supply Hole

BB 29 Dia. [51] Power Supply Knockout

1

CC 2

DD

⁄29 Dia. [64] Power Supply Knockout

7

⁄89 Dia. [22] Field Control Wiring Hole

SERVICE VALVE CONNECTIONS

UNIT SUCTION LIQUID

575A090 1

1

⁄89 [28.6]

1

⁄29 [12.7]

Page 3

Table 1 — Physical Data

UNIT 575A 090

OPERATING WEIGHT (lb)

Aluminum Coils (Standard) 540

Copper Coils (Optional) 608

RIGGING WEIGHT (lb)

Aluminum Coils (Standard) 590

Copper Coils (Optional) 658

REFRIGERANT* R-22

COMPRESSOR Reciprocating, Semi-Hermetic

Quantity...Type 1...06DA818

Quantity Cylinders 4

Speed (rpm) 1750

Oil Charge (oz) (ea) 88

OUTDOOR FAN Propeller; Direct Drive

Quantity...rpm 1...1100

Diameter (in.) 26

Motor Hp (NEMA)

Nominal Airflow (cfm) 6500

OUTDOOR COIL Enhanced Copper Tubes,

Face Area (sq ft) 18.0

Storage Capacity (lb)† 16.56

Fins/in. 17.0

Rows (No.) 2

CONNECTIONS (Sweat)

Suction (in.) 1

Liquid (in.)

CONTROLS

Pressurestat Settings (psig)

High Cutout 426 6 7

Cut-in 320 6 20

Low Cutout 7 6 3

Cut-in 22 6 5

Defrost Thermostat

Initiate Defrost (F) 28

Terminates Defrost (F) 65

LEGEND

NEMA — National Electrical Manufacturing Association

*Unit is factory supplied with holding charge only.

†Storage capacity of coil with coil 80% full of liquid R-22 at 120 F.

Aluminum Lanced Fins

3

⁄

4

1

⁄

8

1

⁄

2

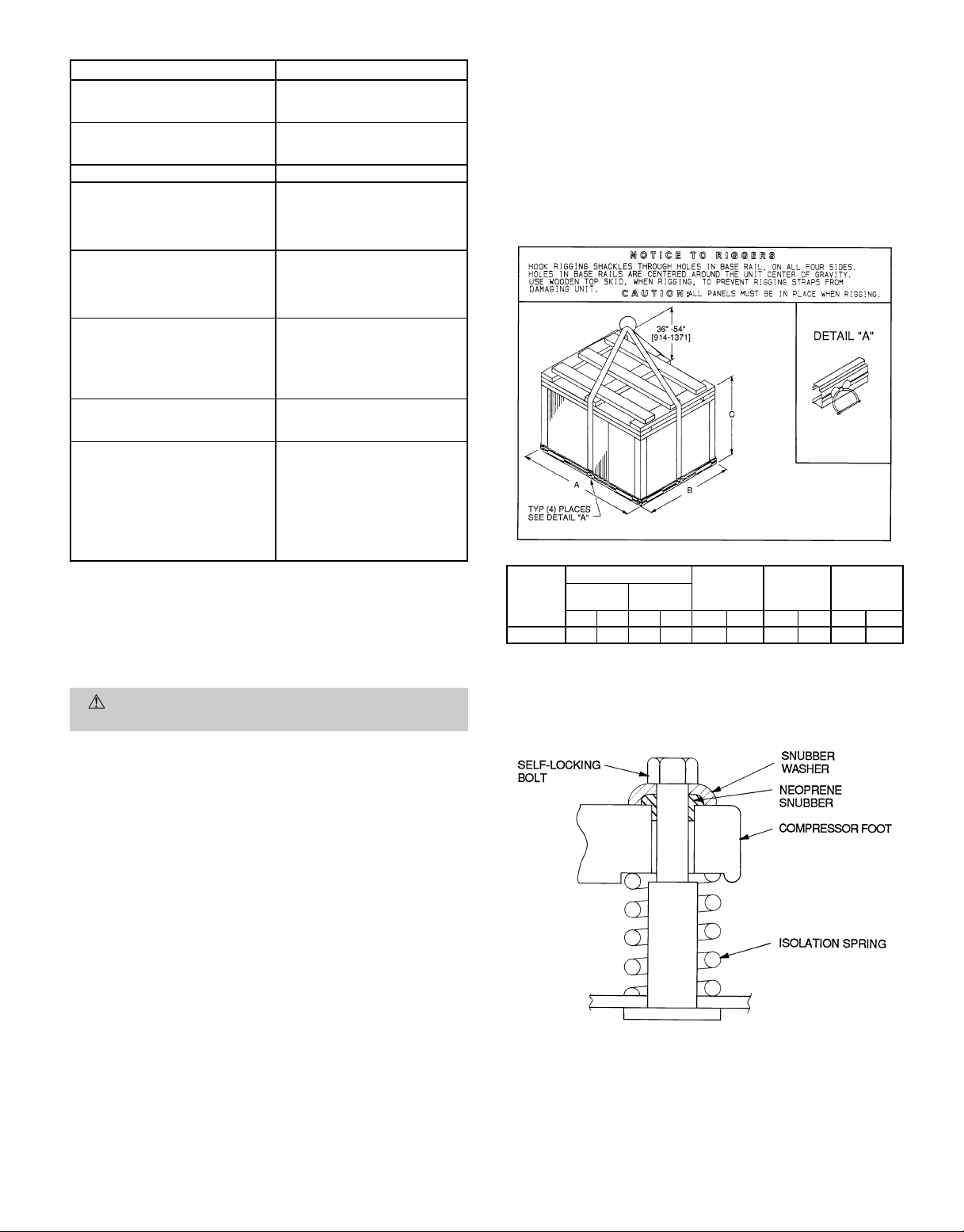

II. RIG AND MOUNT THE UNIT

CAUTION:

Be sure unit panels are securely in place

prior to rigging.

B. Mounting

The unit must be elevated to ensure drainage from basepan

during sub-freezing conditions and to prevent or limit blockage of outdoor coil during snowfall. Consideration should be

given to specific geographical areas when determining height

of unit elevation.

C. Compressor Mounting

As shipped, compressors are held down by 4 bolts.After unit

is installed, loosen each bolt until the snubber washer can be

moved with finger pressure. See Fig. 4.

MAX WEIGHT

UNIT

575A090 590 268 658 298 45.0 1143 38.5 989 43.5 1105

Al — Aluminum-Fin

Cu — Copper-Fin

w/Al

Coil

Lb Kg Lb Kg in. mm in. mm in. mm

w/Cu

Coil

ABC

Fig. 3 — Rigging Label

A. Rigging

The unit is designed for overhead rigging. Refer to rigging

label for preferred rigging method. Spreader bars are not required if top crating is left on unit. All panels must be in place

when rigging. (See Fig. 3.) As further protection for coil faces,

plywood sheets may be placed against sides of unit, behind

cables. Run cables to a central suspension point so that angle

from the horizontal plane is not less than 45 degrees. Raise

and set unit down carefully.

If it is necessary to roll unit into position, mount unit on rails,

using a minimum of 3 rollers. Apply forceto rails, not unit. If

unit is to be skidded into position, place it on a large pad and

drag it by the pad. Do not apply any force to unit.

Raise from above to lift unit from rails or pad when unit is in

final position.

After unit is in position, remove all shipping wrapping and

top crating.

Fig. 4 — Compressor Mounting

—3—

Page 4

III. COMPLETE REFRIGERANT PIPING CONNECTIONS

Suction connection is sweat with plastic cap; liquid connection is sweat with plastic cap. Refer to Table 2 for the proper

line sizes. Follow standard piping practices.

Table 2 — Refrigerant Piping Sizes

LINEAR LENGTH OF PIPING — ft

UNIT

575A

090

L—Liquid Line OD — Outside Diameter S—Suction Line

NOTES:

1. Pipe sizes are based on a 2° F loss for liquid and suction lines.

2. Pipe sizes are based on the maximum linear length shown for each

column, plus a 50% allowance for fittings.

3. Charge units with R-22 in accordance with unit installation

instructions.

0-25 25-50 50-75 75-100

Line Size (in. OD)

LSLSLSLS

1

⁄

2

11⁄

5

8

⁄

8

LEGEND

11⁄

5

8

⁄

8

13⁄

3

8

⁄

4

13⁄

8

A. Size Refrigerant Lines

Consider length of piping required between 575A unit and

524A-H unit, amount of liquid lift, and compressor oil return. See Table 3. Refer to 524A installation instructions for

additional information.

Table 3 — Liquid Line Data

UNIT

575A

090

LEGEND

db — Dry Bulb

wb — Wet Bulb

NOTES:

1. The liquid lift in cooling mode is based on 80/67 F (db/wb ) entering

indoor-air temperature and a 95 F outdoor-air temperature, with R-22

refrigerant, at an indoor airflow of 3000 cfm.

2. The liquid lift in heating mode is based on 70/60 F (db/wb) entering

indoor-air temperature and a 47/43 F (db/wb) outdoor-air temperature, with R-22 refrigerant, at an indoor airflow of 3000 cfm.

MAX

ALLOWABLE

LIQUID LIFT (ft)

Heating Cooling

75 65 7 2

Max Allowable

Pressure Drop

LIQUID LINE

Max Allowable

(psi)

Temp Loss

(F)

B. Filter Drier and Moisture Indicator

See Fig. 5. The filter drier is factory supplied and fieldinstalled in the liquid line. Moisture indicator is fieldsupplied and should be installed just after liquid line shutoff

valve. Do not use a receiver; there is none provided with unit

and one should not be used.

NOTE: Unit is shipped with R-22 holding charge. System pressure must be relieved before removing caps. Recover refrigerant prior to brazing.

Pass nitrogen or other inert gas through piping while brazing to prevent formation of copper oxide.

C. Liquid Line Solenoid Valve

A field-supplied liquid line solenoid valve (LLSV) is recommended when piping system length exceeds 75 feet. The LLSV

must be of the biflow type, suited for use in heat pump

systems.

NOTE: Part number EF23JS214 (Sporlan model CB14S2,

5

⁄8-in. ODF/7⁄8-in. ODM) is recommended and is available from

the Replacement Components Division. This solenoid requires field-supplied Sporlan MKC-2 coils.

Wire the solenoid in parallel with the compressor contactor

coil.

Install the LLSV near the outdoor unit. The flow arrowmust

be pointed toward the outdoor unit.

D. Safety Relief

Afusible plug is located on top of the accumulator.See Fig. 6.

Note that all safety relief components are factory installed.

Do not cap fusible plug. If local code requires additional

safety device(s), install as directed.

E. Suction Piping at Indoor Coil and TXV Sensing Bulb

Location

Suction piping must be designed so that refrigerant is thoroughly mixed after it leaves the indoor coil suction header.

The thermostatic expansion valve (TXV) sensing bulb must

also be correctly located. This ensures that the TXV sensing

bulb receives reliable readings. Install the suction piping as

follows:

1. Install a minimum of two 90-degree elbows upstream of

the TXV bulb location.

2. Locate the TXV bulb on a vertical riser where possible.

If a horizontal location is necessary, secure the bulb at

approximately the 4 o’clock position or the 8 o’clock position. See Fig. 7.

3. Make sure that the piping system has no inherent oil

traps, and that the piping layout does not allow oil to

migrate into an idle indoor coil.

4. Complete refrigerant piping from indoor coil to outdoor

coil before opening liquid and suction lines at the 575A

unit. See Tables 1 and 2 for piping selection data.

—4—

Page 5

LEGEND

NEC — National Electrical Code

TXV — Thermostatic Expansion Valve

*Accessory item.

†Field supplied.

NOTES:

1. All piping must follow standard refrigerant piping techniques.

2. All wiring must comply with the applicable local and national codes.

3. Wiring and piping shown are general points-of-connection guides

only and are not intended for, or to include all details for, a specific installation.

4. Liquid line solenoid valve (solenoid drop control) is recommended to prevent refrigerant migration to the compressor. A biflow type solenoid valve is required.

5. Filter drier must be of the biflow type, suitable for heat pump duty.

6. Internal factory-supplied TXV and bypass check valve not shown.

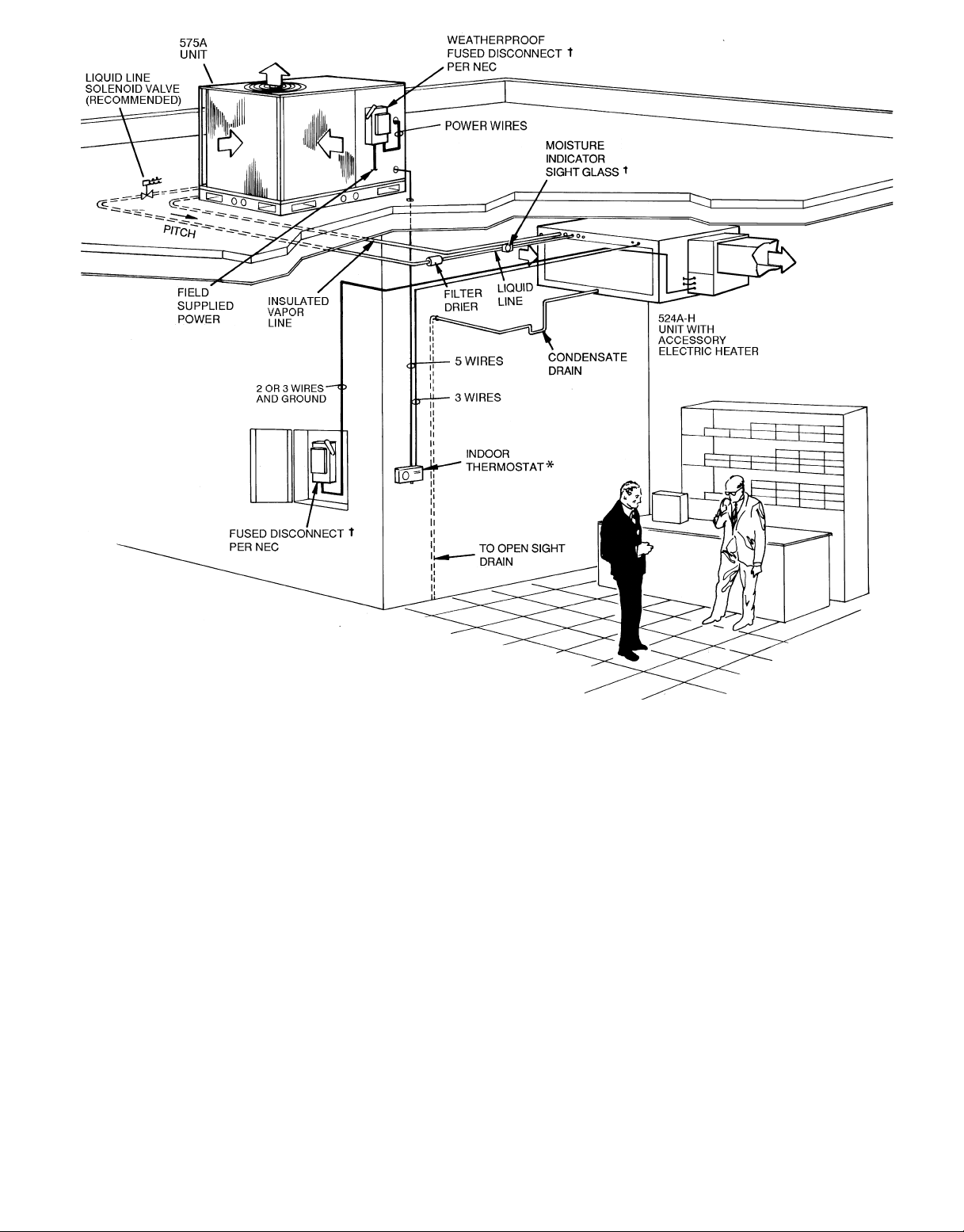

Fig.5—Typical Piping Diagram, 575A/524A-H

—5—

Page 6

Fig. 6 — Fusible Plug Locations

A. Field Power Supply

All units except 208/230-v units are factory wired for the voltage shown on the nameplate. If the 208/230-v unit is to be

connected to a 208-v power supply, the transformer must be

rewired by disconnecting the black wire from the 230-v

orange wire on the transformer and connecting it to the 208-v

red wire from the transformer. The end of the orange wire

must then be insulated.

Refer to unit label diagram for additional information. Short

wire leads (pigtails) are provided for field wire connections.

Use factory-supplied splices or UL approved copper/aluminum

connector.

When installing units, provide a disconnect per NEC.

All field wiring must comply with NEC and local

requirements.

Install field wiring as follows:

1. Install conduit through side panel openings.

2. Install power lines to connections as shown in Fig. 8.

Wrap connections with electrical tape.

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (also see

Table 4). Voltages between phases must be balanced within

2% and the current within 10%. Use the formula shown in

Table 4, Note 2, to determine the percentage of voltage imbalance. Operation on improper line voltage or excessive phase

imbalance constitutes abuse and may cause damage to electrical components. Such operation invalidates any applicable

unit warranty.

B. Accessory Electric Heat

If the system is to be equipped with an accessory electric heater,

refer to the 524A-H090 installation instructions and Table 5.

LEGEND

TXV — Thermostatic Expansion Valve

NOTE: The 8 o’clock position is shown above.

Fig. 7 — TXV Sensing Bulb Location

IV. MAKE ELECTRICAL CONNECTIONS

WARNING:

Unit cabinet must have an uninterrupted,

unbroken electrical ground to minimize the possibility

of personal injury if an electrical fault should occur. This

ground may consist of electrical wire connected to unit

ground lug in control compartment, or conduit approved for electrical ground when installed in accordance with National Electrical Code (NEC) ANSI

(American National Standards Institute)/NFPA 70

(National Fire Protection Association) and local electrical codes. Failure to follow this warning could resultin

the installer being liable for personal injury of others.

C—Contactor

NEC — National Electrical Code

LEGEND

Field Wiring

Factory Wiring

Splice Connection

(Factory Supplied)

Fig. 8 — 575A090 Power Wiring Connections

—6—

Page 7

Table 4 — Electrical Data

UNIT

NOMINAL VOLTAGE

575A

090

FLA — Full Load Amps

HACR — Heating, Air Conditioning and Refrigeration

LRA — Locked Rotor Amps

MCA — Minimum Circuit Amps

NEC — National Electrical Code

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

NOTES:

1. In compliance with NEC requirements for multimotor and combina-

tion load equipment (refer to NEC Articles 430 and 440), the overcurrent protective device for the unit shall be fuse or HACR breaker.

2. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply voltage is

greater than 2%.

voltage imbalance.

= 100 x

(V-Ph-Hz)

208/230-3-60 187 254 31.5 160 3.1 42.5 50 45 177

460-3-60 414 508 15.7 80 1.4 21.0 25 25 89

LEGEND

Use the following formula to determine the percent

max voltage deviation from average voltage

average voltage

VOLTAGE RANGE COMPRESSOR OFM POWER SUPPLY MINIMUM DISCONNECT

Min Max RLA LRA FLA MCA

MAX FUSE OR

HACR BRKR AMPS

Example: Supply voltage is 460-3-60.

(AB) 457 2 452=5v

(BC) 464 2 457=7v

(AC) 457 2 455=2v

Maximum deviation is 7 v.

Determine percent voltage imbalance

% Voltage Imbalance = 100

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than

2%, contact your local electric utility company immediately.

AB = 452 v

BC = 464 v

AC = 455 v

Average Voltage =

7

457

= 1.53%

FLA LRA

452 + 464 + 455

3

1371

=

3

= 457

Table 5 — Accessory Electric Heater Data

UNIT

524A-H

090

MCA — Minimum Circuit Amps

MOCP — Maximum Overcurrent Protection (Amps)

*Sizes shown are for single-point connection of electric heat accessory

and air handler.

HEATER RATING

VOLTAGE

240 .694 .751 .918 1 — — — —

480 — — — — .694 .840 .918 1

NOTE: The following equation converts kW of heat energy to Btuh:

kW x 3,412 = Btuh.

NOMINAL kW V-PH-HZ

5

10

15

25

35

LEGEND

200 208 230 240 400 440 460 480

240-3-60 CAELHEAT001A00 12.0 25.6 30

480-3-60 CAELHEAT002A00 6.0 12.3 15

240-3-60 CAELHEAT004A00 24.1 40.7 50

480-3-60 CAELHEAT005A00 12.0 19.8 25

240-3-60 CAELHEAT007A00 36.0 55.7 80

480-3-60 CAELHEAT008A00 18.0 27.4 40

240-3-60 CAELHEAT010A00 60.1 85.8 125

480-3-60 CAELHEAT011A00 30.1 42.4 60

240-3-60 CAELHEAT013A00 84.0 115.8 175

480-3-60 CAELHEAT014A00 42.1 57.4 80

ACTUAL SITE VOLTAGE

HEATER

PART NO.

NOTES:

1. MCAand MOCP values apply to both standard and alternate factorysupplied motors.

2. Electrical resistance heaters are rated at 240 v or 480 v. To determine heater capacity (kW) at unit nameplate voltage, multiply 240-v

or 480-v capacity by multipliers found in table below.

HEATER

AMPS

MCA* MOCP*

—7—

Page 8

C. Field Control Wiring

Install an approved accessory thermostat assembly according to installation instructions included with the accessory.

Locate thermostat assembly on a solid wall in the conditioned space to sense average temperature in accordance with

thermostat installation instructions.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections

on unit (shown in Fig. 9) as described in following Steps 1

through 3:

1. Pass the control wires through the hole provided in the

corner post. (See Fig. 10.)

2. Feed wire through the raceway built into the corner post

to the 24-v barriers located on the left side of the control box. The raceway provides the required clearance

between the high- and low-voltage wiring.

3. Connect thermostat wires to screw terminals of lowvoltage connection board.

NOTE: 39 VAis available for field-installed accessories. Control power requirement for heat pump outdoor unit is 36 VA

(sealed). The factory-supplied control transformeris rated at

75 VA.

NOTE: For wire runs, use the following insulated wire:

LENGTH

Ft M AWG sq mm

0-50 0-15.2 35 18 0.82

50-75 15.2-22.9 35 16 1.30

Over 75 Over 22.9 35 14 2.08

LEGEND

AWG — American Wire Gage

INSULATION

RATING (C)

SIZE

All wire larger than no. 18 AWG (American Wire Gage) cannot be directly connected to the thermostat and will require

a junction box and splice at the thermostat.

CORNER

POST

RACEWAY THERMOSTAT

FIELD CONNECTION

POWER WIRING

CONNECTIONS

Fig. 10 — Field Control Wiring Raceway

START-UP

I. PRELIMINARY CHECKS

1. Check that all internal wiring connections are tight and

that all barriers, covers, and panels are in place.

2. Field electrical power source must agree with unit nameplate rating.

3. Ensure all service valves are open. Ensure all compressor service valves are backseated.

4. Verify that compressor holddown bolts have been loosened and that flat/snubber washers can be rotated by

finger pressure (snug, but not tight).

5. Verify compressor crankcase heater is securely in place.

Crankcase heater must operate for at least 24 hours before start-up.

6. Note that compressor oil level is visible in the sight glass.

7. Check for leaks in refrigerant system by using soap bubbles

and/or electronic leak detector.

8. Check voltage imbalance as shown in Table 4, Note 2.

9. Check that both outdoor and indoor units are properly

mounted in accordance with installation instructions and

applicable codes.

II. EVACUATE AND DEHYDRATE

Evacuate and dehydrate entire refrigerant system using methods described in GTAC II, Module 4, System Dehydration.

C—Cooling

H—Heating

HR — Heater Relay

IFC — Indoor Fan Contactor

Fig. 9 — Control Wiring Connections

LEGEND

LLSV — Liquid Line Solenoid

SUPL — Supplemental

TB — Terminal Block

Valve

III. REFRIGERANT AND OIL CHARGE

Refer to GTAC II, Module 5, Charging Recovery, Recycling,

and Reclamation.

NOTE: Use of a T otalclaim t refrigerationrecovery unit is highly

recommended when recovering refrigerant.

Unit panels must be in place when unit is operating during

charging procedure.

Unit is shipped with holding charge only. Weigh in 15 lb of

R-22 to start unit.

A. Refrigerant Charging

Use Cooling Charging Chart (see Fig. 11). Vary refrigerant

until the conditions of the chart are met. Note that charging

chart is different from the type normally used. Chart is based

on charging the units to the correct subcooling for the various operating conditions. Accurate pressure gage and temperature sensing device are required. Connect the pressure

gage to the service port on the liquid line service valve. Mount

the temperature sensing device on the liquid line, close to the

liquid line service valve, and insulate it so that outdoor ambient temperature does not affect the reading.Indoor airflow

must be within the normal operating range of the unit.

Operate unit a minimum of 15 minutes. Ensure pressure and

temperature readings have stabilized. Plot liquid pressure and

temperature on chart and add or reduce charge to meet curve.

Adjust charge to conform with charging chart, using liquid

pressure and temperature to read chart.

—8—

Page 9

Fig. 11 — Cooling Charging Chart — 575A090

B. Oil Charging

Allow unit to run for about 20 minutes. Stop unit and check

compressor oil level. Add oil only if necessary to bring oil into

view in sight glass. See Table 1 for oil charge. Use only ap-

proved compressor oil as follows:

Suniso 3GS and WF32-150

Do not reuse drained oil or use any oil that has been exposed

to atmosphere. Procedures for adding or removing oil are given

in Refrigerant Service Techniques manual.

If oil is added, run unit for additional 10 minutes. Stop unit

and check oil level. If level is still low, add oil only after determining that piping system is designed for proper oil return and that system is not leaking oil.

IV. REFRIGERANT SERVICE PORTS

Each unit system has 3 service ports; one on the suction line,

one on the liquid line, and one on the compressor discharge

line. Be sure caps on the ports are tight.

V. SEQUENCE OF OPERATION

When power is supplied to unit, the transformer (TRAN) is

energized. The crankcase heater is also energized.

A. Cooling

With the thermostat in the cooling position, and when the

space temperature comes within 2° F of the cooling set point,

the thermostat makes circuit R-O. This energizes thereversing valve solenoid (RVS) and places the unit in standby condition for cooling.

As the space temperature continues to rise, the second stage

of the thermostat makes, closing circuit R-Y. When compressor time delay (5 ± 2minutes) is completed, a circuit is made

to contactor (C ), starting the compressor (COMP) and outdoorfan motor (OFM). Circuit R-G is made at the same time, energizing the indoor-fan contactor (IFC) and starting the indoorfan motor (IFM) after one-second delay.

When the thermostat is satisfied, contacts open, deenergizing C. The COMP, IFM, and OFM stop.

As shown in Fig. 12, cooling mode refrigerant flow is as

follows:

1. Hot refrigerant gas from compressor flows through the

reversing valve and is directed to the outdoor coil vapor

header.

2. Once at the outdoor coil vapor header, hot refrigerant

gas flows up to check valve ‘‘A,’’ which is closed. All refrigerant is then directed to complete a path through the

lower 6 coil circuits (6 passes in each circuit).

3. Refrigerant flows through from the liquid header side

outlets into the transfer header, where it flows upward.

4. Refrigerant leaves the transfer header through side con-

nections in 4 locations and enters the middle coil circuits (4 coil circuits above check valve ‘‘A’’).

5. Refrigerant leaves the 4 middle coil circuits and enters

the top portion of vapor header. The refrigerant moves

up to the top 2 remaining coil circuits, where it enters

the subcooler section.

6. Subcooled refrigerant leaves the coil circuits through the

side outlets. It passes through check valve ‘‘B’’ into the

system liquid line and then into the indoor coil.

7. Liquid refrigerant is expanded and evaporated to a low-

pressure vapor in the indoor coil. Refrigerant vapor then

returns to the outdoor unit through the system vapor

line, where it is drawn through the reversing valve

and accumulator and back to the compressor suction

connection.

B. Heating

On a call for heat, thermostat makes circuits R-Y and R-G.

When compressor time delay (5 ± 2 minutes) is completed, a

circuit is made to C, starting COMP and OFM. Circuit R-G

also energizes IFC and starts IFM after a 1-second delay.

If room temperature continues to fall, circuit R-W is made

through second-stage thermostat bulb. If optional electric heat

package is used, a relay is energized, bringing on supplemental electric heat. When thermostat is satisfied, contacts

open, deenergizing contactor and relay; motors and heaters

deenergize.

As shown in Fig. 13, heating mode refrigerant flow is as

follows:

1. Hot gas from compressor flows through the reversing valve

and is directed to the system vapor line and indoor coil

vapor header (not shown). Refrigerant is condensed and

subcooled in the indoor coil and returns to the outdoor

unit through the system liquid line.

2. Check valve ‘‘B’’ is closed and all liquid refrigerant enters the liquid header.

3. Refrigerant leaves the liquid header through 12 locations. It is then expanded in fixed orifice metering devices contained within the outlet tubes.

4. Refrigerant evaporates to low pressure vapor as it completes its passage through the 12 parallel coil circuits

(6 passes each).

5. Refrigerant moves from the coil circuits into the vapor

header, where it is drawn through the reversing valve

and accumulator and back to compressor suction

connection.

—9—

Page 10

Fig. 12 — Cooling Mode Operation

C. Defrost

Defrost board (DB) is a time and temperature control, which

includes a field-selectable time period between checks for frost

(30, 50, and 90 minutes). Electronic timer and defrost cycle

start only when contactor is energized and defrost thermostat (DFT) is closed (below 28 F).

Defrost mode is identical to Cooling mode, except outdoorfan motor (OFM) stops and a bank of supplemental electric

heat turns on to warm air supplying the conditioned space.

Defrost mode is terminated when the DFT reaches 65 F.

VI. CHECKING COOLING AND HEATING CONTROL

OPERATION

Start and check the unit for proper control operation as

follows:

1. Place room thermostat SYSTEM switch in an OFF position. Observe that blower motor starts when F ANswitch

is placed in ON position and shuts down when FAN switch

is placed in AUTO position.

2. Place SYSTEM switch in COOL position and FANswitch

in AUTO position. Set control below room temperature.

Observe that compressor, outdoor fan, and indoor fan

motors start. Observe that cooling cycle shuts down when

control setting is satisfied.

3. Place system switch in HEATposition. Set control above

room temperature. Observe that compressor,outdoor fan,

indoor-fan motor,and electric heaters (if equipped) start.

Observe that heating cycle shuts down when control setting is satisfied.

4. When using an automatic changeover room thermostat,

place both SYSTEM and FAN switches in AUTO positions. Observe that unit operates in Cooling mode when

temperature control is set to call for cooling (below room

temperature), and unit operates in Heating mode when

temperature control is set to call for heating (above room

temperature).

VII. MALFUNCTION

The high-pressure switch, loss-of-charge switch, and compressor overtemperature safety are located in a Cycle-LOC™ circuit that prevents heat pump operation if these safety devices

are activated.

The lockout system can be reset by adjusting the thermostat

to open the contacts (down for heating mode, up for cooling

mode) deenergizing the Cycle-LOC circuitry.Compressor overcurrent protection is achieved with overload breakers which

are temperature-sensitive and will automatically reset.

Unit is equipped with a no-dump reversing valve circuit. When

unit is in cooling mode, reversing valve remains in cooling

position until a call for heating is requested by thermostat.

When unit is in heating mode, reversing valve remains in heating position until there is a call for cooling.

—10—

Page 11

SERVICE

Fig. 13 — Heating Mode Operation

CAUTION:

cal power to unit to avoid shock hazard or injury from

rotating parts.

I. CLEANING

Inspect unit interior at the beginning of each cooling season

and as operating conditions require.

A. Outdoor Coil

Inspect coil monthly. Clean outdoor coil annually and as required by location or outdoor-air conditions.

Clean coil as follows:

1. Turn off unit power.

2. Remove and save top panel screws on outdoor unit.

3. Remove outdoor coil corner post. See Fig. 14. To hold

top panel open, place coil corner post betweentop panel

and side panel. See Fig. 15.

4. Remove bracket holding coil sections together at return

end of outdoor coil. Carefully separate the outer coil section 3 to 4 in. from the inner coil section. See Fig. 16.

5. Use a water hose or other suitable equipment to flush

down between the 2 coil sections to remove dirt and debris. Clean the outer surfaces with a stiff brush in the

normal manner.

6. Reposition the outer coil section and secure the sections

together. Remove the coil corner post from between the

top panel and side panel. Install the coil corner post and

replace all screws removed in Step 2.

When servicing unit, shut off all electri-

Fig. 14 — Cleaning Outdoor Coil

—11—

Fig. 15 — Propping Up Top Panel

Page 12

IV. COMPRESSOR REMOVAL

See Table 1 for compressor information. Follow safety codes

and wear safety glasses and work gloves.

1. Shut off power to unit. Remove unit access panel (front

of unit).

2. Remove refrigerant from system using refrigerant removal methods described in Refrigerant Service Techniques manual.

3. Disconnect compressor wiring at compressor terminal

box. Disconnect high-pressure switch.

4. Remove bolts from discharge service valve and suction

flange.

Fig. 16 — Separating Coil Sections

II. LUBRICATION

A. Compressors

Compressor has its own oil supply. Loss of oil due to a leak in

the system should be the only reason for adding oil after the

system has been in operation. See Start-Up, Oil Charging

section.

B. Fan Motor Bearings

Fan motor bearings are permanently lubricated. No further

lubrication is required.

III. OUTDOOR FAN ADJUSTMENT (Fig. 17)

1. Shut off unit power supply.

2. Remove outdoor-fan assembly (grille, motor,motor cover,

and fan).

3. Loosen fan hub setscrews.

4. Adjust fan height as shown in Fig. 17.

5. Tighten setscrews.

6. Replace outdoor-fan assembly.

CAUTION:

compressor may cause higher levels of vibration when

unit is restored to service.

5. Remove crankcase heater from compressor base.

6. Remove compressor holddown bolts and lift compressor off basepan.

7. Remove compressor from unit.

8. Clean system. Add new liquid line filter drier (biflow

type).

9. Install new compressor and position in unit. Connect

suction and discharge lines to compressor.Connect highpressure switch. Ensure that compressor holddown bolts

are in place. Connect wiring. Install crankcase heater.

10. Evacuate and recharge unit.

11. Restore unit power.

Excessive movement of copper lines at

—12—

Fig. 17 — Outdoor-Fan Adjustment

Page 13

LEGEND

N.C. — Normally Closed

TROUBLESHOOTING CHART, HEATING CYCLE

—13—

Page 14

LEGEND

TXV — Thermostatic Expansion Valve

TROUBLESHOOTING CHART, COOLING CYCLE

Copyright 1995 Carrier Corporation CATALOG NO. BDP-3357-502

Page 15

I. PRELIMINARY INFORMATION

START-UP CHECKLIST

OUTDOOR: MODEL NO.

INDOOR: MODEL NO.

ADDITIONAL ACCESSORIES

B. Pre-Start-Up

OUTDOOR UNIT

IS THERE ANY SHIPPING DAMAGE?

IF SO, WHERE:

WILL THIS DAMAGE PREVENT UNIT START-UP? (Y/N)

CHECK POWER SUPPLY. DOES ITAGREE WITH UNIT? (Y/N)

HAS THE GROUND WIRE BEEN CONNECTED? (Y/N)

HAS THE CIRCUIT PROTECTION BEEN SIZED AND INSTALLED PROPERLY? (Y/N)

ARE THE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY? (Y/N)

HAVE COMPRESSOR HOLDDOWN BOLTS BEEN LOOSENED (Snubber washers are snug, but not tight)?

(Y/N)

CONTROLS

ARE THERMOSTAT AND INDOOR-FAN CONTROL WIRING

CONNECTIONS MADE AND CHECKED? (Y/N)

ARE ALL WIRING TERMINALS (including main power supply) TIGHT? (Y/N)

HAS CRANKCASE HEATER BEEN ENERGIZED FOR 24 HOURS? (Y/N)

SERIAL NO.

SERIAL NO.

(Y/N)

INDOOR UNIT

HAS WATER BEEN PLACED IN DRAIN PAN TO CONFIRM PROPER DRAINAGE? (Y/N)

ARE PROPER AIR FILTERS IN PLACE? (Y/N)

HAVE FAN AND MOTOR PULLEYS BEEN CHECKED FOR PROPER ALIGNMENT? (Y/N)

DO THE FAN BELTS HAVE PROPER TENSION? (Y/N)

HAS CORRECT FAN ROTATION BEEN CONFIRMED? (Y/N)

PIPING

IS LIQUID LINE SOLENOID VALVE LOCATED AT THE OUTDOOR UNIT AS RECOMMENDED? (Y/N)

HAVE LEAK CHECKS BEEN MADE AT COMPRESSOR, OUTDOOR COIL, INDOOR COIL, TXV

(Thermostatic Expansion Valve), SOLENOID VALVES, FILTER DRIER, REVERSING VALVE, CHECK VALVE, AND

FUSIBLE PLUGS WITH A LEAK DETECTOR? (Y/N)

LOCATE, REPAIR,AND REPORTANY LEAKS.

HAVEALL COMPRESSOR SERVICE VALVES BEEN FULLY OPENED (BACKSEATED)? (Y/N)

HAVE LIQUID LINE SERVICE VALVE AND SUCTION LINE SERVICE VALVE BEEN OPENED? (Y/N)

IS THE OIL LEVEL IN COMPRESSOR CRANKCASE INTO VIEW IN THE COMPRESSOR SIGHT GLASS?

(Y/N)

CHECK VOLTAGE IMBALANCE

LINE-TO-LINE VOLTS: AB

(AB + AC + BC)/3 = AVERAGE VOLTAGE =

MAXIMUM DEVIATION FROM AVERAGE VOLTAGE =

VOLTAGE IMBALANCE = 100 X (MAX DEVIATION)/(AVERAGE VOLTAGE) =

IF OVER 2% VOLTAGE IMBALANCE, DO NOT ATTEMPT TO START SYSTEM!

CALL LOCAL POWER COMPANY FOR ASSISTANCE.

VAC VBC V

V

V

%

CL-1

Page 16

C. Start-Up

CHECK INDOOR-FAN SPEED AND RECORD.

CHECK OUTDOOR-FAN SPEED AND RECORD.

AFTER AT LEAST 15 MINUTES RUNNING TIME, RECORD THE FOLLOWING MEASUREMENTS:

COOLING

OIL PRESSURE

SUCTION PRESSURE

SUCTION LINE TEMP

DISCHARGE PRESSURE

DISCHARGE LINE TEMP

ENTERING OUTDOOR-AIR TEMP

LEAVING OUTDOOR-AIR TEMP

INDOOR ENTERING-AIR DB (dry bulb) TEMP

INDOOR ENTERING-AIR WB (wet bulb) TEMP

INDOOR LEAVING-AIR DB TEMP

INDOOR LEAVING-AIR WB TEMP

COMPRESSOR AMPS (L1/L2/L3) / /

NOTES:

HEATING

CUT ALONG DOTTED LINE

Copyright 1995 Carrier Corporation CATALOG NO. BDP-3357-502CL-2

----------------------------------------------------------------------------------------

Loading...

Loading...